Page 1

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

SEL SERIES ELECTRIC

TAILGATE SPREADER

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

Page 2

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

INCLUDED IN THIS MANUAL:

Safety Instructions-------------------------------------

Control

H

arness

Trough

Spinner

Spinner Spread Pattern

Operating Instructions ----------------------------------------------------------------Recommended Regular Maintenance---------------------------

Assembly Parts Drawing & Parts List ---------------------------------

Spinner Assembly Parts Drawing & Parts List ----------------------------------Name Plate Information --------------------------------------------------------------------------------Warranty----------------------------------------------------------------------------------------------------

Electric

and Wiring Diagram

mounting instructions

Assembly and

Specifications & Installation --------------------

Installation ------------------------------

Instructions ------------------------------

-------------------------------

-----------------------------------

--------------------------

-------

---------------------

------------------------

-----

-------------------------

----

-----------------------------

------------------------

------------

---

----------

---------------------------

---------------------

-----------

--------------

----

--------------

------------

----

-------------

----

-------------

- 3-5

6

7-

10-11

12-14

15-16

1

7-18

19

21-28

29-32

33

34

9

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 2

Page 3

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

SAFETY PRECAUTIONS

The best safety device is a careful operator!

This symbol means ATTENTION!

Become Alert!

Your safety is involved!

Please read and understand completely before doing!

BEFORE PERFORMING MAINTENANCE OPERATIONS, PARK VEHICLE ON LEVEL GROUND.

SET PARKING BRAKE, SHUT OFF ALL POWER, AND MAKE SURE ALL MOVEMENT HAS STOPPED.

IF BODY IS RAISED, IT MUST BE SECURELY BLOCKED SO IT CANNOT COME DOWN.

SUPPORT BLOCKS MUST NOT BE REMOVED UNTIL THERE IS NO DANGER OF ANYONE BEING UNDER BODY

WHEN BODY IS LOWERED.

Improper use of this equipment can result

in serious injury. To reduce this

possibility, give complete and undivided

attention to the job at hand, and follow these safety

precautions.

PREPERATION:

Know your controls. Read this instruction manual. Learn

how to stop the equipment quickly in an emergency.

Do not allow children to operate machine; nor adults to

operate it without proper instructions.

Keep all individuals not involved in the use of the

equipment a safe distance away.

A

copy of this manual should be available in the cab at all

times. A copy may be obtained from your local dealer or

.

OPERATION:

Do not exceed rated capacities of chassis or hoist.

Observe and shut off all equipment controls before

starting engine so equipment will not unintentionally

operate when engine is started.

A

lways check area around machine before engaging or

operating controls.

Vehicle should be on a flat surface prior to raising bed.

Operation on slippery uneven terrain may result in

equipment damage or personal injury.

Know the material you are hauling and plan your haul to

avoid “set up” or freezing of the load in the dump body.

In the event that a load becomes stuck or frozen in the

body, do not abuse, overload, or damage the truck, hoist,

or body in efforts to quickly free the load. It may be

necessary to thaw indoors to safely remove such a load.

In the event that shoveling or mechanical means are

used to free the stuck load, be sure the load is NOT

hoisted and the tailgate, if opened, is secured properly

before starting this effort. If hoisted, a stuck load, or

portion, could release unexpectedly and cause injury to

personnel or damage to the body, truck, or surroundings.

Some materials such as mud, or sludge, may shift easily

when wet, resulting in increased tendency to overturn the

truck on curves, unstable ground, or side slope situations.

Reduce load size, speeds, and side slopes, and use care

and planning to avoid this potential occurrence.

Unload the body and securely prop and block a raised

body before any service, inspection, or repair work is

started.

Be sure the PTO is disengaged before traveling. Failure

to disengage the PTO from driving the pump/valve when

in transit may allow the dump body to rise unintentionally.

This may lead to loss of vehicle control, accidental injury

and/or property damage.

Lift points are provided to safely lift body assembly.

Never lift or handle loaded body, empty material prior to

handling the body.

Always wear relatively tight and belted clothing when

operating equipment. Loose jackets, shirts sleeves or

other loose clothing should not be worn because of the

danger of catching them in moving parts or controls.

Stop and inspect equipment if unusual movement,

sounds, or noises are observed. Repair damage before

restarting and operating the equipment.

Disengage power to all operating equipment: (1) before

leaving operator’s position, (2) before making any repairs

or adjustments, or (3) when not in use.

Take all possible precautions when leaving the

equipment unattended; such as disengaging the

hydraulic system, shifting vehicle out of gear, setting

parking brake, shutting off engine and removing key.

Never leave raised body unattended.

download from www.

meyerproducts

.com

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 3

Page 4

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

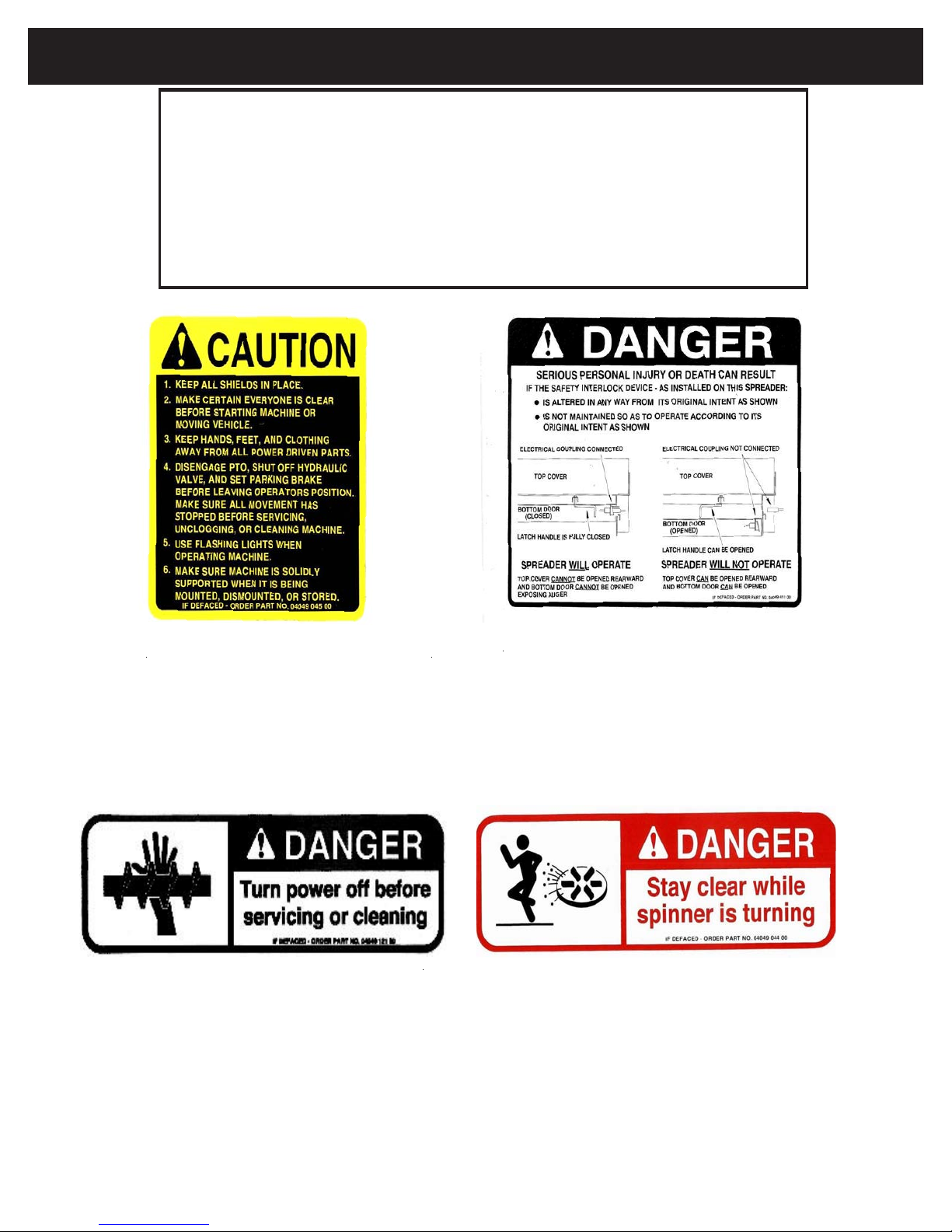

This decal appears on the left end,

or the right end of the spreader

trough. It cautions all to observe

general safety procedures when

operating this equipment.

NOTICE!

Your spreader is equipped with a safety interlock device. This device must be

disconnected before the spreader trough bottom door and the spreader trough top

cover can be opened exposing the auger. This device positively disconnects all

contact with a turning auger.

This decal appears on the back of the

spreader cover plate at the right end of

the spreader. It alerts all to the danger

associated with the improper use of

the Safety Interlock Device.

This decal appears on the back of the spreader

trough cover plate. It alerts all to the danger of being

caught in the dropout opening or from the top of the

spreader trough where serious personal injury could

result.

This

decal appears near the spinner assembly on the

back of the spreader trough cover plate. It alerts all

to the danger of being struck by material being

spread by the spinner assembly which could result in

serious personal injury.

electric

power from the auger drive motor to prevent accidental bodily injury due to

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 4

Page 5

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

Stay clear while

spinner is turning

IF DEFACED - ORDER PART NO. 04049 044 00

DANGER

IF DEFACED - ORDER PART NO. 04049 121 00

DANGER

ORIGINAL INTENT AS SHOWN

IS ALTERED IN ANY WAY FROM ITS ORIGINAL INTENT AS SHOWN

IF THE SAFETY INTERLOCK DEVICE - AS INSTALLED ON THIS SPREADER:

IS NOT MAINTAINED SO AS TO OPERATE ACCORDING TO ITS

SERIOUS PERSONAL INJURY OR DEATH CAN RESULT

SPREADER WILL OPERATE

AND BOTTOM DOOR CANNOT BE OPENED

TOP COVER CANNOT BE OPENED REARWARD

BOTTOM DOOR

LATCH HANDLE IS FULLY CLOSED

EXPOSING AUGER

(CLOSED)

ELECTRICAL COUPLING CONNECTED

TOP COVER

SPREADER WILL NOT OPERATE

IF DEFACED - ORDER PART NO. 04049 411 00

TOP COVER CAN BE OPENED REARWARD

AND BOTTOM DOOR CAN BE OPENED

LATCH HANDLE CAN BE OPENED

(OPENED)

BOTTOM DOOR

ELECTRICAL COUPLING NOT CONNECTED

TOP COVER

5. USE FLASHING LIG HTS WHEN OPERATING MACHINE.

IF DEFACED - ORDER PART NO. 04049 045 00

6. MAKE SURE MACHI NE IS SOLIDLY SUPPORTED

WHEN IT IS BEIN G MOUNTED, DISMOUNTED,

OR STORED.

2. MAKE CERTAIN EV ERYONE IS CLEAR BEFORE

STARTING MACHIN E OR MOVING VEHICLE.

ALL POWER DRIVEN PARTS.

4. DISENGAGE PTO , SHUT OFF HYDRAULIC VALVE,

3. KEEP HANDS, FEET, AND CLOTHING AWAY FROM

1. KEEP ALL SHIELDS IN PLACE.

OR CLEANING MACHINE.

OPERATORS POS ITION. MAKE SURE ALL MOVEMENT

HAS STOPPED BEFO RE SERVICING, UNCLOGGING,

AND SET PARKIN G BRAKE BEFORE LEAVING

SAFETY DECAL LOCATIONS

ITEM PRODUCT QTY DESCRIPTION

39 62515 1 DECAL, DANGER (AUGER) (9 X 2 3/4”)

40 62006 1 DECAL, DANGER (SPINNER) (9 X 2 3/4”)

41 62007 1 DECAL, CAUTION (4 1/4 X 4 “)

42 64055 1 DECAL, SAFETY INTERLOCK ELEC.

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 5

Page 6

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

A

N

D

I

N

S

T

A

L

L

A

T

I

O

N

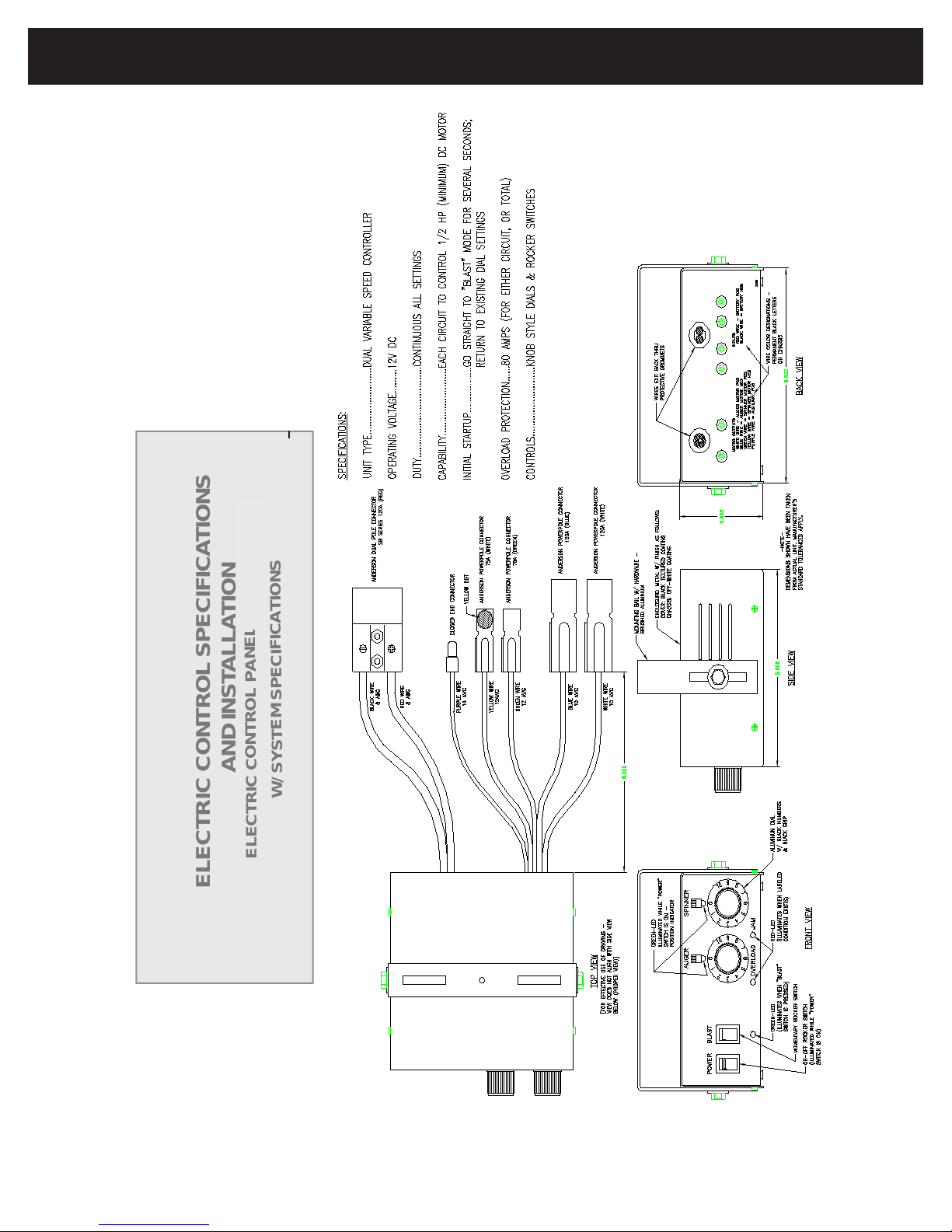

ELECTRIC CONTROL SPECIFICATIONS

W

/

S

Y

S

T

E

M

S

P

E

CIF

I

CAT

I

O

NS

E

L

E

CTRI

C

CONTROL

P

ANEL

04623-008-00

63962

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 6

Page 7

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

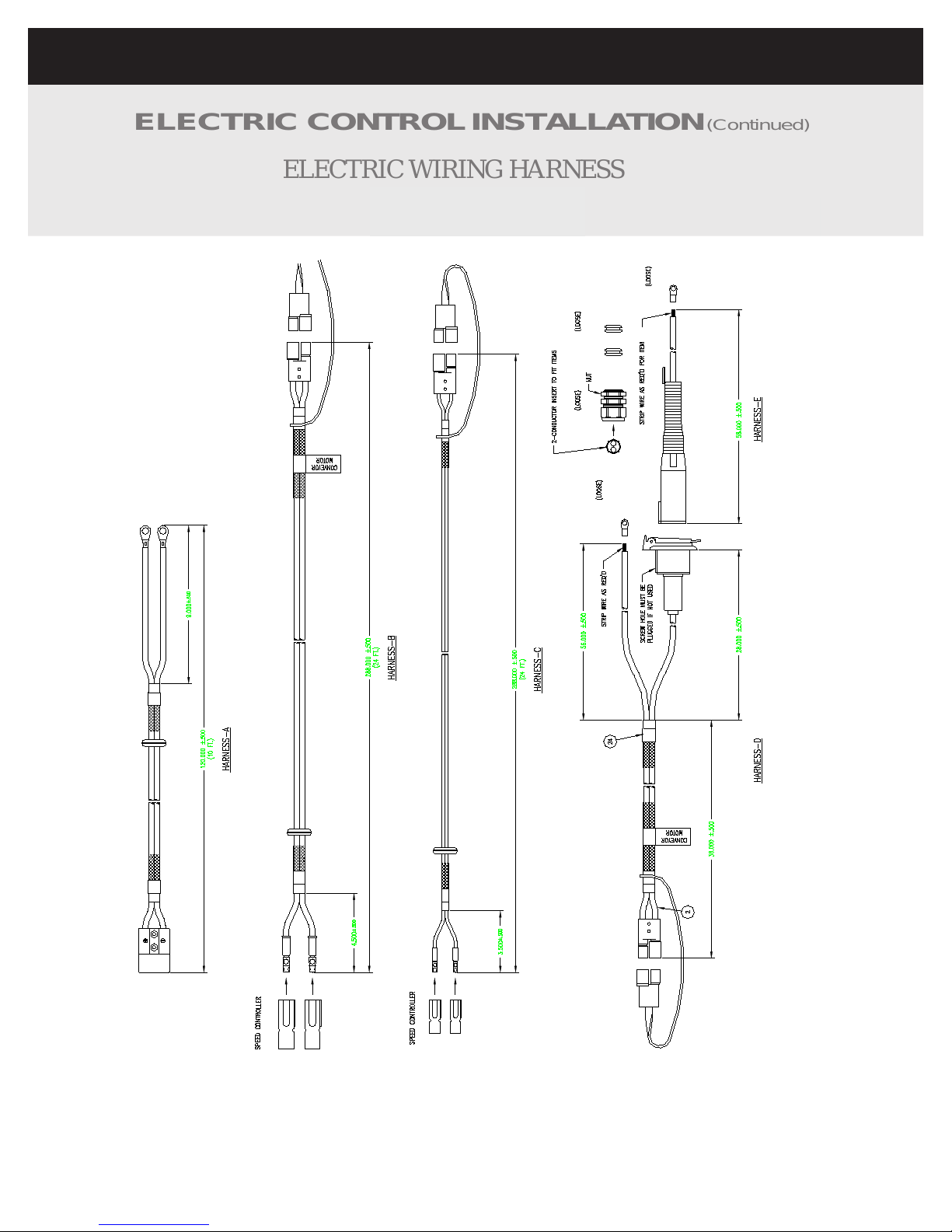

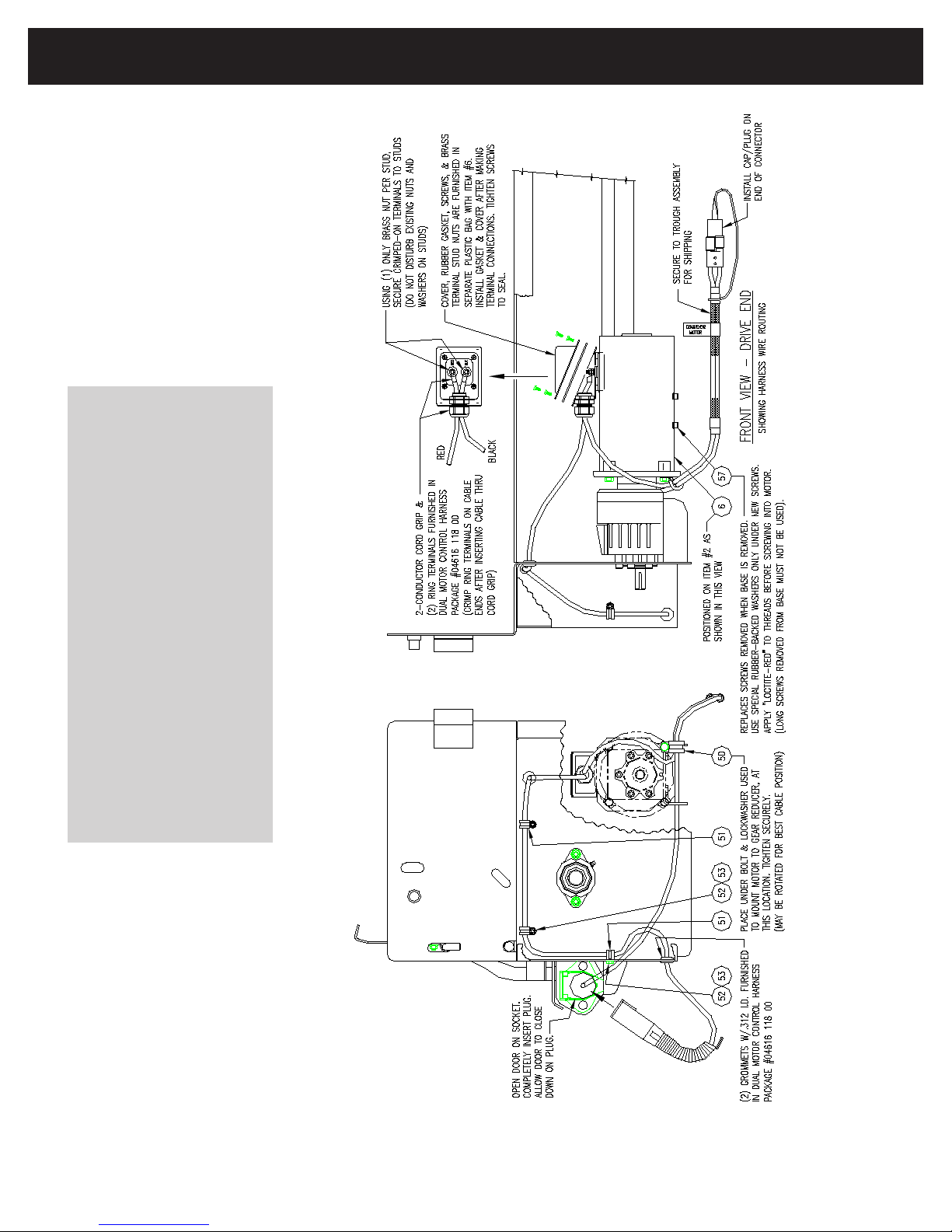

ELECTRIC WIRING HARNESS

04616-118-00

ELECTRIC CONTROLINSTALLATION

63963

(Continued)

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 7

Page 8

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

DRIVE END VIEW

64020 (SS TROUGH ASSY)

64019 (CS TROUGH ASSY)

64022 ( SS CD TROUGH ASSY)

64021 ( CS CD TROUGH ASSY)

WIRING HARNESS ROUTING

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 8

Page 9

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

PARTS LIST CONT’D

64019 (CS TROUGH ASSY)

64020 (SS TROUGH ASSY)

64021 (CS CD TROUGH ASSY)

64022 (SS CD TROUGH ASSY)

ITEM PRODUCT QTY DESCRIPTION

6 64015 1 MOTOR, 12 V 1650RPM 60A 1/2 HP

50 64023 1 CLAMP, CUSHIONED 3/4” WIDE 1/2”

51 63245 3 CLAMP, CUSHIONED 3/8” LOOP SS

52 CS 20003 3 BOLT, 1/4-20 X 3/4” HH G5 ZP

SS 62189 3 BOLT, 1/4-20 X 3/4” HH SS

53 CS 62187 3 NUT, 5/16-18 SER FLANGE ZP

SS 62690 3 NUT, 5/16-18 SER FLANGE SS

57 64024 4 SCREW, M6--1.0 X 10 SCH SS

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 9

Page 10

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

NOTES

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 10

Page 11

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

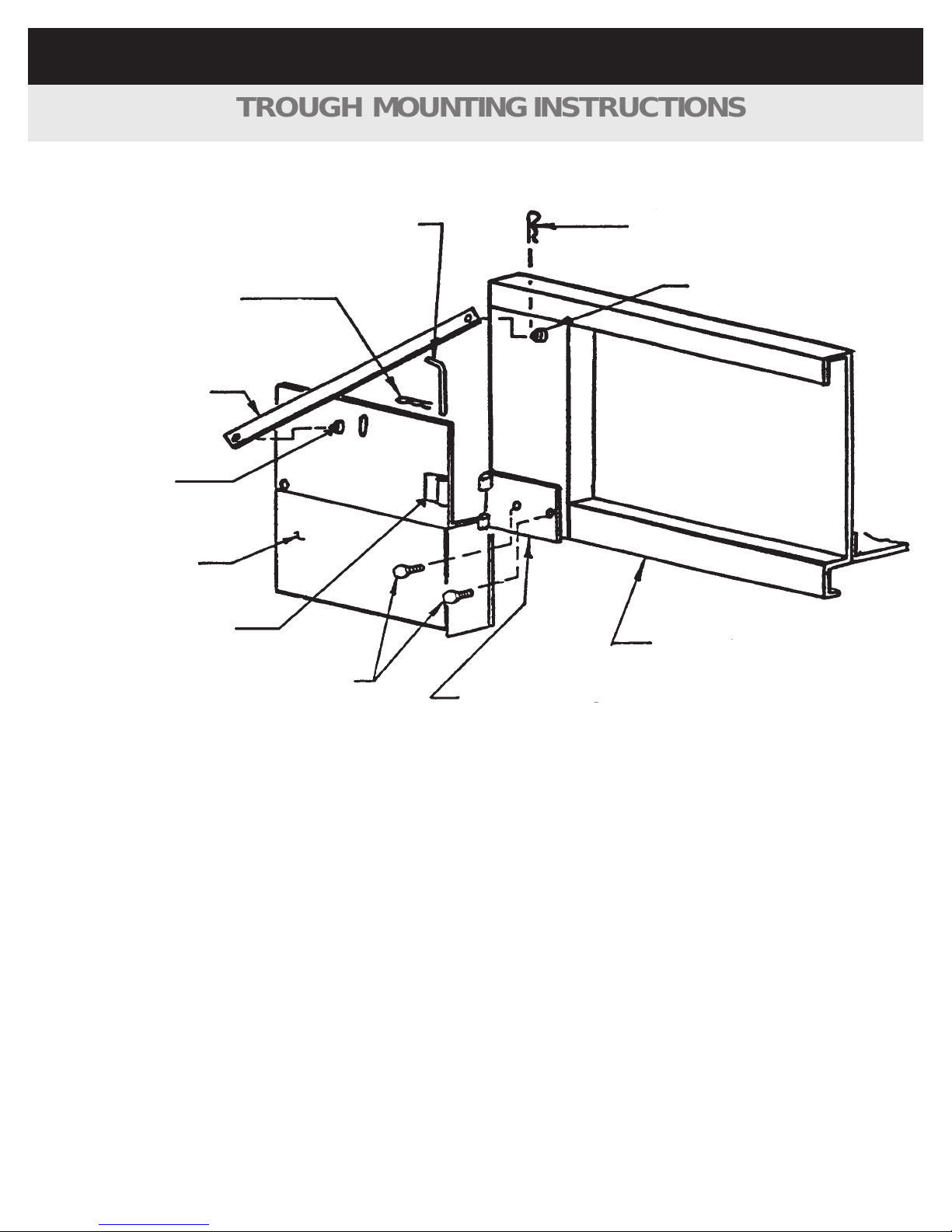

TROUGH MOUNTING INSTRUCTIONS

Hinge Pin

Hairpin Keeper (Large)

Hanger Iron Brace

Brace pin

Spreader

Detach Bracket

1/2” X 1 1/4”

Bolts

Quick Detach Plate

Truck Dump Body

Brace pin

Hairpin Keeper (Large)

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 11

Page 12

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

TROUGH MOUNTING INSTRUCTIONS

(Continued)

GENERAL:

This spreader is designed to mount rigidly on the rear of the truck dump body, below the tailgate, and supported by brackets bolted to the rub rails of the dump body. Instructional drawing

Support spreader and other heavy components solidly when positioning for mounting on truck

dump body.

IMPORTANT:

On occasion, due to improper handling during shipmen

t or storage, the vertical ends of the

trough get bent in or out slightly. Be sure these are square and true before installation. Once

installed, the mounting brackets should prevent further deformation.

1. Position the spreader under the dump body tailgate with the auger drive housing to

the right side of the truck. The trough lip on the forward side of the spreader should

be as close as possible to t

he cross member under the floor of the dump body.

The tailgate of the dump body should lay down horizontally over the spreader, yet the

spreader must be mounted up under the tailgate as high as possible.

2. Pin quick detach plates to spreader detach brackets.

3. Position quick detach plates against dump body cornerposts and clamp in a level

position. Weld adequately to support loaded spreader trough. I

f bolting, is desired,

solidly.

4. Position hanger iron brace on brace pin located on spreader endplates.

5. Locate brace pins on dump body cornerposts approximately as shown using braces

for exact positioning. (Braces may require bending for proper fit.)

6. Weld brace pins solidly to dump body, and retain braces at each end with hairpin

keepers.

7. Carefully remove temporary spreader positioning apparatus

.

.

8. If there is a gap between the trough lip and the dump body rear cross member, a

“spillboard” of about 3/16” x 2” steel may be welded or bolted to the forward lip of the

spreader to form a seal under the dump body floor. It may have to be notched or cut

to fit around tailgate latches or other obstructions on the rear of the dump body.

DANGER

drill (2) holes for 1/2” bolts simultaneously through bracket, cornerpost and bolt

is included in this manual to show the details on page 11.

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 12

Page 13

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

SUPPORT SPINNER ASSEMBLY SOLIDLY WHEN

MOUNTING ON SPREADER.

SPINNER ASSEMBLY PROCEDURE:

engage threads in motor shaft a minimum of 3/8” when bolt is tight.

bolts and flange nuts.

a. Appropriate spinner height depends on truck frame ground clearance. A shorter

spinner height for light and medium duty trucks with contractor style bodies, a

taller spinner height for heavy duty trucks with full size dump bodies.

llar in middle notch of spinner extension mounting bracket, slide

spinn

er hinge rod through both the mounting bracket and lock collar.

MOUNTING PROCEDURES:

TRUCK SHOULD BE ON LEVEL SURFACE.

1. Install spinner assembly on spreader by sliding the hinge rod into the mounting tabs on

bottom door. Insert (2) keeper pins into hinge rod. Center and lock spinner assembly

between mounting tabs.

2. Raise and lower dump body to check spinner ground clearances. Adjust

spinner height if needed. Repeat step if adjustments are made.

DANGER

“SEL” SERIES SPREADERS

INSTALLATION OF SPINNER ASSEMBLY ON

1

. Attach spinner disc to hub with 5/16” x 1 1/2” bolts, flatwashers and flange nuts.

2

. Apply anti-seize compound to spinner motor shaft.

3

. Mount spinner disc/hub assembly on spinner motor shaft.

4

. Secure disc/hub assembly to motor shaft with proper size hardware (provided). Bolt should

5

. Attach spinner frame assembly to spinner extension mounting bracket with (4) 3/8” X 1”

6

. While holding lock co

7.Pin spinner cariage bracket to the trough and bottom door. Insert lynch pins

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 13

Page 14

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

EQUAL TO

X

Y

This diagram to used as refer-

ence only

Y

EQUAL TO

X

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 14

Page 15

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 15

Page 16

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

SpreadÊpatternÊadjustment,Êcont'd

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 16

Page 17

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

OPERATING INSTRUCTIONS

1. WHEN STARTING UP NEW EQUIPMENT, BE SURE EVERYONE IS STANDING CLEAR, WATCH

FOR ANYTHING THAT MAY REQUIRE SHUTTING SYSTEM DOWN. EQUIPMENT MUST BE

STARTED UP SLOWLY AND WATCHED FROM A SAFE DISTANCE. WATCH FOR ANYTHING THAT

MAY BE HITTING SOMETHING THAT IT SHOULD NOT BE HITTING, AND LISTEN FOR SOUNDS

THAT ARE ABNORMAL. CORRECT ANYTHING THAT IS ABNORMAL BEFORE CONTINUING USE

OF THE EQUIPMENT.

2. BEFORE INSTALLATION, MAINTENANCE, CLEANING, OR REMOVAL OF SPREADER, ALL

INITIAL START UP:

motor when disconnected. The spreader is shipped with the interlock device in the disconnected position and

must be connected for operating the spreader.

opened, and slower as knobs are closed.

DANGER

,

ELECTRICAL CONNECTIONS MUST BE DISCONNECTED

.

(Left hand mounted spinner should turn in CCW rotation

as viewed from above spinner.

,

Auger should turn in direction which makes

auger fliting appear to move towards trough dropout

opening.)

1. Connect

electrical harnesses

to safety interlock, spreader and spinner.

2

. Keep auger and spinner knobs on

controller to zero

position.

3

.

Push power switch to

“ON” position.

4

. Examine auger and spinner to see if they are functioning properly. (They will be operating slowly.)

6

.

Open knobs to other positions and check to see if spinner and auger operate faster as knobs are adjusted.

7

. Shut

power switch to off

This spreader is equipped with a

elctrical

safety interlock device designed to interrupt

electrical

flow to the auger

5

.

Open control

knobs to other positions and check to see if spinner and auger operate faster as knobs are

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 17

Page 18

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

OPERATING SPREADER:

OPERATING INSTRUCTIONS

(Continued)

PREPARING SPREADER FOR USE:

1. Position spreader cover plate vertically and secure with latches.

2. With dump body empty, unlatch dump body tailgate from bottom and open as wide as possible

but not bearing against cover plate, set the stop (or spread) chains.

3. Loosen spinner lock and slide spinner assembly to far left and retighten lock. (Position

for spreading three or four lane highway from right lane.)

4. Put spreading material in dump body and raise dump body to fill spreader trough.

5. Lower dump body to safe position.

6. Press controller power switch to “ON” position. Spread small amount of

material to determine placement of material at various spinner and auger speeds with spinner in this far left

position.

7. Press controller switch to “OFF” position and shut off truck engine.

8. Loosen spinner lock and slide spinner assembly to far right and retighten lock. (Position for

spreading behind truck and to extreme right covering up to four lanes from left lane.)

9. Start truck engine

.

10. Press controller switch to “ON” position. Spread small amount of material to determine

placement of material at various spinner and auger speeds with spinner in this

far right position

.

11. It should now be visible that various spread patterns may be obtained by placing spinner at various

positions from left to right, and by changing spinner speeds on valve.

1. For operating electrical system, follow same procedures as for preparing spreader for use.

2. Any speed knob setting changes may be made while truck is in motion.

3. Spinner and auger may be stopped at the same time, without changing their valve settings, by

pressing power switch to “OFF” position.

4. For normal use of dump truck, cover plate may be laid flat over spreader trough and locked in place

.

Dump body tailgate may be opened from top or bottom.

5. When using truck for normal hauling and dumping, it is recommended that electrical safety interlock be

disconnected. Push dust cap onto disconnect.

6. Refer to safety interlock danger decal on trough cover plate for proper use of safety interlock.

7. To avoid spinner damage, spinner may be removed when truck is used for extensive hauling. Protect

electric disconnects with appropriate plugs and caps.

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 18

Page 19

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

RECOMMENDED REGULAR MAINTENANCE

DANGER

SERIOUS PERSONAL INJURY CAN RESULT FROM BEING CAUGHT IN A TURNING AUGER, A TURNING

SPINNER, OR OTHER OPERATING TRUCK EQUIPMENT. BEFORE PERFORMING MAINTENANCE

OPERATIONS, PARK VEHICLE ON LEVEL GROUND. SET PARKING BRAKE, SHUT OFF ALL POWER,

AND SHUT OFF TRUCK ENGINE. ALWAYS REPLACE SHIELDS AND COVERS WHEN MAINTENANCE IS

COMPLETE.

1. Clean electricalÊplugs before taking apart or connecting.

2. Protect electricalÊplugs while in use and after taking apart with dustÊcaps

or other suitable protection.

3

. Auger bearing requires periodic greasing every 15 hours of use and more

frequent greasing during periods of greater use.

4. Greasing spinner hinge rod at support pivot points is suggested.

5. Hosing down and cleaning spreader after each use, and repainting or oiling after

each season will greatly prolong spreader life. To open bottom door and top cover,

disconnect

electrical safety interlock and pivot around to end of spreader.

6. Spreader trough should be completely emptied after each use during severe cold

weather to prevent material from freezing around auger.

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 19

Page 20

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

PARTS LISTING

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 20

Page 21

ER

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

)

)

)

)

D TROUGH ASSY

D TROUGH ASSY

TROUGH ASSY

TROUGH ASSY

64019 (CS

AND HOLD DOWN CLIPS

64020 (SS

64022 (SS C

64021 (CS C

TOP VIEW SHOWN WITHOUT TOP COV

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 21

Page 22

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

PARTS LIST

64019 (CS TROUGH ASSY)

64020 (SS TROUGH ASSY)

64021 (CS CD TROUGH ASSY)

64022 (SS CD TROUGH ASSY)

ITEM PART NUMBER QTY DESCRIPTION

1 CS 64025 1 WELD, TROUGH, 10G CS

CS C/D 64026 1 WELD, TROUGH, 10 GA CS CENTER DROP

SS 64027 1 WELD, TROUGH 10 G S2

SS C/D 64028 1 WELD, TROUGH, 10 GA S2 CENTER DROP

2 64029 1 REDUCER, GEAR 29.4:1

3 64030 4 BOLT, M10-1.5 X 20 SCH SS

5 63993 5 SCREW, M8-1.25 X 20 SCH SS

6 64015 1 MOTOR, 12 V 1650 RPM 60 A 1/2 HP

8 62480 1 WASHER, FELT 1 1/4” ID X 2 1/2” OD

9 63051 1 WELD, AUGER, SA (2 1/2” TUBE)

64031 1

12 CS 62611 9

SS 62743 9

13 64032 1 SPROCKET, 50BL21-1 1/4” BORE

14 64033 1 SPROCKET, 50BL16-3/4” BORE

16 64034 1 BUSHING, TENSIONER STANDOFF S3

17 CS 20051 1 BOLT, 3/8-16 X 1 1/2” HH G5 ZP

SS 64035 1 BOLT, 3/8-16 1 1/2” HH SS

18 CS 64037 1 PLATE, WHEEL TENSIONER 10G CS

SS 64037 1 PLATE, WHEEL TENSIONER 10G S2

20 64038 1 BOLT, SHOULDER 1/2 X 1 1/2” HH

21 64039 1 ROLLER, THNSIONER UHMW

23 CS 64040 1 COVER, CHAIN 10G CS

SS 64041 1 COVER, CHAIN 10G S2

24 CS 63994 3

SS

36 CS 64042 1 COVER, ANTI-FLOW 10G CS

SS 64043 1 COVER, ANTI-FLOW 10G S2

37 CS 61233 2 KEEPER, HAIRPIN LARGE

SS 63193 2 KEEPER, HAIRPIN LARGE SS

48 60421 1 KEY, 1/4: SQ. X 1 1/4”

56 CS 64044 1 FLATWASHER, 3/8” U.S.S. ZP

SS 63565 1 FLATWASHER, 3/8” U.S.S. SS

57 64024 4 SCREW, M6-1.0 X 10 SCH SS

62746

3

WELD, AUGER, SA (2 1/2” TUBE) CENTER DROP

NUT, 3/8-16 SER FLANGE ZP

NUT, 3/8-16 SER FLANGE SS

BOLT, 3/8-16 X 3/4” CA G5 ZP

BOLT, 3/8-16 X 3/4” CA SS

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 22

Page 23

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

IF DEFACED - ORDER PART NO. 04049 411 00

TOP COVER

(OPENED)

BOTTOM DOOR

ELECTRICAL COUPLING NOT CONNECTED

LATCH HANDLE CAN BE OPENED

AND BOTTOM DOOR CAN BE OPENED

TOP COVER CAN BE OPENED REARWARD

SPREADER WILL NOT OPERATE

ORIGINAL INTENT AS SHOWN

IS ALTERED IN ANY WAY FROM ITS ORIGINAL INTENT AS SHOWN

IS NOT MAINTAINED SO AS TO OPERATE ACCORDING TO ITS

SERIOUS PERSONAL INJURY OR DEATH CAN RESULT

TOP COVER

IF THE SAFETY INTERLOCK DEVICE - AS INSTALLED ON THIS SPREADER:

(CLOSED)

SPREADER WILL OPERATE

ELECTRICAL COUPLING CONNECTED

EXPOSING AUGER

AND BOTTOM DOOR CANNOT BE OPENED

LATCH HANDLE IS FULLY CLOSED

TOP COVER CANNOT BE OPENED REARWARD

BOTTOM DOOR

IF DEFACED - ORDER PART NO. 04049 121 00

DANGER

REAR VIEW

64019 (CS TROUGH ASSY)

64020 (SS TROUGH ASSY)

64022 (SS CD TROUGH ASSY)

64021 (CS CD TROUGH ASSY)

IF DEFACED - ORDER PART NO. 04049 044 00

DANGER

Stay clear while

spinner is turning

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 23

Page 24

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

PARTS LIST CONT’D

64019 (CS TROUGH ASSY)

64020 (SS TROUGH ASSY)

64021 (CS CD TROUGH ASSY)

64022 (SS CD TROUGH ASSY)

ITEM PART NUMBER QTY. DESCRIPTIONS

7 CS 20049 4 BOLT, 3/8-16 X 1 HH G5 ZP

SS 62697 4 BOLT, 3/8-16 X 1 HH SS

12 CS 62611 9 NUT, 3/8-16 SER FLANGE ZP

SS 62743 9 NUT, 3/8-16 SER FLANGE SS

17 CS 20051 1 BOLT, 3/8-16 X 1 1/5” HH G5 ZP

SS 64035 1 BOLT, 3/8-16 X 1 1/2” HH SS

19 CS 20305 8 LOCKNUT, 3/8-16 Nl ZP

SS 63348 8 LOCKNUT, 3/8-16 Nl SS

24 CS 63994 3 BOLT, 3/8-16 X 3/4” CA G5 ZP

SS 62746 3 BOLT, 3/8-16 X 3/4” CA SS

25 CS 64045 1 WELD, BOTTOM DOOR 10 G CS

CS C/D 64046 1 WELD, BOTTOM DOOR, 10G CD CENTER DROP

SS 64047 1 WELD, BOTTOM DOOR 10G SS

SS C/D 64048 1 WELD, BOTTOM DOOR10G SS CENTER DROP

26 64003 2 LATCH, BOTTOM DOOR CS

64004 2 LATCH, BOTTOM DOOR S3

27 CS 63279 2 LOCKNUT, 5/8-11 TOP LOCK ZP

SS 63425 2 LOCKNUT, 5/8-11 TOP LOCK SS

28 CS 20068 2 BOLT, 3/8-16 X 2 1/2” HH G5 ZP

SS 63198 2 BOLT, 3/8-16 X 2 1/2” HH SS

29 CS 64049 1 WELD, TOP COVER 10G CS

SS 64050 1 WELD, TOP COVER 10G S2

30 CS 64051 1 CLIP, HOLD-DOWN 10 G CS

SS 64052 1 CLIP, HOLD-DOWN 10 G S2

31 CS 64053 1 HANDLE, LIFT CS

SS 64054 1 HANDLE, LIFT S3

32 63280 2 BRACKET, S2

33 63283 4 BOLT, 5/16-18 X 5/8” CA SS

34 63310 4 NUT, 5/16-18 SER FLANGE SS

35 CS 62443 2 FORMING, HANDLE, ZP

SS 62731 2 HANDLE, SS

39 62515 1 DECAL, DANGER (AUGER)

40 62006 1 DECAL, DANGER (SPINNER)

42 64018 1 DECAL, SAFETY INTERLOCK ELECTRIC

54 CS 63305 2 BOLT, 5/16-18 X 3/4” CA G5 ZP

SS 62640 2 BOLT, 5/16-18 X 3/4’ CA SS

55 63304 2 NUT, 5/16-18 X 3/4” CA G5 ZP

63310 2 NUT, 5/16-18 X 3/4’ CA SS

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 24

Page 25

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

CROSS SECTIONAL VIEW

END PLATE VIEW

(REAR VIEW SECTION A-A)

64019 (CS TROUGH ASSY)

64020 (SS TROUGH ASSY)

64022 (SS CD TROUGH ASSY)

64021 (CS CD TROUGH ASSY)

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 25

Page 26

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

PARTS LIST CONT’D

64019 (CS TROUGH ASSY)

64020 (SS TROUGH ASSY)

64021 (CS CD TROUGH ASSY)

64022 (SS CD TROUGH ASSY)

ITEM PART NUMBER QTY DESCRIPTION

10 61163 2 BEARING, 1 1/4”

11 CS 20066 4 BOLT, 3/8-16 Z 1 1/4” HH G5 ZP

SS 62695 4 BOLT, 3/8-16 X 1 1/4” HH SS

12 CS 62611 9 NUT, 3/8-16 SER FLANGE ZP

SS 62743 9 NUT, 3/8-16 SER FLANGE SS

19 CS 20305 8 LOCKNUT, 3/8-16 Nl ZP

SS 62638 8 LOCKNUT, 3/8-16 Nl SS

24 CS 63994 3 BOLT, 3/8-16 X 3/4” CA G5 ZP

SS 62746 3 BOLT, 3/8-16 X 3/4” CA SS

29 CS 64049 1 WELD, TOP COVER 10G CS

SS 64050 1 WELD, TOP COVER 10G S2

30 CS 64051 1 CLIP, HOLD-DOWN 10 G CS

SS 64052 1 CLIP, HOLD-DOWN 10 G S2

31 CS 64053 1 HANDLE, LIFT CS

SS 64052 1 HANDLE, LIFT S3

32 63280 2 BRACKET, S2

33 63283 4 BOLT, 5/16-18 X 5/8” CA SS

34 63310 4 NUT, 5/16-18 SER FLANGE SS

35 CS 62443 2 FORMING, HANDLE, ZP

SS 62731 2 HANDLE, SS

36 CS 64042 1 COVER, ANTI-FLOW 10 G CS

SS 64043 1 COVER, ANTI-FLOW 10G S2

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 26

Page 27

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

DRIVE END VIEW

64019 (CS TROUGH ASSY)

64020 (SS TROUGH ASSY)

64021 (CS CD TROUGH ASSY)

64022 (SS CD TROUGH ASSY)

127 Walnut Street

R

Lindenwood, IL 61049

(888) 825-7323

May be covered by one or more of these patents:

5669531 0

3851804

3332691

3189355

3510066

Description:

Serial Number:

P, TA, S - -, S3, - - - - - -

0103-1323

00119-651-01

Part Number:

1. KEEP ALL SHIELDS IN PLACE.

2. MAKE CERTAIN EVER YONE IS CLEAR BEFORE

STARTING MACHINE OR MOVING VEHICLE.

3. KEEP HANDS, FEET, A ND CLOTHING AWAY FROM

ALL POWER DRIVEN PARTS.

4. DISENGAGE PTO, SHUT OFF HYDRAULIC VALVE,

AND SET PARKING BRAKE BEFORE LEAVING

OPERATORS POSITI ON. MAKE SURE ALL MOVEMENT

HAS STOPPED BEFOR E SERVICING, UNCLOGGING,

OR CLEANING MACHINE.

5. USE FLASHING LIGH TS WHEN OPERATING MACHINE.

6. MAKE SURE MACHIN E IS SOLIDLY SUPPORTED

WHEN IT IS BEING MOUNTED, DISMOUNTED,

OR STORED.

IF DEFACED - ORDER PART NO. 04049 045 00

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 27

Page 28

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

PARTS LIST CONT’D

64019 (CS TROUGH ASSY)

64020 (SS TROUGH ASSY)

64021 (CS CD TROUGH ASSY)

64022 (SS CD TROUGH ASSY)

ITEM PRODUCT QTY DESCRIPTION

2

3

5

6

8

64029

64030

63993

64015

62480

1

4

5

1

1

10 61163 2 BEARING, 1 1/4”

11 CS 20066 4 BOLT, 3/8-16 Z 1 1/4” HH G5 Z

SS 62695 4 BOLT, 3/8-16 X 1 1/4” HH SS

12 CS 62611 9 NUT, 3/8-16 SER FLANGE ZP

SS 62743 9 NUT, 3/8-16 SER FLANGE SS

13

14

64032

64033

1

1

15 64056 1 CHAIN, ROLLER #50-48 PITCH W/C

16

64034

1

17 CS 20051 1 BOLT, 3/8-16 X 1 1/5” HH G5 ZP

SS 64035 1 BOLT, 3/8-16 X 1 1/2” HH SS

18 CS

SS

20

21

64036

64037

64038

64039

1

1

1

1

22 64057 1 SPRING, EXTENSION 6”

23 CS

SS

64040

64041

1

1

24 CS 63994 3 BOLT, 3/8-16 X 3/4” CA G5 ZP

SS 62746 3 BOLT, 3/8-16 X 3/4” CA SS

41 62007 1 DECAL, CAUTION

48

56 CS

SS

60421

64035

63565

1

1

1

REDUCER, GEAR 29.4:1

BOLT, M10-1.5 X 20 SCH SS

SCREW, M8-1.25 X 20 SCH SS

MOTOR, 12 V 1650 RPM 60 A 1/2 HP

WASHER, FELT 1 1/4” ID X 2 1/2” OD

SPROCKET, 50BL21-1 1/4” BORE

SPROCKET, 50BL16-3/4” BORE

BUSHING, TENSIONER STANDOFF S3

PLATE, WHEEL TENSIONER 10G CS

PLATE, WHEEL TENSIONER 10G S2

BOLT, SHOULDER 1/2 X 1 1/2” HH

ROLLER, TENSIONER UHMW

COVER, CHAIN 10G CS

COVER, CHAIN 10G S2

KEY, 1/4: SQ. X 1 1/4”

FLAT WASHER, 3/8” U.S.S. ZP

FLAT WASHER, 3/8” U.S.S. SS

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 28

Page 29

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

Assembled Spinner Image

1

2

7

5

4

6

10

6

11

9 12

8

13 14

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 29

Page 30

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

Assembled Spinner Image

Parts Listing

ITEM PRODUCT QTY DESCRIPTION

1 63271 2 ROD, HINGE, S3

2 22083 4 PIN, LYNCH

NS 63447 1 ROD, CARRIAGE SUPPORT S3

4 62769 1 COLLAR, SET 1”

5 62459 1 LOCK, SPINNER, S3

6 CS 64009 1 WELD, SPINNER FRAME 10G CS

SS 64010 1 WELD, SPINNER FRAME 10G SS

7 CS 64011 1 WELD, SPINNER CARRIAGE, 10 G CS

SS 64012 1 WELD, SPINNER CARRIAGE, 10G SS

8 64013 1 DISC, POY 18” 1.62 BORE CCW

9 CS 64014 1 WELD, SPINNER HUB CS

10 34102 1 MOTOR, 12V 1650rpm 60A 1/2 HP

11 64016 1 BOLT, M6-1.0 X 40 mm HH SS

12 64017 1 LOCKNUT M6-1.0 TOP LOCK SS

13 63268 4 BOLT, 5/16 - 18 X 1 1/4” HH SS

14 62743 5 NUT, 5/16 SER FLANGE SS

NS 62695 4 BOLT, 3/8-16 X 1 1/4” HH SS

NS 22230 4 FLATWASHER, 3/8” U.S.S. SS

NS 62743 4 NUT, 3/8-16 SER FLANGE SS

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 30

Page 31

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

CARRIAGE MOUNTING EXPLODED VIEW

2

1

6

1

3

10

17

16

18

7

8

19

14

15

4

5

13

12

9

11

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 31

Page 32

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

FRONT MOUNTED SPINNER CARRIAGE

ASSEMBLY PARTS LIST

ITEM PRODUCT QTY DESCRIPTION

1 63271 2 ROD, HINGE, S3

2 22083 4 PIN, LYNCH

3 63447 1 ROD, CARRIAGE SUPPORT S3

4 62769 1 COLLAR, SET 1”

5 CS 64009 1 WELD, SPINNER FRAME 10G CS

SS 64010 1 WELD, SPINNER FRAME 10G SS

6 CS 64011 1 WELD, SPINNER CARRIAGE, 10 G CS

SS 64012 1 WELD, SPINNER CARRIAGE, 10G SS

7 64013 1 DISC, POY 18” 1.62 BORE CCW

8 CS 64014 1 WELD, SPINNER HUB CS

9 34102 1 MOTOR, 12V 1/2 HP

10 63193 1 KEEPER, HAIRPIN LARGE, SS

11 62695 4 BOLT, 3/8-16 X 1 1/4” HH SS

12 22230 4 FLAT WASHER, 3/8” U.S.S. SS

13 62743 4 NUT, 3/8-16 SER FLANGE SS

14 63268 4 BOLT 5/16-18 X 1/1/4” HH SS

15 63173 5 FLATWASHER 5/16 U.S.S. SS

16 63310 5 NUT 5/16-18 SER FLANGE SS

17 64016 1 BOLT, M6-1.0 X 40 mm HH SS

18 64017 1 LOCKNUT, M6-1.0 TOP LOCK SS

19 62459 1 LOCK, SPINNER, S3

NS 62273 1 BOLT 5/16-18 1 1/2” HH SS

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 32

Page 33

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

CALL YOUR AUTHORIZED MEYER PRODUCTS DEALER FOR PARTS AND SERVICE

MEYER PRODUCTS (216) 486-1313

FAX (216) 486-9775

email: warranty@meyerproducts.com

NOTICE: INSTRUCTIONAL MATERIAL AND PARTS LISTS INCLUDED IN THIS MANUAL

ARE SUBJECT TO CHANGE WITHOUT NOTICE.

NAME PLATE INFORMATION

•

When ordering parts or requesting information or assistance, always include

the information listed below.

•

The Model Number and Serial Number for the Spreader are shown on the name

plate.

•

The space below is provided as a convenient place to record these numbers;

just fill in the blanks.

MODEL NUMBER________________________________

SERIAL NUMBER________________________________

DATE PURCHASED_______________________________

DEALER PURCHASED FROM______________________

DEALER’S SERVICE DEPARTMENT PHONE NUMBER

18513 Euclid Ave.

Cleveland, OH 44112

(216) 486-1313

Part Number: XXXXX

Description: P, SJDS - MEYER SPREDER

XXXXXX

May be covered by one or more of these patents:

Serial Number: XXXXX

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 33

Page 34

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

t

SPREADER ONE YEAR WARRANTY

Meyer Products (“Meyer”) warrants to the original purchaser only that it will repair, or, at the sole option of Meyer,

replace any part of the new Meyer covered product which proves to be defective in workmanship or material

under normal use for a period of one year from the date of delivery to the original purchaser. This warranty is no

transferable or assignable. The original purchaser’s sole and exclusive remedy against Meyer and Meyer’s sole

obligation for any and all claims, whether for breach of contract, warranty, tort (including negligence) or otherwise

shall be limited to providing, through its Distributor/Sub Distributor network, all labor and or parts necessary to

correct such defects free of charge. Any cost incurred in returning the product to the Distributor/Sub-Distributor is

the responsibility of the original purchaser.

The gasoline engine used in this product is covered by its own warranty as provided by the engine manufacturer.

A copy of this warranty is included with the engine.

EXCLUSIONS

THIS WARRANTY DOES NOT COVER PAINT, EXCEPT EXPENDABLE PARTS SUCH AS PINS, SPREADER FINS,

AND OTHER NORMAL WEAR ITEMS. MEY ER SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT OR

CONSEQUENTIAL DAMAGES ARISING FROM ANY CLAIMS ARISING HEREUNDER, OR FOR DAMAGES

RESULTING FROM LACK OF NECESSARY MAINTENANCE, OR FROM MISUSE, ACTS OF GOD, ALTERATION

OF A MEYER PLOW, SPREADER OR PART, OR FROM USE OF PARTS OR HYDRAULIC FLUID NOT SUPPLIED

BY MEYER. USE OF THE MEYER SNOWPLOW, SPREADER FOR ANY PURPOSE OTHER THAN PLOWING

SNOW OR SPREADING APPROVED MATERIAL ARE EXAMPLES OF AN ABUSE AND MISUSE.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

WARRANTY SERVICE

In order to obtain service under this warranty, the original purchaser must return the Meyer claimed defective

product to the Distributor/Sub-Distributor from whom the product was purchased or to any authorized Meyer

Distributor/Sub-Distributor, transportation and freight charges prepaid. Only Meyer Distributor/Sub-Distributors

are authorized to perform the obligations under these warranties.

GENERAL

It is the responsibility of the original purchaser to establish the warranty period by verifying the original delivery

date. A bill of sale, cancelled check or some other appropriate payment record may be kept for that purpose. It

is recommended, but not required, that the consumer verify the original delivery date by immediately returning the

attached Warranty Registration Card. No person is authorized to change this warranty or to create any warranty

other than that set forth herein. This warranty gives you specific legal rights and you may also have other rights

which vary from state to state.

Meyer Products

18513 Euclid Avenue

Cleveland, Ohio 44112

Phone (216) 486-1313

Fax (216) 486-3073

E-Mail advertising@meyerproducts.com

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 34

Page 35

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

NOTES

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 35

Page 36

SEL INSTALLATION AND OPERATING INSTRUCTION MANUAL

MEYER PRODUCTS, LLC

18513 EUCLID AVE.

CLEVELAND, OHIO 44112-1084

PHONE: (216) 486-1313

FAX: (216) 486-9775

email:warranty@meyerproducts.com

website: www.meyerproducts.com

IMPORTANT

INFORMATION

ENCLOSED

36

WWW.MEYERPRODUCTS.COM 00122-517-01 SEPTEMBER 2009

PAGE 36

Loading...

Loading...