FORMULA MIXER

Models F355 • F470 • F585 • F700 • F815 • F1015 • F1215

PB-MIXER-19

Owner / Operator’s Manual

2019 Model Year & Later

10 / 2018

6990633 (1-13) Printed in U.S.A. © Bobcat Company 2013

1.0 IMPORTANT INFORMATION

Model No.

Mixer Serial No.

Trailer Serial No.

Date of Purchase

Dealership

Dealership Phone No.

Mixer Body

Serial Number

Trailer Serial Number

Model Year / Vertical Mixer / Model / Sequence Of Build

VM 0700

201

Vertical Mixer Trailer / Model Year / Sequence Of Build

VMT 19

201

TRAILER (Model F585-F1215)

EXAMPLE: VMT19201

19

MIXER

EXAMPLE: 19VM0700201

The mixer serial number plate is located on the left hand side of the mixing tub. The trailer serial number plate

(Model F585-F1460) is located on the left hand side of the trailer hitch.

Please enter the model, serial number and additional information in the space provided for future reference.

Always use your serial number when requesting information or when ordering parts.

HOW TO READ YOUR SERIAL NUMBER

Meyer Manufacturing Corporation

674 W. Business Cty Rd A

Dorchester, WI 54425

Phone: 1-800-325-9103

Email: sales@meyermfg.com

Website: www.meyermfg.com

Meyer Manufacturing Corporation - 2 -

Fax: 715-654-5513

2.0 PRE-DELIVERY & DELIVERY CHECK LIST

Meyer Manufacturing Corporation

Phone: 715-654-5132 • Toll-Free: 1-800-325-9103 • P.O. Box 405 • Dorchester, WI 54425

PB Mixer Check List

All shields and guards are in place and securely

fastened.

All PTO shields turn freely.

All bolts and other fasteners are secure and tight.

All mechanisms operate trouble free.

All grease fittings have been lubricated, gear

boxes filled to proper levels, and all roller chains

are oiled. See “Lubrication” section of this

manual.

Cross Conveyor Belt or Chain are at proper

tension. See “Adjustments” section in this

manual.

All decals are in place and legible.

All stop/tail/turn lights work properly.

PRE-DELIVERY CHECK LIST

After the New Meyer Mixer has been completely set-up,

check to be certain it is in correct running order before

delivering it to the customer.

The following is a list of points to inspect:

Check off each item as you have made the proper

adjustments and found the item operating

satisfactorily. Any adjustments made, MUST be

according to specifications defined in this manual.

DELIVERY CHECK LIST

The following check list is an important reminder of

valuable information that MUST be passed on to the

customer at the time the unit is delivered.

Check off each item as you explain it to the

customer.

Explain to the customer that pre-delivery check

list was fully completed.

Give customer the Owner & Operator’s Manual.

Instruct to read and completely understand its

contents BEFORE attempting to operate the

mixer.

Explain and review with customer the New Meyer

mixer manufacturer’s warranty.

Show the customer where to find the serial

number on the implement.

Explain and review with the customer “Safety

Precautions” section of this manual.

Explain and review with customer the proper

“Start-up and Operating Procedures” sections of

this manual.

Explain and review with customer the

recommended loading and unloading

procedures.

Demonstrate the start-up and shutdown controls,

proper hydraulic hose storage and tip holder used

to keep system clean from contaminants.

Explain the importance of cross conveyor chain

or belt tension, and the need to watch and tighten

during the break-in period.

Explain that regular lubrication and proper

adjustments are required for continued proper

operation and long life of the mixer. Review with

the customer the “Lubrication” and “Adjustments”

sections of this manual.

Fully complete this “PRE-DELIVERY &

DELIVERY CHECK LIST” with the customer.

This Pre-Delivery & Delivery Check List must be gone through by the Selling Party and the Customer to validate the

Owner’s Registration Form.

Formula Mixer Check List - 3 - www.meyermfg.com

1-800-325-9103

Meyer Manufacturing Corporation

674 W. Business Cty Rd A

Dorchester, WI 54425

Phone: 1-800-325-9103

Fax: 715-654-5513

Email: sales@meyermfg.com

Website: www.meyermfg.com

Meyer Manufacturing Corporation - 4 - Formula Mixer Check List

3.0 INTRODUCTION

IMPORTANT: You are urged to study this manual and follow the instructions carefully. Your efforts will be

repaid in better operation and service as well as a savings in time and repair expense. Failure to read this

manual and understand the machine could lead to serious injury. If you do not understand instructions in

this manual, contact either your dealer or Meyer Manufacturing Corp. at Dorchester, WI 54425.

WARRANTY: At the front of this manual is the Owner’s Registration Form. Be sure your dealer has

completed this form and promptly forwarded a copy to Meyer Manufacturing to validate the

manufacturer’s warranty. The product model and serial number are recorded on this form and on the

inside of the front cover for proper identification of your Meyer equipment by your dealer and the

manufacturer when ordering repair parts. The serial number is stamped in the front left-hand side of the

mixing tub. On F700 model and larger the Trailer has a serial number located on the left hand side of the

hitch.

Congratulations on your purchase of a new Meyer farm equipment product. Undoubtedly you have given

much consideration to your purchase and we’re proud that you have selected Meyer. Pride in craftsmanship,

engineering and customer service have made Meyer products the finest in the farm equipment industry today.

There is no substitute for quality. That is why thousands of people like you have purchased Meyer farm

equipment. They felt it was the best equipment to serve their farming needs, now and in years to come. We

ask that you follow our policy of “safety first”, and we strongly suggest that you read through the Operator’s

& Parts manual before operating your Meyer farm equipment. Meyer Manufacturing Corporation wants to

thank you for not compromising quality. We are determined to offer excellence in customer service as well as

provide you with the very best value for your dollar.

Sincerely,

All Employees of

MEYER MANUFACTURING CORPORATION

When the PTO is referred to, it means power takeoff from the tractor.

The formula mixer may be referred to as mixer, implement, equipment or machine in this manual.

Manufacturer’s Statement: Meyer Manufacturing Corporation reserves the right to make improvements in design, or

changes in specifications at any time, without incurring any obligation to owners of units previously sold. This supersedes

all previous published instructions.

PB-MIXER-19 - 5 - www.meyermfg.com

1-800-325-9103

FEATURES

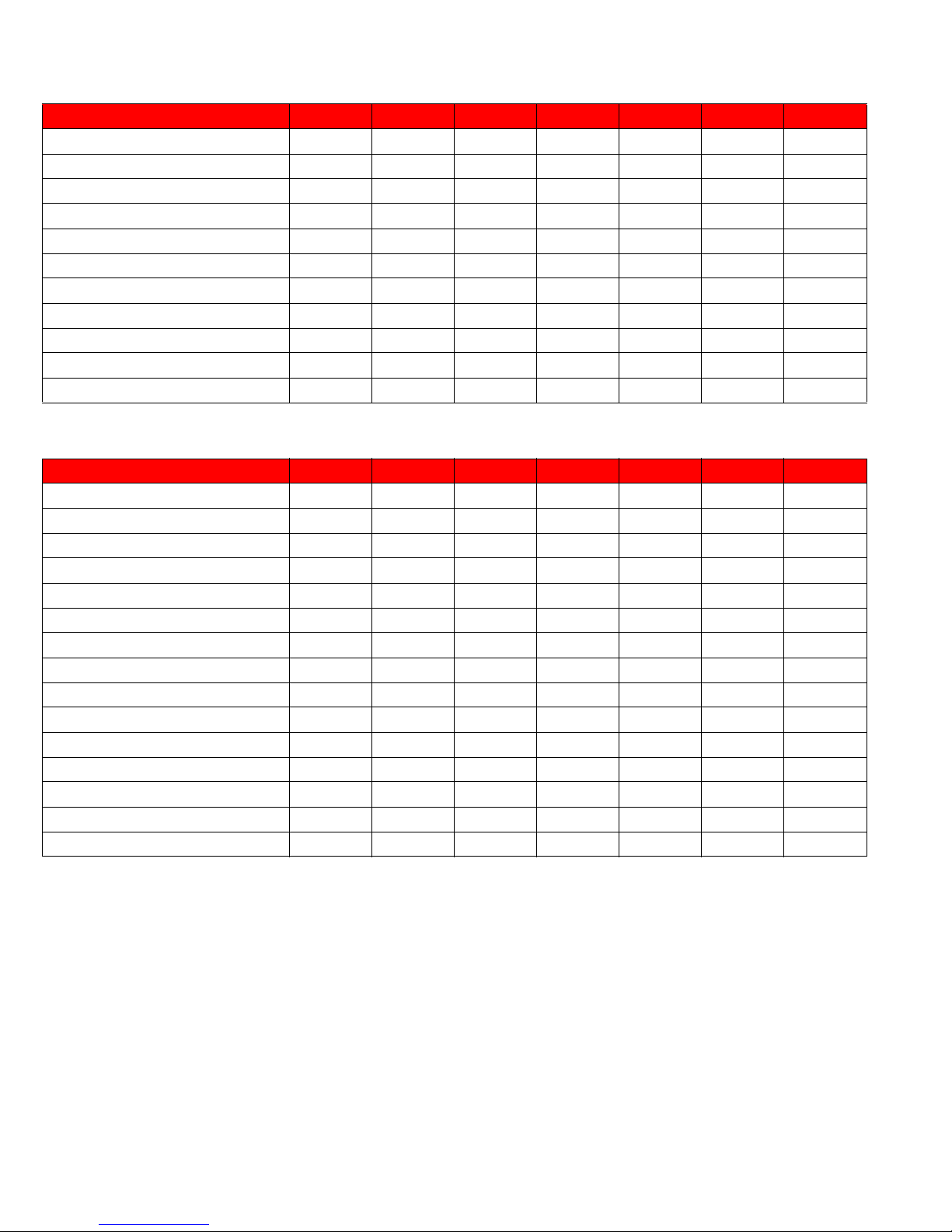

DESCRIPTION F355 F470 F585 F700 F815 F1015 F1215

Twin Mixing Augers STD STD STD STD STD STD STD

Replaceable Scrapers STD STD STD STD STD STD STD

Hardened Knives STD STD STD STD STD STD STD

Hay Stops STD STD STD STD STD STD STD

Ladder STD STD STD STD STD STD STD

Jack Stand STD STD STD STD STD STD STD

Torque Disconnect PTO’s STD STD STD STD STD STD STD

2-Speed (Electric Shift) N/A N/A STD STD STD STD STD

Straight Drive STD STD N/A N/A N/A N/A N/A

Heavy -Duty Gearboxes STD STD STD STD STD STD STD

Single Axle Trailer STD STD STD STD STD STD STD

OPTIONS

DESCRIPTION F355 F470 F585 F700 F815 F1015 F1215

Tandem Axle Trailer N/A N/A OPT OPT OPT OPT OPT

Side Discharge Door Right/Left OPT OPT OPT OPT OPT OPT OPT

Front Discharge Door OPT OPT OPT OPT OPT OPT OPT

Rear Discharge Door OPT OPT OPT OPT OPT OPT OPT

Front Cross Conveyor OPT OPT OPT OPT OPT OPT OPT

Side Door Conveyor OPT OPT OPT OPT OPT OPT OPT

Viewing Platform N/A OPT OPT OPT OPT OPT OPT

Slide Tray OPT OPT OPT OPT OPT OPT OPT

Safety Chain OPT OPT OPT OPT OPT OPT OPT

Magnets OPT OPT OPT OPT OPT OPT OPT

Hay-Retention Ring OPT OPT OPT OPT OPT OPT OPT

Capacity Belt Extension OPT OPT OPT OPT OPT OPT OPT

Hardened Knives (Additional) OPT OPT OPT OPT OPT OPT OPT

Tank Liner OPT OPT OPT OPT OPT OPT OPT

Baffle Liner OPT OPT OPT OPT OPT OPT OPT

Meyer Manufacturing Corporation - 6 - PB-MIXER-19

TABLE OF CONTENTS

1.0 IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 PRE-DELIVERY & DELIVERY CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.0 MANUFACTURER’S WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.0 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.1 SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.2 SAFETY SIGNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.3 SHUTOFF & LOCKOUT POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.3.1 Shutoff & Lockout Power Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.0 PRE-OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 PRODUCT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1.1 General Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.1.2 Before Loading The Formula Mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 LIGHT HOOK-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.3 HYDRAULIC HOOK-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.4 PTO DRIVELINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.4.1 Drawbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.4.2 Cutout Clutch (F585-F1215 Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4.3 Shear Bolt PTO, Primary (F355/F470) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5 HITCHING TO TRACTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5.1 Jack Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.6 START-UP AND SHUT-DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.6.1 Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.6.2 Shut-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.7 TRANSPORTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.7.1 Safety Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.7.2 Tire / Wheel Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.7.3 Brake Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.7.4 Tractor Towing Size Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.8 OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.1.1 Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

PB-MIXER-19 - 7 - www.meyermfg.com

1-800-325-9103

7.2 LOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2.1 Loading Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7.3 MIXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

7.4 PLATFORM OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5 FOLDING LADDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

7.6 UNLOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

7.7 UNHOOKING THE TRACTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.9 HAY STOP ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7.9.1 Hay Stop Lock Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.10 MIXER TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

8.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

8.1 LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

8.1.1 Daily or every 8-10 loads: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

8.1.2 Weekly: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

8.1.3 Monthly: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

8.1.4 Every 40 hours: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.1.5 50 hours: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

8.1.6 Semiannually (500 - 600 hours): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1.7 Annually (1500 hours): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

8.1.8 Every Two Years or When Discolored: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1.9 Gearbox Oil Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

8.1.9.1 Planetary Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.1.9.2 2-Speed Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.2 ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

8.2.1 Side Discharge Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

8.2.2 Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

8.2.3 Front Discharge Conveyor - Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.4 Auger Scraper Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.5 Auger Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.6 PTO Cutout Clutch Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.7 Knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

8.2.7.1 Knife Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.7.2 Adding Knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.7.3 Knife Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.7.4 Knife Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.7.5 Replacing Damaged or Worn Knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.3 STORING THE MIXER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

8.4 RETURNING THE MIXER TO SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.5 REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

8.5.1 Shutoff & Lockout Power Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Meyer Manufacturing Corporation - 8 - PB-MIXER-19

9.0 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.1 MODELS F355, F470, F585 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.2 MODELS F700, F815, F1015 AND F1215 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

MAINTENANCE RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

PB-MIXER-19 - 9 - www.meyermfg.com

1-800-325-9103

Meyer Manufacturing Corporation - 10 - PB-MIXER-19

4.0 MANUFACTURER’S WARRANTY

MEYER FORMULA MIXER

4/2014

I. The “Owner’s Registration Form” must be completed in full and promptly returned to Meyer Mfg. Corp. for

this warranty to become both valid and effective. All warranties on New Meyer Mixers shall apply only

to the

original retail customer from an authorized Meyer Mfg. Corp. dealership.

II. This warranty shall not

apply to any Meyer Mixer which has been subjected to misuse, negligence, alteration,

accident, incorrect

operating procedures, has been used for an application not designed for or pre-authorized

by Meyer in writing, has had the serial numbers altered, or which shall have been repaired with parts other

than those obtained through Meyer Mfg. Corp. Meyer is not responsible for the following: Depreciation or

damage caused by normal wear, lack of reasonable and proper maintenance, failure to follow the operator's

manual recommendations or normal maintenance parts and service. Meyer is not responsible for rental of

replacement equipment during warranty repairs, damage to a power unit (including but not limited to a truck

or tractor), loss of earnings due to equipment down time, or damage to equipment while in transit to or from

the factory or dealer.

III. Meyer Mfg. Corp. warrants New Meyer Mixer to be free from defects in material and workmanship under

recommended use and maintenance service, as stated in the operator’s and parts manuals, as follows:

A. Meyer Mfg. Corp. will repair or replace F.O.B. Dorchester, WI, as Meyer Mfg. Corp. elects, any

part of a new Meyer Mixer which is defective in material or workmanship

:

i. Without charge for either parts or labor during the first (1) year from purchase date to the

original retail customer.

B. In addition to the above basic warranty, Meyer Mfg. Corp. will repair or replace F.O.B.

Dorchester, WI as Meyer Mfg. Corp. elects:

i. Any part of the following which is defective in material or workmanship (not neglect to

recommended use and service) with a “pro-rated” charge for parts only (not labor) during

the stated time period from date of purchase to the original retail customer. 1st year

100%, 2nd year 100%, 3rd year 50%, 4th year 25%, 5th year 10%

a. The Formula Mixer Planetary Gearbox. Meyer Part #'s 119-16-13.4-1,

119-18-13.92-1, 119-21-25.57-1, 119-32-24.8-1.

IV. COMMERCIAL USE: Coverage as in paragraph III.A.i. only, except warranty coverage is for (90) days for parts

and labor to the original commercial retail customer.

V. Repairs eligible for labor warranty must be made by Meyer Mfg. Corp. or an authorized Meyer dealership. The

original retail customer is responsible for any service call and/or transportation of the mixer to the dealership or

the factory for warranty service.

VI. Except as stated above, Meyer Mfg. Corp. shall not be liable for injuries or damages of any kind or nature,

direct, consequential, or contingent, to persons or property. This warranty does not extend to loss of crop or for

any other reasons.

VII. No person is authorized to give any other warranties or to assume any other obligation on Meyer Mfg. Corp.’s.

behalf unless made or assumed in writing by Meyer Mfg. Corp. This warranty is the sole and exclusive warranty

which is applicable in connection with the manufacture and sale of this product and Meyer Mfg. Corp.’s

responsibility is limited accordingly.

Purchased Product Warranty

:

This warranty does not apply to component parts not manufactured by Meyer such as but not limited to wheels, tires,

tubes, PTO shafts, clutches, hydraulic cylinders, scales, tarps, etc.

PB-MIXER-19 - 11 - www.meyermfg.com

1-800-325-9103

Meyer Manufacturing Corporation - 12 - PB-MIXER-19

5.0 SAFETY

This symbol is used to call attention to instructions

concerning personal safety. Be sure to observe and

follow these instructions. Take time to be careful!

The signal word DANGER on the machine and in the manual identifies

a hazardous situation which, if not avoided, WILL

result in death or

serious injury.

The signal word WARNING on the machine and in the manual

indicates a potentially hazardous situation which, if not avoided,

COULD

result in death or serious injury.

The signal word CAUTION on the machine and in the manual

indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This notice identifies procedures which must be followed to avoid

damage to the machine.

Meyer Mfg. Corp. equipment is manufactured with operator safety in mind. Located on the equipment are various safety

signs to aid in operation and warn of hazardous areas. Pay close attention to all safety signs on the equipment.

Carefully follow the operating and maintenance instructions in this manual and all applicable safety laws. Failure to follow

all safety procedures may result in serious injury or death.

Before attempting to operate this equipment, read and study the following safety information. In addition, make

sure that every individual who operates or works with the equipment, whether family member or employee, is

familiar with these safety precautions.

Meyer Mfg. Corp. provides guards for exposed moving parts for the operator’s protection; however, some areas

cannot be guarded or shielded in order to assure proper operation. The operator’s manual and safety signs on

the equipment itself warn you of hazards and must be read and observed closely!

Danger, Warning, Caution, and instructional decals and plates are placed on the equipment to protect anyone working on

or around this equipment, as well as the components of the equipment. All personnel operating or maintaining this

equipment must familiarize themselves with all Danger, Warning, Caution, and instructional decals and plates.

PB-MIXER-19 - 13 - www.meyermfg.com

1-800-325-9103

5.1 SAFETY PRECAUTIONS

All individuals who will operate this equipment must read

and completely understand this Operator’s And Parts

Manual. Operator must have instructions before operating

the machine. Untrained operators can cause injury or death.

• DO NOT allow anyone to operate, service, inspect or otherwise handle this equipment until all operators have read

and understood all of the instructional materials in this Operator’s And Parts Manual and have been properly trained

in its intended usage.

• For an operator to be qualified, he or she must not use drugs or alcohol which impair alertness or coordination while

working. An operator who is taking prescription drugs must get medical advice to determine if he or she can safely

operate a machine and the equipment.

• Make sure all personnel can READ and UNDERSTAND all safety signs.

• DO NOT allow minors (children) or inexperienced persons to operate this equipment.

• DO NOT operate until all shields and guards are in place and securely fastened.

• DO NOT step up on any part of the equipment that is not designated as a ladder or viewing platform at any time.

• DO NOT adjust, clean or lubricate while the equipment is in motion.

• Inspect when first delivered and regularly thereafter; that all connections and bolts are tight and secure before

operating.

• Know how to stop operation of the equipment before starting it!

• Make certain everyone is clear of the equipment before applying power.

• Keep hands, feet and clothing away from moving parts. Loose or floppy clothing should not be worn by the operator.

• Observe all applicable traffic laws when transporting on public roadways (where legal to do so). Check local laws for

all highway lighting and marking requirements.

• Shut off and lock out power before adjusting, servicing, maintaining or clearing an obstruction from this machine. (See

5.3 SHUTOFF & LOCKOUT POWER on page 24.)

• Always enter curves or drive up or down hills at a low speed and at a gradual steering angle.

• Never allow riders on either tractor / truck or equipment.

• Keep tractor / truck in a lower gear at all times when traveling down steep grades.

• Stay away from overhead power lines. Electrocution can occur without direct contact.

• Use only properly rated undercarriage and tires.

Meyer Manufacturing Corporation - 14 - PB-MIXER-19

Safety Precautions For Tractor Towed Units:

• Do not exceed 20 mph (32 kph). Reduce speed on rough roads and surfaces.

• Always install a SMV emblem on pull-type equipment when transporting on roadways and keep clean and bright.

• Always yield to oncoming traffic in all situations and move to the side of the road so any following traffic may pass.

Safety Precautions For Truck Mounted Units:

• Comply with state and local laws governing highway safety and movement of machinery on roadways.

Safety Precautions For Hydraulic System:

• Check hydraulic tubes, hoses and fittings for damage and leakage. Never use hands to check for leaks. Hydraulic

tubes and hoses must be properly routed and have adequate support and secure clamps. Tighten or replace any parts

that show leakage.

• Always clean fluid spills. Do not use gasoline or diesel fuel for cleaning parts. Use commercial nonflammable solvents.

PB-MIXER-19 - 15 - www.meyermfg.com

1-800-325-9103

5.2 SAFETY SIGNS

Read all safety signs on the equipment and in this manual. Keep all

safety signs clean and replace any damaged or missing safety signs

before operating the equipment. Do Not remove any safety signs.

Safety signs are for operator protection and information.

To prevent serious injury or death:

Read and understand owner’s manual

before using. Review safety precautions

annually.

Observe all applicable traffic laws when

transporting on public roadways (where

legal to do so). Check local laws for all

highway lighting and marking requirements.

Securely attach to towing unit. Use a

high strength appropriately sized hitch

pin with a mechanical retainer and

attach safety chain.

Do not exceed the chassis or tire load

rating. Maximum gross weight is the

lesser of the two.

Do not exceed 20 mph (33 kph).

Slow down for corners and rough terrain.

Do not drink and drive.

No riders allowed when transporting.

Before moving running gear, be sure

required lights and reflectors are

installed and working.

Before maintenance or repair, stop

vehicle, set tractor parking brake,

and remove ignition key.

Place safety stands under frame and

chock wheels before working on tires or

running gear.

Maintain wheel bolts at torque as

recommended in the manual.

If equipped with brakes, maintain proper

adjustment.

46-0800-8 1

CAUTION

FRONT OF MIXER

PART NO. 46-0004-2

6

2

1

4

3

5

7

PART NO. 46-0800-8

1

PART NO. 46-3600-9

2

PART NO. 46-0800-6

3

6

4

PART NO. 46-3600-6

PART NO. 46-0800-7

5

PART NO. 46-3600-2

(Located on trailer frame underneath housing)

7

Meyer Manufacturing Corporation - 16 - PB-MIXER-19

CAUTION

46-0001-62 1

Use Flashing Warning

Lights when transporting

on ALL highways (public

roadways) at ALL times.

EXCEPT

WHEN PROHIBITED BY LAW!

(Check w/local law enforcement)

By all State and Federal laws, implement lights

do not replace the SMV (Slow-Moving Vehicle)

Identification Emblem. All towed agricultural

vehicles must display SMV Emblems when

traveling LESS than 20 mph (32 kph).

FRONT OF MIXER

1

2

3

4

5

PART NO. 46-0001-213

1

PART NO. 46-8500-7

2

3

PART NO. 46-0001-35

PART NO. 46-0001-62

4

5

PART NO. 46-0001-22

PB-MIXER-19 - 17 - www.meyermfg.com

1-800-325-9103

FRONT OF MIXER

1

2

3

PART NO. 46-0001-210

1

PART NO. 46-0001-205

2

PART NO. 46-0001-213

3

Meyer Manufacturing Corporation - 18 - PB-MIXER-19

1

PART NO. 46-0001-211

1

LEFT SIDE OF MIXER

PART NO. 46-0001-212

(Located under mixing tub)

PB-MIXER-19 - 19 - www.meyermfg.com

1-800-325-9103

RIGHT SIDE OF MIXER

1

3

3

2

4

3

PART NO. 46-0001-213

1

PART NO. 46-0001-211

PART NO. 46-0001-212

(Located under mixing tub)

2

PART NO. 46-0001-206

(Both sides on some models)

WARNING

OIL INJECTION HAZARD

RELIEVE PRESSURE BEFORE

SERVICING.

DO NOT CHECK WITH HANDS.

IF INJURED SEEK EMERGENCY

MEDICAL ATTENTION.

46-8500-7 1

PART NO. 46-8500-7

3

4

(Behind Belting - Not Shown)

Meyer Manufacturing Corporation - 20 - PB-MIXER-19

RIGHT SIDE OF MIXER

1

3

2

4

PART NO. 46-0001-205

4

2

PART NO. 46-0001-209

3

1

PART NO. 46-0001-4

PART NO. 46-0001-207

(Located on top of shield) (Located under shield)

PB-MIXER-19 - 21 - www.meyermfg.com

1-800-325-9103

BACK OF MIXER

1

1

2

2

2

1

PART NO. 46-0001-205

PART NO. 46-0001-208

3

SIDE DOOR CONVEYOR (OPTION)

PART NO. 46-0001-213

3

Meyer Manufacturing Corporation - 22 - PB-MIXER-19

LEFT SIDE OF MIXER

1

2

3

2

2

PART NO. 46-0001-209

1

PART NO. 46-0001-206

(Both sides on some models)

PART NO. 46-0001-210

3

PB-MIXER-19 - 23 - www.meyermfg.com

1-800-325-9103

5.3 SHUTOFF & LOCKOUT POWER

It is important that everyone who works on this equipment is properly

trained to help ensure that they are familiar with this procedure and

that they follow the steps outlined above. This manual will remind you

when to Shutoff & Lockout Power.

Any individual that will be adjusting, servicing, maintaining, or clearing an obstruction from this machine needs

to ensure that this machine stays safely “OFF” until the adjustment, service, or maintenance has been

completed, or when the obstruction has been cleared, and that all guards, shields, and covers have been

restored to their original position. The safety of all individuals working on or around this machine, including

family members, are affected. The following procedure will be referred to throughout this manual, so be familiar

with the following steps.

5.3.1 Shutoff & Lockout Power Recommendations

1. Think, Plan and Check

a. Think through the entire procedure and identify all the steps that are required.

b. Plan what personnel will be involved, what needs to be shut down, what guards / shields need to be removed, and

how the equipment will be restarted.

c. Check the machine over to verify all power sources and stored energy have been identified including engines,

hydraulic and pneumatic systems, springs and accumulators, and suspended loads.

2. Communicate - Let everyone involved, including those working on or around this machine, that work is being done

which involves keeping this machine safely “OFF”.

3. Power Sources

a. LOCKOUT - Shut off engines and take the key, or physically lock the start/on switch or control. Disconnect any

power sources which are meant to be disconnected (i.e. electrical, hydraulic, and PTO of pull-type units).

b. TAGOUT - Place a tag on the machine noting the reason for the power source being tagged out and what work is

being done. This is particularly important if the power source is not within your sight and/or will need to be isolated

for a longer period of time.

4. Stored Energy - Neutralize all stored energy from its power source. Ensure that this machine is level, set the parking

brake, and chock the wheels. Disconnect electricity, block moveable parts, release or block spring energy, release

pressure from hydraulic and pneumatic lines, and lower suspended parts to a resting position.

5. Test - Do a complete test and personally double check all of the above steps to verify that all of the power sources are

actually disconnected and locked out.

6. Restore Power - When the work has been completed, follow the same basic procedures, ensuring that all individuals

working on or around this machine are safely clear of the machine before locks and tags are removed and power is

restored.

Meyer Manufacturing Corporation - 24 - PB-MIXER-19

6.1 PRODUCT INSPECTION

DO NOT allow anyone to operate, service, inspect or otherwise

handle this equipment until all operators have read and understand

all of the instructional materials in this Operator’s And Parts Manual

and have been properly trained in its intended usage.

Verify that the equipment is securely fastened to the tractor.

Verify that all electrical / hydraulic connections and bolts / hardware

are tight and securely fastened before operating the equipment.

Always keep all shields and guards in place and securely fastened.

Keep hands, feet and clothing away.

Wear safety glasses to prevent eye injury when any of the following

conditions exist:

• When fluids are under pressure.

• Flying debris or loose material is present.

• Tools are being used.

Failure to heed may result in serious personal injury or death.

Hydraulic fluid escaping under pressure can have sufficient force to

cause injury. Keep all hoses and connections in good serviceable

condition. Failure to heed could result in serious personal injury or

death.

Check that all gear cases and oil bath enclosures contain oil and

that bearings and joints have been greased. (See maintenance

section).

6.0 PRE-OPERATION

PB-MIXER-19 - 25 - www.meyermfg.com

1-800-325-9103

6.1.1 General Inspection

Inspect the mixer, chassis, axles, spindles, tires, hitches & all safety

shielding, safety signs and safety lighting regularly. These parts if

not watched closely, could pose potential injury or death. If any part

is found in need of repair, follow the SHUTOFF & LOCKOUT POWER

recommendations and have qualified personnel repair immediately.

Check to be sure that the gearcases contain oil and that bearing and joints have been greased. See Lubrication section

for more information.

1. Check the mixer for proper assembly, adjustment and lubrication. Check the machine for proper oil supply. If unit is

equipped with a front or side conveyor, oil the apron chains and check to be sure all bolts and set screws are tight.

2. Make sure that all guards and shields are in place, secured and functioning as designed.

3. Check for and remove any foreign objects in the mixing chamber and discharge opening.

4. Check that all hardware is in place and is tight.

5. Watch for any cracks that may have developed in the welds. If found, have qualified personnel repair immediately.

6. Check the hitch for proper location and alignment and clamp load of attaching bolts. If the upper clevis bar becomes

excessively worn, the hitch assembly should be turned over so the unworn hitch bar is on top. Replace if both bars

are worn. Worn or damaged parts, particular bolts should be replaced before failure.

6.1.2 Before Loading The Formula Mixer

Before loading the mixer, check the following items:

1. Check to see that the discharge door is closed.

2. Be sure no one is inside mixer.

3. Test run the mixer.

a. Make sure the mixer is empty, then start the mixer.

b. Run the mixer and front conveyor (or chain and slat) if equipped for at least five minutes at 3/4 of rated PTO RPM.

c. Raise and lower the door several times.

d. Disengage the machine, turn off the tractor engine, and then remove the driveline.

e. Check the drive components to be sure they are not abnormally hot.

Meyer Manufacturing Corporation - 26 - PB-MIXER-19

6.2 LIGHT HOOK-UP

Do not exceed maximum PSI or a motor failure could result.

Hydraulic fluid escaping under pressure can have sufficient force to

cause injury. Keep all hoses and connections in good serviceable

condition. Failure to heed could result in serious personal injury or

death.

NOTE: The lighting system provided is intended for being transported by an agricultural tractor.

Ensure that lights and indicators are clean and in good working order. When attaching to a towing vehicle other than a

tractor always check lighting for proper operation as wiring may vary. Connect to the standardized 7-pin socket located at

the back of the tractor.

Color Function SAE Terminal SAE Connector

Red Ground 1

Not Used 2

Yellow Left Turn & Hazard 3

Not Used 4

Green Right Turn & Hazard 5

Brown Tail Lights 6

Auxiliary Power 7

Viewed From Back

NOTE: The brake wire should only be connected to the #4 terminal if the #4 terminal on the tractor is

confirmed to be a brake light terminal. If the tractor does not have a brake light terminal, cap / seal

off the end of the brake wire of the implement (secure to other wires).

6.3 HYDRAULIC HOOK-UP

Pull Type: Requires 25 GPM @ 3000 PSI.

Call the factory if additional information is needed.

PB-MIXER-19 - 27 - www.meyermfg.com

1-800-325-9103

6.4 PTO DRIVELINE

Shutoff and lockout power before adjusting, servicing, maintaining,

or clearing an obstruction from this machine. Failure to heed may

result in serious personal injury or death.

Do not operate without PTO guard on implement and tractor. Maintain

PTO drive shaft guard tubes in good operating condition. Replace

them if damaged and not turning freely. Failure to heed may result in

serious personal injury or death.

6” - 12”

8” Recommended

14” - 540 RPM, 1 3/8-6

16” - 1000 RPM 1 3/8-21

20” - 1000 RPM 1 3/4-20

15” - 22”

GROUND

The tractor half of the PTO drive shaft assembly must be locked securely to the tractor output shaft and the implement

half of the PTO drive shaft assembly must be locked securely to the mixer drive line.

See your PTO Installation, Service, and Safety Instruction Manual for additional PTO details. Call the factory for a

replacement manual at 1-800-325-9103.

See your ADMA Safety Manual for further safety situations and precautions that you should familiarize yourself and those

that may be operating this equipment. Call the factory for a replacement manual at 1-800-325-9103.

6.4.1 Drawbar

This mixer may be either 540 or 1000 RPM depending on

the model. Do not operate 540 RPM implements at 1000

RPM, or 1000 implements at 540 RPM.

Set your tractor drawbar to conform to the standard

dimensions as shown. An improperly located hitch point

may cause damage to the universal joints of the PTO

drive shaft. This will ensure that the PTO drive shaft will

not be over extended.

Meyer Manufacturing Corporation - 28 - PB-MIXER-19

6.4.2 Cutout Clutch (F585-F1215 Models)

1

Do not allow anyone to stand between the tongue or hitch and the

tractor when backing up to the equipment.

Keep hands, legs and feet from under tongue and hitch until jack is

locked into place.

The clutch is designed to limit the amount of torque transferred to the

machine through the driveline. If excessive torque is developed the clutch

will disengage. A loud ratcheting sound will be heard and the transfer of

power to the machine will be disrupted. This may occur when mixing or

unloading a heavy mix or if an obstruction has lodged within the mixer.

This is to protect the driveline from damage. To re-engage the machine,

simply shut down the PTO and allow the driveline to come to a stop. The

PTO can then be re-engaged to restart the mixer. The cutout clutch will

either re-engage upon shut down of the PTO or just before it comes to a

complete stop.

6.4.3 Shear Bolt PTO, Primary (F355/F470)

The primary driveline on the F355 & F470 has a shear bolt design. When the torque reaches its maximum load, the shear

bolt will shear to protect the system. Replace the 3/8”-16 x 1” grade 5 shear bolt and 3/8-16 locknut to reset the PTO.

6.5 HITCHING TO TRACTOR

Before hitching to the tractor, make sure that there is sufficient ballast on the front axle of the tractor.

Depending on conditions, the ballast weight needs to be adjusted to optimize tractor drive. The front axle load must

never, under any circumstances, be less than 20% of the tractor's unladen weight.

Move to the operator’s position, start the engine and release the parking brake.

Move the tractor in front of the mixer. Slowly move the tractor backwards towards the mixer and align the drawbar with the

implement’s hitch.

NOTE: Lower or raise the mixer jack to properly align the drawbar and hitch.

Fasten the mixer hitch to the tractor drawbar with a properly sized hitch pin with safety retainer. (Reference ANSI/ASABE

AD6489-3 Agricultural vehicles - Mechanical connections between towed and towing vehicles - Part 3: Tractor drawbar.)

Connect the tractor half of the PTO drive shaft assembly. The PTO must be locked securely to the tractor output shaft and

the implement half of the PTO drive shaft assembly must be locked securely to the mixer drive line.

Before operation and after hitching the tractor to the implement, connect the hydraulic hoses (if applicable) and light cord

to the tractor. Place the jack into the storage position. (See 6.5.1 Jack Storage on page 30.)

PB-MIXER-19 - 29 - www.meyermfg.com

1-800-325-9103

6.5.1 Jack Storage

Keep hands, legs and feet from under tongue and hitch until jack is

locked into place.

1

2

DO NOT allow anyone to operate, service, inspect or otherwise handle

this equipment until all operators have read and understand all of the

instructional materials in this Operator’s And Parts Manual and have

been properly trained in its intended usage.

Before operating the equipment, look in all directions and make sure

no bystanders, especially small children are in the work area.

Shutoff and lockout power before adjusting, servicing, maintaining,

or clearing an obstruction from this machine. Failure to heed may

result in serious personal injury or death.

Always keep all shields and guards in place and securely fastened.

Keep hands, feet and clothing away.

After hitching the mixer to the tractor.

Using the handle, raise the jack off the ground and remove the pin.

Move the jack (Item 1) to the storage mount under the left hand

side of the mixing tub. Reinstall the pin (Item 2) to lock the jack into

the transport position.

NOTE: Keeping jack stored in proper position will keep it from

getting damaged during transportation.

6.6 START-UP AND SHUT-DOWN

Meyer Manufacturing Corporation - 30 - PB-MIXER-19

6.6.1 Start-Up

Before Loading The Mixer:

Enter the tractor and start the engine.

Check to see that the discharge door is closed.

Be sure no one is inside the mixer.

Test run the mixer.

a. Make sure the mixer is empty, then start the mixer.

b. Slowly engage the PTO and operate at idle speed.

c. Run the mixer and front conveyor (or chain and slat) if equipped for at least five minutes at 3/4 of rated PTO RPM.

d. Raise and lower the door several times.

e. Disengage the machine, turn off the tractor engine, and then remove driveline.

f. Check the drive components to be sure they are not abnormally hot.

6.6.2 Shut-Down

Disengage the PTO.

Fully lower all doors.

Park the tractor on a flat, level surface.

Engage the parking brake, stop the engine and exit the tractor.

Remove the driveline and all electrical and hydraulic components.

Check drive components to be sure components are not abnormally hot.

PB-MIXER-19 - 31 - www.meyermfg.com

1-800-325-9103

6.7 TRANSPORTING

AVOID SERIOUS INJURY OR DEATH

• Read and understand owner’s manual before using. Review

safety precautions annually.

• Before operating the mixer, look in all directions and make sure

no bystanders, especially small children are in the work area.

• No riders allowed when transporting.

• Do not drink and drive.

• Before moving, be sure required lights and reflectors are

installed and working.

• Before maintenance or repair, stop vehicle, set parking brake,

and remove ignition key.

• Place safety stands under frame and chock wheels before

working on tires or chassis.

• Maintain wheel bolts at torque as recommended in the manual.

• If equipped with brakes, maintain proper adjustment.

Pull-Type Units

• You must observe all applicable traffic laws when transporting

on public roadways. Check local laws for all highway lighting

and marking requirements.

• Use flashing warning lights when transporting on ALL highways

(public roadways) at ALL times (Tractor towed models) EXCEPT

WHEN PROHIBITED BY LAW! (Check w/local law enforcement).

• By all state and federal laws, implement lights do not replace the

SMV (Slow-Moving Vehicle) identification emblem. All towed

agricultural vehicles must display SMV emblems when traveling

LESS than 25 mph (32 kph).

• Check for traffic constantly. Be sure you can see that no one is

attempting to pass you and that all traffic is sufficiently clear

from you before making any turns.

• Securely attach to towing unit. Use a high strength appropriately

sized hitch pin with mechanical retainer and attach safety chain.

• Do not exceed 20 mph (32 kph). Slow down for corners and

rough terrain.

Failure to heed may result in serious personal injury or death.

To Prevent Serious Injury Or Death

• Keep hands and body out of the hitch area when attaching

towing vehicle.

• Keep body clear of crush point between towing vehicle and load.

• Keep hands, legs and feet from under tongue and hitch until jack

is locked into place.

Meyer Manufacturing Corporation - 32 - PB-MIXER-19

NOTE: For Truck Mounted models, an Optional Highway Lighting Package is available to assist in meeting these

To Prevent Serious Injury Or Death

• Shift to lower gear before going down steep grades.

• Avoid traveling on slopes or hills that are unsafe.

• Keep towing vehicle in gear at all times.

• Never exceed a safe travel speed (which may be less than 20

MPH.).

• Check that the braking and lighting systems are in good

condition. Be sure that the tractor has adequate brakes to stop

the loaded mixer.

If you will travel on public roads and it is legal to do so, you must

know all rules governing such operation. This will include lighting

and brake requirements in addition to traffic rules.

A safety chain must be installed to retain the connection between

the tractor (or other towing vehicle) and implement whenever

traveling on public roads in case the hitch connection would

separate.

2

1

If you do not have a safety chain, or a replacement safety chain is

needed, see your local Meyer dealer who will supply you with the

proper chain for your application. Do not operate on public roads

until you are able to travel with the safety chain properly installed.

requirements. See your Meyer Dealer for Details.

6.7.1 Safety Chain

The chain must be of adequate size to hold the weight of the loaded

mixer. See your ag cart or wagon owner / operator’s manual and

parts book, which is also available at www.meyermfg.com.

NOTE: If using a grab hook at the end(s) of the chain to secure

the chain to itself, a hook latch (Item 1) must be installed.

The length of the safety chain is not to be longer than necessary to

turn without interference. If any chain links or attachment hardware

are broken or stretched, repair before using. Store chain so it does

not corrode or become damaged. Do not use this chain for other

implements because the strength and length of the chain may not be

adequate. Identify this chain for use on this particular mixer.

NOTE: Do not use the intermediate support (Item 2) as the attaching point.

PB-MIXER-19 - 33 - www.meyermfg.com

1-800-325-9103

6.7.2 Tire / Wheel Torque

• Clean adjoining surfaces.

• Re-torque wheel nuts after 50-100 miles.

• Check wheel nut torque every 10,000 miles and re-torque as necessary.

MEYER EQUIPMENT WHEEL TORQUE

BOLT / STUD SIZE SOCKET SIZE PRESS FORMED

WHEEL CENTER

BOLT TYPE HEAVY DUTY WHEEL

CENTER

5/8” 15/16” 100 ft. lbs. Bevel Nut 160 ft. lbs.

1-1/16” Flange Nut

3/4” 1-1/8” NA Flange Nut 378 ft. lbs.

1-1/2”

TIRE INFLATION

TIRE SIZE PLY PSI

385 / 65R x 22.5 Recap 100

245 / 70R x 19.5 Recap 100

380 / 60R x 16.5 - 73

6.7.3 Brake Information

Check that the braking and lighting systems are in good condition. Be sure that the tractor has adequate brakes to stop

the mixer.

See your tractor / chassis manual for brake and braking Information.

6.7.4 Tractor Towing Size Requirements

Use the following charts to help calculate the minimum tractor weight when towing without implement brakes. The

minimum tractor weight, up to 20 mph (33 kph) needs to be 2/3’s of the box Gross Weight (GW). Gross Weight is

calculated by the empty weight of the box and undercarriage combined added to the Load Weight. Then take the Gross

Weight and multiply it by 0.667 and you will get the Minimum Required Weight of the Tractor. A tractor with this

recommended weight for your machine is normally adequate for towing the loaded machine under average conditions.

Unit weight will vary depending on door and option selected.

Meyer Manufacturing Corporation - 34 - PB-MIXER-19

Gross Weight

1

MIXER WEIGHT,

EMPTY (LBS)

UNDERCARRAIGE

WEIGHT (LBS)

++=GW

++=

++=

++=

Minimum Required Weight of the Tractor

LOAD (LBS) GROSS WEIGHT (GW)

(LBS)

2/3 GROSS

WEIGHT

MINIMUM TRACTOR

WEIGHT (LBS)

(GW) (LBS)

0.667 x GW = TW

x=

6.8 OPTIONAL EQUIPMENT

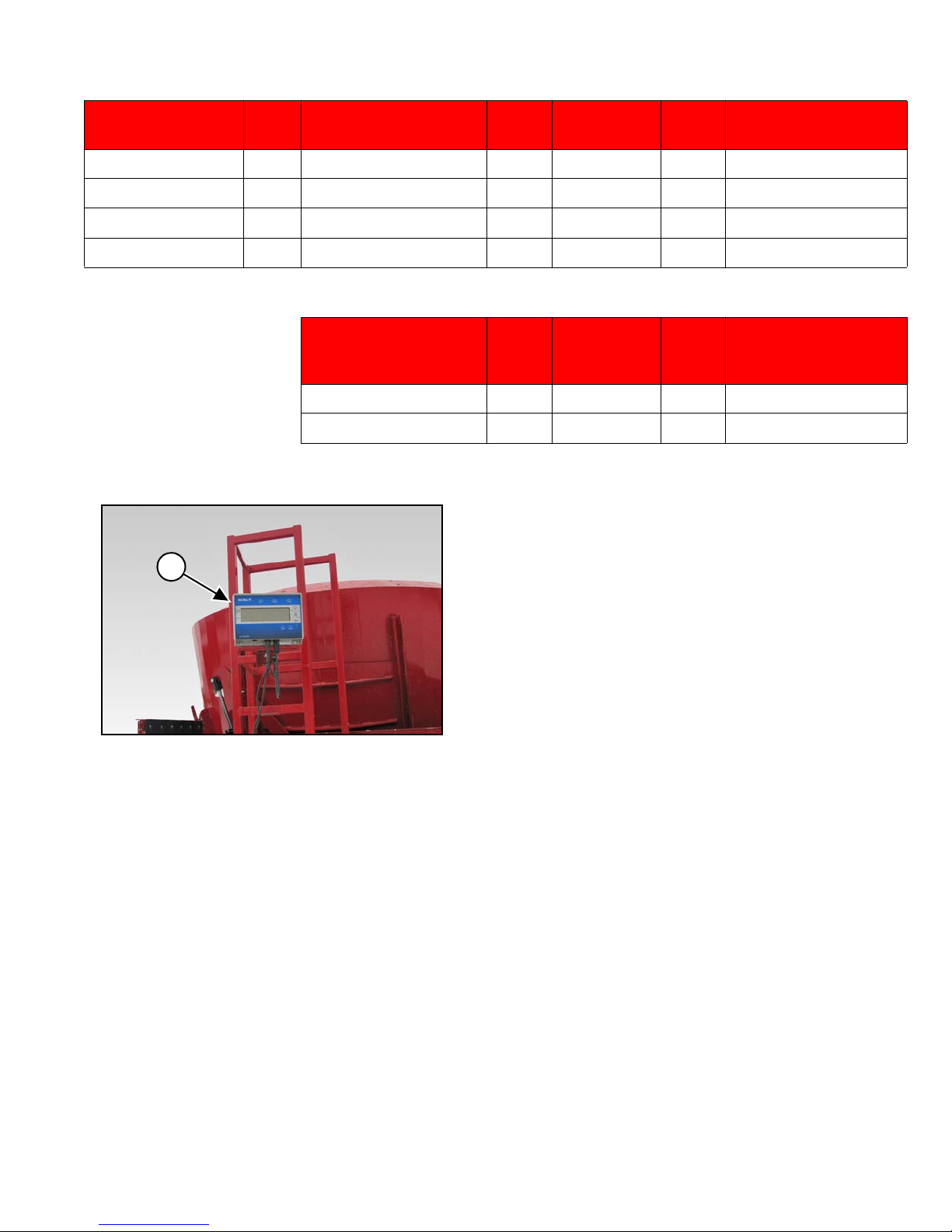

Digital Scale Indicator

Refer to scale indicator (Item 1) manufacturer's operator manual for

operation and maintenance.

NOTE:Some scale drift may occur after the scale is turned on

but should level out within 10 to 15 minutes. Temperature

changes may also cause some drifting.

See your Digi-Star manual for additional scale information.

PB-MIXER-19 - 35 - www.meyermfg.com

1-800-325-9103

Meyer Manufacturing Corporation - 36 - PB-MIXER-19

7.0 OPERATION

DO NOT allow anyone to operate, service, inspect or otherwise

handle this mixer until all operators have read and understand all of

the instructional materials in this Operator’s And Parts Manual and

have been properly trained in its intended usage.

Before operating the mixer, look in all directions and make sure no

bystanders, especially small children are in the work area.

Do not climb or step onto the platform or ladder before the parking

brake has been applied.

Turn on level ground. Slow down when turning.

Go up and down slopes, not across them.

Keep the heavy end of the machine uphill.

Do not overload the machine.

Check for adequate traction.

Always operate at the rated PTO speed but DO NOT EXCEED THE

RATED PTO SPEED. If the mixer is operated faster than the rated PTO

speed the strain on the drive train and mixer is greatly increased.

Do not force hay into the auger with loader or any other device.

Be aware of the overall size of the mixer to allow clearance through

doorways.

Never hand feed material into mixer while it is running. Augers may

cut or grab hands, clothing, or material being loaded, causing severe

injury. Always stop the tractor's engine before hand loading

materials.

7.1 GENERAL

The mixer is designed for blending dairy and beef rations. The mixer performance can vary according to the difference in

material, loading sequence, mixing speed and unloading methods. The following guidelines should be understood before

operating the mixer.

A new mixer will need an initial run-in period to polish the augers and mixer sides to achieve correct material movement

inside the mixer. Until the unit is polished inside the user may experience material spillage, dead spots, or increased

horsepower requirements. The load size may need to be reduced until the unit is polished inside.

7.1.1 Material

Some feed materials will need to be processed alone in the mixer before they can be efficiently mixed with other feed

materials.

• Large square or round bales of alfalfa

• Large square or round bales of high moisture content

• Large square or round bales of long mixed grasses, wheat or oat hay and crop residue bales (straw or soybean

stubble)

• Very light and bulky feed material

NOTE: Always remove any twine, net, or plastic wrap from bales before loading into mixer.

PB-MIXER-19 - 37 - www.meyermfg.com

1-800-325-9103

7.2 LOADING

DO NOT ENTER MIXER CHAMBER WHILE MIXER IS RUNNING! Shut

off and lock out power before attempting to clear an obstruction or to

perform work inside the mixing chamber. (See 5.3 SHUTOFF &

LOCKOUT POWER on page 24.)

Be aware of power lines and other overhead obstructions when

loading with a telescopic arm or loader. Failure to obey warnings

could cause serious injury or death.

Comply with the safety instructions stipulated in the User Manuals

for the operation / handling equipment used for loading the mixer.

Shutoff and lockout power before adjusting, servicing, maintaining,

or clearing an obstruction from this machine. Failure to heed may

result in serious personal injury or death.

Do not climb or step onto the platform or ladder before the parking

brake has been applied.

Overloading may cause failure of axles, tires, structural members,

hitches, loss of vehicle control. DO NOT

exceed maximum gross

weight. (See 9.0 SPECIFICATIONS on page 63.)

NOTE: Overloading can have detrimental effects on the integrity of the implement and it’s safe use. Overloading

will void warranty and increase risk to the operator's safety. Always be aware of your gross weight.

MAXIMUM FORMULA MIXER GROSS WEIGHT MATERIAL ESTIMATED WEIGHT

PER CUBIC FOOT

MODEL LBS MATERIAL LBS / CU.FT.

F355 Soybeans 47 lbs.

F470 Cotton Seed (Dry) 20 lbs.

F585 Corn (Shelled) 45 lbs.

F700 Corn Silage 30 lbs.

F815 Haylage 20 lbs.

F1015 Source: SAE D384.2

F1215

NOTE: Maximum Gross Weight is the lesser value between the implement, chassis, or tires.

When loading material into the mixer with an end-loader, dump the material into the center of the mixer.

1. Be sure that mixer is parked on a level surface.

2. The tractor should be straight in line with the mixer.

3. Completely close the mixer discharge door(s).

4. Set hay stops according to the instructions in this manual.

5. Enter the tractor and start the engine.

6. Engage the PTO / hydraulics.

7. Set the tractor engine to operate at approximately 3/4 of rated PTO speed.

8. Load baled hay into the center of the mixer.

Meyer Manufacturing Corporation - 38 - PB-MIXER-19

9. Allow mixer enough time to process the bale before adding other ingredients (4-10 minutes).

When loading from a raised bay or platform, adopt the necessary

measures (safety rails, etc.) to avoid people or equipment from falling

into the machine.

Load all ingredients as quickly as possible. Allow a final mix time of

3-7 minutes, or whenever the load looks consistently mixed.

Never load long stem bales last. They will not be processed or mixed

into the ration and may cause unloading difficulties or spillage.

NOTE: Processing of long stem forages will continue as other materials are added and mixed. Be careful not to

over process these materials before adding other ingredients.

NOTE: Using the mixer two speed shiftable gearbox, roughages can be processed in “Low” or “High” depending

on how fast the bale needs to be processed.

7.2.1 Loading Steps

NOTE: The loading sequence could vary.

The following is an example of a typical loading sequence:

1. Load and process long stemmed materials.

2. Load haylage and corn silage.

3. Load minerals, proteins, and other small quantity ingredients.

4. Load grains, wet and dry commodities, etc.

5. Load all liquid fats, water, other liquids. Always load liquids at the center of the mixing chamber.

PB-MIXER-19 - 39 - www.meyermfg.com

1-800-325-9103

7.3 MIXING

DO NOT ENTER MIXER CHAMBER WHILE MIXER IS RUNNING! Shut

off and lock out power before attempting to clear an obstruction or to

perform work inside the mixing chamber. (See 5.3 SHUTOFF &

LOCKOUT POWER on page 24.)

Always operate at the rated PTO speed but DO NOT EXCEED THE

RATED PTO SPEED. If the mixer is operated faster than the rated PTO

speed the strain on the drive train and mixer is greatly increased.

Do not force hay into the auger with loader or any other device.

VIEWING PLATFORM

Normal mixing speed is 3/4 to full PTO speed. Time available to mix, thoroughness of the mix, and ingredients are all

factors that must be considered when deciding on when and how fast to operate the mixer.

7.4 PLATFORM OPERATION

Park the tractor on a flat, level surface.

Engage the parking brake.

NOTE: Always maintain a three-point contact at all times when

getting on and off the ladder. Use the ladder rails and steps

when climbing the ladder.

Meyer Manufacturing Corporation - 40 - PB-MIXER-19

7.5 FOLDING LADDER

1

2

Shutoff and lockout power before adjusting, servicing, maintaining, or

clearing an obstruction from this machine. Failure to heed may result

in serious personal injury or death.

DO NOT ENTER MIXER CHAMBER WHILE MIXER IS RUNNING! Shut

off and lock out power before attempting to clear an obstruction or to

perform work inside the mixing chamber. (See 5.3 SHUTOFF &

LOCKOUT POWER on page 24.)

To unfold the ladder, release latch (Item 1) and pull ladder fully out (Item

2). To return ladder to storage position, pull ladder out to “unlock” it and

guide the ladder support back up to its original position. Replace latch.

7.6 UNLOADING

NOTE: Unload the mixed ration within a short time of mixing. A fully loaded mixer which is bounced over rough

terrain or allowed to settle will require more horsepower during start-up.

1. Enter the tractor, start the engine, release the parking brake.

2. Move the tractor and mixer to the unloading area.

3. Be sure that mixer is parked on a level surface.

4. The tractor should be straight in line with the mixer.

5. Shift hydraulic sliding base discharge into working position, or lower slide tray / incline extension / chain and slat (if

equipped).

6. Using the two speed shiftable gearbox, shift the gearbox into “Low” to ease the start of a full load for unloading.

7. Engage the PTO.

8. Set the tractor engine to operate at approximately 1/2 of rated PTO speed.

9. Open discharge door slowly to adjust the amount of material to be discharged. Adjust door height or conveyor speed

for desired flow of feed.

10. After the load begins to discharge, increase the tractor RPM to full rated PTO speed to ensure fast and thorough clean

out while driving forward along the discharge path.

NOTE: The mixer PTO MUST be stopped before shifting the 2-speed gearbox to prevent damage to the gearbox.

11. The 2-speed gearbox can be shifted into “HIGH” during the unloading process. Stop the PTO prior to shifting. This will

help remove any feed remaining on the augers and assist in keeping an even feed flow until the mixer is empty.

NOTE: For Truck Mounted Models, do not operate above the rated 1500 RPM engine speed.

12. When finished unloading, reduce engine speed to idle and disengage the PTO / hydraulics.

PB-MIXER-19 - 41 - www.meyermfg.com

1-800-325-9103

13. Move the mixer forward, away from the unloaded material.

If any component fails, shut off all power to the mixer and move the

mixer to a safe work area. Repair or replace damaged components

before proceeding with unloading of the mix.

Keep hands, legs and feet from under tongue and hitch until jack is

locked into place.

14. Close the discharge door.

15. Shift hydraulic sliding base discharge into storage position, or raise slide tray / incline extension / chain and slat (if

equipped).

16. Park the mixer on a flat, level surface.

17. Engage the parking brake, stop the engine and exit the tractor.

18. Disconnect the driveline.

7.7 UNHOOKING THE TRACTOR

1. Park the implement on level ground. Put the tractor controls in neutral, set the parking brake, and turn the engine off

before dismounting.

2. Place wheel chocks in front and in back of the implement wheels on opposite sides to prevent the implement from

rolling after the tractor is unhooked.

3. Remove the hydraulic hose ends from the tractor hydraulic ports and secure the hose ends in the key slot holes on

the front of the mixer to keep them clean.

4. Remove the light cords and any optional equipment connections.

5. Remove the jack from the storage mount and reinstall the jack to the mount. Crank the jack down until the hitch lifts

off the tractor draw bar.

6. Remove the hitch pin.

7. Unhook safety chain from tractor drawbar and intermediate support.

8. Slowly drive the tractor away from the implement.

Meyer Manufacturing Corporation - 42 - PB-MIXER-19

7.9 HAY STOP ADJUSTMENT

Do not adjust the hay stops while the mixer is running. Moving feed

inside the mixer can make the hay stop move suddenly causing

injury to the person making the adjustment.

Never operate the mixer without the hay stop lock bolt installed.

1

2

Hay Stop

Position A

Hay Stop

Position B

Hay Stop

Position C

Hay Stop

Position D

Hay Stop

Position E

7.9.1 Hay Stop Lock Bolt

The hay stop lock bolt (Item 1) prevents the hay stop from rotating

past the intended range of operation. If the hay stop bolt and the

positioning pin (Item 2) are removed, the hay stop could contact the

moving auger and cause damage to the hay stop and auger.

Position Setting Material

A High Light and bulky material (dry grasses)

B Medium High Alfalfa bales and other forages

C Neutral Unrestrained movement of feed

D Medium Low Heavier rations

E Low Aggressive cutting

PB-MIXER-19 - 43 - www.meyermfg.com

1-800-325-9103

7.10 MIXER TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE SOLUTIONS

Forage is cut too short • Reduce the initial processing time.

• Adjust hay stops to a less aggressive or neutral position.

• Reduce total loading time.

• Reduce the mixer RPM to limit aggressiveness in processing.

• Modify the knife type, quantity, setting or placement.

• If the machine is equipped with a 2 speed shiftable gearbox, shift into “Low”.

Spillage is Occurring • Reduce load size.

• Reduce tractor and/or mixer RPM.

• Make sure machine is level.

• The load size may need to be reduced until the unit is polished inside.

• Adjust hay stops to a less aggressive or neutral position.

• Adjust knives to a less aggressive position.

• If spillage still occurs, the optional side extensions or hay retention ring may

need to be installed.

Requiring High Horsepower • Reduce load size.

• Adjust hay stops to a less aggressive or neutral position.

• The load size may need to be reduced until the unit is polished inside.

• Modify the knife type, quantity, setting, or placement.

• If the machine is equipped with a 2 speed shiftable gearbox, shift into “Low”.

Dead Spots • The load size may need to be reduced until the unit is polished inside.

• The auger scraper may need to be adjusted. (See the Adjustments Section.)

Digital Scale Indicator • Refer to scale manufacturer’s operator manual for operation and maintenance.

• Some scale drift may occur after the scale is turned on but should level out

within 10 to 15 minutes.

• Temperature changes may also cause some drifting.

Meyer Manufacturing Corporation - 44 - PB-MIXER-19

8.0 MAINTENANCE

SHUTOFF & LOCKOUT POWER before adjusting, cleaning, lubricating

or servicing the machine. (See 5.3 SHUTOFF & LOCKOUT POWER on

page 24.)

Fluid such as hydraulic fluid, grease, etc. must be disposed of in an

environmentally safe manner. Some regulations require that certain

spills and leaks on the ground must be cleaned in a specific manner.

See local, state and federal regulations for the correct disposal.

1

Front Gearbox

Reservoir

Rear Gearbox

Reservoir

1

2

2-Speed

Gearbox Reservoir

8.1 LUBRICATION

NOTE: When welding do not allow electrical current to flow through bearings, roller chains, or scale weigh bars.

Ground the welder directly to the part being welded. Always disconnect the power cord from scale

indicator before welding.

NOTE: Use a grease type that is composed of a high quality lithium complex or better, unless otherwise stated.

We recommend using a #1 grade in colder temperatures or a #2 grade in warmer temperatures.

NOTE: Over lubrication is a major cause of bearing failures. Please relubricate conservatively when unsure of

bearing requirements.

8.1.1 Daily or every 8-10 loads:

NOTE: See Specifications, Page 53 for proper oil type and capacities.

Check the planetary gearbox oil levels daily to prevent abnormal

component wear. Add new oil to the reservoir tank (Item 1) if the oil

level is not at the oil reservoir mark.

Check for any oil leaks. If leaks occur, correct the source of the

leak.

Check the 2-speed gearbox oil level daily to prevent abnormal

component wear. Add new oil to the reservoir tank (Item 2) if the oil

level is not at the oil reservoir mark.

Check for any oil leaks. If leaks occur, correct the source of the leak.

PB-MIXER-19 - 45 - www.meyermfg.com

1-800-325-9103

8.1.2 Weekly:

1

1

3

2

1

1

Optional Equipment Maintenance (If Equipped)

Clean out under chain return shield (Item 1).

Oil Hubs

• Check the oil level in each wheel hub (Item 1). The oil should be

1/2” high in the sight glass (Item 2). If low, add EP80/90 gear

lube through the pop out rubber plug (Item 3) at the center of the

hub.

8.1.3 Monthly:

Driveline

NOTE: The number of input bearings will vary depending upon your model mixer.

NOTE: Shielding has been removed for illustration purposes only.

Grease all input bearings (Item 1).

Meyer Manufacturing Corporation - 46 - PB-MIXER-19

Optional Equipment Maintenance (If Equipped)

Tandem Inner / Outer Bearings

2

3

3

Front Cross Conveyor - Left Hand Side

Front Cross Conveyor - Right Hand Side

3

3

Grease the tandem inner / outer bearings (Item 2).

Grease the four (4) front cross conveyor bearings (Item 3).

PB-MIXER-19 - 47 - www.meyermfg.com

1-800-325-9103

Side Door Conveyor (If Equipped)

1

1

xxxxxxxxxxxxxxxxSide Door Conveyor Option

Rear Discharge Door

1

Grease the four (4) side door conveyor bearings (Item 1) (both

sides).

8.1.4 Every 40 hours:

Oil Door Pivots (Item 1).

8.1.5 50 hours:

First oil change in the planetaries and 2-speed gearbox. (See page

53).

Meyer Manufacturing Corporation - 48 - PB-MIXER-19

Grease all PTO driveline zerks.

For 118-VM-0001-55, 118-VM-0013-55

For 118-VM-0023-55 and 118-VM-0024-55

For 118-VM-0011-55, 118-VM-0020-55, 118-VM-0025-55, 118-VM-0026-55, and 118-VM-0027-55

Double Universal Joint

3

2

Grease all universal joints (Item 2) and the slide (Item 3).

PB-MIXER-19 - 49 - www.meyermfg.com

1-800-325-9103

8.1.6 Semiannually (500 - 600 hours):

Shading indicates correct amount of grease.

When you lubricate the wheel-end cavity with

approved grease, pack the area of the hub

between the two bearings with grease only up to

the smallest diameter of the bearing cups. Do not

install too much grease in the wheel-end cavity.

Remove excess grease, which can contaminate

the brakes and affect bearing life and braking

Shading indicates correct amount of grease.

performance. Damage to components can result.

Change oil in the 2-speed gearbox.

Grease Packed Hubs

• Use a pressure packer to pack the bearing cones with grease by

forcing grease into the cavities between the rollers and cage

from the large end of the cone. If a pressure packer is not

available, pack the bearings by hand.

• Apply a light coat of grease to the spindle bearing journals.

• Pack the area of the hub between the two bearings with grease up to the smallest diameter of the bearing cups.

Remove excess grease.

• Install and tighten the hub retention hardware. Apply a light coat of approved NLGI 1 or 2 grease to the hubcap interior

and across the face of the outer locknut. This will indicate that NLGI 1 or 2 grease was used, as well as help prevent

corrosion of these parts.

Meyer Manufacturing Corporation - 50 - PB-MIXER-19

8.1.7 Annually (1500 hours):

1

1

Change oil in the planetaries and 2-speed gearbox. (See page 53).

Grease the wheel bearings (Item 1).

8.1.8 Every Two Years or When Discolored:

Oil Hubs

• Drain oil from wheel hubs (Item 1) and refill with EP80/90 oil

every 2 yrs or if oil becomes discolored from water or other

contamination.

PB-MIXER-19 - 51 - www.meyermfg.com

1-800-325-9103

8.1.9 Gearbox Oil Change

SHUTOFF & LOCKOUT POWER before adjusting, cleaning, lubricating

or servicing the machine. (See 5.3 SHUTOFF & LOCKOUT POWER on

page 24.)

Fluid such as hydraulic fluid, grease, etc. must be disposed of in an

environmentally safe manner. Some regulations require that certain

spills and leaks on the ground must be cleaned in a specific manner.

See local, state and federal regulations for the correct disposal.

2

Front Gearbox

Reservoir

Rear Gearbox

Reservoir

3

1

4

5

Planetary For 585 - 1215 Models

Planetary For 355 - 470 Models

NOTE:

• In order to avoid sludge deposits, change the oil while the gear unit is still warm.

• For an effective oil change, the unit should be flushed with a liquid detergent recommended by the lubricant supplier.

• The mixer should be level when changing gearbox oil.

8.1.9.1 Planetary Gearbox

Draining

All Models: Place a container of sufficient capacity under the

gearbox (Item 4).

355 / 470 Models: Drain the planetary by removing the drain plug

(Item 5).

585 / 700 / 815 / 1015 / 1215 Models: Drain the planetary by

loosening the hose clamp and removing the hose.

All Models: Rinse the bottom hose with clean oil to remove any

metal particles or trapped water. Reattach hose, clamp, or drain

plug. After the unit is completely drained, reinstall the drain plug or

hose and hose clamp.

Filling

Filling with an oil pump:

(Call the factory to purchase an oil pump kit, Part #: VA-OP.)

Loosen the hose clamp and detach the lower hose (1) on the

reservoir (Item 2). Unbolt reservoir and lay so the top hose and

reservoir is below the hose used for filling (1).

Connect oil pump to lower hose and fill with oil until the catch basin

fills with approximately 2 quarts of oil. Discard this oil if it is dirty.

Reattach the lower hose (1) with the hose clamp. Bolt the reservoir

back in place. Fill the reservoir to the oil level mark and reinstall the

cap (Item 3).

NOTE: See Planetary Lubrication Specifications on page 53.

Inspect the reservoirs breather, make sure it is not plugged, and

check for leaks.

Meyer Manufacturing Corporation - 52 - PB-MIXER-19

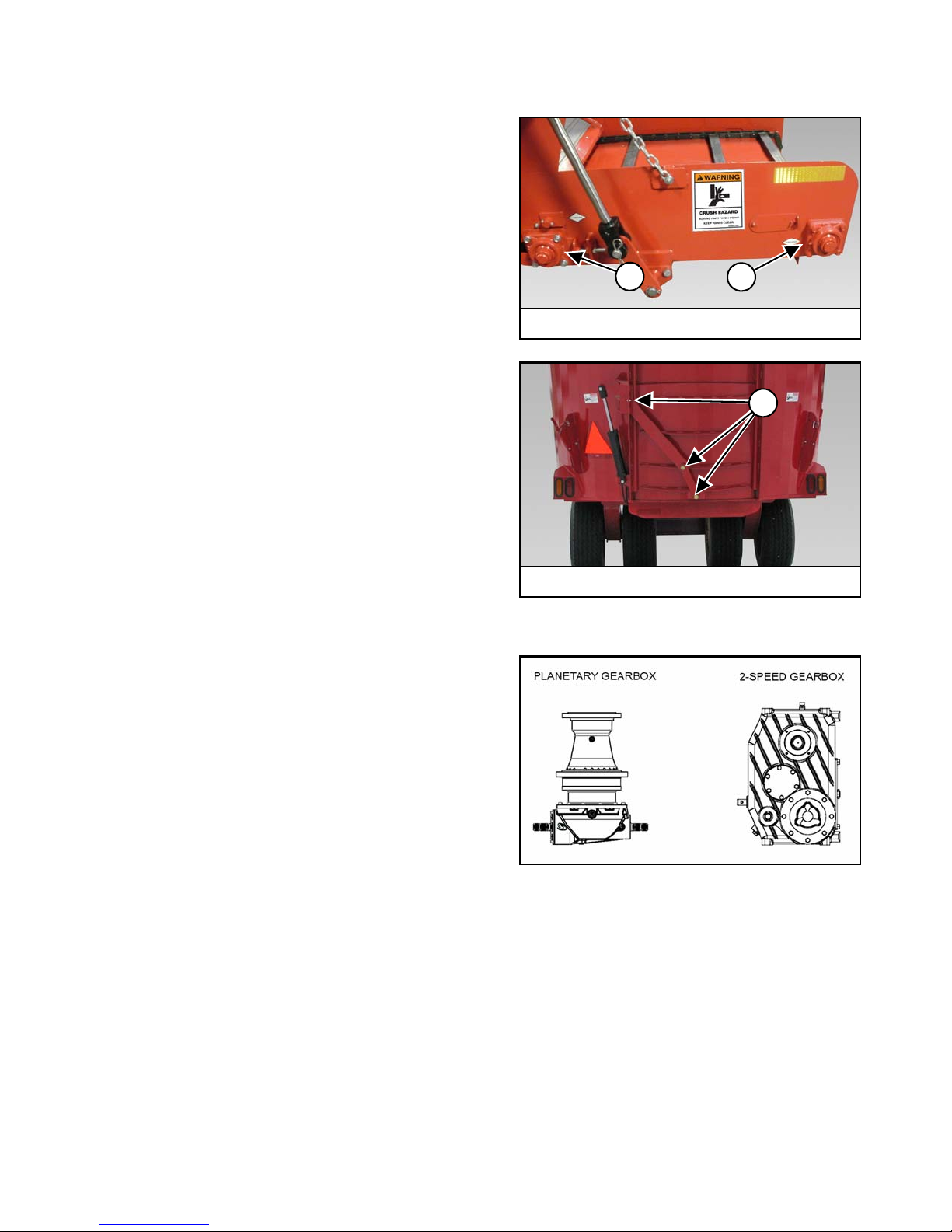

PLANETARY LUBRICATION SPECIFICATIONS

2-Speed Gearbox

Reservoir

Check the gearbox oil levels regularly to prevent abnormal

component wear. Add oil to the reservoir tanks if oil level is not at

the oil level mark.

Model Part Number Description Oil Type Capacity

355 / 470 119-16-13.4-1 1600 Planetary 13.4:1 Synthetic ISO 220 Or Equivalent Approx. 23.5 Quarts

585 / 700 119-18-13.92-1 1800 Planetary 13.92:1 Synthetic ISO 220 Or Equivalent Approx. 14.8 Quarts

815 / 1015 119-21-25.67-1 2100 Planetary 25.57:1 Synthetic ISO 220 Or Equivalent Approx. 18.5 Quarts

1215 119-32-24.8-1 3200 Planetary 24.8:1 Synthetic ISO 220 Or Equivalent Approx. 24.3 Quarts

8.1.9.2 2-Speed Gearbox

Draining

Place a container of sufficient capacity under the gearbox.

Drain the unit by removing the plug from the bottom of the gearbox.