Meyer E-Z PLUS MDII STP-7.0, E-Z PLUS MDII STP-7.5 Installation Manual

Form 1-746 R

April, 2005

Parts & Installation Instructions

E-Z PLUS™/MDII™ Models STP-7.0 and STP-7.5

13

11

15

12

14

6

7

1

22

4

1

19

25

2

3

18

20

17

21

26

24

29

23

31

32

30

27

Parts List

28

8

3

16

14

2, 3

4

5

10

15

15

13

2

12

9

8

14

Item STP-7.0 Qty. STP-7.5 Qty. Description

09243 1 09244 1 Moldboard Assembly

1 12033 1 12475 1 • Moldboard Frame

2 12368 2 12368 2 • Rubber Insert Outside rib STP

3 12369 2 12369 2 • Rubber Insert Inside rib STP

4 12054 1 12474 1 • Plastic Sheet

5 12053 1 12471 1 • Snow Deflector

6 12030 1 12487 1 • Bar Reinforcement

7 12029 1 12491 1 • Angle Support

8 09132 1 09796 1 • Cutting Edge

9 08184 1 08184 1 • Bolt C 1/2-13 x 1-3/4” Gr. 5

--------- ---- ---------- ---- & Locknut (Kit of 9 each)

10 22193 8 22193 9 • Bolt H 3/8-16 x 1” Gr.2

11 22191 7 22191 6 • Bolt C 3/8-16 x 1” Gr. 1

12 22190 12 22190 14 • Bolt C 1/2-13 x 1-3/4” Gr. 5

13 20314 15 20314 1 5 • Locknut 3/8-16

14 20307 12 20307 1 4 • Locknut 1/2-13

15 20353 15 20353 2 4 • 3/8” Flatwasher

12070 1 12467 1 Snow Deflector Kit

16 09126 2 09126 2 • Runner & Spindle Assembly

17 07006 1 07006 1 • • Runner

18 20363 10 20363 1 0 • • Flat Washer 1-1/4”

19 22083 1 22083 1 • • Linch Pin

20 12057 1 12057 1 • • Spindle

21 20101 1 20101 1 • • Bolt H 1/2-13 x 3”

22 20307 1 20307 1 • • Locknut 1/2-13

16515 1 16515 1 Sector and A-Frame Carton

23 21534 2 21534 2 • Lift Chain 5/16 x 36”

24 12326 1 12326 1 • Sector

25 13711 1 13711 1 • A-Frame (11” x 34” x 22-1/8”)

26 07017 3 07017 3 •• Trip Spring

09916 1 09116 1 • Plow Marker Kit

08738 1 08738 1 • Hardware Bag

27 09119 2 09119 2 •• Pivot Pin w/Fttg.& Cotter Pin

28 09124 3 09124 3 •• Eye Bolt w/ Locknut & Cap

29 09122 1 09122 1 •• King Bolt w/ Locknut

30 8518001026 2 8518001026 2 •• 7/16-14 NC U-Bolt

31 8501001007 4 8501001007 4 •• 7/16-14 NC Nut

32 20328 4 20328 4 •• Lockwasher

Parts indented are included in the assembly under which they are indented.

Meyer Products reserves the right, under its continuing product improvement program, to change construction or design details,

specifications and prices without notice or without inncurring any obligation.

INSTALLATION INSTRUCTIONS

Note: The following instructions cover assembly of

Moldboard, Sector and A-Frame. Refer to separate

instructions for installation of plow mounting and hydraulic

system.

A. Liberally coat Pivot Pins (27) with chassis lubricant.

B. Attach Sector (24) to Moldboard (1) with Pivot Pins (27)

(grease fitting facing outward) and insert Cotter Pin.

Grease Pivot Pin using grease fitting.

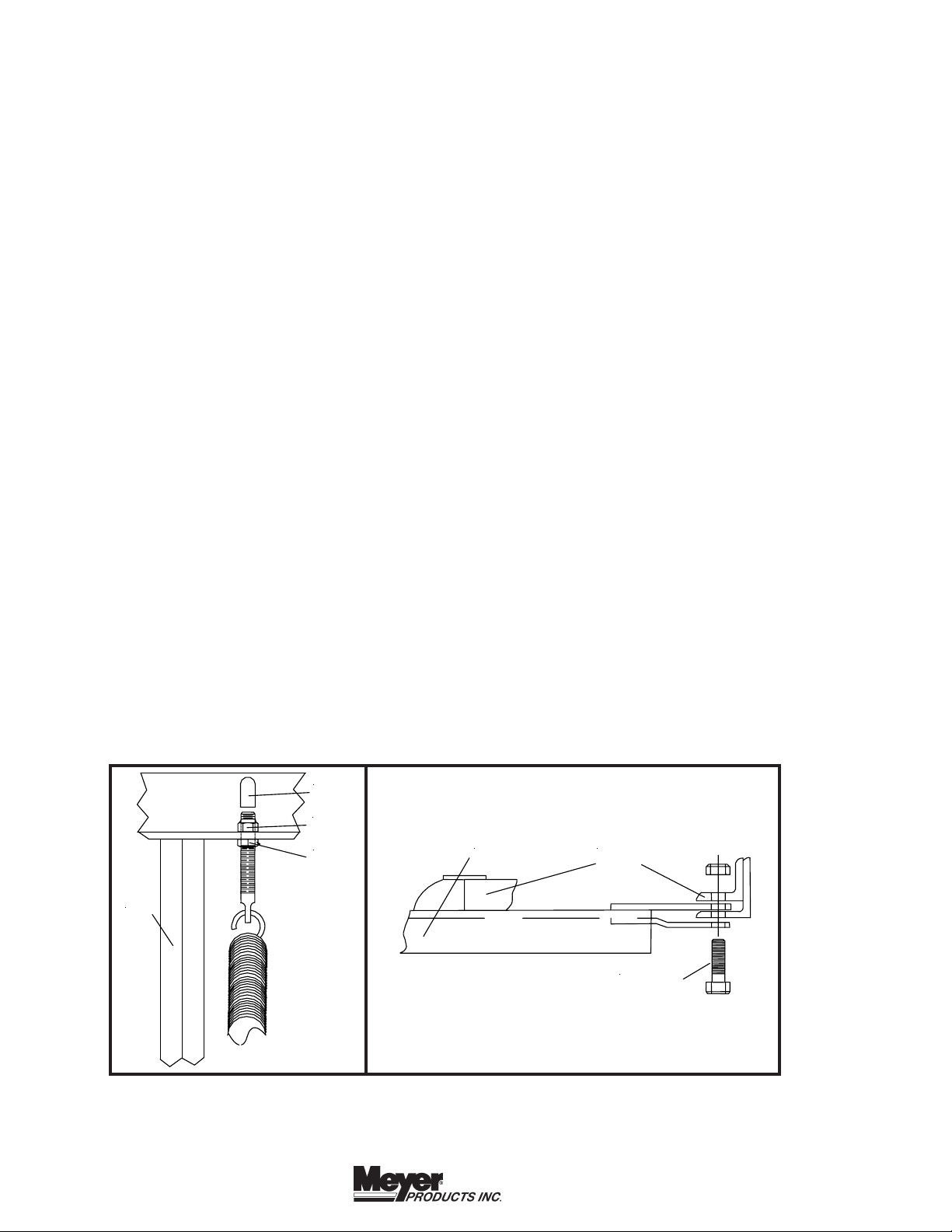

C. Attach Eye Bolts (28) to Moldboard (1) and trip Springs

(26) to Sector (24), making certain locknuts (28) are

positioned as shown in Figure 1.

D. Make certain each Eye Bolt (28) is in a vertical position

as shown in figure 1 so that the Eye Bolt (28) and Trip

Spring (26) hinge properly when moldboard trips.

Note: Proper tension is attained when Trip Spring (26) coils

just begin to separate and then tightening top locknut four

additional turns. Tighten bottom Locknut (20530) to secure

Eyebolt in position. Install Eyebolt caps (07031) over

exposed threads. See Figure 1.

RIB

E. Attach A-Frame to Sector (24) as shown in Figure 2.

IMPORTANT: Install King Bolt (29) from bottom so that

locknut is on top.

07031

20309

20530

A-Frame Sector

King Bolt

© 2005 Printed in the U.S.A.

Figure 1

Figure 2

18513 Euclid Ave. • Cleveland, Ohio 44112-1084

Phone 486-1313 (Area Code 216)

email warranty@meyerproducts.com

www.meyerproducts.com

Loading...

Loading...