Page 1

PARTS & INSTALLATION INSTRUCTIONS

MDII™and EZ MOUNT PLUS™

SNOW PLOW MOUNTING 17195

2017 & Later FORD F250 thru F550

4x4 MODELS

Snow Plow Preparation Package 86M

End user must be given this instruction sheet prior to delievery of this Snow Plow.

SAFETY DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION Indicates an potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Form 1-1151

July 2016

CAUTION used without the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, will result in property damage.

IMPORTANT NOTICE

In conjunction with FMVSS (Federal Motor Vehicle Safety Standards) and OEM (Original Equipment Manufacturer) guidelines,

Meyer Products has designed this plow package with the following guidelines:

Installation of a snowplow may effect your new vehicle warranty.

For more information consult your Vehicle Owner's Manual / Vehicle Dealer.

The vehicle must not be operated when overloaded. In all cases, the loaded vehicle weight, including the entire

snowplow system, all aftermarket accessories, driver, passenger, options, nominal fluid levels, and cargo must not

exceed the front/rear Gross Axle Weight Rating (GAWR), and total Gross Vehicle Weight Rating (GVWR). These

weights ratings are specified on the safety compliance certification label on the driver's side door opening. The use

of rear ballast weight may be required to prevent exceeding the front GAWR.

According to the NHTSA (National Highway Traffic Safety Administration) new and untitled vehicles need to be verified by the installer that

snowplow and ballast (if needed) do no exceed the front/rear GAWR and total GVWR.

Read the Meyer Owner's Manual before operating or servicing a snowplow. FOLLOW THESE INSTRUCTIONS

EXPLICITLY.

GENERAL INFORMATION

SAFETY PRECAUTIONS should be used when Hydraulic Unit is in OPERATION and plow is in a RAISED

position. Lower plow to ground when vehicle is PARKED in case of hydraulic failure.

Check contents against the parts list to determine all are correct and included, and also to familiarize yourself with them.

Warranty does not apply to a Meyer or Diamond product which has been negligently or improperly assembled or

installed.

CAUTION: To avoid harm to vehicles electrical system always disconnect battery before beginning installation.

DO NOT BURN holes or WELD vehicle frame. This may cause frame failure.

OVERHAUL and SERVICE INFORMATION are covered on separate instructions.

Meyer Products LLC reserves the right, under its continuing product improvement program, to change construction or design details,

specifications and prices without notice or without incurring any obligation.

Meyer Products LLC

18513 Euclid Ave. • Cleveland, Ohio 44112-1084

Phone 486-1313 (Area Code 216)

www.meyerproducts.com• email info@meyerproducts.com

© 2016 Printed in the U.S.A.

6 Angell Lane • Damariscotta, ME 04543-4507

Meyer Products LLC

Phone 563-2227(Area Code 207)

www.meyerproducts.com• email info@meyerproducts.com

Page 2

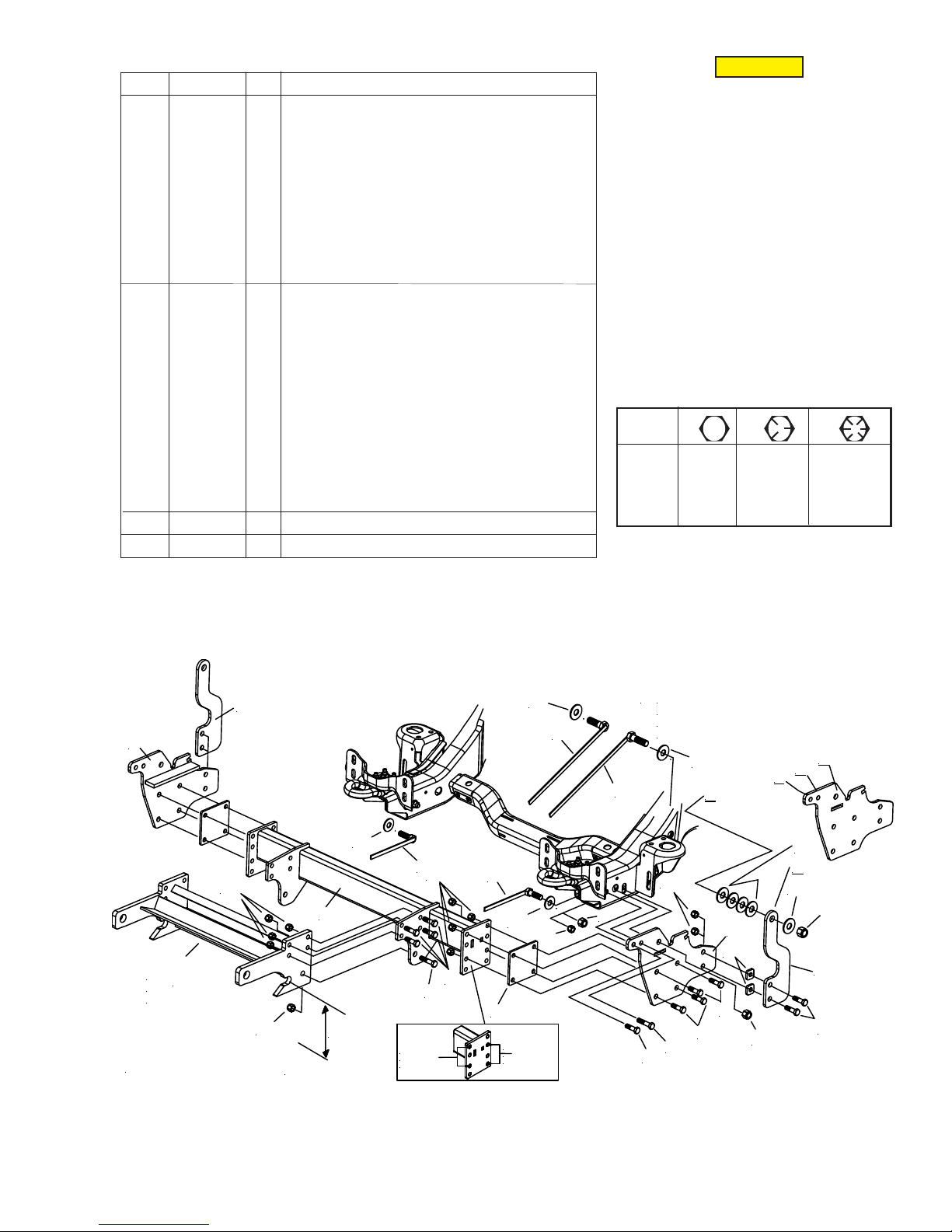

PARTS LIST

ITEM PART NO. QTY. DESCRIPTION

17195 1 MOUNTING CARTON

1 18985 1 • R.H. Side Assembly

2 18986 1 • L.H. Side Assembly

3 19807 1 • Rear Brace Weldment

4 18987 2 • Strap

5 19821 2 • Handle Bolt (16") 3/4-10 x 2-1/4" Gr.5

6 19823 2 • Handle Bolt (8") 5/8-11 x 2" Gr.5

7 19995 2 • Spacer 1/4"

08135 1 • Hardware Bag

8 20096 18 •• Bolt H 1/2-13 x 1-3/4” Gr. 5

9 20141 4 •• Bolt H 5/8-11 x 2” Gr. 5

10 20307 22 •• Locknut ESNA 1/2-13

11 20309 6 •• Locknut ESNA 5/8-11

12 20310 2 •• Locknut ESNA 3/4-10

13 20357 2 •• Flatwasher 5/8”

14 20359 12 •• Flatwasher 3/4"

15 11291 4 •• Spacer

16 20097 4 •• Bolt H 1/2-13 x 2" Gr. 5

* 19370 1 Universal Clevis (Part of Plus CLF Carton)

** 11770 1 Universal Clevis (Part of MDII CLF Carton)

Parts indented are included in the carton, bag or assembly under which

they are indented.

CAUTION

CAUTION: To avoid harm to vehicles

electrical system always disconnect battery

before begining installation.

DO NOT BURN holes or WELD vehicle frame.

This may cause frame failure.

IMPORTANT

After first use, retighten all mounting bolt

connections to specified torque. All mounting

bolt connections to be checked periodically

for tightness.

Locknuts are furnished DO NOT tighten bolts

and nuts until installation is complete (unless

otherwise specified), then be sure to tighten

all attaching parts per specified torque chart.

TORQUE CHART FOOT

Bolt Nut Size Gr. Gr. Gr.

1/4 - 20 4 - 5

5/16 - 18 9 - 11

3/8 - 16 17 - 20 26 - 29

7/16 - 14 42 - 46 60 - 66

1/2 -13 64 - 72 90 - 100

5/8 - 11 127 - 141 179 - 198

THIS MOUNTING CARTON CAN BE USED WITH

THE MDII OR EZ MOUNT PLUS CLF CARTONS.

2 5 8

NOTE:

1

Clevis Frame

*

packed in CLF

Carton

FIGURE 1

10

Add spacer Flatwashers (15) as needed

11

**

until Stra p (4 ) clears the s ta b iliz e r b a r.

Due to vehicle frame variances, the quantity

of spacer Flatwashers required may vary .

14

5

D

10

2

14

C

B

A

**

D

14

12

4

14

5

13

6

10

3

6

13

10

15

8

4

9

8

8

11

16

11

11-1/4"

GROUND

SPRING CODE "x"

6,000 lb.

Front g.a.w.r.

7

SPRING CODE "V"

5,200 lb.

Front g.a.w.r.

8

8

Page 3

VEHICLE RECOMMENDATIONS

• A ballast weight may be required to prevent front GAWR

overloading. If required, ballast must be securely attached

at least 18 inches behind the rear axle.

E. Attach lower holes of the L.H. & R.H. Straps (4) to

L.H. and R.H. Side Assembly (1 & 2)using

1/2-13 x 2" bolt (16), Spacers (15) (if necessary) and

locknut (10). Snug all bolts during installation. Do

not tighten at this time.

• Front end wheel alignment and headlight aim may require

readjustment after installation of equipment, and is the

responsibility of the equipment installer. Failure to adjust

front wheel alignment may cause premature uneven tire

wear. If required, reset to chassis manufacture’s

specifications found in the Ford Shop Manual.

• Rear ballast is determined by weighing a vehicle's front

and rear axles and adding weight behind the rear axle

until front axle weight is under or equal to the vehicle

specific front GAWR while not exceeding the rear

GAWR and GVWR.

• Vehicle option packages may vary. If in doubt, it is

always a good idea to weigh the vehicle to ensure all

weight ratings are not exceeded with plow in the raised

position.

INSTALLATION INSTRUCTIONS

A. Remove bumper and retain Hardware. They will be

reused.

B. Position L.H. Side Assembly (2) onto driver's side of

vehicle frame aligning the top three holes in Side

Assembly (2) with existing holes in vehicle frame.

Atttach Side Assembly (2) to vehicle frame at hole (A)

using 1/2-13 x 1-3/4" bolt (8) and Locknut (10). At

Hole (B) using 5/8-11 x 2" bolt (9) and Locknut (11).

At Hole (C) using Handle Bolt (6), flatwasher (13) and

locknut (11). Per illustration. Snug all bolts during

installation. Do not tighten at this time.

F. Position the Rear Brace Weldment (3) between the

L.H. & R.H. Side Assembly (1 & 2). Use Spacer Plate

1/4" (7) on driver side or both sides only if necessary

(Vehicle frame variances). Attach Rear Brace Weldment

to Side Assemblies (1&2) using 1/2-13 x 1-3/4" bolt

(8), locknut (10). Snug all bolts during installation.

Do not tighten at this time.

REAR BRACE WELDMENT (3) CAN BE ADJUSTED UP

OR DOWN between Side Assembly (1&2).

Match vehicle Spring Code Information with hole locations

in figure 2. Information on Spring codes can be found in

the lower right hand corner of tag located in the driver's

side door jam. Example: V/B or X/B.

NOTE: 2011 & later Diesel equipped vehicles may need

to use spring code X mounting location to avoid

interference with vehicle power steering cooler.

Spring Code V= 5200 lb Front g.a.w.r.

Spring Code X= 6000 lb Front g.a.w.r.

Spring Code

"X"

Spring Code

"V"

C. Follow same procedure when mounting R.H. Side

Assembly (1) to passenger side of vehicle frame.

D Position L.H. & R.H. Straps (4) to L.H. and R.H. Side

Assembly. Loosely attach lower holes of the L.H. &

R.H. Straps (4) to L.H. and R.H. Side Assembly. Mark

top hole in L.H. & R.H. Straps (4) to Hole (D) on both

the driver and passenger side of vehicle frame. Drill a

3/4" hole only on the outside of the vehicle frame at

hole (D). Attach strap (4) per illustration using Handle

Bolt (5), flatwasher (14) to inside of frame rail. If

necessaryspace out strap (4) using flatwashers (14)

behind Strap (4), and locknut (12). See ** note on

Figure 1.

Snug all bolts during installation. Do not tighten

at this time.

FIGURE 2

Meyer Products assumes no responsibility for installations

not made in accordance with these instructions.

Loading...

Loading...