Meyer ELECTRO LIFT E-46, ELECTRO LIFT E-46H, ELECTRO LIFT E-47, ELECTRO LIFT E-47H, ELECTRO LIFT E-57 Service Manual

...Page 1

FORM NO. 1-562-R16

October, 2005

Price: $4.25

ELECTRO LIFT

power units

service manual

MODELS

®

E-46, E-46H

E-47, E-47H

E-57, E-57H

18513 Euclid Ave. • Cleveland, OH 44112-1084

Meyer Products Inc.

Phone (216) 486-1313

email•warranty@meyerproducts.com

© 2005 Printed in the U.S.A.

6 Angell Lane• Damariscotta, ME 04543-9720

Diamond Equipment

Phone (207) 563-2227

www.diamondplow.com • email info@diamondplow.com

Page 2

FOREWARD

This Service Manual includes complete information for servicing the following Electro Lift® Units:

E - 46 and E - 46H

E - 47 and E - 47H

E - 57 and E - 57H

IMPORTANT: Maintenance and repairs must be performed with the moldboard on the ground.

The information is grouped according to the type of work being performed, such as diagnosis and testing,

disassembly and reassembly. Special tools and specifications are also included in this manual.

All information, illustrations and product descriptions contained in this manual are correct at publication

time. We do, however, reserve the right to make changes at any time without prior notice.

MEYER PRODUCTS INC.

SECTION INDEX

Section Number Section Title ..................................................... Page

0 GENERAL INFORMATION AND

MAINTENANCE ........................................................ 1

1 GENERAL DESCRIPTION AND

THEORY OF OPERATION ........................................ 4

2 DIAGNOSIS ............................................................. 23

3 REPAIR PROCEDURE .............................................. 30

4 SPECIFICATIONS ..................................................... 53

Meyer Products Inc. reserves the right, under its continuing product improvement program, to change construction or

design details, specifications and prices without notice or without incurring any obligation.

Page 3

SECTION 0 - GENERAL INFORMATION AND MAINTENANCE

CONTENTS

GENERAL INFORMATION .................................................. 2

•M

ODEL IDENTIFICATION .................................................... 2

•M

ODEL IDENTIFICATION AND

SERIAL NUMBER LOCATION .............................................. 2

•M

OTOR IDENTIFICATION ................................................... 2

MAINTENANCE ................................................................... 2

•G

ENERAL MAINTENANCE ................................................... 2

•C

LEANLINESS ................................................................. 2

•V

EHICLE ELECTRICAL SYSTEM ........................................... 3

•C

HECK REGULARLY ......................................................... 3

POST-SEASON MAINTENANCE ....................................... 3

•M

EYER HYDRAULIC FLUID M-1 ......................................... 3

•R

EPLACEMENT OF HYDRAULIC FLUID ................................... 3

•F

ILTERS ........................................................................ 3

•P

ROTECTION AGAINST RUST

AND

CORROSION ............................................................ 3

-1-

Page 4

GENERAL INFORMATION

R

Model Identification

®

The Electro Lift

unit is an electrically powered hydraulic

mechanism specifically designed for use with the Meyer

Snow Plow and is available in four models as follows:

E-46 Raises and lowers plow hydraulically

(2-way) and is used with TM, ST and

C series Snow Plows.

E-46H Raises and lowers plow hydraulically

(2-way) and is used with HM series

Snow Plows.

E-47/E-57 Raises, lowers and angles plow

hydraulically (7-way) and is used with

TM, ST and C series Snow Plows.

E-47H/E-57H Raises, lowers and angles plow

hydraulically (7-way) and is used with

the MDII, HM and Diamond series

Snow Plows.

Model Identification and Serial Number Location

Inclusion of the model number and serial number is

extremely important when writing up warranty claim

forms and product report forms for proper evaluation

and follow up.

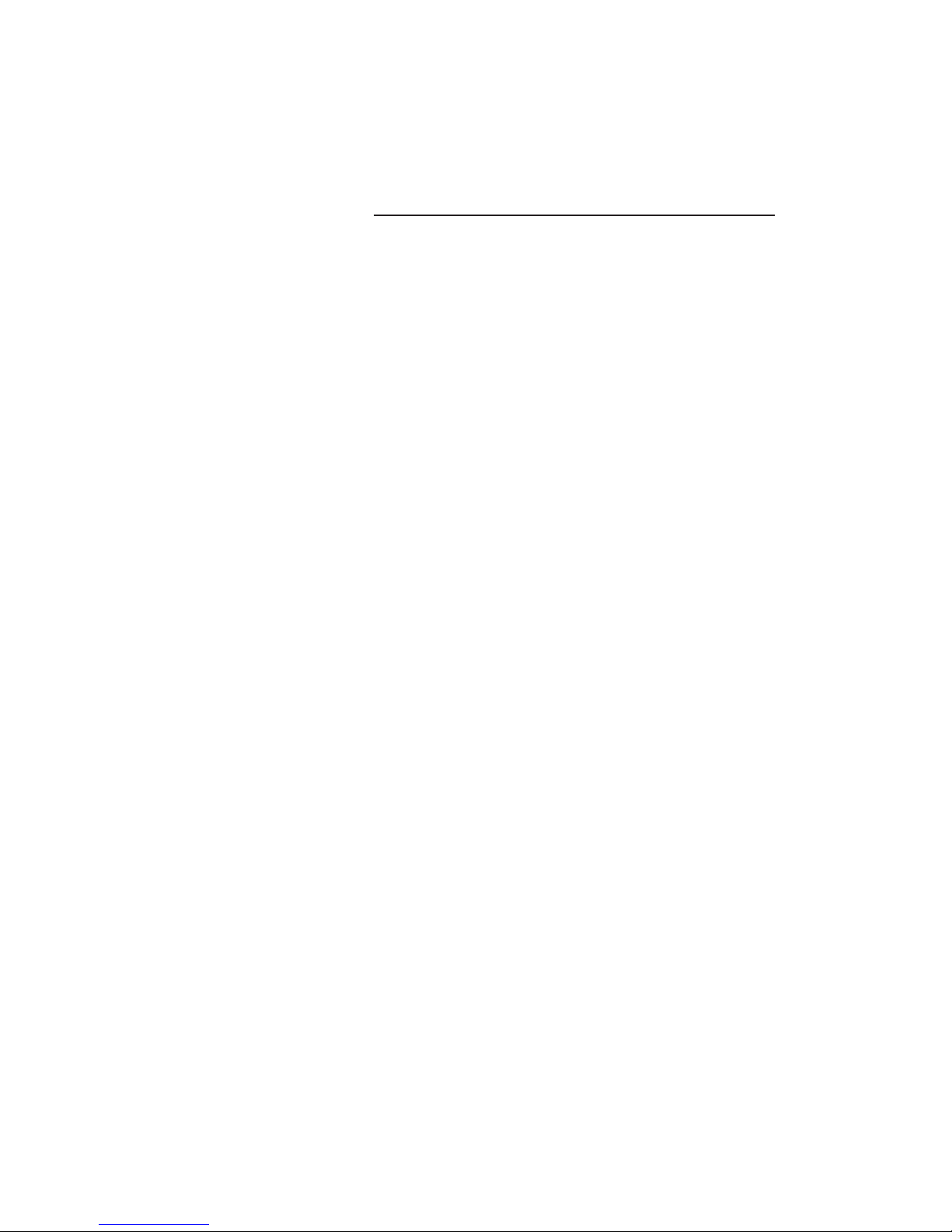

Motor Identification

Three different brand motors are used on the Electro

Lift® units American Bosch, Prestolite and Iskra.

Proper identification of the brand and supplier part

number is necessary when seeking local parts and

service sources.

The motor with which a specific Electro Lift® unit is

equipped can be identified by the distinctive

characteristics shown in figure 0-2.

DOMED COMMUTA T O

END COVER

STEEL ST AM PED

PRESTOLITE

MKW -4007-12V

FLAT COMMUT ATOR

END COVER

E

T

I

L

O

T

S

E

R

P

3" Dia.

3" Dia.

The basic model number is located on the name plate

located as shown in Figure 0-1. To determine whether

it is the standard or “H” model, measure the dimension

shown in Figure 0-1. The serial number is located on

the bottom of the base or on the name plate.

NAME PLATE

"

8

/

1

-

8

H

7

5

E

,

H

7

4

E

,

H

6

4

E

"

4

/

1

-

6

7

5

E

,

7

4

E

,

6

4

E

STEEL ST AMP ED

AMERICAN BOSCH

MO 551046A

ISKRA

Label 15829

AMJ4739 12V 1,6kw

SINGLE and TWO TERMINAL

4-1/2" Dia.

FIGURE 0-2

MAINTENANCE

The following maintenance information is intended as

a basic guide for providing the Electro Lift

®

unit with

the proper service and care. Sustained heavy duty

operation or operating under adverse conditions may

necessitate more frequent servicing.

xxxxx

FRONT VIEW

SERIAL NUMBER

(ON FRONT SIDE)

FIGURE 0 -1

General Maintenance

Cleanliness

The greatest enemy to any hydraulic system is dirt or

contamination. Therefore, cleanliness must be stressed

at the time of installation, servicing and repairing.

-2-

Page 5

Vehicle Electrical System

Maximum performance and efficiency of the Electro

Lift® unit requires that the vehicle’s electrical system

be properly maintained and consist of:

Battery ----------- 70 Amp. Hr. Minimum or

550 Cold Cranking Amps.

Alternator ------ 60 Amp. Minimum

Check Regularly

1. Battery Terminals - Must be clean and free of

corrosion.

2. Electrical Connections - Must be free of corrosion

and tight.

3. Battery - Must be in first-class condition.

4. Alternator (or Generator) and Regulator - Must be

functioning to specifications.

5. Hydraulic Fluid Reservoir Level - A significant drop

in hydraulic fluid level indicates a leak which must

be located and corrected. Insufficient hydraulic fluid

may result in severe damage.

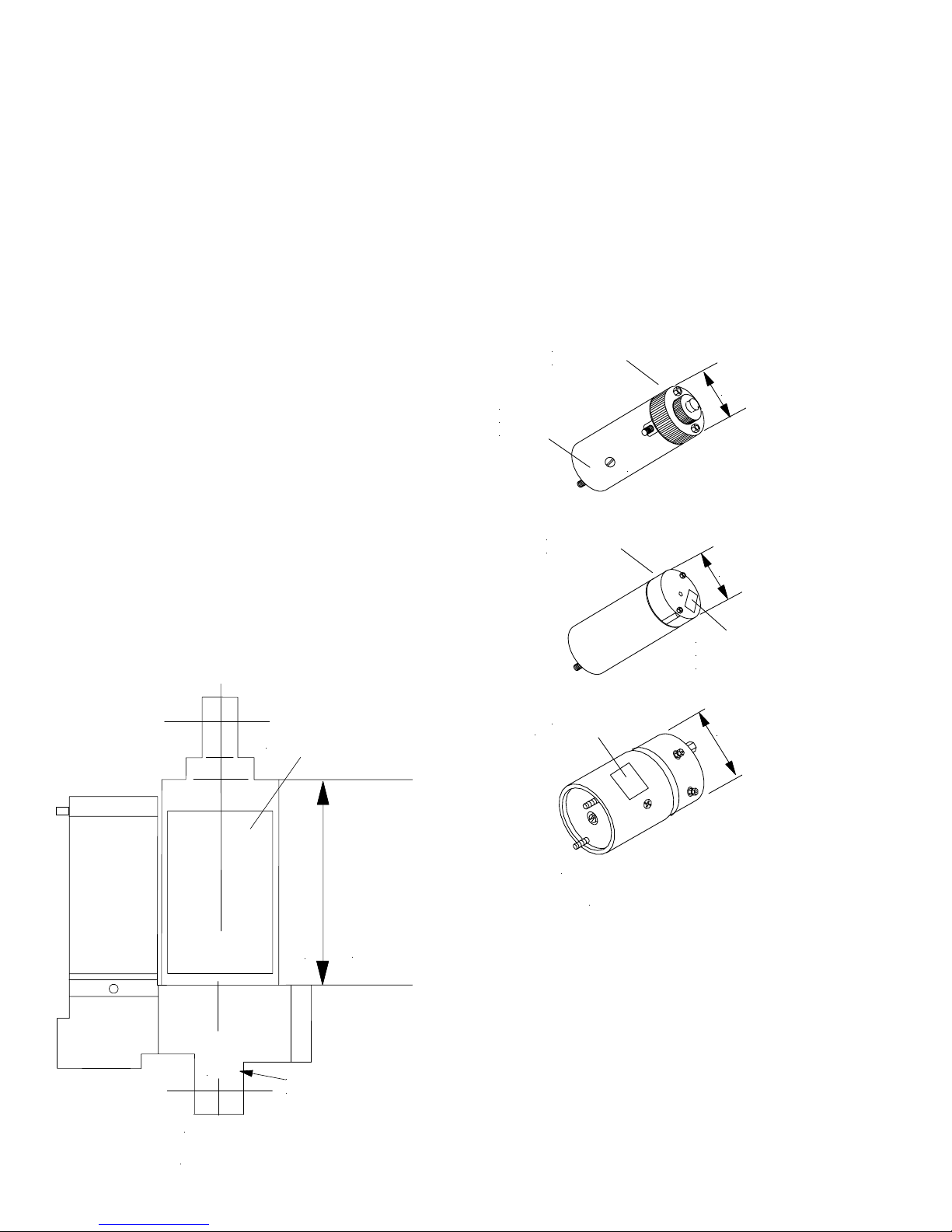

POST-SEASON MAINTENANCE

Meyer Hydraulic Fluid M-1.

FILLER PLUG

DRAIN PLUG

FILTER S

FIGURE 0-3

LIFT ROD

D

R

A

I

N

Meyer Hydraulic Fluid M-1 is a specially formulated

mineral oil which maintains an almost constant

viscosity from normal to sub-zero temperatures.

Because it remains free flowing at extremely low

temperatures, the performance and efficiency are not

affected.

Meyer Hydraulic Fluid M-1 also contains an additive

which neutralizes moisture accumulating in the fluid

due to condensation. It is effective for a maximum of

one year’s use.

Meyer Products Inc. will not be liable for damages

resulting from the use of inferior or other fluids or

oils.

Replacement of Hydraulic Fluid

After a season’s use, completely drain the hydraulic

fluid (including hydraulic fluid in hoses and cylinders

on Power Angling models). Drain fluid through filler

hole shown in Figure 0-3 or drain hole in base by

completely retracting lift rod and unbolting unit to pour

fluid out or using a suction pump. On Power Angling

models, disconnect the fittings at the Angling cylinders,

completely retract the cylinder rods and purge

cylinders and hoses of all hydraulic fluid. Flush the

complete system including unit, hoses and Power

Angling rams with a non wax (Napthenic) cleaner. If

kerosene (Parrafinic) is used to flush the system, the

system must be flushed again to remove any kerosene

with a (Napthenic) based cleaner that is wax free .

Refill Electro Lift

®

unit with M-1 Fluid by fully

retracting lift rod (Ram) and filling reservoir to 1-1/2

“ below the filler hole. On Power Angling models,

fill and bleed hoses and Power Angling cylinders

by loosening hydraulic fittings at cylinders until they

leak. Power angle plow repeatedly from one side to

the other until fluid flows steadily from the leaking

fittings while maintaining a constant check on the

reservoir fluid level.

Raise and lower the plow several times and with lift

rod fully retracted, give a final check to the fluid level

and replace filler plug.

Filters

Clean the two filters (only one in E-46 and E-46H; two

in Power Angling units) located in base of unit with

mineral spirits or equivalent and blow out with

compressed air. See Figure 0-3 for filter locations.

Protection Against Rust and Corrosion

When the Electro Lift® unit is not used for extended

periods, protect the chromed lift rod (Ram) by fully

extending it and coating it with chassis lubricant. Full

extension of the lift rod (Ram) fills the cylinder with

hydraulic fluid. On Power Angling models, coat the

exposed portions of the Power Angling cylinder rods

(Rams) with chassis lubricant to protect them against

rust and corrosion.

-3-

Page 6

SECTION 1 - GENERAL DESCRIPTION AND THEORY OF OPERATION

CONTENTS

GENERAL DESCRIPTION ................................................................................................. 5

THEORY OF OPERATION................................................................................................. 5

UNCTIONS .................................................................................................................. 5

•F

•• Models E-46 and E-46H ................................................................................... 5

•• Models E-47, E-47H and E-57, E-57H ........................................................... 5

•ELECTRICAL AND FLOW CHARTS ...................................................................................... 6-18

ELECTRO LIFT® UNIT COMPONENTS ......................................................................... 19

•M

OTORS ...................................................................................................................... 19

•• American Bosch ............................................................................................... 19

•• Prestolite ............................................................................................................ 19

•• Iskra .................................................................................................................... 19

YDRAULIC PUMP .......................................................................................................... 19

•H

•P

RESSURE RELIEF VALVE ................................................................................................ 19-20

OLENOID VALVES ......................................................................................................... 20

•S

•• Cartridge ............................................................................................................ 20

•• Coil...................................................................................................................... 20

“A” Solenoid Valve............................................................................................. 20

“B” Solenoid Valve............................................................................................ 20

“C” Solenoid Valve ........................................................................................... 20

•CHECK VALVES .............................................................................................................. 21

•P

ILOT CHECK VALVE ...................................................................................................... 21

•C

ROSSOVER RELIEF VALVES ............................................................................................ 21

WITCH (MODELS E-46 AND E-46H) ............................................................................ 21

•S

•S

WITCHES (POWER ANGLING MODELS) ............................................................................ 21

•• Dual Switch Control ........................................................................................... 21-22

•• Single Lever Control .......................................................................................... 22

•• Electro-Touch Control......................................................................................... 22

•S

OLENOID SWITCH ........................................................................................................ 22

ILTERS ....................................................................................................................... 22

•F

-4-

Page 7

GENERAL DESCRIPTION

THEORY OF OPERATION

Electro Lift® unit is an electrically powered and

electrically controlled hydraulic mechanism specifically

designed for use with Meyer Snow Plows. The standard

model E-46 raises and lowers the plow hydraulically

with an integral 6" stroke hydraulic cylinder while the

model E-46H performs the identical task for larger plows

with an integral 8" stroke hydraulic cylinder.

In addition to raising and lowering the plow

hydraulically, the model E-47, E-47H and

E-57, E-57H angles the plow hydraulically, left and

right, via remote hydraulic cylinders.

The Electro Lift® unit consists of a specially designed

high torque 12-volt DC motor which is directly coupled

to a gear-type hydraulic pump. The pump obtains its

supply of hydraulic fluid from an integral reservoir which

totally surrounds the integral hydraulic cylinder which

raises and lowers the plow.

Included in all models is an electrically controlled and

powered solenoid valve cartridge “A” which is

energized to allow the plow to lower by gravity.

The models E-47 and E-57 include an integral valve

body which contains two additional electrically

controlled solenoid valve cartridges. Solenoid valve

cartridge “B” is energized to route the pressurized

hydraulic fluid to the integral hydraulic cylinder to raise

the plow. Solenoid valve cartridge “C” is energized to

route the pressurized hydraulic fluid to the left remote

hydraulic cylinder to angle the plow to the right. Angling

the plow to the left only requires energizing the electric

motor since the normal route for the pressurized

hydraulic fluid is to the right remote hydraulic cylinder.

FUNCTIONS

®

The Electro Lift

models perform basic functions.

Because certain of these basic functions are

accomplished differently in the models E-46 and

E-46H as opposed to the Power Angling models will

be treated separately where necessary.

Models E-46 and E-46H

The two basic functions performed are:

• Raise snow plow

• Lower snow plow and float

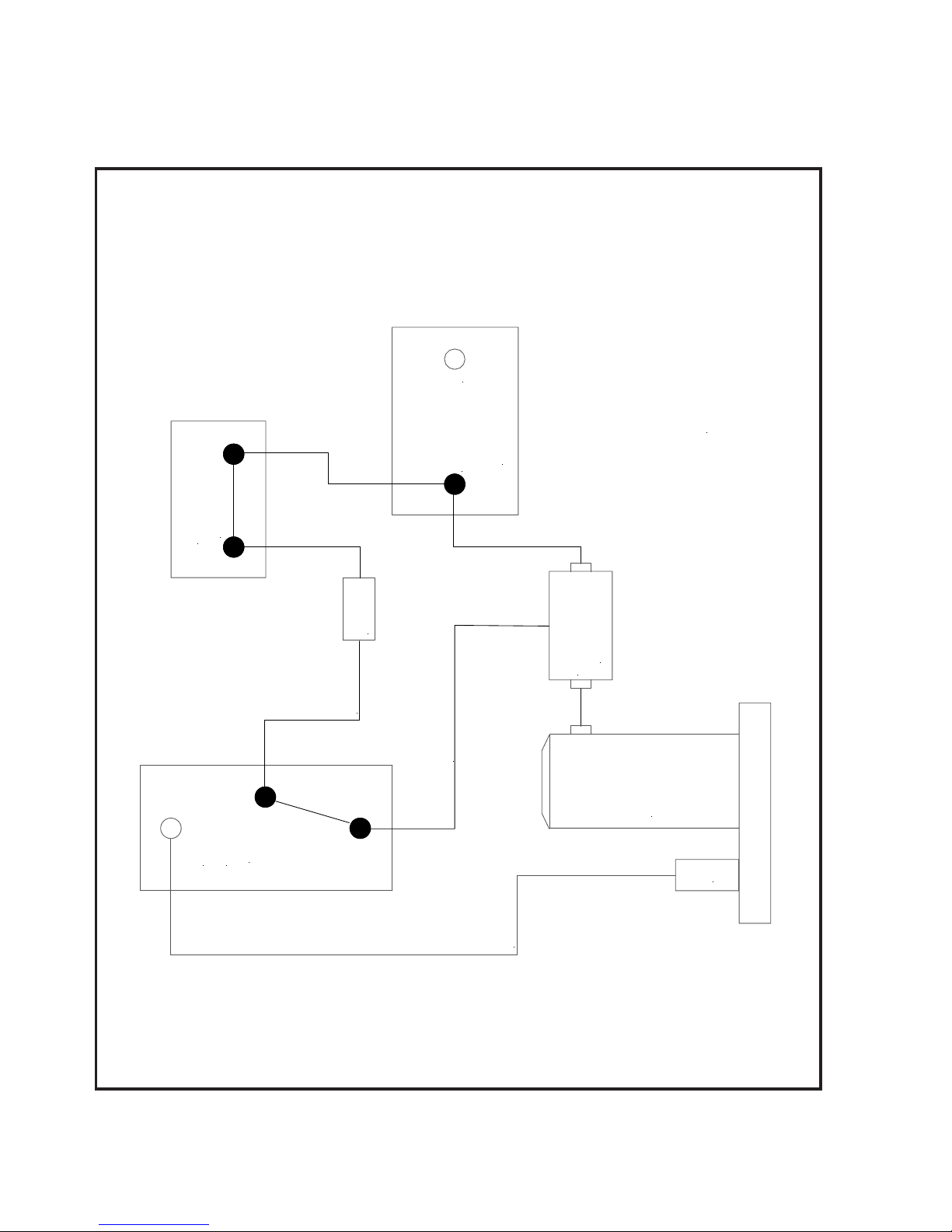

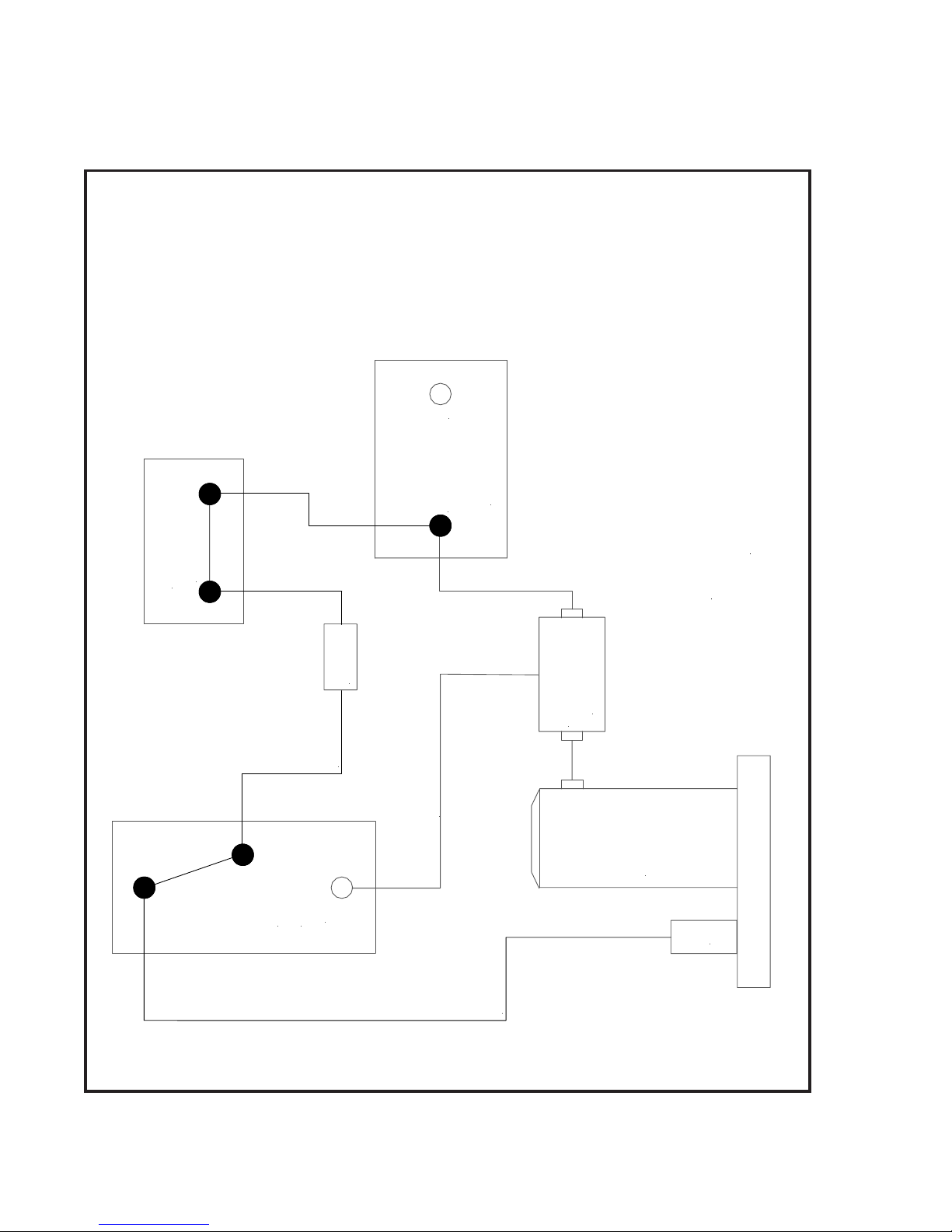

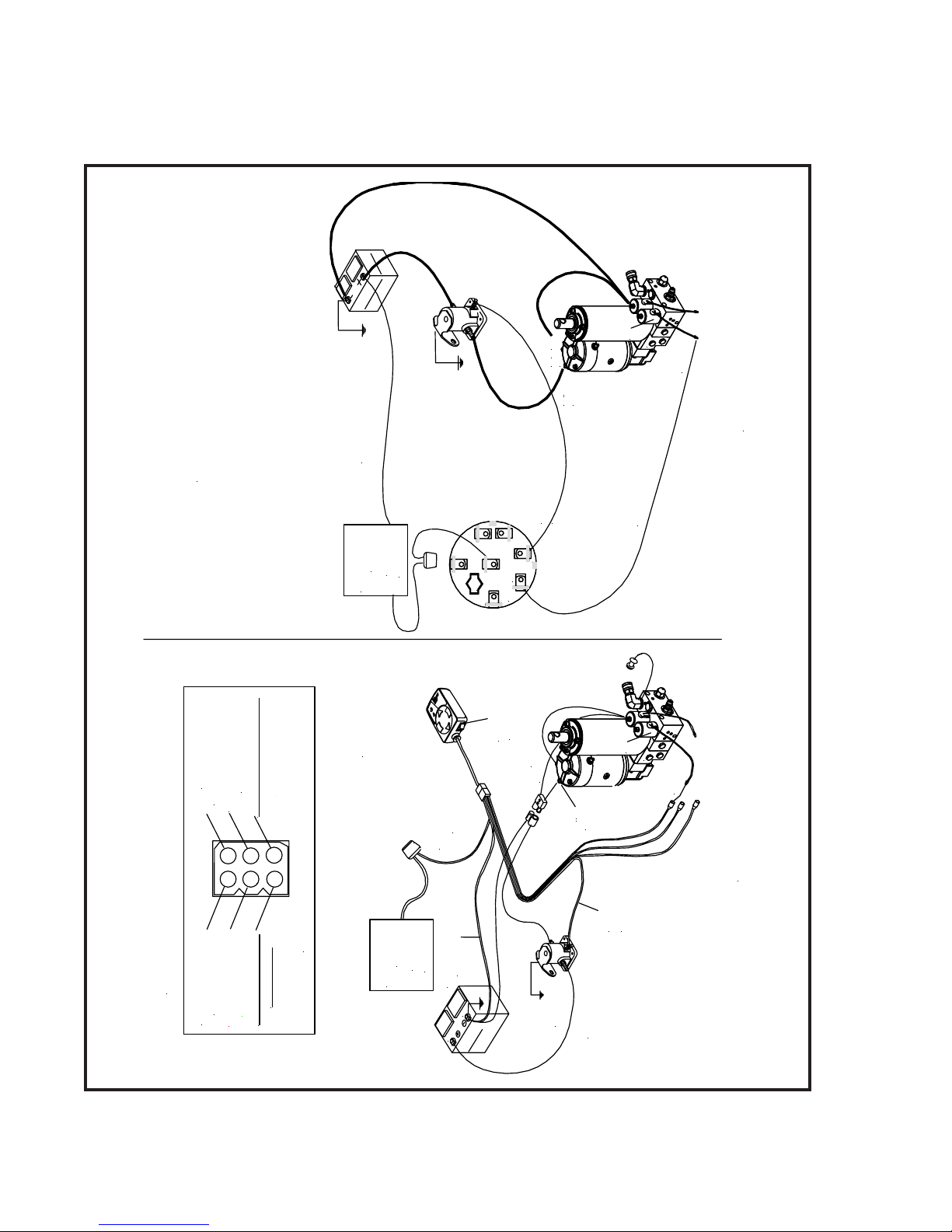

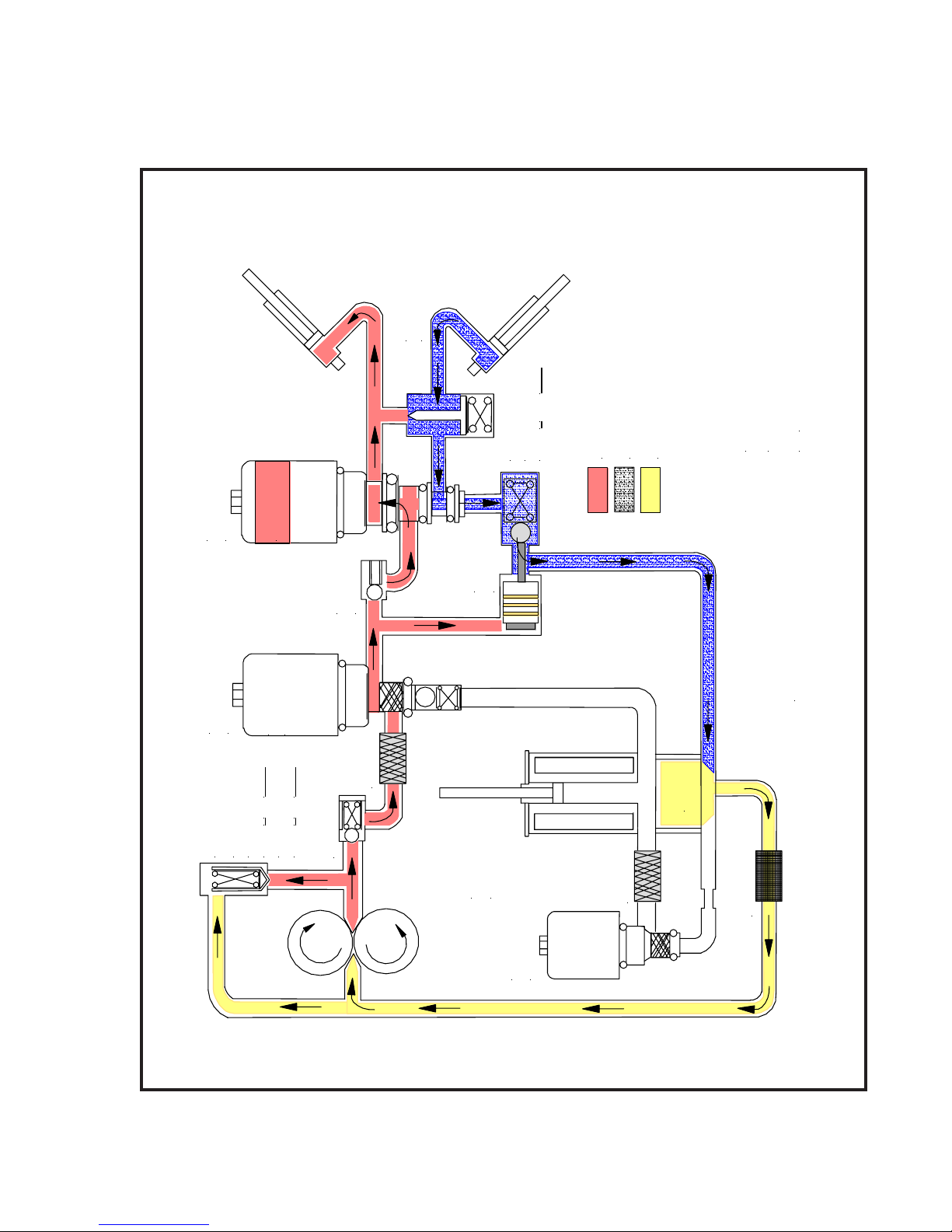

Refer to Figures 1-1 and 1-2 (pages 6 thru 9) for

electrical and hydraulic flow chart for each function.

Each figure explains which component is actuated and

related in each function.

Models E-47, E-47H and E-57, E-57H

The four basic functions performed are:

• Raise snow plow

• Lower snow plow

• Angle snow plow to right

• Angle snow plow to left

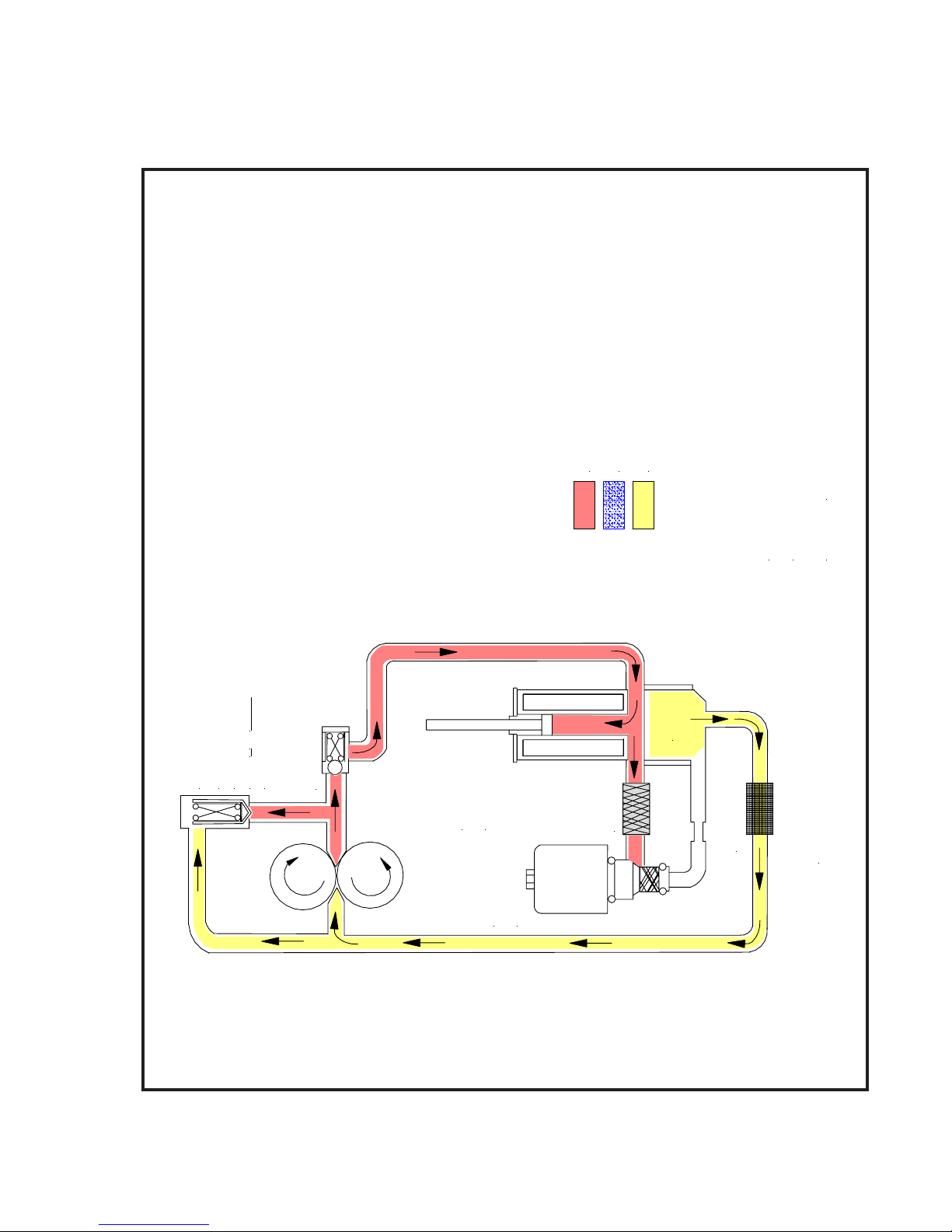

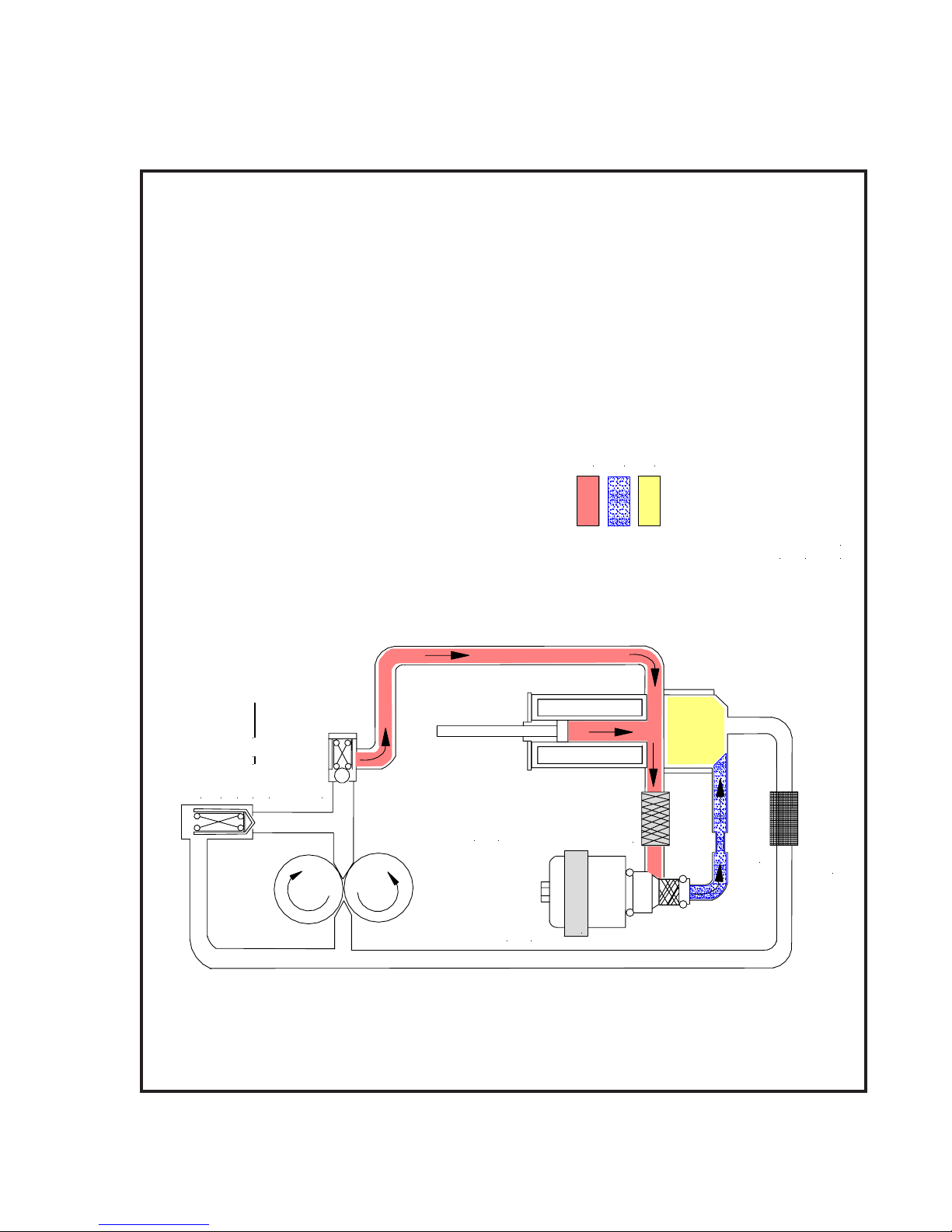

Refer to Figures 1-3 through 1-6 (pages 6 thru 18) for

electrical and hydraulic flow chart for each function.

Each figure explains which component is actuated and

related in each function.

Additional components which control and supply

electrical current to the Electro Lift® unit are an operator

controlled toggle switch; a solenoid switch to supply

high amperage current to the unit’s motor; a wiring

harness to distribute low amperage current between

the toggle switch or switches, motor solenoid and the

solenoid valve cartridge(s); and short heavy gauge

cables to distribute high amperage current directly from

the positive terminal of the vehicle’s battery and ground

the unit directly to the negative terminal of the vehicle’s

battery.

-5-

Page 8

-

RAISE

SWITCH

IGNITION

LOWER

SWITCH

RAISE &

FUSE

BLACK

WHITE

+

BATTERY

SOLENOID

FIGURE 1-1A

SWITCH

MOTOR

A

BLACK

-6-

Page 9

- OPE R ATING

- RETURN

- INTAKE or DRAIN

RAISE

HYDRAULIC FLOW CHART

MODELS E-46 & E-46H

TANK

PRESSURE

RE L IEF

E-46 & E-46H

1650 + 50 P.S.I.

CHECK VALVE

LIFT

CYLINDER

FILTER

STRAINER

FIGURE 1-1B

"A"

-7-

SOLENOID

Page 10

SWITCH

IGNITION

FUSE

BLACK

-

+

WHITE

BATTERY

FIGURE 1-2A

LOWER/FLOAT

SWITCH

SOLENOID

SWITCH

RAISE &

MOTOR

LOWER

A

BLACK

-8-

Page 11

- OPERATING

- RET U RN

- INTAKE or DRAIN

HYDRAULIC FLOW CHART

LOW ER/FLOA T

MOD ELS E-46 & E-46H

TANK

PRESSURE

RE L IEF

E-46 & E-46H

1650 + 50 P.S.I.

CHECK VALVE

LIFT

CYLINDER

"A"

SOLENOID

ENERGIZED

FILTER

STRAINER

FIGURE 1-2B

-9-

Page 12

SL IK - STIKSINGLE LEVER

CONTROLLER

GROUND

(BLUE WIRE)

(ORANGE WIRE)

POWER TO SWITCH

6

3

ELECTRO -TO UCH

CONT R OLLE R

(BLACK WIRE)

(GREEN WIRE)

TO "A" SOLENOID

TO "C" SOLENOID

(WHITE WIRE)

TO MOTOR SOLENOID

4

5

2

1

(RED WIRE)

TO "B" SOLENOID

"B"

N

N

I

I

A

A

R

R

D

D

RAISE

Ignition Switch

RAISE

D1NEGATIVE

A2POSITVE

WHITE WIRE - ENERGIZED

Moto r Solenoid

L

E

E

S

N

U

"ON"

F

10

A

P

H

C

T

I

W

E

S

R

I

O

W

T

E

R

U

E

L

B

W

O

1

0

A

P

GENUINE PARTS

C - H

C - H

Meyer

Meyer

F

H

F

C

O

T

/

I

N

W

S

O

E

V

I

1

T

D

A

G

E

N

2

A

"

B

"

E

V

T

I

S

O

P

.

D

E

Z

I

G

R

E

N

E

s

i

d

i

o

en

l

o

S

"

B

"

e

r

i

w

d

e

R

N

N

I

I

A

A

R

R

D

D

D

E

R

FIGURE 1-3A

FIGURE 1-3A

D

E

N

R

I

U

W

O

R

E

G

L

G

E

END OF TOUCH PAD HARNESS

E

N

H

S

N

A

C

U

A

"ON"

Ignition S w itc h

R

T

F

I

P

O

W

S

G

E

N

Y

R

E

S

T

O

T

P

A

B

D

N

U

O

R

G

E

E

T

I

R

I

H

W

W

R

E

W

O

P

-10-

Page 13

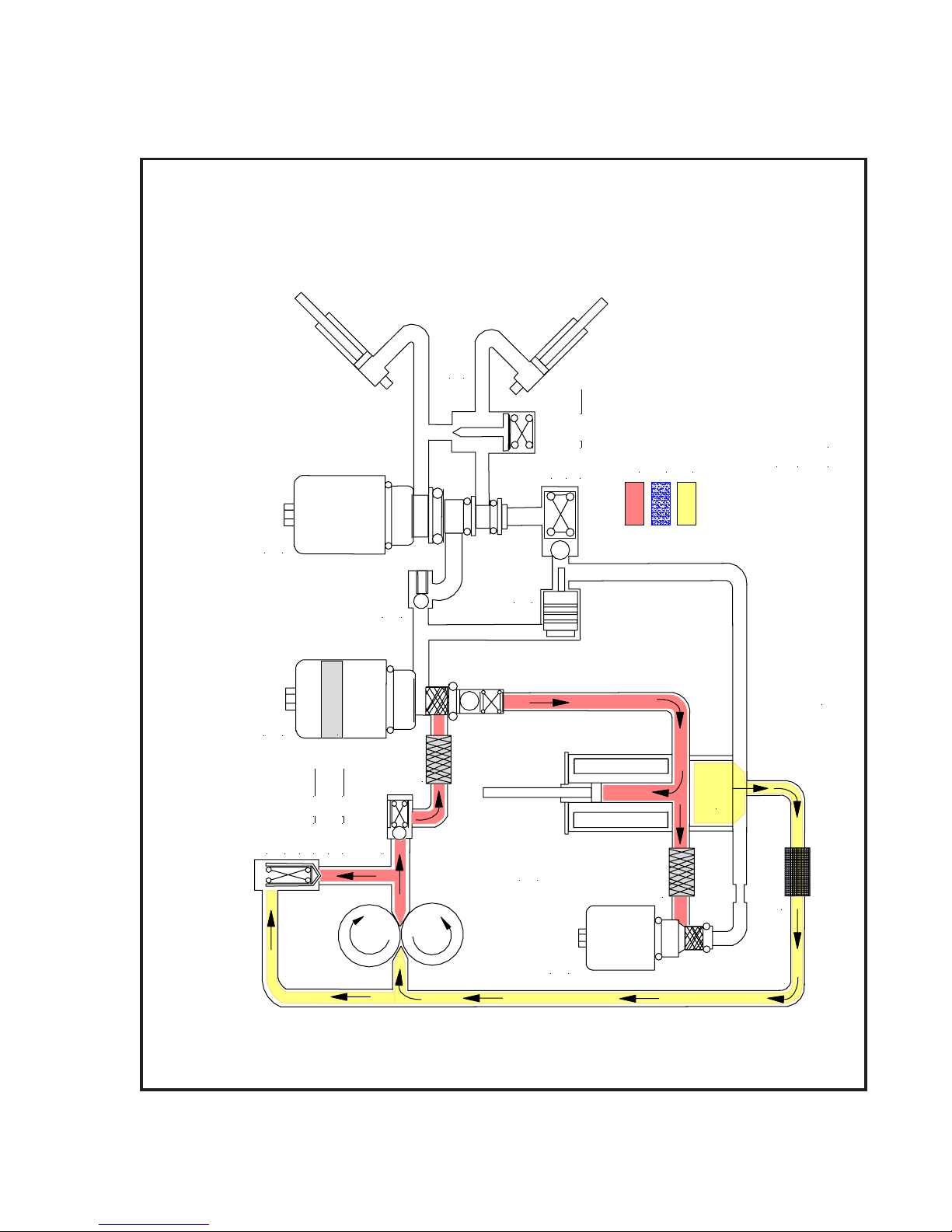

POWER ANGLING

CYLINDERS

RAISE

HYDRAULIC FLOW CHART

M ODELS E - 4 7 & E-57

- OPERATING

- RETURN

CROSSOVER

REL IEF

3800 + 400 P.S. I

"C"

SOLENOID

PILOT

CHECK

VALVE

CHECK

- INTAKE or DRAIN

FIGURE 1-3B

"B"

SOLENOID

ENERGIZED

FILTER

TANK

PRESSURE

RELIEF

E-47

1650 + 50 P.S. I.

E-57

2000 + 0 P.S. I.

CHECK VAL VE

LIFT

CYLINDER

FILTER

STRAINER

"A"

SOLENOID

-11-

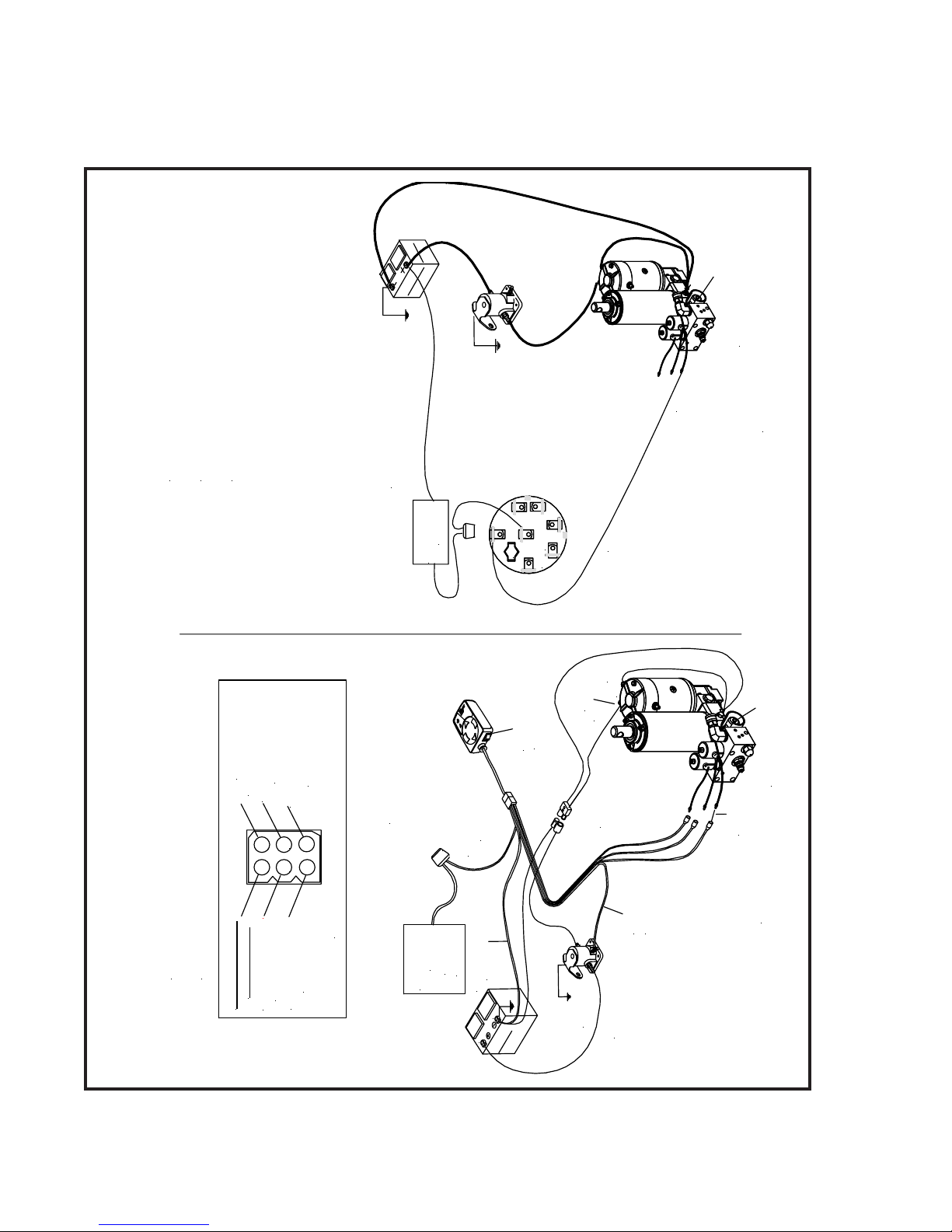

Page 14

S

S

TIK

LIK -

SINGLE LEVER

CONTROLLER

LOWE R/FLOA T

d

i

o

n

e

l

o

S

"

A

"

e

r

i

w

k

c

a

l

B

.

D

E

Z

I

G

R

E

N

E

s

i

d

i

o

n

e

l

o

S

"

A

"

e

r

i

w

10

"ON"

Ignition Sw itc h

GENUINE PARTS

C - H

C - H

Meyer

Meyer

k

c

a

l

B

FIGURE 1-4A

ELECTRO -TOUCH

CONTROLLER

GROUND

(BLUE WIRE)

(ORANGE WIRE)

POWER TO SWITCH

TO MOTOR SOLENOID

5

6

2

3

(BLACK WIRE)

(GREEN WIRE)

TO "A" SOLENOID

TO "B" SOLENOID

TO "C" SOLENOID

E

V

I

1

T

D

A

G

E

E

N

V

T

2

F

H

F

C

O

T

/

I

W

N

S

H

C

T

(WHITE WIRE)

LOWE R/FLOA T

4

I

W

S

TO

R

E

W

O

1

0

A

P

O

E

R

I

W

E

U

L

B

I

A

S

O

P

d

i

o

n

e

l

o

S

"

A

"

e

r

i

W

k

c

a

l

B

K

C

A

L

B

1

D

E

N

R

I

U

W

O

END OF TOUCH PAD HARNESS

"ON"

(RED WIRE)

Ignition Switch

R

E

G

L

G

E

E

N

H

S

N

A

C

U

A

R

T

F

I

P

O

W

S

G

E

N

Y

R

E

T

S

O

T

P

A

B

D

N

U

O

R

G

E

E

T

I

R

I

H

W

W

R

E

W

O

P

FIGURE 1-4A

-12-

Page 15

POWER ANGLING

CYLINDERS

- OPERATING

- RETURN

CROSSOVER

RE LIEF

3800 + 400 P.S.I

"C"

SOLENOID

PILOT

CHECK

VALVE

CHECK

- INTAKE o r DRAIN

HYDRAULIC FLOW CHART

LOW ER/FLOA T

MODELS E-4 7 & E-57

FIGURE 1-4B

"B"

SOLENOID

FILTER

TANK

PRESSURE

RELIEF

E-4 7

1650 + 50 P.S.I.

E-5 7

2000 + 0 P.S.I.

CHECK V ALVE

LIF T

CYLINDER

FILTER

STRAINER

-13-

"A"

SOLENOID

ENERGIZED

Page 16

SLIK - S T IKSINGLE LEVER

ELECTRO -TOUCH

CONT R OLLER

CONTROLLER

GROUND

(ORANGE WIRE)

(BLACK WIRE)

TO "A" SOLENOID

(BLUE WIRE)

(WHITE WIRE)

POWER TO SWITCH

TO MOTOR SOLENOID

5

6

2

3

(RED WIRE)

(GREEN WIRE)

TO "B" SOLENOID

TO "C" SOLENOID

"C"

N

N

I

I

A

A

R

R

D

D

D1NEGATIVE

A2POSITVE

e

r

i

w

n

RIGHT ANGLE

L

E

E

S

N

U

A

"ON"

F

P

Ignition Switch

RIGHT ANGLE

4

1

0

A

H

TC

I

WHITE WIRE - ENERGIZED

Motor Solenoid

10

W

E

S

R

I

O

W

T

E

R

U

E

L

B

W

O

P

GENUINE PARTS

C - H

C - H

Meyer

Meyer

F

H

F

O

TC

/

I

W

N

S

O

E

V

I

1

T

D

A

G

E

N

E

V

T

2

I

A

S

O

P

e

e

r

G

"

B

"

N

N

I

I

A

A

R

R

D

D

1

D

E

N

R

I

U

W

O

R

E

G

L

G

END OF TOUCH PAD HARNESS

E

E

N

H

S

N

A

U

A

"ON"

Ignition Switch

R

TC

F

I

P

O

W

S

G

E

N

Y

R

E

T

S

O

T

P

A

B

D

N

U

O

R

G

E

E

T

I

R

I

H

W

W

R

E

W

O

P

.

D

E

Z

I

G

R

E

N

E

s

i

d

i

o

n

e

l

o

S

"

C

"

FIGURE 1-5A

N

E

E

R

G

FIGURE 1-5A

-14-

Page 17

POWER ANGLING

CYLINDERS

HYDRAULIC FLOW CHART

MODELS E-47 & E-57

- OPE R ATING

- RETURN

CROSSOVER

RELIEF

3800 + 400 P.S.I

"C"

SOLENOID

ENERGIZED

PILOT

CHECK

CHECK

VALVE

- INTAKE o r D R A IN

ANGLE RIGHT

FIGURE 1-5B

"B"

SOLENOID

NOT

ENERGIZED

FILTER

TANK

PRESSURE

RELIEF

E-4 7

1650 + 50 P.S.I.

E-5 7

2000 + 0 P.S.I.

CHECK VALVE

LIFT

CYLINDER

FILTER

STRAINER

"A"

SOLENOID

-15-

Page 18

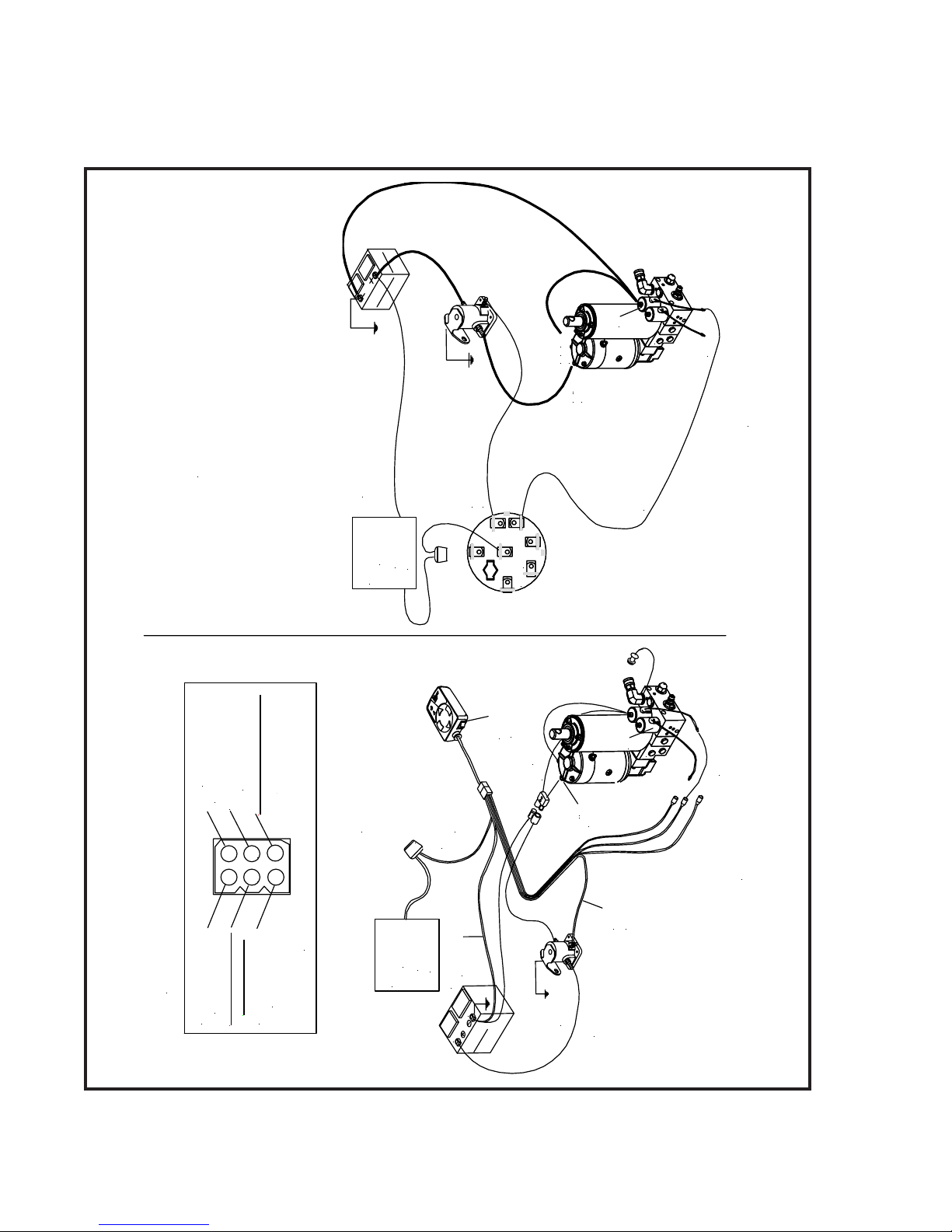

D1NEGATIVE

A2POSITVE

"C"

N

N

I

I

A

A

R

R

D

D

FIGURE 1-6A

SLIK - S T IKSINGLE LEVER

ELECTRO -TOUCH

CONT R OLLER

CONTROLLER

GROUND

(ORANGE WIRE)

(BLACK WIRE)

TO "A" SOLENOID

POWER TO SWITCH

TO "C" SOLENOID

6

3

(BLUE WIRE)

(GREEN WIRE)

LEFT ANGLE

L

E

E

S

N

U

A

"ON"

F

P

Ignition Switch

(WHITE WIRE)

TO MOTOR SOLENOID

LEFT ANGLE

4

5

2

1

END OF TOUCH PAD HARNESS

(RED WIRE)

TO "B" SOLENOID

1

0

A

E

S

U

"ON"

F

Ignition Switch

WHITE WIRE - ENERGIZED

Motor Solenoid

H

TC

I

10

W

E

S

R

I

O

W

T

E

R

U

E

L

B

W

O

P

GENUINE PARTS

C - H

C - H

Meyer

Meyer

F

H

F

O

TC

/

I

W

N

S

O

E

V

I

1

T

D

A

G

E

N

2

A

"

B

"

N

N

I

I

A

A

R

R

D

D

E

V

T

I

S

O

P

FIGURE 1-6A

D

E

N

R

I

U

W

O

R

E

G

L

G

E

N

H

N

A

A

R

TC

I

P

O

W

S

G

E

N

Y

R

E

T

S

O

T

P

A

B

D

N

U

O

R

G

E

E

T

I

R

I

H

W

W

R

E

W

O

P

-16-

Page 19

POWER ANG LING

CYLINDERS

ANG LE LEFT

HYDRAULIC FLOW CHART

MODELS E-4 7 & E-57

- OPERATING

- RETURN

CROSSOVER

REL I E F

3800 + 400 P.S. I

NOT

"C"

SOLENOID

"B"

SOLENOID

ENERGIZED

PILOT

CHECK

CHECK

VALVE

NOT

ENERGIZED

- INTAKE or DRAIN

FILTER

TANK

FIGURE 1-6B

PRESSURE

RE L IE F

E-47

1650 + 50 P.S. I.

E-57

2000 + 0 P.S.I.

CHECK VALVE

LIFT

CYLINDER

FILTER

STRAINER

"A"

SOLENOID

-17-

Page 20

-

-

BATTERY

+

SWITCH

IGNITION

FUSE

BLACK

WHITE

WHITE

SWITCH

SWITCH ANGLE

BLACK

&

RAISE

LOWER

GREEN

WHITE

RED

SWITCH

SOLENOID

MOTOR

BLACK

LOWER/FLOAT

C

B

A

WHITE

SWITCH

IGNITION

FUSE

BLACK

WHITE

SWITCH

SWITCH ANGLE

&

RAISE

BLACK

LOWER

BATTERY

+

ANGLE RIGHT

SWITCH

SOLENOID

MOTOR

C

GREEN

B

WHITE

RED

A

BLACK

-

BATTERY

+

SWITCH

IGNITION

FUSE

BLACK

WHITE

WHITE

SWITCH

&

RAISE

SWITCH ANGLE

LOWER

GREEN

BLACK

WHITE

SWITCH

SOLENOID

MOTOR

RED

BLACK

RAISE

C

B

A

WHITE

SWITCH

IGNITION

BLACK

WHITE

SWITCH

SWITCH ANGLE

BLACK

&

RAISE

LOWER

-

BATTERY

+

ANGLE LEFT

FUSE

GREEN

WHITE

SOLENOID

RED

SWITCH

MOTOR

C

B

A

BLACK

DUAL SWITCH WIRING

-18-

Page 21

ELECTRO LIFT® UNIT COMPONENTS

ELECTRO LIFT® UNIT COMPONENTS

MOTORS ( 3”) E-46, E-46H and E-47, E-47H

The 12-volt DC high torque motor used on the Electro

®

Lift

units are interchangeable among all four models.

Its function in all four applications is to drive the

hydraulic pump. The motor is only energized and

operating when pressurized hydraulic fluid is required.

Two different brand motors were used. While they are

interchangeable and have nearly identical performance

characteristics, they have distinctive design differences.

American Bosch

The American Bosch motor is a four pole, permanent

magnet motor which consists primarily of a 3" diameter

solid steel frame, armature, brushes and ceramic

permanent magnet fields. Because the fields are

permanent magnets, they do not require electrical

current to operate. Therefore, the motor requires lower

amperage to produce a given amount of power.

Electro Lift® units equipped with an American Bosch

motor cannot be used on vehicles with a positive

ground electrical system since the motor will rotate

backwards. Positive ground vehicles will require

modification of the brush assembly.

Prestolite - (obsolete)

MOTOR (4-1/2”) E-57, E-57H

Iskra - Single and Two terminal

The Iskra motor is a four pole, electromagnet motor

which consists primarily of a 4-1/2" diameter solid steel

frame, armature, brushes, field coils and pole pieces.

This motor can be used on vehicles with either the

common negative ground electrical system or the

positive ground electrical system.

HYDRAULIC PUMP

The pump in a hydraulic system employs an external

source of power to apply a force to a liquid. A pump

develops no power of its own. It simply transfers power

from an external source (the electric motor on the

Electro Lift® unit) to the liquid in the hydraulic system.

The basic operating principles of the hydraulic pump

used in the Electro Lift® units are quite simple. Figure

1-7 illustrates the basic components of a positive

displacement gear type pump and their functions. The

pumping action takes place within the pump chamber

which is connected to the reservoir by the intake line.

The pump chamber has an outlet line in which the liquid

under motion and pressure leaves the pump to perform

work.

RESERVOIR

ELECTRIC

MOTOR

F

L

O

W

DRIVE GEAR

OUTLET LINE

INTAKE LINE

DRIVEN GEAR

PUMP CHAMBER

PUMP HOUSING

F

L

O

W

FIGURE 1-7

PRESSURE RELIEF VALVE

A basic pressure relief valve is shown in

Figure 1-8. It consists of a poppet valve and a valve

spring. Both are located in a passage which connects

the inlet passage to the outlet passage. The poppet

valve is normally held closed by the valve spring,

sealing the connecting passage from the pressurized

outlet passage. The poppet valve, being a piston, is

exposed to the pressurized hydraulic fluid in the outlet

passage. Whenever the hydraulic pressure against the

poppet valve becomes greater than the pressure being

exerted on the poppet valve from the opposite

direction by the valve spring, the poppet valve will

open. This allows some of the pressurized hydraulic

fluid to flow through the connecting passage to the

non pressurized inlet passage. The effect is to lower

the pressure in the outlet passage which will allow the

valve spring to close the poppet valve again.

OUTLET PORT

POPPET

VALVE

VALVE

SPRING

PUMP HOUSING

INLET PORT

FIGURE 1-8

-19-

Page 22

ELECTRO LIFT® UNIT COMPONENTS CONT.

Under a condition, such as when a hydraulic cylinder

is extended to the end of its stroke, eliminating

additional space for the pressurized hydraulic oil to

be pumped into, the alternate opening and closing of

the poppet valve controls the pump’s pressure output

and provides an escape for the pressurized hydraulic

fluid.

The pressure relief valve used in the Electro Lift® pump,

while more sophisticated than the one described,

functions in the same manner. The pump pressure relief

valve may be adjusted on the E-46 & E-47 models to

the specified pressure of 1650 P.S.I. by adjusting the

set screw after installing a suitable pressure gauge of

2500 P.S.I. in the circuit. Note: The E-57 Model has a

nonadjustable pressure relief valve and is factory set

to 2000 P.S.I.

SOLENOID VALVES

Hydraulic valves are simple in concept and all have

the same basic function: Control the direction of oil

flow. One type of Solenoid Valve is used on the models

E-46 and E-46H and three types are used on models

that Power Angle.

Each Solenoid Valve consists of two components: the

Cartridge and the Coil.

WINDING

COIL

ARMATURE

VALVE SPOOL

FIGURE 1-9

“A” Solenoid Valve

The “A” Solenoid Valve is used in all Models. The “A”

Cartridge contains a poppet valve whose static or

de-energized position is closed. Its energized position

is open.

On all four models, the “A” Solenoid Valve retains

hydraulic fluid in the lift cylinder. It is energized

(opened) to allow the hydraulic fluid to flow from the

lift cylinder back to the reservoir, enabling the plow to

lower by gravity.

Cartridge

The Cartridge consists of the hydraulic valve

mechanism and an armature which enables the

valve mechanism to be operated and controlled

electrically. The Cartridge is designed to screw in

and out of the Electro Lift

®

units much like the

typical “spark plug”.

Coil

The Coil is the electrical component which operates

the Cartridge’s valve mechanism by producing

magnetism which pulls the Cartridge’s armature

toward it. Since the armature is connected to the

valve mechanism’s only moving part, it is pulled

by the armature.

Figure 1-9 illustrates the typical Coil. Whenever

electrical current flows to the Coil, it flows through

the winding, which consists of numerous turns of

copper wire. The flow of current through the

winding produces a magnetic field which pulls the

soft iron armature further into the Coil.

The armature pulls the valve spool or poppet valve

into its alternate (energized) position. Not illustrated

is an integral coil spring, which is compressed

when the armature is pulled by the magnetism.

When the current flow ceases, the magnetic field

disappears and the compressed coil spring pushes

the armature back to its original (de-energized)

position.

The “A” Solenoid Valve is designed to remain energized

(open) while the plow is lowered, plowing snow. This

is the “float” feature which insures that the plow

maintains contact with the ground contour.

“B” Solenoid Valve

The “B” Solenoid Valve is used on the Power Angle

Electro Lift® models. The “B” Cartridge contains a

spool valve whose static (de-energized) position allows

the pressurized hydraulic fluid to flow to the

“C” Solenoid Valve. In the energized position, the

pressurized hydraulic fluid is diverted to the lift cylinder,

raising the plow.

“C” Solenoid Valve

The “C” Solenoid valve is used on the Power Angle

Electro Lift® models. The “C” Cartridge contains a

spool valve whose static (de-energized) position allows

the pressurized hydraulic fluid to flow to the right power

angling cylinder which angles the plow to the left. At

the same time, it allows the hydraulic fluid being forced

from the retracting left power angling cylinder to flow

through the “C” Cartridge back to the reservoir.

In the energized position, the pressurized hydraulic

fluid is diverted to the left power angling cylinder,

angling the plow to the right. Also, the hydraulic fluid

being forced from the retracting right power angling

cylinder flows through the “C” Cartridge back to the

reservoir.

-20-

Page 23

CHECK VALVES

ELECTRO LIFT® UNIT COMPONENTS CONT.

Check valves are very simple devices that have two

basic functions: They prevent fluid from passing through

them in one direction, but they allow fluid to pass

through them in the opposite direction.

In all four Power Angling models a pump check valve

is used to prevent hydraulic fluid from leaking back

through the pump to the reservoir. Its function on the

E-46 and E-46H models is more critical since it is the

only means by which pressurized hydraulic fluid

pumped into the lift cylinder is prevented from leaking

out through the pump, causing the plow to slowly come

down.

The E-47 and E-57 models incorporate two additional

check valves, necessary because the “B” and “C”

Solenoid Valves, being spool valves, have some

leakage.

One check valve is located between the “B” Solenoid

Valve and the lift cylinder. It prevents the hydraulic fluid

in the lift cylinder from leaking back through the “B”

Solenoid Valve which could cause the weight of the

plow to angle the plow to the left by forcing hydraulic

fluid through the “C” Solenoid Valve into the right power

angling cylinder.

In this instance, the pressure is not produced by

the pump but rather by the damaging force. As an

example, assume that the right corner of the plow

runs into the end of a curb. The impact will attempt

to collapse the right power angling cylinder. As a

result, very high hydraulic pressure is produced

within the cylinder. When the produced pressure is

high enough, it opens the crossover relief valve,

allowing the highly pressurized hydraulic fluid to

flow directly to the left power angling cylinder.

When the crossover relief valve functions in this

manner, the excessive pressure is released, the

excessive energy produced by the impact is

absorbed, and the result is only a change in angled

position of the plow.

The crossover relief valve may be adjusted to the

specified pressure of 3800 P.S.I. ± 400 by turning the

3/8” hex cap screw after installing a suitable pressure

gauge of 4000 P.S.I. in the circuit. TIGHTEN (TURN IN)

ADJUSTMENT SCREW TO INCREASE PRESSURE.

See Figure 3-63. Disassembly/ Reassembly figures

3-42 thru 3-62.

SWITCH

(Models E-46 and E-46H)

The other check valve is located between the “B” and

“C” Solenoid Valves. It prevents the hydraulic fluid in

either power angling cylinder from being forced

through the “B” Solenoid Valve to the left cylinder.

PILOT CHECK VALVE

The pilot check valve is more sophisticated in that it

incorporates a piston in addition to the ball, seat and

spring. It is located between the “C” Solenoid Valve

and reservoir. It has two functions: The first is to prevent

the hydraulic fluid in either power angling cylinder from

leaking back to the reservoir. The second is to allow

the hydraulic fluid from the retracting power angling

cylinder during the angling cycle to return to the

reservoir. This is accomplished by the pressurized

hydraulic fluid moving the piston which forces the check

ball off its seat.

CROSSOVER RELIEF VALVE

When plowing snow, a snow plow can be exposed to

damaging forces caused by impact with hidden

obstructions, ends of curbs, etc. With power angling,

these damaging forces can damage not only the snow

plow but also the vehicle. The crossover relief valve

has the function of protecting the snow plow system

against these damaging forces under normal snow

plowing conditions. The crossover relief valve, cannot

protect the system from damaging forces that are too

great due to abusive snow plowing conditions.

Basically, the crossover relief valve functions exactly

like the previously described pump relief valve. It’s

designed to open at a specific pressure.

A single three-position toggle switch Is used on the

E-46 and E-46H models. The positions are:

• Off (Center Position)

• Raise (Up Position)

• Lower and Float (Down Position)

In the “off” position, the switch conveys no current.

In the “raise” position, the switch conveys current to

the solenoid switch. When released, an internal spring

returns the toggle to the “off” position.

In the “lower and float” position, the switch conveys

current to the “A” Solenoid Valve. When released, the

toggle will stay in the “lower and float” position. The

toggle must be manually returned to the “off”

position.

SWITCHES (Power Angling Models)

Dual Switch Control

Two three-position toggle switches are used on the

E-47 and E-47H models. The first, to raise and lower

the plow, has the same positions as the toggle switch

used on the E-46 and E-46 H models. However,

because it functions differently, it is a completely

different switch.

In the “off” position, the switch conveys no current.

In the “raise” position, the switch conveys current

to the solenoid switch and the “B” Solenoid Valve.

When released, an internal spring returns the toggle

to the “off” position.

-21-

Page 24

ELECTRO LIFT® UNIT COMPONENTS CONT.

SWITCHES (Power Angling Models) Cont.

Dual Switch Control

The second toggle switch is to angle the plow. The

positions are:

•Off (Center Position)

•Angle Left (Left Position)

•Angle Right (Right Position)

In the “off” position, the switch conveys no current.

In the “angle left” position, the switch conveys

current to the solenoid switch. When released, an

internal spring returns the toggle to the “off”

position.

In the “angle right” position, the switch conveys

current to the solenoid switch and to the “C”

Solenoid Valve. When released, an internal spring

returns the toggle to the “off” position.

Single Lever Control

A single lever control is also used on the Electro

®

Lift

models. This switch (five-position) functions the

same as the two three-position toggle switches

previously discussed.

Electro-Touch® Control Pad

IMPORTANT:

The power lead to the switch should be connected

to a terminal on the fuse panel that is HOT ONLY

when the ignition switch is in the “ON” position.

When the control switch is powered up, yellow lights

illuminate the arrows of the individual functions. The

up arrow for raise, the left arrow for angle left, the

right arrow for angle right and the down arrow for

lower or float.

Holding the down arrow for a full second will activate

a light located in the upper left corner of the

Electro-Touch® switch. This light indicates the snow

plow is now in the float position. In this position the

snow plow will be able to follow the contour of the

road and the snow plow can also be angled to the

left or right. Touching the up arrow will automatically

cancel the float position.

CAUTION: When the snow plow is not in operation,

the Electro-Touch

®

Control Switch should be in the

“OFF” position.

SOLENOID SWITCH

®

The Electro Lift

motor requires more current or

amperage to operate than the vehicle wiring, vehicle

ignition switch or toggle switches have the capacity

to handle. The solenoid switch is essentially a heavy

duty switch with the capacity to handle the heavy

current required by the motor. It is closed electrically

by the solenoid to convey the heavy current directly

from the vehicle battery via heavy gauge electrical

cable. The solenoid, which functions essentially the

same as the previously described solenoid valves,

receives its low amperage current at the proper

times via the wiring harness. This solenoid must be

grounded to operate properly.

FILTERS

Cleanliness is perhaps the single most important

ingredient in assuring a hydraulic system’s reliability.

Should the hydraulic fluid become contaminated,

malfunction and permanent damage to the

hydraulic system may occur. For this reason, all

the Electro Lift

®

units are equipped with a filter

system consisting of:

E-46 E-47, E-57

E-46H E-47H, E-57H

X X A fine screen strainer on the

reservoir pump inlet.

X X A filter screen between the lift

cylinder and “A” Solenoid Valve.

X A high pressure filter on the pressure

side of the pump.

With this system, the hydraulic fluid is filtered as it

leaves the reservoir on its way to the pump and on the

Power Angling units filtered again as it leaves the

pump. Because clean hydraulic fluid is most

important to insure “A” Solenoid Valve reliability, the

hydraulic fluid leaving the lift cylinder is filtered

before passing through the “A” Solenoid Valve. The

filter screen and high pressure filter are easily

removed for periodic cleaning or replacement.

This switch is short circuit, open circuit and

temperature protected. If any of these conditions

exists, the overload light will illuminate. The overload

light is located just below the float light in the upper

left corner of the Touch Pad. Reset is accomplished

by cycling the power to the Touch Pad via the on/

off switch located to the left of the cord as it enters

the Touch Pad.

NOTE: Additional filter screens are added to the

“A”, “B” and “C” Cartridge Valves.

IMPORTANT:

Should the hydraulic fluid become contaminated,

it will be necessary to replace all the hydraulic oil in

the system. The complete system (hydraulic unit,

power angling cylinders and hoses) should be

flushed. Flush the system with Meyer Hydra-Flush™

Fluid M-2.

-22-

Page 25

SECTION 2 - DIAGNOSIS

CONTENTS

GENERAL INFORMATION............................................................................ 24

TESTING TIPS ............................................................................................... 24

“RAISE” Troubleshooting ............................................................................. 25

“LEAK DOWN” Troubleshooting ................................................................. 26

“LOWER” Troubleshooting .......................................................................... 26

“ANGLE LEFT” Troubleshooting.................................................................. 27

“ANGLE RIGHT” Troubleshooting ............................................................... 28

“WILL NOT HOLD ANGLE” Troubleshooting ............................................ 29

“CROSSOVER RELIEF VALVE” Flow Chart............................................... 29

-23-

Page 26

DIAGNOSTIC FLOW CHART FOR

E-46, E-47 and E-57 ELECTRO LIFT® UNITS

These charts are intended to be used as an aid in diagnosing problems on the Electro Lift® units. They are not a substitute for factory

training and experience. Be certain to read the General Information and Testing Tips sections before attempting any troubleshooting.

IMPORTANT: Maintenance and repairs must be performed with the moldboard on the ground.

General Information

Before any troubleshooting is started, make certain the following conditions are met.

1. The moldboard is pointing straight ahead. This can often be done by coupling the left cylinder into the right cylinder and

pushing the moldboard by hand.

2. The power angling cylinders must be installed correctly on to the A- frame. The left cylinder (Driver’s side) has a hose

attached with a male half of a coupler at the end; the right cylinder (Passenger side) has a hose attached with a female half

of a coupler at the end.

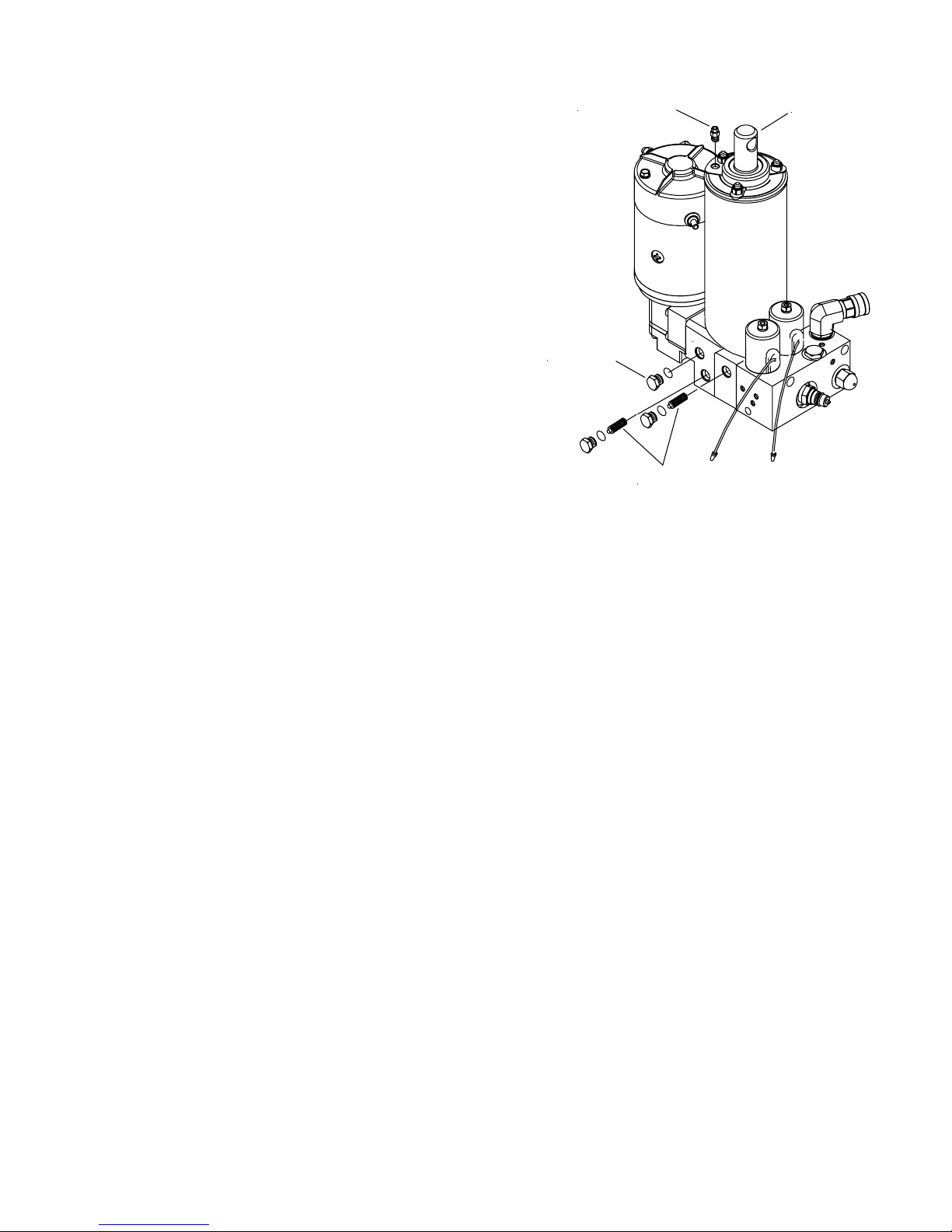

3. The solenoid coils must be on their proper valve. The “C” coil (green wire) must be next to angling fittings. The “B” coil

(red wire) is located to the front of the Electro Lift® Unit. The “A” coil (black wire) is smaller and is located on the back side

of the unit. (See Drawing).

TESTING TIPS

Many tests do not require removing the Electro Lift® unit from the vehicle. However, more thorough testing can be per-

formed using the Meyer Test Stand which allows direct pressure and amperage readings.

1. Using a screwdriver or other small tool to check for magnetism of the solenoid coils “A”, “B”, “C”. Place the tool on the nut

securing the coil and have an assistant operate the switch. You should feel strong magnetic attraction.

2. Use a test light or volt meter to determine whether there is power at the harness or switch. The current 22154 Electro-Touch

Control has been redesigned. Note: The Electro-Touch Controller now has raised buttons and its circuitry has been changed

from analog to digital, functions have not changed. For troubleshooting for power at the solenoids do not disconnect wires.

To check for power, prick the wire through the insulation for testing. The control knows when a short or an open connection

occurs and will go into overload mode for the function being activated. To reset the controller turn the switch on and off. The

Electro-Touch Control will not operate if not wired properly. Controller must be grounded, Orange wire from switch harness

attaches to the negative terminal of the battery. Reference Form 1-795 for wiring diagram.

3. When determining AMP draw of the motor, always obtain the highest value possible, i.e, at maximum raise or maximum

angle with motor running.

4. Proper rotation for the 3” motor (American Bosch) is indicated by an arrow located on top side of the (Part # 15026) pump.

5. The pump shaft of a good pump can be turned smoothly using two fingers. If it can’t be turn easily, the pump is too tight and

must be replaced.

6. Pump pressure can be measured at an angle hose (note pressure at full angle) or in the pressure filter port (an adaptor is

necessary for the filter port). Note: The E-57 Electro Lift® Unit has a non adjustable pressure relief valve.

7. Flush the complete system including unit, hoses and power angling rams with Meyer Hydra-Flush™ Fluid M-2.

To Ignition Switch

(Accessory Side)

FUSE

22092

20A

White

Motor Solenoid

(Must be grounded)

15680

D

R

A

I

D

R

A

I

N

P

N

L

U

G

F

I

L

T

E

R

S

Coupler

Weather Cap

To P a s s e n ge r S i d e

Power Angling Ram.

(Angle Left)

Pressure Relief

Filler Plug

"B"

G

R

E

R

E

E

N

D

"

"

B

C

"

"

B

L

A

C

K

"

A

"

To D ri v e r ' s S id e

"C"

Coupler

Weather Plug

"A"

Ground

A2

NE

B

A

T

T

E

+

-

To Motor

G

P

O

S

R

Y

D1

To Positive

Battery Terminal

Power Angling Ram.

(Angle Right)

-24-

Page 27

SNO

W PLOW WILL NOT RAISE

Does th e

Motor Operate?

YES

Is the fluid level

1-1/2" below

filler hole?

YES

Does the snow plow

angle to the left

instead of raising?

YES

NO

Is there power

going to

the mo to r?

YES

Remo v e motor .

Does motor run when

12 volts is applied?

YES

Can the pump

shaft turn by

hand?

YES

Replace pump.

NO

ADD M-1

Fluid

Does the snow plow

NO

angle when the

An g le S witch

is activate d ?

YES

Clean or Replace

"A" Valve.

-Retest -

Does snow plow

raise?

NO

YES

Is the "A" V alve

stuck in the

open position?

Disassemble unit Inspect O-rings,

NO

Cylinder,Piston

assembly .

Look for blockage in

Sump Casting

passages.

NO

Inspec t M o to r -

NO NO

Armature, Brushes

Repair or Replace

Motor as necessary

Is Ground Cable

attached to the

Negative (-)

Battery Terminal?

NO

Is there pressure

(or flow) at the

Filter port?

YES

Can pump relief pressure

be adjusted to

1650 +

E-46 & E-47

Are all electrical

connections clean

and tight?

Is Battery Charged?

NO

YES

Is there power

Is there power

going to the

motor solenoid,

at White Wire?

NO

leaving the

switch?

Check switch

for Continuity

YES YES

Replace the

Motor

Solenoid.

Are the

NO NO

Filters

Clogged?

YES

Clean

or

Replace

Filters.

NO

50 P.S.I

YES

Charge Battery Clean and tighten

all electrical

Connections.

Replace the

Wiring

Harness.

Is the moto r tu rnin g

the proper direction?

NO

Check for clogged

strainer - Is oil getting

to the pump?

YES

Is the pump

shaft turning

tightly?

Replace

the

Pump.

NO

Replace

the

Pump.

NO

Check Wires at

Molded connector.

YES

Is the Fuse

OK?

YES

Replace the

Raise

Switch .

NO

NO

Does the motor

armatu re tu rn

tightly?

YES

Repair or Replace

the mot o r.

Replace Fuse.

Check for short

NO

in Harness,

"B" Coil, Switch

Connections,

Motor Solenoid,

Electric Motor .

Check Brushes for

proper installation or

replace motor.

Clean strainer

and flush the

system completely.

Does the "B" Coil

(Red W ire ) h av e

magnetism?

NO

YES

Are the "B" Valve

O-Rings in good

Conditio n?

NO

Replace

O-Rings.

YES

Replace P .A. Block

Clean or

Replace the

"B" Valve

and retest.

NO

with E-46 plate and

retest. - Does snow

plow Raise now?

YES

Replace

P.A. Bl ock

NO

Replace

Sump Base.

Is there power to

the "B" Coil?

(Red Wire)

at Harness

YES

Replace

"B" Coil.

NO

-25-

Is there power

leaving the switch

at the red wire?

YES

Replace

the wiring

harness.

NO

Are wires in

molded connector

making contact

with the switch?

YES

Replace

the Raise

switch.

Page 28

SNOW PLOW LEAKS DOW N

Does th e

NO

snow plow drop

straight down?

YES

Are "A" Valve O-rings

in good condition?

Does "A" Valve stem

move fr e e ly?

YES

E-47: Dissasemble unit

Inspect O-Rings,Cylinder,

Piston Assemb ly.

Doe s it hold no w?

NO

NO

Does the snow plow

drop and angle

to the le ft?

YES

Replace

"B" Check Valve

Does it now hold?

Replace O-Rings

Replace "A" Valve

"E- 4 6 ONLY"

Replace Pump Check Valve

(Rem e mber to c o in th e b a ll to th e se a t).

Does it now Hold?

NO

Replace

Sump Base

NO

Replace

"B" Valve

Does it now hold?

NO

NO

Dissasemble unit

Inspect O-Rings,Cylinder,

Piston A ssembly.

Doe s it h o ld n o w?

Replace

Sump Base

NO

Replace

Sump Base

Does "A " Coil

(Black Wire) have

magnetism?

YES

Replace "A" Va lve

Does it now lower?

SNOW PLOW W ILL NOT LOW ER

NO

Is there power to the

"A" C oil (Bla c k Wire)

at harness?

NO

Check for a clogged

filter or a blocked

passageway.

YES

Replace

"A" Coil

NO

Is there power leaving

the switch at th e

Black Wire?

YES

NO

Check for Bent or

Siezed Ram

Assembly.

Replace

Harness

-26-

NO

A re wires in molde d

connector making contact

with th e switch ?

YES

Is Fuse

OK?

YES

Replace

Switch

NO

Replace the fuse Check for short in

harness, "A" Coil,

Switch connections.

Page 29

SNO

Can the snow plow

Raise?

YES

Does th e motor run

when angle switch

is pushed?

NO

NO

W PLOW WILL NOT ANGLE LEFT

See the Raise

Flow C h a rt

Section

Are the wires in

Is there p o w er to

the motor solenoid?

(White Wire)

NO

Is there power

leaving the switch?

YES

NO

molded connector

making contact with

the switc h ?

YES

YES

Does the snow plow

raise instead of

angling left?

YES

Clean or replace the

"B" Valve.

Retes t

Does the snow plow

NO

angle to the right when

the angle switch is

pushed left?

YES

Clean or replace the

"C" Valve.

Retes t

Replace Harness

Is the ampere draw

NO

less than 100 amperes

while trying to angle

snow p lo w?

YES

Is the Pilo t p is to n in

NO

good condition?

(worn/sloppy or Missing)

YES

Are "C" Valve

O-Rings in good

condition?

YES

Clean or replace

the Crossover Relief.

Does the snow plow

now an gle?

NO

NO

NO

NO

Replace

Piston

Replace

O-Rings

Replace the

P .A. Block

Replace Angle

Switch

Can the snow plow be

angled by hand when

the P.A. Rams a re

disconnected from A-Frame?

YES

Will the snow plow angle

right & left if n o t allo wed

to travel to e x tre me

angled position?

YES

T em porarily put 1/2" blocks

between the Sector and

A-Frame to limit the degree

of angle. Will the snow plow

now angle?

Weld

1-1/2" x 1-1/2" x 1/2"

spacers to the A-Frame

stops.

YES

Relieve the interference

NO

between the

Sector and A-Frame.

NO

Does pressure remain

in angle hose when the

motor is not running?

YES

If both hoses are stiff

inspect the Pilot Check

Piston and "C" Valve

for bindin g .

Replace both the

NO

Coupler sets and/or

clean or replace the

"C" Valve.

If one hose is stiff

inspect the the "C"

valve for binding.

Replace Coupler sets.

-27-

Page 30

SNOW PLOW WILL NOT ANGLE RIGHT

Can the snow plow

Raise ?

YES

Does the motor run

when angle switch

is pushed?

YES

Does the snow plow

raise ins te a d of

angling le ft?

YES

Clean or replace the

"B" Valve.

Rete st

NO

NO

Is there p o wer to

the motor solenoid?

(White Wire)

NO

Can the snow plow

angle to the Left?

Does the "C" Coil

have magnetism?

(Green Wire)

See the Raise

Flow Chart

Section

YES

NO

Is there p o wer

leaving the switch?

YES

Replace Harness

Is there p o wer to

NO

the "C " C oil?

(Green wire at harness)

YES

NO

NO

Are the wires in

molded connector

making contact with

the switch?

YES

Replace Angle

Switch

Is there power

leaving the switch?

YES

NO

Are the wires in

molded connector

making contact with

the sw itc h ?

YES

YES

Are "C" Valve

O-Rings in good

condition?

YES

Clean or replace

the Crossover Relief.

Does the snow plow

now angle?

NO

Replace the

"C" Coil.

Retes t

Replace

O-Rings

Replace both the

Coupler sets and/or

clean or replace the

"C" Valve.

NO

Replace Harness

Replace the

P.A. Block

Replace Angle

Switch

-28-

Page 31

SNOW PLOW WILL NOT HOLD ANGLE

Are the Rams mushy?

Can you push the moldboard

6" to 8" by h a n d?

YES

Bleed air from the system

and snug up gland nuts.

Check couplers and fittings

for leak s.

"B"

SOLENOID

NO

Does the moldboard

hold left angle & release

from rig ht angle ?

YES

Inspect "C" Valve O-rings

Change if necessary. Does

snow plow now angle?

Are the "C" Valve

NO

O-Rings in poor

cond itio n ?

YES

Replace O-Rings

Change Pilot Check

NO

Ball a n d Seat.

does snowplow

now hold?

Is Crossover Relief set

NO

at 3800 +

Are Crossover O-Rings

in go od co n dition?

Inspect Crossover Relief.

NO

(Rebuild or Replace)

Does snow plow now

hold angle?

Crossover Relief Valve

"C"

SOLENOID

400 P .S.I.?

YES

Replace the

P.A. Block

Set C r o s s over R e lie f to

NO

380 0 +

Replace Crossover O-Rings

or complete Crossover .

NO

Replace the

P.A. Block

Pressure

400 P .S.I.

CHECK

VALVE

PILOT

CHECK

CROSSOVER

R E L IE F

3800 + 400 P.S.I

POWER AN GLING

CYLINDERS

-29-

Page 32

SECTION 3 - REPAIR PROCEDURES

CONTENTS

GENERAL INFORMATION .................................................................. 31

UNIT DISASSEMBLY AND REASSEMBLY ........................................ 31

Disassembly .................................................................................... 31

Reassembly ..................................................................................... 31

• Additional Reassembly Points ................................................... 31

PUMP...................................................................................................... 31

Shaft Seal Replacement ................................................................ 31

ELECTRO LIFT

Exploded View ................................................................................ 32

Parts Breakdown ............................................................................ 33

Disassembly Photos ....................................................................... 34-41

Reassembly Photos........................................................................ 41-43

CROSSOVER RELIEF VALVE

Disassembly .................................................................................... 44-45

Reassembly ..................................................................................... 46-49

BRUSH REPLACEMENT ..................................................................... 50

Iskra Brush Replacement .............................................................. 50

American Bosch Brush Replacement.......................................... 50-51

VALVE CARTRIDGES “A”, “B” & “C” .................................................. 51

“A” Cartridge .................................................................................... 51

“B” & “C” Cartridges ...................................................................... 51

®

SPECIAL TOOLS .................................................................................. 52

SPECIFICATIONS ................................................................................

53

-30-

Page 33

GENERAL INFORMATION

Using the proper guidelines and precautions, all four

model Electro Lift® units are easy to disassemble and

reassemble. Figure 3-1 (page 32) is an exploded view

which applies to all four models. It should be used as

the primary reference for proper reassembly. Where

necessary, this section includes additional information,

photographs and illustrations to assure proper and

efficient repairs.

UNIT DISASSEMBLY AND REASSEMBLY

Model E-46, E-46H, and Power Angling units with the

exception of the Power Angling Valve Assembly, the

parts and disassembly / reassembly procedures are

common to all models.

Many repair procedures, including removal and

replacement of the “B” and “C” Solenoid Valves, can

be accomplished without removing the unit from the

vehicle. While Figures 3-2 through 3-62 show the unit

clamped in a vise, make all possible repairs on the

vehicle when possible.

NOTE: Pump Assembly should not be disassembled

since it cannot be serviced with the exception of the

pressure relief valve (pages 19-20) and pump shaft seal

which is covered separately in this section.

Motor should be taken to the appropriate (American

Bosch or Prestolite) authorized service station in your

area for all parts and service with the exception of brush

replacement. Procedure for American Bosch motor

brush replacement is covered separately in this section.

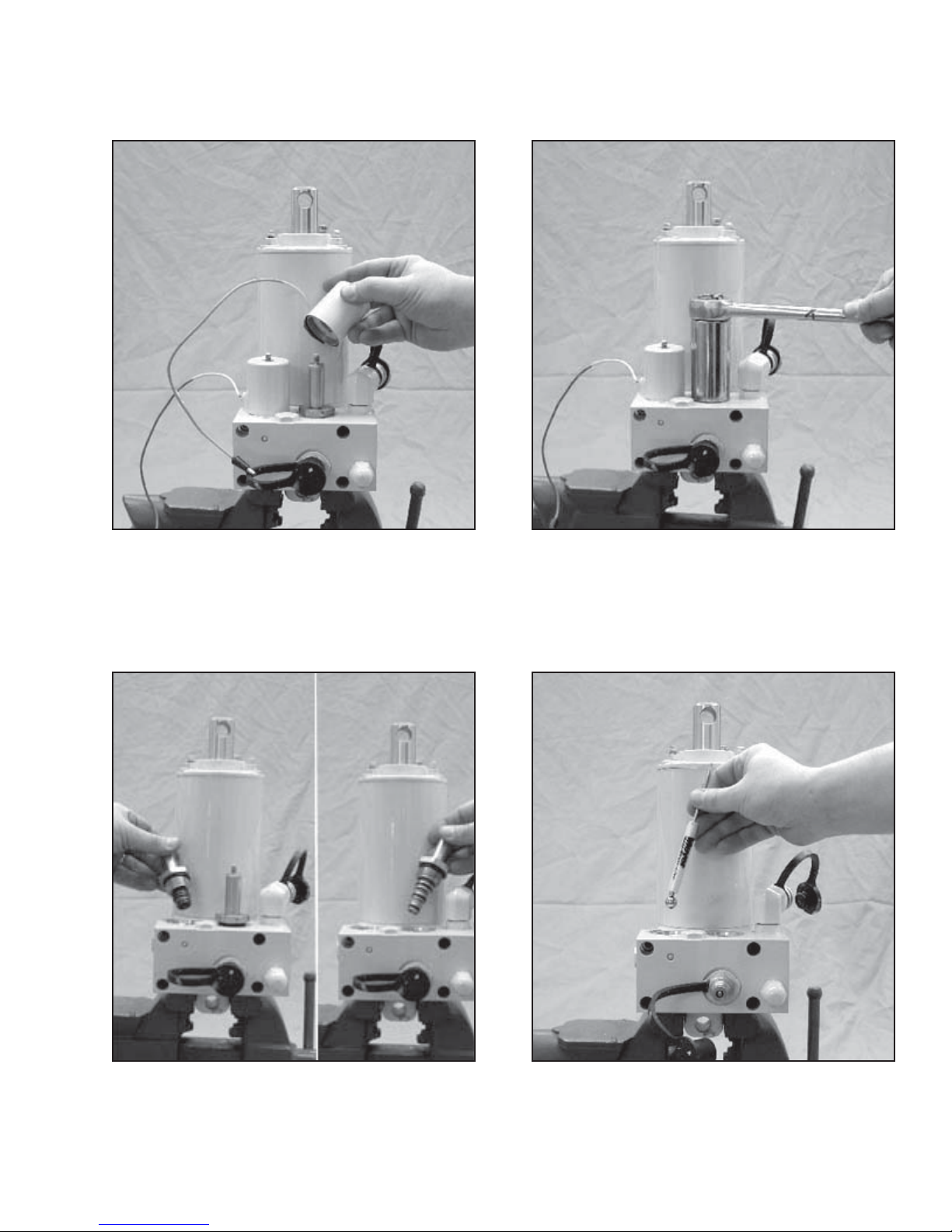

Disassembly

Reassembly

See Figures 3-31 through 3-41 (pages 41-43) for

important reassembly points on any of the four models.

See Figures 3-49 through 3-62 (Pages 46-49) for

Crossover Relief reassembly.

Additional Reassembly Points

O-Rings- Coat liberally with hydraulic fluid and

position carefully to minimize possibility

of damage during assembly.

Fasteners- Torque all fasteners which are specified to

insure proper reliability and prevent

damage due to over-tightening.

PUMP

Shaft Seal Replacement

NOTE: Do not disassemble pump assembly.

1. Remove motor as shown in Figures 3-4 and 3-5

(page 34).

2. Using an appropriate tool, pry out the original shaft

seal, being careful not to damage the shaft or pump

housing.

3. Liberally coat the replacement seal I.D. with

hydraulic fluid and apply a very light film of

Permatex Form-A-Gasket No. 2 or equivalent to

the replacement seal O.D.

See Figures 3-2 through 3-11 (pages 34-36), Figures

3-25 through 3-31 (pages 39-41) for important

disassembly points on any of the four models.

See Figure 3-12 (page 36) for important disassembly

points on the E-46 and E-46H models.

See Figures 3-13 through 3-24 (pages 36-39) for

important disassembly points on the Electro Lift® units.

See Figures 3-42 through 3-48 (Pages 44-45) for

Crossover Relief disassembly.

4. Carefully slide the replacement seal

(metal side up) over the shaft until it is squarely

against the pump housing.

5. Center a 11/16" hex deep socket over the seal and

use it and a plastic or leather mallet to squarely

drive the seal into the pump.

6. Replace the motor as shown in Figures 3-39

through 3-40 (page 43).

-31-

Page 34

63

56

89

57

58

59

73

65

61

62

60

81

55

80

68

69

79

64

55

71

70

72

66

67

54

53

32

44

52

75

76

77

78

86

87

88

Adjustable cross-over relief valve.

Note: Oil seepage, if any, at O-ring (86)

is normal, DO NOT attempt to stop this

seepage by further tightening of the

Acorn Nut.

85

84

83

74

ELECTRO LIFT

Exploded View

Caution:

Tor q u e t o

100-125 in.-lbs.

46

Notch on

underside

Backup

73

O Ring

O Ring

Backup

O Ring

Backup

Caution:

Tor q u e t o

75-85 in. lbs.

34

33

43

82

91

35

44

47

37

36

15

16

17

13

21

20

12

10

11

31

30

90

E-46 only

19

18

14

38

45

®

Caution:

To r q u e to

10 in.-lbs.

Caution:

Tor q u e t o

100-125 in.-lbs.

23

28

24

27

25

26

29

41

42

49

50

"A" Solenoid

Caution:

To rq ue to

100-125 in.-lbs.

22

("H" Units ONLY)

39

40

48

50b

51

49b

(A2)

(+)

9

48b

51

Caution:

Tor qu e t o

45-55 in.-lbs.

Sealant

3

(D1)

(-)

2

8

1

9

NON

ADJUSTABLE

4

7

6

Note: For Prestolite Motors extra set

of holes must be drilled and tapped.

15054

15026

15581

39

40

41

42

15043

45

38

E-46 & E47

Motor & Pump Assy.

-32-

45-55 in.-lbs.

Caution:

Sealant

Caution:

Tor q u e t o

Torque to

100-125 in.-lbs.

Locknut 5/16-24

15611

Page 35

PARTS BREAKDOWN

E-46, E-47 & E-47H

E-57 & E-57H

ELECTRO-LIFT

STANDARD- LONG STROKE-

UP THROUGH HM-9 & HM-10

ITEM 1-1/8" x 6" Stroke 1-1/8" x 8" Stroke QTY. DESCRIPTION

1 15869 15869 1 Pump & Motor Assy. (12 volt)

1b 15890 15890 1 Pump & Motor Assy. (24 volt)

2a 15727 15727 1 • Motor - 12 Volt (2 Terminal)

2b 15891 15891 1 • Motor - 24 Volt (2 Terminal)

3 15889 15889 1 • Pump Assy.

4 15874 15874 1 ••Kit - Pump Relief Valve

5 15870 15870 1 •• Relief Valve Assy.

6 15878 15878 1 •• Plug w/O-Ring

7* 15875 15875 1 Seal Kit Relief Valve

8 15877 15877 1 Pump Shaft Seal

9 22339 22339 3 Soc. Head 5/16-18 x 1-3/4"

10 15045 15204 1 Cylinder Tank

11* 15131 15131 1 O-Ring 3-1/2 I.D.

12* 15163 15163 1 O-Ring 1-15/16 I.D.

13* 15198 15198 1 O-Ring 1-1/8 I.D.

14 15194 15194 1 Cover & Seal Assy.

15* 05119 05119 1 • Wiper

16* 15131 15131 1 • O-Ring 3-1/2 I.D.

17 15199 15199 1 • Sleeve

18 21805 21805 1 • Reducer Bushing 1/4 x 1/8

19 21806 21806 1 • Pressure Relief Valve

20 15207 15205 1 Cylinder

21 15209 15209 1 Washer (Grooves Down)

22 15335 15761 1 Ram Assembly

23 15208 15206 1 • Ram

24 15158 15158 1 • Piston

25 15219 15219 1 • Piston Follower

26 15760 15760 1 • Spacer

27* 15162 15162 1 • Packing Cup

28* 15125 15125 1 • O-Ring 7/16 I.D.

29 20316 20316 1 • Locknut 1/2-13

30 15573 15573 1 Base & Strainer Assy.

31 15326 15326 1 • Strainer

32 15641 15641 2 • Filter Kit - 9/16"

33 15619 15619 1 •• Filter

34 21999 21999 1 •• Plug w/O-Ring - 9/16"

35 15042 15203 3 Stud

36 15621 15621 1 Baffle

37 21980 21980 2 Retainer Ring

38 15574 15574 1 Pump Check Valve Kit

39* 15124 15124 1 • O-Ring 3/8 I.D.

40 1 • Seat

41 1 • Ball, 9/32

42 1 • Spring

C-9 ONLY

E-57 E-57H

15865 15866 1 Lift Ass'y. (Unit only) 12 volt

15881 15885 1 Lift Ass'y. (Unit only) 24 volt

08473 08473 1 Pressure Relief Valve Kit

Parts indented are included in assembly under which they are indented.

PARTS LIST

ITEM 1-1/8" x 6" Stroke 1-1/8" x 8" Stroke QTY. DESCRIPTION

43* 15122 15122 3 O-Ring 1/4 I.D.

44 21999 21999 1 Drain Plug w/O-Ring - 9/16"

45* 15127 15127 1 O-Ring 5/8 I.D.

46* 21929 21929 3 Washer, Nyltite 5/16

47 20697 20697 3 Locknut 5/16 - 24

48 15972 15972 1 "A" Solenoid Assembly

49 15905 15905 1 •• "A" Coil, Black Wire (12V)

50 15660 15660 1 •• "A" Cartridge Valve

51* 15431 15431 1 ••• Seal Kit, "A" Valve

48b 15661 15661 1 "A" Solenoid Assembly

49b 15659 15659 1 •• "A" Coil, Black Wire Plastic

50a 15660 15660 1 •• "A" Cartridge Valve

51b* 15431 15431 1 ••• Seal Kit, "A" Valve

52 15758 15758 1 • Valve Assy. w/Coup. (12V)

53 22295 22295 1 • Forged 90 Degree Elbow

54 22294 22294 1 • Coupler, Female Half

55 22293 22293 1 • Coupler, Male Half

56 15639 15639 1 • Kit-Pilot Check Valve

57 1 •• Ball, Steel

58 1 •• Spring

59 1 •• Plug

60 15609 15609 1 • Piston

61 15359 15359 1 • Plug Valve Block

62* 15126 15126 1 •• O-ring 9/16 I.D.