Meyer ELECTRO LIFT E-46, ELECTRO LIFT E-46H, ELECTRO LIFT E-47, ELECTRO LIFT E-47H, ELECTRO LIFT E-57 Service Manual

...

FORM NO. 1-562-R16

October, 2005

Price: $4.25

ELECTRO LIFT

power units

service manual

MODELS

®

E-46, E-46H

E-47, E-47H

E-57, E-57H

18513 Euclid Ave. • Cleveland, OH 44112-1084

Meyer Products Inc.

Phone (216) 486-1313

email•warranty@meyerproducts.com

© 2005 Printed in the U.S.A.

6 Angell Lane• Damariscotta, ME 04543-9720

Diamond Equipment

Phone (207) 563-2227

www.diamondplow.com • email info@diamondplow.com

FOREWARD

This Service Manual includes complete information for servicing the following Electro Lift® Units:

E - 46 and E - 46H

E - 47 and E - 47H

E - 57 and E - 57H

IMPORTANT: Maintenance and repairs must be performed with the moldboard on the ground.

The information is grouped according to the type of work being performed, such as diagnosis and testing,

disassembly and reassembly. Special tools and specifications are also included in this manual.

All information, illustrations and product descriptions contained in this manual are correct at publication

time. We do, however, reserve the right to make changes at any time without prior notice.

MEYER PRODUCTS INC.

SECTION INDEX

Section Number Section Title ..................................................... Page

0 GENERAL INFORMATION AND

MAINTENANCE ........................................................ 1

1 GENERAL DESCRIPTION AND

THEORY OF OPERATION ........................................ 4

2 DIAGNOSIS ............................................................. 23

3 REPAIR PROCEDURE .............................................. 30

4 SPECIFICATIONS ..................................................... 53

Meyer Products Inc. reserves the right, under its continuing product improvement program, to change construction or

design details, specifications and prices without notice or without incurring any obligation.

SECTION 0 - GENERAL INFORMATION AND MAINTENANCE

CONTENTS

GENERAL INFORMATION .................................................. 2

•M

ODEL IDENTIFICATION .................................................... 2

•M

ODEL IDENTIFICATION AND

SERIAL NUMBER LOCATION .............................................. 2

•M

OTOR IDENTIFICATION ................................................... 2

MAINTENANCE ................................................................... 2

•G

ENERAL MAINTENANCE ................................................... 2

•C

LEANLINESS ................................................................. 2

•V

EHICLE ELECTRICAL SYSTEM ........................................... 3

•C

HECK REGULARLY ......................................................... 3

POST-SEASON MAINTENANCE ....................................... 3

•M

EYER HYDRAULIC FLUID M-1 ......................................... 3

•R

EPLACEMENT OF HYDRAULIC FLUID ................................... 3

•F

ILTERS ........................................................................ 3

•P

ROTECTION AGAINST RUST

AND

CORROSION ............................................................ 3

-1-

GENERAL INFORMATION

R

Model Identification

®

The Electro Lift

unit is an electrically powered hydraulic

mechanism specifically designed for use with the Meyer

Snow Plow and is available in four models as follows:

E-46 Raises and lowers plow hydraulically

(2-way) and is used with TM, ST and

C series Snow Plows.

E-46H Raises and lowers plow hydraulically

(2-way) and is used with HM series

Snow Plows.

E-47/E-57 Raises, lowers and angles plow

hydraulically (7-way) and is used with

TM, ST and C series Snow Plows.

E-47H/E-57H Raises, lowers and angles plow

hydraulically (7-way) and is used with

the MDII, HM and Diamond series

Snow Plows.

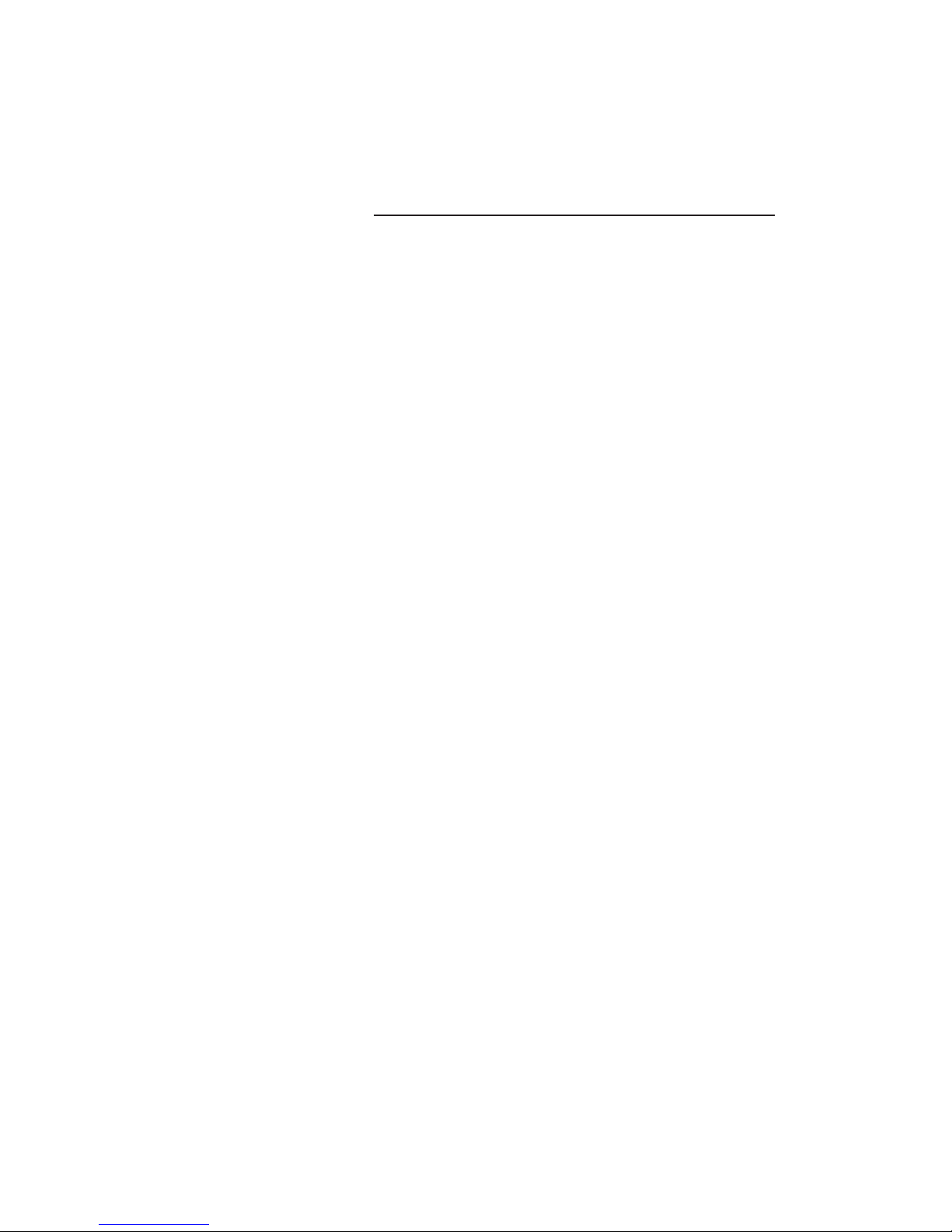

Model Identification and Serial Number Location

Inclusion of the model number and serial number is

extremely important when writing up warranty claim

forms and product report forms for proper evaluation

and follow up.

Motor Identification

Three different brand motors are used on the Electro

Lift® units American Bosch, Prestolite and Iskra.

Proper identification of the brand and supplier part

number is necessary when seeking local parts and

service sources.

The motor with which a specific Electro Lift® unit is

equipped can be identified by the distinctive

characteristics shown in figure 0-2.

DOMED COMMUTA T O

END COVER

STEEL ST AM PED

PRESTOLITE

MKW -4007-12V

FLAT COMMUT ATOR

END COVER

E

T

I

L

O

T

S

E

R

P

3" Dia.

3" Dia.

The basic model number is located on the name plate

located as shown in Figure 0-1. To determine whether

it is the standard or “H” model, measure the dimension

shown in Figure 0-1. The serial number is located on

the bottom of the base or on the name plate.

NAME PLATE

"

8

/

1

-

8

H

7

5

E

,

H

7

4

E

,

H

6

4

E

"

4

/

1

-

6

7

5

E

,

7

4

E

,

6

4

E

STEEL ST AMP ED

AMERICAN BOSCH

MO 551046A

ISKRA

Label 15829

AMJ4739 12V 1,6kw

SINGLE and TWO TERMINAL

4-1/2" Dia.

FIGURE 0-2

MAINTENANCE

The following maintenance information is intended as

a basic guide for providing the Electro Lift

®

unit with

the proper service and care. Sustained heavy duty

operation or operating under adverse conditions may

necessitate more frequent servicing.

xxxxx

FRONT VIEW

SERIAL NUMBER

(ON FRONT SIDE)

FIGURE 0 -1

General Maintenance

Cleanliness

The greatest enemy to any hydraulic system is dirt or

contamination. Therefore, cleanliness must be stressed

at the time of installation, servicing and repairing.

-2-

Vehicle Electrical System

Maximum performance and efficiency of the Electro

Lift® unit requires that the vehicle’s electrical system

be properly maintained and consist of:

Battery ----------- 70 Amp. Hr. Minimum or

550 Cold Cranking Amps.

Alternator ------ 60 Amp. Minimum

Check Regularly

1. Battery Terminals - Must be clean and free of

corrosion.

2. Electrical Connections - Must be free of corrosion

and tight.

3. Battery - Must be in first-class condition.

4. Alternator (or Generator) and Regulator - Must be

functioning to specifications.

5. Hydraulic Fluid Reservoir Level - A significant drop

in hydraulic fluid level indicates a leak which must

be located and corrected. Insufficient hydraulic fluid

may result in severe damage.

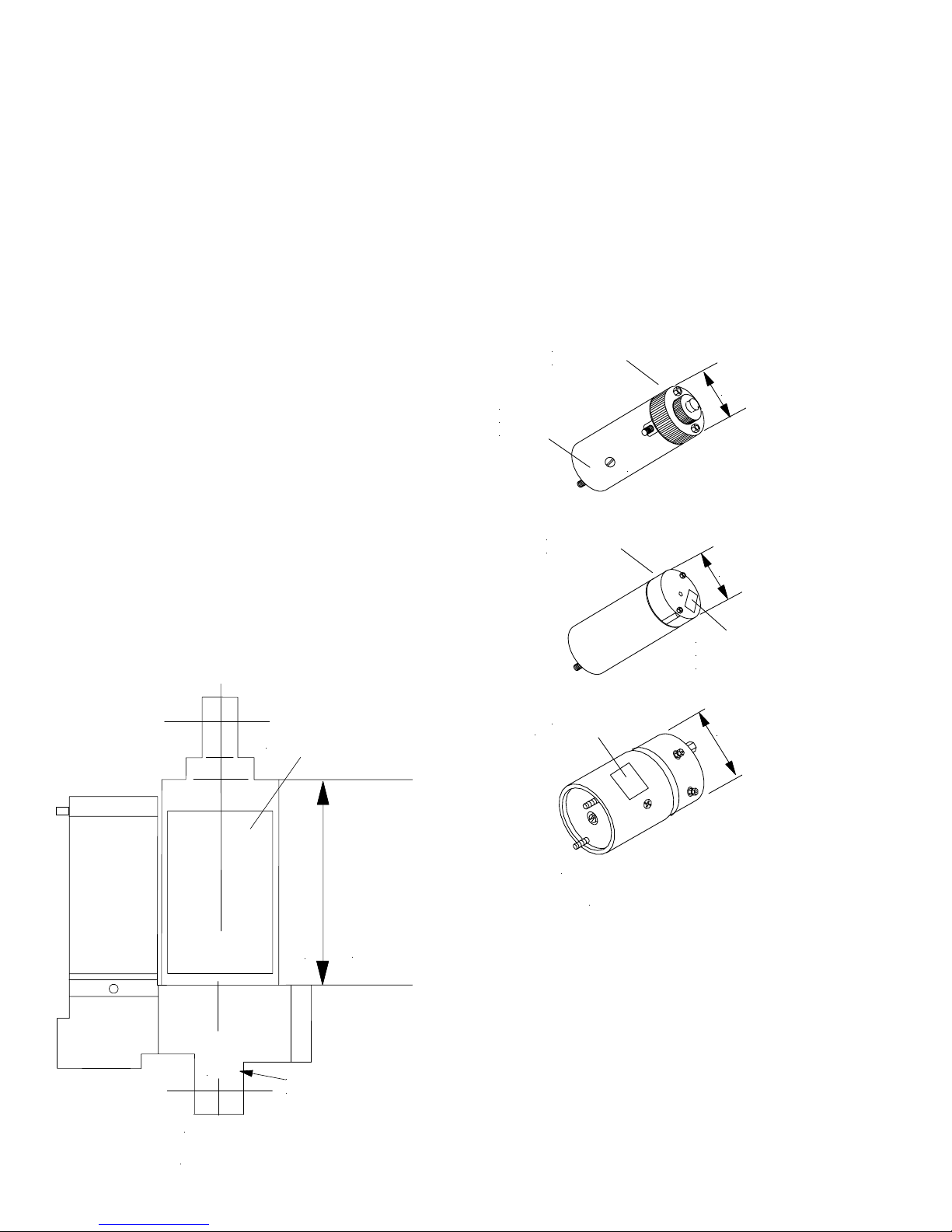

POST-SEASON MAINTENANCE

Meyer Hydraulic Fluid M-1.

FILLER PLUG

DRAIN PLUG

FILTER S

FIGURE 0-3

LIFT ROD

D

R

A

I

N

Meyer Hydraulic Fluid M-1 is a specially formulated

mineral oil which maintains an almost constant

viscosity from normal to sub-zero temperatures.

Because it remains free flowing at extremely low

temperatures, the performance and efficiency are not

affected.

Meyer Hydraulic Fluid M-1 also contains an additive

which neutralizes moisture accumulating in the fluid

due to condensation. It is effective for a maximum of

one year’s use.

Meyer Products Inc. will not be liable for damages

resulting from the use of inferior or other fluids or

oils.

Replacement of Hydraulic Fluid

After a season’s use, completely drain the hydraulic

fluid (including hydraulic fluid in hoses and cylinders

on Power Angling models). Drain fluid through filler

hole shown in Figure 0-3 or drain hole in base by

completely retracting lift rod and unbolting unit to pour

fluid out or using a suction pump. On Power Angling

models, disconnect the fittings at the Angling cylinders,

completely retract the cylinder rods and purge

cylinders and hoses of all hydraulic fluid. Flush the

complete system including unit, hoses and Power

Angling rams with a non wax (Napthenic) cleaner. If

kerosene (Parrafinic) is used to flush the system, the

system must be flushed again to remove any kerosene

with a (Napthenic) based cleaner that is wax free .

Refill Electro Lift

®

unit with M-1 Fluid by fully

retracting lift rod (Ram) and filling reservoir to 1-1/2

“ below the filler hole. On Power Angling models,

fill and bleed hoses and Power Angling cylinders

by loosening hydraulic fittings at cylinders until they

leak. Power angle plow repeatedly from one side to

the other until fluid flows steadily from the leaking

fittings while maintaining a constant check on the

reservoir fluid level.

Raise and lower the plow several times and with lift

rod fully retracted, give a final check to the fluid level

and replace filler plug.

Filters

Clean the two filters (only one in E-46 and E-46H; two

in Power Angling units) located in base of unit with

mineral spirits or equivalent and blow out with

compressed air. See Figure 0-3 for filter locations.

Protection Against Rust and Corrosion

When the Electro Lift® unit is not used for extended

periods, protect the chromed lift rod (Ram) by fully

extending it and coating it with chassis lubricant. Full

extension of the lift rod (Ram) fills the cylinder with

hydraulic fluid. On Power Angling models, coat the

exposed portions of the Power Angling cylinder rods

(Rams) with chassis lubricant to protect them against

rust and corrosion.

-3-

SECTION 1 - GENERAL DESCRIPTION AND THEORY OF OPERATION

CONTENTS

GENERAL DESCRIPTION ................................................................................................. 5

THEORY OF OPERATION................................................................................................. 5

UNCTIONS .................................................................................................................. 5

•F

•• Models E-46 and E-46H ................................................................................... 5

•• Models E-47, E-47H and E-57, E-57H ........................................................... 5

•ELECTRICAL AND FLOW CHARTS ...................................................................................... 6-18

ELECTRO LIFT® UNIT COMPONENTS ......................................................................... 19

•M

OTORS ...................................................................................................................... 19

•• American Bosch ............................................................................................... 19

•• Prestolite ............................................................................................................ 19

•• Iskra .................................................................................................................... 19

YDRAULIC PUMP .......................................................................................................... 19

•H

•P

RESSURE RELIEF VALVE ................................................................................................ 19-20

OLENOID VALVES ......................................................................................................... 20

•S

•• Cartridge ............................................................................................................ 20

•• Coil...................................................................................................................... 20

“A” Solenoid Valve............................................................................................. 20

“B” Solenoid Valve............................................................................................ 20

“C” Solenoid Valve ........................................................................................... 20

•CHECK VALVES .............................................................................................................. 21

•P

ILOT CHECK VALVE ...................................................................................................... 21

•C

ROSSOVER RELIEF VALVES ............................................................................................ 21

WITCH (MODELS E-46 AND E-46H) ............................................................................ 21

•S

•S

WITCHES (POWER ANGLING MODELS) ............................................................................ 21

•• Dual Switch Control ........................................................................................... 21-22

•• Single Lever Control .......................................................................................... 22

•• Electro-Touch Control......................................................................................... 22

•S

OLENOID SWITCH ........................................................................................................ 22

ILTERS ....................................................................................................................... 22

•F

-4-

GENERAL DESCRIPTION

THEORY OF OPERATION

Electro Lift® unit is an electrically powered and

electrically controlled hydraulic mechanism specifically

designed for use with Meyer Snow Plows. The standard

model E-46 raises and lowers the plow hydraulically

with an integral 6" stroke hydraulic cylinder while the

model E-46H performs the identical task for larger plows

with an integral 8" stroke hydraulic cylinder.

In addition to raising and lowering the plow

hydraulically, the model E-47, E-47H and

E-57, E-57H angles the plow hydraulically, left and

right, via remote hydraulic cylinders.

The Electro Lift® unit consists of a specially designed

high torque 12-volt DC motor which is directly coupled

to a gear-type hydraulic pump. The pump obtains its

supply of hydraulic fluid from an integral reservoir which

totally surrounds the integral hydraulic cylinder which

raises and lowers the plow.

Included in all models is an electrically controlled and

powered solenoid valve cartridge “A” which is

energized to allow the plow to lower by gravity.

The models E-47 and E-57 include an integral valve

body which contains two additional electrically

controlled solenoid valve cartridges. Solenoid valve

cartridge “B” is energized to route the pressurized

hydraulic fluid to the integral hydraulic cylinder to raise

the plow. Solenoid valve cartridge “C” is energized to

route the pressurized hydraulic fluid to the left remote

hydraulic cylinder to angle the plow to the right. Angling

the plow to the left only requires energizing the electric

motor since the normal route for the pressurized

hydraulic fluid is to the right remote hydraulic cylinder.

FUNCTIONS

®

The Electro Lift

models perform basic functions.

Because certain of these basic functions are

accomplished differently in the models E-46 and

E-46H as opposed to the Power Angling models will

be treated separately where necessary.

Models E-46 and E-46H

The two basic functions performed are:

• Raise snow plow

• Lower snow plow and float

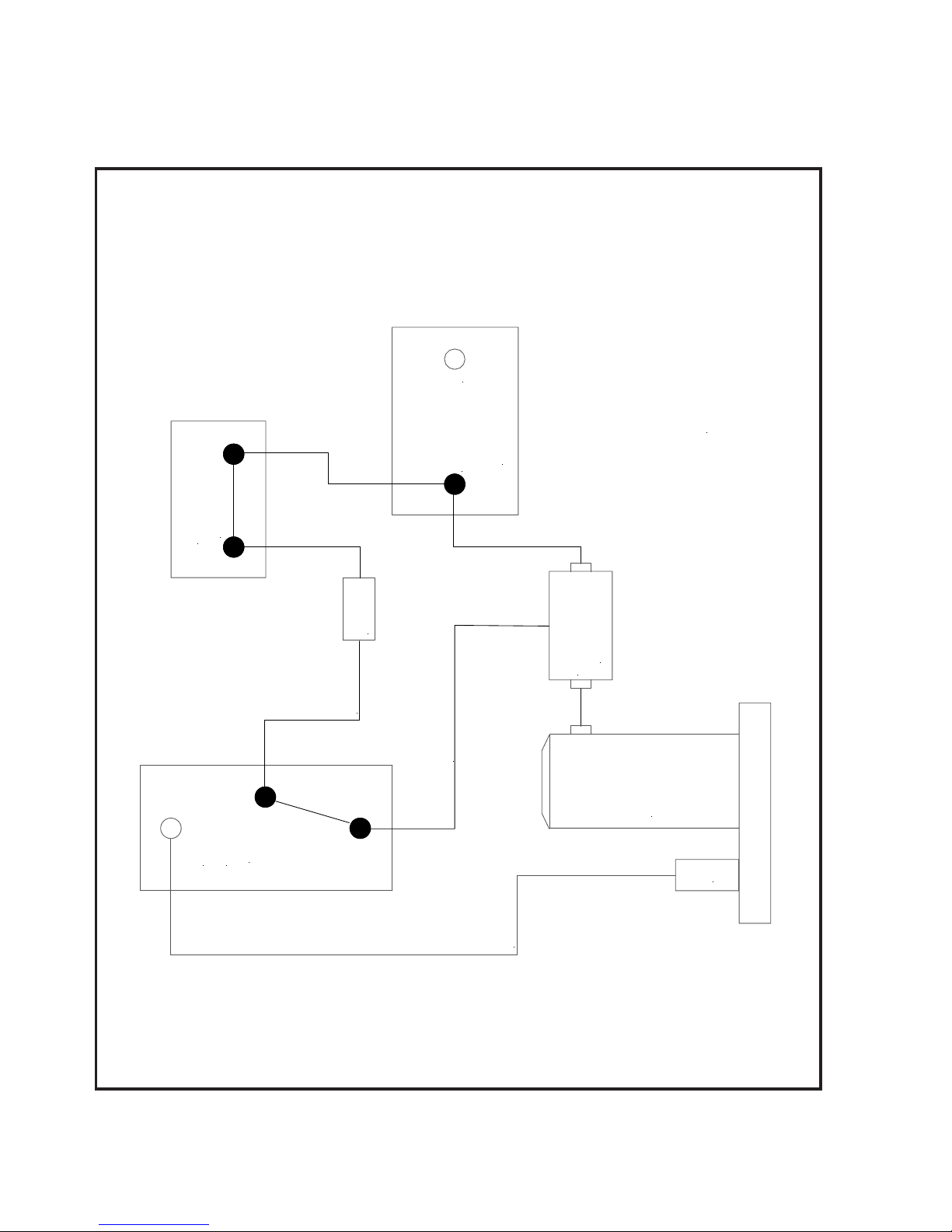

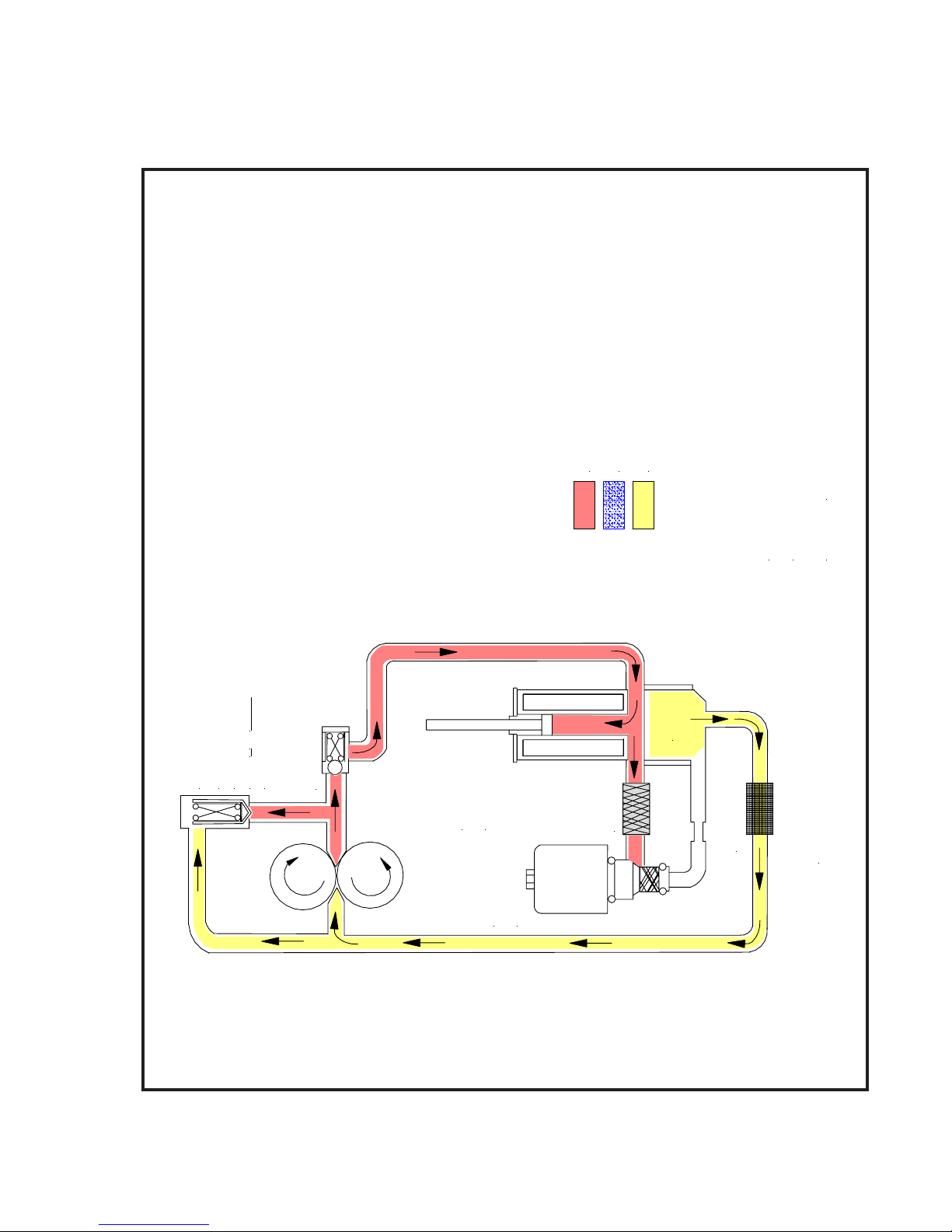

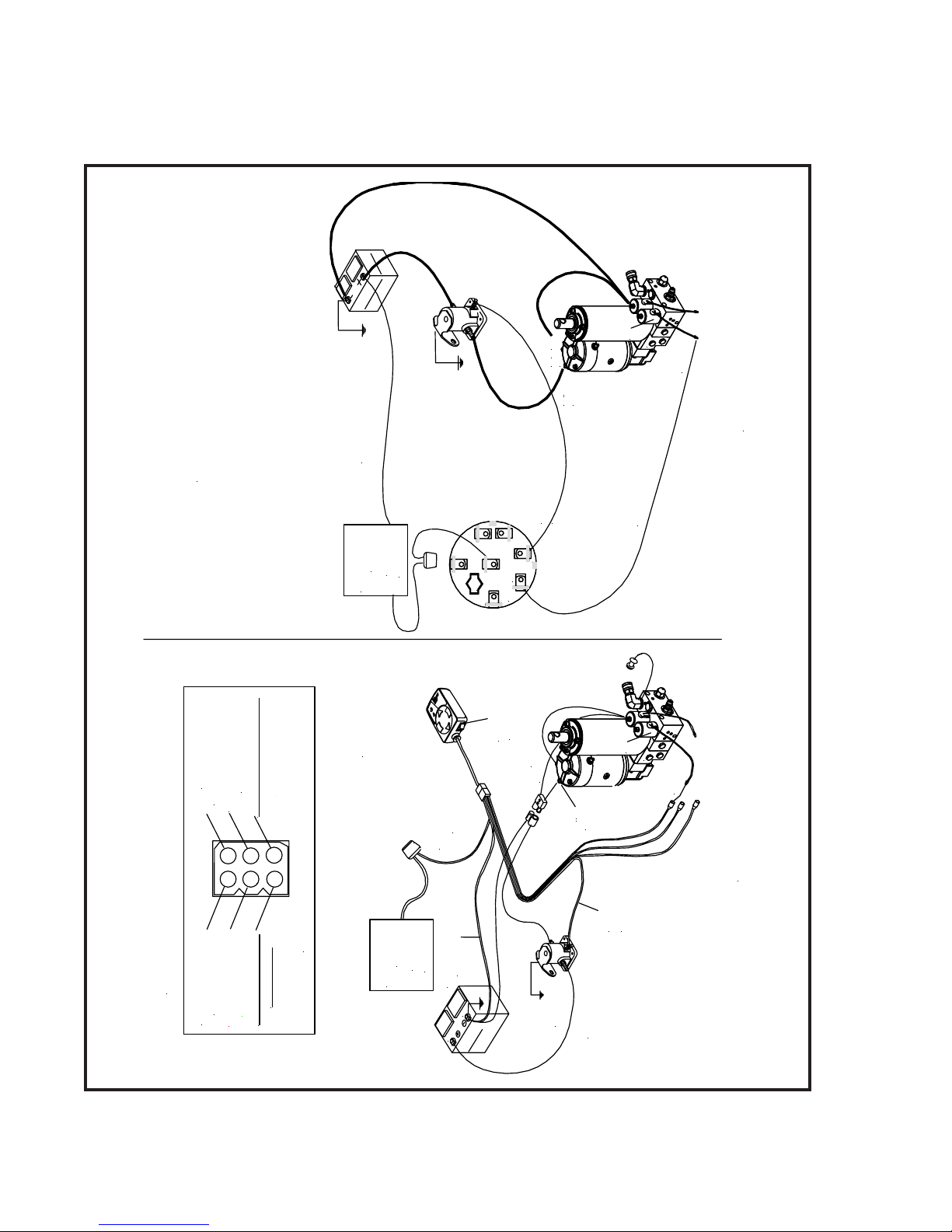

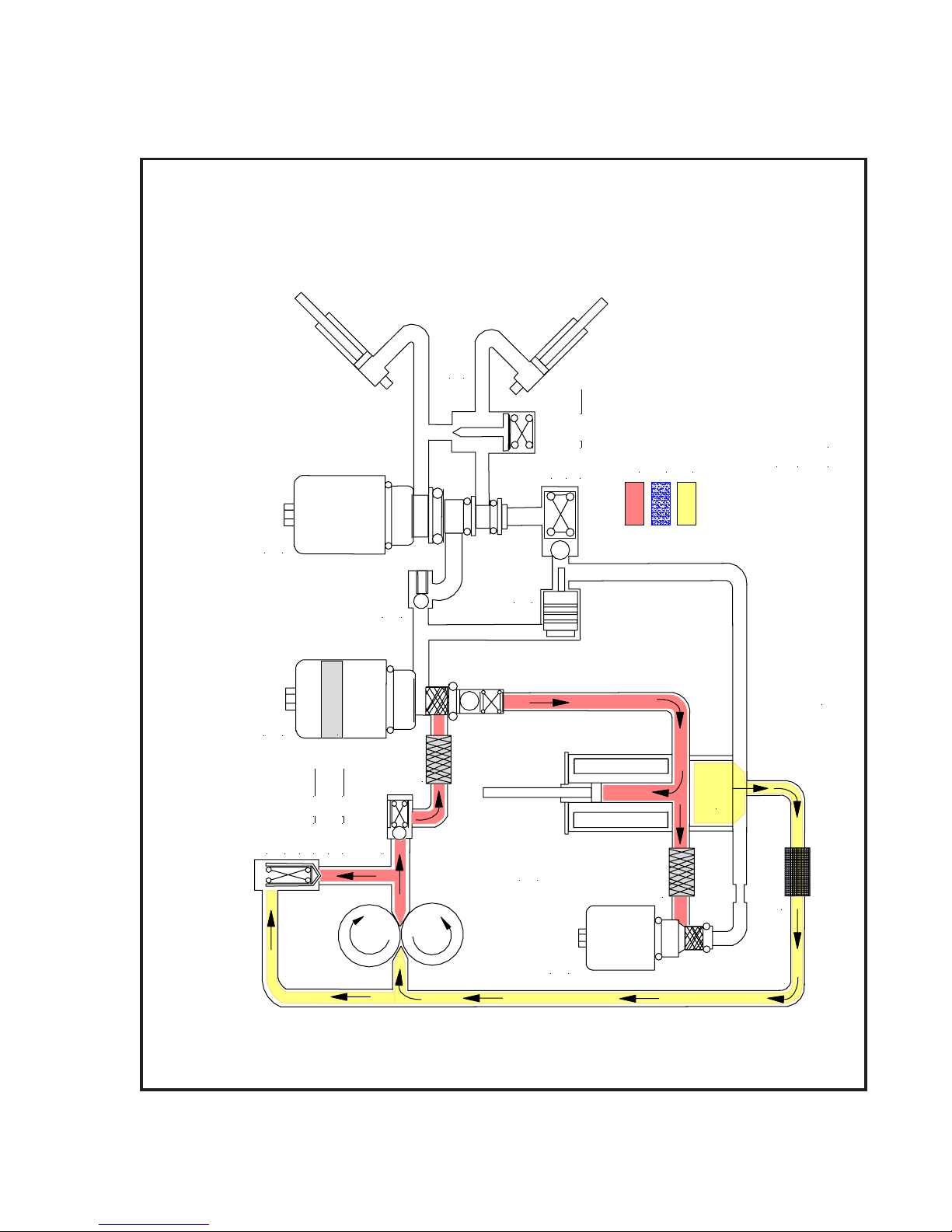

Refer to Figures 1-1 and 1-2 (pages 6 thru 9) for

electrical and hydraulic flow chart for each function.

Each figure explains which component is actuated and

related in each function.

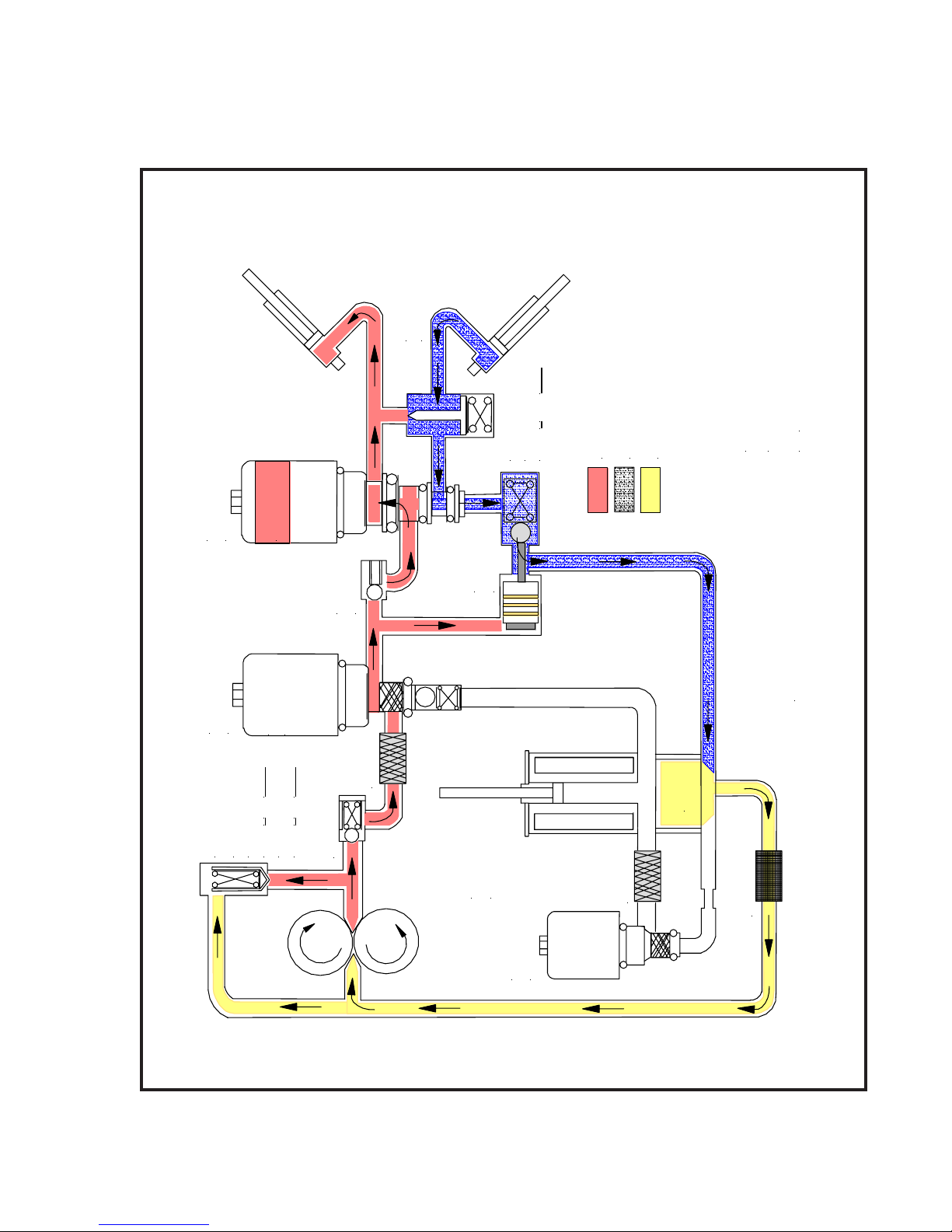

Models E-47, E-47H and E-57, E-57H

The four basic functions performed are:

• Raise snow plow

• Lower snow plow

• Angle snow plow to right

• Angle snow plow to left

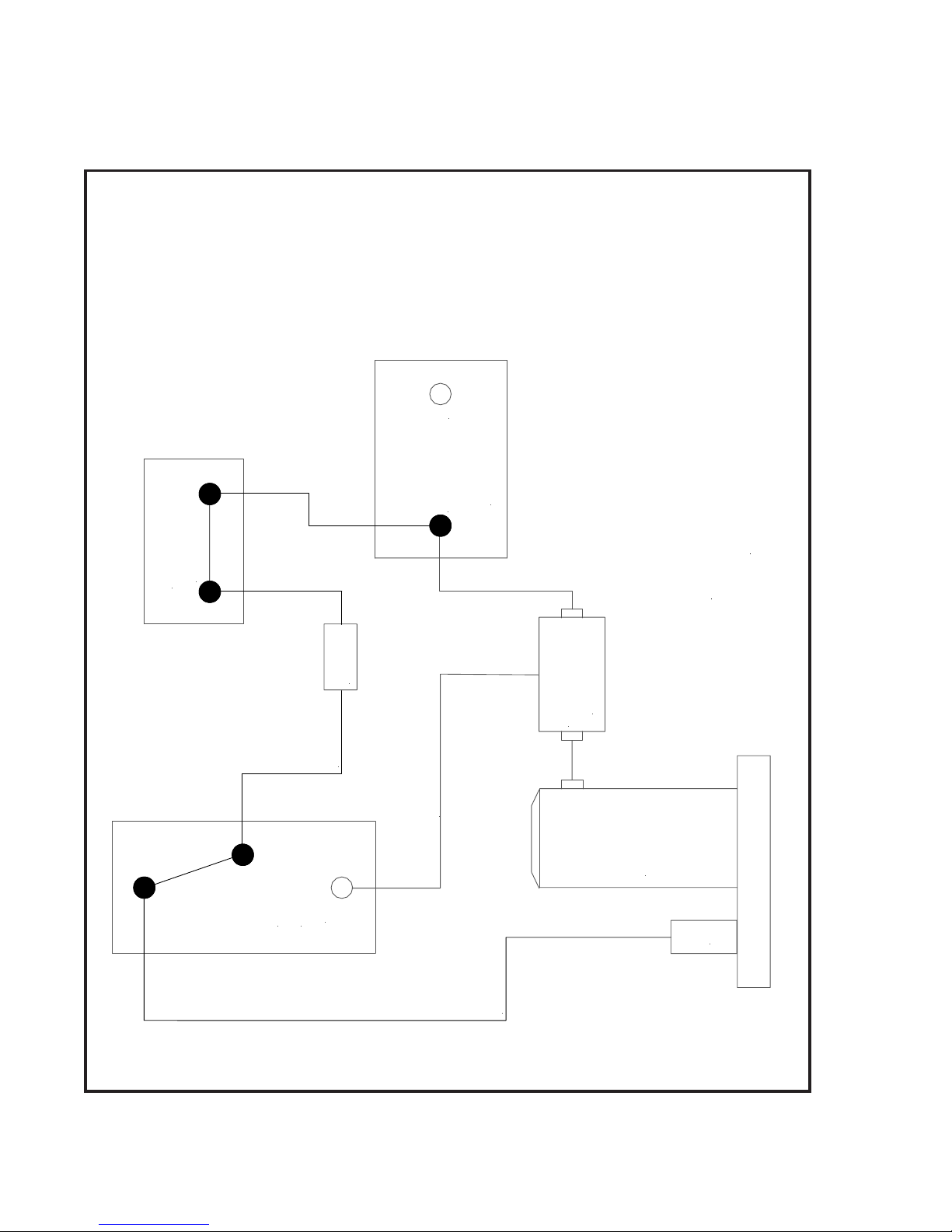

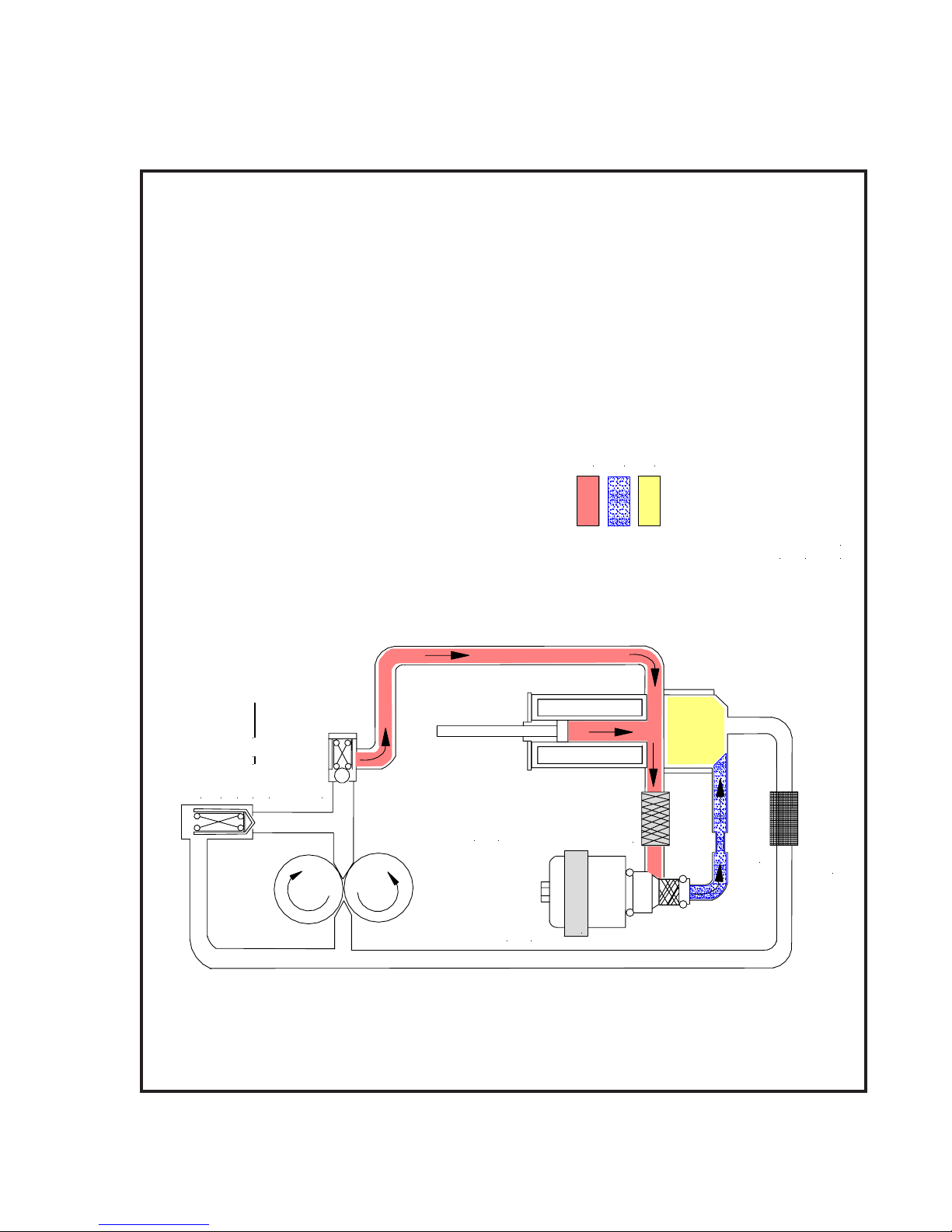

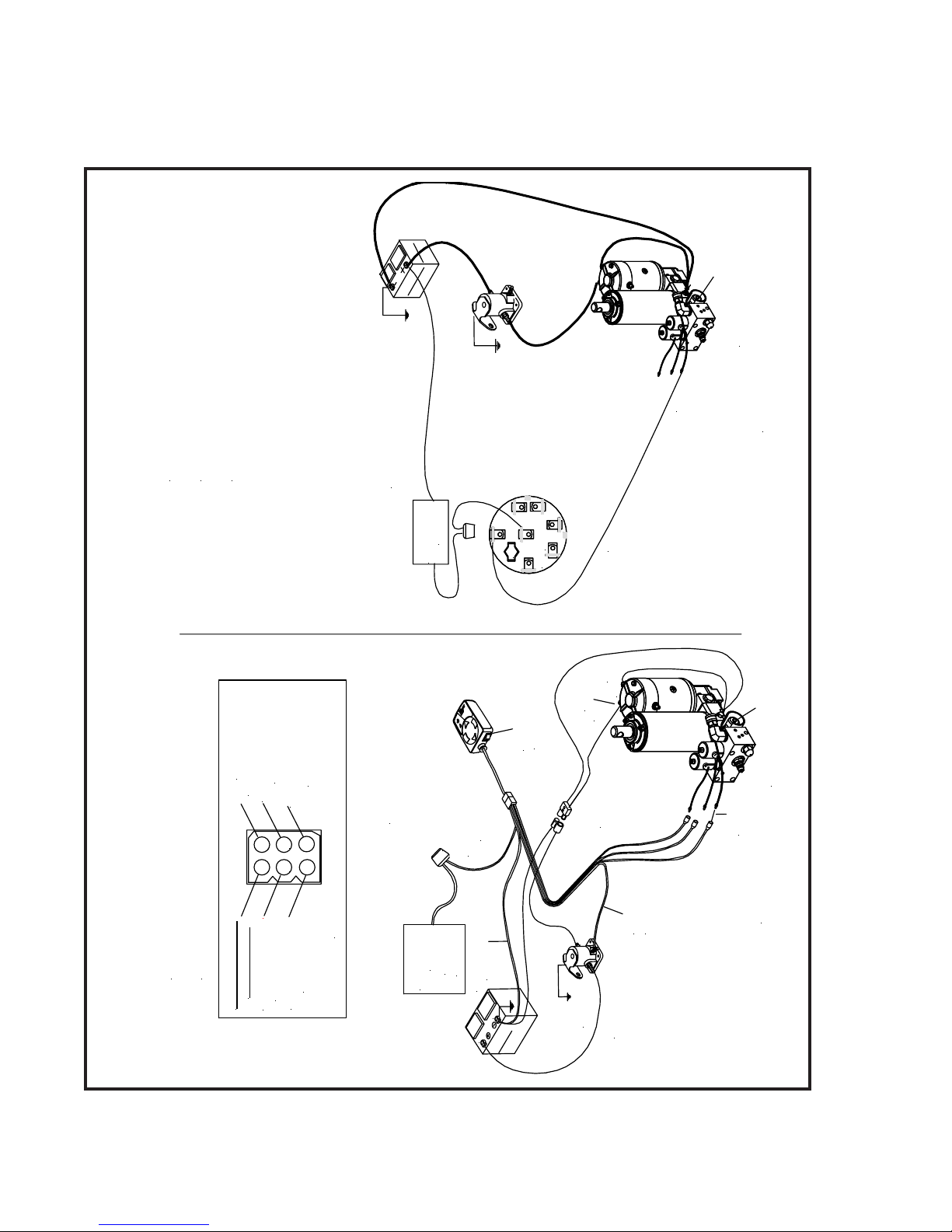

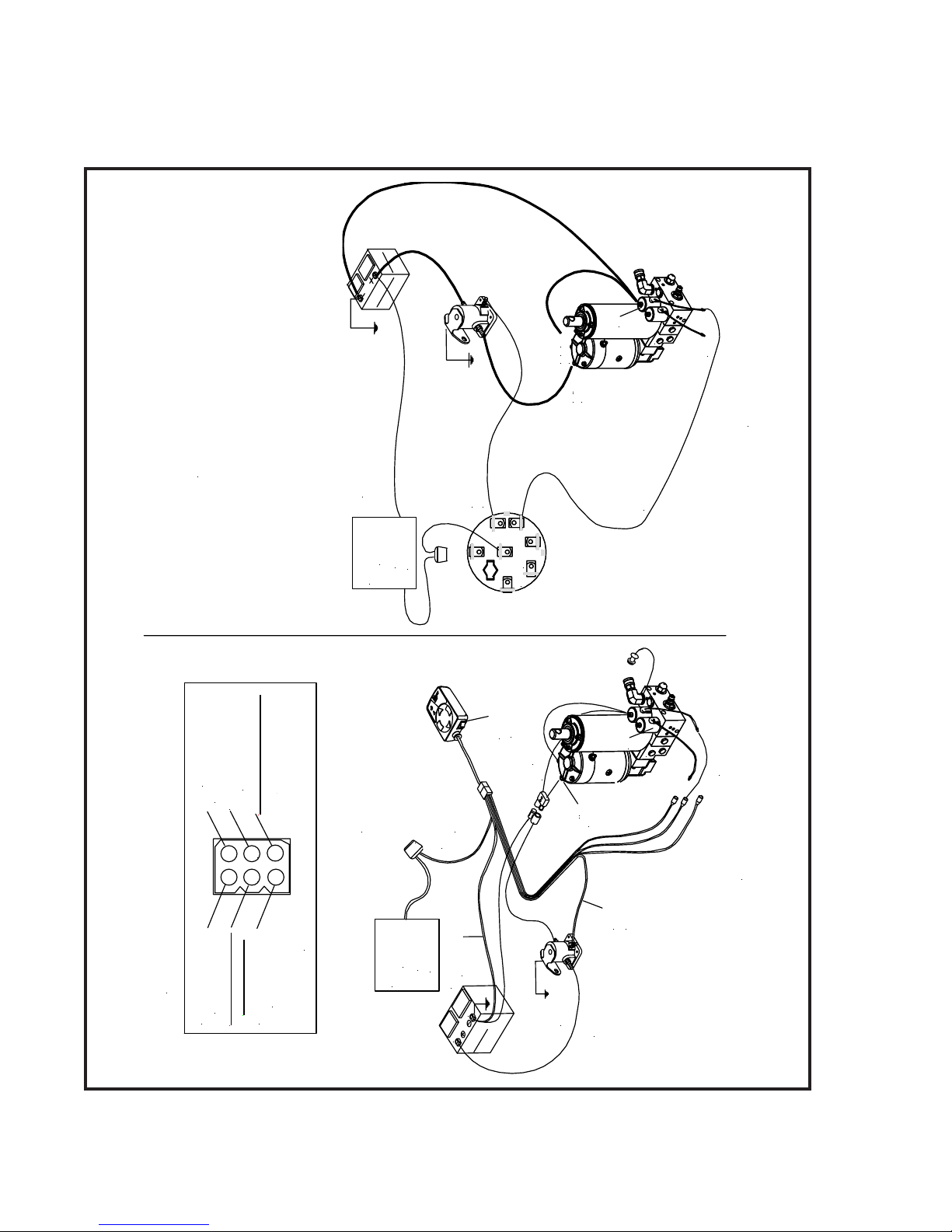

Refer to Figures 1-3 through 1-6 (pages 6 thru 18) for

electrical and hydraulic flow chart for each function.

Each figure explains which component is actuated and

related in each function.

Additional components which control and supply

electrical current to the Electro Lift® unit are an operator

controlled toggle switch; a solenoid switch to supply

high amperage current to the unit’s motor; a wiring

harness to distribute low amperage current between

the toggle switch or switches, motor solenoid and the

solenoid valve cartridge(s); and short heavy gauge

cables to distribute high amperage current directly from

the positive terminal of the vehicle’s battery and ground

the unit directly to the negative terminal of the vehicle’s

battery.

-5-

-

RAISE

SWITCH

IGNITION

LOWER

SWITCH

RAISE &

FUSE

BLACK

WHITE

+

BATTERY

SOLENOID

FIGURE 1-1A

SWITCH

MOTOR

A

BLACK

-6-

- OPE R ATING

- RETURN

- INTAKE or DRAIN

RAISE

HYDRAULIC FLOW CHART

MODELS E-46 & E-46H

TANK

PRESSURE

RE L IEF

E-46 & E-46H

1650 + 50 P.S.I.

CHECK VALVE

LIFT

CYLINDER

FILTER

STRAINER

FIGURE 1-1B

"A"

-7-

SOLENOID

SWITCH

IGNITION

FUSE

BLACK

-

+

WHITE

BATTERY

FIGURE 1-2A

LOWER/FLOAT

SWITCH

SOLENOID

SWITCH

RAISE &

MOTOR

LOWER

A

BLACK

-8-

- OPERATING

- RET U RN

- INTAKE or DRAIN

HYDRAULIC FLOW CHART

LOW ER/FLOA T

MOD ELS E-46 & E-46H

TANK

PRESSURE

RE L IEF

E-46 & E-46H

1650 + 50 P.S.I.

CHECK VALVE

LIFT

CYLINDER

"A"

SOLENOID

ENERGIZED

FILTER

STRAINER

FIGURE 1-2B

-9-

SL IK - STIKSINGLE LEVER

CONTROLLER

GROUND

(BLUE WIRE)

(ORANGE WIRE)

POWER TO SWITCH

6

3

ELECTRO -TO UCH

CONT R OLLE R

(BLACK WIRE)

(GREEN WIRE)

TO "A" SOLENOID

TO "C" SOLENOID

(WHITE WIRE)

TO MOTOR SOLENOID

4

5

2

1

(RED WIRE)

TO "B" SOLENOID

"B"

N

N

I

I

A

A

R

R

D

D

RAISE

Ignition Switch

RAISE

D1NEGATIVE

A2POSITVE

WHITE WIRE - ENERGIZED

Moto r Solenoid

L

E

E

S

N

U

"ON"

F

10

A

P

H

C

T

I

W

E

S

R

I

O

W

T

E

R

U

E

L

B

W

O

1

0

A

P

GENUINE PARTS

C - H

C - H

Meyer

Meyer

F

H

F

C

O

T

/

I

N

W

S

O

E

V

I

1

T

D

A

G

E

N

2

A

"

B

"

E

V

T

I

S

O

P

.

D

E

Z

I

G

R

E

N

E

s

i

d

i

o

en

l

o

S

"

B

"

e

r

i

w

d

e

R

N

N

I

I

A

A

R

R

D

D

D

E

R

FIGURE 1-3A

FIGURE 1-3A

D

E

N

R

I

U

W

O

R

E

G

L

G

E

END OF TOUCH PAD HARNESS

E

N

H

S

N

A

C

U

A

"ON"

Ignition S w itc h

R

T

F

I

P

O

W

S

G

E

N

Y

R

E

S

T

O

T

P

A

B

D

N

U

O

R

G

E

E

T

I

R

I

H

W

W

R

E

W

O

P

-10-

POWER ANGLING

CYLINDERS

RAISE

HYDRAULIC FLOW CHART

M ODELS E - 4 7 & E-57

- OPERATING

- RETURN

CROSSOVER

REL IEF

3800 + 400 P.S. I

"C"

SOLENOID

PILOT

CHECK

VALVE

CHECK

- INTAKE or DRAIN

FIGURE 1-3B

"B"

SOLENOID

ENERGIZED

FILTER

TANK

PRESSURE

RELIEF

E-47

1650 + 50 P.S. I.

E-57

2000 + 0 P.S. I.

CHECK VAL VE

LIFT

CYLINDER

FILTER

STRAINER

"A"

SOLENOID

-11-

S

S

TIK

LIK -

SINGLE LEVER

CONTROLLER

LOWE R/FLOA T

d

i

o

n

e

l

o

S

"

A

"

e

r

i

w

k

c

a

l

B

.

D

E

Z

I

G

R

E

N

E

s

i

d

i

o

n

e

l

o

S

"

A

"

e

r

i

w

10

"ON"

Ignition Sw itc h

GENUINE PARTS

C - H

C - H

Meyer

Meyer

k

c

a

l

B

FIGURE 1-4A

ELECTRO -TOUCH

CONTROLLER

GROUND

(BLUE WIRE)

(ORANGE WIRE)

POWER TO SWITCH

TO MOTOR SOLENOID

5

6

2

3

(BLACK WIRE)

(GREEN WIRE)

TO "A" SOLENOID

TO "B" SOLENOID

TO "C" SOLENOID

E

V

I

1

T

D

A

G

E

E

N

V

T

2

F

H

F

C

O

T

/

I

W

N

S

H

C

T

(WHITE WIRE)

LOWE R/FLOA T

4

I

W

S

TO

R

E

W

O

1

0

A

P

O

E

R

I

W

E

U

L

B

I

A

S

O

P

d

i

o

n

e

l

o

S

"

A

"

e

r

i

W

k

c

a

l

B

K

C

A

L

B

1

D

E

N

R

I

U

W

O

END OF TOUCH PAD HARNESS

"ON"

(RED WIRE)

Ignition Switch

R

E

G

L

G

E

E

N

H

S

N

A

C

U

A

R

T

F

I

P

O

W

S

G

E

N

Y

R

E

T

S

O

T

P

A

B

D

N

U

O

R

G

E

E

T

I

R

I

H

W

W

R

E

W

O

P

FIGURE 1-4A

-12-

POWER ANGLING

CYLINDERS

- OPERATING

- RETURN

CROSSOVER

RE LIEF

3800 + 400 P.S.I

"C"

SOLENOID

PILOT

CHECK

VALVE

CHECK

- INTAKE o r DRAIN

HYDRAULIC FLOW CHART

LOW ER/FLOA T

MODELS E-4 7 & E-57

FIGURE 1-4B

"B"

SOLENOID

FILTER

TANK

PRESSURE

RELIEF

E-4 7

1650 + 50 P.S.I.

E-5 7

2000 + 0 P.S.I.

CHECK V ALVE

LIF T

CYLINDER

FILTER

STRAINER

-13-

"A"

SOLENOID

ENERGIZED

SLIK - S T IKSINGLE LEVER

ELECTRO -TOUCH

CONT R OLLER

CONTROLLER

GROUND

(ORANGE WIRE)

(BLACK WIRE)

TO "A" SOLENOID

(BLUE WIRE)

(WHITE WIRE)

POWER TO SWITCH

TO MOTOR SOLENOID

5

6

2

3

(RED WIRE)

(GREEN WIRE)

TO "B" SOLENOID

TO "C" SOLENOID

"C"

N

N

I

I

A

A

R

R

D

D

D1NEGATIVE

A2POSITVE

e

r

i

w

n

RIGHT ANGLE

L

E

E

S

N

U

A

"ON"

F

P

Ignition Switch

RIGHT ANGLE

4

1

0

A

H

TC

I

WHITE WIRE - ENERGIZED

Motor Solenoid

10

W

E

S

R

I

O

W

T

E

R

U

E

L

B

W

O

P

GENUINE PARTS

C - H

C - H

Meyer

Meyer

F

H

F

O

TC

/

I

W

N

S

O

E

V

I

1

T

D

A

G

E

N

E

V

T

2

I

A

S

O

P

e

e

r

G

"

B

"

N

N

I

I

A

A

R

R

D

D

1

D

E

N

R

I

U

W

O

R

E

G

L

G

END OF TOUCH PAD HARNESS

E

E

N

H

S

N

A

U

A

"ON"

Ignition Switch

R

TC

F

I

P

O

W

S

G

E

N

Y

R

E

T

S

O

T

P

A

B

D

N

U

O

R

G

E

E

T

I

R

I

H

W

W

R

E

W

O

P

.

D

E

Z

I

G

R

E

N

E

s

i

d

i

o

n

e

l

o

S

"

C

"

FIGURE 1-5A

N

E

E

R

G

FIGURE 1-5A

-14-

POWER ANGLING

CYLINDERS

HYDRAULIC FLOW CHART

MODELS E-47 & E-57

- OPE R ATING

- RETURN

CROSSOVER

RELIEF

3800 + 400 P.S.I

"C"

SOLENOID

ENERGIZED

PILOT

CHECK

CHECK

VALVE

- INTAKE o r D R A IN

ANGLE RIGHT

FIGURE 1-5B

"B"

SOLENOID

NOT

ENERGIZED

FILTER

TANK

PRESSURE

RELIEF

E-4 7

1650 + 50 P.S.I.

E-5 7

2000 + 0 P.S.I.

CHECK VALVE

LIFT

CYLINDER

FILTER

STRAINER

"A"

SOLENOID

-15-

Loading...

Loading...