Page 1

1-634

May , 2003

DIAGNOSTIC FLOW CHART FOR

E-46, E-47 and E-57 ELECTRO LIFT

These charts are intended to be used as an aid in diagnosing problems on the Electro Lift® units. They are not a substitute for

factory training and experience. Be certain to read the General Information and Testing Tips sections before attempting any troubleshooting.

General Information

Before any troubleshooting is started, make certain the following conditions are met.

1. The moldboard is pointing straight ahead. This can often be done by coupling the left cylinder into the right cylinder and

pushing the moldboard by hand.

2. The power angling cylinders must be installed correctly on to the A- frame. The left cylinder (Driver’s side) has a hose

attached with a male half of a coupler at the end; the right cylinder (Passenger side) has a hose attached with a female half

of a coupler at the end.

3. The solenoid coils must be on their proper valve. The “C” coil (green wire) must be next to angling fittings. The “B” coil

(red wire) is located to the front of the Electro Lift® Unit. The “A” coil (black wire) is smaller and is located on the back side

of the unit. (See Drawing).

TESTING TIPS

®

UNITS

Many tests do not require removing the Electro Lift® unit from the vehicle. However, more thorough testing can be performed

using the Meyer Test Stand which allows direct pressure and amperage readings.

1. Using a screwdriver or other small tool to check for magnetism of the solenoid coils “A”, “B”, “C”. Place the tool on the nut

securing the coil and have an assistant operate the switch. You should feel strong magnetic attraction.

2. Use a test light or volt meter to determine whether there is power at the harness or switch.

3. When determining AMP draw of the motor, always obtain the highest value possible, i.e, at maximum raise or maximum

angle with motor running.

4. Proper rotation for the 3” motor (American Bosch) is indicated by an arrow located on top side of the (Part # 15026) pump.

5. The pump shaft of a good pump can be turned smoothly using two fingers. If it can’t be turn easily, the pump is too tight

and must be replaced.

6. Pump pressure can be measured at an angle hose (note pressure at full angle) or in the pressure filter port (an adaptor is

necessary for the filter port). Note: The E-57 Electro Lift® Unit has a non adjustable pressure relief valve.

7. Flush the complete system including unit, hoses and power angling rams with a non wax (Napthenic) cleaner. If kerosene

(Parrafinic) is used to flush the system, the system must be flushed again to remove any kerosene with a (Napthenic)

based cleaner that is wax free.

To Ignition Switch

(Accessory Side)

FUSE

22092

20A

White

Motor Solenoid

(Must be grounded)

15680

D

R

A

I

D

A

R

I

N

P

N

L

U

G

F

L

I

E

T

Coupler

Weather Cap

R

S

To Passenger Side

Power Angling Ram.

(Angle Left)

Pressure Relief

Filler Plug

"B"

G

R

E

R

E

E

N

D

"

"

B

C

"

"

B

L

A

C

K

"

A

"

To Driver's Side

"C"

Coupler

Weather Plug

"A"

Ground

A2

B

A

T

T

+

-

To Motor

N

E

G

P

O

S

E

R

Y

D1

To Positive

Battery Terminal

Power Angling Ram.

(Angle Right)

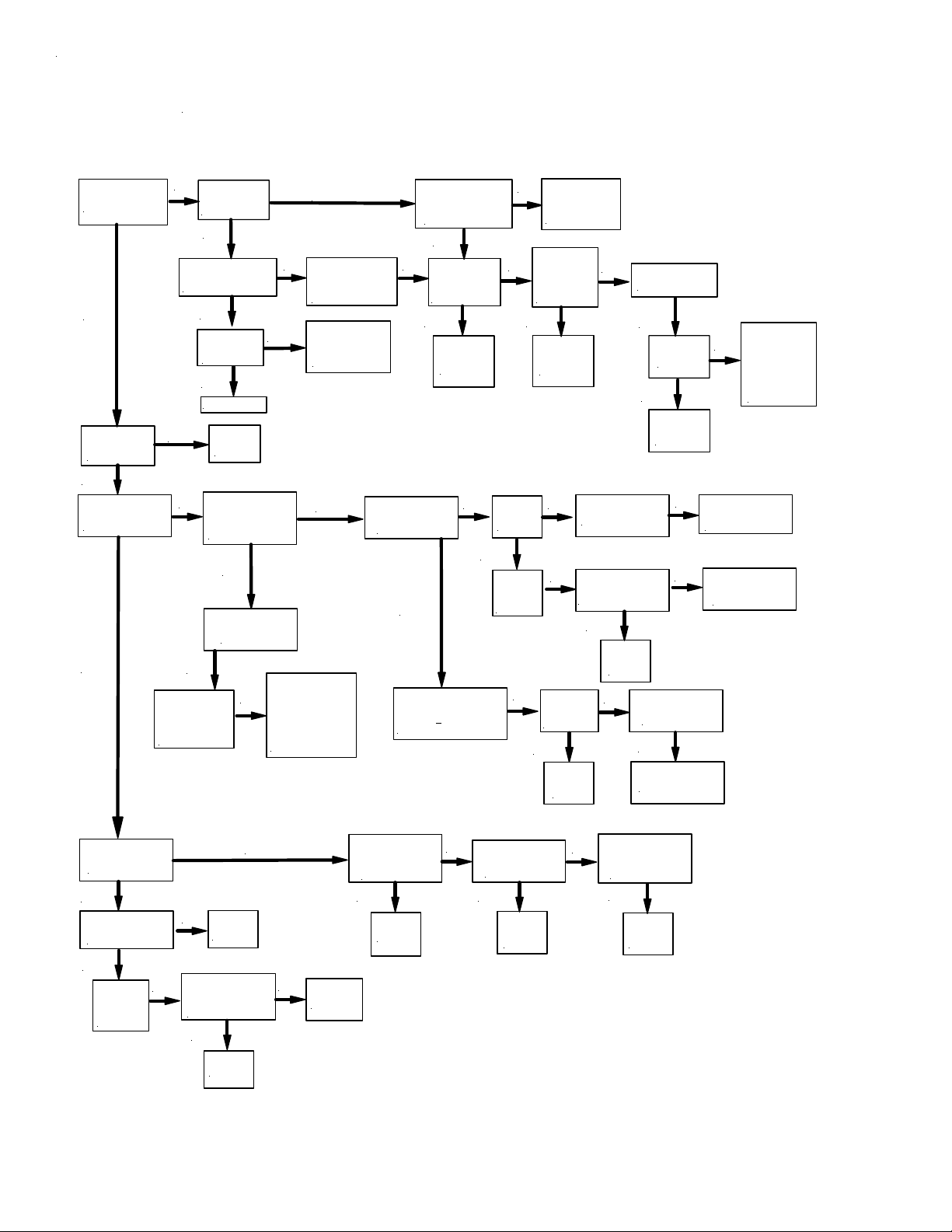

Page 2

SNOW PLOW WILL NOT RAISE

Does the

Motor Operate?

YES

Is the fluid level

1-1/2" below

filler hole?

YES

Does the snow plow

angle to the left

instead of raising?

YES

NO

Is there power

going to

the mo to r ?

YES

Remo v e motor.

Does motor run when

12 volts is applied?

YES

Can the pump

shaft turn b y

hand?

YES

Replace pump.

NO

ADD M-1

Fluid

Does the snow plow

NO

angle when the

An g le Switch

is activa te d ?

YES

Clean or Replace

"A" Valve.

-Retes t Does snow plow

raise?

NO

YES

Is the "A" Valve

stuck in the

open position?

Disassemble unit Inspect O-rings,

NO

Cylinder,Piston

assem bly.

Look for blockage in

Sump Casting

passages.

NO

Inspec t Motor -

NO

Armature, Brushes

Repair or Replace

Motor as necessary

Is Ground Cable

attached to the

Negative (-)

Battery Termina l?

NO

Are all electrical

connections clean

and tight?

Is Battery Charged?

YES

Is there power

NO

going to the

motor solenoid,

at White Wire?

YES YES

Replace the

Motor

Solenoid.

Is there pressure

(or flow) a t the

Filter port?

YES

Can pump relief pressure

be adju s te d to

50 P.S.I

1650 +

E-46 & E-47

Charge Battery -

NO

Clean and tighten

all electrical

Connections.

Is there power

leaving the

NO

switch?

Check switch

for Cont inuity

Replace the

Wiring

Harness.

Are the

NO NO

Filters

Clogged?

YES

Clean

or

Replace

Filters.

NO

NO

Is the pump

shaft turn ing

tightly?

YES

NO

Is the m o to r tu rn in g

the proper direction?

Check for clogged

strainer - Is oil getting

to the pu mp?

YES

NO

Replace

the

Pump.

Check Wires at

Molded connector.

YES

YES

Replace

the

Pump.

YES

Repair or Replace

the m ot o r.

Is the Fu s e

OK?

Replace the

Raise

Switch .

NO

NO

Does the motor

armatu re turn

tightly?

Replace Fuse.

Check fo r s h o r t

NO

in Harn e s s ,

"B" Coil, Sw itch

Connections,

Motor Solenoid,

Electric M otor.

Check B ru s hes for

proper installation or

replace motor.

Clean s tra in e r

and flush the

system completely.

Does th e "B" Coil

(Red Wire) have

magnetism?

YES

Are the "B" Valve

O-Rings in good

Condition?

YES

Clean or

Replace the

"B" Valve

and retest.

NO

Replace P.A. Block

NO

with E-46 plate and

retest. - D o e s s n o w

plow Raise now?

YES

Replace

O-Rings.

Replace

P.A. Bl o ck

NO

NO

Replace

Sump Base.

Is there power to

the "B" Coil?

(Red Wire)

at Harness

YES

Replace

"B" Coil.

NO

Is there power

leaving the switch

at the red wire?

YES

Replace

the wiring

harness.

NO

Are wires in

molded connector

making contact

with the switch?

YES

Replace

the Raise

switch.

Page 3

SNOW PLOW LEAKS DOW N

Does the

NO

snow plow drop

straight down?

YES

Are "A" Valve O-rings

in good co n d itio n ?

Does "A" V alve stem

move freely?

YES

E-47: Dissasemble unit

Inspect O-Rings,Cylinder,

Piston Assembly.

Does it hold now?

NO

NO

Does the snow plow

drop and angle

to the left?

YES

Replace

"B" Chec k Valve

Does it now hold?

Replace O-Rings

Replace "A" Valve

"E-46 ONL Y "

Replace Pump Check Valve

(Remember to coin the ball to the seat).

Does it now Hold?

NO

Replace

Sump Base

NO

Replace

"B" V a lve

Does it now hold?

NO

NO

Dissasemble unit

Inspect O-R ing s,C ylin de r,

Piston As se m b ly.

Does it hold now ?

Replace

Sump Base

NO

Replace

Sump Base

Does "A" Coil

(Black Wire) have

magnetism?

YES

Replace "A" V alve

Does it now lower?

SNO W PLO W WILL N O T LO WER

NO

Is there pow er to the

"A" Co il (B la c k Wire)

at harness?

NO

Check for a clogged

filter or a blocked

passageway .

YES

Replace

"A" Coil

NO

Is there power leaving

the switch at the

Black Wire?

YES

NO

Check for Bent or

Siezed Ram

Assem b ly.

Replace

Harness

NO

Are wires in molded

connector making contact

with the switch?

YES

YES

Replace

Switch

Is Fuse

OK?

NO

Replace the fuse Check for short in

harness, "A " Coil,

Switch connections.

Page 4

Can the snow plow

Raise?

YES

Does the motor run

when angle switch

is pushed?

SNOW PLOW WILL NO T A NG LE LEFT

See the Raise

NO

Flow Chart

Section

NO

Is there power to

the motor solenoid?

(White Wire)

NO

Is there power

leaving the switch?

YES

NO

Are the wires in

molded connector

making contact with

the switch?

YES

YES

Does the snow plow

raise instead of

angling left?

YES

Clean or replace the

"B" Valve.

Retest

Does the snow plow

NO

angle to the right when

the angle switch is

pushed left?

YES

Clean or replace the

"C" Valve.

Retest

Replace Harness

Is the ampere draw

NO

less than 100 amperes

while trying to angle

snow plow?

YES

Is the P il o t p is to n i n

NO

good condition?

(worn/sloppy or Missing)

YES

Are "C" Valve

O-Rings in good

condition?

YES

Clean or replace

the Crossover Relief.

Does the snow plow

now angle?

NO

NO

NO

NO

Replace

Piston

Replace

O-Rings

Replace the

P.A. Bl ock

Replace Angle

Switch

Can the snow plow be

angled by hand when

the P.A. Rams are

disconnected from A-Frame?

YES

Will the snow plow angle

right & le ft if n o t a llo wed

to travel to extreme

angled position?

YES

T emporarily put 1/2" blocks

between the Sector and

A-Frame to limit the degree

of angle. Will the snow plow

now angle?

Weld

1-1/2" x 1-1/2" x 1/2"

spacers to the A-Frame

stops.

YES

Relieve the interference

NO

between the

Sector and A-Frame.

NO

Does pressure remain

in angle hose when the

motor is not running?

YES

If both hoses are stiff

inspect the Pilot Check

Piston and "C" Valve

for binding.

Replace both the

NO

Coupler sets and/or

clean or replace the

"C" Valve.

If one hose is stiff

inspect the the "C"

valve for binding.

Replace Coupler sets.

Page 5

SNOW PLOW W ILL NOT ANGLE RIGHT

Can the snow plow

Rais e ?

YES

Does the motor run

when angle switch

is pushed?

YES

Does the snow plow

raise instead of

angling left?

YES

Clean or replace the

"B" Valve.

Retest

NO

NO

Is there p o wer to

the motor solenoid?

(Wh ite Wire)

NO

Can the snow plow

angle to the Left?

Does the "C" Coil

have magnetism?

(Green Wire)

See the Raise

Flow Chart

Sectio n

YES

YES

NO

Is there power

leaving the switch?

YES

Replace Harness

Is there power to

NO

the "C" Coil?

(Green wire at harness)

YES

Replace the

"C" Coil.

Rete st

NO

NO

Are the wires in

molded connector

making contact with

the switch?

YES

Replace Angle

Switc h

Is there power

leaving the switch?

YES

Replace Harness

NO

Are the wires in

molded connector

making contact with

the switch?

YES

Replace Angle

Switch

Are "C" Valve

O-Rings in good

condition?

YES

Clean or replace

the Crossover Relief.

Does the snow plow

now angle?

NO

Replace

O-Rings

Replace both the

Coupler sets and/or

clean or replace the

"C" Valve.

NO

Replace the

P.A. Block

Page 6

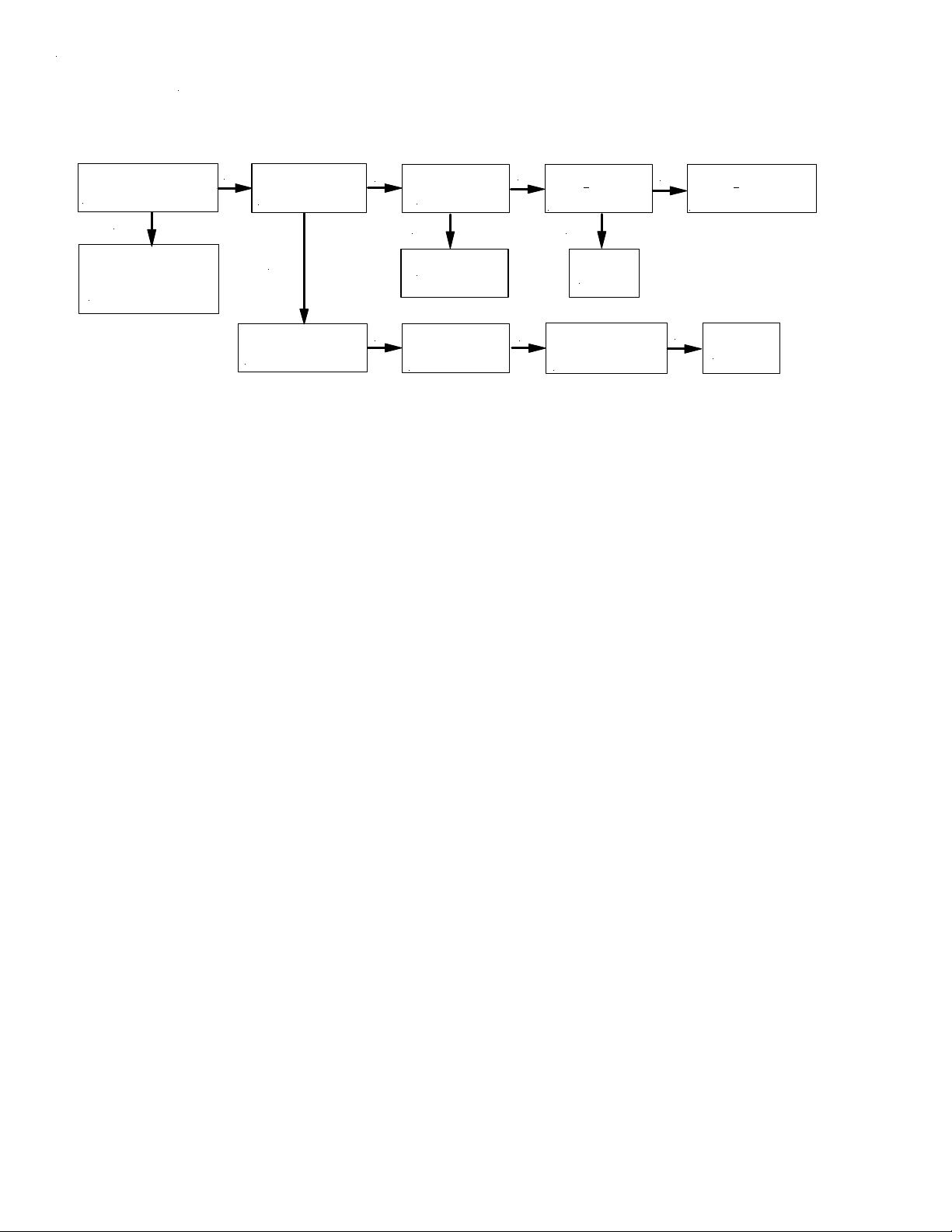

SNOW PLO W W ILL NO T HO LD ANGLE

A r e the Rams mushy?

Can you push the moldboard

6" to 8 " by hand?

YES

Bleed air from the system

and snug up gland nuts.

Check couplers and fittings

for le a ks.

NO

Does the moldbo ard

hold le ft a ng le & re lea s e

from r ig ht angle?

YES

Inspe ct "C" Valve O -rin g s

Change if necess ary. Does

snow plow now angle?

Are the "C" Valve

NO

O-Rings in poor

condition?

YES

Replace O-Rings

Cha nge Pilot C heck

NO

Ball and Seat.

does snowplow

no w hold?

Is Crossover Relief set

NO

at 3800 +

Are Crossover O-Rings

in good conditio n ?

YES

Replace the

P.A. Block

Inspe ct Crossove r Relief.

NO

(Rebuild or Replace)

Does snow p low now

hol d angle?

400 P.S.I.?

Set Crossover Relief to

NO

380 0 +

Replace Crossov er O -R ings

or complete Crossover .

NO

400 P.S.I.

Replace the

P.A. Block

Loading...

Loading...