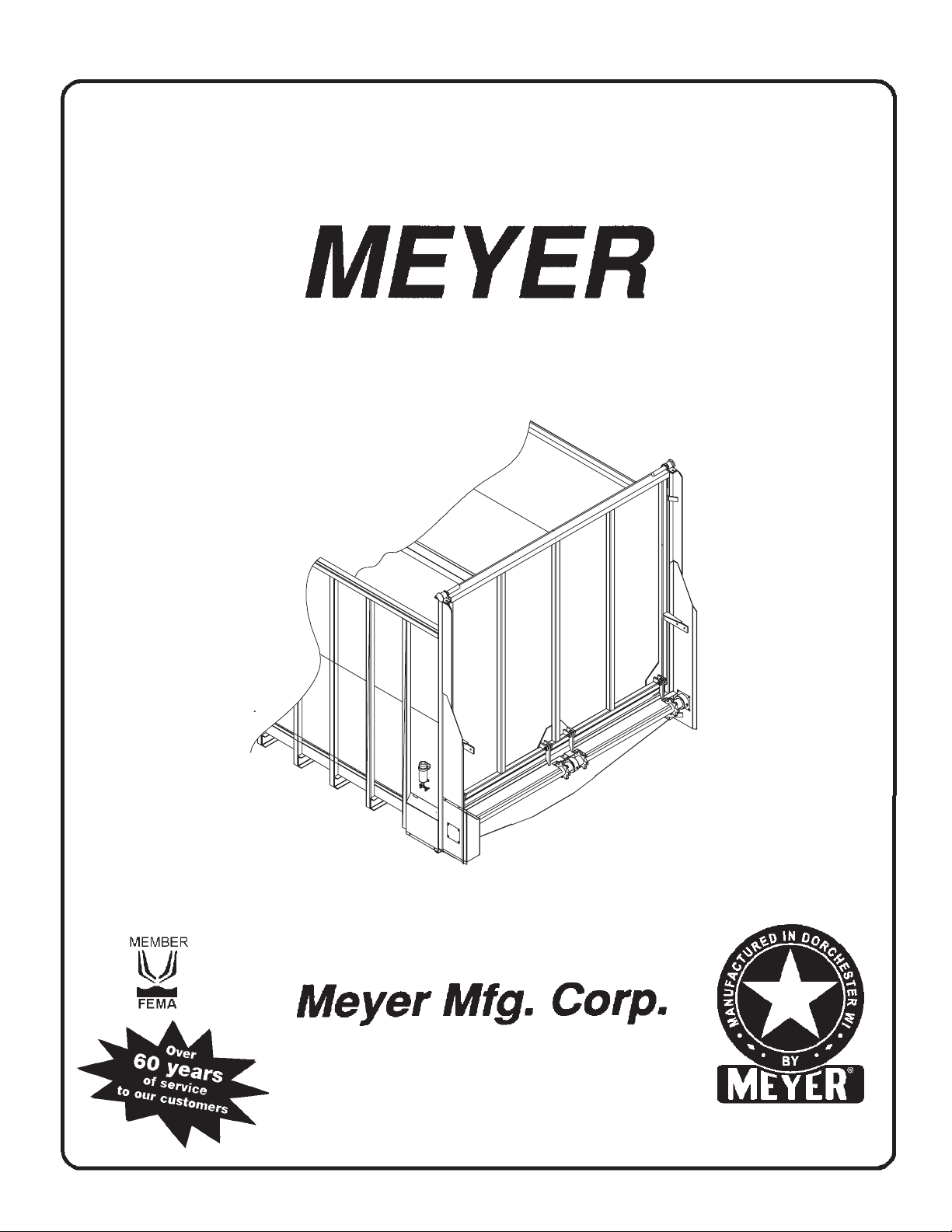

Page 1

OPERATORS AND PARTS MANUAL NO. 02-05-8100

FOR

8100 SERIES

“BOSS”

REAR UNLOAD FORAGE BOX

MODELS: 8118

8120

8122

8124

04/03

DO NOT OPERATE EQUIPMENT UNTIL THIS MANUAL HAS BEEN READ AND UNDERSTOOD.

MANUFACTURED BY

County Hwy. A West

P.O. Box 405

Dorchester, Wisconsin 54425-0405

Phone 715-654-5132 • FAX 715-654-5513

1-800-325-9103

www.meyermfg.com

E-mail: sales@meyermfg.com

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS .....................................................................1

MANUFACTURER’S WARRANTY ............................................................2

INTRODUCTION ..........................................................................3

SAFETY PRECAUTIONS ...................................................................4

SAFETY FIRST ........................................................................5

SAFETY FIRST ........................................................................6

PRE-OPERATION .........................................................................7

TRANSPORTING..........................................................................8

REAR UNLOAD

LUBRICATION ...........................................................................13

ADJUSTMENTS..........................................................................15

#19-0038 2:1 RATIO GEARBOX ......................................................16

REPAIR PARTS..........................................................................16

MAIN DRIVE SHAFT (PTO DRIVE) ....................................................17

#18-0119 (OPTIONAL) UNIVERSAL JOINT TELESCOPING ASSEMBLY W/GUARD .............18

GEARBOX & CHAIN DRIVE..........................................................19

HYDRAULIC PLUMB TO THE FRONT..................................................21

HYDRAULIC DRIVE (OPTIONAL FRONT MOUNT)#8100 - HYD ..............................22

APRON ..........................................................................23

8100 MAIN BODY ..................................................................25

REAR DOOR .....................................................................27

OPTIONAL DOUBLE DOOR .........................................................29

ROLLER CHAIN OILER .............................................................31

HIGHWAY TRANSPORT AG LIGHTS ..................................................32

8100 OPTIONAL GRAIN KIT .........................................................33

GATE DELAY PACKAGE (#8100 -GATE) (PRIOR TO SN 0781253)............................35

GATE DELAY PACKAGE (#8100 -GATE) (SN #0781253 & LATER) ............................37

OPTIONAL WAGON MOUNT KIT (#8100 - WAGON) ......................................39

MAINTENANCE RECORD .................................................................40

SPECIFICATIONS ........................................................................41

NOTES.................................................................................42

OPERATION ...............................................................10

8100 Rear Unload --1--

Page 3

01/01/00

NEW MEYER REAR UNLOAD FORAGE BOX

MANUFACTURER’S WARRANTY

I. The “Product Registration & Inspection Certificate” along with the original billing invoice “Owners Registration Form” must

be completed in full and promptly returned to Meyer Mfg. Corp. for this warranty to become both valid and effective. All war

ranties on New Meyer Forage Boxes shall apply only

dealership.

to the original retail customer from an authorized Meyer Mfg. Corp.

-

II. This warranty shall not

dent, incorrect

Mfg. Corp.

III. Meyer Mfg. Corp. warrants New Meyer Forage Boxes to be free from defects in material and workmanship under recom

mended use and maintenance service, as stated in the Operator’s and Parts Manual," as follows:

A. Meyer Mfg. Corp. will repair or replace F.O.B. Dorchester, WI, as Meyer Mfg. Corp. elects, any part of a new Meyer

B. In addition to the abovebasic warranty, Meyer Mfg. Corp. will repair or replaceF.O. B. Dorchester, WI as Meyer Mfg.

Five (5) Years: The D667XH pintle main apron chain assembly.

operating procedures, or whichshall have been repaired with parts other than those obtained through Meyer

Forage Box which is defective in material or workmanship:

Corp. elects:

apply to any Meyer Forage Box which has been subjected to misuse, negligence, alteration, acci

1. Without charge for either parts or labor during the first (1) year from purchase date to the original retail

customer.

2. Without charge for parts only

tomer.

1. Any part of the following which is defective in material or workmanship (not neglect to recommended

use and service) without charge for parts only

purchase to the original retail customer:

2. Any part of the following which is defective in material or workmanship (not neglect to recommended

use and service) with a “pro-rated” charge for parts only

date of purchase to the original retail customer:

during the second (2) year from purchase date to the original retail cus

(not labor) during the stated time periods from date of

(not labor) during the stated time period from

-

-

-

Ten (10) Years: a. The all welded steel frame box structure.

IV. COMMERCIAL USE: Coverage as in paragraph III A1 ONLY, except warranty coverage is for (90) days for parts and labor

to the original commercial retail customer.

V. Repairs eligible for labor warranty must be made by Meyer Mfg. Corp. or an authorized Meyer dealership. The original retail

customer is responsible for the transportation of the forage box to the dealership for warranty service or for any service call

expenses.

VI. Except as stated above, Meyer Mfg. Corp. shall not be liable for injuries or damages of any kind or nature, direct, conse

quential, or contingent, to persons or property. This warranty does not extend to loss of crop or for any other reasons.

VII. No person is authorizedto give any other warranties or toassume any other obligation on Meyer Mfg.Corp.’s. behalf unless

made or assumed in writingbyMeyer Mfg. Corp. This warranty is the sole and exclusivewarranty which is applicable in con

nection with the manufacture and sale of this product and Meyer Mfg. Corp.’s responsibility is limited accordingly

Optional Equipment-Tarp, scales etc. warranty-See original equipment warranty.

--2-- 8100 Rear Unload

-

-

Page 4

INTRODUCTION

Congratulations on your purchase of a new Meyer Rear

Unload Forage Box. Undoubtedly you have given much

consideration to your purchase and we’re proud that you

have selected Meyer. Pride in craftsmanship, engineer

ing and customer service have made Meyer products the

finest in the farm equipment industry today.

The Model 8100 is available as a truck mounted unit or

mounted to a wagon runninggear pulled and powered by

a farm tractor. When the PTO is referred to, it means

power takeoff from the truck or from the tractor, which

ever applies. If you have a wagon model, the PTO drive

is by a rotating drive shaft connecting the tractor PTO to

the forage box drive line. This is referred to as the PTO

drive shaft. The PTO drive shaft is connected to the trac

tor for unloading, and disconnected and placed in a stor

age bracket when traveling and filling the forage box.

The Model 8100 may be referred to as rear unload box,

forage box, box or rearunload forage box in this manual.

This SAFETY ALERT SYMBOL means ATTENTION! BE CAREFUL! YOUR SAFETY IS INVOLVED! It

stresses an attitude of HEADS UP FOR SAFETY. When

you see this symbol, be alert to the possibility of PERSONAL INJURY and carefully read the message that follows.

Meyer Manufacturing Corporation reserves the right to

make improvements in design, or changes in specifica

tions at any time, without incurring any obligation to own

ers of units previously sold.

-

This supersedes all previous published instructions.

-

IMPORTANT:

At the front of this manual is a Product Registration and

Inspection Certificate. Be sure your dealer has com

pleted this certificate and promptly forwarded a copy to

Meyer Manufacturing to validate the manufacturer’s

warranty. The product model and serial number are re

corded on this certificate and below for proper identifica

tion of your Meyer Forage Box by your dealer and the

manufacturer when ordering repair parts. The serial

number is stamped in the front upright of the left-hand

side.

Model No.___________________________________

-

-

-

-

-

WARNING: NEVER OPERATE WITHOUT ALL

COVERS, SHIELDS AND GUARDS IN PLACE. KEEP

HANDS, FEET AND CLOTHING AWAY FROM

MOVING PARTS. SOME COVERS AND GUARDS

HAVE BEEN REMOVED FOR ILLUSTRATIVE PUR

POSES ONLY IN THIS MANUAL. FAILURE TO HEED

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEATH.

There is no substitute for quality. That is why thousands

of people like you have purchased Meyer farm equip

ment. They felt it was the best equipment to serve their

farming needs, now and in years to come. We ask that

you follow our policy of “safety first,” and we strongly

suggest that you read through the owner’s manual be

fore operating your Meyer farm equipment.

Meyer Manufacturing Corporation wants to thank you for

not compromising quality. We are determined to offer ex

cellence in customer service as well as provide you with

the very best value for your dollar.

Sincerely,

Serial No.___________________________________

Date of Purchase_____________________________

At the back of this manual is the repair parts section. All

-

replacement parts are to be obtained from or ordered

through your Meyer dealership. When ordering repair

parts, refer to the parts section and give complete infor

mation including quantity, correct part number, detailed

description and even Model No. and Serial No. of the for

age box which needs repair parts.

-

NOTE: All references to right hand (RH) , left hand (LH),

front and rear apply to the product as viewed from the

rear of the box.

-

You are urged to study this manual and follow the in

structions carefully. Your efforts will be repaid in better

operation and service as well as a savings in time and re

-

pair expense. Failure to read this manual and under

stand the machine could lead to serious injury. If you do

not understand instructions in this manual, contact either

your dealer or Meyer Manufacturing Corp. at

Dorchester, WI 54425.

-

-

-

-

-

All Employees of

MEYER MANUFACTURING CORPORATION

8100 Rear Unload --3--

Page 5

SAFETY PRECAUTIONS

This symbol is usedto call attention to instructions concerningpersonal safety. Be sure to observe and

follow these instructions. Take time to be careful!

WARNING: BEFORE ATTEMPTING TO OPERATE THIS FORAGE BOX, READ AND STUDY THE FOL

LOWING SAFETY INFORMATION. IN ADDITION, MAKE SURE THAT EVERY INDIVIDUAL WHO OPERATES

OR WORKS WITH THE FORAGE BOX, WHETHER FAMILY MEMBER OR EMPLOYEE, IS FAMILIAR WITH

THESE SAFETY PRECAUTIONS.

Require anyone who will operate this forage box to read and completely understand this owner’s manual. Give necessary instruc

tions.

DO NOT operate, service, inspect or otherwise handle this forage box until all operators have read this Owner’s Manual and have

been properly trained in its intended usage.

DO NOT allow minors (children) or inexperienced persons to operate this forage box.

DO NOT clean, adjust or lubricate while the forage box is in motion.

Inspect when first delivered and regularly thereafter; that all connections and bolts are tight and secure before operating.

Know how to stop operation of the forage box before starting it!

DO NOT operate until all shields and guards are in place and securely fastened.

Make certain everyone is clear of the forage box before applying power.

Keep hands, feet and clothing away from moving parts. Loose or floppy clothing should not be worn by the operator.

Observe all applicable traffic laws when transporting on public roadways (where legal to do so). Check local laws for all highway

lighting and marking requirements.

Always install a SMV emblem on forage box for transporting on roadways and keep this emblem clean and bright.

DO NOT step up on any part of the forage box at any time. DO NOT use the PTO guard as a step.

Keep the forage box away from power lines. Contact with electric lines may result in serious injury or death by electrocution!

There are additional Safety precautions associated with Truck mounted units:

If theforage box becomes clogged, shut off the truck, setpark brake, remove keys, keep keys in your possession, and allow all mechanism to stop.

Then, clean or work on the forage box as required.

Always shut off the truck, remove keys, keep keys in your possession to prevent accidental startup or unexpected movement be

fore working on forage box.

There are additional Safety precautions associated with Tractor towed units:

If the forage box becomes clogged, shut offthetractorengine and allow all mechanisms to stop. Disconnect PTO shaft. Then, clean

or work on the forage box as required.

Always shut off power and disconnect PTO shaft from tractor to prevent accidental startup or unexpected movement before work

ing on forage box.

DO NOT step over the power take-off shaft. Stay clear of the PTO at all times.

Keep PTO shaft telescoping tube shields turning freely. Keep PTO master shield on tractor. Replace damaged or missingshields.

Never operate PTO above normal 540 RPM rating. Never

Use only properly rated running gear and tires.

DO NOT tow at speeds in excess of 20 MPH when transporting this forage box. Never exceed a safe travel speed.

MEYER MFG. CORP. PROVIDES GUARDS FOR EXPOSED MOVING PARTS FOR THE OPERATOR’S PROTECTION; HOW

EVER, SOME AREAS CANNOT BE GUARDED OR SHIELDED IN ORDER TO ASSURE PROPER OPERATION. THE OPERA

TOR’S MANUAL AND DECALS ON THE FORAGE BOX ITSELF WARN YOU OF DANGERS AND MUST BE READ AND

OBSERVED CLOSELY!

connect forage box PTO shaft to a 1000 RPM tractor PTO.

-

-

-

-

-

-

Study the Above Safety Rules

FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

--4-- 8100 Rear Unload

Page 6

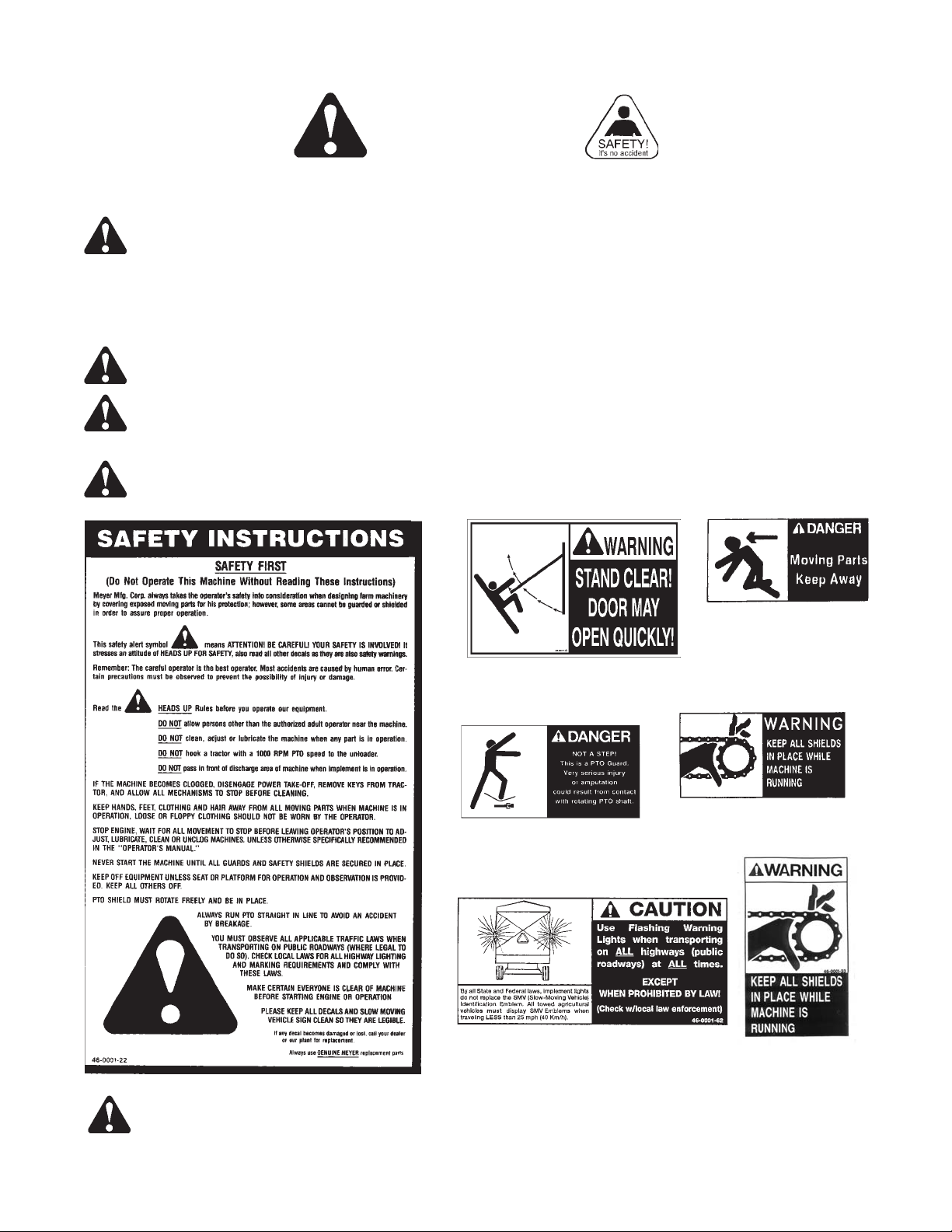

D - on PTO Drive Shaft Guard - Tractor

Pulled MODELS (not shown).

SAFETY FIRST

E

C - both sides

A

F

B

E

CAUTION: READ ALL DECALS ON THE FORAGE BOX AND IN THIS MANUAL. KEEP THESE DECALS CLEAN AND

REPLACE ANY LOST OR DESTROYED DECALS. BECOME FAMILIAR WITHALL TRUCK OR TRACTOR AND FORAGEBOX

CONTROLS.

8100 Rear Unload --5--

G

Page 7

SAFETY FIRST

The Meyer Forage Box is manufactured with operator safety in mind. Located on the forage box are various decals to

aid in operation and warn of danger or caution areas. Pay close attention to all decals on the forage box.

DO NOT REMOVE ANY DECALS. IF DECALS ARE LOST, DAMAGED OR IF FORAGE BOX

IS REPAINTED, REPLACE DECALS. REMEMBER: DECALS ARE FOR YOUR PROTECTION

AND INFORMATION.

A brief definition of signal words that are used in this manual is as follows:

DANGER Indicates an imminently hazardoussituation that, if not avoided, will resultin death or serious injury.

WARNING Indicates a potentially hazardous situation that, if not avoided could result in death or serious injury,

and includes hazards that are exposed when guards are removed.

CAUTION Indicates a potentiallyhazardous situation that, if not avoided mayresult in minor or moderate injury.

DECAL C.

PART NO. 46-0001-20

DECAL B.

PART NO. 46-0011-D

DECAL E.

DECAL D.

PART NO. 46-0004-2

DECAL F.

DECAL A.

PART NO. 46-0001-22

CAUTION: READ ALL DECALS ON THE FORAGE BOX AND IN THIS MANUAL. KEEP THESE DECALS CLEAN AND

REPLACE ANY LOST OR DESTROYED DECALS. BECOME FAMILIAR WITHALL TRUCK OR TRACTOR AND FORAGEBOX

CONTROLS.

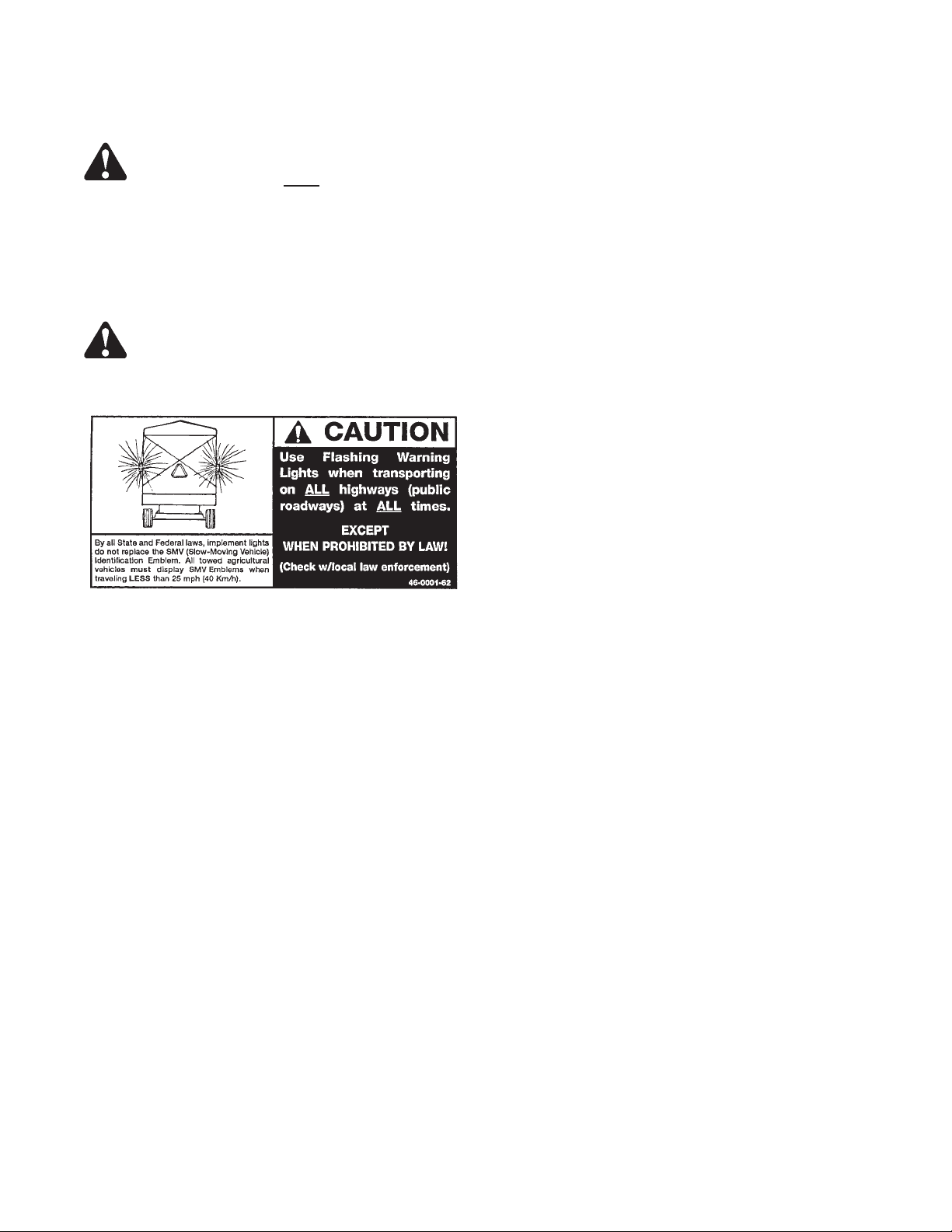

PART NO. 46-0001-62

PART NO. 46-0001-4

DECAL G.

PART NO.

46-0001-33

--6-- 8100 Rear Unload

Page 8

PRE-OPERATION

Whenever adjusting, cleaning, lubricating or otherwise

servicing this forage box, you must shutoff and lockout

power to the box. Because this box can be truck

mounted or powered by a tractor, methods vary. On

truck mounted units, the connection between the PTO

and box is permanently installed and not intended to be

disconnected. On trucks, disengage the PTO drive, turn

off the engine, set the parking brake, remove the ignition

keys and keep them in your possession to prevent any

one else from accidentally applying power to the box un

expectedly. On tractor pulled units, the connection

between the tractor PTO and box is by a removable PTO

drive shaft. For tractors, disengage the PTO drive, turn

off the engine, set the brakes and disconnect the PTO

drive shaft from the tractor.

DANGER: DO NOT OPERATE WITHOUT PTO

GUARD ON MACHINE AND ON TRACTOR OR TRUCK.

FAILURE TO HEED MAY RESULT IN SERIOUS PER

SONAL INJURY OR DEATH.

-

-

GUARDS IN OPERATING CONDITION. REPLACE

THEM IF DAMAGED AND NOT TURNING FREELY.

FAILURE TO HEED MAY RESULT IN SERIOUS PER

SONAL INJURY OR DEATH.

DANGER: MAINTAIN PTO DRIVE SHAFT

-

-

Throughout this manual, when directed to shutoff and

lockout power, be familiar with the previously described

procedures for the type of machine you are operating.

References in this manual are made to the PTO drive

shaft and are applicable to tractor pulled MODELS.

Be sure your forage box is properly mounted to the truck

frame or to the wagon running gear. Consult your dealer

if you have any questions about proper installation. A tie

down kit from the manufacturer and illustrated in the

parts listing of this manual is available for wagon applications.

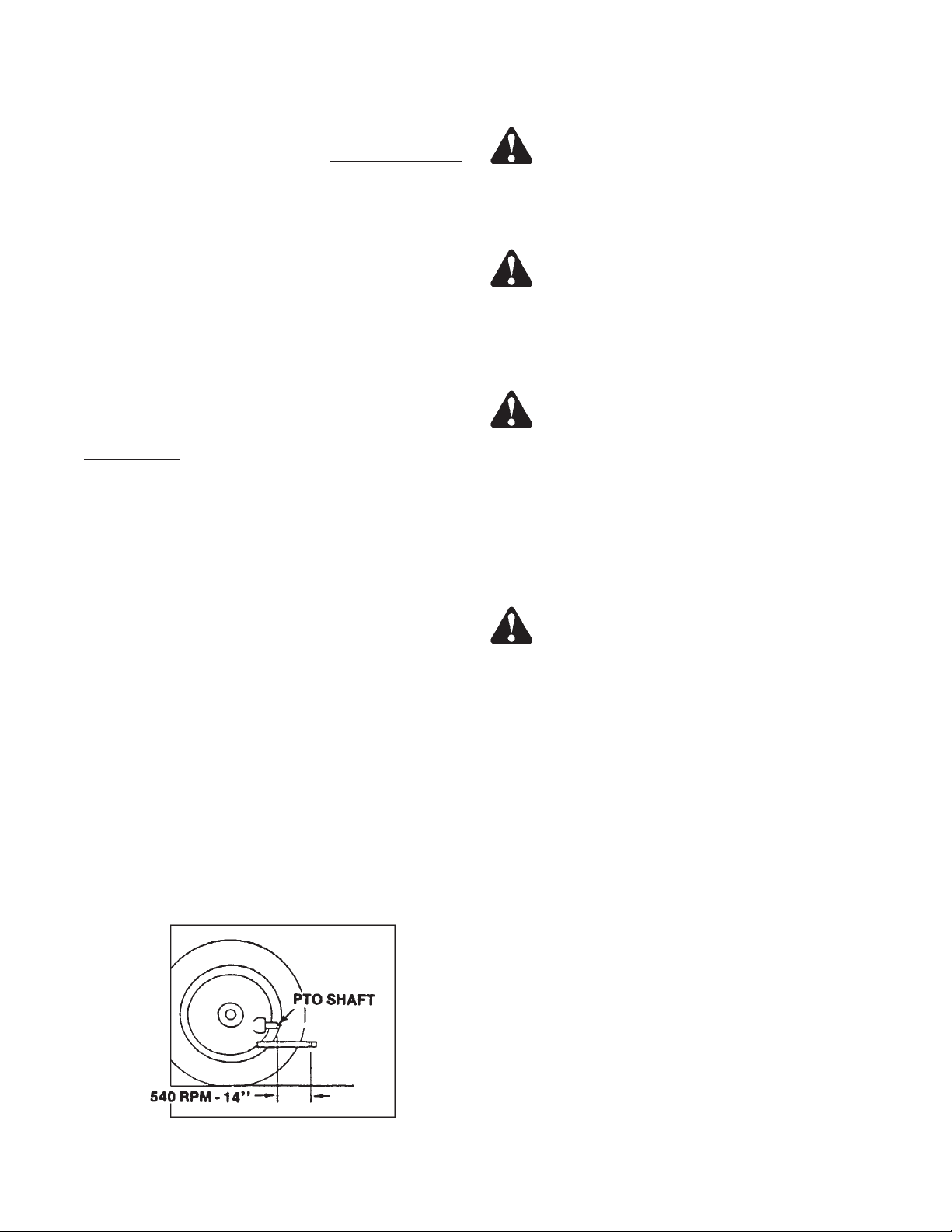

Input speed to the forage box line shaft must be 540 rpm

maximum. On trucks the PTO drive must be reduced to

obtain this speed. For tractors, select the 540 rpm option

according to manufacturers instructions.

For tractor pull model, set your tractor drawbar to con

form to the standard dimensions shown on the following

illustration. This will ensure that the PTO drive shaft will

not be over extended.

WARNING: INSPECT REGULARLY THAT ALL

CONNECTIONS AND BOLTS ARE TIGHT AND SE

CURE BEFORE OPERATING. FAILURE TO HEED MAY

RESULT IN SERIOUS PERSONALINJURY OR DEATH.

Inspect the forage box for proper adjustments as this will

ensure maximum machine performance. See “Adjustments” section. Grease and oil the forage box as required. See “Lubrication” section.

WARNING: DO NOT OPERATE UNTIL ALL

SHIELDS AND GUARDS ARE IN PLACE AND SECURELY FASTENED. FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

-

-

Before filling the box, slowly engage the PTO and oper

ate box at idle speed to ensure it is operating properly.

DRAWBAR & PTO RELATIONSHIP

8100 Rear Unload --7--

-

Page 9

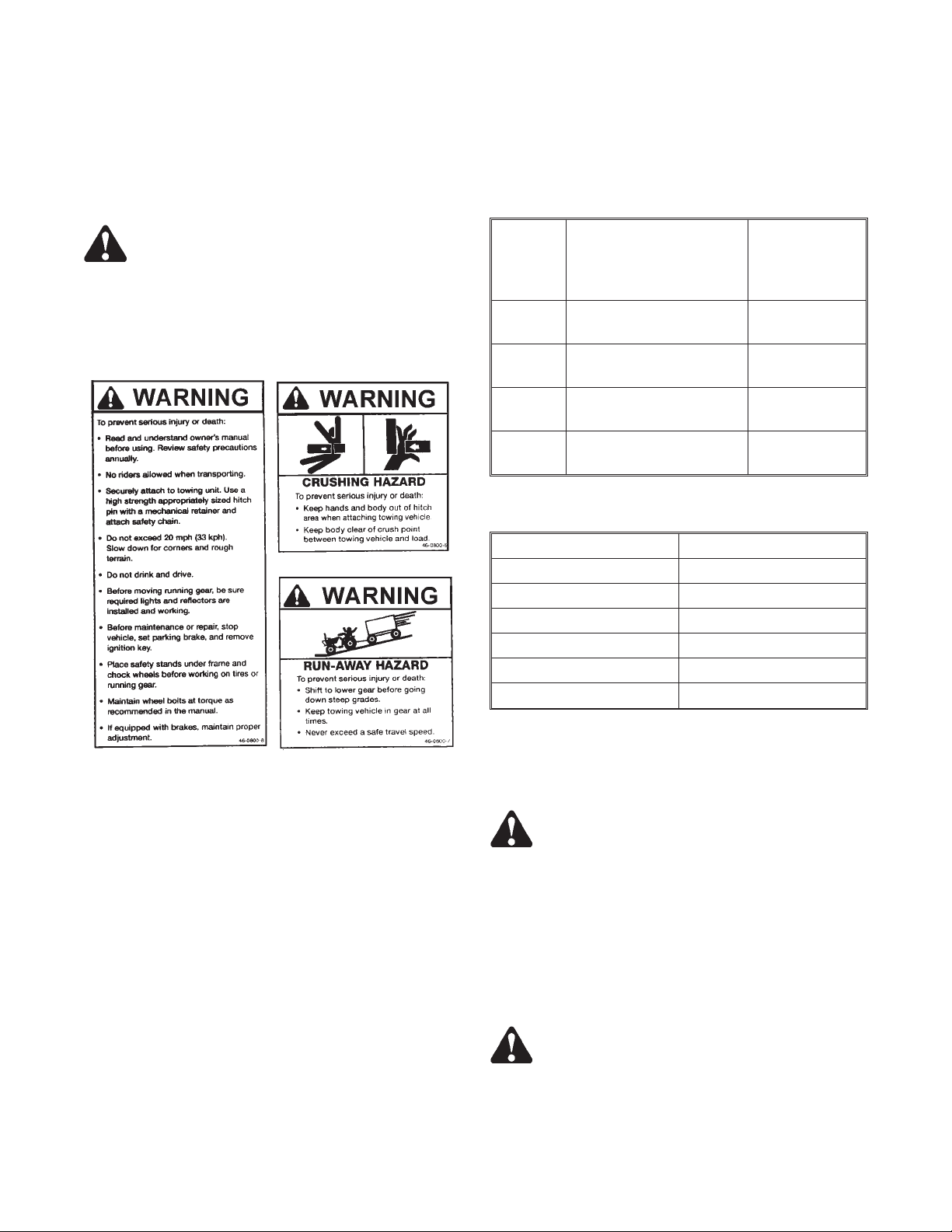

TRANSPORTING

On tractor pulled MODELS, always disconnect the PTO

drive shaft from the tractor and return it to the PTO stor

age bracket on the box front before transporting. Failure

to do this may result in equipment damage.

WARNING: INSTALL A SMV EMBLEM ON

REAR OF FORAGE BOX FOR TRANSPORTING ON

ROADWAYS. KEEP THIS EMBLEM CLEAN AND

BRIGHT. FAILURE TO HEED MAY RESULT IN SERI

OUS PERSONAL INJURY OR DEATH.

TRACTOR TOWING SIZE REQUIREMENTS

Use the following chart for calculating the minimum trac

tor weight.

MODEL FORAGE BOX EMPTY

WEIGHT + LOAD = GW

-

8118 5,200 + _____ = _____ 2/3 of box

8120 5,400 + _____ = _____ 2/3 of box

8122 5,700 + _____ = _____ 2/3 of box

8124 6,200 + _____ = _____ 2/3 of box

MATERIAL ESTIMATED WEIGHT PER CUBICFOOT

MATERIAL LBS / CU. FT.

SOYBEANS 47 LBS.

COTTON SEED DRY 20 LBS.

CORN (SHELLED) 45 LBS.

CORN SILAGE 30 LBS.

HAYLAGE 20 LBS.

SAWDUST 17 LBS.

MINIMUM

TRACTOR

WEIGHT UP

TO 20 MPH

gross weight

gross weight

gross weight

gross weight

-

Be sure and observe that the rear discharge door is

latched closed before traveling on roadways.

If you will travel on public roads and it is legal to do so,

you must know all rules governing such operation. This

will include lightingand brake requirements inaddition to

traffic rules. You may also be required to install a safety

chain device on the running gear.

SOURCE: ASAE

NOTE: HEAPED LOADS HAVE SIGNIFICANTLY

HIGHER CAPACITIES

WARNING: MAKE CERTAIN EVERYONE IS

CLEAR OF EQUIPMENT BEFORE APPLYING

POWER. FAILURE TO HEED MAY RESULT IN SERI

OUS PERSONAL INJURY OR DEATH.

Your running gear for tractor pulled model probably has

a telescoping tongue for convenience to hitch up. Always

back up and lock this tongue in the operating position af

ter hitching.

WARNING: YOU MUST OBSERVE ALL AP

PLICABLE TRAFFIC LAWS WHEN TRANSPORTING

ON PUBLIC ROADWAYS. CHECK LOCAL LAWS

FOR ALL HIGHWAY LIGHTING AND MARKING RE

-

-

-

-

--8-- 8100 Rear Unload

Page 10

QUIREMENTS. FAILURE TO HEED MAY RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

WARNING: DO NOT TOW

CESS OF 20 MPH. FAILURE TO HEED MAY RESULT

IN SERIOUS PERSONAL INJURY OR DEATH.

Operating speed is dictated by the terrain over which you

are traveling. Always use caution. Avoid traveling on

slopes or hills that are unsafe.

CAUTION: USE FLASHING WARNING LIGHTS

WHEN TRANSPORTING ON ALL PUBLIC ROAD

WAYS, EXCEPT WHEN PROHIBITED BY LAW.

AT SPEEDS IN EX

-

-

Check for traffic constantly. Be sure you can see that no

one is attempting to pass you and that all traffic is sufficiently clear from you before making any turns.

TRUCK MOUNT FORAGE BOXES

Depending on the make and model of truck it may be

necessary to install a light converter (MEYER PART

#56-0028). Converter will allow signal lights and brake

lights to operate according to DOT lighting standard. Call

factory for more information.

8100 Rear Unload --9--

Page 11

REAR UNLOAD OPERATION

Whenever adjusting, cleaning, lubricating or otherwise

servicing this forage box, you must shutoff and lockout

power to the box. Because this box can be truck

mounted or powered by a tractor, methods vary. On

truck mounted units, the connection between the PTO

and box is permanently installed and not intended to be

disconnected. On trucks, disengage the PTO drive, turn

off the engine, set the parking brake, remove the ignition

keys and keep them in your possession to prevent any

one else from accidentally applying power to the box un

expectedly. On tractor pulled units, the connection

between the tractor PTO and box is by a removable PTO

drive shaft. For tractors, disengage the PTO drive, turn

off the engine, set the brakes and disconnect the PTO

drive shaft from the tractor.

Throughout this manual, when directed to shutoff and

lockout power, be familiar with the previously described

procedures for the type of machine you are operating.

References in this manual are made to a PTO drive shaft

and are applicable to tractor pulled MODELS.

WARNING: MAKE CERTAIN EVERYONE IS

WELL CLEAR OF EQUIPMENT BEFORE APPLYING

POWER. FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

Tractor Pulled:

Always park the forage box and unloading tractor

in a straight line. Minimize the unloading angle on

the PTO drive shaft

to prevent wearing of universal

joints when connected to the unloading tractor

PTO. Shift the unloading tractor to “Neutral” or

“Park”. Set the brakes and turn power off. Remove

the PTO drive shaft

from the forage box PTO stor

age bracket and connect it to the tractor PTO. Be

sure the PTO yoke is securely locked to the tractor

PTO.

WITH EXTREME FORCE. KEEP ALL PERSONS

WELL CLEAR OF THE FORAGE BOX AND UN

LOADING AREA. FAILURE TO HEED MAY RESULT

IN SERIOUS PERSONAL INJURY OR DEATH.

From the operator’s seat, restart, and SLOWLY

the PTO to start the apron chains and to open the rear

door. Once the door opens, regulate the discharge flow

with the engine speed. Do not operate above rated en

gine PTO speed.

-

Unloading is best observed from the operator’s seat.

Keep moving the forage box forward to prevent silage

from being carried underneath into the main apron chain

return area.

The front of the box has a plexiglass window for conve

nient observation.

WARNING: DO NOT STEP OVER THE PTO

DRIVE SHAFT. STAY WELL CLEAR OF THE PTO AT

ALL TIMES. FAILURE TO HEED MAY RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

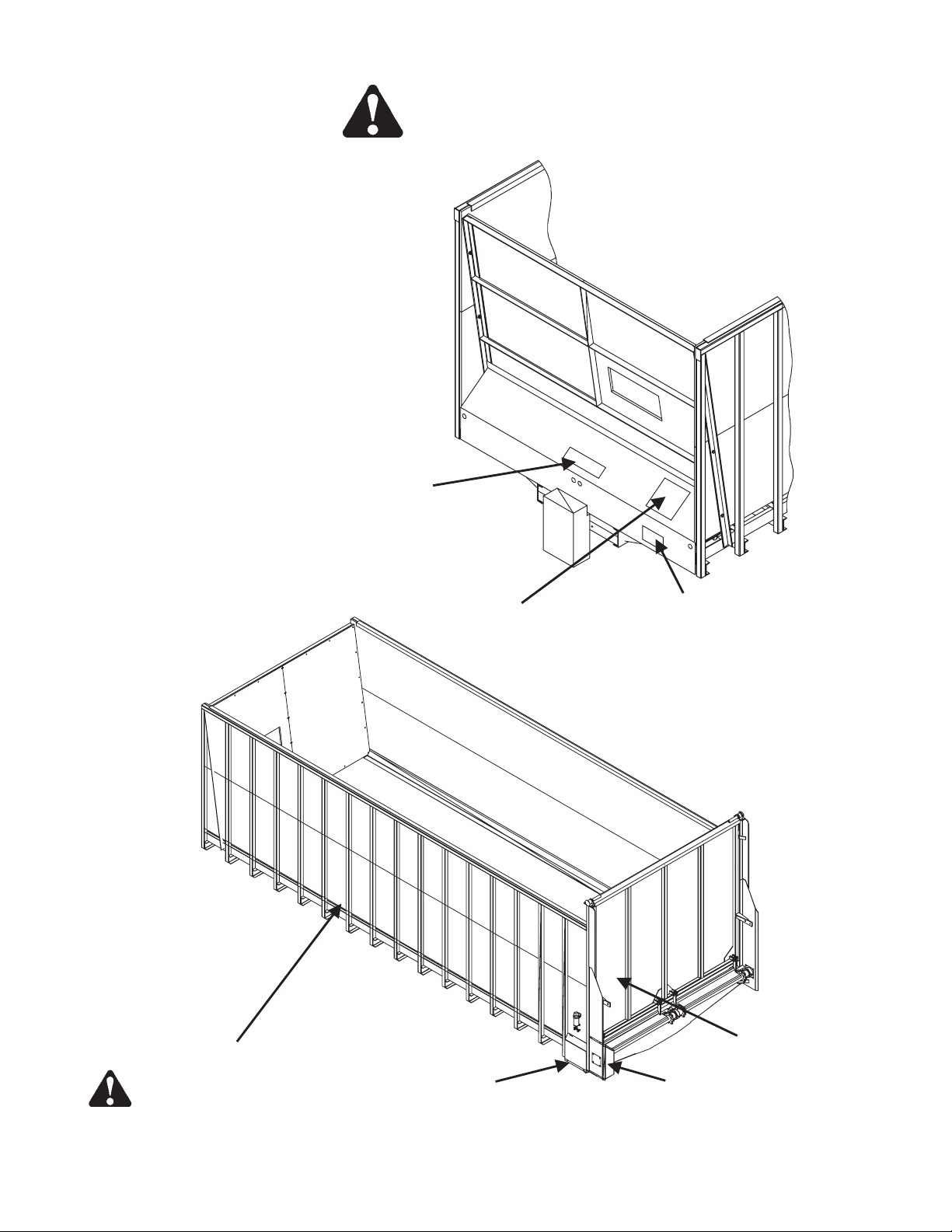

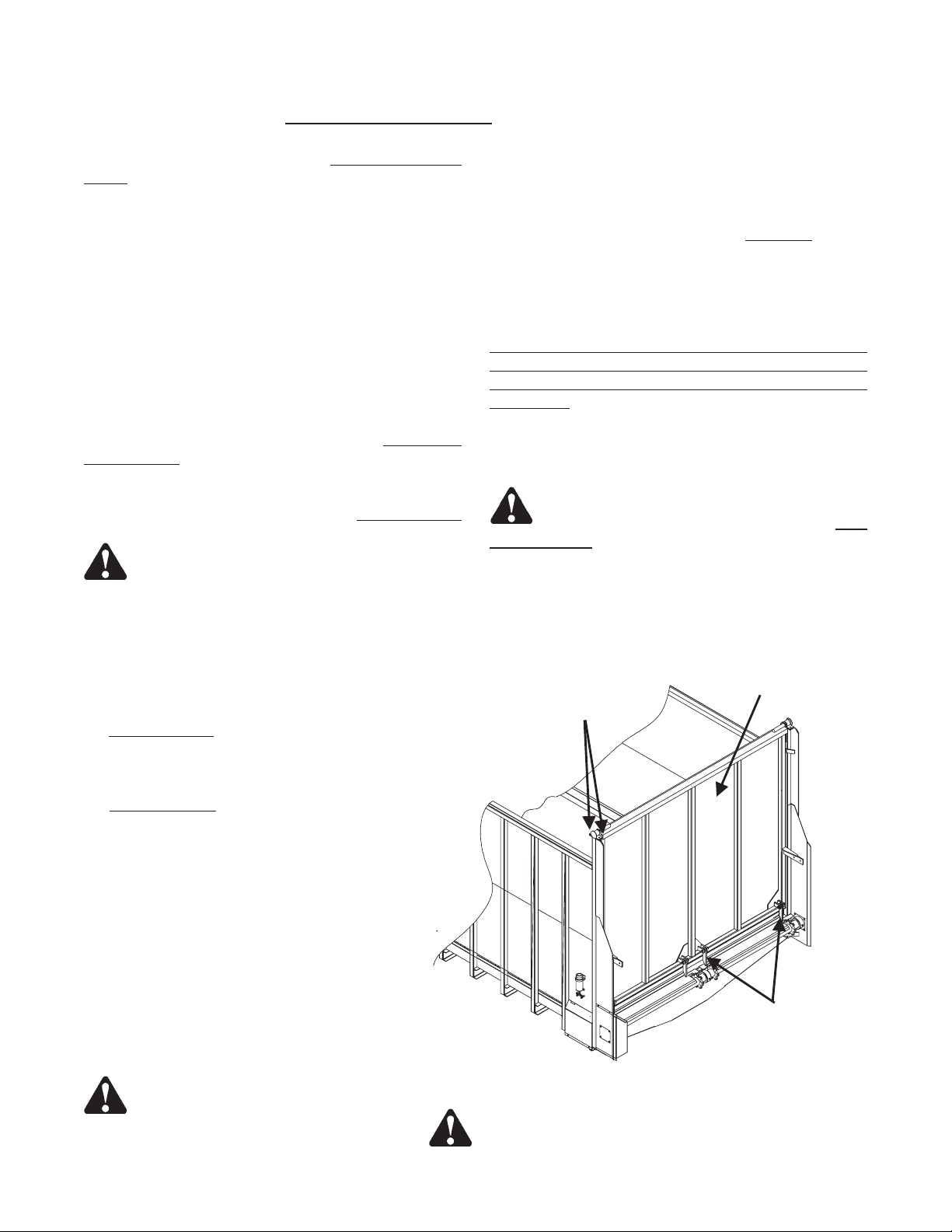

REAR

DISCHARGE

DOOR

HINGE BOLTS

-

engage

-

-

Make sure all persons are well clear of the forage

box and the unloading area.

The rear discharge door opens automatically by

releasing its latches as the main aprons begin to

move. The rear discharge door can spring open

with extreme force when its latches release. See

figure 1. Pressure of forage against the rear door

causes it to spring open very quickly.

WARNING: THE REAR DISCHARGE

DOOR CAN SPRING OPEN QUICKLY AND

REAR DOOR

LATCHES

FIGURE1. REAR OPENING DISCHARGE DOOR

CAUTION - QUICK RELEASE

--10-- 8100 Rear Unload

Page 12

WARNING: DO NOT STEP UP ON ANY PART

OF THE FORAGE BOX AT ANY TIME. FAILURE TO

HEED MAY RESULT IN SERIOUS PERSONAL INJURY

OR DEATH.

DANGER: NEVER ENTER THE FORAGE BOX

FOR ANY REASON WITHOUT FIRST SHUTTING OFF

AND LOCKING OUT POWER. FAILURE TO HEED

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEATH.

The unloading process described is to be performed by

the operator alone. This will eliminate unexpected

“start-ups” and minimize other hazards that could result

by more than one person in control. If the forage box

should become clogged, shut off all power to the forage

box and wait for all motion to stop. Shut off and lockout

power. Then clean out the machine.

When finished unloading reduce engine speed to idle

and disengage the PTO drive. Pull the rear unload box

straight ahead to pull the door away from the unloaded

pile of forage. When free, gravity will allow the door to

swing shut and the door latches will engage the apron

chain links to secure it shut. Observe that this happens

properly.

Tractor Pulled:

Set the brakes and turn the tractor “OFF”. When all

movement has stopped, disconnect the PTO drive shaft

from the tractor and return it to its storage bracket. Secure it with the rubber tie down strap.

WARNING: DISCONNECT PTO DRIVE SHAFT

BEFORE CLEANING, ADJUSTING, LUBRICATING

OR SERVICING THIS MACHINE. FAILURE TO HEED

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEATH.

Never enter the forage box for any reason if there is any

possibility of power being applied to the unit.

Allow box to completely clean out the last load of forage.

It is recommended to lube the rear unload box before

storage to exclude moisture from bearings. Apply oil to

roller chain drives with gravity oil luber and to the apron

chains with a brush. This is also a good time to inspect all

adjustments and check for parts that need repair or re

placement. Performing these tasks now will guarantee

that the box is ready for use at the beginning of the next

season.

Never use “live” power to aid in the clean-out of a

clogged machine. If any mechanism fails, move the for

age box to a safe work area and then repair the mecha

nism before proceeding with unloading of the forage. If

repairs require removal of forage from inside the forage

box, remove the rear discharge door (bolted hinges on

top of each side) and empty the forage manually by hand

through the rear opening.

8100 Rear Unload --11--

-

-

-

Page 13

This Page Intentionally Blank

--12-- 8100 Rear Unload

Page 14

LUBRICATION

WARNING: SHUT OFF AND LOCK OUT

POWER BEFORE CLEANING, ADJUSTING, LUBRI

CATING OR SERVICING THIS MACHINE. FAILURE

TO HEED MAY RESULT IN SERIOUS PERSONAL IN

JURY OR DEATH.

DAILY LUBRICATION

(every 8-10 loads)

It is recommended to lube the forage box before storage

to exclude moisture from bearings. Apply oil to roller

chain drives with the gravity oil luber and to the main

-

apron chains with a brush.

-

It is also a goodtime to inspect all adjustments andcheck

for parts that need repair or replacement. Performing

these tasks now will guarantee that the forage box is

ready for use at the beginning of the next season.

Grease (2) PTO drive shaft universal joints (not il

lustrated). Grease (1) PTO drive shaft telescoping

Shaft and tube. Zerk accessible through the plastic

guards (not illustrated)

Oil (2) roller chains on apron drive. This is done by

opening the ball valve on the gravity oiler while

unloading, once per day.

WARNING: DO NOT STAND BEHIND UNIT

WHILE PERFORMING THIS OPERATION.

Refill the gravity oiler atthe beginning of each day.

Grease two jack shaft bearings. Lube line for bearing under box is routed to the side of the box for convenience.

Oil (4) rear gate latch pivot bolts.

Maintain oil in the gearbox at the check plug level.

-

Grease (3) main apron shaft bearings.

BEGINNING OF CROP MAINTENANCE

(approximately 100-150 loads)

Change oil in the gear box after the first season of use

and yearly thereafter. Use #80-90 wt. Gear Lube Oil.

Lighter oil may be usedin temperatures lower than 20° F.

END OF CROP CLEANUP AND MAINTENANCE

Allow box to completely clean out last load of forage.

Clean out all forage material from inside the box and on

the outside of the box.

8100 Rear Unload --13--

Page 15

(UNDER BOX)

BOTH SIDES

SHOWN W/SHIELD REMOVED

LUBRICATION DIAGRAM

--14-- 8100 Rear Unload

Page 16

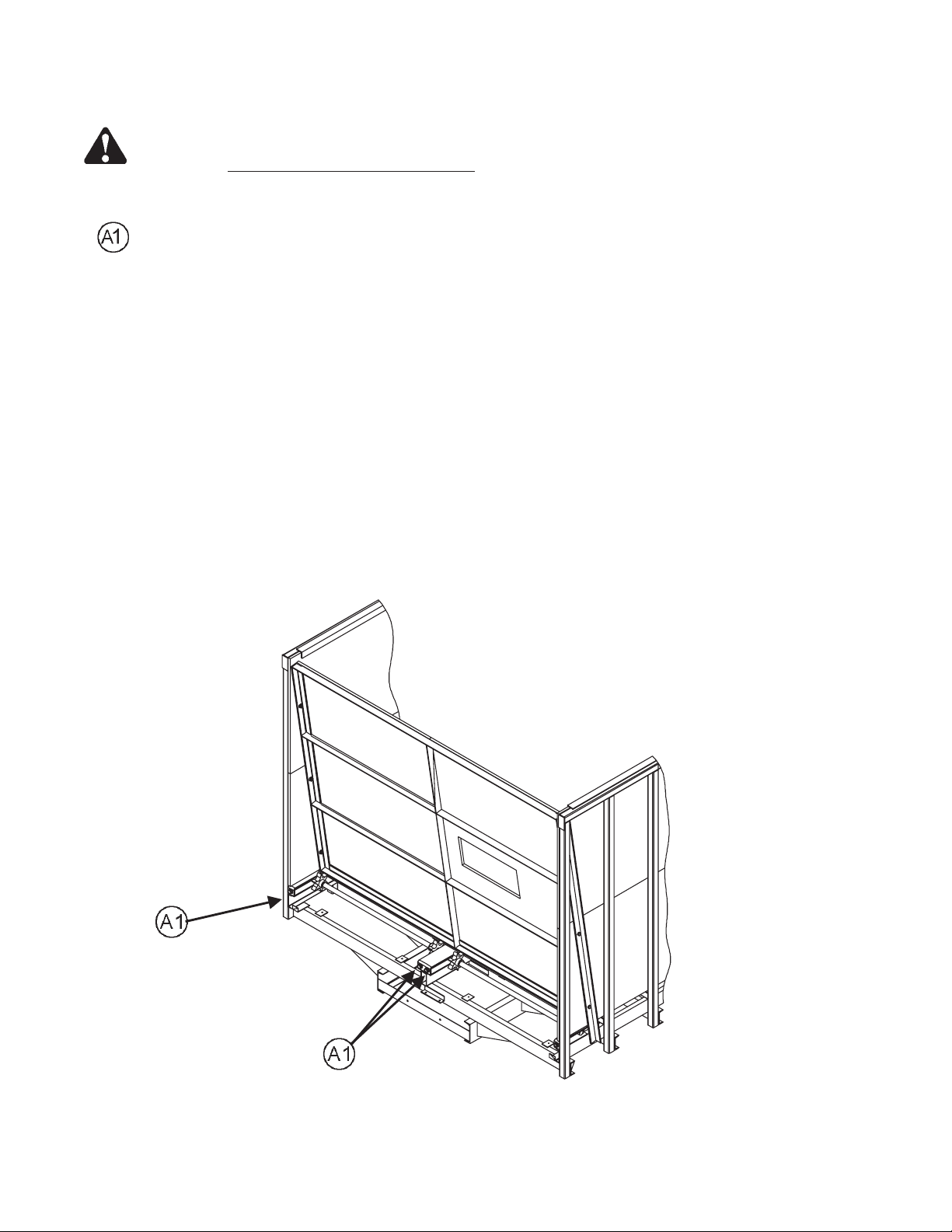

ADJUSTMENTS

WARNING: SHUT OFF AND LOCK OUT POWER BEFORE CLEANING, ADJUSTING, LUBRICATING OR

SERVICING THIS MACHINE. FAILURE TOHEED MAY RESULT IN SERIOUS PERSONAL INJURYOR DEATH.

Correct tension on the apron chains is when the

apron chain slat is 1/8” to 1/4” off the return slides (three

feet from the front of the box). To tighten chains, tighten

the adjuster bolts at each end of the front sprocket

shafts. Each apron chain has its own sprocket shaft.

Tighten the adjuster bolts at each end of the shaft

equally.

The roller chain drives are tensioned by automatic spring

loaded tension blocks. Periodically eye bolts will need to

be adjusted to maintain proper spring tension. Springs

should be stretched to obtain approximately 1/16” gap

between windings.

BOTH SIDES

Front Shields Removed To Illustrate Service Components.

Do Not Remove This Shield To Perform The Service.

ADJUSTMENT DIAGRAM

8100 Rear Unload --15--

Page 17

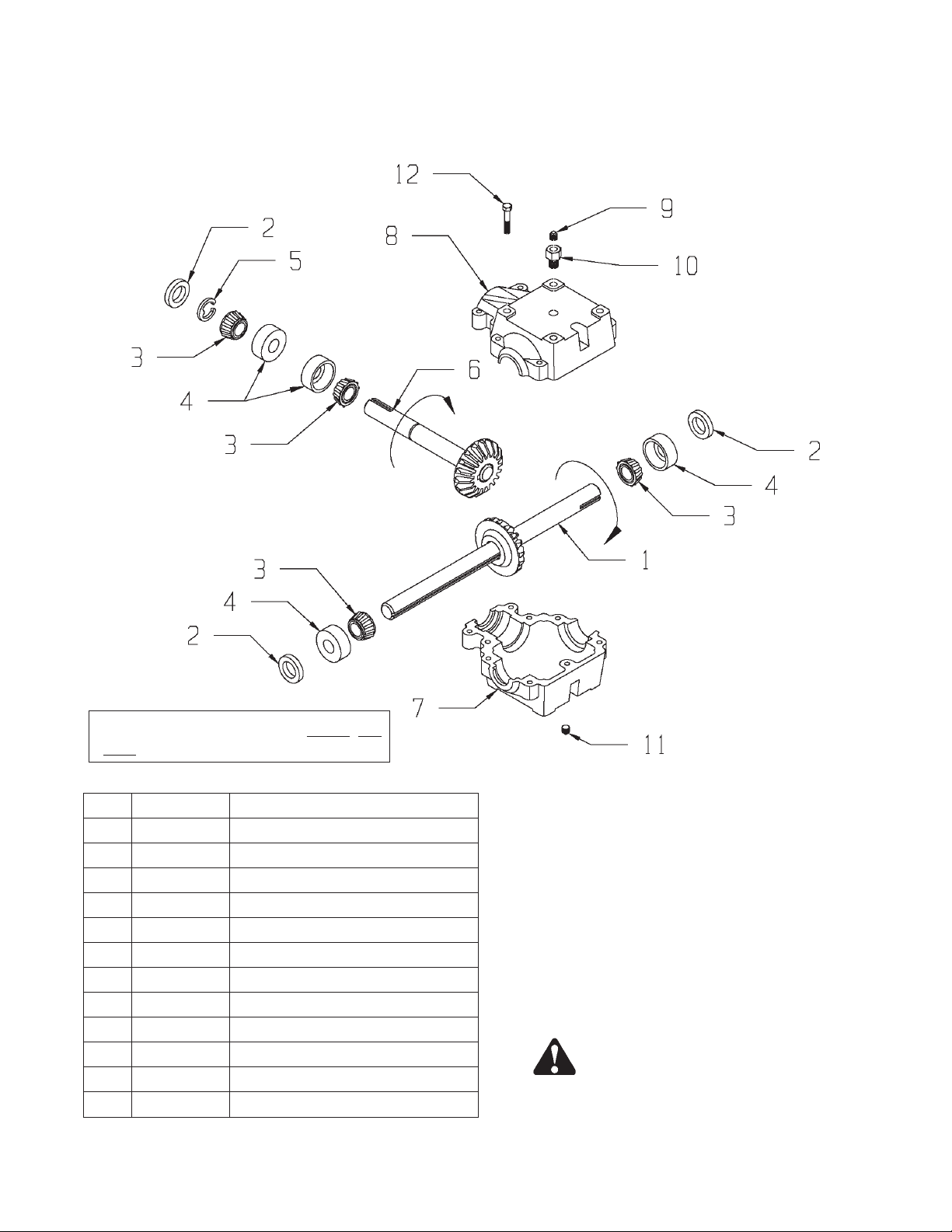

REPAIR PARTS

#19-0038 2:1 RATIO GEARBOX

Use #80-90 wt. Gear Lube Oil ONLY. DO

NOT USE GREASE FOR LUBRICANT.

KEY PART NO. DESCRIPTION

1 19-0034-4 Output Shaft/Gear Assembly

2 19-0018-2 Seal

3 19-0018-3 Bearing Cone

4 19-0016-3 Bearing Cup

5 19-0018-4 Retaining Ring

6 19-0034-3 Input Shaft/Gear Assembly

7 19-0043-1 Gearbox Casting (Tapped Holes)

8 19-0041-2 Gearbox Casting (Thru Holes)

9 19-0002-17 Vent Plug, 5 PSI

10 19-0023-2 Bushing, ½-14 NPT

11 19-0016-5 Plug, ½-14 NPT

12 19-0016-11 Bolt, 3/8-16 x 1.50 SHCS

NOTE: Gearbox may be flipped 180 degrees if

input power rotation is opposite standard rota

tion. (Truck mount boxes only)

CAUTION: VERIFY CORRECT DRIVE

ROTATION BEFORE OPERATING. FAILURE

TO DO SO MAY RESULT IN SEVERE EQUIP

MENT DAMAGE.

-

-

--16-- 8100 Rear Unload

Page 18

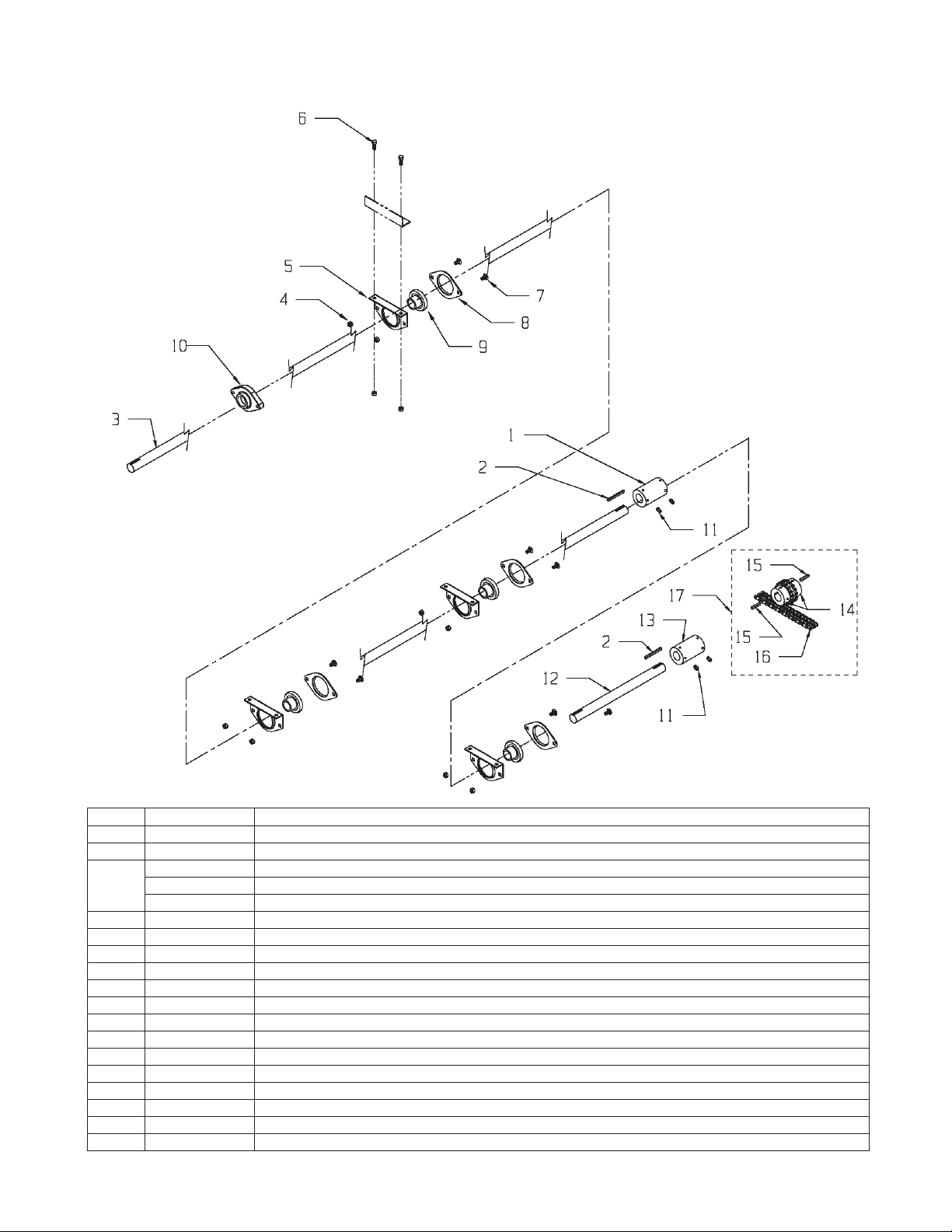

MAIN DRIVE SHAFT (PTO DRIVE)

KEY PART NO. DESCRIPTION

1 37-0007 Shaft Coupler 1-1/4” Bore

2 35-0014 Key, ¼ x ¼ x 4-1/2”

3 23-0094 8118 Center Drive Shaft, 1-1/4” x 186”

23-0100 8120 Center Drive Shaft, 1-1/4” x 202”

23-0091 8122/8124 Center Drive Shaft, 1-1/4” x 234”

4 810-3816-Z 3/8-16 Spin Locknut

5 14-0003-1 1-1/4” Pillow Block Flange

6 851-3816-1Z Bolt, 3/8-16 x 1, Machine Bolt Grade 5

7 850-3816-1Z Bolt, 3/8-16 x 1, Carriage Bolt Grade 5

8 14-0003-2 1-1/4” Two Bolt Flange

9 14-0002-3 1-1/4” Bearing w/Lock Collar

10 14-0046 1-1/4” Two Hole Flange Cast Bearing

11 827-3118-.38 Set Screw, 5/16-18 x .375

12 23-0098 8124 Center Drive Shaft Ext, 1-1/4” x 32”

13 37-0007 Shaft Coupler 1-1/4” Bore (Prior to Serial #0781227)

14 37-0017-1 1-1/4" Bore Chain Coupler

15 35-0012 Key, 1/4x1/4x1-1/2"

16 37-0013-2 Coupler Chain

17 37-0020 Chain Coupler Assembly 1-1/4" W/Keys (Serial #0781227 & Later)

8100 Rear Unload --17--

Page 19

#18-0119 (OPTIONAL) UNIVERSAL JOINT TELESCOPING ASSEMBLY

W/GUARD

KEY PART NO. DESCRIPTION

18-0117 Joint Assembly

1 18-0117-1-1 1 3/8-6 Spline Yoke ASGE

2 18-0117-1-2 Cross and Bearing Kit

3 18-0117-1-3 Inboard Yoke and Bar Welded

Assy.

4 18-0117-2-1 Inboard Yoke, Tube and

Sleeve Welded Assy.

6 18-0119-1-1 Overrunning Clutch Assembly

7 18-0117-1-4 Shield Cone 5-Rib

8 918-0208-2-4 Bearing Ring SC25

9 18-0117-1-6 Outer Shield Tube Oval

10 18-0117-2-3 Inner Shield Tube Round

11 918-0208-2-9 Screw-Included in Item #7

12 918-0208-2-7 Safety Chain

13 918-0208-2-8 Decal Outer-Included in Item

#9

KEY PART NO. DESCRIPTION

14 918-0208-1-10 Decal Inner-Included in Item #4

15 18-0117-1-1-1 ASGE Collar Kit-Included in

Item #1

16 18-0117-1 Tractor Male Half Complete

17 18-0119-1 Implement Female Half Shaft

Complete

18 24-0118 Shield Assembly (Optional

PTO Drive)

19 24-0118-1 PTO Shield Welded Bracket

20 24-0118-2 PTO Flexible Shield

21 32-0025 PTO Flexible Shield Clamp

22 38-0016 5/16” Roll Pin (Optional PTO

Drive)

23 35-0021 Key, 1/4 x 1/4 x 1-3/4

24 18-0117-1-7 Shield Cone, 4-Rib

--18-- 8100 Rear Unload

Page 20

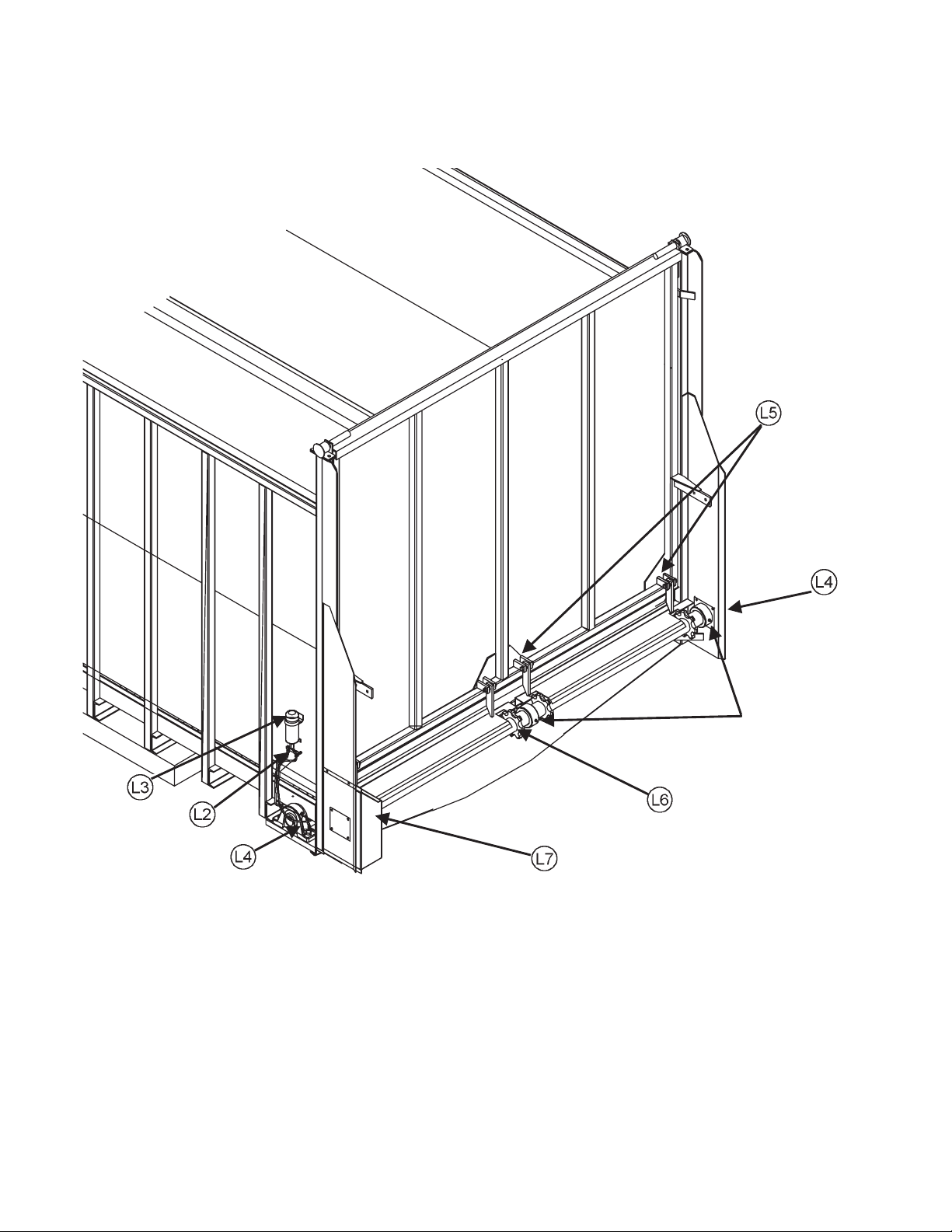

GEARBOX & CHAIN DRIVE

8100 Rear Unload --19--

Page 21

GEARBOX & CHAIN DRIVE

KEY PART NO. DESCRIPTION

1 30-0002 Zerk, 1/8 NPT Straight

2 930-3602 68F-04X02 Male Connector Brass Compression

3 14-0044 Bearing, 2” Pillow Block

4 933-3636 46” Copper Grease Line

5 25-8006-1 Gearbox Mount Channel

6 11-0117 #80-59 Roller Chain

7 10-0080 80B12 1-3/8” Bore 5/16” Kwy Sprocket

8 35-0013 Key, 5/16 x 5/16 x 1.5

9 19-0038 Superior Gearbox 2:1

10 35-0014 Key, ¼ x ¼ x 4.5

11 851-7510-1.75Z Bolt, 3/4-10 x 1-3/4” Hex Head Machine Bolt

12 912-0017 1-3/8” Nylon Roller Complete

12A 912-0015-1 Nylon Roller Only

12B 912-0015-2 Inner Sleeve

13 851-7510-4Z Bolt, 3/4-10 x 4 Hex Head Machine Bolt

14 929-3601 Spring, Extension

15 813-3118-Z Nut, 5/16-18

16 933-3804 5/16 x 5” Eyebolt #124032, 5” Overall 3” Threads ZN

17 23-0097 Jack shaft, 2” x 59”

18 814-7510-Z Nut, 3/4-10 Center Locknut

19 25-8007-1 80 Chain Tightener Weldment

20 851-6311-2.5Z Bolt, 5/8-11 x 2-1/2 Hex Head Machine Bolt

21 805-0063-Z Washer, 5/8” Flat

22 810-5013-Z Nut, ½-13 Spin Locknut

23 806-0050-Z Washer, ½ Internal Tooth

24 11-0123 #120-37 Roller Chain

25 805-0063-Z Washer, 5/8” Flat

26 851-5013-1.25Z Bolt, ½-13 x 1.25 Hex Head Machine Bolt

27 910-0003 Sprocket, 80B45, 2” Bore, ½” KWY

28 35-0024 Key, ½” x ½” x 2-1/2” (1045 Mat)

29 912-0016 7/8” Nylon Roller Complete

29A 912-0016-1 Nylon Roller Only

29B 912-0016-2 Inner Sleeve

30 10-0085 Sprocket, 120B9, 2” Bore ½” KWY

31 810-6311-Z Nut, 5/8-11 Spin Locknut

32 25-8031-1 120 Chain Tightener Weldment

--20-- 8100 Rear Unload

Page 22

HYDRAULIC PLUMB TO THE FRONT

KEY PART NO. DESCRIPTION

1 55-0088 Hydraulic Motor

2 55-0048 5/8-3/4" Adapter O-Ring Base

3 55-0007-B 3/4" Check Valve

4 29-0012 Spring

5 55-0033 Clamp Assembly

6 55-0034 ½" 2-Wire x 120" Hose Assy.

7 55-0013 Pioneer Coupler Male Tip

8 25-0249-1 Holder For Hydraulic Hose Ends

9 25-0209 Hydraulic Hose Bracket

10 851-3816-1Z Bolt, 3/8-16 x 1" Hex Head

11 35-0019-H Key, 1/4 x 1/4 x 1-1/4" (Hard)

W/Rounded Ends

12 25-8042-1 Hydraulic Motor Mount Bracket,

Rear

13 37-0012 Coupler 1" to 1-1/4" (Prior to Se

rial #0781227)

14 35-0021 Key, 1/4 x 1/4 x 1-3/4"

15 25-0210-4 Hydraulic Pipe Holder Clamp

16 55-0029 2-Wire 3/4" Hose x 36" Long

17 55-0030 3/4" Black Steel Coupler

KEY PART NO. DESCRIPTION

18 55-0062 3/4" Hydraulic Pipe x 161" -

55-0024 3/4" Hydraulic Pipe x 185" -

55-0022 3/4" Hydraulic Pipe x 209" -

55-0020 3/4" Hydraulic Pipe x 233" -

19 55-0079 3/4" Black Tee Fitting

20 55-0081 3/4" Steel Plug

21 851-3816-2.25HHCS 3/8-16 x 2-1/4"

22 815-3816-Z 3/8-16 Nylon Insert Locknut

23 37-0013-1 1" Bore Chain Coupler

24 37-0017-1 1-1/4" Bore Chain Coupler

25 37-0013-2 Coupler Chain

26 35-0019-H Key, 1/4x1/4x1-1/4" (Hard)

27 35-0021 Key, 1/4x1/4x1-3/4"

28 37-0019 Chain Coupler Assembly 1" to

8118

8120

8122

8124

W/Rounded Ends

1-1/4" W/Keys (Serial #0781227

& Later)

8100 Rear Unload --21--

Page 23

HYDRAULIC DRIVE (OPTIONAL FRONT MOUNT) #8100 - HYD

KEY PART NO. DESCRIPTION

1 55-0088 Hydraulic Motor

2 55-0048 5/8-3/4" Adapter ORB

3 55-0007-B 3/4" Check Valve

4 29-0012 Spring

5 55-0033 Clamp Assembly

6 55-0034 1/2" 2-Wire x 120" Hose

Assembly

7 55-0013 Pioneer Coupler Male Tip

8 25-0249-1 Hydraulic Hose End Holder

9 25-0209 Hose Hanger Bracket

10 851-3816-1Z Bolt 3/8-16x1" Hex Head

11 35-0019-H Key, 1/4x1/4x1-1/4" (Hard)

W/Rounded Ends

12 25-8041-1 Hydraulic Motor Mount Bracket

KEY PART NO. DESCRIPTION

13 37-0012 Welded Coupler 1" to 1-1/4"

(Prior to Serial #0781227)

14 35-0021 Key, 1/4x1/4x1-3/4"

15 25-8040-1 Motor Bracket Cover

16 55-0085 1/2x5/8" ORB Straight Fitting

17 55-0044 3/4x1/2" Steel Hex Bushing

18 37-0013-1 1" Bore Chain Coupler

19 37-0017-1 1-1/4" Bore Chain Coupler

20 37-0013-2 Coupler Chain

21 35-0019-H Key, 1/4x1/4x1-1/4" (Hard)

W/Rounded Ends

22 35-0021 Key, 1/4x1/4x1-3/4"

23 37-0019 Chain Coupler Assembly 1" to

1-1/4" W/Keys (Serial #0781227

& Later)

--22-- 8100 Rear Unload

Page 24

APRON

8100 Rear Unload --23--

Page 25

APRON

KEY PART NO. DESCRIPTION

1 851-3816-1Z Bolt, 3/8-16 x 1" Hex Head

2 24-8002 Front Drive Shield (Mechanical Truck Mount)

3 815-3816-Z 3/8-16 Nylon Locknut

4 24-8001 Front Apron Chain Shield

5 25-8009 Apron Chain Tightener Bolt

6 10-0075 Idler Sprocket w/Bushing

13-0018 Bushing, 1-1/4" ID x 1-5/8" OD x 1-1/2" Long

7 25-8010 Tightener Block Weldment

8 851-2520-1Z Bolt, 1/4-20 x 1" Hex Head

9 23-0095 Left Hand Idler Shaft Assembly

10 11-0125 Main Apron Chain Assembly (24 Ft.) 667XH

11-0107 Main Apron Chain Assembly (22 Ft.) 667XH

11-0131 Main Apron Chain Assembly (20 Ft.) 667XH

11-0121 Main Apron Chain Assembly (18 Ft.) 667XH

11 11-0107-2 Pintle Chain Link-D667

12 11-0107-6 Rivet, 7/16 x 1"

13 11-0107-5 Slat

14 11-0107-3 Attachment Link-D667XH

15 810-5013-Z ½-20 Spin Locknut

16 14-0041 RH/LH Main Drive Shaft Bearing Assembly

17 30-0002 1/8" NPT Straight Zerk

18 23-0096 Main Drive Shaft Assembly

19 851-5013-1.25Z Bolt, ½-13 x 1-1/4" Hex Head

20 30-0009 Coupler 1/8" NPT x 3/4" Long

21 11-0107-1 Slat w/Attachment Links

22 30-0006 1/8" NPT x 90 Degree Zerk

23 23-0090 RH Idler Shaft Assembly

24 810-2520-Z 1/4-20 Spin Locknut

25 30-0016 1/8" NPT Close Nipple

26 701-.75-1.75-16 Chain Return Slide Rail (As Required)

701-.75-1.75-18 Chain Return Slide Rail (As Required)

701-.75-1.75-20 Chain Return Slide Rail (As Required)

27 25-8000-1 Front Gate Center Support

28 14-0048 Replacement Split Center Bearing Assembly

29 100-8020-65 Front Stringer Support Plate

--24-- 8100 Rear Unload

Page 26

8100 MAIN BODY

8100 Rear Unload --25--

Page 27

8100 MAIN BODY

KEY PART NO. DESCRIPTION

1 100-8022 8124 Main Frame & Side Assembly

100-8020 8122 Main Frame & Side Assembly

100-8021 8118 Main Frame & Side Assembly

100-8023 8120 Main Frame & Side Assembly

2 49-0089 Plexiglass Viewing Window

3 100-8010-8 Fiberglass Plywood Panel (with Viewing Hole) 96.5 x 69.75"

4 708-96.5-69.75 Fiberglass Plywood Panel 96.5 x 69.75"

5 100-8010 Front Gate Assembly Complete

100-8010-1 Front Gate Welded Frame Only

6 851-5013-1.5Z ½-13 x 1-1/2" Hex Head Bolt

7 810-5013-Z ½-13 Spin Locknut

8 24-8005-1 Shield Bottom Seal, 120 Drive Chain

9 33-1008 Plywood Tee Molding (By the foot)

10 709-48-206.5 8118 Superslick Floor Panel 48 x 206-1/2"

709-48-222.5 8120 Superslick Floor Panel 48 x 222-1/2"

709-48-254.5 8122 Superslick Floor Panel 48 x 254-1/2"

709-48-286.5 8124 Superslick Floor Panel 48 x 286-1/2"

11 708-70.75-264 Fiberglass Plywood Side Panel 70.75 x 264" (8118, 8120, 8122)

708-70.75-296 Fiberglass Plywood Side Panel 70.75 x 296" (8124)

12 829-14-1.88 1/4-14 x 1-7/8" Self Tapping Screw

13 850-25201.25Z 1/4-20 x 1-1/4" Carriage Bolt

14 810-2520-Z 1/4-20 Spin Locknut

15 803-12-.63 #12 Phillips Pan Head Screw

17 25-8008 Fender (Optional on Truck Mount Models)

18 49-0085 Front Gate Belting

19 24-8005-2 Shield, 120 Drive Chain

20 24-8003 Shield, 120 Drive Chain

21 24-8004 Shield, Jack Shaft

22 25-8020-1 LH Rear/Center Floor Chain Guide 96"

25-8029-1 LH Center Floor Chain Guide 48"

23 25-8024-1 Center Rear Floor Chain Guide 96"

25-8027-1 Center Floor Chain Guide 96"

25-8028-1 Center Floor Chain Guide 48"

24 25-8022-1 RH Center Chain Guide 96"

25-8030-1 RH Center Chain Guide 48"

25 25-8021-1 Center Floor Chain Guide End Cap

26 25-8023-1 Right Floor End Cap

27 25-8019-1 Left Front Floor End Cap

28 100-8070 End Cap

29 825-3118-1.5 5/16-18x1-1/2” Self Threading Floor Screw

30 25-8203-1 Front Floor Cover

--26-- 8100 Rear Unload

Page 28

REAR DOOR

8100 Rear Unload --27--

Page 29

REAR DOOR

KEY PART NO. DESCRIPTION

1 851-5013-2.5Z ½-13 x 2.5 Hex Head Machine Bolt

2 828-0050-Z ½" SAE Flat Washer

3 100-8012-7 Back Gate Latch

4 814-5013-Z ½-13 Center Locknut

5 851-2520-.75Z 1/4-20 x .75 Hex Head Machine Bolt

6 49-0086 Back Gate Belting

7 25-8005-1 Belting Attaching Strip, Right Hand

8 25-8005-2 Belting Attaching Strip, Left Hand

9 100-8013 Back Gate Assembly Complete, (Standard Height Gate 82-1/2")

100-8060 Back Gate Assembly Complete, (High Back Gate 94-1/2")

9A 100-8013-1 Back Gate Welded Assembly, (Standard Height Gate 82-1/2")

100-8060-1 Back Gate Welded Assembly, (High Back Gate 94-1/2")

10 708-95.5-80.25 Fiberglass Plywood Panel, 95.5 x 80.25"

11 810-5013-Z ½-13 Spin Locknut

12 851-5013-1.5Z ½-13 x 1.5 Hex Head Machine Bolt

13 100-8012-15 Back Gate Hinge Weldment

14 100-8013-6 Gate Stop

15 815-5013-Z ½-13 Nylon Locknut

16 810-2520-Z 1/4-20 Spin Locknut

17 100-8062 Right Pivot Extension Assembly (High Gate Only)

18 100-8063 Left Pivot Extension Assembly (High Gate Only)

19 100-8060-1-7 High Gate Top Panel (High Gate Only)

--28-- 8100 Rear Unload

Page 30

OPTIONAL DOUBLE DOOR

8100 Rear Unload --29--

Page 31

OPTIONAL DOUBLE DOOR

KEY PART NO. DESCRIPTION

1 100-8100-20 Right Hand Door Welded Assembly

100-8100 Right Hand Door Complete

2 100-8101-20 Left Hand Door Welded Assembly

100-8101 Left Hand Door Complete

3 100-8102 Double Door Gate Hinge Pin Weldment

4 100-8103 Double Door Bottom Linkage Arm Weldment

5 100-8104 Double Door Linkage Pipe Weldment

6 100-8105 Double Door Linkage Tie Rod Weldment

7 100-8106 Double Door Linkage Clevis Weldment

8 100-8107 Double Door Linkage Pivot Shaft Weldment

9 100-8108 Double Door Solenoid Mount Bracket

10 24-8100 Double Door #120 Chain Shield

11 55-0154 Double Door Air Chamber

12 16-0027 Double Door ½" Swivel Eyelet

13 14-0002-3 1-1/4" Bearing W/Lock Collar

14 14-0003-1 1-1/4" 2-Hole Pillow Block Flange

15 14-0003-2 1-1/4" 2-Hole Plain Flange

16 100-8100-6 Double Door Latch

17 100-8100-16 Door Panel

THE FOLLOWING ITEMS ARE NOT ILLUSTRATED

49-0033 Double Door Back Gate Belting 5" x 42"

55-0150 3/8" Air Line (25’ Required)

55-0151 3/8" Hex Plug

55-0152 3/8 x 3/8 x 90 Degree Elbow

55-0153 3/8" x 1/8" Connector

55-0155 12 Volt Solenoid Valve

--30-- 8100 Rear Unload

Page 32

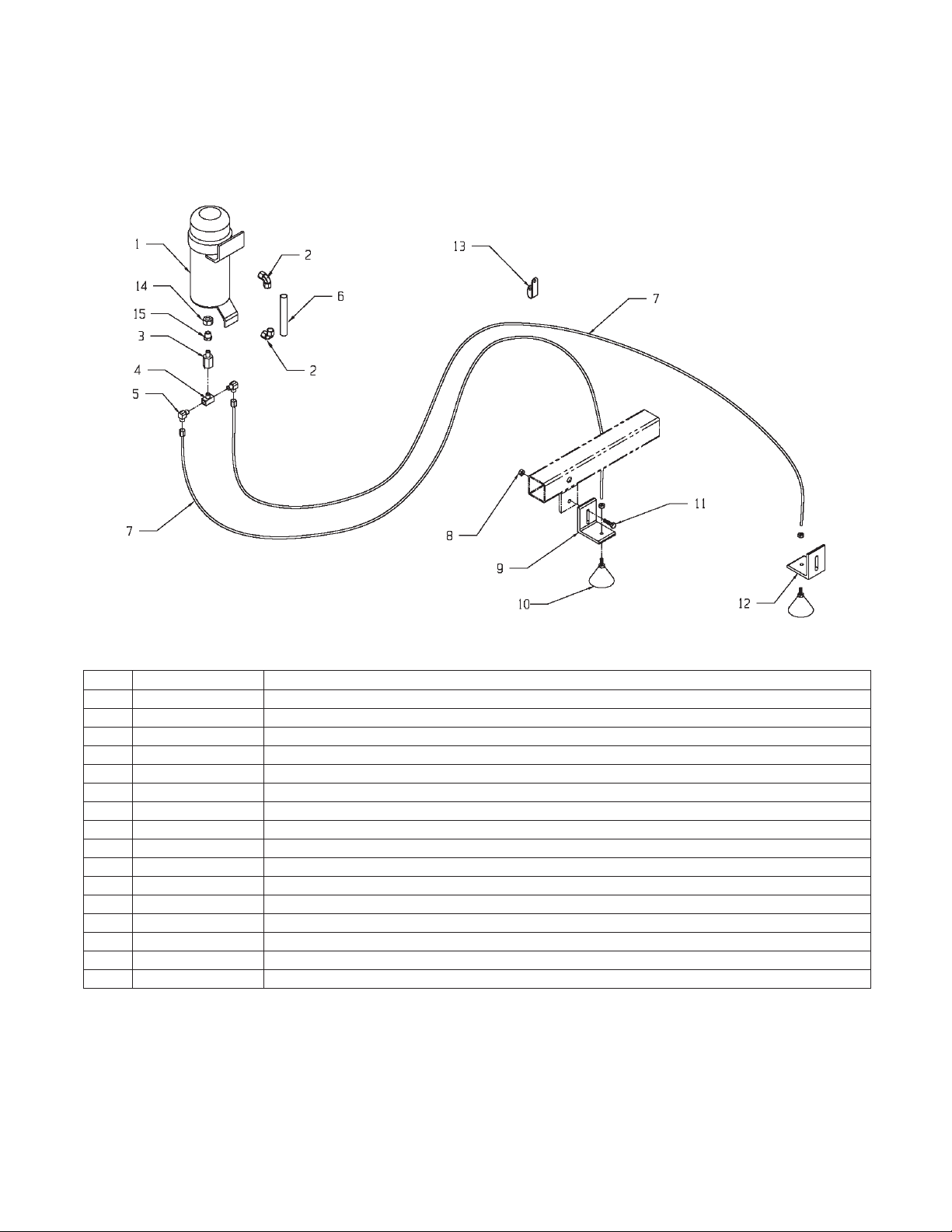

ROLLER CHAIN OILER

KEY PART NO. DESCRIPTION

1 33-8001-1 Oil Reservoir

33-8002 8100 Oil Reservoir Complete w/Fittings

2 30-0015 1/4 x 90 Degree Elbow

3 33-8000-6 Ball Valve

4 33-8001-3 Brass Tee

5 33-8000-5 90 Degree Brass Compression Fitting

6 33-8001-2 Oiler Site Tube

7 952-0001-1-21 Tubing, 5/32" Nylon

8 810-3118-Z 5/16-18 Spin Locknut

9 33-8000-10 Brush Holder

10 952-0001-1-25 Brush Assembly with 5/32" Insert & ½-20 Nut

11 851-3118-1Z 5/16-18 x 1" Hex Head Bolt

12 33-8000-7 #80 Chain Brush Holder, 3/16x1-1/2x10-3/8"

13 08-0050 5/16" Loom Clamp

14 33-8001-4 1/8" NPT Nut

15 33-8001-5 1/8" NPT Nipple

8100 Rear Unload --31--

Page 33

HIGHWAY TRANSPORT AG LIGHTS

KEY PART NO. DESCRIPTION

1 56-0009 7-Way “Stor-A-Way” (Optional)

2 56-0005 Coil Cable Assembly (Optional)

2A 56-0012 7-Contact Plug End

3 56-0005-1 4 Pole Plug Only (Optional)

4 56-0004 #1232 4-Way Socket (4 Pin)

5 56-0001-3 Bezel Blank, Black

6 32-0026 14” Nylon Tie Strap

7 56-0003 Ag Light Harness w/Tri Plugs (Prior to Serial #0681201)

56-0032 Ag Light Harness W/Module (Serial #0681201 & Later)

8 56-0002 Dual Light RH w/Tri Plug (Prior to Serial #0681201)

56-0031 Dual Light RH w/4-Plug (Serial #0681201 & Later)

8A 56-0022 Truck Mount Dual Light RH w/Tri Plug (Prior to Serial #0681201)

56-0031-TR Truck Mount Dual Light RH w/4-Prong (Serial #0681201 & Later)

9 56-0001 Dual Light LH w/Tri Plug (Prior to Serial #0681201)

56-0030 Dual Light LH w/4-Plug (Serial #0681201 & Later)

9A 56-0021 Truck Mount Dual Light LH w/Tri Plug (Prior to Serial #0681201)

56-0030-TR Truck Mount Dual Light LH w/4-Prong (Serial #0681201 & Later)

10 56-0001-4 #1157 Bulb

11 32-0024 3/8” Plated Loom Clip

12 46-0001-62 Caution Tail Light Decal

13 56-0001-2 Red Lens

14 56-0001-1 Amber Lens

15 56-0028 Tail Light Converter (Truck Mount Only)

--32-- 8100 Rear Unload

Page 34

8100 OPTIONAL GRAIN KIT

8100 Rear Unload --33--

Page 35

OPTIONAL GRAIN KIT

KEY PART NO. DESCRIPTION

1 25-8060 Grain Kit Main Body

2 25-8061 Grain Kit Gate Weldment

3 124 1" Pillow Block Bearing

4 323 1" Lock Collar

5 10-0001 Sprocket 50B13, 1" Bore, 1/4" Keyway

6 23-0099 Gate Shaft 1" x 32"

7 851-3816-2Z 3/8-16 x 2" M.B. Zinc

8 15-0006-1 Universal Knuckle

9 15-0006-2 Universal Sleeve Assembly

15-0006 Complete Universal Knuckle/Sleeve Assy.

10 815-3816-Z 3/8-16 Nylon Insert Locknut

11 25-8062 Grain Kit Door Handle

12 25-8027 Handle Lock Chain

13 49-0089 Plexiglas Window 2-1/2" Radius

13A 33-0049 Window Weather-strip (By the Foot) (Not Shown)

14 49-0087 Poly Bottom Panel

15 25-8078 R.H. Gate Stop Weldment Hi/Lo Gate (Prior to Serial #0781239)

25-8178 R.H. Gate Stop Hi/Lo Gate (Serial #0781239 & Later)

16 25-8079 L.H. Gate Stop Weldment Hi/Lo Gate (Prior to Serial #0781239)

25-8179 L.H. Gate Stop Hi/Lo Gate (Serial #0781239 & Later)

17 49-0036 L.H. Chain Return Seal

18 49-0035 R.H. Chain Return Seal

19 25-8067-1 Chain Return Seal Mount Strap

20 52-0005-2 24" Broom (Prior to Serial#0781239)

52-0005-6-1 35-1/2" Broom Notched (Serial #0781239 & Later)

21 100-8013-6 Rear Gate Stop

22 851-5013-1.5Z ½-13 x 1-1/2" M.B. Zinc

23 815-5013-Z ½-13 Nylon Insert Locknut Zinc

24 52-0005-3 18-1/2" Broom (Prior to Serial #0781239)

52-0005-6-3 7-3/4" Left Inner Broom (Serial #0781239 & Later)

52-0005-6-4 12-1/4" Right Inner Broom (Serial #0781239 & Later)

52-0005-4 Right Inner 21" Broom (Prior to Serial #0781239)

25 49-0088 Side Gate Belting Seal 1/8x21/2x66”

26 57-0009-2 S-Hook

27 33-0028 Handle Nut

28 811-5013-4Z ½ x4" Eyebolt (6" Overall)

29 25-8065 Seal Gasket (Prior to Serial #0781239)

25-8060-26 Lower Side Seal Filler Panel (Serial #0781239 & Later)

30 25-8066 Main Roller Center Mount Cover

31 25-8060-21 Rear Belting Seal Metal Strip

32 49-0042 Rear Belting Seal

33 25-8060-27 Side Seal Filler Panel (Serial #0781239 & Later)

34 25-8060-23 Rear Light Mount Bracket

35 56-0050 Light Harness and Lamp Kit

56-0050-1 Center Lamp Bar Only

56-0050-2 Left Rear Lamp Only

56-0050-3 Harness Only

56-0050-4 Right Rear Lamp Only

36 56-0051 Light Harness Jumper-Y-Plug Assy.

--34-- 8100 Rear Unload

Page 36

GATE DELAY PACKAGE (#8100 - GATE) (PRIOR TO SN 0781253)

GATE DELAY INSTRUCTIONS & ADJUSTMENTS

The purpose of the gate delay system is to hold the rear swinging gate in the open position until the apron has cleaned

all of the forageout of the box. By adjusting the flow controlthe speed in which the gatecloses can be regulated. When

the flow control is properly adjusted the gate will slowly close as the remainder of the forage is being unloaded. Once

the box is completely unloaded the gate delay will reach a trip position with the trip arm moving the lower cylinder shaft

out of the horizontal slot and allow the gate to trip closed and latch. For proper operation adjust as follows. When the

gate is completely closed (tight to rear upright) the cable and eyebolt assembly should be adjusted so the cable has no

slack. Cable should be tight but not over tightened. If cable and eyebolt is over tightened the lower cylinder will trip out

of the L-shaped slot on the lower bracket prematurely and the gate will try to close before the cylinder is fully extended.

If the cable and eyebolt is too loose the lower cylinder will not trip out of the L-shaped slot and the cylinder will reach its

maximum stroke and the trip arm will still not be in the tripped position allowing the gate to close. The gate will be held

open by the top cylinder bracket and the bracket may become damaged over time. The eyebolt and cable will need to

be adjusted periodically to maintain proper operation.

8100 Rear Unload --35--

Page 37

GATE DELAY PACKAGE (#8100 - GATE)

Used prior to SN 0781253

KEY PART NO. DESCRIPTION

1 55-0095 1/8" to 3/8" NPT Reducer

2 30-0015 1/4x90 Degree Elbow

3 25-8095 Oil Reservoir Assembly

4 55-0097 3/8 to 3/8" Hydraulic Nipple

5 55-0094 Flow Control Valve

6 55-0096 3/8 NPT x 90 Degree Male Pipe Elbow

7 25-8096 Gate Release Trip Arm Assembly

8 25-8092-1 Gate Regulator Top Shaft Assy.

9 25-8090-1 Top Cylinder Bracket Assy.

10 55-0093 Hydraulic Cylinder

11 952-0007-1 7-1/4" Nylon Tie Strap

12 25-8098 Cable/Eyebolt Assy.

13 25-8097-1 Lower Sleeve Spacer

14 25-8093-1 Lower Shaft Plate Assy.

15 25-8095-6 Top Copper Line Assy.

16 25-8101 Ground Control Rod Assy. W/Grip

17 51-0007 Handle Grip

18 933-3804 5/16 x 4” Eyebolt

19 825-25-1Z 1/4x1" Self Tapping Screw

--36-- 8100 Rear Unload

Page 38

GATE DELAY PACKAGE (#8100 - GATE) (SN #0781253 & LATER)

8100 Rear Unload --37--

Page 39

GATE DELAY PACKAGE (#8100 - GATE)

SN #0781253 & Later

KEY PART NO. DESCRIPTION QTY.

1 25-8090-1 8100 GATE TOP CYLINDER BRACKET 1

2 25-8105 SIDE MOUNT GRND CONT ROL ROD 1

3 25-8104 SIDE MOUNT OIL RESEVOIR 1

4 25-8093-1 8100 GATE LOWER SHAFT BRACKET 1

5 24-8009 SIDE MT OIL RES 12" HOSE SHIELD 25-1/2" AR

6 24-8010 SIDE MNT OIL RES HOSE SHIELD 13-1/2" AR

7 55-0093 HYD CYLINDER 2" BORE 8" STROKE 18-1/4" 1

8 955-3802-10 CYLINDER PIVOT PIN WITH CLIP 1

9 952-0001-7 NYLON TIE STRAPS 1

10 55-0094 FLOW CONTROL 1

11 55-0096 3/8" NPTF 90* MALE PIPE ELBOW 1

12 55-0193 1/4"x 52" LONG HOSE HI GATE W/EXT AR

55-0192 1/4"x 40" LONG HOSE REG GATE NO/EXT AR

13 55-0194 1/4"x 62-1/2"" LONG HOSE HI GATE W/EXT AR

55-0193 1/4"x 52" LONG HOSE REG GATE NO/EXT AR

14 811-3816-3Z 3/8-16x3" EYEBOLT ZINC 1

25-8098 GATE TRIP CABLE ASSEMBLY W/EYEBOLT 1

15 810-3816-Z 3/8 SPIN LOCK NUT 2

16 36-0009 1/8" STAINLESS AIRCRAFT CABLE (BY THE FT) 2.41

17 823-19-2 3/16X2" COTTER PIN 1

18 25-8092-1 REAR GATE TOP SHAFT ASSY. 1

19 25-8106-1 GROUND CONTROL ROD BRACKET 1

20 55-0196 3/8Mx1/4" SWIVEL FEMALEx90 ELBOW 1

21 55-0195 3/8 MALE-1/4FEMALE STREET ELBOW 2

22 55-0191 1/4" MALE TO 1/4" FEMALE SWIVEL COUPLER 1

23 25-8096 GATE RELEASE TRIP ARM ASSEMBLY 1

24 25-8097-1 GATE LOWER SLEEVE SPACER 1

25 33-1003 RUBBER GROMMET 1

--38-- 8100 Rear Unload

Page 40

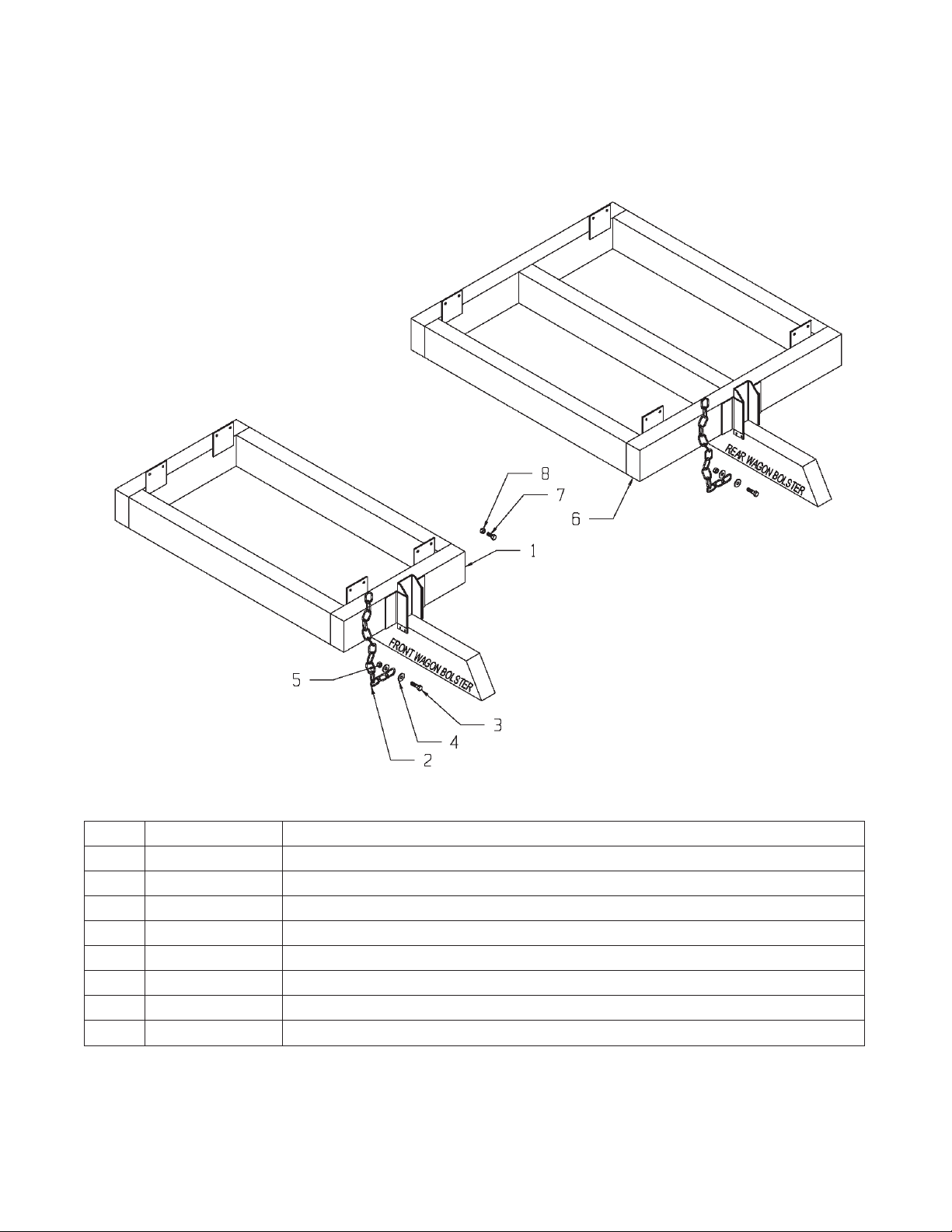

OPTIONAL WAGON MOUNT KIT (#8100 - WAGON)

KEY PART NO. DESCRIPTION

1 25-8025 Wagon Mount Weldment - Front

2 75-0341-4-HD Chain, 61” Long

3 851-3816-1.5Z Bolt, 3/8-16 x 1.5 Hex Head Machine Bolt

4 805-0038-Z Washer, 3/8” Flat

5 814-3816-Z Nut, 3/8-16 Center Lock

6 25-8026 Wagon Mount Weldment - Rear

7 851-5013-1.25Z Bolt, ½-13 x 1.25 Hex Head Machine Bolt

8 815-5013-Z ½-13 Nylon Locknut

--39-- 8100 Rear Unload

Page 41

MEYER FORAGE BOX “MAINTENANCE RECORD”

Model No. ____________________ Serial No. ____________________

Delivery Date: ____________________

DATE SERVICE PERFORMED DATE SERVICE PERFORMED

--40-- 8100 Rear Unload

Page 42

“SPECIFICATIONS”

Truck Mount Models

DIMENSIONS

Inside Length 18' 19'-4" 22' 24'8"

Inside Width 97" 97" 97" 97"

Inside Height 72.5" 72.5" 72.5" 72.5"

Overall Length 18'9" 20'1" 22'9" 25'5"

Overall Width 102" 102" 102" 102"

Overall Height - Tailgate 103" 103" 103" 103"

Overall Side, Height w/6"

Stringers

Weight 6100# 6520# 7120# 7760#

Stringer Width (Truck Mount) 33-1/2" 33-1/2" 33-1/2" 33-1/2"

Capacity (Struck level) cu. ft. 880 978 1075 1200

SPECIFICATIONS

Maximum Net Load 25 ton 25 ton 25 ton 25 ton

Roller Chain Drive - Aprons 80 - 120 80 - 120 80 - 120 80 - 120

Apron Chains (Pintle) 667XH 667XH 667XH 667XH

HP Requirements (Min.) - Truck 50 HP 50 HP 50 HP 50 HP

Rear Drive Shaft - Heavy Duty 2-1/2" Hvy Tubing 2-1/2" Hvy Tubing 2-1/2" Hvy Tubing 2-1/2" Hvy Tubing

Upright Spacing 16" on center 16" on center 16" on center 16" on center

Upright Constructions 2" x 2" Tubing 2" x 2" Tubing 2" x 2" Tubing 2" x 2" Tubing

Power Source (540 RPM) PTO or Hyd. PTO or Hyd. PTO or Hyd. PTO or Hyd.

Unloading Time (PTO) 30 sec. 30 sec. 30 sec. 30 sec.

OPTIONS

All Fiberglass Plywood Sides STD. STD. STD. STD.

All Superslick Floor STD. STD. STD. STD.

Automatic Roller Chain Tighteners STD. STD. STD. STD.

Automatic Rear Door Latching STD. STD. STD. STD.

Front Gate Viewing Window STD. STD. STD. STD.

Semi-Automatic Roller Chain Oiler STD. STD. STD. STD.

Tandem Axle Tire Fenders STD. STD. STD. STD.

Transport ag. Lights STD. STD. STD. STD.

Roll Tarp Cover OPT. OPT. OPT. OPT.

Personalized Farm Name on

Sides

Truck Mount Tie Down Kit/Factory

Mount

8118 8120 8122 8124

REAR UNLOAD

90" 90" 90" 90"

STD. STD. STD. STD.

OPT. OPT. OPT. OPT.

Manufactured by:

Meyer Mfg. Corp.

County Hwy. A West

P.O. Box 405

Dorchester, Wisconsin 54425-0405

Phone 715-654-5132 · FAX 715-654-5513

1-800-325-9103

www.meyermfg.com

E-mail: sales @meyermfg.com

Farm Equipment Buyers Trust the Name Meyer!

--41-- 8100 Rear Unload

Page 43

NOTES

--42-- 8100 Rear Unload

Page 44

A

Loading...

Loading...