Meyer 4216, 3216, 4222, 3218, 4218 User Manual

...

OPERATORS AND PARTS MANUAL NO. 03-6-TSS-F&R

FOR

3200 & 4200 SERIES

TSS VARIABLE SPEED MODEL

Front & Rear

Unload Forage Boxes

with Independent Outfeed Clutch

3200 SERIES:

Model 3216

Model 3218

Model 3220

DO NOT OPERATE EQUIPMENT UNTIL THIS MANUAL HAS BEEN READ AND UNDERSTOOD.

4200 SERIES:

Model 4216

Model 4218

Model 4220

Model 4222

10/03

Manufactured by

County Hwy. A West

P.O. Box 405

Dorchester, Wisconsin 54425-0405

Phone 715-654-5132 • FAX 715-654-5513

1-800-325-9103

www.meyermfg.com

E-mail: sales@meyermfg.com

TABLE OF CONTENTS

TABLE OF CONTENTS ...................................................................1

MANUFACTURER’S WARRANTY ..........................................................3

INTRODUCTION ........................................................................4

SAFETY PRECAUTIONS .................................................................5

SAFETY FIRST .........................................................................6

WARNING: .............................................................................8

EMERGENCY STOP TRIP LOCATIONS ..................................................8

OPERATION OF THE EMERGENCY STOP ...............................................8

RESETTING THE EMERGENCY STOP ..................................................8

PRE-OPERATION .......................................................................9

TRANSPORTING........................................................................9

TRUCK MOUNT FORAGE BOXES......................................................11

FRONT UNLOAD DRIVE COUPLER “SET-UP” (PTO OR HYDRAULIC DRIVE) ......................11

REAR UNLOAD

FRONT UNLOAD

FORAGE BOX CONTROL LEVERS ........................................................15

UNLOADING THE FORAGE BOX ..........................................................16

START UP PROCEDURES ...............................................................16

SHUTDOWN PROCEDURES .............................................................17

REAR UNLOAD

LUBRICATION .........................................................................20

DAILY LUBRICATION ................................................................20

BEGINNING OF CROP MAINTENANCE .................................................20

END OF CROP CLEANUP AND MAINTENANCE ..........................................21

TWO-SPEED OPERATION ...............................................................22

CONTROL LEVER ..................................................................22

UNLOADING THE FORAGE BOX ......................................................22

START UP PROCEDURES:

TWO SPEED LUBRICATION AND MAINTENANCE............................................24

ROLLER CHAIN DRIVES .............................................................24

RANGE CONTROL CLUTCH ENGAGEMENT .............................................24

DAILY LUBRICATION MAINTENANCE ..................................................24

BEGINNING OF CROP MAINTENANCE .................................................24

END OF CROP CLEANUP AND MAINTENANCE ..........................................24

DRIVE COUPLER “SET-UP” (PTO OR HYDRAULIC DRIVE) .......................13

VARIABLE SPEED OPERATION WITH INDEPENDENT OUTFEED CLUTCH ........15

OPERATION PTO OR HYDRAULIC DRIVE.....................................18

...........................................................22

CLEAN-OUT PANEL..............................................................25

CROSS CONVEYOR CHAIN .......................................................25

MAIN APRON CHAINS ............................................................25

3200 & 4200 Series --1–

ADJUSTMENTS........................................................................25

ROLLER CHAIN DRIVES ..........................................................28

RANGE CONTROL CLUTCH ADJUSTMENT ..........................................28

VARIABLE SPEED BELT REPLACEMENT ............................................28

VARIABLE SPEED CONTROL ADJUSTMENT .........................................28

INDEPENDENT OUTFEED CLUTCH BELT REPLACEMENT..............................29

INDEPENDENT OUTFEED CLUTCH ADJUSTMENT ....................................29

REPAIR PARTS ........................................................................31

TROUBLE SHOOTING ..................................................................62

SPECIFICATIONS ......................................................................63

3200 & 4200 Series --2–

NEW MEYER (FRONT & REAR UNLOAD) FORAGE BOX

Jan. 1, 1995

MANUFACTURER’S WARRANTY

I. The “Product Registration & Inspection Certificate” along with the original billing invoice “Owner’s Registration Form”

must be completed in full and promptly returned to Meyer Mfg. Corp. for this warranty to become both valid and effective.

All warranties on New Meyer Forage Boxes shall apply only

Corp. dealership.

to the original retail customer from an authorized Meyer Mfg.

II. This warranty shall not

dent, incorrect

Meyer Mfg. Corp.

III. Meyer Mfg. Corp. warrants New Meyer Forage Boxes to be free from defects in material and workmanship under recom

mended use and maintenance service, as stated in the Operator’s and Parts Manual," as follows:

A. Meyer Mfg. Corp. will repair or replace F.O.B. Dorchester, WI, as Meyer Mfg. Corp. elects, any part of a new Meyer

Forage Box which is defective in material or workmanship:

1. Without charge for either parts or labor during the first (1) year from purchase date to the original retail

2. Without charge for parts only

B. In addition to the above basic warranty, Meyer Mfg. Corp. will repair or replace F.O. B. Dorchester, WI as Meyer Mfg.

Corp. elects:

1. Any part of the following which is defective in material or workmanship (not neglect to recommended

Two (2) Years: a. The 3200 and 4200 Series enclosed main apron drive Superior gearbox assembly, Meyer

apply to any Meyer Forage Box which has been subjected to misuse, negligence, alteration, acci

operating procedures, or which shall have been repaired with parts other than those obtained through

customer.

during the second (2) year from purchase date to the original retail cus

tomer.

use and service) without charge for parts only

purchase to the original retail customer:

#19-0024 and #19-0025.

b. The D667H and D667X pintle main apron chain assembly.

(not labor) during the stated time periods from date of

-

-

-

2. Any part of the following which is defective in material or workmanship (not neglect to recommended

use and service) with a “pro-rated” charge for parts only

date of purchase to the original retail customer:

Ten (10) Years: a. The all bolted or all welded steel frame box structure.

b. The aluminized steel or galvaneal steel painted panels which comprise the sides and rear of the

box portion (not front unit) of the forage box, upon evidence satisfactory to Meyer Mfg. Corp., that

any such panel either rusted or corroded through or cracked or split.

IV. COMMERCIAL USE: Coverage as in paragraph III A1 ONLY, except warranty coverage is for (90) days for parts and la

bor to the original commercial retail customer.

V. Repairs eligible for labor warranty must be made by Meyer Mfg. Corp. or anauthorized Meyerdealership. Theoriginal re

tail customer is responsible for the transportation of the forage box to the dealership for warranty service or for any ser

vice call expenses.

VI. Except as stated above, Meyer Mfg. Corp. shall not be liable for injuries or damages of any kind or nature, direct, conse

quential, or contingent, topersons orproperty. This warranty does notextend to loss of cropor for any other reasons.

VII. No person is authorized to give any other warranties or to assume any other obligation on Meyer Mfg. Corp.’s. behalf un

less made or assumed in writing by MeyerMfg. Corp. This warranty is the sole and exclusivewarranty which is applicable

in connection with themanufacture andsale of this product andMeyer Mfg. Corp.’s responsibility islimited accordingly.

VIII. This warranty is effective on all sales of Meyer Forage Boxes made after serial #95T2201.

(not labor) during the stated time period from

Optional Equipment-Tarp, scales etc. warranty-See original equipment warranty.

-

-

-

-

-

3200 & 4200 Series --3–

INTRODUCTION

Congratulations on your purchase of a new Meyer farm

equipment product. Undoubtedly you have given much

consideration to your purchase and we’re proud that you

have selected Meyer. Pride in craftsmanship, engineer

ing and customer service have made Meyer products the

finest in the farm equipment industry today.

There is no substitute for quality. That is why thousands

of people like you have purchased Meyer farm equip

ment. They felt it was the best equipment to serve their

farming needs, now and in years to come. We ask that

you follow our policy of “safety first,” and we strongly sug

gest that you read through the owner’s manual before

operating your Meyer farm equipment.

Meyer Manufacturing Corporation wants to thank you for

not compromising quality. We are determined to offer ex

cellence in customer service as well as provide you with

the very best value for your dollar.

REMEMBER:

FARM EQUIPMENT BUYERS

TRUST THE NAME MEYER!

Sincerely,

All Employees of

MEYER MANUFACTURING CORPORATION

Meyer Mfg. Corp. reserves the right to make improve

ments in design, or changes in specifications at any time,

without incurring any obligation to owners of units previ

ously sold.

IMPORTANT:

At the front of this manual is a Product Registration and

Inspection Certificate. Be sure your dealer has com

pleted this certificate and promptly forwarded a copy to

Meyer Manufacturing to validate the manufacturer’s

warranty. The product model and serial number are re

corded on this certificate and below for proper identifica

tion of your Meyer Forage Box by your dealer and the

manufacturer when ordering repair parts. The serial

number plate is found near the control levers on your for

age box and stamped in the front corner of the left hand

end frame.

-

Model No. _________________________________

Serial No. _________________________________

Date of Purchase ___________________________

At the back of this manual is the repair parts section. All

replacement parts are to be obtained from or ordered

through your Meyer dealership. When ordering repair

parts, refer to the parts section and give complete information including quantity, correct part number, detailed

description and even Model No. and Serial No. of the forage box which needs repair parts.

NOTE: All references to right hand (RH) , left hand (LH),

front and rear apply to the product as viewed from the

rear of the box.

IMPORTANT: The standard forage box header unit

discharges to the LH side and the parts illustrations de

pict these units. If you have an optional RH unit, always

-

specify the part number shown in this book followed by

-RH. Nearly all header parts appear similar to the stan

-

dard unit but are really mirror images. Box parts are all

identical. If you specify -RH and there is no difference

in the item you wish to order, this will be properly inter

preted at the factory and will not cause any problem.

-

-

-

-

-

-

-

This supersedes all previous published instructions.

3200 & 4200 Series --4–

SAFETY PRECAUTIONS

This symbol is used to call attention to instructions concerning personal safety. Be sure to observe and

follow these instructions. Take time to be careful!

WARNING: BEFORE ATTEMPTING TO OPERATE THIS FORAGE BOX, READ AND STUDY THE FOL

LOWING SAFETY INFORMATION. IN ADDITION, MAKE SURETHAT EVERYINDIVIDUAL WHO OPERATES OR

WORKS WITH THE FORAGE BOX, WHETHER FAMILY MEMBER OR EMPLOYEE, IS FAMILIAR WITH THESE

SAFETY PRECAUTIONS.

The emergency stop mechanism stops only the front unloading unit from operating and not the rear unloading oper

ation of the forage box! Trip the emergency stop regularly with the trip cables to ensure that it will shut the front un

loading unit down in an emergency.

Require anyone who will operate this forage box to read and completely understand this owner’s manual. Give necessary instruc

tions.

DO NOT operate, service, inspect or otherwise handle this forage box until all operators have read this Owner’s Manual and have

been properly trained in its intended usage.

DO NOT allow minors (children) or inexperienced persons to operate this forage box.

If the forage box becomes clogged, shut off the tractor engine and allow all mechanisms to stop. Disconnect PTO shaft or hydraulic

drive supply hoses (relieve hydraulic pressure). Then, clean or work on the forage box as required.

Always shut off power and disconnectPTO shaftor Hydraulic drive supply hoses (relieve hydraulicpressure) from tractor to prevent

accidental startup or unexpected movement before working on forage box.

DO NOT clean, adjust or reset the emergency stop while the forage box is in motion.

Make sure all hydraulic fittings are tight and that all hoses are in good condition. Hydraulic fluid escaping under pressure can have

sufficient force to penetrate skin and cause serious injury. Never investigate for hydraulic leaks by using a part of the body to feel for

escaping fluid.

Inspect when first delivered and regularly thereafter; that all connections and bolts are tight and secure before operating.

-

-

-

-

Know how to stop the unloading unit of the forage box before starting it!

DO NOT operate until all shields and guards are in place and securely fastened.

Make certain everyone is clear of the forage box before applying power.

Keep hands, feet and clothing away from moving parts. Loose or floppy clothing should not be worn by the operator.

Stay well clear of the cross conveyor and discharge opening while operating.

DO NOT step up on any part of the forage box at any time. DO NOT use the PTO guard as a step.

DO NOT step over the power take-off shaft. Stay clear of the PTO at all times.

Keep PTO shaft telescopingtube shieldsturning freely. Keep PTO mastershield on tractor. Replace damagedor missing shields.

Never operate PTO above normal 540 RPM rating. Never

Keep the forage box away from power lines. Contact with electric lines may result in serious injury or death by electrocution!

Use only properly rated running gear and tires.

DO NOT tow at speeds in excess of 20 MPH when transporting this forage box. Never exceed a safe travel speed.

Observe all applicable traffic laws when transporting on public roadways (where legal to do so). Check local laws for all highway

lighting and marking requirements.

Always install a SMV emblem on forage box for transporting on roadways and keep this emblem clean and bright.

MEYER MFG. CORP. PROVIDES GUARDS FOR EXPOSED MOVING PARTS FOR THE OPERATOR’S PROTECTION; HOW

EVER, SOME AREAS CAN NOT BE GUARDED OR SHIELDED IN ORDER TO ASSURE PROPER OPERATION. THE OPERA

TOR’S MANUAL AND DECALS ON THE FORAGE BOX ITSELF WARN YOU OF DANGERS AND MUST BE READ AND

OBSERVED CLOSELY!

connect forage box PTO shaft to a 1000 RPM tractor PTO.

-

-

Study the Above Safety Rules

FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

3200 & 4200 Series --5–

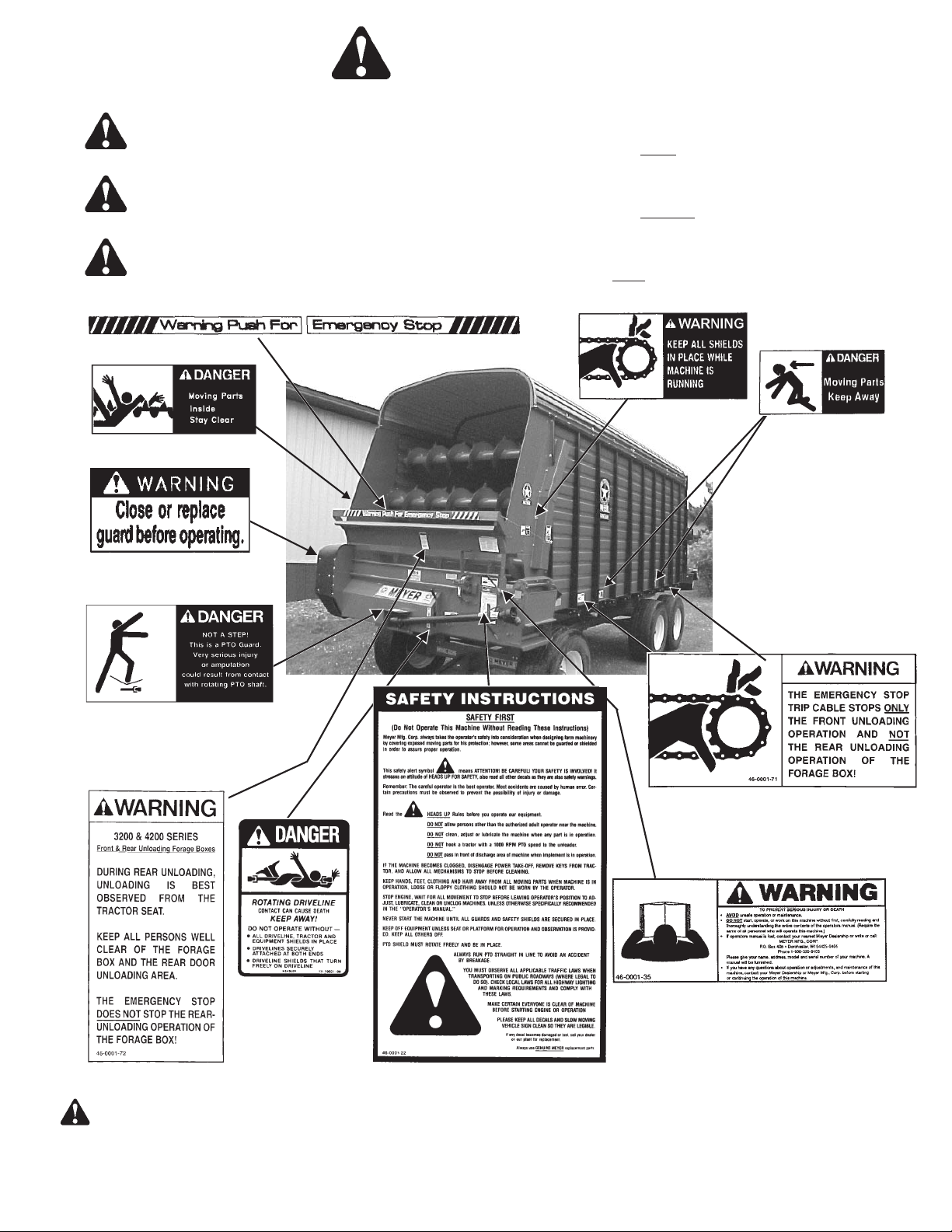

SAFETY FIRST

A brief definition of signal words that are used in this manual is as follows:

DANGER indicates an imminently hazardous situation which, if not avoided, WILL

jury.

WARNING indicates a potentially hazardous situation which, if not avoided, COULD

injury and includes hazards that are exposed when guards are removed.

CAUTION indicates a potentially hazardous situation which, if not avoided, MAY

It is also used to alert against unsafe practices.

46-0001-14 46-0001-15

46-0001-5

46-0001-26

(INSIDE COVER)

result in death or serious in

result in death or serious

result in minor or moderate injury.

46-0001-4

46-0001-20

-

46-0004-2

(ON PTO GUARD)

46-0001-71

13-10021-00

46-0001-72

CAUTION: READ ALL DECALS ON THE FORAGE BOX AND IN THIS MANUAL. KEEP THESE DECALS CLEAN AND RE

PLACE ANY LOST OR DESTROYED DECALS. BECOME FAMILIAR WITH ALL TRACTOR AND FORAGE BOX CONTROLS.

46-0001-22

46-0001-35

-

3200 & 4200 Series --6–

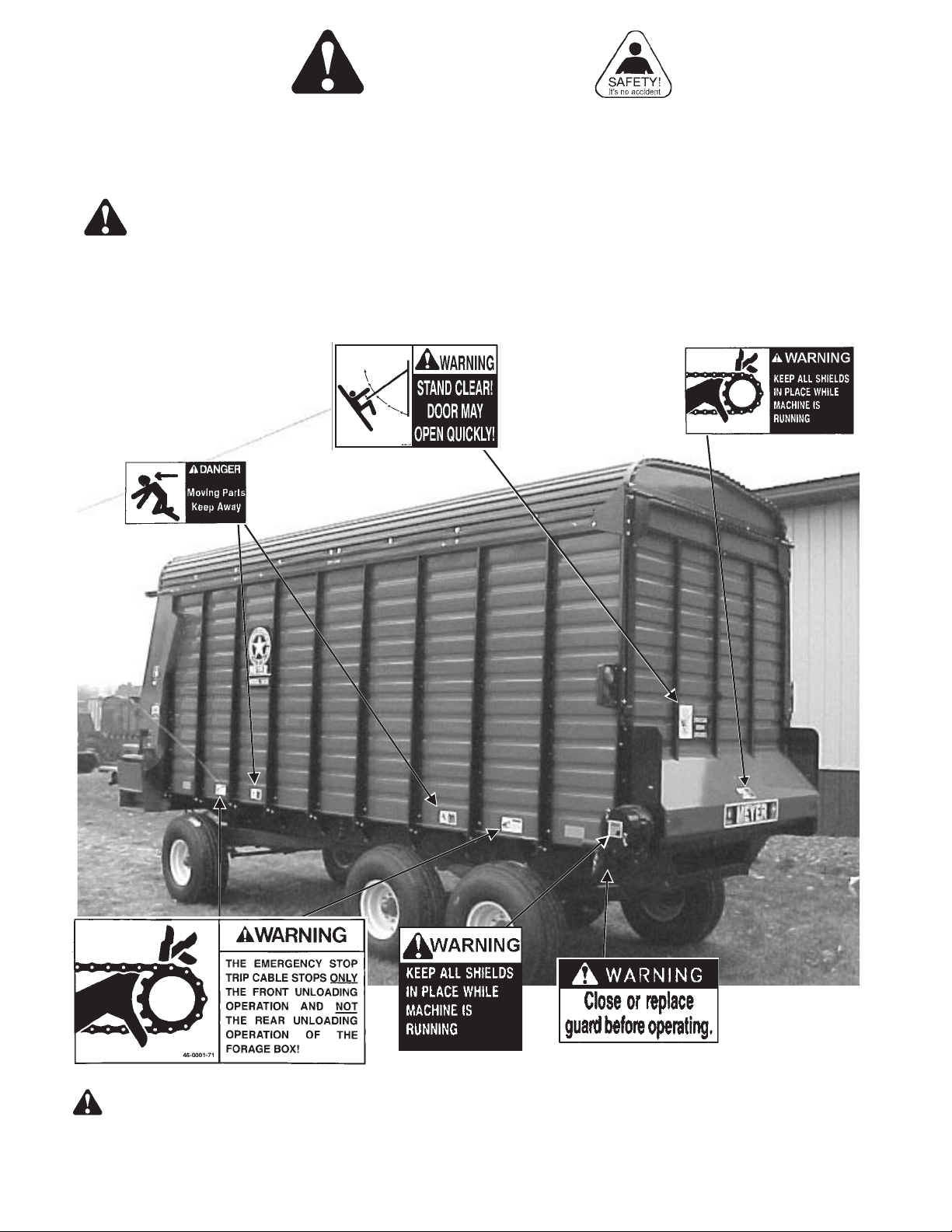

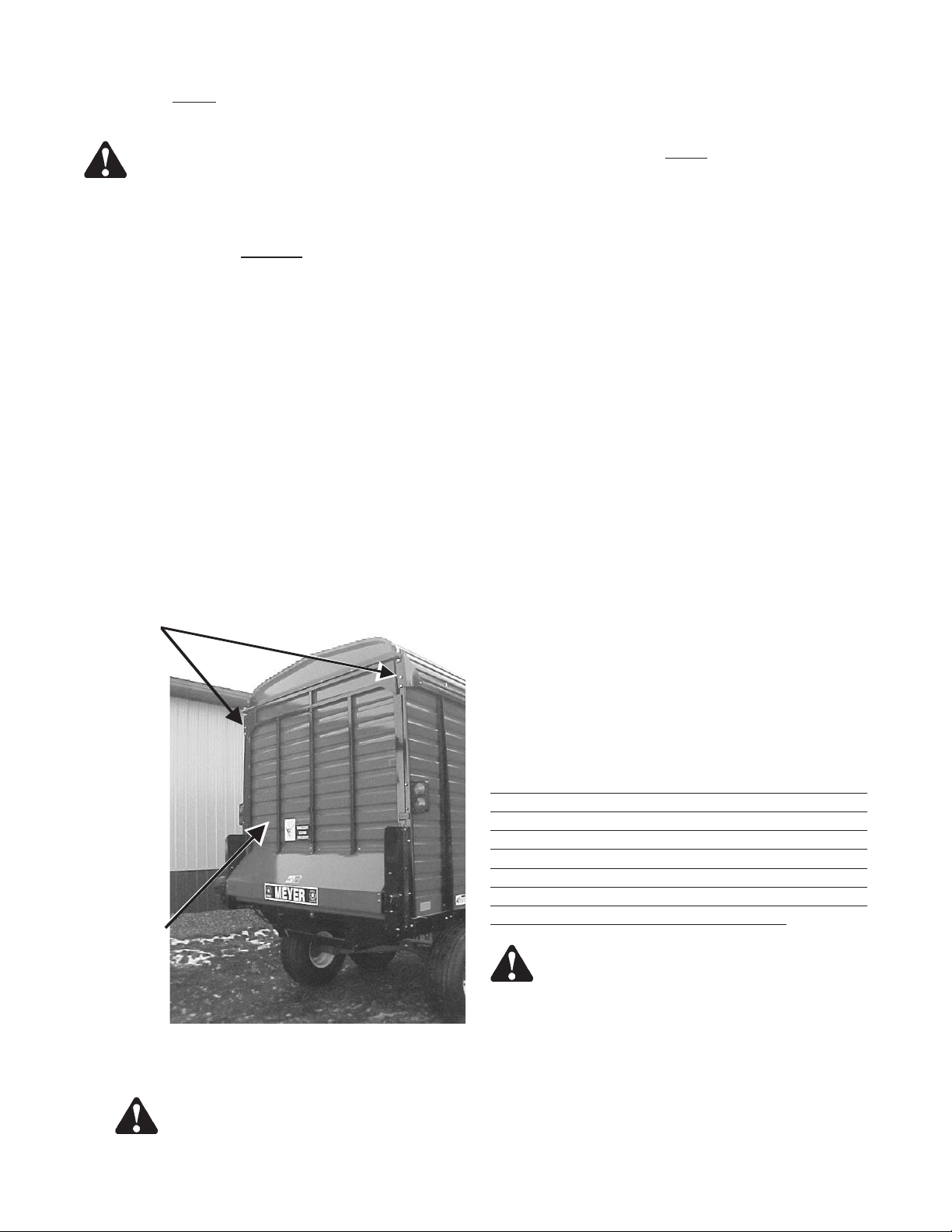

SAFETY FIRST

The Meyer Forage Box is manufactured with operator safety in mind. Located on the forage box are various decals to

aid in operation and warn of danger or caution areas. Pay close attention to all decals on the forage box.

DO NOT REMOVE ANY DECALS. IF DECALS ARE LOST, DAMAGED OR IF FORAGE BOX IS REPAINTED,

REPLACE DECALS. REMEMBER: DECALS ARE FOR YOUR PROTECTION AND INFORMATION.

46-0001-4

46-0011

46-0001-20

46-0001-4

46-0001-71

CAUTION: READ ALL DECALS ON THE FORAGE BOX AND IN THIS MANUAL. KEEP THESE DECALS CLEAN AND RE

PLACE ANY LOST OR DESTROYED DECALS. BECOME FAMILIAR WITH ALL TRACTOR AND FORAGE BOX CONTROLS.

3200 & 4200 Series --7–

46-0001-26

(UNDER SHIELD)

-

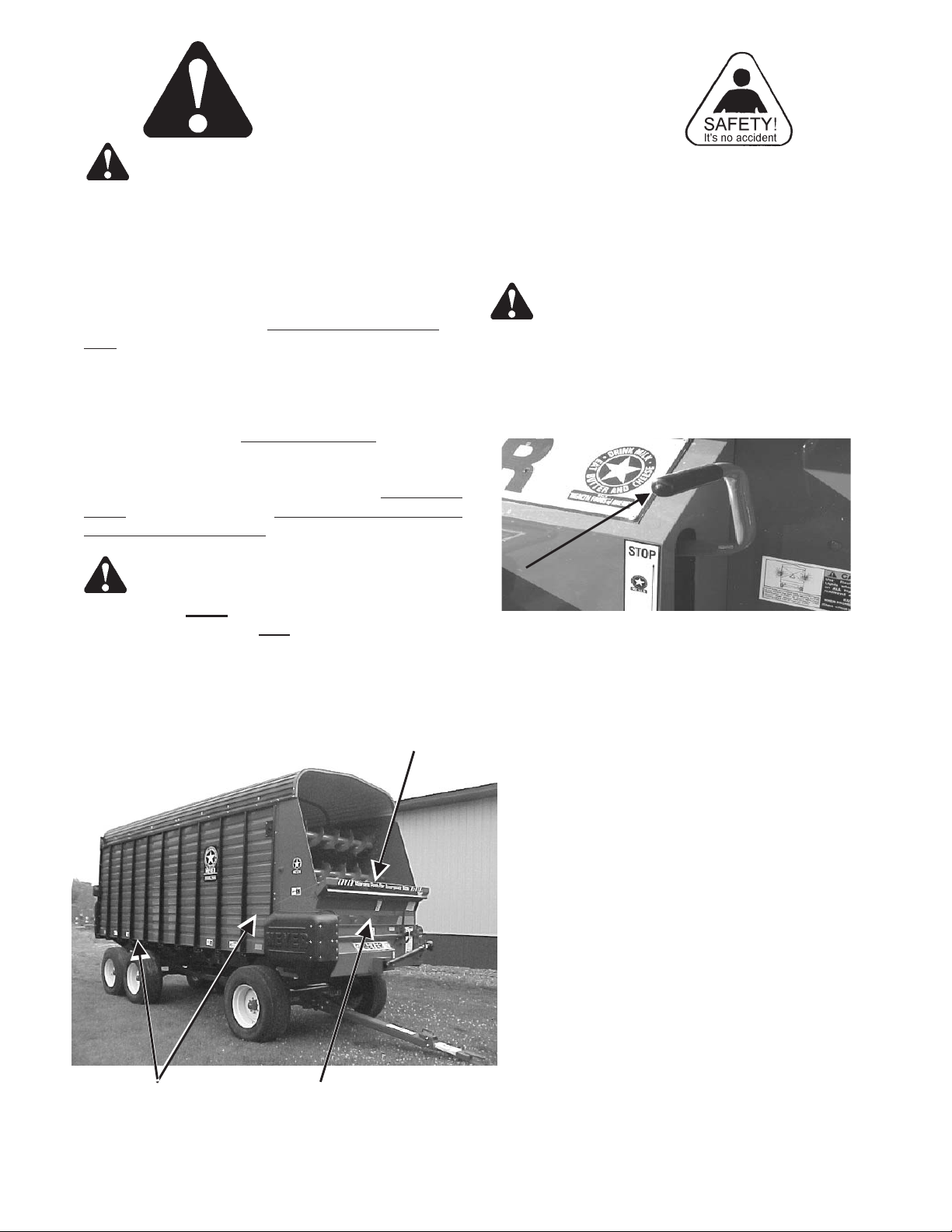

WARNING:

WARNING: IF FOR ANY REASON THE EMERGENCY STOP MECHANISM DOES NOT FUNCTION PROPERLY,

DO NOT USE THE MACHINE UNTIL IT IS REPAIRED. FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL IN

JURY OR DEATH.

-

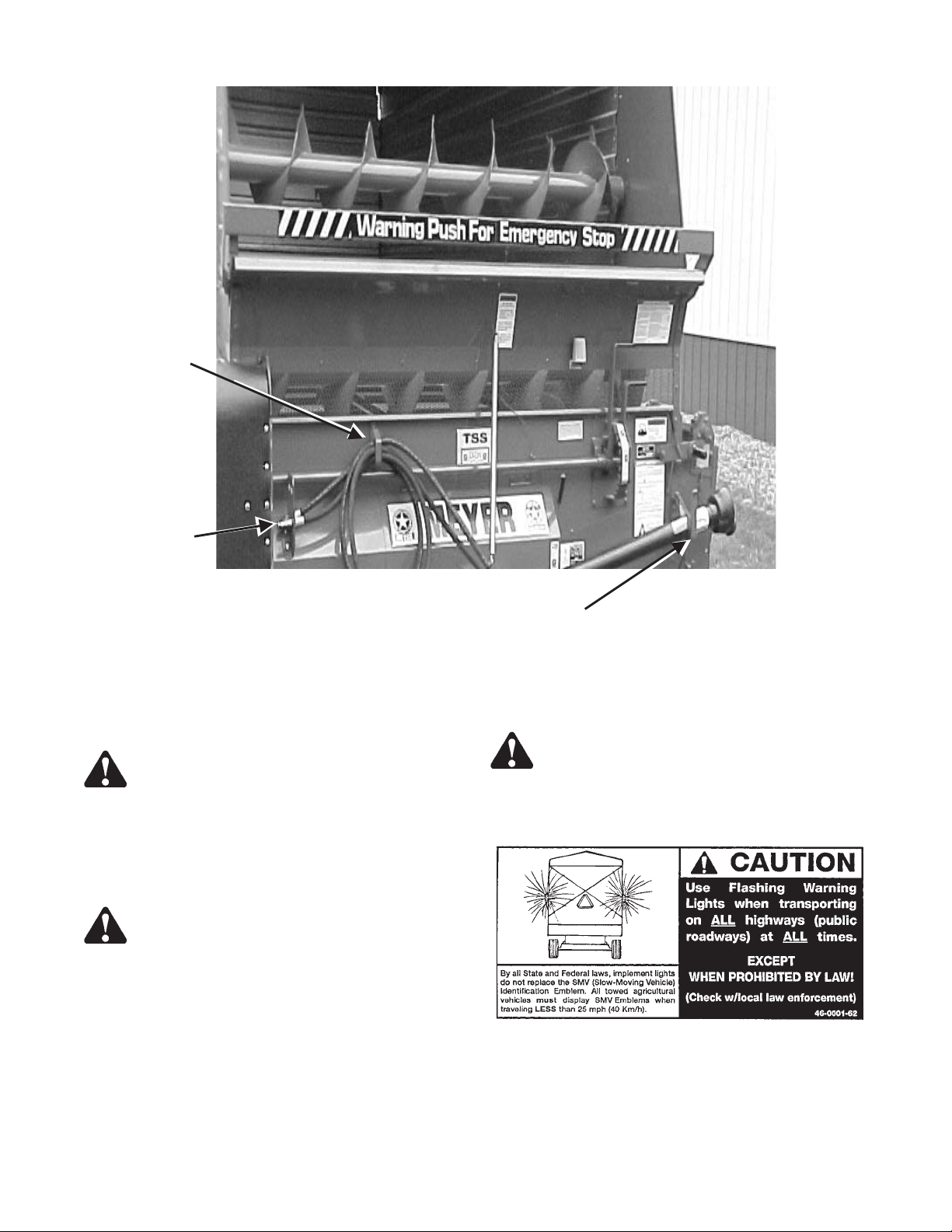

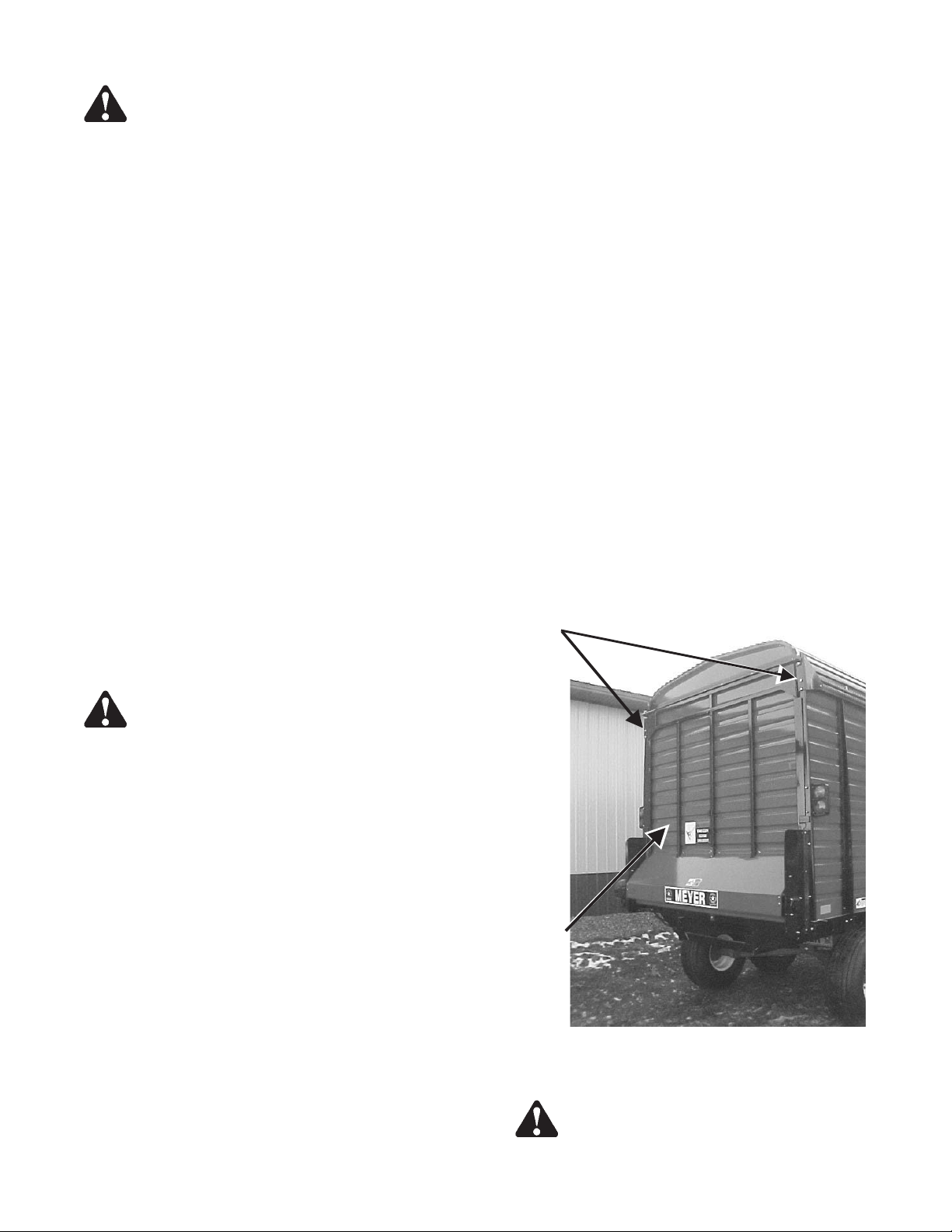

OPERATION OF THE EMERGENCY STOP

Across the upper edge of the front unloading unit is a

“Warning Push For Emergency Stop” pushbar. By

pushing on this bar during front unloading operation

only, the forage box will shut down in an emergency.

Emergency stop trip cables connected to the “Emer

gency Stop” pushbar extend along both sides and down

the front of the forage box. Pulling on these trip cables

will also shut down the front unloading unit

box in an emergency.

Note: The emergency stop mechanism DOES NOT

STOP the PTO drive shaft, nor the rear unloading op

eration of the forage box.

WARNING: THE EMERGENCY STOP MECHANISM STOPS ONLY

FROM OPERATING AND NOT

OPERATION OF THE FORAGE BOX!

THE FRONT UNLOADING UNIT

THE REAR UNLOADING

of the forage

EMERGENCY STOP TRIP LOCATIONS

EMERGENCY STOP

PUSH BAR

RESETTING THE EMERGENCY STOP

WARNING: DO NOT RESET THE EMER

GENCY STOP MECHANISM UNTIL ALL PEOPLE,

TOOLS AND OTHER OBJECTS ARE WELL CLEAR

OF THE FORAGE BOX. FAILURE TO HEED MAY RE

-

SULT IN SERIOUS PERSONAL INJURY OR DEATH.

-

INDEPENDENT OUTFEED CLUTCH CONTROL

LEVER

To reset the emergency stop mechanism, fully engage the INDEPENDENT OUTFEED CLUTCH con

trol lever into the “RUN” position.

Check frequently to be assured that the emergency

stop mechanism is in proper operating condition.

Slowly engage the tractor PTO and operate the for

age box at an idle speed to ensure it is operating

properly. Push the emergency stop bar across the

upper edge of the front unloading unit, to ensure that

the forage box can be shut down in an emergency.

-

-

-

-

EMERGENCY STOP TRIP

CABLES EXTENDING

ALONG BOTH SIDES

3200 & 4200 Series --8–

EMERGENCY STOP

TRIP CABLE AT

FRONT

Reset the emergency stop and recheck using the

emergency stop trip cables at various locations to en

sure that the forage box can be shut down in an emer

gency. Periodically repeat emergency stop

inspections during the operating season and at all

times keep excessive slack out of the emergency

stop trip cables.

-

-

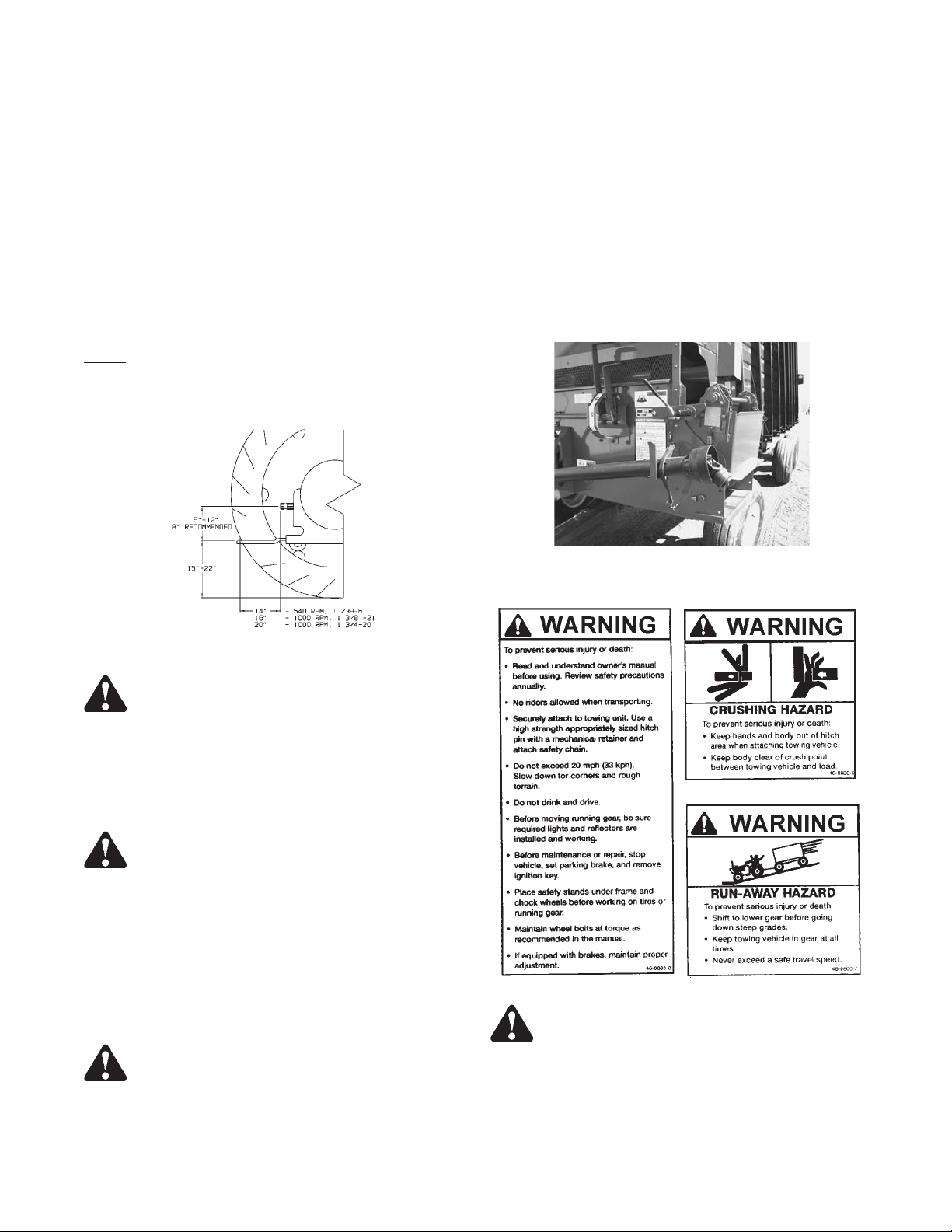

PRE-OPERATION

TRANSPORTING

Be certain your forage box is properly mounted to the

running gear. Consult your dealer if you have any ques

tions about the tie down kit from the manufacturer and il

lustrated in the parts listing of this manual.

DO NOT fill the cross conveyor unloading area with for

age to get extra capacity. Overloading puts unnecessary

pressures and strains on the cross conveyor and auger

drive.

This forage box is to be operated with 540 rpm PTO

. Set your tractor drawbar to conform to the stan

ONLY

dard dimensions as shown on the following illustration.

This will ensure that the PTO drive shaft will not be over

extended.

Always disconnect the PTO drive shaft from the tractor

and return it to the PTO storage bracket on the unloading

unit before transporting. Failure to do this may result in

equipment damage.

If you have a fold down cross conveyor extension, al

ways transport with this extension folded up to reduce

your width. Check and observe that the rear discharge

door is completely latched closed before traveling on

roadways.

-

FOLD DOWN CROSS CONVEYOR EXTENSION

-

DRAWBAR & PTO RELATIONSHIP

DANGER: DO NOT OPERATE WITHOUT PTO

GUARD ON MACHINE AND ON TRACTOR. MAINTAIN

PTO DRIVE SHAFT GUARDS IN OPERATING CONDI

TION. REPLACE THEM IF DAMAGED AND NOT

TURNING FREELY. FAILURE TO HEED MAY RESULT

IN SERIOUS PERSONAL INJURY OR DEATH.

WARNING: INSPECT REGULARLY THAT ALL

CONNECTIONS AND BOLTS ARE TIGHT AND SE

CURE BEFORE OPERATING. FAILURE TO HEEDMAY

RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

Inspect the forage box for proper adjustments as this will

ensure maximum machine performance. See “Adjust

ments” section. Grease and oil the forage box as re

quired. See “Lubrication” section.

WARNING: DO NOT OPERATE UNTIL ALL

SHIELDS AND GUARDS ARE IN PLACE AND SE

CURELY FASTENED. FAILURE TO HEED MAY RE

SULT IN SERIOUS PERSONAL INJURY OR DEATH.

-

-

-

-

WARNING: INSTALL A SMV EMBLEM ON

REAR OF FORAGE BOX FOR TRANSPORTING ON

ROADWAYS. KEEP THIS EMBLEM CLEAN AND

BRIGHT. FAILURE TO HEED MAY RESULT IN SERI

OUS PERSONAL INJURY OR DEATH.

-

-

3200 & 4200 Series --9–

HOSE HOLDER

BRACKET

HOSE TIP HOLDER

IMPORTANT: Support hoses on

Hose Holder Bracket to relieve

weight & stress from hose tip holder.

PROPER PTO DRIVE SHAFT AND HYDRAULIC HOSE STORAGE

PTO DRIVE SHAFT

STORAGE HANGER

Your running gear probably has a telescoping tongue for

convenience to hitch up. Always back up and lock this

tongue in the operating position after hitching.

WARNING: YOU MUST OBSERVE ALL APPLI

CABLE TRAFFIC LAWS WHEN TRANSPORTING ON

PUBLIC ROADWAYS. CHECK LOCAL LAWS FOR

ALL HIGHWAY LIGHTING AND MARKING REQUIRE

MENTS. FAILURE TO HEED MAY RESULT IN SERI

OUS PERSONAL INJURY OR DEATH.

WARNING: DO NOT TOW AT SPEEDS IN EX

CESS OF 20 MPH. FAILURE TO HEED MAY RESULT

IN SERIOUS PERSONAL INJURY OR DEATH.

Operating speed is dictated by the terrain over which you

are traveling. Always use caution. Avoid traveling on

slopes or hills that are unsafe.

If you will travel on public roads and it is legal to do so,

you must know all rules governing such operation. This

will include lighting and brake requirements in addition to

traffic rules. You will also be required to install a safety

chain device on the running gear.

CAUTION: USE FLASHING WARNING LIGHTS

-

WHEN TRANSPORTING ON ALL PUBLIC ROAD

WAYS, EXCEPT WHEN PROHIBITED BY LAW.

-

-

-

Check for traffic constantly. Be sure you can see that no

one is attempting to pass you and that all traffic is suffi

ciently clear from you before making any turns.

-

-

3200 & 4200 Series -- 10 –

Truck Mount Forage Boxes

Depending on the make and model of truck it may be necessary to install a light converter (MEYER PART #56-0028.)

Converter will allow signal lights and brake lights to operate according to DOT lighting standard. Call factory for more

information.

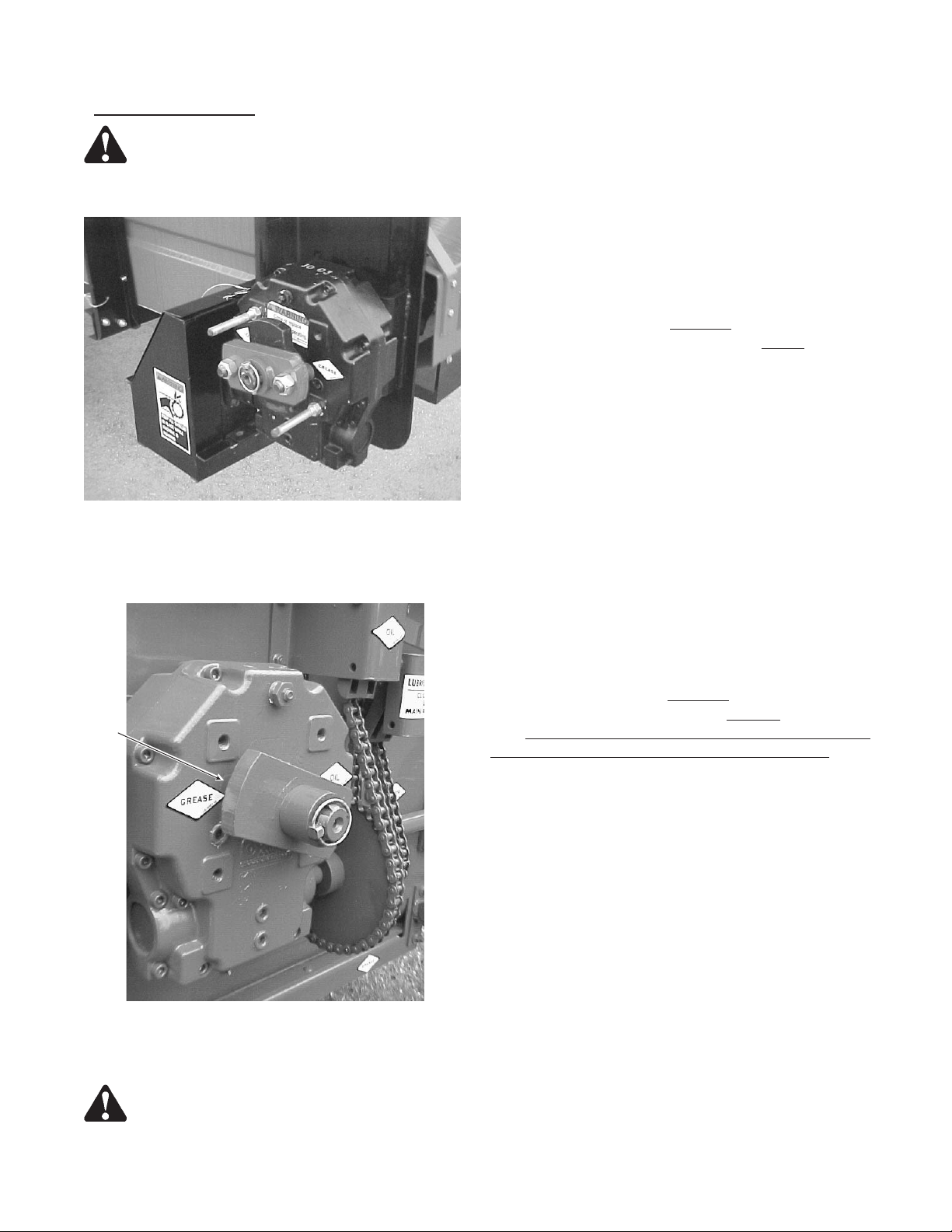

FRONT UNLOAD DRIVE COUPLER “SET-UP”

(PTO OR HYDRAULIC DRIVE)

WARNING: DISCONNECT PTO DRIVE SHAFT AND HYDRAULIC HOSES (RELIEVE HYDRAULIC PRES

SURE) BEFORE CLEANING, ADJUSTING, LUBRICATING OR SERVICING THIS FORAGE BOX. FAILURE TO

HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

STEP 1

Install Coupling Plate and lynch pin onto the large gear

box assembly, splined shaft at the FRONT

box.

(Shield Removed For Illustration Purposes Only)

COUPLING PLATE

of the forage

-

-

STEP 2

QUILL

ZERK

(Shield Removed For Illustration Purposes Only)

SLEEVE SPACER

WARNING: DO NOT OPERATE WITHOUT ALL SHIELDS, GUARDS AND COVERS INSTALLED. FAILURE

TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

3200 & 4200 Series -- 11 –

IMPORTANT! (MUST PERFORM)

Install sleeve spacer and lynch pin onto the hydraulic

drive gearbox at the REAR

splined shaft will be idling in reverseand thegearbox quill

zerk must be greased daily.

of the forage box. The internal

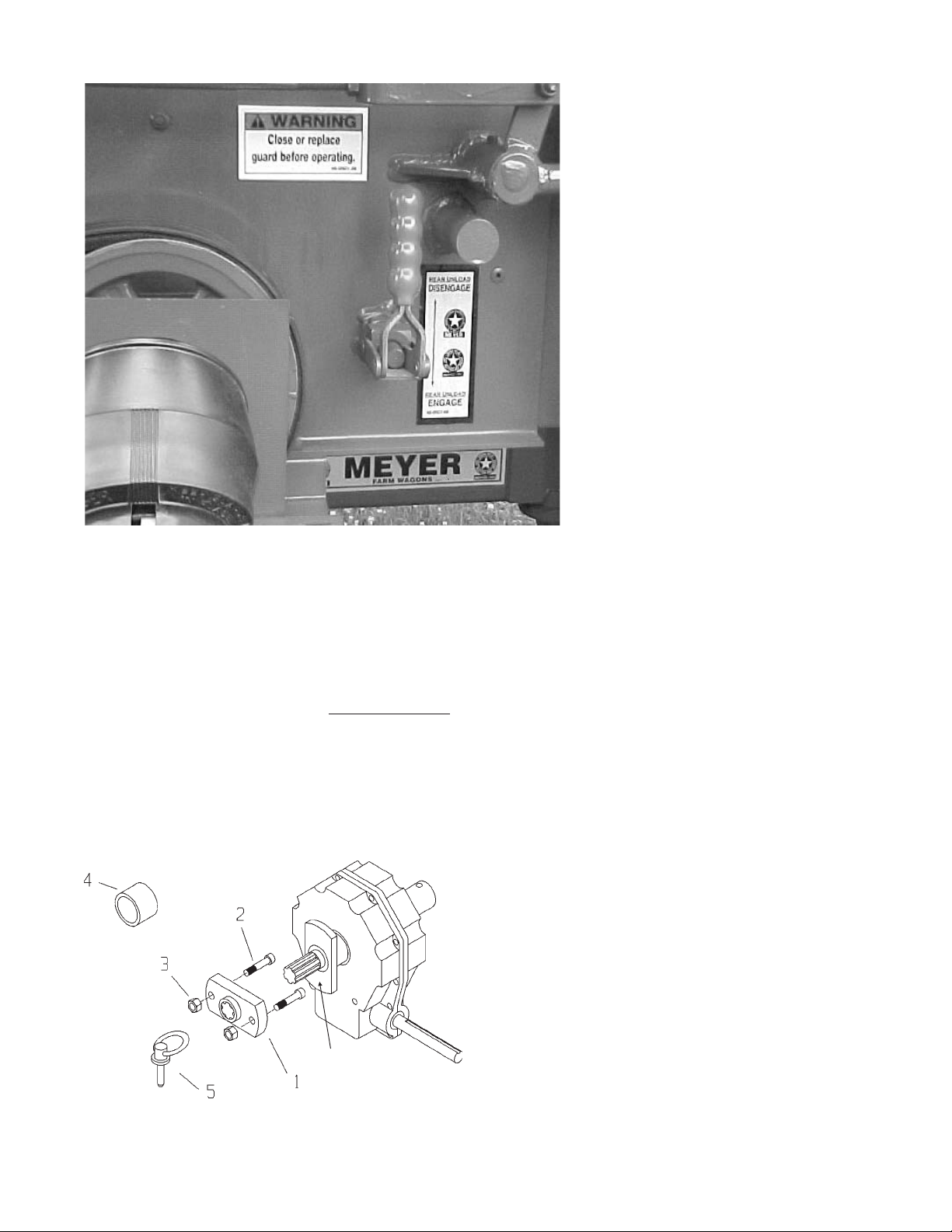

STEP 3

Move the lever for PTO drive rear unloading

to the “Disengage” position (UP).

(Shield Removed For Illustration Purposes Only)

PTO DRIVE REAR UNLOAD DISENGAGE LEVER

Operating Procedures: See Front Unload “VARIABLE SPEED OPERATION with IOC”

Page 15

#37-0010 COUPLING PLATE ASSEMBLY COMPLETE

GEARBOX

DRIVE PLATE

3200 & 4200 Series -- 12 –

KEY PART NO. DESCRIPTION

1 37-0010-4 Coupler Plate

2 831-7516-2 Drive Bolt, 3/4-16 x 2 Allen Head

GR8

3 884-7516-Z 3/4-16 Flange Top Lock Nut

4 43-0020 Idler Sleeve Spacer

5 823-0002 Lynch Pin

REAR UNLOAD DRIVE COUPLER “SET-UP” (PTO OR HYDRAULIC DRIVE)

WARNING: DISCONNECT PTO DRIVE SHAFT AND HYDRAULIC HOSES (RELIEVE HYDRAULIC PRES

SURE) BEFORE CLEANING, ADJUSTING, LUBRICATING OR SERVICING THIS FORAGE BOX. FAILURE TO

HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

STEP 1

Install Coupling Plate and lynch pin onto the large gear

box assembly on the splined shaft at the REAR

age box.

(Shield Removed For Illustration Purposes Only)

COUPLING PLATE

of the for

-

-

-

QUILL

ZERK

SLEEVE SPACER

(Shield Removed For Illustration Purposes Only)

STEP 2

IMPORTANT! (MUST PERFORM)

Install sleeve spacer and lynch pin onto the large gearbox assembly, splined shaft at the FRONT

box. The internal splined shaft will be idling in reverse

and the gearbox quill zerk must be greased daily.

of the forage

WARNING: DO NOT OPERATE WITHOUT ALL SHIELDS, GUARDS AND COVERS INSTALLED. FAILURE

TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

3200 & 4200 Series -- 13 –

INDEPENDENT OUTFEED CLUTCH LEVER

STEP 3

Move the Independent Outfeed Clutch lever to

“STOP” (UP).

NOTE: The PTO driven independent outfeed

clutch can be used to clean out accumulation of

forage from the front unit cross conveyor without

changing the drive coupler for forage box rear un

loading.

STEP 4a (PTO DRIVE) or

Move the lever for PTO drive rear unloading to

the “ENGAGE” position (DOWN).

-

(Shield Removed For Illustrated Purposes Only)

PTO DRIVE REAR UNLOAD ENGAGE LEVER

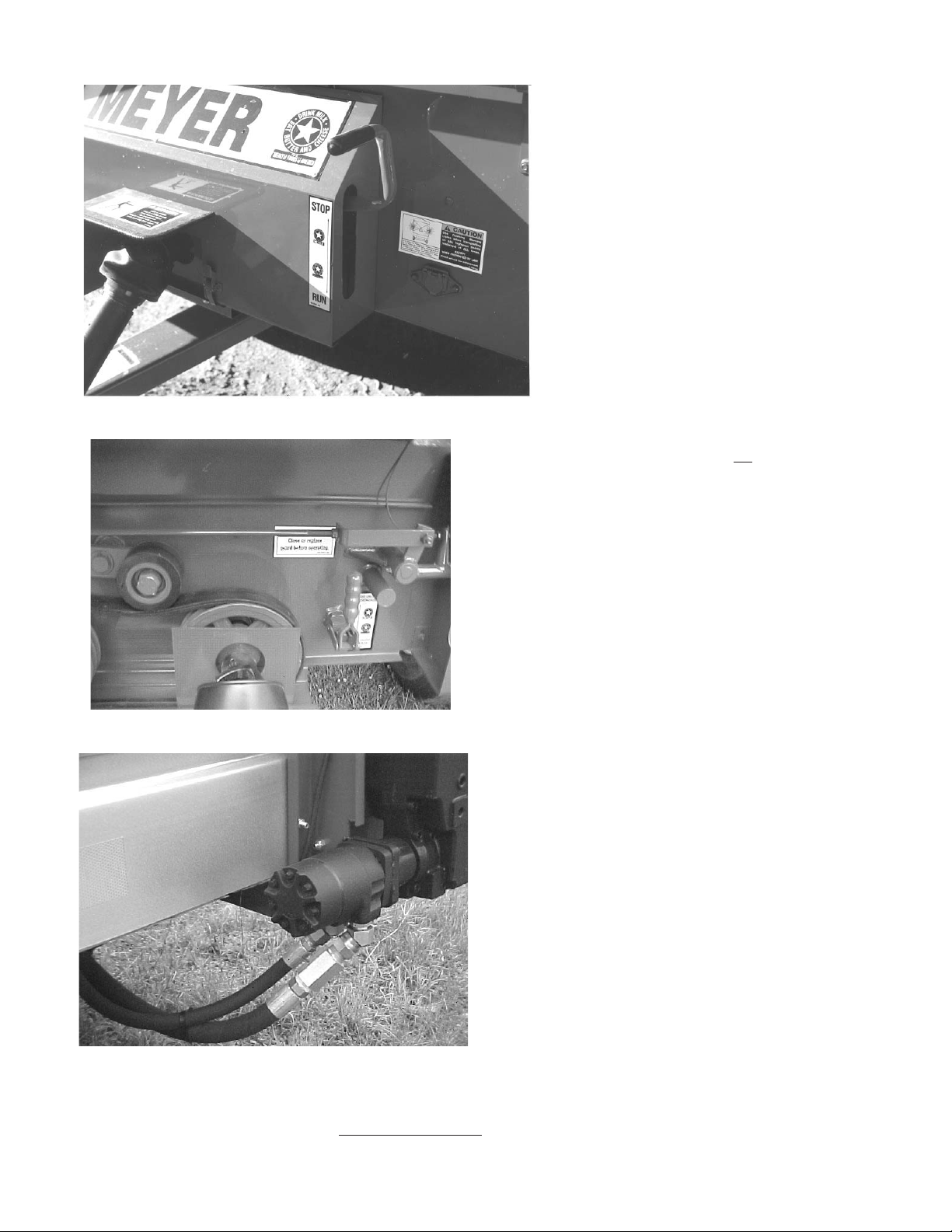

STEP 4b (HYDRAULIC DRIVE)

Couple both supply and return line hydraulic hoses of

the forage box to the hydraulic outlets of the towing trac

tor.

NOTE: The rear unloading gearbox and hydraulically

driven motor, hydraulic return line features a check

valve to protect and prevent any accidental damage

by mistakenly, or incorrectly coupling hydraulic hoses

to the tractor. The check valve is equipped with a re

verse flow feature which will allow the box to run in a

reverse direction for drive plate removal. Reverse hy

draulic flow approximately 10-15 seconds to rotate

gearbox drive plate away from the removable drive

HYDRAULIC CHECK VALVE AT REAR OF BOX

plate. DO NOT RUN IN REVERSE FOR UN

LOADING!

Operating Procedures: See “REAR UNLOAD OPERATION” (HYD or PTO) Page 18

-

-

-

-

3200 & 4200 Series -- 14 –

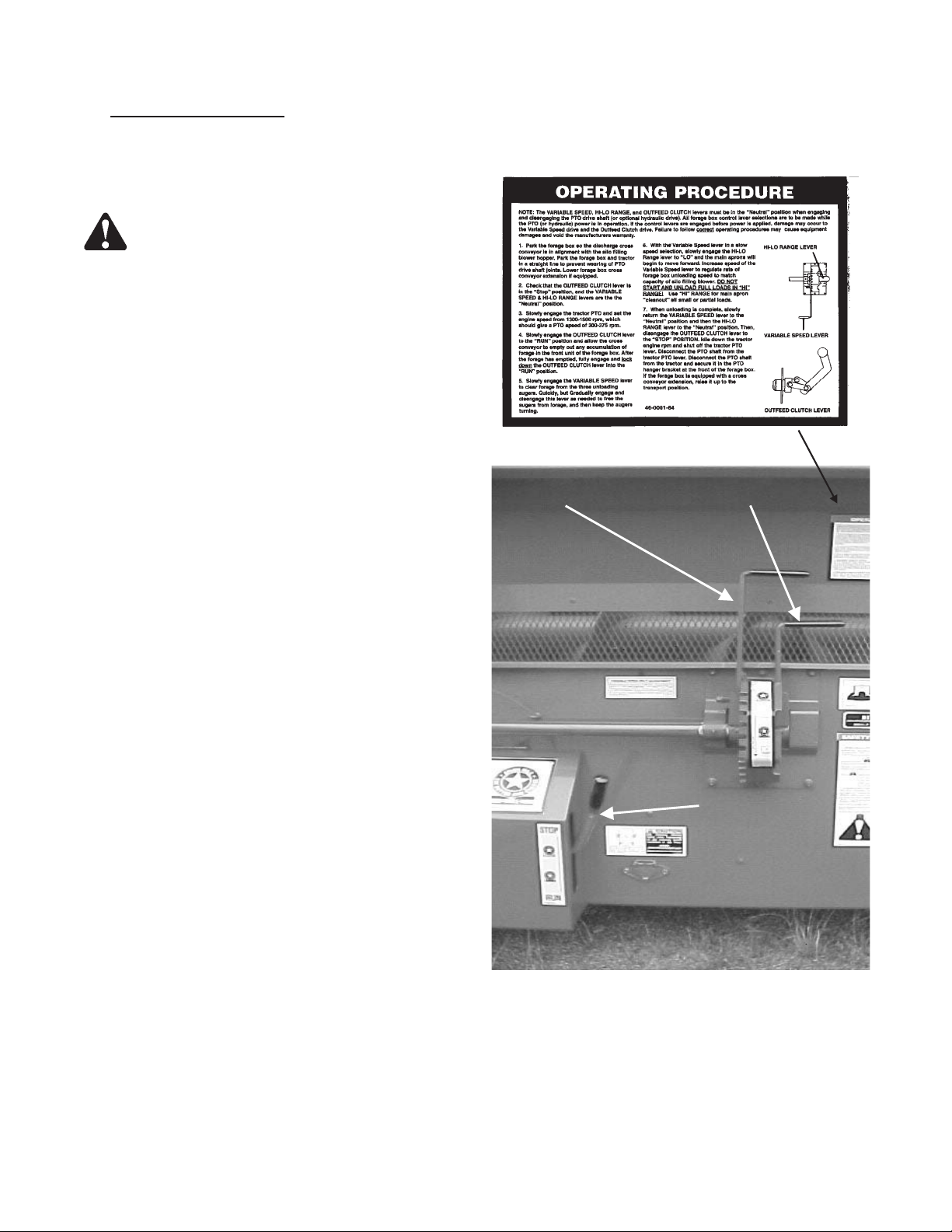

FRONT UNLOAD VARIABLE SPEED OPERATION WITH INDEPENDENT

OUTFEED CLUTCH

DECAL #46-0001-64

FORAGE BOX CONTROL LEVERS

WARNING: NEITHER THE VARIABLE SPEED

NOR THE HI-LO RANGE CONTROL LEVER WILL DIS

ENGAGE THE CROSS CONVEYOR. ONLY THE TRAC

TOR PTO, INDEPENDENT OUTFEED CLUTCH, OR

EMERGENCY STOP MECHANISM WILL STOP THE

CROSS CONVEYOR . FAILURE TO HEED MAY RESULT

IN SERIOUS PERSONAL INJURY OR DEATH.

Facing the front of the forage box, the lower most RH

control lever is the INDEPENDENT OUTFEED CLUTCH

control. Moving this control lever down into the “Run” po

sition engages the cross conveyor and main drive mech

anism. Engage this control lever into the “Run” position

for normal operation. Once this control leveris engaged,

it acts as the emergency stop when pushing on the

“Warning Push for Emergency Stop” push bar or when

pulling on the emergency stop trip cables.

-

-

-

-

VARIABLE

SPEED

CONTROL

LEVER

HI-LO RANGE

CONTROL

LEVER

The LH control lever is the VARIABLE SPEED control.

Moving this control lever regulates rotational speed of

the unloading augers and the forward speed of the main

apron chains, in conjunction with the HI-LO RANGE control. At the uppermost notch on the control quadrant, the

VARIABLE SPEED control is in “Neutral” position. In this

position, neither the main apron chains advance, nor do

the unloading augers rotate under load, regardless of the

position of the HI-LO RANGE control. Moving the VARI

ABLE SPEED control lever down on the control quadrant

increases speed of both auger rotation and main apron

chain forward travel.

The RH control lever is the HI-LO RANGE control. Cen

ter detent is the “Neutral” position. Shifting the lever up

on the control quadrant is “LO” RANGE and shifting the

lever fully down is “HI” RANGE. Range selection affects

the forward speed of the main apron chains only. In the

“Neutral” position, the main apron chain does not travel

forward.

-

IOC CONTROL

-

Three levers control operating the front unloading unit of

the forage box.

LEVER

3200 & 4200 Series -- 15 –

1. INDEPENDENT OUTFEED CLUTCH - IOC

2. VARIABLE SPEED

3. “HI-LO RANGE”

UNLOADING THE FORAGE BOX

START UP PROCEDURES

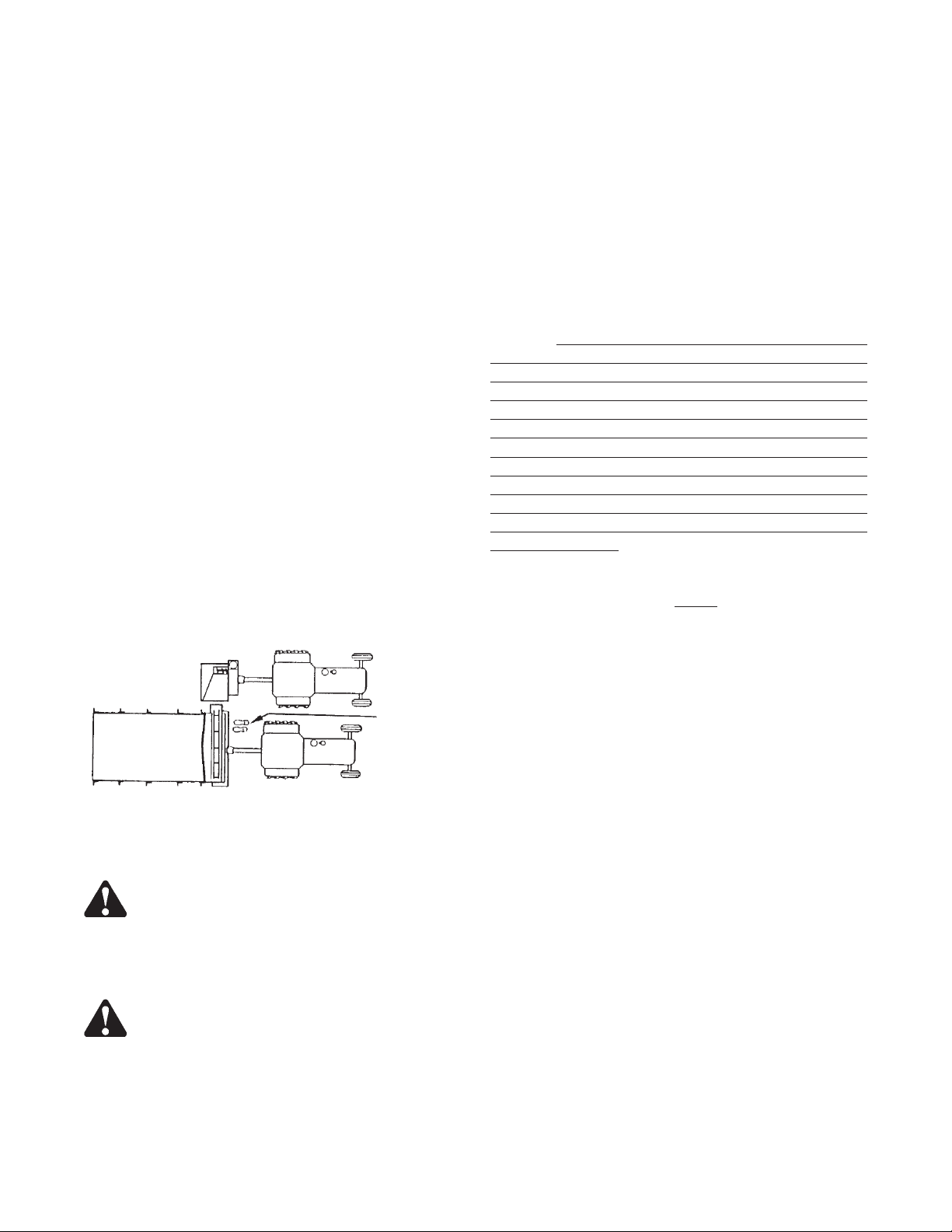

Pull the forage box into position and park so that the

cross conveyor discharge opening is in alignment with

the silo filling blower hopper. If the forage box is

equipped with a fold down cross conveyor extension, it

can be lowered before pulling in front of the blower. After

a couple of parking trails, you may become familiar with

the correct parking place and be able to lower the cross

conveyor extension after parking. Always park the for

age box and unloading tractor in a straight line. Minimize

the unloading angle on the PTO drive shaft to prevent

wearing of universal joints when connected to the un

loading tractor PTO. Shift the unloading tractor to “Neu

tral” or “Park” and set the brakes.

NOTE: Normal operation is using a farm tractor. If using

some other vehicle, exercise equivalent caution when

parking and exiting this vehicle.

Properly dismount from the tractor and approach the for

age box by walking along the left side of the tractor as

shown in the following diagram. Do not approach the for

age box from the right side of the machine (left hand unload). Approach the left front area of the forage box, as

this is where the control levers are located. Standing in

the operator position will not require crossing the PTO

drive shaft at any time during the unloading operation.

Remove PTO drive shaft from the forage box PTO stor

age bracket and connect to the tractor PTO. Be sure the

PTO yoke is securely locked to the tractor PTO. If using

an optional hydraulic drive, couple the hydraulic hoses to

the power supply.

Check that the INDEPENDENT OUTFEED CLUTCH

control lever is in the “Stop” position and the VARIABLE

SPEED & HI-LO RANGE control levers are in the “Neu

tral” positions.

NOTE: The INDEPENDENT OUTFEED CLUTCH,

VARIABLE SPEED, and HI-LO RANGE control levers

must be in their “Stop” or “Neutral” positions when en

gaging and disengaging the PTO drive shaft (or optional

hydraulic drive). All forage box control lever selections

are to be made while the PTO (or hydraulic) power is in

operation. If the control levers are engaged before

power is applied, damage may occur to the Variable

Speed drive or Independent Outfeed Clutch drive or

both. Failure to follow correct operating procedures

may cause equipment damage and may void the manu-

facturers warranty.

At this time, start the silo filling blower. Return to the forage box unloading tractor, slowly

engage the PTO, and

set the engine speed from 1300-1500 rpm. to give a PTO

speed of 300-375 rpm.

-

-

-

LH Side

OPERATOR

POSITION

RH Side

OPERATOR TRAFFIC PATTERN

WARNING: DO NOT STEP OVER THE PTO

DRIVE SHAFT. STAY WELL CLEAR OF THE PTO AT

ALL TIMES. FAILURE TO HEED MAY RESULT IN SE

RIOUS PERSONAL INJURY OR DEATH.

WARNING: DO NOT STEP UP ON ANY PART

OF THE FORAGE BOX AT ANY TIME. FAILURE TO

HEED MAY RESULT IN SERIOUS PERSONAL IN

JURY OR DEATH.

Return to the operator’s position adjacent to the forage

box controls. Intermittently engage the INDEPENDENT

OUTFEED CLUTCH control lever to the “Run” position

and allow the cross conveyor to empty out any accumula

tion of forage in the front unloading unit. After the forage

has emptied, fully engage the INDEPENDENT

OUTFEED CLUTCH control lever into the “Run” position.

Next, engage the VARIABLE SPEED control lever to

clear forage from the three unloading augers. Intermit

tently move the lever between “Neutral” and the 1

and/or 2ndnotch settings on the control quadrant. This

will engage and disengage the augers at a slow speed to

clear them without the main apron moving forward; be

cause the HI-LO RANGE control leveris stillin “Neutral.”

-

With the augers cleared and running and the VARIABLE

SPEED control lever in a slow speed setting, move the

RANGE control lever to “LO” and the main apron chain

will begin to move forward. Moving the VARIABLE

SPEED control lever down on the control quadrant will

increase speed of both auger rotation and main apron

-

forward travel. Keep increasing speed of theVARIABLE

SPEED control to regulate rate of forage box unloading

speed to match the capacity of the silo filling blower.

-

-

st

-

3200 & 4200 Series -- 16 –

Slow up, but do not stop the VARIABLE SPEED control

when shifting to “HI” RANGE.

CAUTION: YOU CAN MOVE THE RANGE CON

TROL LEVER TO “HI” FOR CLEAN-OUT AT THE END

OF UNLOADING AND YOU MAY ALSO FIND IT TO BE

AN APPROPRIATE SPEED SELECTION FOR SMALL

OR PARTIAL LOADS.

DO NOT START AND UNLOAD

FULL LOADS IN “HI” RANGE.

SHUTDOWN PROCEDURES

For proper operation, it is IMPORTANT that when un

loading is completed to slowly

SPEED control lever to the “Neutral” position and then

-

the HI-LO RANGE control lever to the “Neutral” position.

return the VARIABLE

Then, disengage the INDEPENDENT OUTFEED

CLUTCH control lever to the “Stop” position. This will

prepare the forage box front unloading unit for proper

“start-up” on the next load of forage.

-

NOTE: Control lever settings must be made while the

forage box front unloading unit is in operation. Moving

the control levers with the unloading unit stopped will be

difficult or impossible. This may cause equipment dam

ages and may void the manufacturer’s warranty.

When finished unloading the forage box, perform the

“Shut Down Procedures.”

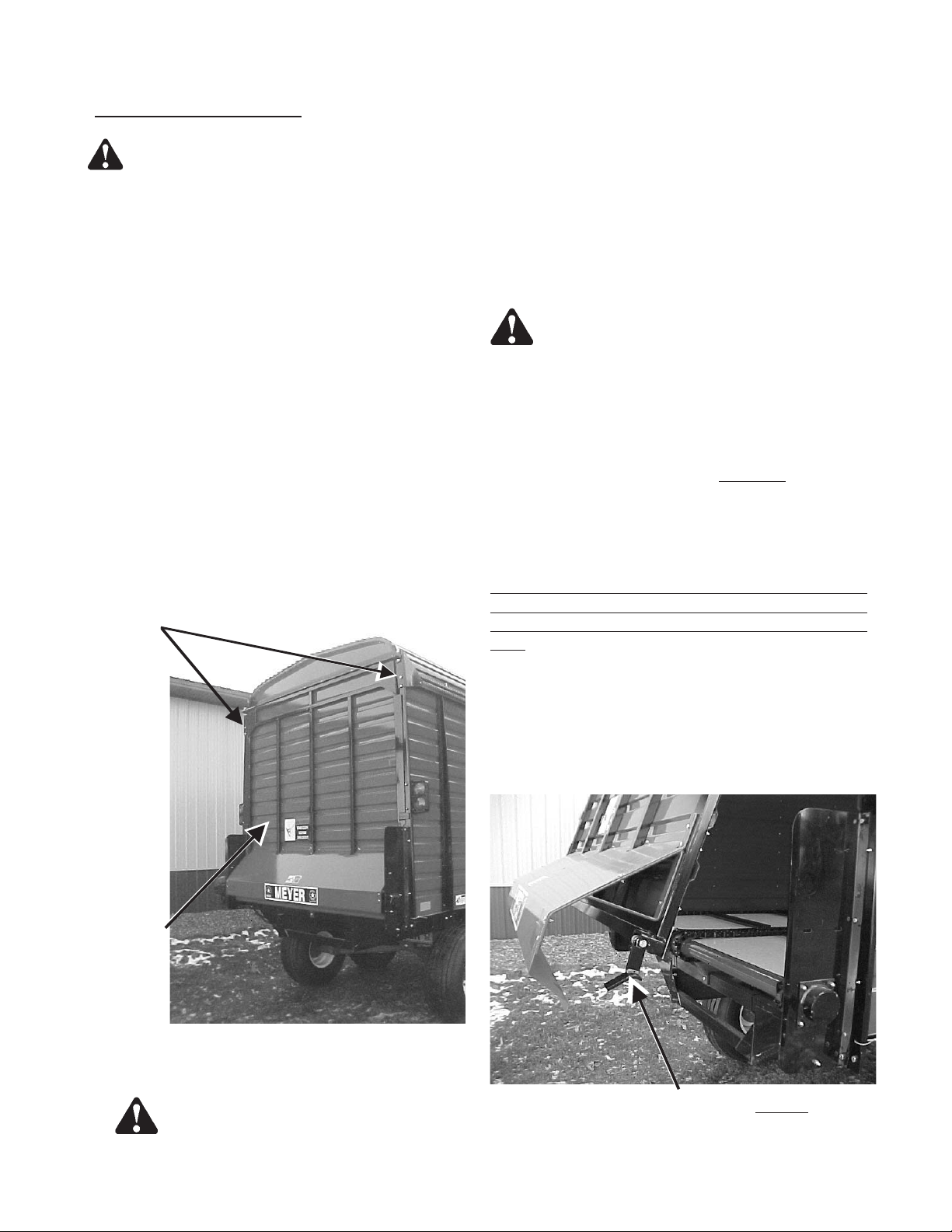

HINGE

BOLTS

NOTE: Control lever settings must be made while the

forage box front unloading unit is in operation. Moving

the control levers with the unloading unit stopped will be

difficult or impossible. This may cause equipment dam

ages and may void the manufacturers warranty.

Idle down the tractor engine rpms. Disengage the PTO

drive shaft and turn the tractor “OFF.” When all move

ment has stopped, disconnect the PTO drive shaft from

the forage box unloading tractor and return it to the PTO

storage bracket. Secure the PTO drive shaft into the

PTO storage bracket with the rubber tie down strap.

Shut down the silo filling blower tractor and wait for all

motion to stop. If the forage box is equipped with a cross

conveyor extension, raise it up to the transport position

and securely latch if before traveling on roadways.

The unloading process described is to be performed by

the operator alone. This will eliminate unexpected

“start-ups” and minimize other hazards that could result

by more that one person in control. If the forage box or

silo filling blower should become clogged, shut off all

power to the forage box and blower. Wait for all motion

to stop. Disconnect PTO drive shaft or hydraulic supply

and return hoses. Then, clean out the machine.

-

-

REAR

DISCHARGE

DOOR

REAR OPENING DISCHARGE DOOR

CAUTION (QUICK RELEASE!)

3200 & 4200 Series -- 17 –

Never use “live” power to aid in the clean-out of a

clogged machine. If any mechanism fails, move the for

age box to a safe work area and then repair the mecha

nism before proceeding with unloading of the forage. If

repairs require the removal of forage from inside of the

forage box, then remove the rear discharge door (bolted

hinges on top of each side) and then empty the forage

manually by hand through the rear opening.

DANGER: NEVER ENTER THE FORAGE BOX

OR FRONT UNLOADING UNIT FOR ANY REASON

WITHOUT FIRST DISCONNECTING PTO DRIVE

SHAFT OR HYDRAULIC HOSES FROM POWER

SUPPLY. FAILURE TO HEED MAY RESULT IN SERI

OUS PERSONAL INJURY OR DEATH.

Never enter the forage box for any reason if there is any

possibility of power being applied to the unit.

-

-

-

REAR UNLOAD OPERATION PTO OR HYDRAULIC DRIVE

Make sure all persons are well clear of the forage box

WARNING: MAKE CERTAIN EVERYONE IS

WELL CLEAR OF EQUIPMENT BEFORE APPLYING

POWER. FAILURE TO HEED MAY RESULT IN SERI

OUS PERSONAL INJURY OR DEATH.

Always park the forage box and unloading tractor in a

straight line. Minimize the unloading angle on the PTO

drive shaft to prevent wearing of universal joints when

connected to the unloading tractor PTO. Shift the un

loading tractor to “Neutral” or “Park”and setthe brakes.

NOTE: Normal operation is using a farm tractor. If using

some other vehicle, exercise caution when parking and

exiting this vehicle.

Remove the PTO drive shaft from the forage box PTO

storage bracket and connect it to the tractor PTO. Be

sure the PTO yoke is securely locked to the tractor PTO.

Move the Independent Outfeed Clutch control lever to

the “Stop” position. If using a hydraulic drive, couple the

hydraulic hoses to the power supply. Be sure the hydraulic hoses are securely locked to the tractor hydraulic

couplers.

HINGE

BOLTS

and the unloading area.

-

The rear discharge door opens automatically by releas

ing its latches as the main aprons begin to move. The

rear discharge door can spring open with extreme force

when its latches release. Pressure of forage against the

rear door causes it to spring open very quickly.

-

WARNING: THE REAR DISCHARGE DOOR

CAN SPRING OPEN QUICKLY AND WITH EXTREME

FORCE. KEEP ALL PERSONS WELL CLEAR OF THE

FORAGE BOX AND UNLOADING AREA. FAILURE

TO HEED MAY RESULT IN SERIOUS PERSONAL IN

JURY OR DEATH.

Return to the tractor, restart, and SLOWLY

tractor PTO or hydraulics to start the apron chains and to

open the rear door. Once the door opens, regulate the

discharge flow with the tractor engine speed. Do not operate above rated tractor engine RPM speed.

Unloading is best observed from the tractor seat. Keep

moving the forage box forward to prevent silage from being carried underneath into the main apron chain return

area.

engage the

-

-

REAR

DISCHARGE

DOOR

REAR OPENING DISCHARGE DOOR

CAUTION (QUICK RELEASE!)

3200 & 4200 Series -- 18 –

REAR DISCHARGE DOOR LATCH

(Typical both sides)

WARNING: DO NOT STEP UP ON ANY PART OF

THE FORAGE BOX AT ANY TIME. FAILURE TO HEED

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEATH.

When finished unloading, reduce engine speed to idle

and disengage the tractor PTO or hydraulics. Pull the

forage box straight ahead to pull the rear door away from

the unloaded pile of forage. Gravity will allow the rear

door to swing shut. The rear door latches will engage to

secure it closed. Visibly observe that rear discharge door

properly latches close.

The unloading process described is to be performed by

the operator alone. This will eliminate unexpected

“start-ups” and minimize other hazards that could result

by more than one person in control. If the forage box

should become clogged, shut off all power to the forage

box and wait for all motion to stop. Disconnect PTOdrive

shaft or hydraulic supply and return hoses and then

clean out the machine.

Never use “live” power to aid in the clean-out of a

clogged machine. If any mechanism fails, move the forage box to a safe work area and then repair the mechanism before proceeding with unloading of the forage. If

repairs require removal of forage from inside of the forage box, then remove the rear discharge door (bolted

hinges on top of each side) and then empty the forage

manually by hand through the rear opening.

HINGE

BOLTS

DANGER: NEVER ENTER THE FORAGE BOX

OR FRONT UNLOADING UNIT FOR ANY REASON

WITHOUT FIRST DISCONNECTING THE PTO DRIVE

SHAFT OR HYDRAULIC HOSES FROM POWER

SUPPLY. FAILURE TO HEED MAY RESULT IN SERI

OUS PERSONAL INJURY OR DEATH.

Never enter the forage box for any reason if there is any

possibility of power being applied to the unit.

-

REAR

DISCHARGE

DOOR

REAR OPENING DISCHARGE DOOR

CAUTION (QUICK RELEASE!)

3200 & 4200 Series -- 19 –

Loading...

Loading...