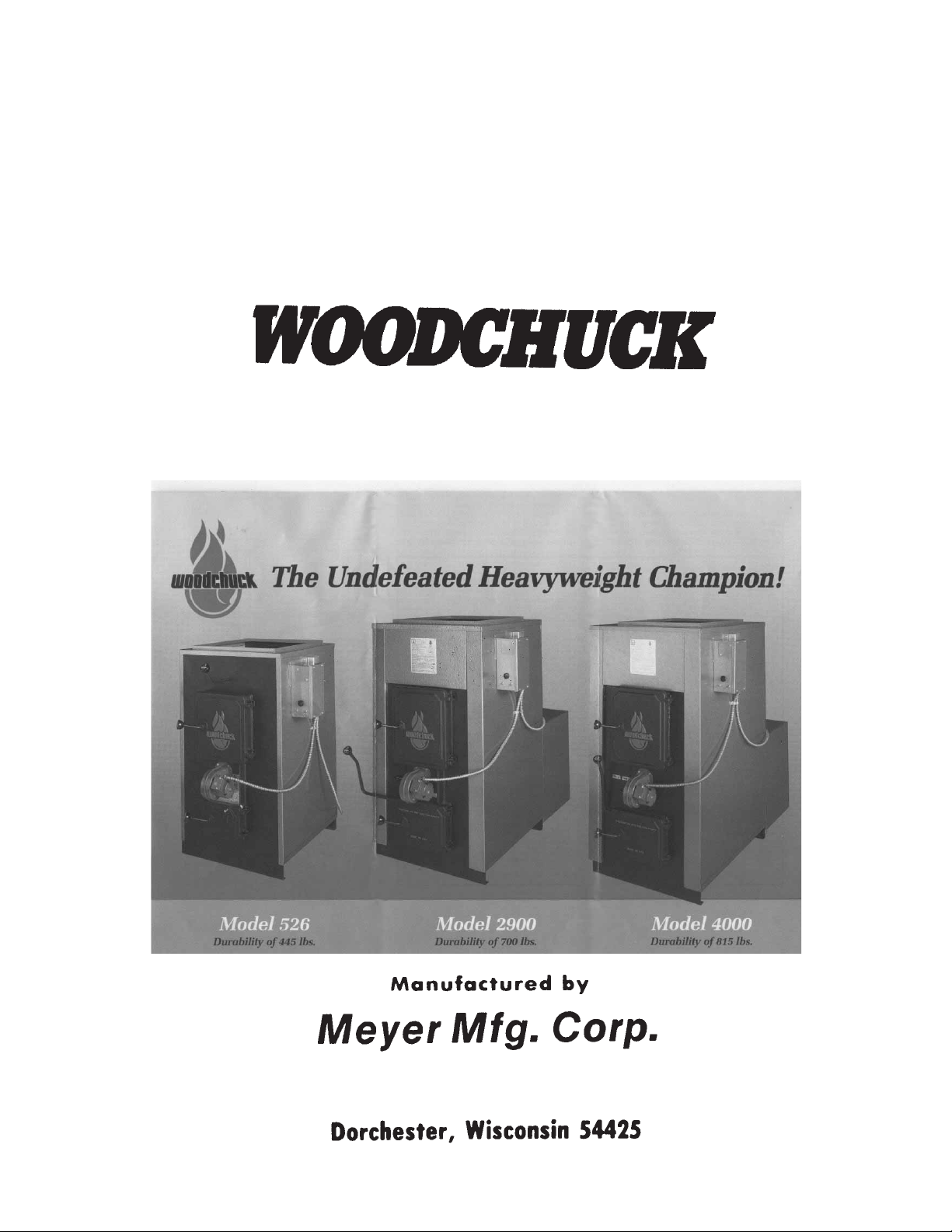

Meyer 4000, 2900, 526 User Manual

INSTRUCTION AND PARTS BOOK

FOR

MODELS 526, 2900, & 4000

Installation must be made in accordance with local and state codes which

may differ from manual. Save these instructions.

WOOD/COAL FURNACES

07/97

Phone 715/654-5132

Fax 715/654-5513

INTRODUCTION

Dear Woodchuck Owner,

Congratulations on your purchase of a Woodchuck heating appliance. Un

doubtedly you have given much consideration to your purchase and we’re

proud that you have selected a Woodchuck. Pride in craftsmanship and engi

neering have made your Woodchuck the finest heating appliance available to

day.

Solid fuels are abundant and inexpensive. Wood is our only renewable

source of fuel and conservative estimates put our coal reserves at 800 years.

Our dual fuel units provide the savings and comfort of solid fuels and the con

venience of electric heat in one attractive package.

There is no substitute for quality. That is why thousands of people like you

have purchased a Woodchuck. They also felt it was the best equipment to

serve their heating needs, now and in years to come. We ask that you follow

our policy of “safety first” and we strongly suggest that you read through the

owner’s manual before installing and operating your furnace.

For a lifetime of satisfaction, thank you for not compromising with quality.

Sincerely,

Donald A. Meyer

President

MEYER MANUFACTURING CORP.

-

-

-

-

We are constantly improving and updating our product in order to provide the

highest quality and value possible. Consequently pictures might sometimes dif

fer slightly from the actual product.

-

TRANSPORTATION DAMAGES

Before reading this manual and proceeding with the installation, inspect your new Woodchuck to make sure there

were no shipping damages. If you find there have been damages incurred, call your dealer immediately. He will

then take a course of action to correct the problem.

2

TABLE OF CONTENTS

Page

Introduction..........................................................................................................................................................2

Table of Contents ................................................................................................................................................3

Furnace Safety ....................................................................................................................................................4

Specifications ......................................................................................................................................................5

General Information.............................................................................................................................................6

High Quality Construction ................................................................................................................................6

Efficiency .........................................................................................................................................................6

Comfort ............................................................................................................................................................6

Additional Comfort And Saving........................................................................................................................7

Operation.............................................................................................................................................................8

Common Sense ...............................................................................................................................................8

! If You Have Chimney Fire !............................................................................................................................8

! Important ! Operation Procedure In The Event of Power Failure ..................................................................8

Operating Your Woodchuck Furnace ..............................................................................................................9

Startup..........................................................................................................................................................9

Burning Wood In Your Woodchuck..................................................................................................................9

Helpful Hints...............................................................................................................................................10

Ash Removal..............................................................................................................................................10

Burning Coal In Your Woodchuck..................................................................................................................11

Starting A Coal Fire....................................................................................................................................11

Recharging.................................................................................................................................................11

Banking ......................................................................................................................................................11

Bituminous Recharging ..............................................................................................................................11

Helpful Hints...............................................................................................................................................11

Ash Removal..............................................................................................................................................12

Maintenance......................................................................................................................................................12

Trouble Shooting ...............................................................................................................................................13

Installation .........................................................................................................................................................15

General Requirements...................................................................................................................................15

Placement And Minimum Clearances............................................................................................................15

Chimney Installation ......................................................................................................................................17

Installing Your Woodchuck ............................................................................................................................18

Stove Pipe Installation ...................................................................................................................................18

Installation Of A Barometric Draft ..................................................................................................................18

Air Duct Installation........................................................................................................................................19

Woodchuck Final Assembly...........................................................................................................................20

Optional Shaker Grate Installation-Model 526 ...........................................................................................20

Install Shaker Grate Handle, Model 2900 Only..........................................................................................21

Install Firebrick ...........................................................................................................................................22

Install Optional Catalytic Combustor ..........................................................................................................22

Assemble Manual Draft-Model 526 Only ...................................................................................................23

Install Comfort Control Center And Forced Draft Blower ...........................................................................23

Install Circulating Blower............................................................................................................................24

Assemble Filter Box ...................................................................................................................................24

Electrical Hookup .......................................................................................................................................25

Repair Parts ......................................................................................................................................................27

3

FURNACE SAFETY

THERE ARE INHERENT HAZARDS ASSOCIATED WITH THE OPERATION OF WOOD/COAL FURNACES. FOR

YOUR SAFETY READ, UNDERSTAND, AND HEED THE FOLLOWING:

DANGER:

RISK OF FIRE OR EXPLOSION. DO NOT BURN GARBAGE, GASOLINE, DRAIN OIL, OR OTHER FLAMMABLE

LIQUIDS. FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

DANGER:

NEVER USE CHEMICALS OR FLUIDS SUCH AS GASOLINE, CHARCOAL LIGHTER FLUID, DRAIN OIL, FUEL

OIL OR KEROSENE TO LIGHT A FIRE IN YOUR WOODCHUCK. FAILURE TO HEED MAY RESULT IN SERIOUS

PERSONAL INJURY OR DEATH.

DANGER:

DURING OPERATION, LOADING AND ASH DOORS, AND EXPOSED FIREBOX ARE EXTREMELY HOT. NEVER

TOUCH THESE PARTS WHEN HOT. FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY.

CAUTION:

· Risk Of Fire

· Do Not Operate With Fuel Loading Or Ash Removal Doors Open.

· Do Not Store Fuel Or Other Combustible Material Within Marked Installation Clearances.

· Under Certain Conditions Of Use, Creosote Buildup May Occur Rapidly. Inspect And Clean Flues And Chimney

Regularly.

· Wait 10 Seconds On First Latch Before Refueling. Opening Loading Door Rapidly Can Cause A Flame To Flash

Out The Door. Use Caution When Opening Loading Door.

· Unsafe To Load Coal Above Top Of Brick.

· Keep Ash Pan Out Of Unit During Operation. Ash Pan Can Get Very Hot.

· Ash Can Must Be Placed On A Noncombustible Surface.

· Never Use Anything But An Air Tight Metal Container To Dump Your Ashes In. Every Year Many Fires Are

Caused By Emptying Ashes Into Cardboard Boxes Or Paper Bags.

·

Proven Fact - Small Red Embers Buried In Ash Cans Stay Red Hot For Days. Ashes Are A Good Thermal Insu

lator And Keep Enough Oxygen Away So Embers Do Not Burn Out.

-

THERE ARE ADDITIONAL HAZARDS ASSOCIATED WITH IMPROPER INSTALLATION OF WOOD/COAL FUR

NACES AND WITH SERVICE AND MAINTENANCE OF WOOD/COAL FURNACES. FOR YOUR SAFETY READ,

UNDERSTAND, AND HEED THE FOLLOWING:

WARNING:

DISCONNECT APPLIANCE FROM ELECTRICAL SUPPLY BEFORE SERVICING UNIT. FAILURE TO HEED MAY

RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

CAUTION:

·

Equipment Must Be Installed By A Qualified Heating Person.

·

Only “class A” All-fuel Or Solid Fuel Chimneys Intended Foe Use With Your Woodchuck Should Be Used.

·

Furnace Must Be Installed On A Noncombustible Floor Or 3/8" Thick Fireproof Millboard Or Equivalent.

FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

4

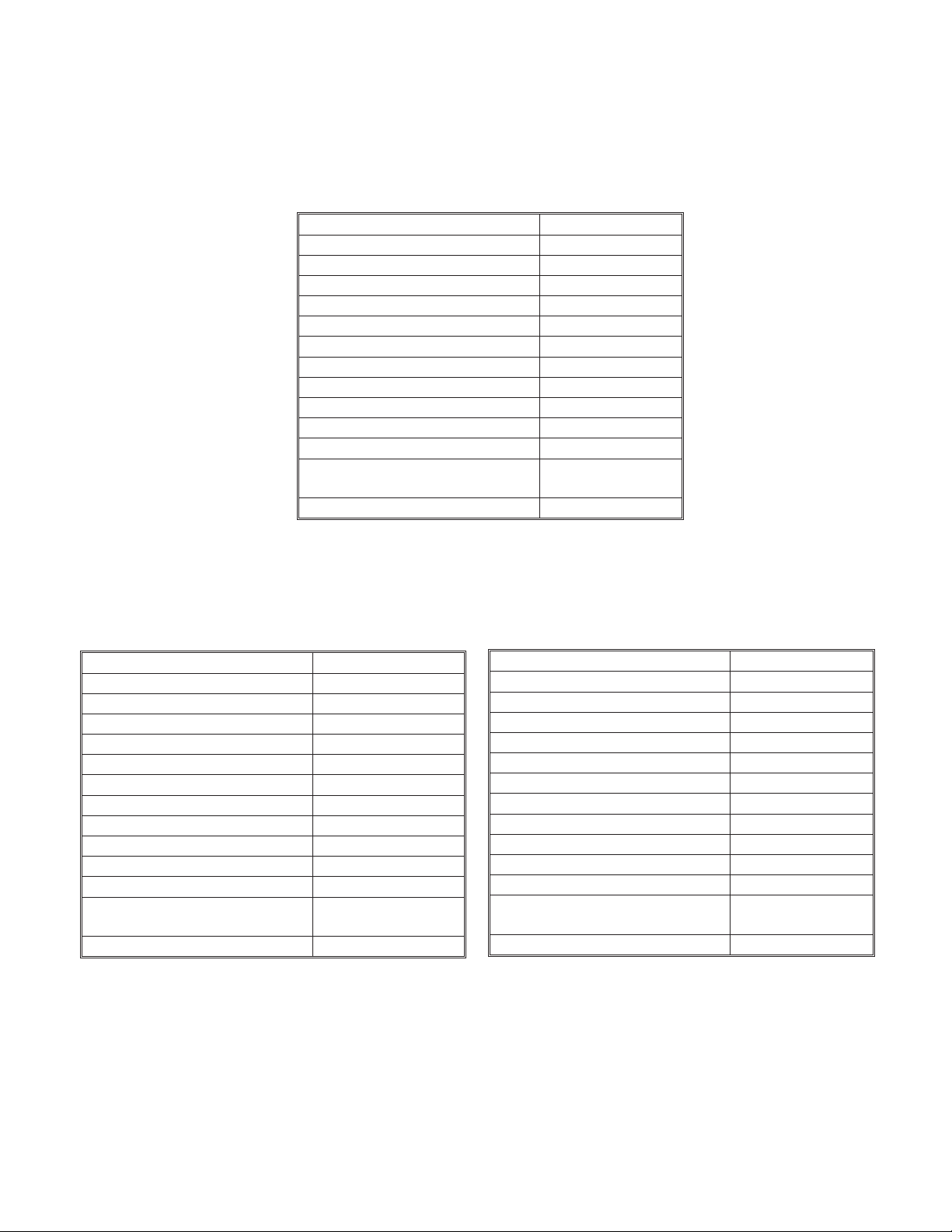

-

SPECIFICATIONS

MODEL 526

Height 42.5"

Width 24"

Depth 26"

Blower 850 to 1850 CFM

Max. BTU Capacity 120,000

Log Size 22"

Loading Door Size 14"x12"

Weight, Approx. 445 lbs.

Warm Air Plenum 20"x23"

Flue Outlet 6" Dia.

Flue Collar Height 41" Overall Height

Secondary Heat Exchange YES

Listings UL391, CSA B366,

1-M ETLM

Firebox Chamber 6.10 cu. ft.

MODEL 2900

Height 48.5"

Width 26"

Depth 28"

Blower 850 to 1850 CFM

Max. BTU Capacity 150,000

Log Size 22"

Loading Door Size 15"x13"

Weight, Approx. 700 lbs.

Warm Air Plenum 20"x23"

Flue Outlet 8" Dia.

Flue Collar Height 47" Overall Height

Secondary Heat Exchange YES

Listings UL391, CSA B366,

1-M ETLM

Firebox Chamber 7.70 cu. ft.

Height 51.5"

Width 26"

Depth 33"

Blower 850 to 1850 CFM

Max. BTU Capacity 180,000

Log Size 24"

Loading Door Size 15"x13"

Weight, Approx. 815 lbs.

Warm Air Plenum 20"x23"

Flue Outlet 8" Dia.

Flue Collar Height 50" Overall Height

Secondary Heat Exchange YES

Listings UL391, CSA B366,

Firebox Chamber 9.10 cu. ft.

MODEL 4000

1-M ETLM

DISCLAIMER NOTICE

The heating capacity specifications are provided as guidelines only and in no way guarantee the output or capacity

of the units. The actual BTU output depends on the type of fuel being burned and its condition, the thermostat set

ting, the draft adjustments and the chimney that the unit is installed into.

-

5

GENERAL INFORMATION

Woodchuck furnaces represent the ultimate in solid

fuel and dual fuel heating appliances. From the mas

sive model 4000 to the economy model 526, each unit

is designed to be attractive, durable and efficient while

providing the safety and comfort you and your family

deserve.

HIGH QUALITY CONSTRUCTION

Constructed of high grade, heavy gauge, hot rolled

steel plate, the firebox is continuously welded for an

airtight seal and structural strength. The heavy duty

cast iron doors are equipped with a positive latching

device for your safety. The loading door has a

two-step safety latch. The large cast iron grates pro

vide for durability and help promote efficient combus

tion of the fuel. The firebox is lined with heavy duty

firebrick and is done so without any retainers to warp

or burn out. These features together with high quality

electrical components provide the safety, efficiency

and total control possible only in a Woodchuck. Total

control means that you can better avoid overheating

the unit and developing excessive and unsafe temperatures.

Woodchuck furnaces are subjected to the most stringent test criteria applicable by an independent third

party testing laboratory and listed/labeled as having

met or exceeded those standards. Finally, any machine, even this Woodchuck, is only as safe as the

person operating it. This is why we have compiled this

comprehensive manual to assist you in operating your

Woodchuck properly and safely. Please read and fol

low all instructions.

EFFICIENCY

The total efficiency of a unit is broken down into com

bustion efficiency and transfer efficiency. We know

that when woodburning, 20% of it burns as fixed car

bon. The other 80% is in the gaseous state as it burns.

Therefore, to obtain efficient combustion of the wood it

is necessary to introduce 20% of the oxygen “under”

the fire to promote combustion of the solid material

and 80% “over” the fire where it can readily react with

the gaseous material. Coal burns just the opposite of

wood. 80% of it burns as fixed carbon and 20% burns

in the gaseous state. Therefore, before a furnace can

burn coal or wood efficiently, it must provide the 80/20

ratio of combustion air and allow the operator to re

verse the ratio depending on the fuel being used.

Combustion air must be warm when it enters the fire

box to further promote complete combustion. Your

Woodchuck furnace provides all these features and

more. Here is how: when combustion air enters a

Woodchuck furnace it enters into a “draft

channel." Here it comes into contact with the hot fire

box front and is warmed before entering the firebox.

The draft channel is equipped with adjustable orifices

which provide for the 80/20 distribution of the combus

tion air. A lever on the front of Models 2900/4000 al

lows for quick and easy adjustment of these orifices to

correspond to the fuel being used. As the air enters

the firebox it strikes a deflector which creates a turbu

lence and causes the oxygen to mix thoroughly with

the gases for complete combustion.

Finally, Woodchuck Model 2900/4000 furnaces are de

signed to accept a catalytic combustor. This device will

cause the small amount of unburned fuel to ignite be

fore entering the secondary heat exchanger. The ben

efits of all this are threefold:

A.) You obtain very high combustion efficiencies,

meaning you use less fuel.

B.) You reduce the amount of unburned fuel that can

collect in your chimney as creosote and hence reduce

the hazard of a chimney fire.

C.) You virtually eliminate pollution of the air we all

breathe.

Transfer efficiency refers to how effectively we transfer

the heat generated inside the firebox to the rooms we

want to heat. Insufficient blower capacity will result in

poor transfer allowing the unused heat to escape up

the chimney. This is why we utilize a blower with such

large air handling capacity. The large surface area of

the firebox and secondary heat exchanger provide for

efficient transfer.

-

COMFORT

Comfort and efficiency are closely related. The more

efficient the heating system is, the more comfortable

you and your family are. Not only are the Woodchuck

furnaces efficient, they can actually increase the effi

ciency of your home.

On a furnace with a conventional single speed

blower, the speed of the blower is a compromise be

tween comfort and efficiency. If the blower has a

large enough capacity to heat the home in the cold

est weather it will cycle rapidly in milder weather so

the system air is not as warm. If this air is moved too

rapidly it can actually feel cool. Air that is moving at

3 ft. per second will feel 4° cooler than stationary air

at the same temperature. If the blower capacity is

-

-

-

-

-

-

-

-

-

-

6

enough to operate properly in mild weather, it will not

be large enough to keep the house

warm in cold weather. This could cause the furnace to

overheat and a loss of heat up the chimney. The result

then is a compromise which is neither efficient or com

fortable. Woodchuck furnaces, however, have a three

speed circulation blower which can be adjusted via a

three position rotary switch on the Comfort Control

Center. This allows the user to select the blower speed

to meet the air movement requirements of the installa

tion. In addition, when the weather is mild and the fur

nace is operating at a lower output, the blower can be

set on low to gently move the air. Similarly, when it is

cold and the furnace is operated at higher levels of

heat, output can be switched to higher speeds.

more comfortable and lose less heat through your ceil

ings as illustrated in figure 2.

This situation can be especially troublesome in

multi-level homes as illustrated in figure 3. As soon as

the blower shuts off, the air in the home begins to strat

ify; warm air rising to the upper levels and cool air col

lecting in the lower levels. The lower levels become

increasingly uncomfortable until the blower turns on

again. Unfortunately, the upper levels are still warm so

they become uncomfortably warm before the blower

turns off. By allowing for a steadier, more continuous

operation of the blower the entire house stays at a

more constant and comfortable level, figure 4.

ADDITION COMFORT AND SAVING

-

-

-

But how can all this improve the efficiency of your

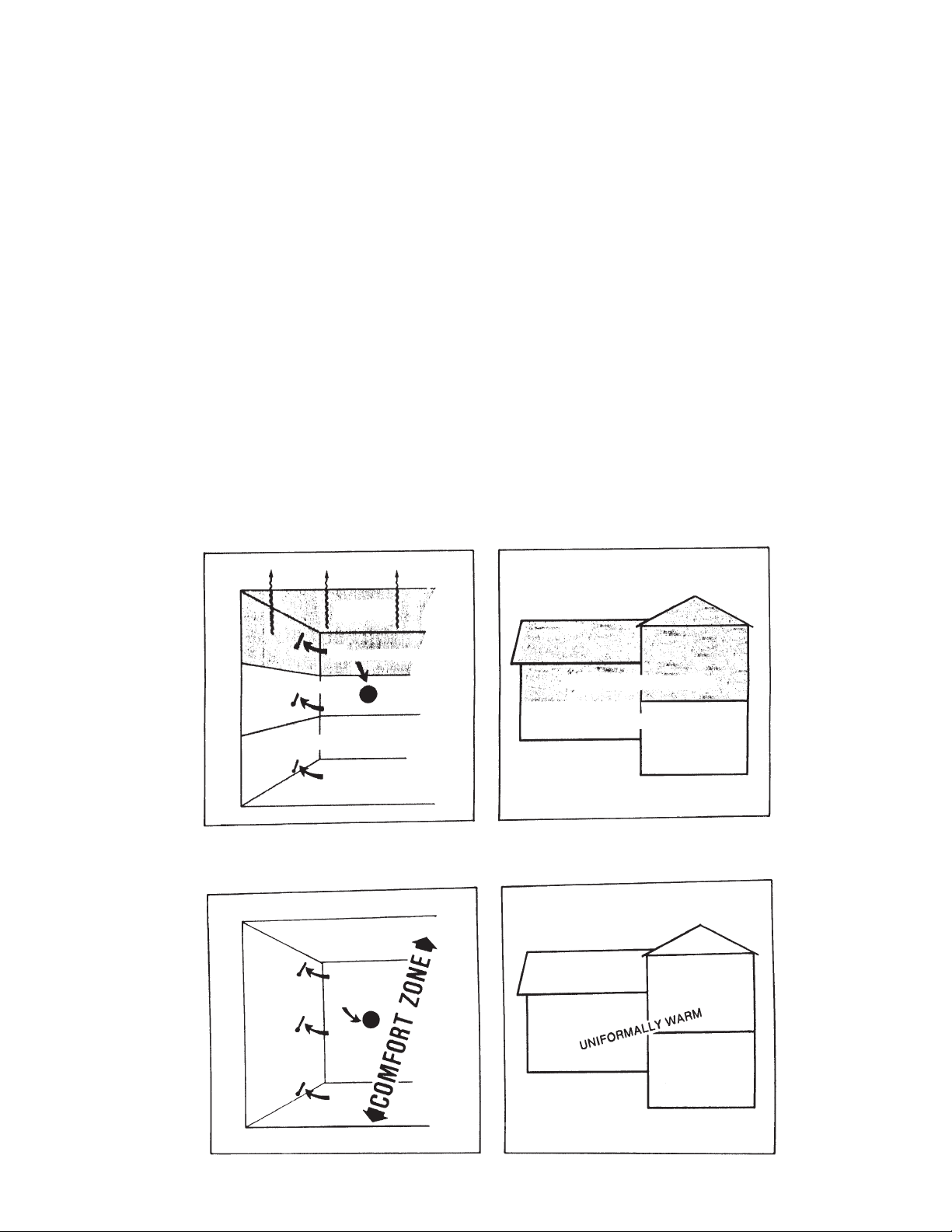

home? As figure 1 illustrates, heated air rises away

from the living area and stratifies. This causes large

temperature differentials between the ceiling where

heat is lost rapidly through conduction and the floor

where children often play. By allowing for continuous

air movement, even during periods of low heat output,

this stratification is not allowed to take place. You are

WASTED HEAT

ZONE

82°

THERMOSTAT

COMFORT ZONE

74°

DISCOMFORT ZONE

60°

FIGURE 1

Options are available for your Woodchuck furnace, and

one of these deserve special mention. The Aqua-Si

phon is capable of pre-heating your domestic water

free of charge during the heating season for additional

saving to you.

UNCOMFORTABLY HOT

UNCOMFORTABLY COLD

FIGURE 3

-

75°

THERMOSTAT

74°

73°

FIGURE 2

FIGURE 4

7

OPERATION

COMMON SENSE

Please read the following before firing your furnace. It is

most important that you follow these suggestions and

limitations in order to maintain your warranty and guar

antee the long life of your furnace.

NOTE: Smoke detectors and fire extinguishers should

always be a part of your equipment.

This furnace is an airtight unit designed to burn 6-8

hours per load of wood or coal. If the furnace is being

fired hot constantly with full flames and operating at

only 2-4 hour burn cycles, it may be over fired. Your

home heating needs may be too great for the size of

furnace you have purchased. Your furnace can be dam

aged if fired at extremely high temperatures.

Forced firing or abuse can be detected upon inspection

AND WILL VOID YOUR WARRANTY.

DANGER:

RISK OF FIRE OR EXPLOSION. DO NOT BURN GARBAGE, GASOLINE, DRAIN OIL, OR OTHER FLAMMABLE LIQUIDS. FAILURE TO HEED MAY RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

! IF YOU HAVE CHIMNEY FIRE !

Meyer Mfg. Corp. recommends the following actions:

1. Shut any doors and air inlet dampers and draft con

trol. This should take no longer than a few seconds.

CLOSED

2. Alert everyone in the house.

3. Call the fire department.

NOTE: Emptying a large box of baking soda will slow

down the fire in your Woodchuck.

Keeping your chimney and stove pipe clean is the best

insurance against chimney fires.

-

MANUAL DRAFT

! IMPORTANT !

OPERATION PROCEDURE IN THE

EVENT OF POWER FAILURE:

Your Woodchuck can operate and produce heat without

electric power. This is one of the features built into every Woodchuck.

The following steps should be taken in the event of an

electrical power failure:

-

DANGER:

NEVER USE CHEMICALS OR FLUIDS SUCH AS

GASOLINE, CHARCOAL LIGHTER FLUID, DRAIN

OIL, FUEL OIL OR KEROSINE TO LIGHT A FIRE IN

YOUR WOODCHUCK. FAILURE TO HEED MAY RE

SULT IN SERIOUS PERSONAL INJURY OR DEATH.

CAUTION:

·

RISK OF FIRE

·

DO NOT OPERATE WITH FUEL LOADING OR

ASH REMOVAL DOORS OPEN.

·

DO NOT STORE FUEL OR OTHER COMBUSTI

BLE MATERIAL WITHIN MARKED INSTALLATION

CLEARANCES.

·

INSPECT AND CLEAN FLUES AND CHIMNEY

REGULARLY.

·

UNDER CERTAIN CONDITIONS OF USE, CREO

SOTE BUILDUP MAY OCCUR RAPIDLY.

·

WAIT 10 SEC. ON FIRST LATCH BEFORE RE

FUELING.

·

LOAD FUEL CAREFULLY OR DAMAGE MAY RE

SULT.

-

-

-

-

1. Locate all heating duct dampers

damper), if any, to open position.

2. Turn manual draft controls to this position.

Ash door should never be used

in power failure.

3. Remove filter box service access cover, allowing

cooler air to move hot air through the furnace, cooling

the plenum and the house hot air duct system.

If power fails, to avoid product damage, close manual

draft completely. Forced draft and natural draft are pre

set.

In the event of a runaway fire, close all drafts. Close

smoke damper halfway.

(not smoke pipe

CLOSED

MANUAL DRAFT

-

8

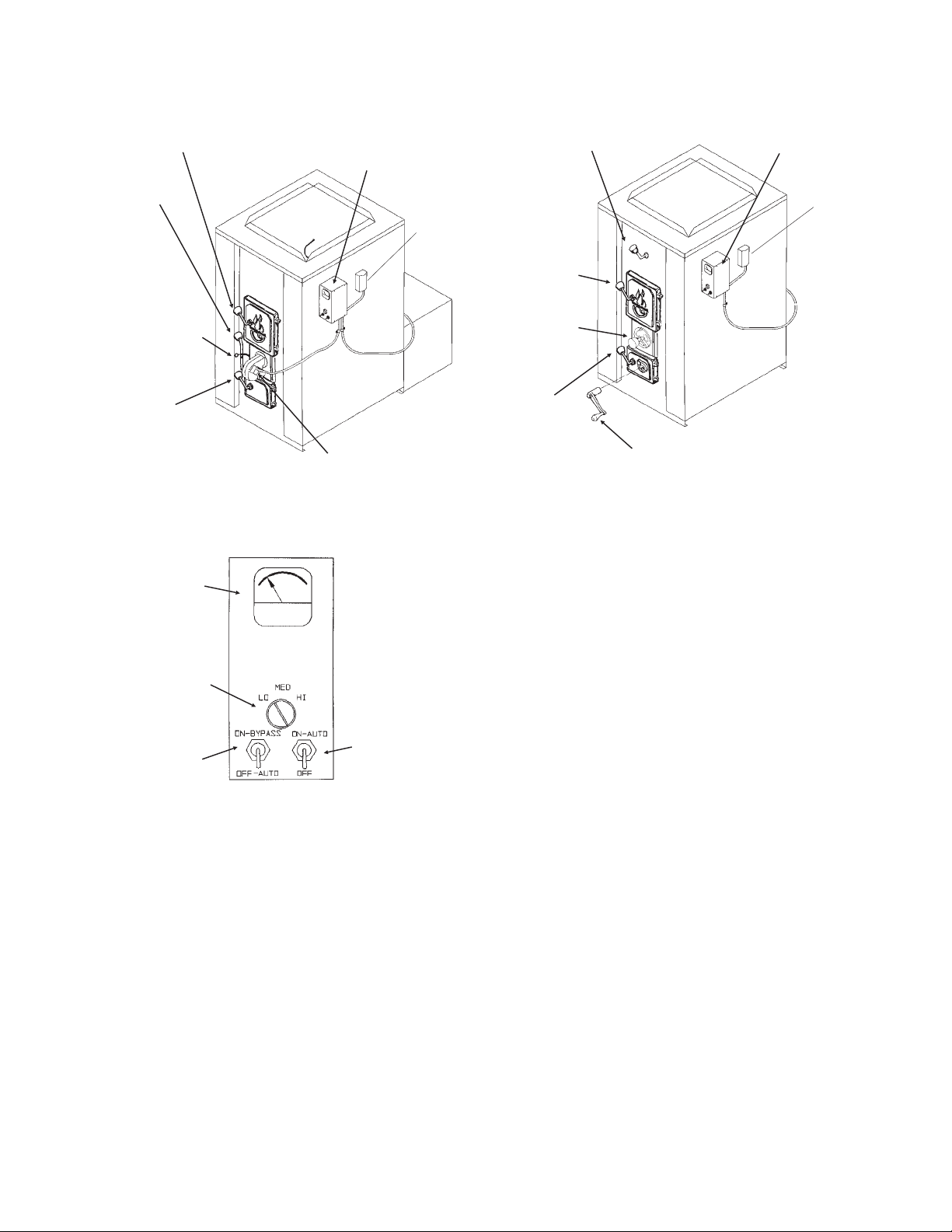

SHAKER

GRATE

DOUBLE LATCH

LOADING DOOR

COMFORT

CONTROL CENTER

FAN/LIMIT

HEAT EXCHANGER

CONTROL ROD

DOUBLE LATCH

LOADING DOOR

COMFORT

CONTROL CENTER

FAN/LIMIT

DRAFT CHANNEL

SELECTOR - 80/20

COMBUSTION AIR

RATIO CONTROL

MODELS

ASH DOOR

2900/4000

FORCED DRAFT

BLOWER

FIGURE 5 WOODCHUCK CONTROLS

(OPTIONAL)

TEMPERATUR

E GAUGE

CIRCULATING

BLOWER

DRAFT BLOWER

LO-LIMIT BYPASS

DRAFT BLOWER

MANUAL SWITCH

FIGURE 6 COMFORT CONTROL CENTER

OPERATING YOUR WOODCHUCK

FURNACE

MANUAL DRAFT

(Forced Draft Is

Optional)

ASH DOOR

SHAKER GRATE CRANK.

SHAKER GRATES ARE OPTIONAL

MODEL 526

NOTE: All models are equipped with a “low limit” which

will not allow the auto draft to operate when the unit is

not warm. To start auto draft, turn Lo-Limit toggle switch

on comfort control center to “On”, figure 6.

Now you are ready to light a fire.

BURNING WOOD IN YOUR WOODCHUCK

1. Adjust draft channel selector, figure 5, to appropriate

fuel setting on model 2900/4000. On Model 526 with

manual draft, open it. Place several pieces of crumpled

paper in the center of your Woodchuck. Criss-cross a

couple of handfuls of dry kindling wood 3/4" thickness,

then several small dry pieces of firewood. Ignite the pa

per and close the door. Do not attempt to open the door

immediately after igniting the fire. There could be a

flame flash out.

-

STARTUP

Never leave ash pan in unit. Use only when cleaning

out ashes.

First thing is to check that your main blower and draft

blower are in proper working order before lighting a fire.

To check main blower, push button on fan/limit control

for manual override testing. When finished, reset to au

tomatic position, figure 5. Next, turn thermostat upstairs

to high temperature so draft blower turns on.

2. It will take 5-10 minutes for the fire to establish itself.

Once you have some good red hot burning embers,

add larger pieces of wood. All chimneys and hookups

are different. After 3-4 fires, you’ll find out how your unit

works for the best starting.

3. After about 30-40 minutes you can adjust the draft

according to your needs. Adjust smoke pipe damper ac

cording to your needs also.

-

9

-

NOTE: On airtight units, the burning time is controlled

mostly by the draft controls on the furnace, contrary to

the old type of pot belly stoves where the smoke pipe

damper controlled the burning time.

NOTE: With new steel, there is a small amount of oil or

dirt on the metal and you may smell an odor. Provide

adequate ventilating to home during the first operation.

Your new Woodchuck is capable of putting out many

BTU’s, so treat it with respect. Don’t fully load your fur

nace or open all drafts fully until you have become thor

oughly familiar with the operation of the furnace.

NOTE: A full load does not always give the best results

for your needs.

4. When loading your Woodchuck with existing hot

coals, rake red hot embers over grates evenly. Put a

few small pieces of wood on the coals first, then

load-up.

5. If you have the automatic draft control, turn low limit

by-pass switch to “On”. Turn thermostat up to activate

auto draft and proceed as with manual draft. Once the

unit is warmed up you can turn the low limit by-pass

switch to “OFF”. This will allow the auto draft to shut off

if the unit runs out of fuel while you are gone.

CAUTION:

WAIT 10 SECONDS ON FIRST LATCH BEFORE REFUELING. OPENING LOADING DOOR RAPIDLY CAN

CAUSE A FLAME TO FLASH OUT THE DOOR. THIS

OCCURS WHEN THERE IS UNBURNT FUEL AND A

LARGE AMOUNT OF GASES ON TOP OF THE FIRE

BOX. WHEN THE DOOR IS OPEN, OXYGEN IS COM

BINED WITH GASES AND IGNITES. USE CAUTION

WHEN OPENING LOADING DOOR.

HELPFUL HINTS

Adjust the draft to the proper setting for your home

needs. The chimney, hookups, and kind of wood will

also be a factor.

Your Woodchuck is capable of holding very large logs.

DO NOT try to add a log that is larger than you can

easily place in the furnace. You will get the best effi

ciency when you add only the amount of wood needed

fora6to8hour burn.

cluded in the owner’s manual package for monitoring

stack temperature. Install the flue temperature ther

mometer at the rear of the furnace on the smoke pipe

where it connects to the collar on the back of the

Woodchuck. 300-400 degrees should be maintained

when the Woodchuck is operating in the burn cycle with

the forced draft blower running to eliminate a creosote

build up. (If the unit has a manual draft or a natural

draft, monitor the flue temperature when the drafts are

in the open position). Depending on the weather, you

may not need a full load of wood for a good over night

burn. You will get best efficiency when you add only the

amount of wood needed until the next time you are

available to load.

Always try to place the logs so air can flow between

them -this will enhance combustion considerably.

ASH REMOVAL

When burning wood, run your poker over top of the

grate to be sure grate slots are clear of burnt fuel. This

should be done every morning when there is just a bed

of hot coals.

CAUTION

NEVER LET ASHES BUILD-UP TO GRATE LEVEL.

THIS WILL GREATLY REDUCE THE LIFE SPAN OF

YOUR GRATE.

Wood ash is useful as a fertilizer, particularly because

of its potassium content. Ashes will also decrease the

acidity of garden soil.

-

-

·

KEEP ASH PAN OUT OF UNIT DURING OPERA

TION. ASH PAN CAN GET VERY HOT.

·

ASH CAN MUST BE PLACED ON A

NONCOMBUSTIBLE SURFACE.

·

NEVER USE ANYTHING BUT AN AIR TIGHT

METAL CONTAINER TO DUMP YOUR ASHES IN.

EVERY YEAR MANY FIRES ARE CAUSED BY

EMPTYING ASHES INTO CARDBOARD BOXES

OR PAPER BAGS.

·

PROVEN FACT- SMALL RED EMBERS BURIED

IN ASH CANS STAY RED HOT FOR DAYS.

-

ASHES ARE A GOOD THERMAL INSULATOR

AND KEEP ENOUGH OXYGEN AWAY SO THE

EMBERS DO NOT BURN OUT.

CAUTION

-

-

In the spring and fall, the weather is mild, which will al

low you to burn very large loads of wood for long peri

ods of time and hence accumulate very large amounts

of creosote. KEY: Stack temperature should be

300°F-400°F for good burning. An external flue temper

ature thermometer (Woodchuck part #08-0084) is in

-

-

-

-

10

Loading...

Loading...