Mettler Toledo Heavy PO TE0002 Users Manual

MCFA

Forklift Scale

Service Manual

Preliminary

A17082300A

(3/05).00

© Mettler-Toledo, Inc. 2004, 2005

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose without the express written permission

of Mettler-Toledo, Inc.

U.S. Government Restricted Rights: This documentation is furnished with Restricted Rights.

METTLER TOLEDO

Publication Revision History

An overview of this manual’s revision history is compiled below.

Publication Name: MCFA Forklift Scale Service Manual

Publication Part Number:

17082300A Publication Date: 2/04

Part Number Date Revisions

17082300A(.01) 10/04

17082300A(.02) 12/04

A17082300A 3/05

Revised load cell calibration procedure on pages 4-15, 7-1, and 7-2. Changed

caution message on page 2-2. Added caution message on page 2-8.

Changed title on front cover to MCFA Forklift Scale Service Manual. Changed name

of product on page 1-1 to MCFA forklift scale. Added instructions to raise the forks

off the ground to power-up sequence on page 3-1.

Added information about Triplex version of scale: tools list and installation (Chapter

2), maintenance (Chapter 5), load cell replacement (Chapter 6), and parts list

(Chapter 8). Replaced screen shots in Chapters 3, 4, 6, and 7. Revised parts lists

and added parts for USB port and side shifter options (Chapter 8). Added new

Chapter 9 describing installation of USB port and side shifter options.

INTRODUCTION

This publication is provided solely as a guide for individuals who have received Technical Training in

servicing the METTLER TOLEDO product.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE REFINEMENTS OR

CHANGES WITHOUT NOTICE.

Precautions

READ this manual BEFORE

operating or servicing this

equipment.

FOLLOW these instructions

carefully.

SAVE this manual for future

reference.

DO NOT allow untrained

personnel to operate, clean,

inspect, maintain, service, or

tamper with this equipment.

ALWAYS DISCONNECT this

equipment from the power

source before cleaning or

performing maintenance.

CALL METTLER TOLEDO for parts,

information, and service.

WARNING

PERMIT ONLY QUALIFIED PERSONNEL TO SERVICE THIS

EQUIPMENT. EXERCISE CARE WHEN MAKING CHECKS,

TESTS, AND ADJUSTMENTS THAT MUST BE MADE WITH

POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS CAN

RESULT IN BODILY HARM.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD,

CONNECT TO PROPERLY GROUNDED OUTLET ONLY. DO NOT

REMOVE THE GROUND PRONG.

WARNING

DISCONNECT ALL POWER TO THIS UNIT BEFORE INSTALLING,

SERVICING, CLEANING, OR REMOVING THE FUSE. FAILURE TO

DO SO COULD RESULT IN BODILY HARM AND/OR PROPERTY

DAMAGE.

WARNING

BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC COMPONENTS OR

INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT, ALWAYS REMOVE

POWER AND WAIT AT LEAST 30 SECONDS. FAILURE TO OBSERVE THESE PRECAUTIONS

COULD RESULT IN BODILY HARM OR DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT.

CAUTION

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC

SENSITIVE DEVICES.

DANGER

BE SURE TO BLOCK THE LIFT BRACKET WHEN IT IS IN THE

RAISED POSITION. FAILURE TO OBSERVE APPROPRIATE SAFETY

PRECATIONS COULD RESULT IN BODILY HARM OR PROPERTY

DAMAGE.

DANGER

DO NOT REMOVE THE BOLTS FROM MORE THAN ONE FLEXURE

AT A TIME WHILE THE CARRIAGE IS INSTALLED ON THE

FORKLIFT. UNBOLTING MORE THAN ONE FLEXURE COULD

RESULT IN BODILY HARM OR PROPERTY DAMAGE.

DANGER

IF USED IN A HAZARDOUS AREA, THE HAZARDOUS AREA MUST

BE MADE SAFE PRIOR TO INSTALLATION, REPLACEMENT, OR

TROUBLESHOOTING. FAILURE TO COMPLY COULD RESULT IN

PERSONAL INJURY, DEATH, AND/OR PROPERTY DAMAGE.

CAUTION

CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY METTLER TOLEDO COULD

VOID THE AUTHORITY TO OPERATE THIS EQUIPMENT.

CAUTION

THERE IS A RISK OF EXPLOSION IF A BATTERY IS REPLACED WITH AN INCORRECT T YPE OF

BATTERY. DISPOSE OF BATTERIES ACCORDING TO LOCAL REGULATIONS. FOR DISPOSAL

INFORMATION, REFER TO THE PRODUCT INFORMATION SHEET FOR NICKEL METAL

HYDRIDE BATTERIES (NiMH) AT www.panasonic.com OR REFER TO THE RECHARGEABLE

BATTERY RECYCLING CORPORATION (www.rbrc.org).

Contents

1

Introduction.................................................................................................... 1-1

FCC Notice..........................................................................................................................1-2

2

Installation..................................................................................................... 2-1

General ..............................................................................................................................2-1

Tools.................................................................................................................................... 2-1

Install Scale Controller........................................................................................................2-2

Remove the Forklift Truck’s Lift Bracket.................................................................................2-2

Install the Simplex Scale Carriage.......................................................................................2-6

Install the Triplex Scale Carriage.........................................................................................2-9

Batteries...........................................................................................................................2-12

Geo Index.........................................................................................................................2-13

Shift Adjustment................................................................................................................2-13

3

Scale Operations ............................................................................................ 3-1

Power-up Sequence.............................................................................................................3-1

Weighing Screen.................................................................................................................3-1

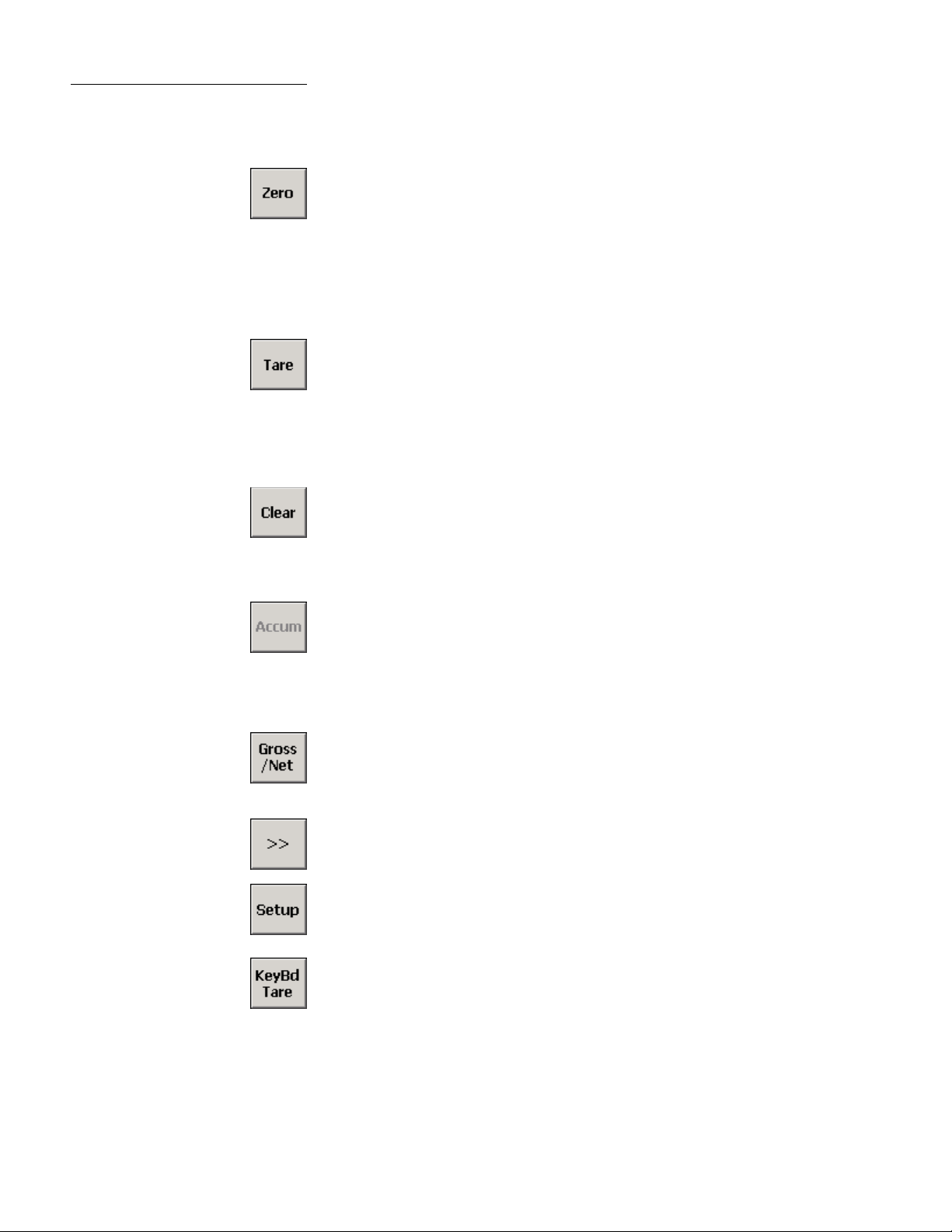

Push Buttons......................................................................................................................... 3-2

Weighing Operations...........................................................................................................3-3

Gross Weighing .................................................................................................................... 3-3

Net Weighing with Push Button Tare....................................................................................... 3-4

Net Weighing with Keyboard Tare........................................................................................... 3-4

Accumulating Gross Weights.................................................................................................. 3-5

Accumulating Net Weights..................................................................................................... 3-5

SmartWeigh Transactions...................................................................................................... 3-6

4

Scale Setup.................................................................................................... 4-1

Setup Screens.....................................................................................................................4-1

Scale..................................................................................................................................4-1

Filter.................................................................................................................................... 4-1

Tare ..................................................................................................................................... 4-4

Zero..................................................................................................................................... 4-5

Stability................................................................................................................................4-7

Battery Levels....................................................................................................................... 4-9

Calibration ......................................................................................................................... 4-13

Factory Use......................................................................................................................... 4-19

Reset.................................................................................................................................. 4-20

Application .......................................................................................................................4-21

Accumulate......................................................................................................................... 4-21

SmartWeigh........................................................................................................................ 4-21

Memory.............................................................................................................................. 4-23

Reset.................................................................................................................................. 4-25

Terminal...........................................................................................................................4-25

Date/Time........................................................................................................................... 4-25

Passwords.......................................................................................................................... 4-26

Calibrate Touch................................................................................................................... 4-27

Operating System................................................................................................................ 4-27

Brand Setup........................................................................................................................ 4-29

Reset.................................................................................................................................. 4-30

Communications...............................................................................................................4-30

Scale Radio........................................................................................................................ 4-30

COM1................................................................................................................................. 4-35

Reset.................................................................................................................................. 4-37

Maintenance.....................................................................................................................4-37

Log..................................................................................................................................... 4-37

Diagnostics......................................................................................................................... 4-38

Reset.................................................................................................................................. 4-43

Exit Setup.........................................................................................................................4-43

5

Routine Care and Maintenance........................................................................ 5-1

General ..............................................................................................................................5-1

Cleaning.............................................................................................................................5-2

6

Troubleshooting.............................................................................................. 6-1

General ..............................................................................................................................6-1

Error Messages...................................................................................................................6-2

Scale Controller..................................................................................................................6-4

Check Mechanical Components............................................................................................6-4

Check Overload Gaps ..........................................................................................................6-5

Check Wiring......................................................................................................................6-6

Check Force Data................................................................................................................6-6

Check Load Cells ................................................................................................................6-7

Load Cell Replacement........................................................................................................6-8

Removing a Chain Load Cell (Simplex).................................................................................. 6-8

Installing a New Chain Load Cell (Simplex) ......................................................................... 6-11

Removing a Drag Load Cell (Simplex).................................................................................. 6-12

Installing a New Drag Load Cell (Simplex)........................................................................... 6-13

Removing a Chain Load Cell (Triplex).................................................................................. 6-15

Installing a New Chain Load Cell (Triplex) ........................................................................... 6-18

Removing a Drag Load Cell (Triplex).................................................................................... 6-19

Installing a New Drag Load Cell (Triplex)............................................................................. 6-20

Adjust Load Cell Force.......................................................................................................6-22

7

Calibration..................................................................................................... 7-1

General ..............................................................................................................................7-1

Calibrate Load Cells............................................................................................................7-1

Span Adjustment.................................................................................................................7-3

Calibrate Linearity...............................................................................................................7-5

Calibrate Angles .................................................................................................................7-8

Establish Zero...................................................................................................................7-13

8

Service Parts.................................................................................................. 8-1

9

10

Scale Controller..................................................................................................................8-1

Scale Carriage....................................................................................................................8-2

Telemetry Enclosure............................................................................................................8-6

Side Shifter Kit....................................................................................................................8-8

Forklift Scale Options...................................................................................... 9-1

USB Port.............................................................................................................................9-1

Side Shifter Kit....................................................................................................................9-2

Appendix ..................................................................................................... 10-1

Geo Index.........................................................................................................................10-1

Chapter 1: Introduction

FCC Notice

1

Introduction

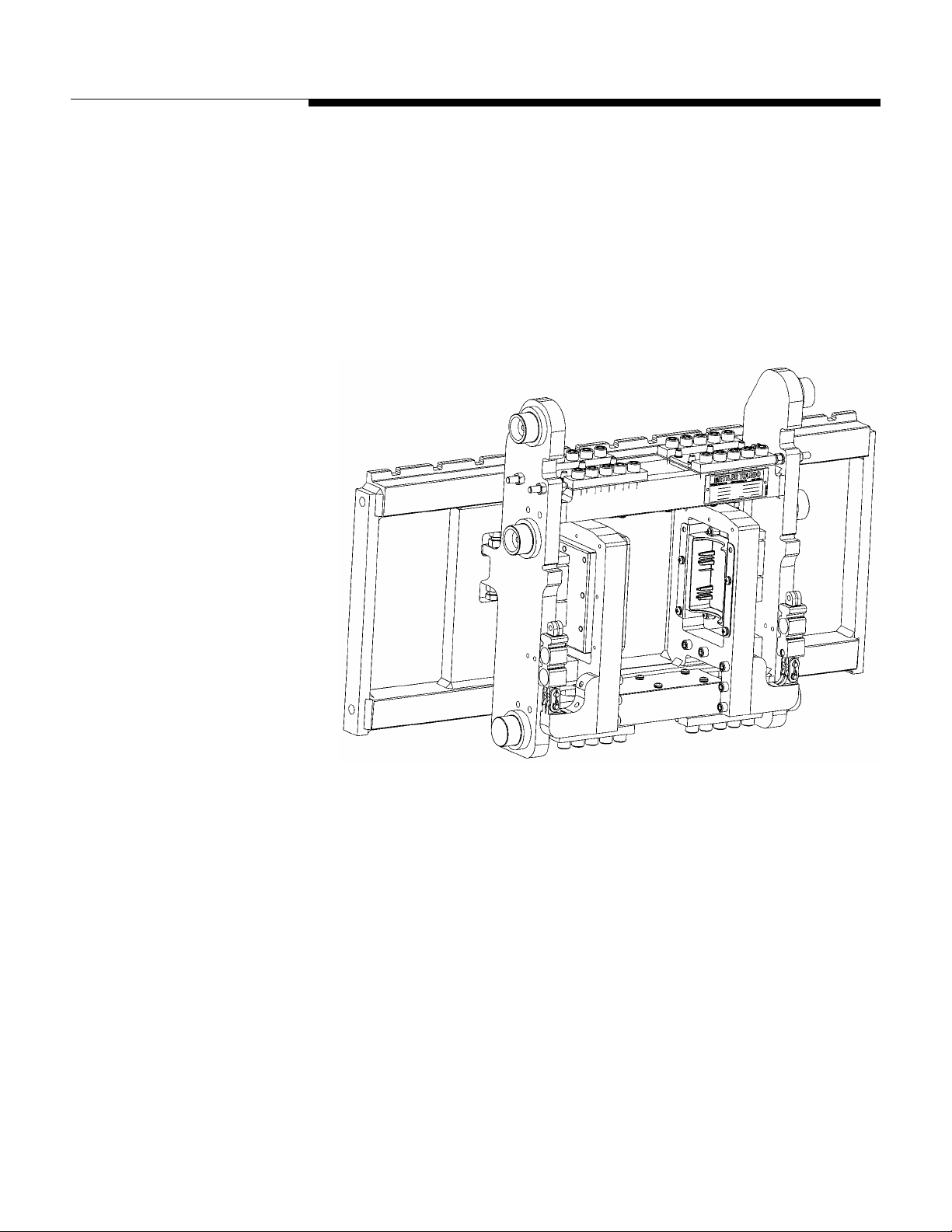

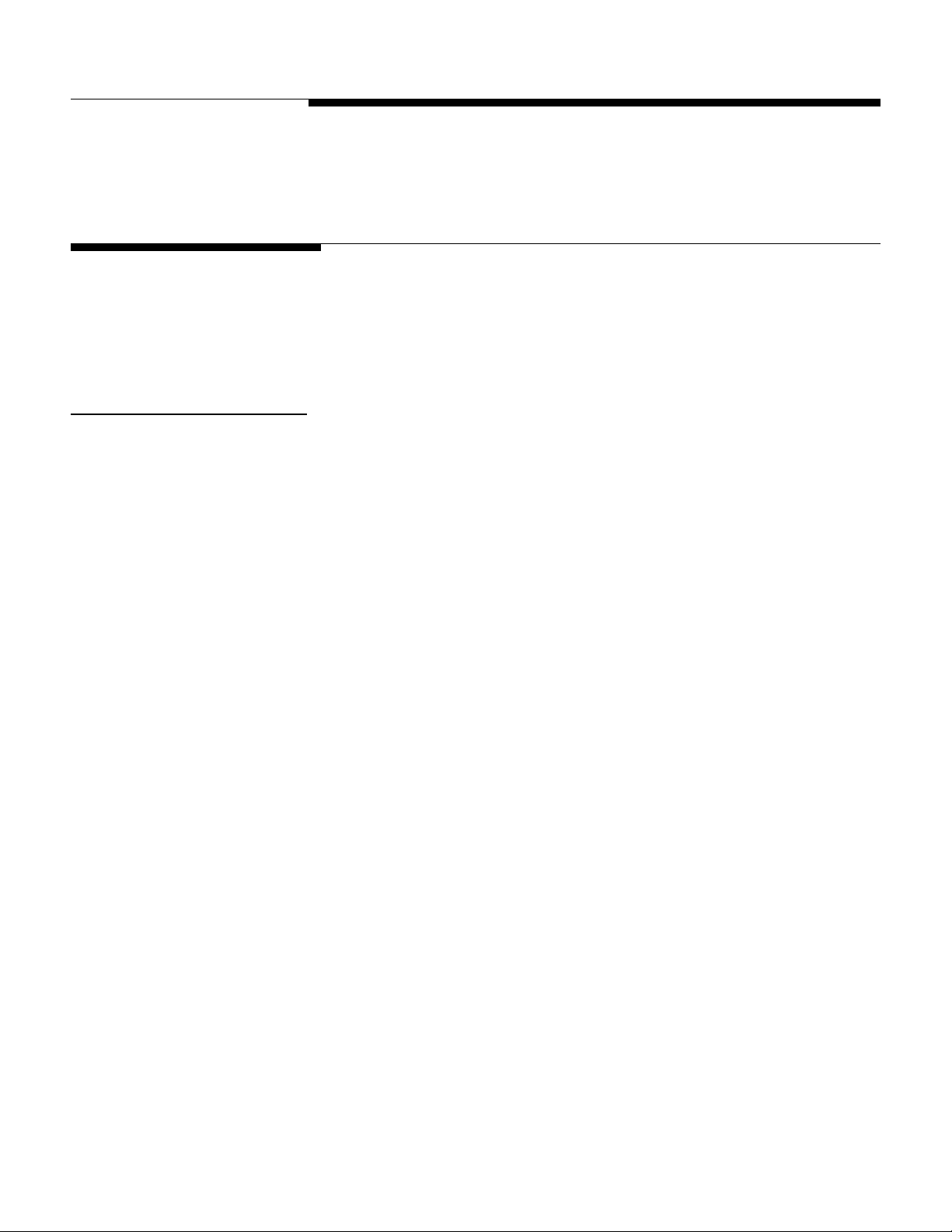

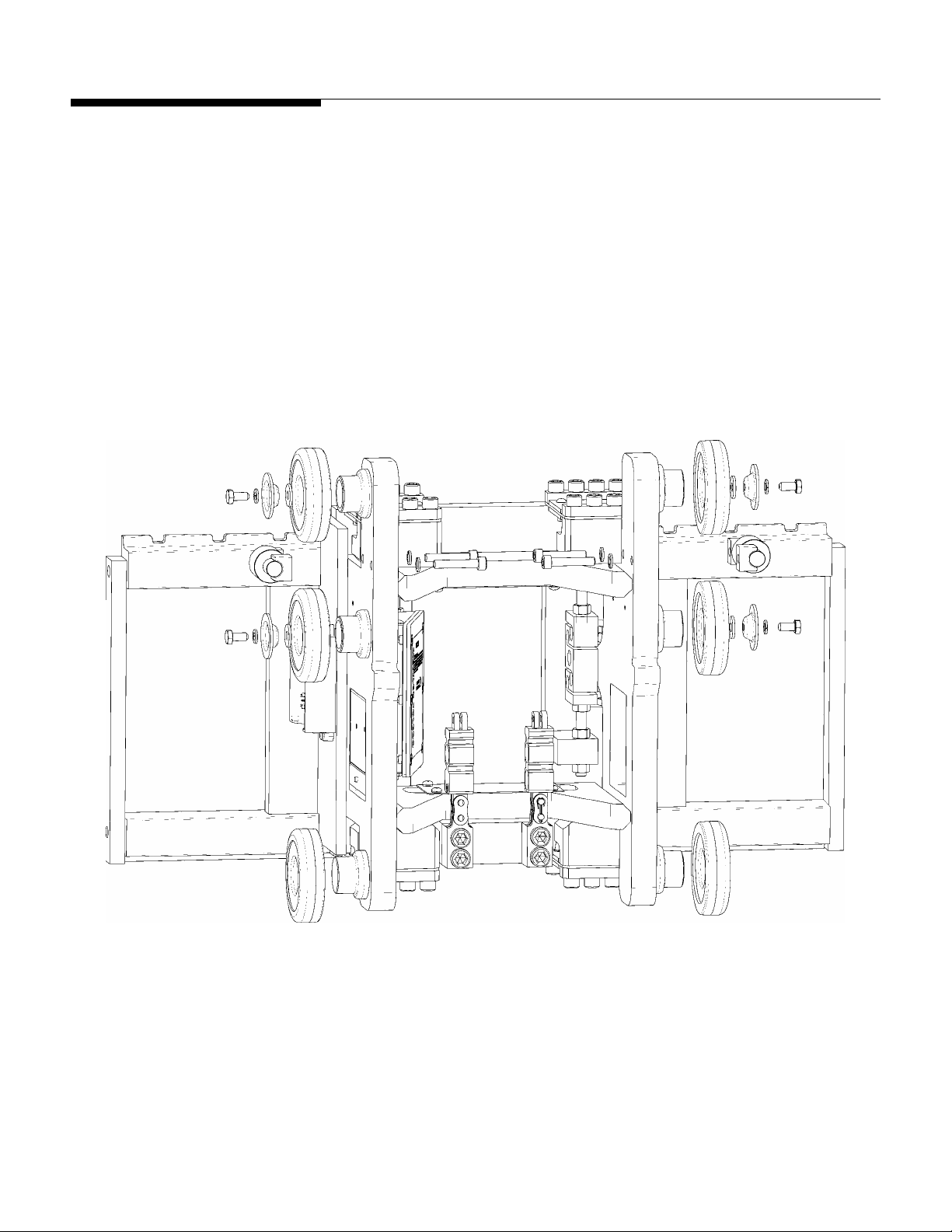

The MCFA forklift scale is a fully electronic scale with a capacity of 5,000 lb (2,000

kg). The scale consists of two components: (1) a scale carriage, which is installed in

place of the forklift truck’s lift bracket, and (2) a scale controller, which is mounted on

the forklift truck’s head guard. The scale carriage and controller communicate by radio,

so there are no wiring connections between them to limit the movement of the forks.

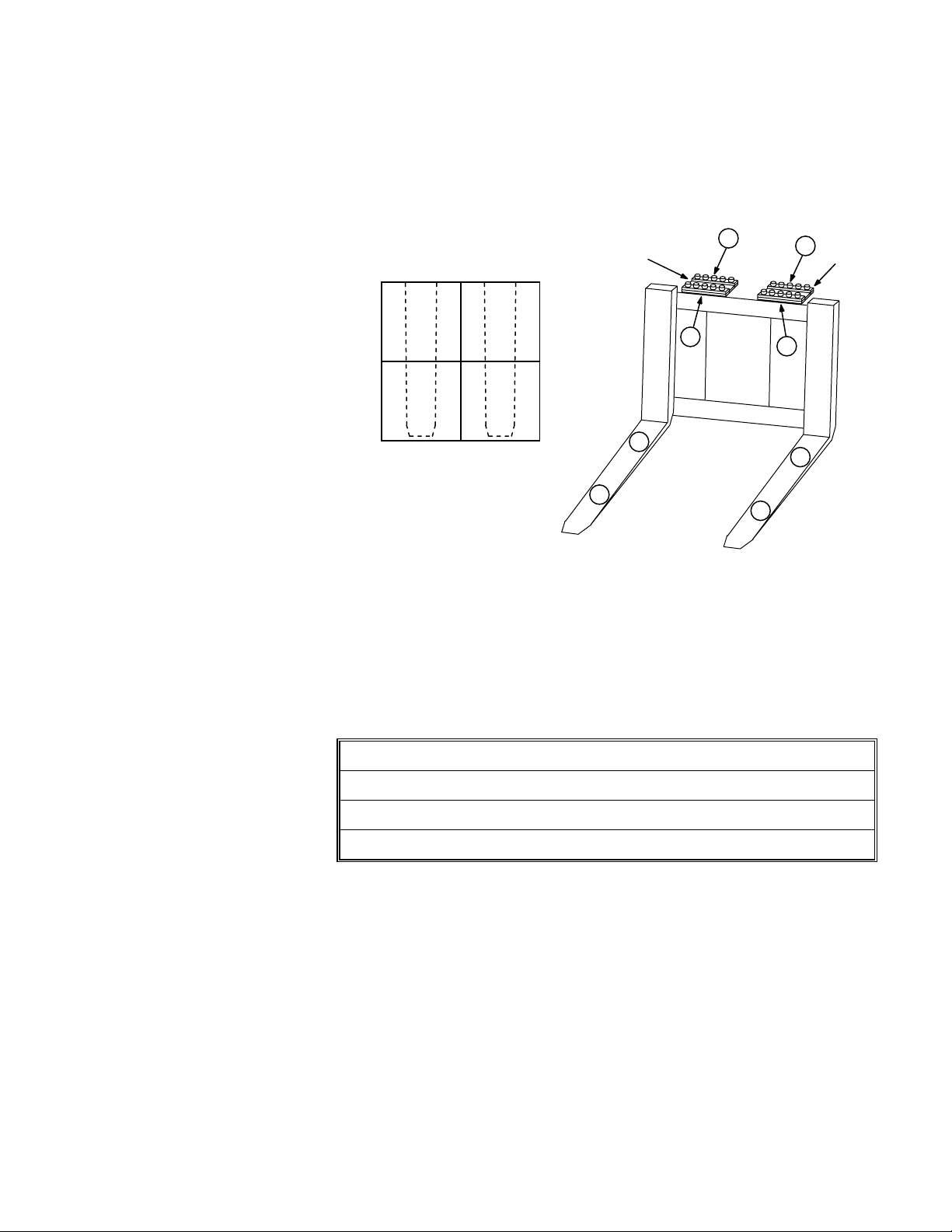

Figure 1-1: Forklift Scale Carriage (Simplex Version)

This manual explains how to install, operate, and service the MCFA forklift scale. If any

information in the manual is incorrect or missing, please use the Publication Suggestion

Report at the back of the manual to tell us about it.

(3/05)

1-1

METTLER TOLEDO MCFA Forklift Scale Service Manual

FCC Notice

MCPC Scale Controller (FCC ID: RITSC0001)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

MCSB Simplex Scale Carriage (FCC ID: RITTE0001)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

MCTB Triplex Scale Carriage (FCC ID: RITTE0002)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

CAUTION

CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY METTLER TOLEDO COULD

VOID THE AUTHORITY TO OPERATE THIS EQUIPMENT.

1-2

(3/05)

Chapter 2: Installation

General

2

Installation

General

Tools

When you receive your forklift scale, check all items against the shipping bill of lading.

If any items are missing, notify the carrier immediately. Inspect the packing container

and scale for freight damage. If you find damage, contact your freight carrier

immediately in order to collect damages.

The following tools are needed to install and calibrate a forklift scale:

Simplex Version

Crane or lifting device (capacity 2,500 lb)

Torque wrench with 3/8-inch hex bit attachment (flexure bolts)

12-mm wrench (main roller bolts)

14-mm wrench (side roller assembly bolts)

24-mm wrench (chain anchor nuts)

3/4-inch wrench (bumper bolts and drag load cell mounting nuts)

10-mm wrench (bolts for mounting controller)

Triplex Version

Crane or lifting device (capacity 2,500 lb)

Torque wrench with 5/16-, 3/8-, and 1/2-inch hex bit attachments

12-mm wrench (main roller bolts)

16-mm wrench (side roller assembly bolts)

24-mm wrench (chain anchor nuts)

3/4-inch wrench (bumper bolts and drag load cell mounting nuts)

10-mm wrench (bolts for mounting controller)

1.25-inch open-end wrench

(3/05)

2-1

METTLER TOLEDO MCFA Forklift Scale Service Manual

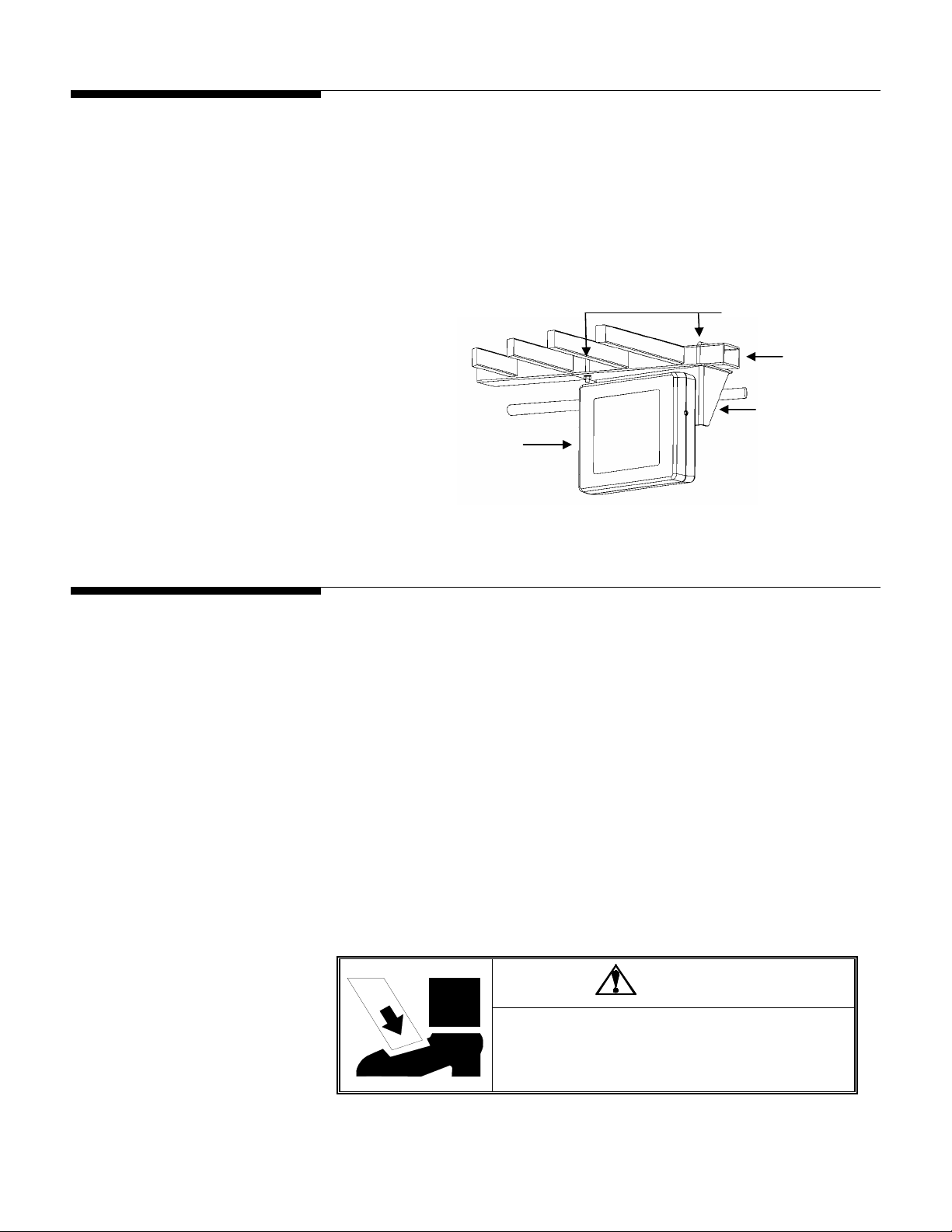

Install Scale Controller

1.

Use a pair of U-bolts to attach the mounting bracket to the forklift truck’s head

guard. Position it so that the driver will be able to view the controller easily.

2.

Bolt the controller to the mounting bracket, using four hexagonal head screws and

washers (see Figure 2-1).

3.

Connect the controller to the forklift truck’s time-delay relay harness. The harness

should be installed according to the manufacturer’s instructions.

U-Bolts

Head Guard

Mounting Bracket

Scale Controller

Figure 2-1: Scale Controller and Mounting Bracket

Remove the Forklift

Truck’s Lift Bracket

1.

Park the forklift truck on a level surface, and make sure the mast is in the vertical

position.

2.

Remove both of the forks.

3.

If the forklift truck is equipped with a load backrest extension, remove the load

backrest extension.

4.

Raise the mast so that the lift bracket is at a comfortable working height (3 or 4 feet

off the ground).

5.

Wrap a sling securely around the lift bracket’s upper fork bar.

6.

Attach the sling to a crane (or other lifting device with a capacity of at least 500

lb), and use the crane to raise the lift bracket so that the chains have some slack in

them.

DANGER

BE SURE TO BLOCK THE LIFT BRACKET WHEN IT IS IN THE

RAISED POSITION. FAILURE TO OBSERVE APPROPRIATE

SAFETY PRECATIONS COULD RESULT IN BODILY HARM OR

PROPERTY DAMAGE.

2-2

(3/05)

Chapter 2: Installation

Remove the Forklift Truck’s Lift Bracket

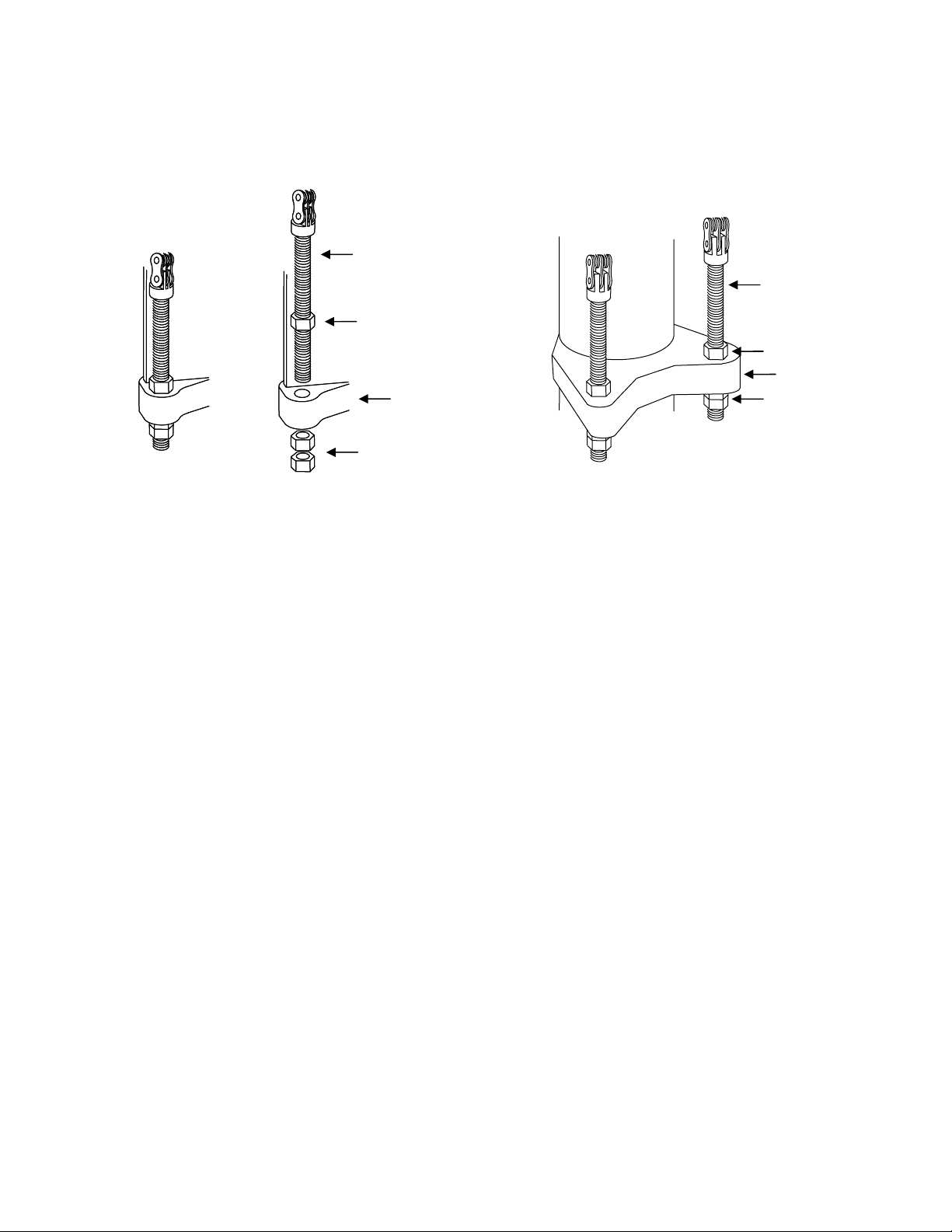

7.

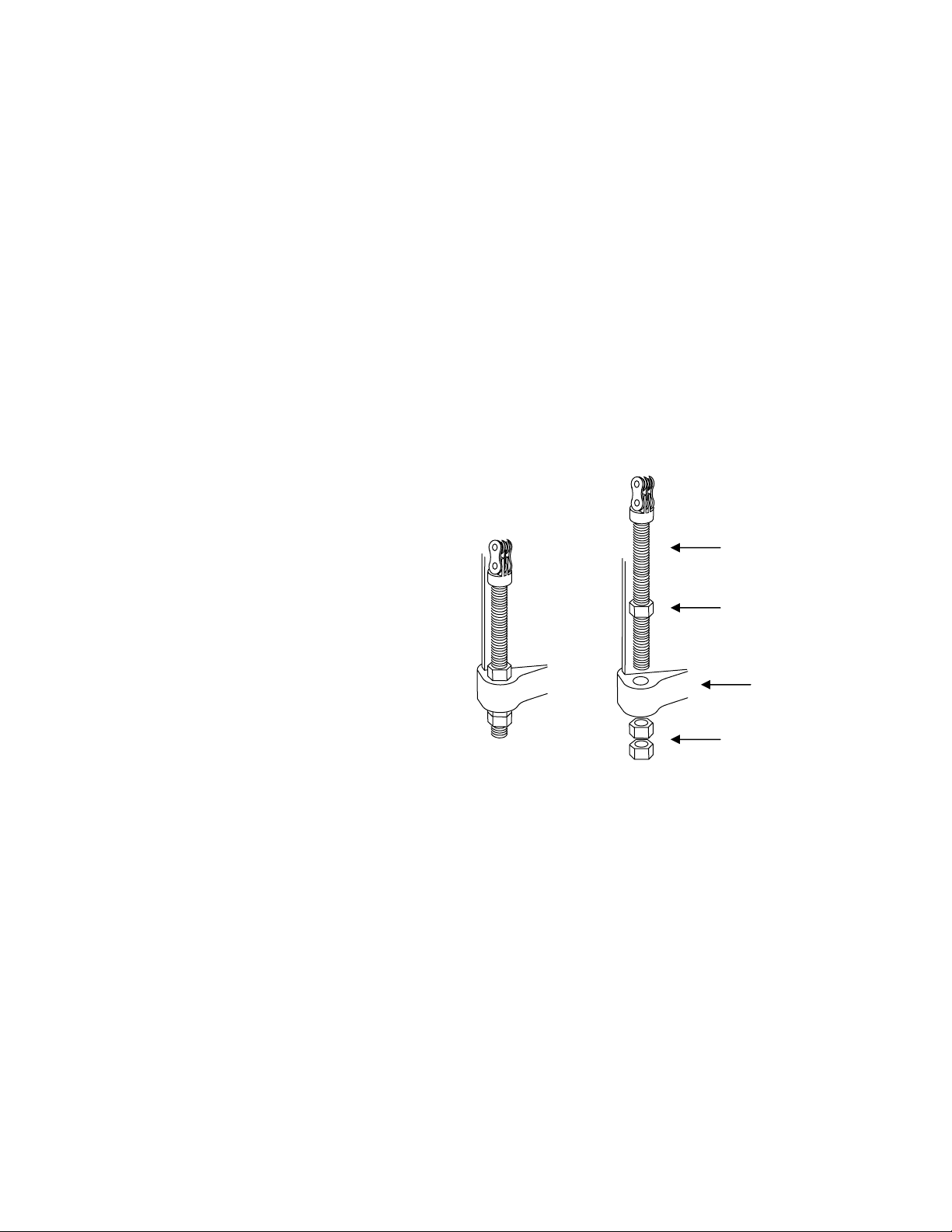

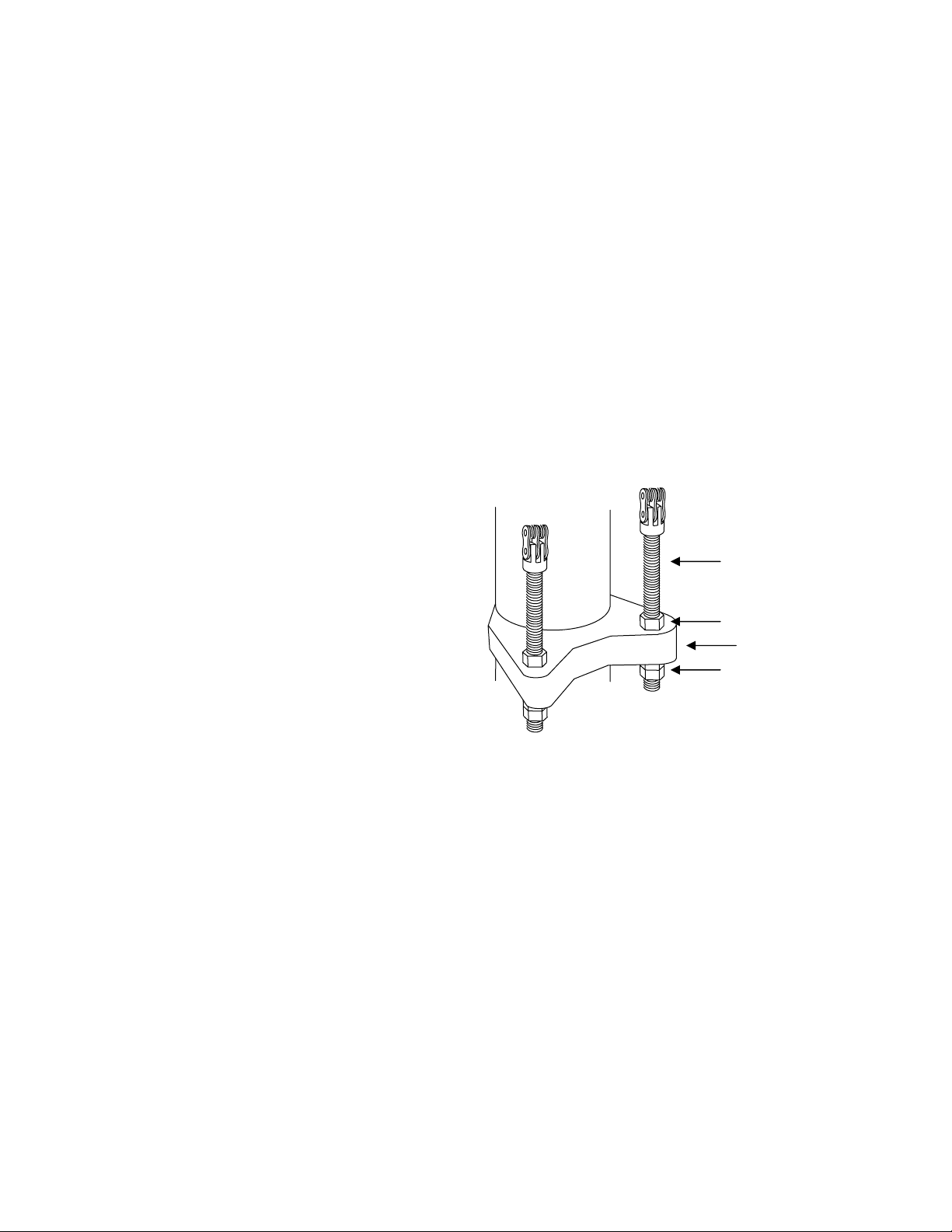

Disconnect the two chain anchors from the mast by removing the lower jam nut

from each anchor (see Figure 2-2). Keep the nuts with the chain anchor to use

them for installing the scale carriage.

Chain Anchor

Chain Anchor

Jam Nut

Jam Nut

Mast

Jam Nuts

Mast

Simplex Version

Jam Nuts

Triplex Version

Figure 2-2: Chain Anchor Assembly

8.

Remove the chains from the pulleys at the top of the mast. Then position the chains

over the front of the lift bracket so that they will not interfere with removing the lift

bracket from the mast.

9.

Raise the bottom of the inner mast at least 2 feet off the floor to allow enough room

to remove the lift bracket from the bottom of the mast.

10.

Use the crane to lower the lift bracket to the floor and remove it from the bottom of

the mast.

11.

Place the lift bracket on a stable working surface, with the front side of the lift

bracket facing downward to provide easy access to the rollers and chain mounts.

12.

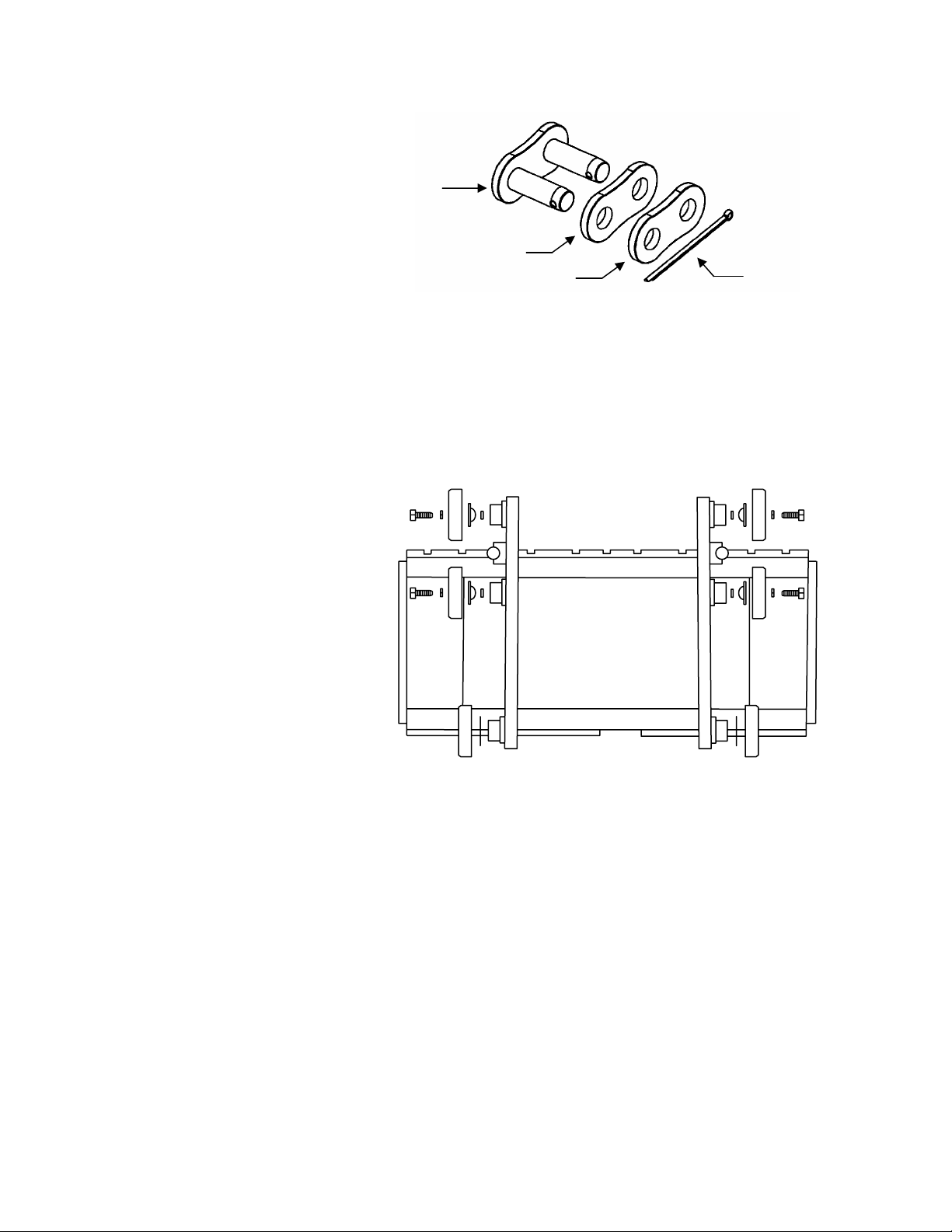

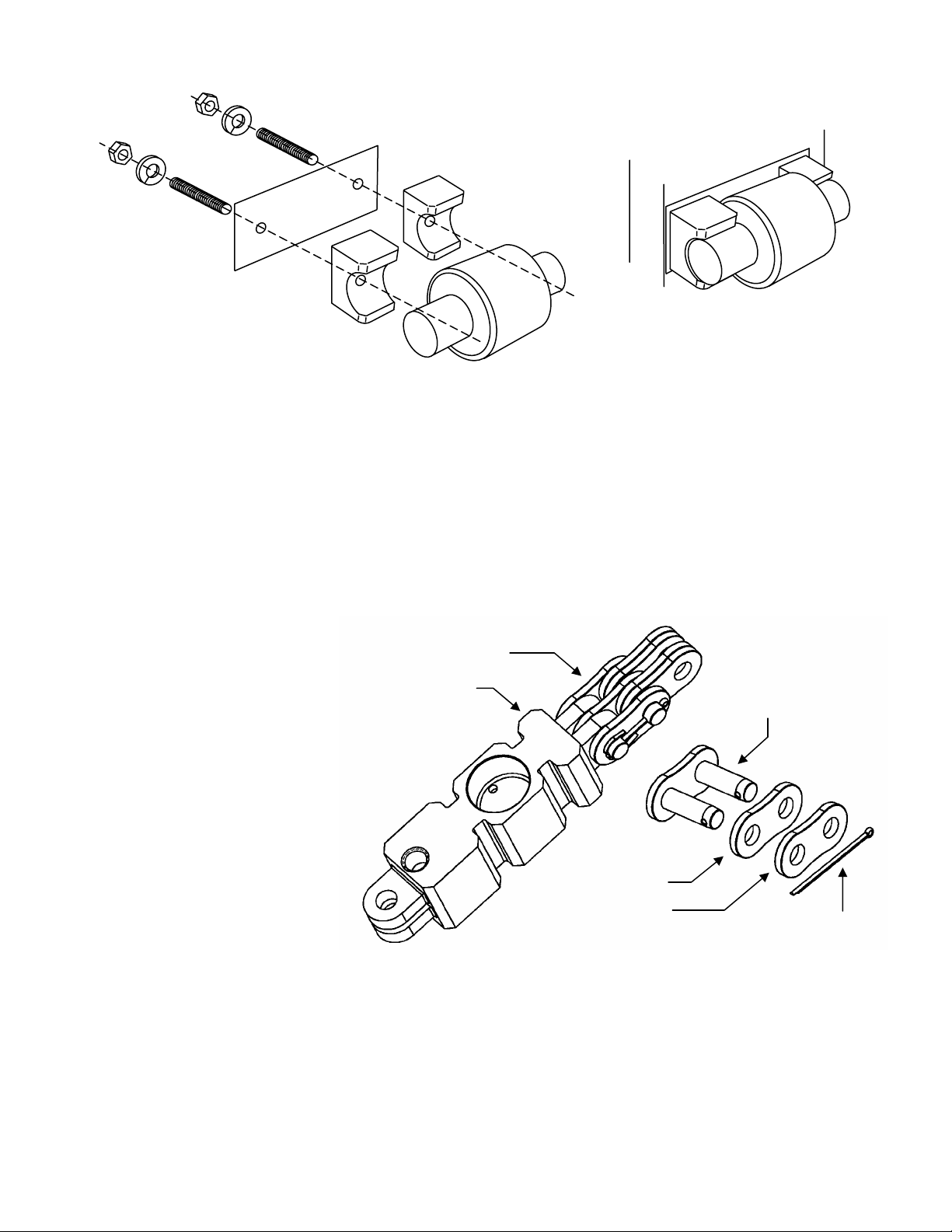

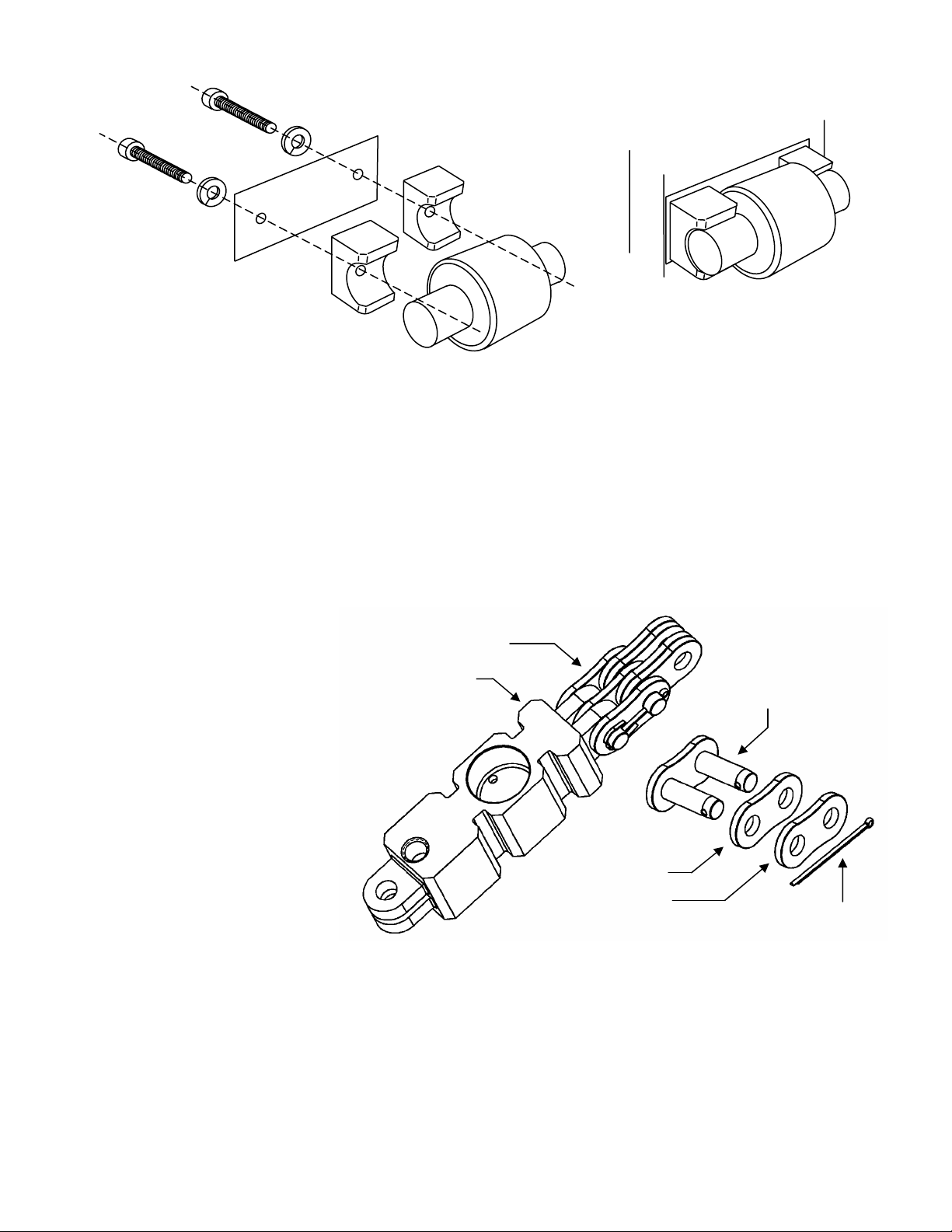

Disconnect the two chains from the lift bracket. Remove the cotter pin from the

master link that is connected to the 90° joint in each chain (see Figure 2-3). Then

take apart the master link, using a C-clamp or similar device to press the master

link through the link plates. Do not use a hammer or other tool to strike the master

link. It could damage the link. Keep the chains and master links to install on the

scale carriage.

(3/05)

2-3

METTLER TOLEDO MCFA Forklift Scale Service Manual

Master Link

Link Plate (Large Holes)

13.

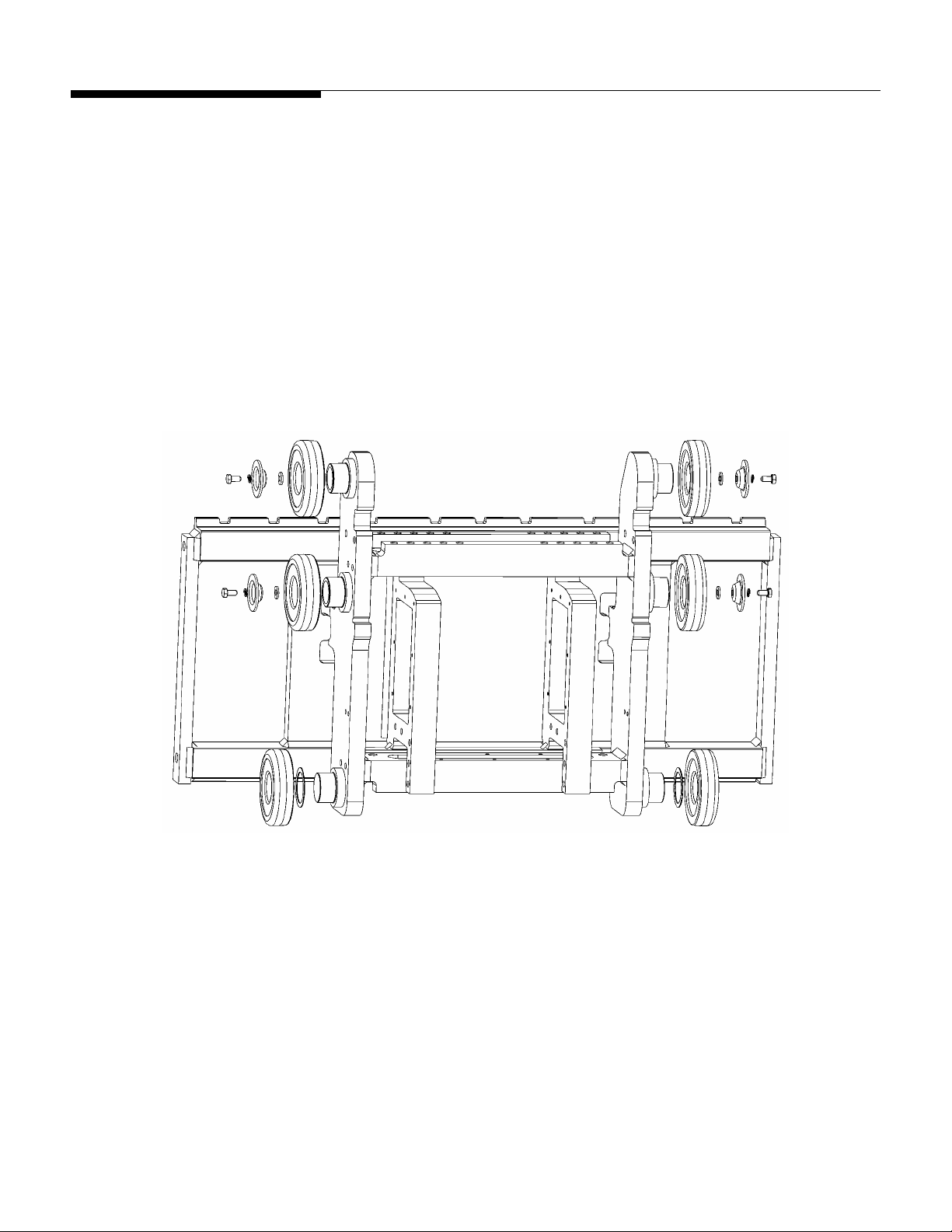

Remove the six main rollers from the lift bracket (see Figure 2-4). The two top

rollers on each side of the lift bracket are secured with screws. The bottom roller on

each side of the lift bracket can be removed by hand. Save the rollers, screws,

washers, and shims so that you can install them on the scale carriage.

Link Plate (Small Holes)

Figure 2-3: Master Link Assembly

Cotter Pin

2-4

(3/05)

Figure 2-4: Remove Main Rollers

14.

Locate the side roller on each side of the lift bracket. Remove the two bolts that

secure each side roller assembly to the lift bracket (see Figure 2-5). Keep these

assemblies together because you will need to install them on the scale carriage.

Note the position of any shims used in the assemblies.

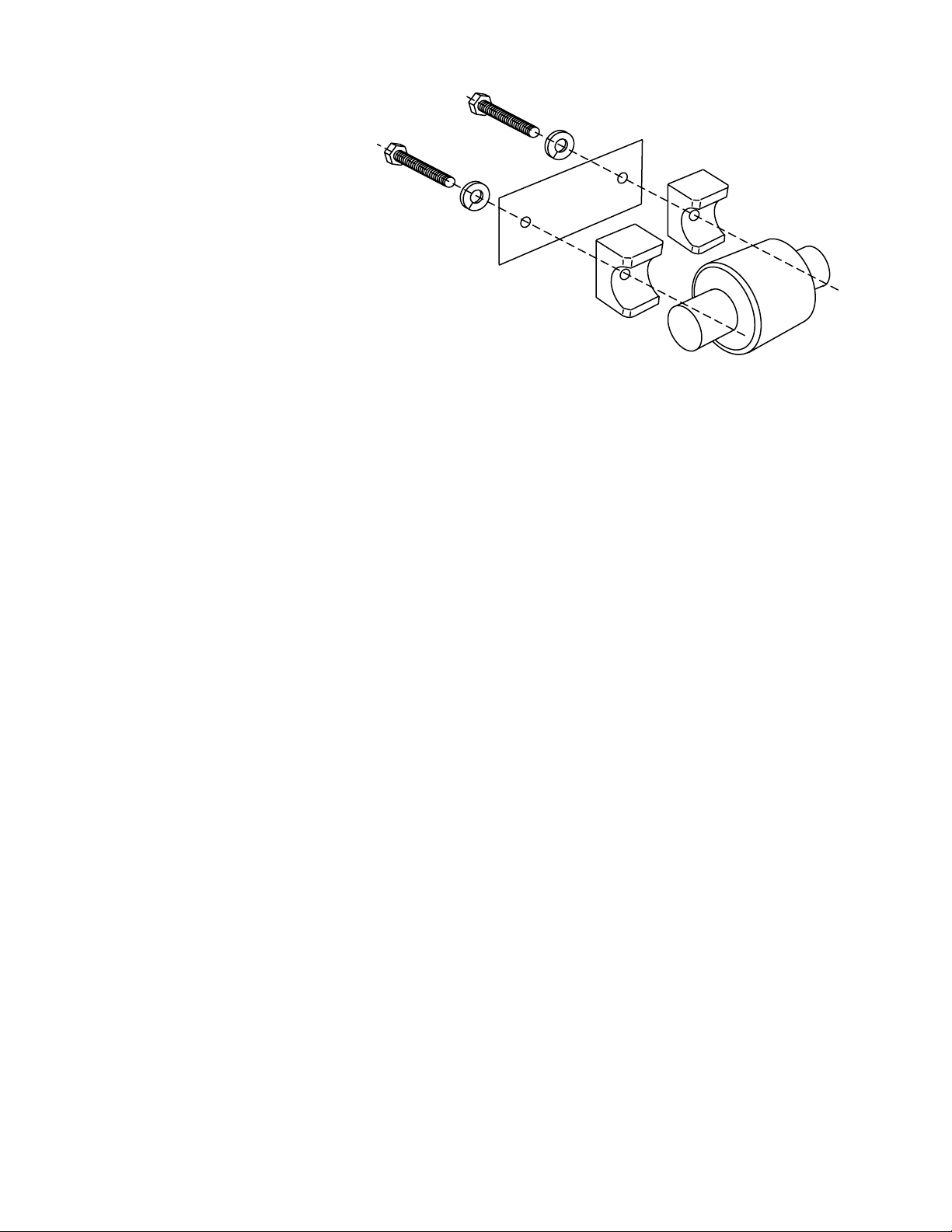

Figure 2-5: Side Roller Assembly

15.

Set the lift bracket aside, and remove the sling from it.

Chapter 2: Installation

Remove the Forklift Truck’s Lift Bracket

(3/05)

2-5

METTLER TOLEDO MCFA Forklift Scale Service Manual

Install the Simplex

Scale Carriage

1.

Park the forklift truck on a level surface, and make sure the mast is in the vertical

position.

2.

Place the scale carriage on a stable working surface, with the front side of the

carriage facing downward to provide easy access to the rollers and chain load

cells.

3.

Install the two lower main rollers by sliding them onto the roller shafts at the bottom

of each side of the scale carriage (see Figure 2-6). Be sure to install any shims that

were removed from the forklift truck’s lift bracket.

4.

Install the other four main rollers on the scale carriage, securing them with the bolts

that were removed from the lift bracket (see Figure 2-6).

2-6

(3/05)

Figure 2-6: Install Main Rollers

5.

Mount the two side roller assemblies (including shims) on the scale carriage (see

Figure 2-7). Do not use the bolts that were removed from the lift bracket. Instead,

use the studs and nuts provided with the scale carriage. Align the two holes in each

side roller assembly with the holes located midway between the two bolted rollers

on each side of the carriage. Insert the studs in the holes and screw them into the

assembly. Then place the washers and nuts on the ends of the studs and tighten

them against the carriage.

Chapter 2: Installation

Install the Simplex Scale Carriage

Figure 2-7: Side Roller Assembly

6.

Use a master link to connect each chain to one of the chain load cells on the scale

carriage. Assemble the master link as shown in Figure 2-8. Using a C-clamp or

similar device, press the master link assembly together just enough so that you can

insert the cotter pin in the holes. If the link is too tight, it can bind against the load

cell and chain mount. If the link does not rotate freely on the load cell or chain,

press the master link back through the link plates until it rotates freely.

NOTE: When a forklift scale is installed, a standard chain should have 34 links

(including master links). Add or remove links if necessary.

Assembled Master Link

Chain Load Cell

Master Link

Link Plate

(Large Holes)

Link Plate

(Small Holes)

Figure 2-8: Connect Chain to Load Cell with Master Link

Cotter Pin

7.

Position the chains over the front of the carriage so that they will not interfere when

you install the carriage in the forklift mast.

8.

Raise the bottom of the inner mast at least 2 feet off the floor to allow enough room

to install the carriage from the bottom of the mast.

9.

Wrap a sling securely around the upper part of the scale carriage.

(3/05)

2-7

METTLER TOLEDO MCFA Forklift Scale Service Manual

10.

Attach the sling to a crane (or other lifting device with a capacity of at least 500

lb), and use the crane to lift the scale carriage. Position the carriage so that its

main rollers fit into the bottom of the mast channel. The chain load cells are loca

on the back side of the scale carriage.

11.

Raise the carriage to a comfortable working position, keeping the main rollers

aligned inside the mast channel. Move the carriage up and down several times

make sure that it moves freely within the mast. If the carriage fits too tightly within

the mast, you might need to remove shims from the bottom rollers or side rollers.

ted

to

12.

Position two blocks of wood (3 inches high) on the floor under the carriage’s lowe

fork bar. Lower the inner mast and carriage until the fork bar rests on the blocks.

13.

Route the chains over the pulleys at the top of the mast.

14.

Remove the lower nut from each chain anchor and insert

the anchor into the hole in

the mast, below and behind the chain pulleys. Place the lower nut on the threaded

anchor and tighten it until both it and the upper nut are tight against the mast (see

Figure 2-9). You will need to adjust the anchors later, so do not tighten the nuts too

much. Make sure there is no slack in the chains, so that the carriage does not drop

when you remove the sling.

Chain Anchor

Jam Nut

Mast

r

2-8

(3/05)

Jam Nuts

Figure 2-9: Chain Anchor Assembly

5.

Remove the sling from the scale carriage.

1

16.

Raise the carriage slightly. Put the forks ba

ck on the lift truck, positioning a fork at

the next to last notch on each side of the carriage.

17.

Lower the carriage to the floor so that the stages of

the mast are completely

collapsed.

18.

Adjust the c

hain anchors so that each chain has 3/4 inch of slack. This will allow

room for the chains to adjust when the mast is set at an angle. With the mast in the

vertical position and the carriage fully lowered, the distance between the floor and

the bottom of the scale carriage should be 76 to 80 mm (about 3 inches).

19.

After installing the scale controller and scale carriage, place a pallet on the fo

and exercise the scale to make sure that all components seat properly. Repeatedly

place a test weight on the scale, positioning it on the center of the scale and at

each corner of the scale.

rks

Install the Triplex Scale

Carriage

Chapter 2: Installation

Install the Triplex Scale Carriage

1.

Park the forklift truck on a level surface, and make sure the mast is in the vertical

position.

2.

Place the scale carriage on a stable working surface, with the front side of the

carriage facing downward to provide easy access to the rollers and chain load

cells.

3.

Install the

two lower main rollers by sliding them onto the roller shafts at the bottom

of each side of the scale carriage (see Figure 2-10). Be sure to install any shim

that were removed from the forklift truck’s lift bracket.

4.

the other four main rollers on the scale carriage, securing them with the bolts

Install

that were removed from the lift bracket (see Figure 2-10).

s

Figure 2-10: Install Main Rollers

5.

Mount the two side roller assemblies (including shims) on the scale carriage (see

Figures 2-10 and 2-11). Align the two holes in each side roller assembly with the

h o bolted rollers on each side of the carriage.

oles located midway between the tw

Use two socket head screws and washers to secure each side roller assembly.

(3/05)

2-9

METTLER TOLEDO MCFA Forklift Scale Service Manual

Figure 2-11: Side Roller Assembly

6.

Use a master link to connect each chain to one of the chain load cells on the scale

carriage. Assemble the master link as

similar device, press the master link assembly together just enough so that you can

insert the cotter pin in the holes. If the link is too tight, it can bind against the load

cell and chain mount. If the link does not rotate freely on the load cell or chain,

press the master link back through the link plates until it rotates freely.

shown in Figure 2-12. Using a C-clamp or

NOTE: When a forklift scale is installed, a standard chain should have 33 links

(including master links). Add or remove links if necessary.

As

sembled Master Link

Chain Load Cell

Master Link

Link Plate

(Large Holes)

Link Plate

(Small Hol

Figure 2-12: Connect C d C nk

hain to Loa ell with Master Li

es)

Cotter Pin

2-10

(3/05)

7.

Position the chains over the front of the carriage so that they will not interfere when

you insta

.

Raise the bottom of the inner mast at least 2 feet off the floor to allow enough room

8

ll the carriage in the forklift mast.

to install the carriage from the bottom of the mast.

9.

Wrap a sling securely around the upper par

t of the scale carriage.

Chapter 2: Installation

Install the Triplex Scale Carriage

10.

Attach the sling to a crane (or other lifting device with a capacity of at least 500

lb), and use the crane to lift the scale carriage. Pos

main rollers fit into the bottom of the mast channel. The chain load

ition the carriage so that its

cells are located

on the back side of the scale carriage.

11.

Raise the carriage to a comfortable working position, keeping the main rollers

aligned inside the mast channel. Move the carriage up and down several times to

make sure that it moves freely within the mast. If the carriage fits too tightly within

the mast, you might need to remove sh

ims from the bottom rollers or side rollers.

12.

Position two blocks of wood (3 inches high) on the floor under the carriage’s lower

fork bar. Lower the inner mast and carriage until the fork bar rests on the blocks.

13.

Route the chains over the pulleys at the top of the mast.

14.

Remove the lower nut from each chain anchor and insert the anchor into the hole in

the mast, below and behind the chain pulleys. Place the lower nut on the threaded

anchor and tighten it until both it and the upper nut are tig

Figure 2-13). You will need to adjust the anchors later, s

ht against the mast (see

o do not tighten the nuts

too much. Make sure there is no slack in the chains, so that the carriage does not

drop when you remove the sling.

Chain Anchor

Jam Nut

Mast

Jam Nuts

Figure 2-13: Chain Anchor Assembl

y

15.

Remove the sling from the scale carriage.

16.

Raise the carriage s , positioning a fork at

lightly. Put the forks back on the lift truck

the next to last notch on each side of the carriage.

17.

Lower the carriage to the floor so that the s

tages of the mast are completely

collapsed.

18.

Adjust the chain anchors so that each chain has 3/

4 inch of slack. This will allow

room for the chains to adjust when the mast is set at an angle. With the mast in the

vertical position and the carriage fully lowered, the distance between the floo

the bottom o

19.

After installing the scale controller and scale carriage, place a pallet on the forks

f the scale carriage should be 76 to 80 mm (about 3 inches).

and exercise the scale to make sure that all components seat properly. Repeatedly

place a test weight on the scale, positioning it on the center of the scale and at

each corner of the scale.

(3/05)

r and

2-11

METTLER TOLEDO MCFA Forklift Scale Service Manual

Batteries

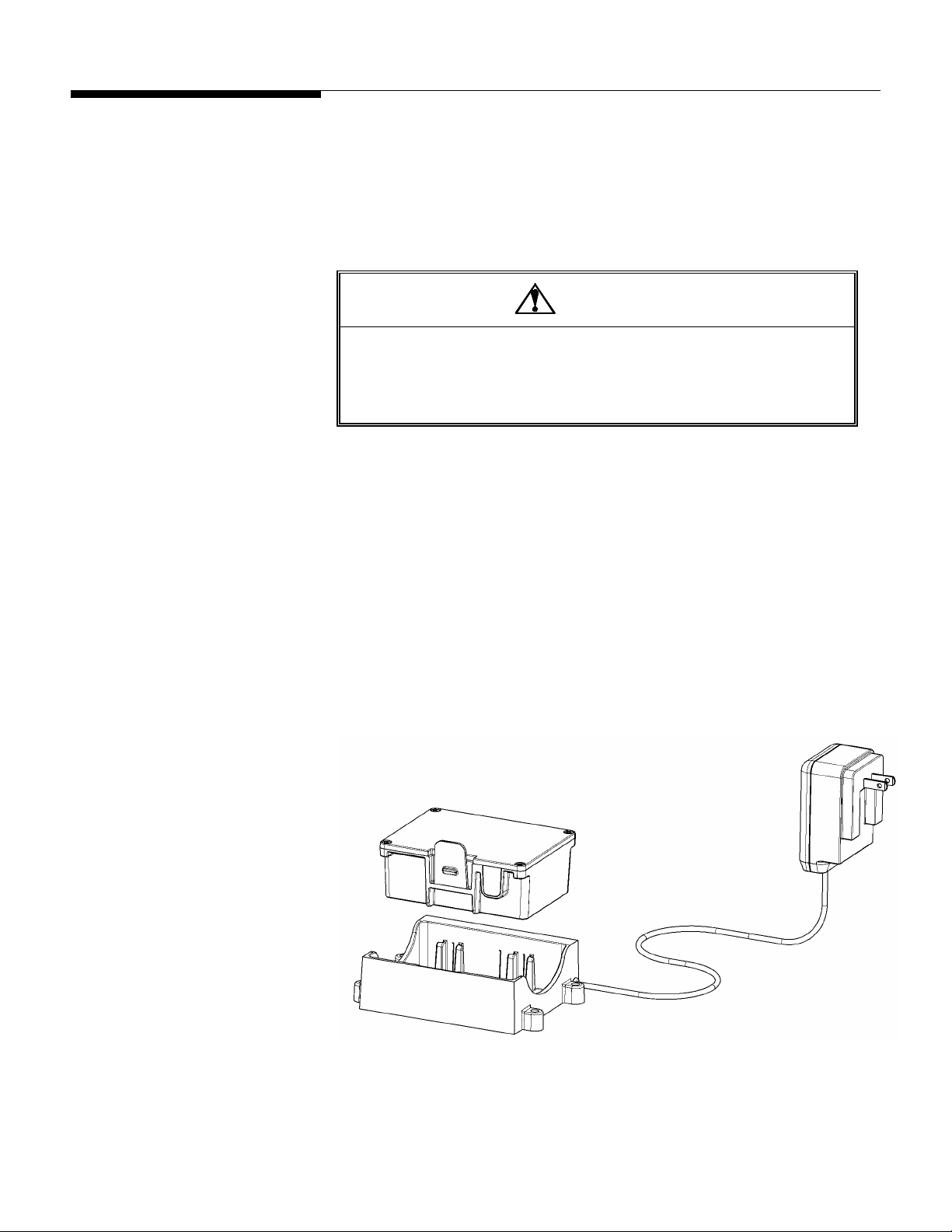

A 12-volt battery pack is used to power the scale’s load cells and carriage radio. The

scale is supplied with two batteries and a battery charger. New batteries must be

charged before they can be used. A fully charged battery will allow you to operate the

scale for up to 36 hours. The battery level indicator on the scale controller’s main

weighing screen alerts the driver when the battery’s voltage level is low.

CAUTION

THERE IS A RISK OF EXPLOSION IF A BATTERY IS REPLACED WITH AN INCORRECT

TYPE OF BATTERY. DISPOSE OF BATTERIES ACCORDING TO LOCAL REGULATIONS.

FOR DISPOSAL INFORMATION, REF NFORMATION SHEET FOR

NICKEL METAL HYDRIDE BATTERIE sonic.com OR REFER TO

THE RECHARGEABLE BATTERY RECYCLING CORPORATION (www.rbrc.org).

ER TO THE PRODUCT I

S (NiMH) AT www.pana

• tion the

To install a battery, insert it in the scale carriage’s battery compartment. Posi

battery so that the metal contacts on its side fit against the metal contacts in

the

battery compartment.

To remove a battery, press the plastic tab toward the center of the battery and pull

•

the battery out of the battery compartment.

•

To charge a battery, insert it in the battery charger (see Figure 2-14). Then plug the

battery charger into a standard electrical

outlet (110 volts). It will take 12 to 16

hours to provide the initial charge for a new battery. Once a battery has been used,

it should take no more than 3 to 4 hours to

recharge it. A red light on the battery

charger indicates that the battery is being charged. A green light indicates that the

battery is fully charged. When a battery is fully charged, the charger goes into

trickle mode, so there is no danger of damaging a battery by overcharging it.

2-12

Figure 2-14: Battery and Batter Charger

(3/05)

Geo Index

Chapter 2: Installation

Geo Index

To compensate for local gravitational forces, change the geo index to the setting for the

location where the scale will be used. The factory default setting is 16 (the geo index for

Worthington, Ohio, USA). To determine the geo index for a location, refer to the

appendix (Chapter 10). You must know the geographical coordinate for the location

and the elevation above sea level.

1.

To change the geo index, enter the scale controller’s setup mode by touching the

Setup button on the main weighing screen.

2.

Touch the Scale button, touch the Calibration button, and then touch the Where

Used button.

3.

A keypad is used to enter the geo index. Type a number in the data field by

touching the numeric keys on the keypad (the range is 0 to 31). Touch the Clear

button if you wish to clear the data field and start over.

4.

Touch the Enter button to confirm your selection or the Cancel button to cancel any

changes that you made.

Shift Adjustment

Forklift scales are calibrated at the factory and should not need to be recalibrated when

they are installed. You should, however, check the scale after installing it to see if it

needs to be shift adjusted. A correctly adjusted scale will give you the same weight

reading no matter where on the forks you place a test weight. If the weight readings at

the shift test locations are out of tolerance, shift adjust the scale to correct the problem.

Park the forklift truck on a level surface, place a pallet on the forks, raise the forks 12 to

15 inches off the ground, set the mast to the vertical position, and shut off the forklift

truck’s motor. Then check the scale’s repeatability by placing a test weight on the same

location on the pallet several times to make sure that you get the same weight reading

each time.

After verifying the scale’s repeatability, check to see if the scale needs to be shift

adjusted. For shift adjustments, we recommend using test weights equal to one half the

scale’s maximum weighing capacity. The test weights must meet the specified National

Institute of Standards and Technology Handbook 44 accuracy requirements.

NOTE: When performing a shift adjustment, use the weight readings on the data screen

instead of those on the main weighing screen. The weight readings on the data screen

are displayed to two decimal places, although the number in the second decimal place

might not be stable.

(3/05)

2-13

METTLER TOLEDO MCFA Forklift Scale Service Manual

Shift Test Locations

Place a pallet or other flat surface (approximately 4 feet by 4 feet) on the forks and

make sure that it is level. Figure 2-15 shows test weight locations (1, 2, 3, and 4) at

the center of each quadrant of the pallet. Place the test weight at location 1 and record

the weight reading. Then move the test weight to location 2 and record the weight

reading. Continue until you have taken a weight reading at each of the four locat

ions.

Heel Heel

Flexure

B

C

Flexure

1

4

A

D

2 3

Toe Toe

1

4

2

3

Figure 2-15: Shift Adjustment Locations (Simplex Version Shown)

Ideally, the scale will give you the same weight reading at all four locations. The weight

readings at the heel and toe of either or both forks should be within Handbook 44

tolerance requirements (±2.5 lb for weights up to 2,500 lb). If the weight readings are

out of tolerance, you will need to shift adjust the scale. This is done by adding shims to

the flexures at the locations shown in Figure 2-15. To determine where to add shims,

refer to Table 2-1.

2-14

(3/05)

If weigh

t reading 1 is greater than 2

If weight reading 2 is greater than 1

If weight reading 3 is greater than 4

If weight reading 4 is greater than 3

→

→

→

→

Shim at location A

Shim at location B

Shim at location C

Shim at location D

Table 2-1: Shim Locations

The shims adjust the differences between the weight readings at the heel and toe of an

dividual fork. Adjust the weight readings so that they are as near to equal as possible.

in

If one weight reading is slightly higher, it should be the reading at the toe of the fork.

Shimming at the front of a flexure (location A) will increase the weight reading at the toe

of the fork (location 2). Because the shim affects the entire fork, it will also slightly

increase the weight reading at the heel (location 1).

Shimming at the back of a flexure (location B) will decrease the weight reading at the

toe of the fork (location 2). Because the shim affects the entire fork, it will also slightly

decrease the weight reading at the heel (location 1).

A pallet places load on both forks. So when a pallet is used, shimming under a flexure

will affect the readings at all four test weight locations. For example, shimming at

Chapter 2: Installation

Shift Adjustment

location A or B will ch

ange the readings at locations 1 and 2, but it will also change the

readings at locations 3 and 4 to a lesser extent.

Keep in mind that, in addition to balancing the weight readings at the heel and toe of

each fork, you are also trying to balance the weight readings of the two forks.

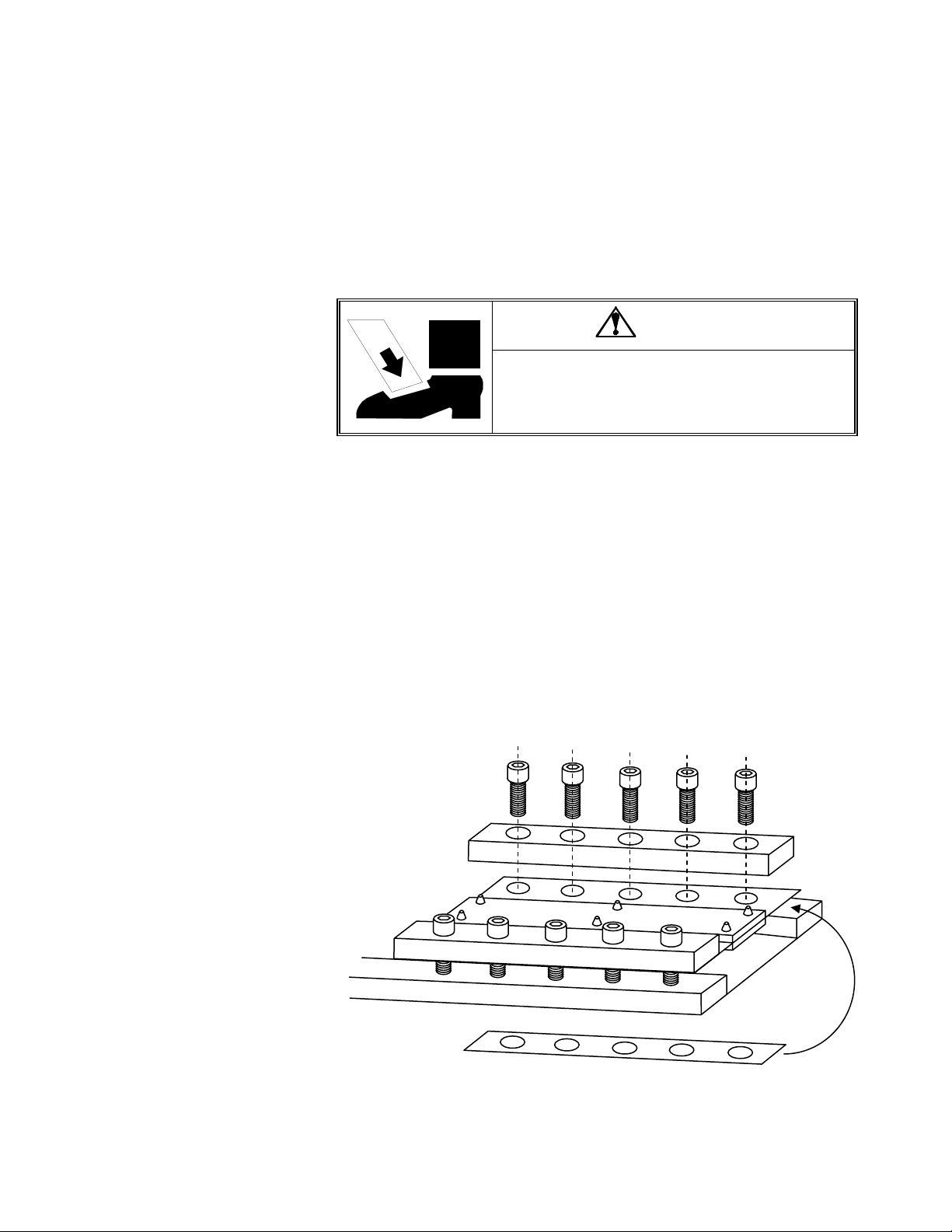

Shimming Procedure

o not remove the bolts from more than one flexure at a time. The flexures connect the

D

o se

tw ctions of the scale carriage. If you unbolt the two top or bottom flexures, the

ections of t rriage c separate an injury or damage the flex .

s he ca ould d cause ures

DANGER

DO NOT REMOVE THE BOLTS FROM MORE THAN ONE

FLEXURE AT A TIME WHILE THE CARRIAGE IS INSTALLED

N THE FORKLIFT. UNBOLTING MORE THAN ONE FLEXURE

O

OULD RESULT IN BODILY HARM OR PROPERTY DAMAGE.

C

1.

Remove the bolts from the side of the flexure where shims will be added.

.

Loosen the bolts on the opposite side of the flexure.

2

.

Place a shim under the flexure, aligning the bolt holes in the sh with those in the

3

im

flexure. We recommend starting with the thinnest shim and gradually increasing

the shim thickness as needed to balance the weight readings.

4.

Repl ).

ace the bolts that were removed, and tighten all bolts (torque to 90 ft-lb

5.

Repeat steps 1-4 for the second flexure if needed.

6.

Take new weight readings at all four test weight locations. If the weight readings

are still not equal, repeat the procedure to add additional shimming.

7.

When you have finished shift adjusting the scale, you should get approximately th

same weight re

ading at all four test weight locations.

Remove bolts

to add shim

e

Lo

osen bolts

on opposite

side of flexure

Figure 2-16: Shimming Procedure (Sim

plex Version Shown)

(3/05)

shim

Add

under flexure

2-15

Chapter 3: Scale Operations

Power-up Sequence

3

Scale Operations

Power-up Sequence

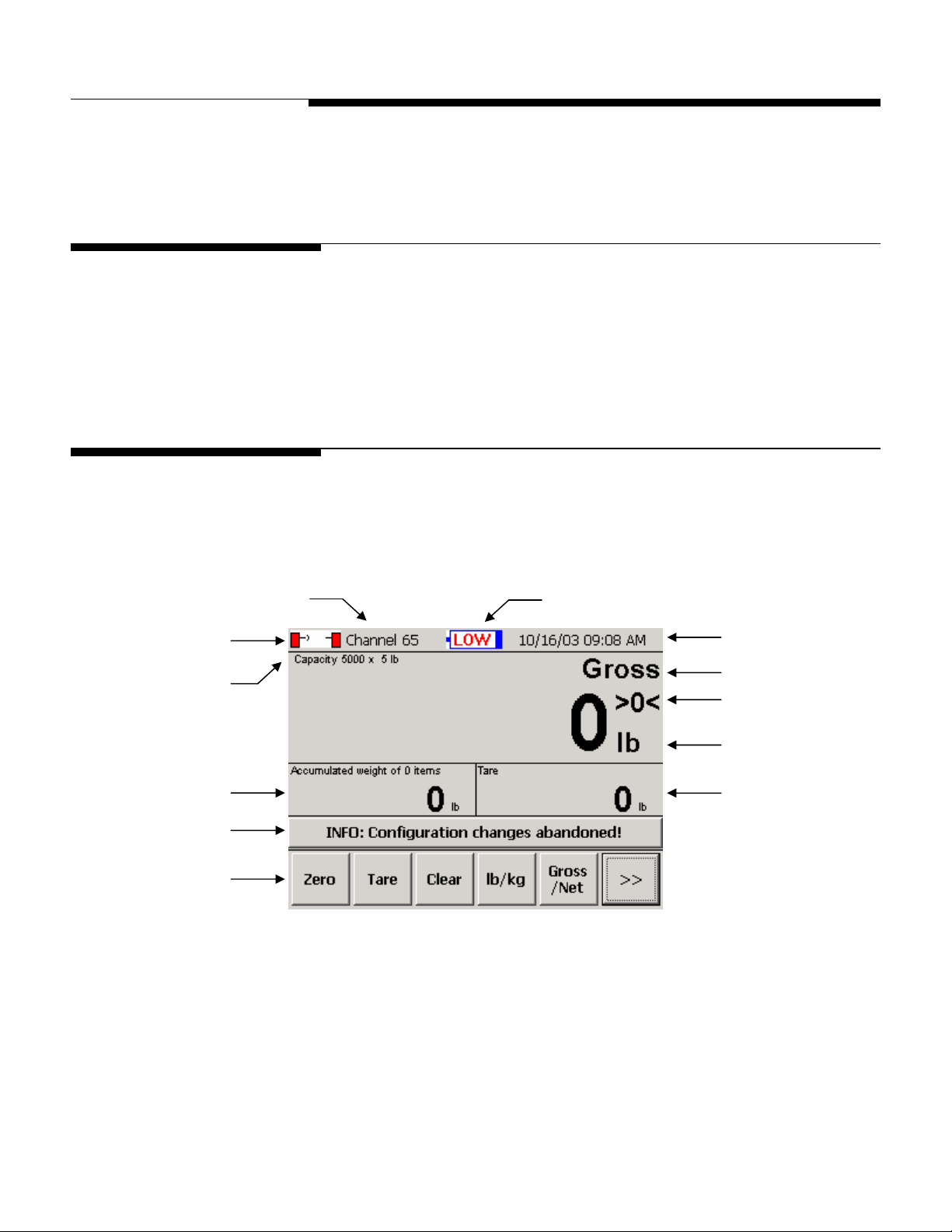

Weighing Screen

Radio Channel

Radio Communication

Remove all load from the forks and raise the forks off the ground whenever you power

up the scale controller. Start the forklift truck’s motor, and then press the on/off button in

the upper right-hand corner of the controller’s front cover. During the controller’s powerup sequence, it will display the version number and build number of the scale software.

When the controller is fully powered up, it will display the main weighing screen.

All weighing operations can be performed from the scale controller’s main weighing

screen. In addition to displaying current weight data, the screen provides push buttons

used to perform weighing operations and to enter setup mode.

Battery Level Indicator

Time and Date

Maximum Capacity

and Increment Size

Accumulated Weight

Message Bar

Push Buttons

Weighing Mode

“~” Indicates when

Scale is in Motion

Weight Reading

Tare Weight

Figure 3-1: Main Weighing Screen

Radio Communication: When the indicator is green, the radios are communicating.

When it is red, there is no communication.

Battery Level Indicator: The blue color indicates the battery level. The indicator will

display a warning message when the battery level is low and when the battery needs to

be changed. The battery discharge cradle has a low-voltage cutoff that shuts off power

to the scale carriage when the battery voltage drops to the “change battery” level

(approximately 10.5 volts).

(3/05)

3-1

METTLER TOLEDO MCFA Forklift Scale Service Manual

Push Buttons

The push buttons at the bottom of the main weighing screen are used to perform

weighing functions and to enter setup mode.

Zero

The Zero button is used to zero the scale manually. This feature can be used if the

weight reading on the screen does not return to zero when all load has been removed

from the scale. In order for this button to zero the scale manually, (1) the scale must be

in gross weighing mode and (2) the weight reading on the screen must be within the

range specified in the manual range setup feature. The scale also includes an automatic

zero maintenance (AZM) feature. When AZM is enabled, the scale will be zeroed

automatically if the weight reading is within a specified range.

Tare

The Tare button is used to assign the weight that is currently on the scale as a tare

weight. The tare weight is the weight of an empty pallet or container. It is subtracted

from the gross weight (weight of the loaded pallet or container) to determine the net

weight (weight of the item on the pallet or the material in the container). The tare weight

will be displayed in the Tare field. This button will work only if push button tare is

enabled in scale setup.

Clear

The Clear button is used to remove a tare weight reading or accumulated weight

reading that is displayed on the screen. To remove a tare weight reading, touch the

Clear button and then touch the Tare button. To remove an accumulated weight

reading, touch the Clear button and then touch the Accum button.

Accumulator

The Accum button is used to accumulate a series of weights and sum them to calculate

a total weight. When you touch the Accum button, the gross or net weight that is

displayed on the screen will be added to the weight reading in the Accumulated Weight

field. This button will be available only if basic accumulate is enabled in application

setup.

Gross/Net

The Gross/Net button is used to switch between gross and net weight readings on the

screen. In order to switch to a net weight reading, you must first assign a tare weight.

This button will work only if gross/net switching is enabled in scale setup.

>>

The double arrow button is used to display additional push buttons on the screen.

Setup

The Setup button is used to enter setup mode on the controller. For an explanation of

the setup features and how to use them, refer to the “Scale Setup” section of this

manual.

3-2

(3/05)

Keyboard Tare

The Keybd Tare button is used to enter a tare weight manually. The tare weight is the

weight of an empty pallet or container. It is subtracted from the gross weight (weight of

the loaded pallet or container) to determine the net weight (weight of the item on the

pallet or the material in the container). When you touch the Keybd Tare button, a

keypad will appear on the screen. Type the tare weight by touching the numerical keys

on the keypad. Then touch the

Enter button. The tare weight will be displayed in the Tare

field. This button will work only if keyboard tare is enabled in scale setup.

Chapter 3: Scale Operations

Weighing Operations

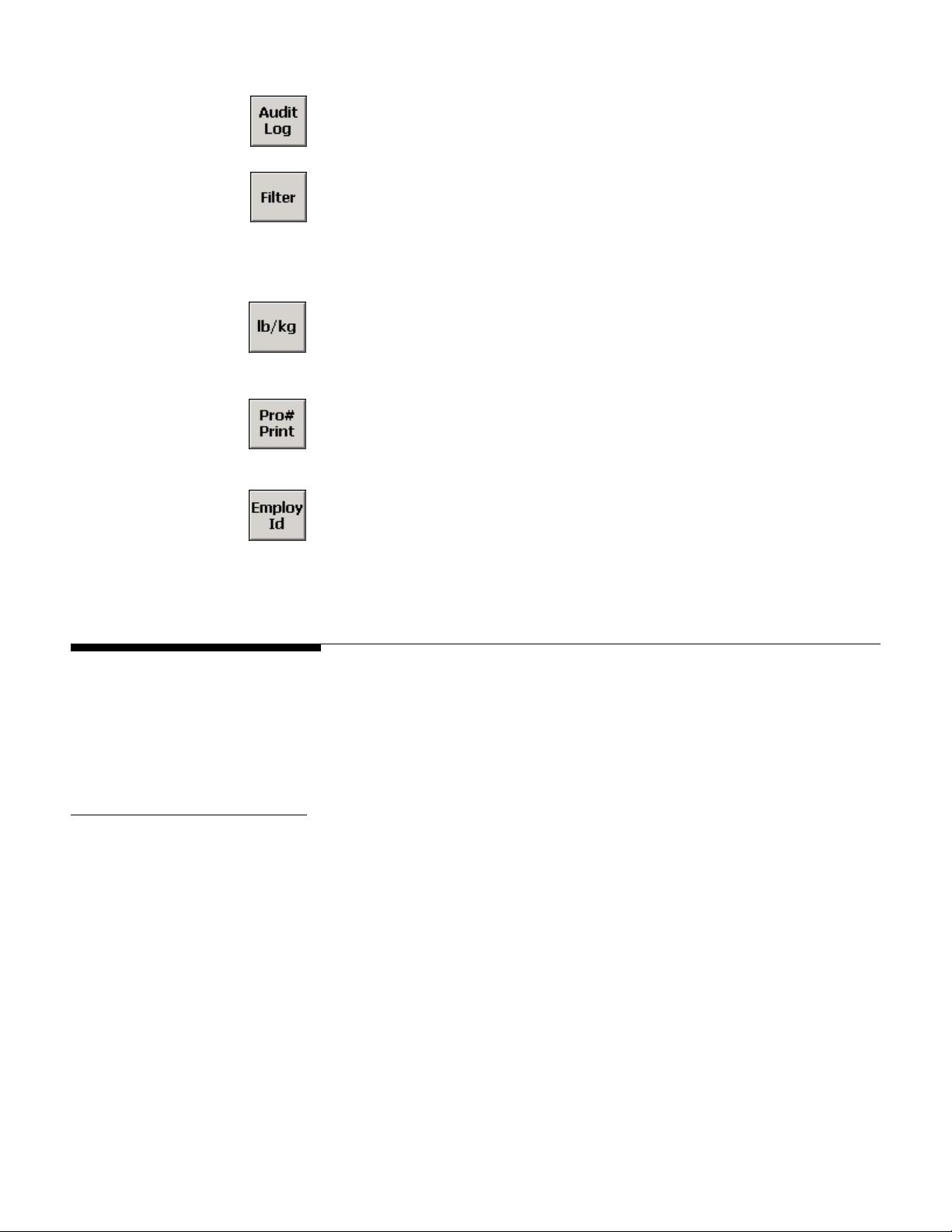

Audit Log

The Audit Log button is used to view the scale’s log that is required for Weights and

Measures audits. The log lists all calibration and configuration changes.

Filter

The Filter button is used to adjust the vibration filtering for the scale. It lets you adjust

filtering without entering setup mode. You can disable filtering or specify a filtering level

(Light, Lt/Med, Medium, Med/Hvy, or Heavy). Any changes made using this button will

be lost when the scale controller is shut off. At power-up, the scale will revert to the filter

settings that are specified in setup mode.

lb/kg

The lb/kg button is used to switch between weight readings in pounds and kilograms. It

changes the unit of measure for all weights displayed on the screen. This button will

work only if unit switching is enabled in scale setup.

Pro Number

The Pro# Print button is used to enter a shipping number for a SmartWeigh transaction

and create a record of the transaction. This button will be available only if advanced

accumulate is enabled in application setup.

Employee ID

Weighing Operations

Gross Weighing

The Employ ID button is used to enter an Employee ID for a SmartWeigh transaction.

This button will be available only if advanced accumulate is enabled in application

setup. When you touch the button, a keypad will appear on screen. Type the Employee

ID by touching the keys on the keypad. Then touch the Enter button.

This section describes the scale’s basic weighing operations, which are performed from

the controller’s main weighing screen. You can display a gross weight, use a tare

weight to determine a net weight, and use the accumulator to calculate the sum of a

series of gross or net weights.

Use the following procedure to find the gross weight of an item:

1.

Lift the item with the forklift.

2.

The gross weight will be displayed in the Weight field.

(3/05)

3-3

METTLER TOLEDO MCFA Forklift Scale Service Manual

Net Weighing with Push

Button Tare

Push button tare must be enabled in scale setup. Use the following procedure to find the

net weight of an item:

1.

Lift the empty pallet (or container) with the forklift.

2.

The weight will be displayed as a gross weight in the Weight field.

3.

Touch the Tare button.

4.

The weight of the pallet (or container) will be displayed in the Tare field. The

reading in the Weight field will change to zero.

5.

Lift the loaded pallet (or container) with the forklift. You can remove the pallet (or

container) from the forklift to fill it or fill it while it is on the scale.

6.

The net weight of the item will be displayed in the Weight field. If you wish to view

the gross weight of the loaded pallet (or container), touch the Gross/Net button.

7.

If auto clear is enabled, the gross/net weight and tare weight readings on the screen

will automatically return to zero when the load is removed from the scale.

Otherwise, the tare weight will remain on the screen and can be used to weigh

another loaded pallet (or container). To clear the tare weight, touch the Clear button

and then the Tare button.

Net Weighing with

Keyboard Tare

Keyboard tare must be enabled in scale setup. Use the following procedure to find the

net weight of an item:

1.

Lift the loaded pallet (or container) with the forklift.

2.

The weight will be displayed as a gross weight in the Weight field.

3.

Touch the Keybd Tare button.

4.

A keyboard will appear on the screen. Type in the tare weight of the pallet (or

container) by touching the numerical keys on the keyboard. When the correct tare

weight is displayed in the keyboard’s data field, touch the Enter button.

5.

The net weight of the item will be displayed in the Weight field. If you wish to view

the gross weight of the loaded pallet (or container), touch the Gross/Net button.

The tare weight will be displayed in the Tare field.

6.

If auto clear is enabled, the gross/net weight and tare weight readings on the screen

will automatically return to zero when the load is removed from the scale.

Otherwise, the tare weight will remain on the screen and can be used to weigh

another loaded pallet (or container). To clear the tare weight, touch the Clear button

and then the Tare button.

NOTE: You can also use keyboard tare to enter a tare weight before lifting the loaded

pallet (or container) with the forklift.

3-4

(3/05)

Loading...

Loading...