Page 1

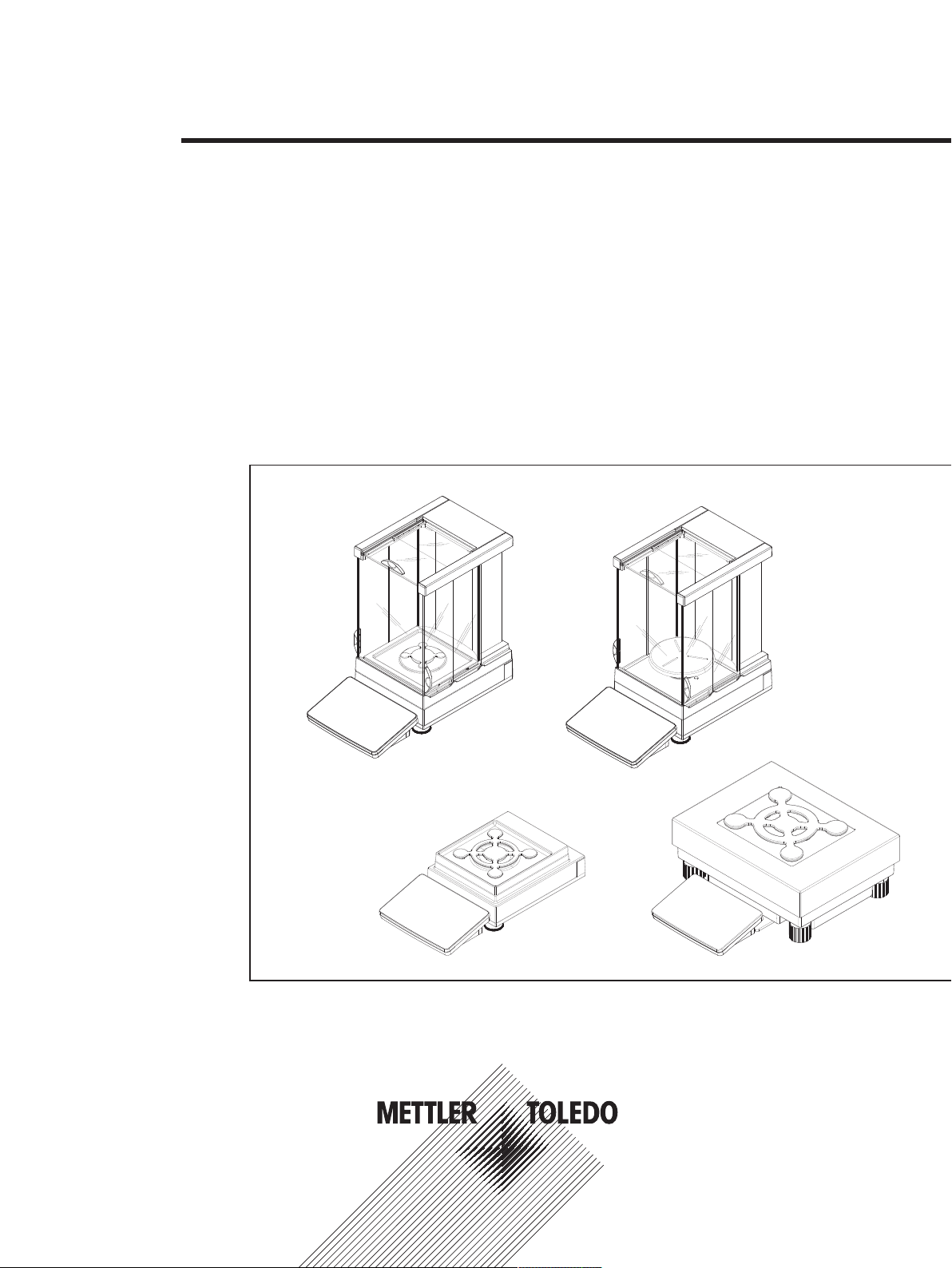

Precision Balances and Comparators

Reference Manual

XPR

Page 2

Page 3

Table of Contents

1 Introduction 7

1.1 Conventions and symbols used in these Reference Manual............................................... 8

2 Safety Information 9

2.1 Definition of signal warning symbols.............................................................................. 9

2.2 Product safety information ............................................................................................ 9

3 Overview and Functions 12

3.1 Overview S weighing platform ....................................................................................... 12

3.2 Overview L weighing platform........................................................................................ 15

3.3 Type plate................................................................................................................... 16

3.4 Terminal ..................................................................................................................... 18

3.5 User Interface .............................................................................................................. 19

4 Installation and putting into Operation 20

4.1 Scope of delivery ......................................................................................................... 20

4.2 Selecting the location ................................................................................................... 22

4.3 Unpacking the balance................................................................................................. 23

4.4 Assembling balances with S weighing platform ............................................................... 23

4.5 Assembling balances with L weighing platform ............................................................... 29

4.6 Connecting the balance to the mains.............................................................................. 31

4.7 Setting up the balance.................................................................................................. 32

4.8 Below-the-balance weighing ......................................................................................... 33

3.1.1 Balances with Pro Draft Shield........................................................................ 12

3.1.2 Comparators with Pro Draft Shield................................................................... 13

3.1.3 Balances without Pro Draft Shield ................................................................... 14

3.1.4 Interface board.............................................................................................. 15

3.2.1 Balances...................................................................................................... 15

3.2.2 Comparators ................................................................................................ 16

3.2.3 Interface board.............................................................................................. 16

3.5.1 Main sections at a glance .............................................................................. 19

4.1.1 Balances with S weighing platform.................................................................. 20

4.1.2 Comparators with S weighing platform ............................................................ 21

4.1.3 Balances with L weighing platform.................................................................. 21

4.1.4 Comparators with L weighing platform............................................................. 22

4.4.1 Attaching the terminal to the weighing platform................................................. 23

4.4.2 Balances 0.1 mg with Pro Draft Shield and SmartPan weighing pan................... 24

4.4.3 Balances 1 mg with Pro Draft Shield ............................................................... 26

4.4.4 Comparators 0.1 mg and 1 mg with LevelMatic weighing pan ........................... 27

4.4.5 Balances 1 mg with SmartPan weighing pan ................................................... 27

4.4.6 Balances 5 mg / 10 mg with SmartPan weighing pan....................................... 28

4.4.7 Balances 0.1 g............................................................................................. 28

4.5.1 Attaching the terminal to the weighing platform................................................. 29

4.5.2 Balances 0.1 g and 1 g................................................................................. 29

4.5.3 Balances 10 mg with SmartPan weighing pan ................................................. 30

4.5.4 Removing the transport arrestments (only for comparators) ............................... 30

4.5.5 Comparators 1 mg / 5 mg with LevelMatic weighing pan .................................. 31

4.7.1 Switching on the balance ............................................................................... 32

4.7.2 Leveling the balance...................................................................................... 32

4.7.3 Performing a simple weighing ........................................................................ 32

4.7.3.1 Zeroing .................................................................................................. 32

4.7.3.2 Taring.................................................................................................... 32

4.7.3.3 Performing General Weighing ................................................................... 33

4.7.4 Setting the balance to standby mode ............................................................... 33

4.7.5 Switching off the balance ............................................................................... 33

Table of Contents 1Precision Balances and Comparators

Page 4

4.8.1 S weighing platform ...................................................................................... 33

4.8.2 L weighing platform....................................................................................... 34

4.9 Transporting the balance .............................................................................................. 34

4.9.1 Carrying the balance over short distances ........................................................ 34

4.9.2 Transporting the balance over long distances ................................................... 35

4.9.3 Packaging and storage.................................................................................. 35

5 Operation 36

5.1 User Interface .............................................................................................................. 36

5.1.1 Main screen "General weighing" ..................................................................... 36

5.1.2 Work screen "Balance menu" ......................................................................... 37

5.1.3 Work screen "Methods".................................................................................. 37

5.1.4 Work screen "Protocol" .................................................................................. 38

5.1.5 Surface navigation of the touchscreen.............................................................. 39

5.1.6 Input dialog.................................................................................................. 39

5.1.6.1 Entering characters and numbers.............................................................. 39

5.1.6.2 Changing date and time........................................................................... 40

5.1.7 System status icons ...................................................................................... 40

5.1.8 Weighing status icons ................................................................................... 40

5.2 Balance menu............................................................................................................. 41

5.2.1 Leveling aid.................................................................................................. 41

5.2.2 History......................................................................................................... 41

5.2.2.1 Changes ................................................................................................ 43

5.2.3 Balance info................................................................................................. 43

5.2.4 User management......................................................................................... 43

5.2.4.1 Activating the user management ............................................................... 43

5.2.4.2 Logging in.............................................................................................. 44

5.2.4.3 Logging out............................................................................................ 44

5.2.4.4 Managing users and user groups.............................................................. 44

5.2.4.5 Inactivating the user management............................................................. 48

5.2.4.6 Service request for resetting password or balance ....................................... 48

5.2.5 Settings........................................................................................................ 49

5.2.5.1 Balance settings...................................................................................... 49

5.2.5.2 Devices / Printer settings.......................................................................... 55

5.2.6 Maintenance................................................................................................. 58

5.2.6.1 Import / export data................................................................................. 59

5.2.6.2 Formatting RFID tag................................................................................. 59

5.2.6.3 Updating the software .............................................................................. 60

5.2.6.4 Resetting................................................................................................ 60

5.2.6.5 Service................................................................................................... 60

5.2.7 Exit / Block the balance ................................................................................. 61

5.2.7.1 Logout / unblocking the balance ............................................................... 61

5.2.7.2 Creating an unblocking password ............................................................. 61

5.2.7.3 Blocking / unblocking the balance............................................................. 62

5.2.7.4 Logout ................................................................................................... 62

6 Software description 63

6.1 Weighing Methods....................................................................................................... 63

6.1.1 Introduction.................................................................................................. 63

6.1.2 Methods Overview......................................................................................... 63

6.1.3 Method General weighing............................................................................... 64

6.1.3.1 Method description.................................................................................. 64

6.1.3.2 Creating a new method for general weighing .............................................. 64

6.1.3.3 Method settings....................................................................................... 65

6.1.3.4 Cloning a method ................................................................................... 74

6.1.3.5 Deleting a method................................................................................... 74

6.1.4 Method Interval weighing ............................................................................... 75

6.1.4.1 Method description.................................................................................. 75

Table of Contents2 Precision Balances and Comparators

Page 5

6.1.4.2 Creating a new method for interval weighing .............................................. 75

6.1.4.3 Method settings....................................................................................... 75

6.1.4.4 Cloning a method ................................................................................... 78

6.1.4.5 Deleting a Method ................................................................................... 78

6.1.5 Method Piece counting .................................................................................. 79

6.1.5.1 Method description.................................................................................. 79

6.1.5.2 Creating a new method for piece counting.................................................. 79

6.1.5.3 Method settings....................................................................................... 79

6.1.5.4 Cloning a method ................................................................................... 87

6.1.5.5 Deleting a method................................................................................... 88

6.1.6 Method Simple formulation............................................................................. 89

6.1.6.1 Method description.................................................................................. 89

6.1.6.2 Creating a new method for simple formulation............................................ 89

6.1.6.3 Method settings....................................................................................... 90

6.1.6.4 Cloning a method ................................................................................... 98

6.1.6.5 Deleting a method................................................................................... 98

6.1.7 Method Titration ............................................................................................ 99

6.1.7.1 Method description.................................................................................. 99

6.1.7.2 Creating a new method for Titration ........................................................... 99

6.1.7.3 Method settings....................................................................................... 100

6.1.7.4 Cloning a method ................................................................................... 107

6.1.7.5 Deleting a method................................................................................... 107

6.1.8 Method Density determination......................................................................... 108

6.1.8.1 Method description.................................................................................. 108

6.1.8.2 Creating a method density determination.................................................... 108

6.1.8.3 Method settings....................................................................................... 109

6.1.8.4 Cloning a method ................................................................................... 114

6.1.8.5 Deleting a method................................................................................... 114

6.1.9 Using method templates ................................................................................ 115

6.1.9.1 Define a template .................................................................................... 115

6.1.9.2 Define a template in the method defining process........................................ 115

6.1.9.3 Define templates in a current task.............................................................. 115

6.1.9.4 Work with templates................................................................................ 116

6.2 Tasks ......................................................................................................................... 116

6.2.1 Deleting a task.............................................................................................. 116

6.3 Tests .......................................................................................................................... 116

6.3.1 Overview routine tests.................................................................................... 116

6.3.1.1 Eccentricity test ....................................................................................... 116

6.3.1.2 Repeatability test..................................................................................... 117

6.3.1.3 Sensitivity tests ....................................................................................... 117

6.3.2 Creating an own new test............................................................................... 117

6.3.3 Test parameter settings .................................................................................. 118

6.3.3.1 Eccentricity test ....................................................................................... 118

6.3.3.2 Repeatability test..................................................................................... 120

6.3.3.3 Sensitivity test......................................................................................... 123

6.3.4 Defining a test weight .................................................................................... 126

6.3.5 Deleting a test............................................................................................... 126

6.3.6 Printing a test ............................................................................................... 127

6.3.7 Editing a test ................................................................................................ 127

6.3.8 See the test history ........................................................................................ 127

6.4 Adjustments ................................................................................................................ 127

6.4.1 Internal adjustment........................................................................................ 127

6.4.1.1 Editing an internal adjustment................................................................... 127

6.4.1.2 Performing an internal adjustment............................................................. 129

6.4.2 External adjustment....................................................................................... 129

6.4.2.1 Editing an external adjustment.................................................................. 129

6.4.2.2 Perform a external adjustment .................................................................. 129

Table of Contents 3Precision Balances and Comparators

Page 6

6.4.2.3 See adjustment history............................................................................. 130

7 Maintenance 131

7.1 Maintenance table........................................................................................................ 131

7.2 Performing routine tests................................................................................................ 131

7.3 Cleaning..................................................................................................................... 131

7.3.1 Disassembling for cleaning ............................................................................ 131

7.3.2 Cleaning agents............................................................................................ 133

7.3.3 Cleaning the balance..................................................................................... 133

7.3.4 Commissioning after cleaning ........................................................................ 134

7.4 Updating the software................................................................................................... 134

7.4.1 Update the software....................................................................................... 134

7.4.2 Commissioning after software update .............................................................. 135

8 Troubleshooting 136

8.1 Error messages ........................................................................................................... 136

8.2 Error symptoms........................................................................................................... 136

8.3 Putting into operation after correcting a fault.................................................................... 138

9 Technical Data 139

9.1 General technical data.................................................................................................. 140

9.1.1 Balances with S weighing platform.................................................................. 140

9.1.2 Balances with L weighing platform.................................................................. 141

9.2 Model-specific technical data ........................................................................................ 142

9.2.1 Balances with S weighing platform.................................................................. 142

9.2.1.1 Readability 0.1 mg, with Pro Draft Shield................................................... 142

9.2.1.2 Readability 1 mg, with Pro Draft Shield and SmartPan weighing pan ............ 144

9.2.1.3 Readability 1 mg, with SmartPan weighing pan.......................................... 146

9.2.1.4 Readability 5 mg, with SmartPan weighing pan.......................................... 147

9.2.1.5 Readability 10 mg, with SmartPan weighing pan........................................ 148

9.2.1.6 Readability 0.1 g .................................................................................... 151

9.2.2 Comparators with S weighing platform ............................................................ 153

9.2.2.1 Redability 0.1 mg, with Pro Draft Shield..................................................... 153

9.2.2.2 Readability 1 mg .................................................................................... 154

9.2.3 Balances with L weighing platform.................................................................. 155

9.2.3.1 Readability 10 mg, with SmartPan weighing pan........................................ 155

9.2.3.2 Readability 0.1 g .................................................................................... 156

9.2.3.3 Readability 1 g ....................................................................................... 158

9.2.4 Comparators with L weighing platform............................................................. 159

9.2.4.1 Redability 1 mg ...................................................................................... 159

9.2.4.2 Readability 5 mg .................................................................................... 160

9.2.4.3 Readability 10 mg .................................................................................. 161

9.3 Dimensions................................................................................................................. 162

9.3.1 Balances with S weighing platform.................................................................. 162

9.3.1.1 Readability 0.1 mg, with Pro Draft Shield and SmartPan weighing pan ......... 162

9.3.1.2 Readabilty 1 mg, with Pro Draft Shield and SmartPan weighing pan ............. 163

9.3.1.3 Readabilty 1 mg, with SmartPan weighing pan........................................... 164

9.3.1.4 Readabilty 5 mg / 10 mg, with SmartPan weighing pan.............................. 165

9.3.1.5 Readability 0.1 g .................................................................................... 166

9.3.2 Comparators with S weighing platform ............................................................ 167

9.3.2.1 Readability 0.1 mg, with Pro Draft Shield and LevelMatic weighing pan ........ 167

9.3.2.2 Readability 1 mg, with Pro Draft Shield and LevelMatic weighing pan ........... 168

9.3.2.3 Readability 1 mg, with XP-W12 draft shield and LevelMatic weighing pan..... 169

9.3.2.4 Readability 1 mg, with Pro Draft Shield...................................................... 170

9.3.3 Balances with L weighing platform.................................................................. 171

9.3.3.1 Readability 10 mg, with SmartPan weighing pan........................................ 171

9.3.3.2 Readability 0.1 g / 1 g ............................................................................ 172

9.3.4 Comparators with L weighing platform............................................................. 173

Table of Contents4 Precision Balances and Comparators

Page 7

9.3.4.1 Readability 1 mg / 5 mg, with XP-W64 draft shield and LevelMatic weighing

pan ....................................................................................................... 173

9.3.4.2 Readability 5 mg / 10 mg........................................................................ 174

9.3.5 Draft shield XP-W12 (for models with S weighing platform)............................... 175

9.3.6 Draft shield XP-W64 (for models with L weighing platform)).............................. 176

10 Accessories and Spare Parts 177

10.1 Accessories................................................................................................................. 177

10.2 Spare parts ................................................................................................................. 183

10.2.1 Balances S weighing platform ........................................................................ 183

10.2.2 Comparators S weighing platform ................................................................... 185

10.2.3 S Platform miscellaneous............................................................................... 186

10.2.4 Balances L weighing platform......................................................................... 187

10.2.5 Comparators L weighing platform ................................................................... 188

10.2.6 L platform miscellaneous ............................................................................... 189

10.2.7 Pro Draft Shield............................................................................................. 190

10.2.8 Packaging.................................................................................................... 191

10.2.8.1 Packaging XPR-S, XSR-S models with draft shield....................................... 191

10.2.8.2 Packaging XPR-S, XSR-S models, no draft shield........................................ 192

10.2.8.3 Packaging XPR-L, XSR-L models, 2-digits.................................................. 193

10.2.8.4 Packaging XPR-L, XSR-L models, 1- and 0-digits ....................................... 194

11 Information on standards 195

12 Disposal 196

Index 197

Table of Contents 5Precision Balances and Comparators

Page 8

Table of Contents6 Precision Balances and Comparators

Page 9

1 Introduction

Thank you for choosing a METTLER TOLEDO balance.

The balances of the XPR line combine a large number of weighing and adjustment possibilities with excep-

tionally convenient operation.

The XPR line comprises a range of balances which differ from each other in relation to their weighing range and

resolution.

The following features are common to all models of the XPR line:

• Fully automatic adjustment using internal weights.

• Built-in level sensor and leveling aid for fast and easy leveling.

• Seven inch capacitive color TFT-touchscreen.

• Various methods that can be defined individually.

• Various routine tests that can be defined individually.

• Functions to manage user groups and user rights.

• Functions to collect data such as settings that have been changed or objects that have been deleted/added.

Disclaimer for comparators

In this document, the term "balance" is used to describe both balances and comparators.

Comparators are characterized by their higher resolution compared to balances and are mainly used for differ-

ential weighing application, such as the calibration of standard weights. Beside standard balance tests,

comparators have also been tested with differential repeatability (ABA repeatability) during production.

This information is valid for models of the line/s:

XPR2004SC XPR26003LC

XPR5004SC XPR32003LD5C

XPR2003SC XPR64003LD5C

XPR5003SC XPR64002LC

XPR10003SC

Software version

This Reference Manual refers to the originally installed > software version V 2.0.201.6.

Finding more information

u www.mt.com/xpr-precision

u www.mt.com/comparators

u www.mt.com/library

For further questions, please contact your authorized METTLER TOLEDO dealer or service representative.

u www.mt.com/contact

Introduction 7Precision Balances and Comparators

Page 10

1.1 Conventions and symbols used in these Reference Manual

Refers to an external document.

Key and/or button designations and display texts are shown in graphic or bold text (e.g.

Note

Prerequisites

§

1 Steps

2 ...

ð Intermediate results

ð Results

(no symbol)

for useful information about the product.

, Balance menu).

Introduction8 Precision Balances and Comparators

Page 11

2 Safety Information

Two documents named "User Manual" and "Reference Manual" are available for this instrument.

• The User Manual is printed and delivered with the instrument.

• The electronic Reference Manual contains a full description of the instrument and its use.

• Keep both documents for future reference.

• Include both documents if you transfer the instrument to other parties.

Only use the instrument according to the User Manual and the Reference Manual. If you do not use the

instrument according to these documents or if the instrument is modified, the safety of the instrument may be

impaired and Mettler-Toledo GmbH assumes no liability.

2.1 Definition of signal warning symbols

Safety notes are marked with signal words and warning symbols. These show safety issues and warnings.

Ignoring the safety notes may lead to personal injury, damage to the instrument, malfunctions and false results.

General hazard Electrical shock

WARNING

CAUTION

NOTICE

A hazardous situation with medium risk, possibly resulting in death or severe injury if

not avoided.

A hazardous situation with low risk, resulting in minor or moderate injury if not avoided.

A hazardous situation with low risk, resulting in damage to the instrument, other

material damage, malfunctions and erroneous results, or loss of data.

Personal protective equipment

Chemical resistant safety gloves are intended to protect hands against aggressive

chemicals.

The protective goggles protect the eyes from flying parts and liquid splashes.

2.2 Product safety information

Intended use

This balance is designed to be used in laboratories by trained staff. The balance is intended for weighing

purposes.

Any other type of use and operation beyond the limits of technical specifications without written consent from

Mettler-Toledo GmbH is considered as not intended.

General safety information

This balance complies with current industry standards and the recognized safety regulations; however, it can

constitute a hazard in use. Do not open the balance housing: The balance contains no user-serviceable parts.

In the event of problems, please contact a METTLER TOLEDO representative.

Always operate and use your instrument only in accordance with the instructions contained in this document.

The instructions for setting up your new instrument must be strictly observed.

Safety Information 9Precision Balances and Comparators

Page 12

If the instrument is not used according to the "Reference Manual", protection of the instrument may be

impaired and Mettler-Toledo GmbH assumes no liability.

Staff safety

This printed document must be read and understood before using the balance. This printed document must be

retained for future reference.

The balance must not be altered or modified in any way. Only use METTLER TOLEDO original spare parts and

accessories.

Safety Information10 Precision Balances and Comparators

Page 13

Safety notes

WARNING

Danger of death or serious injury due to electric shock!

Contact with parts that contain a live current can lead to injury and death. If the balance

cannot be shut down in an emergency situation, people can be injured or the balance can be

damaged.

1 Only use the original universal AC/DC adapter delivered with your balance.

2 Check that the voltage printed on the balance is the same as your local power supply

voltage.

ð If this is not the case, under no circumstances connect the AC/DC adapter to the power

supply, but contact a METTLER TOLEDO representative.

3 Only plug the adapter into a socket which is grounded.

NOTICE

Damage to the balance due to wrong usage.

1 Only use indoors in dry locations.

2 Do not use pointed objects to operate the touchscreen.

3 Only use original METTLER TOLEDO accessories and peripheral devices.

4 Do not open the balance housing. It contains no user-serviceable parts. Contact a

METTLER TOLEDO representative in case of any issue.

FCC Rules

This device complies with Industry Canada licence-exempt RSS standard(s) and part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that may cause undesired operation of the device.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Safety Information 11Precision Balances and Comparators

Page 14

3 Overview and Functions

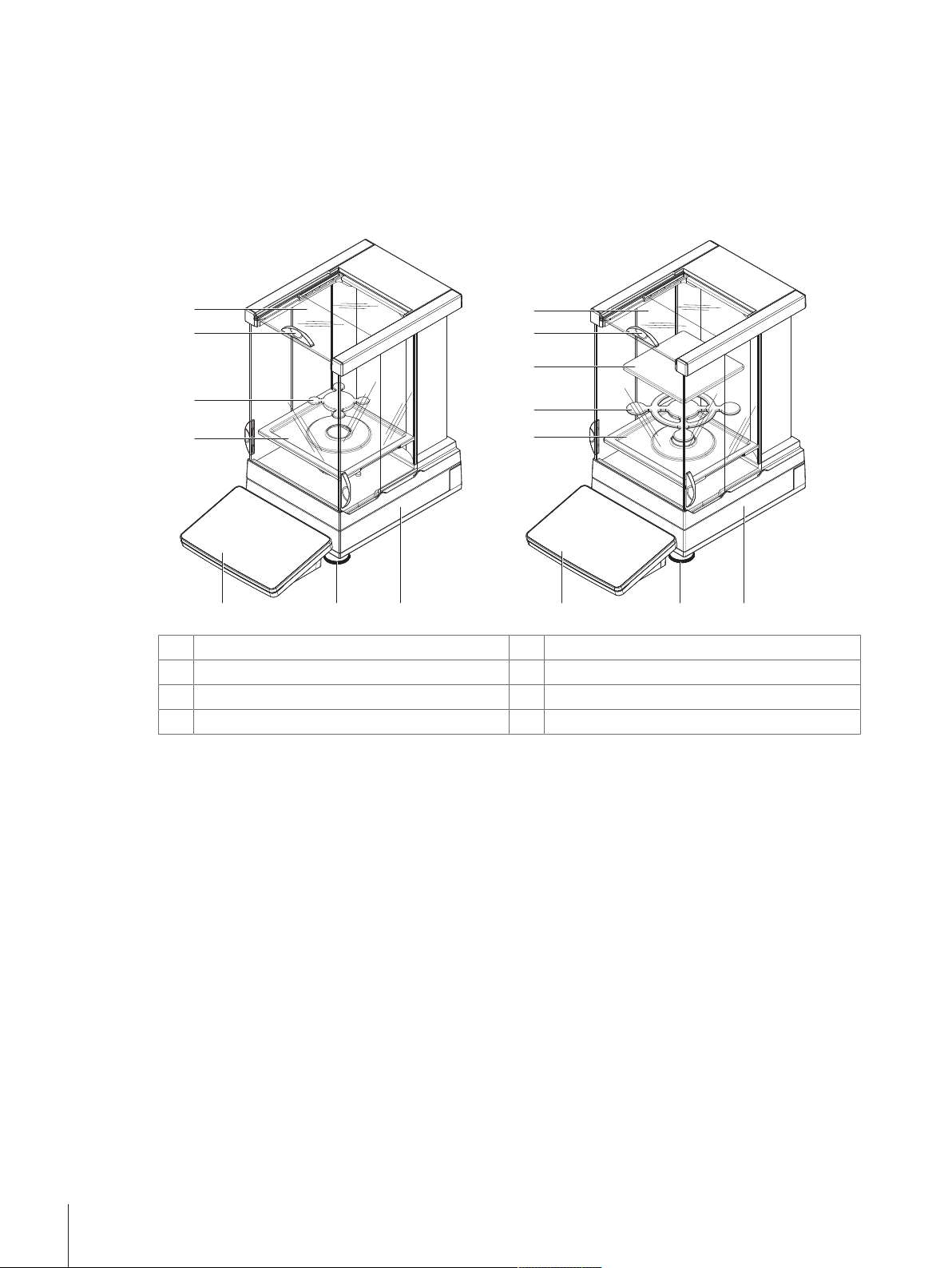

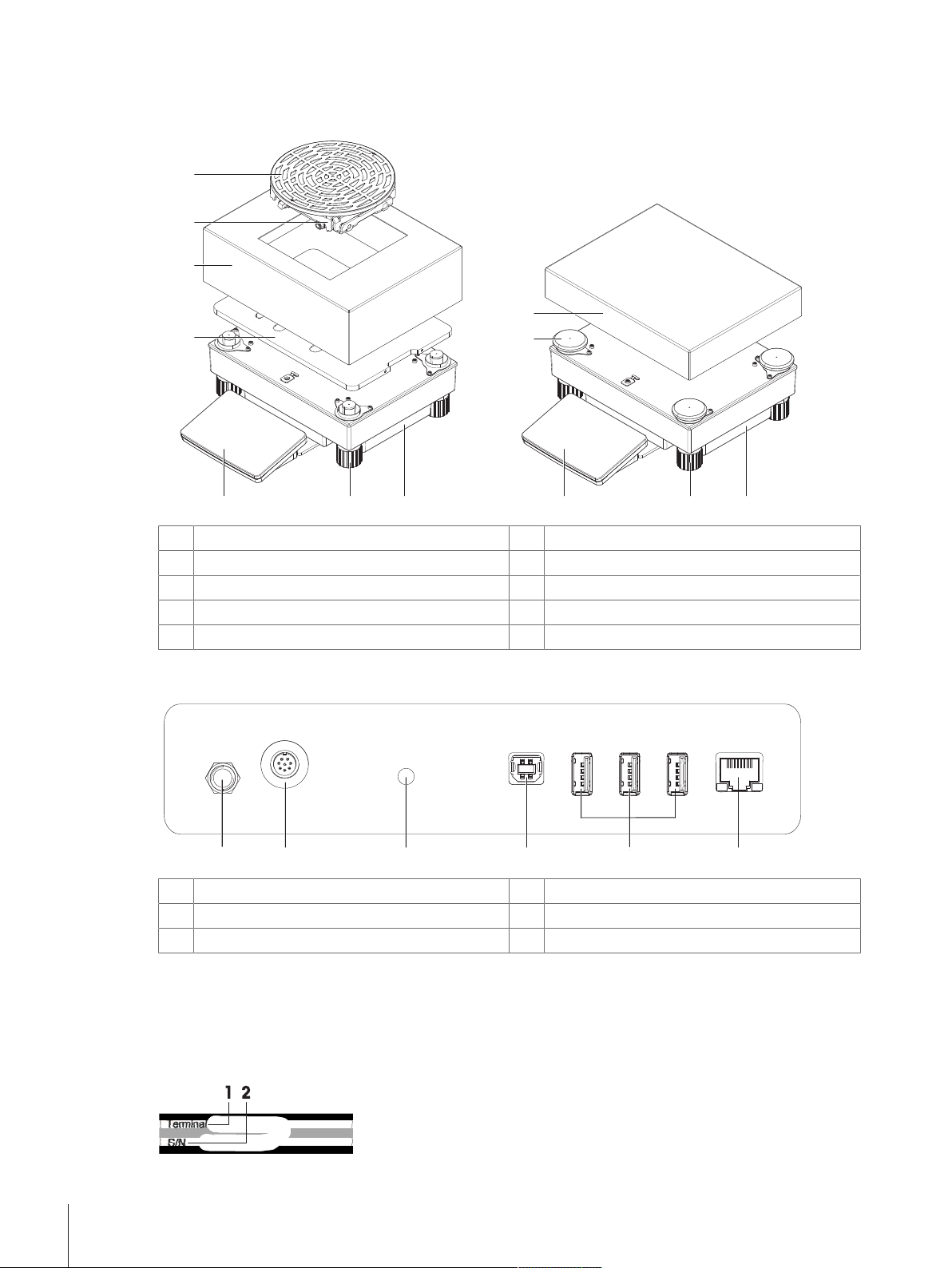

7

8

0.1 mg

1 mg

1

2

5

6

1

2

3

5

78

4

4

6

3.1 Overview S weighing platform

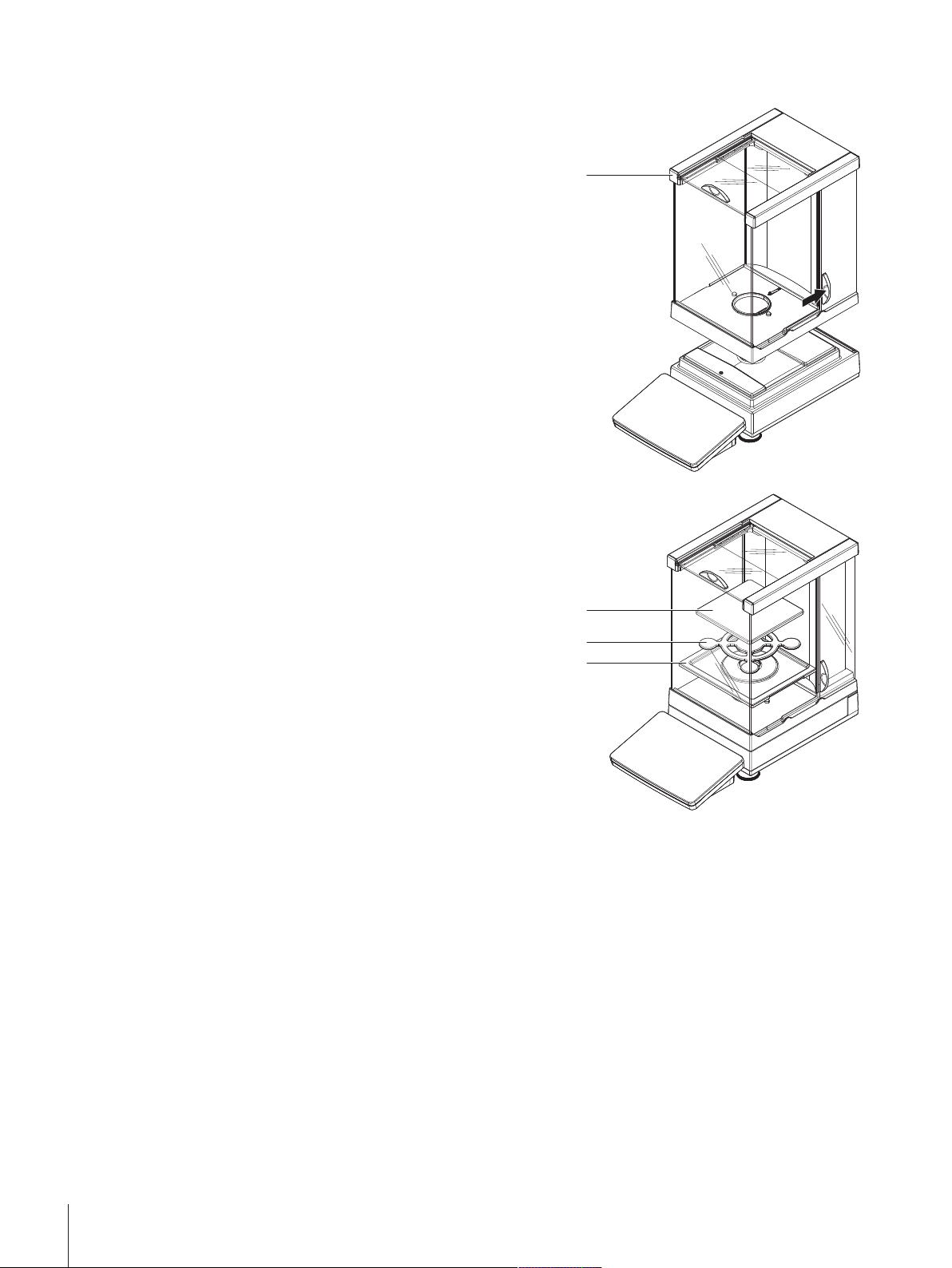

3.1.1 Balances with Pro Draft Shield

DripTray

1

SmartPan weighing pan

2

Weighing pan

3

Pro Draft Shield door handler

4

Pro Draft Shield

5

Weighing platform with protective cover

6

Leveling foot

7

Terminal with protective cover

8

Overview and Functions12 Precision Balances and Comparators

Page 15

3.1.2 Comparators with Pro Draft Shield

10

0.1 mg / 1 mg

1

3

8

9

11

2

4

8

6

7

10 9

11

5

7

Bottom plate

1

DripTray

2

LevelMatic weighing pan holder

3

SmartPan weighing pan

4

LevelMatic weighing pan

5

Weighing pan

6

Pro Draft Shield door handler

7

Pro Draft Shield

8

Weighing platform with protective cover

9

Leveling foot

10

Terminal with protective cover

11

Overview and Functions 13Precision Balances and Comparators

Page 16

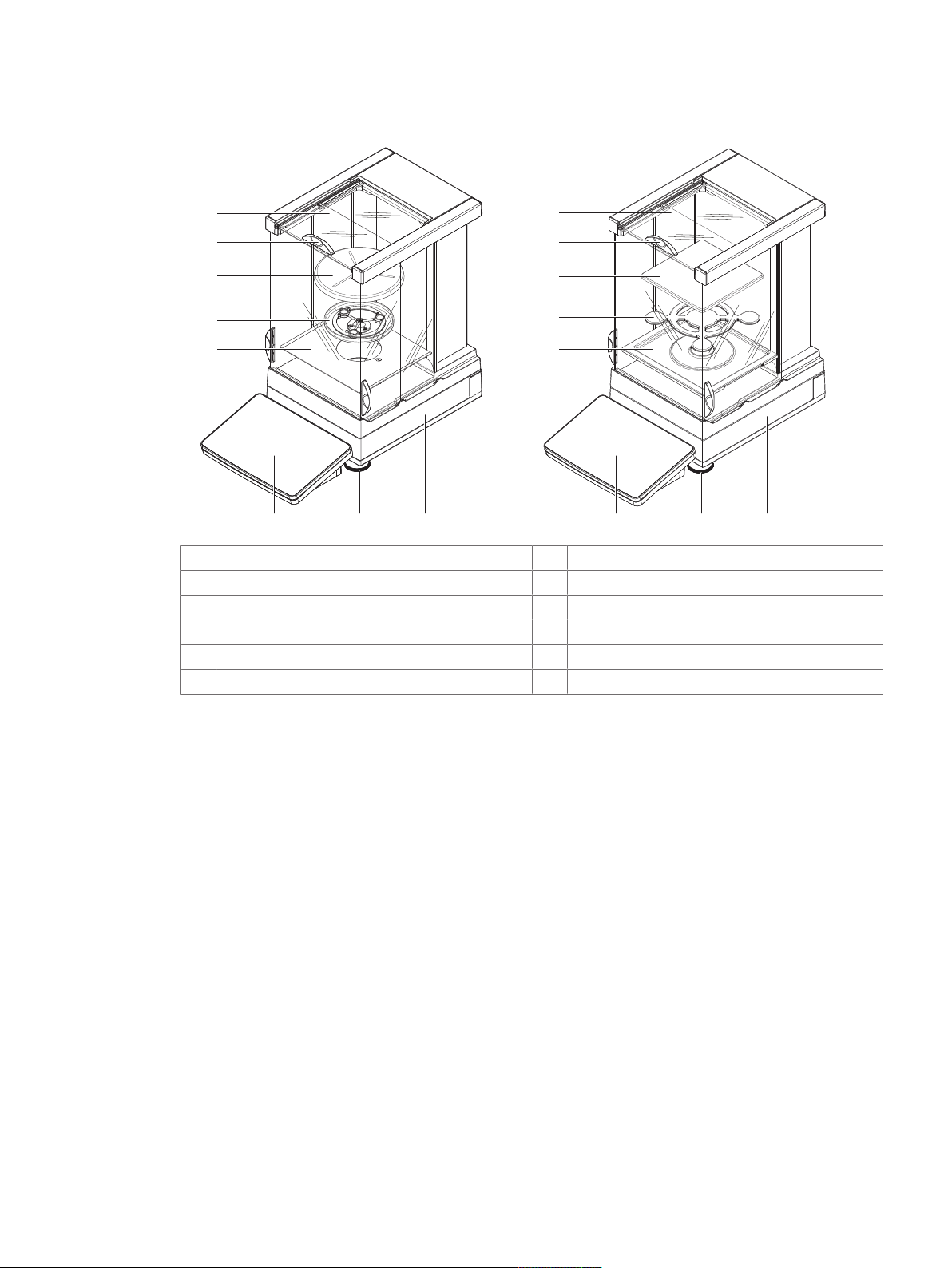

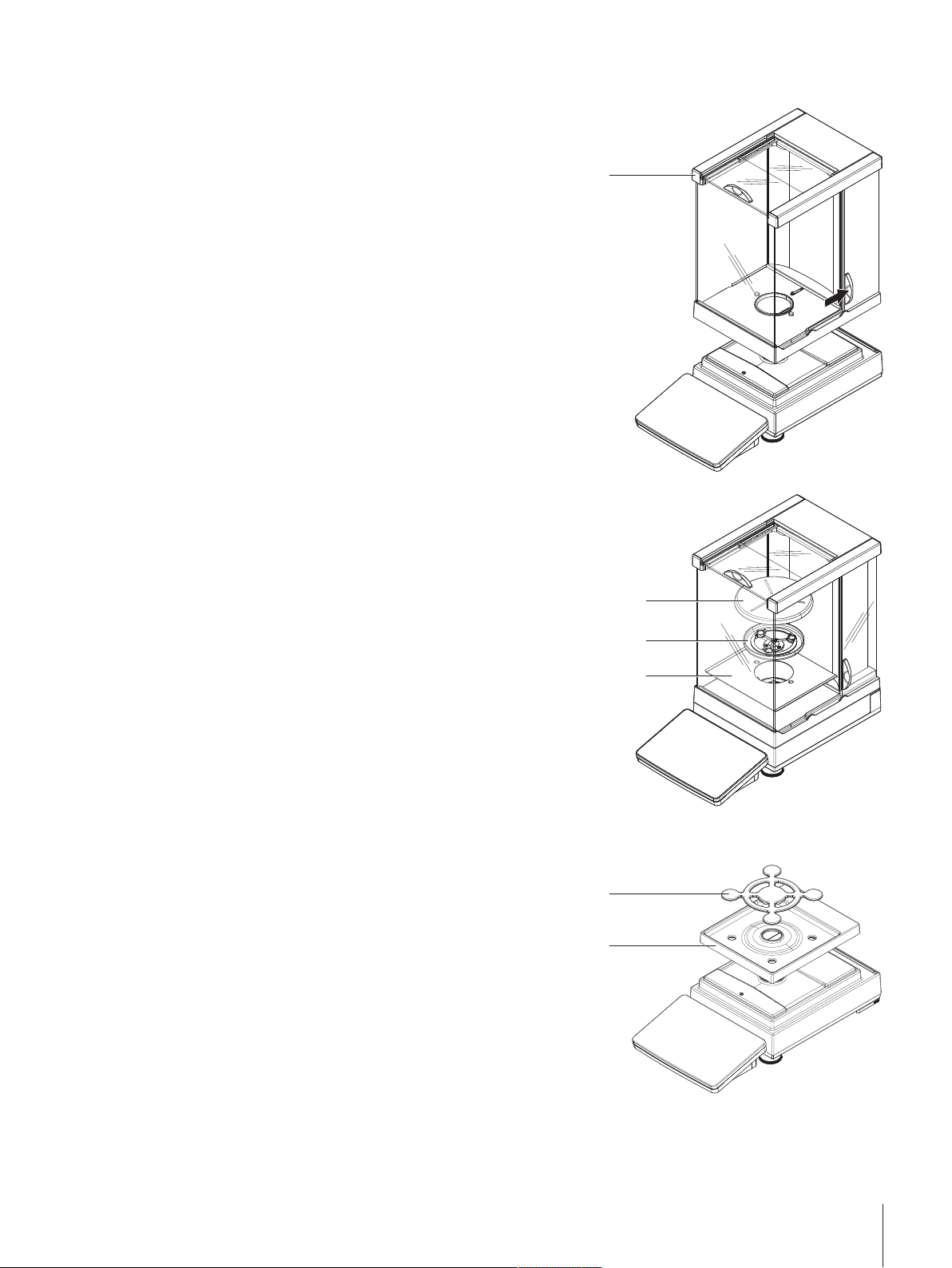

3.1.3 Balances without Pro Draft Shield

7

910

1 mg

5 mg / 10 mg

11

22

33

55

0.1 g

11

22

33

44

6

6

7

7

9

9

10

10

55

8

Weighing pan support cap

1

DripTray

2

SmartPan weighing pan

3

Weighing pan support

4

Weighing pan with protective cover

5

Safety foot

6

Weighing platform with protective cover

7

Fastening plate with position screws

8

Leveling foot

9

Terminal with protective cover

10

Overview and Functions14 Precision Balances and Comparators

Page 17

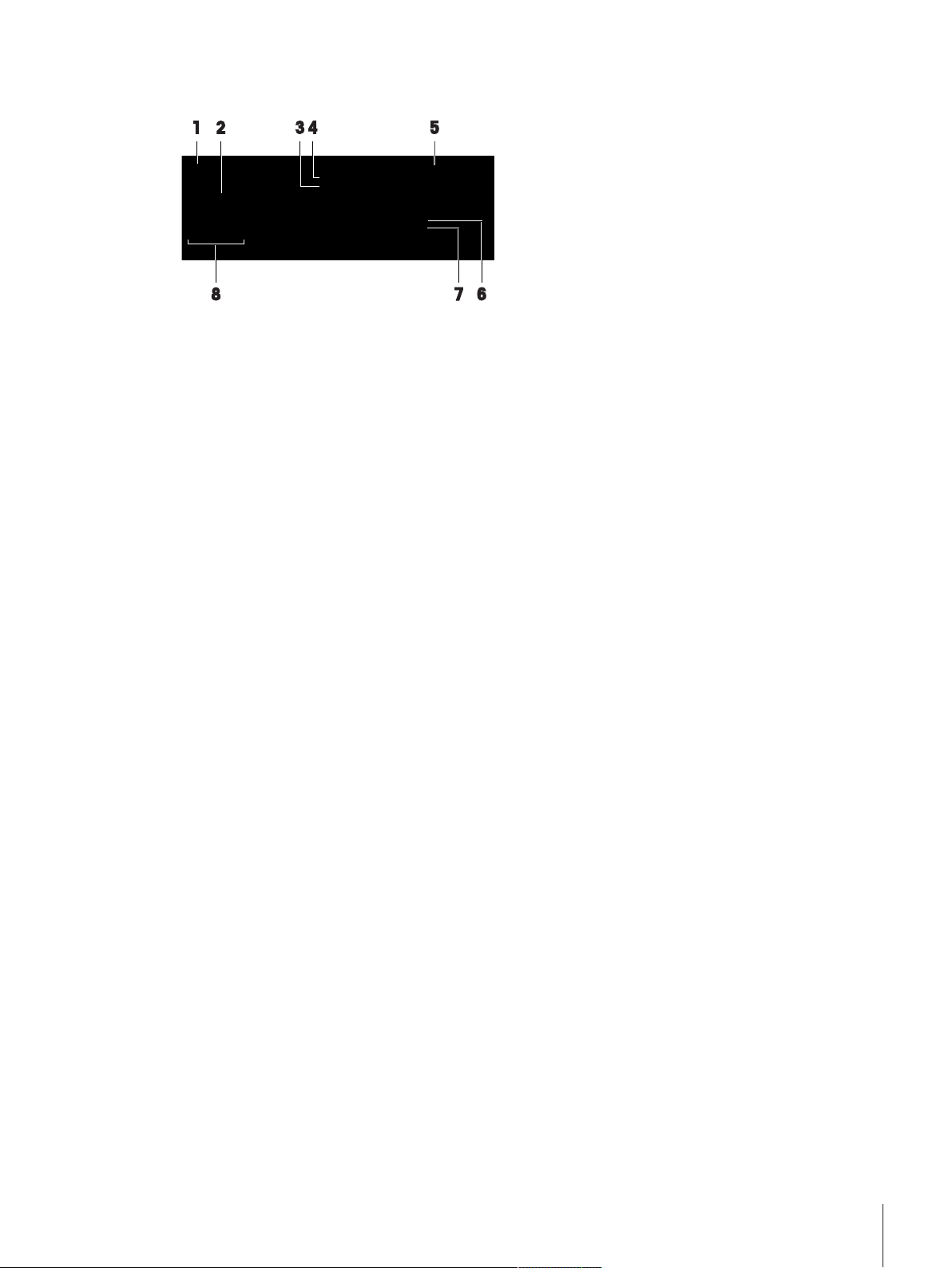

3.1.4 Interface board

11

2

3

6 7

5

4

10 mg

0.1 g / 1 g

7

1

2

3

6

8

1

4

5

9789

Ethernet port

1

USB device ports

2

Fixations for optional terminal stand

3

Service seal

4

3.2 Overview L weighing platform

3.2.1 Balances

USB host port

5

Socket for terminal connection cable

6

Socket for AC/DC adapter

7

Weighing pan support cap

1

Adapter plate

2

Draft shield element

3

SmartPan weighing pan

4

Weighing pan with protective cover

5

Weighing pan

6

Weighing platform

7

Leveling foot

8

Terminal with protective cover

9

Overview and Functions 15Precision Balances and Comparators

Page 18

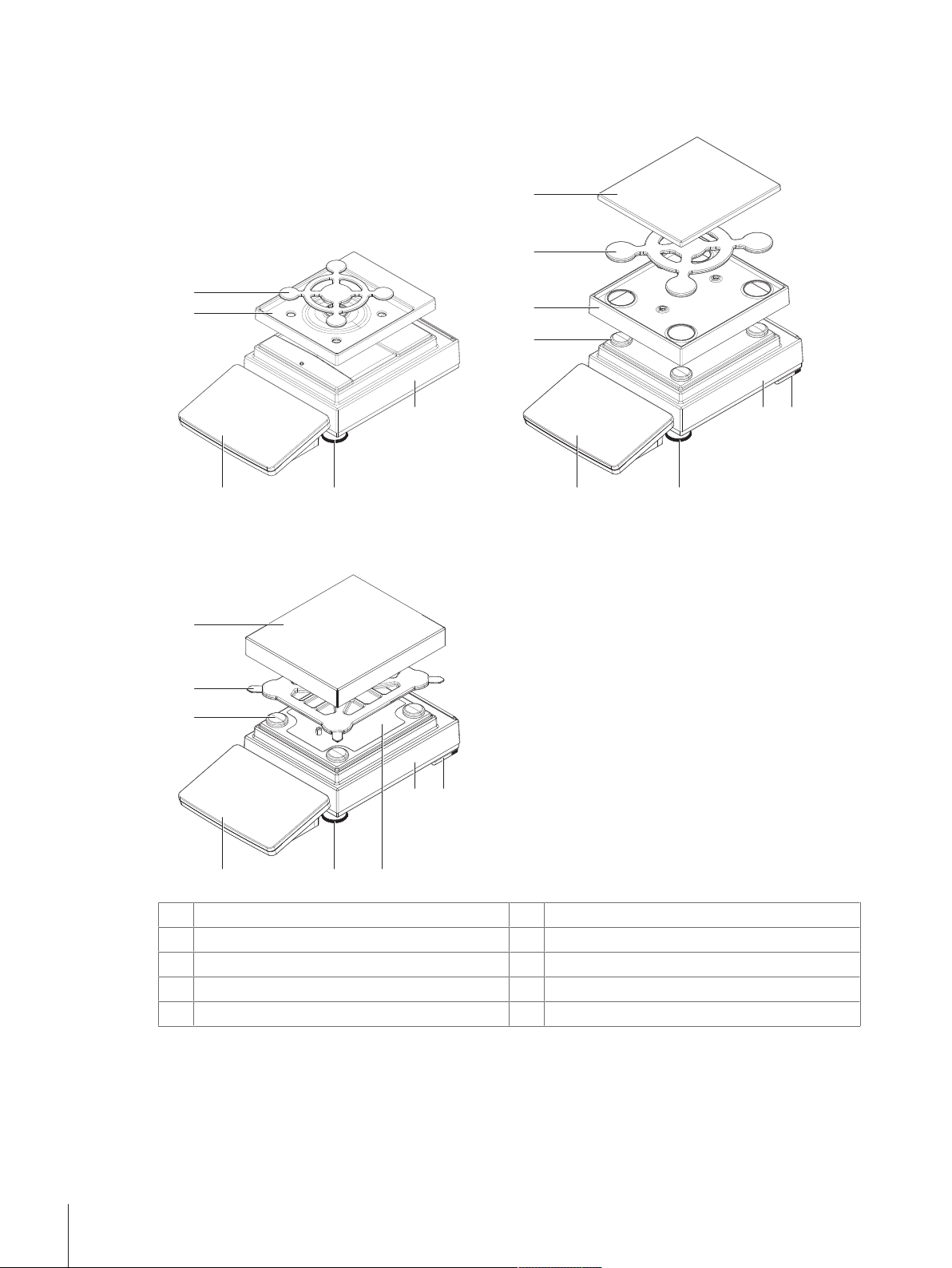

3.2.2 Comparators

1 mg / 5 mg / 10 mg

8

9

1

4

8

9

7

2

7

3

5

6

11 22 4

5

6

3

3.2.3 Interface board

3.3 Type plate

Adapter plate with LevelMatic base plate

1

Weighing pan support cap

2

Draft shield element

3

Weighing pan

4

LevelMatic weighing pan holder

5

Socket for AC/DC adapter

1

Socket for terminal connection cable

2

Service seal

3

LevelMatic weighing pan

6

Weighing platform

7

Leveling foot

8

Terminal with protective cover

9

USB host port

4

USB device ports

5

Ethernet port

6

The information on the type plate helps to identify the balance and terminal.

Terminal type plate

The terminal type plate is located on the terminal and contains the following information:

Overview and Functions16 Precision Balances and Comparators

1. Terminal type

2. Terminal serial number

Page 19

Weighing unit type plate

The balance type plate is located on the side of the weighing unit and contains the following information:

1. Designation of balance model

2. Year of manufacture

3. Readability

4. Maximum capacity

5. Manufacturer

6. Balance type

7. Serial number

8. Power supply

Overview and Functions 17Precision Balances and Comparators

Page 20

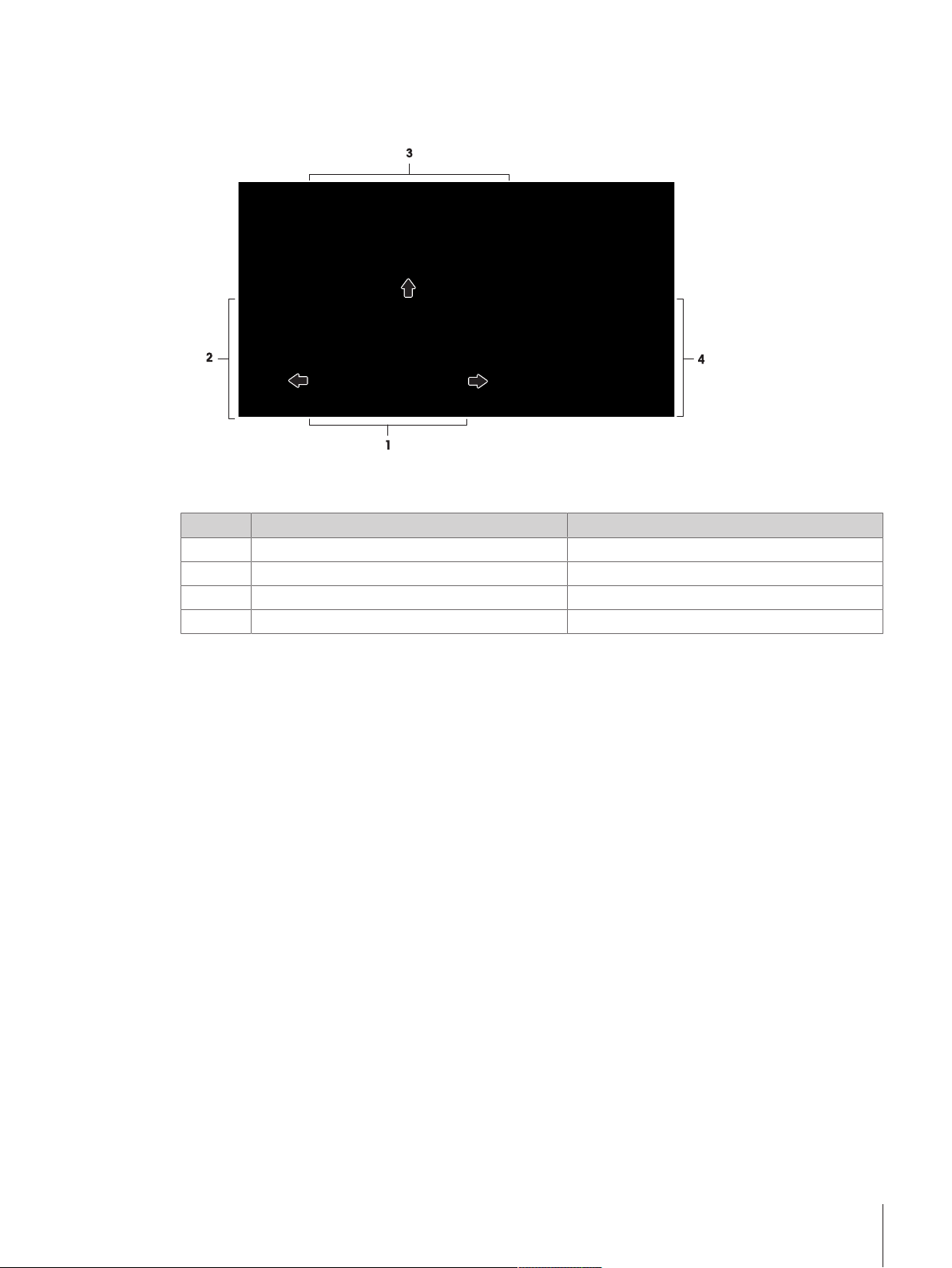

3.4 Terminal

11

22 33

44

55

No. Key Name Explanation

1

2

3

4

5

ON/OFF Switches the balance on/off.

- 7 inch capacitive TFT

touchscreen

Tare Tares the balance.

Zero Zeroes the balance.

Home To return from any menu level to the home screen.

By tapping

, the balance is not completely switched off but

goes into standby mode. To switch the balance completely off, it

must be unplugged from the power supply.

Note

Do not disconnect the balance from the power supply unless the

balance is not used for an extended period of time.

The touchscreen shows information about the current weighing

process.

This function is used when the weighing process involves

containers. After taring the balance, the screen shows Net which

indicates that all displayed weights are net.

The balance must always be zeroed before starting the weighing

process. After zeroing, the balance sets a new zero point.

Overview and Functions18 Precision Balances and Comparators

Page 21

3.5 User Interface

3.5.1 Main sections at a glance

The user interface is divided in a main weighing screen and working screen where all the menus and setting

can be found.

No. Screen More information

1 Main weighing screen [Main screen "General weighing"}Page36]

2 Working screen Balance menu [Work screen "Balance menu"}Page37]

3 Working screen Methods [Work screen "Methods"}Page37]

4 Working screen Protocol [Work screen "Protocol"}Page38]

Overview and Functions 19Precision Balances and Comparators

Page 22

4 Installation and putting into Operation

4.1 Scope of delivery

NOTICE

Risk of damage to the instrument due to the use of unsuitable parts!

Using unsuitable parts with the instrument can damage the instrument or cause it to

malfunction.

− Only use parts from METTLER TOLEDO that are intended to be used with your instrument.

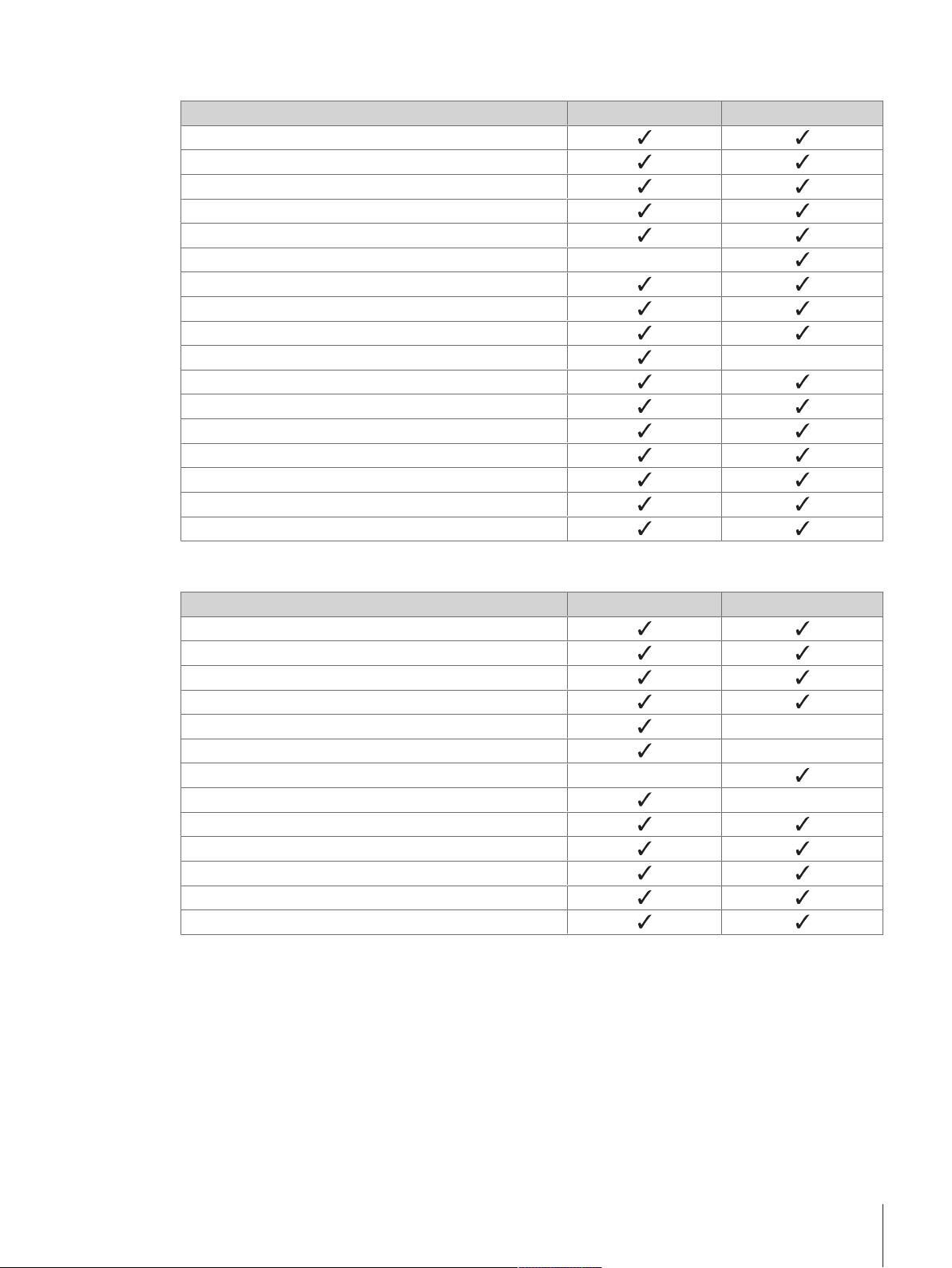

4.1.1 Balances with S weighing platform

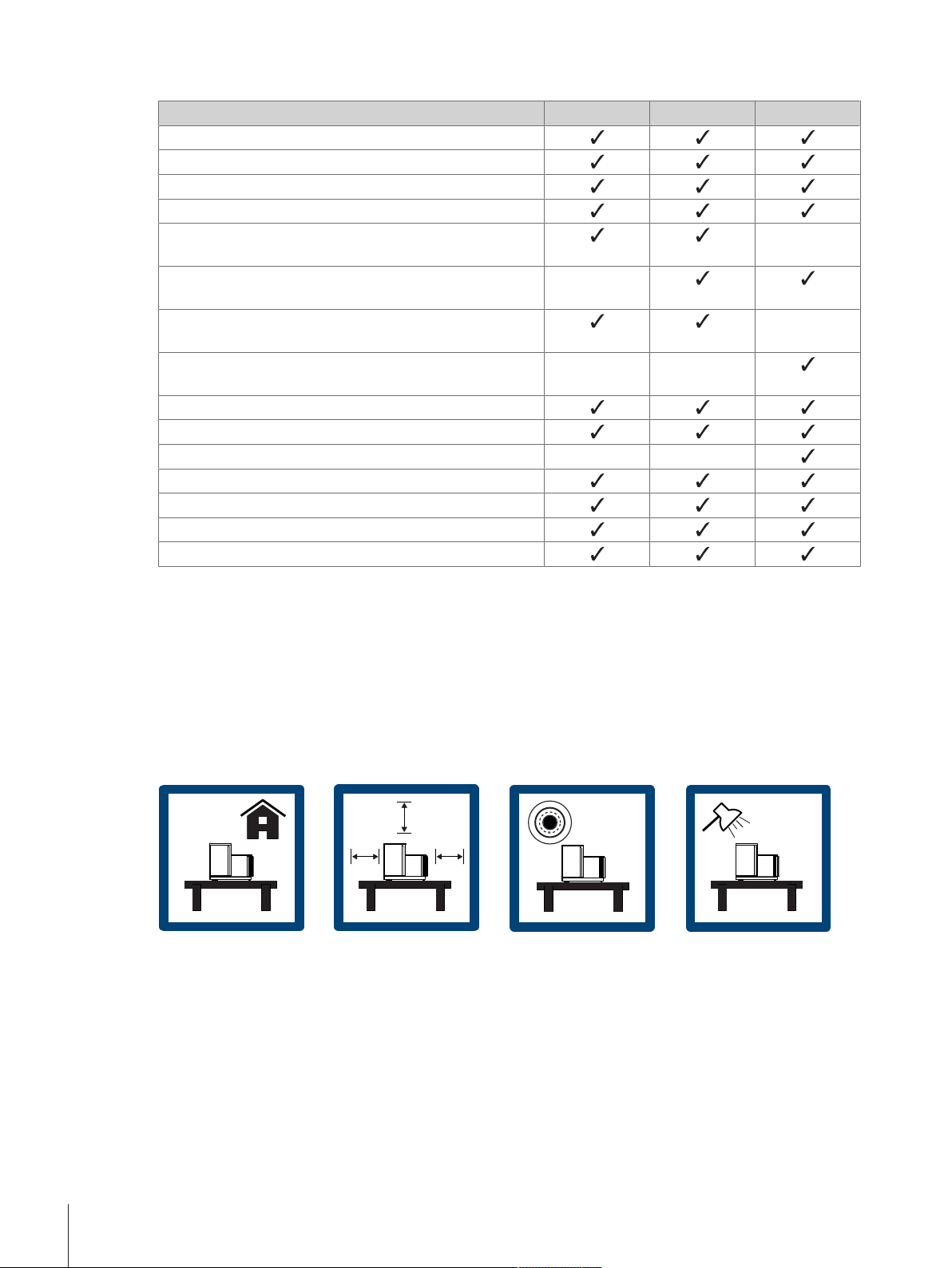

Components 0.1mg

with Pro

Draft

Shield

Weighing platform with protective cover

Terminal with protective cover

Terminal support

Terminal connection cable (pre-assembled)

Pro Draft Shield – – –

Weighing pan 127 x 127 mm – – – –

Weighing pan 172 × 205mm – – – –

Weighing pan 193 × 223mm – – – –

SmartPan weighing pan –

Weighing pan support – – – –

DripTray –

Ring seal – – – –

Weighing hook for below-the-balance weighing

AC/DC adapter

Power cable (country-specific)

User Manual

Production certificate

CE declaration of conformity

1mg

with Pro

Draft

Shield

1 mg

without

Pro

Draft

Shield

5mg /

10 mg

0.1g

Installation and putting into Operation20 Precision Balances and Comparators

Page 23

4.1.2 Comparators with S weighing platform

Components 0.1mg 1mg

Weighing platform with protective cover

Terminal with protective cover

Terminal support

Terminal connection cable (pre-assembled)

Pro Draft Shield (not for XPR10003SC)

Draft shield XP W12 (only for XPR10003SC) –

SmartPan weighing pan

LevelMatic weighing pan Ø 130 mm (not for XPR2003SC)

Bottom plate

Ring seal –

Weighing hook for below-the-balance weighing

AC/DC adapter

Power cable (country-specific)

User Manual

Mass calibration software MC Link

Production certificate

CE declaration of conformity

4.1.3 Balances with L weighing platform

Components 10mg 0.1g / 1g

Weighing platform

Terminal with protective cover

Terminal support

Terminal connection cable

Draft shield element –

Weighing pan 172 × 205mm –

Weighing pan 280 × 360mm –

SmartPan weighing pan –

AC/DC adapter

Power cable (country-specific)

User Manual

Production certificate

CE declaration of conformity

Installation and putting into Operation 21Precision Balances and Comparators

Page 24

4.1.4 Comparators with L weighing platform

Components 1mg 5 mg 10mg

Weighing platform

Terminal with protective cover

Terminal support

Terminal connection cable

Draft shield element XP W64 (only for XPR26003LC and

XPR64003LD5C)

Weighing pan 280 × 360mm (not for XPR64003LD5C

and XPR64002LC)

LevelMatic weighing pan Ø 220 mm with draft shield

element and weighing pan holder (not for XPR32003LD5C)

Weighing pan Ø 220 mm with draft shield cover (only for

XPR64002LC)

AC/DC adapter

Power cable (country-specific)

Transport case (only for XPR64002LC) – –

User Manual

Mass calibration software MC Link

Production certificate

CE declaration of conformity

–

–

–

– –

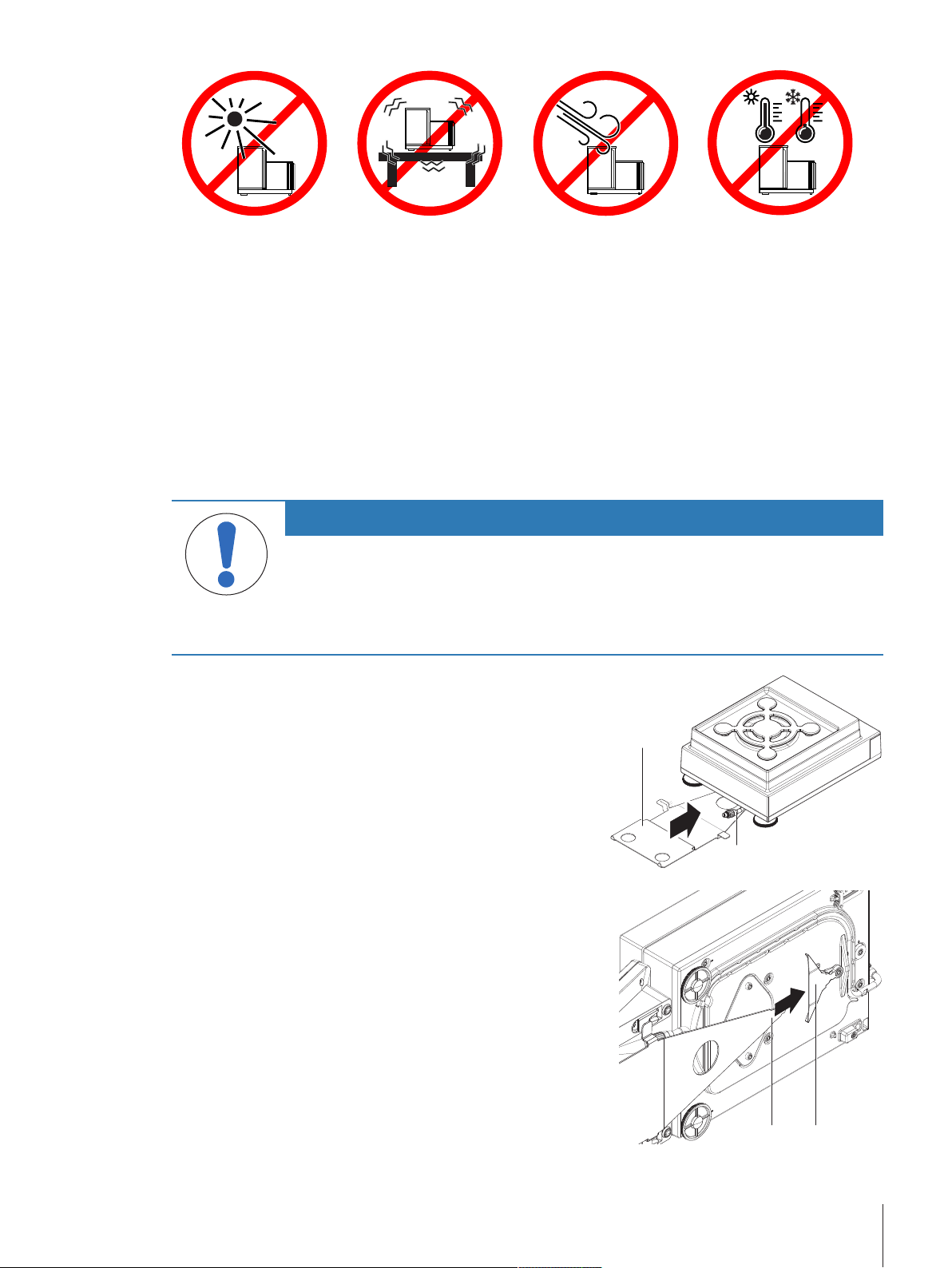

4.2 Selecting the location

A balance is a sensitive precision instrument. The location where it is placed will have a profound effect on the

accuracy of the weighing results.

Requirements of the location

Ensure there is:

• indoor on stable table • with sufficient distance

(> 15 cm)

Avoid:

• direct sunlight • vibrations • strong drafts • temperature fluctu-

• in level • adequately lit

ations

Installation and putting into Operation22 Precision Balances and Comparators

Page 25

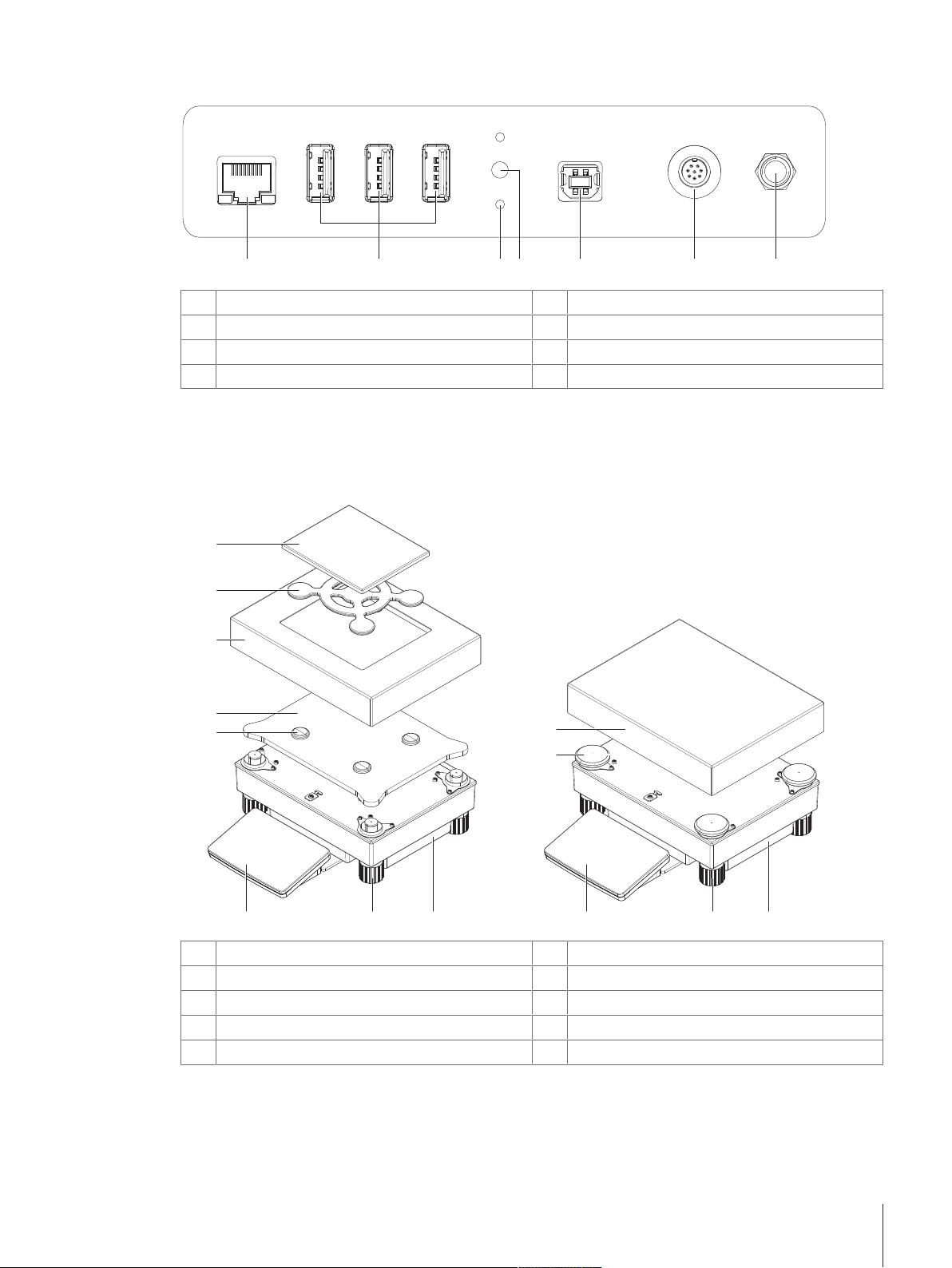

4.3 Unpacking the balance

11

2

3 4

Open the balance packaging and check for transportation damage or missing parts. Please inform a METTLER

TOLEDO service representative in the event of missing or defective parts.

METTLER TOLEDO recommends retaining the original box with its packaging elements. Use the packaging

elements to store and to transport the balance.

4.4 Assembling balances with S weighing platform

4.4.1 Attaching the terminal to the weighing platform

The terminal is usually placed in front of the weighing platform on the terminal support. The terminal can also

be placed individually, e.g. beside the weighing platform or it can be fixed on an additional terminal stand.

NOTICE

Damage to the balance

The weighing platform and the terminal are not safely fixed by the terminal support and may

fall off when carrying.

− Remove the terminal from the weighing platform and place it on the weighing pan when

carrying the balance.

1 Place the weighing platform on a flat surface.

2 Position the terminal support (1) in front of the

weighing platform. The plug of the pre-mounted

terminal connection cable (2) must lie between the

terminal support (1) and the weighing platform.

3 Push the terminal support towards the weighing

platform. The far end of the terminal support (3) must

be pushed into the lock element (4) at the bottom of

the weighing platform.

4 Use the terminal connection cable to connect the

terminal with the weighing platform.

Installation and putting into Operation 23Precision Balances and Comparators

Page 26

5 Place the terminal on top of the terminal support.

1

2

43

6 Push the terminal towards the weighing platform until

the terminal locks into the terminal support.

ð The terminal is mounted and connected to the

weighing platform.

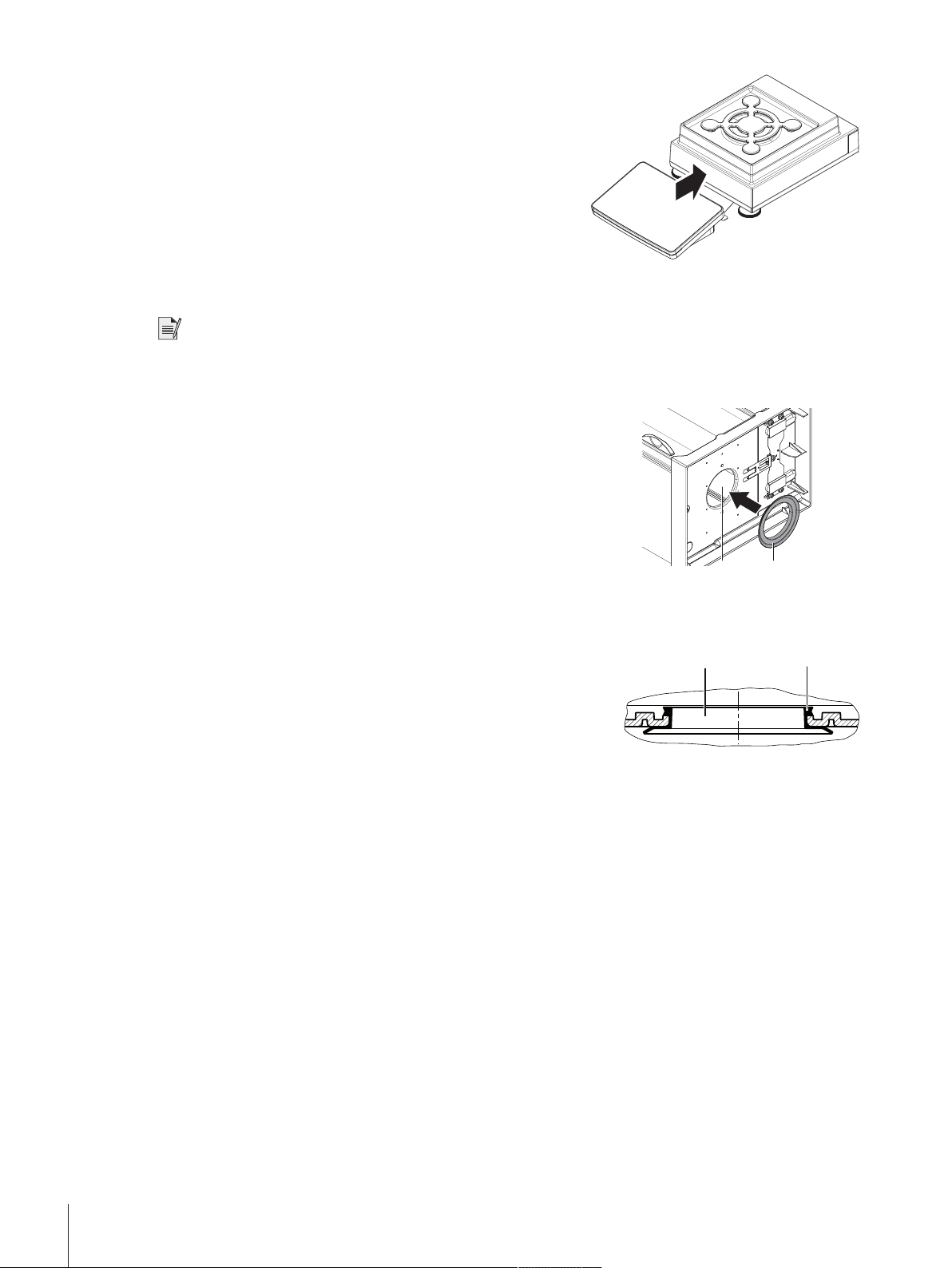

4.4.2 Balances 0.1 mg with Pro Draft Shield and SmartPan weighing pan

Note

The 0.1 mg balances with Pro Draft Shield are equipped with a ring seal. The aim of the ring seal is to isolate

the weighing chamber from draft and must always be correctly installed at the bottom of the Pro Draft Shield.

1 Turn the Pro Draft Shield carefully sideways into

horizontal position.

2 Push the ring seal (2) through the opening (1) on the

bottom of the Pro Draft Shield.

3 Fix the ring seal in the opening of the Pro Draft Shield.

The ring seal (3) must be properly fixed into the

opening. The upper edge (4) of the ring seal must lay

all around the bottom of the Pro Draft Shield.

4 Turn the Pro Draft Shield carefully back into vertical

position.

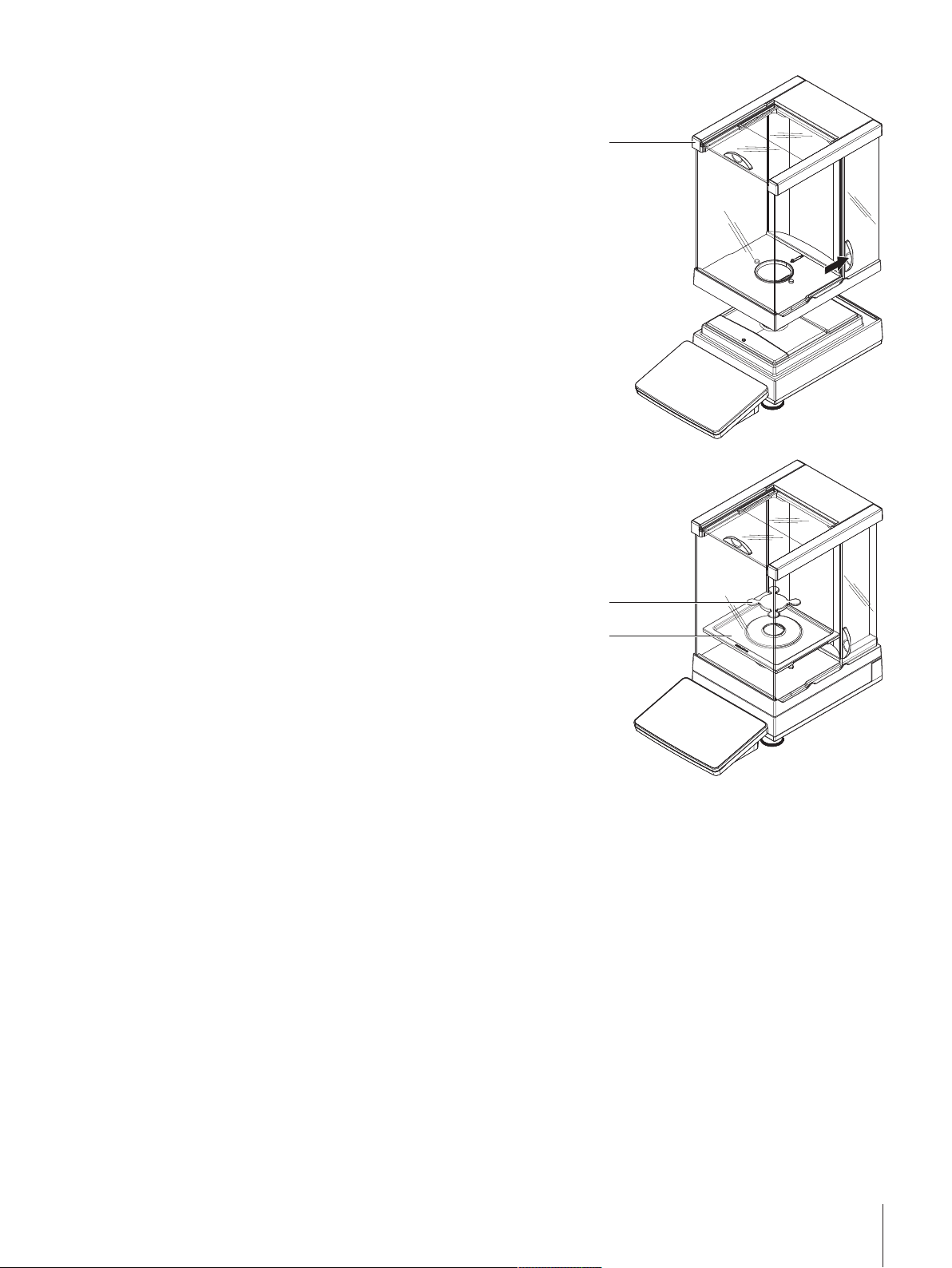

Installation and putting into Operation24 Precision Balances and Comparators

Page 27

5

5 Open the Pro Draft Shield with the door handlers on

6

7

both sides.

6 Hold the Pro Draft Shield on the top bars (5) on both

sides and place it on top of the weighing platform.

7 Place the DripTray (6) into the Pro Draft Shield.

8 Place the SmartPan weighing pan (7) into the Pro

Draft Shield on top of the DripTray (6).

Installation and putting into Operation 25Precision Balances and Comparators

Page 28

4.4.3 Balances 1 mg with Pro Draft Shield

1

2

3

4

1 Open both side doors of the Pro Draft Shield.

2 Hold the Pro Draft Shield on the top bars (1) on both

sides.

3 Place the Pro Draft Shield on top of the weighing

platform.

4 Place the DripTray (2) into the Pro Draft Shield.

5 Place the SmartPan weighing pan (3) into the Pro

Draft Shield on top of the DripTray (2).

6 The weighing pan (4) is optional and can be placed

into the Pro Draft Shield on top of the SmartPan

weighing pan (3).

Installation and putting into Operation26 Precision Balances and Comparators

Page 29

4.4.4 Comparators 0.1 mg and 1 mg with LevelMatic weighing pan

1

2

3

4

11

22

1 Open both side doors of the Pro Draft Shield.

2 Lift the Pro Draft Shield by holding on the top bars (1)

on both sides.

3 Place the Pro Draft Shield on top of the weighing

platform.

4 Place the bottom plate (2) into the Pro Draft Shield.

5 Place the LevelMatic holder (3) into the Pro Draft

Shield on top of the bottom plate (2).

6 Place the LevelMatic weighing pan (4) into the Pro

Draft Shield on top of the LevelMatic weighing pan

holder (3).

4.4.5 Balances 1 mg with SmartPan weighing pan

1 Place the DripTray (1) on top of the weighing platform.

2 Place the SmartPan weighing pan (2) on top of the

DripTray (1).

3 The weighing pan can be placed on top of the

SmartPan weighing pan if needed.

Installation and putting into Operation 27Precision Balances and Comparators

Page 30

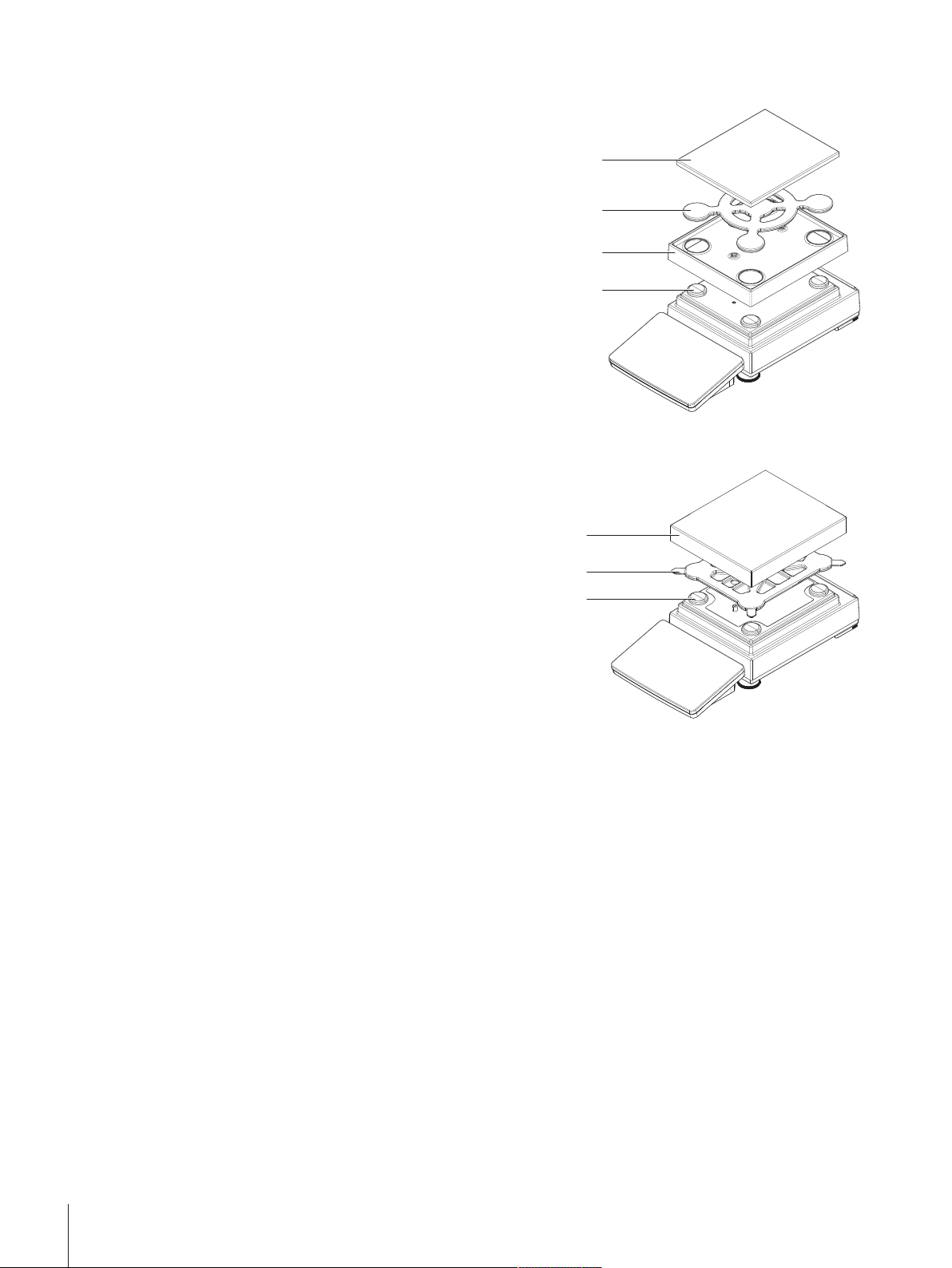

4.4.6 Balances 5 mg / 10 mg with SmartPan weighing pan

11

22

33

4

2

3

11

1 Place the weighing pan support caps (1) on top of the

weighing platform.

2 Place the DripTray (2) on top of the weighing platform.

3 Place the SmartPan weighing pan (3) on top of the 4

weighing pan support caps (1).

4 Place the weighing pan with the protective cover (4)

on top of the SmartPan weighing pan (3).

4.4.7 Balances 0.1 g

1 Place the 4 pan support caps (1) on top of the

weighing platform.

2 Place the weighing pan support (2) on top of the 4

weighing pan support caps (1).

3 Place the weighing pan with the protective cover (3)

on top of the weighing pan support (2).

Installation and putting into Operation28 Precision Balances and Comparators

Page 31

4.5 Assembling balances with L weighing platform

1

2

3

2

11

4.5.1 Attaching the terminal to the weighing platform

The terminal can be attached to the long side or to the short side of the L weighing platform.

1 Turn the weighing platform upside down.

2 Dismantle the screws (1) on the long side or the

screws (2) on the short side of the weighing platform.

3 Connect the terminal to the weighing platform with the

terminal connection cable.

4 Attach the terminal support to the long side or to the

short side of the weighing platform. Fix the terminal

support with the screws from the weighing platform.

5 Insert the terminal connection cable (3) into the cable

channel.

Note

When inserting the terminal connection cable into the cable channel, the terminal connection cable must be

inserted simultaneously from both directions. The terminal connection cable must not have any play between

the plug and the cable channel (see picture).

6 Turn the weighing platform.

4.5.2 Balances 0.1 g and 1 g

1 Place the weighing pan support caps (1) on top of the

weighing platform.

2 Place the weighing pan (2) on top of the weighing pan

support caps (1).

Installation and putting into Operation 29Precision Balances and Comparators

Page 32

4.5.3 Balances 10 mg with SmartPan weighing pan

2

3

11

4

5

1

1 Place the adapter plate (1) on top of the weighing

platform.

2 Place the weighing pan support caps (2) on top of the

adapter plate.

3 Place the draft shield element (3) on top of the adapter

plate (1).

4 Place the SmartPan weighing pan (4) on top of the

weighing pan support caps (2).

5 Place the weighing pan (5) on top of the SmartPan

weighing pan (4) if needed.

4.5.4 Removing the transport arrestments (only for comparators)

Note

Before installing the weighing pan, the transport arrestments on top of the weighing platform must be removed.

Keep the transport arrestments for transporting the comparator.

1 Remove the transport arrestments (1) at the top of the

weighing platform.

2 Close the openings with the enclosed plastic covers.

Installation and putting into Operation30 Precision Balances and Comparators

Page 33

4.5.5 Comparators 1 mg / 5 mg with LevelMatic weighing pan

2

11

3

4

1 Place the adapter plate with the LevelMatic base plate

(1) on top of the weighing platform.

2 Place the draft shield element (2) on top of the adapter

plate (1).

3 Place the LevelMatic weighing pan holder (3) on top of

the LevelMatic base plate (1).

4 Place the LevelMatic weighing pan (4) on top of the

LevelMatic weighing pan holder (3).

4.6 Connecting the balance to the mains

WARNING

Risk of death or serious injury due to electric shock.

Contact with parts that contain a live current can lead to injury and death.

1 To connect the balance, only use the supplied three-core power cable with equipment

grounding conductor.

2 Only use a three-pin power socket with earthing contact.

3 Only use standardized extension cable with equipment grounding conductor.

4 Do not disconnect the equipment grounding conductor.

NOTICE

Note

The balance is supplied with an AC/DC adapter and a country-specific power cable. The AC/DC adapter is

suitable for use with the following voltage range:

100 – 240 VAC, 50/60Hz.

Connect the balance to the mains as follows:

Risk of damage to the balance due to short circuit.

Damage to the insulation on the AC/DC adapter can result in a short circuit and damage the

balance.

1 Only use the original AC/DC adapter supplied with your balance.

2 Route the cable so that it cannot be damaged by external influences.

3 Make sure that the power plug is always accessible.

Installation and putting into Operation 31Precision Balances and Comparators

Page 34

1 Check whether your local power supply falls within the range of the delivered AC/DC adapter. If this is not

11

22

the case, under no circumstances connect the AC/DC adapter to the power supply, but contact a METTLER

TOLEDO representative.

2 Connect the AC/DC adapter (2) to the AC/DC socket

(1).

3 Use the power cable to connect the AC/DC adapter to

the mains.

ð The balance performs a self-test after connection to the

power supply and is then ready to use.

4.7 Setting up the balance

4.7.1 Switching on the balance

When the balance is connected to the mains it starts automatically.

EULA (End User License Agreement)

When the balance is switched on for the first time, the EULA (End User License Agreement) appears on the

screen. Read the conditions, tap I accept the terms in the license agreement. and tap

OK.

Note

Before the balance can be used, it must warm up first. The warm-up time is at least 30 minutes after

connecting the balance to the power supply. When the balance was switched on from standby-mode, the

balance is ready for operation immediately.

4.7.2 Leveling the balance

When the balance is switched on for the first time or when it is switched on after the location of the balance has

been changed, the message Balance is out of level appears. By tapping

Follow the instructions on the screen to level the balance.

Navigation:

Balance menu > Leveling aid

Note

A leveled balance and a stable installation are prerequisites for accurate weighing results.

4.7.3 Performing a simple weighing

When the balance is switched on for the first time, the method work screen of the method General Weighing

opens (the method work screen is described in more detail in the section Method work screen).

4.7.3.1 Zeroing

1 Clear the weighing pan.

2 Close the weighing chamber if the balance has a draft shield.

3 Tap

ð The balance is zeroed.

to zero the balance.

the function Leveling aid opens.

4.7.3.2 Taring

If a weighing container is used, the balance must be tared.

Installation and putting into Operation32 Precision Balances and Comparators

Page 35

1 Clear the weighing pan.

22

11

2 Close the weighing chamber if a draft shield is being used.

3 Tap

4 Open the weighing chamber if a draft shield is being used.

5 Place the container on the weighing pan.

6 Close the weighing chamber if a draft shield is being used.

7 Tap

ð The balance is tared.

to zero the balance.

to tare the balance.

4.7.3.3 Performing General Weighing

1 Place the weight on top of the weighing pan and wait until the weight value is stable.

2 Tap

ð The weighing process was successfull. The weight value has been transferred to the section Protocol.

Add to protocol.

4.7.4 Setting the balance to standby mode

The balance can be set to standby mode by holding

again.

4.7.5 Switching off the balance

To completely switch off the balance it must be disconnected from the mains. By holding

only into standby mode.

Note

When the balance was completely switched off for some time, it must be warmed up for at least 30 minutes

before it can be used.

4.8 Below-the-balance weighing

All models with S weighing platform are equipped with a weighing hook for below-the-balance weighing.

Models with L weighing platform are not equipped with a weighing hook. The weighing hook for L weighing

platforms can be ordered as an accessory.

Note

Before preparing the balance for below-the-balance weighing, the balance must be switched off, disconnected

from the mains and all components (e.g. draft shield, terminal or weighing pan) must be removed from the

weighing platform.

4.8.1 S weighing platform

. The standby mode can be finished by holding

the balance goes

1 Disconnect the balance from the mains and remove all

elements from the weighing platform.

2 Turn the weighing platform to the side.

3 Dismantle the screws (1) and remove the cover plate

(2).

4 Turn the weighing platform back and reinstall all

components.

ð The hook is accessible and can be used for below-the-

balance weighing.

Installation and putting into Operation 33Precision Balances and Comparators

Page 36

4.8.2 L weighing platform

2

11

NOTICE

Damage to the comparator

Make sure that the transport arrestments have been correctly removed from the comparator

before installing the weighing hook. Otherwise the outstanding transport arrestments might

damage the balance or the surface where the balance is placed.

1 Turn the weighing platform upside down.

2 Dismantle the screws (1) and remove the cover plate

(2).

3 Install the hook.

4 Turn the weighing platform to its normal position and

reinstall all components.

ð The balance is ready for below-the-balance weighing.

4.9 Transporting the balance

NOTICE

Damage to the draft shield, terminal or additional terminal stand

Do not hold the balance only by the glass draft shield, by the terminal or by the terminal

stand when carrying the balance.

− Remove the terminal of the S weighing platform from the terminal support and place the

terminal on top of the weighing pan. Always hold the weighing platform with both hands

when carrying the balance.

4.9.1 Carrying the balance over short distances

1 Switch off the balance and disconnect the balance from the mains.

2 Unplug all interface cables if necessary.

3 Hold the weighing platform with both hands.

4 Remove the terminal from the terminal support element and place the terminal on top of the weighing

platform (only for S weighing platform).

5 Carry the balance in horizontal position to the new location.

Installation and putting into Operation34 Precision Balances and Comparators

Page 37

4.9.2 Transporting the balance over long distances

NOTICE

Damage to the comparator

Always attach the transport arrestments on top of the weighing platform when transporting the

comparator over long distances. Otherwise the comparator might get damaged during transportation.

METTLER TOLEDO recommends using the original packaging for transportation or shipment of the balance or

balance components over long distances. The elements of the original packaging are developed specifically for

the balance and its components and ensure maximum protection during transportation.

4.9.3 Packaging and storage

Package

Store all parts of packaging in a safe place. The elements of the original packaging are developed specifically

for the balance and its components and ensure maximum protection during transportation or storage.

Storage

Only store the balance under the following conditions:

• Indoor and in the original packaging

• according to the environmental condition, see chapter "Technical data"

• When storing for longer than 6 months, the rechargeable battery may become empty (only Date and Time

get lost).

Installation and putting into Operation 35Precision Balances and Comparators

Page 38

5 Operation

General Weighing

Sample ID

Task ID

Methods

Protocol

Info

weight

Administrator

Enter here

Enter here

Cancel task

Edit

Complete

More

Add to protocol

sample 1

sample 2

sample 3

sample 4

5.1 User Interface

5.1.1 Main screen "General weighing"

Pos. Name Description

User name Shows the name of the current user.

1

Level indicator Indicates if the balance is leveled (green) or not (red).

2

Weighing value field Shows the current weighing value.

3

Info weight Shows the current weighing value in another unit.

4

5 Drawer Protocol

6 Sample status OK

7 Sample status Not

OK

8 Button Add to

protocol

Weighing action field This field contains actions referring to the current task.

9

Method information

10

area

Weighing-in aid Defines a target weight with upper und lower tolerances.

11

Weighing value area In this area the result of the current weighing process is shown.

12

13 Method name

Shows the recent weighing results.

The result fulfilled the criteria for a green status bar, e. g.:

• Balance is in level.

• Internal adjustment performed and ok.

• Weighing result within the defined tolerance range (only if tolerance defined).

Result criteria are not fulfilled, e. g., " The weighing result was out of the defined

tolerances".

Adds the result to the protocol.

Depending on the selected method the button can have different functions.

Contains information about sample, method or task IDs.

Shows the name of the current method.

Operation36 Precision Balances and Comparators

Page 39

5.1.2 Work screen "Balance menu"

1

2

3

4

5

6

Leveling aid

History

Balance info

Settings

Balance menu

Maintenance

Complete

More

Enter here

Enter here

Solid

Methods

Protocol

Start

Blocking

Methods

Methods list

Tasks

Tests

Adjustments

Delete

Clone

Edit New

Print

Start method

Pos. Name Description

1 Leveling aid

2 History

3 Balance info

4 Settings

5 Maintenance

6 Exit / Block balance

Opens the leveling dialog.

Opens the history dialog.

Shows Balance information.

Opens the complete settings dialog.

Opens the balance maintenance dialog.

Opens the logout / block balance dialog.

5.1.3 Work screen "Methods"

Pos. Name Description

Methods list Working with Methods.

1

• General Weighing

• Interval Weighing

• Piece Counting

• Simple Formulation

• Titration

• Density Determination

The Methods can be edited, cloned, started or created.

Tasks A method/task can be started and then a task is associated with this method.

2

There can be up to one task for each method.

Operation 37Precision Balances and Comparators

Page 40

Pos. Name Description

Protocol

General Weighing

Result State

Sample ID

Gross weight

Stability

Level state

MinWeigh state

Tolerance state

OK

OK

Not OK

Not OK

Test and adjustment state

No MinWeigh defined

No tolerance defined

Timestamp

06/24/2018

Cancel task Exclude result More Complete

Test Working with routine test.

3

Adjustments Lists all internal or external adjustments. Adjustment can be edited, created and

4

5.1.4 Work screen "Protocol"

• Sensitivity tests

• Repeatability tests

• Eccentricity tests

Routine test can be edited, started or created.

started.

Pos. Name Description

Result state Shows the state of the weighing process.

1

Sample ID Shows the Sample ID of the weighing.

2

Gross weight Shows the gross weight.

3

Timestamp Shows the individual timestamp of each weighing item.

4

Balance status Shows stability, level state of the balance, minimum weight, tolerance state and

5

6 Cancel task

7 Exclude result

8 More Opens the dialog More.

test and adjustment state.

Cancels the current running task.

Excludes the current protocol result.

• Start adjustment

• Change display unit

• Configure tare

• Configure zero

• Save as method with templates

Operation38 Precision Balances and Comparators

Page 41

Pos. Name Description

9 Complete Opens the dialog Complete task.

• Print task label manually

• Print protocol manually

• Export protocol manually

5.1.5 Surface navigation of the touchscreen

NOTICE

Damage to the touch screen due to pointed or sharp objects

− Operate the touch screen with your fingers.

The surface navigation of the touch screen works like a common touchscreen.

For selecting or activating an icon or a function

− Tap it.

For scrolling a screen or a scroll bar

− Move it up/down.

For using a drawer

− Drag it.

5.1.6 Input dialog

5.1.6.1 Entering characters and numbers

Pos. Name Explanation

Input field Shows the data that has been entered.

1

Delete Deletes the character left of the current curser position. The curser can be

2

positioned by using the touchscreen.

Discard Closes the keyboard dialog.

3

Confirm Confirms the entered data.

4

Numbers and special

5

characters

Shift Switches between lower or upper case letters.

6

Menu section title Shows the title of the current setting section.

7

Switches into the special character mode.

Operation 39Precision Balances and Comparators

Page 42

5.1.6.2 Changing date and time

Pos. Name Explanation

Pick button Increment

1

Picker field Shows the defined time or date.

2

Pick button Decrement

3

Note

The format of date and time can be defined in the settings via the options Date format and Time format.

5.1.7 System status icons

System messages can appear due to a user action, a user input or a system process. Some messages leave it

up to the user to choose upon acting, they will disappear after acknowledging. Other messages remain

persistent, so the user can defer them but eventually has to handle them. These messages can be seen in the

main status bar on the upper right-hand side of the display.

Icon Name Description

The balance is out of level. The balance must be leveled. Information about leveling the

Information Information messages appear due to user actions or system

Warning Warning messages appear due to user actions or system

balance can be found in the section Leveling the balance. When

the balance is leveled the symbol

processes and offer opportunities that are related to the current

action or process.

processes that could lead to a problem that can be prevented.

appears.

Error Error messages appear due to user actions or system processes

5.1.8 Weighing status icons

Weighing status icons appear due to the weight value matching certain quality criteria. The information on the

status can be looked by tapping on any of the visible weighing status icons.

Icon Name Description

Stability indicator When the stability indicator appears, the balance is not stable.

Net indicator Appears when the tare key has been pressed and the tare weight

Minimum weight violation The current weight value undershoots the defined minimum

that have failed. It is mostly still possible to handle such a

problem.

Make sure that the balance is placed at an adequate location.

Information about the adequate location can be found in the

section [Selecting the location}Page22].

has been subtracted.

weight definition. Make sure that the weight is not below the

minimum weight.

Operation40 Precision Balances and Comparators

Page 43

Calculated value The current weight value is calculated. The symbol only appears

GWP

GWP

GWP

when a container has been used with the function Pretare.

Balance invalid The current balance configuration is invalid or quality criteria have

not been fulfilled according to the GWP approved definition.

Weight not ready The current weight measurement is not ready according to the

GWP approved definition. This can be caused by undershooting

the minimum weight, an overload or an underload.

Weight ready The current weight measurement is ready according to the GWP

approved definition. It can be added to the protocol.

5.2 Balance menu

The Balance menu contains general settings and information.

To open the section Balance menu tap the drawer symbol

The section Balance menu is divided into the following sub-sections.

Leveling aid (see [Leveling aid}Page41] )

•

History (see [History}Page41] )

•

Balance info (see [Balance info}Page43] )

•

User management (only appears when user management is activated), (see [User

•

management}Page43])

•

Settings (see Settings )

Maintenance (see [Maintenance}Page58] )

•

Block balance (see [Exit / Block the balance}Page61])

•

on the left side of the screen.

5.2.1 Leveling aid

Exact horizontal positioning and stable installation is essential for repeatable and accurate weighing results.

With the Leveling aid the balance can be leveled.

Navigation:

For more information see chapter Leveling the balance.

Note

After leveling the balance an internal adjustment must be performed.

5.2.2 History

The balance permanently records the tests and adjustments that are performed. In the section History they are

recorded.

Navigation:

The section History is divided into the following sub-sections.

•

Adjustments, see below.

Tests, see below.

•

Service, see below.

•

Changes (only appears when change history is activated), see below.

•

Balance menu > Leveling aid

Balance menu > History

Operation 41Precision Balances and Comparators

Page 44

Adjustments

Navigation:

Balance menu > History > Adjustments

Note

A maximum of 500 entries can be stored in the adjustments history.

Symbol Description Procedure

Filter Tap to Filter the adjustment history by a defined date range or by a user ID.

Print

Close Tap to return to the section History

Tap to print the adjustment history list.

Tests

Navigation:

Balance menu > History > Tests

Note

A maximum of 500 entries can be stored in the test history.

Symbol Description Procedure

Filter Tap to Filter the test history by a defined date range or by a user ID.

Print

Close Tap to return to the section History.

Tap to print the test history list.

Service

Navigation:

Balance menu > History > Service

Note

A maximum of 500 entries can be stored in the service history.

Symbol Description Procedure

Filter Tap to Filter the service history by a defined date range or by technician.

Print

Close Tap to return to the section History.

Tap to print the service history list.

Operation42 Precision Balances and Comparators

Page 45

5.2.2.1 Changes

The function Change history is an administration tool to improve the quality of the weighing process. Information such as added methods or settings changes are being listed. Tap into the list to display detailed information about the data.

Navigation:

"Changes" is deactivated in the factory settings. To activate "Changes", see Weighing / Quality.

Note

A maximum of 5000 entries can be stored in the change history.

Symbol Description Procedure

Balance menu > History > Changes

Filter Tap to Filter the adjustment history by a defined date range or by a user ID.

5.2.3 Balance info

Navigation:

The section Balance info shows numerous information about the specific balance such as:

• Identification

• Hardware

• Software

• Maintenance

Symbol Description Procedure

Print

Close Tap to return to the section History

Balance menu > Balance info

License

agreement

Close Tap to return to the section History.

Tap to print the adjustment history list.

Tap to open the licence agreement.

5.2.4 User management

In the section User management, rights for users and user groups can be defined. Users can be assigned to

user groups. When the user management is active, the login dialog opens at every system start.

5.2.4.1 Activating the user management

The user management is inactivated in the factory settings. To activate the user management follow:

Navigation:

1 Tap

ð The dialog Activate user management opens.

2 Tap

ð The dialog

3 Tap New password and enter the new password.

Balance menu > Settings > General > User management.

and select Active.

Next.

Set administrator password (optional) opens.

Operation 43Precision Balances and Comparators

Page 46

4 Confirm the new password again and tap

ð The dialog closes.

5 Confirm the activated user management in the section General, tap

ð The User management is active. The login dialog opens at every system start.

5.2.4.2 Logging in

To login:

1 Select a user and enter the password.

2 Tap

ð You are logged in and your user name is displayed on the main screen.

Login.

5.2.4.3 Logging out

To logout follow:

Navigation:

− Tap

ð You are logged out.

Balance menu > Exit/ Block balance

Logout.

5.2.4.4 Managing users and user groups

OK.

OK

Navigation:

The section User management is divided into the following sub-sections:

General Settings for all users.

•

Users Settings for all single users.

•

Groups Settings for user groups.

•

Balance menu > Users

Printing user list

An overview of all users and user groups can be printed by tapping

Print all.

General

Navigation:

Parameter Description Values

Automatic logout

Wait time

User proposals

Password reset Defines if the password can be reset from the login screen. Allowed* | Not allowed