Mettler Toledo XPR106DUH, XPR36, XPR36DR, XPR36C, XPR226DR Mettler Toledo XPR Balances Literature

...Page 1

Weighing Solutions

XPR Balances

Trust the results

Ensure compliance

Increase productivity

Excellence XPR Balances

Go Beyond Weighing

Page 2

Understanding Sample Value

We Understand

The Value of Your Sample

Samples are the core of every analysis. Achieving reliable analytical results is

dependent on the accuracy of the initial sample weighing, and you want to be

surethat your precious samples are used economically. Efficient and error-free

weighing processes save time, money and materials, and investing in abalance

thatconsistently delivers results you can trust soon pays off.

XPR balances meet the challenge of handling rare, expensive or demanding samples

in often complex applications. You can trust that your sample preparation will be

right-first-time to avoid errors in downstream processing. Options for customization

ensure you always get the best results and maximize resources; weighing is more

efficient and you reduce the total cost of your analysis.

Trust the results Ensure compliance Increase productivity

METTLER TOLEDO’s history of

weighing innovations spans over

a century. We are the trusted

partner for National Measurement

Institutions, USP and countless

calibration laboratories around

the world. Trust in our solutions

for quality weighing results.

METTLER TOLEDO supports

you to meet your internal

quality standards as well as

external regulations such as

ISO, GMP etc. Our full workflow

solutions help you comply

with FDA ALCOA+ data integrity

requirements.

With increasing pressure to

improve throughput and reduce

costs, weighing automation and

right-first-time solutions can help

you meet your targets. We offer

you a wide range of solutions to

simplify weighing workflows and

ensure efficient processes.

2

Page 3

“This sample is at the core of my analysis. I want to be sure I get the results right the first time”.

3

Page 4

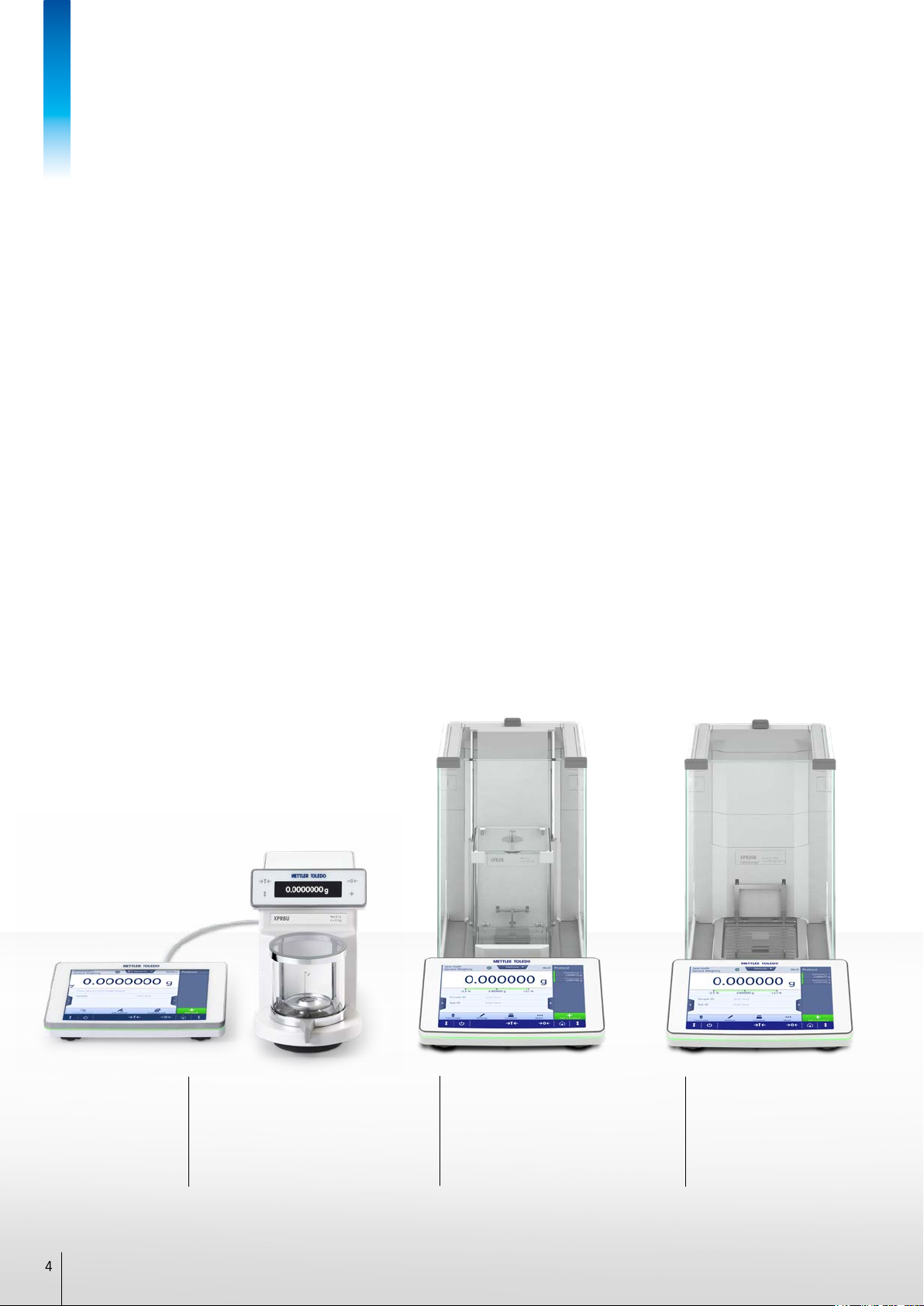

XPR Balance Portfolio

Trusted Solutions for Your Sample

Choosing your new balance is an important decision that concerns more

thanjustreadability and capacity. It is vital to also consider your specific

processandquality needs and to be sure your balance meets applicable

regulatory requirements.

XPR Balance Portfolio

Our portfolio is the answer to your everyday weighing challenges and enables

you toachieve uncompromised excellence in weighing. The XPR portfolio

rangesfrom ultra-microbalances through to high capacity precision balances.

Whether you want to weigh a few micrograms or several kilograms of your

samples, XPRbalances enable you to achieve outstanding weighing accuracy.

Micro Weighing

Max. capacity: 2 g – 10 g

4

Micro-Analytical Weighing

Max. capacity: 32 g – 52 g

Analytical Weighing

Max. capacity: 120 g – 320 g

Page 5

XPR Benefits at a Glance

Common user interface

All balances across the XPRline feature the same terminal with thesame intuitive XPR

user interface. Operators can switch smoothly between tasks on different balances.

Assured process tolerances

The unique GWP Approved function provides a warning if the weight value is outside your

process tolerances. You have theconfidence of knowing your results are always valid.

Unmatched performance

Thanks to high resolution weighing cells, XPR balances offer the best repeatability and

lowest minimum weight for each balance type. Active Temperature Control provides

extraordinary thermal stability for outstanding weighing performance.

Flexible solutions

A wide range of accessories andoptions makes it easy to customize your balance for

yourweighing applications.

METTLER TOLEDO’s Good Weighing Practice (GWP®) helps you to select

therightbalance for your needs based on your process requirements.

Precision Weighing (small platform)

Max. capacity: 200 g – 10 kg

Precision Weighing (large platform)

Max. capacity: 10 kg – 64 kg

5

Page 6

Trusted Results

Trusted Results

Means More than Collecting Data

Every sample analysis generates data. You can trust XPR balances to deliver

reliable results, but how secure are your processes? Has all your data been

recorded correctly? Are there any mistakes in your calculations? Will your data

pass an audit?

LabX software offers you more than a complete data management system for your

laboratory. With central control of instruments, tasks and users, SOP guidance on

the balance terminal, and elimination of manual transcription, LabX provides ultimate

security, increases efficiency and ensures full data integrity.

Assured data integrity Optmized lab processes Instrument management

Lab1

Lab2

• Guaranteed traceability

• Data collecting and archiving

• Meet ALCOA+ data integrity

requirements

• Audit-ready anytime

• Tailored reporting

• SOP user guidance on

thebalance

• Automatic recording,

calculation and transfer

ofdata(incl. metadata)

• Eliminate transcription errors

Lims

ELN

• Central management of

instruments

• Easy integration to other lab

systems (LIMS, ELN, LES, SAP)

6

Page 7

One-for-all solution

You can connect one or more instruments to a single PC which can even be located outside your

laboratory as the system works via your internal network. All administrative work is automated so

yourwhole process can be digitalized—the paperless lab is here!

Balances

Automated Quantos Dosing Systems

UV-VIS Spectrophotometers

Density Meters & Refractometers

Titrators & Karl Fischer Titrators

pH Meters

Auotmated Sample Changers

7

Page 8

XPR Microbalances

XPR Microbalances

Taking Weighing to New Limits

With precious samples available only in the smallest quantities, you need to get

your analyses right first time to avoid wasting material, money and time. Thanks

to unique design features, XPR balances deliver unmatched accuracy, and built-in

active quality assurance functions give you the peace of mind that your results

are valid and meet all your process requirements.

XPR microbalances support you to deliver traceable and compliant results in line with

industry-wide standards, such as those from the US Pharmacopeia or Euramet.

Smallest sample sizes Two-terminal convenience Space-saving footprint

Even under challenging weighing

conditions, XPR microbalances

deliver a unique level of precision

with exceptionally low minimum

weights. The XPR6U offers

0.1μg readability and 0.15 μg

repeatability.

The SmartView terminal is right

where you need it with all the

basic functions at your fingertips:

tare, zero, open door and accept

weight result. The main terminal

can be conveniently placed

outside your safety cabinet.

Active Temperature Control

enables all the XPR microbalance

technology to be combined in

one compact unit, in contrast

to other microbalances which

typically have two. The small

footprint saves valuable bench

space.

8

Page 9

LabX Solution: Instant process information

LabX allows you to centrally control laboratory processes while working directly on

the instrument terminal. It performs all calculations automatically and provides instant

confirmation on whether each result meets predefined process tolerances.

This is especially relevant, for example, in filter weighing for emissions testing. Complex

calculations for air buoyancy correction are done automatically.

9

Page 10

XPR Micro-Analytical Balances

XPR Micro-Analytical Balances

Direct Dosing of Very Small Samples

XPR micro-analytical balances are perfect for accurately weighing the smallest

amounts of your valuable samples directly into labware of different sizes.

Theextremely high accuracy and low minimum weight make it possible to

weighvery small quantities, leading to considerable material and cost savings.

With capacity up to 52 g, very small samples can be conveniently weighed out

intolarger containers, simplifying weighing processes and avoiding the need for

sample transfer.

Economical sample use Fast and stable results Avoid sample transfer

XPR micro-analytical balances

are capable of weighing down

to 1.2 mg at 52 g capacity

(according to USP). You only

need to use the tiniest amounts

of expensive, rare and potent

substances.

The SmartGrid weighing pan

significantly reduces the effects

of air turbulence on the weighing

cell. Stabilization time is

reduced and results are faster—

particularly beneficial when

working in a fume cupboard.

By dosing directly into your tare

container, you avoid the tedious

back-weighing and recalculation

processes associated with

sample transfer via e.g. weighing

paper—and you don’t lose any

of your precious samples.

10

Page 11

LabX Solution: Generate customized reports automatically

Set up report templates with the information you require. Thanks to LabX, you can print out

a report automatically at the end of each process. All data is saved securely in a centralized

database enabling results to be accessible and reports to be generated at any time.

This is especially relevant, for example, when preparing standards and sample solutions

for research projects. The user can define which set of data is most relevant for his

experiment and create reports accordingly.

11

Page 12

XPR Analytical Balances

XPR Analytical Balances

Valid Results Every Time

Successful analyses begin with accurate weighing, and, thanks to smart quality

assurance features, XPR analytical balances deliver valid results first time, every

time. Seamlessly integrating into your existing information system, XPR analytical

balances support the highest requirements for security, efficiency and compliance.

With our wide range of accessories and modules, it has never been so easy to upgrade

your balance to perfectly fit your process needs and ensure the efficient handling of

eventhe most demanding of samples. LabX laboratory software provides a full workflow

solution to optimize processes and guarantee data integrity.

Right-first-time results Consistent workflows Easy automation upgrade

Intelligent functions, such as

StatusLight, LevelControl and

GWP Approved, help ensure

right-first-time results by actively

monitoring that all relevant

conditions for correct weighing

are met.

Process and balance settings

for different weighing tasks

can be saved on the balance

as individual methods. Easily

accessed, users have a quick

and convenient way to start tasks

and every user follows the same

procedure.

XPR analytical balances are

easily extended to provide

automated powder and / or liquid

dosing. Automated dosing offers

a level of accuracy and user

safety which is impossible to

match in a manual process.

12

Page 13

LabX Solution: Audit-ready any time

LabX provides SOP user guidance on all connected instruments and saves all process

information in a secure, centralized database. With full support for regulatory compliance,

LabX helps you meet FDA ALCOA+ requirements for data integrity.

This is especially relevant, for example, in case of batch release or quality control

procedures. All weighing data, including metadata, is stored centrally at the time of

creation, and is quickly available for review or audits.

13

Page 14

Anti-Static Solutions

Anti-Static Solutions

Eliminate a Hidden Error Source

Electrostatic charging occurs through normal sample and tare container

handling and is one of the biggest hidden sources of weighing errors.

Inaddition, samples can be difficult to handle, the balance may not settle

andit’s hard to replicate results.

Thanks to the patented StaticDetect function, XPR micro-analytical and analytical

balances detect electrostatic charges on samples and containers and provide

awarning to the user. With the use of an ionizer, electrostatic charges can be

completely eliminated to avoid any influence on the weighing result.

14

Resulting force due to

static charge on sample

and / or container

Mechanism for

static detection

1.2 m g

Static Error

Our StaticDetect technology shows

the possible error of static charges

ona weighing result in real time.

Page 15

3

2

1. StaticDetect

StaticDetect measures the

weighing error due to electrostatic

charging and provides a warning

if user tolerances are exceeded.

StaticDetect works in both

standard conditions and in more

challenging environments such

as a fume hood.

1

2. Anti-static kits

The optional ionizing module

can be set to work automatically

when the draft shield doors are

closed, eliminating electrostatic

charges inside the weighing

chamber in just a few seconds.

Freestanding ionizers are also

available.

3. ErgoClip holders

ErgoClips hold sample containers

securely on your balance and

also act as Faraday Cages to

shield the weighing cell against

any electrostatic influences that

may be present.

15

Page 16

XPR Precision Balances

XPR Precision Balances

Weigh at 1 mg without a Draft Shield

XPR precision balances provide you with fast and accurate weighing results, even

under the toughest weighing conditions. The innovative SmartPan™ weighing pan

minimizes the effects of air currents on the weighing cell, enabling even 1 mg

balances to be used without a draft shield in standard conditions.

The intuitive interface provides intelligent functions to simplify weighing processes while

smart quality assurance features automatically monitor the status of your balance to

ensure your results are always valid.

Fast and accurate results Efficient processes Error-free data transfer

4.0

3.0

2.0

1.0

Settling Time (s)

2 × faster

0.0

The high stability provided

by SmartPan means you get

your results up to twice as

fast compared to a standard

weighing pan. Even when

weighing in challenging

conditions, repeatability is

improved up to two-fold.

Standard Pan

Safety Cabinet

SmartPan

Saved weighing methods make it

quick to start daily tasks. Results

and task data are automatically

recorded on the built-in results

protocol. Time-consuming

and error-prone manual data

input / output can be eliminated.

Multiple interfaces (4 USB,

1LAN) provide error-free data

transfer and many connection

possibilities. XPR balances

automatically recognize and

configure a connected device

in seconds, enabling you to get

started right away.

16

Page 17

LabX Solution: Central instrument management

LabX provides you with a full overview of all connected instruments, no matter where they

are located, enabling you to centrally manage all instruments, tasks and users. LabX also

notifies you if a balance test or service is due, making it easy to ensure all instruments are

kept up to date and weighing results are valid.

This is especially relevant, for example, for formulations which are carried out in different

locations across your company (such as your production floor). At any time, you can see

the status of all activities and even view results in real-time.

17

Page 18

XPR High Capacity Precision Balances

Solid Performance in Tough Conditions

XPR large platform precision balances deliver outstanding weighing performance

even in harsh environments. The extremely durable construction is your guarantee

of reliable results for years to come.

Customizable weighing methods, the built-in results protocol and intelligent quality

assurance features help streamline your weighing processes and ensure valid results.

These flexible balances offer wide-ranging solutions to meet the needs of almost any

high capacity weighing application.

XPR High Capacity Precision Balances

Outstanding performance Extremely durable High accuracy

The Monobloc™ weighing cell

delivers fast and precise results.

The LevelMatic pan offers the

highest weighing accuracy,

whilst SmartPan, standard

on 0.01 g readability models,

provides exceptional stability

inbusy areas.

Overload protection guards

the weighing cell during the

loading and unloading of heavy

items. The full metal housing is

chemically resistant and protects

against dust and splashing

liquids, ensuring a long balance

lifetime.

The XPR26003LC has 26.1 kg

capacity and 1 mg readability

enabling you to accurately

weigh small quantities in

larger containers. Perfect when

you have a low net sample

weight and need exceptional

repeatability.

18

Page 19

LabX Solution: Seamless integration

LabX integrates seamlessly with LIMS and various ERP systems, in order to manage and

store weighing data. Electronic end-to-end data transfer saves time, eliminates transcription

errors and supports the move towards a paperless lab.

This is especially relevant, for example, for gas filling applications. Results are automatically

transferred to your ERP, or other external systems, for lean material and data management.

19

Page 20

Consistently Accurate Results

Consistently Accurate Results

In Three Simple Steps

As a key stage in your workflow, accurate weighing is essential to ensure you

deliverquality products in a cost-effective manner. In accordance with our globally

recognized Good Weighing Practice™ (GWP

team can help you achieve consistently accurate and reliable weighing results.

The scientific based GWP® program matches your weighing process requirements to

theperformance of the balance and the necessary maintenance activities. This approach

ensures selection of the appropriate balance and protects you from experiencing

undetected sample waste and unnecessary process repetitions. Our expertise means

you can enjoy top weighing performance, maximum uptime and compliance with the

norms and standards relevant to your industry, while maintaining budget control.

®

), METTLER TOLEDO’s Sales and Service

1. Selection 2. Installation 3. Calibration and routine testing

Our free GWP® Recommendation

service provides documentary

evidence that the selected

balance meets your specific

process, quality and regulatory

requirements. It gives you the

knowledge you need to make

the correct balance purchase

decision.

Our Installation Pacs document

balance installation and

qualification in accordance with

regulations and provide guidance

on controlling environmental

influences that may affect

accuracy. The integral user

training ensures balances are

used correctly from day one.

Balance calibration is essential

for accurate results. GWP®

Verification service proves

balance accuracy on-site and

includes an optimal routine

testing and calibration schedule,

specification of the required

test weights, and the ideal

maintenance plan.

20

Page 21

Your METTER TOLEDO service technician uses the information from your GWP® Verification and the balance

calibration to program the built-in GWP Approved quality assurance function. GWP Approved prompts you to

carry out calibration and routine balance tests in accordance with your specific accuracy requirements. A record

of alltests is maintained that is suitable for audit purposes. Yourbenefit: GWP Approved documents the proven

validity of every single result over the balance lifetime.

Good Weighing Practice™

The Highest Quality Standard in Weighing

www.mt.com/gwp

21

Page 22

Accessories

Accessories

Small Details. Big Difference.

METTLER TOLEDO balances can be customized with accessories and peripheral

devices to meet the needs of virtually any application. Our expertly designed

accessories make your work easier, reduce fatigue, and increase accuracy and

productivity.

View our range of over 200 accessories online.

www.mt.com/accessories

Peripheral devices Sample preparation Anti-static solutions

Choose from a wide range

of devices to optimize your

weighing processes, including:

• Printers for fast, high quality

printouts on paper and labels

• Barcode reader for error-free

data transfer

• Foot switch for ergonomic

balance operation

Convenient, safe sample

preparation and transfer:

• ErgoClip container holders

forone-step dosing

• SmartPrep dosing funnels

foreasy sample transfer

• Spatulas

Innovative anti-static solutions

for fast and efficient elimination

of electrostatic charges from

yoursamples and containers:

• XPR ionizing module

• Free-standing ionizing

electrodes

• ErgoClip container holders

foruse as Faraday Cages

22

Page 23

Weighing pans / draf t shields Balance protection Test weights

For improved weighing

performance and more reliable

results:

• Draft shields to protect the

weighing cell from air currents

• Weighing pans and magnetic

protection shield pan

• Kit for bullion weighing

Ensure your balance stays

safeat all times:

• Protective covers for the

balance, terminal and

weighing pan guard against

dirt and damage

• Anti-theft devices prevent

unauthorized balance removal

• Dedicated cases for safe

transportation

For routine testing and calibration

of balances:

• Weight sets

• CarePacs

• Weight handling tools

23

Page 24

XPR Minimum Weights

What is Your Smallest Sample?

When selecting your balance, it is important to consider the smallest net sample

weight that you want to weigh. The balance minimum weight is the smallest load

that can be weighed on the balance within the allowed uncertainty. Any loads below

the minimum weight may not achieve the required weighing accuracy and cannot be

trusted to be correct.

24

XPR Minimum Weights

The specific minimum weight for each balance should be determined during installation

at its place of operation. XPR’s MinWeigh function ensures your samples are always

above the determined minimum weight.

Microbalances and Analytical Balances

Minimum

Sample Weight1)Readability Model Weighing range

0.3 mg 0.0001 mg XPR2U

XPR6U

0.6 mg 0.0005 mg XPR6UD5

0.82 mg 0.001 mg XP R10

1 mg XPR2

1.2 m g 0.001 mg XPR36C

XPR56C

1.4 m g 0.001 mg XPR36

XPR56

2 mg 0.001 / 0.01 m g XPR36DR

XPR56DR

6 mg 0.002 / 0.00 5 m g XP R106DU H

8 mg 0.005 / 0.01 m g XPR226CDR

10 m g 0.005 / 0.01 m g XPR226DR

14 m g 0.01 / 0.1 mg XP R105D R

XPR225DR

0.01 mg XPR205

20 mg 0.01 / 0.1 m g XPR205DU

XPR225DU

41 mg 0.05 mg XPR205D5

XPR305D5

82 mg 0 .1 m g XPR204

1)

Typical minimum sample weight according to USP Chapter 41; measurement at ≤5% load.

2.1 g

6.1 g

6.1 g

10.1 g

2.1 g

8.1 g

32 g

52 g

32 g

52 g

32 g

11 g

52 g

41 g

41 g

81 g

121 g

121 g

121 g

120 g

121 g

120 g

220 g

220 g

220 g

220 g

220 g

220 g

220 g

220 g

320 g

Page 25

METTLER TOLEDO helps you select the right balance

Do you know which balance meets your requirements for accuracy, compliance and quality?

Taketheworry outofbalance selection with our GWP® Recommendation service which is available

globally free ofcharge. GWP®Recommendation considers:

• The smallest net weight to be weighed

• The largest weight to be weighed (including tare)

• The weighing accuracy required

• The environmental conditions and the weighing application

GWP® Recommendation provides documented evidence that the selected balance meets metrological, environmental and

regulatoryrequirements.

www.mt.com/gwp-recommendation

Precision Balances

Minimum

Sample Weight1)Readability Model Weighing range

≥120 mg 0.1 m g XPR404S

≥140 mg XPR504S

≥160 mg 0.1 / 1 mg XPR504SDR

≥240 mg 0.1 m g XPR204S

≥600 mg 0.1 m g XPR2004SC

≥820 mg 1 mg XPR1203S

≥1 g XPR303SN

XPR303S

XPR603S

XPR603SN

≥1.2 g XPR3003S

≥1.6 g 0.1 m g XPR5004SC

1 / 10 mg XPR603SDR

XPR603SNDR

≥2 g 1 mg XPR5003S

≥4 g 1 mg XPR10003SC

≥6 g 5 mg XPR3003SD5

XPR6003SD5

≥8 g 1 mg XPR26003LC

≥8.2 g 10 mg XPR1202 S

XPR2002S

XPR4002S

XPR6002S

XPR8002S

XPR10002S

≥10 g 10 / 100 mg XPR6002SDR

≥13 g 5 mg XPR32003LD5C

≥20 g 10 mg X P R15 0 02L

5 mg XPR64003LD5C

≥36 g 10 / 100 mg XPR20002LDR

10 m g XPR64002LC

10 m g XPR6 4002LC-T

≥82 g 0.1 g XPR4001S

XP R6001S

XPR8001S

XPR10001S

XPR10001L

XP R16 0 01L

XP R 320 01L

XP R 64001L

≥820 g 1 g XPR32000L

XPR64000L

1)

Typical minimum sample weight according to USP Chapter 41; measurement at ≤5% load.

101 g

210 g

310 g

310 g

120 g

120 g

410 g

510 g

510 g

610 g

610 g

610 g

610 g

1.2 k g

1.2 k g

2.3 kg

2.1 k g

1.2 k g

3.1 kg

5.1 k g

5.1 k g

10.1 k g

3.1 kg

6.1 kg

4.1 k g

6.1 kg

8.1 kg

10.1 k g

6.1 kg

4.2 kg

4.1 k g

6.1 kg

8.1 kg

10.1 k g

10.1 k g

26.1 k g

32 .1 k g

15.1 kg

64.1 kg

20.1 k g

64.1 kg

64.1 kg

16.1 k g

32 .1 k g

64.1 kg

32 .1 k g

64.1 kg

25

Page 26

XPR Technical Specications

XPR Micro and Micro-Analytical

Technical Specifications

XPR Microbalances

Readability 0.0001 mg / 0.0005 mg

XPR2U XPR6U XPR6UD5

Material number 30279196 30279276 30279285

Maximum capacity 2.1 g 6.1 g 6.1 g

Readability 0.0001 mg 0.0001 mg 0.0005 mg

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

1)

Typical value

2)

Minimum weight typical at 5% load

Readability 0.001 mg

Material number

Maximum capacity

Readability

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

1)

Typical value

2)

Minimum weight typical at 5% load

1)

(5% load) 0.00015 mg 0.00015 mg 0.0003 mg

1)

1)

(5% load) 0.0004 mg 0.0005 mg

1)

1)

2)

1)

2)

0.010 mg 0.018 mg 0.018 mg

<10 s <15 s <8 s

0.03 mg 0.03 mg 0.06 mg

2)

0.3 mg 0.3 mg 0.6 mg

XPR10 XPR2

30279296

10.1 g

0.001 mg

0.020 mg 0.010 mg

<8 s <8 s

0.082 mg 0.1 m g

2)

0.82 mg 1.0 m g

30279267

2.1 g

0.001 mg

26

XPR Micro-Analytical

Readability 0.001 mg

XPR36C XPR36 XPR36DR XPR56C XPR56 XPR56DR

Material number 30594503 30594493 30594498 30355547 30355535 30355539

Maximum capacity (full range / fine range) 32 g 32 g 32 g / 8.1 g 52 g 52 g 52 g / 11 g

Readability (full range / fine range) 0.001 mg 0.001 mg 0.01 mg /

1)

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan t ype SmartGrid,

1)

Typical value

2)

Minimum weight typical at 5% load

(5% load) 0.0006 mg 0.0007 mg 0.001 mg 0.0006 mg 0.0007 mg 0.001 mg

1)

1)

2)

0.06 mg 0.06 mg 0.08 mg 0.08 mg 0.08 mg 0.08 mg

3.5 s 3.5 s 2.5 s 3.5 s 3.5 s 2.5 s

0.12 mg 0.14 m g 0.2 mg 0.12 m g 0.14 m g 0.2 mg

2)

1.2 m g 1.4 m g 2 mg 1. 2 m g 1.4 m g 2 mg

Hanging

weighing pan

SmartGrid SmartGrid SmartGrid,

0.001 mg

0.001 mg 0.001 mg 0.01 m g /

0.001 mg

SmartGrid SmartGrid

Hanging

weighing pan

Page 27

XPR Analytical

Technical Specifications

XPR Analytical

Readability 0.005 mg / 0.01 mg

XPR106DUH XPR226CDR XPR226DR XPR205

Material number 30532226 30594507 30594478 3 0 35 5 411

Maximum capacity (full range / fine range) 120 g / 41 g 220 g / 121 g 220 g / 121 g 220 g

Readability (full range / fine range) 0.005 mg /

0.002mg

1)

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

1)

Typical value

2)

Minimum weight typical at 5% load

(5% load) 0.003 mg 0.004 mg 0.005 mg 0.007 mg

1)

1)

2)

0.15 m g 0.25 mg 0.25 mg 0.25 mg

4 s 5 s 2 s 2 s

0.6 mg 0.8 mg 1 mg 1.4 m g

2)

6 mg 8 mg 10 m g 14 mg

XPR205DU XPR225DR XPR225DU XPR105DR

Material number 30469076 30594483 30594488 30355342

Maximum capacity (full range / fine range) 220 g / 81 g 220 g / 121 g 220 g / 121 g 120 g / 41 g

Readability (full range / fine range) 0.1 mg / 0.01 m g 0.1 mg / 0.01 mg 0.1 mg / 0.01 mg 0.1 mg / 0.01 m g

1)

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

1)

Typical value

2)

Minimum weight typical at 5% load

(5% load) 0.007 mg 0.007 mg 0.007 mg 0.007 mg

1)

1)

2)

0.4 mg 0.3 mg 0.4 mg 0.25 mg

1.5 s 1.5 s 1.5 s 1.5 s

2 mg 1.4 mg 1.4 m g 1.4 m g

2)

20 mg 14 mg 14 mg 14 m g

0.01 mg /

0.005mg

0.01 mg /

0.005mg

0.01 mg

Readability 0.05 mg / 0.1 mg

XPR205D5 XPR305D5 XPR204

Material number 30469150 30469154 3 0 3 5 5 419

Maximum capacity (full range / fine range) 220 g 320 g 220 g

Readability (full range / fine range) 0.05 mg 0.05 mg 0 .1 m g

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

1)

Typical value

2)

Minimum weight typical at 5% load

1)

(5% load) 0.02 mg 0.02 mg 0.04 mg

1)

1)

0.4 mg 0.6 mg 0.4 mg

1.5 s 1.5 s 1.5 s

2)

4.1 m g 4.1 m g 8.2 mg

2)

41 mg 41 mg 82 mg

27

Page 28

XPR Technical Specications

XPR Precision

Technical Specifications

XPR Precision S-Platform

Readability 0.1 mg

XPR204S XPR404S XPR504SDR XPR504S XPR2004SC XPR5004SC

Material number 30 315631 30 315 628 30315239 30 315652 303176 28 303176 4 0

Maximum capacity (full range / fine range) 210 g 410 g 510 / 101 g 510 g 2.3 kg 5.1 kg

Readability (full range / fine range) 0.1 m g 0.1 m g 1 / 0.1 mg 0.1 m g 0 .1 m g 0.1 m g

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan SmartPan SmartPan SmartPan SmartPan SmartPan,

1)

Typical value

2)

Minimum weight typical at 5% load

1)

(5% load) 0.12 mg 0.06 mg 0.4 mg 0.07 mg 0.3 mg 0.8 mg

1)

1)

2)

0.4 mg 0.48 mg 0.3 mg 0.3 mg 6.8 mg 8 mg

2 s 2 s 2 s 2 s 3.5 s 3.5 s

24 mg 12 mg 16 mg 14 m g 60 mg 160 mg

2)

240 mg 120 m g 160 m g 14 0 mg 600 mg 1,6 0 0 m g

Standard pan,

LevelMatic

SmartPan,

Standard pan,

LevelMatic

28

Readability 1 mg

XPR303SN

Material number 30316446 30315753 3 0 316 52 9 30 316 525 30 316 5 40

Maximum capacity (full range / fine range) 310 g 310 g 610 / 120 g 610 / 120 g 610 g

Readability (full range / fine range) 1 mg 1 mg 10 / 1 m g 10 / 1 mg 1 mg

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan SmartPan Standard pan,

1)

Typical value

2)

Minimum weight typical at 5% load

3)

Supplied without draft shield (available as an accessory)

1)

(5% load) 0.5 mg 0.5 mg 0.8 mg 0.8 mg 0.5 mg

1)

1)

2)

1.2 m g 1.2 m g 6 mg 6 mg 1.2 m g

1.5 s 1.5 s 1.5 s 1.5 s 1.5 s

100 m g 100 mg 16 0 mg 16 0 mg 10 0 mg

2)

1 g 1 g 1.6 g 1.6 g 1 g

3)

XPR303S XPR603SNDR3)XPR603SDR XPR603SN

SmartPan Standard pan,

SmartPan

SmartPan

SmartPan

3)

Page 29

Readability 1 mg

XPR603S XPR1203S XPR3003S XPR5003S XPR10003SC

Material number 30316504 30316563 3 0 316701 30 316 9 90 3 0 317 6 41

Maximum capacity 610 g 1,210 g 3.1 kg 5 .1 k g 10 .1 k g

Readability 1 mg 1 mg 1 mg 1 mg 1 mg

1)

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan Standard pan,

(5% load) 0.5 mg 0.4 mg 0.6 mg 1 mg 2 mg

1)

1)

2)

1.2 m g 1.5 mg 1.8 m g 3 mg 34 mg

1.5 s 1.5 s 2 s 2 s 3.5 s

100 m g 82 mg 120 m g 200 mg 400 mg

2)

1 g 820 mg 1.2 g 2 g 4 g

SmartPan

Standard pan,

SmartPan

Standard pan,

SmartPan

Standard pan,

SmartPan

SmartPan,

Standard pan,

LevelMatic

1)

Typical value

2)

Minimum weight typical at 5% load

Readability 5 mg / 10 mg

XPR3003SD5 XPR6003SD5 XP R12 02S XPR2002S XPR4002S

Material number 30 31670 5 30316548 3031712 3 3 0 316996 3 0 31726 9

Maximum capacity 3.1 kg 6 .1 k g 1, 210 g 2.1 k g 4 .1 k g

Readability 5 mg 5 mg 0.01 g 0.01 g 0.01 g

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan Standard pan,

1)

Typical value

2)

Minimum weight typical at 5% load

1)

(5% load) 3 mg 3 mg 4 mg 4 mg 4 mg

1)

1)

4 mg 5 mg 15 mg 25 mg 25 mg

2 s 2 s 1.2 s 1.2 s 1.2 s

2)

600 mg 600 mg 820 mg 820 mg 820 mg

2)

6 g 6 g 8.2 g 8.2 g 8.2 g

SmartPan

Standard pan,

SmartPan

Standard pan,

SmartPan

Standard pan,

SmartPan

Standard pan,

SmartPan

XPR6002SDR XPR6002S XPR8002S XPR10002S

Material number 30 317458 30317428 30317466 30317433

Maximum capacity 6.1 / 1.2 kg 6.1 k g 8 .1 k g 10.1 kg

Readability 0.1 / 0.01 g 0.01 g 0.01 g 0.01 g

1)

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan Standard pan,

1)

Typical value

2)

Minimum weight typical at 5% load

(5% load) 5 mg 4 mg 4 mg 4 mg

1)

1)

2)

30 mg 12 mg 12 m g 12 mg

1.2 s 1.2 s 1.5 s 1.5 s

1 g 820 mg 820 mg 820 mg

2)

10 g 8.2 g 8.2 g 8.2 g

SmartPan

Standard pan,

SmartPan

Standard pan,

SmartPan

Standard pan,

SmartPan

Readability 0.1 g

XPR4001S XPR6 001S XPR8001S XPR10001S

Material number 30 317447 303174 91 3 0317 511 3 0 31748 3

Maximum capacity 4.1 k g 6.1 k g 8 .1 k g 10.1 k g

Readability 0.1 g 0.1 g 0.1 g 0.1 g

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan Standard pan Standard pan Standard pan Standard pan

1)

Typical value

2)

Minimum weight typical at 5% load

1)

(5% load) 40 mg 40 mg 40 mg 40 mg

1)

1)

50 mg 50 mg 120 m g 120 m g

0.8 s 0.8 s 1 s 1 s

2)

8.2 g 8.2 g 8.2 g 8.2 g

2)

82 g 82 g 82 g 82 g

29

Page 30

XPR Technical Specications

XPR Precision

Technical Specifications

Readability 1 mg / 5 mg

XPR26003LC XPR32003LD5C XPR64003LD5C

Material number 30 3176 42 3 0 317 6 4 3 3 0 317644

Maximum capacity 26.1 k g 32.1 k g 6 4 .1 k g

Readability 1 mg 5 mg 5 mg

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan LevelMatic Standard pan LevelMatic

1)

Typical value

2)

Minimum weight typical at 5% load

1)

(5% load) 4 mg 6.5 mg 10 m g

1)

1)

140 m g 14 0 m g 650 mg

8 –12 s 8 –12 s 8 –12 s

2)

800 mg 1.3 g 2 g

2)

8 g 13 g 20 g

Readability 10 mg

XPR15002L XPR20002LDR XPR64002LC XPR64002LC-T

Material number 30 317522 303175 26 30 3176 45 30317646

Maximum capacity (full range / fine range) 15.1 k g 20.1 / 4.2 kg 64.1 k g 64.1 kg

Readability (full range / fine range) 0.01 g 0.1 / 0.01 g 0.01 g 0.01 g

1)

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan Standard pan,

1)

Typical value

2)

Minimum weight typical at 5% load

3)

Transportable balance with a carrying case

(5% load) 10 m g 18 mg 18 mg 18 mg

1)

1)

2)

12 m g 25 mg 650 mg 650 mg

1.5 s 1.5 s 8 –12 s 8 –12 s

2 g 3.6 g 3.6 g 3.6 g

2)

20 g 36 g 36 g 36 g

SmartPan

Standard pan,

SmartPan

Standard pan Round pan

3)

XPR Precision L-Platform

Readability 0.1–1 g

XPR10001L XPR16 001L XPR32001L X PR6 4001L XPR32000L XPR64000L

Material number 30317530 303175 42 303162 92 30316477 3031648 5 3031649 3

Maximum capacity 10.1 k g 16.1 kg 3 2 .1 k g 6 4 .1 k g 32.1 k g 6 4 .1 k g

Readability 0.1 g 0.1 g 0.1 g 0.1 g 1 g 1 g

Repeatability

Sensitivity offset, nominal load

Settling time

Minimum weight (k = 2, U =1%)

Minimum weight (according to USP)

Weighing pan Standard pan Standard pan Standard pan Standard pan Standard pan Standard pan

1)

Typical value

2)

Minimum weight typical at 5% load

1)

(5% load) 40 mg 40 mg 40 mg 40 mg 400 mg 400 mg

1)

1)

120 m g 200 mg 250 mg 300 mg 320 mg 320 mg

1.5 s 1.5 s 1.5 s 1.8 s 1.2 s 1.5 s

2)

8.2 g 8.2 g 8.2 g 8.2 g 82 g 82 g

2)

82 g 82 g 82 g 82 g 820 g 820 g

30

Page 31

LabX Laboratory Software

License Options

LabX laboratory software is available in two editions with all configurations and options

handled vialicense keys. LabX Express is installed on one computer and enables you

toconnect up to three instruments. LabX Server can be installed on multiple computers

andhas a range of advanced options available; up to 30instruments can be connected.

LabXis licensed per connected instrument, not for each computer. Further Option Licenses

can be added according to your needs.

Whether your setup is standalone or fully integrated with your existing information system,

LabX works behind the scenes to take care of all your datawhile you concentrate on

youranalyses.

LabX Express

Suitable for small or standalone

systems with one PC and a maxi-

mum of3 connected instruments

Starter Pack Expres s 1153120

LabX Balance Express

Balance License

IncludedOptional

Product Database 111531 0 3

Auto Im port / Exp ort 1115 310 5

User Management 1115 3 10 2

Balance License 1115 3 2 2 0

(2 additional)

LabX Server

Suitable for networks with

multiple PCs and a maximum

of30connected instruments

Starter Pack Server 1153121

LabX Balance Server

Balance License

Auto Im port / Exp ort

User Management

Product Database 111531 0 3

Regulation 1115 310 4

Report Designer 1115 310 6

System Integration 1115 31 0 7

Balance License 1115 3 2 2 0

(29 additional)

LabX Services

METTLER TOLEDO offers full support

throughout allstages of the LabX

lifecycle:

• Method Development

• Installation

• Training

• Validation

• Maintenance

The range has been carefully designed

to allow you to choose just the services

necessary to match individual user

needs and complement your system

requirements. For further details,

contact your local METTLER TOLEDO

representative.

Page 32

Visit our Lab Library

For Guides, Webinars and White Papers

www.mt.com/lab-library

METTLER TOLEDO Group

Laboratory Weighing

Local contact: www.mt.com/contacts

Subject to technical changes

©06/2020 METTLER TOLEDO. All rights reserved

30475887B

Group MarCom RITM642331 JK/MB

www.mt.com/balances

For more information

*30475887*

Loading...

Loading...