Page 1

Operating Instructions

METTLER TOLEDO

Viper BC counting scale

Ref n

Ref 10

Page 2

2

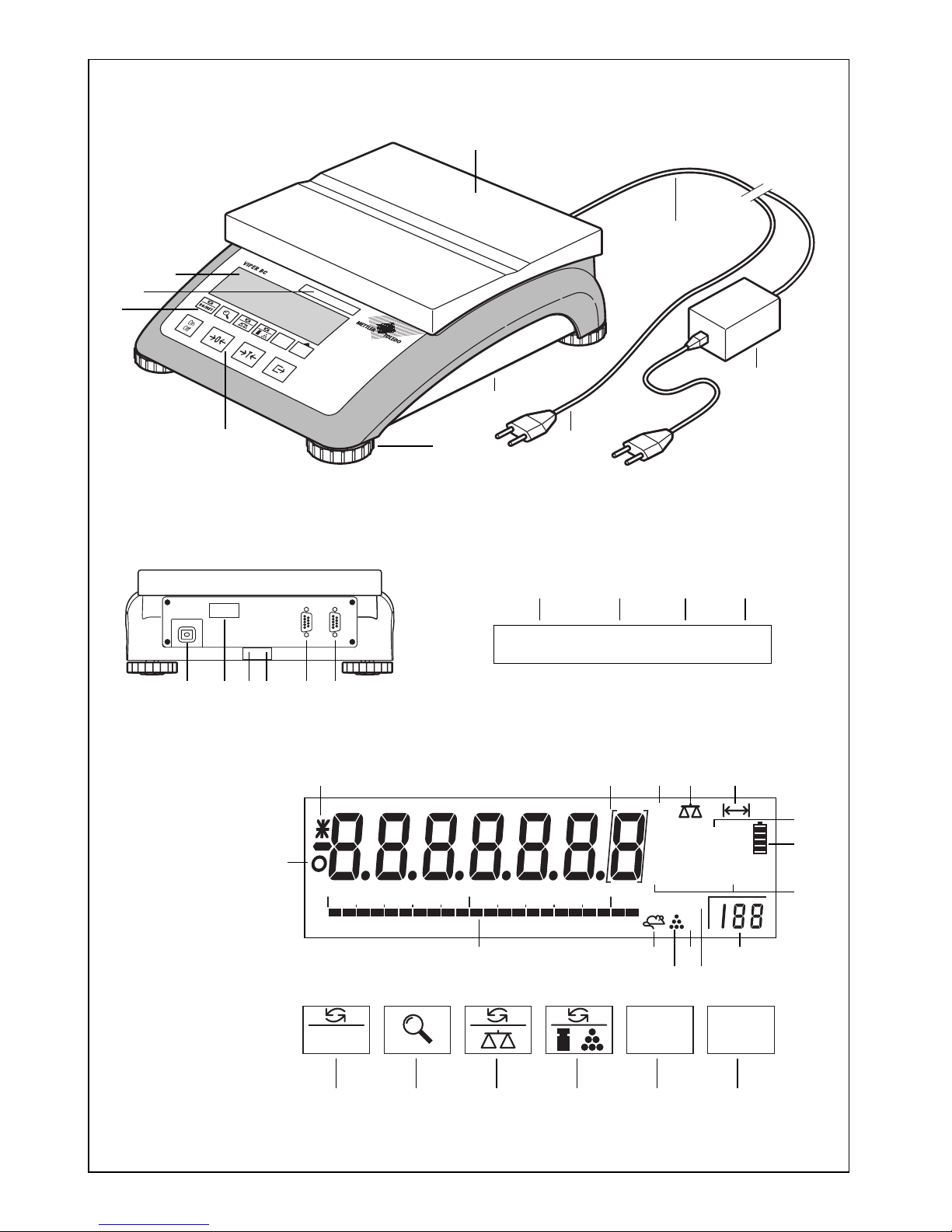

Overview

Rear of scale

Scale specifications (example)

Display

Function keys

R

e

f n

R

e

f 1

0

9101114 1213

Max1: 3kg Min1: 20g e1: 1g d1: 1g

Max2: 6kg Min2: 40g e2: 2g d2: 2g

1815 16 17

28 29 3026

1

3

4

7

8

8a

8b

kg

tbz

P

CS

NET

12

C

om

%

0 50 100

%

Auto Opt

∑

12

B/G

32

21

22

192324

25

31

33

20

27

2

Ref nRef 10

BG/NET

34 35 36 37 38 39

5

6

Page 3

3

1 keypad

2 function keys

3 scale specifications

4 display

5 weighing pan

6 adhesive label for MonoBloc version

7 adjustable feet

8 power supply:

8a: power cord (scale w/o battery)

8b: AC adapter (scale with battery)

Rear of scale

9 RS232C interface

10 second interface RS232C (optional)

11 spirit level (only on certified scales and those

with MonoBloc weighing cells)

12 hole for antitheft device

13 model plate

14 power cord or jack for AC adapter

Scale specifications

15 maximum loads (ranges 1/2)

16 minimum loads (ranges 1/2)

17 verification scale interval (certified scale)

(ranges 1/2)

18 max. resolutions (ranges 1/2)

Display

19 own number of reference pieces

20 automatic reference optimization

21 totalization symbol (no function)

22 piece counting symbol

23 dynamic weighing symbol

24 weighing range bar graph

25 stability detector

26 changed resolution (only certified scales)

27 certification brackets (certified scales e =10d)

28 active interface (for master mode)

29 active scale (in 2-scale systems)

30 weighing range display

31 symbols for net/gross weight

32 battery discharge status

33 weighing unit

Function keys

34 toggle between net and gross weight display

35 increased resolution of the weight display in

weighing mode or displayed weight of an

individual component in counting mode (displayed for 3 seconds)

36 switch to second scale (in 2-scale systems)

37 toggle between piece count and weight dis-

play

38 reference piece weight determination with 10

pieces

39 reference piece weight determination with var-

iable number of pieces

Page 4

4

Contents

1 Putting into service .......................................................................................... 5

1.1 Unpacking and checking contents ................................................................................... 5

1.2 Safety and environmental protection ................................................................................ 5

1.3 Positioning and leveling the scale ................................................................................... 6

1.4 Connecting to power supply ............................................................................................ 7

1.5 Battery operation............................................................................................................7

2 Weighing......................................................................................................... 8

2.1 Switching on and off and zeroing .................................................................................... 8

2.2 Simple weighing ............................................................................................................ 8

2.3 Weighing with tare ......................................................................................................... 9

2.4 Recording weighing results ............................................................................................. 9

2.5 Special functions (master mode)..................................................................................... 9

3 Piece counting ............................................................................................... 10

3.1 Counting pieces into a container ................................................................................... 10

3.2 Counting out pieces from a container............................................................................. 11

3.3 Automatic reference opitimization .................................................................................. 11

3.4 Adding mode ............................................................................................................... 12

3.5 Piece counting with 2-scale systems ............................................................................. 12

4 Master mode ................................................................................................. 13

4.1 Overview and operation ................................................................................................ 13

4.2 Scale calibration (adjustment) ...................................................................................... 13

4.3 Scale settings .............................................................................................................. 14

4.4 Interface configuration .................................................................................................. 16

4.5 Printing master mode settings ....................................................................................... 18

4.6 Saving settings and exiting master mode ....................................................................... 18

4.7 Making a typical setting in master mode ........................................................................ 18

5 Other important information ........................................................................... 19

5.1 Error messages ........................................................................................................... 19

5.2 Cleaning instructions.................................................................................................... 20

5.3 Declaration of conformity .............................................................................................. 21

5.4 Technical data ............................................................................................................. 23

5.5 Accessories ................................................................................................................. 25

5.6 Interface commands .................................................................................................... 25

Page 5

5

1 Putting into service

Please read through these operating instructions carefully and adhere to them at all times. If you discover

that materials are missing or that the wrong ones have been supplied, or if you have any other problems

with your scale, please refer to the dealer or salesperson concerned, or if necessary to the METTLER

TOLEDO representative responsible.

1.1 Unpacking and checking contents

• Remove the scale and accessories from the packaging.

• Check for completeness. The basic scope of supply comprises:

– scale

– weighing pan

– AC adapter (only for models with integrated battery)

– operating instructions (this booklet)

– any special accessories as per packing list

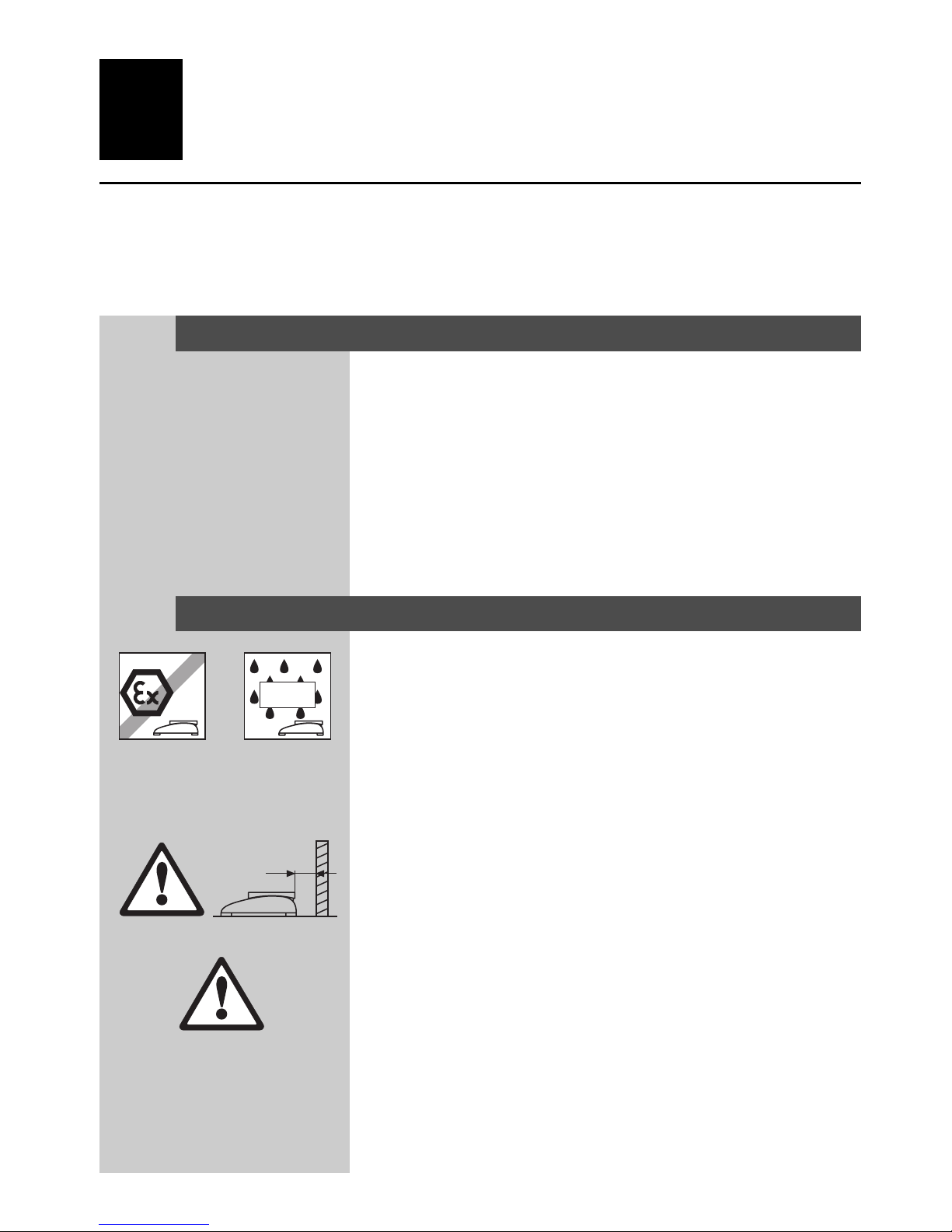

1.2 Safety and environmental protection

• Do not use the scale in hazardous areas (unless it is clearly identified as being approved for these areas).

• For service in wet areas or dusty environments, or if wet cleaning

is necessary, scales with IP 65 ingress protection must be used.

But even these scales must not be used in environments where

there is a risk of corrosion. The scales must never be drenched or

immersed in a liquid.

• If the power cord is damaged, the scale must no longer be operated. Therefore check the cable regularly and ensure that a free space

of about 3 cm is left at the rear of the scale, so that the cable is not

kinked too severely.

• Never tamper with the retaining screws for the load plate support

underneath the weighing pan.

• When the weighing pan is removed, never insert a solid object

underneath the load plate support.

• It is not permitted to open the scale by removing the screws in its

base.

IP65

ca. 3cm

Page 6

6

• Only use approved accessories and peripherals.

• Handle the scale carefully; it is a precision instrument. Blows on

the weighing pan must be avoided, and heavy overloads must not

be placed on it.

• Important instructions when using Viper scales in the food sector:

those parts of the scale can come into contact with food products

have smooth surfaces and are easy to clean. The materials used

do not splinter and are free from contaminants. In food processing

areas it is recommended that a protective cover (Section 5.5) is

used. This must be cleaned regularly, just like the scale itself.

Damaged or heavily contaminated protective covers must be

replaced immediately.

• When the scale is finally taken out of service, observe the current

environmental regulations. If the scale is equipped with a battery,

this contains heavy metals and therefore must not be treated as

normal refuse! Local regulations for disposing of environmentally

hazardous substances must be complied with.

1.3 Positioning and leveling the scale

The correct location is a decisive factor in ensuring accurate weighing

results.

– Choose a stable and vibration-free location (particularly important

for high-resolution scales using Mettler Toledo MonoBloc technology). Place the scale on a surface that is as horizontal as possible

and strong enough to bear its weight when fully loaded.

– Check the ambient conditions (Section 5.4).

– Avoid:

– direct sunlight

– strong drafts (e.g. from fans or air conditioning systems)

– excessive temperature fluctuations.

• Turn the adjustable feet so that the scale is horizontal. If a spirit level

is fitted, the bubble must be located within the inner circle.

Note: The Viper BC has a special filter that accelerates certain procedures (zeroing, taring, determining the reference weight for piece

counting) in a nontranquil environment. This inevitably means that

there is a slight loss of accuracy with the results. For high-precision

results care must be taken to ensure as tranquil and stable an environment as possible, so that the filter is not activated.

Page 7

7

=000∆

Major changes in geographical location:

Every scale is set by the manufacturer to suit the local gravitational

conditions (geographical adjustment value) in the geographical zone

to which the instrument is supplied. If a major change of geographical

location takes place, this setting must be adjusted by a service technician or a new setting made. Certified scales must in addition be recalibrated in accordance with national certification regulations.

1.4 Connecting to power supply

• Before connecting the power supply plug or AC adapter (AccuPac

version), verify that the voltage stated on the model plate is the

same as the local power line voltage.

• Connect the power cord plug or the AC adapter plug to the supply,

then connect the AC adapter (AccuPac version) via the jack at the

rear of the scale.

Powering up the scale initiates a display test in which all the segments

and then the software version are briefly displayed. Once the decimal

zero appears in the display, the scale is ready to operate.

For maximum possible precision, adjust/calibrate the scale after installing it (Section 4.2). Note: Certified scales must be adjusted by

an authorized organization. Please consult your dealer.

1.5 Battery operation

Scales with a built-in battery (AccuPac) can under normal operating

conditions work independently of the AC power line for about 20 hours

(MonoBloc version) or about 30 hours (strain gauge version). Immediately the AC power supply is interrupted (by withdrawing the power

cord plug or if there is a power failure), the scale switches automatically to battery operation. Once the AC power supply is restored,

the scale reverts automatically to AC operation.

The battery symbol indicates the current discharge status of the battery

(1 segment corresponding to about 25% capacity). If the symbol

flashes, the battery must be recharged.

A discharged battery requires at least 8 hours until it is recharged.

During the charging process work with the scale can continue, but

under these conditions a longer charging time is needed.

The battery is protected against overcharging, and the scale can therefore remain permanently connected with the AC power line without

any problems.

Page 8

8

2 Weighing

This section describes how to switch the scale on and off, zero and tare it, weigh materials and record

the results.

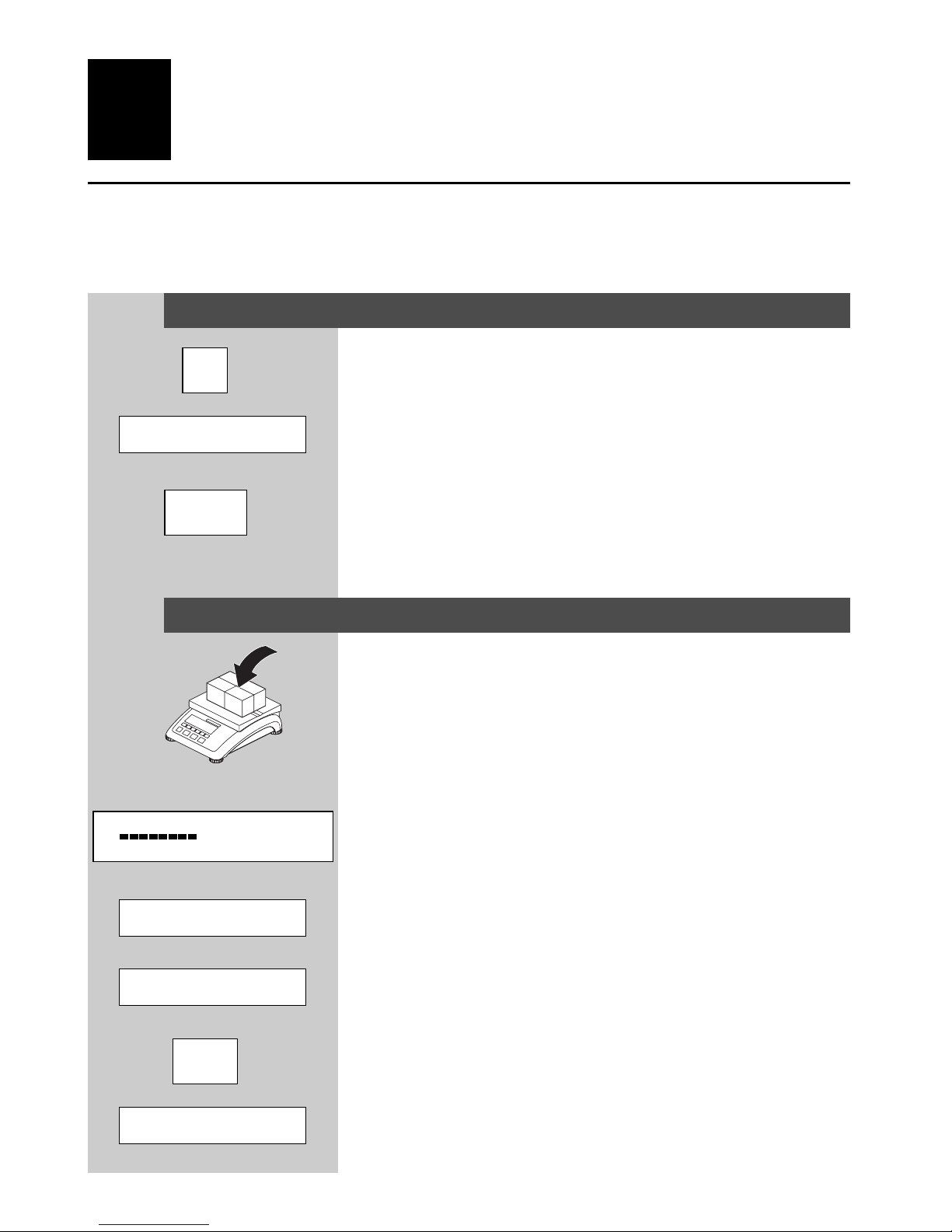

2.1 Switching on and off and zeroing

• Briefly pressing the «On/Off» key switches the scale on or off.

The scale carries out a display test (Section 1.4). Once the weight

display appears, the scale is ready to operate and automatically

zeroed.

Note: When necessary, the scale can be zeroed at any time with

the «Ç» key.

2.2 Simple weighing

• Place the object to be weighed on the scale.

The bar graph at the bottom of the display shows how much of the

weighing range is being used and how much is still available (as

% of nominal scale capacity).

• Wait until the stability detector (a small ring at the left edge of the

display) disappears, then ...

• ... read the indicated weight.

• Pressing the «:» key causes the weighing result to be displayed

in control mode, i.e. with a higher resolution. After a few seconds

the normal weight display reappears automatically. Note: control

mode is not available if the maximum resolution has already been

selected in master mode (Section 4.3).

=000∆

• "416∆

"420∆

Ç

On

Off

"4206∆

%

l l l l l l l l l l l

0 50 100

:

Page 9

9

NET

ç216∆

±

NET

=000∆

#

○○○○

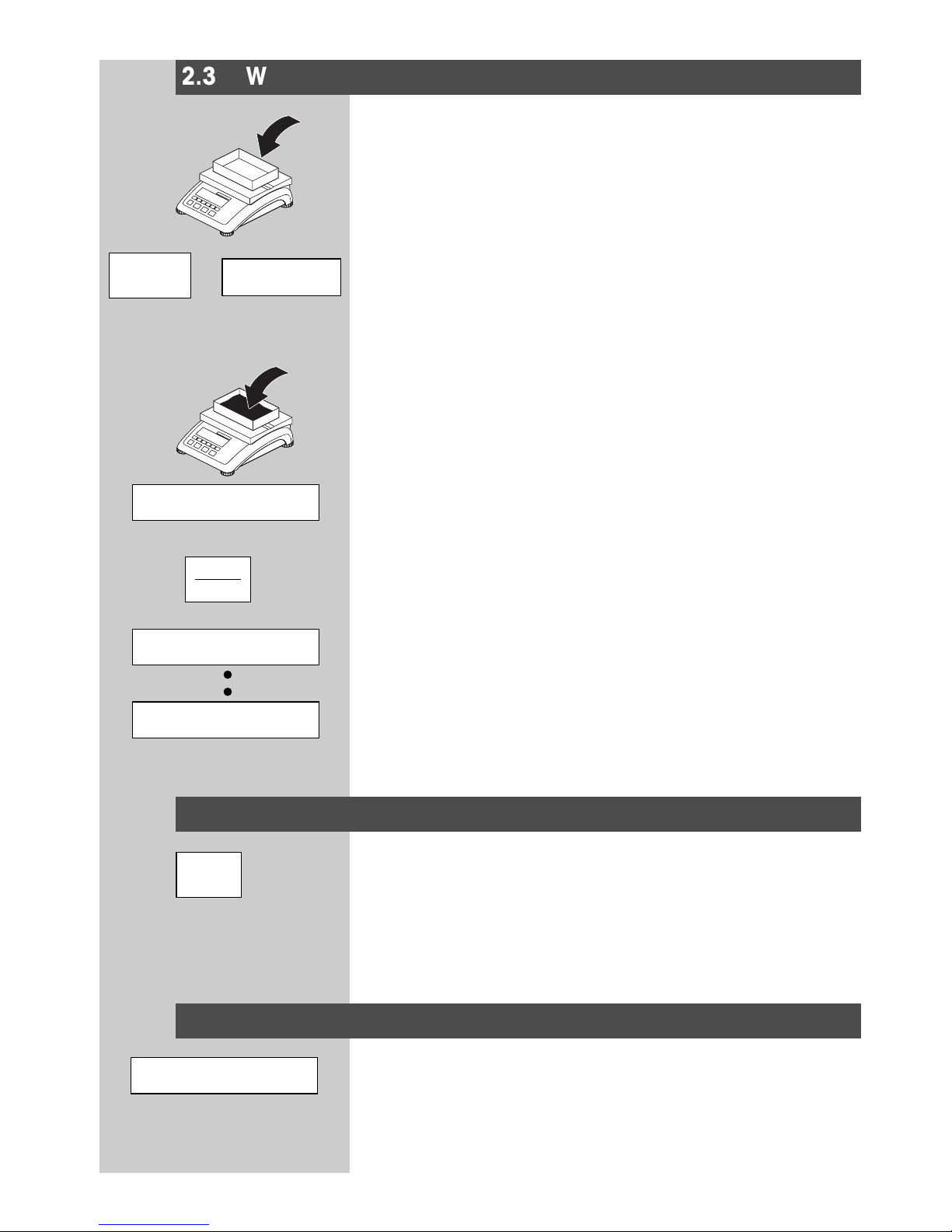

2.3 Weighing with tare

• Place the empty weighing container or packaging on the scale.

• Press the «#» key briefly to tare the scale. The zero display and

the “NET” (net weight) symbol appear. Note: If the automatic tare

function has been activated in master mode (Section 4.3), there is

no need to press the «#» key.

•

Place the material to be weighed in the container, then ...

• ... read the indicated net weight.

• Pressing the «≤ BG/Net» key causes the gross weight to be

displayed (the “B/G” symbol appears). After a few seconds the

scale automatically reverts to displaying the net weight.

2.4 Recording weighing results

• Press the «±» key to send the current weighing result to the

peripheral device (printer, computer) via the interface. Factory

default configures interface 1 for connection to a printer.

Please refer to Section 4.4 for instructions on configuring the

interface(s).

2.5 Special functions (master mode)

In addition to simple weighing functions and piece counting (Section 3), the scale also has additional options and settings that can be

activated in master mode (Section 4).

ç637∆

B/G

NET

ç216∆

≤

BG/Net

MAStEr

Page 10

10

3 Piece counting

Not only can your scale weigh, it can also count. Several powerful functions available for piece counting

are described in this section.

3.1 Counting pieces into a container

• If you work with a weighing container, place this on the pan and

tare the scale with the «#» key.

• Enter the number of reference pieces in the instrument:

• If you have placed exactly 10 pieces in the container, press the

«Ref 10» key.

• If you have placed the number of pieces indicated in the display

above the «Ref n» key, press that key.

The scale now determines the average piece weight, following

which it displays the number of pieces.

• Now place further pieces in the container until the desired number

of pieces has been reached.

As it is unusual for all pieces to have exactly the same weight, piece

counting can be made considerably more accurate with the additional function “Automatic reference optimization" (Section 3.3).

The following numbers of reference pieces can be selected by holding

down the «Ref n» key: 1, 2, 5, 15, 20, 25, 30, 50 and 100 pieces,

as well as the “no” option (in this case the «Ref n» key has no

function).

With the «≤/<» key you can now toggle between piece counting

and weight display at any time.

If the number of pieces is currently displayed, pressing the «:» key

displays the reference piece weight (i.e. the weight of one single

piece) for 3 seconds.

If the weight is displayed, this can be shown at a higher resolution for

3 seconds by pressing the «:» key.

If “Adding mode” (Section 3.4) is activated, the minimum number of

reference pieces necessary with small components is ensured automatically.

Ref 10

:

Ref n

5

▲

#

‹ %68342

g/Pc

Page 11

11

3.2 Counting out pieces from a container

Counting out pieces from a weighing container differs in a few essentials from counting them in (Section 3.1):

• Place the full weighing container on the pan and tare the scale with

the «#» key.

• Remove the desired number of reference pieces from the container.

• Enter the number of pieces removed (reference definition) using the

«Ref 10» or «Ref n» keys (see Section 3.1). The scale then displays

the number of reference pieces removed with a minus sign in front.

Note: The functions “Automatic reference optimization" (Section

3.3) and “Adding mode” (Section 3.4) are also available for

counting out tasks.

• Remove further pieces until the desired number has been reached.

3.3 Automatic reference opitimization

Automatic reference optimization results in more accurate counting

results on piece counting duties. This function can be activated or

deactivated in master mode (Section 4.3). The factory default setting

is with automatic reference optimization active.

Automatic reference optimization requires no action on the part of the

operator. The “Auto Opt” symbol appears in the display when this

function is active.

Automatic reference optimization works both with “Counting in”

(Section 3.1) and “Counting out” (Section 3.2).

Functioning:

In order to optimize the calculated reference piece weight automati-

cally, a number of pieces less than or equal to the number of reference

pieces already on the pan are added to it. The message “Refopt”

appears in the display, and automatic weight optimization is carried

out. This process can be repeated several times.

rEFOPt

Auto Opt

#

Ref 10 Ref n

-10

PCS

NET

Page 12

12

3.4 Adding mode

Adding mode ensures that the number of reference pieces used on

piece counting duties is not too small, which could give rise to

inaccurate results. This function can be activated or deactivated in

master mode (Section 4.3). The factory default setting is with adding

mode inactive.

If you have activated adding mode and the number of pieces placed

on the pan is too small for accurate determination of the reference

weight, you are prompted to place more pieces on the scale (e.g. 5

pieces).

• Place the stipulated number of pieces on the pan. The scale then

determines the reference weight.

Adding mode works both with “Counting in” (Section 3.1) and with

“Counting out” (Section 3.2).

3.5 Piece counting with 2-scale systems

You can hook up your Viper scale to a second scale, e.g. a floor scale

for counting a large number of pieces that would exceed the capacity

of the Viper.

• In master mode select the Viper operating mode for connecting a

second scale. Proceed as follows (Section 4.4):

– “Ref ; 2”: if you want to use the second scale as the reference

scale.

– “Bulk ; 2”: if you want to use the second scale as the bulk

weight scale.

• The interface of the second scale must be set as follows:

– For Viper and Spider scales:

“Mode”: “Dialog” (9600 bd, 8b no parity, Xon/Xoff)

– For PB-S scales:

“Mode”: “Host” (9600 bd, 8b no parity, Xon/Xoff)

– For other METTLER TOLEDO products:

MT-SICS-compatible interface (9600 bd, 8b no parity, Xon/Xoff).

• When piece counting you can toggle between the two scales with

the «≤/;» key.

The scale symbol top right in the display indicates the active scale:

“; 1” = Viper scale, “; 2” = second scale.

When the second scale is active, you can zero and tare it with the

Viper «®» and «#» keys, respectively.

Add 5

≤

;

; 1

; 2

Page 13

13

4 Master mode

In master mode the scale settings can be changed and the various functions activated – to adapt the scale

for individual weighing needs.

4.1 Overview and operation

4.2 Scale calibration (adjustment)

This master mode block is not available with certified scales.

• Remove the load from the weighing pan and then press the «±»

key to start the calibration procedure.

• The flashing display shows the calibration weight. If desired, the

«#» key can be used to select other calibration weights.

• Place the indicated calibration weight on the scale and confirm with

«±».

Note: The calibration procedure can be canceled at any time with

the «On/Off» key.

• Wait until the calibration has been successfully completed (confirmed by the message “done” in the display) and the scale reverts

to weighing mode.

CAL

15000

±

1%000∆

Calibration

CAL

Settings

SCALE

Interface1

1FACE1 1FACE 2

Print

LiSt

End

ENd

NAStEr

▼

▼

▼

▼

▼

▼

▼

▼

▼

▼▼▼▼▼

Section 4.2 Section 4.3 Section 4.4 Section 4.4 Section 4.5 Section 4.6

Weigh mode

Interface 2

▼

*

Hold down «±» key (about 5 seconds)

Briefly press «±» key (“YES”). * Confirm the “MASTER” display

within 3 seconds to enter master mode.

Briefly press «#» key (“NO”)

▼

▼

▼

=000∆

Page 14

14

4.3 Scale settings

The second master mode block contains a total of 13 subblocks for

setting the scale and activating its functions.

Function/Display Settings Remarks

Depends on model, example:

0.01kg/0.02kg/.../0.005kg

Certified scales: changed

settings indicated with “*” and

with no weighing unit. After restart the standard setting (see

certification label) is active.

The symbol “l<—>l 1/2” appears

when set for 2 weighing ranges:

Example: 15kg scale:

1. Range 0 – 6kg

Resolution 2g

2. Range 0 – 15kg

Resolution 5g

In order to switch from the 2nd

range back to the 1st range, the

load must first be removed from

the scale or it must be zeroed.

“g”

1)

, “kg”1), “oz”1), “lb”

1)

Factory setting as per model

plate. “oz” and “lb” not available

for certified scales.

On

1)

Off

Corrects the scale zero automatically. Not available for certified

scales.

On

Off

1)

Resolution

rESolu

Weighing unit

Unit

Automatic zero correction

A -2ErO

Automatic tare function

A - tArE

SCALE

Adding mode

On

Off

1)

Auto reference optimization

On

1)

Off

AddNodE

rEF OPt

Only used for piece counting (Section 3.1).

Only used for piece counting (Section 3.1).

Tares the scale automatically as

soon as the empty weighing container is placed on the pan (“T”

flashes in the display).

1)

factory setting (continued on next page)

Page 15

15

rESEt

End SC

rEStArt

VibrAt

ProcES

Auto memory function

On

Off

1)

Last tare and zero are saved when

scale switched off. Not available

on certified scales.

Vibration adapter

“Med”

1)

“Low”

“High”

normal environment

very tranquil environment (immediate stop for display)

high vibration levels

Weighing process adapter

“Univer”

1)

“Dosing”

“Dynamic”

normal weighing samples

dispensing (e.g. of liquid

or powders)

restless load, e.g. animals

Reset

Resets all “SCALE” settings to

the factory settings.

Confirm reset by pressing «±» or

cancel with «#».

Note: To reset the adjustments, the

prompt “Std On” must be confirmed with «±».

End settings. Exit the “SCALE” block. Press «±» to exit the “SCALE”

block, or «#» to make further

settings.

1)

factory setting

On ( “Yes”)

Off (“No”)

1)

Automatic shutoff

PWrOFF

If function is activated (“Yes” =

factory setting for scales with battery), the scale switches off automatically after some 3 minutes of

inactivity.

Backlighting

On

1)

Off

b.Light

“On” in battery operation = backlit

for about 5 seconds.

Function/Display Settings Remarks

Page 16

16

IFACE1

IFACE 2

4.4 Interface configuration

The scale interfaces can be configured in this block. Note: Settings in

“IFACE 2” can only be made if the second interface is fitted.

Function/Display Settings Remarks

Mode

“Print” (printer)

1) 5)

“Cycle” (series weighing)

2) 5)

“Dialog” (computer)

3) 5)

“Ref ; 2”

4)

“Bulk ; 2”

4)

“2nd Display”

5)

2400 bd, 7b even, Xon/Xoff

2400 bd, 7b even, Xon/Xoff

9600 bd, 8b no parity, Xon/Xoff

2nd scale = reference scale

2nd scale = bulk weight scale

9600 bd, 8b no parity, Xon/Xoff

Transmission protocol

“HONOFF”

1)

“No”

Xon/Xoff protocol

no protocol

ModE

Com 1

ProtoK

Com 1

Bits and parity

“7 Even”

1)

“7 No P”

“8 No P”

“7 Odd”

7 data bits with even parity

7 data bits with no parity

8 data bits with no parity

7 data bits with odd parity

Data transfer rate

300, 600, 1200, 2400

1)

,

4800, 9600, 19200 baud

Data and formatting to be

transferred

“Header” (On

1)

/Off)

6)

“Gross” (On

1)

/Off)

“Net" (On

1)

/Off)

“Tare” (On

1)

/Off)

“PCS” (On

1)

/Off)

“APW” (On

1)

/Off)

“Ref CT” (On

1)

/Off)

“4 LinF” (On

1)

/Off)

“F Feed” (On/Off

1)

)

“Ln for” (Single

1)

/Multi)

report heading

gross weight

net weight

tare

number of pieces

average piece weight

reference quantity

4 empty lines

form feed

“Single” = 1 result per line,

“Multi” = all results on 1 line

Com 1

bAUd

Com 1

dEFStr

Com 1

Note: For older Sprinter 1

printers select 300 baud

(continued on next page)

PAritY

Page 17

17

Reset

Resets all settings of selected

interface to factory settings.

Reset with «±» key (confirming

“Std On” query by pressing «±»

again) or cancel with «#».

End settings

Exit the interface block. Press «±» to exit interface block

or «#» to make further settings.

rESEt

Com 1

End IF1

Com 1

1)

Factory setting for connection to “Sprinter 1” printer.

2)

Data printout when weight changes.

3)

The “Dialog” mode is used for bidirectional communication of the

scale with an external device (e.g. a computer). Further information is given in Section 5.6.

4)

When using the Viper in a 2-scale system (for piece counting, see

Section 3.5).

5)

If this operating mode is selected, the associated default settings

(see “Remarks” column) are automatically adopted.

6)

This setting specifies whether a record header is to appear on the

printouts. This consists of up to 5 lines, each with a maximum of

24 characters (e.g. company name and address). The record

header is created and formatted by means of SICS commands via

the interface (see Section 5.6). A typical record with a header is

shown opposite.

Function/Display Settings Remarks

Mettler-Toledo GmbH

Unter dem Malesfelsen 34

D-72458 Albstadt

Telefon ++49/7431/14 0

Internet www.mt.com

G 7.153 kg

T 0.422 kg

N 6.731 kg

Page 18

18

4.5 Printing master mode settings

In this block all master mode settings can be recorded with a printer.

• Press «±» key to print out the settings.

(Recommended printer: “Sprinter 1”, see Section 5.5 “Accesso-

ries”)

4.6 Saving settings and exiting master mode

In the last master mode block you can save your settings and revert

to weighing mode.

• Press the «±» key to exit master mode.

• Press the «±» key to save the settings or the «#» key to cancel

them. The scale then reverts to weighing mode.

4.7 Making a typical setting in master mode

You want to set the readability (resolution) at 0.01kg.

•

Hold down the «±» key for about 5 seconds to access master

mode, and confirm that you really want this by briefly pressing

«±» (“Yes”) within 3 seconds.

• Skip the first master mode block “CAL” (Calibration, not available

with certified scales) by pressing «#» (“No”).

• Activate the block for scale settings (“Scale”) with «±» (“Yes”).

Use the «#» key (“No”) twice to skip the two subblocks for

adding mode (“Add mode”) and automatic reference optimization

(“Ref Opt”). Activate the subblock for resolution by pressing the

«±» key (“Yes”).

• Press «#» (“No”) repeatedly until the desired resolution (0.1kg)

is displayed, then confirm by pressing «±» (“Yes”).

• Answer the prompt “End” with «±» (“Yes”) as you do not want to

make more settings. If you press «#» (“No”), however, you can

make further settings.

• Answer the prompt “Store?” (Save in memory) with «±» (“Yes”).

The scale reverts to weighing mode and operates with the new

settings. If you reply with «#» (“No”), the changes will not be

saved.

LiSt

ENd

StorE ?

±

±

±

MAStEr

CAL

#

±

=01 ∆

ENd

±

StorE ?

±

=00∆

○○○○

±

SCALE

±

rESOLU

Page 19

19

неееем

î____ï

гггггг

òãnoãô

î_no_ï

5 Other important information

This section gives information on error messages and instructions for cleaning your scale. It also includes

the declaration of conformity and technical data.

5.1 Error messages

Overload

Reduce the load on the scale or the preload.

Underload

Place weighing pan on the scale and ensure that it can move freely.

Weight reading does not stabilize.

1.Ensure a tranquil environment.

2.Ensure that the weighing pan is free to move.

3.Change the setting of the vibration adapter (Section 4.3).

4.If necessary use the dynamic weighing function (Section 4.3).

Function not executed

The selected function could not be carried out.

Not possible to zero scale

Ensure that zeroing is only carried out in the permissible range and

not under overload or underload conditions.

Reference weight too small

The weight placed on the pan is too small to define a valid reference

weight for piece counting. Place a larger number of reference pieces

on the scale.

Err 4

ããnoãã

Page 20

20

No valid reading from reference scale

This message is only given when piece counting with a 2-scale system.

Check the connecting cable between the scales and the interface

settings.

No calibration/adjustment

Disconnect the power cord plug and then plug it in again. (If operating

on the battery, switch the scale off and then on again.) If the error

message reappears, calibrate/adjust the scale (Section 4.2). If this

does not help, contact your dealer or local representative.

Reference piece weight too small

When defining the reference weight, the scale has found that the

resultant weight of one single piece is below the permissible limit.

Piece counting is not possible for articles as small as this.

Unstable weight reading when defining the reference weight

When determining the reference weight, the reading did not stabilize,

and the scale therefore cannot determine the reference weight of a

single piece .

1.Ensure a tranquil environment.

2.Ensure that the weighing pan is free to move.

3.Change the setting of the vibration adapter (Section 4.3).

EAROM checksum error

Disconnect the power cord plug and then plug it in again. (If operating

on the battery, switch the scale off and then on again.) If the error

message reappears, contact your dealer or local representative.

5.2 Cleaning instructions

• Disconnect the scale from the power supply before cleaning it!

• Use a damp cloth (do not use acids, alkalis or strong solvents).

• Wet cleaning is only allowable on scales with IP65 ingress protection.

• If heavily contaminated, the weighing pan, protective cover (if

fitted) and adjustable feet must be removed and cleaned separately.

• With the weighing pan removed, never use a solid object to clean

underneath the load plate support!

• Observe your organization’s internal rules and industry-specific

regulations for cleaning intervals and permissible cleaning agents.

Err 7

Err 53

Err 9

Err 6

Err 5

Page 21

21

5.3 Declaration of conformity

We, Mettler-Toledo (Albstadt) GmbH, Unter dem Malesfelsen 34, D-72458 Albstadt declare

under our sole responsibility that the product

Viper BC from serial no. 2487843, to which this declaration relates

is in conformity with the following directives and standards.

Directive Applicable standard

relating to electrical equipment designed for use EN61010-1 (Safety Regulations)

within certain voltage limits

(73/23/EEC; amended by directive 93/68/EEC)

relating to electromagnetic compatibility EN55022 Emission Class B

(89/336/EEC; amended by directive 93/68/EEC; EN50082-2 Immunity

92/31/EEC) EN61000-3-2 (Harmonic Oscillations)

EN61000-3-3 (Voltage Fluctuations)

relating to non-automatic weighing instruments EN45501 1) (Metrological Aspects)

(90/384/EEC; amended by directive 93/68/EEC)

1)

1)

Applies only to certified scales (approval/test certificate no: T5508 for scales with strain gauge cells,

T5627 for scales with “MonoBloc” cells).

Albstadt, May 2002 Mettler-Toledo GmbH

Roland Schmider, General Manager Heiko Carls, Quality Manager

Important notice for verified weighing instruments in EC countries

Weighing instruments verified at the place of manufacture bear the preceding mark on the

packing label and a green “M” sticker on the descriptive plate. They may be set to work

immediately.

Weighing instruments which are verified in two steps have no green “M” on the descriptive

plate and bear the preceding identification mark on the packing label. The second step of the

verification must be carried out by the approved Mettler-Toledo service or by the W & M

authorities. Please contact your Mettler-Toledo organization.

The first step of the verification has been carried out at the manufacturing plant. It comprises all tests

according to EN45501-8.2.2.

If national regulations in individual countries limit the period of validity of the certification, the operator of

such a scale is himself responsible for its timely re-certification.

[year]

[code]

M

1)

M

M

Page 22

22

USA/Canada

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to both Part 15 of the FCC Rules and the radio interference regulations of the Canadian Department of

Communications. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference, in which case the user will be required to correct the interference

at his own expense.

Cet appareil a été testé et s’est avéré conforme aux limites prévues pour les appareils numériques de classe

A et à la partie 15 des règlements FCC et à la réglementation des radio-Interférences du Canadian Department of communications. Ces limites sont destinées à fournir une protection adéquate contre les interférences néfastes lorsque l’appareil est utilisé dans un environnement commercial. Cet appareil génère,

utilise et peut radier une énergie à fréquence radioélectrique; il est en outre susceptible d’engendrer des

interférences avec les communications radio, s’il n’est pas installé et utilisé conformément aux instructions du mode d’emploi. L’utilisation de cet appareil dans les zones résidentielles peut causer des

interférences néfastes, auquel cas l’exploitant sera amené à prendre les dispositions utiles pour palier aux

interférences à ses propres frais.

Page 23

23

5.4 Technical data

Functions Weighing

Piece counting

Piece counting with second scale

Settings 4 units of weight

Adding mode for reference definition (piece counting)

Automatic reference optimization (piece counting)

Vibration adapter

Weighing process adapter

Automatic tare function

Automatic zero correction

Power-saving shutoff

Display backlighting

Automatic saving of tare and zero

Display LCD (liquid crystal display), 35mm high, backlit, with linear

weighing range display

Ambient conditions The accuracy is guaranteed in the following ranges:

Temperature range: –10 to +40 °C (strain gauge cells)

+10 to +30 °C (MonoBloc cells)

Relative humidity: 15 to 85% RH (no condensation)

Overvoltage category: II

Pollution degree: 2

Maximum altitude 4000m above sea level

Power supply Direct connection to AC power line or via AC adapter

240 V, 50 Hz, 70 mA 120 V, 60 Hz, 90 mA

230 V, 50 Hz, 70 mA 100 V, 50/60 Hz, 90 mA

With extra AC adapter for battery operation: feed for the scale

18 VDC, 0.6 A

Total weight Strain gauge MonoBloc

Small platform: line-voltage scale: 4.6kg 4.7 kg

AccuPac scale: 5.2 kg 5.3 kg

Large platform: line-voltage scale: 8.2 kg 10.5 kg

AccuPac scale: 8.8 kg 11.1 kg

Ingress protection IP43 (optional IP65 (EN 60529) for scales with strain gauge

cells. These scales are identified with an IP65 adhesive label.)

Standard scope of supply Scale complete

Operating instructions

AC adapter (for models with AccuPac)

Page 24

24

Dimensions

A B C* D E

Small platform 335 265 100 240 200

Large platform 370 360 115 350 240

All dimensions in millimeters

* with adjustable feet fully screwed in

Interface technical data

The scale is provided with an EIA RS-232C (CCITT V24/V.28) voltage-controlled interface as

standard. Maximum cable length is 15m. All interfaces are in the form of a 9-pin D-sub female

connector. Instructions for configuring the interfaces are given in Section 4.4.

Interface 1 (standard) 2 (optional)

Type RS232C RS232C

Pin assignment Pin 1 VCC 1 VCC 2

Pin 2 TxD 1 TxD 2

Pin 3 RxD 1 RxD 2

Pin 4 (1) (1)

Pin 5 GND GND

Pin 6 (1) (1)

Pin 7 (1) (1)

Pin 8 (1) (1)

Pin 9 (1) (1)

TxD: transmit data RxD: receive data

GND: signal ground VCC: power supply

(1): pin must not be connected!

C

B

D

A

E

53214

6789

Page 25

25

5.5 Accessories

Article No.

Auxiliary display RS-PD/PASM 21302875

RS232 cable for auxiliary display 1.8m (9-pin D-Sub, m/m, parallel) 21302921

Protective cover for small platform scale 21203207

Protective cover for large platform scale 21203206

Antitheft device 00229175

“Sprinter 1” printer, EURO version 21253399

“Sprinter 1” printer, UK version 21253745

RS232 cable for printer 1.8m (25/9-pin D-Sub, m/m, crossover) 21253677

RS232 cable for 2nd scale 1.8m (9-pin D-Sub, m/m, crossover) 21252588

RS232 cable for PC 1.8m (9-pin D-Sub, m/f, parallel) 00410024

5.6 Interface commands

Your scale can be configured, interrogated and operated from a PC via an RS232C interface.

Preconditions

The following preconditions must be fulfilled to achieve communication between the scale and

a PC:

– The scale must be connected to the RS232C interface of the PC by a suitable cable (see

Section 5.5) .

– The scale interface must be set at “Dialog” mode (see Section 4.4).

– A terminal program must be available on the PC (e.g. “Hyper Terminal”).

– The communications parameters (protocol, bits and parity, data transfer rate) must be set

at the same values in the terminal program and in the scale (see Section 4.4).

Page 26

26

SICS command set

Your scale supports the Mettler Toledo Standard Interface Command Set (MT SICS), all SICS

commands as per “Level 0” and “Level 1” being implemented.

Commands MT-SICS Level 0

I0 Inquiry of all implemented MT-SICS commands

I1 Inquiry of MT-SICS level and MT-SICS versions

I2 Inquiry of balance data

I3 Inquiry of balance SW version and type definition number

I4 Inquiry of serial number

S Send stable weight value

SI Send weight value immediately

SIR Send weight value immediately and repeat

Z Zero

ZI Zero immediately

@ Reset

Commands MT-SICS Level 1

D Balance display

DW Weight display (Display show Weight)

K Key control

SR Send weight value on weight change (Send and Repeat)

T Tare

TA Inquiry/setting of tare weight value

TAC Clear tare value

TI Tare immediately

Commands MT-SICS Level 3R Standard

PW Inquiry/setting of the piece weight

Detailed information on the interface commands is given in the “MT SICS Reference Manual”

(No. 705184, only available in English).

In addition to the standard commands, scale-specific SICS commands also exist to support

product-specific characteristics. These commands are not given in the “MT SICS Reference

Manual”, but in the documentation supplied with the individual scale. At the present time the

Viper scale supports one single specific command for specifying the record header. This

command is described below.

Page 27

27

Specifying the record header

With this command you can define up to 5 lines, each with a maximum of 24 characters, which

is printed out at the head of every record. Normally, the company name and address are printed

on the record in this way. Specify the record header as follows:

• Ensure that the communication between the scale and the PC is in good working order.

• The command for defining the record header is I31_x, where “x” is the line number. Specify

the desired record header as shown in the following example (only the required lines need

be entered):

I31_1_"Mettler-Toledo GmbH" <CR><LF>

I31_2_"Unter dem Malesfelsen 34" <CR><LF>

I31_3_"D-72458 Albstadt" <CR><LF>

I31_4_"Telefon ++49/7431/14 0" <CR><LF>

I31_5_"Internet www.mt.com" <CR><LF>

Please observe the following:

– Every command line must be terminated with <CR><LF> (corresponding to the “Enter”,

“Return” or “ ˛” key on the PC keyboard). The command is then executed immediately.

To correct a line, this needs to be entered again completely.

– The “_” symbol signifies an empty space, and in the above example serves solely to clarify

the syntax. The quotation marks must be entered, as they indicate to the scale that they

enclose a text string and not a command.

– You can insert empty lines by entering an empty space instead of text.

Example: I31_2_"_" <CR><LF> . This defines line 2 as an empty line.

– By entering I31_x <CR><LF> (x = line number) you can interrogate the appropriate line.

– With the command I31_x_" " <CR><LF> (x = line number) you can delete the individual

line again.

• Once the record header has been completely specified (and you do not want to give any further

SICS commands), you can break the connection between the scale and the PC. Important:

for the scale to actually print out the record, the interface mode must be reset at “Print”, and

the setting “Header” must be activated (“On”) for the data to be transferred (“defStr”). A

description of these settings and a specimen record corresponding to the above example are

to be found in Section 4.4.

Page 28

To give your METTLER TOLEDO products an assured future:

METTLER TOLEDO Service preserves the quality, measurement

accuracy and value of METTLER TOLEDO products for years to

come.

Incidentally, the scale can be adjusted to suit your needs. Ask

your METTLER TOLEDO salesperson or specialist scales dealer

for more details.

Subject to technical changes and to the availability of the

accessories supplied with the instruments.

Design registered.

Printed on 100 % chlorine-free paper,

for the sake of our environment.

© Mettler-Toledo (Albstadt) GmbH 2003 21203192D Printed in Germany 0310/2.12

Mettler-Toledo (Albstadt) GmbH, D-72423 Albstadt, Tel. +49-7431 14-0, Fax +49-7431 14-371, Internet: http://www.mt.com

AT Mettler-Toledo Ges.m.b.H., A-1100 Wien, Tel. (01) 604 19 80, Fax (01) 604 28 80

AU Mettler-Toledo Ltd., Port Melbourne, Victoria 3207, Tel. (03) 9644 5700, Fax (03) 9645 3935

BE n.v. Mettler-Toledo s.a., B-1932 Zaventem, Tel. (02) 334 02 11, Fax (02) 378 16 65

BR Mettler-Toledo Indústria e Comércio Ltda., São Paulo, CEP 06465-130, Tel. (11) 421 5737, Fax (11) 725 1962

CH Mettler-Toledo (Schweiz) AG, CH-8606 Greifensee, Tel. (01) 944 45 45, Fax (01) 944 45 10

CN Mettler-Toledo Changzhou Scale Ltd., Changzhou City, Jiangsu 213001, Tel. (519) 664 20 40, Fax (519) 664 19 91

CZ Mettler-Toledo, s.r.o., CZ-100 00 Praha 10, Tel. (2) 72 123 150, Fax (2) 72 123 170

DE Mettler-Toledo GmbH, D-35353 Giessen, Tel. (0641) 50 70, Fax (0641) 52 951

DK Mettler-Toledo A/S, DK-2600 Glostrup, Tel. (43) 27 08 00, Fax (43) 27 08 28

ES Mettler-Toledo S.A.E., E-08908 Hospitalet de Llobregat (Barcelona), Tel. (93) 223 76 00, Fax (93) 223 76 01

FR Mettler-Toledo s.a., F-78222 Viroflay, Tél. (01) 309 717 17, Fax (01) 309 716 16

HK Mettler-Toledo (HK) Ltd., Kowloon HK, Tel. (852) 2744 1221, Fax (852) 2744 6878

HR Mettler-Toledo, d.o.o., CR-10000 Zagreb, Tel. (1) 29 20 633, Fax (1) 29 58 140

HU Mettler-Toledo Kft, H-1173 Budapest, Tel. (1) 257 9889, Fax (1) 257 7030

IN Mettler-Toledo India Pvt Ltd, Mumbai 400 072, Tel. (22) 857 08 08, Fax (22) 857 50 71

IT Mettler-Toledo S.p.A., I-20026 Novate Milanese, Tel. (02) 333 321, Fax (02) 356 29 73

JP Mettler-Toledo K.K., Shiromi, J-Osaka 540, Tel. (6) 949 5901, Fax (6) 949 5945

KR Mettler-Toledo (Korea) Ltd., Seoul (135-090), Tel. (82) 2 518 20 04, Fax (82) 2 518 08 13

MY Mettler-Toledo (M) Sdn.Bhd., 40150 Selangor, Tel. (603) 7845 5773, Fax (603) 7845 8773

MX Mettler-Toledo S.A. de C.V., Mexico CP 06430, Tel. (5) 547 5700, Fax (5) 541 2228

NL Mettler-Toledo B.V., NL-4000 HA Tiel, Tel. (0344) 638 363, Fax (0344) 638 390

NO Mettler-Toledo A/S, N-1008 Oslo, Tel. (22) 30 44 90, Fax (22) 32 70 02

PL Mettler-Toledo, Sp. z o.o., PL-02-929 Warszawa, Tel. (22) 651 92 32, Fax (22) 651 71 72

RU Mettler-Toledo AG, 10 1000 Moskau, Tel. (095) 921 68 12, Fax (095) 921 63 53

SE Mettler-Toledo AB, S-12008 Stockholm, Tel. (08) 702 50 00, Fax (08) 642 45 62

SEA Mettler-Toledo (SEA), 40150 Selangor, Tel. (603) 7845 5373, Fax (603) 7845 3478

SG Mettler-Toledo (S) Pte. Ltd., Singapore 139959, Tel. (65) 890 0011, Fax (65) 890 0012

SK Mettler-Toledo, service s.r.o., SK-83103 Bratislava, Tel. (7) 525 2170, Fax (7) 525 2173

SI Mettler-Toledo, d.o.o., SI-1236 Trzin, Tel. (016) 162 18 01, Fax (061) 162 17 89

TH Mettler-Toledo (Thailand), Bangkok 10310, Tel. (662) 723 0300, Fax (662) 719 6479

TW Mettler-Toledo Pac Rim AG, Taipei, Tel. (886) 2 2579 5955, Fax (886) 2 2579 5977

UK Mettler-Toledo Ltd., Leicester, LE4 1AW, Tel. (0116) 235 0888, Fax (0116) 236 5500

US Mettler-Toledo, Inc., Columbus, Ohio 43240, Tel. (614) 438 4511, Fax (614) 438 4900

For all other countries: Mettler-Toledo GmbH, PO Box VI-400, CH-8606 Greifensee, Tel. (01) 944 22 11, Fax (01) 944 31 70

*P21203192*

Loading...

Loading...