Page 1

To protect your METTLER TOLEDO product‘s future:

METTLER TOLEDO Service assures the quality, measuring accuracy and

preservation of value of all METTLER TOLEDO products for years to come.

Please send for full details about our attractive terms of service.

Thank you.

*P11780223*

Subject to technical changes and to the availability

of the accessories supplied with the instruments.

© Mettler-Toledo GmbH 1999 11780223A Printed in Switzerland 9911/2.12

Mettler-Toledo GmbH, Laboratory & Weighing Technologies, CH-8606 Greifensee, Switzerland

Phone +41-1-944 22 11, Fax +41-1-944 30 60, Internet: http://www.mt.com

Operating instructions

METTLER TOLEDO

MT/UMT balances

Operating instructions METTLER TOLEDO MT/UMT balances

Thank you for purchasing a METTLER TOLEDO MT/UMT microbalance.

The MT/UMT balances open up a new dimension in microweighing: They combine extreme precision and a wide range of weighing and

setting options with an exceptional ease of operation.

Please read these operating instructions through carefully so that you can utilize all possibilities offered by your balance to the full. These

operating instructions also offer valuable support in the form of a glossary and an index.

The present operating instructions apply to all METTLER TOLEDO balances of the MT/UMT series. As the various models have different

performance characteristics, however, special mention is made in the text where this is important for the operation.

Please read through the enclosed booklet “Weighing the right way”. It is intended as a supplement to these operating instructions and

contains additional important tips and information.

If you fold out this page, you will have an overview of your balance that shows you all features at a glance.

Safety has priority

– It is essential you consult the instructions in section 1.2 regarding putting your new balance into operation.

– The MT/UMT balances may be operated only when connected to receptacle outlets with a ground connection.

– The MT/UMT balances must not be operated in hazardous surroundings.

– Never open the balance, it contains no parts which can be serviced, repaired or changed by the user. In the

unlikely event you experience problems with your balance, please contact the responsible service facility.

Page 2

1

Pro

FACT

Max 5,1 g d = 1 µg

MT5

Cancel

AUTOCALIN REMOTE

10/1 g

µ

AZ

Configuration

Menu

Select 1

Set

6

7

Configuration

20

GBNT

On/Off

t

n

i

r

P

34 5

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Menu

Set Re-Zero On/Off

STANDBY

Re-Zero

1

Re-Zero

89

METTLER TOLEDO

2

Print

Select 2

On/Off

Set

u

n

e

M

21 22

Pro

FACT

AUTOCALIN REMOTE

AZ

12

13

10

STANDBY

GBNT

23 24

11

14

Operating instructions METTLER TOLEDO MT/UMT balances

16

15

18

17

METTLER TOLEDO

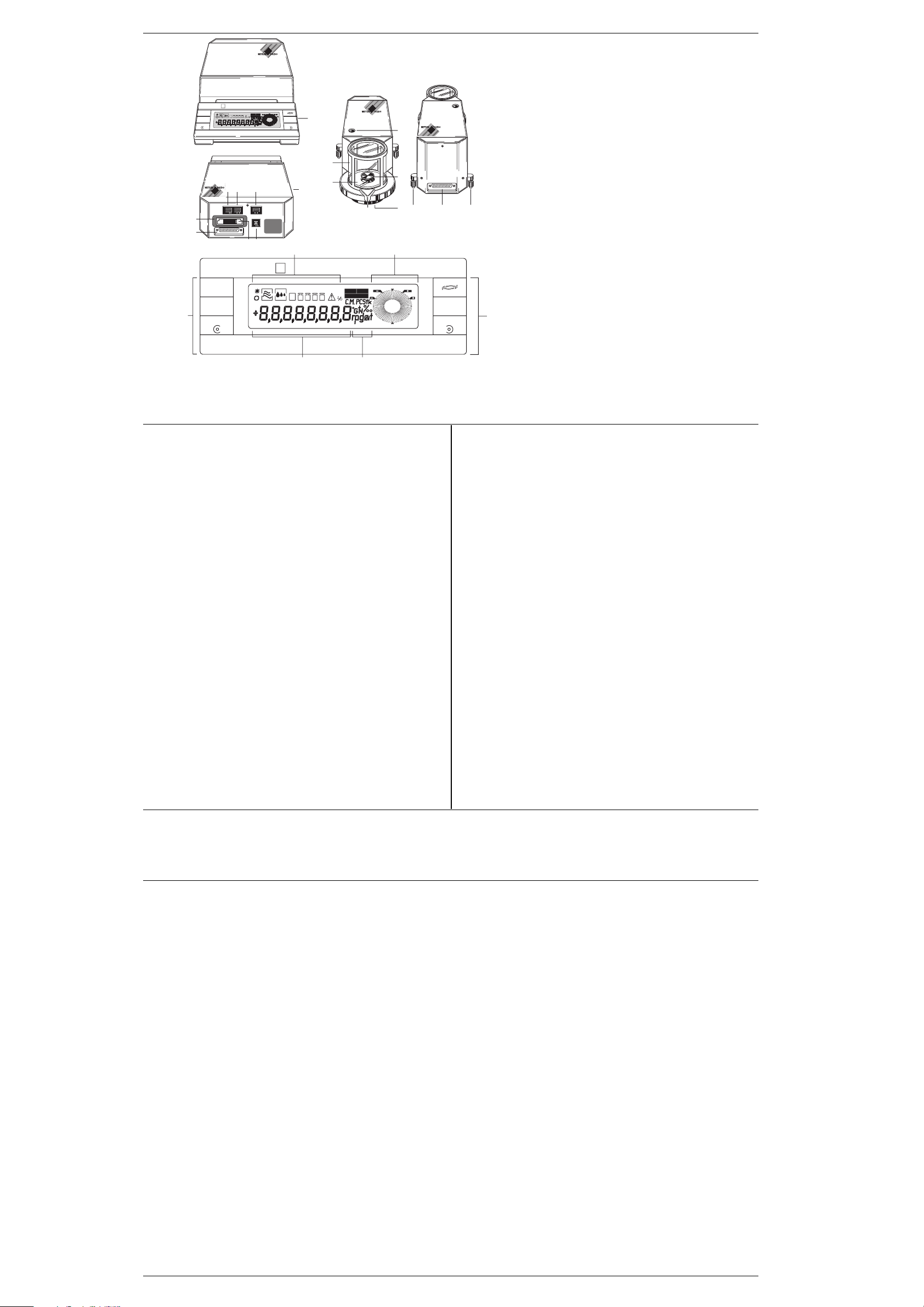

1 Evaluation unit

2 Keypad/display

3 Connection for foot or hand

switch and electrical contacts

4 Connection for data interface

5 Connection to overhead display

11

6 Plug-in slot for program cassette

7 Connection for weighing cell

8 Program cassette, protection of the

configuration parameters

9 Connection for AC adapter

10 Drawer with weghing tongs,

brush and cleaning tweezers

11 Weighing cell

19

18

12 Glass draft shield with glass cover

13 Weighing chamber plate

14 Door handle

15 Weighing pan

16 Level

17 Hanger

18 Screw feet

19 Connection for evaluation unit

Print

Select 2Select 1

20

20 Function keys

21 Status indicators

22 DeltaTrac®

23 Digital display

24 Weight units

Contents

Page

1 Your balance smooths the way 1

1.1 A new era in microweighing 1

1.2 Preparing your balance 2

1.3 Weighing made simple 5

2 Your balance offers high-level operating convenience 9

2.1 An ergonomic glass draft shield 9

2.2 The DeltaTrac® - an informative display 11

2.3 How you can weigh in the coarse and fine range 11

3 Individual adaptation of your MT/UMT 13

3.1 What is the menu? 13

3.2 How to adapt your balance to different types of weighing 17

3.3 How to adapt your balance to the local conditions 18

3.4 How to switch off the fully automatic door function 20

4 Additional possibilities in the configuration register 21

4.1 What is the configuration register? 21

4.2 How is the configuration register used? 22

4.3 In the first sector you return to the factory setting 25

4.4 The second sector offers you numerous adaptation

possibilities 26

4.5 In the third sector you select the weight units

and additional settings 31

4.6 The fourth sector presents a communication-friendly balance 33

4.7 Print out the current configuration 37

4.8 How to protect your settings against inadvertent changes 38

Page

5 Special applications and functions of your balance 39

5.1 Your balance can work with two weight units 39

5.2 Your MT/UMT also weighs in percent and displays

plus/minus deviations 40

5.3 Do you wish to count pieces? 42

5.4 How to trigger the adjustment manually 45

5.5 How to check whether the balance is still adjusted correctly 48

5.6 How to print out the weighing result 49

5.7 You can also operate your balance by remote control 50

6 Important information regarding your balance 51

6.1 The AC adapter offers you a space-saving assembly option 51

6.2 If you change the location of your balance 53

6.3 A well maintained balance is a joy forever 54

6.4 What your balance brings with it 55

6.5 Additional information and accessories for your balance 56

7 Any questions? 56

7.1 What happens if the weight display is unstable? 56

7.2 How can the weighing speed be increased? 59

7.3 What happens if...? 60

7.4 What does this error message mean? 64

7.5 What does this term mean? 65

7.6 How are weight units converted? 75

7.7 Where will I find details of...? 76

Technical specifications 80

Operating instructions METTLER TOLEDO MT/UMT balances

Operating instructions METTLER TOLEDO MT/UMT balances

Printed on recycled paper. Because we care.

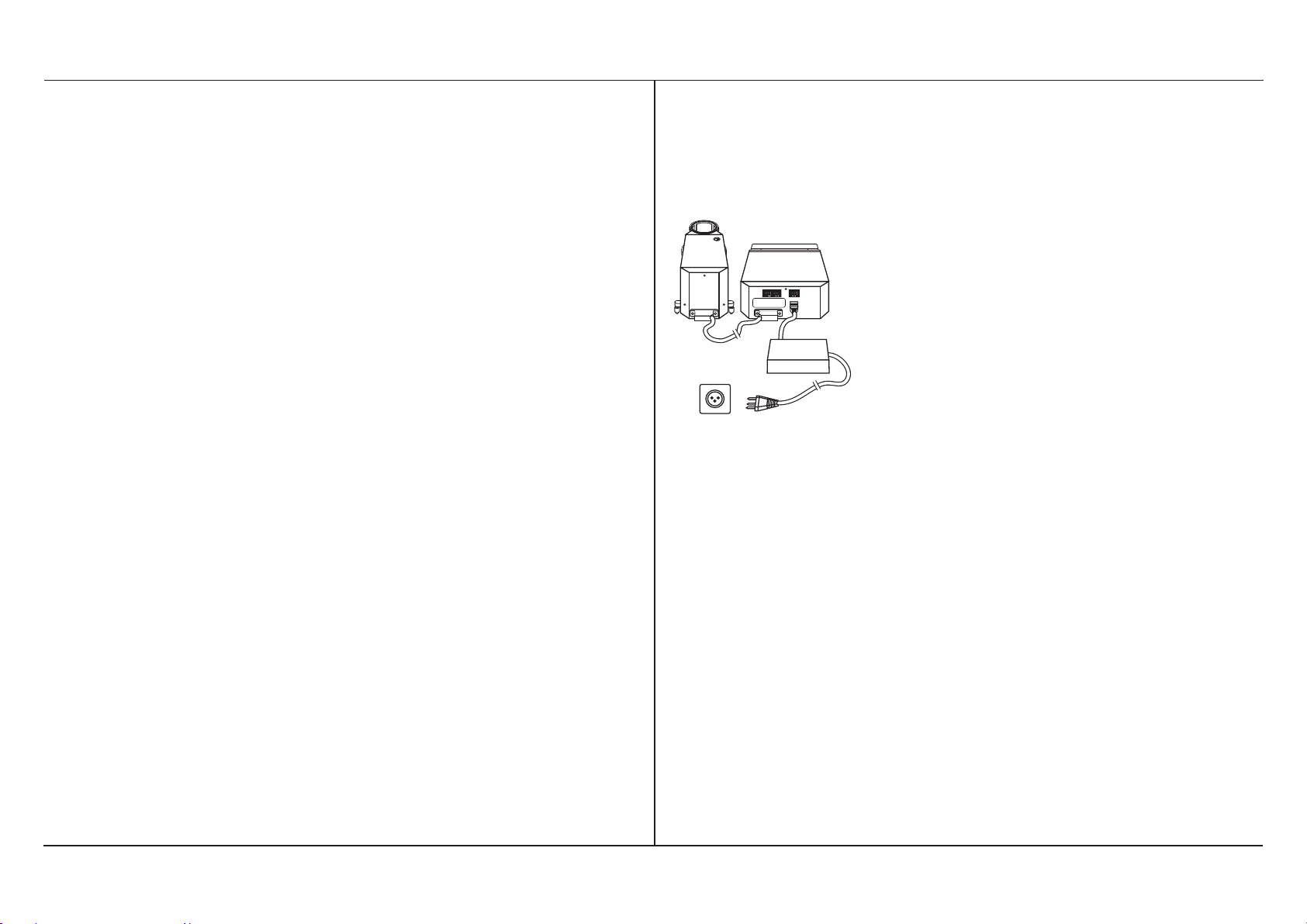

Page 3

Operating instructions METTLER TOLEDO MT/UMT balances

1Your balance smooths the way

1.1 A new era in microweighing

The MT/UMT models open up new

dimensions in microweighing, yet are

simple to operate.

The separation of weighing cell and

evaluation unit ensures maximum precision - disturbing thermal influences

are practically eliminated. Automatic

door functions facilitate operate and

prevent vibrations. And there is no

need whatsoever to concern yourself

with the adjustment - your balance performs the adjustment fully automatically. Built-in data interfaces ensure

that your balance can communicate

with a computer and peripheral devices.

Your balance is distinguished primarily,

however, by its user friendliness: You

attach the weighing cell to the evaluation unit, connect the balance to the

power supply and after 60 minutes

warm-up time (with an acclimatized

balance) you can immediately start

weighing. You thus obtain your first

weighing result in an extremely short

time.

The MT/UMT microbalances offer you

the operating convenience and the possibilities that to date were possible only

with analytical balances. There is, however, no need for you to grapple at the

moment with functions you will not

need until later.

In this first section you will find out how

simply you can start up your new balance and perform normal weighings.

1

Page 4

2

1.2 Preparing your balance

If you fold out the front fold-out, you

have in front of you an immediate

overview of all general illustrations

at a glance.

You need undertake the following

operations only on first-time installation

and each time you change the balance

location.

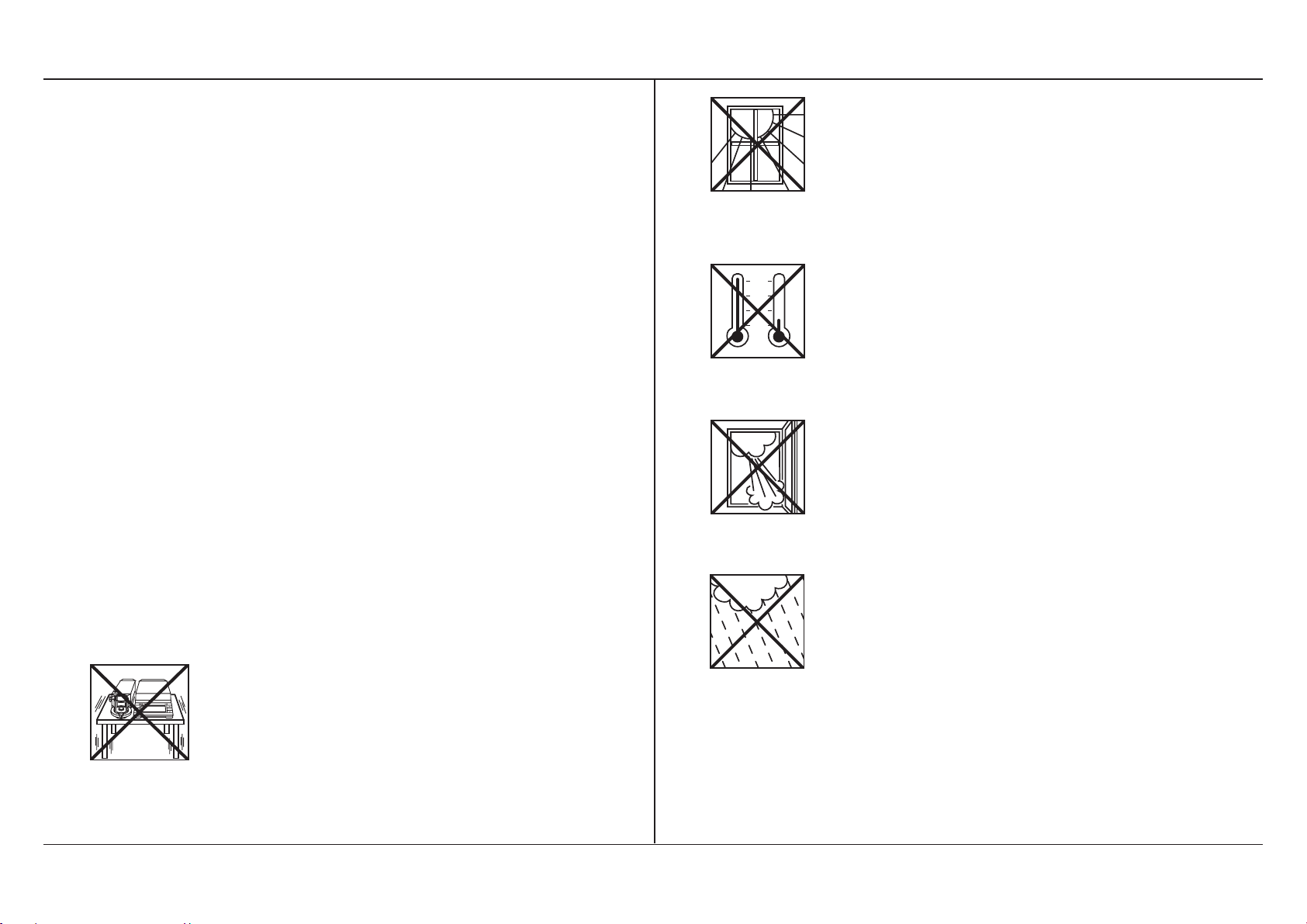

Select a suitable location

Your balance expresses its thanks for

an optimum location by providing you

with excellent weighing results:

30°

20°

10°

0°

- No direct sunlight

- No extreme temperature fluctuations

- No extreme fluctuations in the

atmospheric humidity

- No excessive drafts (e.g. due to

powerful air conditioning units)

- Firm, vibration-free location, as level

C

a

µ

10/1 g

n

c

Co

e

P

nfi

l

M

r

gu

e

i

rat

n

n

S

S

ion

u

t

el

el

e

e

ct

ct

2

1

O

S

R

n

e

e

/

t

-

O

Z

ff

e

r

o

as possible

Additional tips and information regarding an optimum location can be found

in the METTLER TOLEDO brochure “Weighing the right way”, which is

enclosed with your balance.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 5

Operating instructions METTLER TOLEDO MT/UMT balances

Re-Zero

Set

On/Off

Unpack your balance

Your balance is dispatched to you in a

rugged packaging that you should store

in a safe place for possible future transport of the balance.

As soon as you have decided on a suitable location, remove all components

of your new balance from the packaging.

Set up the balance

You can set up the weighing cell to the

left or right of the evaluation unit. The

flexible arrangement of the balance

allows optimum adaptation to your

method of working and to the available

space.

Connect the evaluation unit and the

weighing cell

- Plug the supplied connection cable

into connection socket 7 of the

evaluation unit (marked with “For

connection to weighing cell only”)

and plug the other end into connection socket 19 of the weighing cell

(marked with “For connection to

evaluation unit only”). It is immaterial which end of the cable you connect to the evaluation unit or the

weighing cell.

- The screws of the cable connectors

have holes and can be sealed to

prevent inadvertent separation of

weighing cell and evaluation unit.

3

Page 6

4

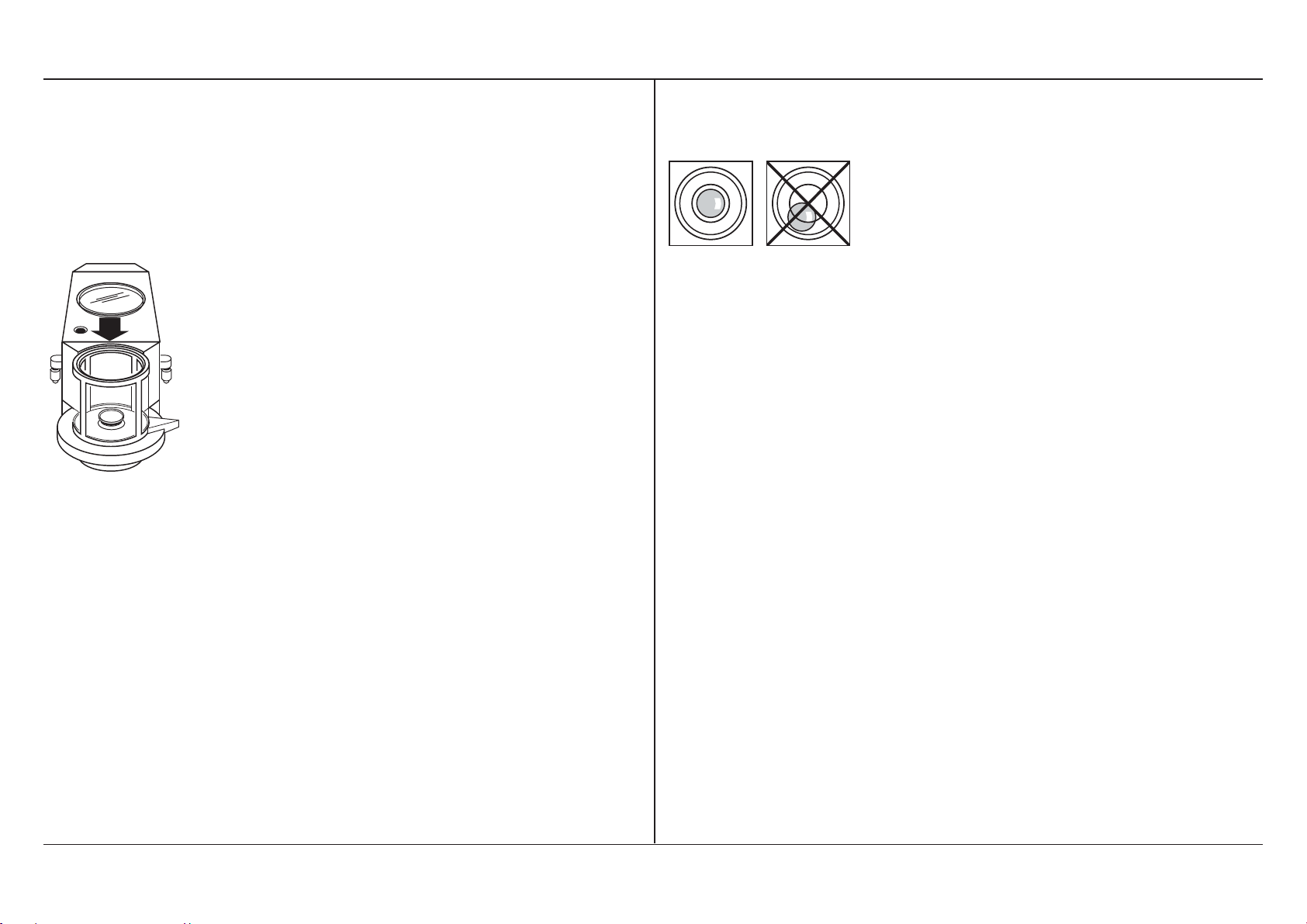

Mount the weighing pan and the

draft shield

- The MT balances are supplied with

mounted weighing pan. You thus

only need to mount the glass cover

on draft shield 12 of the weighing

cell.

- The UMT balances have a smaller

weighing pan than the MT balances

(to avoid cornerload errors). The

weighing pan is already mounted,

on delivery. You thus need only

mount the glass cover on the draft

shield 12 of the weighing cell.

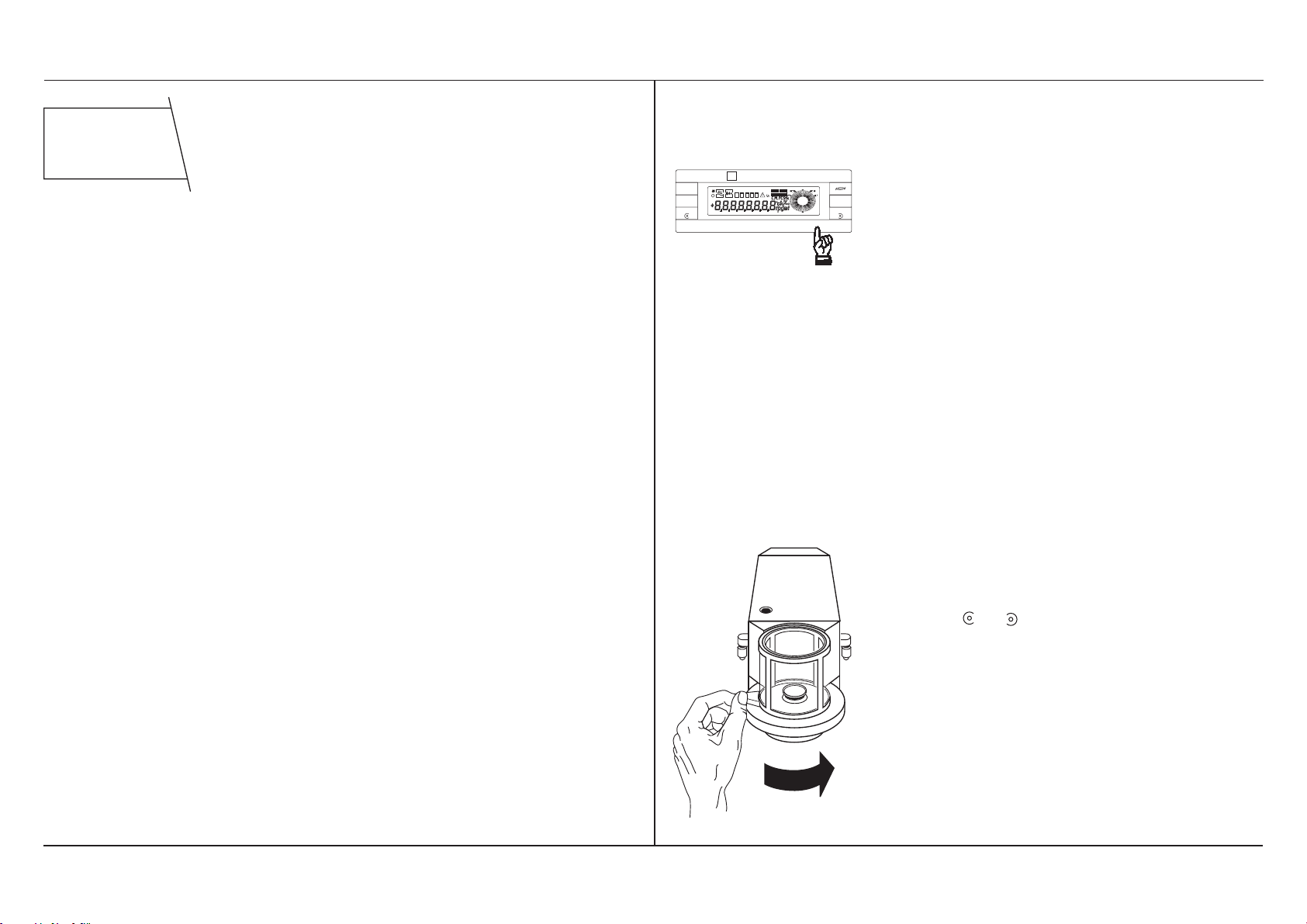

Level your balance

- Turn the two screw feet 18 at the

rear of the weighing cell housing until the air bubble is in the middle of

level 16.

Connect your balance to the power

supply

- Connect the AC adapter supplied to

connection socket 9 at the rear of

the evaluation unit and then to the

power supply.

Operating instructions METTLER TOLEDO MT/UMT balances

- The AC adapter can either be placed on the bench or, to save space,

mounted on the wall. The AC adapter holder and the installation set

with dowels and screws are used for

this. Appropriate details are given in

Section 6.1.

Page 7

Operating instructions METTLER TOLEDO MT/UMT balances

Max 5,1 g d = 1 µg

MT5

METTLER TOLEDO

Pro

FACT

Configuration

Menu

Cancel

10/1 g

µ

Select 2Select 1

AUTOCALIN

REMOTE

AZ

GBNT

STANDBY

Set Re-Zero On/Off

Print

STANDBY

After connection, your balance is on

standby. If your balance is already

acclimatized (depending on the temperature difference between the old

and new location, this takes 6 to 12

hours), it provides you with the first

reliable results after 60 minutes warmup time. After approximately 2 hours

you can count on very accurate weighing results.

1.3 Weighing made simple

- By pressing the «On/Off» key you

switch your balance from standby to

the weighing mode. The balance

now automatically performs a brief

self-test and all display segments

light up briefly.

At the end of the self-test, the balance determines the zero point.

This very precise measurement

takes several seconds, depending

on the stability and acclimatization

of the balance.

- If the draft shield is open, you can

close it by pressing one of the two

keys or or manually by turning

door handle 14.

5

Page 8

6

MT5

Cancel

µ

10/1 g

Configuration

Menu

Set Re-Zero On/Off

METTLER TOLEDO

Pro

FACT

Max 5,1 g d = 1 µg

Your balance is fitted with a fully

automatic door function, which ensures that the draft shield is always

open or closed at the right time.

Section 3.4 describes how you can

switch off this automatic mecha-

------

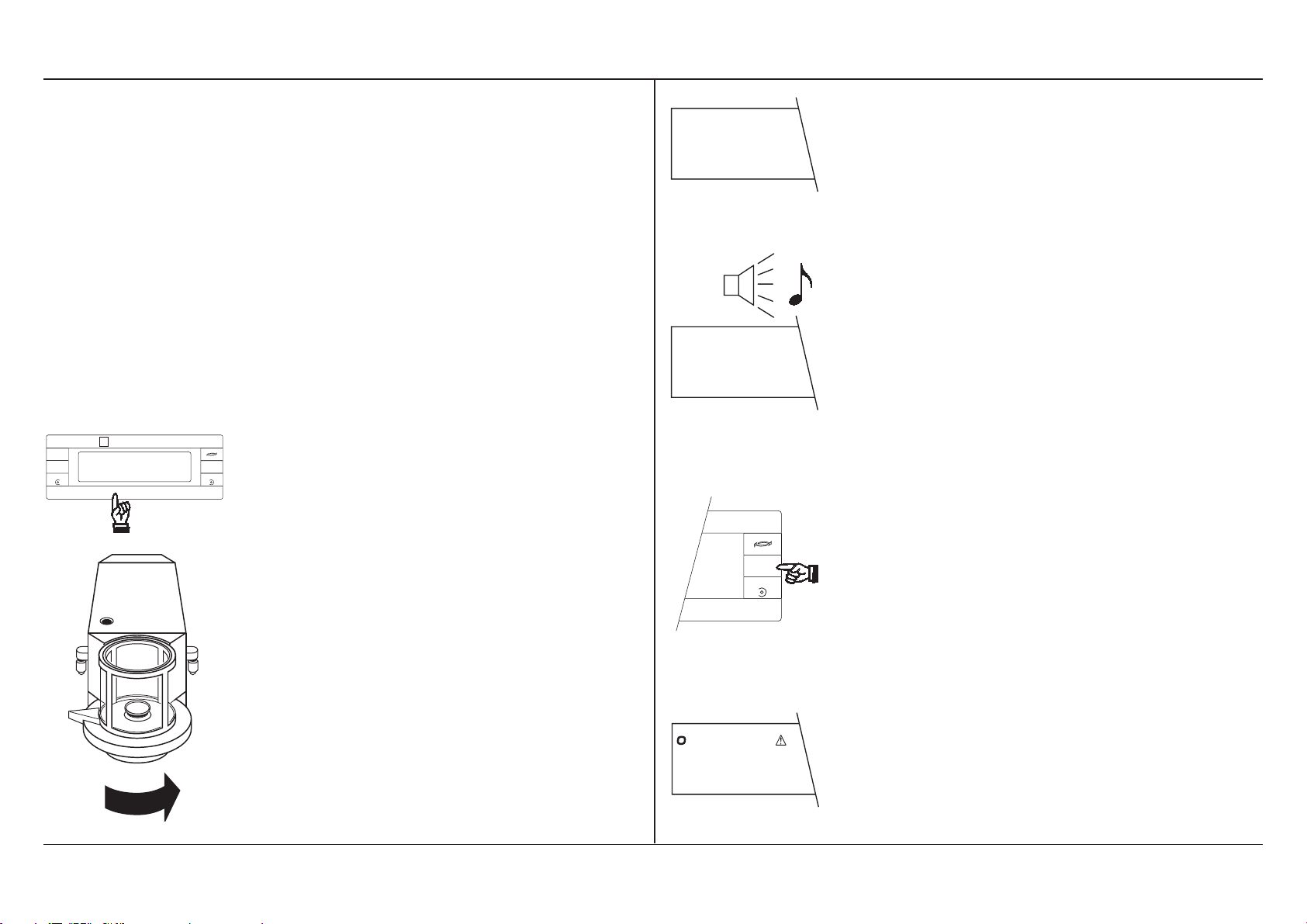

Zeroing of the display (taring) is automatic. While the zeroing is in progress

and the horizontal segments appear in

the display, you can abort the process

by briefly pressing the «Re-Zero» key

again.

nism. On completion of the self-test,

this function opens the draft shield

completely automatically.

As soon as the warning beep sounds,

zeroing of the balance is complete and

the fully automatic door function opens

0.000 mg

the draft shield.

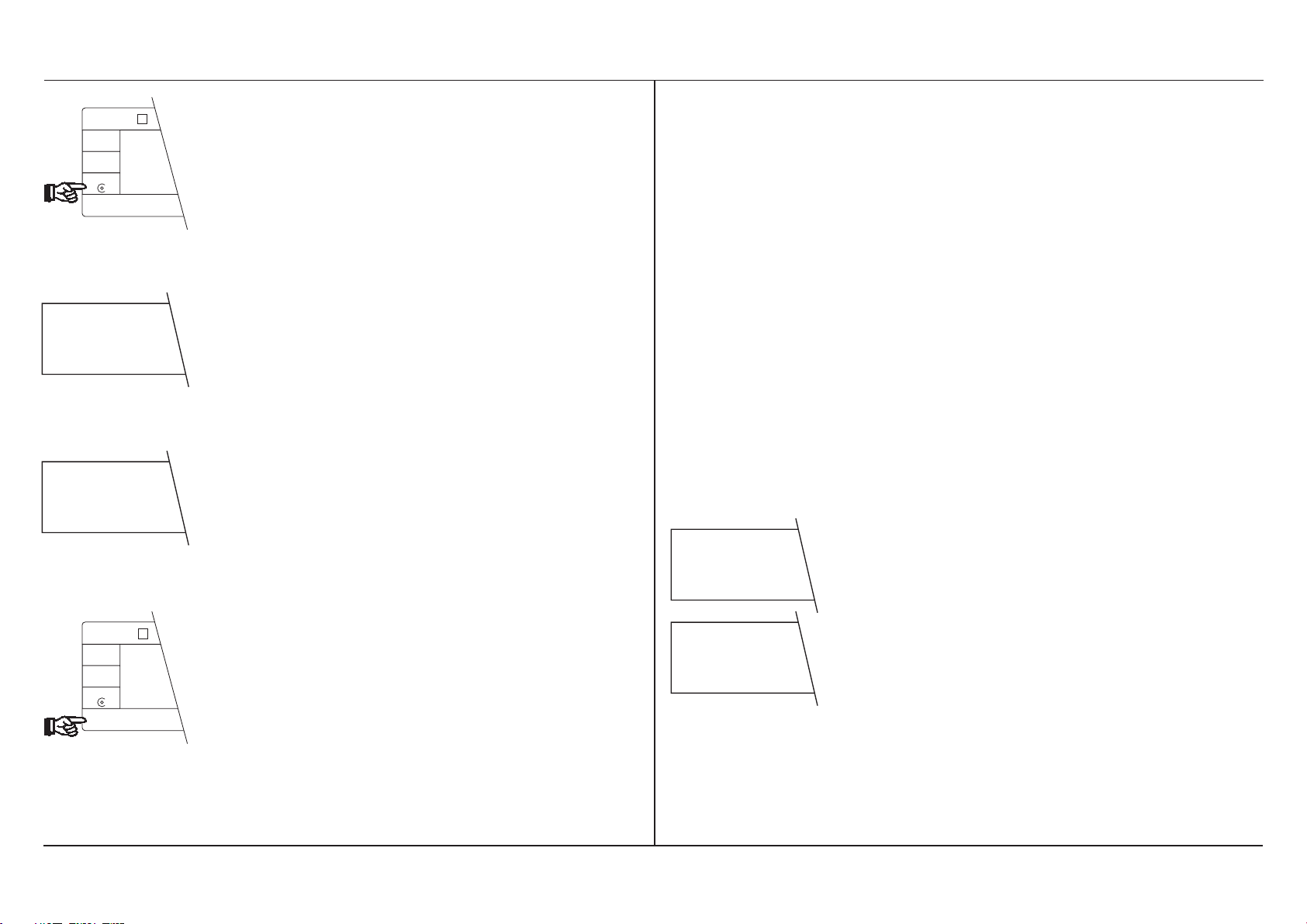

Set your balance to zero (taring):

- If you wish to tare a container, place

Print

Select 2Select 1

it on the balance.

- Press the «Re-Zero» key. The fully

automatic door function closes the

draft shield.

METTLER TOLEDO

Print

Select 2

On/Off

- Load the weighing sample and

press the «Print» key. The fully automatic door function closes the

draft shield.

5.346 mg

Operating instructions METTLER TOLEDO MT/UMT balances

The triangle symbol (print symbol)

and the circle symbol of the stability

detection (ASD) appear in the display.

Page 9

Operating instructions METTLER TOLEDO MT/UMT balances

5.346 mg

5.346 mg

- When the symbol of the stability detection (ASD) fades, the warning

beep sounds; the triangle symbol

also fades and the draft shield

opens automatically.

- Read off the weighing result. The

result remains “frozen” on the display for 5 seconds. This can be recognized by the flashing circle above

the weight unit. If the balance is attached to a printer, the weighing result is automatically printed out.

With this automatic door function, your work steps in weighing

are reduced from 9 to 5!

Configuration

Select 1

of about 5 minutes and then performs

the fully automatic self-adjustment

(proFACT = Fully Automatic Calibration

Technology).

The symbol remains lit up until the balance has adjusted itself or until you

trigger the adjustment by a keystroke.

Section 5.4 shows you how to trigger

the adjustment yourself.

- For switching off the balance, lift

up the «On/Off» key briefly from

below. This closes the draft shield

Pro

FACT

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Menu

Set

Re-Zero

METTLER TOLEDO

Select 2

Print

On/Off

automatically if the fully automatic

door function is switched on. Otherwise, close the draft shield manually

to prevent the ingress of dust and

dirt.

AUTOCALIN

0.367

It is possible that the warning beep

sounds during a weighing and the adjacent symbol appears in the display.

Your balance uses this to show that it

would like to adjust itself. But there is

no need for you to interrupt your work

as the balance waits until you have not

carried out any weighings for a period

7

STANDBY

After being switched off, the balance is

on standby. When it is switched on

again, it needs no warm-up time and is

in immediate operational readiness.

Page 10

8

Some additional tips:

- If you have made a mistake during

weighing, there is no need to worry:

Simply switch off your balance

briefly and then switch it on again.

You will later learn of other possibilities to bring your MT/UMT to weighing readiness again.

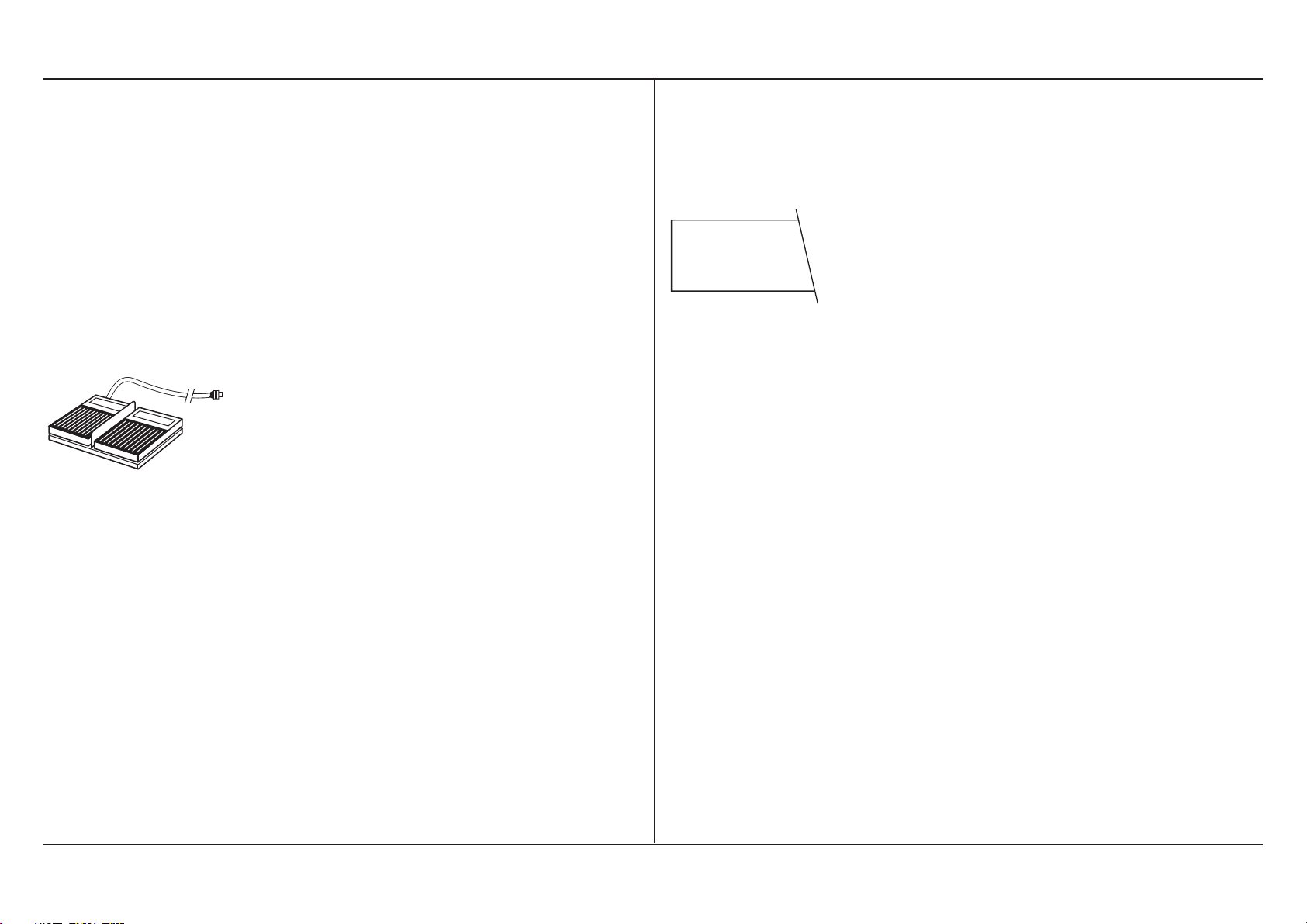

- You can also effect the zeroing (taring) of the balance using the foot or

hand switch (available as an accessory) attached to the balance via

connection 3. Operation with the

foot switch leaves both your hands

free for loading the balance.

-OFF-

After an unexpected power outage,

however, or if you did not switch off

your balance before disconnecting it

from the power supply, when power

is restored again “–

OFF

–” appears

in the display. When the «On/Off»

key is now pressed in such a case,

an extended, internal self-test is first

performed. Here the model designation and the software version are

briefly displayed and all display segments light up for a short space of

time.

- If you ever have to disconnect your

balance from the power supply,

first switch it off by lifting up the

«On/Off» key. After the balance

has been reconnected, it is in the

standby mode and “

STANDBY

”

appears in the display.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 11

Operating instructions METTLER TOLEDO MT/UMT balances

2Your balance offers high-level

operating convenience

2.1 An ergonomic glass draft

shield

The small, circular glass draft shield

reduces the contact surface for disturbing thermal influences and thanks to

the narrow framework allows an unrestricted view of the weighing sample.

The weighing chamber can be opened

at the left or right. The balance is thus

equally convenient to load for left- and

right-handers.

You can operate the draft shield manu-

ally in the traditional manner using

door handle 14.

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

Max 5,1 g d = 1 µg

µ

METTLER TOLEDO

Pro

FACT

The semiautomatic operation can be

effected either with the or key. In

this case, the draft shield is opened

and closed by the motor either to the

right or left.

Print

Select 2

On/Off

- In one-handed operation, you use

one hand to press the or key

and then load the balance using the

same hand.

- In two-handed operation, you press

the or key with one hand and

load the balance using the other

hand.

In certain applications, such as zeroing

(taring) of the balance, the draft shield

opens and closes fully automatically

as you already know from your first

weighing. Manual or semiautomatic operation is also possible when the fully

automatic door function is operative.

9

Page 12

10

The fully automatic door function

primarily facilitates work with the single

or twin foot switch. Section 3.4 shows

you how to switch off the fully automatic door function.

The draft shield of your balance has a

“Learn function”. If the fully automatic

door function is in operation, the draft

shield opens automatically when the

balance is zeroed and when the weighing result is printed out on the side

you desire. For this purpose, the balance notes which of the keys or you

last pressed to open or close the draft

shield.

Pro

FACT

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Configuration

Menu

Select 1

Set

Pro

FACT

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Configuration

Menu

Set Re-Zero On/Off

METTLER TOLEDO

An example:

You used the key, which opens the

draft shield to the right, for the last

door opening.

You now wish to zero the balance and

Print

Select 2Select 1

press the «Re-Zero» key for this.

The draft shield is closed automatically

and when zeroing is complete opens

again to the right. However, if you

wish the draft shield to open to the left,

you must press the key before triggering zeroing.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 13

Operating instructions METTLER TOLEDO MT/UMT balances

24.083

98.215

2.2 The DeltaTrac® - an informative display

The DeltaTrac® 22 is a supplement to

the digital display 23. It provides you

with a pictorial representation of the

weighing range in use and that still

remaining. The dynamics of a weigh-

ing process can be followed on the

DeltaTrac® extremely well. Simply observe the DeltaTrac® during a weighing

and you will immediately understand its

function.

The DeltaTrac® gives you a new feel

for weighing, even with special applications, for example in repeated weighing

in to a specified target value and in percent weighings. You will find further details in Section 5.2.

2.3 How you can weigh in the coarse and fine range

Your balance is equipped with a switch

key which you can use to switch from

the ten times more accurate fine range

to the coarse range.

This switching allows you to work in the

range best suited to your needs.

If, for example, instead of a high resolution you need a stable weighing result

as rapidly as possible, you switch from

the fine range to the course range using the switch key. This makes your

balance very fast and the weighing

results are extremely stable.

11

Page 14

12

You have the following selectable

ranges available:

Balance Fine Coarse Key

range range

MT5 1 µg 0.01 mg 10 / 1 µg

UMT2 0.1 µg 1 µg 1 / 0.1 µg

UMT5 0.1 µg 1 µg 1 / 0.1 µg

With the «10/1 µg» key of the MT balance or the «1/0.1 µg» key of the UMT

balance, you can switch between the

fine range and the coarse range:

- ...the balance operates in the

coarse range.

12.644 mg

- By pressing the «10/1 µg»

(or «1/0.1 µg») key again, you can

return to the fine range.

12.6439 mg

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Configuration

Menu

Select 1

Set

- The balance is measuring in the fine

range

Pro

FACT

- Press the «10/1 µg» (or «1/0.1 µg»)

key and...

Operating instructions METTLER TOLEDO MT/UMT balances

Page 15

Operating instructions METTLER TOLEDO MT/UMT balances

3Your balance is an adaptable balance

For the optimization of your weighing

results and adaptation to your weighing

needs, your balance offers you additional setting options. You undertake

these adaptations in the menu, which

you will now be introduced to.

You can set additional parameters in

the second menu tree of your MT/UMT,

the configuration register (section 4).

3.1 What is the menu?

Overview of the menu functions:

- reference weight in %

- reference weight in pieces

- adjustment

- weighing process adapter

- vibration adapter

- fully automatic door function

You will find a detailed overview of

the menu on pages 78 and 79.

In the menu you match your balance to

the local conditions and to the weighing

tasks. The menu contains various adaptation possibilities, the menu options,

which in turn offer different setting options.

13

Page 16

14

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

In addition, you can also perform several operational steps in the menu for

special applications (percent weighing

and piece counting). Section 5 of these

operating instructions provides you with

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

«Menu» key

- Selection of the menu by briefly

pressing the key in the weighing

mode

more information.

- Selection of the individual menu

options

Pro

FACT

We encourage you to experiment with

the menu to familiarize yourself with it.

You need have no worries here: By

pressing the «Cancel» key you can

return to the weighing mode at any

time without changing any of the

stored settings!

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

«Select 1» key

- Selection of the setting in a menu

option

Pro

FACT

Max 5,1 g d = 1 µg

You perform your weighings in the

weighing mode, the operational mode

of your balance. Weighing mode and

menu are separate. By pressing and

holding the «Configuration» key you

can call up the configuration register.

You can also select the different menu

options and setting possibilities with

keystrokes.

MT5

Cancel

10/1 g

Confi guration

Menu

Select 1

Set

µ

«Set» key

- Confirmation of your selection and

return to the weighing mode. The

selected settings are stored and re-

Pro

FACT

Max 5,1 g d = 1 µg

main so even after the balance has

been switched off.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 17

Operating instructions METTLER TOLEDO MT/UMT balances

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

«Cancel» key

By repeated pressing of the «Menu»

key, all available menu options appear

- Exit the menu and return to the

in the display in succession:

weighing mode without any

changes being made. If you have

made a wrong selection, you can

leave the menu at any time by

pressing the «Cancel» key. You are

CAL Int

- proFACT

fully automatic adjustment and

linearization

then in the weighing mode again

without any change in the settings. Instead of pressing the

«Cancel» key, you can naturally

switch the scale off briefly and then

on again.

- Adaptation to the type of weighing

(weighing process adapter)

15

- Adaptation to the local conditions

(vibration adapter)

- Automatic door function of the draft

shield

door Auto

Page 18

16

A complete overview of the menu can

be found on pages 78 and 79.

Some additional tips:

- Not all menu options are constantly

or exactly displayed in the form

shown; some of them, e.g. the

setting of reference weights

(“Set 100%”) depend on additional

settings in the configuration register,

which we will introduce you to in

Section 4 of these operating instructions.

- If you are in the menu and press no

key for about 1 minute, the balance returns automatically to the

weighing mode. Any changes in

the settings made up to this point

are ignored in this case.

- In the following 3 sections you will

get to know three menu options

(weighing process adapter, vibration

adapter and automatic door function) in detail. The additional setting

options for special applications

(weighing in reference weights for

percent weighings or piece counting

and the adjustment) will be introduced in Section 5.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 19

Operating instructions METTLER TOLEDO MT/UMT balances

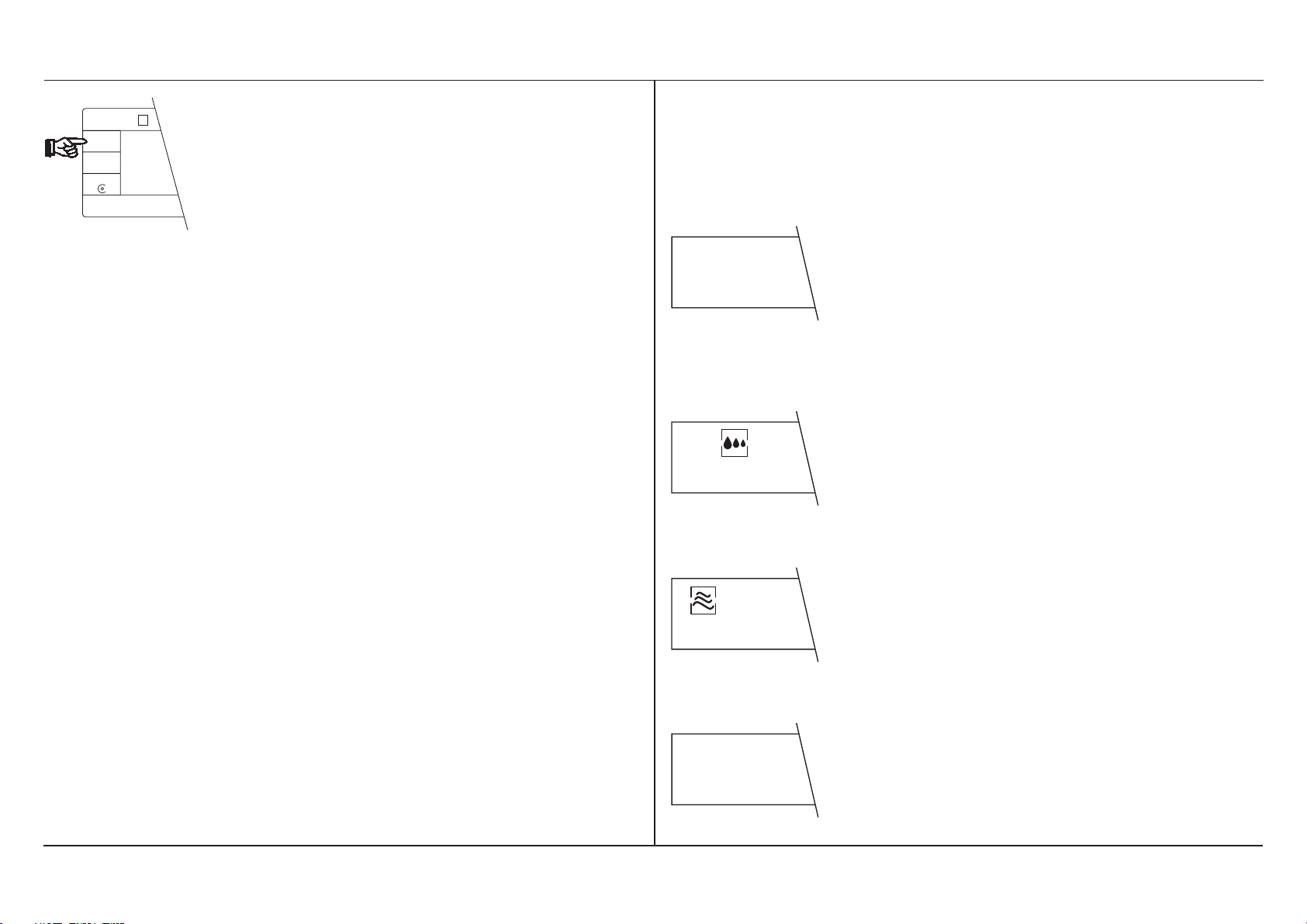

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

3.2 How to adapt your

balance to different

This is the universal setting suitable in principle for all types of

weighing. This setting is preset in

types of weighing

the factory.

Your balance can be matched to different types of weighing (fine dispensing,

absolute weighing, etc.) very simply.

For this purpose, it is equipped with the

so-called weighing process adapter,

which can be set in the menu.

Pro

FACT

The setting absolute weighing is

suitable for the rapid checking of a

weight. During the weighing in, the

last decimal place is suppressed.

- Select the menu by pressing the

«Menu» key briefly.

If you wish to employ fine dispensing (weighing in) of a fine powder or

small amounts of liquid, select the

- Press the «Menu» key repeatedly

until the drop symbol of the weighing process adapter appears in the

display.

weighing in setting. This provides a

continuous display of all decimal

places, and the weight increase can

thus be followed easily.

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

- Select the appropriate setting with

the «Select 1» key:

17

Page 20

18

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

In this position the drop symbol is

invisible, the weighing process

3.3 How to adapt your

balance to the local

adapter is switched off. This setting

is suitable only for special appli-

conditions

cations in which not only the final

result but also the dynamics of the

weighing process are of interest, for

example the recording of weight

changes due to evaporation against

time.

If, despite a closed draft shield, no

stable weighing results are found, the

cause could lie with unfavorable local

conditions such as vibrations.

Very minor, hardly noticeable vibrations

of the weighing table are usually involved.

Pro

FACT

- When you have selected the appropriate setting, press the «Set» key.

This makes the selected settings

active immediately, and the balance

returns to the weighing mode.

With the so-called vibration adapter

your balance can be matched in the

menu to the local conditions.

Pro

FACT

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Configuration

Menu

Select 1

Set

Operating instructions METTLER TOLEDO MT/UMT balances

- Select the menu.

- Press the «Menu» key repeatedly

until the wave symbol of the vibration adapter appears in the display.

Page 21

Operating instructions METTLER TOLEDO MT/UMT balances

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

- Select the appropriate setting with

the «Select 1» key:

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

- When you have selected the appropriate setting, press the «Set» key.

The chosen setting then immediately becomes active, and the balance returns to the weighing mode.

Note:

This setting is suitable for normal

ambient conditions; the balance

operates at moderate speed in this

case. This is the factory setting.

A further reason for an unstable display

of the weighing result could lie, for in-

stance, with electrostatic charging of

the weighing sample or the container.

You will find additional information

This setting is suitable for work in

regarding this in Section 7.1.

unstable surroundings. The balance operates more slowly, but is

less sensitive to external disturbances.

This setting is suitable for very

calm and stable surroundings.

The balance operates very rapidly,

but is relatively sensitive to external

disturbances. This setting is recommended if your balance is located

on a stone table.

19

Page 22

20

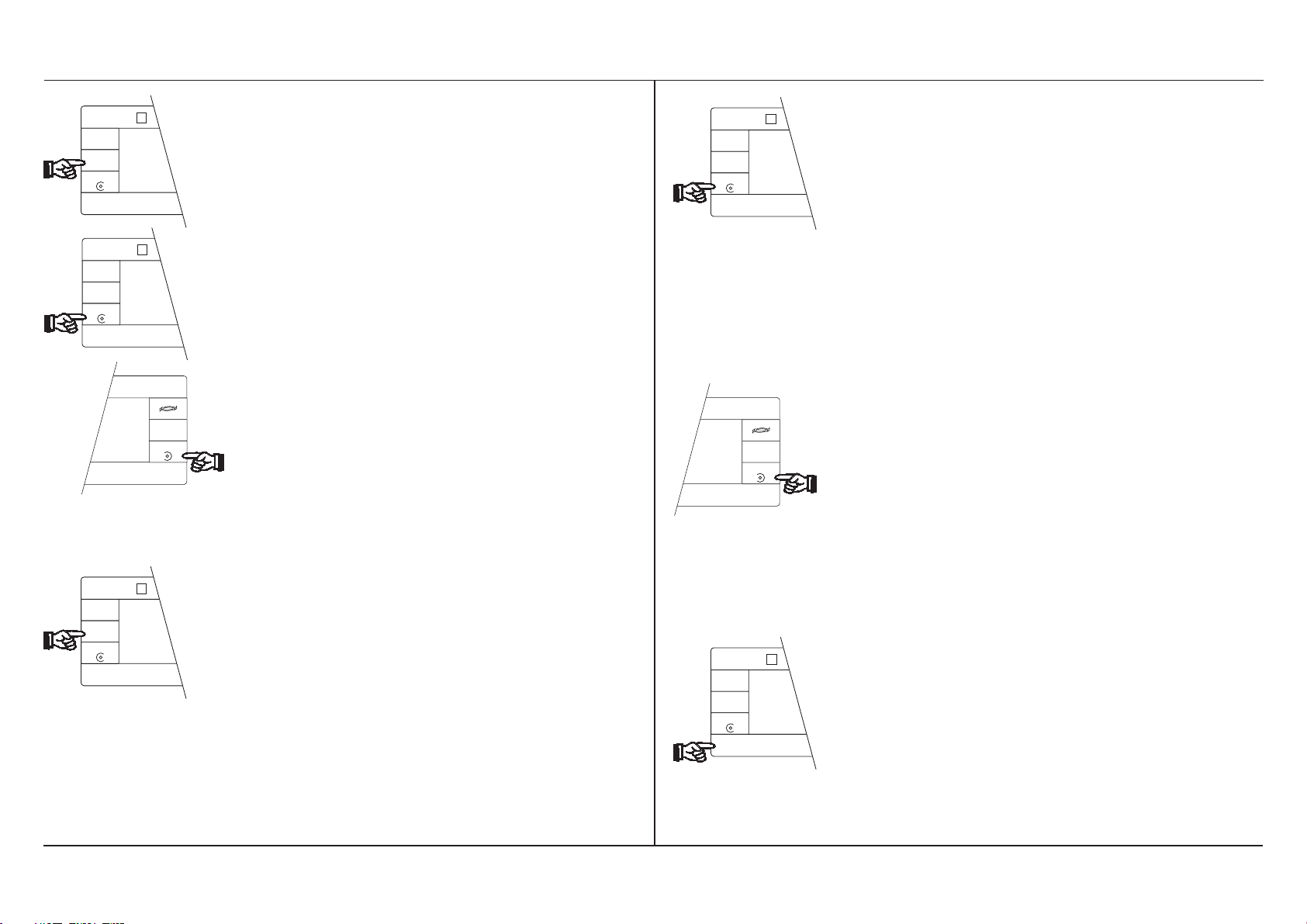

3.4 How to switch off the fully automatic door function

You are already familiar with the convenient automatic door function of your

balance from your first weighing. When

the automatic door operation is switched on, the draft shield closes automatically after the «Re-Zero» key (zeroing/

taring) or the «Print» key (printout of

the weighing result, see Section 5.6)

has been pressed. As soon as the

weight display is stable, the draft shield

is reopened for the next weighing operation (e.g. weighing in, loading the

balance). The draft shield is thus always in the correct position for the next

weighing process. Routine work is particularly facilitated by this automatic operation. It is also useful in the percent

weighing (Section 5.2) and piece counting (Section 5.3) applications.

Pro

FACT

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Configuration

Menu

Select 1

Set

door Auto

When the twin foot switch is used, the

automatic operation leaves both hands

free for weighing in.

If you wish to operate the draft shield

manually or semiautomatically using

the two keys and , however, you can

switch off the automatic door operation:

- Select the menu.

- Press the «Menu» key repeatedly

until the adjacent display appears.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 23

Operating instructions METTLER TOLEDO MT/UMT balances

Pro

FACT

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Configuration

Menu

Select 1

Set

door Auto

door Std

- Using the «Select 1» key, you can

now switch the automatic door

operation off and on again:

Fully automatic door function

switched on

Fully automatic door function

switched off

4 Additional possibilities of your

balance

In addition to the menu, your MT/UMT

balance offers you further, very specific

adaptation possibilities. You perform

these adaptations in the configuration

register, which we will introduce you to

in the following section.

4.1 What is the configuration register?

The configuration register is divided

into four sectors in which you can vary

the following settings:

SEtt INGS

- Operational setting

• Reset

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

- Activate the chosen setting by

pressing the «Set» key and you

will be returned once again to the

weighing mode.

SCALE

- Basic settings

• ASD, automatic stability detector

• Readability

• Readability in the semimicro

range

• Autozero

• proFACT, adjustment and

linearization

21

Page 24

22

Unit

Int -FACE

- Weighing units

weighing unit 1

weighing unit 2

status indicator

beeper

- Interface

data transmission mode

data transmission rate

parity

transmission protocol

end-of-line mode

You will find further details on the

adjustment parameters on pages 78

and 79.

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

4.2 How is the configuration register used?

Hold the short-form operating

instructions in your hand. You will

then have the complete configuration register in front of you at a

glance.

Pro

FACT

We would like to encourage you to experiment with the configuration register

to familiarize yourself with it. You need

have no worries on this score: By

pressing the «Cancel» key, you can

return at any time to the weighing

mode without any of the stored settings being altered!

Operating instructions METTLER TOLEDO MT/UMT balances

Page 25

Operating instructions METTLER TOLEDO MT/UMT balances

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

Max 5,1 g d = 1 µg

µ

Max 5,1 g d = 1 µg

µ

METTLER TOLEDO

Pro

FACT

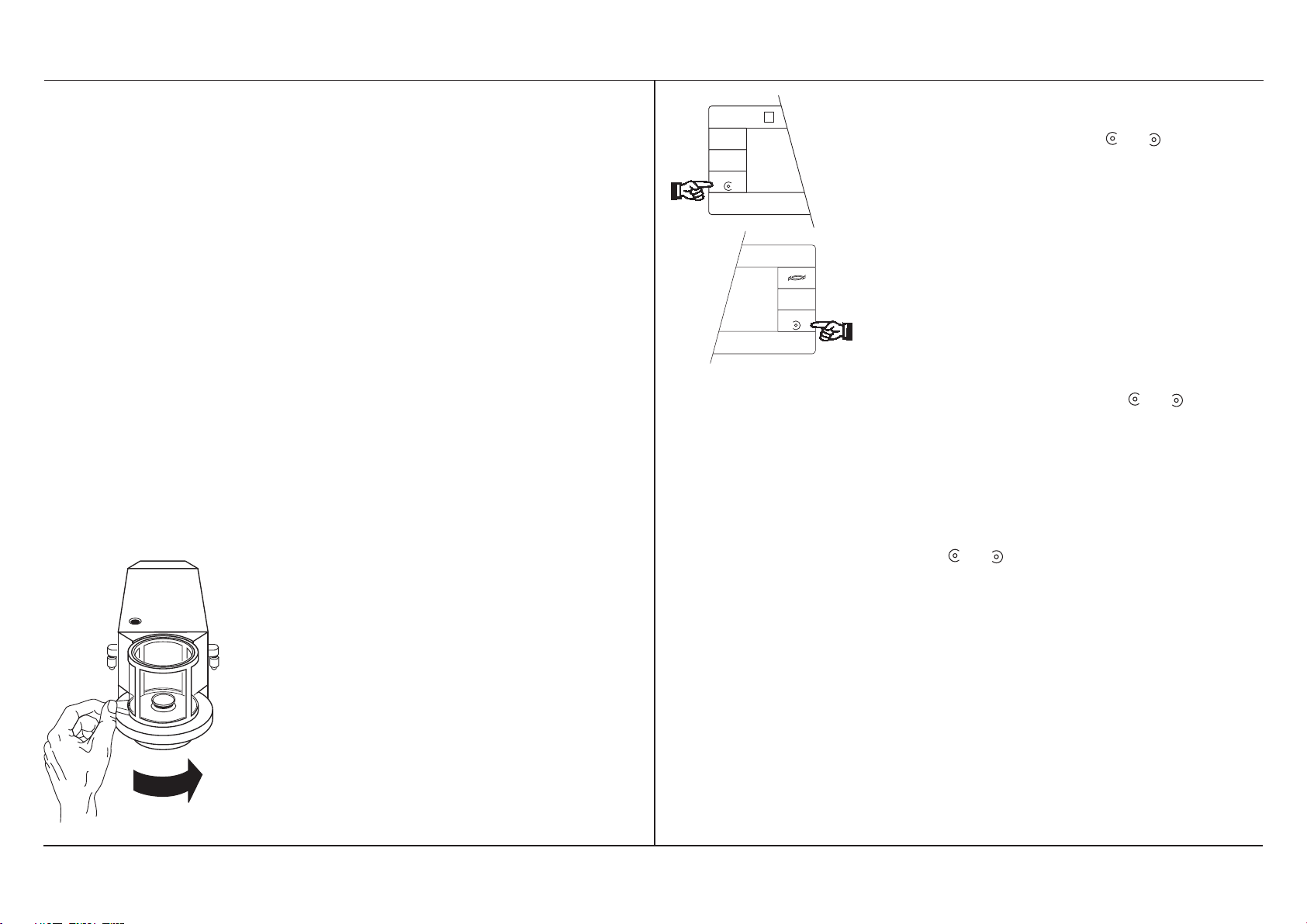

By pressing and holding the

«Configuration» key, you call up the

configuration register.

You select the different

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

- sectors («Configuration» key)

Pro

FACT

- parameters («Select 1» key)

«Select 1» key

Selection of the parameters in a

sector. After the last parameter in

this sector you are returned to the

first.

- settings («Select 2» key)

by simply pressing the appropriate key.

In contrast to the menu, you also need

the «Select 2» key for operation of the

Print

Select 2

On/Off

configuration register.

METTLER TOLEDO

Print

Select 2

On/Off

«Select 2» key

Selection of the desired setting of a

parameter. After the last setting of a

parameter, you are returned to the

first.

«Configuration» key

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

Selection of the configuration register from the weighing mode by

pressing and holding the key

(about 5 seconds). You are then

already in the first sector.

Selection of the individual sectors

in the configuration register with a

brief keystroke. After the last sector

you are returned to the first.

23

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

«Set» key

Confirmation of your selection and

return to the weighing mode. The

selected settings are stored and remain so even after the balance has

been switched off or disconnected

from the power supply.

Page 26

24

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Configuration

Menu

Select 1

Set

2400 bd

Pro

FACT

«Cancel» key

Exit the configuration register and

return to the weighing mode without any changes being stored. If

you have made a wrong selection,

you can quit the configuration register at any time by pressing the

A further tip:

If you are in the configuration register

and you do not press a key for about

1 minute, the balance automatically

returns to the weighing mode. In this

case, any alterations in the settings are

ignored.

«Cancel» key. You are then again

in the weighing mode without any

setting having been altered.

Instead of pressing the «Cancel»

key, you can also switch the

balance off, then immediately on

again.

In the following sections you will learn

what parameters you can select in what

sectors, and what settings are avail-

able. You will find the first example in

the setting of the parameter “Auto-

matic stability detection” (ASD) in

Section 4.4. In the following sections,

you will also find recommendations for

the correct setting of your balance. Fur-

Your balance is naturally not supplied

with an empty configuration register.

We have already included default set-

ther useful tips are contained in the en-

closed booklet “Weighing the right

way”.

tings for you. You can recognize these

factory settings by the asterisk in the

upper left corner of the display.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 27

Operating instructions METTLER TOLEDO MT/UMT balances

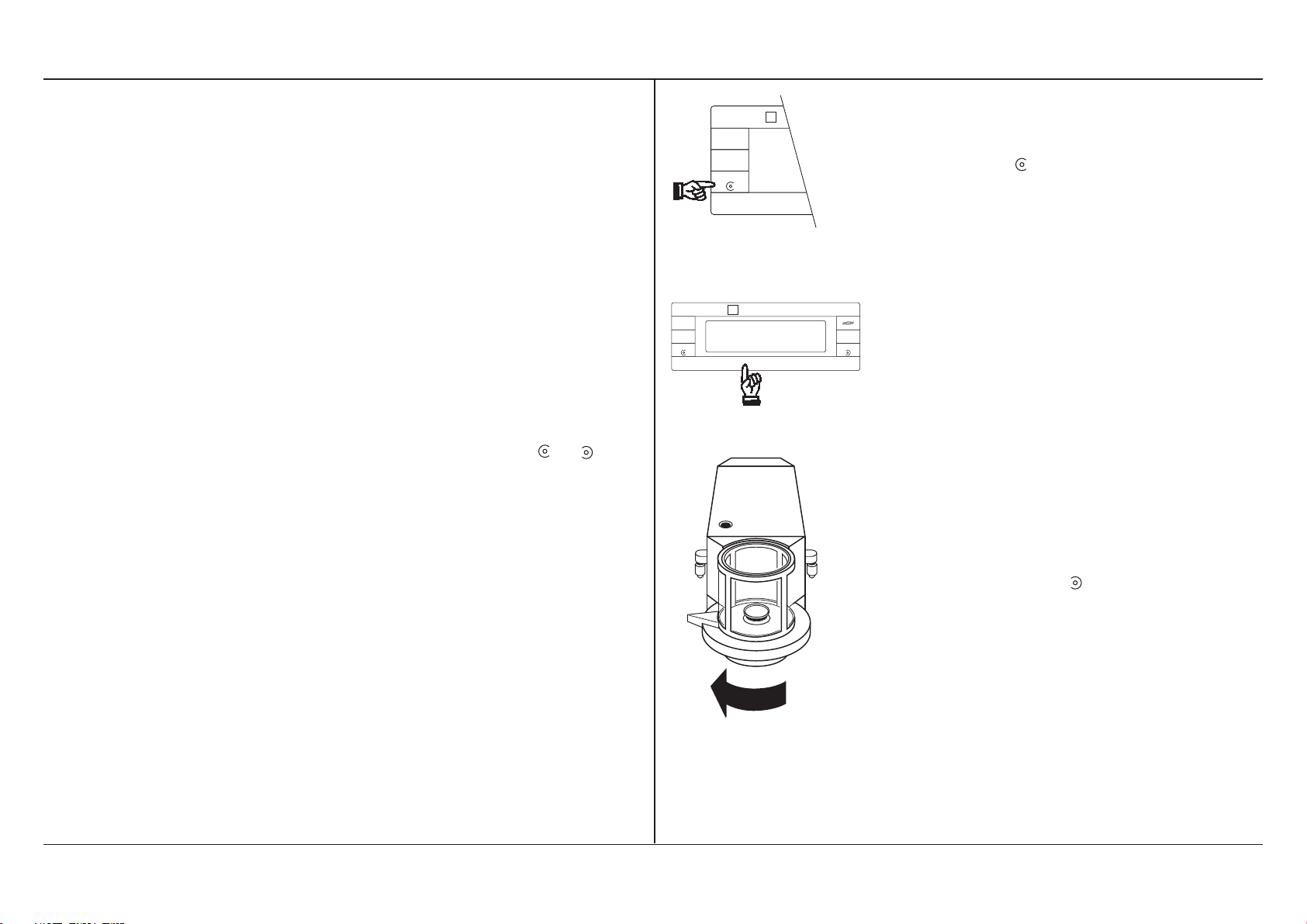

4.3 In the first sector you return to the factory settings

As you have learned in the preceding

section, the configuration register of

your balance has been preset in the

factory. Even if you have modified the

settings, you can return to the factory

setting at any time.

But here all specific settings, even

those in the menu, will be replaced

by the factory settings!

You undertake the return to the factory

settings in the first sector (operational

setting). This sector contains only a

single parameter:

SEttINGS

rESEt

0.000 mg

- You are now in the first sector

(

Settings

) of the configuration

register.

- Select the first (and only) parameter

(«Select 1» key).

- Activate the resetting by pressing

the «Set» key, and the scale returns

automatically to the weighing mode.

You again work with the factory settings.

-ConF-

- Select the configuration register by

pressing and holding the «Configu-

ration» key. As soon as the display

shown opposite appears, release

the key.

25

Page 28

26

SCALE

4.4 The second sector offers

you numerous adaptation

possibilities

- Select the configuration register by

pressing and holding the «Configu-

ration» key. Then select the second

sector (basic settings) by pressing

the «Configuration» key briefly.

In this sector you can select the following parameters and their settings:

Automatic stability detection, (ASD)

The symbol fades and the weighing result is released only when the result is

within the limits selected by you for the

stability.

You have a choice of eight settings. In

the setting

Asd–1–

the display must be

within a preset tolerance limit for one

second for the result to be released as

stable. In the setting

ASd–7–

the result

must be within a preset tolerance limit

for several seconds before being released.

- Select the first parameter, the auto-

matic stability detection (

ASD

), with

the «Select 1» key.

ASd

0.35

Your balance possesses an automatic

stability detection. As long as the

weighing result is unstable, the stability detection symbol remains lit up in

the upper left corner of the display.

Operating instructions METTLER TOLEDO MT/UMT balances

- Select the appropriate setting with

the «Select 2» key. The following il-

lustration shows the relationship between the repeatability and the

weighing speed.

Page 29

Operating instructions METTLER TOLEDO MT/UMT balances

Stage Weighing Repeata-

speed bility

off

very fast good

1

2

3*

4

5

6

7 fast very good

*= factory setting

In the

oFF

position, the balance does

not wait for attainment of stability; each

result is considered stable. This setting

is used in special applications in connection with the serial data interface

(see also Section 4.6 “Data transmission mode”).

Readability (selection of the readout

increments)

d

In this parameter you define the readout increments (digits) for the last decimal place. Readout increments of 1, 2,

5 and 10 are available, and these are

symbolized by the following setting

options:

MT5 UMT2 UMT5

0.01 mg* 1 µg* 1 µg*

0.02 mg 2 µg 2 µg

0.05 mg 5 µg 5 µg

0.1 mg 10 µg 10 µg

* = factory setting

Select readout increments as large as

your application allows; the larger the

readout increments, the faster the operation of your balance.

27

Page 30

28

dF

Readability (selection of the readout

increments) in the fine range

Here you define the readout increments

(digits) for the last decimal place for

weighings in the fine range. Readout

increments of 1, 2, 5 and 10 are available, and these are symbolized by the

following setting options:

MT5 UMT2 UMT5

1 µg* 0.1 µg* 0.1 µg*

2 µg 0.2 µg 0.2 µg

5 µg 0.5 µg 0.5 µg

10 µg 1 µg 1 µg

* = factory setting

AZ

on

oFF

AZ

AZ

Autozero (AZ)

In this parameter you switch the automatic zeroing (autozero) on or off.

When switched on, the zero is automatically corrected for drift or contamination of the weighing pan.

- Autozero on*

- Autozero off

Select readout increments as large as

your application allows; the larger the

readout increments, the faster the operation of your balance.

With the «10/1 µg» (or «1/0.1 µg with

the UMT) key, you toggle between the

coarse and fine range.

Operating instructions METTLER TOLEDO MT/UMT balances

* = factory setting

For particular applications (e.g. monitoring of the zero point in long-term

weighings), it can be an advantage to

switch the autozero function off.

Page 31

Operating instructions METTLER TOLEDO MT/UMT balances

CALIN

CALIN

Auto on

Adjustment and linearization with

proFACT

In this parameter you define the adjustment mode, i.e. the way in which your

balance should be adjusted and

linearized. The following possibilities

are available:

- The MT/UMT balance adjusts and

linearize itself fully automatically

by loading two internal adjustment

weights. The process is initiated as

soon as a change in the operating

conditions makes this necessary.

One of the most important initiation

criteria is a temperature fluctuation

in the surroundings of

± 1.5 °C. You do not have to concern yourself with the adjustment of

the balance. The adjustment and

the simultaneous linearization provide you with the surety that the displayed value matches the mass of

the loaded weight over the entire

weighing range of your MT/UMT.

proFACT

professional fully automatic adjustment and linearization technology

1. Adjustment

The two internal adjustment weights

are loaded. The display is adjusted so

that the loaded weight matches the displayed value. (Correction of the slope

of the straight line).

2. Linearity

The internal weight m1 is loaded alone

and together with the weight m2. The

linearity is adjusted using the different

display values for m1 in both measurements. If the two displayed values, y

1

and y2, are equal, the linearity is ad-

Display value

100%

y

2

50%

y

1

m

1

m

2

Loaded weight

m

1

justed. (Correction of the deviation from

the shape of an ideal straight line).

100%

29

Page 32

30

CALIN

Auto oFF

In this mode you can also initiate

the fully automatic adjustment and

linearization at any time with a keystroke. This is practical, for instance, when your balance reports

during a weighing that it wishes to

adjust itself. Section 5.4 shows you

how to proceed in such a case.

- The fully automatic self-adjustment

with linearization adjustment

(proFACT) described above is

switched off. You can trigger the

adjustment with the internal adjustment weights at a keystroke. After

initiation, the adjustment runs automatically, and at the same time the

measuring range is linearized. Section 5.4 shows you how to proceed

in this case.

CAL

USEr

- You use your own, external adjustment weight for the adjustment.

The procedure is described in Section 5.4 of these operating instructions. proFACT is not active in this

setting.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 33

Operating instructions METTLER TOLEDO MT/UMT balances

Unit

Unit 1

4.5 In the third sector you

select the weight units

The number of decimal places in each

unit is dependent on the balance

model.

and additional settings

By pressing the “ key, you toggle be-

Select the third sector (weight units) in

the configuration register.

In this sector you can select the following parameters and their settings:

Weight unit 1

The following weight units are avail-

Unit 2

û

able:

û

Display Name

tween weight unit 1 (

unit 2 (

Unit 2

). Section 5.1 provides

Unit 1

) and weight

you with further details regarding this

switching. A conversion table for the

weight units is given in Section 7.6.

Weight unit 2

You have available the same weight

units as with weight unit 1 and also the

application units piece and percent:

g gram

mg * milligram

µg microgram

GN grain

dwt pennyweight

ct carat, metric

C.M. carat, metric (GB)

mo momme

* = factory setting

Display Name

g gram

mg milligram

µg * microgram

GN grain

dwt pennyweight

ct carat, metric

C.M. carat, metric (GB)

31

Page 34

32

mo momme

PCS pieces

Stk pieces (German)

% percent

* = factory setting

The number of decimal places in each

unit depends on the balance model.

By pressing the “ key, you toggle between weight unit 1 (

unit 2 (

Unit 2

). You will find further de-

Unit 1

) and weight

tails in Section 5.1. A conversion table

for the weight units is given in Section

7.6.

The application units «piece» and

«percent» are described in detail in

Sections 5.2 and 5.3.

Auto

on

Status indicators

The status indicators 21, such as the

symbols for the vibration adapter and

the weighing process adapter, provide

you with an overview of the selected

settings. These graphic indicators can

be switched on or off.

-A few minutes after the balance has

been switched on, the symbols

fade. *

- The symbols are displayed permanently.

Operating instructions METTLER TOLEDO MT/UMT balances

* = factory setting

Page 35

Operating instructions METTLER TOLEDO MT/UMT balances

bEEP

bEEP on

bEEP oFF

Beeper setting

The audio acknowledgement beep supports the operation of the balance and

the display audibly. You can switch it off

or on.

- audio acknowledgement beep

switched on *

- audio acknowledgement beep

switched off

4.6 The fourth sector presents a communication-friendly balance

- Select the fourth sector in the con-

figuration register (interface).

Int-FACE

For the attachment of a third-party

printer or a PC you can select the

parameters for the data transmission

via the serial data interface and their

settings in this sector. You will find

more detailed information regarding

use of the interface in the instructions

“Bidirectional interface of the

METTLER TOLEDO AT/MT/UMT balances”, which is enclosed with your

balance.

* = factory setting

33

Page 36

34

S.

S. Stb

S. ALL

S. Auto

Data transmission mode

The following setting options are available:

- Send stable: The first stable value

is transferred after initiation of the

print command after release by the

automatic stability detection. *

- Send all: The current value is

transmitted after initiation of the

print command.

- Send automatically: The first sta-

ble value is transmitted automatically after every weight increase

of at least 0.01 g.

Important note:

If you have switched off the automatic

stability detection in sector 2

(

ASD oFF

), all weight values are regarded as being stable. After the

«Print» key has been pressed in this

case, the following values are transmitted:

In setting

the setting

In setting

S.Stb

: The current value as in

S.ALL

S.Auto

.

: The first value after a

weight change of more than 0.01 g.

S. Cont

- Send continuously: All prepared

values are transmitted continu-

ously.

* = factory setting

Operating instructions METTLER TOLEDO MT/UMT balances

Page 37

Operating instructions METTLER TOLEDO MT/UMT balances

bd

2400 bd

Data transmission rate (baud rate)

The data transmission rate (baud rate)

determines the speed of the transmission via the serial interface. The unit is

the baud (1 baud (bd) = 1 bit/second).

The following transmission rates are

available:

- 150 db

- 300 db

- 600 bd

- 1200 bd

- 2400 bd *

- 4800 bd

- 9600 bd

* = factory setting

PAr

PAr -E-

PAr -O-

Parity

With the aid of the parity test, simple bit

errors in the data transmission can be

recognized by a parity check. The following setting options are available:

- Parity Even *

- Parity Odd

35

- Parity Off

PAr oFF

- Parity Space

PAr SPc

* = factory setting

Transmission protocol (HandShake)

Page 38

36

HS

HS PAUSE

HS CL

These settings allow matching of the

data transmission to various serial receivers. The following settings are

available:

- Pause of 1 second

(for METTLER TOLEDO GA42

Printer)*

- METTLER TOLEDO transmission

protocol. In this operating mode, the

end-of-line mode is automatically

set to “

crLF

” and can not be

changed.

HS HArd

HS Soft

EOL

- Hardware handshake (DTR/CTS)

- Software handshake (XON/XOFF)

* = factory setting

End-of-line mode

Two setting options are available:

HS oFF

- No handshake

- Carriage return and line feed at end

of line *

EOL crLF

- Carriage return at end of line

EOL cr

* = factory setting

Operating instructions METTLER TOLEDO MT/UMT balances

Page 39

Operating instructions METTLER TOLEDO MT/UMT balances

Important note:

If

HS CL

is set in the transmission protocol, the end-of-line mode is set automatically to

EOL crLF

and can not be

changed.

4.7 Print out the current

configuration

You can print out the configuration currently stored on an attached printer.

This record is useful if you work with

different configurations. You then know

at all times which values should be set

for which application.

METTLER TOLEDO

Print

Select 2

On/Off

STD 10.1.11

TYPE : MT 5

1.00.00

= STORED SETTINGS =

-SCALEASD

d (Step)

dF (Step)

AutoZero

Cal

-UNITUnit 1

Unit 2

Symbols

Sound

: 3

: 1

: 1

: on

: auto on

: mg

: ug

: auto

: on

Proceed as follows for the printout:

- Select the configuration register.

- Press the «Print» key, and the current configuration will be printed out.

A further tip: Always print out your

specific configuration. You thus

have a record of your settings and

even if you return to the factory settings, you can restore your configuration at any time.

-INTERFACESend Mode

Baudrate

Parity

Handshake

Line End

===================

37

: stb

: 2400

: even

: Pause

: CRLF

Page 40

38

4.8 How to protect your settings against inadvertent change

As you know, with one press of the

«Set» key your individual settings in

the configuration register are stored.

These are available at any time (even

if the balance has since been disconnected from the power supply).

You are not, however, protected

against inadvertent alterations, for

instance by other balance users.

To safeguard the settings, proceed as

follows:

- Grasp the bracket of program cassette 8 and withdraw this carefully

from the plug-in slot 6.

- Remove the jumper with a thin pin

or a needle from the contact pins.

- Disconnect the cable of the AC

adapter from the receptacle.

- Remove the cover of the plug-in slot

6 at the rear of your balance.

Operating instructions METTLER TOLEDO MT/UMT balances

unprotected

protected

- If you wish to protect your individual

settings in the configuration register

against inadvertent changes, place

the jumper across both contact pins.

Page 41

Operating instructions METTLER TOLEDO MT/UMT balances

- Slide the program cassette 8 into

the plug-in slot 6 up to the stop and

replace the cover. Plug the cable of

the AC adapter into the receptacle.

If you have secured your settings,

the configuration register is no

longer accessible and alterations are

no longer possible.

- To remove the safeguard, proceed

in the reverse sequence.

5 Special applications and functions of

your balance

Your balance is also prepared in the

best possible way for special cases.

Applications and functions built in as

standard expand the possibilities of

your balance and facilitate the operation. The following section familiarizes

you with these applications and functions.

5.1 Your balance can work with two weight units

39

With your balance you can toggle between two preselected weight units at

any time. Section 4.5 of these operating instructions shows you how to select and store these two weight units in

the configuration register.

Page 42

40

68.432 µ

METTLER TOLEDO

Print

Select 2

On/Off

You have, for example, selected “mg”

as weight unit 1 and “ct” as weight unit

2 in the configuration register. You can

switch between these two units at a

keystroke:

The balance is operating with weight

unit 1.

- Press key “ briefly and ...

5.2 Your balance also works with percentages and shows plus/minus deviations

This built-in application allows you to

weigh in to a preset value (100%) and

to determine deviations from a target

value.

So that this application appears in the

menu, you must set the unit to percent

(%) under the parameter “Weight

unit 2” (

(

Unit

ter as described in Section 4.5.

Unit 2

) in the “Weight units”

) sector of the configuration regis-

0.3422617

- ...the balance now works with

t

c

weight unit 2. By pressing the “

key again, you can return to weight

unit 1.

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

- Press the «Menu» key briefly and

µ

the balance prompts you to load the

reference weight.

Pro

FACT

Max 5,1 g d = 1 µg

The table in section 7.6 shows you the

conversion factors between the various

weight units.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 43

Operating instructions METTLER TOLEDO MT/UMT balances

SEt 100 %

Note: This request appears only if

weight unit 2 is set to percent (%).

- Open the draft shield and load the

reference weight.

- Press the «Set» key and the draft

shield closes automatically if the automatic door function is switched on.

If not, close the draft shield manually or by pressing one of the two

keys or and then press key

«Set».

-2.5% 100% +2.5%

- As soon as the horizontal dashes

disappear, the reference weight has

been read in and your balance is

ready for weighing. If the automatic

door function is switched on, the

draft shield opens automatically on

completion of the weighing process.

If not, open it yourself. Remove the

reference weight.

The DeltaTrac® now shows a plus and

a minus marking that displays the tolerance limits of plus and minus 2.5%.

Now first weigh in coarsely:

- Place the empty container on the

pan and set the balance to zero (taring).

------

As long as the horizontal dashes are

displayed, your balance is weighing the

reference weight.

41

Page 44

42

67.40 %

coarse indicator

98.70 %

100.00 %

fine indicator

- Add the weighing sample at a

steady rate to the container until the

coarse indicator on the DeltaTrac®

is pointing vertically downward.

This shows that the approximate

target weight has now been

reached.

Now perform the fine weighing:

- After the coarse weighing in, you

now add the weighing sample carefully until the fine indicator on the

DeltaTrac® is pointing vertically

upward.

- When the fine and the coarse pointers form a vertical line, the set

weight is within ±0.25% of the target.

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

5.3 Do you wish to count pieces?

First your balance needs to know that

you wish to perform piece counting.

You make this setting in the third sector

of the configuration register (

where you set weight unit 2 (

“

PCS

” (English) or “

Stk

This setting is described in Section 4.5.

Pro

FACT

- Open the draft shield manually or by

pressing one of the two keys or .

Unit

),

Unit 2

” (German).

) to

You also have a fine range available in

the weight unit %, in which additional

decimal places are displayed.

With the “ key you can display either

the percentage or the weight (see

also Section 5.1).

Operating instructions METTLER TOLEDO MT/UMT balances

- If you wish to count into a con-

tainer, load the empty container.

Page 45

Operating instructions METTLER TOLEDO MT/UMT balances

MT5

Cancel

µ

10/1 g

Configuration

Menu

Set Re-Zero On/Off

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Configuration

Menu

Select 1

Set

Pro

FACT

METTLER TOLEDO

Pro

FACT

Max 5,1 g d = 1 µg

- If you wish to count out of a container, load the full container.

- Set the scale to zero (taring).

Print

Select 2Select 1

- Your balance now needs the weight

of a reference piece number.

Press the «Menu» key briefly.

Pro

FACT

Max 5,1 g d = 1 µg

MT5

Cancel

µ

10/1 g

Configuration

Menu

Select 1

Set

SEt 10

SEt 20

SEt 50

SEt 100

Pcs

Pcs

Pcs

- Select the desired reference piece

number with the «Select 1» key.

The following piece numbers are

available:

10 20 50 100

Note: We advise you to select a

reference piece number as large as

possible since your balance determines the average weight per piece.

Since it is seldom the case that all

pieces are equally heavy, the reference weight that is stored is naturally more accurate the greater the

reference piece number.

Pcs

SEt 10

Pcs

Note: This menu selection appears

only when weight unit 2 is set to

piece (

PCS

or

Stk

).

- If you wish to count into a container, add the selected number of

pieces (reference piece number) of

the weighing sample to the container.

43

Page 46

44

- - - - - -

- If you wish to count out of a container, remove the selected number

of pieces from the container.

- Press the «Set» key, and the draft

shield closes automatically if the

automatic door function is switched

on. If not, close the draft shield

manually or by pressing the or

key and then press the «Set» key.

As long as the horizontal dashes are

displayed, your balance is weighing the

reference weight.

- As soon as the horizontal dashes

disappear, the reference piece

number and the reference weight

have been read in and your balance

is ready for counting or weighing.

+67

-24

Pcs

Pcs

If the automatic door function is

switched on, the draft shield opens

automatically on completion of the

weighing-in process. If not, open it

yourself.

Depending on how you have weighed

in the reference weight, you can now:

- Count into the container with dis-

play of the total number of pieces in

the container or...

- ...count out of the container with

display of the number of pieces removed from the container.

You can use the “ key to display ei-

ther the piece number or the weight

(see also section 5.1).

Operating instructions METTLER TOLEDO MT/UMT balances

Page 47

Operating instructions METTLER TOLEDO MT/UMT balances

AUTOCALIN

0.367

5.4 How to trigger the adjustment manually

In the factory the balance is preset to

proFACT. The MT/UMT balance adjusts and linearizes itself as soon as a

change in the ambient conditions

makes this necessary. You thus need

not concern yourself with the adjustment. But you also have the possibility

to trigger the motorized adjustment with

the internal adjustment weights at all

times at a keystroke. This can be practical if the audio warning beep sounds

during a weighing and the adjacent

symbol appears in the display. This is

how your balance shows you that it

would like to adjust itself. You can now

either interrupt your work at the next

convenient opportunity for about 5 minutes, when the balance will adjust itself,

or you yourself can trigger the motorized adjustment by pressing a key.

CALIN

Auto off

CAL

USEr

You select the adjustment mode in sector 2 (

SCALE

) of the configuration register (see Section 4.4). In addition to

the fully automatic self-adjustment,

you have two further adjustment possibilities available:

- You trigger the automatic adjust-

ment with the internal adjustment

weights, with simultaneous auto-

matic linearization of the measuring

range at a keystroke.

- The manual adjustment with an

external adjustment weight, without linearization of the measuring

range.

If you have switched off the automatic

self-adjustment, you should adjust the

balance occasionally.

45

Page 48

46

AUTOCALIN

CAL Int

Automatic adjustment with the internal adjustment weights at a keystroke

You have this adjustment mode available if you have set the parameter

“adjustment and linearization” in sector 2 of the configuration register (basic

settings) either to

CALIN Auto oFF

CALIN Auto on

.

or

- Repeatedly press the «Menu» key

briefly until the adjacent display

appears.

CAL End

0.000 mg

- You can follow the adjustment and

linearization procedure in the

numerical display and on the

DeltaTrac®, and you also hear

when the internal weights are

loaded.

Completion of the adjustment and

linearization process is displayed

briefly,...

...the audio warning beep sounds and

the balance returns to the weighing

mode.

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

Pro

FACT

- Trigger the adjustment procedure by

pressing the «Set» key. The draft

shield now closes automatically if

the automatic door function is

switched on. If not, close the draft

shield manually or by pressing the

or key.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 49

Operating instructions METTLER TOLEDO MT/UMT balances

CAL USEr

Manual adjustment with an external

adjustment weight

You wish to use your own external adjustment weight for the adjustment and

have set the parameter proFACT (adjustment and linearization) to

CAL USEr

in sector 2 of the configuration register (basic settings). In this

mode, the automatic adjustment with

the built-in adjustment weights is

switched off.

- Repeatedly press the «Menu» key

briefly until the adjacent display

appears.

CALIN

5.000000

5

g

CALIN

0.000000

After a short time, the audio warning

beep sounds and the requested,

model-dependent adjustment weight

appears in the display (for example, 5 g

in the MT5 case).

- Open the draft shield, load the

requested adjustment weight and

close the draft shield.

- Wait until the audio warning beep

sounds. The display now requests

the removal of the adjustment

weight.

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

- Open the draft shield, remove the

adjustment weight and close the

Pro

FACT

- Trigger the adjustment procedure by

5

g

draft shield.

pressing the «Set» key. The draft

shield now closes automatically if

the automatic door function is

switched on. If not, close the draft

shield manually or by pressing the

or key.

0.000000

As soon as the audio warning beep is

heard and the adjacent display appears, the adjustment is finished and

your balance is again in the weighing

mode.

47

Page 50

48

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

Set

µ

Max 5,1 g d = 1 µg

5.5 How to check whether

the balance is still ad-

Note:

This display does not appear if you

have set the parameter “adjustment

justed correctly

and linearization” to

CAL USEr

in

the configuration register (adjust-

In the factory, the balance is set to

proFACT, professional fully automatic

adjustment and linearization technol-

ment with your own external adjustment weight). Please also see the

note at the end of this section.

ogy. A check of the adjustment is not

necessary in this mode. If you have selected the automatic adjustment mode

with manual triggering (

oFF

) in sector 2 of the configuration

CALIN Auto

CAL tESt

- Select the adjustment test by pressing the «Select 1» key.

register (see Section 4.4), it is advisable to check the adjustment with the

internal adjustment weights occasionally.

Pro

FACT

MT5

Cancel

10/1 g

Configuration

Menu

Select 1

- Select the menu by pressing the

«Menu» key briefly.

Pro

FACT

Max 5,1 g d = 1 µg

µ

- Start the test by pressing the «Set»

key. If the fully automatic door function is switched on, the draft shield

Set

now closes automatically. If not, you

first close the draft shield manually

or by pressing the or key and

then the «Set» key.

AUTOCALIN

CAL Int

- Repeatedly press the «Menu» key

briefly until the adjacent display

appears.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 51

Operating instructions METTLER TOLEDO MT/UMT balances

5.000001

5.000000

The internal weights are now loaded,

without the balance being adjusted,

and the current, model-dependent adjustment value displayed, interrupted

by the display

tESt

.

- When you have read off the value,

abort the test by pressing the «Set»

or «Cancel» key. The balance is

then again in the weighing mode.

Notes:

If the deviation of the adjustment

weight is more than ±0.00015% (1.5

ppm) from the full load, the balance

should be adjusted (see Section 5.4).

If you work with your own, external adjustment weights (parameter “adjustment and linearization” set to

USEr

in the configuration register), you

CAL

can check the adjustment of the balance by loading your own, external adjustment weights.

METTLER TOLEDO

Print

Select 2

On/Off

5.6 How to print out the weighing result

You can output the weighing result via

the interface connection 4 on a printer.

If you wish to attach a third-party

printer, you match the parameters of

the data interface to the specifications

in the printer handbook (see Section 4.6). You will find further details in

the instructions “Bidirectional interface

of the METTLER TOLEDO AT/MT/UMT

balances”, which is also enclosed.

- In the weighing mode press the

«Print» key briefly.

49

Page 52

50

5.346 mg

5.346 mg

- As soon as the result is stable, it is

transferred via the interface connection 4 to the printer. Up to the transmission, the triangle symbol is lit up

in the display. If the transmission

has not yet taken place, you can

abort the procedure by pressing the

«Print» key again briefly.

After the transmission, the result is

kept for about 5 seconds in the display for checking purposes, and a

ring symbol flashes at the upper

right.

- Notes:

The type of transmission depends

on the selected data transmission

mode, which you have set in the

fourth sector of the configuration

register (see Section 4.6). If you

have selected the

mode and the automatic door function is switched on, the draft shield

is closed, the result transmitted and

S.Stb

or

S.Auto

then the draft shield opened again.

If not, you close the draft shield

manually or by pressing the or

key.

- The transmission command can

also be triggered with the hand or

foot switch (available as an accessory).

5.7 You can also operate

your balance by remote

control

The complete operation (keypad and

draft shield) as well as the menu and

the configuration register of your balance can also be controlled via a com-

puter. This allows you to incorporate

your balance in an automation system

and, for instance, is also suitable for

loading by a robot.

Operating instructions METTLER TOLEDO MT/UMT balances

Page 53

Operating instructions METTLER TOLEDO MT/UMT balances

The draft shield, the zeroing (taring) of

the balance and the print command can