Page 1

Part No. 84401

2000 Two-Channel Instrument

for pH, ORP, Conductivity, Resistivity,

Dissolved Oxygen, Dissolved Ozone

Instruction Manual

Page 2

IMPORTANT SAFETY INFORMATION

• Follow all warnings, cautions, and instructions indicated on and supplied with this product.

• Install equipment as specified in this instruction manual. Follow appropriate local and national

codes.

• Use only factory documented components for repair. Tampering or unauthorized substitution of

parts and procedures can affect the performance and cause unsafe operation of your process.

• Protective covers must be in place unless qualified personnel are performing maintenance.

• If this equipment is used in a manner not specified by the manufacturer, the protection provided by

it against hazards may be impaired.

WARNINGS:

• Installation of cable connections and servicing of this product require access to shock hazard

voltage levels.

• Main power and relay contacts wired to separate power source must be disconnected before

servicing.

• Main power must employ a switch or circuit breaker as the disconnecting device for the equipment.

• Electrical installation must be in accordance with the National Electrical Code and/or any other

applicable national or local codes.

• Safety and performance require that this instrument be connected and properly grounded through

a three-wire power source.

• RELAY CONTROL ACTION: the 2000 instrument relays will always de-energize on loss of power,

equivalent to normal state, regardless of relay state setting for powered operation. Configure any

control system using these relays with fail-safe logic accordingly.

• PROCESS UPSETS: Because process and safety conditions may depend on consistent operation

of this instrument, provide appropriate means to maintain operation during sensor cleaning,

replacement or sensor or instrument calibration.

This manual includes specific safety information with the following designations and formats:

WARNING: OF POTENTIAL FOR PERSONAL INJURY.

CAUTION: of possible instrument damage or malfunction.

NOTE: important operating information.

On the instrument indicates: Caution, risk of electric shock

On the instrument indicates: Caution (refer to accompanying documents)

Page 3

TABLE OF CONTENTS

Chapter 1: Getting Started............................................................................................ 1

Introduction..................................................................................................................1

Features ...................................................................................................................... 1

Overview of Operation................................................................................................. 1

Installation & Setup Procedure....................................................................................2

Chapter 2: Installing the 2000 ...................................................................................... 3

Unpacking.................................................................................................................... 3

Installation ...................................................................................................................3

Electrical Connections.................................................................................................3

Chapter 3: Using the 2000............................................................................................ 7

Applying Power to the 2000......................................................................................... 7

The Display.................................................................................................................. 7

The Keypad................................................................................................................. 8

Using the Menus.......................................................................................................... 9

Installing a Sensor..................................................................................................... 10

Measurement Designations.......................................................................................10

Displaying Measurements ......................................................................................... 10

Alarm Indications.......................................................................................................12

Chapter 4: Making Measurements............................................................................. 13

Measurement Process ............................................................................................... 13

Measurement Types.................................................................................................. 13

Selecting a Measurement Type.................................................................................17

Cell Constants........................................................................................................... 17

Conductivity Temperature Compensation.................................................................. 18

pH/ORP Temperature Compensation ........................................................................ 19

Dissolved Oxygen Temp and Pressure Compensation. ............................................ 20

AC Power Frequency.................................................................................................20

Chapter 5: Using Setpoints ........................................................................................ 21

Overview.................................................................................................................... 21

Setpoint Signal .......................................................................................................... 21

Setpoint Value........................................................................................................... 21

Setpoint State............................................................................................................21

Assigned Relay.......................................................................................................... 22

Programming a Setpoint............................................................................................ 22

USP & EP Setpoints.................................................................................................. 23

Page 4

Chapter 6: Using Relays.............................................................................................24

Description................................................................................................................. 24

Electrical Connections............................................................................................... 24

Delay Time ................................................................................................................ 24

Hysteresis.................................................................................................................. 24

Relay State................................................................................................................24

Programming a Relay................................................................................................ 24

Chapter 7: Using Analog Outputs .............................................................................. 27

Description................................................................................................................. 27

Programming the Analog Outputs ............................................................................. 27

Analog Output Calibration.......................................................................................... 29

Chapter 8: Meter Calibration...................................................................................... 30

Overview.................................................................................................................... 30

Calibration Verification...............................................................................................30

Calibration Procedure................................................................................................ 31

Chapter 9: Sensor Calibration.................................................................................... 34

Conductivity/Resistivity Cell Constants......................................................................34

Conductivity/Resistivity Sensor Calibration................................................................ 34

pH/ORP Sensor Calibration....................................................................................... 36

pH Sensor Diagnostics.............................................................................................. 38

Dissolved Oxygen Sensor Calibration ....................................................................... 38

Dissolved Ozone Sensor Calibration......................................................................... 42

Chapter 10: Security/Lockout.....................................................................................44

Security Features ...................................................................................................... 44

Changing the Password............................................................................................. 44

Enabling the Lockout................................................................................................. 44

Accessing a Locked Menu......................................................................................... 44

Chapter 11: Other Functions...................................................................................... 46

Averaging .................................................................................................................. 46

System Reset............................................................................................................ 46

Setting the Temperature Source................................................................................ 47

Sending Data to a Printer or Computer ..................................................................... 47

Chapter 12: Troubleshooting ..................................................................................... 49

Off-Line Self-Diagnostics...........................................................................................49

On-Line Diagnostics ................................................................................................. 49

Troubleshooting......................................................................................................... 50

Recovery Procedure ................................................................................................. 50

Chapter 13: Service..................................................................................................... 51

Fuse Replacement .................................................................................................... 51

Reducing 2000 Patch Cord Length............................................................................ 51

Recommended Spare Parts List................................................................................ 52

Accessories............................................................................................................... 52

Chapter 14: Technical Illustrations............................................................................ 53

Menu Trees ............................................................................................................... 54

Overall Dimensions.................................................................................................... 57

Panel Cutout.............................................................................................................. 58

Exploded Assembly................................................................................................... 58

Pipe Mounting............................................................................................................ 59

Page 5

Sealed Back Cover Assembly ................................................................................... 59

Printed Circuit Board Layout...................................................................................... 60

Rear Panel Wiring and Patch Cords.......................................................................... 61

Conductivity Calibrators.............................................................................................62

Meter Calibration Connections .................................................................................. 62

SPECIFICATIONS........................................................................................................ 63

RATINGS......................................................................................................................65

WARRANTY ................................................................................................................. 66

Page 6

Page 7

CHAPTER 1: GETTING STARTED

Setpoints (alarms): 4 independent alarms

INTRODUCTION

The 2000 is an analytical and process control

instrument for measuring solution properties. It

can process two sensor inputs for pH, ORP

(redox potential), conductivity or resistivity, or one

sensor input for dissolved oxygen or dissolved

ozone, in all combinations except for ozone and

four-electrode conductivity. A liquid crystal display

conveys measuring data and setup information.

The display is backlit for viewing in all lighting

conditions. The menu structure allows the

operator to modify all operational parameters by

using keys on the front panel. A menu-lockout

feature, with password protection, is available to

prevent the unauthorized use of the meter. The

2000 can have up to four relays for process

control.

The 2000 instrument is equipped with a

communication interface that can be configured

as either an RS422 or an RS232. This interface

provides real-time data output and complete

instrument configuration capabilities for central

monitoring via personal computer or

Programmable Logic Controller (PLC). An

external isolator for the digital communications

signal is required if measurements other than

conductivity with 0.1/cm cell constants are being

made. For coverage of communications, see

Manual 84423.

FEATURES

Display: 16 character backlit LCD.

Measurements: pH, ORP (redox potential),

resistivity, conductivity, dissolved oxygen,

dissolved ozone, °C, °F, total dissolved solids,

%rejection, difference, ratio, %HCl, %NaOH,

%H2SO4.

Measurement Channels: 2.

Signal Inputs per channel: 2 (total of 4 signals

for measurement).

Measurement Cycle Time: 1 second (4

measurements processed per second).

Programmable: all setup information is stored in

non-volatile memory.

programmable as high, low, USP, or EP limits.

Relays: up to 4 with programmable delay time

and hysteresis.

Outputs: 2 analog outputs (0/4-20mA).

Communications: RS232/RS422 interface, bi-

directional; external isolator recommended with

measurements other than conductivity with

0.1/cm cell constants.

Security: keypad lockout with password.

Calibration: complete instrument, output, and

sensor calibration; can be NIST traceable.

Built-In Diagnostics: several self tests can be

initiated at any time.

OVERVIEW OF OPERATION

When power is applied to the 2000, the

initialization process begins. The instrument will

perform a number of self tests. Any problems

detected during these tests will be reported by a

displayed message.

Next, all setup parameters (setpoints, states,

relay conditions, etc.) are restored from a nonvolatile memory.

The meter will then begin the measurement

process. A complete measurement cycle is

performed once per second and consists of the

following:

1. Measure four signals and compute four

measurements.

2. Check setpoints against the measurements.

3. Control the relays.

4. Update analog output signals.

5. Transmit measurement data over the

communication port.

6. Display data (if not displaying a menu).

At any time during this process the menus can be

accessed by pressing one of the menu keys. The

display of a menu will not affect the measurement

process.

Chapter 1 Getting Started 1

Page 8

INSTALLATION & SET UP

PROCEDURE

The following guideline shows the steps

necessary to install a 2000 meter and begin

operation.

1. Follow the meter installation procedure for

physically mounting the meter, as outlined in

Chapter 2. The meter may be mounted in a

panel, on a pipe, or on a wall.

Optional: the rear cover is required for wall

and pipe mounting. Drill holes as needed for

conduit or cable grips, install the cover and

wire the meter before wall or pipe mounting.

2. Make all necessary electrical connections to

the meter after panel mounting. The wiring

procedure is outlined in Chapter 2.

3. Required wiring: input power and sensor

cables.

CAUTION: Be certain that patch cord is wired

specifically for the type of sensor to be

connected or damage could result.

12. Optional: program the relays as shown in

Chapter 6.

13. Optional: program other features such as

averaging method, special temperature

compensation, security/password, etc, as

needed.

4. Optional wiring: relays, analog outputs, and

serial port.

5. Set appropriate input line frequency to

reduce measurement noise. See AC

POWER FREQUENCY in Chapter 4.

6. Instrument calibration is performed at the

factory to specifications. Re-calibration is not

necessary. If QA/QC practice requires it,

meter calibration may be verified as outlined

in Chapter 8.

7. Connect sensors to the patch cords.

8. Select the desired measurements for each

sensor as shown in SELECTING A

MEASUREMENT TYPE in Chapter 4.

9. Enter sensor constants from the label of

each cell as outlined in ENTERING/EDITING

CELL CONSTANTS in Chapter 9. DO NOT

PERFORM A SENSOR CALIBRATION

except for pH, dissolved oxygen or ozone.

10. Optional: program the analog outputs as

shown in Chapter 7. DO NOT

AN OUTPUT CALIBRATION.

PERFORM

11. Optional: program the setpoints as shown in

Chapter 5.

2 Getting Started Chapter 1

Page 9

CHAPTER 2: INSTALLING THE 2000

UNPACKING

Each 2000 is packed in an individual

biodegradable carton. Retain the packaging in the

event that the instrument must be returned to

Thornton for service or calibration.

This carton should contain:

1 - 2000 Instrument

1 - Set of panel mounting hardware with

gasket

1 - 02192 kit of 2 ferrite bead noise

suppression modules

1 - 84401 Instruction Manual

1 - 84402 Startup Instruction Sheet

1 - Certificate of Calibration

INSTALLATION

The 2000 can be mounted in a panel, on a pipe

or attached to a wall.

Panel Mounting Cutout

and Installation

The panel cutout should measure 7.56 inches

wide by 3.780 inches high (192 mm X 96 mm).

Drill four holes for the #10 mounting screws. See

Figure 14.3 for panel cutout size and mounting

screw hole spacing. When mounting multiple

instruments on the same panel, note the front

flange dimensions in Figure 14.2 in order to allow

enough space between instruments.

Panel cutouts should be clean and free of burrs

and sharp edges. The proper dimensions allow

an instrument to slide freely into the cutout.

Install the panel gasket (supplied with instrument)

on the instrument mounting flange. Slide the

instrument into the cutout and secure it with the

mounting screws.

CAUTION: Do not over tighten the screws as

this may crack the case.

If the rear cover is used in a panel mounted

installation, the 2000 unit must be installed in the

panel opening before the rear cover is installed.

Wall Mounting

The 2000 can be easily mounted to a wall when

the rear cover is installed. The flanges on the

ends of the cover contain holes for screws to

fasten the assembly to the wall. A layout for

drilling mounting holes is included in the wall

mount kit.

Pipe Mounting

The 2000 can be mounted to a pipe with the pipe

mounting accessory kit. The assembly is shown

in Figure 14.5.

ELECTRICAL

CONNECTIONS

All electrical connections are made at plug-in

terminal blocks at the rear of the 2000 case.

WARNING: MAKE SURE POWER TO ALL

WIRES IS TURNED OFF BEFORE PROCEEDING WITH THE INSTALLATION. HIGH

VOLTAGE MAY BE PRESENT ON THE INPUT

POWER WIRES AND RELAY WIRES.

CAUTION: A good power earth ground

connection is required for safety and for

proper operation of the instrument. To prevent

electrostatic discharge (ESD) from damaging

the instrument during installation, the installer

must also be electrically grounded i.e., wear a

conductive wrist strap connected to earth

ground.

Do not run power and relay wiring in the same

conduit or parallel with sensor and output

signal wiring to prevent interference.

Input Power and Relay Connections

Terminal block TB1 contains connections for the

input line power and relay contacts. Depending

upon the model number, the 2000 will have either

2 or 4 relays. Table 2.1 shows the wiring

sequence.

All relays have “dry contacts”; they are potentialfree and require external power to be wired in

series with the load and instrument terminals.

Relays 3 and 4, if specified, are solid state AC-

Chapter 2 Installation 3

Page 10

only relays (triacs) and require a minimum current

of 10 mA to switch reliably. With very small loads

such as a neon bulb, test meter or PLC, a load

resistor is required in parallel with the load, e.g. a

10K ohm, 2 watt resistor, for operation with 115

VAC.

WARNING: IF THE INPUT VOLTAGE

JUMPERS ARE CHANGED YOU MUST LABEL

THE UNIT WITH THE NEW VOLTAGE

REQUIREMENT. ALSO, THE FUSE MUST BE

CHANGED TO THE PROPER RATING TO

AVOID RISK OF FIRE HAZARD

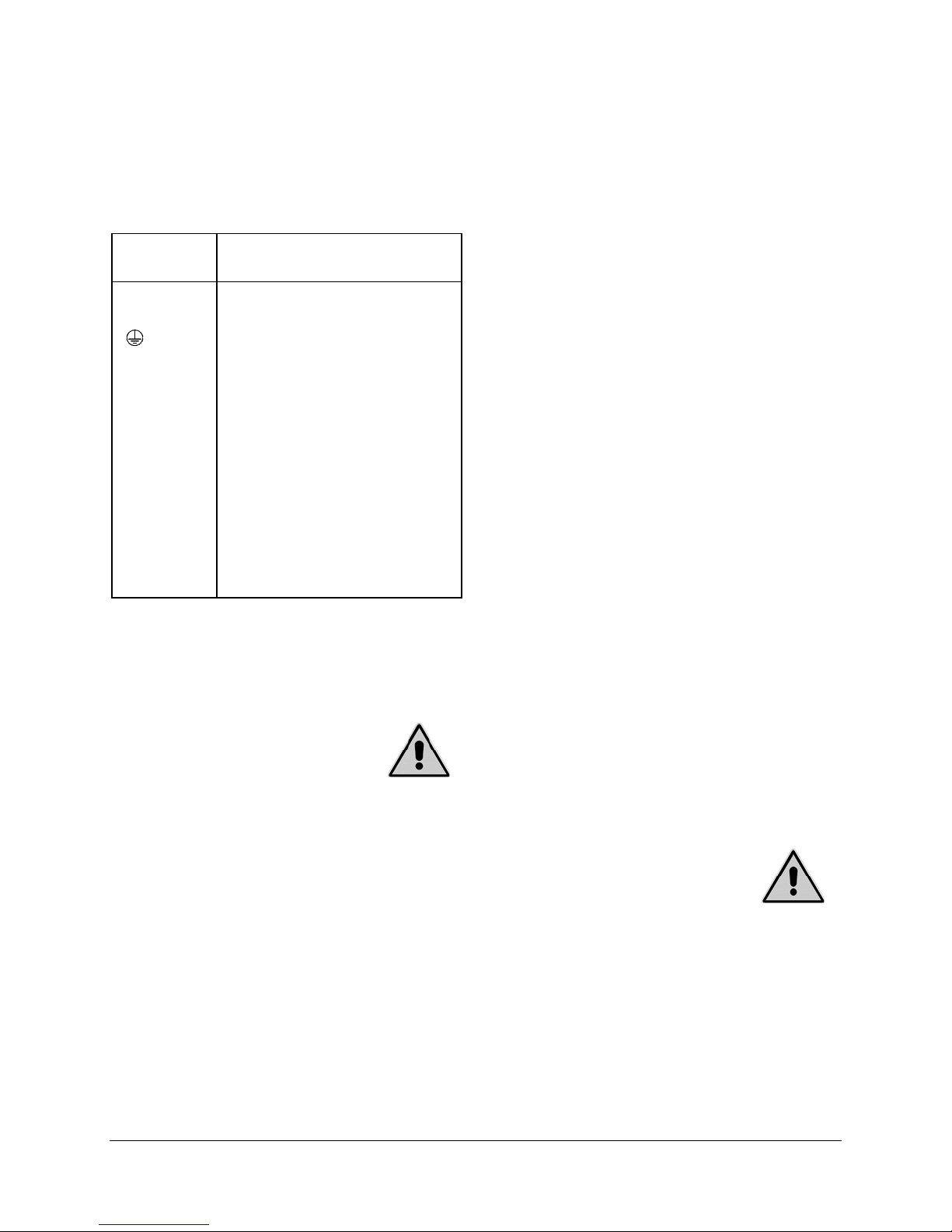

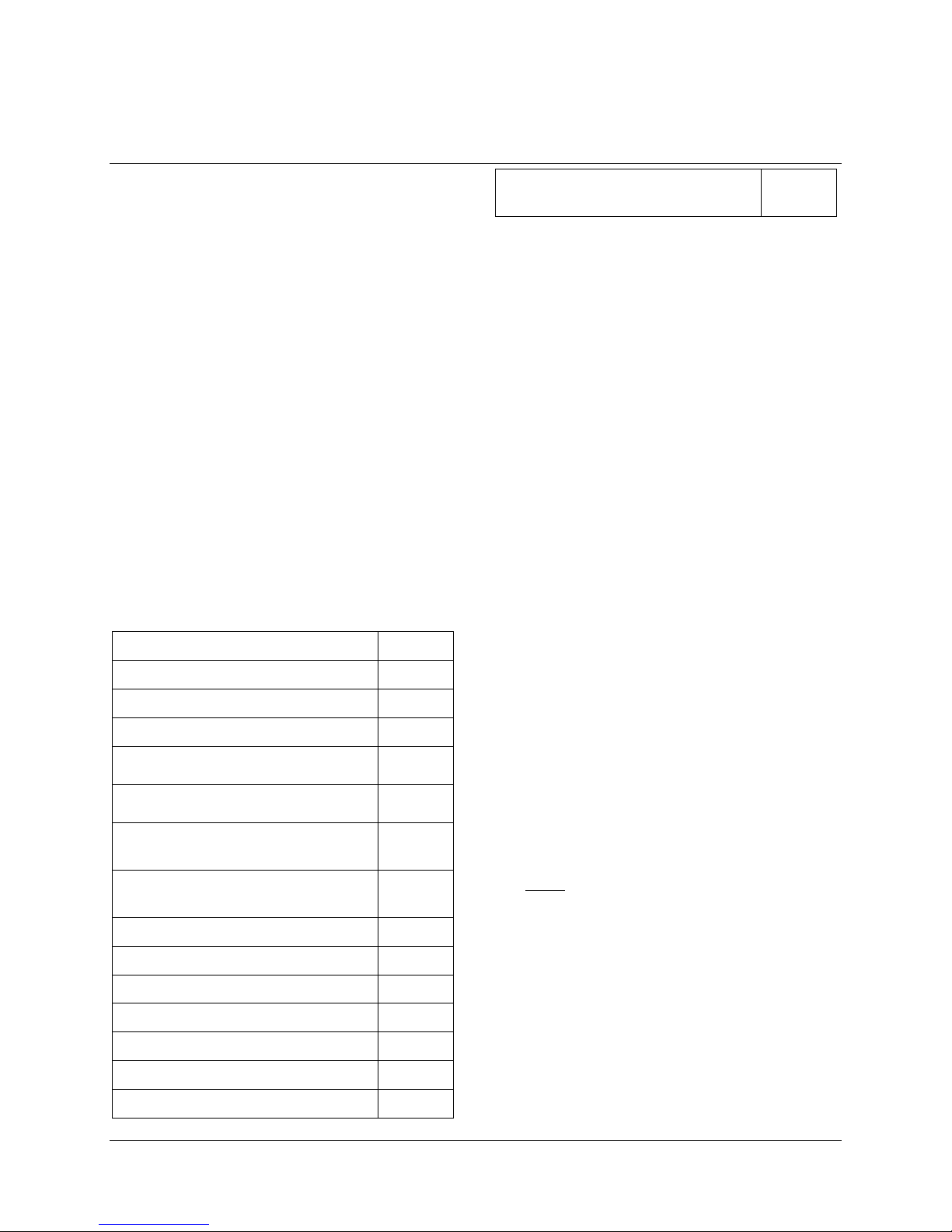

TB1

Label

Input Power & Relay

Function

L 115V/230 VAC Line

N 115V/230 VAC Neutral

Earth Ground

NC1 Relay1: Normally Closed

C1 Relay1: Common

NO1 Relay1: Normally Open

NC2 Relay 2: Normally Closed

C2 Relay 2: Common

NO2 Relay 2: Normally Open

C3 Relay 3: Common

NO3 Relay 3: Normally Open

C4 Relay 4: Common

NO4 Relay 4: Normally Open

Table 2.1: Input Power & Relay Connections

WARNING: MISWIRING THE AC POWER MAY

DAMAGE THE INSTRUMENT AND WILL VOID

ALL WARRANTIES.

Setting Input Voltage

for 115 VAC or 230 VAC

The input voltage for a 2000 can be set for either

90-130 VAC or 180-250 VAC operation. The input

voltage is preset at the factory and is indicated on

the serial number label on the side of the unit.

Jumpers on the printed circuit board can be

changed to change the input voltage. See Figure

14.7. W4 jumper pins are located between the

power transformer and the fuse. For 90-130 VAC

operation jumper pins 1-2 and 3-4 must be used.

For 180-250 VAC operation only a jumper on pins

2-3 must be installed. The jumpers can be

accessed by removing two screws from the back

panel and carefully lifting the panel off.

Fuse requirements:

For 90-130 VAC: 1/8 Amp, SB, 250 VAC

For 180-250 VAC: 1/16 Amp, SB, 250 VAC

NOTE: If the line power frequency is changed,

select the correct setting (see AC POWER

FREQUENCY in Chapter 4).

Setting Input Voltage for 24 VDC

The 2000 can be operated from a +24 VDC

power supply instead of the typical 90-130 VAC

or 180-250 VAC source.

NOTE: 24 VDC power supply must be isolated

from earth ground and between instruments. Use

a DC/DC power isolator if necessary.

Remove any AC power connections from terminal

block TB1.

1. Move circuit board jumper W6 to the 24V

position (left two pins) as shown in Figure

14.7.

2. Connect + 24V DC power to the connection

labeled PS+ on terminal block TB3. Connect

the power supply ground to the connection

labeled PS- on TB3.

WARNING: AC POWER CONNECTIONS MUST

BE REMOVED WHEN USING THE +24V

POWER INPUT.

NOTE: The +24 VDC input is not fused within the

meter. Use an external fuse.

AC Power Wiring

In order to maintain safety for the electrical

installation, no more than 6 mm of insulation is to

be removed from each conductor before fully

inserting into the electrical terminal.

The plug-in terminal blocks for all connections

will accept wire sizes from 26 AWG (0.126 mm

to 14 AWG (2.08 mm

to 12 AWG (3.31 mm

2

), solid or stranded and up

2

) stranded only.

2

)

4 Installation Chapter 2

Page 11

Output Connections

Connections for all outputs are made to terminal

block TB4. The serial port can be configured as

an RS232 port (shown in Table 2.2.) or an RS422

port (shown in Table 2.3). An external isolator for

digital communications is strongly recommended

to prevent ground loop problems.

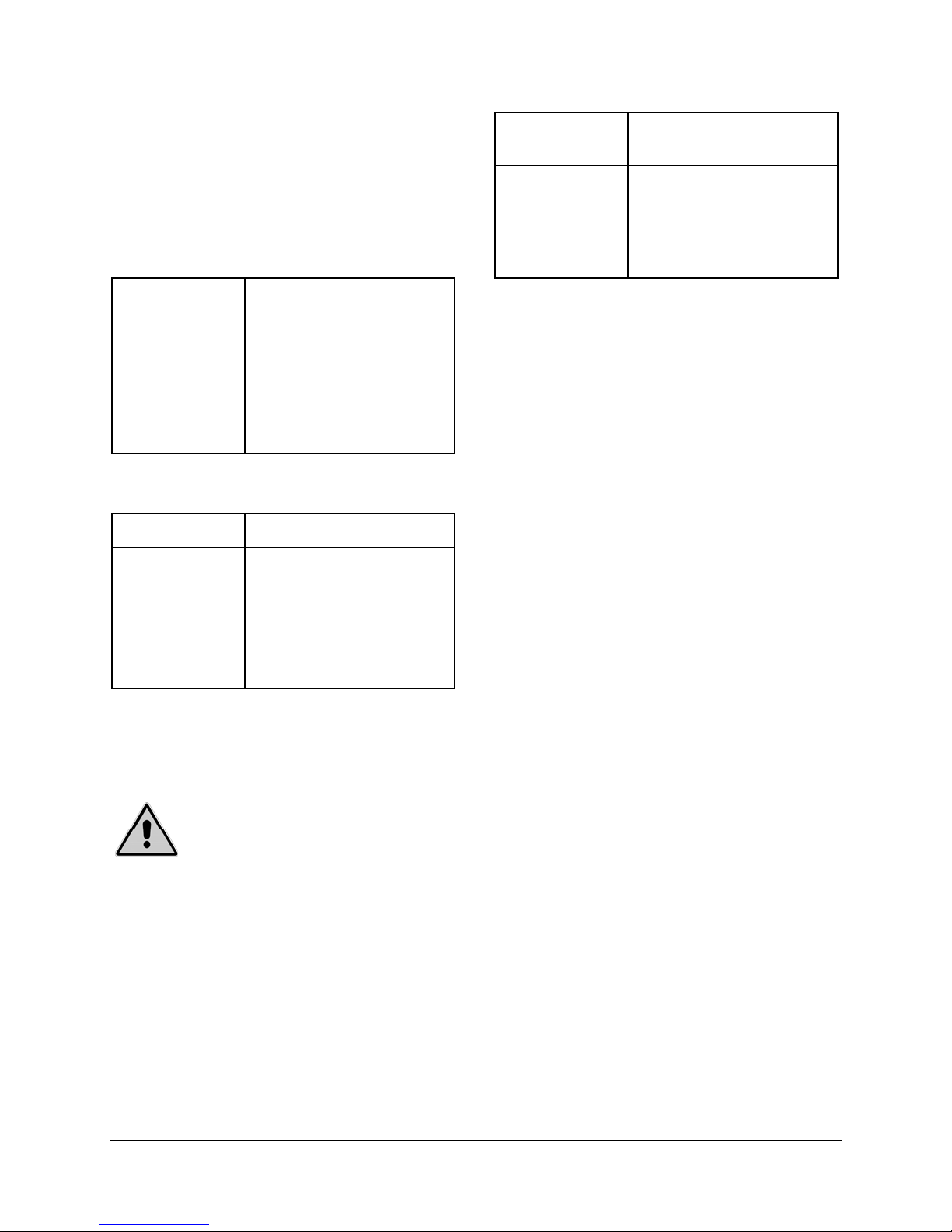

TB2

Label

AO2- Output 2 (-)

AO2+ Output 2 (+)

AO1- Output 1 (-)

AO1+ Output 1 (+)

Analog Output

Function

TB2 Label RS232 Function

DGND Ground

TXD+ Not Used

TXD- Transmit Data

RXD+ Not Used

RXD- Receive Data

Table 2.2: RS232 Connections

TB2 Label RS422 Function

DGND Ground

TXD+ Transmit Data Positive

TXD- Transmit Data Negative

RXD+ Receive Data Positive

RXD- Receive Data Negative

Table 2.3: RS422 Connections

Each analog output has + and – connections.

Analog outputs are self-powered with a maximum

load resistance of 500 ohms.

CAUTION: Do not connect analog outputs to

circuits supplying power.

CAUTION: Do not connect analog output

cable shield(s) to the adjacent DGND

terminals. Connect shield(s) only to one of the

earth ground terminals next to AC line power.

Table 2.4: Analog Output Connections

Sensor Patch Cord Connections

The sensors are connected to plug-in terminal

blocks TB2 and TB3. Each channel has nine

terminals for the sensors plus earth ground.

Patch cords, 1XXX-67 or 58 080 20X series, for

the 2000 have a connector on one end and tinned

leads on the other end. Table 2.5. shows the

wiring pattern for each type of sensor.

CAUTION: Wiring for each type of sensor is

different. Miswiring patch cords may damage

sensors and will void all warranties. Verify

wire colors in table 2.5. Disconnect power

before wiring sensors to prevent damage to

the input circuit.

If sensors other than conductivity must be

wired with the instrument powered, make the

PS- connection first to prevent damage to the

input circuit.

To meet CE electromagnetic compatibility

requirements for emissions Class B, install a

ferrite suppression module from kit 02192 on

each sensor patch cord as close to the instrument

as possible.

NOTE: For ultrapure water conductivity

measurements with all-plastic piping, especially

semiconductor wet benches, it is recommended

to connect a jumper from one of the three earth

ground terminals to sensor ground terminal

SIG6(6) on TB3 for Channel A. This will prevent

possible instrument damage due to electrostatic

charges that build up in plastic piping systems.

Do not use a ground jumper with higher

conductivity water, with metal piping or with pH or

ORP measurements.

Chapter 2 Installation 5

Page 12

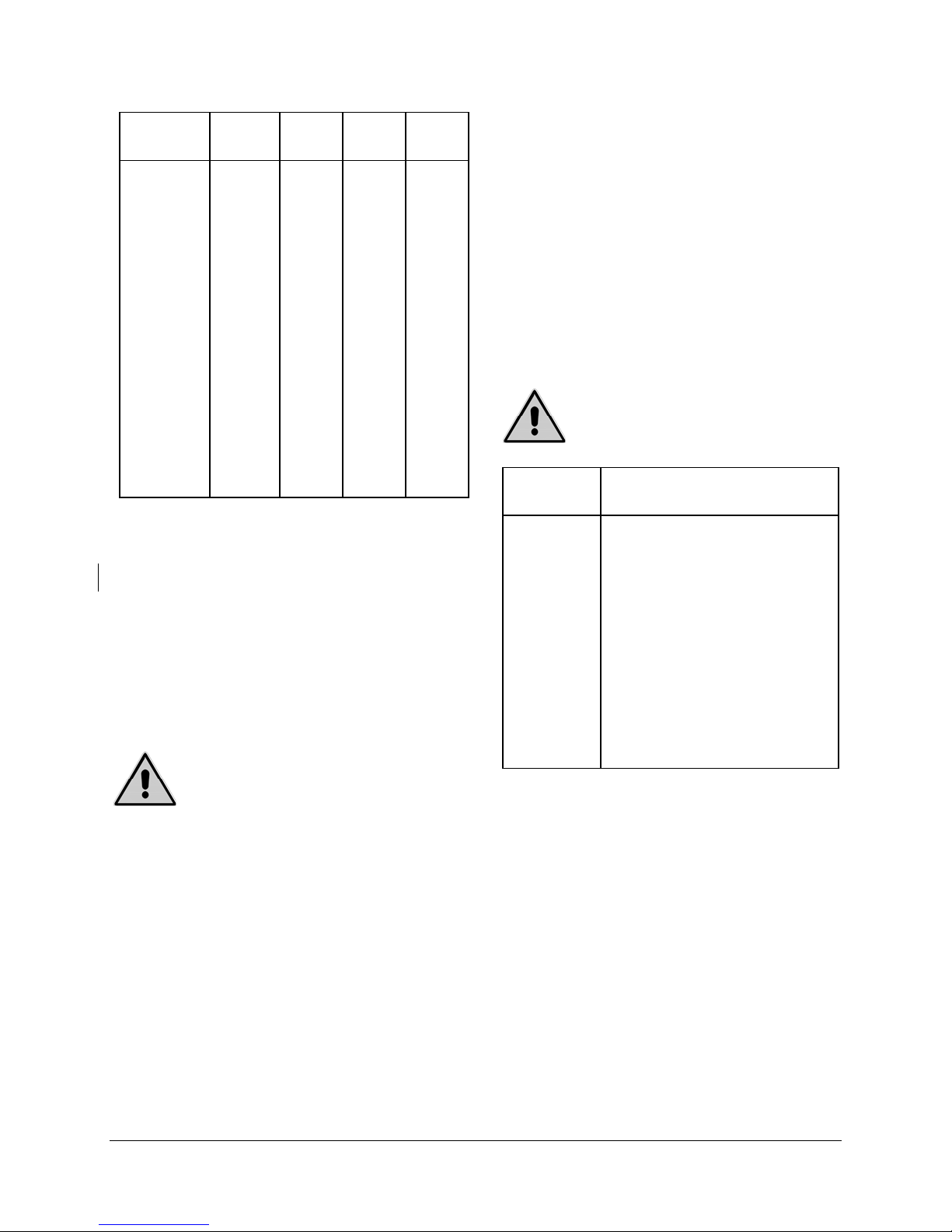

Terminal Cond/

Resistivity

EARTH GND*

PS-

+5V (9)

I/O (8) Ch A**

I/O (8) Ch B**

SIG7(7)

SIG6(6)

SIG5(5)

SHIELD

BLACK

-

-

-

-

BLUE

RED

pH/ORP Dissolved

Oxygen

SHIELD

BLACK

BLUE

-

-

WHT/BLU

-

RED

-

BLACK

BLUE

WHT/BLU

RED

SHIELD

-

CLEAR

Ozone

SHIELD

BLACK

BLUE

WHT/BLU

RED

JUMP-5***

-

CLEAR

Alternative 3-Lead Conductivity

Sensor Connections

Tinned-lead cells with 1000 Pt or 500 Ni-Fe RTDs

may be used with the 2000. These sensors, with

integral leadwire and no connector, enable the

lead to pass through small openings. The

sensor/instrument separation is limited to less

than 50 feet (20 feet recommended).

Somewhat lower accuracy may result.

Connections are given in Table 2.6. Jumpers

should be 22 gauge to match the conductor size

in the cable, for secure terminal connections.

SIG4(4)

SIG3(3)

SIG2(2)

SIG1(1)

* Connect to any of three earth ground terminals.

** Connections for dissolved oxygen and ozone use

both channel A and B I/O terminals regardless of

which channel is assigned for that measurement.

*** Install a wire jumper between terminals 5 and 7.

For instruments with firmware version 2.0 and earlier

(before April 2004), pH, ORP and dissolved oxygen

connections must connect the black wire to SIG6(6)

instead of PS-. Ozone measurement requires firmware

version 4.0 or higher.

GREEN

WHITE

CLEAR

WHT/BLUE

GREEN

WHITE

CLEAR

GREEN

WHITE

-

GREEN

WHITE

-

-

-

-

Table 2.5: Sensor Patch Cord Connections

Voltage and current measuring terminals are

rated for overvoltage category II.

Sensor Models/Types

240-, 243- 2-Electrode Conductivity

244- 4-Electrode Conductivity

363- & 1200- pH or ORP

367- dissolved oxygen

Terminals Three-lead Conductivity

Sensor Wiring

+5V (9)

I/O (8)

SIG7(7)

SIG6(6)

SIG5(5)

SIG4(4)

SIG3(3)

SIG2(2)

SIG1(1)

-

Jumper to SIG(6)

Jumper to SIG(5)

CLEAR (shield)

WHITE

Jumper to SIG(1)

RED

Table 2.6: Alternative Sensor Connections

With these 2_8 Series Dot Two sensors there is

no label with factory-supplied precision calibration

constants. Only the nominal value 0.1/cm for cell

constant and 1.0 for temperature constant are

entered into the 2000.

With all tinned-lead sensors, when meter

calibration is desired, the cell must be

disconnected and a patch cord installed in its

place to accept a calibrator.

368- dissolved ozone

6 Installation Chapter 2

Page 13

CHAPTER 3: USING THE 2000

APPLYING POWER TO THE 2000

After applying power to the meter, the display will

show an introduction message for three seconds

and then begin making measurements. This

message shows the model number and the

software version number as follows:

In the menus, an underline cursor and flashing

(bold) characters will indicate a field that can be

changed. A typical menu appears as follows:

SP1=17.00 M High

68XX Ver X.X

While the message is being displayed the

instrument is performing self diagnostics. Various

circuits are tested during this process and any

failure will be noted with a message. The

diagnostics can be repeated at any time via the

menus.

The default measurement display is the primary

readings from the sensors on channel A and B as

shown below:

A1.76µS B2.11µS

All 2000 meters are calibrated from the factory

and normally require no further calibration. If

QA/QC practice requires it, the instrument be

calibrated after installation. See Chapter 8 for

more information on meter calibration.

THE DISPLAY

The 2000 uses a 1 line by 16 character

alphanumeric display to convey all measurement

and setup information. This instrument will display

one or two measurements, each with channel

indication and unit of measure. A typical display

of measurement data is:

This menu indicates that setpoint #1 is

programmed at a value of 17.00 M (million) and is

set as a high limit. The cursor is under the digit

“7” indicating that the UP and DOWN keys can be

used to change it. The RIGHT and LEFT keys will

move the cursor to the next or previous field.

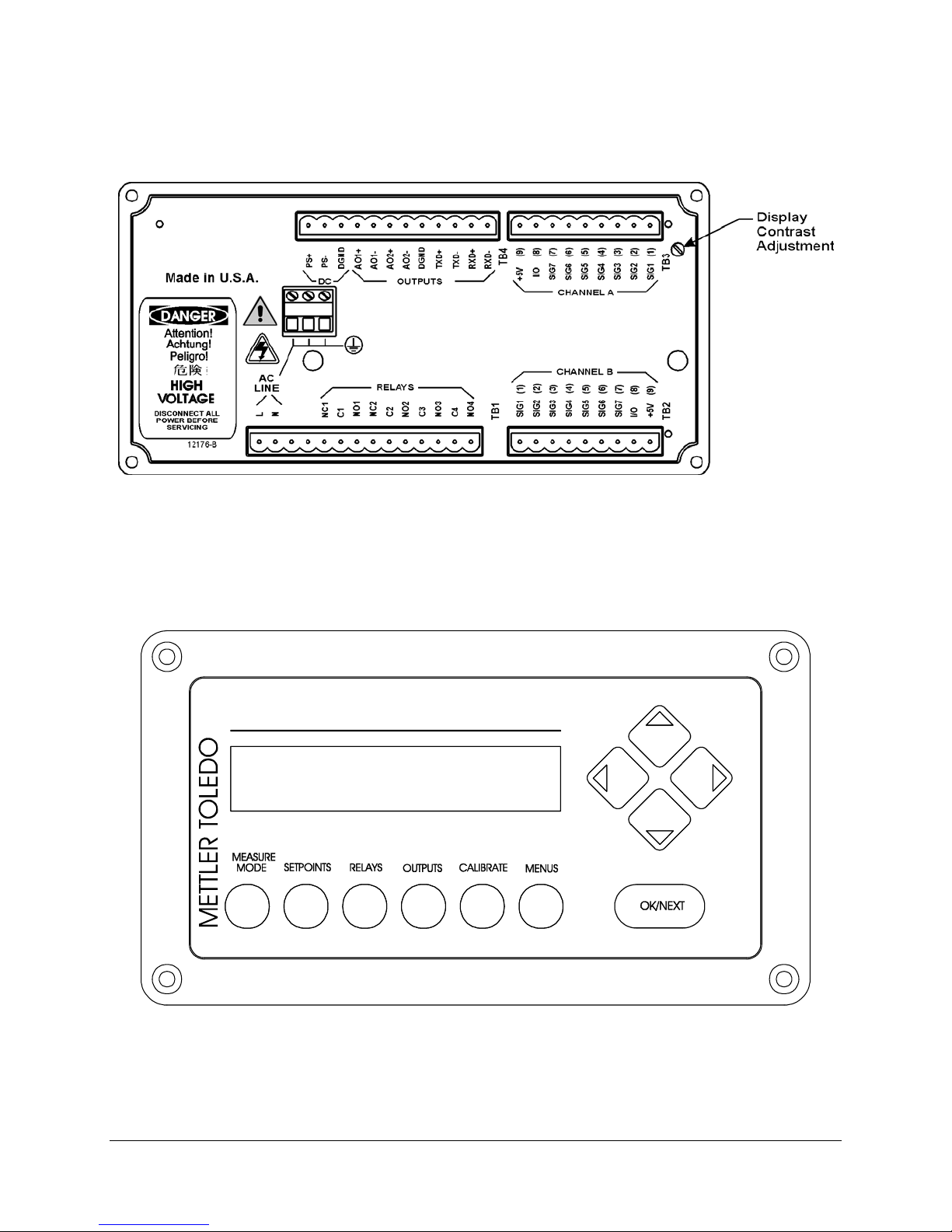

Display Contrast Adjustment

The contrast quality of the display can change

with ambient temperature. The display contrast is

adjusted from the factory for operation at

standard room temperature (25°C). If the meter is

operated at an ambient temperature that is much

different then it may be necessary to make an

adjustment. A potentiometer is accessible from

the back side of the instrument to change the

contrast. Use a small slotted screwdriver to gently

turn the potentiometer. A counter-clockwise turn

will increase the contrast and a clock-wise turn

will decrease the contrast. The rear panel is

shown in Figure 3.1.

A7.76pH B2.10µS

This display indicates that channel A is

measuring 7.76pH and channel B is measuring

2.10µS/cm. The display of the other

measurements can be achieved by pressing the

UP or DOWN keys.

Chapter 3 Using the 2000 7

Page 14

Figure 3.1: 2000 Rear Panel

THE KEYPAD

The 2000 is equipped with an 11-key keypad as shown in Figure 3.2.

THORNTON

A1.076µS

Figure 3.2: 2000 Front Panel

8 Using the 2000 Chapter 3

B1.055µS

2000

Page 15

The keypad has 6 keys that provide direct access

to specific menus as follows:

instrument to accept the options that are

displayed and move to the next menu.

1. MEASURE MODE - menus to change

measurement modes.

2. SETPOINTS - menus for programming

setpoints.

3. RELAYS - menus for programming relays.

4. OUTPUTS - menus for programming

outputs.

5. CALIBRATE - menus to perform calibration.

6. MENUS - all other menus (cell constants,

security, compensation, averaging, etc.).

The other keys are referred to as control keys

and are used to make changes within a menu.

1. OK/NEXT Key - used to accept a selection

and proceed to the next menu level.

2. UP Key - up arrow is used to scroll up

through a list of options.

3. DOWN Key - down arrow is used to scroll

down through a list of options.

4. LEFT Key - left arrow is used to move the

cursor to the left within a menu.

5. RIGHT Key - right arrow is used to move the

cursor to the right within a menu.

USING THE MENUS

There are six menu keys across the bottom of the

2000 front panel. The first five of these keys

(MEASURE MODE, SETPOINTS, RELAYS,

OUTPUTS, AND CALIBRATION) are used to

enter specific menus. These menus allow the

modification of parameters most frequently used

by the operator. The sixth key labeled MENUS

allows access to all other menus for various

functions such as setting compensation methods,

security levels, etc.

The UP and DOWN arrow keys scroll vertically

through the menus. Part or all of the display

changes to the next option whenever an UP or

DOWN arrow key is pressed. A field is defined as

a section of the display that can be changed. The

characters of the field will also blink. The LEFT

and RIGHT arrow keys move the underline cursor

across the display from one field to the next.

Pressing the OK/NEXT arrow key causes the

Numbers are set one digit at a time using the

arrow keys. The LEFT and RIGHT arrow keys are

used to position the underline cursor below the

digit to be changed. The UP and DOWN arrow

keys are then used to change the value of the

digit. Each digit can be scrolled through the

values: .(decimal point), 0, 1, 2, 3, 4, 5, 6, 7, 8,

and 9 The first digit of any number can also be

set to a negative sign (-).

To exit the menus either scroll completely through

a set of menus with the OK/NEXT key or press

any of the six menu keys at any time. The meter

will display a prompt asking if the recent changes

should be saved.

Save Changes Yes

To save the changes press the OK/NEXT key

with “Yes” on the display. To discard the changes

use the UP or DOWN arrow keys to change “Yes”

to “No”, then press the OK/NEXT arrow key.

If the instrument is displaying a menu and a key

is not pressed for two minutes, the instrument will

automatically exit the menus without saving any

changes. When performing a calibration the

operator may need to wait for a measurement to

stabilize so the menu time-out feature is

automatically disabled.

Menu Example

Press the MEASURE MODE key and the display

will show:

A=S/cm (AUTO)

This menu indicates that the Channel A primary

measurement is set for conductivity (S/cm) with

auto ranging. The section “S/cm” is the field to

be changed and will be flashed as long as the

cursor is under it. Pressing the UP arrow key will

change the “S/cm” to “Ω-cm”. The RIGHT arrow

key will move the cursor to the “(AUTO)” field.

A=Ω/cm (AUTO)

Chapter 3 Using the 2000 9

Page 16

The OK/NEXT key is used to accept the entry

and move to the next menu. When the last menu

level is reached the following message is

displayed:

b = channel B secondary measurement

Upper case letters are used to indicate the

primary measurements and lower case letters are

used to indicate the secondary measurements.

Save Changes Yes

Pressing the OK/NEXT key will save the changes

and exit the menus. The UP and DOWN arrow

keys can be used to change the “Yes” to “No”.

Pressing the OK/NEXT key with “No” will discard

the changes and exit the menus.

INSTALLING A SENSOR

Each sensor is equipped with a cell and

temperature sensor (except ORP). Conductivity

sensors have calibration constants for these

elements that must be programmed into the

meter for proper operation. These factors are

printed on the sensor (as well as a Certificate of

Calibration supplied with each conductivity

sensor). The label may look like this:

RES M=1.0034 TEMP M=1.0015

RES M is the conductivity cell constant, and

TEMP M is the temperature sensor constant. pH

preamps will have a pH A (adder) constant. Long

life 367-110 dissolved oxygen sensors have Cell

M (multiplier), Cell A (adder) and TEMP M

(multiplier) constants. See ENTERING/ EDITING

CELL CONSTANTS in Chapter 9 for information

on entering cell constants.

Each of the four calculated measurements can be

one of the following:

1. pH

2. ORP (redox potential)

3. Resistivity

4. Conductivity

5. Total Dissolved Solids (TDS)

6. Degrees C

7. Degrees F

8. % Rejection

9. Difference (A-B or B-A)

10. Ratio (A/B or B/A)

11. %HCl

12. %NaOH

13. %H2S0

14. Dissolved Oxygen

15. Dissolved Ozone

16. Power plant calculations of pH, CO

chlorides or sulfates from conductivity

4

2

DISPLAYING MEASUREMENTS

,

MEASUREMENT DESIGNATIONS

The 2000 instrument will measure four

fundamental signals during each measurement

cycle. These measurements are the conductivity,

pH or dissolved oxygen and temperature of the

probe on channel A and the conductivity or pH

and temperature of the probe on channel B.

The 2000 can process and display four calculated

measurements. They are referred to as A

primary, A secondary, B primary and B

secondary. These measurements are designated

by a single letter as follows:

A = channel A primary measurement

a = channel A secondary measurement

B = channel B primary measurement

10 Using the 2000 Chapter 3

Changing the Display

of Measurements

The 2000 display can show either one or two

measurements at a time. The display of

measurements can be changed by using the UP

or DOWN arrow keys. Pressing one of these keys

will cause the meter to change the display mode

(show an alternative set of data).

The display modes for two measurements per

line are:

Mode #1: A primary and B primary (three

significant digits displayed for each parameter):

A1.76µS B2.11µS

Page 17

Mode #2: A secondary and B secondary (three

significant digits displayed for each parameter).

Press the MENUS key and the following menu

will appear:

a25.2°C b25.1°C

Mode # 3: A Primary and A Secondary (four

significant digits displayed for each parameter):

A1.764µS 25.10°C

Mode #4: B primary and B Secondary (four

significant digits displayed for each parameter):

B2.109µS 25.12°C

Note that when two measurements from the

same channel are displayed, the secondary

measurement indicator ( a or b) is not displayed.

This allows for greater precision in the display of

the primary measurement.

The default display setting (after a system reset)

is mode #1 (A Primary & B Primary).

The display modes for one measurement per line

are:

Mode #1: A Primary:

Menus use arrows

Press the UP arrow key until “Display Menus” is

displayed.

Display Menus

Press the OK/NEXT key to access this menu.

Use the Up or DOWN keys to toggle the field until

“Disp Format” appears. Press OK/NEXT to

access this menu.

Set: Disp Format

Use the UP and DOWN keys to toggle the field

between “1” and “2”.

Measure per Line: 1

Press OK/NEXT when done. The meter will ask if

changes should be saved.

Save Changes Yes

A 1.765µS/cm

Mode #2: A Secondary:

a 25.25 deg C

Mode #3: B Primary:

B 2.109µS/cm

Mode # 4: B Secondary:

b 25.12 deg C

Setting the Number of Measurements

per Display Line

The 2000 can be set to display either one or two

measurements per line.

To change this feature:

Press OK/NEXT key to save the changes and

return to the display of measurement data.

Measurement Display Scrolling

The 2000 has an automatic display scrolling

feature for measurement data. With this feature

enabled, the display will show channel A data for

5 seconds and then show channel B data for 5

seconds. Secondary measurements are not

shown if a single measurement is selected per

display line. The process is repeated indefinitely.

To enable or disable this feature:

Press the MENUS key and the following menu

will appear:

Menus use arrows

Press the UP arrow key until “Display Menus” is

displayed.

Display Menus

Chapter 3 Using the 2000 11

Page 18

Press the OK/NEXT key to access this menu

Set: Auto Scroll

Use the Up or Down arrow keys to toggle the field

until “Auto Scroll” appears. Press OK/NEXT to

access this menu.

Auto Scroll=off

Use the UP or DOWN arrow keys to toggle the

field from “Off” to “On”. Press the OK/NEXT key

when done. The meter will ask if changes should

be saved.

Save Changes Yes

Press the OK/NEXT key to save the changes and

return to the display of measurement data.

ALARM INDICATIONS

A setpoint can be programmed as a high limit, a

low limit, USP or EP (temperature-dependent

pharmaceutical water conductivity) limits. When a

measurement is higher than a high, USP or EP

point or lower than a low point then the setpoint is

in alarm state. This condition is indicated by

flashing the corresponding measurement value in

the normal operating display. See Chapter 5:

Using Setpoints.

12 Using the 2000 Chapter 3

Page 19

CHAPTER 4: MAKING MEASUREMENTS

MEASUREMENT PROCESS

The 2000 will process two measurements from

each of the two channels. The measurements of

each channel are referred to as the primary and

the secondary measurement. The instrument will

process a total of four different measurements

per cycle.

Measurements are designated as follows:

A = channel A primary measurement

a = channel A secondary measurement

B = channel B primary measurement

b = channel B secondary measurement

Upper case letters indicate primary

measurements and lower case letters indicate

secondary measurements.

MEASUREMENT TYPES

Each of the four measurements (channel A

primary, etc.) is programmed as one of the

following with corresponding 1 or 2-character

display:

Measurement

pH

ORP (redox potential)

Resistivity

Conductivity – siemens/cm,

siemens/m

Total Dissolved Solids (TDS), ppm,

ppb

Dissolved Oxygen – g/L, ppm, ppb,

% saturation

Dissolved Ozone – ppm (mg/L),

ppb (µg/L)

Temperature – Deg C, Deg F

% Rejection

Difference (A-B or B-A)

Ratio (A/B or B/A)

%HCl - Hydrochloric Acid

%NaOH - Sodium Hydroxide

%H2S04 - Sulfuric Acid

Display

pH

V

Ω

S, Σ

PM, PB

g, pm,

pb, %

Z,

z

°C, °F

%R

d

r

%H

%N

%S

Power cycle chemistry calculations

of pH, CO

, Chloride, Sulfate

2

PH, CD,

Cl, Sf

pH and ORP (Redox potential)

pH is displayed with fixed range. ORP is

displayed in fixed range millivolts (mV).

Resistivity

Resistivity is expressed in ohms-centimeter (Ω-

cm). This measurement can be displayed with a

prefix in front of the units. The prefixes are k (kilo

or 1,000) and M (Mega or 1,000,000).

The display can be set for a fixed range such as

Ω-cm, KΩ-cm (1,000Ω-cm), or MΩ-cm (Mega or

1,000,000Ω-cm). The 2000 can also be set for

auto ranging where the range will be

automatically adjusted for the most appropriate

display. The range is set via the measure mode

menus.

1,000,000 Ω-cm = 1,000 KΩ-cm = 1 MΩ-cm

Conductivity

Conductivity is expressed in siemens per

centimeter (S/cm) and is the reciprocal of

resistivity. This measurement can be displayed

with a prefix in front of the units. The prefixes are

m (milli or 1/1,000) and µ (micro or 1/1,000,000).

The 2000 can also be set for auto ranging where

the range will be automatically adjusted for the

most appropriate display. The range is set via the

measure mode menus.

1 S/cm = 1,000 mS/cm = 1,000,000 µS/cm

Conductivity may also be expressed in siemens

per meter

units as described above. To clearly distinguish

these units in the 2000 display, the symbol “Σ” is

used in place of “S”. In operation, microsiemens

per meter is displayed as µΣ.

(S/m) with a multiplier in front of the

Total Dissolved Solids

Total Dissolved Solids (TDS) is another way to

measure and display conductivity/resistivity data.

TDS is the equivalent of Sodium Chloride (NaCl)

required to produce the measured conductivity-approximately 0.46 ppm TDS per µS/cm. If some

Chapter 4 Making Measurements 13

Page 20

other conversion is desired, it is necessary to

adjust the cell constant to give direct readout. For

example, if a conversion of 0.6 ppm TDS per

µS/cm is desired, the cell multiplier to be entered

into the 2000 is 0.6/0.46 x Multiplier on sensor

label. See Chapter 9, Entering/Editing Sensor

Constants.

TDS is measured in parts per billion (ppb), parts

per million (ppm), or parts per thousand (ppk). A

TDS reading of 10 ppm is equivalent to 10

milligrams per liter. Because of space limitations,

the following abbreviations are used to display

TDS units:

PB = parts per billion

Temperature

Temperature can be measured in degrees

Celsius (°C) or degrees Fahrenheit (°F). The

2000 normally works with a 1000 ohm DIN

platinum RTD sensor which is built into Thornton

most conductivity, dissolved oxygen, dissolved

ozone and most pH sensors. Alternatively, the

2000 can automatically recognize and measure

with a 500 ohm Ni-Fe RTD temperature sensor.

When configured for a 50/cm constant cell only,

the 2000 automatically changes its characteristic

to measure from the 262 ohm @ 25°C thermistor

supplied in those sensors.

PM = parts per million

PK = parts per thousand

Dissolved Oxygen

Dissolved oxygen can be measured in units of

parts per billion (ppb), parts per million (ppm),

and grams per liter (g/L), with or without autoranging between micro and milli (grams per liter).

Abbreviations used in the display mode are pb,

pm, µg and mg, respectively. Note that dissolved

oxygen uses lower case pb and pm to distinguish

it from TDS which uses upper case PB and PM.

NOTE: Select dissolved oxygen as a

measurement after connecting the probe. This

initiates an automatic internal preamp calibration

for highest accuracy at startup and will display

“Saving Changes” for an extended period.

Otherwise, the system will initiate calibration by

itself 1 hour later.

Dissolved Ozone

Dissolved ozone can be measured in units of

parts per billion (ppb) with resolution of 1 ppb or

in units of parts per million (ppm) with resolution

of 0.01 ppm. Abbreviations for units in the normal

display mode are z and Z respectively.

NOTE: Select dissolved ozone as a

measurement after connecting the preamp. This

initiates an automatic internal preamp calibration

for highest accuracy at startup and will display

“Saving Changes” for an extended period.

Otherwise, the system will initiate calibration by

itself 1 hour later.

% Rejection

For reverse osmosis (RO) applications, percent

rejection is measured in conductivity to determine

the ratio of impurities removed from product water

to the total impurities in the incoming feed water.

The formula for obtaining Percent Rejection is:

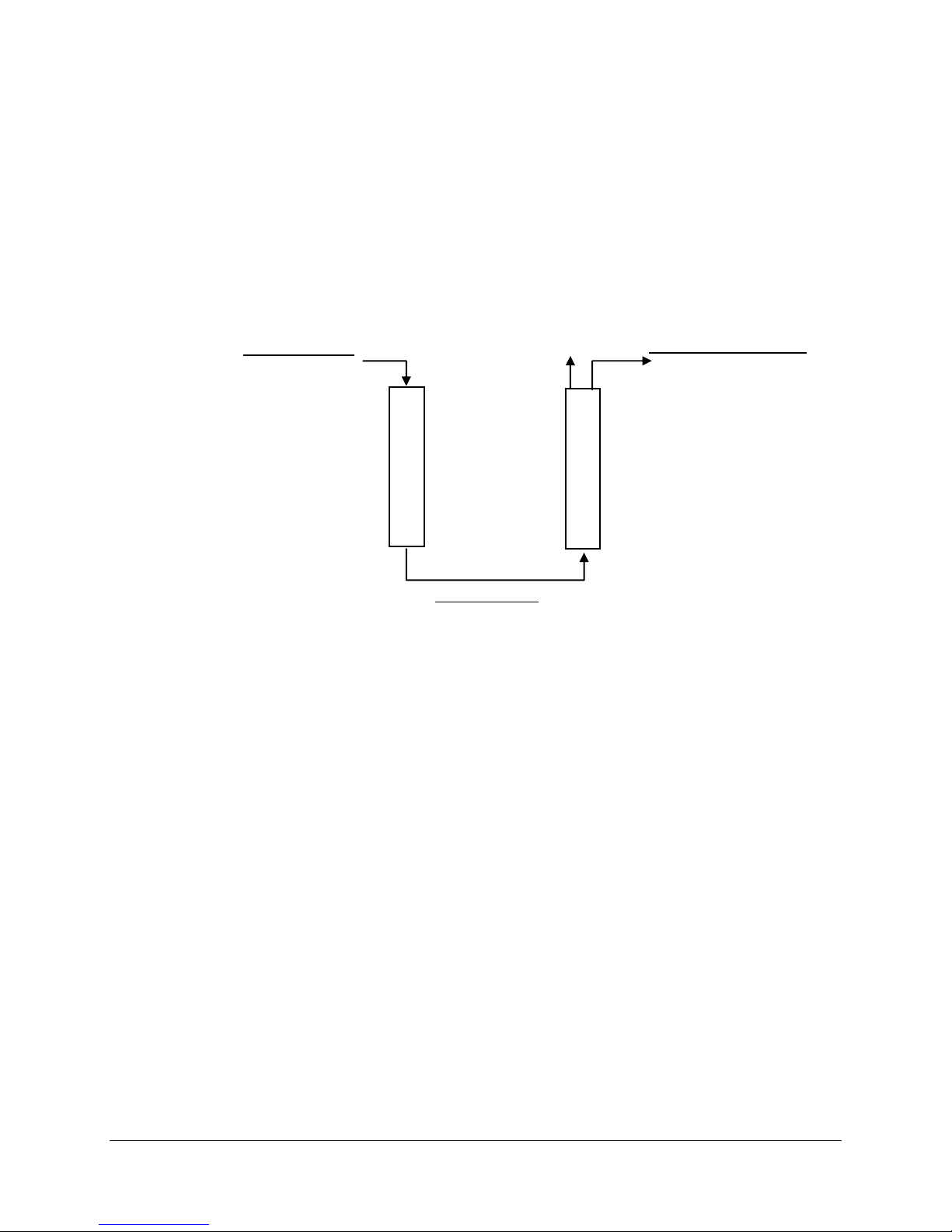

[1 - (Product/Feed)] X 100 = % Rejection

Where Product is the conductivity measurement

of the first sensor and Feed is the conductivity of

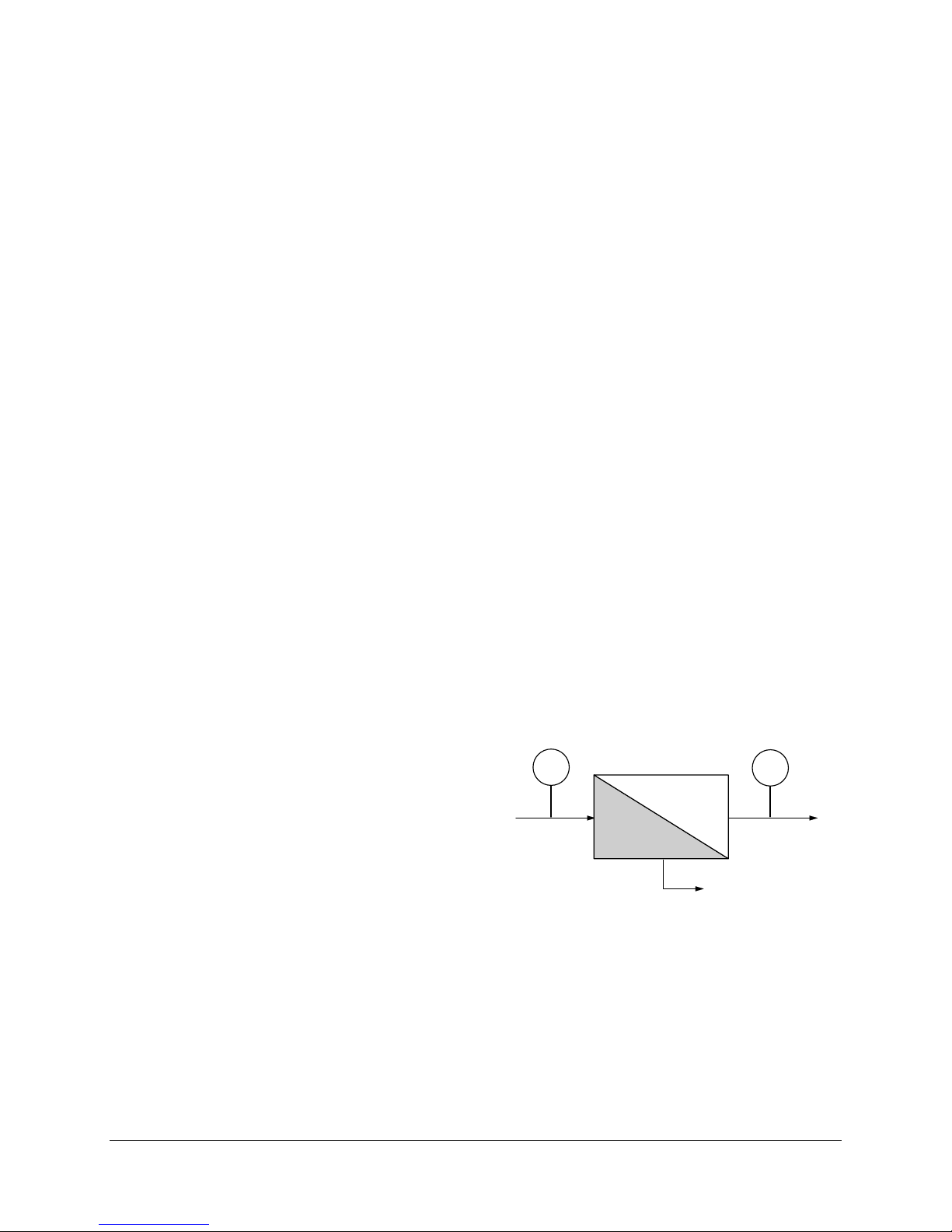

the second sensor. Figure 4.1 shows a diagram

of an RO installation with sensors installed for

Percent Rejection.

CONDUCTIVIY

SENSOR

REVERSE OSMOSIS MEMBRANE

B

FEED PRODUCT

Figure 4.1: % Rejection

IMPORTANT: When preparing the system to

perform a percent rejection measurement, the

product monitoring sensor must be installed in the

channel that will measure percent rejection. If the

product conductivity sensor is installed in channel

A, then percent rejection must be measured in

channel A. Likewise if the product sensor is

installed in channel B, then the percent rejection

REJECT

CONDUCTIVITY

SENSOR

A

14 Making Measurements Chapter 4

Page 21

measurement must also be programmed in

channel B.

Difference (A-B or B-A)

The difference measurement is computed as:

Difference on channel A = A-B.

or

Difference on channel B = B-A.

When the difference is assigned to one channel,

the meter will measure the same type of

measurement mode of the other channel as a

basis. For example, if channel A is set to

measure the difference and channel B is

measuring conductivity, then the 2000 will

measure conductivity on both channels before

computing the difference. The displayed unit for

difference is ‘d’.

Ratio (A/B or B/A)

This measurement is similar to the difference

measurement.

Ratio on channel A = A/B.

Ratio on channel B = B/A.

The displayed unit for ratio is ‘r’.

Concentrations

(%HCl, %NaOH, %H2SO4)

All concentrations are displayed as percent by

weight. Setting a measurement for concentration

automatically activates specialized temperature

compensation for that particular material. The

compensation setting is ignored for that channel.

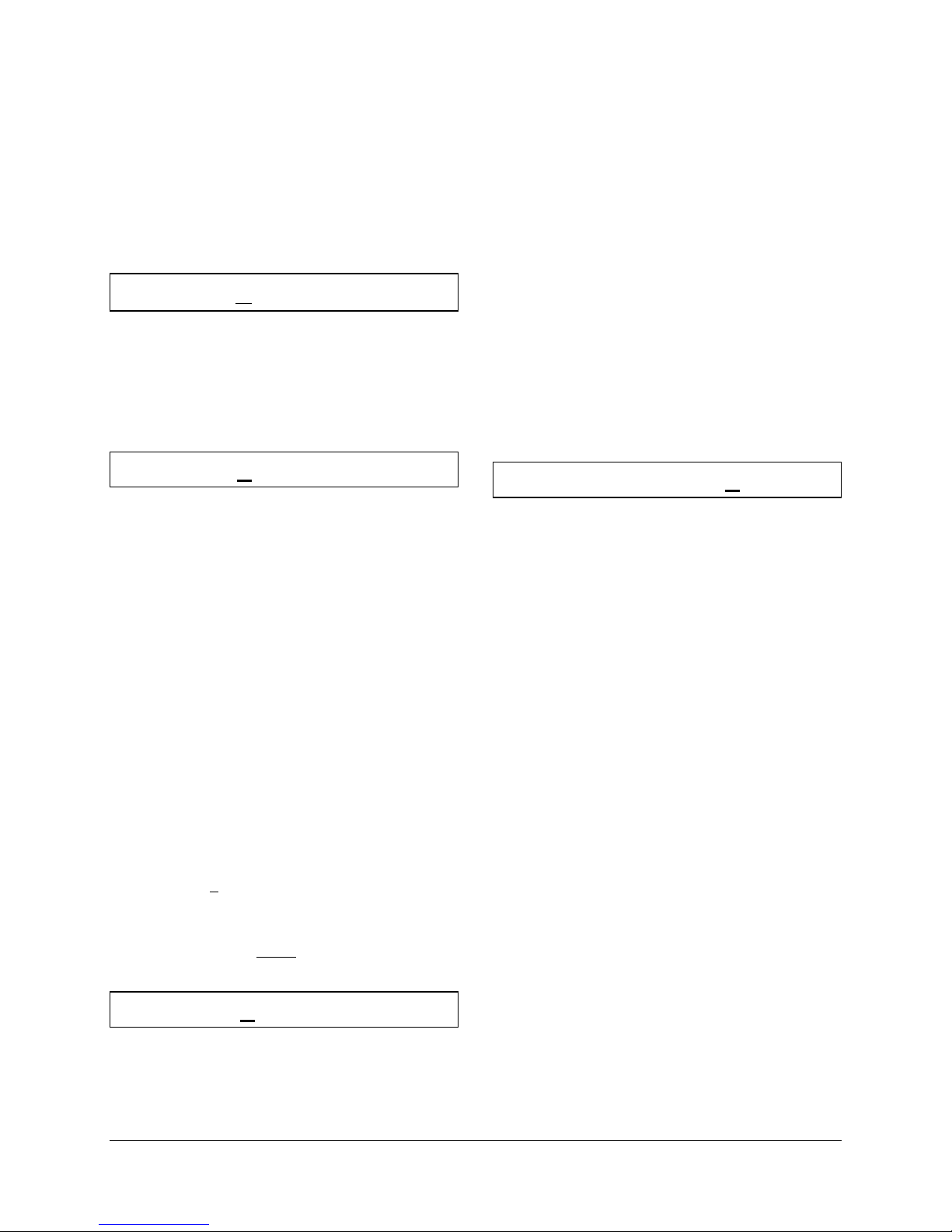

Power Plant Calculated Parameters

The following derived parameters are valid only

for power plant cycle chemistry samples

conditioned by a cation exchanger (and

sometimes a degasifier) as illustrated in Figure

4.2. They are not applicable to other samples and

would give very erroneous results elsewhere.

Because the 2000 can provide two

measurements from a single sensor channel, it

can be configured to display two conductivity

measurements, sample temperature and

calculated pH or CO

measurements.

2

Calculated pH may be obtained very accurately

from specific and cation conductivity values when

the pH is between 7.5 and 10.5 due to ammonia

or amines and when the specific conductivity is

significantly greater than the cation conductivity.

The 2000 uses this algorithm when CALCPH is

selected using the Measure Mode key for the

channel measuring cation conductivity.

For example, set up measurement ‘A’ to be

specific conductivity, measurement ‘a’ to be

temperature, measurement ‘B’ to be cation

conductivity and measurement ‘b’ to be

calculated pH. Set the temperature compensation

mode to “Ammonia” for measurement ‘A’ and to

“Cation” for measurement ‘B.’

Note that if operation goes outside the

recommended conditions, a glass electrode pH

measurement is needed to obtain an accurate

value. On the other hand, the calculated pH

provides an accurate standard for one-point trim

calibration of the electrode pH measurement

when sample conditions are within the ranges

noted above.

Carbon dioxide may be calculated from cation

conductivity and degassed cation conductivity

using tables from ASTM Standard D4519. The

2000 has these tables stored in memory which it

uses when units of CO2ppb are selected under

the Measure Mode key.

For example, set up measurement ‘A’ to be cation

conductivity, measurement ‘a’ to be CO2ppb,

measurement ‘B’ to be degassed cation

conductivity and measurement ‘b’ to be

temperature. Set the temperature compensation

mode to “Cation” for both conductivity

measurements.

Total anions as chlorides or sulfates may be

readout on a degassed cation conductivity

sample using tables from ASTM Standard D4519.

The 2000 has these tables stored in memory

which it uses when selected under the Measure

Mode key by choosing units of “Clppb” or

“SO4ppb” for parts per billion chlorides or

sulfates. Conductivity is non-specific and cannot

determine the actual anions present—it merely

converts the conductivity value as if they were all

chlorides or all sulfates. Set the temperature

compensation mode to “Cation”.

The display units for these derived parameters

are given below.

Chapter 4 Making Measurements 15

Page 22

Measurements Menu Normal Display

PHCALC ( ) PH

CO2ppb ( ) CD

pH calculated from conductivity is designated by

all upper case ‘PH’. pH measured by electrode is

designated by the conventional lower/upper case

‘pH’.

Clppb ( ) Cl

SO4ppb ( ) Sf

Specific Conductivity

+

NH

, OH-, Na+, H+, Cl-, HCO

4

-

3

CO

2

Degassed Cation Conductivity

+

H

, Cl

+

R–NH

R–Na

4

+

Degas Unit

Cation Exchanger

+

R–H

-

, OH-

3

Cation Conductivity

+

H

, Cl-, CO2, HCO

Fig. 4.2: Sample conditioning for specific, cation and degassed cation conductivity

measurements used to calculate pH, CO

and anion concentration on power plant cycle chemistry

2

samples

-

, OH

-

16 Making Measurements Chapter 4

Page 23

SELECTING A MEASUREMENT TYPE

To set or change a measurement type for each of

the four measurements:

Press the MEASURE MODE key and the display

will show the measurement type assigned to

channel A primary. The display may appear as:

The field on the right half side of the display is the

range field. Some measurements can be set for a

fixed range, others can be set only for auto

ranging. For example, conductivity can be set for

micro, milli, units, or auto ranging. To change the

field, use the RIGHT arrow key to move the

cursor under “(Auto)”. Use the UP and DOWN

arrow keys to select the desired range.

A = Ω-cm (AUTO)

This menu indicates that channel A primary

measurement is set for resistivity (Ω-cm) with

auto ranging. The section “Ω-cm” is the first field

to be changed and will be flashed as long as the

cursor is under it. Pressing the UP arrow key will

change the “Ω-cm” to “S/cm”.

The OK/NEXT key is used to accept the entry for

channel A primary and move to the next menu for

setting channel “a” secondary. Press the

OK/NEXT key a third and fourth time to set the

measurement types for channel B primary and

channel “b” secondary, respectively.

When the last menu level is reached (after setting

channel “b” secondary), the following message is

displayed:

A = S/cm (AUTO)

Use the UP and DOWN arrow keys to select the

desired measurement type.

For dissolved oxygen, the sensor should be

connected to the 2000 before selecting this

parameter because the 2000 performs a DO

preamplifier calibration when it is saved (and at

hourly intervals thereafter). Also for this reason

there is a long delay in the saving process.

For conductivity, both temperature compensated

and uncompensated measurement are available.

Uncompensated readings are needed to meet

pharmaceutical water requirements. Select units

of “S/cm” for compensated measurement or “s/cm

U” for uncompensated measurement. Using both

primary and secondary parameters, both

compensated and uncompensated

measurements are available simultaneously. In

normal operation, uncompensated measurements

are identified by a flashing cursor under the units,

for example, “µ

are identified by “µS”.

Another option for conductivity is to display in

units of siemens per meter

SI metric system. The Menu setting is

s”. Normal compensated readings

in accordance with the

Pressing the OK/NEXT key will save the changes

and exit the menus. The UP and DOWN arrow

keys can be used to change the “Yes” to “No”.

Pressing the OK/NEXT key with “No” will discard

the changes and exit the menus.

CELL CONSTANTS

The calibration of each measurement is defined

by a set of constants known as cell constants.

There are two cell constants for each

measurement: a Multiplier Factor and an Adder

Factor. They are used to derive an accurate

measurement from the sensor’s output signal. As

an example, the output of a conductivity sensor

can be represented by the following equation:

R = x / M + A

Where:

R = resistivity value

x = output from cell

M = multiplier factor

Save Changes Yes

A = S/m (AUTO)

The measurement mode will display it as “µΣ” or

“mΣ”.

Chapter 4 Making Measurements 17

A = adder factor

Example: for a typical two-electrode conductivity

sensor the multiplier (M) is 0.1 and the adder (A)

is 0. If the sensor output is 120,000 ohms, then

the actual resistivity of the solution measured is

1.2 Mohm-cm and is calculated as follows:

Page 24

R = x / M + A

R = 120,000/0.1 + 0

The range is 0 - 99%/°C with a default value of

2%/°C.

R = 1,200,000

R = 1.2 Mohm-cm

NOTE: The adder is zero only for two-electrode

conductivity, resistivity and ORP sensors.

The cell constants can be modified via the

menus. For more information see

ENTERING/EDITING CELL CONSTANTS in

Chapter 9.

Cation Compensation

Power industry applications for cation conductivity

measurements with acidic samples are accurately

compensated with this setting. It takes into

account the effects of temperature on the

dissociation of pure water with the presence of

very dilute acids. See ASTM Standard D6504 for

recommendations on this measurement.

Semiconductor acid etch rinse operations are

also more accurately monitored using this setting.

CONDUCTIVITY TEMPERATURE

COMPENSATION

Conductivity, resistivity and TDS measurements

can be compensated for temperature.

Compensation will adjust the measurement to

give an equivalent reading of the solution at 25°C.

For example, the resistivity of ultrapure water at

25°C is18.18 MΩ-cm. The resistivity of ultrapure

water at 30°C is 14.08 MΩ-cm. By compensating

the resistivity reading, the value of pure water will

continue to read 18.18 MΩ-cm.

The 2000 can use one of nine different

compensation methods: standard, linear, cation,

ammonia, alcohol, Light 84, 50% glycol, 100%

glycol or none. Channels A and B can be

programmed with different compensation

methods.

For pharmaceutical USP <645> and EP

conductivity measurements where

uncompensated measurement is required, select

None for compensation. For simultaneous

uncompensated and compensated

measurements, see SELECTING A

MEASUREMENT TYPE earlier in this chapter.

Standard Compensation

The standard compensation method includes

compensation for non-linear high purity effects as

well as conventional neutral salt impurities and

conforms to ASTM standards D1125 and D5391.

Ammonia Compensation

Power industry applications for specific or direct

conductivity on samples with ammonia or ETA

(ethanolamine) are accurately compensated with

this setting. It takes into account the effects of

temperature on the dissociation of pure water

with these very dilute bases.

Alcohol Compensation

This compensation provides for the temperature

characteristic of a 75% solution of isopropyl

alcohol in pure water used for some rinsing

operations in semiconductor manufacture.

Compensated measurements using this solution

may go well above 18 Mohm-cm.

Light 84 Compensation

This compensation matches the earlier high purity

water research results of Dr. T.S. Light published

in 1984. It is provided only for use by institutions

that have standardized on that work. For all other

pure water and general purpose applications,

Standard Compensation (1994 high purity water

research of Thornton & Light) is recommended.

Glycol Compensation

This compensation matches the characteristics of

50% and 100% ethylene glycol in deionized water

cooling/antifreeze solutions.

Linear Compensation

The raw resistance measurement is

compensated by multiplication with a factor

expressed as a “% per °C” (deviation from 25°C).

Setting conductivity compensation

Enabling the compensating feature is done via

the menus as follows:

18 Making Measurements Chapter 4

Page 25

Press the MENUS key and the following menu

will appear:

Menus use arrows

Press the UP arrow key until “Compensation”

menu is displayed.

Compensation

Press the OK/NEXT key to access this menu.

A: Comp = Standard

A1.76µS B2.11µS

PH TEMPERATURE COMPENSATION

The 2000 Instrument provides two types of pH

temperature compensation, described in following

sections. If a temperature sensor is not included

in a particular pH probe, a manual temperature

setting or the temperature from the other channel

sensor may be used instead. See Chapter 11.

With ORP measurement, temperature is not

measured or compensated.

The cursor will be initially placed under channel.

Use the UP and Down arrow keys to change the

channel if desired. Use the RIGHT arrow key to

move the cursor to the method field. Use the UP

and DOWN arrow keys to scroll through the list of

available methods: “Standard”, “Linear”, “Cation”,

“Alcohol”, "Light84", “Glycol 100%”, “Glycol 50%”,

“Ammonia”, or “None”. Selecting “None” disables

the compensation feature. Press the OK/NEXT

key to accept the selection. If “Linear” is selected

then another menu will be displayed where the

linear value can be entered. This menu will

appear as (the actual value may be different):

A: Comp = 2.000%/°C

Adjust the numerical field as desired using the

arrow keys and press OK/NEXT when done. After

setting the compensation state for channel A,

repeat for channel B. Press OK/NEXT when

done. The meter will ask if changes should be

saved.

Save Changes Yes

Press OK/NEXT key to save changes and return

to the display of measurement data.

Compensation Indication

When displaying measurements, the 2000 will

indicate that a measurement is NOT

compensated by displaying a flashing underline

cursor at the units character. The following

display shows that channel A is compensated

and channel B is not compensated (the character

“µ

” has a blinking underline cursor).

Conventional pH Electrode

Temperature Compensation

Electrode Temperature Compensation (Nernst

Response) is provided in most pH instruments.

All pH electrodes produce a millivolt signal with

gain proportional to the absolute temperature.

Electrode temperature compensation normalizes

that variable millivolt output to give pH values.

The default and normal operating setting of the

instrument has this compensation active. Some

specialized measurements may need to disable it

by accessing the "Compensation" setting via the

MENUS key. Compensation for each channel

may be individually turned on or off.

pH Solution Temperature

Compensation

Solution Temperature Compensation allows

settings for compensation of the variable

ionization of pure waters. The change is so small

in more conductive waters that it is usually

ignored, but for high purity water, it is significant.

It is used in addition to the conventional (Nernst)

compensation, described above, which is

normally active. Solution temperature

compensation is used primarily with power plant

and other pure water samples less than 30 µS/cm

conductivity. It references the pH of pure water to

25°C. All other applications should leave the

solution temperature coefficient (STC) set to its

default value of zero.

For pure makeup water or boiling water reactor

samples, the STC should be set to 0.016 pH/°C.

For ammonia, phosphate and/or amine-treated

samples the STC should be set to 0.033 pH/°C.

The appropriate setting for other pure water

Chapter 4 Making Measurements 19

Page 26

compositions may be determined by developing

temperature vs. pH data for the particular sample

with the STC set to zero. The negative slope of

this data becomes the STC value.

Because Solution Temperature Compensation is

unique to the process sample and is different for

buffer solutions, it is not active during calibration.

The 2000 ignores the STC during calibration. For

this reason, the reading in a buffer solution after

calibration may not be the exact value entered.

To read and verify the exact buffer value,

temporarily set the STC to zero.

Setting 50/60 Hz Operation

To set the appropriate filter, press the MENUS

key and the following menu will appear:

Menus use arrows

Press the DOWN arrow key until the “Set

Frequency” menu is displayed.

Set Frequency

The Solution Temperature Coefficient setting is

accessed via the MENUS key / Spec pH Function

/ STC=0.000 pH/C for each channel.

pH Isopotential Point

The isopotential Point, IP, is left at the default

setting of 7.0 for all Thornton and other

conventional pH sensors. Special purpose pH

electrodes with zero potential at values other than

7 pH will have this identified in their instruction

manuals. A different IP setting will allow proper

temperature compensation of these special

electrodes. The IP setting is accessed via

MENUS key / Spec pH Function / IP = 7.000 pH

for each channel.

DISSOLVED OXYGEN TEMP. &

PRESSURE COMPENSATION

For dissolved oxygen and ozone, temperature

compensation is automatically provided for both

the changing permeation rate of gas through the

membrane and for its changing solubility in water.

Press the OK/NEXT key to access this menu.

Frequency = 60

Use UP or DOWN arrow keys to set the desired

frequency. Press the OK/NEXT key when done.

The meter will ask if changes should be saved.

Save Changes Yes

Press OK/NEXT to save changes and return to

the measurement mode.

For dissolved oxygen, during air calibration, the

effective oxygen concentration is affected slightly

by the barometric pressure. Therefore the

barometric pressure should be entered before

calibration.

AC POWER FREQUENCY

The 2000 meter was designed to reduce

fluctuations in measurements by eliminating noise

pickup from the AC power line. The meter can be

set to filter either 50Hz or 60Hz power. Factory

settings are 60 Hz for 90-130 VAC models and 50

Hz for 180-250 VAC models.

20 Making Measurements Chapter 4

Page 27

CHAPTER 5: USING SETPOINTS

4. b - Channel b secondary

OVERVIEW

A setpoint is a limit or alarm point applied to a

measurement. A setpoint can be programmed as

a high limit, a low limit, a USP limit or an EP limit.

(A USP or EP setpoint is a high alarm used for

pharmaceutical water monitoring, described later

in this chapter.) When the measurement value is

higher than a high setpoint, or lower than a low

setpoint, a setpoint error condition exists. The

meter will indicate this condition by blinking the

measurement on the display. The 2000 can also

be programmed to control a relay upon this error

condition. Refer to Chapter 6 for more information

on relays.

Four setpoints are available and can be assigned

to any of the four measurements (A, a, B and b).

More than one setpoint can be assigned to the

same measurement and more than one setpoint

can activate the same relay.

The following parameters can be programmed for

setpoint operation:

1. The assigned signal:

or b) is monitored by the setpoint.

2. The setpoint value:

that triggers the setpoint error condition, with

prefix.

3. The setpoint type:

WFI or EP PW.

4. The assigned relay:

controlled when a setpoint error occurs (this

is optional).

5. Operation on overrange

setpoint will be active when the

measurement is outside its range — yes or

no.

which signal (A, a, B,

the measurement value

High, Low, Off, USP, EP

which relay will be

: Whether or not the

SETPOINT SIGNAL

The setpoint signal is the measurement that will

be monitored by the setpoint. The signal can be

any of the measurements:

1. A - Channel A primary

2. a - Channel a secondary

3. B - Channel B primary

SETPOINT VALUE

The setpoint value is the limit that will trigger a

setpoint error condition. This number is entered

as a four digit number with a suffix.

NOTE: The correct units multiplier suffix must be

entered or the setpoint will not function properly.

The suffixes are:

“µ” (micro) = multiply value by 0.000001

-

6

(10

).

“m” (milli) = multiply value by 0.001 (10-3).

“-” (blank) = multiply value by 1

“K” (kilo) = multiply value by 1,000 (103).

“M” (Mega) = multiply value by 1,000,000 (106).

For example, a setpoint value of 18.18M is

equivalent to 18,180,000.

When programming the setpoint values with TDS

units, the following prefixes should be used (parts

per million is the basis):

m = parts per billion

_ = parts per million

K = parts per thousand

For ppm or ppb dissolved oxygen or ozone, the

ppm or ppb units are the basis and “_” should be

set as the units multiplier suffix.

For g/L dissolved oxygen, g/L is the basis and a

unit multiplier suffix of m - milli or µ - micro should

be used.

SETPOINT TYPE

The setpoint type can be “High”, “Low”, "USP" or

“Off”. A setpoint error condition occurs when the

measurement is above the high or USP limit or

below the low limit.

ASSIGNED RELAY

The assigned relay will change state according to

the setpoint condition. When a setpoint error

condition exists, the assigned relay will change

Chapter 5 Using Setpoints 21

Page 28

state. If the relay is normally closed, then it will be

opened.

Default settings after a system reset: Setpoints

are disabled, no signals assigned, no relays

assigned and values are zero.

PROGRAMMING A SETPOINT

Press the SETPOINTS key to access the first

setpoint menu. This menu is used to assign a

measurement to each of the four setpoints.

SP1 on signal: A

The cursor is under the setpoint number field.

Use the UP and DOWN arrow keys to select the

desired setpoint number (1 to 4). Use the RIGHT

arrow key to move the cursor to the signal field.

Then use the UP and DOWN arrow keys to select

the desired signal. The signal can be set to “-”

which indicates that the setpoint is not assigned

(disabled).

To change the assigned signal of another

setpoint, move the cursor back to the setpoint

number. Change the setpoint number, then move

the cursor back to the assigned signal field.

SP1=.0000 _ off

Press the OK/NEXT key when done to proceed to

the next menu.

The cursor is initially under the setpoint number

field. Select the desired number then move the

cursor to the numerical field. Set the desired

value and prefix.

Examples of numerical entries:

Move the cursor over to the setpoint type field. To

turn the setpoint on, select High, Low or USP.

Press the OK/NEXT key when done to proceed to

the next menu.

The next menu is used to assign a relay to the

setpoint. This is optional. The menu will appear

as:

SP1 use Relay#_

After selecting the desired setpoint number, move

the cursor to the relay field. The choices are: 1 - 4

and “_”. The “_” indicates that there are not any

relays assigned to the setpoint.