Page 1

T2660 Manual Track & Trace 2.1

User Manual

Document Version B

Page 2

Intentionally left blank

2 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 3

Table of Contents

1 Introduction 5

1.1 Intended Audience........................................................................................................ 5

1.2 Intended Use and Foreseeable Misuse ............................................................................ 5

1.3 Original Language ....................................................................................................... 5

1.4 Formatting and Meaning............................................................................................... 5

1.5 Contacting METTLER TOLEDO Service............................................................................. 6

1.6 Additional Documentation............................................................................................. 6

1.7 Warranty .................................................................................................................... 6

2 Important Safety Information 7

2.1 Safety Labels and Notice Labels .................................................................................... 7

2.2 General Protective Procedures ....................................................................................... 9

2.3 Safety Information for Various Activities........................................................................... 9

2.4 Special Hazards .......................................................................................................... 10

2.1.1 Hazard Notifications ...................................................................................... 7

2.1.1.1 Definitions of Signal Words ...................................................................... 7

2.1.1.2 Meaning of Hazard Alert Symbols.............................................................. 7

2.1.2 Mandatory Procedures................................................................................... 8

2.1.3 Prohibited Procedures.................................................................................... 8

2.1.4 Notice.......................................................................................................... 8

2.1.5 Note ............................................................................................................ 9

2.3.1 Transporting and Moving the Equipment .......................................................... 9

2.3.2 Installing...................................................................................................... 10

2.3.3 Operating the Equipment and Monitoring the Inspection Process......................... 10

2.3.4 Testing and Verifying the Equipment ................................................................ 10

2.3.5 Maintaining, Cleaning and Sanitizing the Equipment ......................................... 10

2.4.1 Electricity ..................................................................................................... 10

2.4.2 Strobe Lights ................................................................................................ 10

2.4.3 Lights and Laser Sensors ............................................................................... 11

3 Equipment Description 12

3.1 Function ..................................................................................................................... 12

3.2 Aggregation Principle ................................................................................................... 12

3.3 Equipment Overview..................................................................................................... 13

3.4 Controls Description..................................................................................................... 16

4 Installation 17

4.1 Setting the Equipment in Place ...................................................................................... 17

4.2 Adjusting the Position of Extendible Printer Tables............................................................ 18

5 Operation 20

5.1 Operation Workflow...................................................................................................... 20

5.2 Starting the Equipment.................................................................................................. 20

5.3 Using the Touch Screen ................................................................................................ 21

5.4 Displaying Aggregation Information in PLM..................................................................... 21

5.5 Shutting Down the Equipment........................................................................................ 24

6 Maintenance 25

7 Cleaning 26

7.1 General Cleaning Procedure.......................................................................................... 26

7.2 Cleaning Components Made of Stainless Steel................................................................. 27

7.3 Cleaning Components Made of Aluminum ...................................................................... 27

7.4 Cleaning the Touch Screen............................................................................................ 27

7.5 Cleaning the Hand Scanner........................................................................................... 28

7.6 Cleaning the Glass Plate............................................................................................... 28

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 3 / 38

Page 4

8 Troubleshooting 29

9 Disposal 31

10 Technical Data 32

10.1 Specifications .............................................................................................................. 32

10.2 Dimensional Drawings ................................................................................................. 34

10.3 EU Declaration of Conformity......................................................................................... 36

4 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 5

1 Introduction

1.1 Intended Audience

This User Manual is for all personnel who do the following tasks:

• Setting up a product and changing a product

• Operating the equipment

• Cleaning the equipment

1.2 Intended Use and Foreseeable Misuse

In this manual, the METTLER TOLEDO product inspection solution, including all of its components, is

referred to as the "equipment".

Only use the equipment to inspect and sort products, according to the procedures in this manual. Any other

use of the equipment is considered misuse. If you use the equipment beyond the limits of the design specification without written consent from METTLER TOLEDO, it is considered misuse.

Common foreseeable misuses include the following:

• Disabling safeguards, or operating the equipment without the properly functioning safeguards in place

• Climbing or standing on the equipment

• Adding parts or modifying equipment without approval from METTLER TOLEDO

• Operating the equipment beyond the limits of the design specification

• Not obeying the instructions and safety notes described in this manual

• Using the equipment in a specific environment, unless the equipment is designed for that environment,

for example:

– FDA environments

– Hazardous locations (explosive atmospheres)

– Environments where there is need for aggressive cleaning or sanitization

• Placing anything on the equipment that is not designed to be placed on the equipment

• Operating the equipment in the reverse direction of transport

• Not maintaining the equipment according to the instructions in the manual

• Accessing the area around the conveyors or rejectors while the equipment is running

• Accessing any hazard area before de-energizing and securing it

• Operating without the reject bins in place, if reject bins are included in your equipment

• Operating equipment that is not properly installed or integrated

• Using pens, tools, or any other item instead of a finger on the touchscreens

1.3 Original Language

The original manual is written in English. If you are reading a translated version of this manual, and you

also need the English original manual, you can ask METTLER TOLEDO to supply it. If you have a question

about the intended meaning of any translated text, consult the original English-language manual.

1.4 Formatting and Meaning

The formats used in this manual have determined meanings. If they are used they denote the following:

Format Meaning

PC

'apostrophes' Names of fields, checkboxes, modes, parameters

<angle brackets> wildcard for tab names of devices (individual names

Bold

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 5 / 38

Menu Paths, Buttons at the screen surface, fixed tab

names, names of screens and dialogs

can be assigned)

UI texts

Page 6

1.5 Contacting METTLER TOLEDO Service

Contact your authorized METTLER TOLEDO Service representative about the following products and services:

• Installation

• Integration

• Start-up support

• Commissioning

• Performance verification and audit services to certify that your equipment is maintaining its performance

levels

• Certified, genuine parts

• Emergency repairs and support

• Service contracts customized to your needs

• Customer training

For more information, contact your local and authorized METTLER TOLEDO Service representative using the

link below (and, if necessary, select the applicable country):

http://www.mt.com/contact

When you contact the Service Department, have the following information available, if applicable:

• METTLER TOLEDO order number and date

• Equipment name, model, or type

• Serial number

• Production line name

• Software version

• Precise wording of the displayed error message or detailed fault description

• Pictures or videos of the part or problem

1.6 Additional Documentation

For details on the PLM software refer to the PLM User Manual on www.mt.com/pce-manuals.

For details on the SMC refer to the following manuals on www.mt.com/pce-manuals:

• User Manual on SMC Series 3 hardware

• User Manual on SMC OCV software

• User Manual on SMC JData Trans 3.0 software

The following components are manufactured by suppliers:

• Printer (e.g. Zebra printer)

• Hand scanner (e.g. Bluetooth Honeywell Xenon hand scanner)

For details on these components refer to the supplier's documentation.

1.7 Warranty

For information on warranty, refer to the official METTLER TOLEDO terms and conditions at

http://www.mt.com/us/en/home/site_content/legal/commercial_terms.html.

6 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 7

2 Important Safety Information

All information related to safety in this manual is important. The information in this chapter is general. There

is other important safety information that you must read throughout the manual.

Important Safety Message

Read and understand all the safety information in the following sections as

well as the safety messages in the rest of this manual.

If you do not follow the safety information and messages, this may lead to property

damage and personal injury up to and including death.

2.1 Safety Labels and Notice Labels

The ISO3864 safety labels are installed at potentially hazardous areas on the equipment. They give special

safety-related notifications. The locations of these labels are given in the drawings supplied with your

equipment. There are three types of safety labels:

• Hazard notifications

• Mandatory procedures

• Prohibitive procedures

Additionally, NOTICE labels may appear on your equipment.

The meanings of the different kinds of labels are explained in the following sections.

Before you transport, install, operate or work on the equipment, find out about the location and meanings of

the labels. Maintain the labels so that they are clear of obstructions and are readable. Do not remove any

labels. Replace any label that is no longer readable.

2.1.1 Hazard Notifications

A hazard notification consists of the following:

• Hazard alert symbol (yellow triangle with black symbol)

• Signal word (DANGER , WARNING , or CAUTION )

• Special notifications related to the hazard (as required)

The signal word labels are attached next to the hazard alert symbol labels on the equipment.

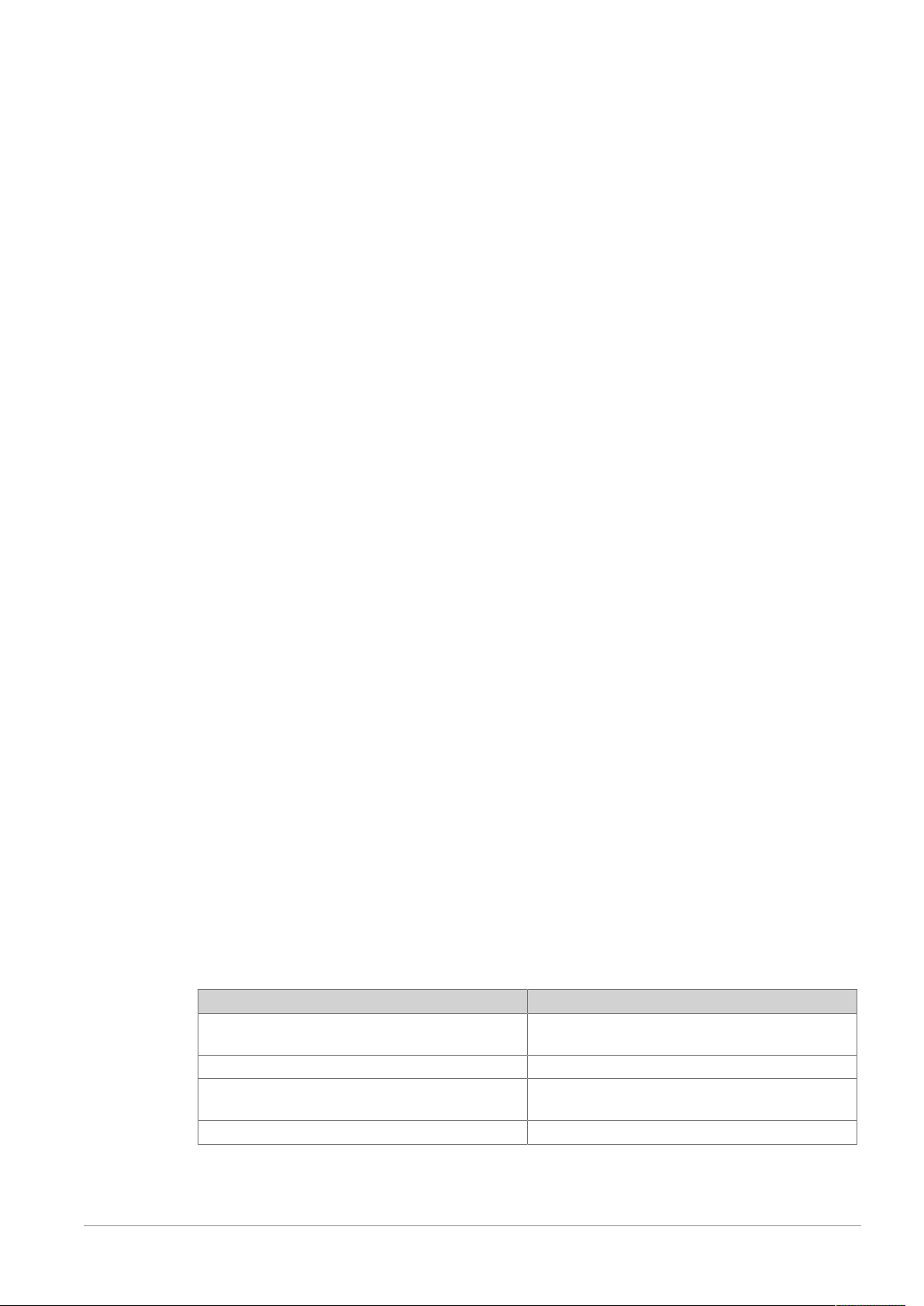

2.1.1.1 Definitions of Signal Words

Signal words describe the level of risk of a particular hazard. The color of the safety label background

indicates the risk, as shown in the following table. The definitions of the signal words are based upon the

ISO3864 definitions.

DANGER (red): This signal word indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING (orange): This signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION (yellow): This signal word indicates a potentially hazardous situation

which, if not avoided, could result in minor or moderate injury.

2.1.1.2 Meaning of Hazard Alert Symbols

The following hazard alert symbols may be installed on your equipment.

Crushing

Cutting

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 7 / 38

Page 8

Impact

Loss of stability

Slipping, tripping

Electrical shock

UV light

Optical radiation

2.1.2 Mandatory Procedures

Mandatory procedures alert personnel to special, required actions. The round labels have blue backgrounds

and white symbols. The symbols describe the required action. The following table lists the mandatory

procedures labels which may be installed on your equipment.

Read the manual

Lockout, tagout

2.1.3 Prohibited Procedures

Prohibited procedures alert personnel to particular actions to avoid. The labels are round with a circular red

band and single diagonal cross bar. The black symbol describes the action to avoid. The following table

lists the prohibited procedure labels that may be installed on your equipment.

Do not operate without safeguards

Do not step on the equipment

2.1.4 Notice

The word NOTICE does not give safety information. It is still an important word to inform you of activities

that may harm the equipment or other property. The following definition is based upon the ANSIZ535

definition.

8 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 9

NOTICE (blue): This indicates important information that is not related to personal

injury which, if ignored, could result in damage to the equipment, damage to

property, malfunctions, erroneous results, or loss of data.

2.1.5 Note

The word NOTE: does not give safety information. It indicates useful supplementary information, hints, and

tips.

2.2 General Protective Procedures

Important Safety Message

Make sure that all personnel who work on or near the equipment are capable

of performing all operations in a safe way.

• Keep the manual in a convenient location near the equipment. Replace the manual if it becomes lost or

damaged.

• Wear Personal Protective Equipment (PPE) in accordance with your plant's safety procedures.

• Understand the hazards of the equipment and the risks related to those hazards before working on or

near the equipment.

• Obey all safety procedures of the local plant.

• Do not wear loose clothing, jewelry, long hair, or anything that can become entangled with the

equipment.

• Be careful around the equipment to avoid hitting your head, arms, or other body parts against the

equipment. Be careful if the equipment is over your head.

• Be careful not to trip over cables or other parts of the equipment.

• Do not move quickly in the area around the equipment.

• Do not climb, hang onto, or use any of the part of the equipment as a support.

• Obey the lockout tagout (LOTO) procedures of the plant.

• If there is a safety-related malfunction when you are operating the equipment, press the emergency stop

device. Tell the responsible supervisor, and follow the applicable steps approved by your company to fix

the malfunction.

2.3 Safety Information for Various Activities

Important Safety Message

Read and understand all parts of the manual before using or working on any

equipment.

The following sections list safety information for particular activities or groups of activities. Refer to the

correct sections in the manual for more detailed instructions.

2.3.1 Transporting and Moving the Equipment

• Only transport or move the equipment if you have the applicable training as defined by your company.

• Your company has sole responsibility for the safe moving and transporting of the equipment.

• Use safe moving procedures during transporting to maintain stability and to prevent the equipment from

tipping or falling.

• Disconnect the electrical supply, the pneumatic supply, and the communication cables before you move

the equipment.

• Use the correct lifting devices. If you use a forklift, lift the equipment at the correct lift points as shown by

the blue lift point labels.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 9 / 38

Page 10

• Blue lift point labels are placed on the equipment to show recommended locations for lifting. These lift

point locations were tested with the manufacturer's forklift trucks. A qualified rigger must make sure that

the lift points are correct for your lifting equipment.

• When you lift the equipment by hand, obey the safe lifting procedures of your company.

2.3.2 Installing

Only install the equipment if you have the applicable training as defined by your company.

2.3.3 Operating the Equipment and Monitoring the Inspection Process

• Before beginning operation, make sure that the area is safe.

• Know the location and effect of each emergency stop button that controls the equipment.

• Do not operate the equipment without protective guards and doors in place.

• Do not reach into path of the products when any conveyors are in motion.

• Do not reach into the area around any sorting device, when the equipment is turned on.

• Make sure the safety circuit is working correctly.

• Do regular inspections of the equipment.

• If there is a fault or change in the equipment behavior, stop the equipment and inform responsible

personnel.

2.3.4 Testing and Verifying the Equipment

Only do testing and verifying of the equipment if you have applicable training as defined by your company.

2.3.5 Maintaining, Cleaning and Sanitizing the Equipment

• Remove all power from the equipment before doing any work.

• Keep the equipment in good working order.

• Follow a preventative maintenance program.

• Replace parts when needed.

• Obey the lockout tagout (LOTO) procedures of the plant.

• Test (validate) the safety circuit after parts are replaced.

• Only use METTLER TOLEDO approved spare parts and accessories.

• Do not make any unauthorized modifications to the equipment.

• Replace safety labels if damaged, missing, or unreadable.

• Do a visual check of the equipment at least once during a shift to identify any visual damage or faults.

Report any equipment changes to the responsible supervisor immediately.

• When required for a hygienic production environment, do regular sanitizing of the equipment according

to your company's procedures.

• After cleaning or sanitizing, check all cables, connectors, and pneumatic hoses for leakage, loose

connections, rub marks and damage. Tighten, repair, or replace any faulty cables and air tubing, as

necessary.

2.4 Special Hazards

The following sections describe special instructions for equipment that may have special hazards.

2.4.1 Electricity

• Only work on the electrical systems if you have the applicable electrical training as defined by your

company.

• Keep all electrical enclosure doors closed. If the doors have locks on them, keep them locked.

• Remove all power from the equipment before doing any work.

2.4.2 Strobe Lights

• Strobe lights can cause seizures in individuals with photosensitive epilepsy.

10 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 11

• Individuals with photosensitive epilepsy must not operate the equipment.

• Do not operate the equipment when excessively fatigued or after consuming alcohol.

• Do not look directly at the lights, especially at close distances.

• Avoid placing the equipment in areas with reduced lighting.

• If lights are inside of an enclosure, do not open the enclosure doors when lights are flashing.

2.4.3 Lights and Laser Sensors

• Do not stare directly at any lights or lasers.

• Avoid prolonged exposure to ultraviolet (UV) light, infrared (IR) light, and lasers.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 11 / 38

Page 12

3 Equipment Description

1 2

3

4

PLM

3.1 Function

The T2660 Manual Track & Trace is used for the setup of hierarchical levels in manual final packaging

(manual aggregation).

Depending on how the line is structured, aggregation can be conducted in the following forms:

• from item to bundle/case

• from bundle to case

• from case to pallet

• from bundle to pallet

The equipment can also be used off-line as a rework station.

The verification of items is performed by the code reading device (hand scanner or SMC). The codes are

aggregated by the PLM software.

The equipment may comprise up to three hand scanners and up to three printers – one hand scanner and

printer for each aggregation step.

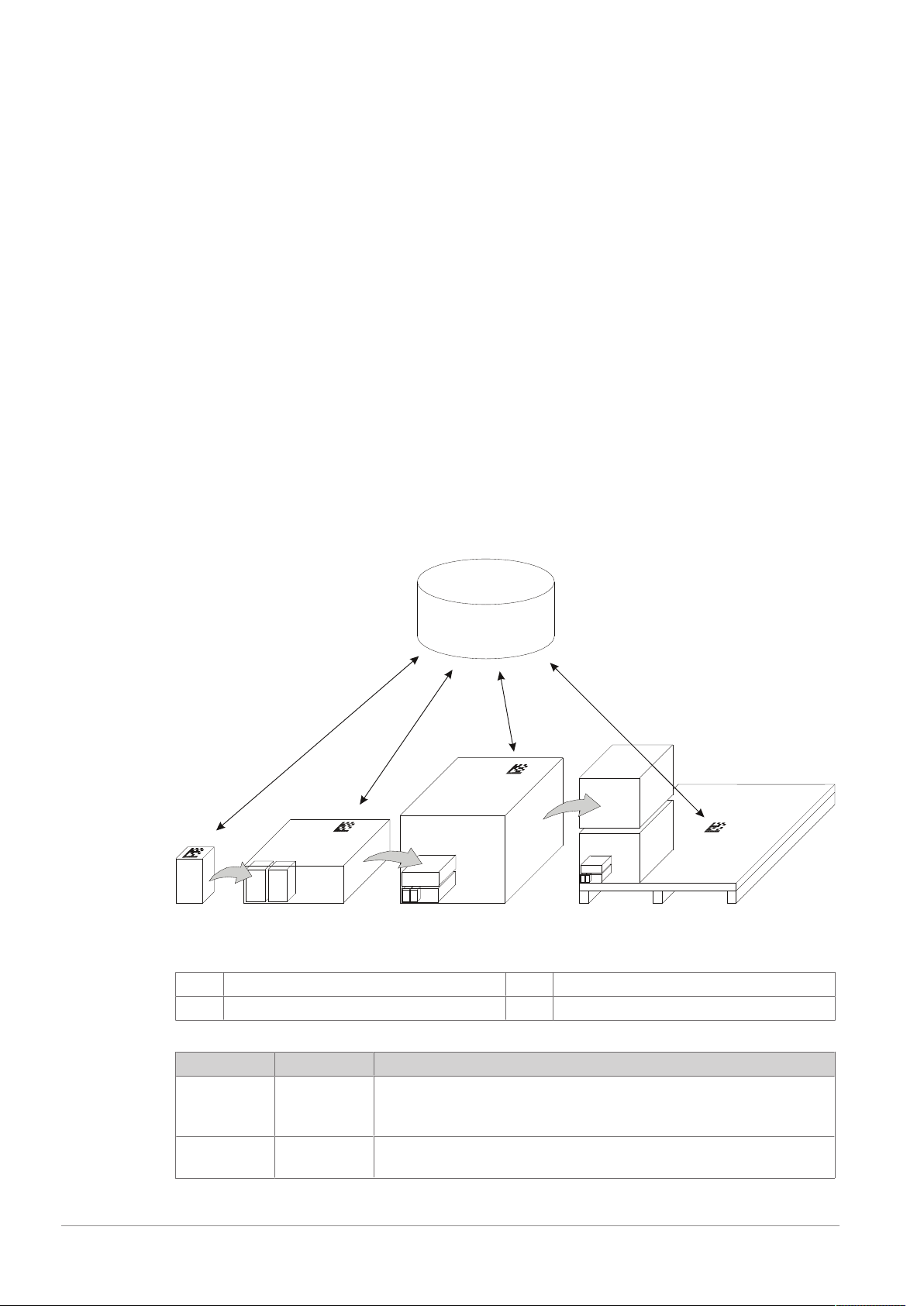

3.2 Aggregation Principle

Aggregation is the classification and capture of the smallest units (e.g. folding boxes) to higher-rank units

(e.g. bundles, cases, and pallets). At each aggregation rank, unambiguous assignment of units to parentchild aggregation ranks is done.

The identification of the units is done by printing on the unit itself or by printing on labels which are attached

to the unit. The following example shows the typical aggregation ranks.

12 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Aggregation Principle with regard to PLM

1

3

In the following table, the terms for aggregation units are described for a line with four aggregation ranks.

Trade Unit Rank Explanation

Item 1 An item is the smallest unit at the aggregation process. An item can be, for

Bundle 2 A bundle consists of several items. Bundles are usually aggregated to a

Item

Case

2

4

example, a folding box, a blister, or a bottle. Items are usually aggregated

to a bundle or directly to a shipping case.

case or directly to a pallet.

Bundle

Pallet

Page 13

Trade Unit Rank Explanation

Case 3 A case is a carton box where either bundles or items are packed into.

Cases are aggregated to a pallet.

Pallet 4 A pallet contains several cases or bundles.

Unit 1/2/3/4 A unit is the term for any aggregation rank. The term 'unit' is used for an

item (rank 1), bundle (rank 2), shipping case (rank 3), or pallet (rank 4).

3.3 Equipment Overview

Number Component Description

1

2

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 13 / 38

Touch screen • 15" touch screen for central operation

• Access to the PLM software

• Includes USB and LAN port

• Attached to the main frame

Swivel arm • Allows adjusting the touch screen as required for easy,

user-friendly operation

Page 14

Number Component Description

3

Hand scanner • Hand scanner for aggregation

• Up to three hand scanners possible

• Two hand scanner versions available:

– Wireless connection via Bluetooth®, with base for

charging

– Hand scanner with USB connection and bracket

4

Inspection table • Height-adjustable

• Operational area where aggregation is performed

• Attached to the main frame

• Includes a guiding rail for easy alignment of the

products and for fixing the reading distance if an SMC

is used

5

6

Base frame • Holds the bottom printer table

• Includes four castors with brakes

Printers and printer tables

Printers

• Up to three printers can be used to print various labels

for the different ranks

• Example configurations:

– with one printer: Case Label Printer (one rank)

– with two printers: Case Label Printer, Pallet Label

Printer (two ranks)

– with three printers: Bundle Label Printer, Case

Label Printer, Pallet Label Printer (three ranks)

Bottom printer table

• Attached to base frame

• Includes telescopic rails

Printer tables at the side (optional)

• Hold additional printer (optional)

• Attached to main frame

• Height-adjustable

• Extendible (optional) · to facilitate servicing at the

printer

7

8

Castor • Allows full range of movement

• Attached to the base frame

• With brakes to secure the equipment

Electrical cabinet The electrical cabinet comprises the following

components:

• IPC (Industrial PC)

• UPS (Uninterruptible Power Supply)

• Main switch

• 230V power supply unit

14 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 15

Number Component Description

9

Main frame The main frame comprises the following components:

• Swivel arm with touch screen

• Inspection table

• Printer tables at the sides (optional)

• Base of wireless hand scanner

• Stack light (optional)

The main frame is attached to the base frame.

The main frame offers three positions to attach

components: left, middle, right. At these positions, a

certain drilling pattern is available that serves as an

adapter for mounting the component and for routing the

cables to the electrical cabinet. If a position is not used,

the drilling pattern is covered. This allows to easily

upgrade the equipment at a later point in time.

The following components can be attached to these

drilling patterns:

• Swivel arm

• Base of the wireless hand scanner

• Stack light (optional)

10

SMC (optional) • Smart Camera (SMC) (optional)

• Can perform print inspection, grading, and/or aggre-

gation of one rank

• Triggered by a capacitive proximity sensor

• Attached to the inspection table by means of the

mounting bracket

• Optional: External illumination for better lighting of the

products

PLM Software

The T2660 equipment is operated by means of the PCE Line Manager software (PLM).

The PCE Line Manager software (PLM) centrally controls and manages units such as printers, cameras,

and scanners on one line. The connected units are provided with statistical data (e.g. batch and expiry

date) at production start and with dynamic data (serial numbers) in the production process. The operator is

able to manage all devices on the line with minimum effort. The selected settings are saved in the central

format database.

For details on the PLM software refer to the PLM User Manual on www.mt.com/pce-manuals.

Stack Light

When using an SMC for the print inspection, a stack light can be purchased (not shown in the picture). The

stack light shows the status of the print inspection performed by the SMC.

Color Description

Green Reading result 'Good'

Red Reading result 'Bad'

The stack light is mounted to the main frame.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 15 / 38

Page 16

3.4 Controls Description

3

2

1

4

5

The following graphic shows the controls at the T2660 equipment.

Rear view

1

3

5

Power cable inlet

LED for UPS

LAN connector

2

4

Main switch

USB connector

16 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 17

4 Installation

DANGER

Electrocution or serious personal injury due to faulty installation

Improperly performing the electrical installation can cause electrocution.

Only qualified personnel may engage the hazardous area (including the electrical

cabinet) and only when appropriate personal protective equipment is used. If the

equipment does not have a power plug, the equipment must only be connected by a

qualified electrician in accordance with national and local electrical codes.

CAUTION

Personal injury or damage to the equipment

The equipment and its software have to be installed by adequately trained personnel only.

For details on the installation refer to the Technical Manual or contact METTLER TOLEDO.

4.1 Setting the Equipment in Place

CAUTION

Impact due to unsecured equipment

Unsecured equipment may move or roll away which increases the danger of impact.

1 Place the equipment on even ground.

2 Apply the brakes.

CAUTION

Tripping due to unsecured equipment

Unsecured equipment may move or roll away which increases the danger of tripping.

1 Place the equipment on even ground.

2 Apply the brakes.

1 Loosen the brakes by pulling up the lever at each castor.

2 Position the equipment at the desired position.

3 Apply the brakes by pushing down the lever at each castor.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 17 / 38

Page 18

NOTE: You can use your foot to loosen or apply the brakes.

4

6

5

2

3

1

Brakes at the castors

4.2 Adjusting the Position of Extendible Printer Tables

Extendible printer tables can be moved backwards or forwards on a guiding rail.

NOTE: The bottom printer table is extendible by default. The printer tables at the sides can be extendible as

an option.

Extendible printer tables are fixed by means of a locking bolt. The locking bolt locks with the holes in the

guiding rail and prevents the printer table from moving unwantedly. For printer tables at the side, the locking

bolt is rotatable when lifted, so that it does not catch with the holes in the guiding rail while being moved.

Front view

1

3

5

18 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Main frame

Bottom printer table

Guiding rail

2

4

6

Locking bolt (not rotatable)

Side printer table

Locking bolt (rotatable)

Page 19

6

2

1

5

4

3

Side view

1

3

5

Main frame

Bottom printer table

Guiding rail

2

4

6

Locking bolt (not rotatable)

Side printer table

Locking bolt (rotatable)

Adjusting the Position of the Bottom Printer Table

1 Lift the locking bolt (2).

2 Move the printer table (3) as required.

3 Let the locking bolt (2) slide into a hole in the guiding rail. Ensure that the locking bolt locks with a hole

to avoid any unwanted movements of the printer table.

Adjusting the Position of the Side Printer Table

1 Lift the locking bolt (6) and rotate it, if applicable. This prevents the locking bolt from catching with the

guiding rail (5).

2 Move the printer table (4) as required.

3 Rotate back the locking bolt (6) and let it slide into a hole in the guiding rail (5). Ensure that the locking

bolt locks with a hole to avoid any unwanted movements of the printer table.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 19 / 38

Page 20

5 Operation

CAUTION

Eye irritation due to optical radiation

Do not stare directly at any lights or lasers, especially at close distance.

Avoid prolonged exposure to ultraviolet (UV) light, infrared (IR) light, and lasers.

Note that optical radiation is not always visible to the eye.

CAUTION

Impact due to unsecured equipment

Unsecured equipment may move or roll away which increases the danger of impact.

1 Place the equipment on even ground.

2 Apply the brakes.

CAUTION

Tripping due to unsecured equipment

Unsecured equipment may move or roll away which increases the danger of tripping.

1 Place the equipment on even ground.

2 Apply the brakes.

5.1 Operation Workflow

The operator uses the hand scanner to scan all labels on the packaging unit. The scanned data is sent to

the PLM software for verification. The PLM verifies the scanned data for correctness and automatically

triggers the label print for the higher unit. The printing system generates the label with the predefined characteristics, e.g. serial number, and prints it out. The hand scanner is also used to conduct a complete verification by verifying that the label is legible. Thus, traceability is completely documented and verifiable up to

the final packing step.

Item to Bundle/Case Aggregation

The items with the previously printed item codes reach the equipment via the conveyor belt. The items are

manually packed in a bundle or case. Each item for a bundle or case is scanned one after the other with the

hand scanner for items. Once the specified number of items has been reached, the printer (e.g. Zebra label

printer) prints the bundle or case label. The label is attached manually to the bundle or case and scanned

with the hand scanner for bundle/case labels. The bundle or case is thereby aggregated.

Bundle to Case Aggregation

The bundles that were previously and correctly labeled in the upstream bundle station, reach the equipment

via the conveyor belt. The bundles are manually packed in a shipping case. Each bundle in a case is

scanned one after the other with the hand scanner for bundles. Once the specified number of bundles has

been reached, the printer (e.g. Zebra label printer) prints the shipping case label. The label is attached

manually to the shipping case and scanned with the hand scanner for case labels. The shipping case is

thereby aggregated.

Case to Pallet Aggregation

All correctly labeled shipping cases are scanned with the handheld scanner and packed on a pallet. Once

the pallet has reached the pre-defined number of shipping cases, the label printer prints the label for the

pallet. The label is attached manually to the pallet and scanned with the hand scanner for pallets.

NOTE: In applications with an SMC, the labels are read and verified by the SMC. The SMC is triggered by the

capacitive proximity sensor.

5.2 Starting the Equipment

1 Check that the equipment is at the intended production position.

2 Check that the power supply cable is connected to a suitable power source. If the power supply is not

established yet, contact your Supervisor.

20 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 21

3 Check that the electrical cabinet is securely closed and locked.

The electrical cabinet is provided with an interlock to disconnect the main switch, and has a fixed guard

that can only be opened with a special key.

4 Switch on the main switch.

ð If applicable, the 'Power on' signal light at the electrical cabinet illuminates.

Main switch (switched on)

5.3 Using the Touch Screen

With a touch screen, you make selections on the screen by touching the menu items and command buttons

with a finger.

• To select or activate an option, press on the corresponding position at the touch screen.

• To type information into a box, press inside the box. An on-screen keyboard opens that allows you to

type the information.

As an alternative, you can connect a common PC keyboard via USB.

NOTICE

Damage to the touch screen

Sharp objects, such as a screw driver, can destroy the touch screen. Only use a finger or

blunt object to operate the touch screen.

Do not use diluting agents, benzene, abrasives, or other strong solvents for cleaning, as

these can damage the display.

Damage due to improper handling are not covered by the warranty.

5.4 Displaying Aggregation Information in PLM

1 Start the equipment.

ð PLM or the remote desktop starts automatically.

2 Log in.

3 In the Home screen, press the hand scanner tab.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 21 / 38

Page 22

4 Take the hand scanner and scan the barcode for the bundle or the case.

Home > Hand Scanner

5 Perform one of the following steps to receive the desired information.

a) To display the code scanned by the hand scanner, press the Show information button.

b) To display the placement of the current order's scanned code in the hierarchy, press Show hierarchy.

The hierarchy is shown in a tree format.

c) To display the progress of the executed aggregation in the current aggregation step, press Show

aggregation.

Home > Hand Scanner > (Scan Code) > Show information

22 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 23

Home > Hand Scanner > (Scan Code) > Show hierarchy

Home > Hand Scanner > (Scan Code) > Show aggregation

For details on the PLM software refer to the PLM User Manual on www.mt.com/pce-manuals.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 23 / 38

Page 24

5.5 Shutting Down the Equipment

WARNING

Personal damage due to running systems

For some equipment, the main switch only controls the electrical cabinet of the equipment

it is mounted to. It may be necessary to switch off several main switches at your line, one

for each equipment that you want to stop. Otherwise conveyor belts or other moving

equipment may continue to move, even if you have switched off the power supply at your

equipment.

1 To shut down the system, suspend or finish the production.

2 Switch off the main switch.

ð The system will shut down properly thanks to the UPS (Uninterruptible Power Supply).

Main switch (switched off)

24 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 25

6 Maintenance

CAUTION

Personal injury or damage to the equipment

The equipment and its components have to be maintained by adequately trained

personnel only. For details on the maintenance refer to the Technical Manual or contact

METTLER TOLEDO.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 25 / 38

Page 26

7 Cleaning

7.1 General Cleaning Procedure

Regular cleaning is very important to keep good system operation. When cleaning your equipment follow

these steps in consultation with your supervisor (if applicable):

1 Ensure that the production is stopped.

2 Switch off the equipment. If applicable, isolate the equipment from the electrical power supply. Follow

LOTO.

3 Let the equipment cool down.

4 Cover electrical equipment and other surrounding equipment that may get damaged by the cleaning

process.

5 Clean the equipment following the instructions in the Cleaning chapters.

6 After cleaning, ensure that all safety labels are available and readable. Replace any worn or missing

safety labels.

7 Return the equipment to its normal operation condition. Follow LOTO. Before you restart the equipment,

make sure that all safety devices are back in their original positions and correctly fastened. For example,

if you removed any guards for cleaning, make sure that you reinstall them.

WARNING

Personal injury due to non-compliance to company-specific LOTO

LOTO (Lockout-Tagout) procedures may differ from company to company. Before starting

to work at the equipment inform yourself about the LOTO procedure at the company or

plant.

WARNING

Personal injury and damage to the equipment due to hot parts

During operation, some parts of the equipment may get hot. To avoid personal injury and

damage to the equipment, let the equipment cool down to room temperature before

handling the equipment (e.g. cleaning or maintenance).

CAUTION

Personal damage due to detergents

Wear sufficient protective clothing and hand protection as recommended by the

manufacturer of any detergents used.

NOTICE

Damage due to careless cleaning

The equipment components are made of different materials that have to cleaned using

different detergents. Only use the detergents given in the respective chapter. Do not use

pure alcohol, concentrated acid, or lye.

To prevent water from entering the equipment make sure that all doors and enclosures are

securely closed.

Do not use a high-pressure jet to hose down the equipment.

NOTICE

Damage to products due to unsuitable cleaning and sanitizing procedures

Depending on the products processed in your application (for example, anti-cancer drugs

or food), cleaning and sanitizing may be subject to special regulations. Ensure to be

informed about any relevant regulations and procedures concerning your specific application.

26 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 27

7.2 Cleaning Components Made of Stainless Steel

Stainless steel generally provides very good protection against corrosion. Stainless steel, however, does not

always remain rust-free. Depending on the operational use and the conditions in the working environment,

stainless steel can become dirty or rusty to some extent. The most common causes are surface rust (fine

iron particles in the air), active gases, the accumulation of sediments, and the build-up of salts.

Overview

Interval 1x per day

Required tools and

working materials

1 Observe the steps explained in the chapter [General Cleaning Procedure}Page26].

2 Remove any superficial damages on the equipment using a stainless steel spray.

3 Clean the stainless steel components using a cloth and a mix of soap and water.

4 Wash off any residues with a suitable amount of water.

5 Dry the equipment using a cloth.

• Spray for stainless steel

• Mix of soap and water

• Water

• Soft, lint-free cloth

7.3 Cleaning Components Made of Aluminum

In general, components made of aluminum are anodized to protect them against corrosion. During

anodization, an invisible, resistant layer of aluminum oxide is created that protects the equipment.

Depending on the operational use and the conditions in the working environment, the equipment can

become dirty to some extent. The most common causes are fine iron particles in the air, active gases, the

accumulation of sediments, and the build-up of salts.

Overview

Interval 1x per day

Required tools and

working materials

• Warm water

• Several soft, lint-free cloths

1 Observe the steps explained in the chapter [General Cleaning Procedure}Page26].

2 Clean the aluminum components using a slightly wet cloth without applying too much pressure. Change

the cloth several times. This prevents the surface from being scratched by dust particles in the cloth.

3 Wash off any residues with a suitable amount of warm water.

4 Dry the equipment using a cloth without applying too much pressure.

7.4 Cleaning the Touch Screen

The material of the touch screen's display varies depending on the selected equipment. Some touch screens

feature protection glass, for example.

Overview

Interval 1x per day

Required tools and

working materials

• Commercial detergent for computer equipment, mild glass cleaner, or mix of

soap and water

• Alcohol-based disinfectant

• Soft, lint-free microfiber cloth

NOTICE

Damage to the display due to solvents

Do not use diluting agents, benzene, abrasives, or other strong solvents, as these can

damage the display.

The system is switched off to avoid any unwanted, accidental input.

§

1 Observe the steps explained in the chapter [General Cleaning Procedure}Page26].

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 27 / 38

Page 28

2 Clean the touch screen using a cloth and a suitable detergent. Do not apply too much pressure.

3 Dry the touch screen using a cloth. Do not apply too much pressure.

4 We recommend to disinfect the touch screen using a alcohol-based disinfectant.

7.5 Cleaning the Hand Scanner

If the hand scanner window is dirty, the hand scanner may not read codes properly any more.

NOTICE

Damage to the scanner due to faulty cleaning procedures

Using abrasive wipes, using solvents such as acetone, or applying other faulty cleaning

procedures may damage the hand scanner (e.g. scratches at the window).

Follow the cleaning procedures in the supplier's documentation.

If other parts of the hand scanner (such as the handle and the housing) are dirty, follow the instructions

below.

Overview

Interval 1x per week

Required tools and

working materials

• Soft, lint-free cloth

• Water or mild solution of detergent and water

• Alcohol-based disinfectant

1 Observe the steps explained in the chapter [General Cleaning Procedure}Page26].

2 Clean the housing of the scanner or of its base using a cloth dampened with water or a mild solution of

detergent and water.

3 Rinse the housing using a clean cloth dampened with water only.

4 We recommend to disinfect the handle of the hand scanner using a alcohol-based disinfectant.

5 For safe cleaning of the scanner window refer to the supplier's documentation.

7.6 Cleaning the Glass Plate

The plate at the front of the camera is made of glass.

Overview

Interval 1x per week

Required tools and

working materials

1 Observe the steps explained in the chapter [General Cleaning Procedure}Page26].

2 Clean the glass plate at the camera front using a cloth and a suitable detergent.

3 Dry the glass plate using a cloth.

• Mild glass cleaner or mild solution of soap and water

• Soft, lint-free cloth

28 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 29

8 Troubleshooting

WARNING

Personal injury due to inadequate qualification

Before attempting any corrective action, be sure that the person doing the action has been

trained on the equipment and has read the entire manual. Failure to do so can result in

injury and/or property damage.

Errors and Malfunctions at the T2660 Equipment

Error/Malfunction Probable Cause Solution

Equipment does not start. No power supply or power supply

not sufficient.

Faulty electrical connection of

equipment.

Corded hand scanner does not

scan (no sound emitted).

Cordless hand scanner does not

scan (no sound emitted).

Equipment moves. Brakes are not applied. Apply the brakes at the castors.

No power supply or power supply

not sufficient.

Faulty electrical connection of

equipment.

Hand scanner is dirty. Clean the hand scanner.

Battery is empty. Charge the hand scanner in the

Bluetooth® connection is interrupted.

Hand scanner is dirty. Clean the hand scanner.

Ground is uneven. Ensure that the equipment is

Check if the 'Power on' signal light

at the electrical cabinet is

illuminated.

Check if main switch is switched

to 'on'.

If the equipment still does not start,

contact your Supervisor.

Check the hand scanner installation.

base.

Re-establish the Bluetooth

connection. See supplier manual

on the hand scanner.

positioned on even ground.

®

Errors and Malfunctions at the SMC

Error/Malfunction Probable Cause Solution

Equipment does not start. No power supply or power supply

not sufficient.

Faulty electrical connection of

equipment.

Image quality is poor. Faulty optical settings. Capture a test image. Contact your

Unsuitable mounting position of

the SMC.

External illumination is not

sufficient.

Faulty alignment of external illumination.

Faulty electrical connection of

external illumination.

Contact your Supervisor.

Supervisor to adjust the optical

settings.

Contact your Supervisor.

Contact your Supervisor.

Contact your Supervisor.

Contact your Supervisor.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 29 / 38

Page 30

Error/Malfunction Probable Cause Solution

Bad products are not detected. Glass plate is covered or dirty. Remove any obstructions.

Clean the glass plate.

Good products are evaluated as

bad.

Faulty electrical connection of

equipment.

Faulty optical settings. Capture a test image. Contact your

Glass plate is covered or dirty. Remove any obstructions.

Faulty optical settings. Capture a test image. Contact your

Contact your Supervisor.

Supervisor to adjust the optical

settings.

Clean the glass plate.

Supervisor to adjust the optical

settings.

Errors and Malfunctions at the PLM

For details on the PLM software refer to the PLM User Manual on www.mt.com/pce-manuals.

30 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 31

9 Disposal

In conformance with the European Directive 2012/19/EU on Waste Electrical and

Electronic Equipment (WEEE) this device may not be disposed of in domestic waste. This

also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment. If you have any questions, please contact

the responsible authority or the distributor from which you purchased this device. Should

this device be passed on to other parties, the content of this regulation must also be

related.

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 31 / 38

Page 32

10 Technical Data

10.1 Specifications

Specifications of the Main Frame

Specification Description

Material Stainless steel

Dimensions (HxWxD) inmm100 x 750 x 760

Weight in kg 40

Specifications of the Base Frame

Specification Description

Material Stainless steel

Dimensions (HxWxD) inmm760 x 1000 x 250

Weight in kg 35

Specifications of the Inspection Table

Specification Description

Material • Table: Stainless steel

Dimensions (HxWxD) in

mm

Working height (in mm) The inspection table is adjustable to the following heights:

Weight in kg • Table: 18

• Product guiding: Anodized aluminum

• Table: 730 x 600 x 54

• Product guiding: 720 x 30 x 10

• 805

• 830

• 855

• 880

• 905

• 930

• 955

• 980

• Product guiding: 2

Specifications of the Printer Table

Specification Description

Material • Table: Stainless steel sheet metal

• Telescopic rails: Galvanized steel

Dimensions (HxWxD) inmm400 x 635 x 50

Weight in kg 8.5

Specifications of the Electrical Cabinet

Specification Description

Electrical cabinet

760 x 760 x 300

(HxWxD) in mm

Material Stainless steel

Power supply 115/230VAC, 50/60Hz, single phase, ≥500VA

LAN connection 100/1000MBit/s

Weight in kg 80 to 100

32 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 33

Specifications of the Touch Screen

Specification Description

Size 15"

Material of the housing Stainless steel

Dimensions of touch

456 x 336 x 65

screen housing (HxWxD)

in mm

Weight of touch screen

10

with housing in kg

Specifications of the Bluetooth® Hand Scanner

Specification Description

Connection Bluetooth

®

Range 10m

Cable length of base inmm1600

Battery Lithium ion (min.1800mAH)

Details on hand scanners can be found in the supplier's documentation.

Specifications of the USB Hand Scanner

Specification Description

Connection USB

Cable length in mm 3000

Operating voltage 4 to 5.5VDC (low-voltage device)

Details on hand scanners can be found in the supplier's documentation.

Specifications of the Stack Light

Specification Description

Power supply 24VDC

Colors Red and green

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 33 / 38

Page 34

10.2 Dimensional Drawings

273

1711

1033

800

556

1081

790

635

273

800

1033

1711

1218

790

1078

T2660 with one printer

T2660 with two printers

34 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 35

608/678

275

2146

1399

747

R751

1005

685

604

1002

560/630

1033

1711

800/825/850/

875/900

1168

416

798

439

435

1653

730

458

T2660 with three printers

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 35 / 38

Page 36

10.3 EU Declaration of Conformity

36 / 38 T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

Page 37

Intentionally left blank

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B 37 / 38

Page 38

Pharmacontrol Electronic GmbH

Harzstraße 1

64646 Heppenheim, Germany

Tel. +49 6252 6736 0

Fax +49 6252 6736 111

www.mt.com

Subject to technical changes.

© Pharmacontrol Electronic GmbH 10/2019

T2660 Manual Track & Trace 2.1 - User Manual - Document Version B

www.mt.com/pce

For more information

Loading...

Loading...