Page 1

User Manual

T2611 - Manual Serialization

Document Version E

Page 2

Intentionally left blank

2 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 3

Table of Contents

1 Introduction 5

1.1 Intended Audience........................................................................................................ 5

1.2 Intended Use and Foreseeable Misuse ............................................................................ 5

1.3 Original Language ....................................................................................................... 5

1.4 Contacting METTLER TOLEDO Service............................................................................. 5

1.5 Additional Documents .................................................................................................. 6

2 Safety Notes 7

2.1 Safety Labels and Notice Labels .................................................................................... 7

2.2 General Protective Procedures ....................................................................................... 8

2.3 Safety Information for Various Activities........................................................................... 8

2.4 Special Hazards .......................................................................................................... 9

2.1.1 Hazard Notifications ...................................................................................... 7

2.1.1.1 Definitions of Signal Words ...................................................................... 7

2.1.1.2 Meaning of Hazard Alert Symbols.............................................................. 7

2.1.2 Mandatory Procedures................................................................................... 7

2.3.1 Transporting and Moving the Equipment .......................................................... 8

2.3.2 Installing...................................................................................................... 9

2.3.3 Operating the Equipment and Monitoring the Inspection Process......................... 9

2.3.4 Testing and Verifying the Equipment ................................................................ 9

2.3.5 Maintaining, Cleaning and Sanitizing the Equipment ......................................... 9

2.4.1 Electricity ..................................................................................................... 9

2.4.2 Strobe Lights ................................................................................................ 9

3 Equipment Overview 10

3.1 Equipment Function ..................................................................................................... 10

3.2 Equipment Description.................................................................................................. 11

4 Transporting, Moving, and Storage 13

4.1 Transporting the Equipment........................................................................................... 13

4.2 Storing the Equipment .................................................................................................. 14

4.3 Unpacking the Equipment ............................................................................................. 14

5 Installation 15

5.1 Mechanical and Electrical Installation............................................................................. 15

5.2 Setting up the Equipment .............................................................................................. 15

5.2.1 Set up the hand scanner ................................................................................ 15

5.2.2 Set up the Smart Camera ............................................................................... 16

5.2.2.1 Setting up a Product in SMC ..................................................................... 17

5.2.2.2 Final Result for SMC setup........................................................................ 25

5.2.3 Set up the printer........................................................................................... 26

6 Operation 27

6.1 Starting the Equipment.................................................................................................. 27

6.2 Setting the Box Size...................................................................................................... 27

6.3 Workflow .................................................................................................................... 28

6.3.1 Workflow 1: Print - Verify - Commission .......................................................... 28

6.3.2 Workflow 2: Decommission ........................................................................... 31

6.4 Shutting down the Equipment........................................................................................ 32

7 Maintenance 33

7.1 Changing the Printer Cartridge....................................................................................... 33

8 Cleaning 35

8.1 Visual Inspection and Cleaning of the System.................................................................. 35

8.2 Visual inspection of Gaskets/Seals ................................................................................. 35

8.3 Cleaning the Touch Screen............................................................................................ 35

8.4 Cleaning the Print Head................................................................................................ 35

8.5 General Advice on Stainless Steel Maintenance................................................................ 36

T2611 - Manual Serialization - User Manual - Document Version E 3 / 40

Page 4

9 Disposal 37

10 Technical Data SMC Series 3 38

4 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 5

1 Introduction

1.1 Intended Audience

This manual is written for non-technical personnel. For the purpose of this manual, non-technical personnel

are those who do not have specialized knowledge and training in the installation, commissioning,

integration, validation, or major maintenance of the equipment.

This manual gives basic information for the following activities:

• Transporting and setting the equipment in place

• Setting up a product and changing a product

• Operating the equipment

• Maintaining and cleaning the equipment

1.2 Intended Use and Foreseeable Misuse

In this manual, the METTLER TOLEDO vision solution, including all of its components, is referred to as the

"equipment".

The equipment must only be used for the visual inspection of products, according to the procedures in this

manual. Any other use of the equipment is considered misuse.

Common foreseeable misuses include the following:

• Replacing or modifying parts without approval from METTLER TOLEDO

• Operating the equipment beyond the limits of the technical specifications

• Not obeying the instructions and safety notes described in this manual

• Using the equipment in a hazardous environment

1.3 Original Language

The original manual is written in English. If you are reading a translated version of this manual, and you

also need the English original manual, you can ask METTLER TOLEDO to supply it. If you have a question

about the intended meaning of any translated text, consult the original English-language manual.

1.4 Contacting METTLER TOLEDO Service

Contact your authorized METTLER TOLEDO Service representative about the following products and services:

• Installation

• Integration

• Start-up support

• Commissioning

• Performance verification and audit services to certify that your equipment is maintaining its performance

levels

• Certified, genuine parts

• Emergency repairs and support

• Service contracts customized to your needs

• Customer training

For more information, contact your local and authorized METTLER TOLEDO Service representative using the

link below (and, if necessary, select the applicable country):

http://www.mt.com/contact

When you contact the Service Department, have the following information available, if applicable:

• METTLER TOLEDO order number and date

• Equipment name, model, or type

• Serial number

• Production line name

• Software version

• Precise wording of the displayed error message or detailed fault description

• Pictures or videos of the part or problem

T2611 - Manual Serialization - User Manual - Document Version E 5 / 40

Page 6

1.5 Additional Documents

For details on the individual components of the T2611 Manual Serialization refer to the respective User

Manual:

• User Manual PLM or User Manual PLM direct

• Hardware User Manual Smart Camera (SMC)

• Software User Manual SMC Optical Character / Code Verification

• User Manual on printer (for example Bluhm Weber or Wolke printer)

The following additional documentation is included with your equipment:

• CE Certificate of Conformity (when applicable)

• Wiring diagrams and engineering drawings

6 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 7

2 Safety Notes

Important Safety Message

Read and understand all the safety information in the following sections as

well as the safety messages in the rest of this manual.

If you do not follow the safety information and messages, this may lead to property

damage and personal injury up to and including death.

2.1 Safety Labels and Notice Labels

The ISO3864 safety labels are installed at potentially hazardous areas on the equipment. They give special

safety-related notifications. The locations of these labels are given in the drawings supplied with your

equipment. There are three types of safety labels:

• Hazard notifications

• Mandatory procedures

• Prohibitive procedures

Additionally, NOTICE labels may appear on your equipment.

The meanings of the different kinds of labels are explained in the following sections.

Before you transport, install, operate or work on the equipment, find out about the location and meanings of

the labels. Maintain the labels so that they are clear of obstructions and are readable. Do not remove any

labels. Replace any label that is no longer readable.

2.1.1 Hazard Notifications

A hazard notification consists of the following:

• Hazard alert symbol (yellow triangle with black symbol)

• Signal word (DANGER , WARNING , or CAUTION )

• Special notifications related to the hazard (as required)

The signal word labels are attached next to the hazard alert symbol labels on the equipment.

2.1.1.1 Definitions of Signal Words

Signal words describe the level of risk of a particular hazard. The color of the safety label background

indicates the risk, as shown in the following table. The definitions of the signal words are based upon the

ISO3864 definitions.

DANGER (red): This signal word indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING (orange): This signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION (yellow): This signal word indicates a potentially hazardous situation

which, if not avoided, could result in minor or moderate injury.

2.1.1.2 Meaning of Hazard Alert Symbols

Electrical shock

2.1.2 Mandatory Procedures

Mandatory procedures alert personnel to special, required actions. The round labels have blue backgrounds

and white symbols. The symbols describe the required action. The following table lists the mandatory

procedures labels which may be installed on your equipment.

T2611 - Manual Serialization - User Manual - Document Version E 7 / 40

Page 8

Read the manual

2.2 General Protective Procedures

Important Safety Message

Make sure that all personnel who work on or near the equipment are capable

of performing all operations in a safe way.

• Keep the manual in a convenient location near the equipment. Replace the manual if it becomes lost or

damaged.

• Wear Personal Protective Equipment (PPE) in accordance with your plant's safety procedures.

• Understand the hazards of the equipment and the risks related to those hazards before working on or

near the equipment.

• Obey all safety procedures of the local plant.

• Do not wear loose clothing, jewelry, long hair, or anything that can become entangled with the

equipment.

• Be careful around the equipment to avoid hitting your head, arms, or other body parts against the

equipment. Be careful if the equipment is over your head.

• Be careful not to trip over cables or other parts of the equipment.

• Do not move quickly in the area around the equipment.

• Do not climb, hang onto, or use any of the part of the equipment as a support.

• Obey the lockout tagout (LOTO) procedures of the plant.

• If there is a safety-related malfunction when you are operating the equipment, press the emergency stop

device. Tell the responsible supervisor, and follow the applicable steps approved by your company to fix

the malfunction.

2.3 Safety Information for Various Activities

Important Safety Message

Read and understand all parts of the manual before using or working on any

equipment.

The following sections list safety information for particular activities or groups of activities. Refer to the

correct sections in the manual for more detailed instructions.

2.3.1 Transporting and Moving the Equipment

• Only transport or move the equipment if you have the applicable training as defined by your company.

• Your company has sole responsibility for the safe moving and transporting of the equipment.

• Use safe moving procedures during transporting to maintain stability and to prevent the equipment from

tipping or falling.

• Disconnect the electrical supply, the pneumatic supply, and the communication cables before you move

the equipment.

• Use the correct lifting devices. If you use a forklift, lift the equipment at the correct lift points as shown by

the blue lift point labels.

• Blue lift point labels are placed on the equipment to show recommended locations for lifting. These lift

point locations were tested with the manufacturer's forklift trucks. A qualified rigger must make sure that

the lift points are correct for your lifting equipment.

• When you lift the equipment by hand, obey the safe lifting procedures of your company.

8 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 9

2.3.2 Installing

Only install the equipment if you have the applicable training as defined by your company.

2.3.3 Operating the Equipment and Monitoring the Inspection Process

• Before beginning operation, make sure that the area is safe.

• Make sure the safety circuit is working correctly.

• Do regular inspections of the equipment.

• If there is a fault or change in the equipment behavior, stop the equipment and inform responsible

personnel.

2.3.4 Testing and Verifying the Equipment

Only do testing and verifying of the equipment if you have applicable training as defined by your company.

2.3.5 Maintaining, Cleaning and Sanitizing the Equipment

• Remove all power from the equipment before doing any work.

• Keep the equipment in good working order.

• Follow a preventative maintenance program.

• Replace parts when needed.

• Obey the lockout tagout (LOTO) procedures of the plant.

• Test (validate) the safety circuit after parts are replaced.

• Only use METTLER TOLEDO approved spare parts and accessories.

• Do not make any unauthorized modifications to the equipment.

• Replace safety labels if damaged, missing, or unreadable.

• Do a visual check of the equipment at least once during a shift to identify any visual damage or faults.

Report any equipment changes to the responsible supervisor immediately.

• When required for a hygienic production environment, do regular sanitizing of the equipment according

to your company's procedures.

• After cleaning or sanitizing, check all cables, connectors, and pneumatic hoses for leakage, loose

connections, rub marks and damage. Tighten, repair, or replace any faulty cables and air tubing, as

necessary.

2.4 Special Hazards

The following sections describe special instructions for equipment that may have special hazards.

2.4.1 Electricity

• Only work on the electrical systems if you have the applicable electrical training as defined by your

company.

• Keep all electrical enclosure doors closed. If the doors have locks on them, keep them locked.

• Remove all power from the equipment before doing any work.

2.4.2 Strobe Lights

• Strobe lights can cause seizures in individuals with photosensitive epilepsy.

• Individuals with photosensitive epilepsy must not operate the equipment.

• Do not operate the equipment when excessively fatigued or after consuming alcohol.

• Do not look directly at the lights, especially at close distances.

• Avoid placing the equipment in areas with reduced lighting.

• If lights are inside of an enclosure, do not open the enclosure doors when lights are flashing.

T2611 - Manual Serialization - User Manual - Document Version E 9 / 40

Page 10

3 Equipment Overview

3.1 Equipment Function

The T2611 Manual Serialization is a desktop device for small batch serialization. The system contains a

printer for printing a serialized code onto a carton and a Smart Camera to check the Datamatrix Code and

Human Readable Text. The software allows configuration and visualization.

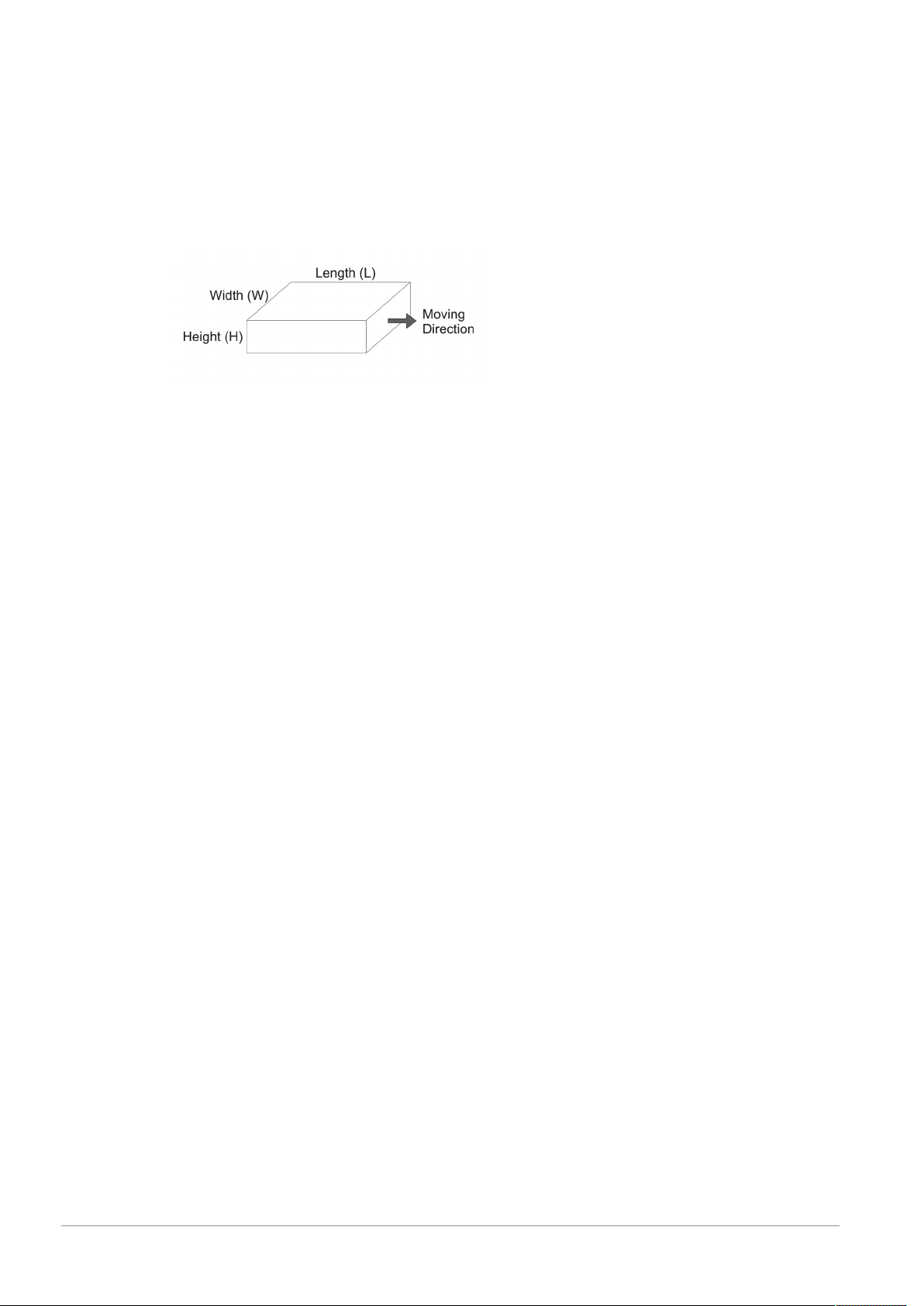

Supported carton sizes:

• Length (L) = 50 ... 360 mm

• Width (W) = 60 ... 190 mm

• Height (H) = 25 ... 220 mm

Smaller heights upon request.

The printer together with the Smart Camera can be moved up and down to allow flexible vertical printing

areas.

10 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 11

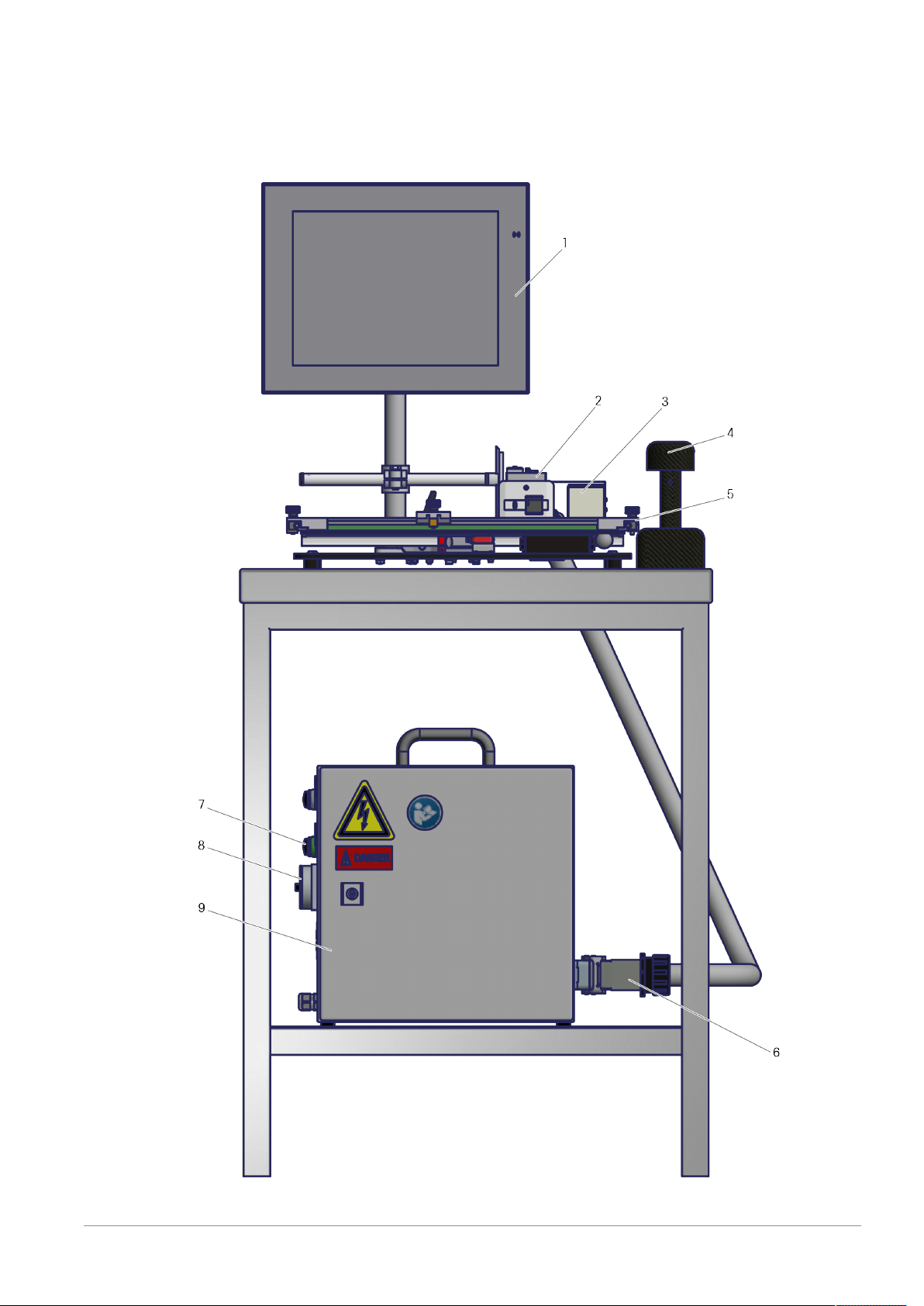

3.2 Equipment Description

The following image is a simplified representation of a T2611 Manual Serialization with a Bluhm printer

(standard option) and an SMC. Other configurations, for example, with a Wolke printer, are possible upon

request. The overall design and principle of operation is the same. Specifications may vary depending on

the selected configuration.

T2611 with Bluhm printer and SMC

T2611 - Manual Serialization - User Manual - Document Version E 11 / 40

Page 12

# Description

1 15" Display Unit

The display unit includes an integrated IPC for PLM/PLM direct.

2 Printer

The printer prints serialized information onto the cartons. The printer communicates to the PLM

or to the PLM direct via Ethernet.

The print head can print a maximum print height of 12mm. Human Readable Text and

Datamatrix Code must fit into this height.

3 Smart Camera

Type320 with 8mm lens

Field of view: 90mmx70mm. All serialized information (Human Readable Text and

Datamatrix Code) must be within the field of view. The maximum print height is 12mm.

4 Bluetooth Hand Scanner

The hand scanner is used for the decommissioning of serial numbers.

5 Moving Plate

The moving plate moves above the fixed ground plate. The carton is placed on the moving plate

and moved manually by the operator. An encoder is mounted to the ground plate and allows

proper printing independently from the speed of the moving plate.

6 Harting Connector

Connects the control cabinet with the devices. Allows operators to easily disconnect the cabinet.

Status light for power supply

7

Main switch

8

9 Control Cabinet

Dimensions (WxHxD): 380mmx422mmx210mm

LEDs at Bluhm printer

As an example, the following picture shows the status LEDs of a Bluhm printer (standard option).

LEDs at Bluhm printer

1

3

Network

Sensor

Ink

2

Status

4

For details on the printers refer to the respective printer manuals.

12 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 13

4 Transporting, Moving, and Storage

WARNING

Lift the system only under the supervision of a competent person who has

sufficient and applicable training.

WARNING

Obey the applicable safety regulations at all times during lifting operations.

NOTICE

METTLER TOLEDO accepts no liability for damage to the system caused by

using incorrect lifting procedures or inadequate lifting equipment.

NOTICE

The equipment can be considerably damaged by shocks or by dropping. Be

careful when moving the equipment and do not tip it or drop it.

4.1 Transporting the Equipment

WARNING

If you unplug the Harting connector to split control cabinet and moving plate

for transport, use carefulness since the connection is very tight.

WARNING

If the equipment is not properly secured when transporting, it may tip over or

drop. This may cause serious injury or death.

Only qualified personnel are allowed to transport the equipment. Secure the

equipment and keep it upright when transporting. Use an appropriately sized

forklift or similar cart.

Make sure that the transport protection is locked and

the moving plate can't move before transporting the

device.

Follow these instructions when transporting the equipment in its original packaging:

• Do not unpack the equipment from its crate or other packaging before reaching the location where it is

to be installed.

• Use lifting and transporting equipment that has the appropriate loading capacity.

T2611 - Manual Serialization - User Manual - Document Version E 13 / 40

Page 14

• Do not tilt or drop the equipment while transporting.

4.2 Storing the Equipment

Follow these instructions for storing the equipment:

• Until the equipment is installed, leave it upright in its original crate or packaging.

• Store the equipment in a clean, dry, climate-controlled room. This protects the equipment from physical

damage and harmful exposure to dirt, dust and moisture.

• Keep all electronic parts in the protective, anti-static pouches until they are used.

If you do not operate the system for some time and want to store it until you use it again, you need to do

the steps that follow:

1 Clean and sanitize the system according to the procedures of your company.

2 Make sure that every part of the system is dry.

3 Wrap the system in cling film or a similar packaging material.

4 Add applicable moisture-absorbing packages, such as desiccant (silica gel) inside the wrapped system.

5 Store the system in a dust-free and dry location in accordance with the environmental conditions below:

ð Temperature range: -10°C (14°F) to 50°C (122°F)

ð Relative humidity: 30% to 85% (non-condensing)

If you want to store the system while it is still packed in the crate after you have received it, follow step 5.

4.3 Unpacking the Equipment

Pharmacontrol Electronic GmbH supplies the equipment in a crate wrapped in plastic wrapping and

banding.

Pharmacontrol Electronic GmbH supplies the equipment attached to a wooden pallet. The pallet may or

may not be inside a wooden or cardboard crate.

Only unpack the equipment after it has reached its final destination.

NOTICE

Take care not to disturb the positioning of the components when removing the

wrapping.

Follow these steps to unpack the equipment:

1. Remove the plastic wrapping and banding.

2. Remove the sidewalls. Then, remove the top of the crate, wood support pieces, and the corner posts.

3. If applicable, remove and discard any blocks and metal brackets that attach the casters or adjustable

feet to the pallet.

4. Loosen and remove the nuts on the bolts which attach the machine feet to the crate. Then, remove the

bolts.

5. Follow the procedure in Moving the Equipment and Setting it in Place to lift the equipment off the pallet

and set it in place.

6. Carefully remove all shrink wrap, bubble wrap, and plastic strapping that may be around the

components of the equipment.

7. Bolts may loosen during shipment. Check to make sure that all of the bolts on the equipment are tight

and secure. Tighten any loose bolts.

8. Recycle or discard the packaging materials.

14 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 15

5 Installation

5.1 Mechanical and Electrical Installation

WARNING

Electrical Damage

Switch off the control cabinet before you unplug the connector between the control cabinet

and the ground plate.

WARNING

Electrical Damage

Do not remove the handle from the control cabinet.

NOTICE

The main switch of the control cabinet shall be easily accessible and located between 0.6

m (2.0 ft) and 1.5 m (4.9 ft) above floor level.

Place the ground plate with printer and HMI on a stable ground (e.g. table).

For the electrical connection refer to the technical manual.

CAUTION

Cable between control cabinet and moving plate

Make sure that the cable between control cabinet and moving plate is placed safe and

that no tripping hazards occur.

Do not change the lower mechanical adjustments!

5.2 Setting up the Equipment

You need to have administrator rights for PLM for creating and setup of the 3 devices:

• Hand Scanner

• Smart Camera

• Printer

5.2.1 Set up the hand scanner

1. Go to System Settings and press Create/edit device

2. Press Add

3. Select "Honeywell_Scanner" and press OK.

T2611 - Manual Serialization - User Manual - Document Version E 15 / 40

Page 16

4. Fill in the field for device name "Hand Scanner Decommission" and press OK.

5.2.2 Set up the Smart Camera

The Smart Camera reads barcodes, data matrix codes and human readable text and compares it with the

data received from the PLM. When the data is valid, the item is further processed. If data is invalid, the item

will be discarded.

When creating the Smart Camera as a device in PLM, you can choose between two different class names:

• PCE_SMC

• PCE_SMC_PRC

The class has the additional parameter 'CommandTimeOut'.

The Smart Camera is editable under System Settings > Edit device settings > (<select

Smart Camera tab>). At the tab menu on the top you can switch between the screens.

System Settings > Edit device settings > (<select smart camera tab>)

Edit the settings at the input fields and dropdown lists.

The table below gives an overview of these settings:

Parameter Description Default value Allowed values

Name Name that has been assigned in the

Camera Alphanumeric

device management settings.

Description Optional description - Alphanumeric

boxingRank Hierarchy level (1) Unit Drop-down list

internalFormats Camera manages internal formats Chechmark set Checkbox

automaticMode When automatic mode is active, manual

Checkmark set Checkbox

operation of the device is not possible.

needDeviceFormat Device appears on the line format Checkmark set Checkbox

showDeviceFrame Activates/deactivates the display of the

Checkmark set Checkbox

device in the menu “overview”.

logLevel Setting of how much data is logged

INFO Drop-down list

(TRACE/DEBUG/INFO/WARN/ERROR)

PLCName Name of the camera for the PLC Cam1 Drop-down list

readerMode PRINT_INSPECTION

PRINT_INSPECTION Drop-down list

AGGREGATE_READER

LINKING_READER

AGG_INSPECTION

LINEFORMAT

autoVerifyAggUnit Possibility of combining with one reading

Checkmark not set Checkbox

process the verification and commission

into the database.

16 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 17

preAggregationReject

autoReject Relevant for aggregation modes only with

forceAggCache The parameter is relevant only for aggre-

useWildcards Activates/deactivates the transfer of the

ConnectGui Activates/deactivates the image

ip IP address of the device 192.168.100.215 Valid IP address

errorImages Activates/deactivates the permanent

debugStatistics

CommandTimeOut Maximum waiting time (milliseconds) for

Units scanned by aggregation reader are

validated direct after read and rejected by

PLC. Default the validation process starts

with the covering box close signal

(content size is reached or close button)

activated setting "autoVerifyAggUnit". If

enabled, the units are not added to aggregation cache if the reading was bad/

incomplete. There is no UI notification in

this case.

gation reader modes with enabled

delayed aggregation where the aggregation cache is closed only after "aggregationReady" signal from PLC. If enabled,

any bad/incomplete/good reading will be

pushed into the delayed aggregation

queue and must be consumed by an

external aggregation ready/abort signal.

Otherwise only good reading is

consumed.

serial number through a placeholder

(*****) it is only checked for length, not

for contents.

processing on the camera

storage of SMC error images in the PCE

Line Manager database.

Stores communication between the PCE

Line Manager and the camera in txt data.

Only for error searches, otherwise this

should be switched off.

response from the device after sending a

command (for example, reference code).

Checkmark not set Checkbox

Checkmark not set Checkbox

Checkmark not set Checkbox

Checkmark set Checkbox

Checkmark set Checkbox

Checkmark not set Checkbox

Checkmark not set Checkbox

5000 Alphanumeric

5.2.2.1 Setting up a Product in SMC

This chapter describes how to set up a product in the Smart Camera. Some step sequences have to be

repeated in order to set several fields. For this the steps are numbered.

Step Action

1 Press Home.

T2611 - Manual Serialization - User Manual - Document Version E 17 / 40

Page 18

Home

Step Action

2 Select the camera bar.

The following screen appears (It may be that the software automatically skips this screen. In this case you

do not need to press menu at this point and you see the subsequent screen):

Home > (<select smart camera bar>)

Step Action

3 Press Menu.

The following screen appears:

Home > (<select smart camera bar>) > Menu

Step Action

18 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 19

4 Press Product management.

The following screen appears:

Home > (<select smart camera bar>) > Menu > Product management

Step Action

5 Press New product.

The following dialog (New product name) appears:

Home > (<select smart camera bar>) > Menu > Product management > New product

Step Action

6 Enter a unique product name.

7 Press Enter on the keyboard.

T2611 - Manual Serialization - User Manual - Document Version E 19 / 40

Page 20

The following dialog (Live image) appears:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard)

Step Action

8 Select live Image.

9 Place item underneath the Smart Camera.

The following screen appears:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image

Step Action

10 Select Next.

20 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 21

The following dialog (Control) appears:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image > Next

Step Action

11 Press OCV control.

The screen looks as follows:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image > Next > OCV control

To set the control window for the expiry date proceed as follows.

Step Action

12 Move the yellow control window in a way that it is arranged around the expiry date. See below.

To set the control window you can use the navigation arrow keys as described in the following table. You

can also move the control window and adjust its borders by dragging and dropping the borders.

Button Function

Navigation arrow keys for functions at the modes. The mode is

selected at the button in the middle.

Button Mode

T2611 - Manual Serialization - User Manual - Document Version E 21 / 40

Page 22

‘scrolling’ The control window can be moved using the arrow keys.

‘zoom in’ The control window can be enlarged using the arrow keys.

‘zoom out’ The control window can be reduced using the arrow keys.

Step Action

13 After the control window is set to the right position, press OK to confirm.

The following Dialog (Threshold) appears:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image > Next > OCV control (arrange control window) > OK (set threshold)

Step Action

14 Move threshold in a way until you can clearly read the font.

15 Then press OK to confirm.

The following dialog (Window with measuring arrows?) appears:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image > Next > OCV control (arrange control window) > OK (set threshold) > OK

Step Action

16 Select Yes.

22 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 23

After pressing Yes, the following dialog (Font Memory) appears:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image > Next > OCV control (arrange control window) > OK

At this dialog you have to choose the font memory you would like to use.

Step Action

17 Select ocrb.

The following dialog (Prepare another control?) appears:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image > Next > OCV control (arrange control window) > OK (set threshold) > OK > Yes

(select font memory)

To set another control window for the <LOT> field you have to repeat the steps (11-15).

Step Action

18 PressYes. (You are automatically led back to proceed from step 11)

19 Repeat steps 11–15

T2611 - Manual Serialization - User Manual - Document Version E 23 / 40

Page 24

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image > Next > OCV control (arrange control window) > OK (set threshold) > OK > Yes

(select font memory)

Step Action

20 Select No.

The following screen appears:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image > Next > OCV control (arrange control window) > OK (set threshold) > OK > Yes

(select font memory) > No

At this screen you see the calculated position of measurement lines.

Step Action

21 Press Next to leave the screen.

24 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 25

After pressing next you get to the following screen:

Home > (<select smart camera bar>) > Menu > Product management > New product > (enter product name) > Enter

(at the keyboard) > Live Image > Next > OCV control (arrange control window) > OK (set threshold) > OK > Yes

(select font memory) > No > Next

You can return to production or add a new control window. To add another control window press Add

control window. You will be redirected to step 11. To return to production close the Product management

dialog by pressing x and press Production at the Main Menu dialog.

5.2.2.2 Final Result for SMC setup

The complete configuration in the end should look like following screenshot:

• DM0 = Data Matrix Search Window

• OCV0-x = Optical Character Verification for GTIN, Batch, Expiry, Serial and others

• The wide DM0 window is used to catch the Data Matrix Code. OCV windows will be moved related to

DM Code.

For optimization of DM Code reading results please adjust the two values marked red:

• Additional information such as linkage of windows or teaching characters for OCV will be found within

the user manual "Optical Character / Code Verification 7.xxx".

T2611 - Manual Serialization - User Manual - Document Version E 25 / 40

Page 26

5.2.3 Set up the printer

1. Go to System Settings and press Create/edit device

2. Press Add

3. Select your printer and press OK.

4. Assign a useful name to your printer (for example: "BluhmWeber Printer").

NOTE: The printer will not be shown within the device list after it was created.

26 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 27

6 Operation

6.1 Starting the Equipment

1. Turn on the T2611 at the main switch.

2. Log in with user name and password (for details see PLM user manual).

6.2 Setting the Box Size

Before starting a production run, you have to set the box size.

Top view

1

3

5

1 Insert the box (1).

2 Move the first guiding rail (2) to the box (1).

3 Tighten the screw (3).

4 Move the second guiding rail (4) towards the printer. Ensure that the distance between the box (1) and

5 Tighten the screw (5).

T2611 - Manual Serialization - User Manual - Document Version E 27 / 40

Box

Screw

Screw

the printer front plate is approximately 2mm to 5mm (see picture below).

2

4

Guiding rail

Guiding rail

Page 28

Distance between Box and Printer

When setting the box size, you have to ensure that the distance between the box (2) and the printer front

plate (1) is approximately 2mm to 5mm.

Side view

1

Printer with printer front plate

6.3 Workflow

There are two principal workflows which can be handled with the T2611:

• Workflow 1: Print - Verify - Commission

With this workflow you can serialize the requested cartons and all good cartons will be part of the order.

• Workflow 2: Decommission

With this workflow you can take cartons you do not want to ship out of an order.

NOTE: In the following chapter, the workflows are described with the help of a Bluhm printer. Other printers

are possible. The overall procedure at the T2611 is the same.

NOTICE

Malfunction and damage due to faulty handling

This chapter only provides basic knowledge on the components of the T2611.

For details on the correct handling of the PLM refer to the PLM manual.

For details on the correct handling of the SMC software refer to the SMC OCV manual.

For details on the correct handling of the printer refer to the respective printer manual.

6.3.1 Workflow 1: Print - Verify - Commission

2

Box

1 Create your required label templates.

Depending on the printer model, you can use Bluhm "idesign touch", for example.

2 Adjust the trigger point in accordance with the printer manual.

28 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 29

3 Create a line format and the devices (printer, SMC) in the PLM (see PLM user manual for details).

4 Create the hand scanner device (globally, see PLM user manual for details).

5 Press Home. Select the Smart Camera by pressing on the respective tab.

T2611 - Manual Serialization - User Manual - Document Version E 29 / 40

Page 30

6 Teach-in the camera (see OCV manual).

NOTE: Before you can teach-in the camera, you have to provide a product that contains the printed

information that the camera has to inspect. To do so, you can start a test run via PLM (see PLM user

manual for details).

NOTICE

It is very important that the Datamatrix searching area extends the maximum horizontal

way (see figure below).

7 Create or import an order.

8 Start the order.

9 Navigate to the camera menu to see the reading result of the camera (Home > Smart Camera device

tab).

10 Place the carton on the moving plate.

11 Move the moving plate to the start position (left end, strobe lights are off).

NOTICE

The carton print side should be as flat as possible to avoid bad printing.

12 Start moving the plate to the right end.

Move the plate consistently and do not stop until you reach the right end.

While the plate is moving, the strobe lights are on and the printer prints the requested serial number

onto the carton. The camera verifies the code with the serial number and the human readable characters

during the movement of the carton.

Move the plate back to the starting position on the left end.

ð If the camera was able to read the code and the reading result was good, you can see a green frame

and the strobe lights are off.

ð If the camera was able to read the code and the reading result was bad, you can see a red frame.

NOTICE

The actual working speed for cartons may vary and depends on various factors (e.g. print

quality, size, carton surface, camera settings).

30 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 31

NOTICE

If you remove the carton before the reading has been finished, an offset of serial number

might occur. In that case stop and restart production to get synchronization again.

13 Place the next carton on the moving plate and start moving the plate to the right end and back to the left

end.

ð The reading result will be displayed.

14 Go on with all cartons you need.

15 Stop the order.

ð The machine is ready for the next order or for shut down.

6.3.2 Workflow 2: Decommission

1 Select the hand scanner for decommissioning.

2 Open the requested order and select Show Hierarchy.

3 Scan the carton.

ð The result will be shown at the PLM.

4 Stop the order.

ð The machine is ready for the next order or for shut down.

T2611 - Manual Serialization - User Manual - Document Version E 31 / 40

Page 32

6.4 Shutting down the Equipment

1. Shut down PLM/PLM direct by selecting the upper right user button.

2. Select PLM shutdown.

3. Turn off the main switch.

32 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 33

7 Maintenance

7.1 Changing the Printer Cartridge

NOTICE

Malfunction and damage due to faulty handling

This chapter only provides basic knowledge. For details on the correct handling of printers

refer to the respective printer manuals.

NOTE: As an example, this chapter explains changing the printer cartridge of a Bluhm printer.

1 Release the lever and remove the printer cartridge.

2 Insert a new printer cartridge into the printer.

T2611 - Manual Serialization - User Manual - Document Version E 33 / 40

Page 34

3 Tighten the printer cartridge with the help of the lever.

34 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 35

8 Cleaning

8.1 Visual Inspection and Cleaning of the System

Recommended inspection

interval

Daily Perform a general visual inspection.

What needs to be done?

WARNING

Cleaning the system when it is hot may cause severe damage.

Only clean the system with liquid when it is cooled down to room temperature.

WARNING

Careless cleaning may cause severe damage.

Never use a high pressure jet to hose down the system.

Do not use caustic cleaning agents containing solvents to clean the system and the

terminal. Never use pure alcohol or concentrated acid or lye.

Use particular care when cleaning in order to avoid damage and, above all, to prevent

water from entering the system.

• Clean the system and terminal using soft cloths dampened with a mild solution of soap and water or a

commercially available glass and plastic cleaner.

8.2 Visual inspection of Gaskets/Seals

Recommended inspection

interval

Monthly Perform a general visual inspection.

What needs to be done?

8.3 Cleaning the Touch Screen

The display surface is made from glass and the casing from stainless steel. To ensure efficient operation,

the surface of the touch screen should be cleaned regularly. Only special cleaning wipes and cleaning

agents should be used:

• Commercial cleaners for computer equipment

• Alcohol-based disinfectants

CAUTION

Solvents can damage the display.

Never use diluting agents, benzene, abrasives or other strong solvents, as these can

damage the display!

8.4 Cleaning the Print Head

Clean the print head every 30 minutes or if the print quality is not sufficient.

T2611 - Manual Serialization - User Manual - Document Version E 35 / 40

Page 36

To clean the print head, press a lint free cloth on the print head. Do not move the cloth, just press it down.

8.5 General Advice on Stainless Steel Maintenance

Stainless steel generally provides much better protection against corrosion when compared with steel or

aluminium. Stainless steel, however, does not always remain rust-free. Stainless steel can also become

dirty or rusty to some extent, depending on the operational use and the conditions in the working

environment. The most common causes are surface rust (fine iron particles in the air), active gases, the

accumulation of sediments and the build-up of salts. These superficial damages can be easily removed by

using a stainless steel spray daily. After cleaning with soap and water, you should check that the residue is

washed off with a suitable amount of water.

36 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 37

9 Disposal

In conformance with the European Directive 2012/19/EU on Waste Electrical and

Electronic Equipment (WEEE) this device may not be disposed of in domestic waste. This

also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment. If you have any questions, please contact

the responsible authority or the distributor from which you purchased this device. Should

this device be passed on to other parties, the content of this regulation must also be

related.

T2611 - Manual Serialization - User Manual - Document Version E 37 / 40

Page 38

10 Technical Data SMC Series 3

The following specifications apply to the SMC Series 3.

Housing Aluminum,

Dimensions as example for camera type no. 320 and housing size 21: LxWxH:

91mmx55mmx55mm

Protection of housing IP65: dust-tight and protection against water jets. No ingress of dust. Water-

protected by a nozzle against enclosure from any direction.

Power supply 24ˆV DC, min. 20V, max. 28V,

Current during start up: max. about 1A,

Current during operation: about 150mA

Image processing Internally, with special machine vision processor.

Inputs 3 inputs 24VDC, max. 28V permanent, response threshold: High: about

>13V, Low: about <7V

Outputs 4 Outputs 24VDC, type PNP, max. 100mA permanent, max. 400mA peak

short-circuit-proof, protected against overload and protected against external

voltage

Interface Ethernet 100/1000Mbit/s, LAN

Interface RS-232

Illumination White LEDs in flash operation

Standard lens (1) C-Mount, 12mm focal length

Standard distance

between object and

camera housing (1)

Standard visible area (1) LxW: 95mmx71mm

Camera inclination angle 0-10 degrees in relation to vertical and product horizontal

Environmental conditions

at transport and storage

Environmental conditions

at operation

Weight 430g

135mm

-20°C (-4°F) to +80°C (+176°F),

Max. humidity 90%, non-condensing

0°C (+32°F) to +50°C (+122°F),

Max. humidity 80%, non-condensing

(1) Other configurations are available.

38 / 40 T2611 - Manual Serialization - User Manual - Document Version E

Page 39

Intentionally left blank

T2611 - Manual Serialization - User Manual - Document Version E 39 / 40

Page 40

Pharmacontrol Electronic GmbH

Harzstraße 1

64646 Heppenheim, Germany

Tel. +49 6252 6736 0

Fax +49 6252 6736 111

www.mt.com

Subject to technical changes.

© Pharmacontrol Electronic GmbH 02/2019

T2611 - Manual Serialization - User Manual - Document Version Een

www.mt.com/pce

For more information

Loading...

Loading...