Page 1

SAG weighing modules

The simple solution for unusual weighing tasks

AG

1/10 d

On

O

ff

O/T

Rapid weight control of target weights from 0.1 g to 210 g

You are filling powders or liquids. You produce small parts from plastic. You make tablets and capsules. You want to

sort your products by weight. You control operations today with random sample checks.

You want to have full control over quality and limit material losses and rejects to a minimum.

Weighing under special conditions

You want to integrate a 5-, 3- or 4-decimal place balance in a robot system. You are looking for a compact weighing

unit with a separate display. You are weighing in a contaminated environment. You want to perform weight

determinations in a confined space or at low air pressure.

The weighing modules SAG285, SAG204 and SAG203F from METTLER TOLEDO provide a simple solution for these

and for many other weighing tasks.

The weighing modules were developed for use in production machinery, for highly accurate weighing under difficult

circumstances and conditions, as well as for accurate weight determination in procedures where timing is critical.

Cal

Menu

F

C

System description

The products SAG285, SAG204 and SAG203F consist of two parts:

• Compact, sealed weighing cell, which can be fixed to a flat base

• Electronic control unit with operating terminal, display and data interface

The weighing cell can be calibrated at any time by the press of a knob or via the data interface using the integrated

calibration weight. With the SAG285 und SAG204 a completely automatic calibration without intervention by the user is

also possible.

While the SAG285 resp. SAG204 has the readability of a classical analytical balance of 0.01 mg resp. 0.1 mg, the

SAG203F with reduced readability of 0.001 g offers an appreciably shorter stabilization time of just one second. It can

therefore be used, in situations where high throughput is important.

The typical areas of application are:

• “one shot” dispensing systems (preset amount is filled in one dose)

• Sorting or “on-line” weight control of small items (tablets, plastic moldings etc.)

• Robot controlled or automated determination of weight

• Weighing in confined fume hoods or fume chambers

• Weighing in a contaminated environment (poisons)

• Weighing under special pressure conditions, e.g. under vacuum

© Mettler-Toledo GmbH 2000 11780282B Printed in Switzerland 0010/40.12

Mettler-Toledo GmbH, Laboratory & Weighing Technologies, CH-8606 Greifensee, Switzerland

Phone +41-1-944 22 11, Fax +41-1-944 30 60, Internet: http://www.mt.com

*P11780282*

Page 2

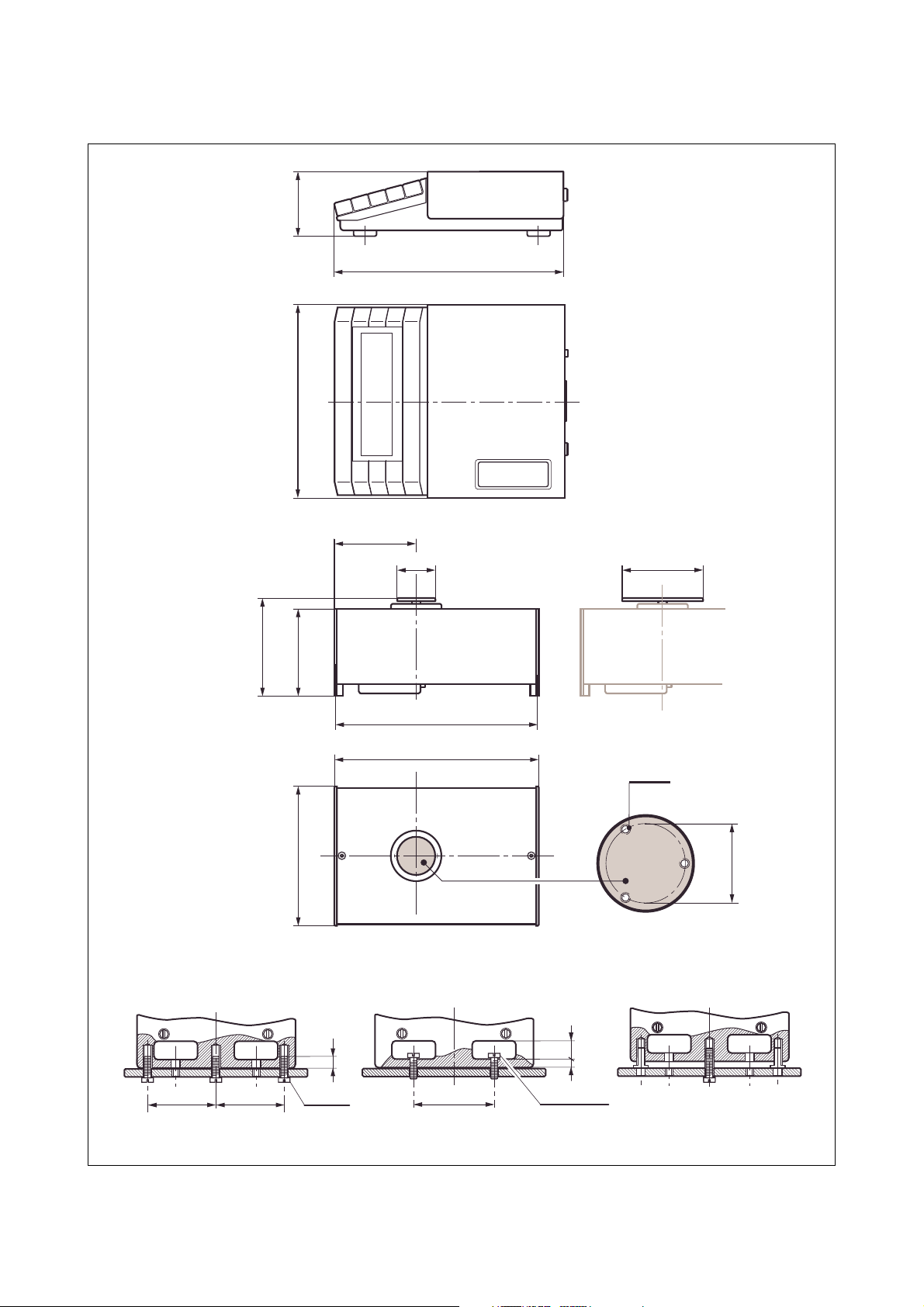

Dimensions

all dimensions in mm

Electronic control unit

Weighing cell

62

178

77

216

Ø

36

Ø

85

Mounting options

from below from above with height adjustment

56 56

92,5 ÷ 97*

82,5 ÷ 87*

130

M5 (3x)

10

185**

193

66

158

M4x16 (2x)

3 x M3

30

Ø

* Height adjustable ** Distance between the attachment points

Page 3

Technical data for weighing modules SAG285, SAG204, SAG203F

For operation refer to "Operating instructions METTLER TOLEDO AG balances"

SAG285 SAG204 SAG203F

6)

Readability 0.01 mg

Max. weighing capacity 41 g

Taring range 0…81 g

Repeatability 0.02 mg

Linearity

Sensitivity drift

1)

1)

± 0.03 mg 6)/± 0.1 mg 6)/± 0.2 mg ± 0.2 mg ± 0.001 g

2 ppm/°C 2 ppm/°C 2 ppm/°C

Stabilization time (typical)

0…30 g ≥ 6 s

30…210 g ≥ 3 s ≥ 3 s 1.2 s

Calibration weight, internal 200 g 200 g 200 g

Calibration weight, external 40/100/200 g 50/100/200 g –

Calibration, internalmanual, full automatic (FACT) manual or via control command

or via control command

Weighing unit 1 g, oz, ozt, GN, dwt, ct, mg, mo, msg g, kg, lb, oz, ozt, GN, dwt, ct,

Weighing unit 2 mg, mo, msg, H tl, S tl, T tl, g, oz, ozt, GN, dwt, ct –

Application functions Piece counting, percent weighing, formulation, –

dynamic weighing

Data interface (with the electronic unit) LocalCAN, RS232

Control commands

3)

MT-SICS (as with AG balances) MT-SICS Level 0 + 1

/0.01 mg 6)/0.1 mg 0.1 mg 0.001 g

6)

/81 g 6)/210 g 210 g 210 g

6)

/0…210 g 0…210 g 0…210 g

6)

/0.05 mg 6)/0.1 mg 0.1 mg 0.5 mg

6)

≥ 3 s 1.0 s

mg, mo, msg

2)

LocalCAN, RS232

(V 2.10 or higher);

Level 2: C3 (Calibration);

M (Menu)

Level 3: MS (Unit);

SS (Send 2 weight values)

2)

Display (with the electronic unit) LCD (passiv)

Weighing pan Ø 85 mm (weight = 68 g), stainless steel and

Ø 36 mm (weight ~ 10 g) (Order No. 238839), aluminium, non-rotatable

Admissible dead load, weighing pan incl. 65 - 71 g

Net weight:

– electronic unit with power adapter 2.1 kg

– weighing cell 2.9 kg

Total weight 6.8 kg

Cable lenght between electronic unit/cell

4)

1.5 m (Sub.D 25pin at both sides)

Fuse Temperature switch

Power supply with AC/AC adapter 115 V - 20 % + 15 %, 50/60 Hz, 195 mA, sec. 12 V, 50/60 Hz, 1.25 A

and country specific cable 230 V - 20 % + 15 %, 50/60 Hz, 90 mA, sec. 12 V, 50/60 Hz, 1.25 A

Power supply direct 9.5 - 17.5 V, 50/60 Hz, 7 VA or 9 - 20 V=, 7 W

(without adapter)

Admissible ambient conditions Use only in closed rooms, installation category II, polution degree 2

Admissible ambient temperature

5)

5 - 40°C

Max. relative atmospheric humidity 80 % RH by 30°C

Height up to aboce sea level 4000 m

1)

Within the temperature range 10 - 30 °C

2)

RS232-C with sep. cable LC-RS9 resp. LC-RS25

3)

Control commands according to “Reference Manual MT-SICS” (delivered with LC-RS cable)

4)

Different lenghts on request (max. 10 m)

5)

Temperature changes may not lead to the formation of water of condensation in the weighing cell or electronic unit.

6)

Values in fine range

Page 4

Technical data for weighing module SAG245

For operation refer to "Operating instructions METTLER TOLEDO AG balances"

SAG245**

6)

6)

/210 g

6)

/0.1 mg

6)

/0…210 g

6)

/0.1 mg

2)

Readability 0.01 mg

Max. weighing capacity 41 g

Taring range 0…41 g

Repeatability 0.02 mg

Linearity

Sensitivity drift

1)

1)

± 0.03 mg 6)/± 0.2 mg

2 ppm/°C

Stabilization time (typical)

0…30 g ≥ 6 s

30…210 g ≥ 3 s

Calibration weight, internal 200 g

Calibration weight, external 40/100/200 g

Calibration, internalmanual, full automatic (FACT) or via control command

Weighing unit 1 g, oz, ozt, GN, dwt, ct, mg, mo, msg

Weighing unit 2 mg, mo, msg, H tl, S tl, T tl, g, oz, ozt, GN, dwt, ct

Application functions Piece counting, percent weighing, formulation, dynamic weighing

Data interface (with the electronic unit) LocalCAN, RS232

Control commands

3)

MT-SICS (as with AG balances)

Display (with the electronic unit) LCD (passiv)

Weighing pan Ø 85 mm (weight = 68 g), stainless steel and

Ø 36 mm (weight ~ 10 g) (Order No. 238839), aluminium, non-rotatable

Admissible dead load, weighing pan incl. 65 - 71 g

Leerseite

Net weight:

– electronic unit with power adapter 2.1 kg

– weighing cell 2.9 kg

Total weight 6.8 kg

Cable lenght between electronic unit/cell 4)1.5 m (Sub.D 25pin at both sides)

Fuse Temperature switch

Power supply with AC/AC adapter 115 V - 20 % + 15 %, 50/60 Hz, 195 mA, sec. 12 V, 50/60 Hz, 1.25 A

and country specific cable 230 V - 20 % + 15 %, 50/60 Hz, 90 mA, sec. 12 V, 50/60 Hz, 1.25 A

Power supply direct 9.5 - 17.5 V, 50/60 Hz, 7 VA or 9 - 20 V=, 7 W

(without adapter)

Admissible ambient conditions Use only in closed rooms, installation category II, polution degree 2

Admissible ambient temperature

5)

5 - 40°C

Max. relative atmospheric humidity 80 % RH by 30°C

Height up to aboce sea level 4000 m

1)

Within the temperature range 10 - 30 °C

2)

RS232-C with sep. cable LC-RS9 resp. LC-RS25

3)

Control commands according to “Reference Manual MT-SICS” (delivered with LC-RS cable)

4)

Different lenghts on request (max. 10 m)

5)

Temperature changes may not lead to the formation of water of condensation in the weighing cell or electronic unit.

6)

Values in fine range

** Production phaseout from May 2000

Loading...

Loading...