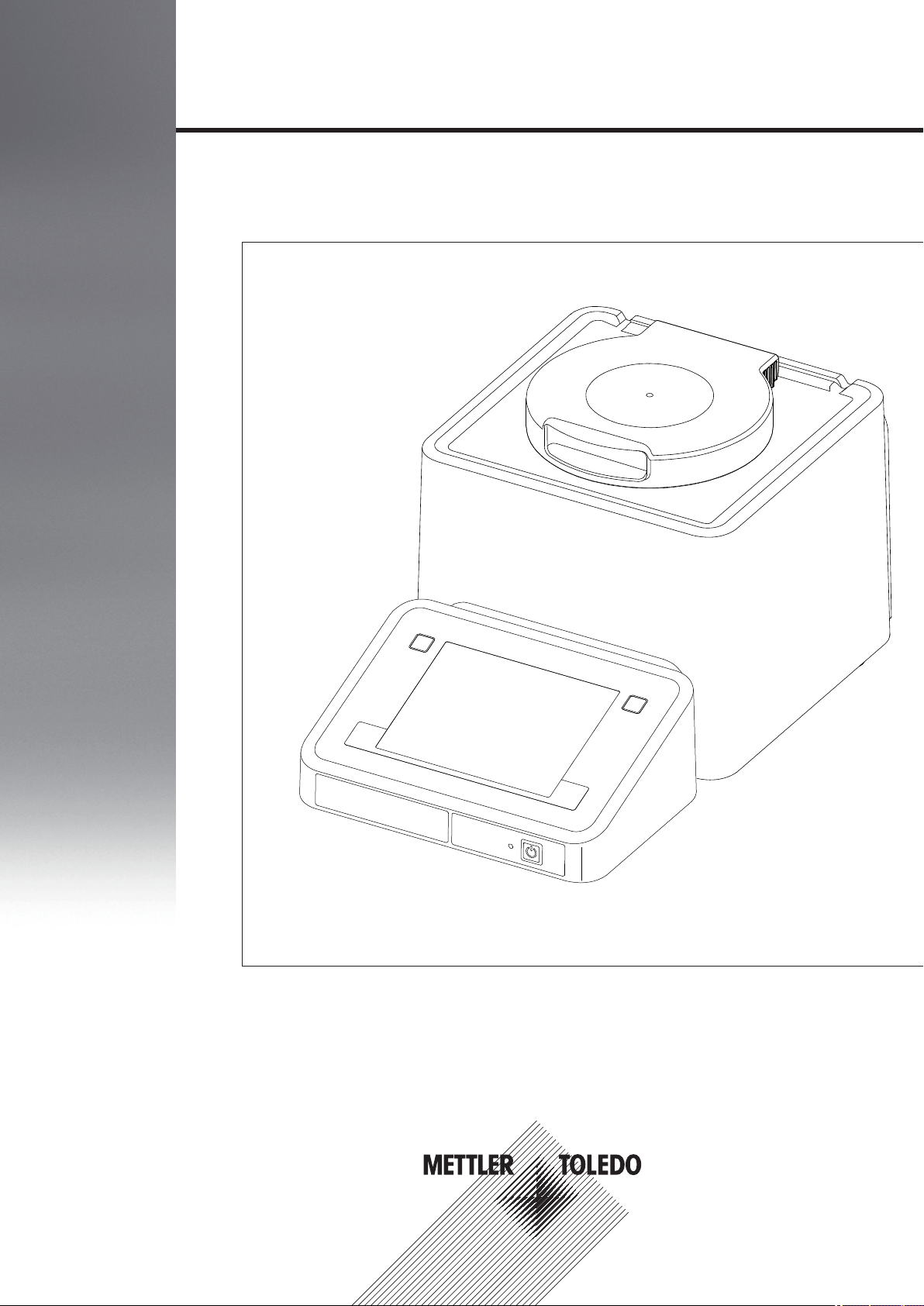

Page 1

Refractometers

RM40 / RM50

Operating Instructions

Page 2

Page 3

Table of Contents

Introduction1 7

Description of the Refractometer2 8

Principles of Refractometry3 10

Description of Functions4 12

Setup5 15

Definition of the Refractive Index3.1 10

Method of Measurement3.2 10

Design of Measuring Cell3.3 10

Layout of the Terminal4.1 12

Operating the Touchscreen4.2 12

Homescreen4.3 12

The User Interface4.4 13

Entering Data in the User Interface.4.4.1 13

Shortcuts4.4.2 14

Adjustments & Tests5.1 15

Adjustment Sets5.1.1 16

Test Sets5.1.2 16

Hardware5.2 16

Cell5.2.1 17

Automation5.2.2 17

External Instruments5.2.3 19

Peripherals5.2.4 20

Sensors5.2.5 23

Auxiliary instruments5.2.6 24

User settings5.3 25

Language5.3.1 25

Screen5.3.2 25

Beep5.3.3 25

Shortcuts5.3.4 26

Keyboards5.3.5 26

Global Settings5.4 26

System5.4.1 26

User Management5.4.2 26

Users5.4.2.1 27

Account Policy5.4.2.2 27

User Groups5.4.2.3 27

Analysis and Resources Behavior5.4.3 28

Physical Properties5.4.4 29

Tables & Values5.5 29

Tables5.5.1 30

Auxiliary Values5.5.2 31

Maintenance & Service5.6 31

MT Service5.6.1 31

Import / Export5.6.2 32

Add External Cell5.6.3 33

Reset to Factory Settings5.6.4 33

Firmware5.6.5 33

Update5.6.6 33

Hardware / Firmware summary5.6.7 34

Board Tests5.6.8 34

Table of Contents 3

Page 4

Cell5.6.9 34

Export Adjustments / Tests / Measurements5.6.10 35

Methods and Products6 36

Methods6.1 36

Establishing Methods6.1.1 36

Creating a Method Copy6.1.2 38

Modifying or Deleting Methods6.1.3 38

Method Syntax6.1.4 38

Standard Data6.1.5 40

Condition6.1.6 40

Method Function6.1.7 41

Title6.1.7.1 42

Configuration6.1.7.2 42

Sample6.1.7.3 42

Fill6.1.7.4 44

Measure6.1.7.5 45

Calculation6.1.7.6 47

Clean6.1.7.7 48

Online Display6.1.7.8 50

Report6.1.7.9 50

Cell Test6.1.7.10 51

Temperature Compensation6.1.7.11 51

Adjustment6.1.7.12 52

Test6.1.7.13 52

Instruction6.1.7.14 52

Auxiliary Value6.1.7.15 52

Wait6.1.7.16 53

Auxiliary instrument6.1.7.17 53

PowerShower6.1.7.18 54

Stir6.1.7.19 55

Line rinse6.1.7.20 56

Park6.1.7.21 56

Products6.2 56

Create Products6.2.1 57

Linking Methods with Products6.2.2 57

Parameters for Products6.2.3 57

Calculations in Products6.2.4 59

Series7 60

Delete Series7.1 61

Creating a series copy7.2 61

Results and Statistics8 62

Statistics8.1 63

Information8.2 63

Data8.3 63

Manual Operation9 65

Automation9.1 65

Action: Dry9.1.1 65

Action: Rinse9.1.2 65

Action: Pump sample9.1.3 66

Action: Move to position9.1.4 66

Table of Contents4

Page 5

Cell9.2 66

Action: Cell conditioning9.2.1 67

Cell Test9.2.2 67

Analysis Sequence10 68

Starting an Analysis10.1 68

Start from Editor (Methods/Products/Series)10.2 69

Start from Homescreen10.3 69

Start via Shortcuts10.4 69

Start with Barcode Reader10.5 69

Start with Handheld Reader10.5.1 70

Start with Built-in Barcode Reader10.5.2 70

Start with ErgoSens10.5.3 70

Continuous run10.6 71

Analysis Termination10.7 71

Errors in the Analysis Sequences10.8 71

Malfunction Types: Error10.8.1 71

Malfunction Types: Terminate error10.8.2 71

Malfunction Types: Critical error10.8.3 72

Tasks and Online Screen11 73

Tasks11.1 73

"Tasks" Button11.1.1 73

Online Screen11.2 73

Method type: Measurement11.2.1 73

Method Type: Adjustment11.2.2 74

Method Type: Test11.2.3 74

Method Type: Clean11.2.4 74

Appendix12 75

Raw Data12.1 75

Result proposals12.2 76

Refractive Index for Water12.3 78

Density12.4 78

Critical errors12.5 80

Index 82

Table of Contents 5

Page 6

Page 7

1Introduction

Simple and compact

The METTLER TOLEDO RM40/RM50 refractometers are modern, compact instruments suitable for use in a vast

diversity of application areas. They can be used, for example, in quality control as well as in research and

development and meet the most demanding requirements.

These compact refractometers perfectly combine simple, easy-to-understand operation with an extremely high

level of measuring accuracy and outstanding reliability. With their plug & play capability, they automatically

detect external devices and sensors.

These refractometers can be operated as standalone instruments or run from a computer using the LabX PC

software. Straightforward user guidance on the large color touchscreen enables intuitive operation. User-defin

able shortcuts allow all functions to be activated directly from the home screen with a single click.

Touchscreen control of the instrument and the method function parameters are described in the Operating

Instructions. The Installation Instructions explain all the necessary steps for setting up your instrument. You are

then guided through the first refractive index measuring process with the aid of a practical example.

If you have any additional questions, METTLER TOLEDO is always available to assist you.

7Introduction

Page 8

2Description of the Refractometer

The RM40 / RM50 refractometers measure the refractive index nD of liquids. The two instruments differ in mea

suring precision. Both instruments:

●

measure liquids whose refractive indices range respectively from 1.3200 to 1.7000 (RM40) and to

1.58000 (RM50).

●

require only minimal sample quantities for measurements (0.5 mL),

●

maintain the temperature of the sample constant with the aid of a built-in Peltier thermostat in a range from

5 to 100°C (RM40) and 5 to 75°C (RM40).

●

directly indicate the sugar content of samples in various sugar units (Brix, invert sugar, HFCS42 or

HFCS55)

●

calculate the concentration of a solution by means of data from measured standard solutions, literature

tables or formulas

●

are equipped with an integrated test function that enables regular testing of the accuracy of the measure

ment,

●

enable checking of the product-related specification limits and generate rolling statistics.

The samples can be introduced manually with a syringe. For the optimal use of the RM refractometers, the fol

lowing pumps and sample changers are available:

●

A peristaltic pump (FillPal):

For the automatic filling, emptying and rinsing of the cell.

●

The autosampler InMotion™

The autosampler for a completely automatic measurement of up to 303 aqueous, low viscous samples in

series.

●

The automatic sample and cleaning unit (SC1):

for fully automated measurements of free-flowing and viscous samples. The system automatically cleans

and dries itself on completion of a measurement so that it is ready for the next measurement.

●

The sample changer (SC30):

The SC30 sample changer for the completely automatic measurement of up to 30 samples in series.

The following devices can be connected:

●

Computer for operation under LabX

●

External measuring cells:

•

METTLER TOLEDO DX40, DX45 or DX50 density - modules

•

METTLER TOLEDO RX40 or RX50 refractive index - modules

●

Barcode reader for scanning sample data, set values of certified standards and for starting measurements

●

finger print reader for user identification

●

Compact printer (USB-P25), to print out results

●

External instruments:

•

METTLER TOLEDO S20 – SevenEasy™ pH

•

METTLER TOLEDO S30 – SevenEasy™ Conductivity

•

METTLER TOLEDO S220 - SevenCompact™ pH/Ion

•

METTLER TOLEDO S230 - SevenCompact™ Conductivity

•

Lovibond colorimeters PFX880/ PFXi880, PFX950/ PFXi950 and PFX995/ PFXi995 series, Tintometer

•

Minolta colorimeters CM-5 / CR-5

●

USB stick

●

External sensors:

•

ErgoSens – Infrared movement sensor for the automatic start of measurements

•

LevelSens – Level sensor for waste bottle

•

AtmoSens – Air pressure sensor for measuring air pressure and taking the latter into account in adjust

ments and tests with air.

Special features of the refractometer:

8 Description of the Refractometer

Page 9

●

A maintenance-free LED is used as a light source for the measurements.

●

The measuring prism is made of sapphire. It is therefore extremely corrosion resistance and very robust. It

also has a high thermal conductivity.

●

For temperature measurement, NTC thermistors with extreme long-term stability are used. This means that

there is no need to regularly readjust the measuring cell.

9Description of the Refractometer

Page 10

3Principles of Refractometry

n

1

n

2

n

1

β

n

2

α

sin

sin

=

1

2

β

β

1

2

3

4

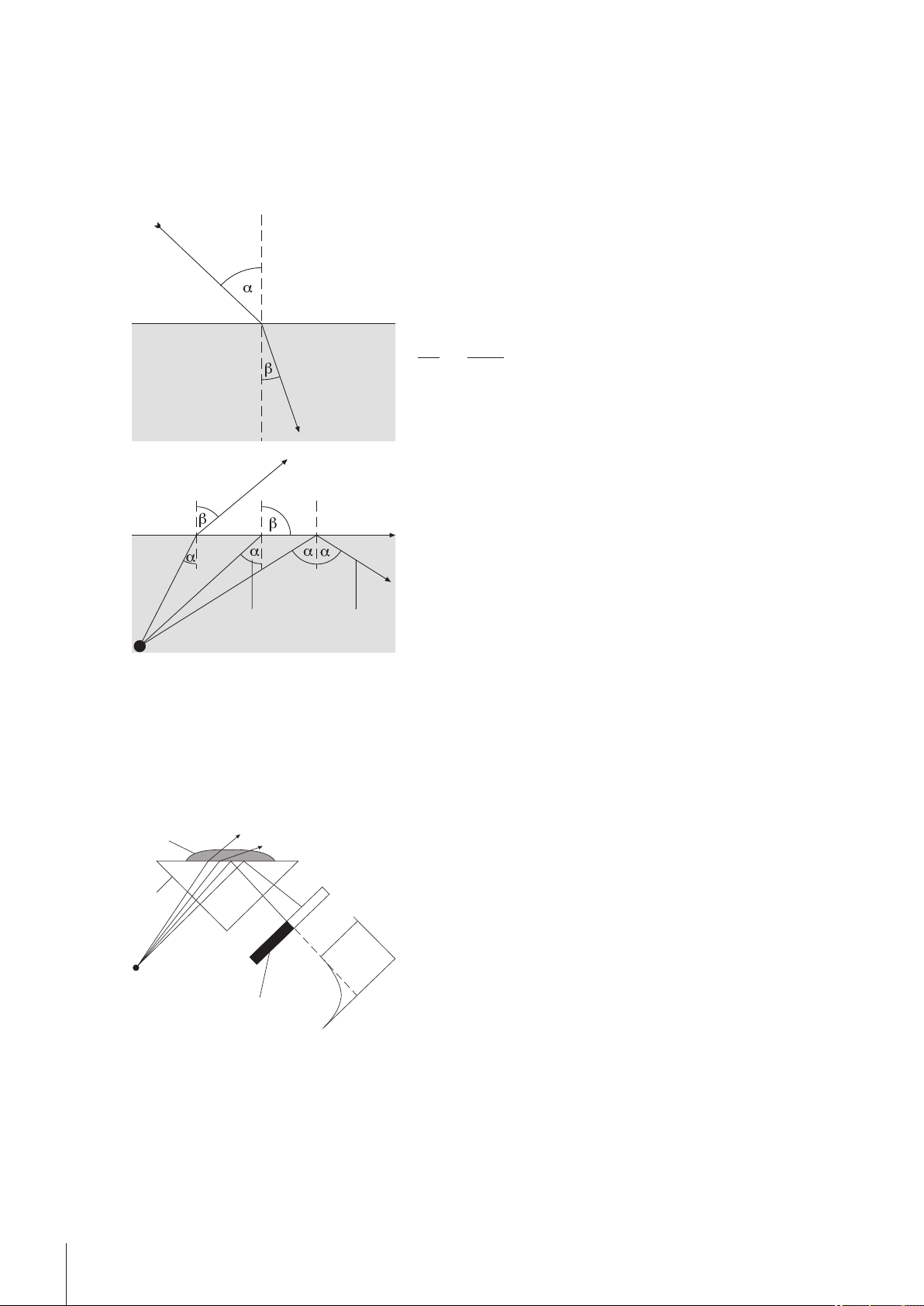

3.1Definition of the Refractive Index

The refractive index of a substance is the ratio of the speed of a light beam in a vacuum to its speed in the sub

stance (dimensionless).

If a light beam crosses at a certain angle from an optically less

dense to an optically denser medium (e.g. from air to water), it

is deflected; when the beam crosses from one medium to

another perpendicularly no directional change takes place.

According to Snell's law, the ratio of the refractive index of the

two media is proportional to the ratio of the incident and refrac

tive angle of the light beam:

If a light beam passes from an optically denser to a less dense

medium, it is also deflected. If the angle of incidence α is

increased, then it reaches a critical value, at which the light

beam no longer enters the less dense medium (refractive angle

= 90°). When this "critical angle" is exceeded, total internal

reflection occurs. The refractive index is calculated from this

critical angle α :

As refraction depends on the wavelength of the incident light, the refractive index n is measured as standard

with the D line of sodium (wavelength 589.3 nm) and designated nD.

The refractive index not only depends on the wavelength of the light but also on the temperature of the mea

sured sample. For this reason the temperature must always be stated along with the result, e.g. n

The standard temperature is 20 °C.

3.2Method of Measurement

= 90o —> sinβ =1

1: Critical angle

2: Total internal reflection

25

.

D

The light emitted from the light source passes through the

prism and hits the sample. In the process it is partly refracted

(angle of incidence < critical angle) and partly reflected (angle

of incidence > critical angle).

The reflected light is measured by means of an optical sensor

(CCD). The boundary between the dark and light area corre

sponds to the critical angle required for calculation of the

refractive index.

1: Light source

2: Prism

3: Sample

4: Optical sensor (CCD)

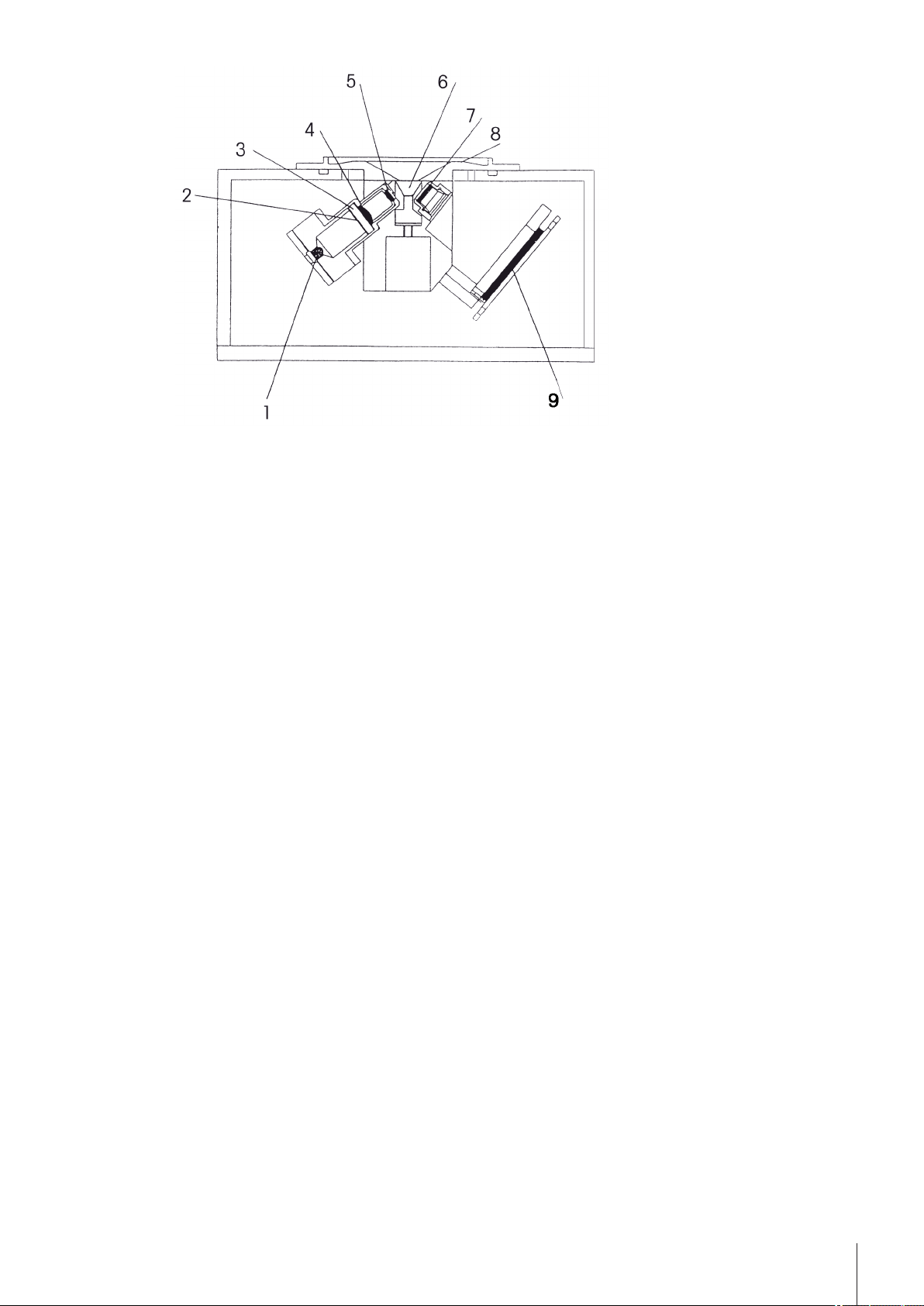

3.3Design of Measuring Cell

The light source is a light-emitting diode (LED), whose beam passes through a polarization filter, an interfer

ence filter (589.3 nm) and various lenses before it reaches the sample via the sapphire prism. The reflected

light (angle of incidence > critical angle) is deflected via a lens to the optical sensor that determines the critical

angle. The temperature in the prism/sample boundary is measured with a built-in sensor.

10 Principles of Refractometry

Page 11

1: Light source

2: Polarization filter

3: Interference filter

4: Lens

5: Lens

6: Prism

7: Lens

8: Measuring cell

9: Optical sensor (CCD)

11Principles of Refractometry

Page 12

4Description of Functions

4.1Layout of the Terminal

The control panel of the terminal consists of an integrated touchscreen and the following buttons, located next

to the touch-sensitive surface of the display: You can press these buttons any time, regardless of which dialog

you are currently using.

●

Two Home buttons that bring you back to the Homescreen.

●

Info, opens the info screen that shows the data related to the specific device.

●

Reset that interrupts the ongoing task and processing of the pending tasks. To continue the waiting tasks,

open the task list (with the Tasks button) and click Resume.

4.2Operating the Touchscreen

The touchscreen is automatically activated when the instrument is switched on.

To select a button or an input element in the dialog window, you simply touch the screen using a soft blunt

object or a fingertip.

It is also possible to select input elements using a USB mouse. To do this, simply connect the mouse to a suit

able USB port on the instrument.

Never touch the surface of the touchscreen with pointed or sharp objects! This may damage the screen!

4.3Homescreen

Home is the first screen that is displayed when you start up the instrument or when you log in. Home is the

main screen. On the left-hand side of the screen you will see five buttons that lead to the following dialog win

dows:

●

Methods / Products: The button leads you to the method or product editor, in which you can create and

administer the methods or products (see "Methods and Products").

●

Series: In this dialog, you can create and manage series of individual samples, e.g. for using a sample

changer (see "Series").

●

Results: Here you administer the results of your analyses (see "Results and Statistics").

●

Setup: You can administer the following points here:

•

Adjustment and test sets

•

The hardware and all resources used by the instrument

•

User and global settings

•

Tables (internal and user defined) and auxiliary values

•

Maintenance and service of the instrument

●

Manual: This button takes you to manual operations.

In addition, there is another area that can be configured individually by each user (with the necessary autho

rization). Each user can store up to eight shortcuts here. With these shortcuts, defined methods, products,

series and manual operations can be started directly from the homescreen (see "Functional Description"): The

user interface > Shortcuts").

●

Standby display: The standby display continuously shows the current cell temperature (Tcell) and set tem

perature (Tset), even if no task is running.

Via the standby display in the Homescreen you open the Cell data dialog.

●

By pressing the home button on the control panel of the terminal, you return to Home.

See also

●

Methods and Products (page36)

●

Series (page60)

●

Results and Statistics (page62)

●

Shortcuts (page14)

12 Description of Functions

Page 13

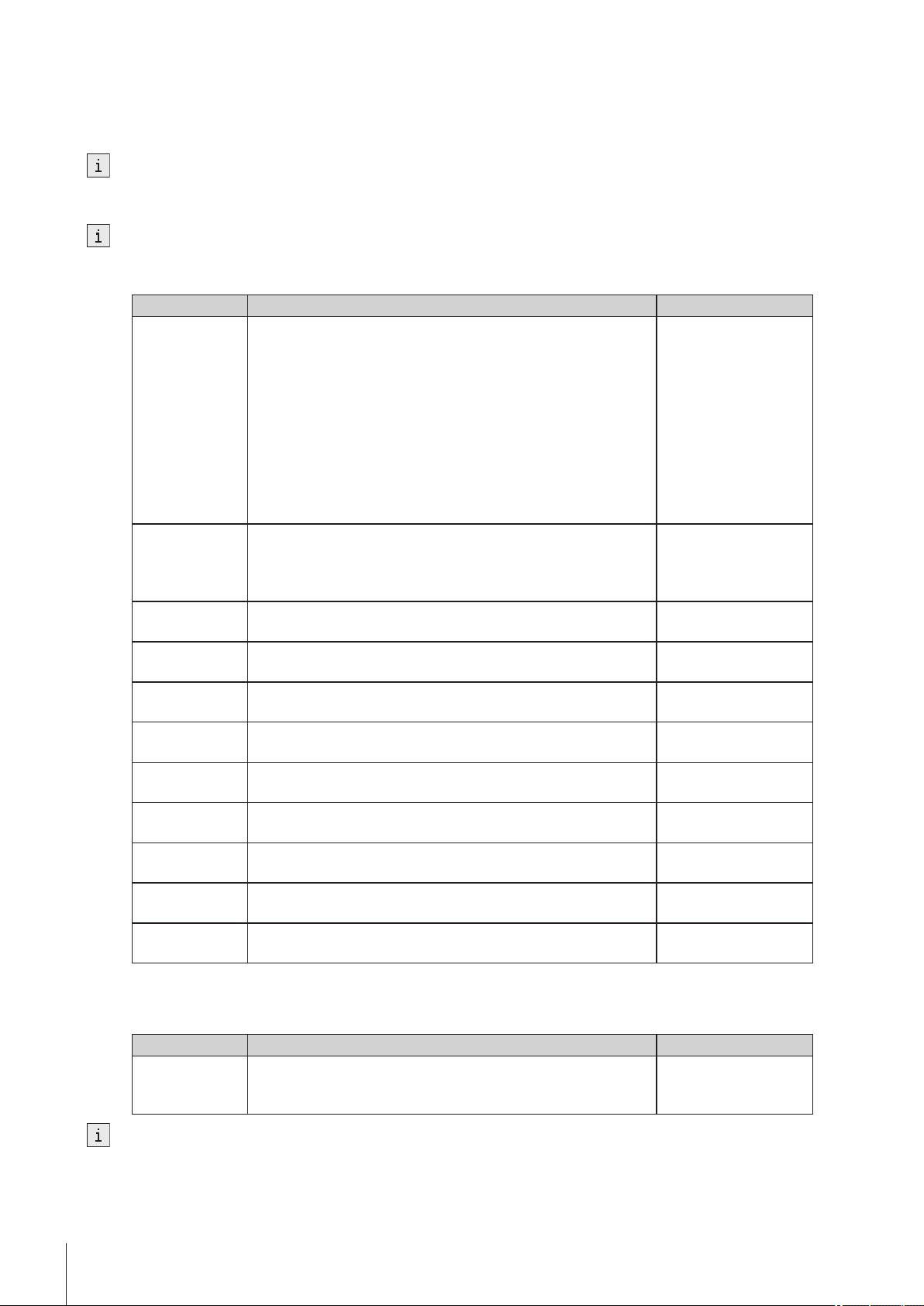

4.4The User Interface

A

B

C

T

1

2

3

T

T

T

T

T

i

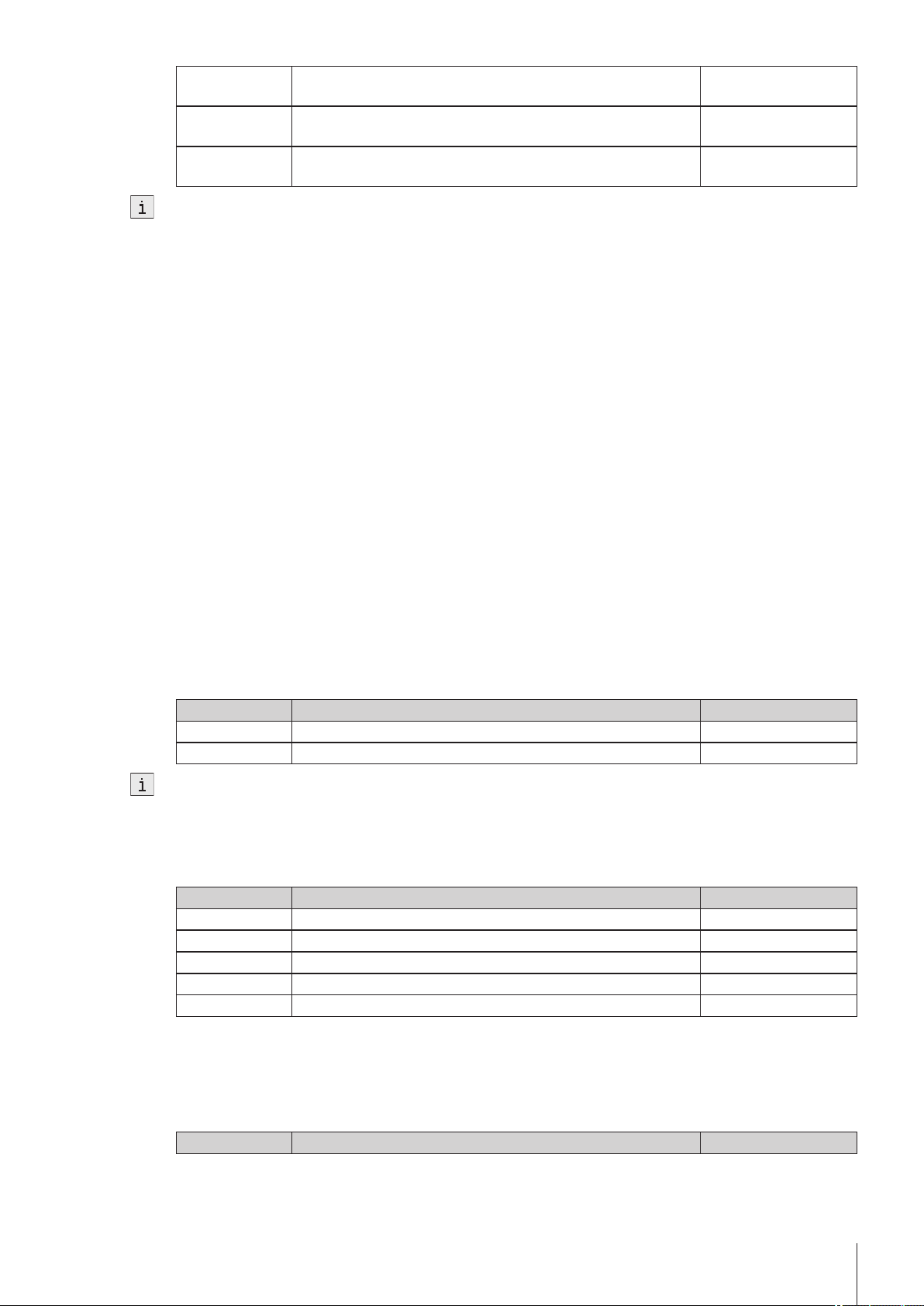

The graphical user interface consists of the following five basic elements:

●

The title bar at the top of the display specifies the name of the current dialog.

●

In the top right-hand corner you will see Tasks button, which signals the presence of ongoing processes

(see "Tasks and online screen: Tasks (page73)").

●

The navigation bar, located below the title bar, specifies the path to the current dialog.

●

The scroll bar on the right-hand side of the screen becomes visible if the content of the screen extends

beyond the viewable area. If this occurs, use either the arrows or the area in between them to move the

viewable area of the screen up or down.

●

Five buttons are located at the bottom of the screen. The function of these buttons varies and depends on

the context of the current dialog.

4.4.1Entering Data in the User Interface.

There are different types of input fields in the user interface. They allow you to enter data or select data from a

list. Input fields can also be deactivated and their contents are then displayed as information only and cannot

be changed in the corresponding dialog.

The various types of input fields are identified by an icon to the right of the screen:

Text input fields

Number input fields

Drop-down lists Selecting these fields opens a drop-down list from which you can

List fields Selecting these fields opens a menu list in a new window.

Parameter field Selecting these fields opens a new dialog with various additional para

Formula fields Freely definable formulas can be entered in these fields

In these fields text can be freely entered.

Numbers can be entered in these fields.

select an entry.

meters.

Info field

In addition to the input fields there are checkboxes that can be checked in order to select certain functionalities.

Checkboxes can affect the scope of the corresponding dialog, i.e. input fields can be hidden or visible depend

ing on whether the checkbox is checked.

The values in deactivated input fields are displayed as information only

and cannot be edited in the corresponding dialog.

13Description of Functions

Page 14

Sorting lists

There are lists that can be sorted alphabetically or numerically by column in ascending or descending order. To

do this, simply touch the parameter in the header row by which you would like to sort the list. A small arrow in

the header row indicates the parameter by which the list is sorted and whether it is sorted in ascending or

descending order.

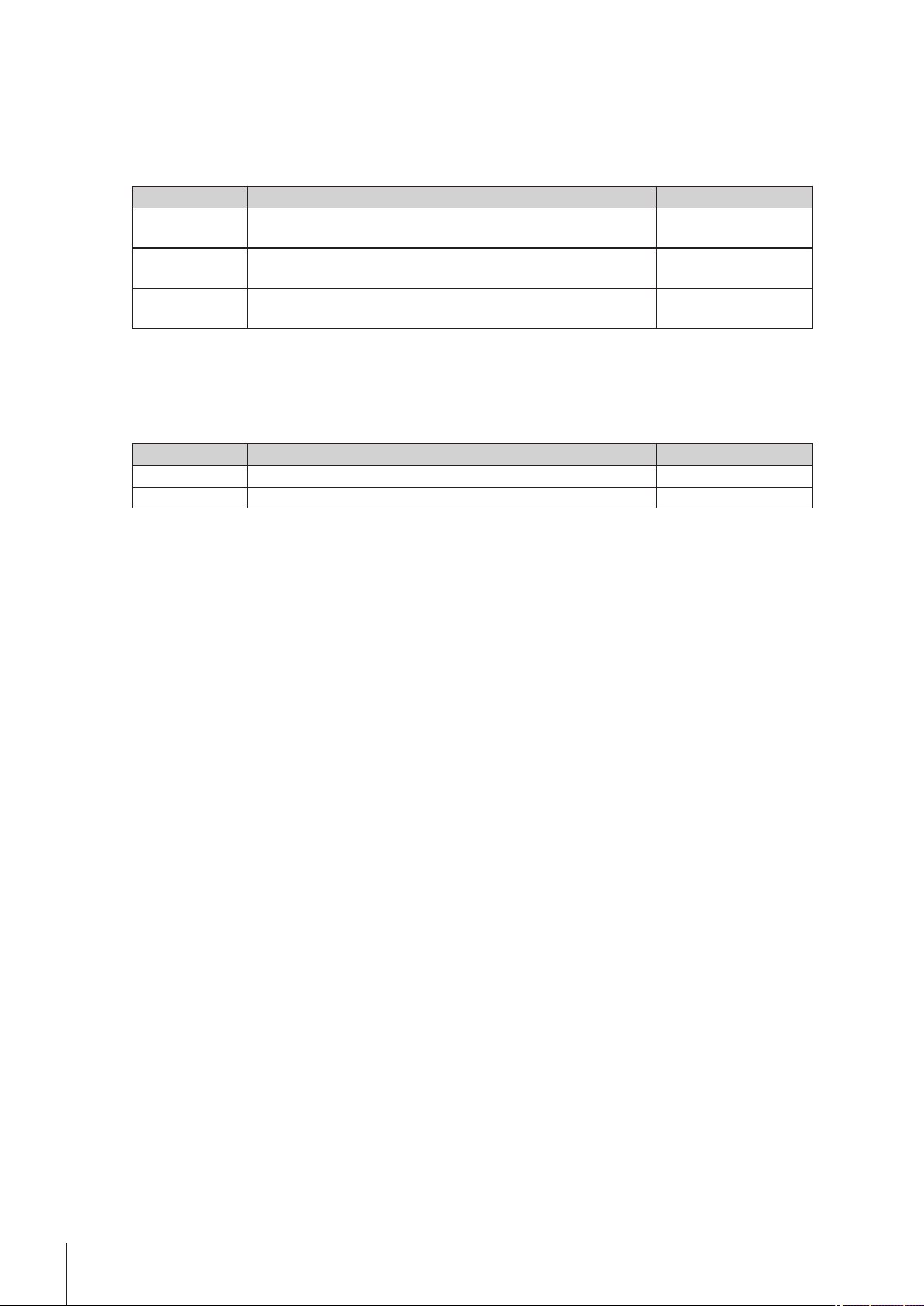

4.4.2Shortcuts

Shortcuts allow you to start methods, series, and manual operations directly from the homepage. You can

locate shortcuts by means of the button AddToHome on the Homescreen. AddToHome is found in the respec

tive Start analysis dialog of the methods, products, series or of the manual operation.

Two types of shortcuts are supported.

Direct shortcuts which, when selected, start the task immediately without warning (only if the other settings

allow this), and

normal shortcuts which take you to the corresponding Start analysis start dialog from which you can start the

task.

Shortcuts are user-specific, i.e. each individual user can create shortcuts for the tasks that they would personal

ly like to conduct. Shortcuts are managed in Setup, under the subcategory "User Settings". Here you can delete

or modify shortcuts, or change their position on the Homescreen.

for methods

for products

for series

Shortcuts

(lead you initially to the

Start analysis dialog)

Direct shortcuts

(task starts immediately, directly and with

out advance warning)

for manual opera

tions

A maximum of 8 shortcuts can be saved on the Homescreen. As soon as this maximum is reached, "AddTo

Home" in the start dialogs of methods, products, series and manual operations is deactivated.

14 Description of Functions

Page 15

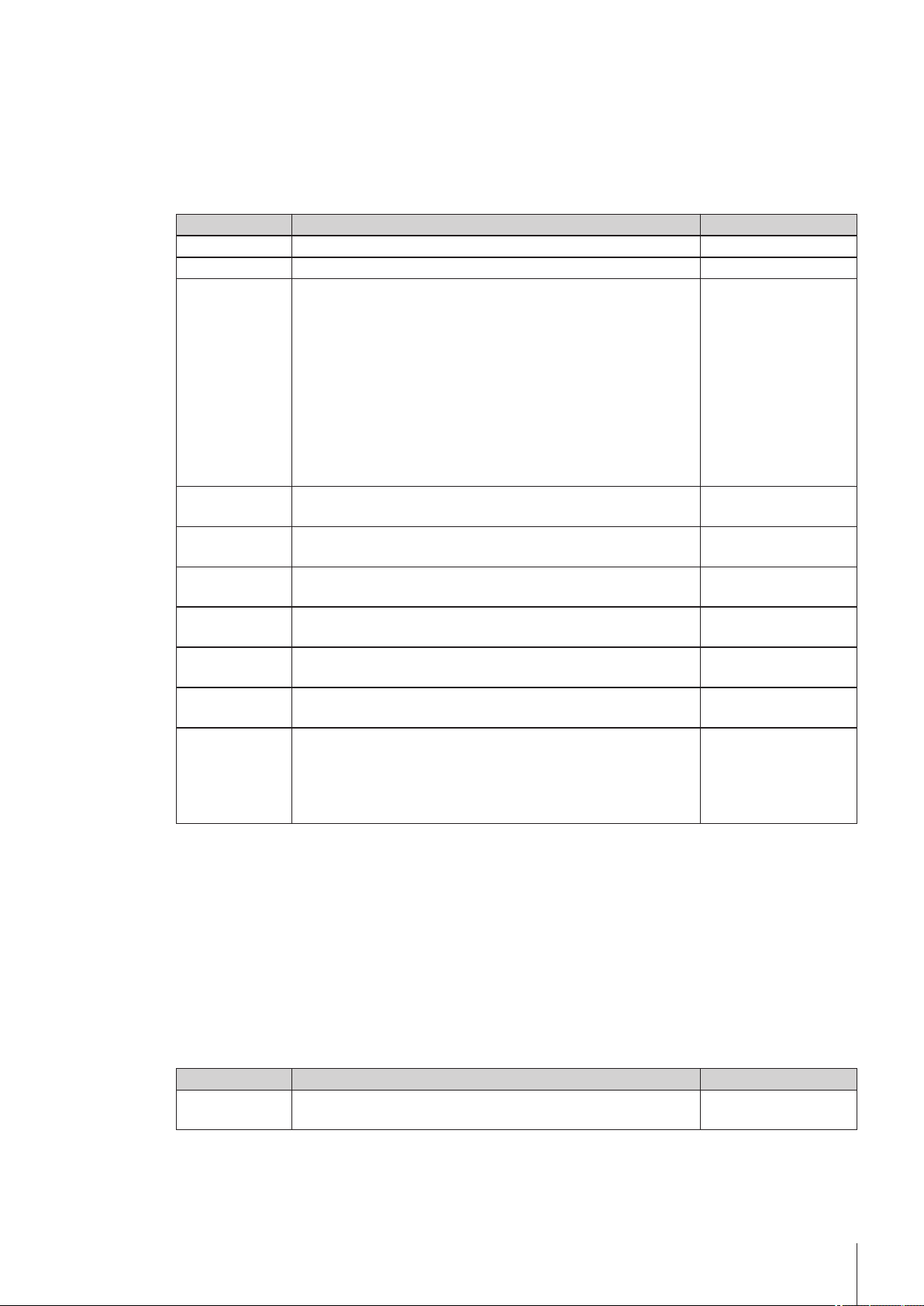

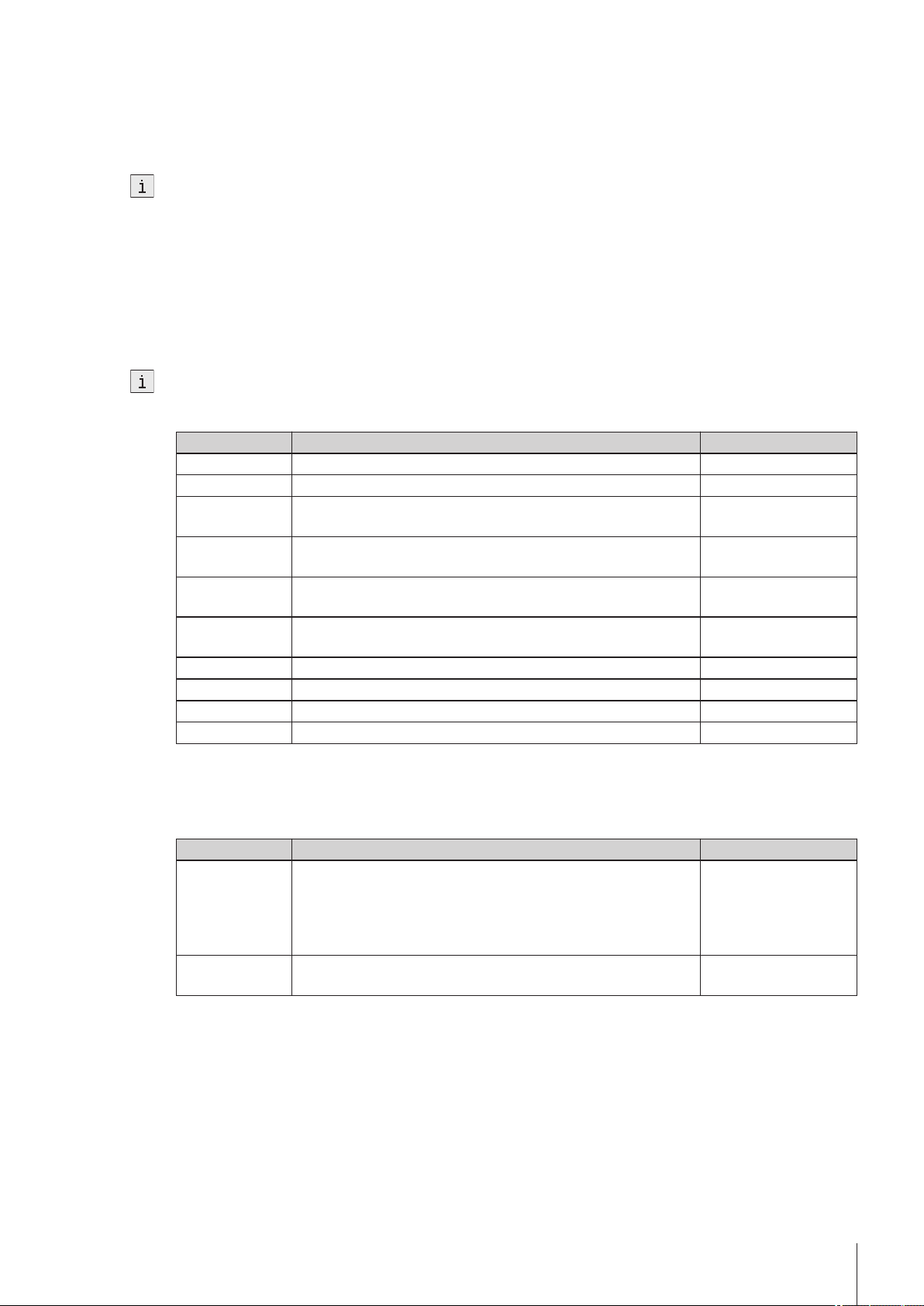

5Setup

This section tells you how to set up the refractometer acccordance with your requirements so that you can carry

out the measurements.

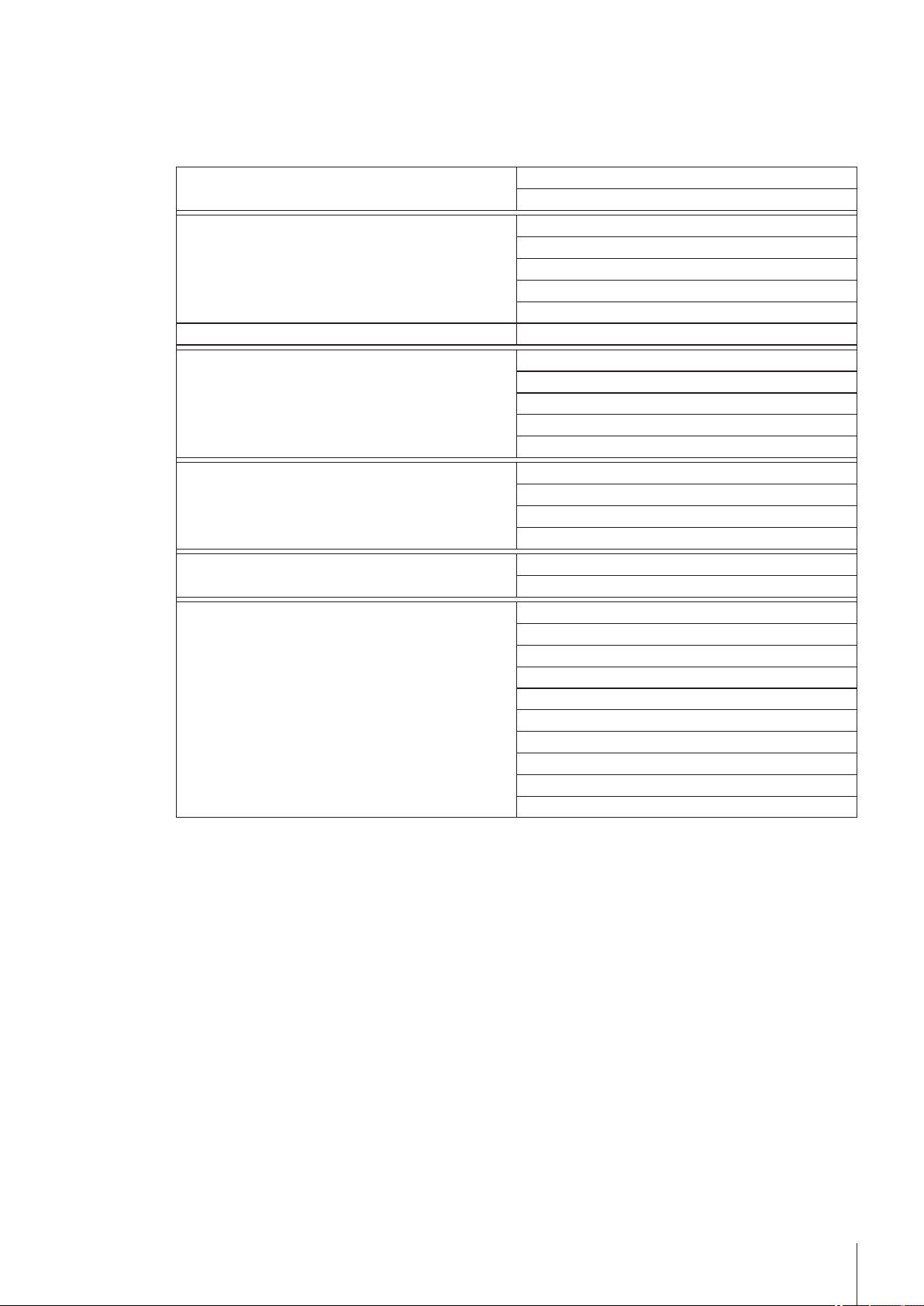

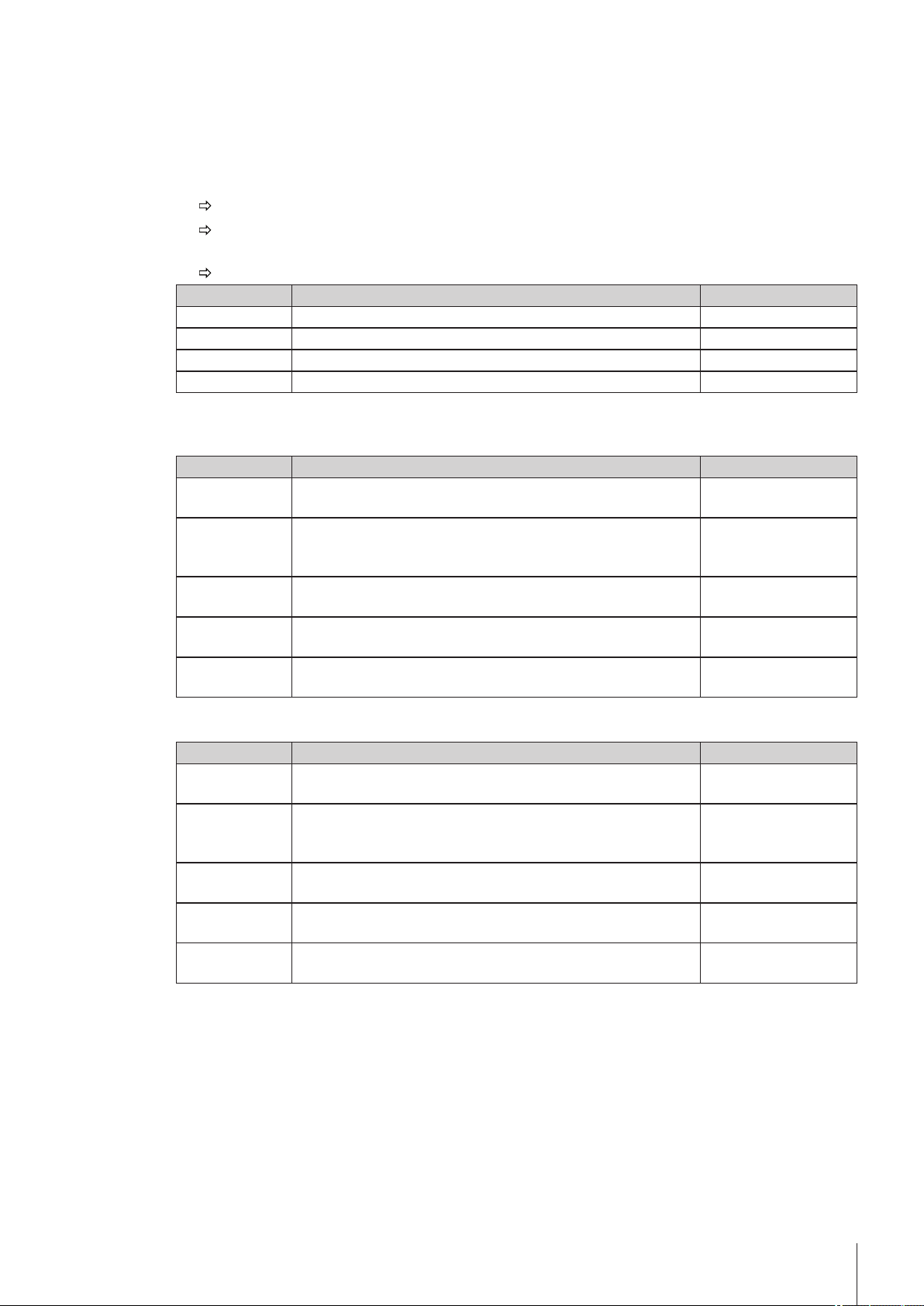

The following summary shows the buttons available in Setup for the various setting options:

Adjustment setsAdjustments & Tests Test sets

Hardware

User settings

Global settings

Maintenance & Service

Cell

Automation

External instruments

Peripherals

Sensors

Auxiliary instruments

Language

Screen

Beep

Shortcuts

Keyboards

System

User management

Analysis and resources behavior

Physical Properties

TablesTables & Values

Auxiliary values

MT service

Import / Export

Add external cell

Reset to factory settings

Firmware

Update

Hardware / Firmware summary

Cell

Touch screen adjustment

Export of adjustments / Tests / Measurements

The "Expired Resources" button

The Expired Resources button is located on the setup overview screen. It provides you with a summary of all

expired resources, stating the: type, name and expiration date of the respective resource.

Expired resources are entered if the setting "Monitoring adjustment set/test set/auxiliary value" is activated dur

ing setup.

Below you will find a detailed description of the setting options available in setup:

5.1Adjustments & Tests

Navigation: Home > Setup > Adjustments & Tests

Adjustment and test sets can be administered as described below. You can create new sets and delete existing

ones (when deleting you receive a prompt with the option to cancel). Before an adjustment or test can be per

formed, an adjustment or test set must be defined.

A maximum of six different adjustment sets or test sets respectively can be entered in the set list.

Before an adjustment or test can be performed, an adjustment or test set must be defined.

15Setup

Page 16

5.1.1Adjustment Sets

Via the button Adjustment sets you will obtain a list of the defined sets. The default set "Air&Water20.00C" is always available and cannot be deleted. When you click the sets, you obtain more detailed information about the individual sets. The parameters "Adjustment mode", "Temperature" and "Set name" are displayed.

Creating adjustment sets

You can create your own adjustment sets via the button New. The Adjustment set parameters dialog opens.

Parameters Description Displayed if

Adjustment mode Defines with which standard the adjustment will be performed.

Temperature Defines at which temperature the adjustment will be performed. Set name The set is uniquely identified in the system via this name. -

Delete adjustment sets

1 To delete a created set, click the desired entry in the Adjustment sets dialog.

2 In the Adjustment set parameters dialog, click the button Delete.

When a set is deleted, the set history will also be deleted. Methods that refer to the deleted set are no

longer executable.

5.1.2Test Sets

-

Set "Standards" requires a valid adjustment with "Air&Water" at

this temperature. (set "Air&Standard" and set "Water&Standard"

are not available for refractometers).

Via the button Test sets you receive a list of the defined sets. The default set "Water20.00C" is always available and cannot be deleted. When you click the test sets, you obtain more detailed information about the individual sets. The parameters "Test mode", "Temperature", "Set name" and depending on the mode "Standard name" are displayed.

Creating test sets

You can create your own test sets via the button New. The Test set parameters dialog is opened.

Parameters Description Displayed if

Test mode Defines with which standard the test will be performed. Temperature Defines at which temperature the test will be performed. Standard name Description of the standards "Test mode" = "Stan

Set name The set is uniquely identified in the system via this name. -

Delete test sets

1 To delete a created set, click the desired entry in the Test sets dialog.

2 In the Test set parameters dialog click the button Delete.

When a set is deleted, the set history will also be deleted. Methods that relate to the deleted set are no

longer executable.

5.2Hardware

Navigation: Setup>Hardware

In this dialog window you can configure all the hardware components connected to the meter. These include:

●

Cell

●

Automation

●

External instruments

●

Peripherals

●

Sensors

●

Auxiliary instruments

dard" or "Brix standard"

16 Setup

Page 17

5.2.1Cell

Navigation: Home > Setup > Hardware > Cell

The measuring cell is connected via an internal interface in the compact device. The instrument can be extend

ed to create a 2–cell instrument (see also "Setup: Maintenance & Service > Add external cell (page33)").

– Touch the button Cell in the Hardware dialog.

Parameters Description Displayed if

Cell Name of the measuring cell Type Measuring cell type Status Shows whether the cell is connected. Serial number Serial number of the cell -

If an adjustment has been performed, an entry in the adjustment set appears in the setup of the corresponding

cell. If you touch the entry, the data of the most recent adjustment that was executed with the set will be dis

played.

Parameters Description Displayed if

Adjustment set By touching the set entry, you obtain the values for the most

Monitoring

adjustment set

Adjustment inter

val

Reminder Before the set expires, a message appears indicating that the

Days before expi

ration

If a test has been performed, an entry in the test set appears in the setup of the corresponding cell. If you touch

the entry, the data of the most recent adjustment that were executed with the set will be displayed.

Parameters Description Displayed if

Test set By touching the set you go to the values for the most recent test

Monitoring test

set

Test interval Service life of test "Monitoring test set"

Reminder Before the set expires, a message appears indicating that the

Days before expi

ration

Via the button History you go to a list that contains a maximum of ten adjustment or test entries for the selected

set. In the process the measured refractive index values are displayed (in the adjustment mode air and water

only the value for water). The history can be displayed in graphic form via the button Graph. You can view the

history data by touching an entry.

With single cell instruments you go directly to the list with the cell parameters

In the case of two cell instruments the connected cells are listed. You have to touch one of the displayed

cells so that the Cell parameters dialog opens.

The Cell parameters dialog is opened.

-

recent adjustment of this set.

Monitoring of the service life of the adjustment can be activated.

The process, if the service life of a set has expired, is defined in

the method function "Measure".

Validity of adjustment "Monitoring adjustment

set" activated

"Monitoring adjustment

adjustment or test has expired.

Specifies the number of days after which a warning is triggered. "Reminder" activated

for this set.

Monitoring of the service life of the test can be activated. The

process, if the service life of a set has expired, is defined in the

method function "Measure".

adjustment or test has expired.

Specifies the number of days after which a warning is triggered. "Reminder" activated

set / test set" activated

activated

"Monitoring adjustment

set / test set" activated

-

-

-

5.2.2Automation

Navigation: Home > Setup > Hardware > Automation

The automation units that can be installed are listed below:

17Setup

Page 18

●

DryPal (drying pump)

●

FillPal (sample pump)

●

SC1 (automation unit for a sample)

●

SC30 (automation unit for 30 samples)

●

InMotion (automation unit for up to 303 samples)

The peripheral devices have an automatic PnP (Plug and Play) – identification. They can also be manually cre

ated in the setup.

Via the button Automation in the Hardware dialog, you access a list with defined automation units. By touch

ing a list entry, you obtain more detailed information about the corresponding automation unit.

Parameters Description Displayed if

Type Instrument Type Power purge unit The external diaphragm (Optional) has a much higher output

than the diaphragm pump integrated in the SC1/SC30. The pump

"Type" = "SC1"/

"SC30"

is actually adjusted at the SC1/SC30.

Heating option This is where the heating option is activated. The temperature is

directly set on the heating unit.

Limit sensor Optical sensor that detects the sample and prevents it leaving the

heated area of the heating option (info field).

External drain

valve

Located in the heating unit. Prevents the samples flowing back

after filling process (info field).

"Type" = "SC1"/

"SC30"

"Type" = "SC1"/

"SC30"

"Type" = "SC1"/"SC30"

Solvent 1 Specifies the solvent at the connection Rinse 1 "Type" = "SC1"/

"SC30"

Solvent 2 Specifies the solvent at the connection Rinse 2 "Type" = "SC1"/

"SC30"

Speed "Low" Value for speed level "Low" of the FillPal or InMotion autosampler

(in % of the maximum speed).

Speed "Medium" Value for speed level "Medium" of the FillPal or InMotion

autosampler (in % of the maximum speed).

Speed "High" Value for speed level "High" of the FillPal or InMotion autosam

pler (in % of the maximum speed).

Rate at 100% Value for max. possible pump output (depending on the installed

"Type" = "FillPal" /

"InMotion"

"Type" = "FillPal" /

"InMotion"

"Type" = "FillPal" /

"InMotion"

"Type" = "InMotion"

pump which is defined as sampling pump).

Stirrer output Specifies the pump/stirrer port on the InMotion where your stirrer

"Type" = "InMotion"

is connected.

Sampling pump

output

PowerShower

output

Specifies the pump/stirrer port on the InMotion where your sam

pling pump is connected.

Specifies the pump/stirrer port on the InMotion where your pump

for PowerShower is connected.

"Type" = "InMotion"

"Type" = "InMotion"

Rate Value for required pump output for PowerShower. "Type" = "InMotion"

Beaker height Specifies the height of the used beakers. "Type" = "InMotion"

A distinction should be made between the following two cases in the installation of instruments:

1.

There is still no setup entry available in the unit (delivery state).

A new entry has been generated and the parameters automatically generated.

2.

A setup entry was previously manually created in the instrument:

The PnP parameters are automatically entered, the remaining parameters, previously edited by the user,

remain unchanged.

18 Setup

When a PnP instrument is unplugged, the status changes to "not installed".

Below is described how you can administer the various devices in setup. This includes the creation of devices

or changing the parameters in the setup.

Create automation units

So that methods for the application of automation units can be created and configured without the automation

unit being connected, these units must be created in the setup via the button New.

Page 19

Delete automation unit

It is not possible to delete the entry of a connected device.

If you want to delete an entry for a unit that is not connected from the list, a message with the termination

option appears indicating that after deletion the methods that use the external instruments will no longer be exe

cutable.

5.2.3External Instruments

Navigation: Home > Setup > Hardware > External instruments

The external instruments that can be installed are listed below. They all have automatic PnP – identification:

●

METTLER TOLEDO S20 – SevenEasy™ pH

●

METTLER TOLEDO S30 – SevenEasy™ Conductivity

●

METTLER TOLEDO S220 - SevenCompact™ pH/Ion

●

METTLER TOLEDO S220 - SevenCompact™ Conductivity

●

Lovibond colorimeters PFX880/ PFXi880, PFX950/ PFXi950 and PFX995/ PFXi995 series, Tintometer

●

Minolta colorimeters CM-5/ CR-5

●

The Lovibond colorimeters can be connected to the USB interfaces. For this purpose the USB – RS232

adapter is required (contained in the connection kit).

●

For each device type only one entry is possible.

Install devices

A distinction should be made between the following two cases in the installation of instruments:

1.

There is still no setup entry available in the unit (delivery state).

A new entry has been generated and the parameters automatically generated.

2.

A setup entry was previously manually created in the instrument:

The PnP parameters are automatically entered, the remaining parameters, previously edited by the user,

remain unchanged.

When a PnP instrument is unplugged, the status changes to "not installed".

●

Via the button External instruments in the Hardware dialog, you can obtain the list of instruments. By touching a list entry, you obtain more detailed information about the corresponding instrument.

Create device

So that methods can be created and configured with external instruments, without having to connect the instru

ment, the setup entries of the external instruments can be manually created via the button New.

●

The pH and conductivity meters can be assigned names individually using the "Instrument" parameter.

Delete devices

It is not possible to delete the entry of a connected device.

If you want to delete an entry for a unit that is not connected from the list, a message with the termination

option appears indicating that after deletion the methods that use the external instruments will no longer be exe

cutable.

SevenEasy™ / SevenCompact™ pH/ion and conductivity meters

1 Select the following for the SevenEasy™ and SevenCompact™ measuring instruments (also refer to the

operating instructions for the measuring instrument concerned):

Manual end point measured value acquisition,

set the unit [pH]" ([mV] not supported).

2 For the SevenCompact pH and conductivity meters, the following must also be selected (also refer to the rel

evant operating instructions):

an interval time of 1s (in menu>Interval measurements),

interface=printer (in menu>Data transmission),

"Send data to interface" (in "Type of data transmission").

19Setup

Page 20

3 For temperature compensation, set the unit [°C] at the measuring instruments. Two types of temperature

compensation exist:

- ATC (automatic temperature compensation) with a temperature sensor connected.

- MTC (manual temperature compensation) with no temperature sensor connected.

Note:

The pH or conductivity meters switch automatically, depending on the arrangement.

If the temperature unit at the pH meter or conductivity meter is set to [°C], the results "TpH" and "TCond" will

be converted to the temperature unit set in the instrument, i.e. either [°C] or [°F] . By contrast, if [°F] is set

at the pH or conductivity meter, no result will be calculated. "--" will be output in the results field.

The conductivity units are [mS/cm]/ [μS/cm] (depending on the range) or [mS/m][μS/m] (depending on the

range). However, the results are expressed in [μS/cm]. If you wish to have the result displayed in [mS/cm] or

[mS/m][μS/m], it will be necessary to recalculate the result using the "Calculation" method function.

Colorimeter

- Lovibond

The Lovibond colorimeter can be used for extinction or transmission measurements. The wavelengths are out

put in 5nm (in the range 420 – 710nm).

A color measurement may take longer than 25s.

- Minolta colorimeters CM-5 / CR-5

The Minolta colorimeters can be used for transmission measurements (liquids).

Transmission data are supplied in 10nm increments within the spectral range 360 – 740nm.

A color measurement takes approximately 1s.

The measurements involve high-energy light flashes. For this reason, color scales are not offered for reflection

measurements in the crude oil industry.

●

The CR-5 colorimeter does not supply any spectral data.

●

Calibration is possible directly at the colorimeter only. The USB link must be disconnected.

●

"Illuminant" and "Observer" can be set in the "Configuration" method function. For more information, see

"Methods and products: Method functions> Configuration (page42)".

- Color scales

Navigation: Home > Setup > Hardware > External instruments > Parameters

– Click on "Colorimeter".

The "External instrument parameters" dialog appears.

If a device has been connected, a list of color scales is displayed via the Color scales button, that were avail

able in the most recently connected device. If the device has been manually configured and no device has yet

been connected, then the list is empty.

See also

●

Continuous run (page71)

5.2.4Peripherals

Navigation: Home > Setup > Hardware > Peripherals

In the dialog Peripherals, the following devices and settings can be configured:

●

Barcode reader

●

USB stick

●

Fingerprint reader

●

Printer

●

Personal Computer (PC) – settings

●

Network settings

●

Network storage

20 Setup

Below is described how you can administer the various devices in setup. This includes the creation of devices

or changing the parameters in the setup.

Page 21

Barcode reader

Barcode readers have Plug&Play (PnP) recognition and can be installed via the USB interface.

The following barcode readers can be installed:

●

Handheld readers

●

Built-in readers

You can create the barcode readers via New. A maximum of one entry can be created for both types.

Parameters Description Displayed if

Type Instrument Type Serial number Serial number of the corresponding device Barcode Informa

tion

Sample ID: on the barcode there is only the sample ID.

Method ID: on the barcode there is the method ID (with this a

-

saved method can be selected during scanning).

Product ID: on the barcode there is the product ID (with this a

saved product can be selected during scanning).

Sample ID/Method ID: on the barcode there are the sample ID

and method ID (with this a saved method can be selected during

scanning).

Sample ID/Product ID: on the barcode there are the sample ID

and product ID (with this a saved product can be selected during

scanning).

Start pos. sample

ID

Number of char

acters

Start pos.

method ID

Number of char

acters

Start pos. prod

uct ID

Number of char

acters

Immediate start If this parameter has been activated, when a task is started with

Start position of the sample ID on the barcode "Barcode information"

with sample ID

Length of the sample ID on the barcode "Barcode information"

with sample ID

Start position of the method ID on the barcode "Barcode information"

with method ID

Length of the method ID on the barcode "Barcode information"

with method ID

Start position of the product ID on the barcode "Barcode information"

with product ID

Length of the product ID on the barcode "Barcode information"

with product ID

"Type" = "Handheld

the barcode reader, the Start analysis dialog is skipped and the

task is started immediately.

reader",

"Barcode information"

with method ID, product

ID or sample ID

Example of barcode with sample ID and method ID (161218522). (Sample ID=1612 and method ID 18522).

●

Start pos. sample ID 1

●

Number of characters 4

●

Start pos. method ID 5

●

Number of characters 5

USB stick

Commercially available USB sticks from USB Version 1.1 are supported.

Fingerprint reader

You can use a fingerprint reader to authenticate users on the titrator. In order to do this, the fingerprint reader

must be activated on the titrator. The following parameters are available for this:

Parameters Description Displayed if

Activate finger

Activates the connected fingerprint reader. -

print reader

21Setup

Page 22

Printer (and USB-RS232 data export)

●

Date can be printed with the USB-P25 (strip printer) or with a network printer.

●

Data can be exported using the USB data export box. The data are exported in the XML (UTF-8) formats.

●

For data export to an RS interface, you need the USB RS232 adapter (USB data export box).

●

As desired, data can be printed either as a summary or in a user defined format (via "Print Mode" parameter

"Report" method function; also see "Methods and products: Methods> Method functions> Report")

For printing/USB data export, the following should be taken into consideration:

●

In the "Report" method function, the "Print / USB-RS232 data export" parameter must be selected.

You can define the following parameters via the Printer button (Home>Setup>Hardware>Peripherals):

Parameters Description Displayed if

Printer type USB compact printer

The USB compact printer does not support all languages. This

printer can only print out a limited quantity of analysis data and

results.

USB-RS232 data export

For the RS-232 data export, the data is transmitted regardless of

the selected language. Only a limited quantity of data and results

can be exported.

Network printer

Every connected printer in your local network that supports HP

PLC 3 or Epson ESC/P 2 can be used.

Status Indicates whether the selected printer type is installed (info field). Only for printer type

"USB compact printer"

and "USB-RS232 data

export"

Baud rate The baud rate for data transmission via the USB-RS232 interface. "Printer type"= "USB-

RS232 data export"

Data bit The number of data bits is displayed (info field). "Printer type"= "USB-

RS232 data export"

Stop bit The number of stop bits is displayed (info field). "Printer type"= "USB-

RS232 data export"

Parity Defines the parity protocol. ("Even", "Odd", "None") . "Printer type"= "USB-

RS232 data export"

Handshake Data transmission via the RS-232 interface ("Xon-Xoff", "None"). "Printer type"= "USB-

RS232 data export"

Type Choose the printer protocol. "Printer type"= "Net

work printer"

Network name Define your local network name here. "Printer type"= "Net

work printer"

Port number Define your local port number here. "Printer type"= "Net

work printer"

Paper size Choose the print-format of the report (A4 / Letter). "Printer type"= "Net

work printer"

22 Setup

PC settings

Only one PC connected per measuring instrument can be present at one time. You can select if you wish to set

up a connection to the laboratory program "LabX".

Parameters Description Displayed if

Set up connec

tion to LabX at

If this parameter is activated, a connection to LabX will be estab

lished on startup.

-

start up

Changes to the PC settings are not implemented until after the measuring instrument is rebooted.

Page 23

Network settings

You can define the following parameters for the network – settings:

Parameters Description Displayed if

Type Type of network connection Obtain IP

address auto

matically

IP Address IP address of the instrument Subnet mask Subnet mask of the device Standard gate

way

The device automatically reboots after any change to the network settings.

Network storage

You can define the following parameters for a network – storage:

Transfer via Method for transferring data

Server PC or server name. Users should have read-write access. Maxi

Share name Name of the share folder User name Define your own user name. Domain Domain name for the user. Password Password for network share. Target folder Name of target folder for PDFs or results.

First folder level Can optional be used to sort data. (None | User name | Instru

Second folder

level

If this device has been activated, the device automatically obtains

an IP address.

Standard gateway of the device "Type" = "Ethernet"

Default: Network share

mum 60 alphanumeric characters.

Arbitrary IP address or name of server (for network share, only

server name allowed).

A pdf_export folder and a results folder are automatically creat

ed in the target folder when specified. If no target folder is speci

fied the folders are created in the root folder.

ment ID | Date | Method ID | Analysis comment)

Default: None

Can optional be used to sort data. (None | User name | Instru

ment ID | Date | Method ID | Analysis comment)

Default: None

"Type" = "Ethernet"

-

-

-

-

"First level folder" =

activated

5.2.5Sensors

Navigation: Home > Setup > Hardware > Sensors

Sensors can be activated in the setup. The following sensors can be connected:

ErgoSens: Infrared sensor for contactless start of measurement (see "Analysis sequence: Start of analyses").

Before you can use ErgoSens, it has to be activated:

Parameters Description Displayed if

Activate

ErgoSens

WasteSens or LevelSens: Level sensors for waste bottle.

It is determined whether the maximum filling level of the waste bottle is reached. If the maximum filling level

has been reached, a message appears prompting the operator to empty the waste bottle. The task is then inter

rupted.

Before you can use WasteSens or LevelSens, it has to be activated:

Activates the ErgoSens -

23Setup

Page 24

Parameters Description Displayed if

Activate

WasteSens/Lev

elSens

If you connect the density - module, you can use an air pressure sensor:

AtmoSens: Atmospheric pressure sensor for measuring the absolute air pressure.

If an AtmoSens is connected, the atmospheric pressure (if required) is measured with the AtmoSens. If no

AtmoSens is connected, the air pressure is read out from the current value from Home > Setup > Global

settings> Physical properties.

Parameters Description Displayed if

Verify AtmoSens

availability

activates the WasteSens or LevelSens -

If this parameter is activated, the use of the AtmoSens is enforced

for tasks which require the pressure.

5.2.6Auxiliary instruments

Navigation: Setup>Hardware>Auxiliary Instruments

Auxiliary instruments can be any instruments that access the 24V output or USB-RS232 adapter of the measur

ing instrument and that are to be used in a method.

An auxiliary instrument that accesses the 24V output is switched on for a predefined period and then switched

off again via the corresponding command. The instruments are controlled via the "Auxiliary instrument" method

function.

Auxiliary instruments form part of a method, while peripheral devices are classified as input/output devices

(printers, barcode readers etc.), which do not have direct access to methods.

Starting from the auxiliary instrument list, you can add new auxiliary instruments or select existing ones or

modify their parameters. In addition, the selected auxiliary instruments can be deleted.

A maximum of 30 auxiliary instruments can be entered.

Choose the New button in the Auxiliary Instruments dialog window to open the Auxiliary Instrument Para meters dialog.

-

1 Before a new auxiliary instrument can be added, you must first use the "Control type" parameter to select

the manner in which the auxiliary instrument is to be controlled:. The following values are available for

"Control type":

24V output

USB-RS-232

2 You can assign a name of your choice to the auxiliary instrument.

The parameters for the control types are listed below:

24V output

Parameters Description Displayed if

Control type Indicates which port on the measuring instrument is to be used

for the auxiliary instrument.

Name A name of your choice. -

USB-RS-232 interface

Parameters Description Displayed if

Control type Indicates which port on the measuring instrument is to be used

for the auxiliary instrument.

Name A name of your choice. Adapter Defines which adapter is used. Maximum 2 auxiliary instruments

of type USB-RS-232 can be used in the same method (by using

adapter 1 and 2)

Baud rate The baud rate for data transmission via the RS-232 interface of

the adapter.

Data bit Defines the number of data bits. "Control type" = "USB-

"Control type" = "USBRS232"

"Control type" = "USBRS232"

RS232"

-

-

24 Setup

Page 25

Stop bit Defines the number of stop bits. (2 stop bits can only be selected

Parity Defines the parity protocol. "Control type" = "USB-

Handshake Data transmission via the RS-232 interface of the adapter. "Control type" = "USB-

A suitable adapter (USB data export box) is required for the USB-RS-232 connection.

5.3User settings

Navigation: > >

These settings contains the options that can be made specifically for each currently logged in user.

You can configure the language, the screen settings (for the touchscreen), the layout of the alphanumeric and

numeric keyboard, the use of beeps, and shortcuts for each user.

5.3.1Language

Navigation: Home > Setup > User settings > Language

The following languages are available:

●

German

●

English

●

French

●

Italian

●

Polish

●

Portuguese

●

Spanish

●

Chinese

●

Russian

if 7 data bits are also selected at the same time.)

"Control type" = "USBRS232"

RS232"

RS232"

The language can be defined both for the operation of the terminal as well as for the protocols that are to be

printed out from a printer.

Parameters Description Displayed if

Touchscreen Language of the user interface Report Language of the printout* -

*

Chinese can not be selected as language for reports

5.3.2Screen

Navigation: Home > Setup > User – settings > Screen

The following parameters can be set in the screen settings:

Parameters Description Displayed if

Primary color Color of the user interface Brightness Brightness of the display Button shape Shape of buttons on the touchscreen Screen saver Activates screen saver Wait time Time for the display of the screen saver Activates screen saver

5.3.3Beep

Navigation: Home > Setup > User settings> Beep

The audio signal is set specifically for each user. You can activate the audio signal in the Audio-Signal set

tings dialog.

Parameters Description Displayed if

25Setup

Page 26

5.3.4Shortcuts

Navigation: Home > Setup > User – settings > Shortcuts

In this dialog, every user has the opportunity to administer his or her own selected shortcuts.

The list of all shortcuts for the logged in user can be viewed. Individual shortcuts can be selected and deleted.

You can determine the following parameters:

Parameters Description Displayed if

Description This text is the name of the shortcut that is displayed in the

Immediate start When the shortcut is pressed, the display switches directly over

Homescreen

Position

5.3.5Keyboards

Navigation: Home > Setup > User – settings > Keyboards

In the Keyboard settings dialog, you can define the layout for the alphanumeric and the numeric input fields.

The following settings are available:

Parameters Description Displayed if

ABC keyboard Defines the layout of the alphanumeric input field. 123 keyboard Defines the arrangement of the keys for the numeric input field. -

Homescreen.

to the online screen without opening the Start analysis dialog.

Selection of the position on the Homescreen -

5.4Global Settings

Navigation: Home > Setup > Global setting

In the Global Settings, you can make general settings to the measuring instrument that apply to all users of the instrument. The settings in this dialog can only be changed by users with the appropriate authorizations.

Global settings include:

●

The system settings

●

User management for creating user accounts and assigning rights.

●

The settings for Analysis and resources behavior.

●

Physical properties for defining the "Temperature unit" and the air pressure.

5.4.1System

Navigation: Home > Setup > Global settings > System

In the System settings dialog the following buttons are available:

●

Identification:In this menu you can give the measuring instrument a freely definable ID consisting of at

least four characters.

In addition the following information is displayed: Device, serial number and firmware version.

●

Date / time:You can define the format used to display the date and time and set the device date and time.

●

Data storage: If this parameter is activated, all results that are saved under Home > Results are deleted

(only when device is shut down).

5.4.2User Management

Navigation: Home > Setup > Global settings > User management

By means of the User management dialog you can administer users and account policies for the instrument.

A maximum of 30 different users can be defined, from which only maximum one may be logged in with the

instrument (1 user operation).

User accounts can be deleted and edited.

There is a default user with the user name "Administrator" (user group: Administrators). This cannot be deleted.

26 Setup

Page 27

5.4.2.1Users

Navigation: Home > Setup > Global settings > User management > User

Via the button New in the User dialog you can open the User parameters of the dialog. It is possible to define

new users here.

"User management" is the only area in which users with administrator rights are able to edit settings and, there

fore, create or make changes to users.

Create a new user in the User parameters dialog as follows:

1 Define a user name.

2 Assign the user to a group. The following user groups are available:

Administrator

Expert

Technician

Operator

For information on the rights of these user groups, see "Setup (Setup: Global settings> User management>

User groups (page27)".

The following parameters are available in the User parameters dialog:

Parameters Description Displayed if

User name The user is uniquely identified in the system via the name. Full Name Complete name of the user. User Group Selection of the user group for the user. Depending on the user

Reset password Resets the password for the user to "123456". Activates "Enforce pass

Lock user Locks the user. Activates "Enforce pass

Enforce pass

word change

Created by The administrator logged in at time of creation Created on Date of creation and time (info field) Modified by The administrator logged in at time of creation Modified at Change date and time (info field) -

-

group the user has various rights.

word/fingerprint"

word/fingerprint"

With the next login the entry of a new password will be enforced. Activates "Enforce pass

word/fingerprint"

5.4.2.2Account Policy

Navigation: Home > Setup > Global setting > User management > Account policies

The following parameters can be edited in the dialog:

Parameters Description Displayed if

Enforce pass

word/fingerprint

Min. password

length

If the parameter "Enforce password" is deactivated, then the instrument starts directly, i.e. not via the login

screen (only if one user is defined – corresponds to the factory settings). If several users are defined, the user

name can be selected in the login screen from a list.

5.4.2.3User Groups

Each user is assigned to a user group. The following four user groups (with decreasing rights going down

ward) should be distinguished:

●

Administrator

●

Expert

If this parameter has been activated, you can only log in by

entering the password (or via the fingerprint reader, if the para

meter "Activate fingerprint reader" is activated, in Home >

Setup > Hardware > Peripherals > Fingerprint

reader).

The minimum length of the user passwords Activates "Enforce pass

word/fingerprint"

-

27Setup

Page 28

●

Technician

●

Operator

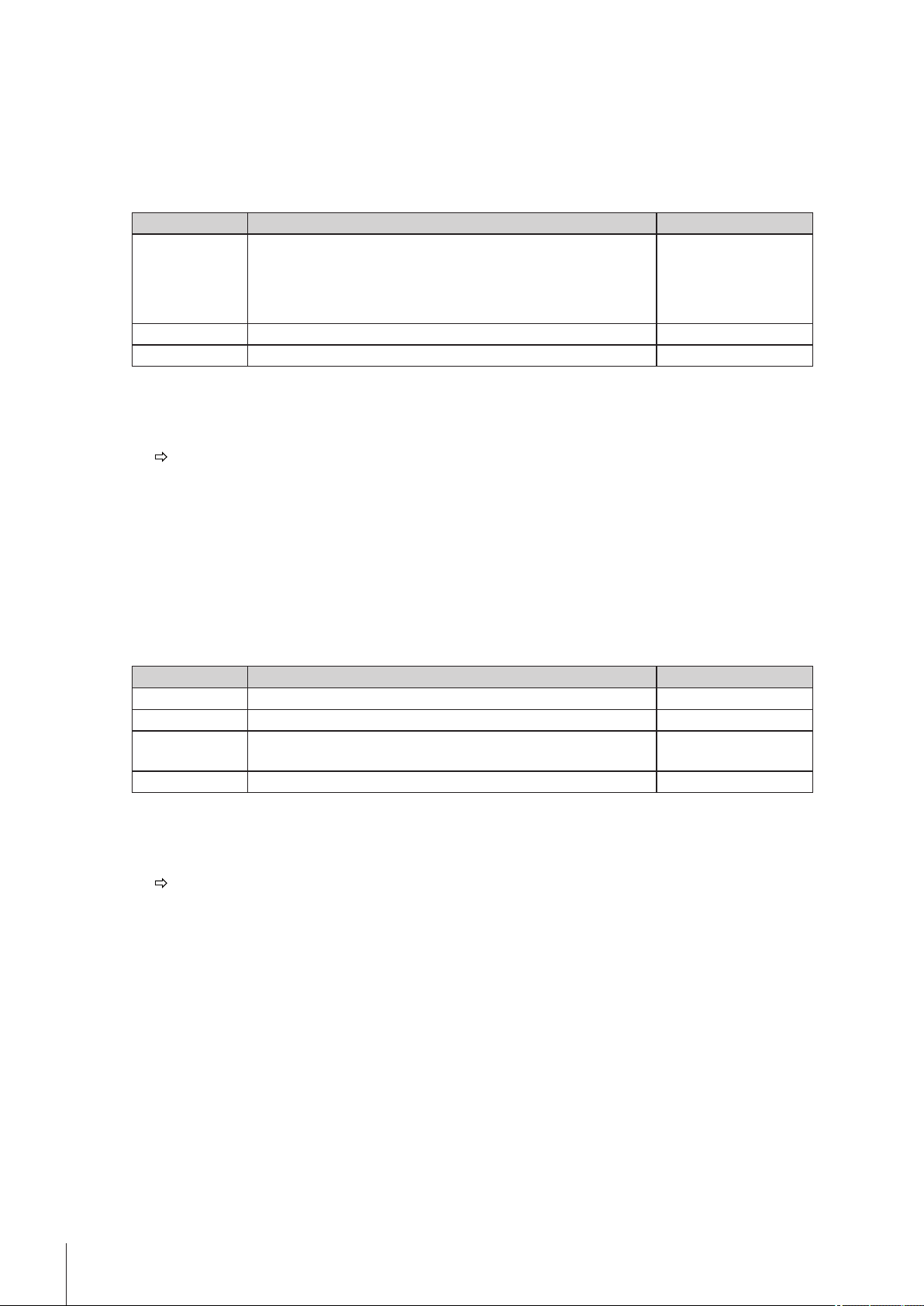

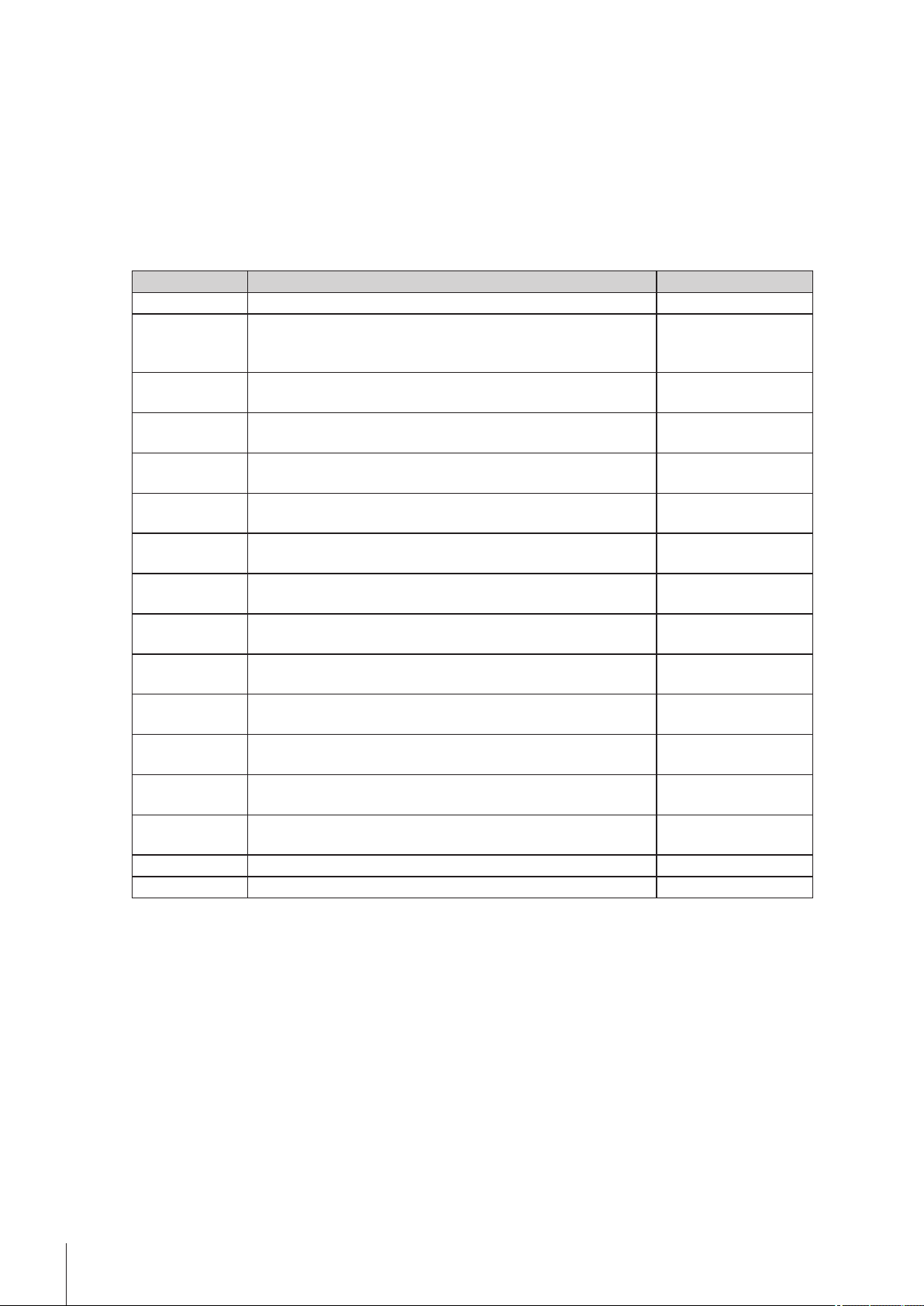

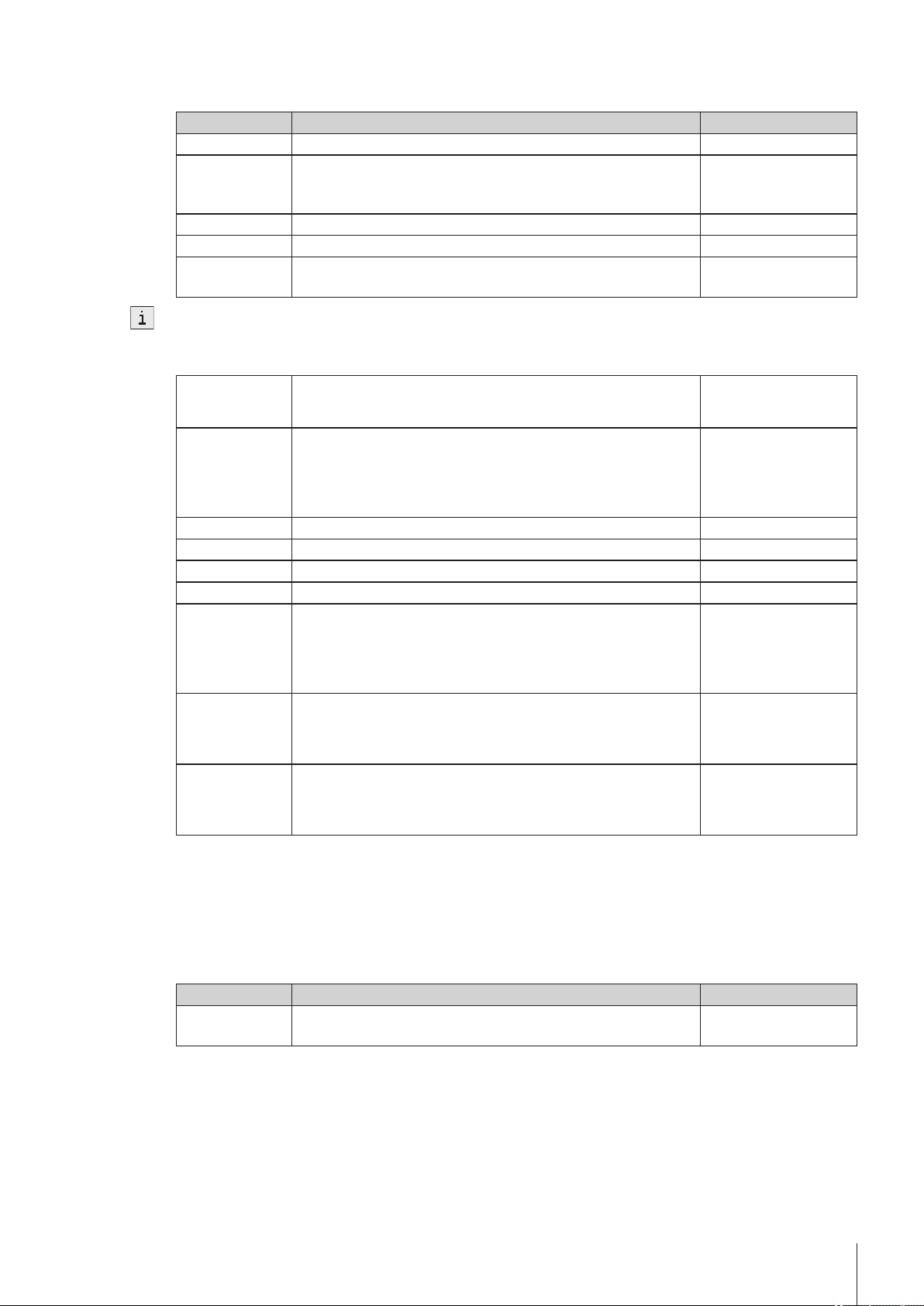

The following table presents the user rights that are assigned to the corresponding user group:

List of user rights

Right Minimum required user group

Start analysis via Shortcuts. Operator

Start analysis via Start button in the Homescreen Operator

Start analysis with ErgoSens Operator

Start analysis from method editor (for method type:

Technician

measurement, cleaning and test), product and series

editor (for method type: measurement, cleaning, test

and adjustment)

Adding/deleting items for series in the Start analysis

Technician

dialog (does not apply for adjustment-type methods)

Executing manual operations Technician

Editing shortcuts

Technician

(Setup>User settings)

Including and excluding results Technician

Deleting results Expert

Adding/deleting items for series in the Start analysis

Expert

dialog (also applies for adjustment-type methods)

Setting the language for touchscreen and reports Expert

Start analysis from method editor (for method type:

Expert

measurement, cleaning, test and adjustment)

Editing methods, products, series Expert

Editing "Adjustments & Tests"

Expert

(Home > Setup )

Editing "Hardware"

Expert

(Home > Setup)

Editing "Analysis and resources behavior"

Expert

(Home > Setup > Global setting)

Editing "Tables & Values"

Expert

(Home > Setup)

Setting the language for reports Expert

Editing "Physical properties"

Expert

(Home > Setup > Global setting)

Running "Maintenance & Service" in Home >

Setup, except:

●

Importing/exporting user management and memo

Expert

ry copy

Running "Maintenance & Service"

(Home > Setup),

including:

●

Importing/exporting user management and memo

ry copy

Editing "User management"

(Home > Setup > Global setting)

5.4.3Analysis and Resources Behavior

Navigation: Home > Setup > Global settings > Analysis and resources behavior.

The following settings can be defined:

28 Setup

Administrator

Administrator

Page 29

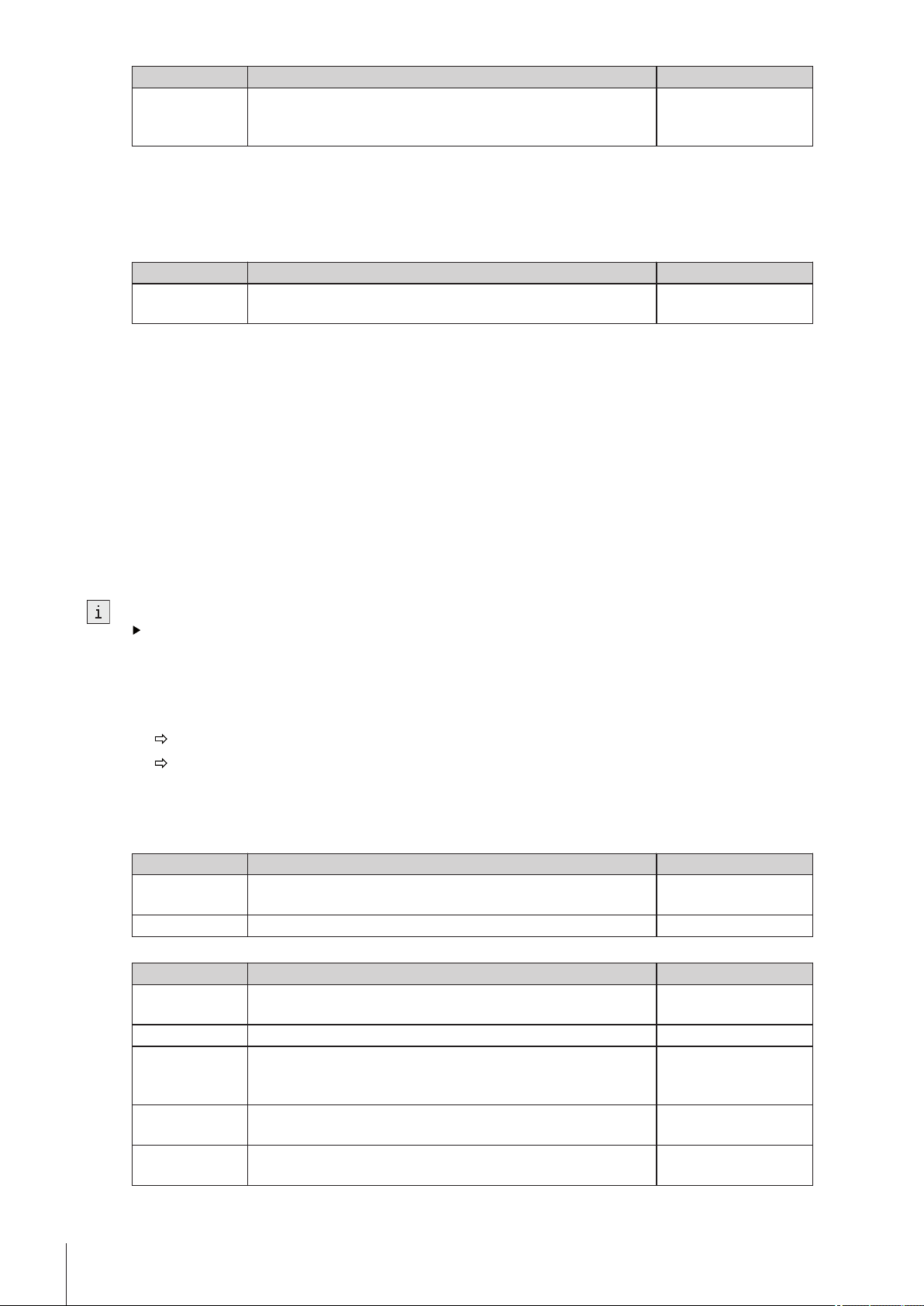

Parameters Description Displayed if

Show required

resources at start

Confirm end of

the analysis

Reset statistics if

sample ID

changes

Verify USB stick

availability

Verify printer

availability

Information on

identification of

PnP resources

Verify network

storage availabil

ity

If this parameter is activated, all resources are shown during

startup that are required for performance of the analysis.

Note: If a required resource is not available, the "Needed

resources" dialog is also shown without this parameter having

being activated.

If this parameter is activated, the OK button is shown at the end

of the task. The task is not ended until you confirm with OK. This

parameter is especially used if the result should remain on the

online screen at the end of the measurement so that, for exam

ple, it can be copied.

If this parameter is activated, the rolling statistics will be interrupt

ed, if the sample ID differs from the previous analysis. If it is not

activated, the rolling statistics will only be interrupted if the

method ID (or product ID) differs from the previous analysis.

If this parameter is activated and a USB stick is used in the

method, the task will be checked when the start is started to see

if the USB stick is available. If none is available the task cannot

be started.

If this parameter is activated and a printer is used in the method,

the task will be checked when the task is started to see if the

printer is available. If the printer is not available the task cannot

be started (does not work for network printers).

If this parameter is activated, a message is shown when a PnP

resource is detected.

If this parameter is activated and network storage is used in the

method, the task will be checked when the task is started to see if

a network storage is available. If no network storage is available,

the task cannot be started.

-

-

-

-

-

-

-

5.4.4Physical Properties

Navigation: Home > Setup > Global setting > Physical properties

In the Physical properties dialog you can defined the parameters "Temperature unit" [oC] or [oF] and "Atmospheric pressure" in [hPa].

Parameters Description Displayed if

Temperature unit Temperature unit applicable for all ranges of the instrument

(global setting). Either Celsius or Fahrenheit can be selected. All

inputs or outputs are in the temperature unit selected here. The

setting is saved after a restart.

Atmospheric

pressure

The atmospheric pressure is only required when using the density - module.

Input of atmospheric pressure that is used for calculating the

nominal value of the air density. The atmospheric pressure is

required for an adjustment or a test with air or a cell test. If the

AtmoSens is connected, the reading will be displayed here.

5.5Tables & Values

Navigation: Home > Setup > Tables & values

The instrument has tables and auxiliary values that can be used for the calculation of results (see also "Results

(page62)").

With measurements the raw data (e.g. temperature value and refractive index) are delivered. These results are

fed into the relevant tables so that corresponding results can be displayed in the respective units.

Tables are always assigned to an application. The list can be sorted according to application.

There are two types of tables:

-

-

29Setup

Page 30

●

METTLER TOLEDO tables:

These tables are included in the factory settings, they are only listed and can be neither edited, viewed nor

deleted.

●

User-defined tables:

Tables are laid out in the form of a value table (X-Y). They can be created, edited and deleted.

Below is a description of how to create your own tables.

In addition to the tables, you can also administer the auxiliary values in setup. The auxiliary values can thereby

be used in formulas. By means of the method function "Auxiliary value", an auxiliary value from any desired

formula can be assigned raw data or calculated results.

See also

●

Results and Statistics (page62)

5.5.1Tables

Navigation: Home > Setup > Tables & values > Tables

By opening the Tables dialog you can see a list of available tables (METTLER TOLEDO and user-defined).

How to create tables in the setup is described below.

You can create a table with the New button.

Parameters Description Displayed if

Name Table name: The name uniquely identifies the table in the system.

Application Application area of table. Facilitates the sorting of the table list. Input value Table heading for the input value. Output value Table heading for the output value. Fit type Definition of the curve type for the calculation.

1 Save the new table.

2 Enter value pairs via New.

Parameters Description Displayed if

"Input value" Input value of the value pair (corresponding to the measuring cell

"Output value" Output value of the value pair (e.g. Brix) -

At least four value pairs must be entered and then saved via the Save button.

– Touch the button Graph. The fit function is graphically presented (the button Graph is only displayed if the

table has been saved).

Note: The axis labeling corresponds to the specified "Input" – (x-axis) and "Output" parameters (y-axis).

The table has been successfully entered. The coefficients are calculated according to the selected function.

There is a "delta" column that shows the deviation from the calculated value at the effective table point (only

for the "Fit type" = "Polynomial"). This column is not shown when the table is being edited.

The name is entered into the formula in the method function "Cal

culation".

-

• Linear interpolation: Corresponds to a segmented curve.

• Lagrange interpolation: Lagrange fit via four points

• 1 order polynom

• 2 order polynom

• 3 order polynom

A dialog opens with the name of the new table.

used, e.g. density or refractive index)

30 Setup

●

In the Table – parameters dialog, you can again remove the table via the Delete button.

●

A table must contain at least 4 and contain a maximum of 200 value pairs.

●

A maximum of 30 user-defined tables may be defined.

●

Tables cannot be deleted or modified when they are currently in use.

●

The table name must be unique.

Page 31

5.5.2Auxiliary Values

Navigation: Home > Setup > Tables & Values> Auxiliary values

Via the New button, you open the Auxiliary values parameters dialog. In it you can use the following parame

ters to define the auxiliary value:

Parameters Description Displayed if

Name Unique designation of the auxiliary value: The name is entered

Comment Short comment on the auxiliary value (e.g. about the unit) Value Numerical value Determination

method

Determination

date

Performed by Person who performed determination Monitoring auxil

iary value

Interval Specifies the time period for monitoring of the auxiliary value. "Monitoring auxiliary

Expiry date Expiry date of auxiliary value (info field) "Monitoring auxiliary

Reminder Defines whether a reminder should be issued before expiry of the

Days before expi

ration

●

A maximum of 100 auxiliary values can be saved in the instrument.

●

Auxiliary values cannot be deleted or modified when they are currently in use.

●

When an auxiliary value is assigned with the "Auxiliary value" method function, this is updated in the setup

immediately after completion of the method function.

-

into the formula in the method function "Calculation".

Type of determination method (info field) -

Date on which determination was performed (info field) -

Specifies whether the auxiliary value is to be monitored. -

value" activated

value" activated

"Monitoring auxiliary

auxiliary value.

value" activated

Specifies the number of days after which a warning is triggered. "Reminder" activated

5.6Maintenance & Service

Navigation: Home > Setup > Maintenance & Service

The following functions are available to you:

●

MT service

●

Import / Export

●

Add external cell

●

Reset to factory settings

●

Firmware

●

Update

●

Hardware / Firmware summary

●

Cell

•

One-point temperature alignment (only for density - module)

•

Whole-range temperature alignment

•

Fan check

•

Add manual adjustment

●

Export of adjustments / tests / measurements

5.6.1MT Service

Navigation: Home > Setup > Maintenance & Service> MT Service

31Setup

Page 32

Via the button MT Service you can open the Last MT services dialog window.

In this dialog, you can view and print out a list of the most recent (max. 10) METTLER TOLEDO services. Under

each date, the user name of the METTLER TOLEDO service technicians and the date and time of the service

appointment are displayed. The most recently performed service always appears at the top of the list.

Via the Settings button in the Last MT services dialog window you can open the Service data dialog window,

via which you can edit the service life of the last service due date. You can define whether a warning should be

issued before the service life expires (requires administrator rights). You can define the following parameters:

●

"Service life" (in days) of the most recently performed service.

●

"Reminder": Defines whether a reminder should be issued before expiry of the service life of the service.

●

"Days before expiration" Number of days before expiration of the service life on which the instrument should

issue a warning.

The entered value must be smaller than the value for the service life (only appears if "Reminder" has been

activated).

5.6.2Import / Export

Navigation: Home > Setup > Maintenance & Service> Import / Export

With the aid of this feature you can save the data on a UBS stick (export) or import data from a stick.

The following can be imported or exported:

●

Single method

●

All methods

●

Single product

●

All products

●

Single series

●

All series

●

Single table (only affects user-specific tables)

●

All tables (only affects user-specific tables)

●

User management

●

Memory copy

The following rules apply for Import / Export:

1.

Import/Export is only possible when a USB stick is connected.

2.

Import/Export is only possible when no task is running.

3.

Products can only be imported if referenced methods are already available on the device required for the

import.

4.

Series can only be imported if referenced methods or products of the series are already available on the

device required for the import.

– In the Maintenance & Service dialog, open the Import / Export dialog window. In this dialog, you can

define the following parameters:

"Action": Data can be exported to a USB stick or imported back from a USB stick.

"Data": Data that is to be exported or imported can be selected.

Memory copy

You can create a memory copy from your data. This includes adjustment and test data, auxiliary values, short

cuts and fingerprints, data relating to automation, peripherals and external instruments. When a firmware

upgrade of the instrument has to be done, the instrument can be restored from the memory copy. The memory

copy can also be imported to another instrument. In this case, the Test and Adjustment history are not imported

and an adjustment of the instrument is required.

Uploading data from a backup copy results in the existing data being overwritten by the data in the memory

copy. In this way you can restore the initial status.

32 Setup

Page 33

●

Not contained in a memory copy are

any saved results, default parameters for manual operations, internal tables, hardware for cell creation or

parameters for added external cells.

●

When you import / export user management settings the entire user management settings with all users and

their properties are exported or imported.

●

If the import is canceled, all previously imported users are deleted and only a default user (administrator) is

created.

●

You must have administrator rights before you can create and reimport a backup copy.

5.6.3Add External Cell

Navigation: Home > Setup > Mainten. & Service > Add external cell

Perform the action "Add external cell". In the Cell dialog box, the cell type must be selected (Home > Setup

> Hardware > Cell).

When you connect the external cell (module), the status changes to "installed" and the effective serial number

is entered.

If the external cell is removed, the entry in the cell list is retained. The status changes to "not installed". The seri

al number and the cell type however continue to be displayed.

5.6.4Reset to Factory Settings

Navigation: Home > Setup > Maintenance & Service > Reset to factory settings

With the button Reset to factory settings you can reset your settings.

If you do this all created data, amendments, settings, setup entries or results are lost.

Before you activate "Reset to factory settings" you should create a memory copy.

5.6.5Firmware

Navigation: Home > Setup > Maintenance & Service > Firmware

With the aid of this feature you can display a list showing the most recent firmware updates. The first entry in

the list corresponds to initial operation.

All list entries are saved with a date and FW version.

5.6.6Update

Navigation: Home > Setup > Maintenance & Service > Update

With the aid of this feature a firmware update of the instrument, device board and cells can be performed via a USB stick. After the button update is touched, all available and associated components that contain firmware are presented in a list (Instrument FW, cell FW, Device Board FW).

You must have administrator access rights.

- The instrument is in idle mode (no task is active).

- To update a cell, the cell must be connected. In the process each update must be performed separately for

each connected cell that is to be updated.

1 Via the button update you can open the Firmware – List dialog. Select the relevant components from this

list.

2 Plug in the USB stick with the firmware update files into the instrument.

The instrument recognizes the USB stick and enables the update.

3 Start the update.

The instrument reboots and starts the update program via the USB stick. The update can be performed in

the update program.

4 When the update program is terminated, the instrument reboots with the normal application.

Instrument update:

33Setup

Page 34

All results, settings, setup entries, methods, products and individual modifications are lost during the instrument

firmware update. On the other hand, the service history, the instrument firmware history and serial number are

all retained.

Cell update:

●

Only updates from connected and recognized cells are offered, whose update file is on the USB stick.

●

With the cell update, no changes are made to the application program and to the individual settings and

methods.

Device board update:

With the device board update, no changes are made to the application program and to the individual settings

and methods.

5.6.7Hardware / Firmware summary

Navigation: Home > Setup > Maintenance & Service > Hardware / Firmware summary

You can view a list with all connected components along with the corresponding information on hardware or

firmware. The list can be saved as a file on a USB stick. The file name contains the serial number of the device

and the current date and time. Example:

HW_SW_Info_5124560983_23_03_2010_08_23.cvs

5.6.8Board Tests

Navigation: Home > Setup > Maintenance & Service > Board tests

With this function, the interfaces of various boards can be tested:

●

Main board

●

Device board

●

External cell board, if an external cell is connected

The sequence for testing the boards is described below:

1 Via the button Board tests you can open the Boards dialog. In this dialog, buttons are provided, which

2 Touch the button for the desired board and you will receive an information list with the connections on the

3 Touch the Start button, to go to the list of test functions.

4 You can select another interface and proceed as described above or you can cancel the test with the Stop

5.6.9Cell

Navigation: Home > Setup > Maintenance & Service > Cell

Via the Cell you get to the service function of the cells.

This dialog window contains the following buttons:

Button Parameters

One-point temperature alignment Adjustment of the cell temperature to the set temperature. The

guide you to the corresponding board information for the connections.