Page 1

Hardware Manual

January 2014

MK-PB-0114-AC Rev A

DCN 2397

In Situ

ReactIR

™

45M

FTIR Spectroscopy

Page 2

© 2014 Mettler-Toledo AutoChem, Inc.

All world rights reserved.

Printed in the USA.

No part of this publication may be stored in a retrieval system, transmitted, or reproduced in any way, including but not

limited to photocopy, photograph, magnetic or other record, without the prior written permission of Mettler-Toledo

AutoChem, Inc.

28 January 2014

TM

iC IR

, ReactIRTM iC ProcessTM, SentinelTM, FiberCompTM, DiCompTM, and SiCompTMare trademarks of Mettler-Toledo

AutoChem, Inc.

Microsoft® and Windows® are either trademarks or registered trademarks of Microsoft Corporation in the United States

and/or other countries.

All other brand and product names are trademarks or registered trademarks of their respective owners.

Address comments to:

Mettler-Toledo AutoChem, Inc.

7075 Samuel Morse Drive

Columbia, MD 21046

Tel: + 1 866.333.6822

Fax: +1 410.910.8600

www.mt.com/reactir

For technical support, contact:

AutoChemCustomerCare@mt.com

The information in this publication is provided for reference only. All information contained in this publication is believed to

be correct and complete. Mettler-Toledo AutoChem, Inc., shall not be liable for errors contained herein nor for incidental or

consequential damages in connection with the furnishing, performance, or use of this material. All product specifications,

as well as the information contained in this publication, are subject to change without notice.

This publication may contain or reference information and products protected by copyrights or patents and do not convey

any license under the patent rights of Mettler-Toledo AutoChem, Inc., nor the rights of others. Mettler-Toledo AutoChem, Inc.

does not assume any liability arising out of any infringements of patents or other rights of third parties.

Mettler-Toledo AutoChem, Inc. makes no warranty of any kind with regard to this manual, including but not limited to the

implied warranties of merchantability and fitness for a particular purpose.

In conformance with the European Directive 2002/96/EC on Waste from Electrical and Electronic Equipment (WEEE), this

device may not be disposed of in domestic waste. This also applies to countries outside the EU, per their specific

requirements.

Please dispose of this product in accordance with local regulations at the collecting point specified for electrical and

electronic equipment.

If you have any questions please contact the responsible authority or the distributor from which you purchased this device.

Should this device be passed onto other parties for private or professional use, the content of this regulation must also be

related.

Thank you for your contribution to environmental protection.

Page 3

Contents

Chapter 1 Introduction

General Policies ........................................................................8

Installation Policy ...........................................................................8

Repair Policy.................................................................................. 8

Computer Service Policy ..................................................................8

Software Upgrades..................................................................... 9

Training Programs ..................................................................... 9

Service and Technical Assistance.................................................9

Chapter 2 Pre-Installation Checklist

[ ] Site Preparation ................................................................ 11

[ ] Space and Weight Requirements.............................................. 11

[ ] Area of Intended Use............................................................... 12

[ ] Environmental Conditions........................................................12

[ ] Utilities.................................................................................. 12

[ ] Internal Paperwork and Approval for Installation.........................14

[ ] Standard and Optional Items .............................................. 14

[ ] Computer Specifications ....................................................14

System Dimensions ................................................................. 15

Chapter 3 Product Description

Overview of the ReactIR 45m System ......................................... 17

Definition of Terms ........................................................................18

ReactIR 45m System Diagram ..................................................18

ReactIR 45m Sampling Technology Configurations...................... 19

DS FiberConduit Probe................................................................... 19

DS Micro Flow Cell........................................................................ 21

DS Fiber-to-Sentinel....................................................................... 22

DS Fiber-to-Gas Cell...................................................................... 22

K4 Mirror Conduit/Sentinel .............................................................23

K6 Mirror Conduit/16 mm Probe..................................................... 23

Chapter 4 Safety

Product Safety ......................................................................... 25

Compliance.................................................................................. 25

Laser Classification .......................................................................26

Grounding the Power Supply ..........................................................26

Operational Safety......................................................................... 26

System Handling ..........................................................................27

METTLER TOLEDO

iiiReactIR™ 45m Hardware Manual

Page 4

Chapter 5 Specifications

Chapter 6 Installation

Contents

Chapter 7 System Readiness

ReactIR 45m Base Unit.............................................................29

Purge .....................................................................................30

iC IR Computer Specifications ....................................................30

Acceptance Criteria........................................................................ 31

Site Preparation (Customer Responsibility)..................................32

Installation Instructions .............................................................32

1. Confirm Site Readiness.............................................................. 32

2. Verify Hardware Configuration/Order Validation .............................32

3. Confirm Hardware Service Agreement and Software Version ...........33

4. Install iC IR Software .................................................................34

5. Perform Initial Setup and Establish System Connections ................34

6. Establish Sampling Technology Conduit Purge (if applicable) ........ 41

7. Apply Power to System and Verify LEDs....................................... 42

8. Launch Software .......................................................................42

9. Configure ReactIR 45m Instrument in Control Software ..................44

Preparing for ReactIR 45m Functional Tests ................................51

Conducting Functional Tests Using iC IR .....................................51

1. Check Alignment (Contrast and Align) .........................................52

2. Clean the Sensor....................................................................... 59

3. Check System Performance ....................................................... 60

4. Check System Stability............................................................... 66

6. Perform IPA Validation/Calibration (if applicable) ..........................68

Chapter 8 Routine Operation

MK-PB-0114-AC Rev A iv

METTLER TOLEDO

ReactIR 45m LED Indicators......................................................77

Preparing for System Use ..........................................................78

Simple Steps to a Successful Experiment ....................................79

1. See An Overview of the Process .................................................79

2. Interface Sampling Technology with Your Chemistry .....................80

3. Align the Probe ........................................................................82

4. Clean the Sensor...................................................................... 83

5. Collect a Background ...............................................................86

6. Set the Data Collection Parameters............................................. 90

Best Practices..........................................................................90

Page 5

Chapter 9 Care and Maintenance

Service Contracts ..................................................................... 93

ReactIR 45m Base Unit.................................................................. 93

ReactIR 45m Sampling Technologies ..............................................94

Maintaining a ReactIR 45m System ........................................... 94

Recommended Maintenance Schedule.............................................95

Customer-Replaceable Parts...........................................................95

ReactIR 45m Relocation, Packaging, and Storage ....................... 95

Chapter 10 Troubleshooting and FAQs

Troubleshooting Tips ............................................................... 97

FAQs ...................................................................................... 98

Appendix A ReactIR 45m Accessories and Options 99

Sampling Technologies ............................................................ 99

ServicePac Installation for ReactIR 45m .....................................99

IPA Module ........................................................................... 101

Appendix B ReactIR Glossary 103

General Terms....................................................................... 103

Software Terms...................................................................... 104

Functional Tests.......................................................................... 104

Hardware Terms .................................................................... 105

Index 107

METTLER TOLEDO

vReactIR™ 45m Hardware Manual

Page 6

Contents

MK-PB-0114-AC Rev A vi

METTLER TOLEDO

Page 7

Introduction

ReactIR™ 45m is an FTIR-based, high performance, in situ reaction analysis system

designed specifically for the chemist and chemical engineer who require the highest level of

precision for kinetic studies and quantitative analysis. It provides real-time information on the

effect of changing reaction conditions such as solvent, catalyst, temperature, and reagent

addition rate, saving valuable resources. Based on the information provided by ReactIR 45m,

scientists are able to correlate, in real time, the impact of varying reaction conditions to

reaction performance—dramatically reducing development time.

This document contains a pre-installation checklist for site preparation, technical

specifications, system configurations, instrument installation and system readiness testing,

routine operation, safety information, as well as care and maintenance information,

troubleshooting tips, and a glossary.

Related Documents

An electronic ReactIR 45m Hardware Documentation Portfolio, shipped with the instrument,

includes the following documents in addition to this manual:

ReactIR Sampling Technology Guide (MK-PBG-0008-AC)

ReactIR Fiber Probe Care and Use Bulletin (MK-PB-0083-AC)

Quick Reference Guides:

• Using a High-Pressure ReactIR Probe Adapter (MK-PB-0089-AC)

• Connecting a DS Optical Interface Module (MK-PB-0051-AC)

• Instrument Performance Assurance (IPA) for ReactIR Systems (MK-PB-0111-AC)

• Reaction Analysis Performance Specifications (MK-RF-0016-AC)

Refer to the iC IR Documentation Portfolio for user guides and associated software

documents. The software portfolio is compiled in iC IR—select it from the Help menu.

1

Check the http://community.autochem.mt.com site for the latest portfolios.

Should you have questions that are not addressed in this documentation, please contact your

local METTLER TOLEDO office or our Customer Care Department using the information under

“Service and Technical Assistance” on page 9. I

f you are viewing this document electronically, click any blue-colored link to go to the related

information and instructions.

METTLER TOLEDO

7ReactIR™ 45m Hardware Manual

Page 8

Symbols in this Manual

To help you recognize information, the following symbols appear throughout this manual.

Please pay particular attention to the sections marked by these symbols.

Note: Information to which you should pay special attention.

1. Introduction

General Policies

METTLER TOLEDO equipment is subject to the installation, repair, and computer service

policies described below.

Installation Policy

Table 1-1 Warnings, Cautions, and Notes

WARNING—Extremely important safety information—Failure to

observe the warning may result in serious personal injury or equipment

damage.

Caution—Important information that tells you how to prevent damage

to equipment or to avoid a situation that may cause minor injury.

Site preparation for the ReactIR 45m equipment is the user's responsibility. Structural

installation details should be prepared and supervised by a certified and registered

professional engineer who is properly qualified to assure a safe installation at your site.

Repair Policy

METTLER TOLEDO warrants its products against defects in materials and workmanship for

twelve months from the date of installation or fifteen months from the date of shipment. For

details, please refer to the warranty provided with the instrument. For assistance, please

contact your Technology and Applications Consultant (TAC) or send an email to

AutoChemCustomerCare@mt.com.

It is recommended that you retain the original packing materials in the event you need to

return the ReactIR 45m. If factory service is required, your METTLER TOLEDO service engineer

will issue you a Return Material Authorization (RMA) form.

Computer Service Policy

If a computer is included as part of your ReactIR 45m system, it will be from a major

manufacturer such as Dell. In the U.S. and some European countries, the manufacturer will

provide warranty service if required. METTLER TOLEDO can assist in diagnosing problems

with computers, but the computer manufacturer will provide parts and labor for repairs under

the service contract.

MK-PB-0114-AC Rev A 8

METTLER TOLEDO

Page 9

Software Upgrades

When applicable, upgrades to the instrument and office software are available for iCare

subscribers. When a new release or service pack is available, all iCare subscribers with a

valid subscription will be notified via email so they can download the installer from the

AutoChem Customer Community website, AutoChemCustomerCare@mt.com. Access to the

site requires a password that you can request from the home page. You can also contact

Customer Care or your METTLER TOLEDO Technology and Applications Consultant (TAC)

using the information on page 9.

Non-iCare subscribers can request a quote for an upgrade by contacting their local Account

Manager or Customer Care.

Training Programs

Training for ReactIR 45m systems is available from the AutoChem Customer Community

website (see link above) and through your METTLER TOLEDO TAC. Use the contact

information under "Service and Technical Assistance".

Service and Technical Assistance

METTLER TOLEDO has offices around the world. Contact the Mettler-Toledo AutoChem, Inc.

headquarters in the USA for technical support or service. To arrange for specific application

assistance from a METTLER TOLEDO Technology and Applications Consultant (TAC) or for

general assistance, contact Mettler-Toledo AutoChem, Inc. through the toll-free number below.

Mettler-Toledo AutoChem, Inc.

(Columbia, MD headquarters)

http://www.mt.com/ReactIR

http://www.mt.com/iCIR

Tel: + 1.410.910.8500

Fax: +1.410.910.8600

Email:

AutoChemCustomerCare@mt.com

Toll Free: +1.866.333.6822

METTLER TOLEDO

9ReactIR™ 45m Hardware Manual

Page 10

1. Introduction

MK-PB-0114-AC Rev A 10

METTLER TOLEDO

Page 11

Pre-Installation Checklist

This chapter outlines the end-user’s responsibility to ensure a successful installation of the

ReactIR™ 45m system and provides information about physical and utility requirements. The

Field Service Engineer (FSE) responsible for performing system installation will send the link

to this document upon initial shipment of system to allow adequate time for site

preparation.The document is on the AutoChem Customer Community website.

Access to the site requires a password that you can request from the home

Note:

Use this chapter of the document as a checklist to verify that all prerequisite steps have been

completed before a scheduled ReactIR 45m system installation. Items on this checklist must

be completed prior to scheduling a date for system installation with a METTLER TOLEDO Field

Service Engineer.

If you have any questions or need assistance please contact AutoChem Customer Care using

the information on page 9. Refer to Chapter 5 on page 29 for detailed system specifications.

page, https://community.autochem.mt.com. Setting up access during preinstallation will facilitate software license activation, which is also done

through the AutoChem Customer Community site.

2

[ ] Site Preparation

Complete the following sections to prepare your site for safe, fully functional use of the ReactIR

45m.

[ ] Space and Weight Requirements

A ReactIR 45m system can be installed on a bench top or inside a fume hood. Allow space

for the base unit with power supply as well as room to maneuver the sampling technology

for reaction analysis. Also, allow adequate space for the control computer.

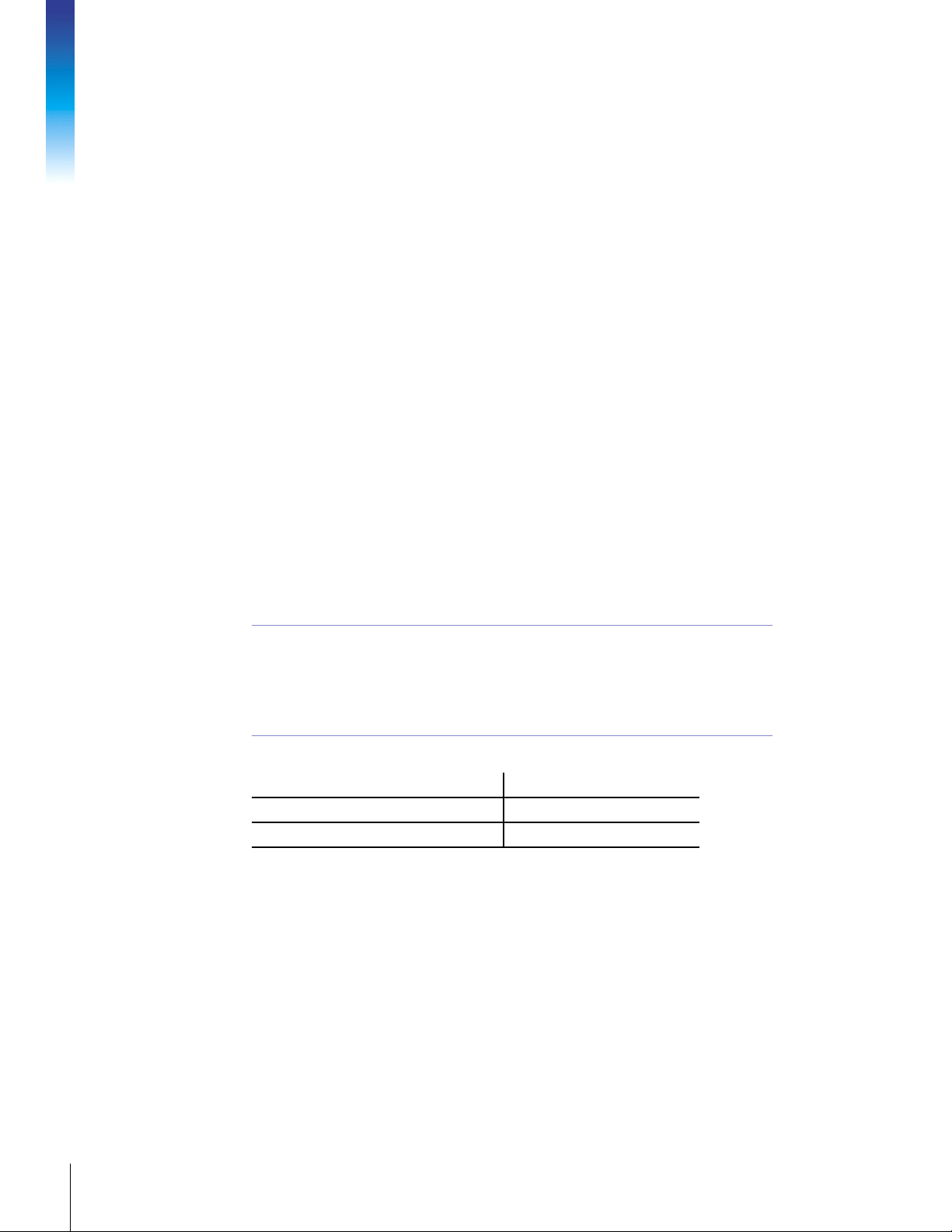

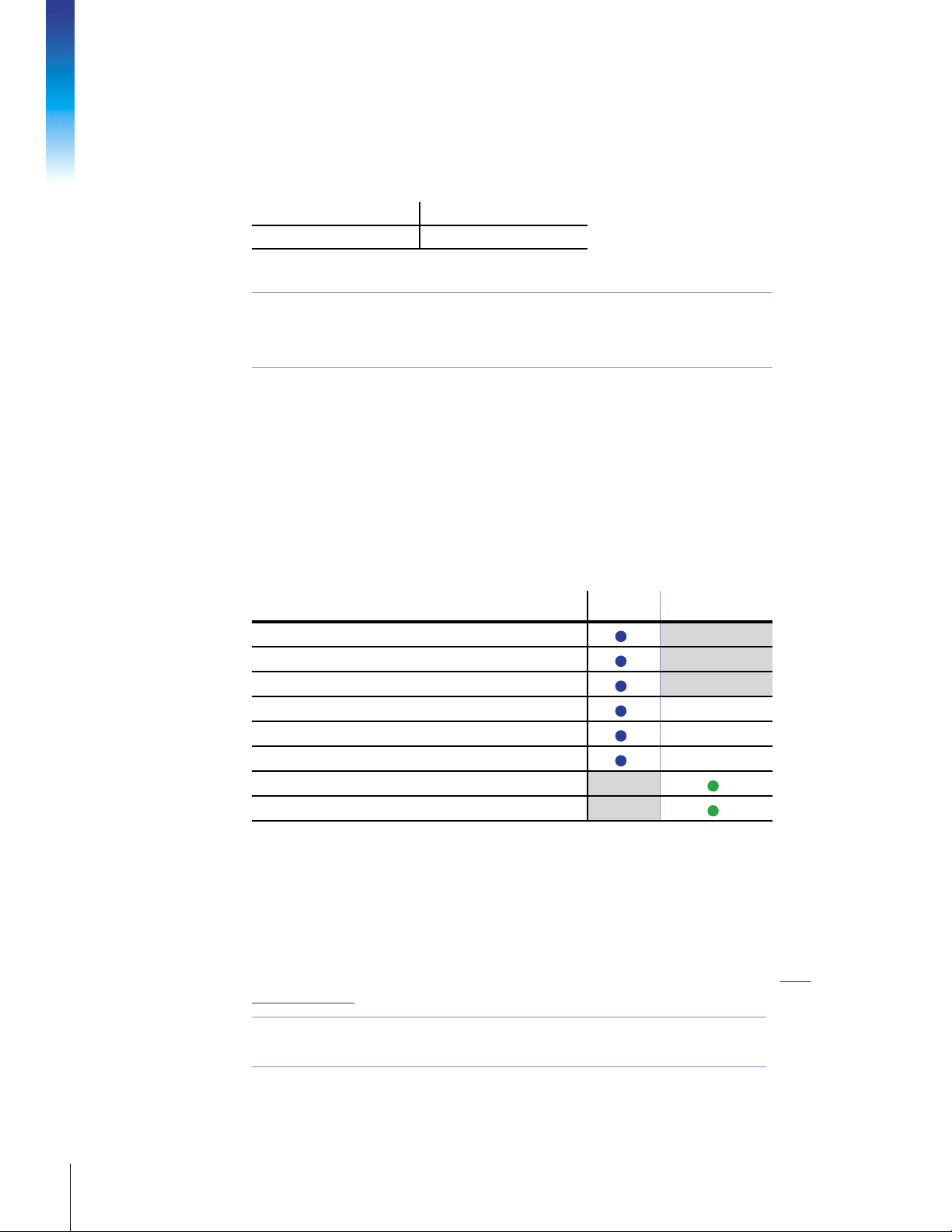

Table 2-1 Site Preparation—System Size and Weight

ReactIR 45m Dimensions* Weight

Base unit (H x W x D) 279 mm x 213 mm x 381 mm

[11 in x 8.4 in x 15 in]

(see drawing on page 15)

Power supply 76 mm x 43 mm x 130 mm

[3.0 in x 1.7 in x 5.1 in]

*Overall system dimensions will vary depending on the selected sampling technology and

do not include the footprint of the control computer.

16 kg [35.3 lb]

0.55 kg [1.2 lb]

METTLER TOLEDO

11ReactIR™ 45m Hardware Manual

Page 12

[ ] Area of Intended Use

The area of intended use requires compliance with the following statements:

The ReactIR 45m system is designed for use in a non-hazardous area in accordance

with governmental bodies in the country of use (see Chapter 4, “Safety”).

System must have adequate benchtop space for conduit and probe

• Fiber probe should not bend beyond 30 centimeters (approximately one foot).

• Probe conduit should not be put into an “S” shape.

System should be:

• Convenient for access at eye level

• Readily accessible for service

If your Standard Operating Procedure (SOP) includes a fume hood, ensure it is installed

prior to the scheduled instrument installation.

The ReactIR 45m should not be placed directly under an air duct or vent which would

expose the system to direct airflow and extreme temperature ramps.

The ReactIR 45m should be placed in a location with minimal vibration present (that is,

no large pumps with heavy vibration on the same bench top).

[ ] Environmental Conditions

Exceeding the maximum allowable ambient temperature and humidity will negatively impact

2. Pre-Installation Checklist

the instrument performance and reaction monitoring data. For proper system stability and

functionality, adhere to the environmental specifications.

Ambient Temperature (Maximum) 40 °C [104 °F]

Ambient Humidity < 60%

Operating Temperature Range 19 °C to 25 °C [66 °F to 77 °F]

[ ] Utilities

ReactIR 45m systems require AC power, instrument air/gas, and communication utilities as

described below.

Note:

The ReactIR 45m base unit should not be placed directly under an air duct

or vent which would expose the system to direct airflow and extreme

temperature ramps. In addition, the ReactIR 45m should be placed in a

location with minimal vibration present (that is, no large pumps with heavy

vibration on the same bench top).

Table 2-2 Site Preparation—Environmental Conditions

MK-PB-0114-AC Rev A 12

METTLER TOLEDO

Page 13

Site Preparation—Electric

Verify that a power outlet is accessible in the area of intended use for the ReactIR 45m and

the control computer. Power specifications are as follows:

Table 2-3 Site Preparation—Utilities (Electric)

AC Power 100–240 VAC ±7%

Maximum Current 2.0 A

Frequency 50/60 Hz

Power supply (provided) Rated DC input: ±12 VDC, 2.5 A and 13.6 VDC, 6 A

Mini Fuse: 5 A, fast acting, internal

BATTERY: CR-2032 3V manganese dioxide lithium coin

battery for real-time clock.

iC IR workstation PC See specific computer manual for voltages (dedicated circuit)

AC Line Conditioner—Power requirements do not include any additional

Note:

device. However, we recommend an AC line conditioner in areas where

power noise is known to exist. The line conditioner should have a power

rating of at least 800 VA.

Site Preparation—Utilities (Air/Gas)

The ReactIR 45m base unit requires a purge. In addition, the ReactIR Fiber-to-Sentinel and

Mirror Conduit sampling technologies also require clean, dry, instrument quality air for purge.

Quality of the air or gas supply must meet the specifications of the American National

Standards Institute/Instrument Society of America (ANSI/ISA) S7.0.01-1996 Quality Standard

for Instrument Air.

Air/gas specifications are as follows:

Table 2-4 Site Preparation—Utilities (Air/Gas)

Pressure 0.69 bar [10 psi]

Flow Rate 4.7 LPM [10 SCFH]

Have a dew point at least 10 °C [18 °F] lower than the minimum temperature to which

any part of the system will be exposed.

Contain less than 1 ppm total oil or hydrocarbons.

Contain less than 1 ppm particulates at a maximum size of three (3) microns.

Be free of any corrosive contaminants and flammable or toxic hazardous gases.

Note:

Pressure and flow regulators are NOT supplied with the equipment and are

the end user’s responsibility.

METTLER TOLEDO

13ReactIR™ 45m Hardware Manual

Page 14

Site Preparation—Utilities (Communication)

The ReactIR 45m communicates to a control computer via USB cable (provided).

Table 2-5 Site Preparation—Utilities (Communication)

Cable USB 2.0

Cable length 10 m [32.8 ft]

For additional specifications, refer to page 29.

Do not to exceed the 10 meter USB cable length as it could result in

Notes:

intermittent communication issues.

Use of USB extenders is not recommended.

[ ] Internal Paperwork and Approval for Installation

If applicable, complete any necessary internal paperwork and approvals required within your

organization for installation and start up of the ReactIR 45m system.

[ ] Standard and Optional Items

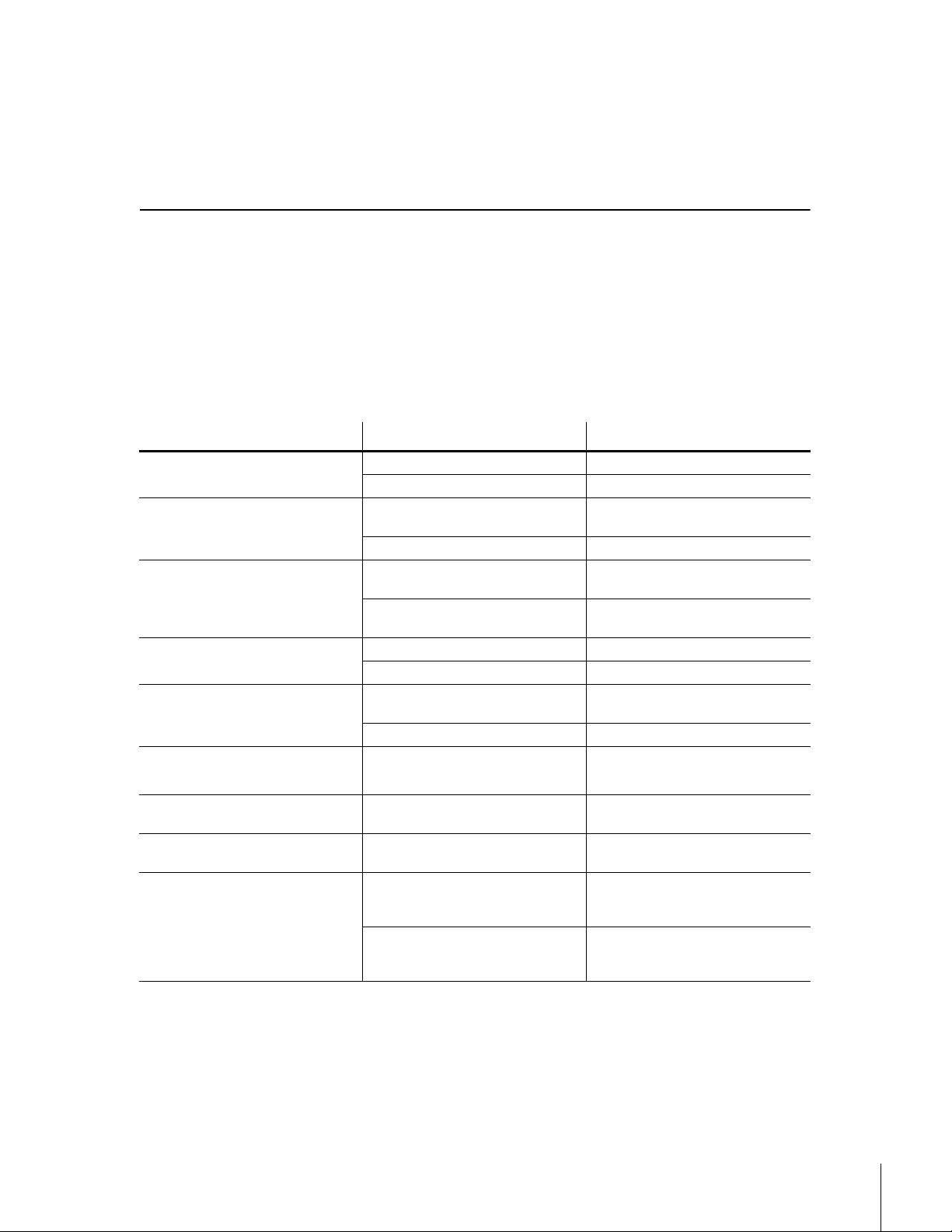

Table 2-6 Site Preparation—Standard and Optional Items

2. Pre-Installation Checklist

Item Standard Accessory / Option

Control Software—iC IR

Power Supply with country-specific AC power cable

USB cable

Funnel

Small flat-head screwdriver for gain adjustment

Choice of appropriate sampling technology

Stabilization Foot (for use with Mirror Conduit to provide stability)

Control computer (iC IR workstation PC)

[ ] Computer Specifications

When a computer is ordered with the system, the iC IR software is preloaded. If you plan to

purchase a new computer or use an existing one, it must meet minimum specifications that

METTLER TOLEDO recommends in the computer specifications listed in the “iC Software

Computer Specifications Guide.” Access this guide from the METTLER TOLEDO website: http:/

/www.mt.com/iC.

MK-PB-0114-AC Rev A 14

METTLER TOLEDO

Note:

Minimum specifications are listed in the “iC Software Computer

Specifications Guide” and also in the “iC IR Installation Guide.”

Page 15

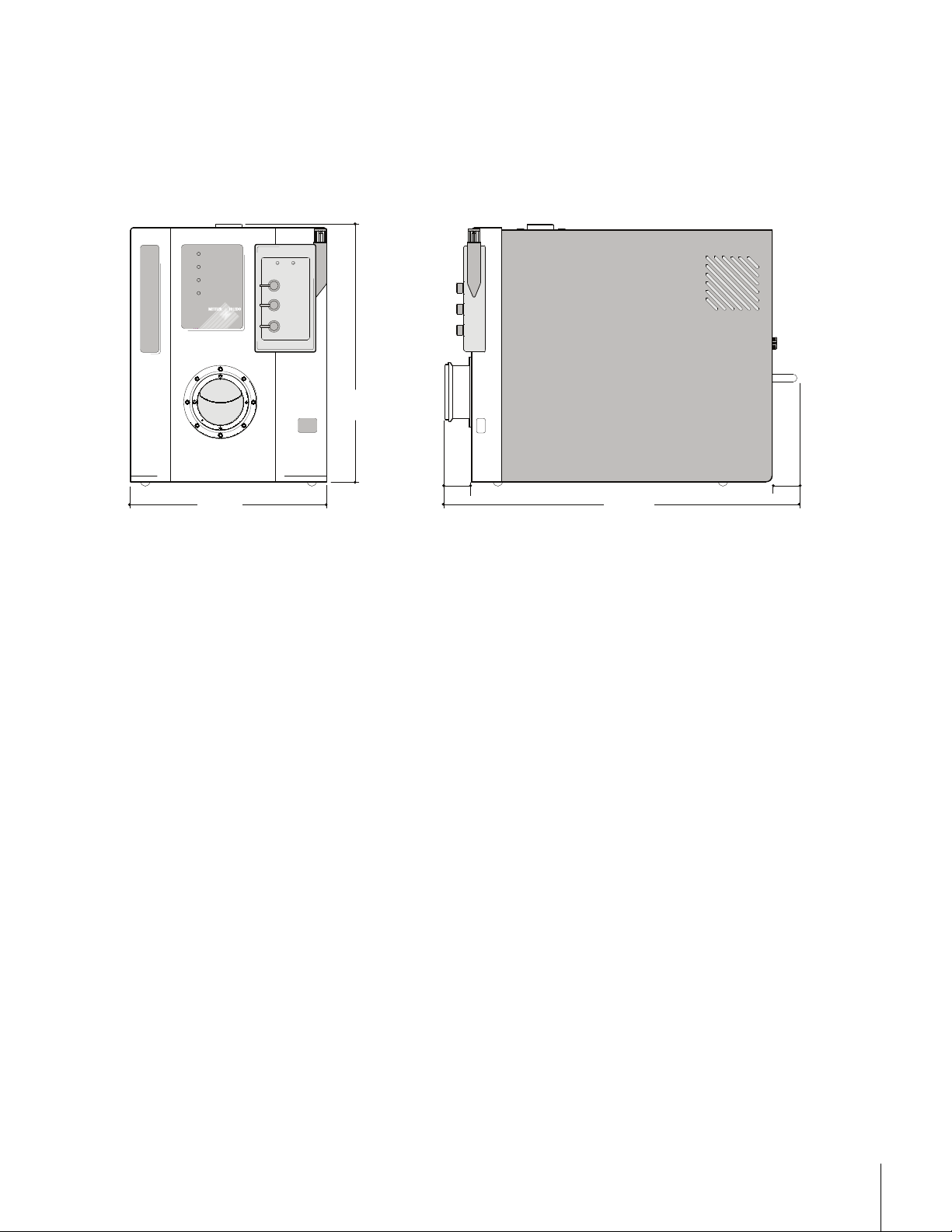

System Dimensions

The diagram in this section show the dimensions of the ReactIR 45m base unit. Allow

additional space for the sampling technology and control computer.

™

ReactIR

POWER

SCAN

MCT OK

TEMP OK

213 mm

[

8.4 in

P1 P2

ACC

RTD 2

RTD 1

279 mm

[

]

11 in

45m

28 mm

[

1.1 in

]

45m

]

381 mm

[

15 in

]

28 mm

[

1.1 in

]

Figure 2-1 ReactIR 45m base unit

METTLER TOLEDO

15ReactIR™ 45m Hardware Manual

Page 16

2. Pre-Installation Checklist

MK-PB-0114-AC Rev A 16

METTLER TOLEDO

Page 17

Product Description

This chapter describes the ReactIR™ 45m and the possible system configurations. A ReactIR

45m system consists of a base unit and sampling technology along with iC IR™ software.

Designed to be simple and easy to use, the system comes in the following overall

configurations that differ by the type of DS sampling technology:

"Overview of the ReactIR 45m System"

"ReactIR 45m System Diagram"

"ReactIR 45m Sampling Technology Configurations"

Overview of the ReactIR 45m System

ReactIR 45m is an FTIR-based, high performance, in situ reaction analysis system designed

specifically for the chemist and chemical engineer who require the highest level of precision

for kinetic studies and quantitative analysis. It provides real-time information on the effect of

changing reaction conditions such as solvent, catalyst, temperature, and reagent addition

rate, saving valuable resources. Based on the information provided by ReactIR 45m,

scientists are able to correlate, in real time, the impact of varying reaction conditions to

reaction performance—dramatically reducing development time.

3

Valuable characteristics of the ReactIR 45m system include:

Ergonomics—No obstruction to daily workflow, easy to monitor every reaction

Minimal purge—Improved data quality without external requirements/costs.

No alignment (FiberConduit only)—Highest quality data assurance without user input.

Minimal alignment in case of Mirror Conduits.

Plug-n-Play sampling—Reproducible measurements

Enhanced understanding of chemistry—Monitor reaction temperature simultaneously

with chemical changes

Note: Sensor sampling technology interfaces are sold separately.

Standard items included with the ReactIR 45m base unit are:

24-hour cooling capacity, Mercury Cadmium Telluride (MCT) detecor

iC IR 4.3 or later software version

USB communications cable

Power Supply with country-specific power cord

Funnel, small flat-head screwdriver

Purge tubing and connectors

Not included but necessary for routine operation are,

Workstation—Laptop or Desktop

METTLER TOLEDO

17ReactIR™ 45m Hardware Manual

Page 18

Sampling Technology: DS AgX Fiber Probe, DS Micro Flow Cell, K4 MirrorConduit/

Sentinel, or K6 MirrorConduit/16 mm Probe, DS Fiber-to-Sentinel, DS Fiber-to-Gas Cell

(MTPN available upon request)

One Year System Warranty (includes standard sampling technologies) purchased with

system). System warranty ends one year after installation or fifteen months after

shipment. Refer to page 93 for detailed warranty packages.

A ReactIR 45m system uses METTLER TOLEDO proprietary software, iC IR, to assure infrared

data collection and analysis possible without the need for an expert. iC IR is the result of many

years of evolution through valuable customer feedback that offers powerful reaction analysis

functions with an easy-to-use user interface. As a wizard-based application, iC IR guides you

through the experience of collecting, analyzing, and visualizing data for real time insight into

your chemistry. In essence, iC IR allows chemists to focus on solving chemistry problems

instead of instrumentation and analysis procedures.

See Chapter 4, “Safety” for safety-related information.

Definition of Terms

Refer to Appendix B on page 103 for the terms used throughout this manual and in the control

3. Product Description

software for a ReactIR 45m system.

This manual uses DS to refer to either DS or DST sampling technology.

DS is an abbreviation for D Sub-miniature, which describes the D-shaped

Note:

connector at the end of the sampling technology that connects to the

ReactIR 45m base unit. The DS or DST designation refers to the design

of the probe tip.

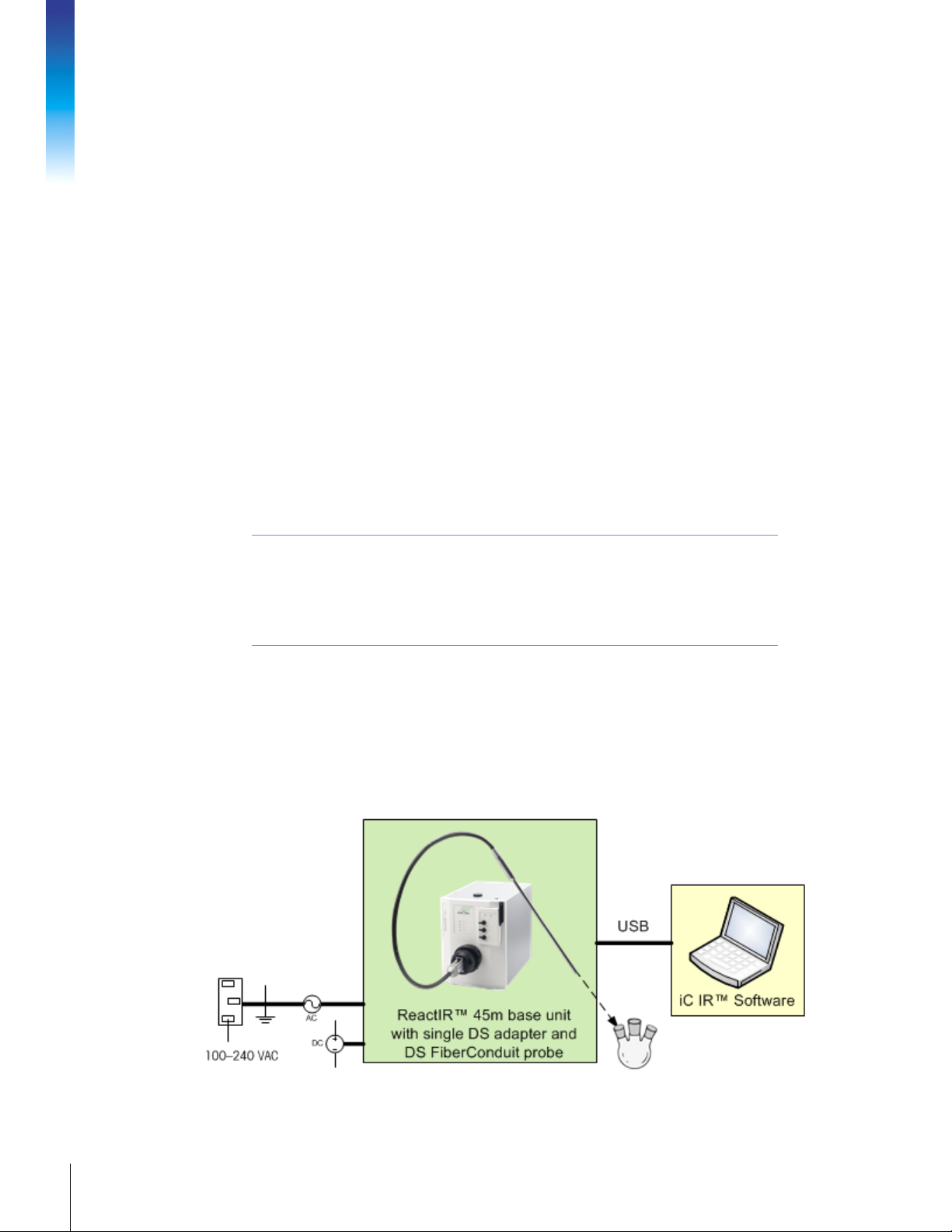

ReactIR 45m System Diagram

The diagram below identifies the components necessary to build up a ReactIR 45m system,

essentially what hardware the customer purchases from METTLER TOLEDO according to

specifications to install and implement the system. Components include the base unit,

computer, communication cable, power cable, and sampling technology.

Figure 3-1 ReactIR 45m system diagram

MK-PB-0114-AC Rev A 18

METTLER TOLEDO

Page 19

The Table 3-1 describes the internal components of a ReactIR 45m base unit: We include the

definitions for an understanding of the components that METTLER TOLEDO representatives

discuss with you during initial training, follow-up service or preventive maintenance. By

design, the ReactIR 45m will not require the user to know the location for alignment or

replacement of these components.

Table 3-1 ReactIR 45m Internal Components

MCT Detector Senses the amount of infrared radiation after passing through a sample. Includes a

detector preamp. Requires liquid nitrogen in the dewar to be operational. (1 L

capacity)

Detector Preamp Electronic board that assists the detector in reaching maximum operating

performance. User adjustment may be necessary when changing sampling

technology, for example from DS FiberConduit Probe to DS Micro Flow Cell or K4/K6

Mirror Conduit.

IR Source Supplies the infrared radiation to the sample

Midget Modulator Mechanical device that affords full spectrum infrared measurements of high

sensitivity in a shorter period of time than traditional dispersive spectroscopy

methods. Also known as the interferometer or heart of the Fourier Transform Infrared

(FTIR) measurement. Produces source radiation specific to FTIR technology.

Interferometer Control

Board Module (ICBM)

Power supplies Supplies electrical power to internal ReactIR 45m components.

Laser Class 1 InGa/AsP/InP laser diode that is an integral component of the modulator.

Circuit board for controlling specific devices related to the interferometer

(modulator).

ReactIR 45m Sampling Technology Configurations

This section describes the sampling technology options available with ReactIR 45m.

"DS FiberConduit Probe"

"DS Micro Flow Cell"

"DS Fiber-to-Sentinel"

"DS Fiber-to-Gas Cell"

"K4 Mirror Conduit/Sentinel"

"K6 Mirror Conduit/16 mm Probe"

Please refer to the “ReactIR Sampling Technology Guide” for details on specific DS and

conduit technologies.

DS FiberConduit Probe

DS FiberConduit Probe systems are suitable for monitoring chemistry in a reaction vessel of

the customers' choice by insertion of the probe into the liquid-based reaction medium. This

ReactIR 45m configuration requires a DS Optical Interface Module (sold separately) in

addition to the DS FiberConduit probe. Temperature monitoring of the reaction mixture is

optional with a DS Optical Interface Module—RTD ready (sold separately).

METTLER TOLEDO

19ReactIR™ 45m Hardware Manual

Page 20

Figure 3-1 ReactIR 45m base unit with Single Optical Interface module (RTD option shown) for DS fiber

Optical Interface Modules

A single or multiple Optical Interface Module attaches to the SIM flange on the front of a the

ReactIR 45m base unit to connect to a DS fiber or DS Micro Flow Cell sampling technology.

Single Optical Interface

3. Product Description

Figure 3-2 Single Optical Interface Module (with RTD cable)

DS MultiplexIR

sampling technology

The figure below shows a Single Optical Interface

module with the optional Resistive Temperature

Device (RTD) cable.

ReactIR 45m can control two DS FiberConduit

probes with the optional MultiplexIR Optical

Interface module. The module includes RTD

technology for monitoring reaction temperature at

each probe.

MK-PB-0114-AC Rev A 20

METTLER TOLEDO

A MultiplexIR system monitors two different or

similar chemical reactions at the same time.

Figure 3-3 MultiplexIR for dual probe configuration

Figure 3-4 shows the MultiplexIR Optical Interface Module connected to the base unit with

two fiber probes.

Page 21

Figure 3-4 ReactIR 45m base unit with DS MultiplexIR Optical Interface Module and two fiber probes

DS Micro Flow Cell

DS Micro Flow Cell systems are suitable for users who elect to flow their reaction chemistry

through a specially designed cell to monitor chemical changes. Monitoring and control of the

flow cell head temperature is available. A DS single optical interface module is required to

interface the DS Micro Flow Cell in this ReactIR 45m configuration.

Figure 3-5 ReactIR 45m base unit with DS Micro Flow Cell (heated)

Figure 3-5 shows the heated model DS Micro Flow Cell which includes a heater controller

and power supply (not shown).

METTLER TOLEDO

21ReactIR™ 45m Hardware Manual

Page 22

DS Fiber-to-Sentinel

A DS Fiber-to-Sentinel configuration is designed for customers who have a need to monitor

chemistry in high pressure autoclaves, large volume circulation loops, or specialty reaction

vessels. Designed for interfacing with the Sentinel probe, which is capable of withstanding

higher temperature and pressure reaction conditions than DS fiber probes. In addition, the

spectral region extends to 4000 wavenumbers versus the 2800 wavenumber upper limit of

the fiber probe. This ReactIR 45m configuration requires a DS single optical interface module.

Temperature monitoring of the reaction mixture is unavailable with this configuration.

3. Product Description

Figure 3-6 ReactIR 45m base unit with DS Fiber-to-Sentinel sampling technology

DS Fiber-to-Gas Cell

Customers who want to monitor gas phase reactions or head space can choose a DS Fiberto-Gas Cell option in combination with a ReactIR 45m base unit. This type of configuration

requires a DS single optical interface for integration of the DS fiber to gas cell.

MK-PB-0114-AC Rev A 22

METTLER TOLEDO

Figure 3-7 ReactIR 45m base unit with DS Fiber-to-Gas Cell sampling technology

Page 23

K4 Mirror Conduit/Sentinel

K4 Mirror Conduit/Sentinel systems monitor liquid chemistry in a specialty reaction vessel or

flow cell available from METTLER TOLEDO. Manipulate the K4 conduit to connect to the

Sentinel probe that is mounted in the specialty vessel. The Sentinel probe offers users the

capability to monitor higher temperature and pressure reaction conditions than DS fiber

probes. In addition, the spectral region extends to 4000 wavenumber versus the 2800

wavenumber upper limit of the fiber probe.

Temperature monitoring of the reaction mixture is unavailable with this configuration.

Figure 3-8 ReactIR 45m base unit with K4 Mirror Conduit sampling technology

K6 Mirror Conduit/16 mm Probe

K6 Mirror Conduit/16mm probe systems monitor chemistry in a reaction vessel of the

customers' choice by inserting the probe into the liquid-based reaction medium. The 16 mm

probe offers users the capability to monitor higher temperature and pressure reaction

conditions than DS fiber probes. In addition, the spectral region extends to 4000

wavenumber versus the 2800 wavenumber upper limit of the fiber probe.

Temperature monitoring of the reaction mixture is unavailable with this configuration.

METTLER TOLEDO

23ReactIR™ 45m Hardware Manual

Page 24

Figure 3-9 ReactIR 45m base unit with K6 Mirror Conduit sampling technology

3. Product Description

MK-PB-0114-AC Rev A 24

METTLER TOLEDO

Page 25

Safety

4

Per the ISO 9001 procedures followed at METTLER TOLEDO, the ReactIR 45m system

adheres to applicable regulations and standards in the area of intended use. Requirements

for compliance with local regulations may be different. The end user of the equipment is

responsible for compliance with all local, corporate, or other applicable regulations.

WARNING—Use of this product in a manner other than described in

this manual may result in serious injury, damage to equipment, and/or

void the warranty of the system.

Warnings, Cautions, and Notes

Three levels of information relate to equipment and user safety. To help you recognize

information, the following symbols appear throughout this manual. Please pay particular

attention to the sections marked by these symbols.

Table 4-1 Warnings, Cautions, and Notes

Note: Information that should receive your attention.

Product Safety

ReactIR 45m systems comply with the directives and laser classifications described below.

Compliance

EMC Directive 2004/108/EC

IEC 61326-1: Electrical Equipment for Measurement, Control and Laboratory Use

Low Voltage Directive 2006/95/IEC

EN61010-1: Safety requirements for electrical equipment for measurement, control,

and laboratory use

Harmonized Standards:

EN61326-1:2006, EN61000-3-2:2008, EN61000-3-3:2006, EN61010-1:2001

Caution—Important information that tells you how to prevent damage

to equipment, or to avoid a situation that may cause minor injury.

WARNING—Important safety information—Failure to observe the

warning may result in serious personal injury or equipment damage.

METTLER TOLEDO

25ReactIR™ 45m Hardware Manual

Page 26

Laser Classification

All ReactIR 45m instruments are in compliance with the U.S. Department of Health and

Human Services (DHHS) Radiation Performance and in accordance with International

Standards.

Class 1 Laser Product

Compliant with DHHS 21 CFR 1040.10 and 1040.11

except for deviations per Laser Notice 50

4. Safety

Grounding the Power Supply

Operational Safety

and

Compliant with IEC 60825-1

WARNING—Make sure to plug the power cable supplied with the

ReactIR 45m system into power supply outlets that are grounded. A

technical fault could otherwise result in death or serious injury.

Connection of cables

Caution—Connect all cables (power and communications) of the

ReactIR 45m system to their respective inputs and outputs before you

switch on the system. Do not disconnect any cables while the system

is in operation as this may cause damage to internal electrical

components.

Handling Liquid Nitrogen

MK-PB-0114-AC Rev A 26

METTLER TOLEDO

Caution—Liquid Nitrogen is used with the ReactIR 45m system to cool

the MCT detector for optimum detector performance. Liquid Nitrogen will

cause severe burns to exposed skin. Ensure use of proper clothing

(gloves) and eye protection before handling Liquid Nitrogen.

NOTE: A caution label is located on the top of the ReactIR 45m base

unit, next to the Liquid Nitrogen fill port.

Liquid Nitrogen “Blow Off”

Caution—When filling the MCT detector with Liquid Nitrogen there is a

chance that the Liquid Nitrogen may “Blow Off” once sufficient pressure

is reached inside the detector cooling chamber. It is recommended to

add Liquid Nitrogen slowly to allow sufficient time for entrained

pressure to release from the cooling chamber and prevent “Blow Off.”

Page 27

Cold Surfaces (Liquid Nitrogen Spills)

Caution—Spills will most likely occur when filling the MCT cooling

chamber with Liquid Nitrogen. Normal Liquid Nitrogen spillage (i.e.

Blow Off) will not damage components of the ReactIR 45m system,

BUT will create COLD surfaces. Avoid touching these cold surfaces

without proper protective clothing. These cold surfaces typically warm

to room temperature within a few minutes (~15 minutes).

Lithium Battery

Caution—The ReactIR 45m base unit includes a CR-2032 3 V

manganese dioxide lithium coin battery for the real-time clock.

Battery is not user-replaceable.

Service

Caution—Never open the enclosure of the ReactIR 45m system or any

of its components. These items are serviced only by a qualified

METTLER TOLEDO AutoChem Service Engineer.

General Caution

System Handling

Disconnect the power supply.

Move the ReactIR 45m base unit in an upright position to avoid spilling any amount of

the liquid nitrogen remaining in the MCT detector dewar.

When moving the ReactIR 45m system, it is highly recommended to use a cart or similar

type device. The system can be hand-carried by using the integrated handle on the rear

of the system. The ReactIR 45m does not have a front sampling attachment port, so lift

using the handle in the rear and support the front from the underside of the enclosure.

DO NOT hand-carry the base unit with the fiber optic or mirror conduit sampling

technology attached to the system. Remove the sampling technology first before moving

the unit.

DO NOT move the system with the conduit attached by using a cart or similar device.

Remove the sampling technology first before moving the unit.

Exclude the following environmental influences:

temperatures below 19 °C and above 40 °C

powerful vibrations

direct sunlight

atmospheric humidity greater than 60%

powerful electric or magnetic fields

Caution—The system can be awkward when handling. Follow the basic

safety steps outlined below

METTLER TOLEDO

27ReactIR™ 45m Hardware Manual

Page 28

4. Safety

ONLY lift the system using the handle in the rear while supporing the front underside of

the ReactIR 45m base unit. Lifting the unit in any other manner may cause damage to

the system or personal injury should the cover unexpectedly become detached.

Position the ReactIR 45m base unit to enable easy disconnection of the DC power cable.

MK-PB-0114-AC Rev A 28

METTLER TOLEDO

Page 29

Specifications

This chapter provides specifications for the ReactIR 45m system in the following sections:

“ReactIR 45m Base Unit” on page 29

“Purge” on page 30

“iC IR Computer Specifications” on page 30

Specifications include those provided by METTLER TOLEDO and those that are your

responsibility as the customer.

Manufacturer Name—Mettler-Toledo AutoChem, Inc.

Manufacturer’s Address—7075 Samuel Morse Drive Columbia, Maryland USA 21046

Product—ReactIR™

Model No—45m

Trademark—METTLER TOLEDO

Intended Use—The use of this product is to provide unattended, in situ data collection and

simultaneous data analysis of chemical reactions. This product is designed to be used in a

ventilated fume hood. Alternatively, this system can be used on a bench top with the flexible

fiber optic conduit positioned inside the fume hood where the reactor is located.

5

ReactIR 45m Base Unit

Materials of construction:

Enclosure Aluminum Alloy 5052-H32

Enclosure finish Iridite and Paint Polane-T

Labels Poly carbonate

Electrical:

Power AC: 100–240 VAC ±7%, 50/60 Hz, 2.0 A

Power supply (provided) Rated DC input: ±12 VDC, 2.5 A and 13.6 VDC, 6 A

Environmental conditions:

Temperature Range Operating: 19 °C to 25 °C [66 °F to 77 °F]

Humidity Ambient: <60% non-condensing

Table 5-1 ReactIR 45m System Specifications

Mini Fuse: 5 A, fast acting, internal

BATTERY: CR-2032 3V manganese dioxide lithium coin battery for real-

time clock.

Ambient (max): 40 °C [104 °F] (invalidates performance specification)

IMPORTANT—System should not be placed directly under an air duct or vent that

would expose the base unit to direct airflow and extreme temperature ramps.

METTLER TOLEDO

29ReactIR™ 45m Hardware Manual

Page 30

Table 5-1 ReactIR 45m System Specifications (continued)

Miscellaneous specifications:

Communications 10 m [32.8 ft], USB 2.0

Detector 24-Hour Cooling Capacity, Mercury Cadmium Telluride (MCT) detector

Size and weight:

Dimensions (H x W x D)

Refer to drawing on page 15.

Weight 16.0 kg [35.3 lb]

The sampling technology selected for the ReactIR 45m system determines additional system

specifications such as the optical range for the instrument. Please refer to the “Sampling

Technology Guide” in your Hardware Documentation Portfolio (or get the latest document

from the AutoChem Customer Community website:

279 mm x 213 mm x 381 mm [11 in x 8.4 in x 15 in]

https://community.autochem.mt.com).

5. Specifications

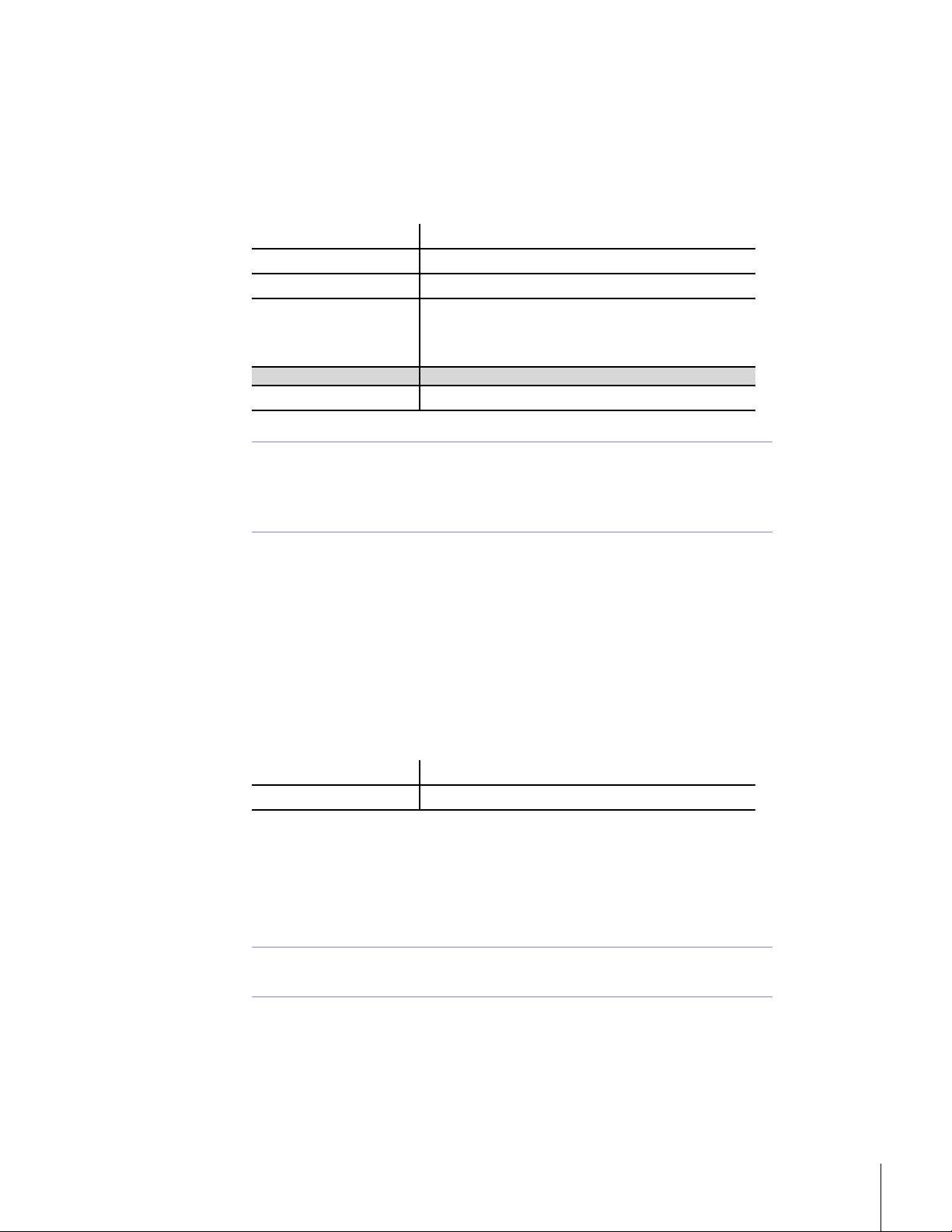

Purge

The ReactIR 45m base unit requires a purge. In addition, the ReactIR Fiber-to-Sentinel, Fiberto-Gas Cell, and Mirror Conduit sampling technologies also require clean, dry, instrument

quality air for purge. If you use the DS Fiber-to-Sentinel (page 21) or the Mirror Conduit

(page 23) sampling technologies, a purge connection is required. Clean, dry, instrument

grade air, nitrogen, or equivalent gas is recommended. Quality of the air or gas supply must

meet the specifications of the American National Standards Institute/Instrument Society of

America (ANSI/ISA) S7.0.01-1996 Quality Standard for Instrument Air.

Pressure 0.69 bar [10 psi]

Flow Rate 4.7 LPM [10 SCFH]

Have a dew point at least 10 °C [18 °F] lower than the minimum temperature to which

any part of the system will be exposed.

Contain less than 1 ppm total oil or hydrocarbons.

Contain less than 1 ppm particulates at a maximum size of three (3) microns.

Be free of any corrosive contaminants and flammable or toxic hazardous gases.

iC IR Computer Specifications

Table 5-2 Purge Specifications

MK-PB-0114-AC Rev A 30

METTLER TOLEDO

When a computer is ordered with the system, the iC IR software is preloaded. If you plan to

purchase a new computer or use an existing one, it must meet minimum specifications that

METTLER TOLEDO recommends in the “iC Software Computer Specifications Guide.” Access

this guide from the METTLER TOLEDO website: http://www.mt.com/iC.

Note:

Minimum specifications are listed in the “iC Software Computer

Specifications Guide” and also in the “iC IR Installation Guide.”

Page 31

Installation

This chapter provides procedures on how to install or reinstall a ReactIR™ 45m system.

Note:

6

METTLER TOLEDO offers one of the following ServicePac options related to

installation and system commissioning:

IPac StarterPac—(Basic Installation) The ReactIR 45m IPac StarterPac is

designed for customers in the Academia, Government, Chemical, and

Polymer Industries needing professional installation by a trained and

authorized METTLER TOLEDO Field Service Engineer (FSE). These customers

have no internal requirements for instrument Calibration/Validation to a

certified NIST Polystyrene Standard for data accuracy. Therefore, the IPac

StarterPac does not include Calibration/Validation using the DS IPA Module.

The customer must purchase the IPac QualityPac for this additional

service.For additional information, see page 99.

IPac QualityPac—The ReactIR 45m IPac QualityPac is designed for

customers in the Pharmaceutical, Biotech, and Food Industries needing

objective evidence and records to satisfy quality requirements of their

organization. These customers have internal requirements for instrument

Calibration Validation to a certified NIST Polystyrene Standard by a trained

and authorized METTLER TOLEDO FSE to ensure data accuracy. For

additional information, see page 100.

Instrument installation and commissioning includes one of the METTLER TOLEDO service

package offerings performed by a METTLER TOLEDO FSE, plus site preparation performed by

the end user. The scope of the installation service includes:

Site requirements verification

Equipment inspection and order validation

System installation and startup

Acceptance Criteria

The IPac StarterPac or IPac QualityPac requires approval signatures from the METTLER

TOLEDO AutoChem FSE and your organization’s ‘Responsible User.’

Note:

Place the signed ServicePac document in a readily accessible location

for reference during system service or maintenance.

An annual Preventive Maintenance service is available for ongoing

instrument validation and calibration (see page 93).

METTLER TOLEDO

31ReactIR™ 45m Hardware Manual

Page 32

Site Preparation (Customer Responsibility)

The ReactIR 45m system pre-installation details are sent to the end user when initial shipment

of the system is scheduled. Refer to Chapter 2, “Pre-Installation Checklist.” Permanent or

temporary installation of a ReactIR 45m system must include the following:

Adequate space and preparation in area of intended use

Electrical supply

Air supply

Environment preparation

A METTLER TOLEDO Field Service Engineer will set up and install the ReactIR 45m system

system after verifying site preparation. Site preparation requirements must be completed

before the engineer arrives on site. Permanent or temporary installation for a ReactIR 45m

6. Installation

must include the steps described in the next section.

Installation Instructions

This section describes the procedures for installing the ReactIR 45m.

“1. Confirm Site Readiness” on page 32

“2. Verify Hardware Configuration/Order Validation” on page 32

“3. Confirm Hardware Service Agreement and Software Version” on page 33

“4. Install iC IR Software” on page 34

“5. Perform Initial Setup and Establish System Connections” on page 34

“6. Establish Sampling Technology Conduit Purge (if applicable)” on page 41

“7. Apply Power to System and Verify LEDs” on page 42

“8. Launch Software” on page 42

“9. Configure ReactIR 45m Instrument in Control Software” on page 44

1. Confirm Site Readiness

A METTLER TOLEDO Field Service Engineer (FSE) checks the ReactIR 45m installation site in

accordance with the product requirements and completes the first section of the ServicePac

offering—IPac StarterPac or IPac QualityPac. The end user must ensure the site is ready prior

to arrival of the FSE based on the “Pre-Installation Checklist” information in Chapter 2.

Proceed to the next step only after confirming the site is ready.

2. Verify Hardware Configuration/Order Validation

A METTLER TOLEDO Field Service Engineer (FSE) will complete the ReactIR 45m ServicePac

document after confirmation that the site has been properly prepared for installation. In

addition to verifying the site preparation and receipt of ordered parts (including service

agreements/programs), the ServicePac document covers all aspects of the final stages of

system installation.

MK-PB-0114-AC Rev A 32

METTLER TOLEDO

Page 33

There are a variety of hardware configuration options based on the type of sampling

technology.

Sampling Technology

Sampling Technology components are purchased separately and include options described

in Chapter 3, “Product Description” starting on page 19.

The FSE will complete the sampling technology section of the ServicePac installation

document with the information specific to the type of technology ordered. FSE will enter N/A

(not applicable) for sections that do not apply to the customer order as well as record the

'wetted materials' and 'pressure/temperature' specifications for the sampling technology, in

accordance with the supplied documentation. Any items that are missing will be entered into

the non-conformances section of the form with an action plan to resolve.

Optional Hardware

Optional components are the control computer and the Instrument Performance Assurance

(IPA) module.

Software

ReactIR 45m control software is iC IR.

Optional Software

Optional software includes iC Quant, ConcIRT Pro, iC Kinetics, iC Data Share, and iC Data

Center.

Documentation

This ReactIR 45m Hardware Manual is included in a Hardware Documentation Portfolio

delivered on a separate Documentation CD with the instrument. During installation, the FSE

installs the portfolio on the control computer.

A software Documentation Portfolio accessible through the iC IR software contains iC software

publications. Access the portfolio from Help > Show Documentation Portfolio.

The latest ReactIR 45m and iC IR software documents are on the AutoChem Customer

Community website: https://community.autochem.mt.com.

3. Confirm Hardware Service Agreement and Software Version

The FSE will use the appropriate sections of the ServicePac document to confirm the hardware

service agreement with expiration date and software that was ordered is contained in the

shipment.

METTLER TOLEDO

33ReactIR™ 45m Hardware Manual

Page 34

4. Install iC IR Software

Before setting up the communications between a computer and the ReactIR 45m base unit,

the FSE will verify that the PC meets the specifications under “iC IR Computer Specifications”

on page 30. The FSE will need the iC IR Instrument License, included with your order, to

operate the ReactIR 45m instrument.

1. Insert the iC IR installation CD in the PC and click Install iC IR #.# (setup.exe) from the

welcome page.

2. Install the software according to the wizard-guided steps.

Refer to the “iC IR Installation Guide” for additional installation information on

administering preferences, licensing, and sharing data between iC/iControl software

applications.

6. Installation

5. Perform Initial Setup and Establish System Connections

The FSE will complete the System Connections in the appropriate ServicePac document while

progressing through these instructions to ensure all ReactIR system hardware is in the proper

location with connectivity to utilities, computer, and sampling technology. Users should

follow and learn the steps taken by the FSE for future reference in the event of relocating the

system. Section F and G are procedures that all users should learn for routine operation.

Initial setup and system connections include the following:

“A. Locate ReactIR 45m Base Unit and Computer at Site” on page 34

“B. Connect power” on page 35

“C. Connect USB Cable” on page 36

“D. Connect System Purge” on page 37

“E. Remove Shipping Constraint from MCT Fill Port” on page 37

“F. Fill the Detector Dewar” on page 37

“G. Connect Sampling Technology” on page 39

Note:

DO NOT proceed with the 'System Start Up' section until all applicable

check boxes are complete.

MK-PB-0114-AC Rev A 34

METTLER TOLEDO

A. Locate ReactIR 45m Base Unit and Computer at Site

1. Place the base unit in the predetermined customer location on a benchtop, in a hood,

or area of intended use per the site preparation requirements.

2. In addition, place the computer in a suitable work location that allows connectivity

through a USB cable.

3. Position the base unit and power supply to enable easy access to the ON/OFF switch.

Page 35

B. Connect power

The power connection (A) is at the back of the ReactIR 45m base unit.

A

Figure 6-1 Power connection at back panel of ReactIR 45m

1. Ensure that your power supply meets the specifications under the electrical

specifications section on page 29.

2. Connect the supplied power cord to the unique connector (A) on the back panel of the

ReactIR 45m base unit.

3. Connect the opposite end into the power supply.

4. Connect the AC power cord to the power supply and an AC outlet or power strip/surge

protector.

5. Connect power to the computer.

METTLER TOLEDO

35ReactIR™ 45m Hardware Manual

Page 36

C. Connect USB Cable

1. Connect the supplied USB communications cable to the USB connector (B) on the back

6. Installation

panel of the ReactIR 45m base unit (Figure 6-2).

B

Figure 6-2 ReactIR 45m—Communications cable connection at back panel

2. Connect the opposite end of the USB communications cable to any available USB port

on the computer where the iC IR software is installed.

3. If the Found New Hardware wizard appears, point to the folder where the drivers were

installed during software installation.

Default installation folder on Windows XP: Program Files > METTLER TOLEDO > iC IR

#.# >Installation folder > FTIR Device Driver >icbm.

Default installation folder on Windows 7:

C:\Program Files (x86)\METTLER TOLEDO\iC IR #.#\FTIR Device Driver\icbm

MK-PB-0114-AC Rev A 36

METTLER TOLEDO

Page 37

D. Connect System Purge

The ReactIR 45m system requires purge with Instrument grade air, nitrogen, or equivalent

gas. Using the purge tubing and connector supplied by METTLER TOLEDO, establish the

purge connection on the rear panel of the ReactIR 45m at the location shown in Figure 6-3

at point (C). Perform this step prior to filling the MCT detector dewar with liquid nitrogen (see

next section).

C

Figure 6-3 Purge connection

E. Remove Shipping Constraint from MCT Fill Port

A ReactIR 45m base unit ships with restraining hardware for the MCT fill port. Remove this

hardware by twisting the locking nut counterclockwise. Save the locking nut for reuse if the

unit needs to be shipped for service in the future.

F. Fill the Detector Dewar

The highly sensitive MCT detector detects and analyzes component concentrations as low as

0.1 weight percent for strong infrared absorbers. To render the detector functional, you must

fill the MCT dewar with liquid nitrogen. The detector operates to maximum performance for

up to 24 hours without refilling.

Caution—Liquid Nitrogen must be handled in accordance with

applicable safety procedures. Liquid Nitrogen will cause severe burns

to exposed skin. Ensure use of proper clothing (gloves) and eye

protection before handling liquid Nitrogen.

NOTE: A caution label is located on the top of the ReactIR 45m base

unit, next to the Liquid Nitrogen fill port.

METTLER TOLEDO

37ReactIR™ 45m Hardware Manual

Page 38

1. Remove the plug from the top of the ReactIR 45m system and insert supplied funnel

6. Installation

2. Pour liquid nitrogen into funnel.

into the fill port.

Figure 6-4 Liquid nitrogen fill port on ReactIR 45m—Plug removed

MK-PB-0114-AC Rev A 38

METTLER TOLEDO

Figure 6-5 Filling Dewar with liquid nitrogen to cool the detector

a. Add several funnels full of liquid nitrogen.

Note:

b. After blow back subsides, add several more funnels full of liquid nitrogen.

c. Once liquid nitrogen spills from the top of the detector, replace the plug.

At some point the nitrogen may blow back, creating a jet of nitrogen

vapor and possibly liquid.

Page 39

G. Connect Sampling Technology

The standard Sample Interface Module (SIM) flange opening on the front of a ReactIR 45m

base unit requires a DS optical interface adapter for use with DS sampling technologies. Use

a Single or MultiplexIR (MUX) DS optical interface adapter to convert the standard SIM.

Figure 6-6 DS optical interface adapters—Single on left, MultiplexIR on right

1. Connect the DS optical interface (single or MultiplexIR) to the base unit and secure

using the clamp provided.

2. If applicable, connect the RTD cable to the RTD 1 or RTD 2 connector on the front of the

ReactIR 45m base unit. The single interface includes a single RTD cable and the

MultiplexIR interface includes two RTD cables.

3. Then, connect the DS sampling technology ordered with the unit to the DS optical

interface on the front panel of the ReactIR 45m, as described below. Go to the section

on page 41 for connection of K4 Conduit/Sentinel and K6 FiberConduit/16mm Probe.

4. (For MultiplexIR only) Connect the ACC cable to the ACC input on the front of the ReactIR

45m for MultiplexIR power.

DS Fiber Probe or Fiber-to-Sentinel

Figure 6-7 Connecting DS FiberConduit sampling technology to Single DS Optical Interface module

To install the FiberConduit probe sampling technology:

1. Orient the DS end of the probe with the retractable cover to the left, as shown on the DS

optical interface entry slot.

METTLER TOLEDO

39ReactIR™ 45m Hardware Manual

Page 40

2. Pull back on the retractable cover that exposes the optical connection and insert the end

3. Secure the sampling technology with the two knurled screws.

To install the Fiber-to-Sentinel sampling technology:

1. Orient the DS end with the retractable cover to the left, as shown on the DS optical

2. Pull back on the retractable cover that exposes the optical connection and insert the end

3. Secure the sampling technology with the two knurled screws.

4. Connect the Sentinel sensor to the opposite end of the FiberConduit, using clamp.

Fiber-to-Gas Cell

Follow the same procedure as for Fiber-to-Sentinel connections (step 1 on page 40 to

6. Installation

step 4).

DS Micro Flow Cell

into the DS SIM to align the unique connector.

interface entry slot.

into the DS SIM to align the unique connector.

Figure 6-8 Connecting DS Micro Flow Cell sampling technology

1. Orient the DS end with the retractable cover to the left, as shown on the DS optical

interface entry slot.

2. Pull back on the retractable cover that exposes the optical connection and insert the end

into the DS SIM to align the unique connector.

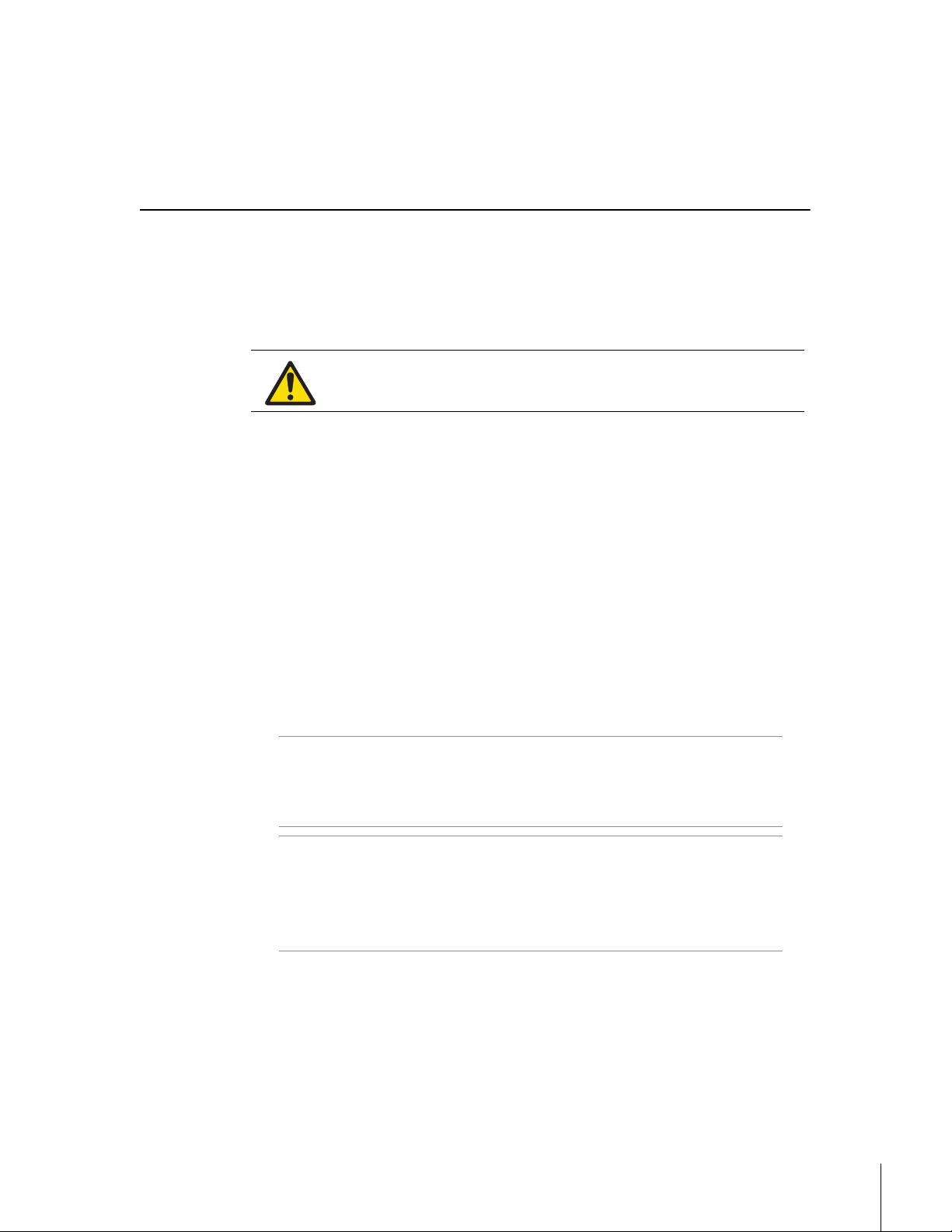

3. Secure the sampling technology with the two knurled screws.

MK-PB-0114-AC Rev A 40

METTLER TOLEDO

Page 41

K4 or K6 Mirror Conduit/Sentinel

The Mirror Conduit sampling technologies connect to the front Sample Interface module (SIM)

flange directly—no DS Optical Interface. Secure the connection using the clamp provided.

Figure 6-9 K6 or K4 Mirror Conduits connect directly to the SIM

1. Orient the open end of the conduit on the SIM flange of the base unit.

2. Secure the conduit sampling technology with the clamp provided.

3. System is ready for alignment.

6. Establish Sampling Technology Conduit Purge (if applicable)

If you use the K4, K6, Fiber-to Sentinel, or Fiber-to-Gas Cell sampling technologies, a purge

is required.

1. Attach a filtered, pressure-controlled air supply to the sampling technology using the

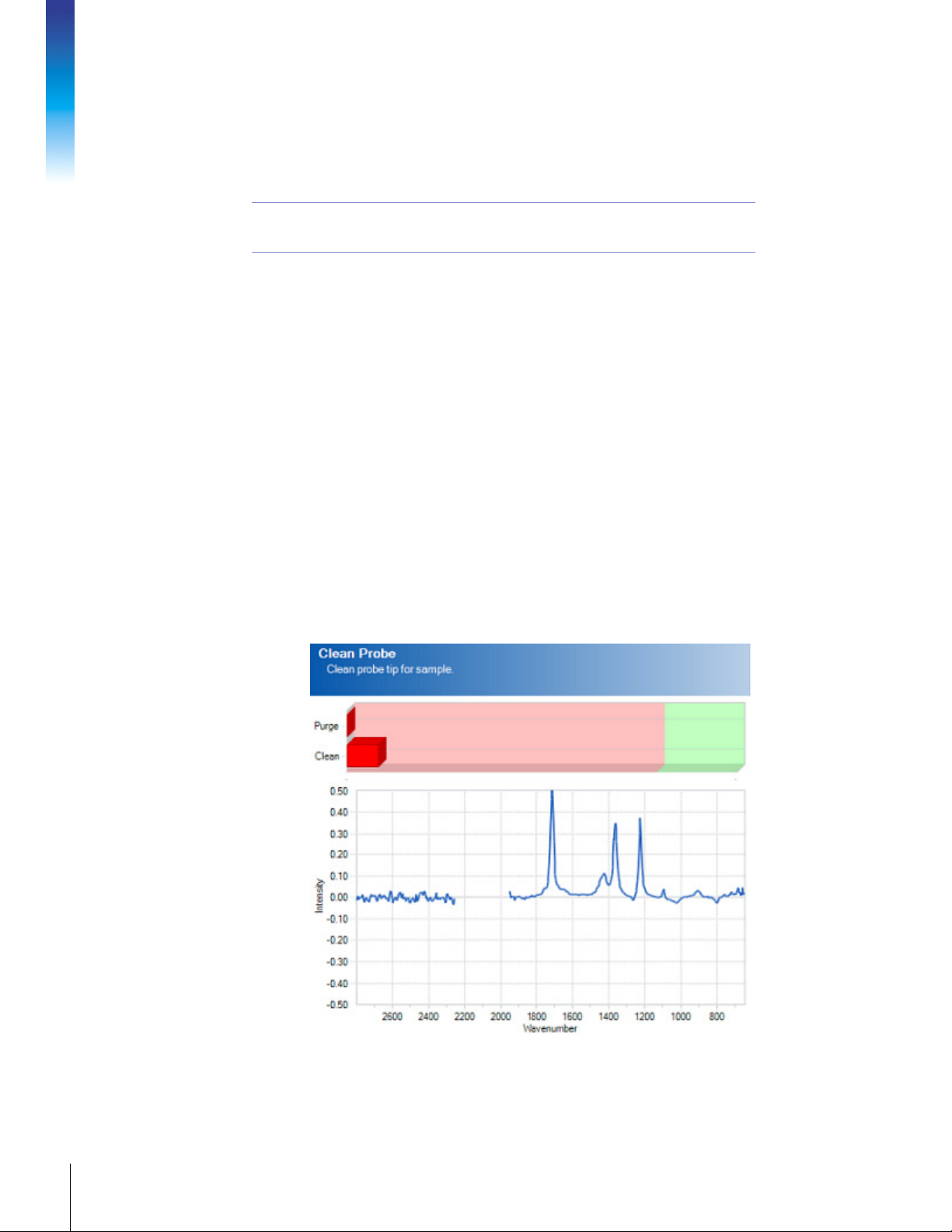

supplied purge tubing and connectors.

2. Set purge pressure to nominal

0.69 bar [10 psi]

and flow rate to

4.7 LPM [10 SCFH].

Figure 6-10 ReactIR 45m with DS Fiber-to-Sentinel sampling technology

41ReactIR™ 45m Hardware Manual

METTLER TOLEDO

Page 42

7. Apply Power to System and Verify LEDs

1. Press the power supply switch to the ‘on’ position to apply power to the ReactIR 45m

2. Verify the LED indicators on the front of the base unit indicate a fully functional system.

8. Launch Software

6. Installation

1. Confirm the iC IR software control computer is ON and the software launches.

system.

In a fully functional system, the Power LED is illuminated, the Scan LED is flashing, the

MCT OK LED is illuminated (dewar filled with liquid nitrogen), and the Temp OK LED is

illuminated when the modulator has reached an operating temperature of 42 °C

(approximately 30 minutes). Refer to “ReactIR 45m LED Indicators” on page 77 for

details. Details are also in the appropriate ServicePac document—IPac StarterPac or

IPac QualityPac.

To start the software, double-click the iC IR icon on the Windows desktop.

You will see the Start Page for iC IR software (Figure 6-11).

MK-PB-0114-AC Rev A 42

METTLER TOLEDO

Figure 6-11 iC IR Start Page

Page 43

If optional software is included with the order, confirm optional software add-ons

launch.

• iC Kinetics is a separate software application with its own Start Page.

Figure 6-12 Optional add-on software—iC Kinetics

• iC Quant and ConcIRT Pro appear as Data-to-Information (D2i) documents from the

iC IR Start Page.

Figure 6-13 Optional add-on software—iC Quant and ConcIRT Pro

• iC Data Share is an add-on to Excel available with an iCare subscription. The

software can be downloaded from the AutoChem Customer Community website.

Refer to Chapter 1, “Introduction” for information on iCare and the community

website.

• iC Data Center is a separate software application that serves as a monitoring and

central storage tool for data acquired by iC and iControl instruments.

METTLER TOLEDO

43ReactIR™ 45m Hardware Manual

Page 44

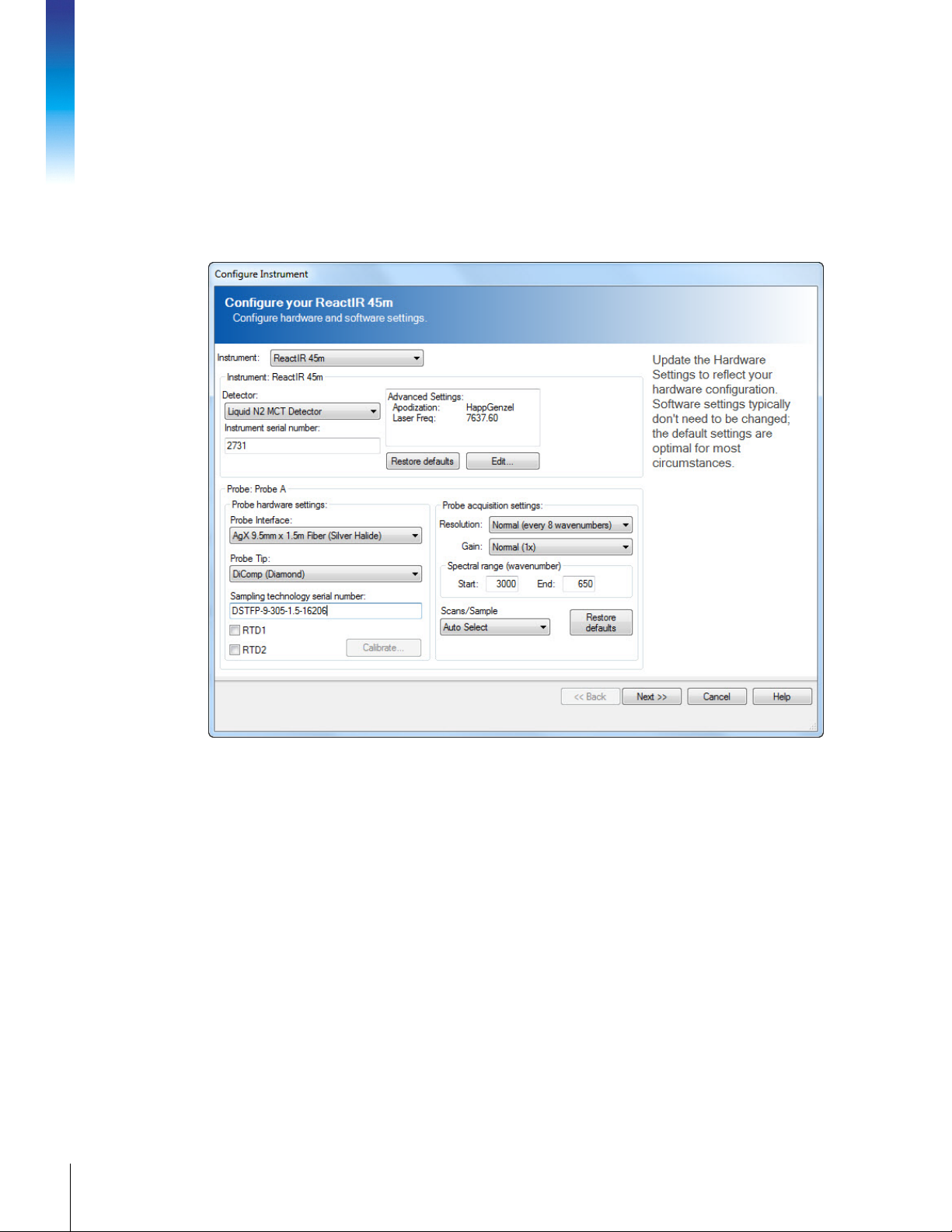

9. Configure ReactIR 45m Instrument in Control Software

The FSE will perform instrument configuration in iC IR software to reflect the hardware

configuration. Record the configuration settings in the appropriate ServicePac document.

1. Click Configure Instrument from the iC IR Start Page.

2. Set the following parameters to match the configuration of the ReactIR 45m, if not

6. Installation

already done at the factory.

MK-PB-0114-AC Rev A 44

METTLER TOLEDO

Figure 6-14 Configure Instrument wizard

• Instrument—Select ReactIR 45m

• Detector—Select the Liquid N2 MCT Detector.

• Instrument serial number—Type in the number from the label on the instrument

back panel.

• Probe Interface—Specify the type of DS FiberConduit or Mirror Conduit sampling

technology in use.

• Probe Tip—SiComp or DiComp

• Sampling technology serial number—Type in the number from the probe’s DS

connector or the Probe/Sentinel attached to a Mirror Conduit.

3. From the Advanced Settings section, the FSE will record the instrument firmware version

in the ServicePac document.

4. In the Probe acquisition settings section:

• Resolution—Normal (every 8 wavenumbers)

Page 45

• Gain—Normal (1x)

Note: Setting may require adjustment with multiple probes (MultiplexIR).

• Spectral range (wavenumber)—This value appears automatically, depending on

the sampling technology.

• Scans/Sample drop-down box, select Auto Select scans.

5. Accept the default for the remaining configuration settings.

Calibrating Resistive Temperature Device (RTD)

Below are the steps required to calibrate the sampling technology RTDs that are built-in DS

FiberConduit sampling technology probes. The FSE will use RTD test plugs or an external

calibrated temperature monitoring device such as a thermocouple to perform the two-point

calibration from the iC IR Configure Instrument page.

Note:

DS and DST Fiber probes support RTD monitoring—Fiber-to-Sentinel, Fiberto-Gas Cell, and K4/K6 Mirror Conduit technologies do not include an RTD.

1. Open the configure instrument wizard, select RTD 1 and click Calibrate to launch the

RTD calibration wizard.

Figure 6-15 Configure Instrument—Optional RTDs

2. Select the RTD1 row and highlight the RTD Device.

• Select ‘new’ using the drop-down arrow and create a new name for the RTD.

• Click Next.

• Select the two-point calibration and click Next.

3. Use one of the following methods to calibrate the RTDs:

45ReactIR™ 45m Hardware Manual

METTLER TOLEDO

Page 46

6. Installation

Using external temperature monitoring device, such as a thermocouple

a. Perform the cooling calibration for RTD 1.

Connect the RTD from the DS Optical Interface to the appropriate RTD connector

on the front of the ReactIR 45m system. (RTD 1, or RTD 1 and RTD 2 for

MultiplexIR)

Connect DS FiberConduit probe to DS Optical Interface.

Cool the DS FiberConduit probe tip (submerge) along with the calibrated

temperature monitoring device to as close to 0 °C as possible.

Wait for the system to stabilize by observing a constant value at the temperature

monitoring device.

In the Reference Temperature section of the calibration wizard, enter the actual

value from the calibrated temperature monitoring device and click Next.

Click Save to record the calibration.

b. Perform the heating calibration for RTD 1.

Heat the DS FiberConduit probe tip (submerge) along with the calibrated

temperature monitoring device to as close to 100 °C as possible.

Wait for the system to stabilize. In the Reference Temperature section enter the

actual value from the calibrated temperature monitoring device and click Next.

Click Save to record the calibration.

MK-PB-0114-AC Rev A 46

METTLER TOLEDO

Using RTD Test plugs

When using RTD test plugs to perform the calibration, the procedure is the same except

the plugs will be used instead of the heating/cooling procedure. The RTD plugs allow

calibration to 0 °C and 98.65 °C that appear on the label for each.

Figure 6-16 RTD test cable with plugs

Page 47

a. Connect IS RTD Test Plug adapter cable to the RTD input on the front of the ReactIR

45m system.

b. Then, one-at-a-time, connect RTD Test Plugs, as follows: (0 °C and 98.65 °C)

1. Connect the RTD Test Plug labeled 0 °C (100 Ω) to the adapter cable.

2. Wait for the system to stabilize by observing a constant value in the calibration

wizard program.

3. In the Reference Temperature section of the calibration wizard, enter the actual

value from the RTD test plug.

4. Connect the second Test Plug labeled 98.65 °C (138Ω) to the adapter cable.

5. Wait for system to stabilize (a constant value appears in calibration wizard.)

6. In the Reference Temperature section of the calibration wizard, enter the actual

value from the RTD test plug.

7. Repeat step 3 to calibrate RTD 2, making sure to use the appropriate connector on the

front of the ReactIR 45m enclosure. Accept the remaining configuration default settings

and click Next.

RTD Calibration Factory Settings—To revert back to the default settings, delete

the RTD Calibration file, and then re-calibrate. The file location is with the

Note:

system log files:

C:\Documents and Settings\All Users\Application Data\METTLER TOLEDO\iC

IR\4.3\RTDDeviceCalibrations.xml, or

C:\ProgramData\METTLER TOLEDO\iC IR\4.3\RTDDeviceCalibrations.xml.

Continuing Instrument Configuration

1. After you click Next on the first Configure Instrument window, the wizard displays an

image of a ReactIR 45m system with the specified sampling technology and a prompt

to clean the probe. Click Next when the probe is ready for alignment procedure.

Figure 6-17 Configure Instrument—Prompt to prepare probe for alignment

47ReactIR™ 45m Hardware Manual

METTLER TOLEDO

Page 48

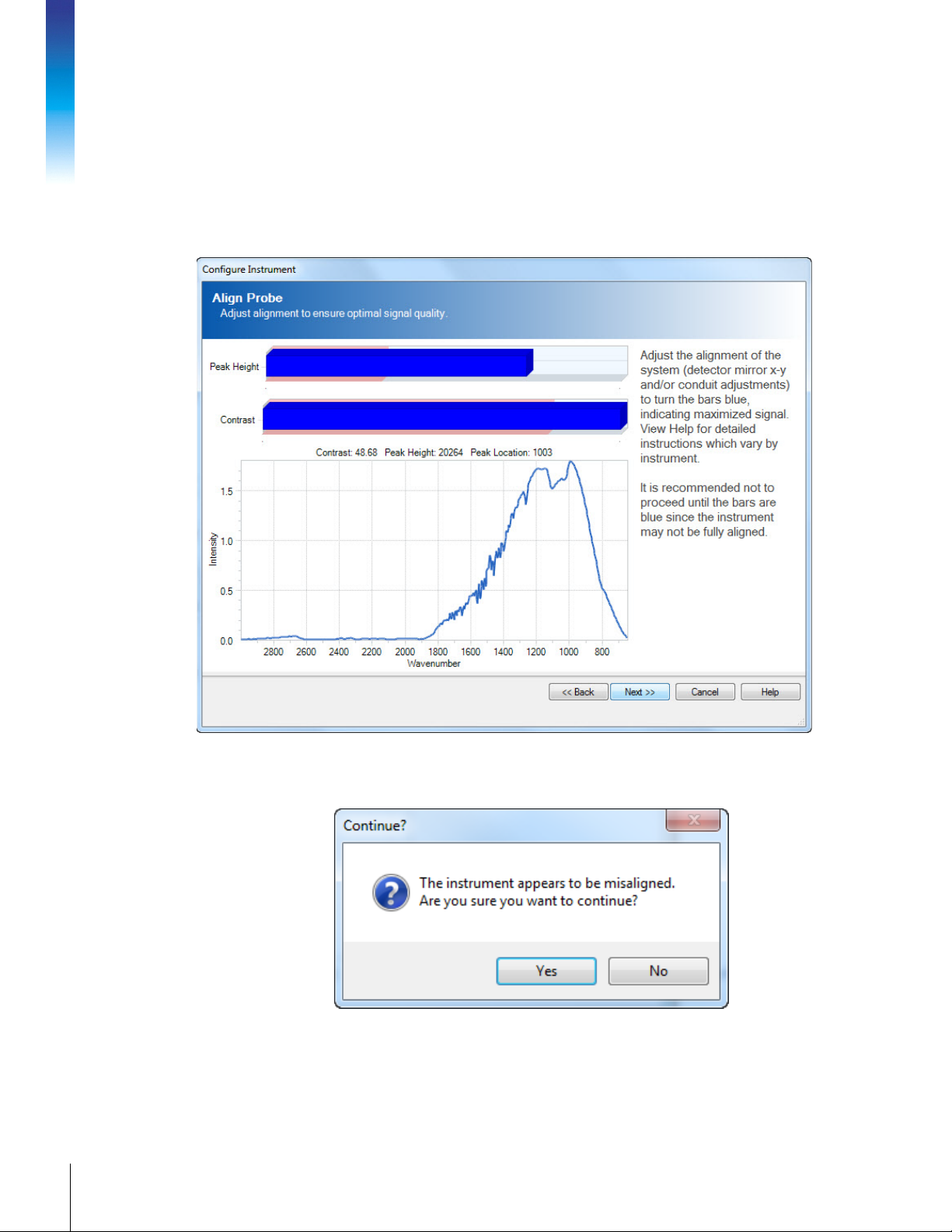

2. In the Align Probe window, observe the Peak Height and Contrast.

6. Installation

• If the bars are blue, the system alignment is optimal. Optimal (maximized) Peak

Height and Contrast indicates plenty of energy is flowing through the system and

sensor to make infrared fingerprints of reaction chemistry components. Click Next.

• If one or both bars are red, the Peak Height is below the 18000– 24000 range and/

or the Contrast is outside of specifications (10–60). Both values should be

maximized within the allowable range, which varies by sampling technology.

MK-PB-0114-AC Rev A 48

METTLER TOLEDO

Figure 6-18 Configure Instrument—Align Probe

If you click Next to proceed when red bars exist, the following message appears:

Figure 6-19 Misalignment message

The instrument is prealigned at the factory. However sampling technology

alignment may be needed to achieve optimal Peak Height and Contrast.

Page 49

For Fiber-to-Sentinel and Mirror Conduit sampling technologies, rotate the

Sentinel/Probe and adjust the last knuckle of the Mirror Conduit (K4 or K6) for

optimal Peak Height (20,000) and Contrast (Minimum of 10). The final

adjustment for Peak Height to reach approximately 20,000 counts may require

adjustment of the preamp gain.

For FiberConduit sampling technologies, adjust the gain if necessary to reach

approximately 20,000 counts using the supplied flat-head screwdriver.

Refer to “Advanced Adjustment Features” on page 54 for gain adjustment details.

3. When the bars are both blue, click Next to continue. If one or both alignment bars

remain ‘red,’ contact METTLER TOLEDO.

4. In the Collect a Clean Reference Background window, click Collect Background to

collect a reference background of the single beam for a clean probe tip sensor without

chemistry (only exposed to air).

Figure 6-20 Configure Instrument—Collect a background single beam

5. Click Finish.

At this point, the first phase of system installation is complete. A METTLER TOLEDO service

engineer fills in the required information in the ServicePac document and proceeds to the next

phase of installation—“System Readiness” testing as described in Chapter 7.

METTLER TOLEDO

49ReactIR™ 45m Hardware Manual

Page 50

6. Installation

MK-PB-0114-AC Rev A 50

METTLER TOLEDO

Page 51

System Readiness

This chapter describes the procedures for system readiness in the following sections:

“Preparing for ReactIR 45m Functional Tests” on page 51

“Conducting Functional Tests Using iC IR” on page 51 .

Caution—If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

Preparing for ReactIR 45m Functional Tests

The second phase of system installation consists of performance tests of the ReactIR 45m

with its sampling technology. A METTLER TOLEDO service engineer performs functional tests

as the second phase of system installation. This phase follows system installation, so the

system is assumed to be powered on and communicating with the control software.

1. Ensure that Instrument Configuration is completed as described under section “9.

Configure ReactIR 45m Instrument in Control Software” on page 44.

2. Verify the ReactIR 45m LEDs are in the fully operational state: Power light is illuminated,

Scan light is flashing, the MCT light is illuminated, and Temp OK light is illuminated.

(Refer to page 77 for illustration and details.)

3. Ensure the ReactIR 45m system has been powered ON for three (3) hours before taking

critical measurements.

7

IMPORTANT /

CRITICAL!

Ensure that the system and probe are not exposed to any heavy

vibration and/or airflow that could result in extreme ambient

Notes:

As needed, review the terminology in Appendix B starting on page 103 to become familiar

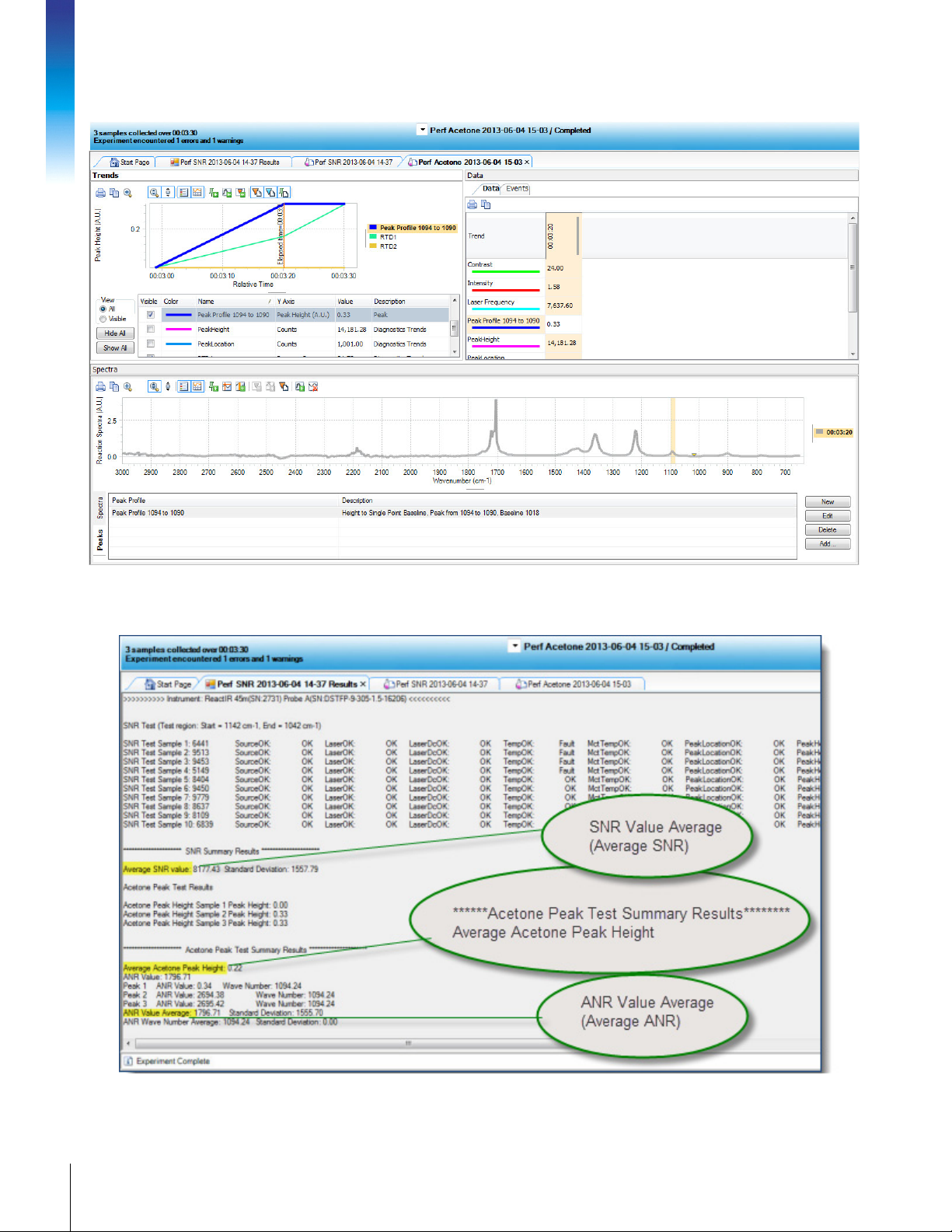

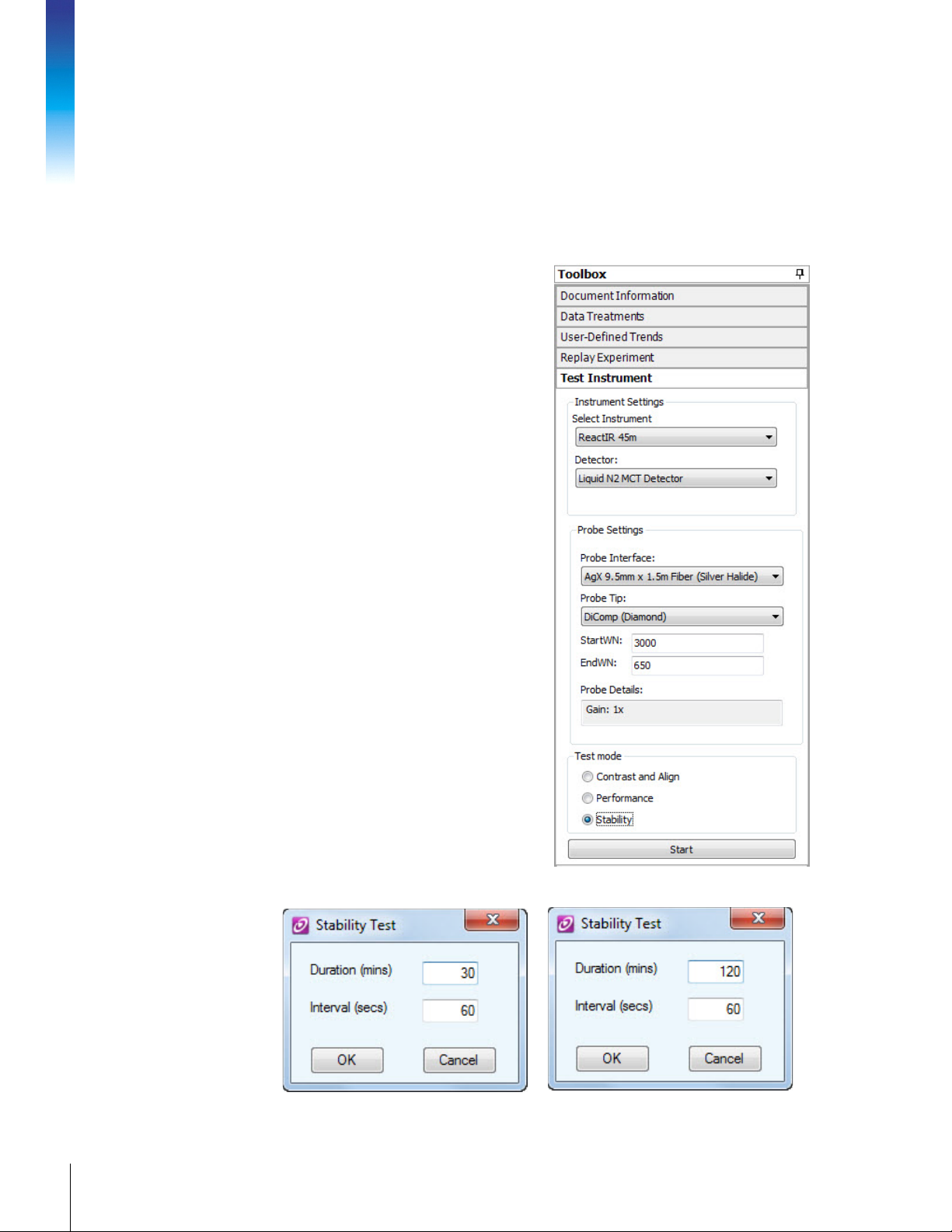

with functional tests.