Page 1

Rainin QuickFlow

Ergonomic Aspiration System

Operating Instructions

Page 2

Rainin QuickFlow

Convenient, Trouble-free Operation

• Continuous and Non-continuous Flow

• Optical Liquid Level Sensor

• Multiple Adapters

• Easy Cleaning

Table of Contents

1 Box Contents .........................................................................................................3

2 Safety ...................................................................................................................5

2.1 Electrical safety ................................................................................................5

2.2 General safety . ................................................................................................6

3 Introduction ..........................................................................................................6

3.1 Device and liquid compatibility ..........................................................................7

4 Setup ....................................................................................................................8

4.1 Prepare workspace ...........................................................................................8

4.2 Check shipping box ..........................................................................................8

4.3 Unpack QuickFlow ...........................................................................................8

4.4 Assemble QuickFlow ........................................................................................9

4.5 Assemble the handle ......................................................................................11

5 Operation ............................................................................................................13

5.1 Select Continuous or Non-continuous aspiration ................................................13

5.2 Power up QuickFlow .......................................................................................14

5.3 Adjust speed ..................................................................................................14

5.4 Full bottle: Level sensor and liquid level alert .....................................................15

5.5 Eject tips or remove Pasteur pipette ..................................................................15

6 Cleaning and Maintenance ...................................................................................16

6.1 Emptying the bottle .........................................................................................16

6.2 Cleaning bottle and cap ............................................................................. ....17

6.3 Cleaning vacuum tube ...................................................................................17

6.4 Autoclaving ...................................................................................................18

7 Spare Parts and Accessories ................................................................................18

7.1 Filter (blue vacuum inlet tube) .........................................................................18

7.2 Handle hang-up ............................................................................................18

8 Specications ......................................................................................................19

9 Troubleshooting ...................................................................................................20

10 Incompatible Liquids and Agents ..........................................................................20

11 Ordering Information ............................................................................................21

12 Warranty .............................................................................................................22

Rainin, Pipetting 360 and TerraRack are trademarks of Mettler-Toledo Rainin, LLC.

©2018 Mettler-Toledo Rainin, LLC. No part of this manual may be copied without the express written permission of

Mettler-Toledo Rainin, LLC.

2

Page 3

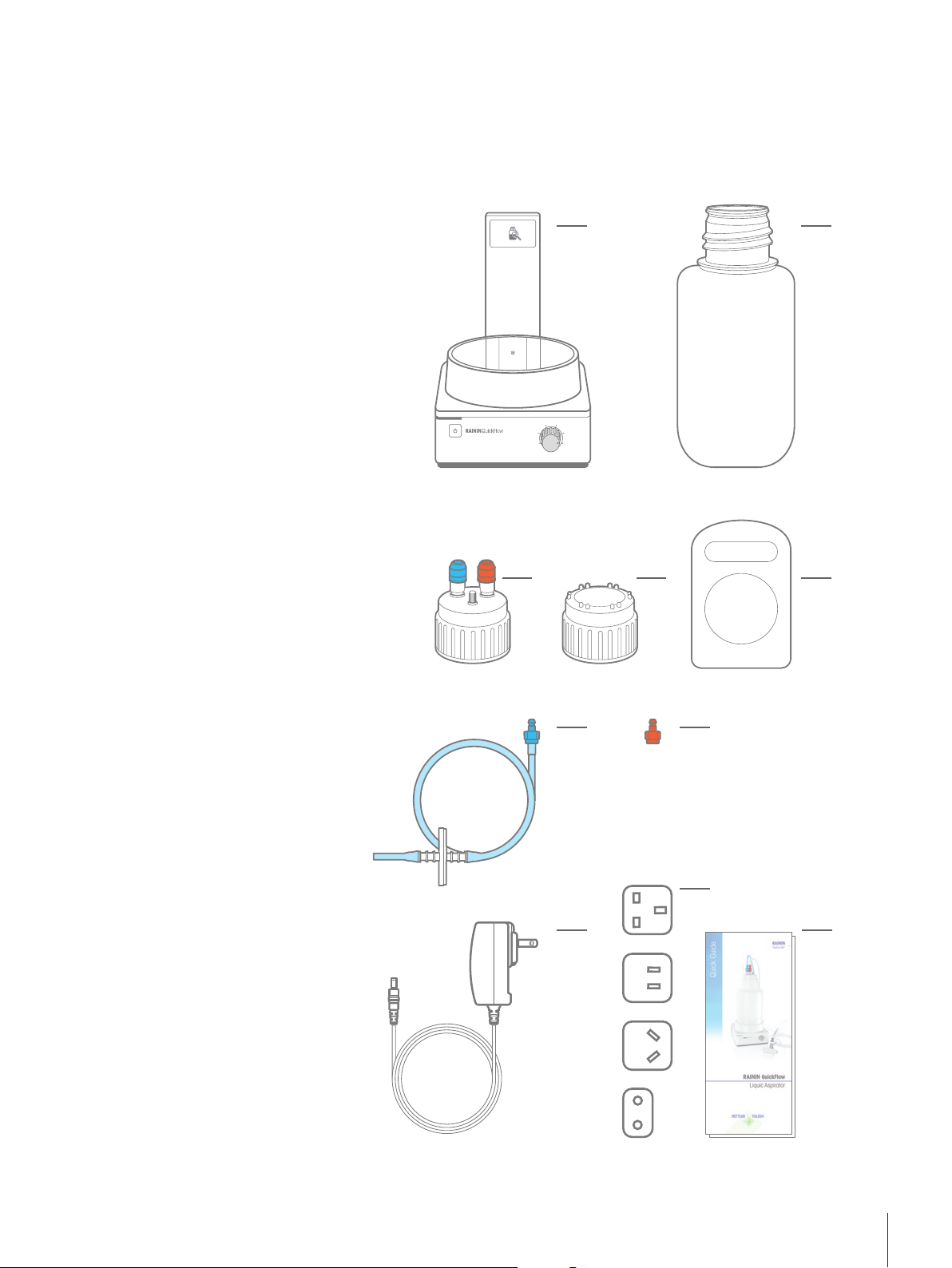

1 Box Contents

Shipping box

a. Base unit

a b

b. 4-liter collecting bottle

1

c. Bottle cap with quick connector

heads

d. Bottle cap with closed top

e. Bottle carrying plate

f. Airflow inlet tube (blue)

g. Quick connector plug (orange)

for vacuum tube

4

Note: The vacuum tube (clear)

is part of the handle kit,

3

5

2

6

1

see next page

h. Power supply

i. Power adapters (4)

j. Quick Reference Guide

k. Handle kit / inner box

(see next page for details)

c d e

f g

h

i

j

Figure 1: QuickFlow shipping box components

3

Page 4

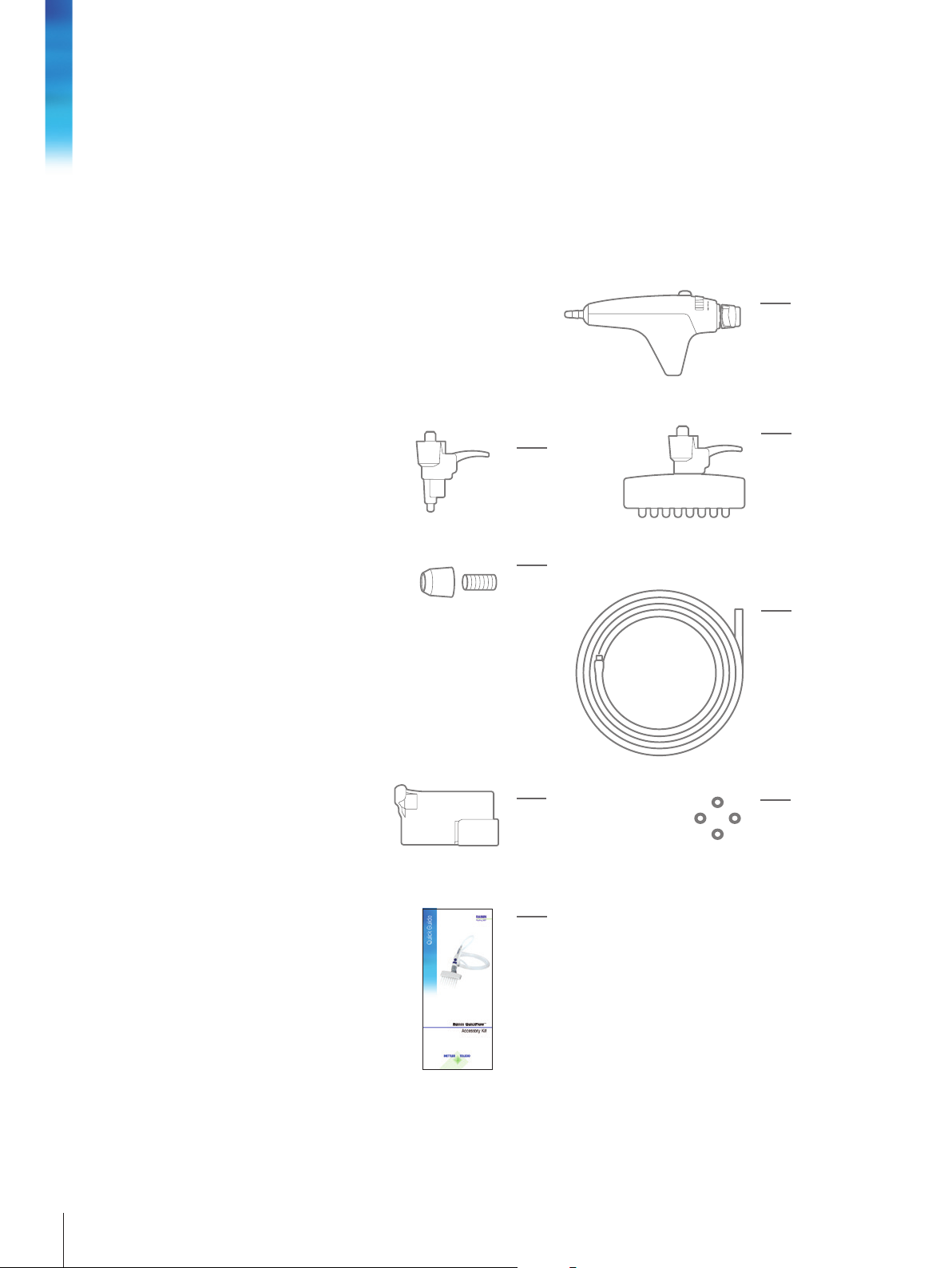

Inner box (handle kit)

a. Handle

b. Single-tip adapter

c. Multi-tip adapter

d. Pasteur pipette adapter (glass/plastic)

e. Vacuum tube (clear)

f. Handle hang up (for safe handle storage)

g. Extra o-rings

h. Quick Reference Guide

a

Box Contents

b

d

f

c

e

g

h

Figure 2: Handle kit contents (inner box)

4

Page 5

2 Safety

Read all Safety warnings before setting up or servicing your Rainin QuickFlow. Always

operate QuickFlow in accordance with this User Manual. For your convenience and future

reference, this manual is available online to download at www.mt.com/quickflow-manual.

Safety notes are marked with signal words and warning symbols. These show safety

issues and warnings. Ignoring the safety notes may lead to personal injury, damage to the

instrument including malfunction, as well as unreliable results.

Safety terms used in this manual

WARNING – a hazardous situation with medium to high risk, possibly resulting in severe

personal injuries (or death) if not avoided, as well as damage to the instrument or laboratory.

CAUTION – a hazardous situation with lower risk, possibly resulting in damage to the

instrument and laboratory, data loss, and/or minor or medium personal injuries if not

avoided.

ATTENTION or NOTE (no symbol) – useful or important information about the product

Safety symbols used in this manual

General Hazard Electrical Hazard

Hand Injury Explosion Hazard

2.1 Electrical safety

WARNINGS

To reduce the risk of electric shock:

- Only use the supplied power cord at the rated line voltage when connecting QuickFlow to

electrical power. Do not modify the power cord in any way or plug it in to an ungrounded

poweroutlet.Fordetailedinformationonthepowersupply,seepage19(Specications).

-Donotopentheinstrument.Nouser-serviceablepartsareinside.Refertoqualiedservice

personnel if help is required. NOTE: Place QuickFlow in an area where it can be easily dis-

connected from power outlet in a case of emergency.

Use this product only as described in this manual. If the equipment is used in a manner not

speciedbythemanufacturer,theprotectionprovidedbytheequipmentmaybeimpaired.

NOTE: Keep the power adapter away from instrument to avoid electric shock caused by

overowing.

5

Page 6

2.2 General safety

WARNINGS

When lifting a full collecting bottle off the QuickFlow base unit, grasp the carrying plate from

both sides and use proper lifting procedures. A filled collecting bottle weighs approximately

Safety

5 kg (11 lbs.)

At all times, keep face and body away from the aspiration tips and pipettes when using

QuickFlow.

CAUTIONS

Always use safe laboratory practices. Wear personal protective equipment (PPE) when using

QuickFlow.

Never move QuickFlow when the collecting bottle is full. Always empty the collecting bottle

before moving the instrument.

Using QuickFlow with strong acids, bases or other aggressive liquids may damage seals,

nozzles, or other parts. Clean up any contamination or accidental splashes immediately.

6

Page 7

3 Introduction

The Rainin QuickFlow is a benchtop liquid aspirator system made by METTLER TOLEDO.

It is designed for the safe and efficient removal of cell culture media and other commonly

used buffers in life sciences research labs.

Adapters snap to an ergonomic handle for precision aspiration control.

Aspiration may be continuous (always on) or touch-actuated via a button on the handle.

A liquid-level sensor integrated into the base unit alerts users when the collecting bottle is

full. This stops the pump to prevent overflow.

QuickFlow is intended for laboratory research purposes only. If used for other purposes,

METTLER TOLEDO is not liable for any resulting damage.

Please read this User Manual carefully, especially regarding safety, setup and basic

operation, before using QuickFlow in real lab conditions. It is the responsibility of the User to

read the instructions and to work in accordance with the standard operating procedures and

general safety guidelines defined by your workplace.

3.1 Device and liquid compatibility

Liquid-touching components of QuickFlow are made from materials including PVDF

(polyvinylidene difluoride), polypropylene and silicone rubber.

Lower concentration (up to 30%) chemicals including

- Bleach

- Acetone

- DMSO

- Trichlorethylene

- Chloroform

- Phenol

and other liquids may be aspirated safely.

7

Page 8

4 Setup

4.1 Prepare a workspace

An ideal workspace is a clean, dry area of bench that is protected from vibration and drafts

and is near an electrical power source. It should be out of direct sunlight.

Setup

QuickFlow requires a working horizontal bench space about 40 cm (18 inch) wide and

40 cm (18 inch) deep. It weighs about 6 kg (13.2 lbs) and is about 51 cm (20 inch) high.

Electrical power: QuickFlow comes with a set of four power adapters to enable operation

in any region.

NOTE: Avoid connecting QuickFlow to a power source used by any device with large current

fluctuations, such as a refrigerator that cycles on and off.

4.2 Check shipping box

QuickFlow is shipped from the manufacturer in one large shipping box. Check the box for

signs of damage. If there is damage to the shipping box or contents, please contact your

METTLER TOLEDO Customer Service or Sales representative.

4.3 Unpack QuickFlow

Open the shipping box. This reveals the first layer of QuickFlow components.

Take out the Quick Reference Guide, handle kit box and the cap with connectors.

Remove the top layer of foam.

Take out the QuickFlow base unit, tubing, power adapters and power supply.

Take out the empty collecting bottle with the bland (flat) cap on.

Keep the shipping box. It will be useful if you ever need to transport QuickFlow

or return it for authorized service.

If any items are missing, please contact your METTLER TOLEDO Customer Service

or Sales representative.

8

Page 9

4.4 Assemble QuickFlow

1. Place the open bottle on the base unit. Take the flat

metal carrying plate, align the large center hole over

the open top of the collecting bottle, and rotate the

plate clockwise until it rests on the shoulder of

the bottle.

2. Place the cap with quick connector heads (orange

and blue) on top of the collecting bottle and rotate the

cap clockwise until the bottle is tightly closed.

3

2

1

4

3

5

2

6

1

3. Close the gray pressure-release valve on top of the

cap between the blue and orange connector heads by

turning it clockwise until it stops. Loosening it counterclockwise opens the pressure-release valve.

4. Unpack the handle and adapter kit to take the clear

vacuum tubing out.

4

3

5

2

6

1

9

Page 10

Setup

5. Attach the orange connector plug to one end of the

clear vacuum tubing.

6. Attach the blue connector-plug end of the blue tube

to the blue connector head by pushing it in firmly.

Attach the orange connector-plug end of the clear tube

to the orange connector head by pushing it in firmly.

7. Firmly push the filter-end of the blue airflow tube

onto the port labelled "Inlet" on the rear of the base

unit. The filter picture points to the correct port.

4

3

5

2

6

1

Inlet

10

Page 11

4.5 Assemble the handle

1. Decide what length of the clear tubing you desire

between QuickFlow and the handle (working end).

Suggested length is not less than 1 meter.

At a desired length(s), cut perpendicularly across the

tube with scissors.

2. Press the open end of the clear tube firmly and fully

over the ridged extrusion on the tube-connecting end

of the handle.

3. (Optional) Splitter – A splitter with additional QuickFlow handle, tube and adapters is sold separately.

QuickFlow supports a maximum of 2 operating

channels at the same time. The splitter can be used to

connect an extra tube.

4. QuickFlow includes three different handle adapters

(see Figure 2 on page 4) :

Inlet

- Single-tip

- Multi-tip (8-channel)

- Glass/plastic Pasteur pipette

The Pasteur adapter fits most extended glass or plastic

pipette tubes. This adapter and pipette combination

allows more liquid to be aspirated with higher flow capacity, and deep vessels can be reached.

Snap an adapter to the handle by gently pressing and

rotating it into position.

5. Insert power cord into the back of the base unit at

the port marked "Power." Connect the other end to a

power outlet.

11

Page 12

Setup

6.LoadRaininUNV250μLtipsoraglass(Pasteur)pipetteonto

appropriate adapter

NOTE: QuickFlow is designed for use with Rainin universal (UNV) tips.

See page 20 for tip ordering information.

- Multi-tip (8-channel) adapter

As with a multichannel pipette, press the QuickFlow adapter nozzles

into a row of 8 tips with sufficient force to make a good seal.

- Single-tip adapter

Press the adapter into pipette tip with sufficient force to make a good

seal

- Pasteur pipette adapter

Insert the glass or plastic pipette tube into the open end of the adapter.

12

Page 13

5 Operation

5.1 Continuous or Non-continuous

Operating Conditions

Keep the machine in the laboratory on the work bench or on another flat

surface such as a table or the floor.

QuickFlow's operating temperature range is 0 °C to 40 °C.

Optimal operation is below 2000 m elevation.

aspiration

Continuous aspiration

Continuous (always-on) aspiration offers more relaxed operation by

bypassing the on/off button on the handle.

To select Continuous aspiration mode, move the sliding switch at the front

of the handle to the left. A solid line indicates Continuous operation.

Turn aspiration on or off at the base by pushing the Power button.

Non-continuous aspiration

If your aspiration task requires pinpoint on/off control, you can activate

and deactivate the vacuum action by pressing the button on the handle.

This is Non-continuous aspiration.

To select Non-Continuous aspiration, move the sliding switch at the front

of the handle to the right, where a dotted line indicates Non-Continuous

operation.

Turn on QuickFlow by pushing the Power button on the front of the base

unit.

Then, press the button on top of the handle to aspirate.

Release the button to halt aspiration.

13

Page 14

5.2 Power up and turn off QuickFlow

WARNING

To reduce the risk of electric shock, use only the supplied power cord at

the rated line voltage when connecting the QuickFlow to your electrical

power supply. Do not modify the power cord in any way or plug it into

an ungrounded power outlet.

1. Make sure the QuickFlow power indicator light is off/dark.

Operation

2. Press the power button for one second to power up the machine.

The indicator light turns green. A slightly audible working pump sound is

normal.

In operation

Green

5.3 Adjust Vacuum Speed

On the QuickFlow base unit, the speed knob rotates from 1 (slow) to

6 (more rapid). Maximum speed is 17 mL/s.

Clockwise rotation speeds up aspiration, and counter-clockwise slows it

down.

NOTE: QuickFlow may stop temporarily to

reset system air pressure.

Status indicator

Power button

• Push 1x to turn on

• Push and hold 5 sec

to turn off

3

2

1

3

2

1

4

5

6

Fast Slow

3

2

1

4

5

6

4

5

6

14

Page 15

A high vacuum pressure within the collecting bottle may interfere with

speed control. If this happens, either:

- Rotate the gray pressure-release valve on top of the cap counter-clock

wise to equalize pressure within the bottle, or

- Use the handle to momentarily aspirate air.

5.4 Full bottle: Level sensor and liquid level alert

When the collecting bottle is full, the level sensor turns off the pump and

alerts the user to empty the bottle.

The pump is disabled until the bottle is emptied.

WARNING:

When working with liquids at

higher than ambient temperature

or with liquids that tend to foam,

the maximum liquid level may be

reduced.

Red(ashing)

Bottle is full

5.5 Eject tips or remove Pasteur pipette

NOTE: Tips or Pasteur pipettes (glass/plastic) cannot be removed when

vacuum flow is on.

If using Continuous aspiration mode, either turn off QuickFlow or switch to

Non-Continuous mode.

The ergonomic trigger design make it easy to discard tips. Pull trigger

using whichever finger is most comfortable.

Full bottle

15

Page 16

Pull off

Cleaning and Maintenance

Figure 3: Ejecting Tips or removing the Pasteur pipette

6 Cleaning and Maintenance

To keep QuickFlow performing optimally, aspirate water or a lowconcentration ethanol or bleach solution as the last step of any aspiration

cycle. Empty and clean the bottle daily, or as needed.

6.1 Emptying the bottle

1. Turn off QuickFlow by pressing the Power button on the front of the

base unit for five (5) full seconds.

2. Turn the gray pressure-release valve on top of the bottle cap counterclockwise to equalize pressure in the bottle.

3. At the top of the collecting bottle, the blue and orange quick connectors join the tubes to the bottle. When a connecting collar is pulled down,

spring forces will lightly "pop" a tube from a connector. To prevent liquid

splashing or spilling from the tube, hold the connector-end of the tube in

one hand while pulling down the connecting collar with the other hand.

Repeat to disconnect both tubes.

16

4. Using the metal handle beneath the cap of the bottle, lift the bottle to

transport to the liquid disposal location.

5. Unscrew cap to empty the bottle. Always follow your lab's policy for a

safe liquid media disposal.

Page 17

4

3

5

2

6

1

4

3

5

2

6

1

4

3

5

2

6

1

4

3

5

2

6

1

Release

pressure

Disconnect

blue connector

Disconnet

orange connector

Figure 4: Emptying the bottle

6.2 Cleaning the handle, adapter, bottle and cap

The QuickFlow handle, adapters, cap and collecting bottle are easily cleaned

in mild soapy water. These parts may be more thoroughly decontaminated

using cleaning agents best matched to the aspirated liquid, such as alcohol

(70%) or bleach (10%) solutions.

NOTE: Extra o-rings for adapters are provided with QuickFlow for

replacement as needed.

6.3 Cleaning the clear vacuum tube

1. Place the empty bottle onto the QuickFlow base unit and screw on the

cap with connectors.

Grab the handles

to lift the bottle

2. Connect both tubes to the cap.

3. Select a cleaning agent based on the substance to be removed from the

tube: for example, 10% bleach solution (proteinaceous liquids) or 70%

alcohol (aqueous liquids), and pour the cleaning agent into a reservoir.

4. Aspirate the cleaning agent for 20 seconds to clean the tube. Ensure

proper ventilation and wear personal protective equipment whenever

solvents are in use.

5. Disconnect tubes and empty the collecting bottle and rinse with water.

17

Page 18

6. Place the empty bottle back on the QuickFlow base unit, screw on the

cap, connect the tubes, and aspirate distilled water for 20 seconds to

rinse the handle and tube.

7. Disconnect tubes and empty the collecting bottle.

6.4 Autoclaving

The QuickFlow handle, tubes, adapters, cap and collecting bottle may be

autoclaved at 121 ºC, 1 Bar, for 15-20 minutes.

NOTE: Cap and collecting bottle must be separated before autoclaving.

IMPORTANT: To autoclave the handle, move the switch to Non-Continuous

mode (dotted line) to keep it at optimum performance.

Do not autoclave the entire machine or any other parts of the machine.

7 Spare parts and accessories

Cleaning and Maintenance

Check with your local sales rep for a full list of QuickFlow spare parts

and accessories.

7.1 Filter (blue vacuum inlet tube)

If liquid splashes into the vacuum inlet tube, the filter will protect the

machine.

If the filter is blocked, disassemble and spin-dry it for reuse. If a filter is

destroyed, disassemble it and replace with a new one.

Pay attention to filter direction when reassembling. The side with indicator

"IN" connects toward the bottle.

7.2 Handle hang-up

When QuickFlow is not being used, you can secure the handle on

a nearby flat vertical surface using the handle hang-up.

Remove the adhesive backing and attach the hang-up

to a nearby surface. Then, insert the QuickFlow handle

as shown.

Hang-up

QuickFlow handle

18

Figure 5: Mounted hang-up with handle resting inside it

Page 19

8Specications

Description

Max. aspiration speed 17 mL/s (with aspiration pipette)

Vacuum range -20KPa – -70KPa

Power adapter input 100 – 240 VAC, 50/60Hz

Device power input 24V DC / 0.625A

Dimensions (H*W*D) 460 x 200 x 400 mm

Weight 4.016 kg (base unit, bottle and accessories)

Shipping weight 5.6 kg (includes packaging)

Max. liquid volume 4L

Tube diamater 4 mm (inner), 8 mm (outer)

Tube length 2 m

Operating range (°C) 0 to 40 °C, Max. 85% RH (non-condensing)

Storage range (°C) -30 to 60 °C, Max. 95% RH (non-condensing)

Power supply

(Manufacturer information)

Model: PSA 15R-240P

Manufacturer: PHIHONG

Manufacturer address:

Keji Road Yinhu Industrial Park, Qingxi Town

Dongguan City, Guangdong Province, China

19

Page 20

Troubleshooting

9

7 Troubleshooting

9

Before performing any troubleshooting, remember to turn off the QuickFlow completely and

remove the power adapter from the instrument.

Problem Probable cause Remedy

Device doesn't run Power switch is off Press the switch and turn on the device.

Power not connected Plug the power adapter and turn on.

Defective main PC Board* See disclaimer below.

Pump keeps running Air leakage Ensure the cap is tightly closed.

Ensure the handle is on non-continuous mode

(with switch moved toward dotted line).

Ensure the pressure-release valve is closed.

Ensure the connecting tubes are airtight at all

connection points.

Defective pump* See disclaimer below.

Defective main PC Board* See disclaimer below.

Slow aspiration

False full bottle

alerts

Aspiration speed is set to minimum Rotate the speed control knob clockwise to set

faster speed.

Blocked tubes Check the tubes and clean. Replace if needed.

Blocked filter Emptythebottleandreplacethelter.

Air leakage Ensure the cap is tightly closed.

Ensure the pressure-release valve is closed.

Check the tube connectors and ensure they are

tight.

Defective pump* See disclaimer below.

Inside wall of the bottle is dirty Clean the bottle with a cleaning agent such as

soapy water, 70% alcohol or a 10% bleach

solution.

Electromagnetic interference

disturbs the level sensor

Viscous or bubbly liquid Move bottle as far forward as possible on the base

Liquid splashes on the inside bottle

wall

Defective sensor* See disclaimer below.

Identify and remove source of electromagnetic

interference.

unit.

Check whether the tube inside the cap is bending;

keep the tube straight.

20

N/A Immediately turn off the instrument, unplug the

power adapter from the instrument and contact

Technical Support or your local METTLER TOLEDO

Power mulfunction

* If any of these occour, please immediately turn off the instrument, unplug the power adapter and contact Technical

Suppport or your local METTLER TOLEDO Service Organization. See page 22 for contact information.

Service Organization.

NEVER open the instrument cover and attempt to

troubleshoot this power problem. For more information, see Section 2.1 on page 5.

10 Incompatible chemicals and agents

QuickFlow should not be used to aspirate full strength corrosive chemicals.

Page 21

11 Ordering information

Part Number Description

30519826 Aspirator, QuickFlow 4L

30519824 QuickFlow Handle Kit – Standard

30519825 QuickFlow Handle Kit – w/ Splitter

QuickFlow Accessories

30524505 Bottle kit, QuickFlow 4L

30524507 Accessory: Handle Hang-up

30520489 2μmFilter–w/Tubing

Rainin Universal Tips for QuickFlow

30 389191 250μLUniversal(UNV)TipsinRT-racks

30 389193 250μLUniversal(UNV)TipsinRT-racks–Sterilized

17014 976 250μLUniversal(UNV)TipsinTerraRack™ – Sterilized

21

Page 22

12 Warranty

Limited Warranty and Limitation of Liability

Seller warrants the merchandise to conform to specifications. Under no circumstances shall

Seller be responsible for alleged nonconformities with respect to any merchandise which

has been used for purposes or in any manner for which it was not intended, or any

merchandise which has been customized or modified without Seller’s prior written consent,

or damaged or misused. As Buyer’s exclusive remedy in the event of breach of warranty,

Seller shall repair or replace, as its option, any nonconforming merchandise or parts thereof

Warranty

for a period of one (1) year after delivery. All claims must be made in writing to the Seller. Any

claims not made within the period specified above shall be deemed waived and released.

The provisions of the foregoing warranties are in lieu of any other warranty, whether express

Troubleshooting

or implied, written or oral (including any warranty of merchantability, fitness for a particular

purpose, title or non-infringement). Seller’s liability arising out of the manufacture, sale or

supplying of a product or its use or its disposition, whether based upon warranty, contract,

tort or otherwise, shall not for any reasons exceed the aggregate purchase price paid by

buyer for such product. In no event shall seller be liable to buyer or any other person or entity

for special, incidental, consequential or exemplary damages (including but not limited to

damages for loss of profits, loss of data or loss of use) arising out of the manufacture, sale,

supply, use, marketing, resale or operation of the merchandise, even if seller has been ad

vised of the possibility of such damages or losses.

Contact information

China: Phone: 4008 878 989

Email: mtservice@mt.com

North America/ Technical Support: Phone: 800 662 7027

E-mail: tech.support@rainin.com

RoW: www.mt.com/contacts

FCC Statement

This device complies with part 15 of FCC Rules. Operation is subject to the following two

conditions. (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

CAN ICES-3(B)/NMB-3(B)

See Section 5 - Specifications for information on electrical power rating and power cord

selection.

22

Page 23

23

Page 24

Mettler-Toledo Rainin, LLC

7500 Edgewater Drive

Oakland, California 94621 USA

Subject to technical changes

© 2018 Mettler-Toledo Rainin, LLC

30532602_EN Rev A

www.mt.com/rainin

For more information

Loading...

Loading...