Page 1

Operating Instructions

Rainin Classic

Manual Pipette

™

Page 2

2

Continuously Adjustable Pipettes

Intent of Use

Rainin Classic air-displacement pipettes are intended for dispensing liquids in the volume

ranges from 0.1 µL to 10 mL in various in-vitro liquid handling applications.

Table of Contents

Description ........................................................................................................................... 3

Autoclaving ........................................................................................................................... 3

Volume Indicator. .................................................................................................................. 3

Safety Filter, PR-5000, PR-10ML ............................................................................................. 4

Tip Selection ......................................................................................................................... 4

Tip Immersion Depth .............................................................................................................. 4

Tip Angle .............................................................................................................................. 5

Operation ............................................................................................................................. 5

Pipetting Guidelines & Precautions .......................................................................................... 6

Pre-Rinsing Recommended .................................................................................................... 6

Reverse Mode Pipetting .......................................................................................................... 6

Pipetting Liquids of Varying Density ......................................................................................... 7

Temperature Considerations .................................................................................................... 7

Acids and Corrosives ............................................................................................................. 7

Storage ................................................................................................................................ 7

Removing/Replacing Ejector Arm ............................................................................................. 8

Troubleshooting and Repairs................................................................................................... 9

Sample Splash ...................................................................................................................... 9

Leaks, Inaccurate Sampling .................................................................................................... 9

Specications ..................................................................................................................... 10

Replacement Parts: Part Numbers and Diagrams ............................................................... 11-13

Service, Calibration and Repair ............................................................................................ .14

Limited Warranty ................................................................................................................. 14

Contacting Rainin ................................................................................................................ 14

Figures

Figure 1 Rainin Classic PR-200 ............................................................................................. .3

Figure 2 Safety Filter ............................................................................................................... 4

Figure 3 Tip Immersion Depth and Tip Angle ............................................................................. 5

Figure 4 Operating Rainin Classic ............................................................................................ 5

Figure 5 Removing Tip Ejector Arm........................................................................................... 8

Contents of Rainin Classic box

Rainin Classic as ordered Quick Reference Guide

Rainin Test Report / Conformance Certicate

If any item is missing please call 800-472-4646 in the US, or contact your local MT ofce or distributor.

Technical Assistance: 800-543-4030

E-mail: tech.support@rainin.com

Made in the USA by Mettler-Toledo Rainin, LLC.

Copyright 2005-2017, Mettler-Toledo Rainin, LLC.

Rainin is a registered trademark and Rainin-Classic is a trademark of Mettler-Toledo Rainin LLC.

Rainin Classic pipettes are manufactured under U.S. Patent # 5,614,153.

Prices and specications are subject to change without notice.

Rainin Classic

™

Rainin Classic

Page 3

3

Description

Eight models of the Rainin Classic continuously adjustable digital pipette cover the entire volume range from

0.1 μL to 10 mL. Rainin Classic pipettes are not limited

to xed volume increments but can be set to any volume

in range, e.g. 6.6, 133.3, 377, 2228 μL. The piston

stroke is set by adjusting a micrometer coupled directly

to a digital volume indicator, which reads in microliters.

The digital volume indicator simplies volume setting

and virtually eliminates calculation errors.

All 2 to 5000 μL Rainin Classic models are equipped

with a stainless steel piston and an o-ring sealing system, which only needs a small amount of oil to function.

The seal in the 10 mL model requires grease for

lubrication.

A stainless steel tip ejector is provided with all models

(except PR-5000 and PR-10ML) for safe disposal of

used tips. The ejector has a quick-release mechanism.

Autoclaving

The shaft and tip ejector are autoclavable: 121°C, 1 bar,

15–20 minutes. (PR-5000, PR-10ML do not use tip

ejectors.)

Volume Indicator

The volume indicator is read from top to bottom. Up to

PR-200, black digits indicate microliters and red digits

tenths and hundredths of microliters. For PR-1000 and

PR-5000, red digits indicate milliliters and black digits

microliters. For PR-10ML, black digits indicate milliliters

and red digit tenths of a milliliter.

Sample values, volume ranges, and smallest incre-

ments for Rainin Classic models are shown below:

Figure 1: Rainin Classic

PLUNGER BUTTON

VOLUME SET

TIP EJECTOR

QUICK

RELEASE

DISPOSABLE

TIP

SHAFT

FRICTION RING

AND VOLUME

ADJUSTMENT

VOLUME

INDICATOR

RUGGED

HIGH-IMPACT

LOW THERMAL

CONDUCTIVITY

POLYMER

STAINLESS STEEL

TIP EJECTOR ARM

EXCEPT 5 and 10 mL

MODELS

TIP EJECTOR

BUTTON

Page 4

4

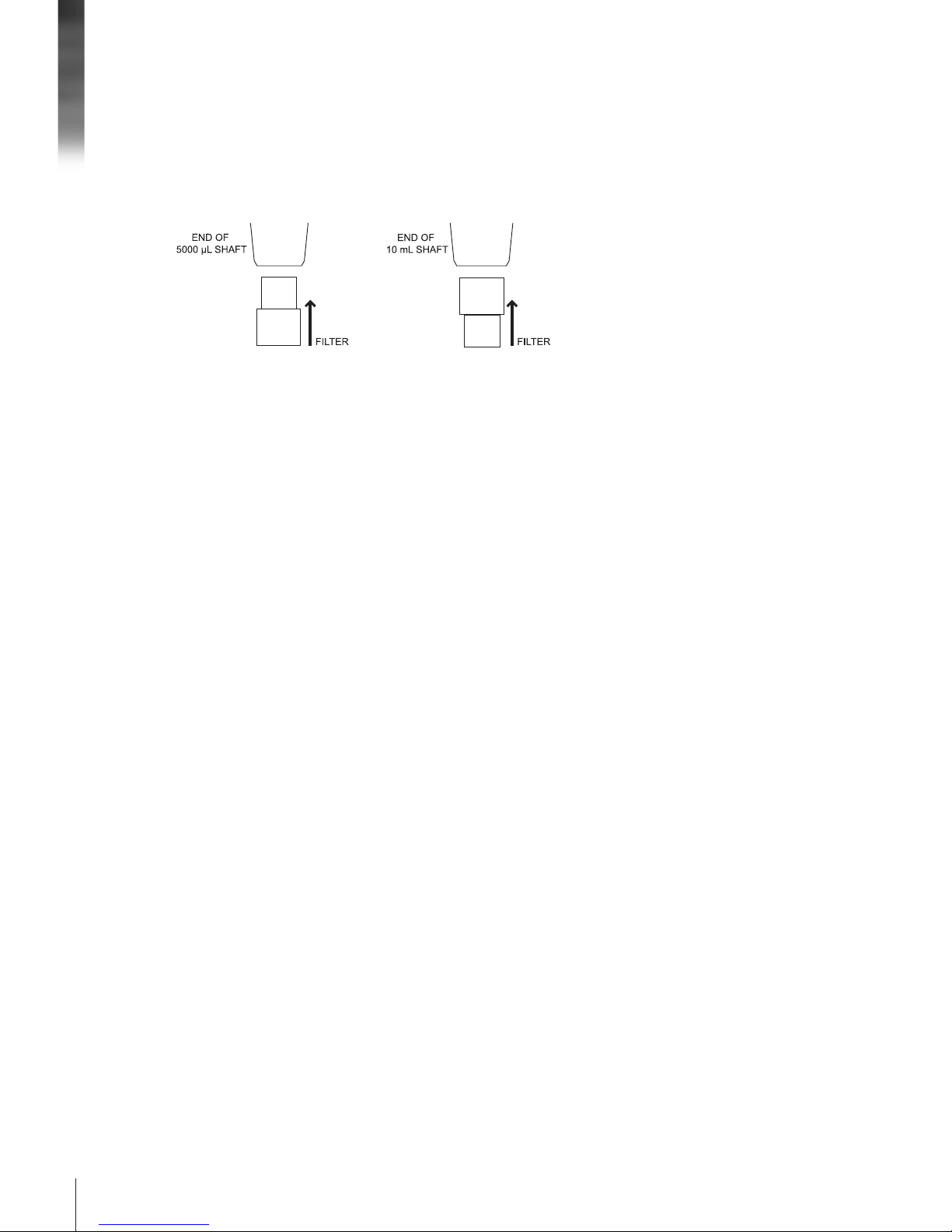

Safety Filter, PR-5000 and PR-10ML

Models PR-5000 and PR-10ML use a safety filter in the shaft to help prevent liquid entering the shaft and

contacting the piston. If the filter gets wet, replace it. For PR-5000 insert the small diameter into the shaft;

for PR-10ML insert the large diameter into the shaft. Part numbers: 17001944 (pack of 100) and 17001945

(pack of 1000).

Tip Selection

Rainin Classic pipettes are calibrated using Rainin tips. Performance to published specications is

guaranteed only when Rainin tips are used. Graduation marks on each Rainin tip are useful for quick

volume checks.

Rainin pipettes and tips are designed together as a pipetting system. Molded from premium-grade virgin polypropylene, all Rainin tips are BioClean and totally inert, so you can be assured of the best pipetting results.

To mount a tip, press the shaft into the end of the tip with light force. The tip will seal properly on the shaft with

minimal force — do not use more force than is required.

n Tips must seal properly on the shaft to assure an air-tight seal and avoid leaks or poor accuracy.

n Tips must be soft and flexible so that the shaft is not scratched or worn prematurely.

n Tips must be free from microscopic flash and particulates.

n The tip orifice must be the correct size, and orifice size and geometry must be consistent from tip to tip.

Otherwise, accuracy and precision will be affected.

n Interior and exterior surfaces must be clear, smooth, and hydrophobic to avoid retention of liquid. Too much

retention results in poor accuracy and reproducibility.

Genuine Rainin tips easily pass these requirements. Rainin cannot accept responsibility for poor performance

resulting from the use of tips by other manufacturers.

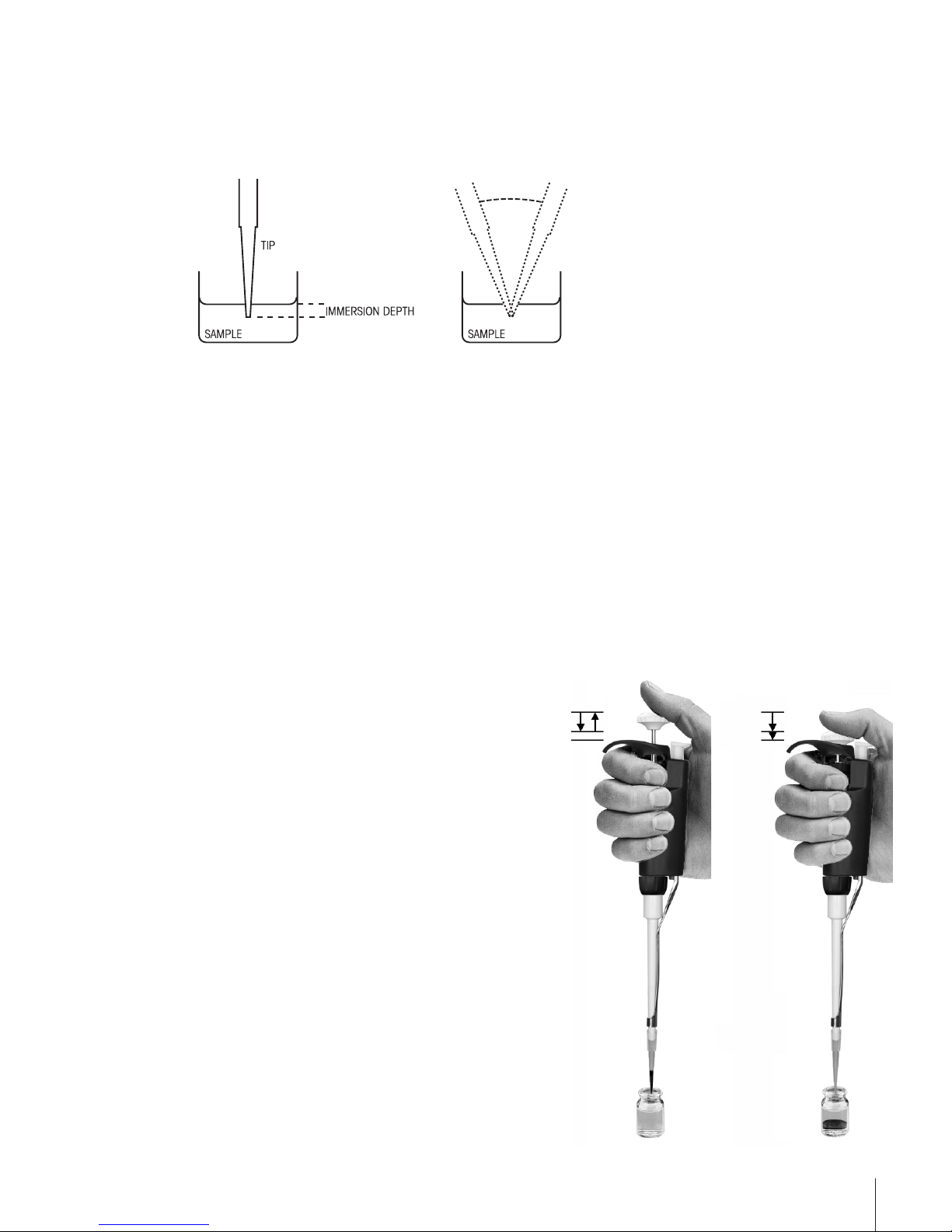

Tip Immersion Depth

The recommended depth for tip insertion into the sample for each model is shown below.

Nominal Volume Volume Range Immersion Depth

2 µL 0.1 - 2 µL 1-2 mm

10 µL 0.5 - 10 µL 1-2 mm

20 µL 2 - 20 µL 2 - 3 mm

100 µL 10 - 100 µL 2 - 3 mm

200 µL 20 - 200 µL 3 - 6 mm

1000 µL 100 - 1000 µL 3 - 6 mm

5000 µL 500 - 5000 µL 6 - 10 mm

10 mL 1 mL - 10 mL 6 - 10 mm

Tip immersion depth is critical and should not be exceeded, or the volume measured may be inaccurate, possibly

out of specication.

Rainin Classic

Figure 2: Safety Filter

Page 5

5

Tip Angle

The tip angle is also important – the pipette should always be used in a position within 20 degrees of vertical.

See Figure 3 below.

Operation

Before pipetting valuable samples, it is good to practice aspirating and dispensing water.

1. Turn the plunger button or the volume adjustment knob until the volume indicator is 1⁄3 revolution above the

desired setting, then turn slowly clockwise until the desired volume shows on the indicator.

2. ALWAYS dial down to the desired volume. This prevents mechanical backlash from affecting accuracy. If you

pass the desired setting, turn the dial 1⁄ 3 revolution higher than desired and dial down to reset the volume.

The friction ring prevents unintentional volume changes.

3. Attach a new disposable tip to the pipette shaft. Press into the tip with only enough force to make a positive

airtight seal.

4. Press the plunger to the FIRST STOP. This part of the stroke is the volume displayed on the indicator.

5. Holding Rainin Classic vertically, immerse

the tip into the sample to the proper depth;

see table on page 4.

6. Allow the plunger to return slowly to the UP

position. Never let it snap up! Figure 4A.

7. Pause briefly to ensure that the full volume of

sample is drawn into the tip.

8. Withdraw the tip from the sample liquid.

If any liquid remains on the outside of the

tip, wipe it carefully with a lint-free tissue,

avoiding the tip orifice.

9. To dispense sample, touch the tip end

against the side wall of the receiving vessel

and depress the plunger slowly to the first

stop. Figure 4B.

Wait 1 second: PR-2 – PR-200

Wait 1-2 secs: PR-1000,

Wait 2-3 secs: PR-5000, PR-10ML

(more for viscous solutions). Then press the

plunger to the SECOND STOP (bottom of

stroke) expelling any residual liquid in the tip.

Figure 4 Operating Rainin Classic

TOP OF

STROKE

1st STOP

2nd STOP

TIP

ANGLE

Figure 3: Tip Immersion Depth and Tip Angle

Page 6

6

Rainin Classic

10. With the plunger fully pressed, withdraw the pipette from the vessel carefully, with the tip

against the vessel wall.

11. Allow the plunger to return to the up position.

12. Discard the tip by depressing the tip ejector button. A fresh tip should be used for each

sample to prevent sample carryover.

Pipetting Guidelines and Precautions

Consistency in all aspects of pipetting procedure will signicantly contribute to optimum

reproducibility. Use a:

• Consistent pickup/dispense rhythm while pipetting.

• Consistent speed and smoothness when you press and release the plunger button.

• Consistent plunger button pressure at the rst stop.

• Consistent immersion depth.

• Minimal angle (< 20° from vertical).

Prevent liquids from being drawn into the shaft by taking the following precautions:

• Use Rainin aerosol-resistant tips, with an internal lter which acts as a barrier to aerosols

and liquids.

• Never invert or lay the pipette down if liquid is in the tip.

• Pipette slowly, holding the pipette < 20° from vertical.

• For PR-5000 and PR-10ML, always use the special safety lters supplied. Part numbers:

17001944 (pack of 100) and 1701945 (pack of 1000).

More information on Good Pipetting Technique can be found at www.mt.com/GPP

Pre-Rinsing Recommended

Some solutions (e.g. serum, protein-containing solutions, and organic solvents) can leave a

lm on the inside tip wall, resulting in an error larger than the tolerance specied. Since this

lm remains relatively constant in successive pipettings with the same tip, excellent precision

may be obtained by relling the tip and using the relled volume as the sample. Successive

samples from this same tip will exhibit good reproducibility (low variance).

Reverse Mode Pipetting

Another way of reducing error due to lm retention is reverse mode pipetting; the operating

sequence is reversed compared to forward pipetting:

1. Mount a disposable tip on the pipette shaft.

2. Press the plunger button fully to the SECOND STOP.

3. Immerse the tip in liquid and return the plunger slowly to the full up position. Wait a

moment for the liquid column to reach equilibrium in the tip.

4. Wipe any excess liquid from the outside of the tip without touching the orice.

5. To dispense, rest the end of the tip against the vessel wall and press the plunger to the

FIRST STOP only. Hold at the FIRST STOP for a few seconds – long enough for the liquid

column to reach equilibrium again.

6. Remove the tip from the receiving vessel without blowing out the remaining liquid.

7. Return excess sample in the tip to the original sample container, if desired. Discard the

used tip.

Page 7

7

Pipetting Liquids of Varying Density

Rainin Classic lets you compensate for solutions of density much different from water, by

setting the volume slightly higher or lower than that required. The compensation amount

must be determined empirically.

E.g., if pipetting 10 μL of CsCl solution, you determine that the volume delivered is actually

8.5 μL (average of 5 samples). Try increasing the volume setting to 11.8 μL and repeat the

measurements. If the volumes delivered are still not close enough to 10 μL, make another

slight volume adjustment until the measurements are as desired.

Very dense liquids may not be suitable for air displacement pipetting. Use Rainin Pos-D

positive displacement pipettes for these liquids.

Temperature Considerations

Warm or cold liquids can be pipetted with good precision by using a consistent pipetting

rhythm. This will help minimize any differences in heating or cooling effects within the pipette.

Use a new tip each time for best accuracy and precision when measuring samples with

temperatures greatly different from ambient, and do not pre-rinse. You will get best results if

there is no delay between picking up the sample and dispensing it. If working in a cold room,

allow the pipette to stabilize at ambient temperature before operation.

Acids and Corrosives

After pipetting concentrated acids or highly corrosive solutions you should disassemble

Rainin Classic and inspect and clean (if necessary) the piston, shaft, and seal assemblies.

Extensive contact with corrosive fumes may corrode the piston. This will result in premature

seal wear and may require refinishing or replacement of the piston. Exposure of internal

components to corrosive fumes can be reduced by using aerosol-resistant tips. These tips

have an internal filter which acts as an aerosol barrier.

Storage

Rainin Classic is a precision instrument and should be treated with the level of care

appropriate for laboratory instrumentation. Several hangers are available to hold Rainin

Classic securely when not in use.

HU-M3: Set of 3 magnetic HangUps™ for mounting on ferrous surfaces. Includes adhesive disks.

(Part# 17003024)

HU-S3: 3 Hang-Ups attached to a

clamp to mount on a shelf.

(Part# 17004992)

CR-7: Free-standing carousel

holds 7 Rainin pipettes.

(Part# 17001255)

Page 8

8

Rainin Classic

Removing the Tip Ejector Arm

The tip ejector on Rainin Classic (2-1000 µL models) can be removed easily using the quick-release tabs.

Refer to the figure below.

1. Press and hold the tip ejector button fully down.

2. With the other hand, press in the quick-release tabs on the tip ejector arm and pull the tip ejector arm

straight down.

Replacing the Tip Ejector Arm

1. Press and hold the tip ejector button fully down.

2. Hold Rainin Classic in one hand and the tip ejector arm in the other hand.

3. Insert the end of the shaft through the large opening in the tip ejector arm.

4. Align the top end of the tip ejector arm with the pushrod inside the handle and push the tip ejector arm into

the handle until the tip ejector arm snaps in place.

5. Make sure that tips fit securely on the shaft.

Figure 5: Removing Tip Ejector Arm

1. Fully depress the

tip ejector button

2. Press in the quick-release tabs

and pull off the tip ejector arm

Page 9

9

Troubleshooting and Repairs

Rainin Classic pipettes give excellent performance and long-term service. Use these procedures in the case of

physical or chemical damage. Refer to the exploded diagrams later in the manual. When removing the shaft from

the pipette body, make sure the spring, seal and o-ring do not detach from the piston, especially on the smaller

models, and note that PR-2 and PR-10 models have small, fragile components that can be broken or misplaced.

Be careful not to bend the piston on these small models. Recalibration of Rainin Classic is only required when the

piston is replaced.

Sample Splash (liquid inside the mechanism)

1. Remove the tip ejector, if fitted. Unscrew the shaft coupling nut holding the shaft to the body.

2. Remove the shaft and inspect the seal assembly and piston for contamination. The piston should be shiny

and free of corrosion. Clean with distilled water or isopropyl alcohol.

3. Dry with a lint-free tissue and reassemble after inspecting the interior of the shaft for contaminants.

4. If staining and/or corrosion of the piston is evident, do not use the pipette. Return to Rainin for service

(see p. 14).

5. Use oil (not grease) to lubricate Rainin Classic components. The only exception is the PR-10ML model,

which uses a sealing system that requires grease.

Leaks, Inaccurate Sampling

1. Loosened shaft. Tighten coupling by hand.

2. Split or cracked shaft. Remove the tip ejector and inspect the shaft for fracture or split end. Replace if neces-

sary. If the shaft was dropped, remove it and the seal assembly to see if the piston is bent. If so, you should

return the instrument: call 800-543-4030 for assistance.

3. Worn seal and / or o-ring. Dismantle as described in “Sample Splash”. Replace the seal and o-ring, referring

to the drawing on page 12 or 13. Pull off the old seal and o-ring, position the new seal and o-ring on the

piston as shown in the drawing, and reassemble the pipette.

4. Bent plunger / damaged friction ring. Call 800-543-4030.

5. Improper reassembly. Remove the tip ejector and shaft. Check the position of the internal assemblies,

especially the seal, against the illustrations.

Page 10

10

Specifications

Rainin Classic

Each Rainin Classic is factory calibrated and carefully checked gravimetrically before shipment

using distilled water and an analytical balance. Water temperature and ambient conditions are

stabilized at 21.5°C ± 1°C. Volumetric corrections are made for both the density of water and

evaporation where applicable.

Consult the free Rainin publication “Procedure for Evaluating Pipette Accuracy and Precision”

(AB-15) for further information, or download a copy from the RAININ website:

http://www.rainin.com/pdf/ab15.pdf

When used in accordance with the pipetting procedures in this manual AND using Rainin tips,

Rainin Classic pipettes will perform to the following specications.

These manufacturer’s specications should be used as guidelines when establishing your own

performance specication.

Volume Increment Accuracy Precision

Model µL µL % µL (±) % µL (≤)

PR-2 0.2 0.002 12 0.024 6 0.012

1.0 2.7 0.027 1.3 0.013

2.0 1.5 0.030 0.7 0.014

PR-10 1.0 0.02 2.5 0.025 1.2 0.012

5.0 1.5 0.075 0.6 0.03

10.0 1 0.1 0.4 0.04

PR-20 2 0.02 7.5 0.15 2 0.04

5 3 0.15 0.9 0.045

10 1.5 0.15 0.5 0.05

20 1 0.2 0.3 0.06

PR-100 10 0.2 3.5 0.35 1 0.1

50 0.8 0.4 0.24 0.12

100 0.8 0.8 0.15 0.15

PR-200 20 0.2 2.5 0.5 1 0.2

100 0.8 0.8 0.25 0.25

200 0.8 1.6 0.15 0.3

PR-1000 100 2 3 3 0.6 0.6

500 0.8 4 0.2 1

1000 0.8 8 0.15 1.5

PR-5000 500 5 2.4 12 0.6 3

2500 0.6 15 0.2 5

5000 0.6 30 0.16 8

PR-10ML 1 mL 20 5 50 0.6 6

5 mL 1 50 0.2 10

10 mL 0.6 60 0.16 16

Specications are subject to change without notice.

Page 11

11

Replacement Parts

The commonly-replaced parts are shown here for each volume range of

Rainin Classic pipettes.

* Part of one-piece piston assembly. Replacement will require recalibration.

Rainin is the only organization authorized to calibrate Rainin Classic pipettes.

Please call 800-662-7027 for information.

See replacement parts diagrams on page 12 and 13.

Model and Product Part Number

Model PR-2 P R-10 PR-20 PR-100 PR-200 PR-1000 PR-5000 PR-10ML

Part 17008648 17008649 17008650 17008651 17008652 17008653 17008654 17008655

A Plunger Button 17008613 17008616 170 08 615 170 08617 170 08618 17 00 8619 1700 862 0 170 08 621

B Plunger Rod 17007869 17007869 170 0786 9 1700 786 9 1700 78 69 1700 78 69 1700 78 69 1700 78 69

C Shaft Coupling 17008416 17008416 170 08416 17 00 8416 170 08 416 17 008 416 N/A N/A

D Shaft 17004985 17004982 170 04 98 6 1700 49 83 1700 498 7 170 04 984 170 048 77 17 00 483 6

E Tip Ejector 17007734 17007734 1700 773 5 170077 32 1700 77 31 1700 77 33 N/A N/A

F O-Ring 170 034 41 17 0 03 441 170 034 47 1700 344 8 17003454 17 00 345 8 170 03 46 5 170 034 69

G Seal 170 0478 2 17 00 4779 170 08 418 17 00 8419 170 08 420 170 08421 1700 478 5 N/A

H Seal Assembly Holder 17004 43 7 170 04 437 170 044 38 17 00 443 5 170 04 43 9 * * *

I Small Spring 170 084 40 1700 844 0 170 084 40 17 00 844 0 17008 44 0 * * *

J Small Spring Positioner 1700 504 4 170 05 044 170 050 44 17 00 50 44 170 05 04 4 * * *

K Large Spring 170 08 437 170 084 37 1700 843 7 170 08 438 170 084 38 * * *

L Large S pring Positione r 170 02 710 170 02 710 170 02 710 170 02 710 170 02 710 * * *

M Filte rs (100) N/A N/A N /A N/A N/A N/A 17001944 17001944

M Filte rs (1000) N/A N/A N /A N/A N/A N /A 170 0194 5 170 01945

Page 12

12

Rainin Classic

Parts Diagrams, PR-2 to PR-100

Replacement Parts Legend

A Plunger Button

B Plunger Rod

C Shaft Coupling

D Shaft

E Tip Ejector

F O-Ring

G Seal

H Seal Assembly Holder

I Small Spring

J Small Spring Positioner

K Large Spring

L Large S pring Positione r

M Filte r (PR-5000, PR-10ML)

Page 13

13

Parts Diagrams, PR-200 to PR-10ML

Page 14

14

Rainin Classic

Service, Calibration and Repair

It is recommended to use only genuine Rainin replacement parts such as seals, o-rings, and

shafts. It is NOT necessary to recalibrate the pipette after changing the seal, o-ring, or shaft.

Recalibration of the pipette is only necessary when the piston is replaced, and should be done

only by qualied factory-trained personnel in a Rainin approved facility.

For pipettes under warranty, please note that the warranty will be voided if the pipette has

been damaged as a result of physical or chemical abuse, or if the pipette has been repaired or

recalibrated by any service facility which is not authorized by Rainin.

In the US, call 800-543-4030 for service.

Service is also available outside the US. See www.mt.com/rainin for more information.

Limited Warranty

See the Limited Warranty and Limitations of Liability Statement on the enclosed Rainin Test

Report / Conformance Certicate. Please complete and return the Warranty Registration Card

on receipt of your pipette.

Rainin pipettes are calibrated with Rainin tips. To assure excellent reproducibility and performance, use only Rainin tips as recommended in this manual. Specied performance is

guaranteed only when Rainin tips are used.

Contacting Rainin

Technical Information: T: 800-543-4030 F: 510-564-1617 tech.support@rainin.com

Pipette Service: T: 800-662-7027 F: 781-935-7631 service@rainin.com

Direct Order Line: T: 800-472-4646 F: 510-564-1617 pipets@rainin.com

Rainin website: www.shoprainin.com

Outside North America: www.mt.com/rainin

Page 15

15

Page 16

220

Mettler-Toledo Rainin, LLC

7500 Edgewater Drive

Oakland, CA 94621

Subject to technical changes

© 2005-2018 Mettler-Toledo Rainin, LLC

17008394 Rev I

www.mt.com/rainin

For more information

Loading...

Loading...