Mettler Toledo PBK989-XS0.6, PBK989-A6, PBK989-A3, PBK-A60, PBK98_-B60 Installation Information

...

Installation Information

PBK9-series

High precision weighing platforms

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper

use of your new equipment according to this User manual and regular calibration and

maintenance by our factory-trained service team ensures dependable and accurate

operation, protecting your investment. Contact us about a service agreement tailored to

your needs and budget. Further information is available at

www.mt.com/service.

There are several important ways to ensure you maximize the performance of your

investment:

1. Register your product: We invite you to register your product at

www.mt.com/productregistration

so we can contact you about enhancements, updates and important notications

concerning your product.

2. Contact METTLER TOLEDO for service: The value of a measurement is proportional

to its accuracy – an out of specication scale can diminish quality, reduce prots and

increase liability. Timely service from METTLER TOLEDO will ensure accuracy and

optimize uptime and equipment life.

– Installation, Conguration, Integration and Training:

Our service representatives are factory-trained, weighing equipment experts. We

make certain that your weighing equipment is ready for production in a cost

effective and timely fashion and that personnel are trained for success.

– Initial Calibration Documentation:

The installation environment and application requirements are unique for every

industrial scale so performance must be tested and certied. Our calibration

services and certicates document accuracy to ensure production quality and

provide a quality system record of performance.

– Periodic Calibration Maintenance:

A Calibration Service Agreement provides on-going condence in your weighing

process and documentation of compliance with requirements. We offer a variety

of service plans that are scheduled to meet your needs and designed to t your

budget.

2

PBK9-series 30233012B

Contents

1 Safety information for operation in the Exarea .................................................... 4

2 Installation .......................................................................................................... 6

2.1 Preparatory work ..................................................................................................6

2.2 Setting up ............................................................................................................7

2.3 Levelling .............................................................................................................. 8

2.4 Lengthening and installing connection cable ............................................................9

2.5 Equipotential bonding in hazardous areas ............................................................... 9

2.6 Connecting PBK98_APW weighing platforms ......................................................... 11

2.7 Commissioning .................................................................................................. 16

3 Conguration possibilities ................................................................................. 17

3.1 General information............................................................................................. 17

3.2 Conguration data in the factory setting ................................................................ 18

4 Planning assemblies.......................................................................................... 19

4.1 Notes on planning............................................................................................... 19

4.2 Preload range ..................................................................................................... 19

4.3 Mounting possibilities .......................................................................................... 20

5 Dimensions ....................................................................................................... 24

3

30233012B PBK9-series

1 Safety information for operation in the

Exarea

▲ The PBK9-series high precision weighing platforms except PBK989-XS0.6 provide

options for operation in Category3 or Category 2 / DIV 1 hazardous areas (gases and

dusts). There is an increased risk in injury and damage when using the explosionprotected weighing platforms in a potentially explosive atmosphere. Special care must

be taken when working in such hazardous areas.

▲ Any protective foils present in the hazardous area, e.g. on the load plate, must always

be removed.

▲ In hazardous areas, the weighing platforms may only be installed, maintained and

repaired by authorized METTLER TOLEDO service personnel.

▲ No modications may be made to the weighing platform and no repair work may be

performed on the system modules. Any weighing platform or system modules that are

used must comply with the specications contained in the installation instructions.

Non-compliant equipment jeopardizes the intrinsic safety of the system, cancels the

"Ex" approval and renders any warranty or product liability claims null and void.

▲ The safety of the weighing system is only guaranteed when the weighing system is

operated, installed and maintained in accordance with the respective instructions.

▲ Also comply with the following:

– the instructions for the system modules,

– the regulations and standards in the respective country,

– the statutory requirement for electrical equipment installed in hazardous areas in

the respective country,

– all instructions related to safety issued by the owner.

▲ The explosion-protected weighing system must be checked to ensure compliance with

the requirements for safety before being put into service for the rst time, following any

service work and every 3 years, at least.

▲ Prevent the build-up of static electricity.

– Always wear suitable working clothes when operating or performing service work

in a hazardous area.

– Avoid strong mechanical rubbing of the powder-coated surfaces against any

material when operating in Category3 or Category 2 / DIV 1.

– Only use the weighing platforms when electrostatic processes leading to propagating

brush discharges are impossible.

▲ Do not use protective coverings for the devices.

▲ Avoid damage to the system components.

▲ If system damage occurs, the system must be put out of operation immediately.

▲ Damaged system components must be replaced immediately.

Competence

Ex approval

Operation

4

Safet y information for operation in the Exarea

PBK9-series 30233012B

▲ Only install or perform maintenance work on the weighing system in the hazardous

areas if the following conditions are fullled:

– the intrinsically safe characteristic values and zone approval of the individual

components are in accordance with one another,

– the owner has issued a permit ("spark permit" or "re permit"),

– the area has been rendered safe and no explosive dust is present and the owner's

safety coordinator has conrmed that there is no danger,

– the necessary tools and any required protective clothing are provided (danger of

the build-up of static electricity).

▲ The explosion protected PBK9-series high precision weighing platforms may only be

operated in hazardous areas of Category3 or Category 2 / DIV1 in conjunction with

weighing terminals that have the appropriate approval and interface specication.

▲ The certication papers (certicates, manufacturer’s declarations) must be present.

▲ Before setting up the system secure the connection between weighing terminal and

weighing platform.

▲ Lay cabling securely so that it does not move and effectively protect it against damage.

▲ Only route cables into the housing of the system modules via the approved earthing

cable glands and ensure proper seating of the seals.

▲ The connection cable may not be separated from the weighing terminal while it is

energized.

▲ Make sure that no conductive dusts exist when removing the plug of load cell.

▲ Only use METTLER TOLDEO approved and marked connection cables.

▲ Secure M12 connectors via hexagon nut and appropriate tools.

Torque range: 1.0 to 1.2Nm.

▲ Connect the weighing platform with an equipotential bonding conductor to the system

safety ground.

▲ Protect the M12 ange socket and the cable connector effectively against mechanical

damage by using the assembled protective bracket.

▲ Avoid direct sunlight radiation.

Installation

5

Safet y information for operation in the Exarea 30233012B PBK9-series

2 Installation

2.1 Preparatory work

2.1.1 Selecting installation location

▲ The foundation at the installation location must be capable to safely support the

weight of the weighing platform at its support points when it carries the maximum

load. At the same time, it should be so stable that no vibrations occur during weighing

operations. These requirements also apply when the weighing platform is integrated in

conveying systems and the like.

▲ Ensure that the ground at the installation location is even.

▲ Ensure that there are no vibrations from machines near the installation site.

▲ Ensure that there are no drafts at the installation site.

EXPLOSION HAZARD

PBK989-XS0.6 is not approved for hazardous areas.

▲ Do not use PBK989-XS0.6 in any kind of hazardous areas.

2.1.2 Ambient conditions

• Use powder-coated/enamelled weighing platforms only in a dry environment.

• In a damp environment, in wet operation or when working with chemicals: Use

stainless-steel weighing platforms.

2.1.3 Accessories

➜ Completely unpack the accessories provided with the weighing platform.

– 1 bottle of oil, suitable for foodstuffs

– 1 set of measuring data signs for selectable congurations

– Optional: ACC409xx-SICSpro-IDNet converter (incl. identcard kit, not for Category2/

DIV1)

6

Installation

PBK9-series 30233012B

2.2 Setting up

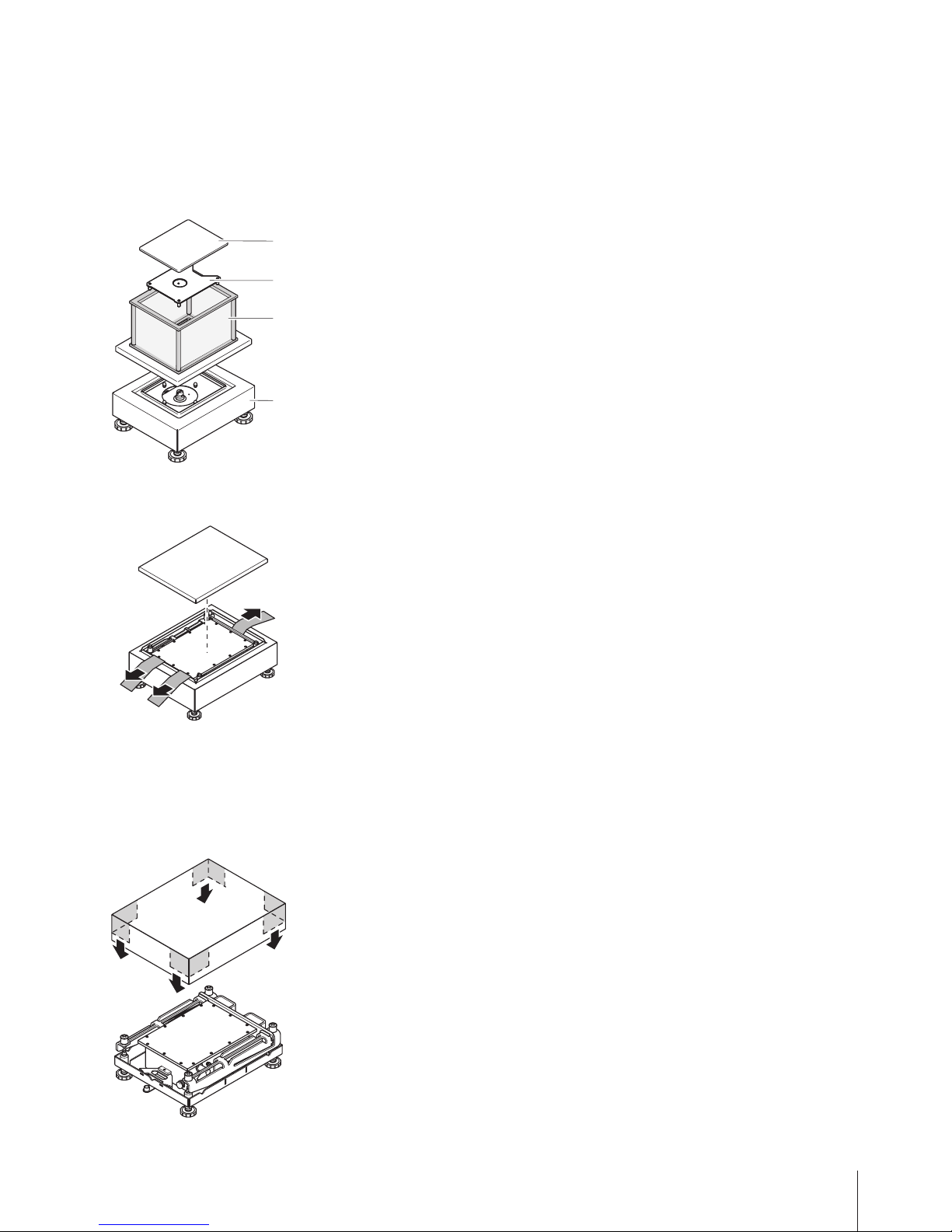

2.2.1 PBK989-XS0.6

1. Unpack weighing platform (1), windshield (2), load plate support (3) and load

plate(4).

2. Mount the load support (3) on the weighing platform.

3. Put the windshield (2) on.

4. Put the load plate (4) on the load support.

2.2.2 PBK989-A3 / PBK989-A6

1. Remove the weighing platform from the packing.

2. Lift off the load plate.

3. Remove the transport locks (3 cardboard strips).

4. Put the load plate on.

2.2.3 PBK989-A15 / PBK989-A30 / PBK-A60

➜ Remove the weighing platform from the packing.

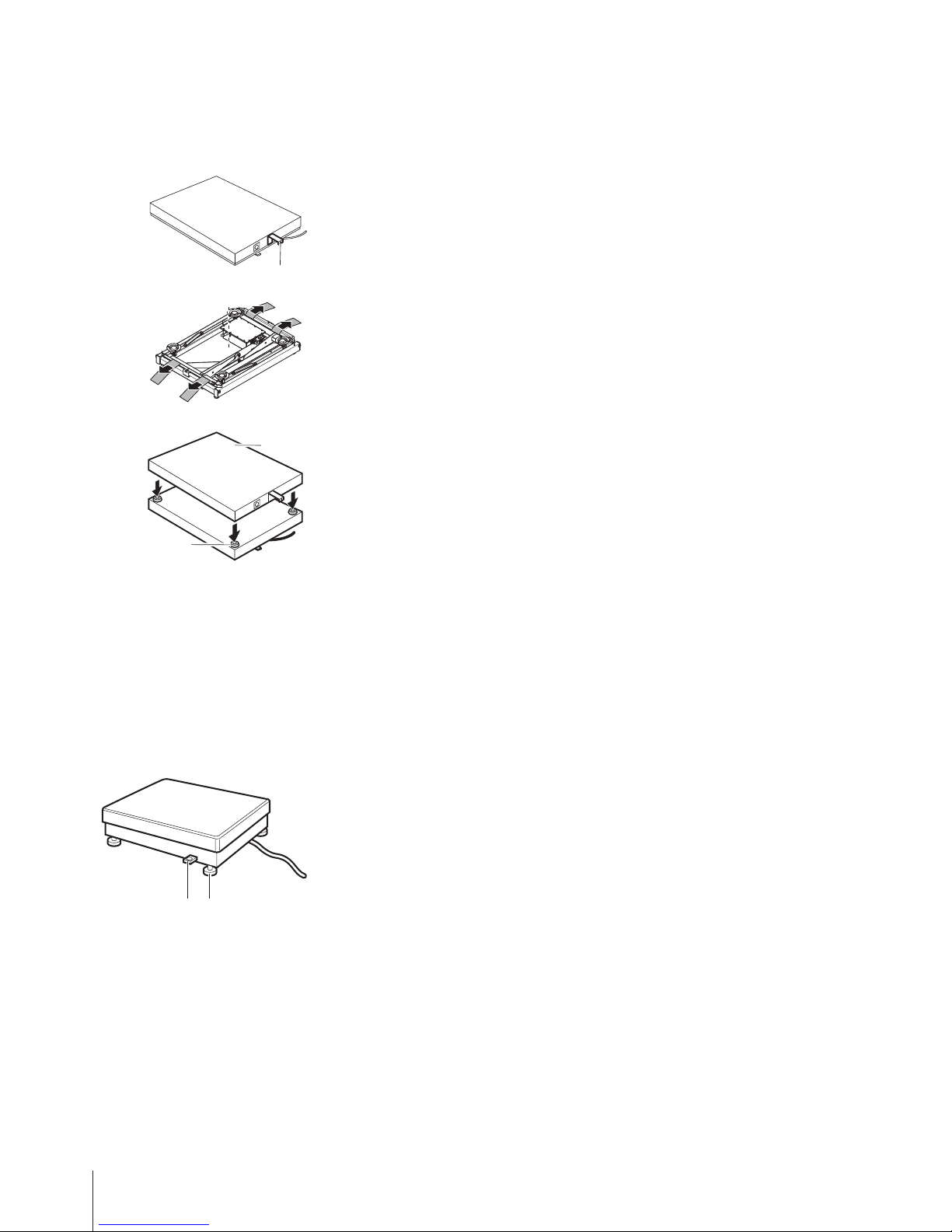

2.2.4 PBK98_-B60 / PBK98_-B120

1. Remove the weighing platform from the packing.

2. Lift off the load plate.

3. Remove the transport locks from the corners (4 cardboard angles).

4. Put the load plate on.

1

2

3

4

7

Installation 30233012B PBK9-series

2.2.5 PBK98_-CC150 / PBK98_-CC300

1. Remove the weighing platform from the packing.

2. Remove the load plate by pivoting the two side handles (1) outward.

3. Remove the transport locks (2 x 2 cardboard strips between lever and base frame +

4 cardboard angles in the corners).

4. Replace the load plate (2) so that the symbol is located above the level indicator.

5. Make sure that the load supports (3) in the corners of the weighing platform are

vertical.

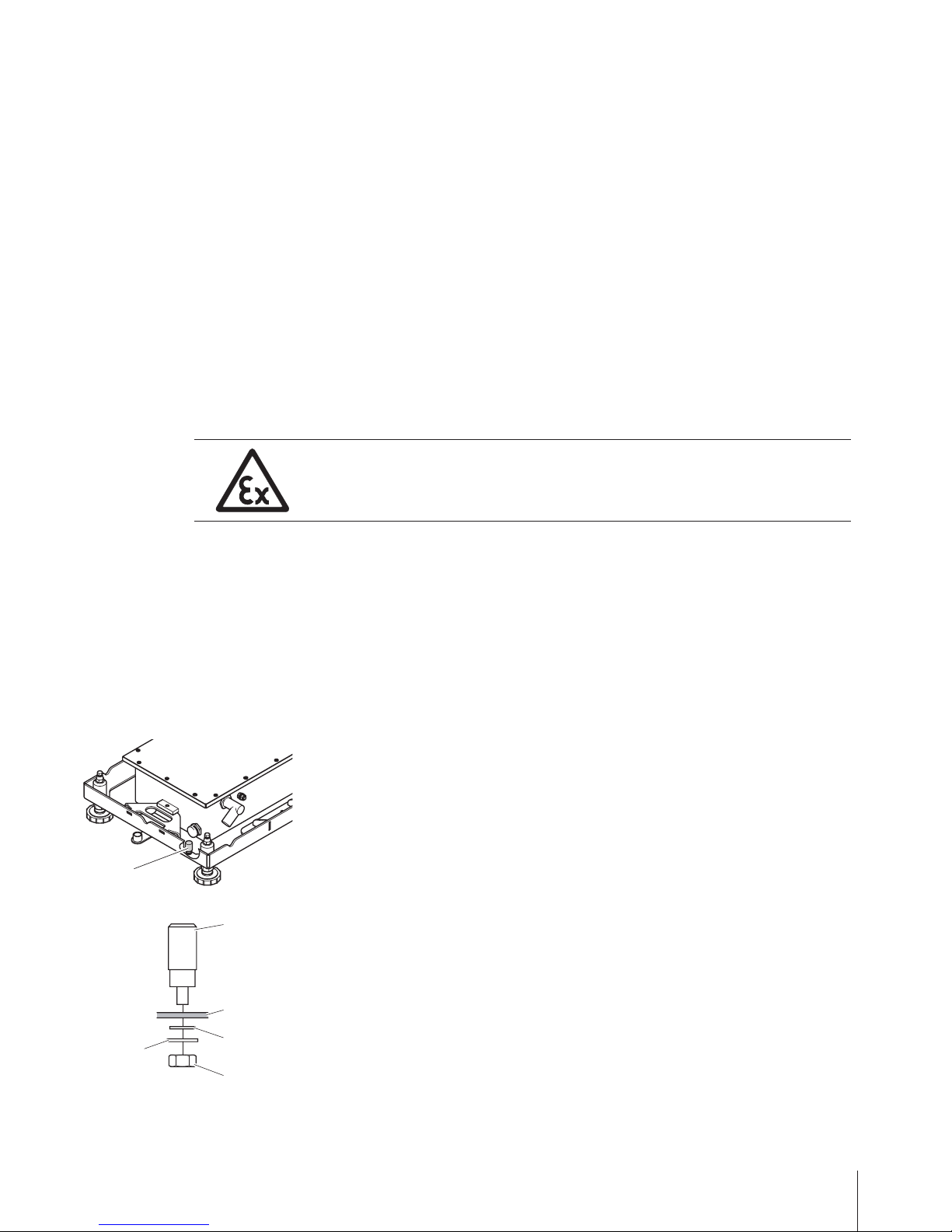

2.3 Levelling

Notes

• Only weighing platforms that have been levelled precisely horizontally provide accurate

weighing results.

• Redo levelling when the weighing platform has been moved.

1. Level the weighing platform with the 4 foot bolts (1) using the level indicator (2): The

air bubble of the level indicator must come to rest within the ring marking.

2. Ensure even contact of the foot bolts. Every foot must stand safely and must have full

contact with its entire surface. Check the stability of the weighing platform by pressing

down on or rocking it at the corners.

3. Lock the foot bolts with the nuts.

1

2

3

2 1

8

Installation

PBK9-series 30233012B

2.4 Lengthening and installing connection cable

The connection cable may be lengthened.

Standard version up to 100 m

Ex version up to 50 m

➜ Route the connection cable directly out of the weighing platform to the weighing

terminal or the ConBloc (PBK98_APW weighing platforms only).

CAUTION

If the cable is laid in a pipe, ensure that the pipe is of a sufcient diameter.

2.5 Equipotential bonding in hazardous areas

EXPLOSION HAZARD

▲ Always use equipotential bonding in hazardous areas.

▲ Use only cables with cross section 4 mm2.

The equipotential bonding must be installed by a professional electrician when using the

weighing platform in hazardous areas. METTLER TOLEDO Service only has a monitoring

and consulting function here.

➜ Connect equipotential bonding (PA) of all devices (weighing platform and service

terminal) in accordance with the country-specic regulations and standards. In the

process, make sure that all device housings are connected to the same potential via

the PA terminals.

Equipotential bonding sizes A /AB

➜ Mount the equipotential bonding clamp (1) on the base frame.

1 Serrated lock washer A 4.3 DIN 6798

2 Hexagonal lock nut M4 DIN 934

3 Base frame

4 Washer 4.3 DIN 125

5 Equipotential bonding clamp

Mounting materials are enclosed with the weighing terminal for hazardous areas.

1

5

3

1

2

4

9

Installation 30233012B PBK9-series

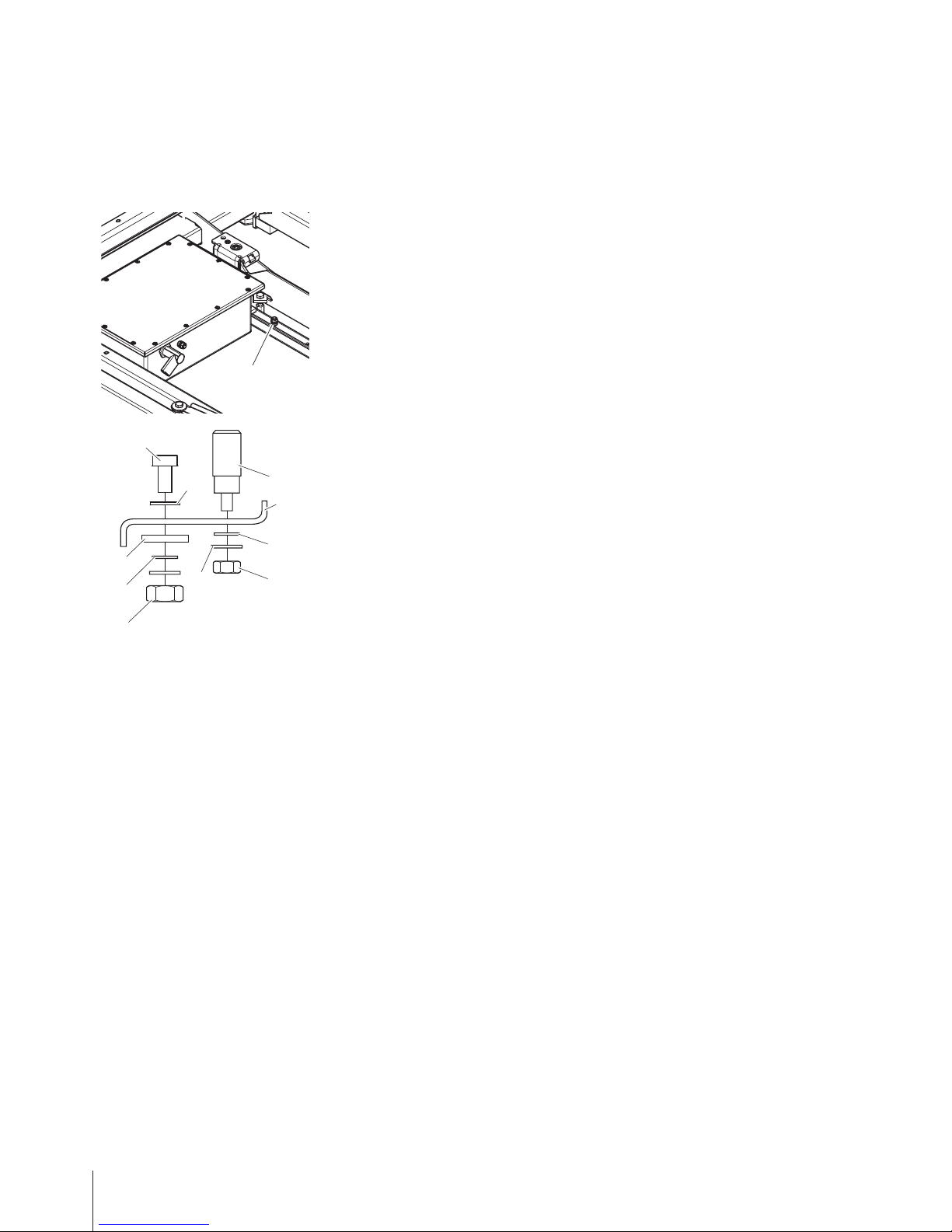

Equipotential bonding sizes B/CC

➜ Mount the equipotential bonding clamp (1) on the base frame.

Mounting materials are enclosed with the weighing terminal for hazardous areas.

1 Serrated lock washer A 4.3 DIN 6798

2 Serrated lock washer A 5.3 DIN 6798

3 Hexagonal lock nut M4 DIN 934

4 Washer 5.3 DIN 125, 2 pcs

5 Cheese head screw M5x16 DIN 912

6 Base frame

7 Hexagonal lock nut M5 DIN 934

8 Washer 4.3 DIN 125

9 Equipotential bonding clamp

10 Equipotential bonding plate

1

9

10

1

3

8

2

6

7

5

4

10

Installation

PBK9-series 30233012B

Loading...

Loading...