Page 1

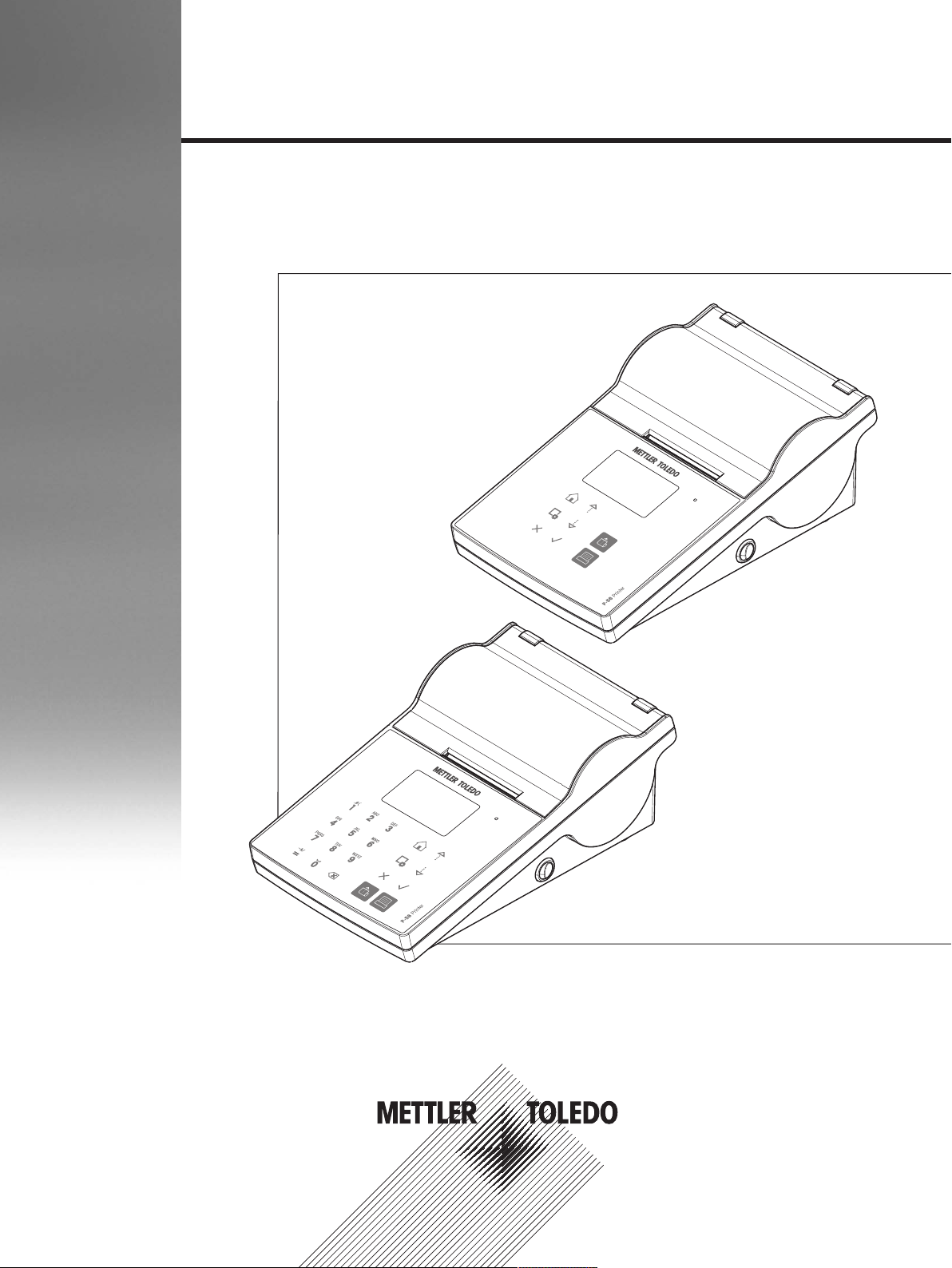

Printer

P-56RUE, P-58RUE

Operating Instructions

Page 2

Page 3

Table of Contents

1 Introduction 3

1.1 Conventions and symbols used in these operating instructions ......................................... 3

2 Safety Information 4

2.1 Definition of signal warnings and symbols...................................................................... 4

2.2 Product specific safety notes ......................................................................................... 4

3 Design and Function 6

3.1 Overview..................................................................................................................... 6

3.2 General keys ............................................................................................................... 7

3.3 Display elements and dialogs ....................................................................................... 8

4 Installation and Putting into Operation 9

4.1 Scope of delivery ......................................................................................................... 9

4.2 Connecting the printer to the power supply...................................................................... 9

4.3 Inserting the paper roll.................................................................................................. 10

4.4 Connecting the printer to a METTLER TOLEDO instrument.................................................. 11

4.5 Connecting the printer to a host computer ....................................................................... 12

4.6 Defining language, date and time .................................................................................. 14

4.7 Printer test................................................................................................................... 14

3.3.1 Basic elements on display ............................................................................. 8

3.3.2 Entry Dialogs................................................................................................ 8

4.4.1 Connecting the printer via the RS232 connection .............................................. 11

4.4.2 Connecting the printer via the USB connection .................................................. 11

4.4.3 Connecting the printer via the Ethernet connection............................................. 12

4.5.1 Installing DirectLabel ..................................................................................... 12

5 Settings 16

5.1 System settings ........................................................................................................... 16

5.1.1 Date / Time .................................................................................................. 16

5.1.2 Language..................................................................................................... 16

5.1.3 Printing........................................................................................................ 16

5.1.4 Display / Audio ............................................................................................. 17

5.1.5 Auto features ................................................................................................ 17

5.1.6 System reset................................................................................................. 17

5.2 Data connection settings............................................................................................... 18

5.2.1 Char set ....................................................................................................... 18

5.2.2 RS232......................................................................................................... 18

5.2.3 Ethernet ....................................................................................................... 18

5.3 Access protection......................................................................................................... 19

5.3.1 Defining the password ................................................................................... 19

5.4 Application settings (only for P-58RUE).......................................................................... 19

5.4.1 Statistics ...................................................................................................... 19

5.4.2 Formulation.................................................................................................. 19

5.4.3 Totaling ....................................................................................................... 20

5.4.4 Labels ......................................................................................................... 20

5.4.4.1 Defining templates................................................................................... 20

6 Applications (only for P-58RUE models) 22

6.1 Statistics..................................................................................................................... 22

6.1.1 Evaluation values.......................................................................................... 22

6.1.2 Functions ..................................................................................................... 22

6.1.3 Performing Statistics...................................................................................... 22

6.2 Formulation................................................................................................................. 23

6.2.1 Evaluation values.......................................................................................... 23

6.2.2 Functions ..................................................................................................... 23

Table of Contents 1Printer

Page 4

6.2.3 Performing Formulation ................................................................................. 23

6.3 Totaling ...................................................................................................................... 23

6.3.1 Evaluation values.......................................................................................... 24

6.3.2 Functions ..................................................................................................... 24

6.3.3 Performing Totaling ....................................................................................... 24

6.4 Labels ........................................................................................................................ 24

6.4.1 Label printing with pre-defined printer templates ............................................... 25

6.4.1.1 Information on templates ......................................................................... 25

6.4.1.2 Label Specifications................................................................................. 25

6.4.1.3 Barcode types......................................................................................... 26

6.4.2 Label printing of user-defined labels designed by PC......................................... 26

7 Maintenance 27

7.1 Replacing the platen roller............................................................................................. 27

7.2 Cleaning the housing ................................................................................................... 28

7.3 Cleaning the printhead and the platen roller .................................................................... 28

7.4 Disposal..................................................................................................................... 29

8 Troubleshooting 30

8.1 Information messages.................................................................................................. 30

8.2 Warning messages...................................................................................................... 31

8.3 Error messages ........................................................................................................... 32

8.4 What to do if…............................................................................................................ 34

9 Technical Data 35

9.1 General technical Data ................................................................................................. 35

9.2 Dimensions................................................................................................................. 37

10 Interface Specifications 38

10.1 RS232C serial port....................................................................................................... 38

10.2 USB device port........................................................................................................... 38

10.3 Ethernet 10/100base-TX RJ45 port................................................................................ 38

11 Accessories and spare parts 39

11.1 Accessories................................................................................................................. 39

11.2 Spare parts ................................................................................................................. 39

11.3 Consumables.............................................................................................................. 40

Index 41

Table of Contents2 Printer

Page 5

1 Introduction

The P-56RUE and P-58RUE are easy-to-handle direct thermal printers for METTLER TOLEDO instruments.

These high-value printers guarantee long-term traceability.

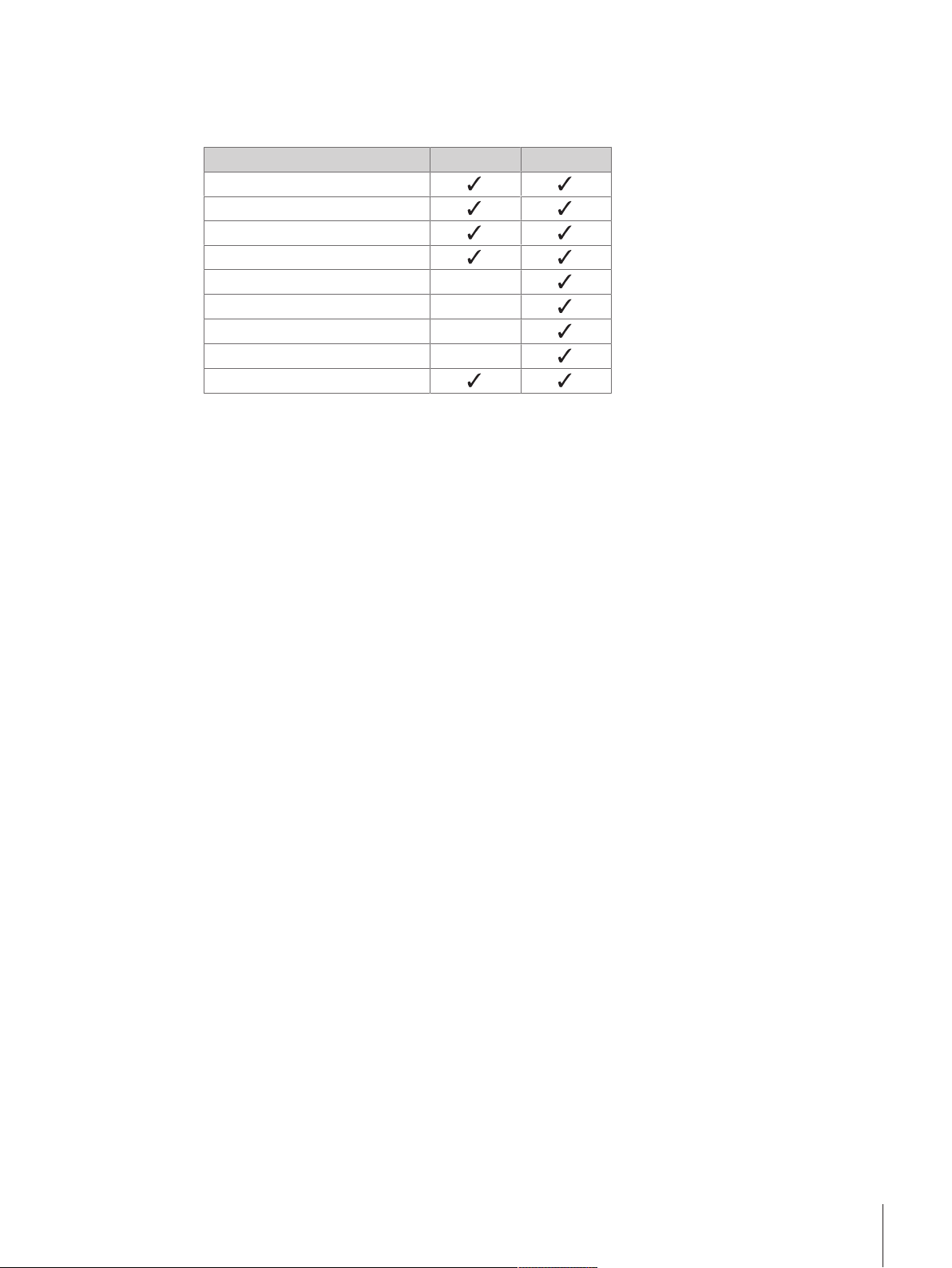

Feature P-56RUE P-58RUE

Auto connection

USB interface

RS232 interface

Ethernet interface

Application Statistics

Application Formulation

Application Totaling

Application Labels

Access Protection

1)

Label printing is possible only from host device e.g. PC.

Software version

These operating instructions are based on the initially installed firmware (software) version V1.04.

Finding more information

—

—

—

—

1)

u www.mt.com/lab-printers

1.1 Conventions and symbols used in these operating instructions

These symbols indicate an instruction:

prerequisites

§

1 steps

2 ...

ð results

Introduction 3Printer

Page 6

2 Safety Information

• Read and understand the information in these Operating Instructions before you use the instrument.

• Keep these Operating Instructions for future reference.

• Include these Operating Instructions if you pass on the instrument to other parties.

If the instrument is not used according to the information in these Operating Instructions or if it is modified,

the safety of the instrument may be impaired and Mettler-Toledo GmbH assumes no liability.

2.1 Definition of signal warnings and symbols

Safety notes are marked with signal words and warning symbols. Ignoring the safety notes may lead to

personal injury, damage to the instrument and malfunctions.

WARNING

for a hazardous situation with medium risk, possibly resulting in death or severe

injury if not avoided.

CAUTION

NOTICE

Note

General hazard Electrical shock Hot surface

for a hazardous situation with low risk, resulting in minor or moderate injury if not

avoided.

for a hazardous situation with low risk, resulting in damage to the instrument, other

material damage, malfunctions and erroneous results, or loss of data.

(no symbol)

for useful information about the product.

2.2 Product specific safety notes

General Safety Information

Your instrument corresponds to the state of the art technology and complies with all recognized safety rules,

however, certain hazards may arise in extraneous circumstances. Do not open the housing of the

instrument: It does not contain any parts which can be maintained, repaired or replaced by the user. If you

ever have problems with your instrument, contact your authorized METTLER TOLEDO dealer or service representative.

This printed document must be read and understood before using the instrument. This printed document

must be retained for future reference.

Always operate and use your instrument only in accordance with the instructions contained in this

document. The instructions for setting up your new instrument must be strictly observed.

If the instrument is not used according to the Operating Instructions, protection of the instrument may

be impaired and METTLER TOLEDO assumes no liability.

The instrument must not be altered or modified in any way. Only use METTLER TOLEDO original spare parts

and accessories.

Safety Notes

WARNING

Risk of electric shock

1 Do not open the AC adapter housing. Make sure that the AC adapter does not come in

contact with liquids.

2 Use only the 3-pin power cable with equipment grounding conductor which was

supplied with your instrument and only a 3-pin grounded outlet must be used.

Safety Information4 Printer

Page 7

NOTICE

Data Loss

Continuous printing can lead to a overheating of the print head. The printing process

stops until the print head has cooled down. During this cooling down phase the printer

must not be switched off, otherwise the buffer data will be lost.

Operating conditions

• The printer must be used in dry interior rooms only.

For the ambient conditions see [General technical Data}Page35].

• The printer should be acclimated to room temperature.

• The printer should not be used in the presence of humidity and liquids.

Safety Information 5Printer

Page 8

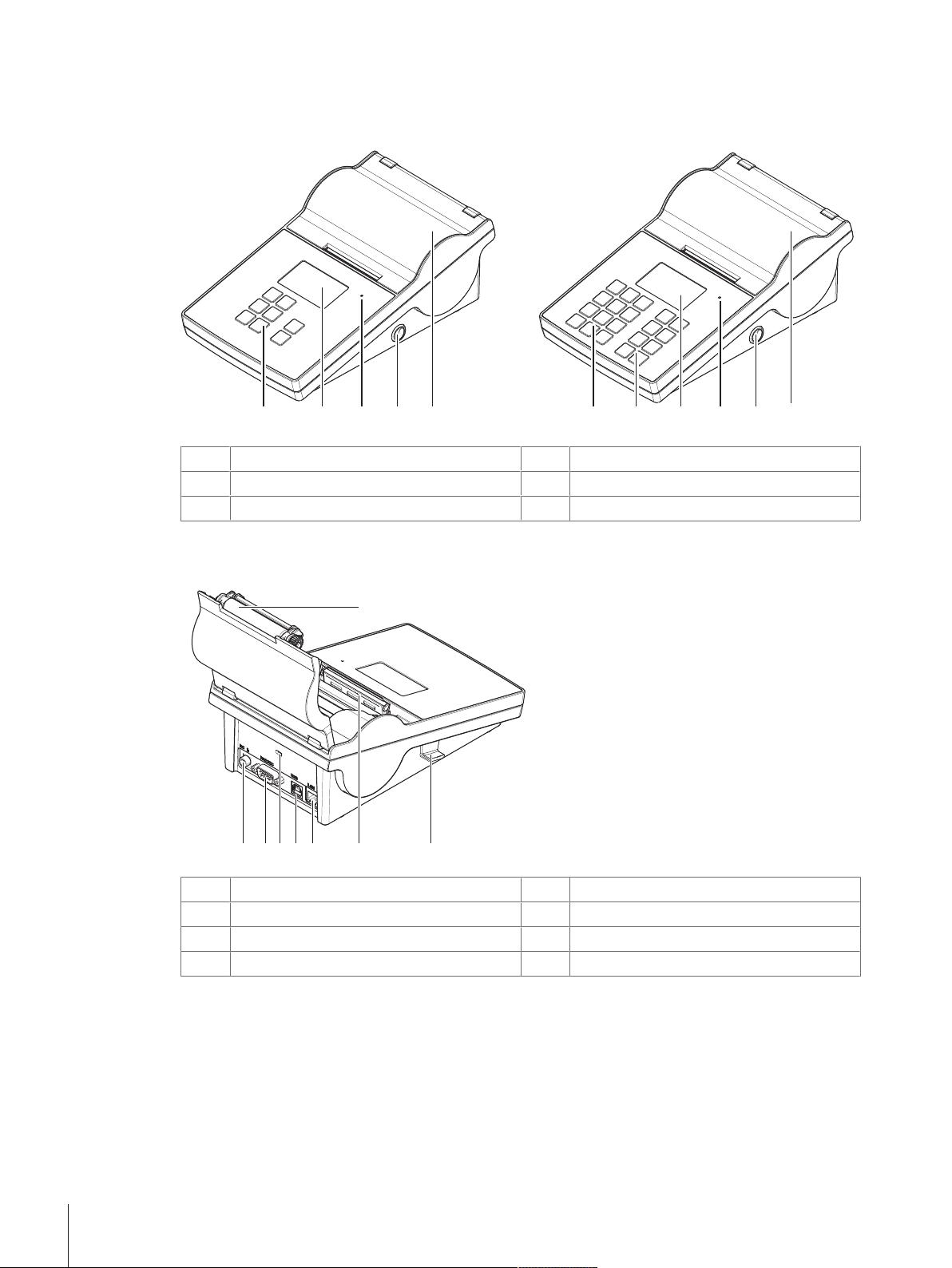

3 Design and Function

P-56RUE P-58RUE

2

3 4 5 6

1

3 4 5 6

2

2 3 4 5 6 7 8

1

3.1 Overview

Alphanumerical keys

1

General control keys

2

Display

3

Platen roller

1

Socket for AC adapter

2

RS232 serial interface (9-pin)

3

Anti-theft slot

4

Triple status indicator

4

Power switch

5

Printer cover

6

USB device connection

5

Ethernet RJ45 connection

6

Thermal printhead

7

Handler to open the printer cover

8

Design and Function6 Printer

Page 9

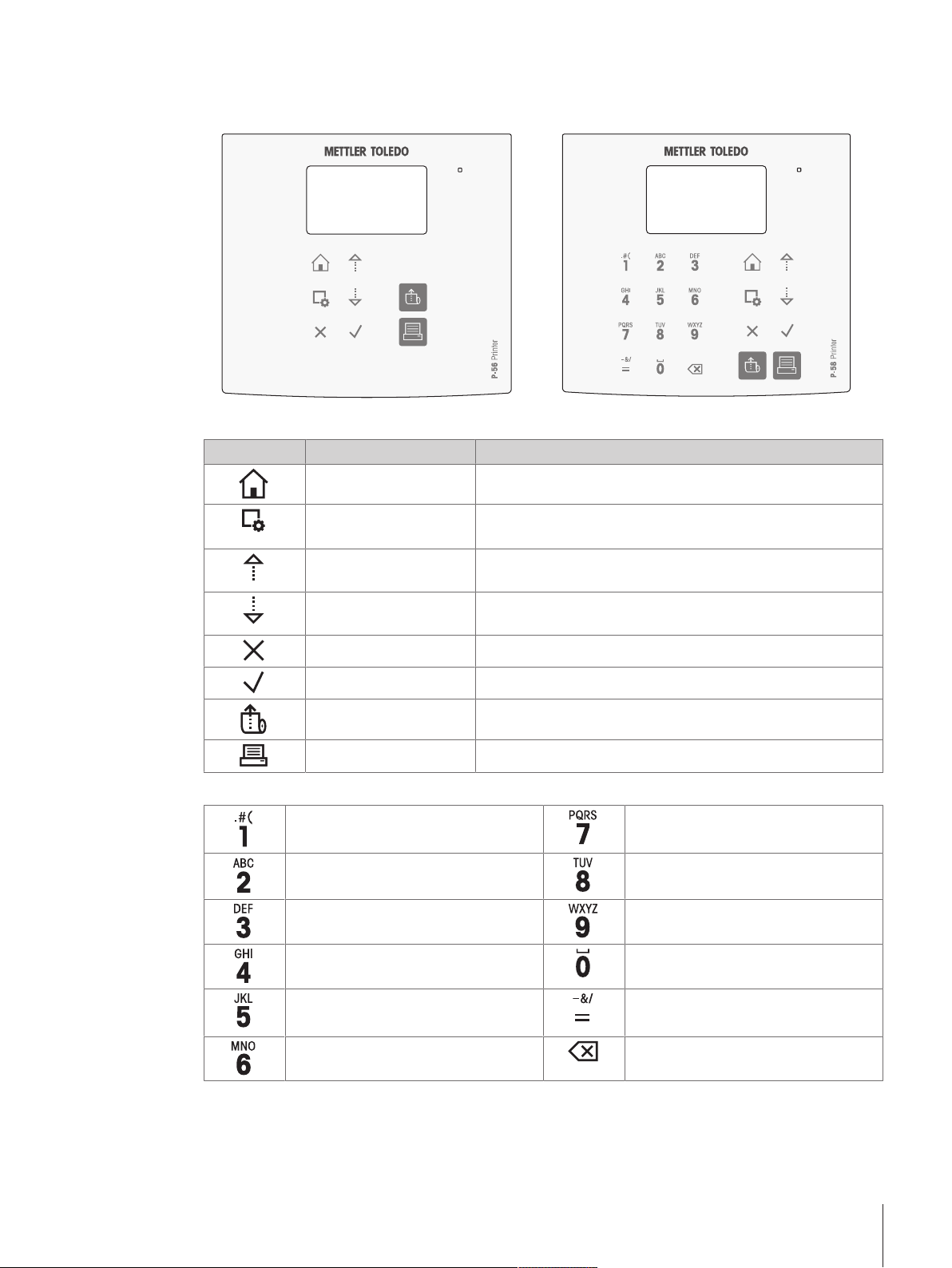

3.2 General keys

General Control keys

P-56RUE P-58RUE

Name Explanation

Home key To return to the printer home screen.

Menu key

Scroll up key To scroll up through a list or to move the curser to the left in a

Scroll down key To scroll down through a list or to move the curser to the right

Cancel key To cancel a running process/application or the last step.

Confirmation key To confirm the current selection.

Paper feed key To feed the paper.

Print key To print parameters or weighing results.

Alphanumerical keys (P-58RUE)

1 . # ( ) , : 7 P Q R S p q r s

2 A B C a b c 8 T U V t u v

3 D E F d e f 9 W X Y Z w x y z

4 G H I g h i 0 ˽

To open the section Settings (P-56RUE).

To open the section Main menu (P-58RUE).

string or number entry screen.

in a string or number entry screen.

5 J K L j k l = - & / + * @ %

Last entry recall of ID

6 M N O m n o Delete key

To delete the last character.

Design and Function 7Printer

Page 10

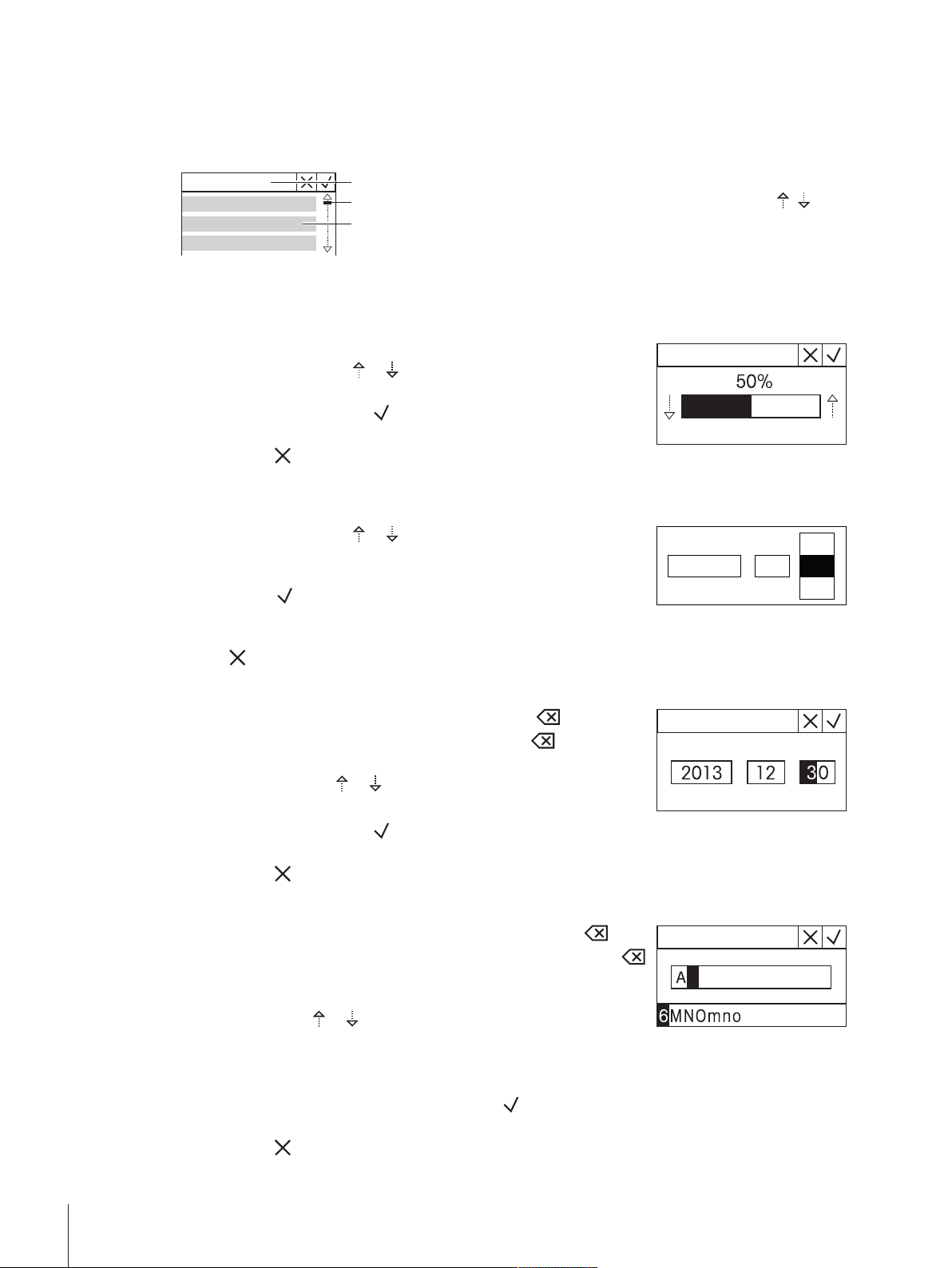

3.3 Display elements and dialogs

1

3

2

31

30

01

MM

122012

YYYY

3.3.1 Basic elements on display

1 Title of menu or selection

2 Scroll display, use the scrolling up and scrolling down keys

3 Settings area

3.3.2 Entry Dialogs

Slider bar

• To increase or decrease the current field value, press the scroll up key

or the scroll down key (

the key.

• Press the confirmation key

• To cancel and for switching back to the last active screen, press the

cancel key

.

Numbers (P-56RUE)

• To increase or decrease the current field value, press the scroll up key

or the scroll down key (

the key.

• To move to the next field when it is not the last field, press the confir-

mation key

. If the current selected field is the last field then the

current valid entry is accepted.

• To cancel and to switch back to the last active screen press the cancel

.

key

or ). Speed up by pressing and holding

to confirm.

or ). Speed up by pressing and holding

, .

Numbers (P-58RUE)

• To remove last character, press briefly the delete key

• To remove all entries, press and hold the delete key

• To move position of blinking cursor by pressing the scroll up key or

the scroll down key (

• Press the numerical keys for entering a value.

• Press the confirmation key

• To cancel and for switching back to the last active screen, press the

cancel key

.

or ).

.

.

.

Alphanumerical strings (P-58RUE)

• To remove a single character, press briefly on the delete key

• To remove a whole character string, press and hold the delete key

.

.

• To move position of blinking cursor, press the scroll up key or the

scroll down key (

• Repeatedly press a numerical key to select the needed character.

or ).

Note

The maximum entry length is 20 characters.

• To confirm an entry, press the confirmation key

• To cancel and to switch back to the last active screen, press the

cancel key

.

.

Design and Function8 Printer

Page 11

4 Installation and Putting into Operation

4.1 Scope of delivery

The following accessories are part of the equipment:

• P-56RUE or P-58RUE thermal printer

• Set of paper rolls

• Universal AC adapter

• Country-specific power cable

• USB cable

• RS232 cable

• User Manual

• Declaration of conformity

• CD-ROM (containing documents in different languages, software and drivers)

4.2 Connecting the printer to the power supply

WARNING

Risk of electric shock

1 Do not open the AC adapter housing. Make sure that the AC adapter does not come in

contact with liquids.

2 Use only the 3-pin power cable with equipment grounding conductor which was

supplied with your instrument and only a 3-pin grounded outlet must be used.

NOTICE

Use only the original AC adapter delivered with your printer.

− Do not try to use this AC adapter for other METTLER TOLEDO instruments, otherwise

they could be damaged.

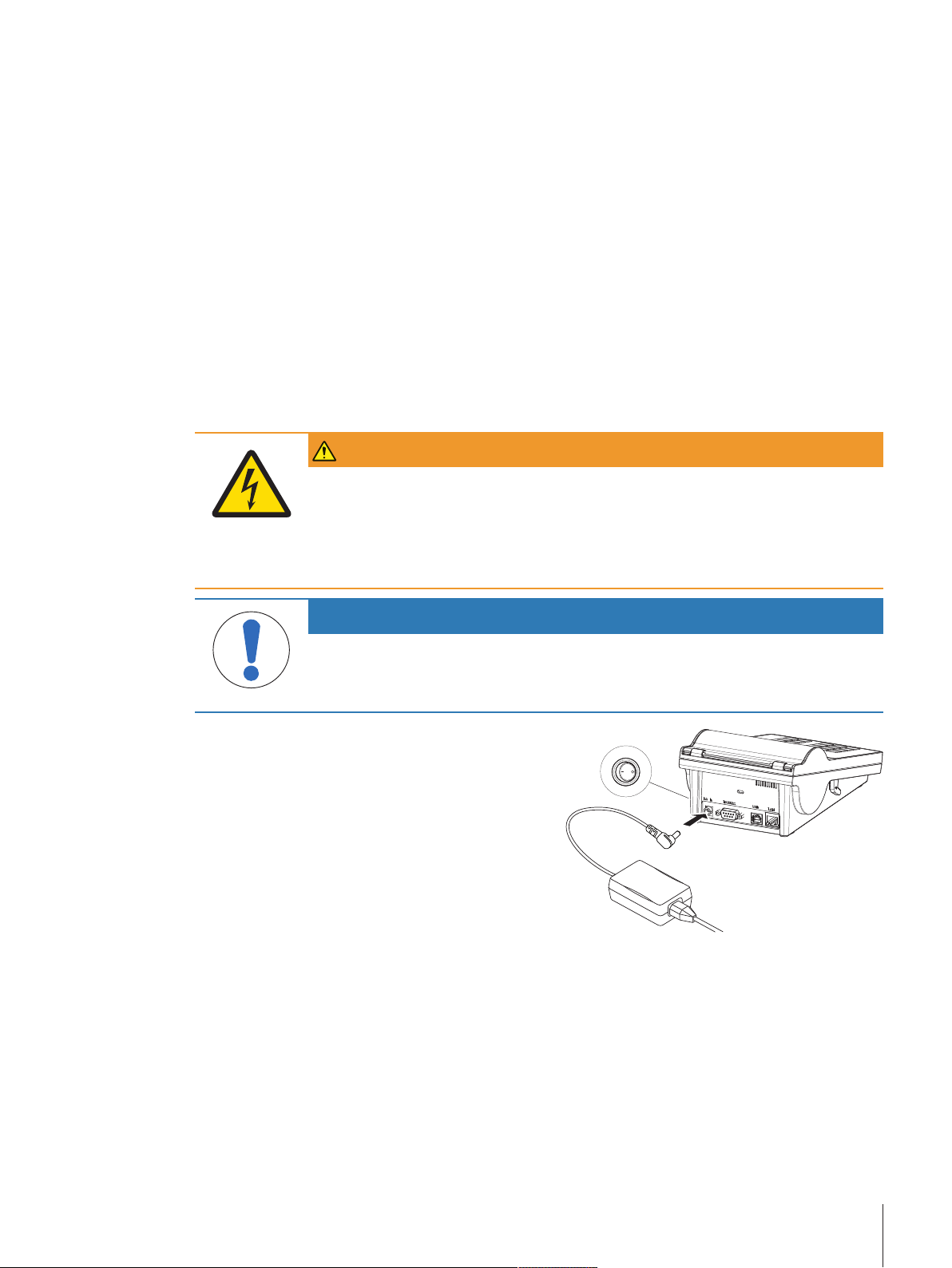

1 Connect the AC adapter to the connection socket on

the back of the printer.

2 Lock the connector with the screw nut.

3 Connect the 3-pin grounded power cable to the

socket for the AC adapter.

4 Connect the power cable to the mains.

5 Switch the printer on.

Installation and Putting into Operation 9Printer

Page 12

4.3 Inserting the paper roll

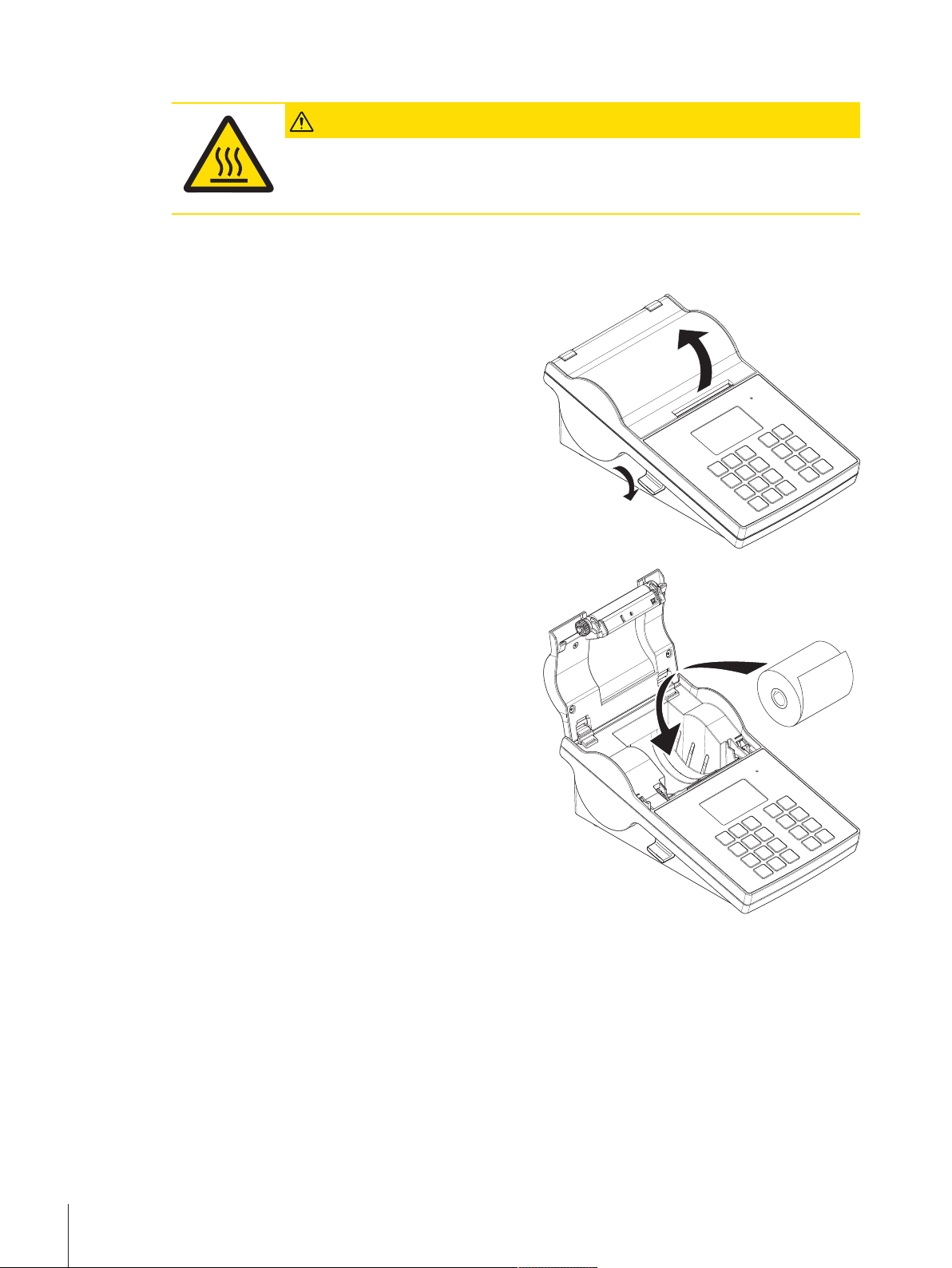

CAUTION

Danger of burns

The thermal printhead is getting hot during the printing process. Wait until the printhead

has cooled down before opening the printer cover.

Note

We recommend to use only specified paper from METTLER TOLEDO, see Accessories and spare parts in the

Operating Instructions.

1 Switch on the printer.

2 Press down the release key.

ð The printer cover opens.

3 Insert the paper roll into the printer frame.

Note

The paper roll must unroll in the correct direction

(see picture).

Installation and Putting into Operation10 Printer

Page 13

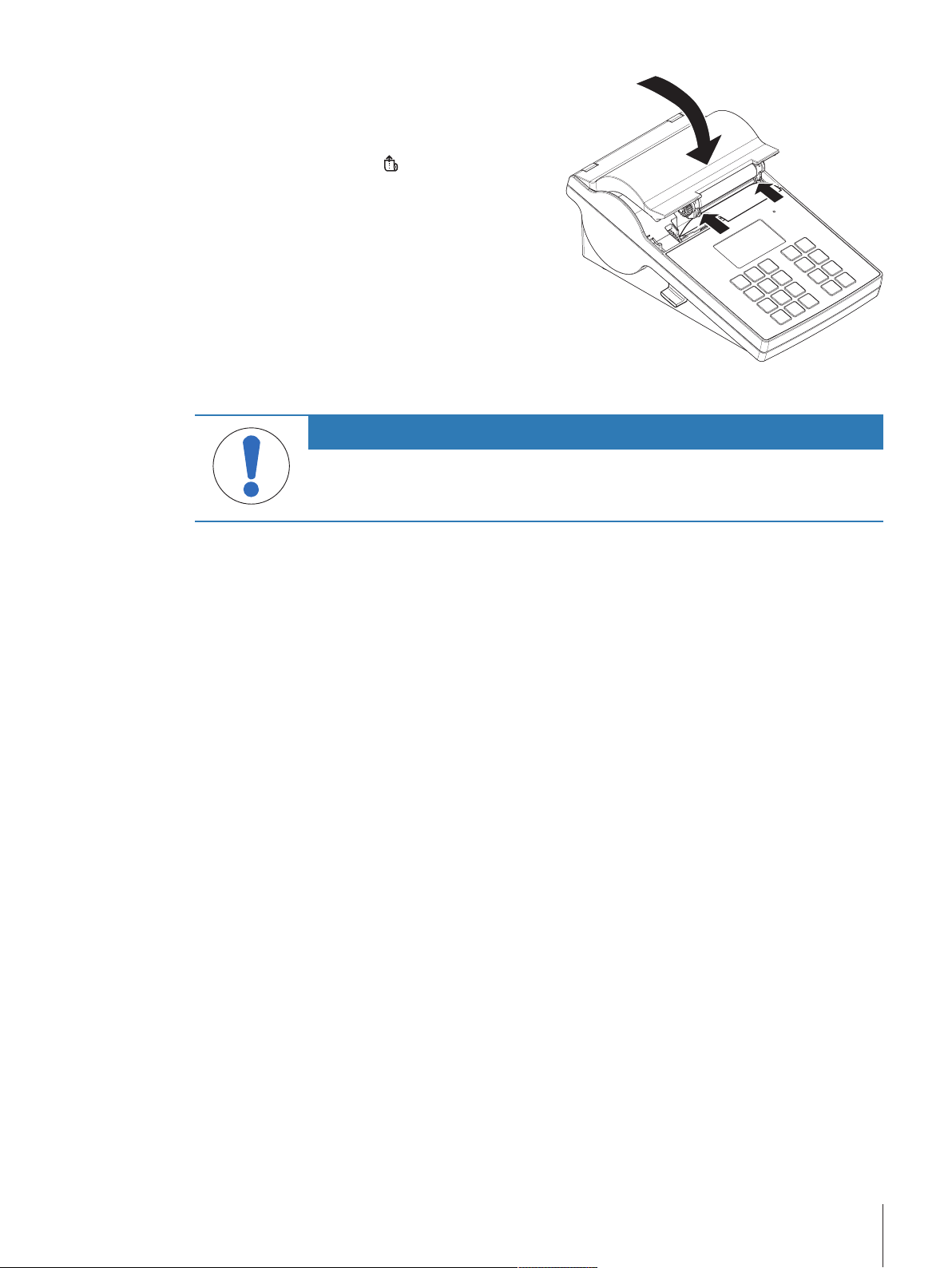

4 Make sure that the paper is in the middle of the

paper guides.

5 Close the printer cover. Firmly press down until it

snaps.

6 Press the paper feed key

to check the paper feed.

4.4 Connecting the printer to a METTLER TOLEDO instrument

NOTICE

We recommend connecting the printer to only one instrument at a time. If several

instruments are connected to the printer at the same time METTLER TOLEDO cannot

assume the correct functionality of the printer.

Note

The printer automatically detects the settings of the connected instrument if the instrument supports this

function.

4.4.1 Connecting the printer via the RS232 connection

1 Connect the printer to the power supply.

2 Use the RS232 cable to connect the printer to the METTLER TOLEDO instrument.

Note

The RS232 connection settings of the printer and of the instrument must be identical.

3 Switch on the printer.

Note

The function Auto connection is switched off by default. It can be switched on if the printer is connected

with the RS232 connection and if the connection settings (Baudrate, Bits / Parity, Handshake) of the

printer differ from the settings of the balance. For more information about activating the function Auto

connection see [RS232}Page18].

Printer default settings

Baudrate: 9600 Stop bits: 1 Bit

Bits / Parity: 8 / None Handshake: XOn/XOff

4.4.2 Connecting the printer via the USB connection

1 Connect the printer to the power supply.

2 Use the USB cable to connect the printer to a METTLER TOLEDO instrument.

3 Switch on the printer.

Note

The system identifies the USB printer automatically. The connected devices can be managed in the

connections settings of the connected METTLER TOLEDO instrument.

Installation and Putting into Operation 11Printer

Page 14

4.4.3 Connecting the printer via the Ethernet connection

1 Connect the printer to the power supply.

2 Use an Ethernet cable to connect the printer directly to a METTLER TOLEDO instrument or indirectly over

the company's Ethernet.

Note

For installation and configuration of the Ethernet interface you need to have basic knowledge of TCP/IPbased networks, and of network technology in general. If necessary, contact the network administrator of

your IT department or your IT support.

4.5 Connecting the printer to a host computer

Note

Before connecting the printer to a PC, the printer driver must be installed first.

Installing the USB driver

1 Go to the site http://www.ftdichip.com/Drivers/VCP.htm

2 Click the windows printer driver (.zip version) or as "setup executable (.exe version).

3 Click save to save it on your specified storage location.

4 Unzip the file if required.

5 Right-click on the *.exe and select Run as Administrator from the menu.

6 Follow the instructions.

ð The installation process was successful, the driver has been installed.

7 Switch off the printer.

8 Connect the printer to the PC with the USB connection.

9 Switch on the printer.

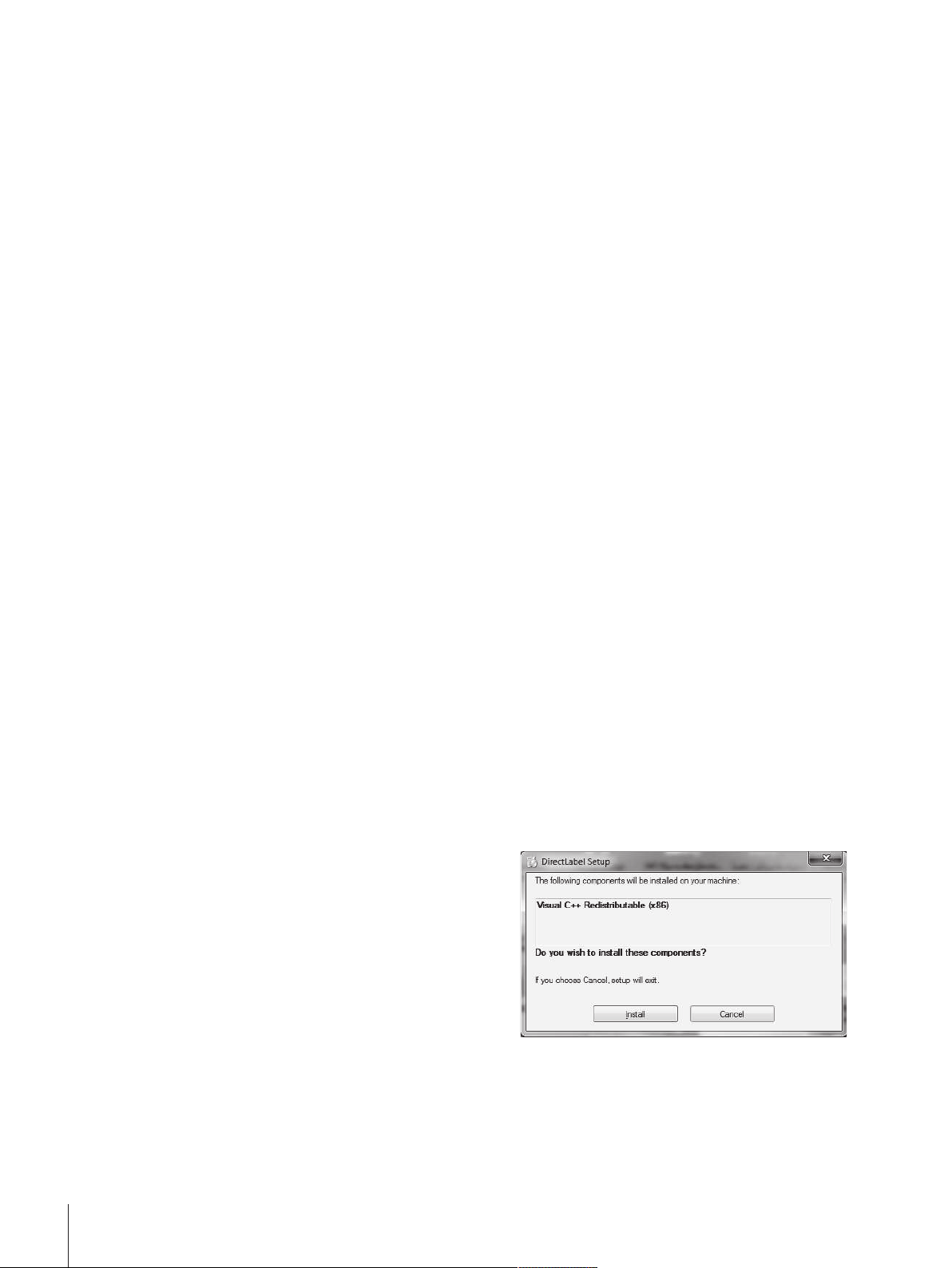

4.5.1 Installing DirectLabel

With the software DirectLabel labels can be individually designed on a PC. The software can be found on

the CD-ROM.

1 Select the DirectLabel software from the CD-

ROM.

2 Save the *.exe file on the local drive.

3 Right-click on the *.exe file, select Run as

Administrator.

4 Follow the installation instructions.

5 Click on Install to install the Visual C++

components.

Installation and Putting into Operation12 Printer

Page 15

6 Follow the instructions in the installation wizard.

7 Click on Next to continue.

8 Select the folder for the program installation.

9 Click on Next to continue.

10 Click on Next to start the installation.

Installation and Putting into Operation 13Printer

Page 16

The software DirectLabel has been successfully

installed.

11 Click on Close to exit.

The software DirectLabel is installed on the host

computer and ready to use.

12 Double click DirectLable icon.

Note

If a Windows security message appears when starting the software, the Windows firewall has blocked the

software. Re-define the firewall rules to unblock the software.

4.6 Defining language, date and time

When using the printer for the first time, we recommend to define the printer language, the current time and

date.

1 Switch on the printer.

ð The message Set language & date / time first! is indicated.

2 Use the scroll keys (

ð Press the confirmation key

3 Chose a date format.

4 Define the date.

5 Chose a time format.

6 Define the time.

ð The language, time and date have been defined.

Note

• These settings are retained even if you disconnect your printer from the power supply.

• Date and time will be changed from a connected instrument if the connected instrument supports date

and time.

• If the connected instrument supports date and time, the menu items are not available.

, ) to chose a language from the list.

.

4.7 Printer test

The printer is equipped with a self-test function. We recommend to use the self-test function regularly to

make sure that the printer is fully operational.

Printing the settings

To print the current settings, the application settings (only for P-58RUE) and the printer firmware settings:

− Switch on the printer while holding the print key

Installation and Putting into Operation14 Printer

.

Page 17

Printing the character table

To print the character table with all fonts and character sets:

− Switch on the printer while holding the paper feed key

.

Printing the character table endlessly

To print the character table with all fonts and character sets:

− Switch on the printer while holding the paper feed key

and the print key .

Note

The character table will be automatically printed until the printer is switched off.

Installation and Putting into Operation 15Printer

Page 18

5 Settings

By pressing the menu key

opens the section Main menu that contains the sub-sections Settings and Applications. For more information about the section Applications see [Applications (only for P-58RUE models)}Page22].

Navigation P-56RUE:

Navigation P-58RUE:

The section Settings does have the following sub-sections:

• System

• Data connection

• Access Protection

• Application (for P-58RUE only)

5.1 System settings

Navigation P-56RUE:

Navigation P-58RUE:

5.1.1 Date / Time

Parameters Explanation Values

Date To set the date. Numerical

Time To set the time. Numerical

Date format To define the date format. D. MMM YY*| MMM

Time format To define the date format. 24:MM*| 12:MM|

* Factory setting

the P-56RUE printer opens directly the section Settings. The P-58RUE printer

Settings

Main menu > Settings

Settings > System

Main menu > Settings > System

DD YY| DD.MM.YY|

MM / DD / YY| YYMM-DD

24.MM| 12.MM

5.1.2 Language

In this section the printer display language can be defined. The following languages can be chosen:

English Pусский

Deutsch 中文

Français 日本語

Italiano 한국어

Español

5.1.3 Printing

Parameters Explanation Values

Darkness To set the darkness of the print. 1 - 100% (80%*)

Speed To set the speed of the printing process.

* Factory setting

High | Medium* | Low

Low (4 inch/second)

Medium (3 inch/second)

Low (2 inch/second)

Settings16 Printer

Page 19

Contents

Parameters Explanation Values

Header To print and to define the header in the print. No header* | Date /

Sample weight To print the sample weight. Off | On*

Signature To print a signature line. Off* | On

* Factory setting

5.1.4 Display / Audio

Parameters Explanation Values

Brightness A control bar to set the display brightness. 1 - 100% (50*)

Contrast A control bar to set the display contrast. 1 - 100% (60*)

Key beep To set the volume of the key beep.

Message beep To set the volume of the message beep.

Off (0 % volume)

Low (33 % volume)

Medium (66% volume)

High (100 % volume)

Off (0 % volume)

Low (33 % volume)

Medium (66% volume)

High (100 % volume)

Time | D / T / Balance

Off | Low | Medium* |

High |

Off | Low | Medium* |

High

* Factory setting

5.1.5 Auto features

Parameters Explanation Values

Standby To switch to standby mode after the preset time. The standby

Backlight To define the time after which the backlight turns automatically

* Factory setting

5.1.6 System reset

Parameters Explanation Values

System reset To reset the printer to factory settings. Yes | No*

* Factory setting

mode can be finished by pressing any key.

off.

Off* | 2 minutes | 5

minutes | 10 minutes |

30 minutes

On* | 30 seconds | 2

minutes | 5 minutes |

10 minutes | 30

minutes

Settings 17Printer

Page 20

5.2 Data connection settings

Navigation P-58RUE:

Navigation P-58RUE:

5.2.1 Char set

Parameters Explanation Values

Char set To chose the character set for printing. The selected character

* Factory setting

5.2.2 RS232

Parameters Explanation Values

Auto connection To automatically detect the settings of the connected device.

Baudrate To select the baudrate. This menu item is only visible when the

Bits / Parity To select the Bits / Parities. This menu item is only visible

Stop bits To select the stop bits. This menu item is only visible when the

Handshake To define the synchronization for the data transfer. This menu

Monitoring To detect the connection status. On* | Off

* Factory setting

Settings > Data connection

Main menu > Settings > Data connection

set must match with the defined printer language.

The connected device must support this function.

option Auto connection is not activated.

when the option Auto connection is not activated.

option Auto connection is not activated.

item is only visible when the option Auto connection is not

activated.

IBM/DOS | IBM/DOS

Cyrillic | IBM/DOS

Japanese | Ansi/Win

Latin 1* | Ansi/Win

Cyrillic | Ansi/Win

Japanese | UTF-8

On | Off*

600 | 1200 | 2400 |

4800 | 9600* |

19200 | 38400 |

57600 | 115200

8 / None* | 7 / None |

7 / Even | 7 / Odd | 7 /

Mark | 7 / Space

1 Bit* | 2 Bits

XOn / XOff* | RTS /

CTS | None

5.2.3 Ethernet

Parameters Explanation Values

DHCP

IP address

Subnet mask To define the subnet within which the ethernet device is

Gateway

Port To define the port number. The connected instruments must

Alias name To define the port number. The connected instruments must

Settings18 Printer

To activate or deactivate the Dynamic Host Configuration

Protocol (DHCP). If this option is activated, all network

parameters assign to this interface automatically.

To define the IP adress of the printer. If the option DHCP is not

activated the system sets the default value 192.168.000.001.

adressable. If the option DHCP is not activated the system sets

the default value 255.255.255.000.

To define the gateway. If the option Auto connection is not

activated the system sets the default value 192.168.000.254.

have the identical port numbers.

have the identical port numbers.

On* | Off

Numerical

(192.168.000.001*)

Numerical

(255.255.255.000*)

Numerical

(192.168.001.000*)

Numerical (9100*)

Numerical (9100*)

Page 21

* Factory setting

5.3 Access protection

With the function Access Protection the settings can be protected with a password to prevent the settings

from unauthorized changes. The password can be defined and changed by the user.

Parameters Explanation Values

Lock To protect the system settings by a password. If the option

Lock is activated, the password must be entered before the

system settings can be accessed.

Password To define a password. The password length is restricted to 12

digits.

* Factory setting

5.3.1 Defining the password

1 Open the section Settings > Access Protection > Password.

2 Enter the old password.

Note

If you define the password for the first time, the default password is 12345678.

3 Enter the new password and press the confirmation key

4 Confirm the new password and press the confirmation key

Note

The new password and the confirmed password must be identical.

On | Off*

Alphanumerical

(12345678*)

.

.

5.4 Application settings (only for P-58RUE)

Navigation:

5.4.1 Statistics

Parameter Explanation

Off*

Input once

Input for each

From balance

* Factory setting

5.4.2 Formulation

Parameter Explanation

Off*

Input once

Input for each

From balance

* Factory setting

Main menu > Settings > Application

No sample ID is prompted.

To prompt the sample ID once when activating the application (max. 20 characters).

To prompt the sample ID every time when requesting the sample weight (max. 20

characters).

To transfer the sample ID from the connected balance, if the balance supports that

feature (max. 20 characters).

No sample ID is prompted.

To prompt the sample ID once when activating the application (max. 20 characters).

To prompt the sample ID every time when requesting the sample weight (max. 20

characters).

To transfer the sample ID from the connected balance, if the balance supports that

feature (max. 20 characters).

Settings 19Printer

Page 22

5.4.3 Totaling

Parameter Explanation

Off*

Input once

Input for each

From balance

* Factory setting

No sample ID is prompted.

To prompt the sample ID once when activating the application (max. 20 characters).

To prompt the sample ID every time when requesting the sample weight (max. 20

characters).

To transfer the sample ID from the connected balance, if the balance supports that

feature (max. 20 characters).

5.4.4 Labels

In this section labels for printing can be defined.

5.4.4.1 Defining templates

5 different templates can be defined. Every template consists of 4 lines and a barcode. The information for

each line can be defined separately. The barcode can be selected from a list. If the information for each line

are not defined, the printer selects default values for each line. Also the number of copies can be defined.

Lines 1 - 4

Parameters Explanation Values

Empty To set an empty line ON| OFF*

Weight To set the weight value with the chosen unit. ON| OFF*

Sample ID

Lot ID

Date / Time To print the current date and time (as defined in the system

Expiry date

Counter To set a counter (10 digits). ON| OFF*

Input once

To prompt the sample ID only once when activating the application Labels.

Input for each

To prompt the sample ID every time when printing the

template.

From balance

To transfer the sample ID from the balance every time when

printing the template.

Input once

To prompt the Lot ID only once when activating the application

Labels.

Input for each

To prompt the Lot ID every time when printing the template.

settings see [Date / Time}Page16]).

Offset

To set a specific number of days.

Fixed Date

To set a specific date.

Input once*| Input for

each| From balance

(max. 20 characters)

Input once*| Input for

each

(max. 20 characters)

ON*| OFF

Offset(30 days*) |

Fixed Date

Note

If no line is defined, the printer sets the following default values: Line 1: Date / Time, Line 2: Sample ID,

Line 3: Weight, Line 4: Empty.

Settings20 Printer

Page 23

Barcode

Parameters Explanation Values

Font To chose a barcode type. For details about the barcode types

see [Labels}Page24].

Code 39 ext. | Code

128 | PDF417 | Aztec

| QR code | Data

matrix

Data To define which data from Line 1-4 are being included in the

barcode.

No | Line 1 | Line 2 |

Line 3 | Line 4 |

Include all

Copies

A specific number of copies can be set by the user (default value: 1 copy).

Design by PC

For the option Design by PC, the DirectLabel software has to be installed and the option has to be activated.

Print templates

With the option Print templates all templates are being printed without real data.

Settings 21Printer

Page 24

6 Applications (only for P-58RUE models)

In this section it is described how to use the applications for the P-58RUE printer.

Navigation:

The P-58RUE printer contains the following applications:

• Statistics

• Formulation

• Totaling

• Labels

6.1 Statistics

With the application Statistics, statistics of weighing values can be generated. 1 to 999 values are

possible.

Navigation:

6.1.1 Evaluation values

• number of samples, n

• average, x

• standard deviation, s

• relative standard deviation, s rel

• sum of all values, Sum

• lowest value (minimum), Min.

• highest value (maximum), Max.

• difference between the minimum and the maximum, Diff

Main menu > Applications

Main menu > Applications > Statistics

6.1.2 Functions

Selection Action

Add sample

Tare

Zero

Sample ID

Display result

Delete last

6.1.3 Performing Statistics

1 Open the application Statistics.

2 Select Continue last to continue the last evaluation.

OR

Select Start new to start a new evaluation.

3 Press the confirmation key

ð Add sample / Tare appears.

4 If you use a container, select Tare.

5 Place the container on the weighing pan and press the confirmation key

6 Select Add sample.

7 Place the first sample and press the confirmation key

ð The stable weight value is displayed, added to the statistics and printed.

Request for adding a sample and printing out of ID and value.

Request for adding a tare.

Request for zeroing the balance.

Entering a sample ID and printing out.

Display of the current result.

Delete of last added sample in memory and printing out.

to confirm.

.

.

Applications (only for P-58RUE models)22 Printer

Page 25

8 Unload sample.

9 To continue, follow the same procedure as for the first sample weight.

10 Press the print key

11 Press the home key

6.2 Formulation

With the application Formulation, 999 individual component weights and container weights can be defined

and printed individually and as a total.

Navigation:

6.2.1 Evaluation values

• number of samples, n

• total sample value, Sum

• total gross value, SumGross

• total tare value, SumTare

6.2.2 Functions

Selection Action

Add sample

Tare

Zero

Sample ID

Display result

Delete last

Main menu > Application > Formulation

for printing results.

or the menu key to exit the application.

Request for adding a sample and printing out of ID and value.

Request for adding a tare and printing out of ID and value.

Request for zeroing the balance.

Entering a sample ID and printing out.

Display of the current result.

Delete of last added sample or tare value in memory and printing out.

6.2.3 Performing Formulation

1 Open the application Formulation.

2 Select Continue last to continue the last evaluation.

OR

Select Start new to start a new evaluation.

3 Press the confirmation key

ð Add sample / Tare / Zero … appears.

4 Select Zero and press the confirmation key

5 If you use a container, select the option Tare.

6 Place the container on the weighing pan and press the confirmation key

7 Select Add sample.

8 Place the first sample and press the confirmation

ð The stable weight value is displayed and printed.

9 Unload sample.

10 To continue, follow the same procedure as for the first sample weight.

11 Press the print key

12 Press the home key

for printing results.

or the menu key to exit the application.

6.3 Totaling

With the application Totaling weighing results can be totaled. 1 to 999 results can be totaled.

Navigation:

Main menu > Application > Totaling

to confirm.

to zero the balance if needed.

.

.

Applications (only for P-58RUE models) 23Printer

Page 26

6.3.1 Evaluation values

• number of samples, n

• sum of all values, Sum

6.3.2 Functions

Selection Action

Add sample

Tare

Zero

Sample ID

Display result

Delete last

6.3.3 Performing Totaling

1 Open the application Totaling.

2 Select the option Continue last to continue the last evaluation.

OR

Select the option Start new to start a new evaluation.

3 Press the confirmation key

ð Add sample / Tare appears.

4 If you use a container, select the option Tare.

5 Place the container on the weighing pan and press the confirmation key

6 Select Add sample.

7 Place the first sample and press the confirmation key

ð The stable weight value is displayed and printed.

8 Unload sample.

9 To continue, follow the same procedure as for the first sample weight.

10 Press the print key

11 Press the home key

Request for adding a sample and printing out of ID and value.

Request for adding a tare and printing out of ID and value.

Request for zeroing the balance.

Entering a sample ID and printing out.

Display of the current result.

Delete of last added sample or tare value in memory and printing out.

to confirm.

.

.

for printing results.

or the menu key to exit the application.

6.4 Labels

With the application Labels predefined label templates can be selected and printed.

Navigation: Main menu

Note

Before using a label it must be defined via Main menu > Settings > Application > Labels. With the application Labels the labels can only be selected but they cannot be edited.

Application Selections Actions

Continue last

Start auto sensing

Applications (only for P-58RUE models)24 Printer

> Application > Labels

Continue with label printing.

Starts gap sensing between the labels

and adjusts them into the correct

position e.g. after changing a roll.

Page 27

Application Selections Actions

xxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxx

1

2

3

4

xxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxx

1

2

3

4

xxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxx

1

2

3

4

2-D

Template 1 Request values and print out Template 1

2…4 2…4

Template 5 Request values and print out Template 5

Design by PC1 Request values and print out Design by

2…9 2…9

Design by PC10 Request values and print out Design by

6.4.1 Label printing with pre-defined printer templates

6.4.1.1 Information on templates

See details below for each template:

Without barcode layout

Print Information Line 1

1

Print Information Line 2

2

Print Information Line 3

3

Print Information Line 4

4

label

label

PC 1 label (only visible if present)

PC 10 label (only visible if present)

With 1-D barcode layout

With 2-D barcode layout

6.4.1.2 Label Specifications

the label templates have fixed sizes according to the labels on the paper roll.

Print Information Line 1

1

Print Information Line 2

2

Print Information Line 3

3

1-D Barcode Line Reserve

4

Print Information Line 1

1

Print Information Line 2

2

Print Information Line 3

3

Print Information Line 4

4

Applications (only for P-58RUE models) 25Printer

Page 28

A

B

C

D

E

6.4.1.3 Barcode types

Code Example Width x height in dots

Code 39 ext. (1-D)

Label width 56mm

A

Label height 18mm

B

Gap between labels

C

Perforation

D

Non adhesive area 10mm

E

432 x 32

Code 128 (1-D)

PDF417 (2-D)

Note

Same layout as 1-D barcode.

Aztec (2-D)

QR code (2-D)

Data matrix (2-D)

6.4.2 Label printing of user-defined labels designed by PC

DirectLabel software

With the DirectLabel software customer-specific labels can be designed and stored with an external host

computer. The software can be found on the CD-ROM. After installing and starting the software, go to the

section Others, chose a language and open the online help. The online help contains information about

how to define costumer-specific labels.

Note

User-defined labels cannot be stored to P-56RUE printers. A host computer is needed to print these labels.

432 x 32

432 x 32

120 x 120

120 x 120

120 x 120

Applications (only for P-58RUE models)26 Printer

Page 29

7 Maintenance

WARNING

Risk of electric shock

1 Before cleaning or performing maintenance work, disconnect the printer and the AC

adapter from the power supply.

2 Take care that no liquid penetrates into the printer or the AC adapter.

NOTICE

Never open the housing of the printer or the AC adapter – they contain no components,

which can be cleaned, repaired or replaced by the user.

Use only the power cable from METTLER TOLEDO.

7.1 Replacing the platen roller

Replace the platen roller if the paper feed does not work correctly and cleaning has no effect.

Removing

Printer is switched-off.

Printer cover is open.

§

1 Pull the two black lock holders (left and

right) outwards for releasing and push

them upwards.

ð Both lock holders are facing up.

2 Remove platen roller.

Inserting

1 Hold the new platen roller as shown on figure 1 and insert it into the holder.

2 Pull the two black lock holders (left and right) outwards and push them downwards until they are

attached (figure 2).

3 Make sure that both black lock holders are in correct position before closing the printer cover.

Maintenance 27Printer

Page 30

Figure 1:

A

B

Figure 2:

7.2 Cleaning the housing

The printer housing is made of top grade, resistant materials. Therefore, all commercially available mild

cleaning agents can be used.

7.3 Cleaning the printhead and the platen roller

CAUTION

Danger of burns

The thermal printhead is getting hot during the printing process. Wait until the printhead

has cooled down before opening the printer cover.

Note

Dirt on the printhead or glue residue from the label may result in inadequate print quality. The printer cover

must therefore always be closed. Keeping dirt and dust away from the paper or labels ensures a good print

quality and a longer lifespan of the print head.

1 Switch-off the printer.

2 Open the printer cover.

3 Remove any label residue or other dirt from the

printhead (A) using a soft lint-free cloth dipped

in alcohol.

4 If necessary, clean the platen roller (B) using a

soft lint-free cloth dipped in alcohol.

Note

• It is suggested to clean the printhead frequently.

• Make sure that there are no metal fragments or

other hard particles on the soft cloth.

Maintenance28 Printer

Page 31

7.4 Disposal

In conformance with the European Directive 2012/19/EU on Waste Electrical and

Electronic Equipment (WEEE) this device may not be disposed of in domestic waste. This

also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment. If you have any questions, please

contact the responsible authority or the distributor from which you purchased this device.

Should this device be passed on to other parties (for private or professional use), the

content of this regulation must also be related.

Thank you for your contribution to environmental protection.

Maintenance 29Printer

Page 32

8 Troubleshooting

Legend

LED

8.1 Information messages

Note

The message appears on the display for 3 seconds or until error is solved. Press

Message Alert Issue Solution

Detecting connection!

Please wait…

Zero is done!

Tare is done!

Data receiving… Green LED

Auto connection

detection canceled!

No connection found!

Printout:

-- No Connection found

– *Please connect

device and switch the

printer off/on. *Alternatively you can change

the settings of the

printer or device.

Printer settings:

Baudrate 9600 Bit/

Parity 8 Bit/None Stop

bit 1 bit Handshake

Xon/Xoff

Set language & date /

time first!

Waiting for stability! Orange LED

Triple status indicator (green, orange, red)

LED on

LED flashing

Beeper voice 5 seconds

Beeper voice twice for 3 seconds

Green LED

— Zero is done! —

— Tare is done! —

— After 90 seconds timeout

Orange LED

Orange LED

Detecting connection! Please wait…

Data receiving… Please wait…

of the message No

connection found or

auto connection was

canceled by pressing

Auto connection failed.

Language, date and time

are not set.

The balance displays

unstable values.

to close the message.

• Set Auto connection to

off.

• Connect the

instrument and switch

.

the printer off/on.

• Set correct printer/

instrument settings.

Set language, date and

time.

Please wait…

Troubleshooting30 Printer

Page 33

8.2 Warning messages

Note

The message appears on the display for 3 seconds or until error is solved. Press

Message Alert Issue Solution

Underload! Orange LED

Overload! Orange LED

Load / Unload! Orange LED

Out of range! Orange LED

No last sample to

Orange LED

delete!

Over heating protection! Red LED

Near end of paper! Orange LED

Firmware updating…

Green LED

Do not switch off!

Date / time not set! Orange LED

When try to

print:

Red LED

Memory error! Orange LED

Balance application error:

underload.

Balance application error: The

weight on the pan exceeds the

weighing capacity of the

balance.

Balance application error: no

variation on the sample

Balance application error:

Sample weight is outside the

allowed range.

Balance application error:

sample value cannot be

deleted from the memory by

pressing

.

Printhead too hot. Continuing

to print may damage the

printhead.

The sensor has detected that

the paper is close to the end.

Firmware update is running. • Do not switch off the printer

• Date and time not set.

• Date and time lost; backup

battery which stores date

and time is empty.

Non-volatile memory and its

data format.

to close the message.

• Check that the weighing

pan is positioned correctly.

• Reduce the weight on the

weighing pan.

• Change sample.

• Unload the pan and load a

new sample weight.

• Only the last stored value

can be deleted.

• Wait a few seconds until

printhead is cooled.

• The paper roll should be

replaced.

while updating.

• Set date and time.

• For charging the built-in

backup battery, we

recommend to connect the

printer to the power supply

and switch on for approximately 24 hours e.g.

– when the printer is

taken into operation for

the first time.

– when the printer was

out of use for a longer

periode.

• Contact your METTLER

TOLEDO representative.

Troubleshooting 31Printer

Page 34

8.3 Error messages

Note

The message appears on the display for 5 seconds or until error is solved. Press

Message Alert Issue Solution

No connection! Red LED

Transmission error! Red LED

Not executable! Orange LED

Action is not allowed! Orange LED

Connection monitor detects no

connection.

Transmission failed. • Check connection.

Balance application error:

Command understood but

currently not executable.

Action not allowed. —

to close the message.

• Check connection.

• Try again later.

• Check the balance.

Barcode print failed! Orange LED

Time out! Orange LED

Memory full! Red LED

Unit change! Orange LED

Buffer overflow! Red LED

Access denied! Orange LED

Wrong password! Orange LED

No match! Orange LED

Wrong setting for barcode in

DirectLabel, e.g. too much

information included for low

resolution.

Action canceled. Waiting time

was longer than 60 seconds.

Tare count is higher than

1000 (Formulation, Totaling,

Statistics).

Balance application error: The

weighing unit on the balance

has been changed during the

application by the user.

During data transmission, the

cache data exceed the

capacity of the buffer.

The buffer has been flushed

and the transmitted data was

lost!

The access to the settings

have been denied by the

system.

The entered password was

wrong.

The new password and the

new confirmed password are

not identical.

• Increase the resolution of

barcode font setting in

DirectLabel.

• Repeat this action.

• Start a new evaluation and

clear the memory.

• Change it back.

• Repeat this action.

• Activate handshake

(Interface setting).

• Reduce baudrate (interface

setting).

• Enter the correct password.

• Enter the correct password.

• Make sure that the new

password and the

confirmed password are

identical.

System errors

Message Alert Problem Solution

Paper run out! Red LED

Out of paper. The printing job

is blocked to protect the print

• Insert a new paper roll.

head but the data are stored.

Paper error! Red LED

• Wrong paper type in use.

• Roll type has been

exchanged.

• Replace the paper/endless

label roll with label roll.

• Start auto sensing (Label

applications).

Troubleshooting32 Printer

Page 35

Message Alert Problem Solution

Cover open! Red LED

Printer cover is open. • Close printer cover.

----- Display Error ----

(Print out)

Keypad error! Please

call service

Red LED

Red LED

Display error. Printer is

blocked.

No keypad detected. Printer is

blocked.

• Please contact METTLER

TOLEDO representative.

• Please contact METTLER

TOLEDO representative.

Troubleshooting 33Printer

Page 36

8.4 What to do if…

Note

If any issue occurs that is not described in this section, please contact your METTLER TOLEDO representative.

Problem Solution

The printer is switched on but

the LEDs do not light up.

The LED lights up red

(ERROR) and printing is interrupted.

The paper roll passes through

the printer but no image is

printed.

The paper roll jams during

printing.

The paper roll does not move

correctly and there is no

printed image on some parts

of the label.

There is no printed image on

part of the paper.

The printed image is

positioned incorrectly.

A label is missed out during

printing.

The printed image is blurred. • Check the darkness setting.

Printer can't connect balance

anymore untill restart balance.

• Check the power supply

• Check whether this is an error in the software settings or the print

commands.

• Check if the used paper roll is suitable.

• Check whether there is a paper jam.

• Check whether the paper roll is finished.

• Check whether the printer cover is closed (the print head is not

positioned correctly).

• Check whether the paper is covering the sensor.

• Make sure that the label roll is loaded the right way up and that it is

suitable material.

• Use the correct power supply (24V).

• Clear the paper jam.

• Clean the print head.

• Clean or replace the platen roller.

• Check whether any label material is stuck to the thermal print head.

• Check whether the starting position has been set incorrectly.

• Check the power supply.

• Check if the platen roller needs cleaning.

• Check if the platen roller needs replacing

• Check the thermal print head for dust or other dirt.

• Check the quality of the paper.

• Check whether there is paper or dust covering the sensor.

• Check whether the paper roll is suitable.

• Make sure that the paper roll is loaded correctly.

• Check the label height.

• Check whether there is dust covering the sensor.

• Check the thermal print head for glue residue or other dirt.

• Switch the printer off and on (restart printer).

Troubleshooting34 Printer

Page 37

9 Technical Data

9.1 General technical Data

Power Supply

AC/DC Adapter: Primary: 100 V - 240 V, ±10%, 50/60 Hz

Secondary: 24 V DC, 2.5 A (with electronic overload protection)

Power supply to the

printer:

Protection and Standards

Overvoltage category II

Degree of pollution 2

Standards for safety and

EMC

Range of application Indoor use only

Environmental Conditions

Height above mean sea

level

Ambient temperature

range

Relative air humidity 20% ~ 80% up to 31°C decreasing linearly to 50% at 40°C, non-condensing

24 V DC, 2.5 A

Declaration of Conformity (part of standard equipment)

up to 4000 m

Operation: 5°C ~ 40°C

Storage: -25°C ~ 60°C

Printer Features

Print technology Direct Thermal

Resolution 8 dots/mm (203 dpi)

Print speed Max. 101.6 mm/s (4 IPS)

Printable width 54 mm (2.12")

Real time clock Date and time

Resident fonts 7 Windows bit map fonts: 6 pt, 7 pt, 10 pt, 12 pt, 24 pt, 16x26, OCR A & B

Barcodes • 1-D Bar codes: Code 39, Code 138

• 2-D Bar codes: PDF417 (layout as 1-D), Datamatrix code, QR code, Aztec

code

Graphics • Support BMP and PCX

• Support ICO, WMF, JPG, EMF file through software

• Support image resize, rotating, mapping and inverse through DirectLabel

software

Interfaces • RS232 port (Male DB 9)

• USB 2.0 device port (B-type)

• Ethernet 10/100base-TX port (Rj-45)

Control Panel • Triple color LED: green, orange or red for status indicating

• 8 tactile keys (P-56RUE), 20 tactile keys (P-58RUE)

Display LCD, backlight, 128 x 64 dots

Display languages English, German, French, Italian, Spanish, Russian, Chinese (simplified),

Japanese, Korean

Technical Data 35Printer

Page 38

Materials

Top housing Die-cast zinc, chromed and plastics (PBT)

Bottom housing Plastics (PBT)

Platen-roller

Media

Width Max. 58 mm (2.28")

Thickness Min. 0.06 mm (0.003") ~ Max. 0.2 mm (0.008")

Roll diameter Max. 60 mm (2.36")

Core diameter 12.7 mm (0.5")

Paper roll wound

Outwards

direction

USB driver

Link http://www.ftdichip.com/Drivers/VCP.htm

Dimension / Weight

Length 220 mm

Height 88 mm

Width 130 mm

Net Weight 1.4 kg, without AC/DC adapter

Technical Data36 Printer

Page 39

9.2 Dimensions

220 mm

130 mm

88 mm

Technical Data 37Printer

Page 40

10 Interface Specifications

15

6

IN

GND

OUT

HAND

SHAKE

IN

DATA

OUT

RxD

TxD

CTS

RTS

10.1 RS232C serial port

Pin No. Function

+12V output control

1

RxD

2

TxD

3

Connect to Pin 6

4

GND

5

Connect to Pin 4

6

RTS

7

CTS

8

Note

The total current to the serial port may not exceed 250 mA.

10.2 USB device port

USB connector type B

Pin No. Function

1

2

3

4

VBUS

D-

D+

GND

10.3 Ethernet 10/100base-TX RJ45 port

RJ45 connector

Pin No. Signal

TX+

TX-

RX+

RX-

1

2

3

4

5

6

7

8

Interface Specifications38 Printer

Page 41

11 Accessories and spare parts

11.1 Accessories

11.2 Spare parts

Bluetooth RS232 serial adapter set ADP-BT-P for wireless

connection between printer and balance. Compatible with

the following balance models (SW V2.20 or higher

required): JP, JS, MS, MS-S, MS-L, ML, MS-TS, ML-T, ME-T,

PHS, PL-E.

• 2 Bluetooth RS232 serial adapter paired (slave/master)

• 1 MT-DB9 male to female connector

• 1 MT-DB9 male to male connector

Bluetooth RS232 serial adapter set for wireless connection

between XPE/XSE/XS balances and P5x printers.

• Paired set of Bluetooth adapters

• RS232 option with 12V power

Anti-theft steel cable 11600361

30086495

30237797

AC/DC adapter (without power cable) 100–240VAC,

50/60Hz, auto switching, 24VDC, 2.5A

Country-specific 3-Pin power cable with grounding

conductor.

Power cable AU 00088751

Power cable BR 30015268

Power cable CH 00087920

Power cable CN 30047293

Power cable DK 00087452

Power cable EU 00087925

Power cable GB 00089405

Power cable IL 00225297

Power cable IN 11600569

Power cable IT 00087457

Power cable JP 11107881

Power cable TH, PE 11107880

Power cable US 00088668

Power cable ZA 00089728

30094772

Accessories and spare parts 39Printer

Page 42

11.3 Consumables

RS9 – RS9 (m/f): connection cable for PC, length = 1 m 11101051

USB (A –B) connection cable, length=1m 30241476

Platen roller 30094770

Thermal labels

Label size: 56mm x 18mm, 6rolls with 550labels per

roll, durability:up to 10 years

Thermal continuous label

58mm, length:13m, 10 rolls, durability: up to 10years

Thermal paper

58mm, length: 27 m, 10rolls, durability: up to 25 years

30094725

30094724

30094723

Accessories and spare parts40 Printer

Page 43

Index

A

Access protection 16, 19

Alphanumerical keys 7

Alphanumerical strings 8

Anti-theft slot 6

Application 16

Formulation 23

Labels 24

Statistics 22

Totaling 23

Application settings 19

Applications 22

Auto connection 11

C

Cancel 7

Cancel key 7

Char set 18

Cleaning printhead 28

Cleaning the housing 28

Confirmation key 7

Connecting to host computer 12

Connecting to the mains 9

Connection

Ethernet 12

RS232 11

Connections

USB 11

Connetion

Host computer 12

D

Darkness 16

Data connection 16

Date 14, 16

Defining the password 19

DirectLabel 12

Disposal 29

Driver installation 12

E

Entering date 8

Entering letters 8

Entering numbers 8

Error Messages 32

Ethernet 12, 18

Ethernet connection 6

F

Features 3

Formulation 23

Performing 23

G

General control keys 6

General safety information 4

H

Home 7

Housing 28

I

Information messages 30

Inserting paper roll 10

Installing direct label 12

K

Key

Alphanumerical 7

Cancel 7

Confirmation 7

Menu 7

Numerical 6

Paper feed 7

Print 7

Scroll down 7

Scroll up 7

L

Labels 20, 24

Language 14

Languages 16

M

Mains 9

Menu 7

Messages 30, 31, 32

N

Numbers 8

Numerical keys 6

P

Paper feed key 7

Paper roll 10

Index 41Printer

Page 44

Password 19

Perfoming Statistics 22

Performing Formulation 23

Performing Totaling 24

Platen roller 27

Platten roller 6

Power supply 9

Print key 7

Printer features 3

Printer menu 7

Printer test 14

Printhead 28

Printing 16

R

Replacing platen roller 27

RS232 18

S

Safety Information 4

Signal words 4

Warning Symbols 4

Scroll down 7

Scroll down key 7

Scroll up 7

Scroll up key 7

Set

Date 14

Language 14

Time 14

Settings 16

Applications 19

Signal words 4

Software version 3

Statistics 22

Performing 22

System 16

System settings 16

V

Version 3

W

Warning messages 31

Warning Symbols 4

T

Time 14, 16

Totaling 23

U

USB 11

USB connection 6

USB driver 12

Index42 Printer

Page 45

Page 46

Mettler-Toledo GmbH

30096749

Im Langacher 44

8606 Greifensee, Switzerland

www.mt.com/contact

Subject to technical changes.

© Mettler-Toledo GmbH 03/2017

30096749C en

www.mt.com/lab-printers

For more information

Loading...

Loading...