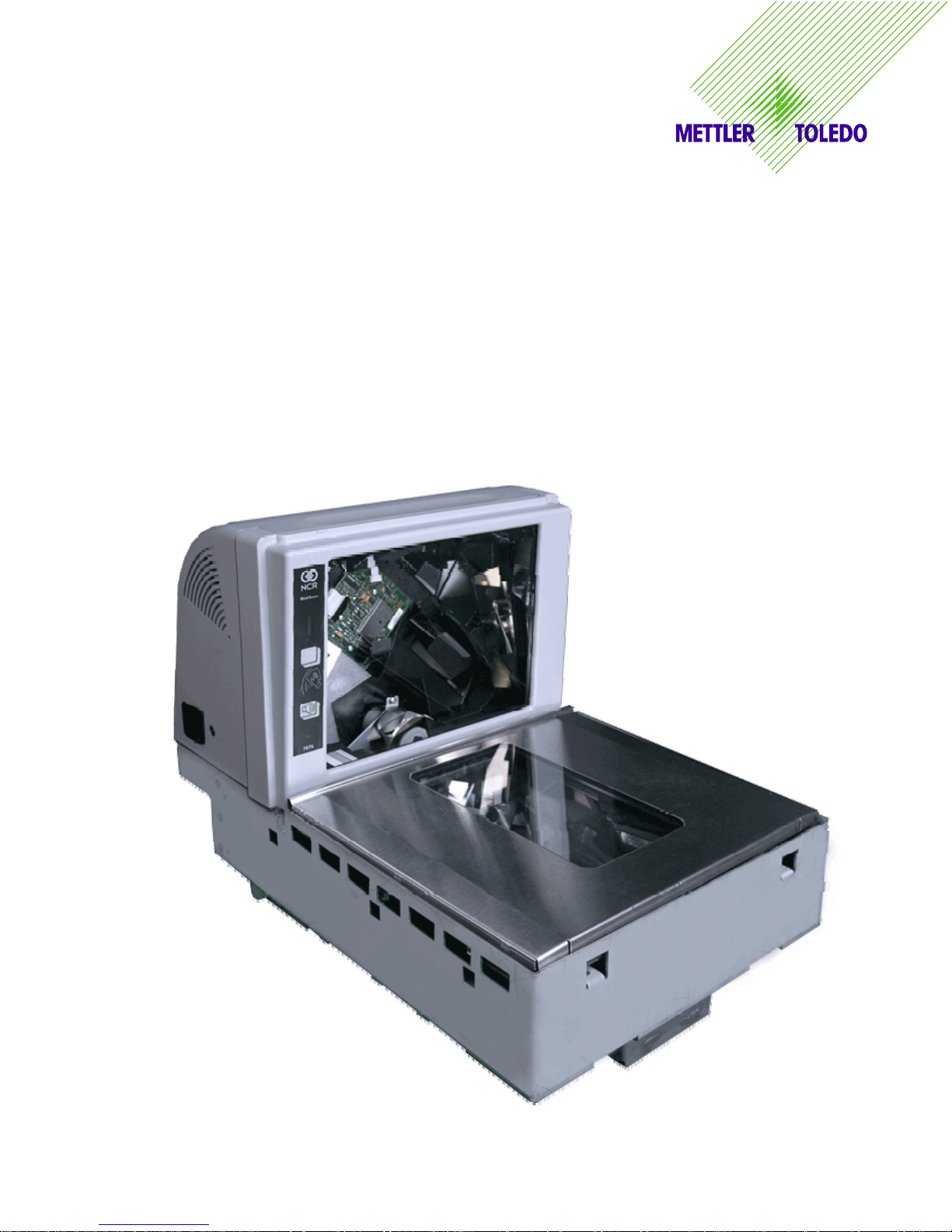

Mettler Toledo NCR RealScan 7876 Service Manual

METTLER TOLEDO

DIVA Service Manual

NCR RealScan 7876 Scanner

72191202 (05/2012) 0.0

INTRODUCTION

This publication is provided solely as a guide for individuals who have purchased the

METTLER TOLEDO Diva scale product.

Information regarding METTLER TOLEDO Technical Training may be obtained by writing to:

METTLER TOLEDO

1900 Polaris Parkway

Columbus, Ohio 43240-2020

(614) 438-4511

©

Mettler-Toledo, LLC 2012

No part of this manual may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose without

the express written permission of Mettler-Toledo, LLC.

U.S. Government Restricted Rights: This documentation is furnished with Restricted Rights.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE REFINEMENTS

OR CHANGES WITHOUT NOTICE.

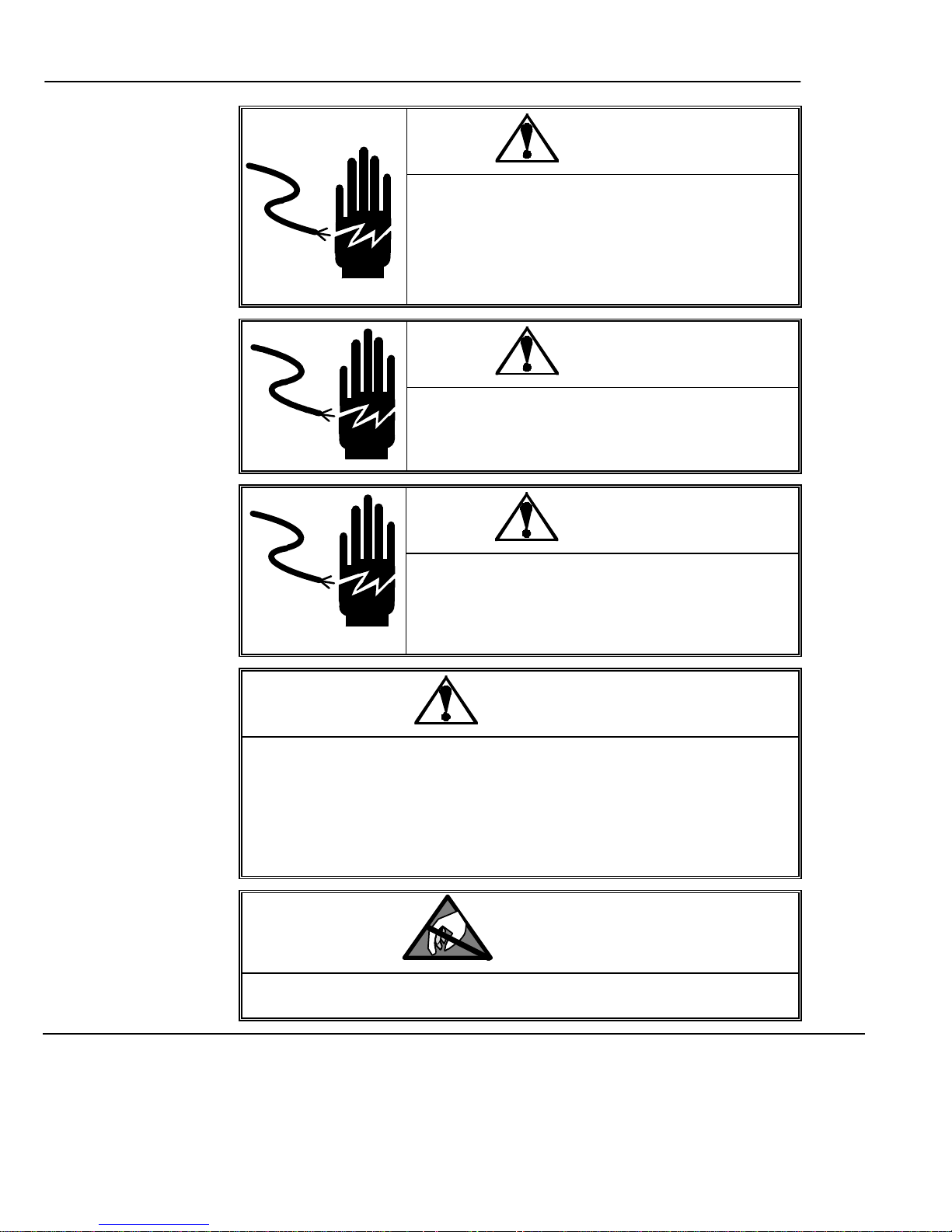

Precautions

ONLY PERMIT QUALIFIED PERSONNEL TO

SERVICE THIS EQUIPMENT. EXERCISE

CARE WHEN MAKING CHECKS, TESTS AND

ADJUSTMENTS THAT MUST BE MADE WITH

POWER ON. FAILING TO OBSERVE THESE

PRECAUTIONS CAN RESULT IN BODILY

HARM.

WARNING

WARNING

FOR CONTINUED PROTECTION AGAINST

SHOCK HAZARD CONNECT TO PROPERLY

GROUNDED OUTLET ONLY. DO NOT

REMOVE THE GROUND PRONG.

WARNING

DISCONNECT ALL POWER TO THIS UNIT

BEFORE REMOVING THE FUSE OR

SERVICING. FAILURE TO DO SO MAY

RESULT IN BODILY INJURY OR PROPERTY

DAMAGE.

CAUTION

BEFORE CONNECTING/DISCONNECTING ANY INTERNAL

ELECTRONIC COMPONENTS OR INTERCONNECTING WIRING

BETWEEN ELECTRONIC EQUIPMENT ALWAYS REMOVE POWER

AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DIS-CONNECTIONS ARE MADE. FAILURE TO

OBSERVE THESE PRECAUTIONS COULD RESULT IN DAMAGE TO

OR DESTRUCTION OF THE EQUIPMENT OR BODILY HARM.

CAUTION

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC

SENSITIVE DEVICES.

Contents

1 INTRODUCTION ..................................................................................................................................................................... 1

1.1 RELIABILITY ........................................................................................................................................................................ 1

1.2 STANDARD FEATURES .......................................................................................................................................................... 1

1.3 PHYSICAL DIMENSIONS ........................................................................................................................................................ 2

1.4 POWER REQUIREMENTS ....................................................................................................................................................... 3

1.5 TEMPERA TURE AND HUMIDITY ............................................................................................................................................. 3

1.6 WEIGHTS AND MEASURES APPROVAL .................................................................................................................................. 3

1.7 OPTION ................................................................................................................................................................................ 3

2 INST ALLA TION ....................................................................................................................................................................... 6

2.1 PRECAUTIONS ...................................................................................................................................................................... 6

2.2 CONTENTS OF PACKAGING ................................................................................................................................................... 6

2.3 SETUP ................................................................................................................................................................................... 6

2.4 POWER UP SEQUENCE ........................................................................................................................................................... 7

2.5 SEALING ............................................................................................................................................................................... 8

3 SET -UP AND CALIBRA TION ............................................................................................................................................... 10

3.1 SERVICE SETUP MODE: ........................................................................................................................................................ 10

3.2 MASTER SETUP MODE:........................................................................................................................................................ 11

3.3 SET UP SOFT SWITCH AND DEFAULT TABLE ........................................................................................................................ 12

3.4 COUNTRY DEFAULTS .......................................................................................................................................................... 14

3.5 GEOCAL

3.6 GEOCAL USA STATE LOCATION CODES ........................................................................................................................... 16

3.7 CALIBRATION ..................................................................................................................................................................... 18

COUNTRY CODES ............................................................................................................................................... 15

4 OPERATING INSTRUCTIONS ............................................................................................................................................ 20

4.1 DISPLAYS ........................................................................................................................................................................... 20

4.2 KEYBOARD ........................................................................................................................................................................ 21

4.3 CURSORS ............................................................................................................................................................................ 21

4.4 OPERATIONS ....................................................................................................................................................................... 22

4.4.1 Weighing and Communication .................................................................................................................................. 22

4.4.2 Backlight function ..................................................................................................................................................... 22

4.4.3 Re-zero Functions ..................................................................................................................................................... 22

4.4.4 Tare Function ............................................................................................................................................................ 22

5 SERVICE AND MAINTENANCE ......................................................................................................................................... 23

5.1 CLEANING AND REGULAR MAINTENANCE ......................................................................................................................... 23

5.2 TROUBLESHOOTING ........................................................................................................................................................... 24

5.3 CONNECTIONS TO A POS .................................................................................................................................................... 24

5.3.1 Communications Pinout ............................................................................................................................................ 24

5.3.2 Handshaking ............................................................................................................................................................. 25

5.4 PARTS AND DESCRIPTIONS .................................................................................................................................................. 26

5.5 REPLACEMENT PARTS ORDER NUMBERS ............................................................................................................................ 28

6 APPENDIX ............................................................................................................................................................................... 30

6.1 PROTOCOLS ........................................................................................................................................................................ 30

6.1.1 NCI – ECR ................................................................................................................................................................ 31

6.1.3 8217 Mettler Toledo .................................................................................................................................................. 36

6.1.4 8213 Mettler Toledo .................................................................................................................................................. 41

6.1.5 EPOS 1 ...................................................................................................................................................................... 45

6.1.6 EPOS 2 ...................................................................................................................................................................... 47

6.1.8 Dialog 06 .................................................................................................................................................................. 50

6.1.9 Dialog 04 / 02 ........................................................................................................................................................... 55

6.1.11 ICL ............................................................................................................................................................................ 59

DIVA Service Manual

3

METTLER TOLEDO

1 Introduction

The DIVA is designed to mount on the NCR RealScan 7876 Bioptic Scanners and communicate with

ECR and POS systems for weighing needs.

1.1 Reliability

The DIVA is developed, produced, and tested in a Mettler Toledo facility that has been audited and

registered according to international ISO 9001 quality standards and ISO 14000 environment control

program.

1.2 Standard Features

Capacity: 6x0.002kg;15 x 0.005kg – both single and dual ranges

15x0.005lb; 30x0.01lb – both single and dual ranges

Platter: Stainless Steel: 260 x 280mm

Tower Display: LCD with backlight, Single Line for Weight Only applications and a Four Line

for Price Computing applications

LCD: 13.5mm high character weight (5 digits); unit price (6 digits); total price (6 digits).

Keyboard: two keys, with tactile and tone feedback when pressing the key.

Power supply: Power provided via connection with the scanner.

A sealable Setup and Calibration Software switch

Basic functions: Zero; Tare

RS-232 interface

DIVA Service Manual

1

METTLER TOLEDO

1.3 Physical Dimensions

The dimensions of the scale with tower is as follows:

DIVA Service Manual

2

METTLER TOLEDO

1.4 Power Requirements

Power is supplied via a Y-cable connected to the Scanner power supply.

1.5 Temperature and Humidity

Working temperature range: -10 to +40 oC (+14 to +114F) at 10 to 85% humidity, non-condensing.

o

Storage temperature range: from -25 to +50

C at 10 to 85% humidity, non-condensing.

1.6 Weights and Measures Approval

EC Type-approval Certificate: T6941

EC Test Certicate: TC6942 (when the scale is used without the Mettler-Toledo displays)

NTEP: Certificate of Conformance Number 06-024

Canadian Approval: AM# 5591

1.7 Option

Remote display bracket

Dual Display

DIVA Service Manual

3

METTLER TOLEDO

year

Mettler-Toledo (ChangZhou) Scale & System Ltd.

Legal Metrology

Declaration of Conformity

Konformitätserklärung

Déclaration de conformité

Declaración de Conformidad

Conformiteitsverklaring

Dichiarazione di conformità

We/Wir/Nous/Nosotros/Noi

Mettler-Toledo (ChangZhou) Scale & System Ltd.

111 ChangXi Road, ChangZhou, JiangSu, 213001, P.R.China

declare under our sole responsibility that the product,

erklären, in alleiniger Verantwortung, dass dieses Produkt,

déclarons sous notre seule responsabilité que le produit,

declaramos, bajo nuestra sola responsabilidad, que el producto,

verklaren onder onze verantwoordelijkheid, dat het product,

dichiariamo sotto nostra unica responsabilitá, che il prodotto,

Model/Type: DIVA

To which this declaration relates , is in conformity with the following standard(s) or other normative document(s),

auf das sich diese Erklärung bezieht, mit der/den folgenden Norm(en) oder Richtlinie(n) übereinstimmt.

Auquel se réfère cette déclaration est conforme à la (aux) norme(s) ou au(x) document(s) normatif(s).

Al que se refiere esta declaración es conforme a la(s) norma(s) u otro(s) documento(s) normativo(s).

Waarnaar deze verklaring verwijst, aan de volende norm(en) of richtlijn(en) beantwoordt.

A cui si riferisce questa dichiarazione è conforme alla/e sequente/i norma/e o documento/i normativo/i.

EC Marking EC Directive: Applicable Standards:

73/23/EEC

Low Voltage Directive

EN60950

EN61326:1997+A1+A2 (Class

89/336/EEC

EMC Directive

B)

EN61000-3-2

EN61000-3-3

For non-automatic weighing instrument used in an Article 1,2.(a) application ,additional

metrological marking according to Annex IV of Council Directive 90/384/EEC must be attached

to the instrument

0103

90/384/EEC

Non-automatic

Weighing Instruments

EN45501 1)

Directive

1) valid only for “DIVA” base in connection with approved terminal.

zulässig nur für“DIVA” Waage zusammen mit zugelassenem Terminal

valid only for la base “DIVA” dans connection with approved le terminal

válido solamente para la base “DIVA” en la conexión con el terminal aprobado.

valido soltanto per la base “DIVA” in relazione al terminale approvato.

ChangZhou, April 2006

Mettler-Toledo (ChangZhou) Scale & System Ltd.

Yang JiaWu, Quality Assurance Manager

DIVA Service Manual

4

METTLER TOLEDO

Important notice for verified weighing instruments

Weighing Instruments verified at the place of manufacture bear the preceding mark on the packing label

M M

M M

The first step of the verification has been carried out at the manufacturing plant. It comprises all tests according to EN 45501-8.2.2.

If national regulations in individual countries limit the period of validity of the certification, the operator of such a scale is himself

responsible for its timely re-certification.

and a green “M” sticker on the descriptive plate. They may be set to work immediately.

Weighing Instruments which are verified in two steps have no green “M” on the descriptive plate and bear

the preceding identification mark on the packing label. The second step of the verification must be carried

out by the approved Mettler-Toledo service or by the W&M authorities. Please contact your Mettler-Toledo

organization.

Wichtiger Vermerk für geeichte Wägeinstrumente in EU-Ländern

Werksgeeichte Waagen tragen vorstehendes Kennzeichen auf dem Packetikett und einen grünen

M M

M M

Der erste Schritt der Eichung wurde im Herstellerwerk durchgeführt. Er umfasst alle Prüfungen gemäß EN45501-8.2.2.

Sofern gemäß den nationalen Vorschriften in den einzelnen Staaten die Gültigkeitsdauer der Eichung beschränkt ist, ist der Betreiber

einer solchen Waage für die rechtzeitige Nacheichung selbst verantwortlich.

“M”-Kleber auf dem Eichschild. Sie dürfen sofort in Betrieb genommen werden.

Waagen, die in zwei Schritten geeicht werden und kein grünes “M” auf dem Eichschild haben, tragen

vorstehendes Kennzeichen auf dem Packetikett. Der zweite Schritt der Eichung ist durch den behördlich

anerkannten Mettler-Toledo Kundendienst oder durch den Eichbeamten durchzuführen. Bitte nehmen Sie

mit dem Mettler-Toledo Kundendienst Kontakt auf.

Remarque Importante pour les Instruments de pesages vérifiés dans les pays membre de l’Union Européenne

Les instruments de pesage vérifiés en usine portent l‘identification ci-contre sur leur emballage et un

M M

M M

La première étape de la vérification a été effectuée en usine. Cela comprend tous les essais suivant la norme EN45501-8.2.2.

Dans la mesure où la durée de la vérification est limitée en fonction des prescriptions nationales dans les différents pays, l’utilisateur

d’une telle balance est lui-même responsable de la vérification ultérieure dans les délais.

Nota importante para básculas verificadas en paises de la UE

M M

M M

La primera fase de la verificación ha sido realizada en origen. Incluye todos los ensayos según lo norma EN45501-8.2.2.

Si el plazo de validez de la verificación está limitado por las normas nacionales de cada estado, el usuario será responsable de las

verificaciones posteriores reglamentarias de su balanza.

autocollant “M“ vert sur la plaque d’identification. Ils peuvent être utilisés après leur installation.

Les instruments de pesage vérifiés en deux étapes portent l’identification ci-contre sur leur emballage et

n’ont pas d’autocollant “M“ vert sur la plaque d’identification. La seconde étape de la vérification doit être

effectuée par le service technique Mettler-Toledo autorisé responsable. Veuillez s.v.p. contacter le service

technique Mettler-Toledo.

Las balanzas verificadas en origen llevan esta indicación en la etiqueta del embalaje y con la etiqueta

“M“ sobre londo verde en la placa de caracteristicas pueden ser utilizadas inmediatamente.

Balanzas cuya verificación se realiza en dos fases llevan esta indicación en la etiqueta del embalaje

(ninguna etiqueta “M“ verde en la placa de caracteristicas). La segunda fase de la verificación debe ser

realizada por personal Mettler-Toledo acreditado, o por la autoridad competente. Rogamos contacten con

el Servicio Técnico de Mettler-Toledo.

Nota Importante per la balance approvate nei paesi UE

Le balance verificate in fabbrica portano questo contrassegno sull’etichetta dell’imballo e con il sigillo “M”

M M

M M

La prima fase della verifica è stata eseguila dal produttore e comprende lutte le prove previste dalla norma EN 45501-8.2.2.

Se la durota di validità della verifica è limitata in accordo con le prescrizioni nazionali vigenti nei singoli paesi, I’utilizzatore stesso di

una bilancia di tale tipa sorà responsabile dell’esecuzione, entro le date di scadenza previsle, delle verifiche periodiche.

su stando verde sulla targhetta metrological possono essere messe in uso immediatamente.

Le balance che vengono verificate in due fasi, portano questo contrassegno sull’etichetta dell’imballo e non

portano il sigillo “M” sulla targhetta metrological. La seconda fase delia verifica dev’essere eseguita dal

servizio assistenza Mettler-Toledo autorizzato, oppure dalla autorità competente. Prego contaltare il vostro

servizio assistenza Mettler-Toledo.

DIVA Service Manual

5

METTLER TOLEDO

A

2 Installation

2.1 Precautions

Before you install your DIVA scale, keep in mind the following factors, which might have a negative

influence on the scale's operation:

Vibration diminishes the scale’s ability to measure accurately. Excessive vibration from

equipment such as conveyors can cause inaccurate and non-repeatable readings.

Be sure the scale is leveled properly.

Air currents can also diminish a scales performance. Avoid placing the scale in front of or

directly under air vents.

Other than items being weighed, keep the scale free from objects rubbing or pressing against

the platter.

2.2 Contents of Packaging

Package contents for all DIVA units include:

DIVA scale base

Operation manual

Display Cable

Tower included and attachment hardware (The optional display may be packed separately)

Sealing Kit

2.3 Setup

1. Open the box, carefully remove the packing material, take all items out of the carton.

2. Attach the display as described below, depending on which version of scale you ordered:

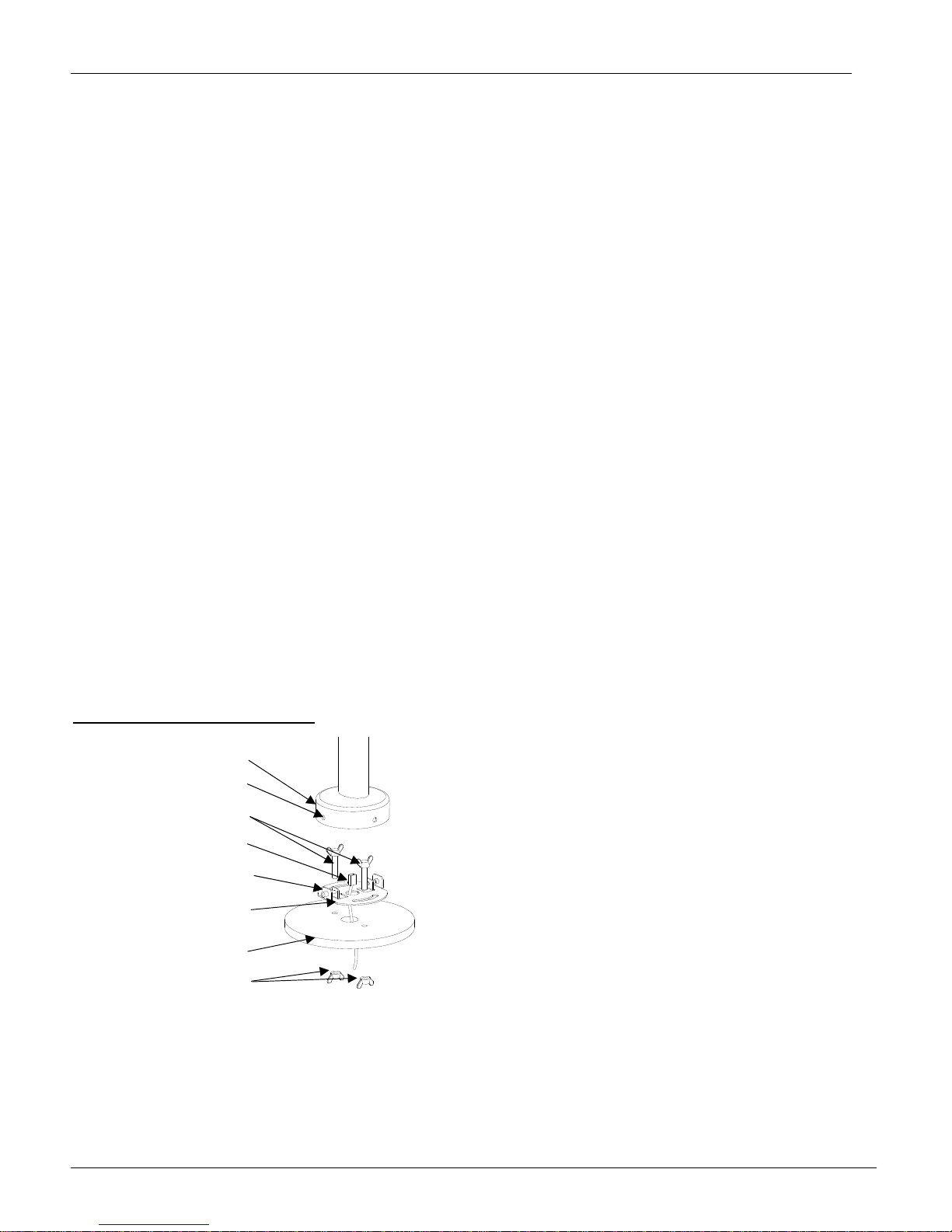

For Price Computing Version:

Tower base

Pin attachment holes

Attachment Screws (2)

Connector of cable

Attachment pins (2)

Tower Mounting Bracket

Table surface

ttachment wing nuts (2)

for Attachment Screws

A: Pull the connector of the cable through the holes of the

table surface and tower mounting bracket;

B: Put (2) screws though the (2) arch holes on the bracket

and (2) holes on the table surface;

C: Attach cover to the surface of table with (2) nuts.

D: Connect the cable to the connector at the bottom of the

tower display

E: Attach the base of the display to the mounting bracket

by insuring that the (2) pins on the bracket are inserted

in the holes of the base to attach the tower and snap

the tower into place.

DIVA Service Manual

6

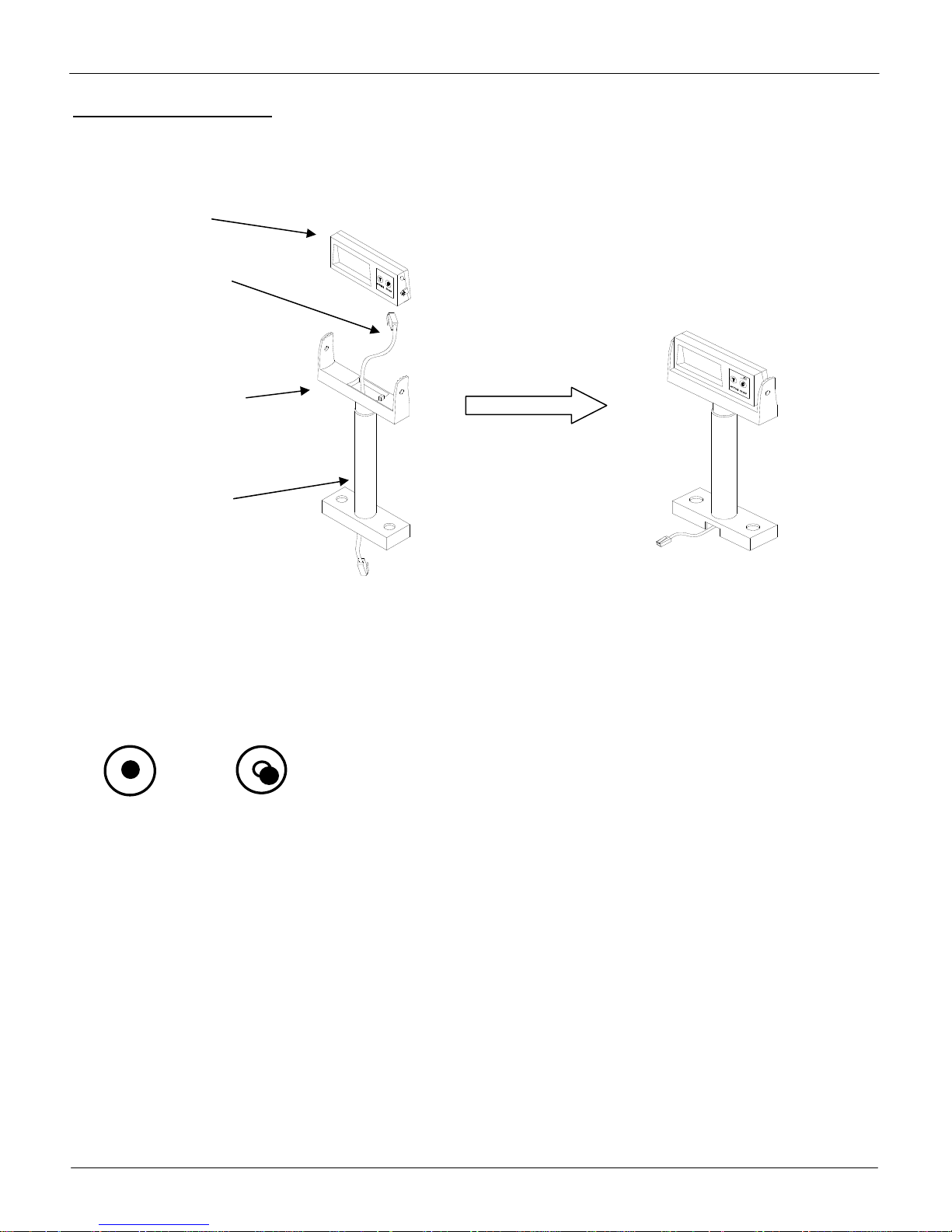

For Weigh Only Version:

The Weigh Only version comes with a tower mount.

Assemble the Weight Only tower as is illustrated here:

Display

Display Cable

Display Bracket

Display Tower

METTLER TOLEDO

3. Attach the Diva scale to the NCR 7876 Scanner as described in the Installation Manual

4. Level the scale by turning the adjustable feet on the bottom of the unit. Adjust the feet until the level

bubble is in the center of the circle.

Bubble indicator:

Correct Wrong

5. Put the platter on top of the DIVA scale.

6. Connect the tower display cable to the appropriate port on the scanner.

7. Connect the power cord from the wall transformer to the scanner.

2.4 Power up sequence

Note: Before powering on the DIVA scale, always make sure there is nothing on the platter.

Apply power to the scanner. The scale will go through a series of self-tests and then will proceed to

normal operating mode. The power-up sequence is as follows:

1. All segments of the display characters are lit. This verifies operation of all segments;

2. The scale displays the country code and GEO code, software part number and revision.

3. The scale then captures zero and is ready for normal operation.

DIVA Service Manual

7

METTLER TOLEDO

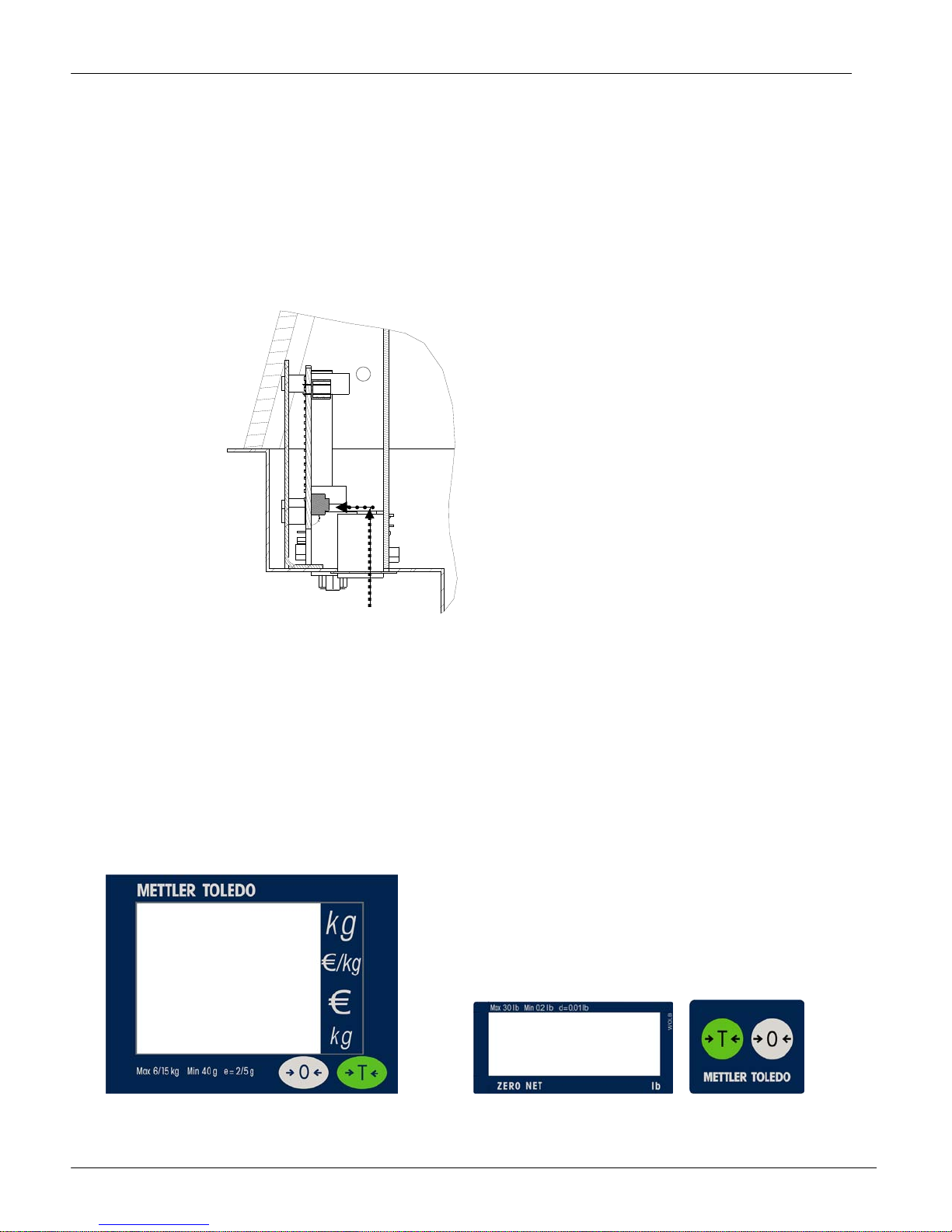

2.5 Sealing

After installation is complete, legal-for-trade applications require sealing the enclosure so the settings

cannot be changed.

The label sealing sequence

Security Sticker 28x19mm, material Vinyl white 3690 E UL, text color black. Need

There are 3 labels that used for sealing. The position for the sealing labels is shown below.

SCANNER HOUSING

(SECURITY LABEL 2)

CALIBRATION BUTTON POSITION

(SECURITY LABEL 1)

LC SCREWS

(SECURITY LABEL 3)

DIVA Service Manual

8

METTLER TOLEDO

For your notes:

DIVA Service Manual

9

METTLER TOLEDO

3 Set-up and Calibration

There are two types of setup modes. The first is called “Service Mode” and it allows full access to all

soft switches and to calibrate the scale. The second is called “Master Mode” and it only allows

access to soft switches that do not affect the metrology of the scale.

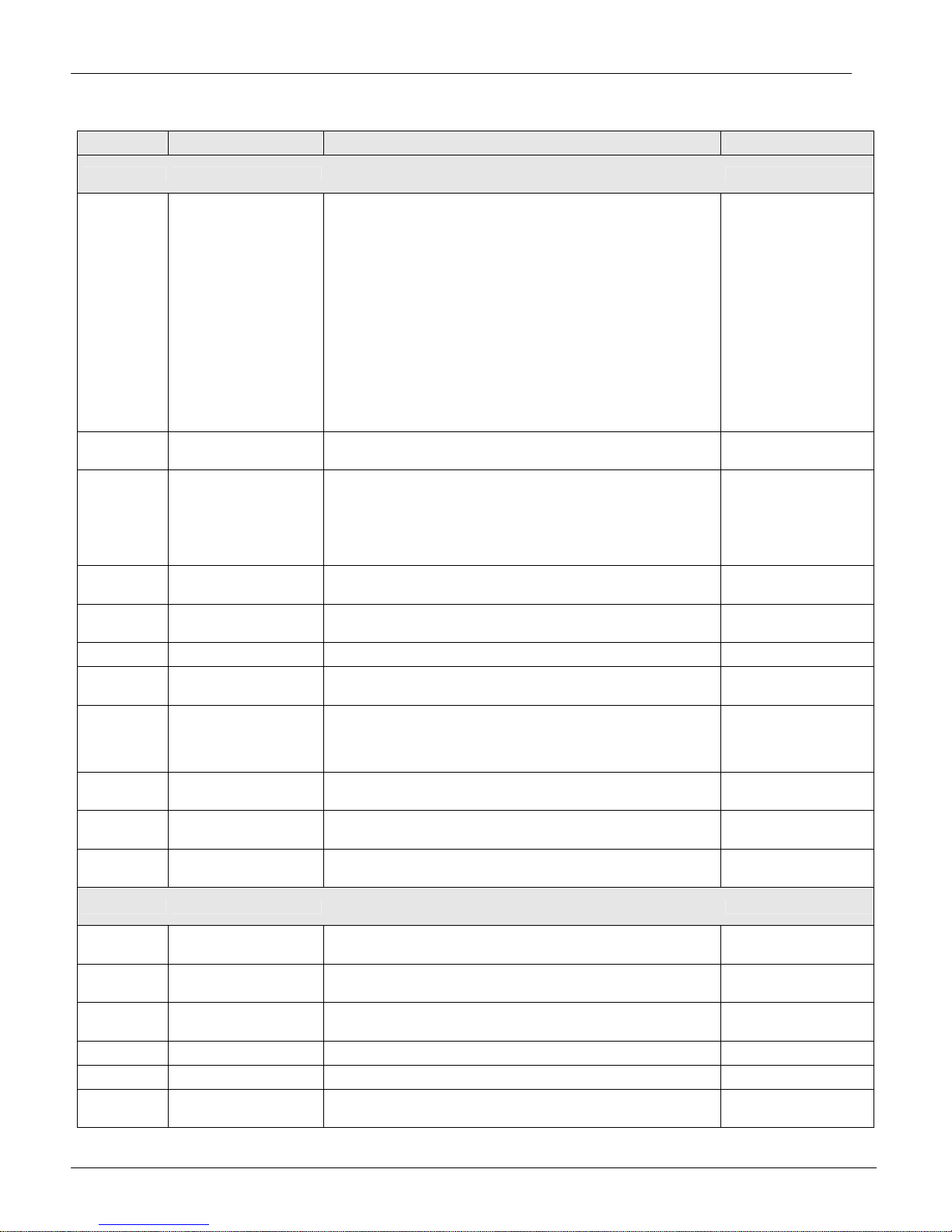

3.1 Service setup mode:

In order to access the Service Mode, break the seal and insert a thin rod like small screwdriver

through the calibration hole and press the button as illustrated:

2

1

To change settings using the Diva display follow the directions below.

During the set up procedure, the display will start off by showing the following.

Price Computing Version Weigh Only Version

1. Insert a thin rod into the calibration hole

2. Move the rod toward the calibration button until

you feel it depress

Conf

DIVA Service Manual

10

Conf

METTLER TOLEDO

Press the Zero Key:

Price Computing Version Weigh Only Version

Grp 1

Grp 1

You can press the Tare key to move to Grp 2, 3, or 4. To go into a particular Group, press the Zero

Key. Below is what you will see when going into the first Step of Group 1.

Price Computing Version Weigh Only Version

Grp 1

Step 1

DE

1.1 DE

Refer to Section 3.3 Setup and Soft Switch Default Table for all available settings.

3.2 Master setup mode:

This mode allows an operator to change certain softswitches not protected behind the seal directly

from the keyboard or through the scanner. To get into Master mode, press and hold >T< key for eight

seconds until “Grp 1” is displayed. Refer to the Section 3.3 Set Up Softswitch and Default Table for

the accessibility of softswitches via keyboard.

The scale can be configured for your specific needs through a special interactive set up procedure. In

order to access the various prompts, you must utilize the following keys during the scale setup mode.

This key is used to accept a choice and then advance one softswitch at a time.

This key is used to step through the options.

DIVA Service Manual

11

METTLER TOLEDO

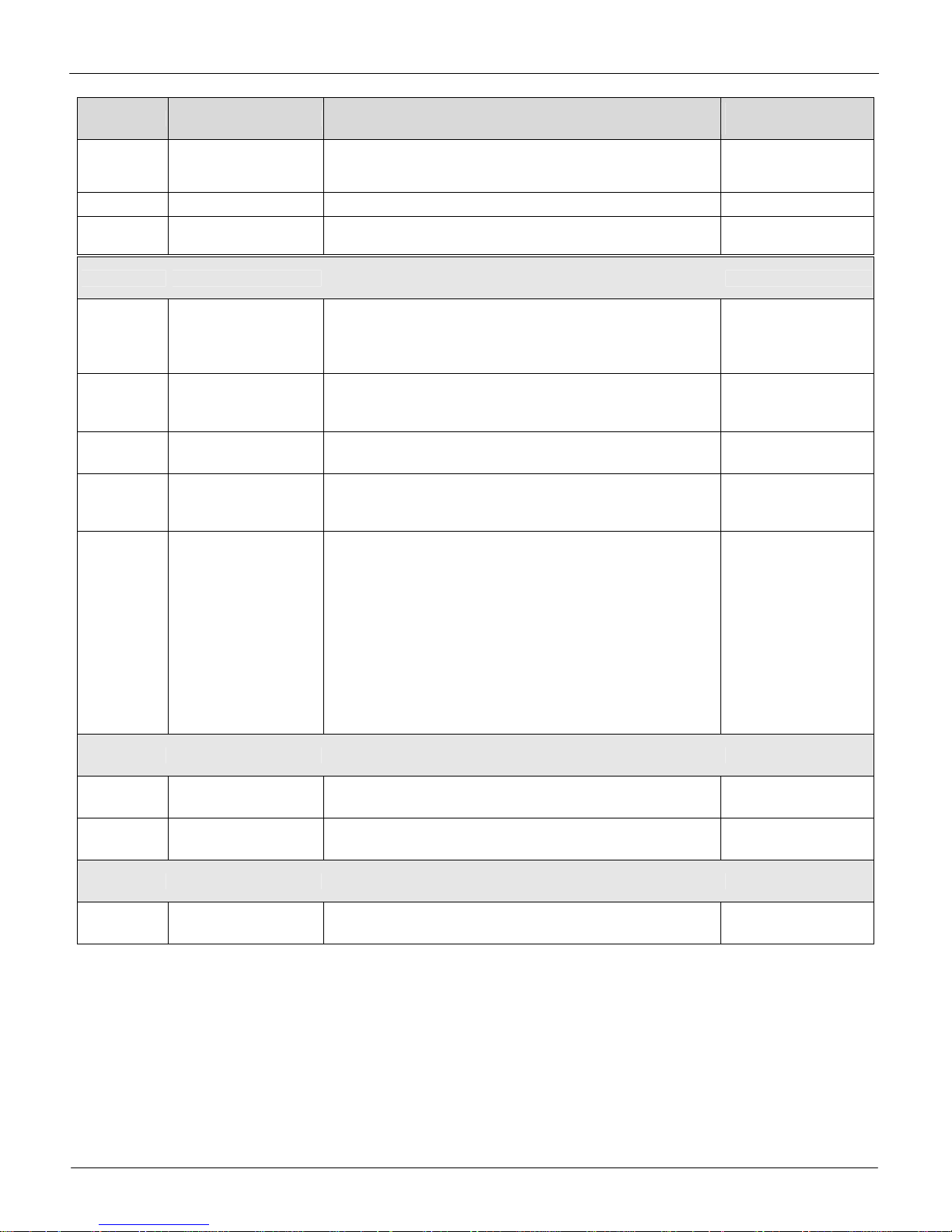

3.3 Set up Soft Switch and Default Table

Group.Step Function Possible Selections Master Mode Access

Group 1

1.1 Country Select

1.2 Initialize to Defaults

1.3 Beeper

1.4 Zero cursor

1.5 Decimal point

1.6* Decimal Position 0 - 3 – Digits right of the decimal for Unit and Total Price fields. No

1.7 Auto-clear of Tare

1.8 Weight unit

1.9 Expanded Weight Display

1.10

1.11 Main Calibration Button

Group 2

2.1 Tare Enable

2.2 Chain Tare Enable

2.3*

2.4 Digital Filter Selection 0 - 3 – Minimal to High No

2.5 GEO 0 through 31 – See GeoCal chart below No

2.6 Calibration

Enable Main PCB Service

Mode Button

Total Price Round

(To Nearest 0 or 5)

Press Zero to Enter

Press Tare to go to Group 2

DE (Germany)

FR (France)

US (USA)

CA (Canada)

AT (Austria and Croatia and Slovenia)

ES (Portugal and Spain)

BE (Belgium, Netherland, Poland and England)

IT (Italy)

CH (Kazachstan and Switzerland)

UA (Ukraine)

RU (Russia)

HU (Hungary)

SK (Slovakia)

CZ (Czechia)

EXPORT (General export)

CN (China)

YES – Soft switches will be reset to factory defaults

NO – Soft switches will remain in current configuration

0 – Beeper will not sound at any time

1 – Scale will not “beep” when a key is pressed

2 – Scale will not sound when a key is pressed, but it will “beep” when

sending command of NCI-ECR

3 – Scale will sound when a key is pressed, and it will “beep” when

sending command of NCI-ECR

ON – Display zero cursor.

OFF – Disable zero cursor.

ON - .

OFF - ,

ON – Tare is automatically cleared when weight is removed.

OFF – Tare is not cleared when weight is removed.

1 – lbs range (0 to 30 lbs)

2 – kg range (0 to 15kg)

3 – kg multi-interval (0 to 6kg, 6 to 15kg)

4 – lbs multi-interval (0 to 15lb, 15 to 30 lb)

ON – Division quantity is displayed, Maximum is 30000.

OFF – Weight is displayed in normal display increments.

ON – Button on Main PCB Enabled

OFF – Button on Main PCB Disabled

ON – Calibration button on the Main PCB is Enabled

OFF – Calibration button on the Main PCB is Disabled

Press Zero to Enter

Press Tare to go to Group 3

ON – Enables tare function.

OFF – Disables tare function.

ON – Enables multiple tares.

OFF – Only one tare per transaction is allowed.

ON – The total price will round up or down to 0 or 5.

OFF – Total price will not be rounded.

No – Do not enter calibration mode

Yes – Calibrate scale

No

No

Yes

Yes

Yes

No

No

No

No

No

Yes

Yes

No

No

DIVA Service Manual

12

r

r

r

Group.Step Function Possible Selections

2.7 Display (1 or 4 Line)

2.8 Display Update Rate 0-100 – Adjust display rate Yes

2.9 Enter Flash Mode

Group 3

3.1 Baud rate

3.2 Parity

3.3 Data

3.4 Bit stop

3.5 Chose Protocol

Group 4

4.1 Weight Change

4.2 Return to Zero

EXIT

SAVE Save or abort setting

0 – None

1 – 1 Line

2 – 4 Line

ON – Enter Flash Mode

OFF – Do not enter Flash Mode

Press Zero to Ente

Press Tare to go to Group 4

0 – 1200

1 – 2400

2 – 4800

3 – 9600

0 – None

1 – Even

2 – Odd

0 – 7 data bit

1 – 8 data bit

0 – None

1 – 1 stop bit

2 – 2 stop bit

0 = Disabled

1 = NCI-ECR (WO)

2 = (reserved)

3 = 8217 Mettler-Toledo (WO)

4 = 8213 Mettler-Toledo (WO)

5 = EPOS 1(WO)

6 = EPOS 2(WO)

7 = (reserved)

8 = Dialog 06 (PC)

9 = Dialog 04/02 (PC)

10 = (reserved)

11 = ICL (WO)

Press Zero to Ente

Press Tare to go to EXIT

00 - No Weight Change Required

yy - 01 to 99 weight change divisions required

0 - No Return to Zero Required

1 - Return to Zero Active

Press Zero to Ente

Press Tare to go to Group 1

SAVE – save all settings and return to weighing mode

ABORT – abort all settings and return to weighing mode

* Used only on the 4 Line display

PC – Price Computing

WO – Weight Only

METTLER TOLEDO

Master Mode Access

Yes

No

Yes

Yes

Yes

Yes

Yes

No

No

Yes

DIVA Service Manual

13

METTLER TOLEDO

M

i

C

lib

ti

Button

3.4 Country Defaults

PC WO WO WO WO WO WO WO WO WO WO WO WO WO WO WO

(Europe) Portugal Poland/ Swiss Export

Germany/ France USA Austria Spain/ Belguim/ Italy Kazachstan/ Ukraine Russia Hungary Slovakia Czechia General China Canada

Function

1.1 Country Code dE fr US AT ES BE iT CH UA rU HU SK C2 OrT CN CA

1.2 Initialize to Defaults No No No No No No No No No No No No No No No No

1.3Beeper 1 1 1 1111 1 11 1 11111

1.4 Zero Cursor Off Off On Off Off Off Off Off Off Off On Off Off On On On

1.5 Decimal Point Off (,) Off (,) On (.) Off (,) Off (,) Off (,) Off (,) Off (,) Off (,) Off (,) On (.) Off (,) Off (,) On (.) On (.) On (.)

1.6Decimal Position($)2 2 2 2222 2 22 0 22222

1.7 Auto Clear Tare On On On On On On On On On On On On On On On On

Group 1 England

DIVA Service Manual

14

1.8 Weight Unit kg (3) kg (3) lb (1) kg (3) kg (3) kg (3) kg (3) kg (3) kg (3) kg (3) kg (3) kg (3) kg (3) kg (3) kg (3) kg (3)

1.9 Expanded Displa y Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off

1.10 Blank Weight Display Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off

– Weigh Only

WO

Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off

– Price Computing,

PC

on

ra

a

n

a

2.1 Tare Enable On On On On On On On On On On On On On On On On

2.2 Chain Tare Enable Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off

2.3 Total Price Round Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off

2.4 Digital Filter 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low) 1 (Low)

2.5 GEO 20 19 15 18 15 15 17 18 21 23 19 19 20 12 12 15

2.6 Calibration No No No No No No No No No No No No No No No No

2.7 Display Type 2 (4Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line) 1 (1Line)

2.8Display Update Rate2 2 2 2222 2 22 2 22222

2.9 Flash Mode Enable Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off Off

3.1 Baud Rate 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb) 3 (9.6kb)

3.2 Parity 2(odd) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even) 1(even)

3.3 Data Bits 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits) 0 (7bits)

3.4Stop Bit 1 1 1 1111 1 11 1 11111

3.5 Protocol 8(Dialog06) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217) 3(8217)

4.1Weight Change 10 10 0 10101010 10 1010 10 10101010 0

1.11

Group 2

Group 3

4.2Return to Zero 0 0 1 0000 0 00 0 00001

Group 4

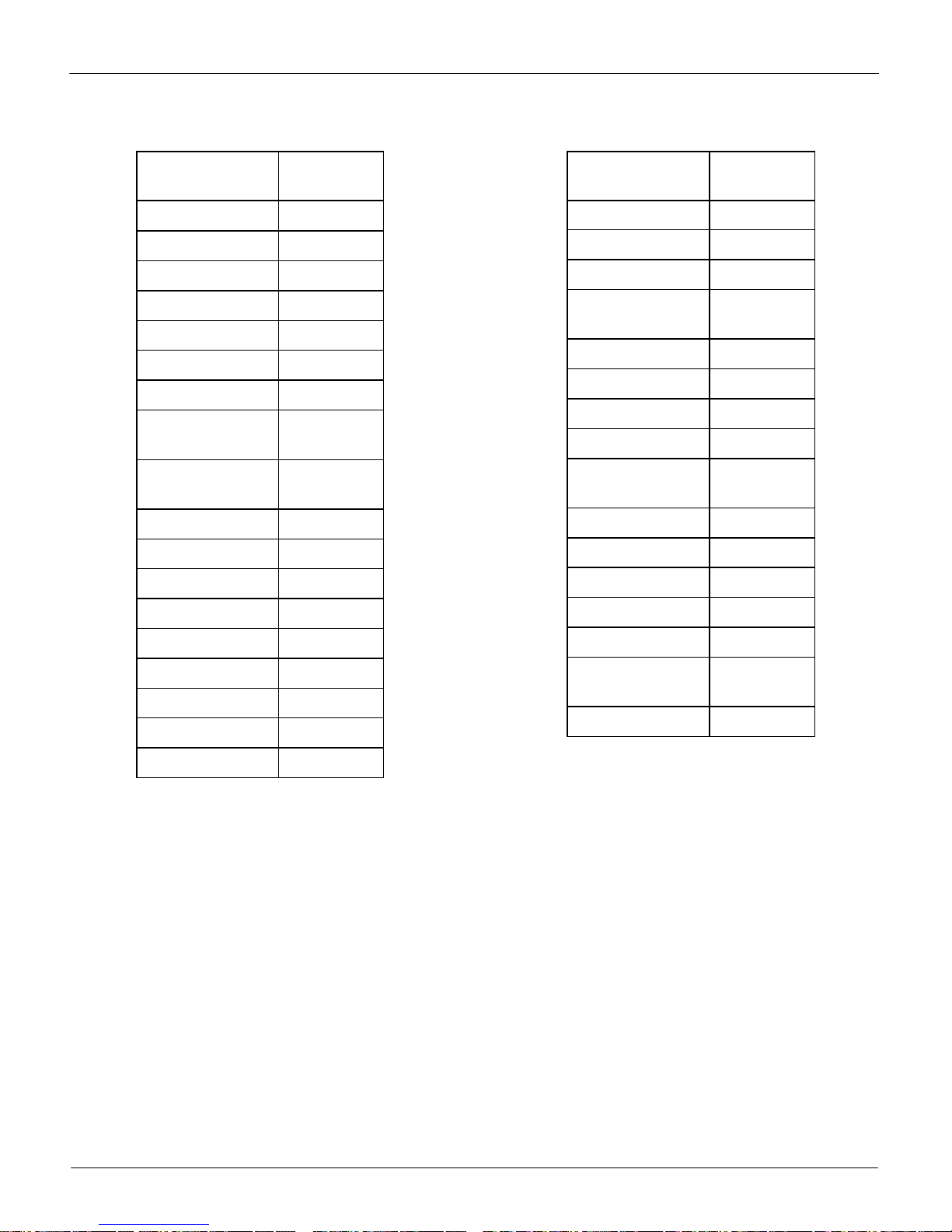

3.5 GeoCal Country Codes

METTLER TOLEDO

Country Geo-Value

Austria 18

Belgium 21

Bulgaria 16

Croatia 18

Czechia 20

Denmark 23

Estonia 24

Finland

France

25*

26

17

19*

Germany 20

Greece 15

Hungary 19

Ireland 22

Country Geo-Value

Liechtenstein 18

Lithuania 22

Netherlands 21

Norway

24*

26

Poland 21

Portugal 15

Romania 18

Russia 23

Sweden

24*

26

Switzerland 18

Slovakia 19

Slovenia 18

Spain 15

Iceland 26

Italy 17

Kazakhstan 18

Latvia 23

Turkey 16

United Kingdom

21*

23

Ukraine 21

* Factory Default

Luxemburg 20

DIVA Service Manual

15

Loading...

Loading...