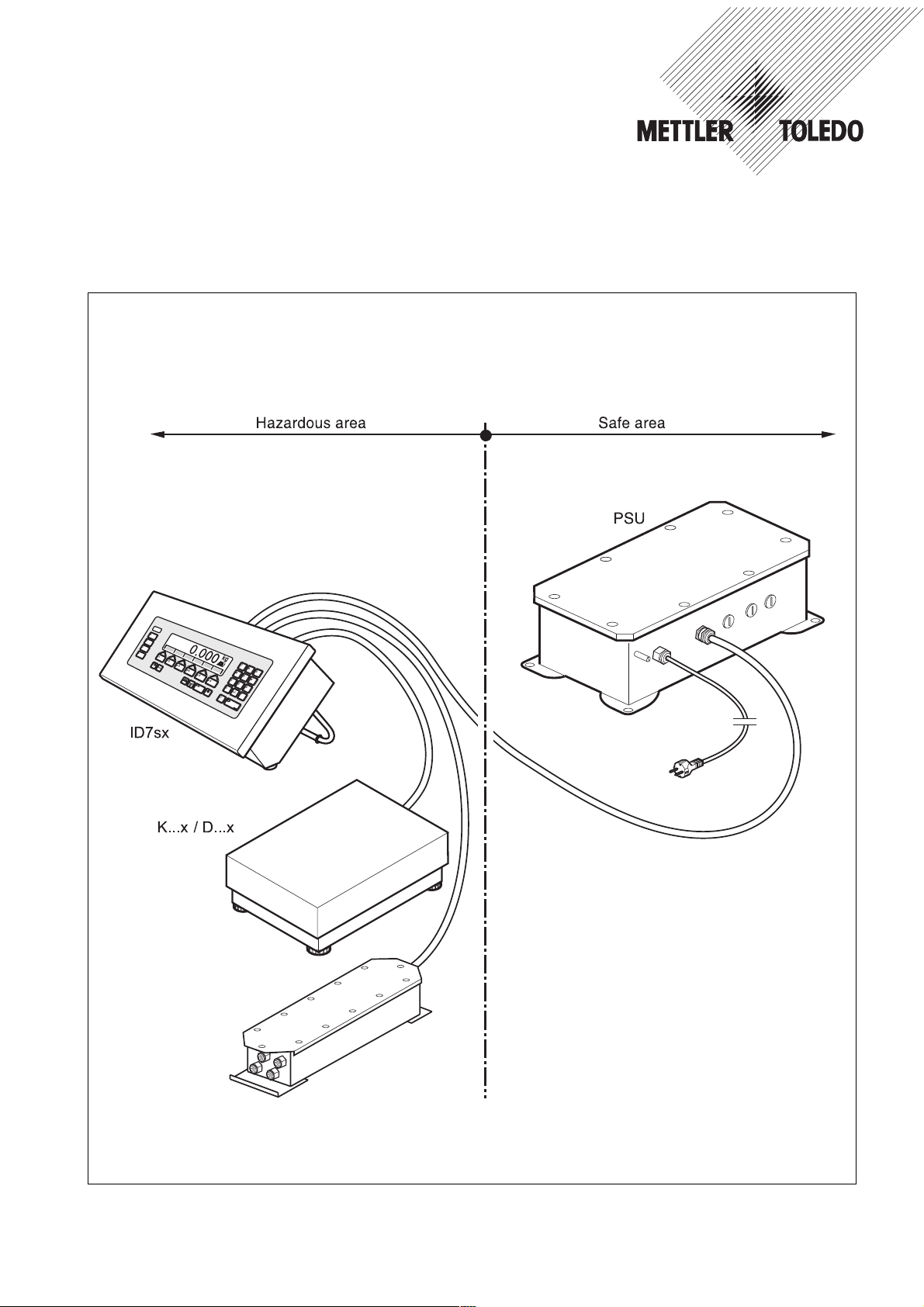

Page 1

Guide for installers

METTLER TOLEDO MultiRange

Explosion-protected weighing system

with the ID7sx weighing terminal

Point Ex

system solution

Page 2

Page 3

ID7sx

Contents

Contents Page

1 Safety instructions ....................................................................... 2

2 System overview ......................................................................... 3

2.1 Typical configurations ................................................................... 3

2.2 Description of the components ....................................................... 6

3 Installation .................................................................................. 7

3.1 Setting up system modules ............................................................ 7

3.2 Connecting devices....................................................................... 10

3.3 Selecting peripheral devices ........................................................... 11

3.4 Equipotential bonding ................................................................... 12

3.5 Connecting power supply .............................................................. 12

4 Optional work.............................................................................. 13

4.1 Making connection cables ............................................................. 13

4.2 Installing additional scale interface or active CL/IDNet module............ 14

4.3 Installing memory module ............................................................. 16

4.4 Installing additional data interface................................................... 17

4.5 Installing digital inputs/outputs ....................................................... 18

4.6 Connecting barcode scanner .......................................................... 19

4.7 Attaching Profibus-DP module........................................................ 20

5 Dimensional drawings ................................................................. 21

5.1 Desk unit ..................................................................................... 21

5.2 Panel unit .................................................................................... 22

5.3 Wall unit...................................................................................... 22

Guide for installers 22008316B 04/09 1

Page 4

Safety instructions

1 Safety instructions

The ID7sx weighing terminal is approved for operation in zone 1 and 21 hazardous

areas. It may only be used in areas in which the causes of static electricity build-up,

which lead to propagating brush discharges, have been eliminated.

If the ID7sx weighing terminal is used in hazardous areas, special care must be

taken. The code of practice is oriented to the "Safe Distribution" concept drawn up by

METTLER TOLEDO.

Competence ▲ The weighing system may only be installed, maintained and repaired by

authorised METTLER TOLEDO service personnel.

Ex approval ▲ No modifications may be made to the terminal and no repair work may be per-

formed on the modules. Any weighing platform or system modules that are used

must comply with the specifications contained in the installation instructions. Noncompliant equipment jeopardises the intrinsic safety of the system, cancels the Ex

approval and renders any warranty or product liability claims null and void.

ID7sx

▲ The safety of the weighing system is only guaranteed when the weighing system

is operated, installed and maintained in accordance with the respective instructions.

▲ Also comply with the following:

– the instructions for the system modules

– the regulations and standards in the respective country

– the statutory requirement for electrical equipment installed in hazardous areas

in the respective country

– all instructions related to safety issued by the owner

▲ The explosion-protected weighing system must be checked to ensure compliance

with the requirements for safety before being put into service for the first time,

following any service work and every 3 years, at least.

Operation ▲ Prevent the build-up of static electricity. Always wear suitable working clothes

when operating or performing service work in a hazardous area.

▲ Do not use protective coverings for the device.

▲ Avoid damage to the system components.

Installation ▲ Only install or perform maintenance work on the weighing system in the

hazardous areas if the following conditions are fulfilled:

– if the intrinsically safe characteristic values and zone approval of the individual

components are in accord with one another,

– the owner has issued a permit ("spark permit" or "fire permit"),

– the area has been rendered safe and the owner's safety co-ordinator has

confirmed that there is no danger,

– the necessary tools and any required protective clothing are provided (danger

of the build-up of static electricity).

▲ The certification papers (certificates, manufacturer’s declarations) must be present.

▲ Lay cabling securely so that it does not move and effectively protet it against damage.

▲ Only route cables into the housing of the system modules via the suitable screw

gland and ensure proper seating of the seals.

2 Guide for installers 22008316B 04/09

Page 5

ID7sx

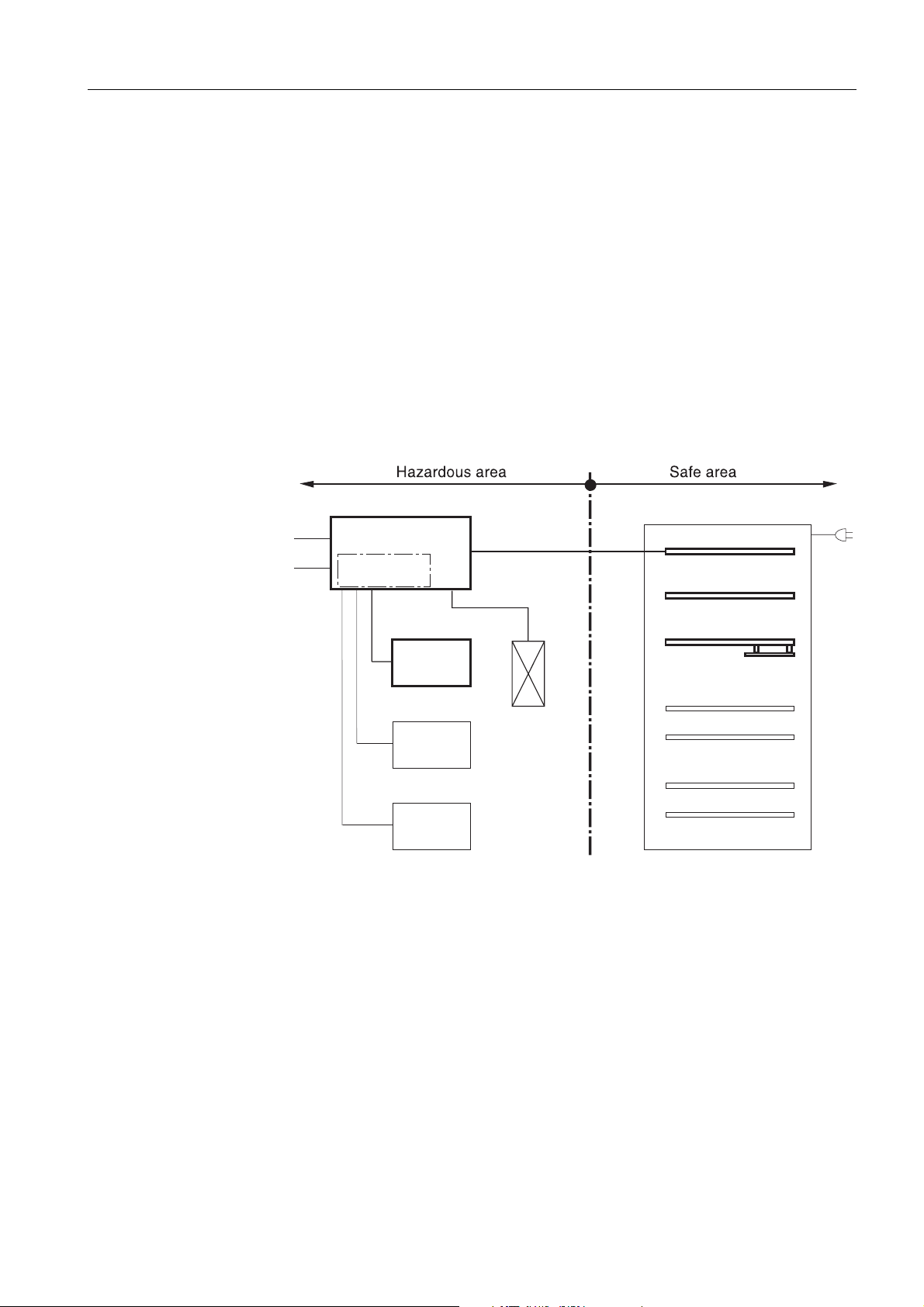

2 System overview

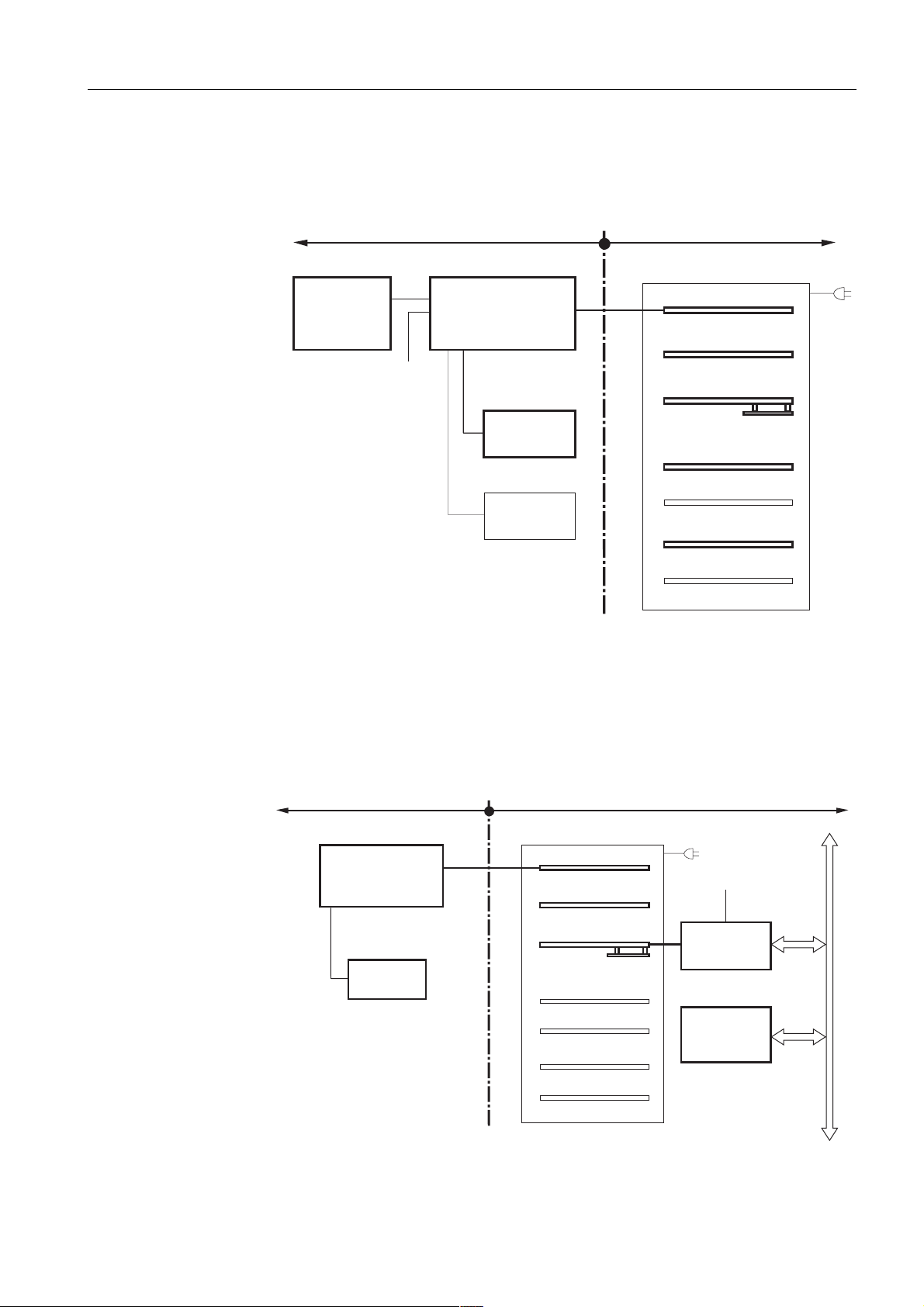

2.1 Typical configurations

Two power supply units are available for a weighing system with the ID7sx weighing

terminal: PSU and PSUx.

PSU Power supply unit in a safe area, multiple-scale connection and

PSUx Power supply unit in hazardous area, connection of only one scale

2.1.1 Weighing terminal ID7sx, PSU and max. 3 weighing platforms

System overview

connection of peripheral devices are possible

possible

RS

CL

Terminal

Analog

interface ***

Ex-i

max. 20 m

ID7sx

Scale 1

K...x *

Scale 2

D...x ** /

Point Ex

system

solution ***

Scale 3

Analog

scale

Ex-i

max. 80 m

I/O

PSU

ID..sx

Terminal

TBrick-Ex

Scale 1

Interface

Com 1

RS232 /

CL20mA

Point-Ex

Scale 2

Com 2

Point-Ex

Scale 3

Com 3

* Only K...x weighing platforms with a TBrick...-Ex measuring cell are

permissible in this configuration.

** D...x weighing platforms with in-built Point Ex A/D converter.

*** Minimum supply impedance 87 Ω in conjunction with slotcard Point-Ex.

Minimum supply impedance 250 Ω in conjunction with slotcard TBrick-Ex.

Guide for installers 22008316B 04/09 3

Page 6

System overview

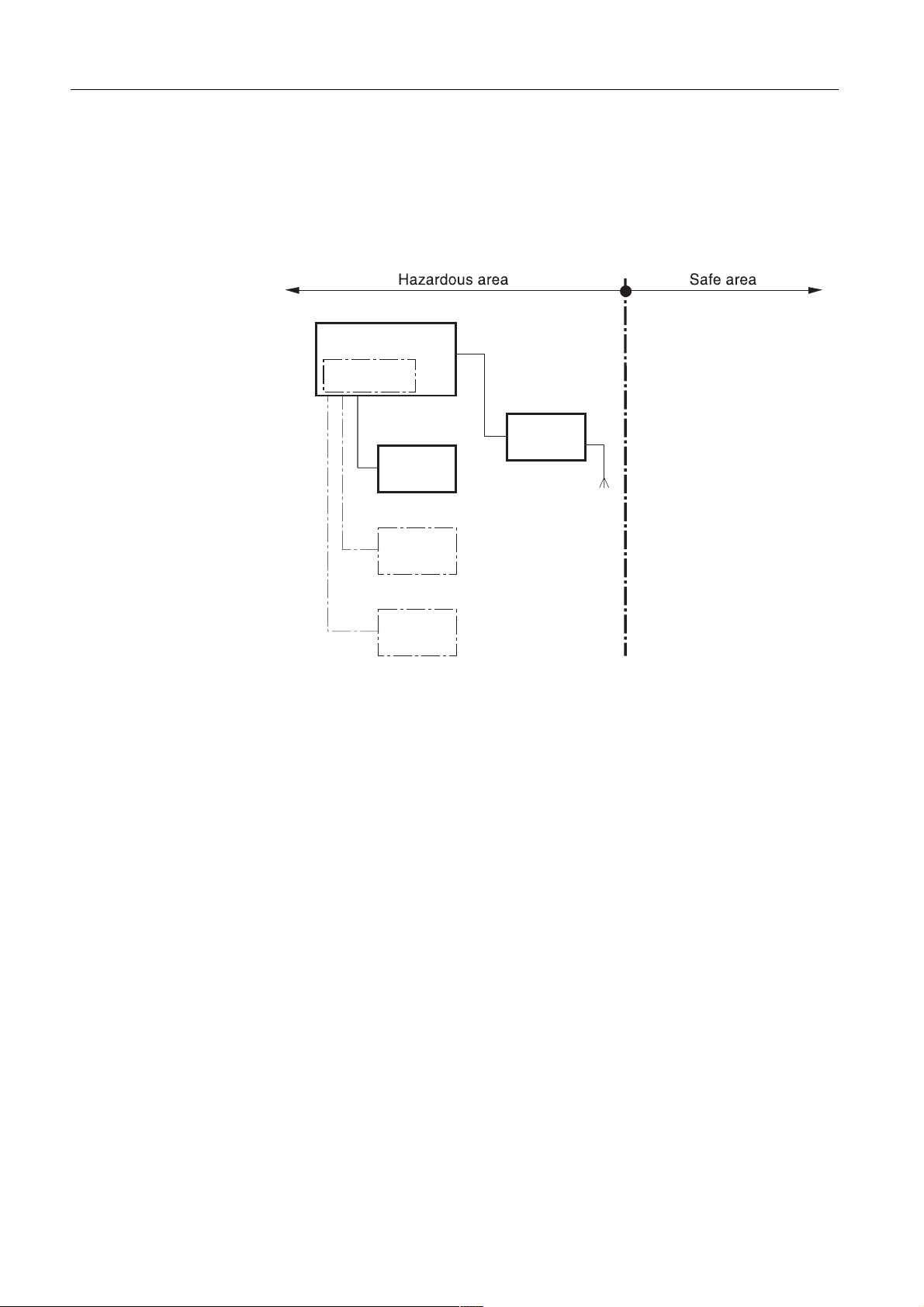

2.1.2 ID7sx weighing terminal, PSUx and 1 weighing platform

In conjunction with the PSUx power supply unit, only one weighing platform (K...x,

D...x, analog scale) or one Point Ex system solution can be connected to the ID7sx

weighing terminal.

Terminal

ID7sx

Analog

interface ***

Ex-i,

max. 20 m

Scale 1

K...x * /

D...x**

Scale 2

Point Ex ***

system

solution

Ex-i

max. 50 m

PSUx

ID7sx

Scale 3

Analog

scale

* Only K...x weighing platforms with a TBrick...-Ex measuring cell are

permissible in this configuration.

** D...x weighing platforms with in-built Point Ex A/D converter.

*** Minimum supply impedance 250 Ω. Here, a maximum of 4 load cells with a

cell impedance ≥1000 Ω can be connected.

4 Guide for installers 22008316B 04/09

Page 7

ID7sx

System overview

2.1.3 ID7sx weighing terminal, PSU, max. 2 weighing platforms and barcode scanner

Barcode scanner

e.g.

ELB SK200

(SC20-MTA1)

Hazardous area

Terminal

RS232

CL

ID7sx

Ex-i,

max. 20 m

K...x-T4*

D...x**/System

solution

Point Ex

Safe area

PSU

ID..sx

Terminal

TBrick-Ex

Scale 1

Interface

Com 1

Point-Ex

Scale 2

Com 2

Viper-Ex (SW)***

Scale 3

Com 3

RS232 /

CL20mA

* Only K...x weighing platforms with a TBrick...-Ex measuring cell are

permissible in this configuration.

** D...x weighing platforms with in-built Point Ex A/D converter.

*** Slotcard Viper-Ex (SW) as a power supply card for barcode scanners.

2.1.4 D7sx weighing terminal, PSU, connection to Profibus-DP

Hazardous area

Terminal

ID7sx

Ex-i,

max. 20 m

K...x-T4*

Safe area

PSU

ID..sx

Terminal

TBrick-Ex

Scale 1

Interface

Com 1

Scale 2

Com 2

Scale 3

Com 3

RS232

24 V DC

Module

Profibus-DP

PLC with

Profibus-DP

interface

Profibus-DP

Guide for installers 22008316B 04/09 5

Page 8

System overview

2.2 Description of the components

2.2.1 Approvals

ID7sx weighing terminal Ignition protection type EN II 2G EEx ib IIC T4 –10 °C to +40 °C

II 2D IP65 T +55 °C

FM Class I, II, III; Division 1; Group A, B, C, D, E, F, G

ID7sx

Power supply unit

See installation instructions for PSU or PSUx

PSU/PSUx

K...x / D...x

See operating/installation instructions of the K...x or D...x weighing platforms.

weighing platforms

System solution Point Ex See guide for installers system solution Point Ex.

2.2.2 Connections

View A

A

1 Weighing platform connections W1, W2, W3

2 I/O (outputs) connection / PSUx connection

3 PSU connection

12345

4 I/O (inputs) connection

5 Connection for serial interfaces C2, C3

2.2.3 Connection options for ID7sx

Scale interfaces Scale 1 Scale 2 Scale 3

IDNet standard optional optional

Analog interface – optional optional

Active CL/IDNet interface – optional optional

Serial interfaces C1 C2 C3

CL20mA standard optional optional

RS232 – optional optional

Digital inputs/outputs 8 I/O-ID7sx optional

Memory module Memory-ID7sx optional

6 Guide for installers 22008316B 04/09

Page 9

ID7sx

3 Installation

Installation

EXPLOSION HAZARD

The explosion-protected weighing system may only be installed according to the

respective guide for installers and the accompanying terminal diagram, depending

on the power supply unit.

Power supply unit Guide for installers Terminal diagram

PSU ME-22006472 PSU-ID7sx

ME-22006478

PSUx/230V ME-22006386 PSUx/230V-ID7sx

ME-22006397

PSUx/120V ME-22006395 PSUx/120V-ID7sx

ME-22006399

3.1 Setting up system modules

3.1.1 Setting up ID7sx weighing terminal

➜ Select a suitable installation site.

Bench stand or floor stand mounting

1. Remove stand clip on the ID7sx.

2. Place weighing terminal onto the bench or floor stand and mount with 4 screws.

Wall mounting

The ID7sx weighing terminal can be mounted to a wall using the wall bracket

(accessory).

Guide for installers 22008316B 04/09 7

Page 10

Installation

ID7sx

Procedure 1. Drill securing holes and fit plugs in accordance with the drilling template on

Page 23.

2. Remove stand clip on the ID7sx.

3. Mount wall stand to weighing terminal with 4 screws.

4. Mount wall stand to the wall with the supplied 3 screws.

Installation in a switch cabinet

The mounting materials and a drilling template are included in the scope of supply.

➜ Discontinue the power supply before beginning installation work.

Producing cut-out on

switch cabinet

1. Tape the drilling template onto the inside of the switch cabinet and mark the

holes with a punch.

2. Drill holes with the specified diameter.

3. Saw out the cut-out for the cover exactly with the sabre saw, as otherwise

protection type IP65/IP66 will no longer be ensured.

4. Remove the drilling template from the switch cabinet again.

Preparing cover 1. Unscrew all screws on the cover of the ID7sx and remove the cover toward the

front.

2. Unplug keyboard and display cables from the IDsx7 PCB.

3

1

2

3

3. Take out the cover seal and cut out the perforated corners of the cover seal (1)

with a sharp knife.

4. Insert the square nuts (2) with the rounded side facing downward.

5. Screw the two setscrews (3) into the holes in the cover as shown.

8 Guide for installers 22008316B 04/09

Page 11

ID7sx

4

Mounting cover on

switch cabinet

Installation

4

567

Mounting lower housing

section

1. Position the cover on the switch cabinet door from the front with the setscrews.

2. Secure the cover with the two centre screws (4) from the inside.

3. Fix the housing claws (6) with the large screws (5) and the washers (7) in all

corners. Do not tighten the screws yet!

1. Reconnect the display and keyboard cables on the ID7sx PCB.

8

6

2. Position the lower housing section on the cut-out and secure it with the housing

claws (6).

3. Secure the device with 8 screws (8) on the cut-out and tighten all screws.

Guide for installers 22008316B 04/09 9

Page 12

Installation

ID7sx

3.1.2 Setting up power supply unit

➜ Set up the power supply unit in accordance with the respective terminal diagram

and the accompanying guide for installers.

3.1.3 Setting up weighing platforms

Note

When operating using the PSU power supply unit, a corresponding slotcard must be

installed for each weighing platform or system solution Point Ex.

➜ Set up weighing platform or analog scale in accordance with the K...x or D...x

operating/installation instructions or guide for installers.

3.2 Connecting devices

Connect the devices in the following order:

1. Weighing platform(s) and/or system solution Point Ex to ID7sx weighing

terminal.

2. Interfaces (I/O, CL, Active CL/IDNet or RS232) if present.

3. ID7sx weighing terminal to PSU or PSUx power supply unit.

4. Equipotential bonding, see Section 3.4.

5. Connect power supply, see Section 3.5.

3.2.1 Preparatory work

Connection of the devices is generally carried out with the accompanying standard

cables. Cables of other lengths can be used instead of the standard cables if they are

made in accordance with Section 4.1. This applies for the connections

• from the weighing platform or system solution Point Ex to the weighing terminal,

• from the weighing terminal to the power supply unit,

• from the interface(s) to the weighing terminal.

3.2.2 General connection procedure

1. Open the device.

2. Insert custom-made cable. To do this

– remove the blind plug

– ensure exact course of cable and properly positioned seals

– tighten screw gland, using a tubular hexagon box spanner if possible

3. Connect cable in the device according to the terminal diagram.

4. Lay cable in the cable holders on the inside of the housing.

5. Attach plug label.

6. Close device.

10 Guide for installers 22008316B 04/09

Page 13

ID7sx

Installation

3.2.3 Connection of the digital inputs/outputs at the ID7sx

CAUTION

Design, calculation and installation of equipment to the digital inputs/outputs is

solely the responsibility of the owner.

1. Connect only intrinsically-safe equipment.

2. Check characteristic values for intrinsic safety in accordance with the conformity

certificate of the ID7sx and the equipment to be connected according to the

conditions in Section 3.3. Document checking of the characteristic values.

3. Make a cable on the weighing terminal side in accordance with Section 4.1 and

on the peripheral side according to the device to be connected. Heed the

maximum cable length here.

4. Connect the cable on the peripheral device side according to the intended device

there. Ensure correct polarity here:

Wiring of the inputs Wiring of the outputs

3.3 Selecting peripheral devices

CAUTION

Refer to the approval documentation of the peripheral device for all characteristic

values of the peripheral device listed in the following.

The following conditions must be fulfilled. See also terminal diagram 22006478:

(ID7sx) ≥ Uo (peripheral device)

1. U

i

(ID7sx) ≥ Io (peripheral device)

2. I

i

3. P

(ID7sx) ≥ Po (peripheral device)

i

4. C

(ID7sx) ≤ Co (peripheral device)

i

(ID7sx) ≤ Lo (peripheral device)

5. L

i

6. L (cable) / R (cable) < L

L (cable) is the length-based inductivity and R (cable) is the length-based

resistance of the cable to be used.

Calculating L

/ Ra for the peripheral device

a max

Using the ignition protection type-dependent energy value e of the peripheral device

yields the following:

L

/ Ra = 32 / 9 * e * Ri (peripheral device) / U

a max

where e = 40 mJ for equipment of ignition protection type IIC.

(peripheral device) / Ra (peripheral device), where

a max

max

Guide for installers 22008316B 04/09 11

Page 14

Installation

ID7sx

3.4 Equipotential bonding

Equipotential bonding must be installed by an electrician authorised by the owner.

METTLER TOLEDO Service only has a monitoring and consulting function here.

➜ Connect equipotential bonding (PA) of all devices (power supply unit, weighing

terminal and weighing platform) in accordance with the terminal diagram and

the country-specific regulations and standards. In the process it must be ensured

that

– all device housings are connected to the same potential via the PA terminals

– no circulating current flows via the cable shielding for intrinsically-safe circuits

– the neutral point for equipotential bonding is as close to the scale as possible

3.5 Connecting power supply

EXPLOSION HAZARD

The mains connection of the power supply unit must be made by a professional

electrician authorised by the owner and in accordance with the respective terminal

diagram and the accompanying installation instructions and the country-specific

regulations.

12 Guide for installers 22008316B 04/09

Page 15

ID7sx

4 Optional work

4.1 Making connection cables

Optional work

Customer-specific weighing platform cables for intrinsically-safe circuits must be

fabricated as follows:

Dimension A

(ID7sx)

2

215 mm

2

215 mm

Dimension B Max. length

1

1

215 mm

80 mm

1

1

80 m

20 m

ID7sx – PSU

ID7sx – weighing

Cable

9x2x0.5 mm

3x2x0.75 mm

platform / system

solution Point Ex

Wire end ferrules

with plastic collar,

crimp connection

A B

Push sleeve over

wires and shield

According to country-specific

regulations for intrinsically-safe circuits

Earthing cable screw gland

Cable shield

1. Cut cable to length and strip cable ends according to dimension A/B.

1

1

2. Shorten shielding on both sides to 10 mm.

3. Strip wire ends.

4. Crimp wire end ferrules onto wire ends with a crimping tool.

5. Push second rear section of earthing cable gland onto cable.

6. Push sleeve over wires and shield. Fold over cable shield.

7. Push on front section of cable gland and screw onto rear section.

Observe the following when connecting the weighing platform

1. When opening the terminal box of the weighing platform, remove the load plate if

necessary.

2. For weighing platforms of type KC, attach the cable to the base frame with a

cable tie in such a way that it does not contact the moving lever system.

3. For K...x weighing platforms, pull off the tear-away screw at the terminal box of

the weighing platform after connection of the weighing platform to the weighing

terminal for safety purposes.

4. Replace load plate if necessary.

Guide for installers 22008316B 04/09 13

Page 16

Optional work

W1

Scale3

S3

ID7sx

4.2 Installing additional scale interface or Active CL/IDNet module

Up to two additional scale interfaces (IDNet or analog) or Active CL/IDNet modules

can be installed in the ID7sx weighing terminal if not already installed at the factory.

The ID7sx, for example, can be connected to another ID7sx as a second display with

the Active CL/IDNet-ID7sx module in the hazardous area.

4.2.1 Installing IDNet interface or Active CL/IDNet module

4

23

1

1. Open housing cover of ID7sx and unplug keyboard, display and backlighting

cables.

2. Mount spacer (1) at W2 or W3.

3. Attach module Scale-ID7sx (2) to connector W2 or W3. Ensure that the locking

tip of the spacer engages here.

4. Remove blind plug from desired scale connection.

5. Insert and mount weighing platform cable. Ensure the correct position of the outer

seal when doing so.

6. Label 6-pin plug (3) on module Scale-ID7sx as "Scale 2" or "Scale 3". The

stickers are located inside the housing.

7. Connect wires of the weighing platform cable or the interface cable from the

master terminal at the 6-pin plug W or W_A in accordance with terminal diagram

22006478.

8. Lay cable in the cable holder on the inside of the housing.

9. Unplug 3-pin plug (4) "S2" or "S3" from the ID7sx mainboard and insert it into

connector S or S_A on module Scale-ID7sx.

10. Reattach keyboard, display and backlighting cables to the mainboard.

11. Close housing cover of ID7sx again. Ensure correct position of housing seal

14 Guide for installers 22008316B 04/09

when doing so.

Page 17

ID7sx

B

S1

1W

S1

S2

S3

Scale3

S3

1

2

4

9

5

6

7

8

10

3

6

Optional work

4.2.2 Installing analog interface

1. Open housing cover of ID7sx and unplug keyboard, display and backlighting

cables.

2. Mount spacer (1) at W2 or W3.

3. Attach module Scale-ID7sx (2) to connector W2 or W3. Ensure that the locking

tip of the spacer engages here.

4. Unplug 3-pin plug (3) "S2" or "S3" from the ID7sx mainboard and insert it into

connector S on module Scale-ID7sx.

5. Label 6-pin plug (4) on module Scale-ID7sx as "Scale 2" or "Scale 3". The

stickers are located inside the housing.

6. If only one Point Ex PCB (9) is installed:

– Mount 2 spacer pins (7) at the housing floor.

– Attach Point Ex PCB and secure with lock washer (6) and nut (8).

7. If two Point Ex PCBs (9) are installed:

– Remove nut (8).

– Attach first Point Ex PCB and secure with lock washer (6) and spacer pin (7).

– Attach second Point Ex PCB and secure with lock washer (6) and nut (8).

8. Remove blind plug from desired scale connection.

9. Insert and mount weighing platform cable. Ensure the correct position of the outer

seal when doing so.

10. Connect wires of weighing platform cable to plug ST1 (5) of the Point Ex PCB (9)

in accordance with terminal diagram 22006478.

Guide for installers 22008316B 04/09 15

Page 18

Optional work

C1

T1

S3

S2

S1

S3

ID7sx

11. Lay cable in the cable holder on the inside of the housing.

12. Connect 6-lead connection cable (10) between the 6-pin plug of the Scale-ID7sx

module and the ST2 plug at the Point Ex PCB.

13. Reattach keyboard, display and backlighting cables to the mainboard.

14. Close housing cover of ID7sx again. Ensure correct position of housing seal

when doing so.

4.3 Installing memory module

A Memory-ID7sx memory module can be installed in the ID7sx weighing terminal if

not already installed at the factory.

1

1. Open housing cover of ID7sx and unplug keyboard, display and backlighting

cables.

2. Insert the module Memory-ID7sx (1) angled to the left into the SIMM slot and

then tilt it to the right until it is perpendicular with the mainboard and the clips

engage.

3. Reattach keyboard, display and backlighting cables to the mainboard.

4. Close housing cover of ID7sx again. Ensure correct position of housing seal

when doing so.

16 Guide for installers 22008316B 04/09

Page 19

ID7sx

C3

C1

T1

S3

S2

S1

W

S3

Optional work

4.4 Installing additional data interface

Up to two additional data interfaces (CL20mA-ID7sx or RS232-ID7sx) can be

installed in the ID7sx weighing terminal if not already installed at the factory.

1

3 2

1. Open housing cover of ID7sx and unplug keyboard, display and backlighting

cables.

2. Mount spacer (1) at C2 or C3.

3. Mount module CL20mA-ID7sx or RS232-ID7sx (2) to connector C2 or C3.

Ensure that the locking tip of the spacer engages here.

4. Remove blind plug from desired interface connection.

5. Insert and mount interface cable. Ensure the correct position of the outer seal

when doing so.

6. Label 4-pin plug on module CL20mA-ID7sx or RS232-ID7sx (3) as "C2" or

"C3". The stickers are located inside the housing.

7. Connect wires of the interface cable to the 4-pin plug in accordance with terminal

diagram 22006478.

8. Lay cable in the cable holder on the inside of the housing.

9. Reattach keyboard, display and backlighting cables to the mainboard.

10. Close housing cover of ID7sx again. Ensure correct position of housing seal

when doing so.

Guide for installers 22008316B 04/09 17

Page 20

Optional work

C1

T1

S3

S2

S1

W1

S3

ID7sx

4.5 Installing digital inputs/outputs

Digital inputs/outputs 8 I/O-ID7sx can be installed in the ID7sx weighing terminal if

not already installed at the factory.

4

1

3

2

1. Open housing cover of ID7sx and unplug keyboard, display and backlighting

cables.

2. Remove the 4 nuts (3) from the mainboard and place 4 spacer pins (1) in their

places.

3. Mount the module 8 I/O-ID7sx (4) to the ID7sx mainboard with 4 nuts.

4. Insert ribbon cable (2) into connector I/O on the ID7sx mainboard.

5. Remove blind plug from the back of the housing.

6. Insert and mount interface cable. Ensure the correct position of the outer seal

when doing so.

7. Connect wires of the interface cable to module 8 I/O-ID7sx.

8. Lay cable in the cable holders on the inside of the housing.

9. Reattach keyboard, display and backlighting cables to the mainboard.

10. Close housing cover of ID7sx again. Ensure correct position of housing seal

when doing so.

18 Guide for installers 22008316B 04/09

Page 21

ID7sx

Optional work

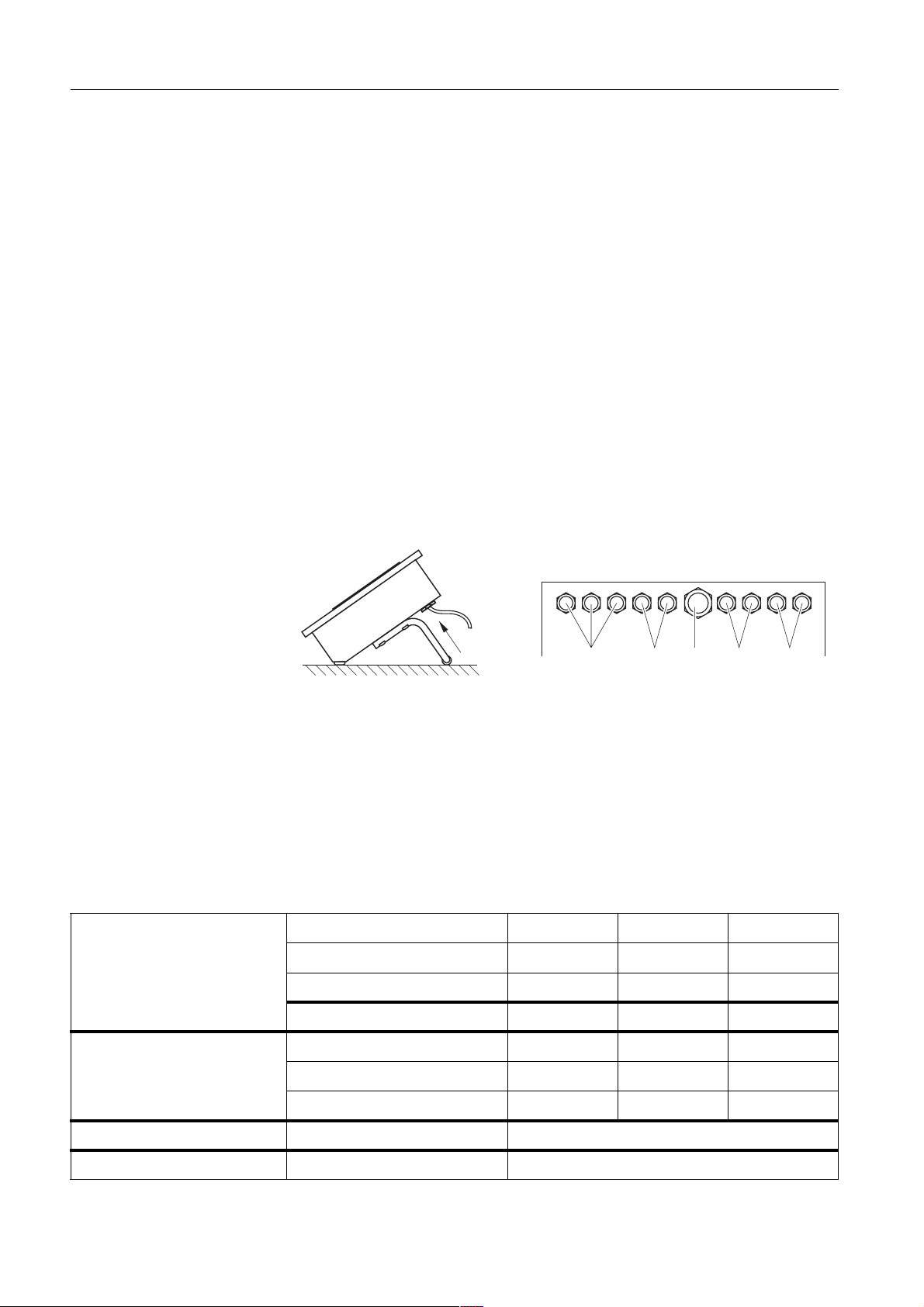

4.6 Connecting barcode scanner

A barcode scanner, e.g. ELB SK200 (SC20-MTA1), can be connected to the ID7sx

weighing terminal via an intrinsically safe RS232 data interface.

The barcode kit for ID7sx consists of the following components:

• Barcode scanner ELB SK200 (SC20-MTA1)

• RS232-ID7sx module

• Viper-Ex slotcard (SW)

• Screw gland

Mounting

1. Install Viper-Ex (SW) slotcard in the PSU. See PSU installation instructions.

2. Install RS232-ID7sx module in the ID7sx weighing terminal as COM2 or COM3.

See Section 4.4.

3. Pull in the barcode scanner cable and mount it with the screw gland.

4. Connect wires of the barcode scanner cable at plug C2 or C3 in accordance with

terminal diagram 22006478.

Caution

The yellow wire insulated with a heat-shrink sleeve may not be connected in the

hazardous area!

Note

• The yellow wire of the barcode scanner cable is insulated with a 1.5 cm heat-

shrink sleeve at the factory.

• The green, brown and white wire of the barcode scanner cable is stripped 3 cm at

the factory and provided with wire-end ferrules.

Heat-shrink sleeve 1.5 cm

yellow

3 cm

wire end ferules

green

brown

white

R./4

R./3

R./2

R./1

Guide for installers 22008316B 04/09 19

Page 22

Optional work

ID7sx

4.7 Attaching Profibus-DP module

The ID7sx can be connected to a Profibus network with the Profibus-DP module.

The Profibus-DP module is a top-hat rail module for installation in the control

cabinet. It requires an external power supply of 24 V DC +/- 20%, 100 mA.

Condition

A slotcard interface with the RS232-PSU module must be installed and connected up

in the PSU for a data interface CL20mA-ID7sx of the ID7sx. See Section 4.4 or the

PSU installation instructions.

1. Insert the Profibus-DP module at the relevant interface connection of the PSU.

2. Connect the Profibus-DP module to the 24 V power supply.

3. Integrate the Profibus-DP module into the Profibus network.

4. In master mode of the ID7sx, select the PROFIBUS DP operating mode for the

relevant interface and set parameters. See ID7sx weighing terminal operating

instructions.

5. De-energise the Profibus-DP module after setting all parameters.

6. Connect the Profibus-DP module to the power supply again. The parameter

settings made are now active and the ID7sx is integrated into the Profibus-DP

network.

20 Guide for installers 22008316B 04/09

Page 23

ID7sx

5 Dimensional drawings

5.1 Desk unit

362

132 127

Dimensional drawings

9

12.5

A - A

250

(4x) M4

194

332

66.5

39

85

50

197

89.5

225

A

5

263

35°

203

60

Dim. in mm

Guide for installers 22008316B 04/09 21

Page 24

Dimensional drawings

ID7sx

5.2 Panel unit

5.3 Wall unit

PA

3

256

410

Dim. in mm

PA

207

55°

77

3

256

353

Dim. in mm

22 Guide for installers 22008316B 04/09

Page 25

ID7sx

Dimensional drawings

Drilling template

125

100

60

(4x) Ø9

3047.5

120

142

Dim. in mm

Guide for installers 22008316B 04/09 23

Page 26

22008316B

Subject to technical changes © Mettler-Toledo (Albstadt) GmbH 04/09 Printed in Germany 22008316B

Mettler-Toledo (Albstadt) GmbH

D-72458 Albstadt

Tel. ++49-7431-14 0, Fax ++49-7431-14 232

Internet: http://www.mt.com

Loading...

Loading...