Page 1

MT-SICS Interface Command

Reference Manual

for Weigh Modules

Page 2

Page 3

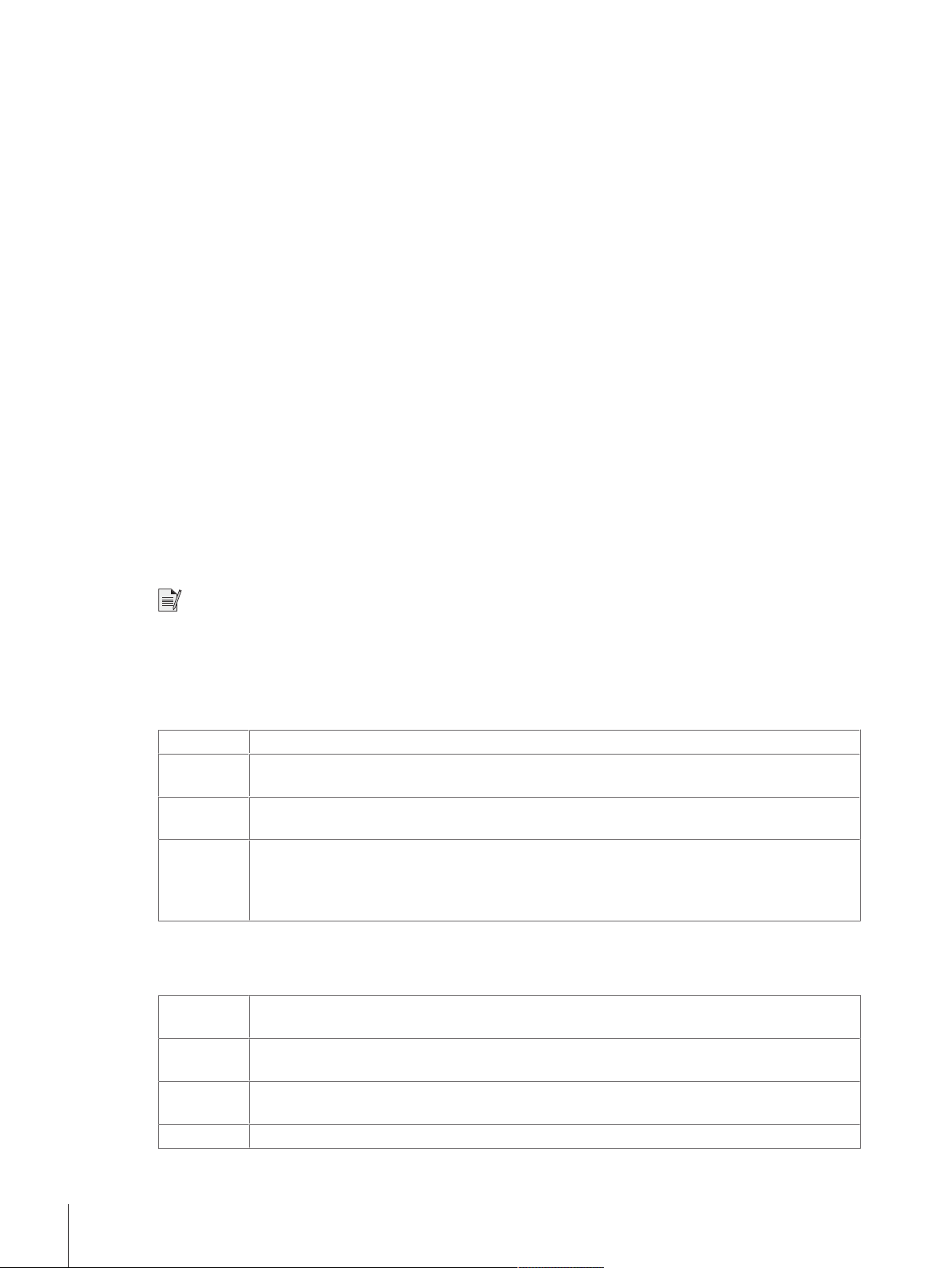

Table of Contents

1 Configuration tool 5

2 Introduction 6

2.1 Command formats....................................................................................................... 6

2.2 Tips for programmers................................................................................................... 13

3 Commands and Responses 15

2.1.1 Language conventions................................................................................... 6

2.1.2 Response formats ......................................................................................... 8

2.1.2.1 Format of responses with weight value ...................................................... 8

2.1.2.2 Format of responses without weight value .................................................. 9

2.1.3 Error messages............................................................................................. 10

2.1.3.1 Command-specific error messages ........................................................... 10

2.1.3.2 General error messages ........................................................................... 10

2.1.4 Specific error messages on weight response .................................................... 12

@ – Cancel ................................................................................................................. 15

A01 – Percent weighing: Reference in % ........................................................................ 16

A02 – Sample identification for samples in weighing application....................................... 17

A03 – Sample name for samples in weighing application................................................. 18

A10 – Nominal, +Tolerance, -Tolerance ......................................................................... 19

A30 – Internal loads..................................................................................................... 20

C – Cancel all commands............................................................................................. 21

C0 – Adjustment setting................................................................................................ 22

C1 – Start adjustment according to current settings.......................................................... 24

C2 – Start adjustment with external weight...................................................................... 26

C3 – Start adjustment with internal weight ...................................................................... 28

C4 – Standard / initial adjustment.................................................................................. 29

C5 – Enabling/disabling step control.............................................................................. 31

C6 – Customer linearization and sensitivity adjustment .................................................... 32

C7 – Customer standard calibration............................................................................... 35

C8 – Sensitivity adjustment........................................................................................... 38

C9 – Scale placement sensitivity adjustment ................................................................... 41

COM – Parameters of the serial interfaces ....................................................................... 44

D – Write text to display................................................................................................ 46

DAT – Date.................................................................................................................. 47

DIN – Configuration for digital inputs.............................................................................. 48

DIS – Digital input status .............................................................................................. 49

DOS – Digital output status ........................................................................................... 50

DOT – Configuration for digital outputs ........................................................................... 51

DOTC – Configurable digital outputs – Weight monitor ..................................................... 52

DW – Show weight ...................................................................................................... 54

E01 – Current system error state.................................................................................... 55

E02 – Weighing device errors and warnings ................................................................... 56

E03 – Current system errors and warnings ..................................................................... 58

F01 – Automatic prefilling configuration.......................................................................... 59

F02 – Material filling duration configuration .................................................................... 60

F03 – Automatic refilling configuration ........................................................................... 61

F04 – Target weight configuration.................................................................................. 62

F05 – Optimization function configuration....................................................................... 63

F06 – Weight monitor function configuration................................................................... 65

F07 – Time monitor function configuration...................................................................... 67

F08 – Filling statistics .................................................................................................. 69

F09 – Filling application status...................................................................................... 70

F10 – Control filling ..................................................................................................... 72

F11 – Report filling state............................................................................................... 74

Table of Contents 1MT-SICS Interface Command

Page 4

F12 – Filling stability criteria configuration ...................................................................... 75

F13 – Filling phase configuration................................................................................... 77

F14 – Automatic tare configuration ................................................................................ 79

F15 – Digital output function configuration...................................................................... 80

F16 – Emptying function configuration ........................................................................... 82

FCUT – Filter characteristics (cut-off frequency) ............................................................... 83

FSET – Reset all settings to factory defaults ..................................................................... 84

I0 – Currently available MT-SICS commands................................................................... 85

I1 – MT-SICS level and level versions ............................................................................. 86

I2 – Device data (Type and capacity)............................................................................. 87

I3 – Software version number and type definition number ................................................. 88

I4 – Serial number ....................................................................................................... 89

I5 – Software material number....................................................................................... 90

I10 – Device identification............................................................................................. 91

I11 – Model designation............................................................................................... 92

I14 – Device information .............................................................................................. 93

I15 – Uptime............................................................................................................... 95

I16 – Date of next service ............................................................................................. 96

I21 – Revision of assortment type tolerances .................................................................. 97

I26 – Operating mode after restart.................................................................................. 98

I27 – Change history from parameter settings ................................................................. 99

I29 – Filter configuration............................................................................................... 100

I32 – Voltage monitoring .............................................................................................. 101

I43 – Selectable units for host unit ................................................................................. 102

I44 – Selectable units for display unit............................................................................. 103

I45 – Selectable environment filter settings...................................................................... 104

I46 – Selectable weighing modes .................................................................................. 106

I48 – Initial zero range ................................................................................................. 107

I50 – Remaining weighing ranges ................................................................................. 108

I51 – Power-on time .................................................................................................... 109

I52 – Auto zero activation settings ................................................................................. 110

I53 – Ipv4 runtime network configuration information....................................................... 111

I54 – Adjustment loads ................................................................................................ 113

I55 – Menu version...................................................................................................... 114

I56 – Scaled weight ramp value .................................................................................... 115

I59 – Get initial zero information.................................................................................... 117

I62 – Timeout.............................................................................................................. 119

I65 – Total operating time............................................................................................. 120

I66 – Total load weighed.............................................................................................. 121

I67 – Total number of weighings ................................................................................... 122

I69 – Service provider address ASCII .............................................................................. 123

I71 – One time adjustment status .................................................................................. 124

I73 – Sign Off.............................................................................................................. 125

I74 – GEO code at point of calibration - HighRes............................................................. 126

I75 – GEO code at point of use - HighRes....................................................................... 127

I76 – Total number of voltage exceeds ........................................................................... 128

I77 – Total number of load cycles.................................................................................. 129

I78 – Zero deviation..................................................................................................... 131

I79 – Total number of zero deviation exceeds ................................................................. 132

I80 – Total number of temperature exceeds..................................................................... 133

I81 – Temperature gradient........................................................................................... 135

I82 – Total number of temperature gradient exceeds ........................................................ 136

I83 – Software identification.......................................................................................... 138

K – Keys control .......................................................................................................... 140

LST – Current user settings............................................................................................ 143

M01 – Weighing mode................................................................................................. 144

M02 – Environment condition ....................................................................................... 145

Table of Contents2 MT-SICS Interface Command

Page 5

M03 – Auto zero function.............................................................................................. 146

M17 – ProFACT: Single time criteria ............................................................................... 147

M18 – ProFACT/FACT: Temperature criterion.................................................................... 149

M19 – Adjustment weight ............................................................................................. 150

M20 – Test weight ....................................................................................................... 151

M21 – Unit ................................................................................................................. 152

M22 – Custom unit definitions....................................................................................... 155

M23 – Readability, 1d/xd ............................................................................................. 156

M27 – Adjustment history............................................................................................. 157

M28 – Temperature value............................................................................................. 158

M29 – Weighing value release...................................................................................... 159

M31 – Operating mode after restart................................................................................ 160

M32 – ProFACT: Time criteria........................................................................................ 161

M33 – ProFACT: Day of the week................................................................................... 162

M34 – MinWeigh: Method ............................................................................................ 163

M35 – Zeroing mode at startup ..................................................................................... 164

M38 – Selective parameter reset .................................................................................... 165

M39 – SmartTrac: Graphic............................................................................................ 166

M43 – Custom unit...................................................................................................... 167

M44 – Command executed after startup response ........................................................... 168

M45 – Electrical termination of RS422/ RS485 data lines................................................. 169

M47 – Frequently changed test weight settings................................................................ 170

M48 – Infrequently changed test weight settings.............................................................. 172

M49 – Permanent tare mode......................................................................................... 174

M66 – GWP: Certified test weight settings....................................................................... 175

M67 – Timeout............................................................................................................ 177

M68 – Behavior of serial interfaces ................................................................................ 178

M69 – Ipv4 network configuration mode ........................................................................ 179

M70 – Ipv4 host address and netmask for static configuration.......................................... 181

M71 – Ipv4 default gateway address ............................................................................. 183

M72 – Ipv4 DNS server address.................................................................................... 185

M89 – Interface command set....................................................................................... 187

M103 – RS422/485 driver mode .................................................................................. 188

M109 – IPv4 device managed network configuration setting............................................. 189

M110 – Change display resolution ................................................................................ 190

MOD – Various user modes .......................................................................................... 192

MONH – Monitor on interface ........................................................................................ 194

NID – Node Identification (for network protocols)............................................................. 195

NID2 – Device node ID................................................................................................. 196

PROT – Protocol mode ................................................................................................. 197

PW – Piece counting: Piece weight ................................................................................ 198

PWR – Switch on / Switch off ........................................................................................ 199

R01 – Restart device.................................................................................................... 200

RDB – Readability........................................................................................................ 201

S – Stable weight value ................................................................................................ 202

SC – Send stable weight value or dynamic value after timeout........................................... 203

SI – Weight value immediately ...................................................................................... 204

SIC1 – Weight value with CRC16 immediately................................................................. 205

SIC2 – HighRes weight value with CRC16 immediately .................................................... 206

SIR – Weight value immediately and repeat .................................................................... 207

SIRU – Weight value in display unit immediately and repeat ............................................. 208

SIS – Send netweight value with actual unit and weighing status ....................................... 209

SIU – Weight value in display unit immediately ............................................................... 212

SIUM – Weight value in display unit and MinWeigh information immediately ...................... 213

SNR – Send stable weight value and repeat on stable weight change................................. 214

SNRU – Send stable weight value with currently displayed unit and repeat on stable weight

change....................................................................................................................... 216

Table of Contents 3MT-SICS Interface Command

Page 6

SR – Send stable weight value and repeat on any weight change ...................................... 218

SRU – Send stable weight value with currently displayed unit and repeat on any weight

change....................................................................................................................... 220

ST – Stable weight value on pressing (Transfer) key ........................................................ 222

SU – Stable weight value in display unit ......................................................................... 223

SUM – Stable weight value in display unit and MinWeigh information ................................ 224

T – Tare...................................................................................................................... 225

TA – Tare weight value ................................................................................................. 226

TAC – Clear tare weight value........................................................................................ 227

TC – Tare or tare immediately after timeout ..................................................................... 228

TI – Tare immediately................................................................................................... 230

TIM – Time.................................................................................................................. 231

TST0 – Query/set test function settings............................................................................ 232

TST1 – Test according to current settings ........................................................................ 233

TST2 – Test with external weight .................................................................................... 235

TST3 – Test with internal weight..................................................................................... 236

TST5 – Module test with built-in weights (scale placement sensitivity test).......................... 237

UPD – Update rate of SIR and SIRU output on the host interface......................................... 239

USTB – User stability criteria.......................................................................................... 240

WMCF – Configuration of the weight monitoring functions................................................. 242

Z – Zero...................................................................................................................... 244

ZC – Zero or zero immediately after timeout..................................................................... 245

ZI – Zero immediately................................................................................................... 246

4 What if...? 247

5 Appendix 248

5.1 Framed protocol .......................................................................................................... 248

Index 251

Table of Contents4 MT-SICS Interface Command

Page 7

1 Configuration tool

METTLER TOLEDO recommends APW-Link™ as a configuration tool

APW-Link™ is a Windows based software.

Features

• Configuration Tree for easy commissioning and parameterization

• Multiple, selectable languages

• Terminal with free configurable buttons

• Automatic baud rate search

• Connection over RS232, USB to RS232 converter and Ethernet TCP/IP possible

• Weight Display with Zeroing and Taring button

• Graph Display with zoom function and x-y Data

• Backup / Restore feature

• Supports all APW weigh modules

• Supported operating systems: Windows XP - Professional - SP3; Windows 7 - Professional / Enterprise /

Ultimate; Windows 8 / 8.1 – Professional / Enterprise; Windows Server 2003/ 2010

Download

http://www.mt.com/apw-link APW-Link™ is free of charge but requires a registration before download.

Configuration tool 5MT-SICS Interface Command

Page 8

2 Introduction

Real weighing applications have very wide-ranging requirements which can at some cases necessitate

weighing up to several hundred tons and at some applications the demanded readability could be very fine,

sometimes as low as one micro-gram. METTLER TOLEDO offers an extensive range of weighing devices in

order to fulfill these versatile requirements. These weighing devices provide a simple interface for a quick

integration with control systems. This integration is further facilitated by standardized commands which enable

certain functions and operations. Throughout this document, the term "weigh module" is used to cover also the

term "(weighing) bridge" which is operated without any terminal. The term "balance" denotes a weighing device

in combination with a terminal.

Version number of the MT-SICS

Each level of the MT-SICS has its own version number which can be requested with the command "I1" from

level 0. You can use the command "I1" via the interface to request the MT-SICS level and MT-SICS versions

implemented on your weigh module.

Data interface at weigh module

Settings of the interface such as baud rate, number of data bits, parity, handshake protocols and connector pin

assignment are described in the Reference Manual of the optional interface and the peripheral instrument or

cable in question.

Data exchange with the weigh module

Each command received by the balance via the data interface is acknowledged by a response of the weigh

module or balance to the initial device.

Commands and balance responses are data strings with a fixed format, and will be described in detail in the

commands.

The existing commands that are available can be called up using the [I0}Page85] command.

Note

Some of the commands work only via the built-in RS232 interface.

2.1 Command formats

Commands sent to the weigh module/balance comprise one or more characters of the ASCII character set.

Here, the following must be noted:

Enter commands only in uppercase. Nevertheless, units have to be capitalized properly.

V The possible parameters of the command must be separated from one another and from the

command name by a space (ASCII 32 dec.).

"text" The possible input for "text" is a sequence of characters (8-bit ASCII character set from 32 dec.

to 255 dec.).

..CR LF Each command must be closed by C

The characters CRLF, which can be inputted using the Enter or Return key of most entry keypads,

are not listed in this description every time, but it is essential they be included for communication with the weigh module/balance.

2.1.1 Language conventions

Throughout this manual, the following conventions are used for command and response syntax:

< > Triangle brackets indicate that you must specify a value for the enclosed parameter. The

brackets are not sent with the command string.

[ ] Square brackets indicate that the enclosed expression is optional and can be omitted. The

brackets are not sent with the command string.

a..b Intervals or ranges are represented using the "dot-dot" notation indicating the set of numbers

from a to b including a and b.

Ü Commands sent to the weigh module/balance.

(ASCII 13 dec., 10 dec.).

RLF

Introduction6 MT-SICS Interface Command

Page 9

Û Response of the weigh module/balance.

Example

Command to balance which writes Hello into the balance display:

DV"Hello"

Ü

Û

DVA

The quotation marks " " must be inserted in the entry

Command executed successfully

The command terminator CRLF is not shown.

Introduction 7MT-SICS Interface Command

Page 10

2.1.2 Response formats

All responses sent by the weigh module/balance to the transmitter to acknowledge the received command have

one of the following formats:

• Response with weight value

• Response without weight value

• Error message

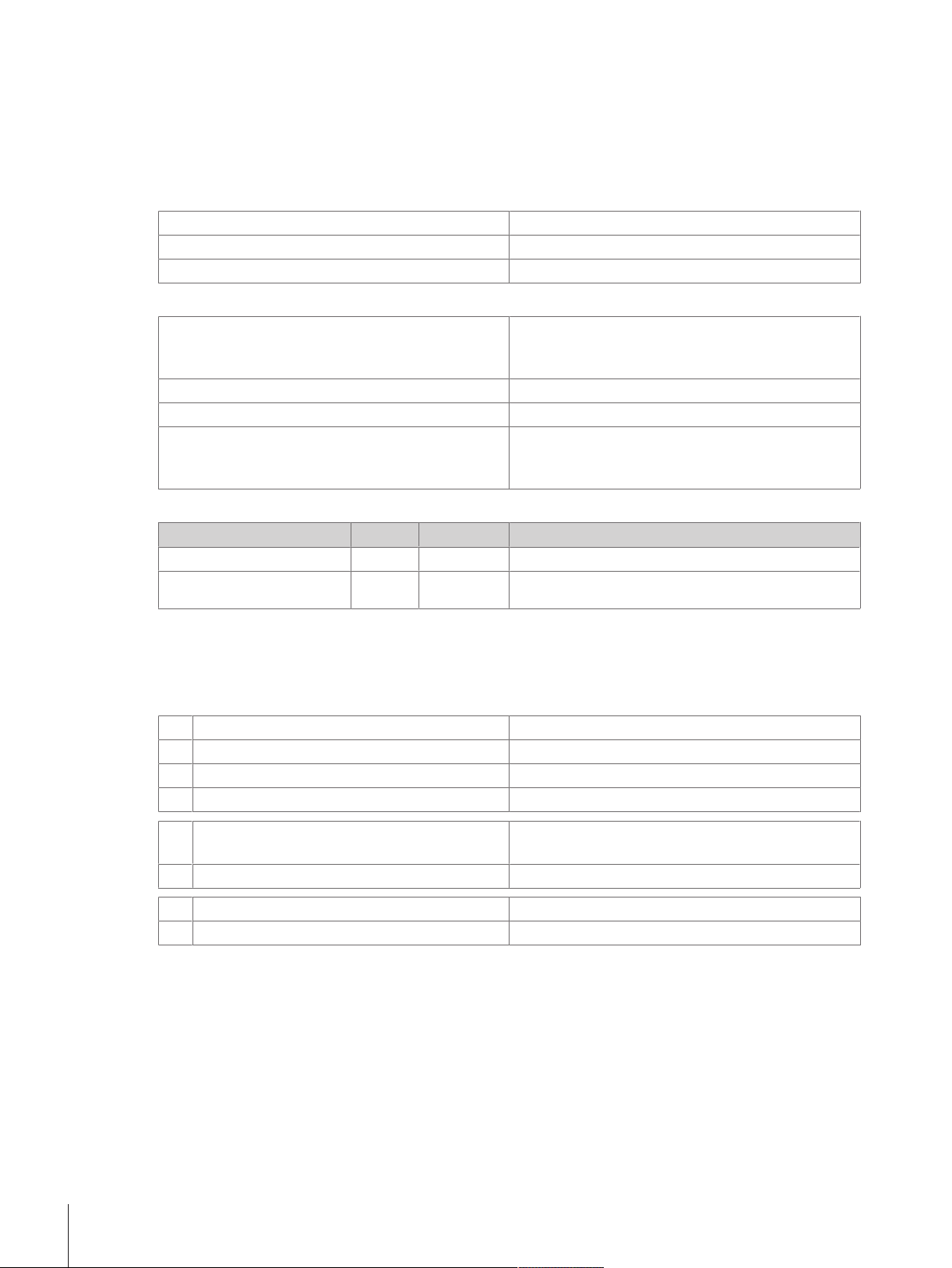

2.1.2.1 Format of responses with weight value

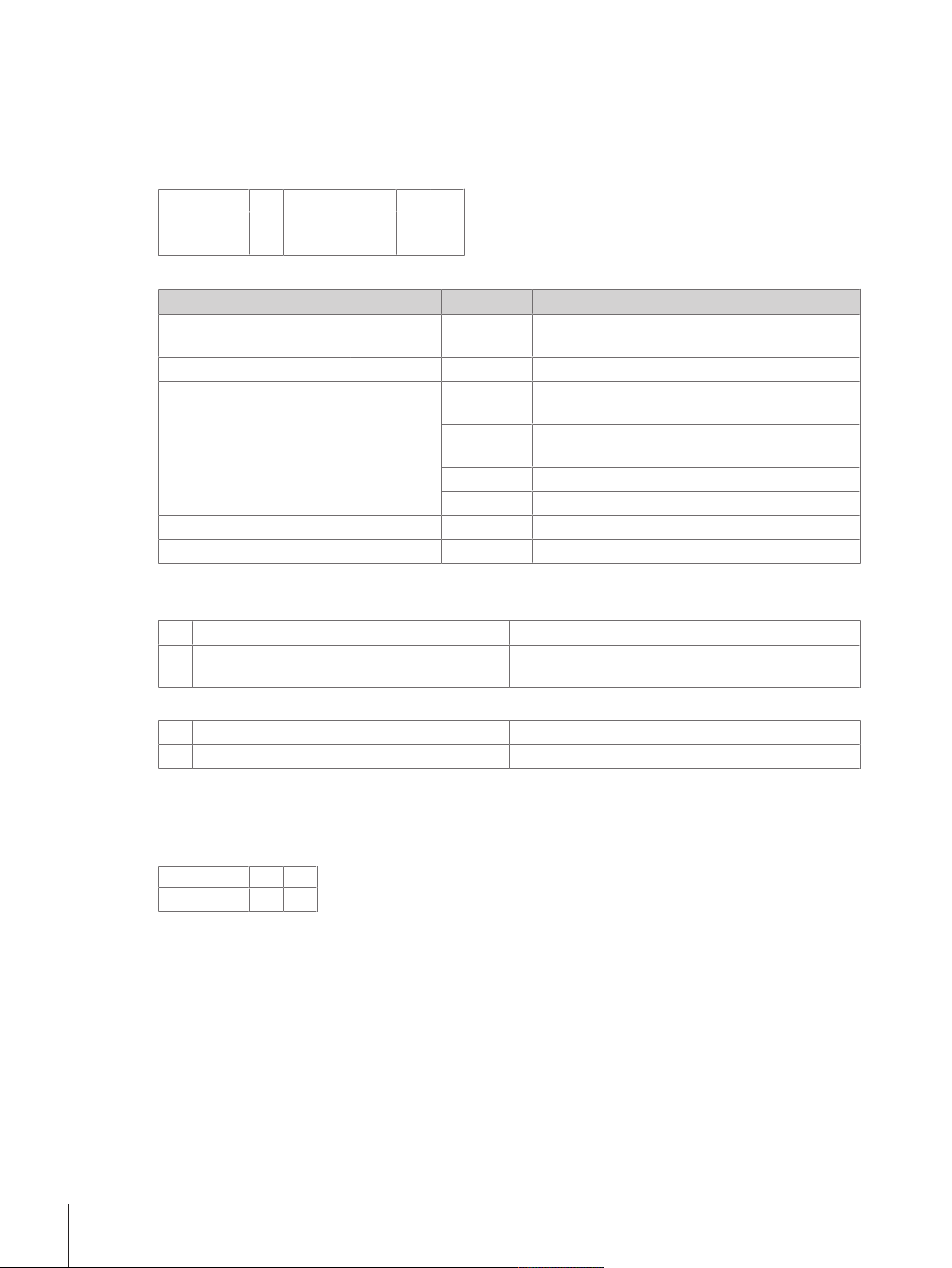

Syntax

A general description of the response with weight value is the following.

<ID>

1-2

characters

Parameters

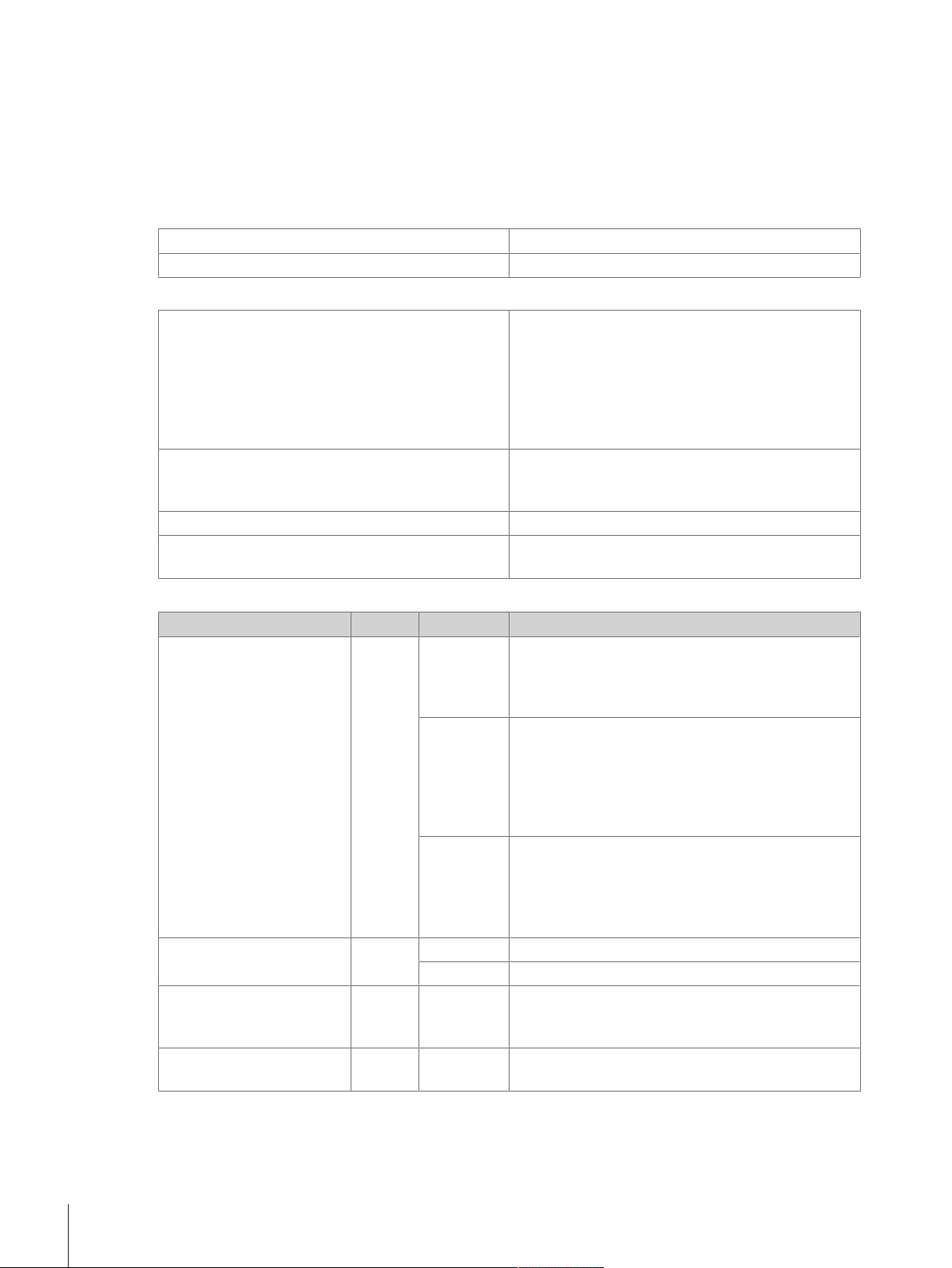

Name Type Values Meaning

<ID>

V

<Status>

<WeightValue>

<Unit>

C

R

L

F

V

<Status>

1

character

V

String Response identification, refers to the invoking

Blank Space (ASCII 32 dec.)

Character

Float Weighing result; shown as a number with 10

String Weight unit as actually set under host unit

Byte Carriage return (ASCII13dec.)

Byte Line feed (ASCII10dec.)

<WeightValue>

10

characters

S

M

D

N

<Unit> CRL

V

F

1-5 characters

command

Stable weight value

Stable weight value, but below minimal weight

([SIUM}Page213] and [SUM}Page224] only)

Unstable ("D" for Dynamic) weight value

Unstable weight value, below minimal weight

([SIUM}Page213] and [SUM}Page224] only)

characters (after a blank/space!), including

decimal point, and minus sign (–) directly in front

of the first digit if the value is negative. The weight

value appears right aligned. Preceding zeros are

not shown except for the zero to the left of the

decimal point.

With METTLER TOLEDO DeltaRange balances,

outside the fine range the last decimal place is

shown as a space.

Examples

Response with stable weight value of 14.256 g:

S

Ü

SVSVVVVV14.256Vg

Û

Request a stable weight value.

Introduction8 MT-SICS Interface Command

Page 11

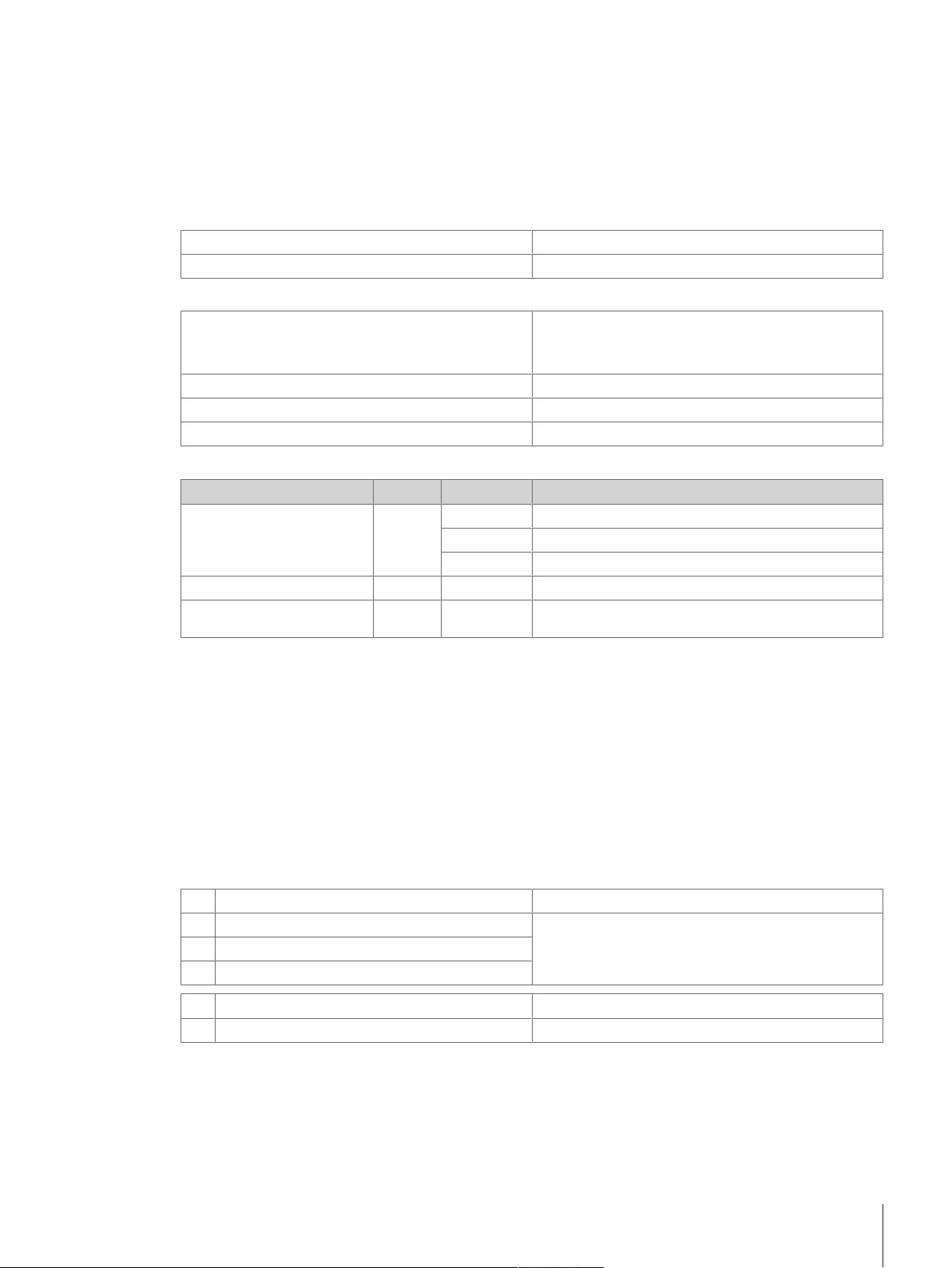

2.1.2.2 Format of responses without weight value

Syntax

A general description of the response without weight value is the following:

<ID>

1-5

characters

V

<Status>

1

character

Parameters… CRL

V

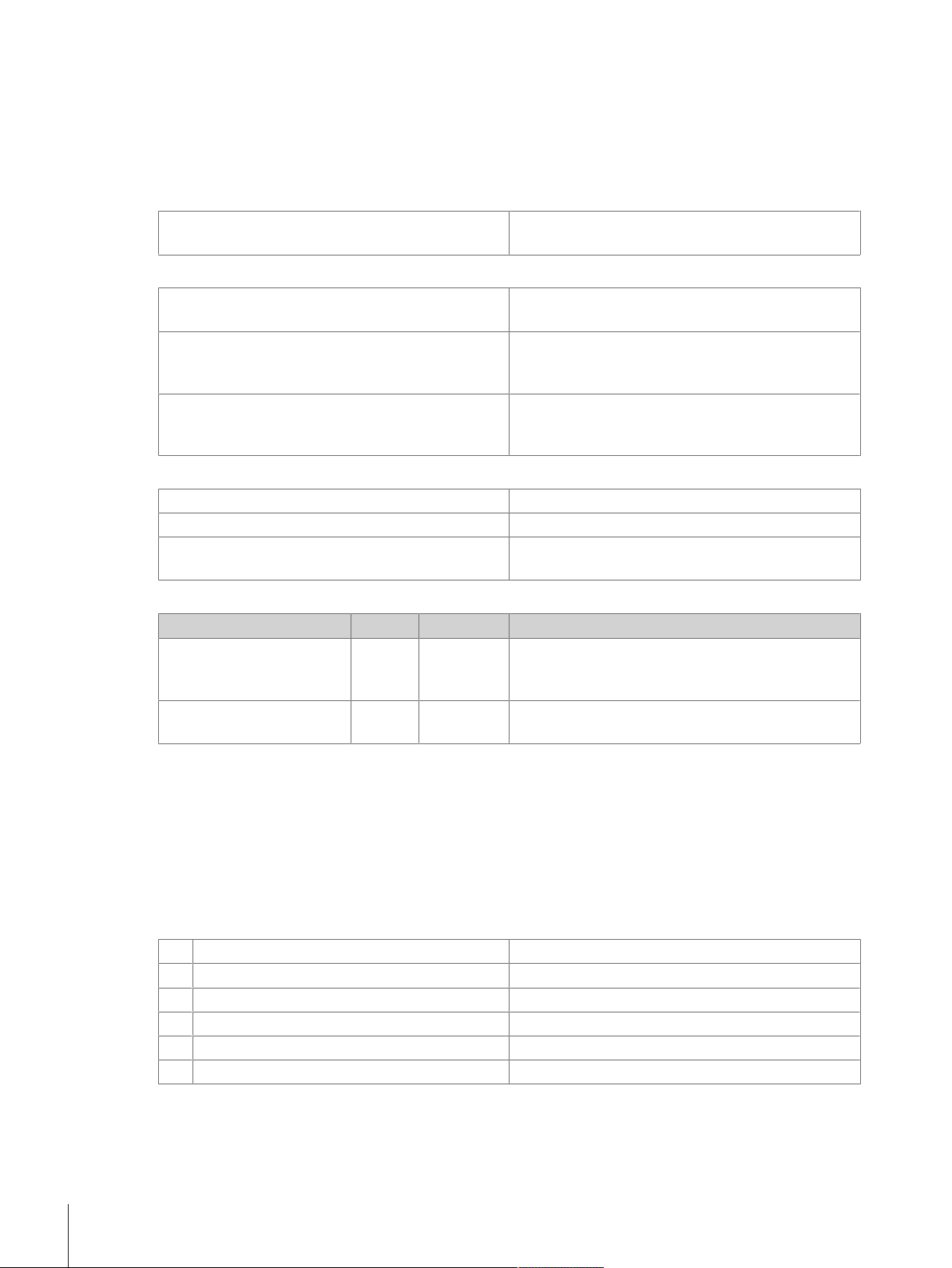

Parameters

Name Type Values Meaning

<ID>

V

<Status>

Parameters…

C

R

L

F

String Response identification, refers to the invoking

Blank Space (ASCII 32 dec.)

Character

A

B

Byte Carriage return (ASCII13dec.)

Byte Line feed (ASCII10dec.)

Examples

Set the update rate to 20 weight values per second:

UPDV20

Ü

UPDVA

Û

F

command

Command executed successfully

Command not yet terminated, additional responses

following

Command-dependent response code

Command executed successfully.

Query the actual update rate:

UPD

Ü

UPDVAV18.3

Û

Update rate is set to 18.3 values per second.

Introduction 9MT-SICS Interface Command

Page 12

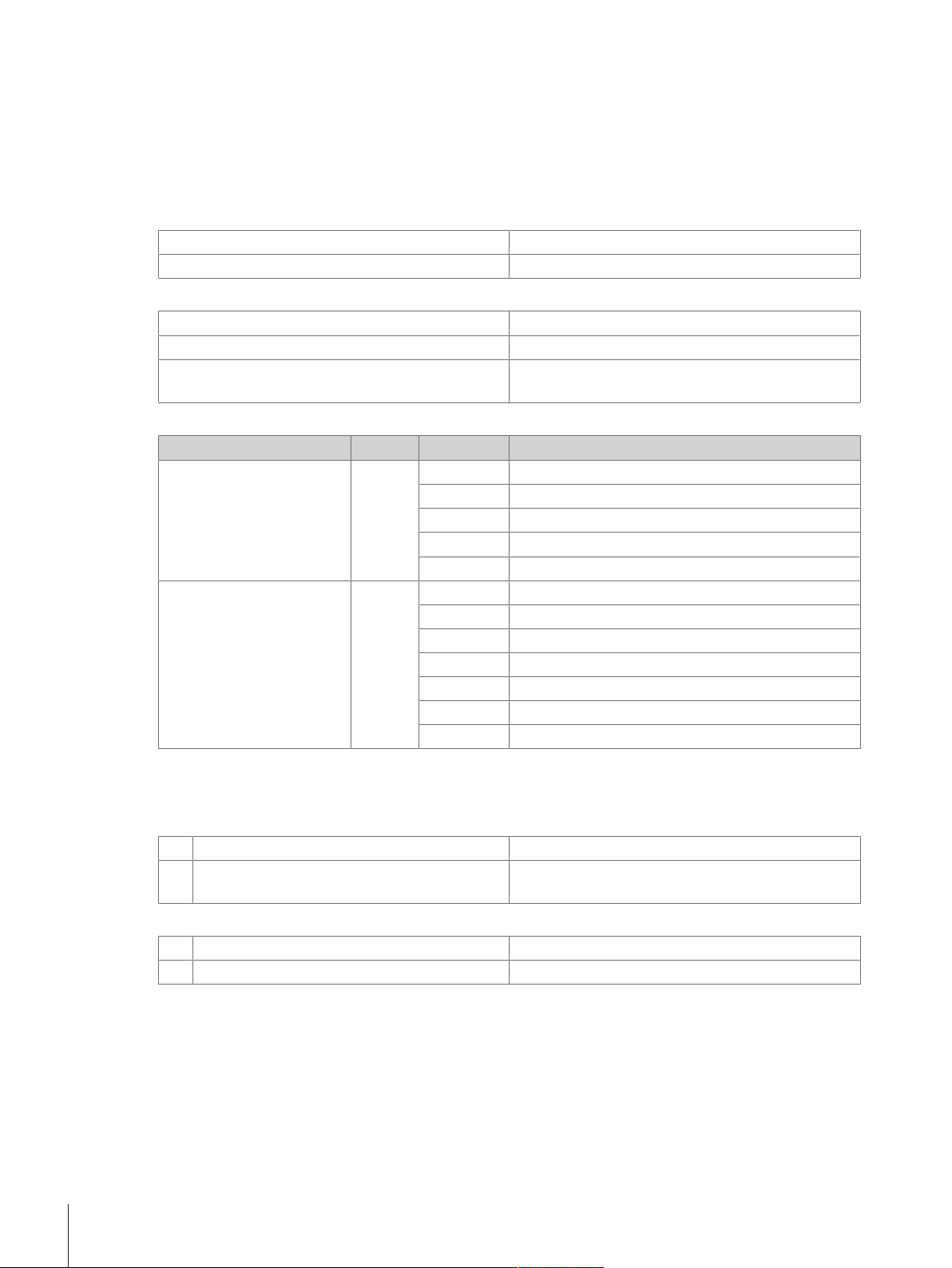

2.1.3 Error messages

2.1.3.1 Command-specific error messages

Syntax

A general description of the response without weight value is the following:

<ID>

1-5

characters

Parameters

Name Type Values Meaning

<ID>

V

<Status>

C

R

L

F

<Status> CRL

V

1

character

String Response identification, refers to the invoking

Blank Space (ASCII 32 dec.)

Character

Byte Carriage return (ASCII13dec.)

Byte Line feed (ASCII10dec.)

F

command

+

Weigh module or balance is in overload range

(weighing range exceeded)

-

Weigh module or balance is in underload range

(e.g. weighing pan is not in place)

L

I

Logical error (e.g. parameter not allowed)

Internal error (e.g. balance not ready yet)

Examples

Trial to set the update rate to 20 weight values per second:

UPDV290

Ü

UPDVL

Û

Response while weigh module or balance is in overload range:

SI

Ü

SV+

Û

2.1.3.2 General error messages

Syntax

There are three different error messages:

<ID> CRL

F

2 characters

Update rate accidentally set to 290.

Command not executed successfully; parameters is

outside valid range.

Request a weight value immediately.

Overload; no weight value available.

Introduction10 MT-SICS Interface Command

Page 13

Parameters

Name Type Values Meaning

<ID>

String

ES

Syntax error:

The weigh module/balance has not recognized the

received command or the command is not allowed

ET

Transmission error:

The weigh module/balance has received a "faulty"

command, e.g. owing to a parity error or interface

break

EL

Logical error:

The weigh module/balance can not execute the

received command

C

R

L

F

Byte Carriage return (ASCII13dec.)

Byte Line feed (ASCII10dec.)

Example

Trial to set the update rate to 20 weight values per second:

UPDV290

Ü

Û

UPDVL

Update accidentally set to 290.

Command not executed succesfully, parameters are

outside valid range.

Response while weigh module is in overload:

SI

Ü

Û

SV+

Send current weight value.

Overload; no weigh value available

Introduction 11MT-SICS Interface Command

Page 14

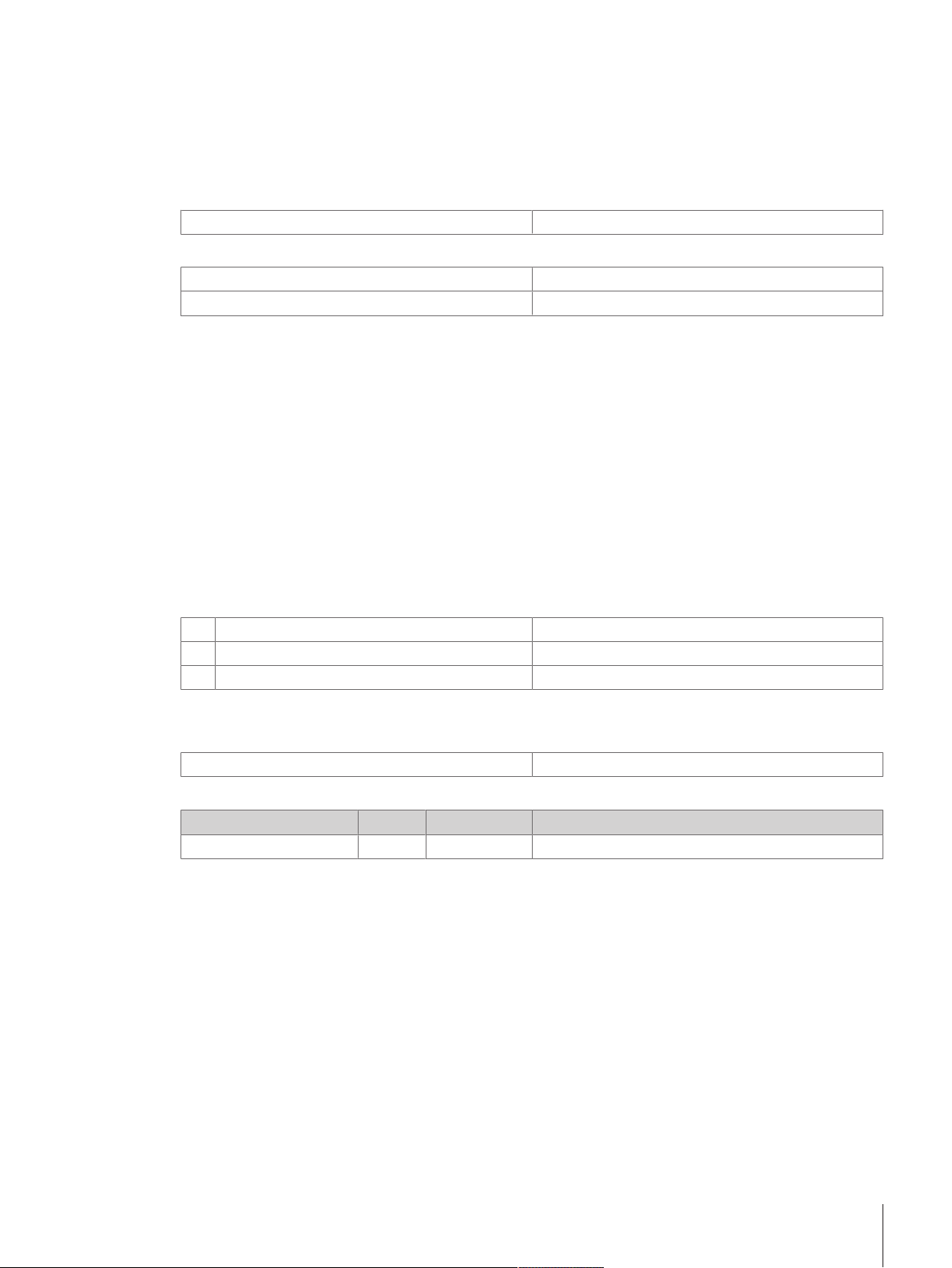

2.1.4 Specific error messages on weight response

Description

If any error is detected in the system, it is no longer possible to get a weight value. In this case the weight value

is overwritten with an error number and trigger code.

We recommend contacting your METTLER TOLEDO representative if any error occurs.

Syntax

The error message has the same format as the weight value (10 characters) and starts always with SVSV.

SVS V V..V

Error

1-2 spaces 1-2 characters 1 character

Total 10 characters (same as weight value) - Filled with spaces on the beginning

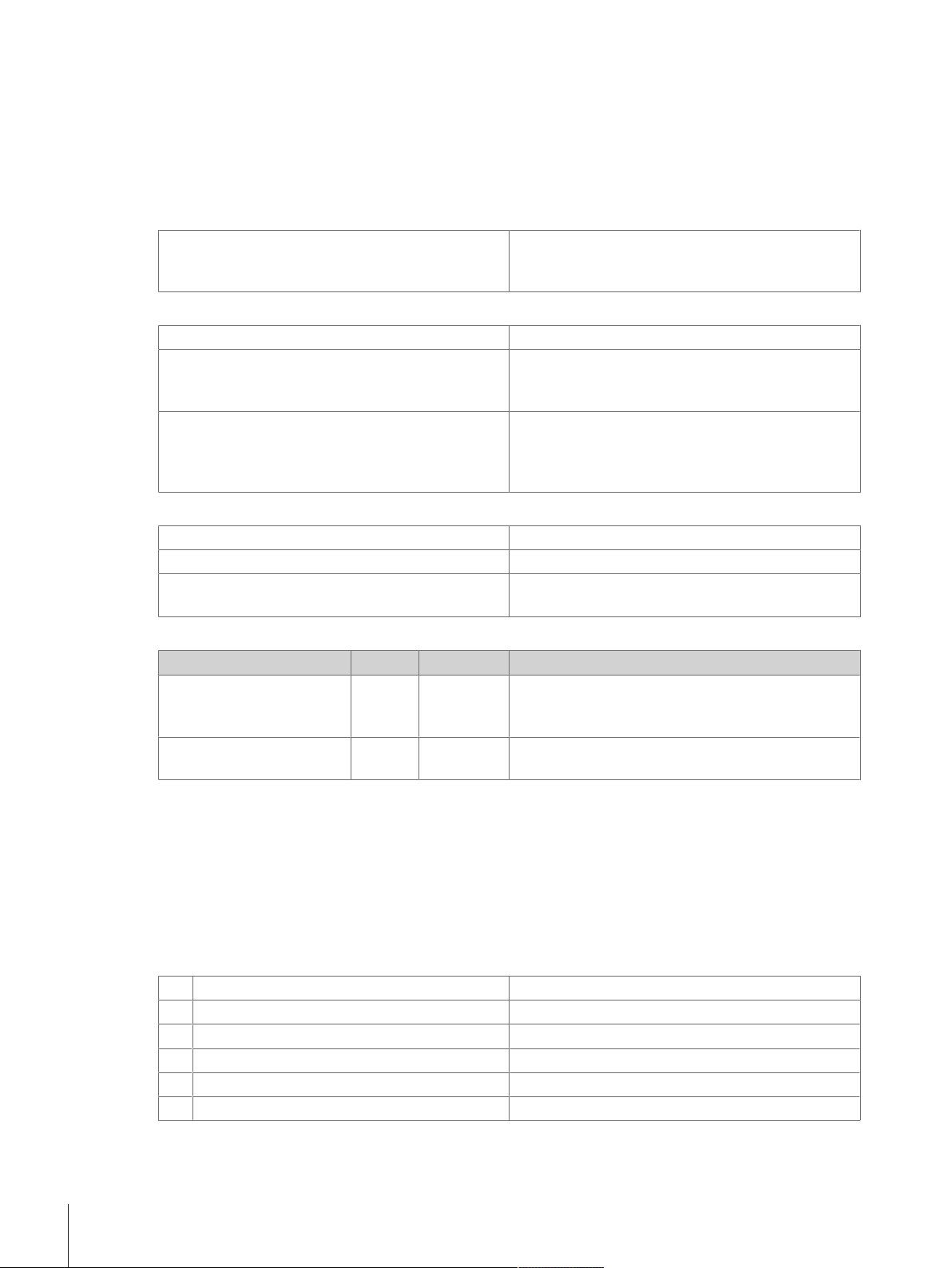

Parameters

Name Type Values Meaning

<ErrorNumber>

<ErrorTrigger>

C

R

L

F

Integer 1 Boot error

String b Error from electronics (weigh module)

Byte Carriage return (ASCII13dec.)

Byte Line feed (ASCII10dec.)

<ErrorNumber> <ErrorTrigger> CRL

V

2 Brand error

3 Checksum error

9 Option fail

10 EEPROM error

11 Device mismatch

12 Hot plug out

14 Weight module / electronic mismatch

15 Adjustment needed

t Error from terminal

F

Examples

SI

Ü

SVSVVErrorV10b

Û

SIR

Ü

SVSVVVErrorV1t

Û

Send current weight value.

EERPOM error on the electronic unit occurred! Check if

every thing is connected correctly. If any error occurs

after power restart, contact your METTLER TOLEDO

representative.

Send current weight value at intervals.

Boot error on the terminal occurred! If any error occurs

after power restart, contact your METTLER TOLEDO

representative.

Introduction12 MT-SICS Interface Command

Page 15

2.2 Tips for programmers

Overview of command of specific models

This reference manual covers the MT-SICS commands for weigh modules/balances. As the weigh modules/

balances can differ based on model and software version, not all the MT-SICS level 2 and 3 commands are

usable on every model. We therefore recommend using the [I0}Page85] command to get an overview of

all commands that are supported by a particular balance.

Planning the use of MT-SICS commands

Investigations of various applications have shown that the vast majority of all system solutions can be handled

with the commands of MT-SICS level 0 and 1. This means for you: if you restrict yourself to the commands of

MT-SICS level 0 and 1, you can expand your system with additional weigh modules, balances from METTLER

TOLEDO without having to change your application programs.

Setup with / without terminal

Use the same setup during configuration and later use: If you intend to use the weigh module without the

terminal, the configuration has to be done without terminal as well. Due to the system’s architecture, the

storage behavioral of configurations is different whether the terminal is attached to the bridge or not: With a

terminal attached, configuration is stored in the terminal’s memory; without a terminal attached, the bridge’s

memory is used. Removing a terminal after configuration means to remove the configuration and activation the

bridge’s (default) configuration. Adding a terminal after configuration means overriding the configuration with

the one stored within the terminal.

Command and response

You can improve the dependability of your application software by having your program evaluate the response

of the weigh module/balance to a command. The response is the acknowledgement that the weigh module/

balance has received the command.

Cancel

To be able to start from a determined state, when establishing the communication between weigh module/

balance and system, you should send a cancel command see [@}Page15] to the weigh module/balance.

When the balance or system is switched on or off, faulty characters can be received or sent.

Parameter values after switching the weigh module/balance on/off

The commands of the standard command are saved on the permanent memory of the weigh module/balance.

This means that all values changed via the interface are saved when the weigh module/balance is switched off.

Several commands in succession

If several commands are sent in succession without waiting for the corresponding responses, it is possible that

the weigh module/balance confuses the sequence of command processing or ignores entire commands.

METTLER TOLEDO DeltaRange balances and weigh modules

If the fine range of DeltaRange balances has been exceeded at the time of transmission, the weigh module/

balance sends a weight value as balance response in which the tenth character is a space.

Update rate and timeout

The update rate for repeated commands and the duration of the timeout (time-limit function) depend on the

weigh module/balance type; see technical data of the weigh module/balance in question.

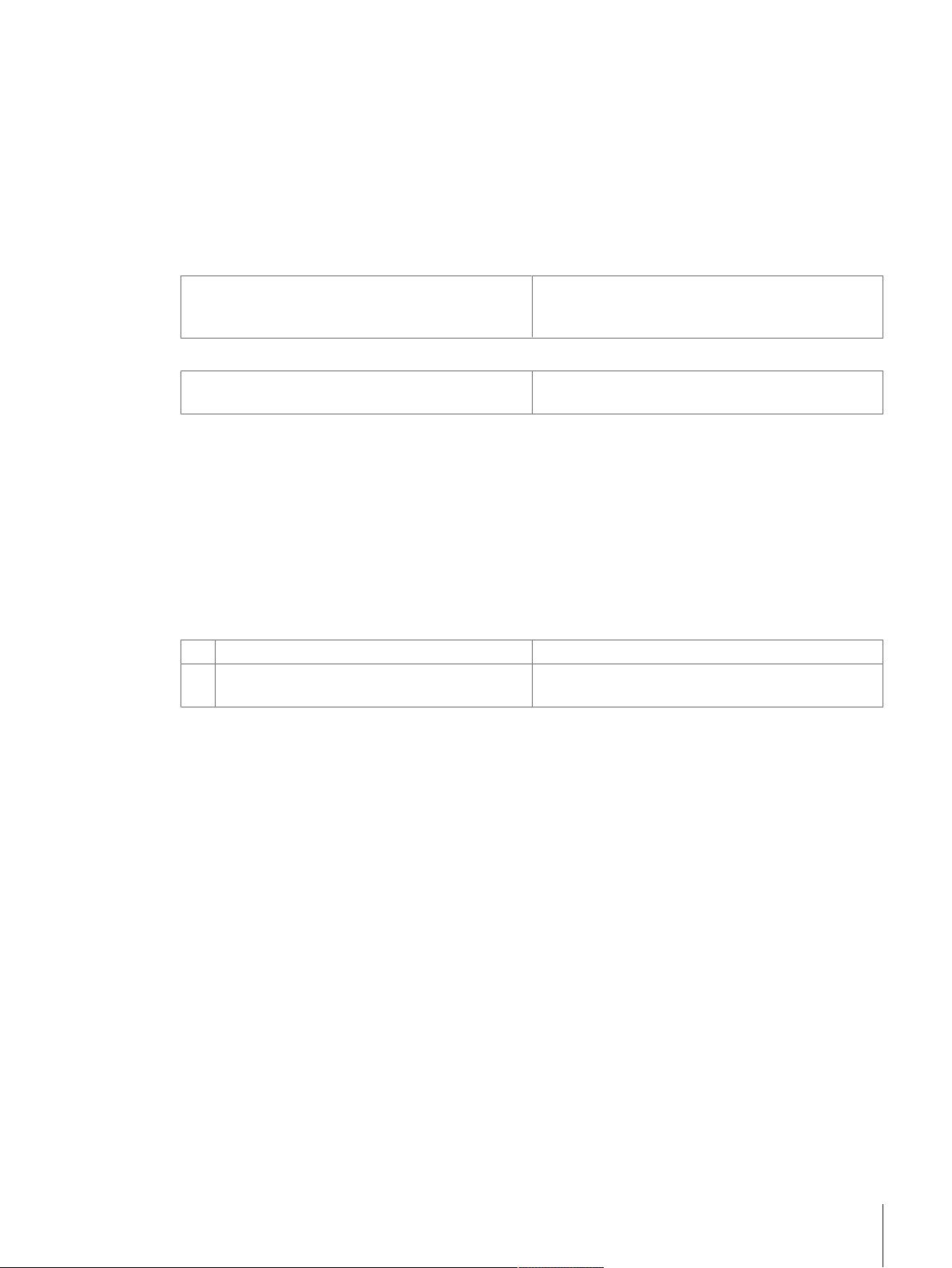

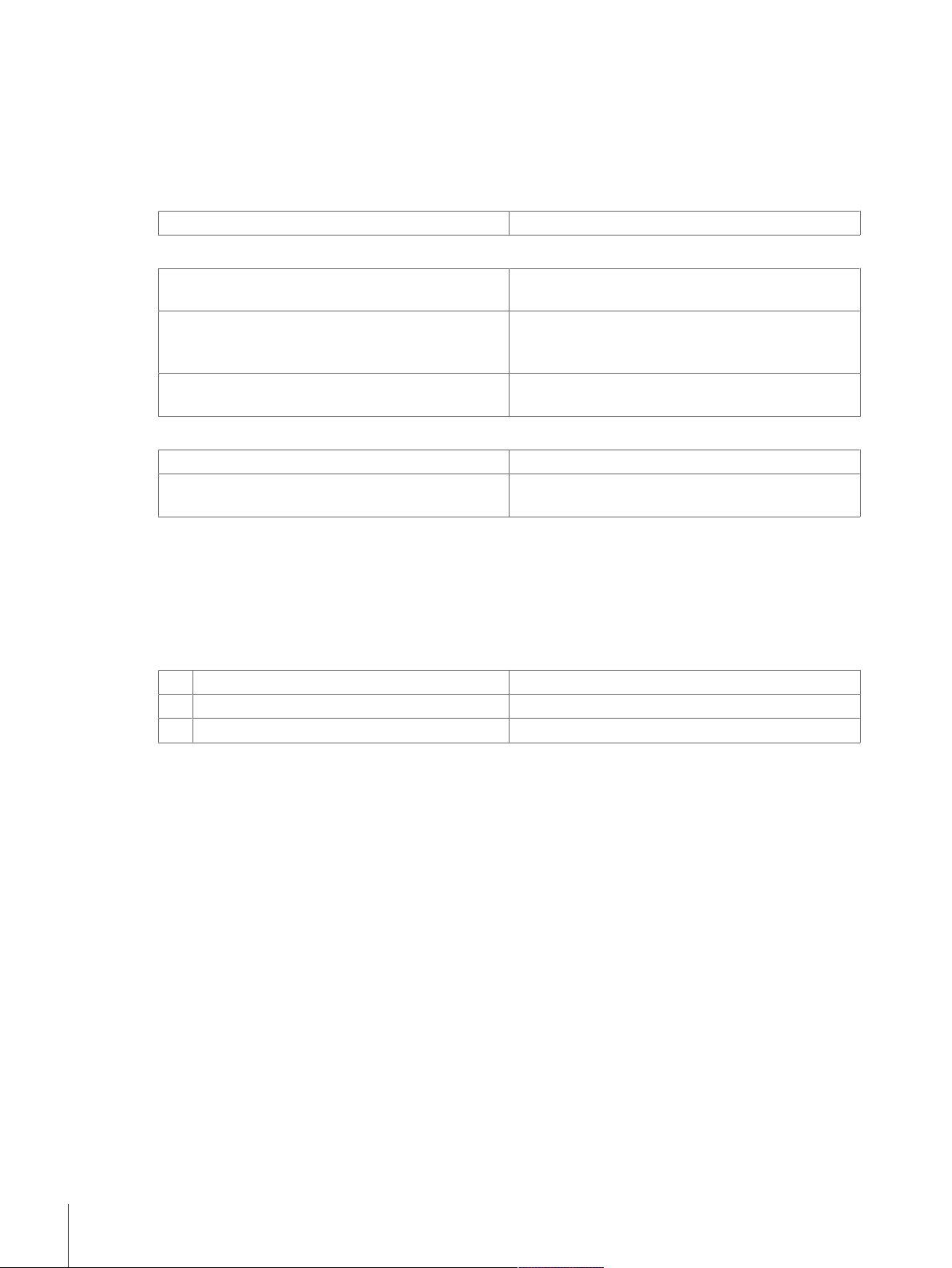

Carriage Return, Line Feed

Depending on the platform, CRLF is not just a "new line" (Java: "newLine()" or C/C++ "\n"):

Platform ‘New Line’

DOS/Windows CRL

Macintosh C

Unix L

F

R

F

Nevertheless, all commands have to be closed by a CRLF (dec: 13, 10; hex: 0D, 0A) which corresponds to

"ENTER" in most human machine interfaces.

Introduction 13MT-SICS Interface Command

Page 16

Quotation marks " "

Quotation marks included in the command must always be entered. If a quotation mark is located within the

string, it may be attained by a backslash (\):

DV"place 4\"filter!"

Ü

DVA

Û

Balance display: place 4" filter!

Weight unit of weight value – host unit

It is always essential to consider the weight unit that is to be used to display weighing results. Depending on

where the results are output, the weigh modules/balances offer the possibility of selecting a particular unit

see [M21}Page152]. This enables the displayed unit and info unit to be shown on the terminal. Host unit

is used to output the weighing results via an interface (host) on the basis of MT-SICS commands. The weight

values and the displayed unit can only be output by means of the SU commands.

Digit [d]

A digit refers to the smallest numerical increment a weigh module, balance can display – this is also referred to

as the weigh modules/balance’s readability. E.g. a WX205 has five decimal places; its digit is 0.01 mg. The

digit is sometimes used as a generic unit.

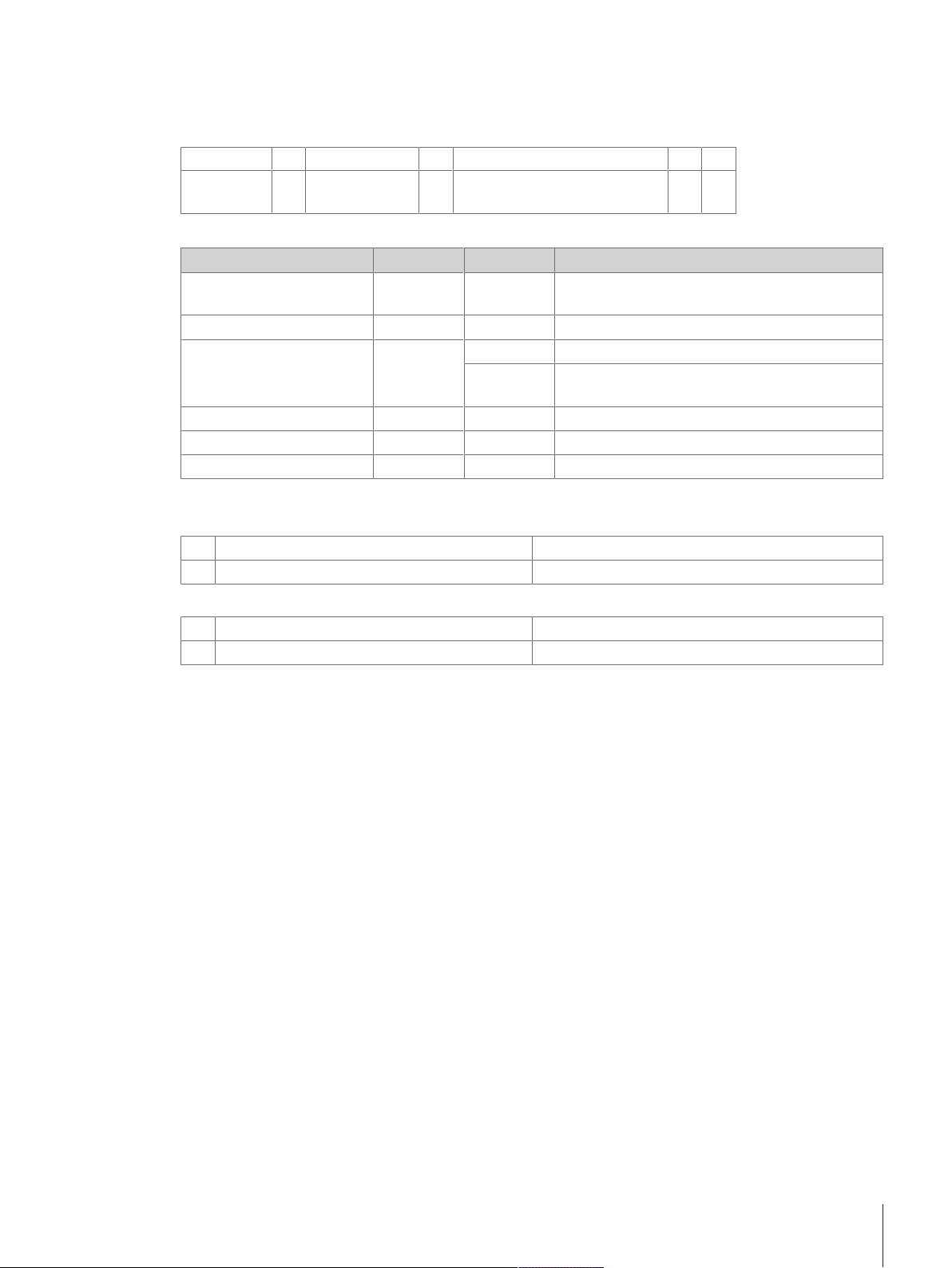

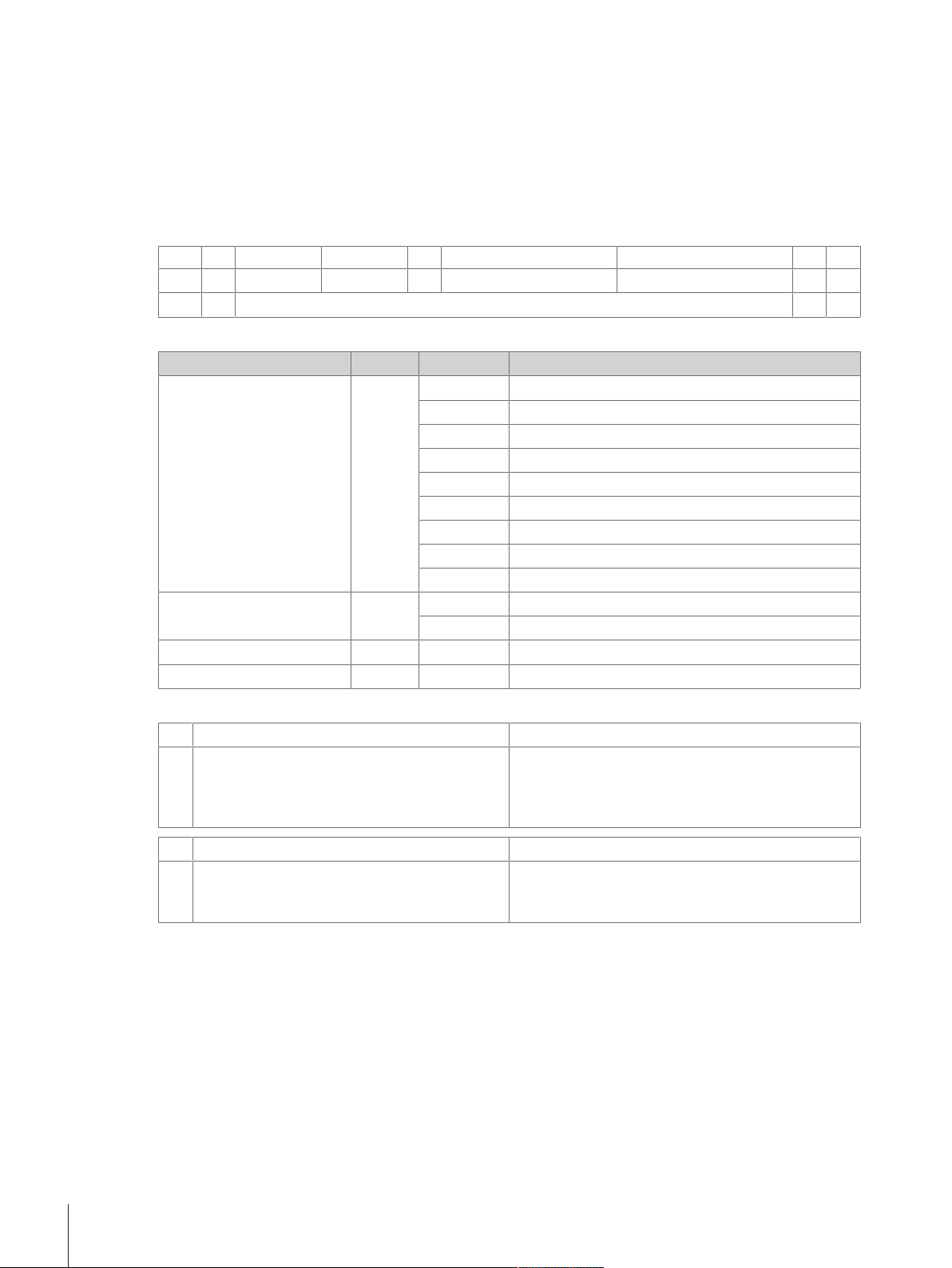

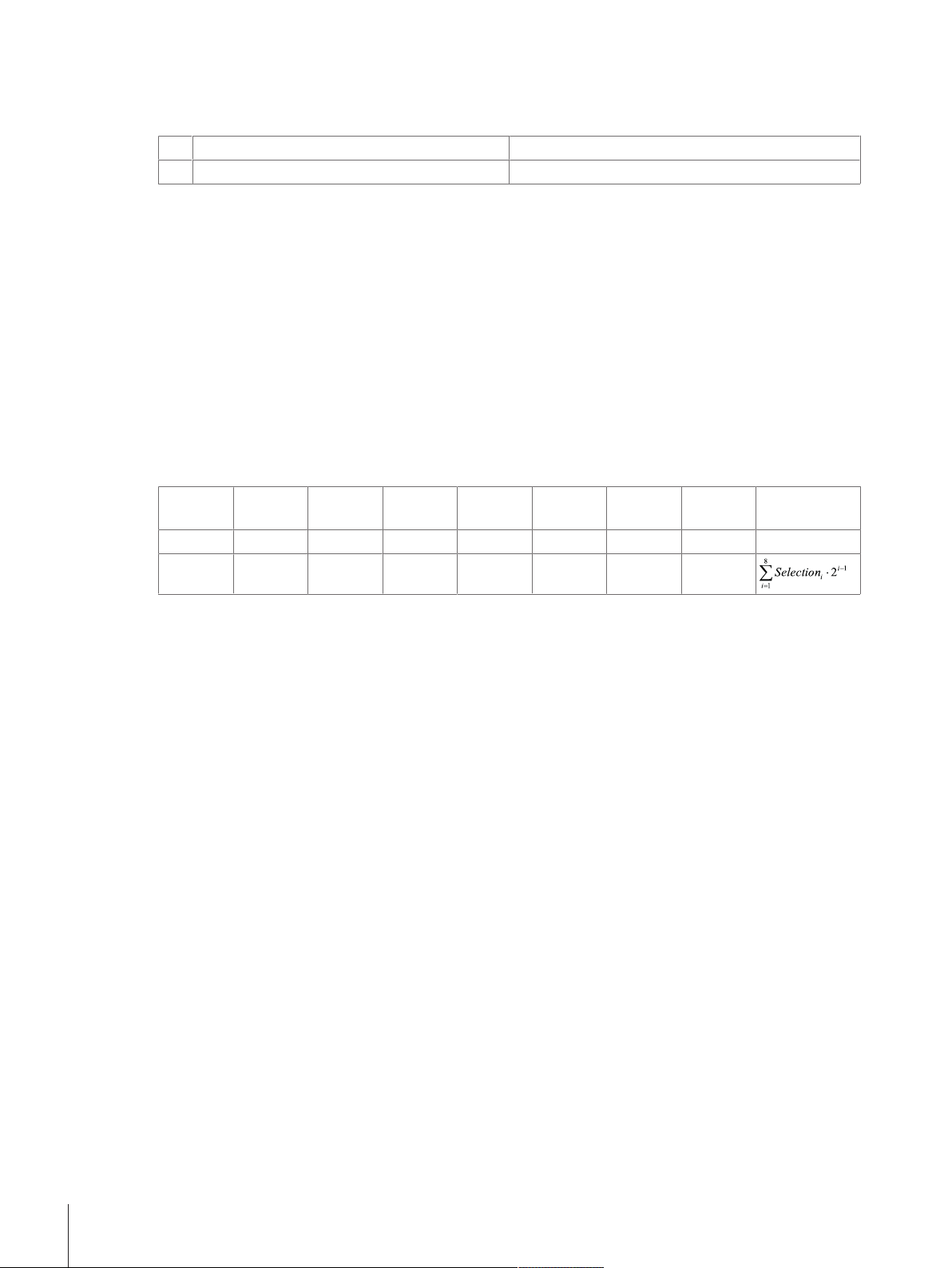

Binary coded multiple selections

Some parameters that allow multiple selections are binary coded: Each possible selection is represented by one

bit, the corresponding parameter equals to the decimal interpretation.

Selection8Selection7Selection6Selection5Selection4Selection3Selection2Selection1Parameter

0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0..255

27 = 128 26 = 64 25 = 32 24 = 16 23 = 8 22 = 4 21 = 2 20 = 1

Responses may easily be interpreted by converting the decimal number to binary again.

Introduction14 MT-SICS Interface Command

Page 17

3 Commands and Responses

@ – Cancel

Description

@ can be used to achieve the same effect as disconnecting and reconnecting the power supply, which empties

the volatile memories. The purpose of this command is to initiate a command sequence.

Syntax

Command

@

Response

I4VAV"<SNR>"

Comments

• All commands awaiting responses are cancelled.

• Key control is set to the default setting KV1.

• The tare memory is not reset to zero.

• If the balance is on standby, it is switched on.

• The cancel command is always executed.

• The emitted serial number corresponds to the serial number of the terminal (if one is present), see

[I4}Page89].

Resets the weigh module/balance to the condition

found after switching on, but without a zero setting

being performed.

Serial number is emitted; the weigh module/balance is

ready for operation.

Example

@

Ü

I4VAV"B021002593"

Û

See also

2 I4 – Serial number}Page89

Cancel

Weigh module or balance is "reset", its serial number

is B021002593.

Commands and Responses 15MT-SICS Interface Command

Page 18

A01 – Percent weighing: Reference in %

Description

Use this command to set or query the reference value for percent weighing.

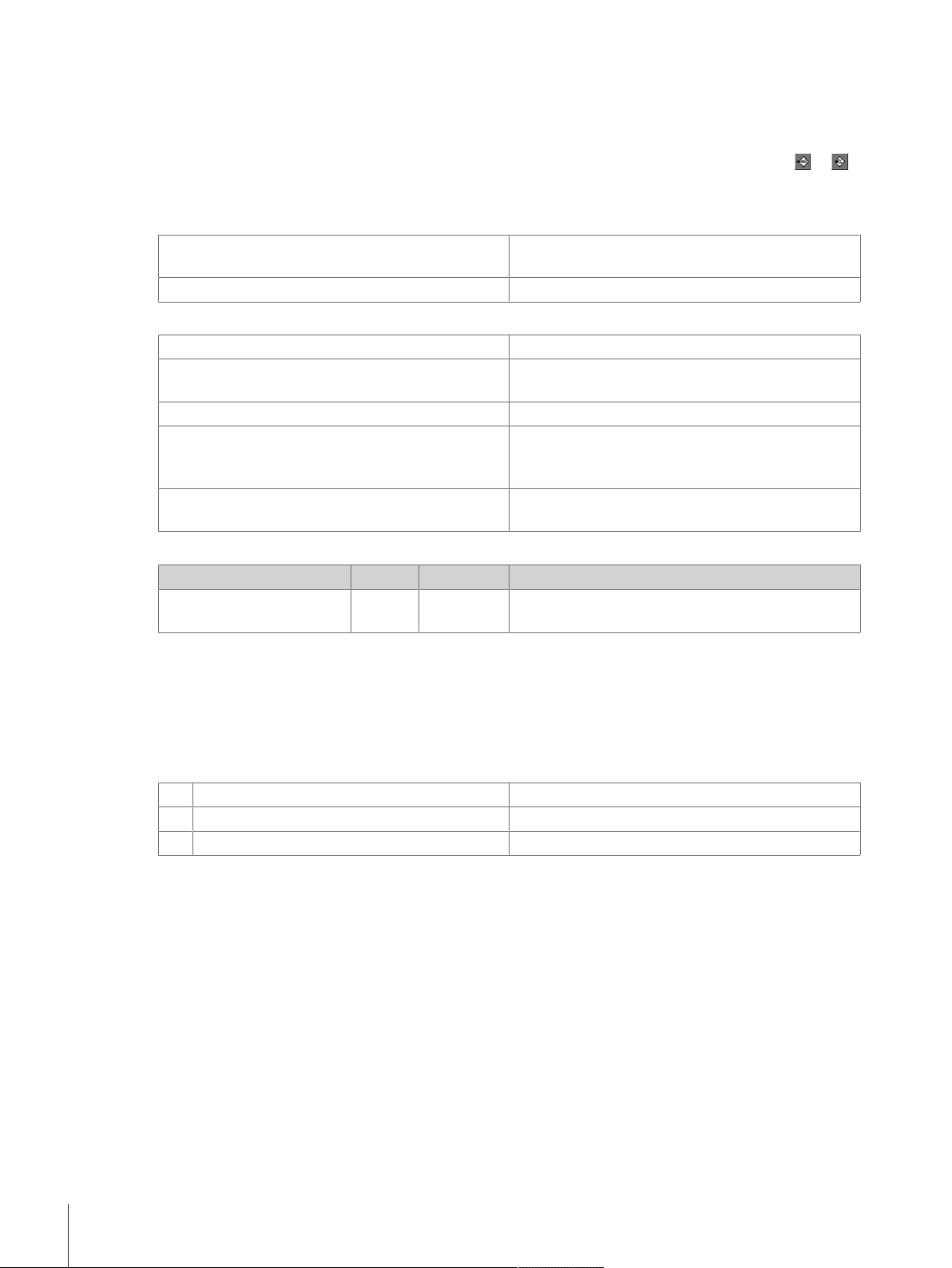

For querying to take place, a reference value must have been saved beforehand (A01 or function key or ).

Syntax

Commands

A01

A01V<Reference>

Responses

A01VAV<Reference>

A01VB

A01VA

A01VI

A01VL

A01VE

Query of the reference for the percent weighing application.

Set the reference for the percent weighing application.

Reference for the percent weighing application is set.

Start to set the reference (waiting for stable weight)

Command understood and executed successfully.

Command understood but currently not executable.

Command understood but not executable (e.g. percent

weighing application is not active or parameter is

incorrect) or no reference value present.

Setting reference aborted (not stable, over- or

underload, abort key,…).

Parameter

Name Type Values Meaning

<Reference>

Float

(0) …100

Reference for the percent weighing application in %;

must be greater than zero.

Comments

• This command can only be used when the application "Percent weighing" is started. For details on

available applications and how the activate them, see M25 and M26.

• Use the SU commands for percent weighing. Otherwise, the results will be displayed in the set unit unless

the host unit is changed to % using [M21}Page152].

Example

A01V100.00

Ü

Û

Û

A01VB

A01VA

Set the reference for percent weighing to 100.00%.

Reference is set, waiting for stable weight.

The reference for percent weighing is set to 100.00%.

Commands and Responses16 MT-SICS Interface Command

Page 19

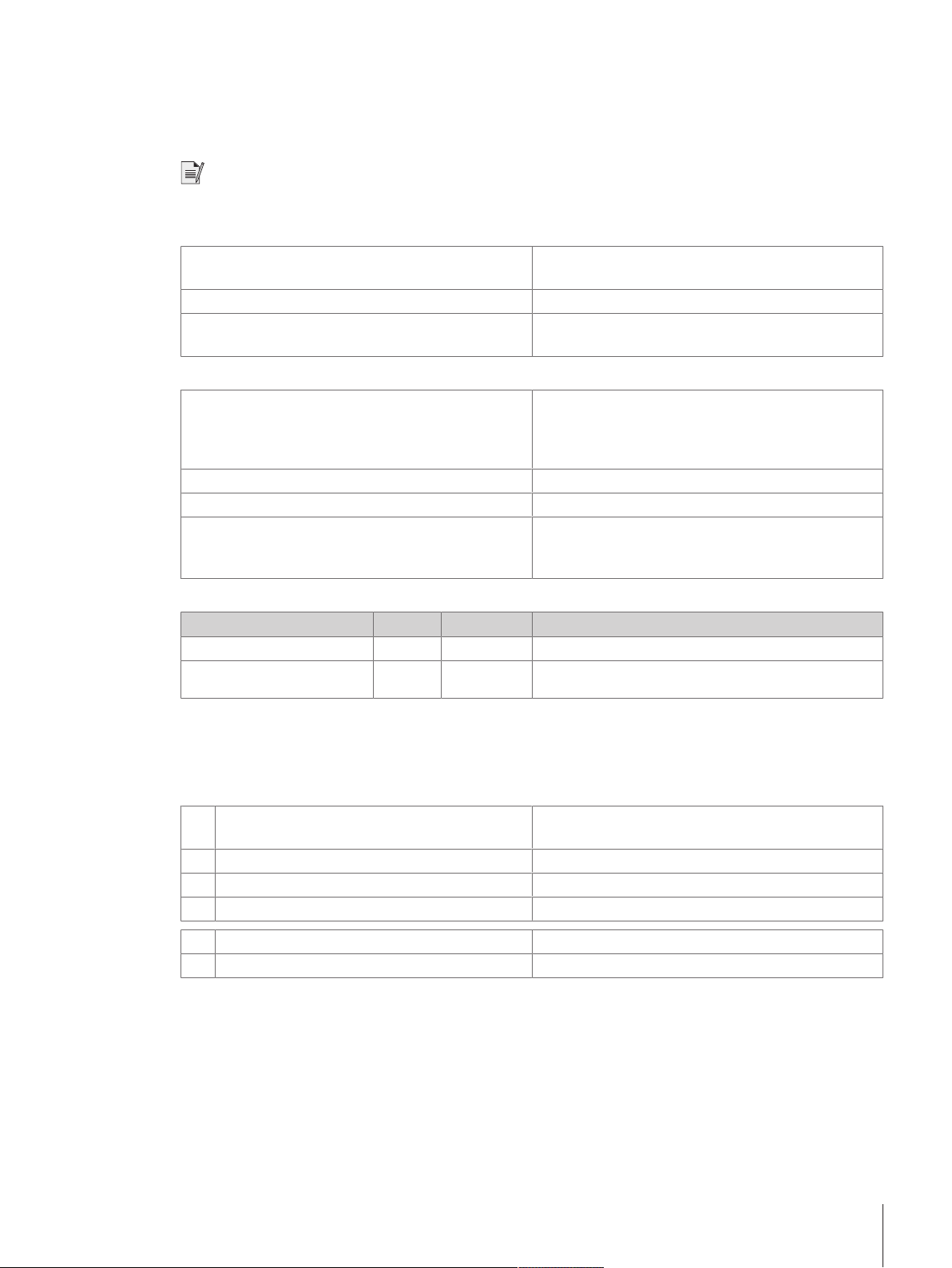

A02 – Sample identification for samples in weighing application

Description

Use A02 to set or query an identification of a sample in weighing application.

Note

Syntax

Commands

A02

A02V<Index>

A02V<Index>V<"Identification">

Responses

A02VBV<Index>V<"Identification">

A02VB…

A02VAV<Index>V<"Identification">

A02VA

A02VI

A02VL

Query the identifications of a sample of the weighing

application.

Query the sample number of the weighing application.

Set the sample number and identification of the

weighing application.

Query the identifications of a sample of the weighing

application.

Command understood and executed successfully.

Command understood but currently not executable.

Command understood but not executable (e.g.

weighing application is not active or parameter is

incorrect).

Parameters

Name Type Values Meaning

<Index>

<"Identification">

Integer

String

1…n

Max 60

chars

Sample number (n is product dependent)

Identification of the sample

Comment

• This command only applies to the "Weighing" application. For details on available applications and how

the activate them, see M25 and M26.

Examples

A02

Ü

Query the identifications of a sample of the weighing

application.

A02VBV1V"12345"

Û

A02VBV2V"67890"

Û

A02VAV3V""

Û

A02V1V"98765"

Ü

A02VA

Û

The identification of sample 1 is "12345".

The identification of sample 2 is "67890".

No identification for sample 3 (empty string).

Set the identification 1 to "98765".

The identification 1 is set to "98765".

Commands and Responses 17MT-SICS Interface Command

Page 20

A03 – Sample name for samples in weighing application

Description

Use A03 to assign an individual name to sample IDs, or query the current name.

Syntax

Commands

A03

A03V<No>

A03V<No>V<"ID">

Responses

A03VBV<No>V<"ID">

A03VBV<No>V<"ID">

A03VAV<No>V<"ID">

A03VA

A03VI

A03VL

Parameters

Name Type Values Meaning

<No>

<"ID">

Integer

String

1…n

Max 24

chars

Query the IDs name of the weighing application.

Query of specific ID.

Set the ID name of the weighing application.

All existing ID names of the weighing application.

Command understood and executed successfully.

Command understood but currently not executable.

Command understood but not executable (e.g.

weighing application is not active or parameter is

incorrect).

Number of weighing ID name

String of weighing ID name

Comment

• This command applies to the "Weighing" application. For details on available applications and how the

activate them, see M25 and M26.

Examples

A03

Ü

A03VBV1V"Batch"

Û

A03VBV2V"Lot"

Û

A03VAV3V""

Û

A03V2

Ü

Query the IDs name of the weighing application.

Name of ID1 is "Batch".

Name of ID2 is "Lot".

Name of ID3 name is empty.

Query the second ID name of the weighing application.

A03VAV2V"Lot"

Û

A03V1V"Batch"

Ü

A03VA

Û

Name of second ID is "Lot".

Set the ID1 name to "Batch".

Name of ID1 is set.

Commands and Responses18 MT-SICS Interface Command

Page 21

A10 – Nominal, +Tolerance, -Tolerance

Description

Use A10 to enter the nominal values, inc. +/- tolerances, or query the current values. As soon as you have

specified the values, the SmartTrac changes and displays the graphic weighing-in aid.

Syntax

Commands

A10

A10V<No>V<Value>V<Unit>

Responses

A10VBV0V<Value>V<Unit>

A10VBV1V<Value>V<Unit>

A10VAV2V<Value>V<Unit>

A10VA

A10VI

A10VL

Parameters

Name Type Values Meaning

<No>

<Value>

<Unit>

Integer

Float Nominal value

String

0

1

2

Max 5

chars

Query of the nominal value, + tolerance, - tolerance.

Set the nominal value, + tolerance, - tolerance.

Query of the nominal value, + tolerance, - tolerance.

Command understood and executed successfully.

Command understood but currently not executable.

Command understood but not executable.

Nominal value

+ tolerance

- tolerance

Weight unit, % with +/- tolerances possible

Comments

• The values will be output differently depending on the application. For details on available applications and

how the activate them, see M25 and M26.

• Specified nominal and tolerance values must be reset manually:

A10V0V0Vg

A10V1V2.5V%

A10V2V2.5V%

• As soon as you have specified the values, the SmartTrac switches to the graphic weighing-in aid.

• Weight and percentage values are rounded, as is the case with values entered manually.

Examples

A10

Ü

A10VBV0V100.12Vg

Û

A10VBV1V5.25Vg

Û

A10VAV2V7.6V%

Û

A10V0V100.12Vg

Ü

A10VA

Û

Query of the nominal value, + tolerance, - tolerance.

Current setting is nominal value 100.12 g, + tolerance

is 5.25 g and - tolerance is 7.6%.

Set the nominal value to 100.12 g.

The nominal value is set 100.12g.

Commands and Responses 19MT-SICS Interface Command

Page 22

A30 – Internal loads

Description

Use A30 to request status of internal loads. This command is used to inquire how many internal weights are

available in the balance and its status.

Syntax

Commands

A30

A30V<Qty>

Responses

A30VAVQtyVStat

A30VI

A30VL

Parameters

Name Type Values Meaning

<Qty>

<Stat>

Integer Number of internal loads

0

1

2

3

Integer Status of internal weights

0

1

2

3

8

9

Query of quantity and status of the internal loads.

Place internal load.

Quantity and status of the internal loads.

Command understood but currently not executable.

Command understood but not executable (incorrect

parameter).

No load placed

Total load placed

First partial load placed

Second partial load placed

No load placed

Total load placed

First partial load placed

Second partial load placed

Error

Not determined (not in defined end position)

Comment

• The number of internal loads depends on the balance model.

Examples

A30

Ü

Û

A30VAV1V0

Query of quantity and status of the internal loads.

There is only one internal load which is currently not

placed.

Control of internal loads

A30V1

Ü

Û

A30VA

Place total internal load.

The load is placed.

Commands and Responses20 MT-SICS Interface Command

Page 23

C – Cancel all commands

Description

Cancel all running commands.

Syntax

Command

C

Responses

CVB

CVA

Comments

• This command has a similar functionality as the command [@}Page15] but responds with a well

defined answer and does not fully reset the device.

• This command is executed always immediately.

• This command cancels all active and pending interface commands correctly and in a safe way on the

interface where cancel was requested. This command does not cancel any commands or procedures that

are not triggered by a SICS command.

• The command C responses with CVA after all active and pending interface commands have been

terminated.

• This command is typically used for repeating commands such as [SIR}Page207] and for adjustment

commands triggering a procedure.

• New procedures/command requests can be initiated right after a CVA.

Cancel running commands.

The cancel running command has been started.

Command understood and executed successfully.

Example

C

Ü

Û

Û

CVB

CVA

Cancel running commands.

Cancel running started.

Command understood and executed successfully.

Command-specific error responses

Response

CVEV<Error>

Current error code.

Parameter of command-specific error

Name Type Values Meaning

<Error>

Integer

0

Error while canceling

Commands and Responses 21MT-SICS Interface Command

Page 24

C0 – Adjustment setting

Description

This command queries and sets the type of adjustment. Additional commands are required to actually trigger

and to define the weight for external adjustment.

Syntax

Commands

C0

C0V<Mode>V<WeightType>

Responses

C0VAV<Mode>V<WeightType>V<"WeightValueV

Unit">

C0VI

C0VA

C0VL

Query of the current adjustment setting.

Set the adjustment setting.

Weight value and unit specify the value of the weight

for an external adjustment requested from the user via

the display, see [C1}Page24]. The unit corresponds to the factory setting of host unit, e.g. gram

(g) with standard balances or carat (ct) with carat

balances respectively. With internal adjustment,

neither weight value nor unit appears.

Command understood but currently not executable

(balance is currently executing another command,

e.g. taring).

Adjustment setting set successfully.

Command understood but not executable (incorrect

parameter; certified version of the balance).

Parameters

Name Type Values Meaning

<Mode>

Integer

0

Mode = Manual

The adjustment can only be triggered manually

A change in the ambient conditions has no influence

on the initiation of the calibration procedure

1

Mode = Auto, status display "AutoCal" or "Cal" not

activated

When a considerable change in the ambient

conditions is determined, the status display "AutoCal"

or "Cal" will be activated; this means the balance will

ask for adjustment

2

Mode = Auto, status display "AutoCal" or "Cal" flashes

The sensors built into the balance have determined a

considerable change in the ambient conditions. The

balance requests an adjustment or at least a test, see

[TST }Page232] x commands

<WeightType>

<2WeightValue">

Integer

String Weight values specify the value of the weight for an

0

1

Internal weight (factory setting)

External weight

external calibration requested from the user via the

display or interface, see [C1}Page24]

<"Unit">

String The unit corresponds to the factory setting of host unit,

e.g. gram (g)

Commands and Responses22 MT-SICS Interface Command

Page 25

Comments

• Setting <Mode> = 1 and <Weight> = 0 corresponds to the menu setting "ProFACT" / "FACT" under "Adjust/

Test".

• [C2}Page26] is independent of C0.

• The value of the external weight can be changed in the menu of the balance under "Adjust/Test ", see

Reference Manual or with [M19}Page150].

• Use [C1}Page24] to start an adjustment defined with C0.

• C0 must be reset manually; [@}Page15] has no effect.

• Check remaining ranges with [I50}Page108] command.

• The parameters are not stored permanently.

Examples

C0

Ü

Query of the current status and setting of the

adjustment.

C0VAV2V1V"VVV100.000Vg"

Û

Current setting of mode is "Auto". The ambient

conditions of the balance have changed so much that

the balance requests an adjustment (<Mode> = 2)

with the external weight (<Weight> = 1). The

adjustment is initiated with the command

[C1}Page24] and requires a weight of

100.000g.

C2

Û

Start external adjustment, see responses of

[C2}Page26].

C0

Û

Query of the current status and setting of the

adjustment.

C0VAV3V1V"VVV100.000Vg"

Û

Û

C0

Adjustment started.

Query of the current status and setting of the

adjustment.

C0VAV4V1V"VVV100.000Vg"

Û

Adjustment successfully executed.

C0V0V1

Ü

C0VA

Û

See also

2 M19 – Adjustment weight}Page150

2 C2 – Start adjustment with external weight}Page26

2 TST0 – Query/set test function settings}Page232

2 TST1 – Test according to current settings}Page233

Set adjustment setting to manual and external.

Adjustment setting set.

Commands and Responses 23MT-SICS Interface Command

Page 26

C1 – Start adjustment according to current settings

Description

C1 is used to trigger an adjustment as defined using the C0 command.

Syntax

Command

C1

First Responses

C1VB

C1VI

C1VL

Further Responses

C1V<"WeightValueVUnit">

C1VA

C1VI

Start the adjustment according to the current setting,

see [C0}Page22].

The adjustment procedure has been started. Wait for

second response see Comments.

Command understood but currently not executable

(balance is currently executing another command).

No further response follows.

Command understood but not executable (e.g.

approved version of the balance). No further response

follows.

Weight request with external adjustment.

Command understood and executed successfully.

The adjustment was aborted as, e.g. stability not

attained or the procedure was aborted with the C key.

Parameters

Name Type Values Meaning

<"WeightValue">

String Weight values specify the value of the weight for a

sensitivity adjustment requested from the user via the

display or interface

<"Unit">

String The unit corresponds to the definition unit, e.g. gram

(g)

Comments

• Commands sent to the balance during the adjustment operation are not processed and responded to in the

appropriate manner until the adjustment is at an end.

• Use [@}Page15] to abort a running adjustment.

• The value of the external adjustment weight needed for adjustment must be set accordingly by an

[M19}Page150] command.

• Check remaining ranges with [I50}Page108] command.

Example

C1

Ü

C1VB

Û

C1V"VVVVVVV0.00Vg"

Û

C1V"VVVV2000.00Vg"

Û

C1V"VVVVVVV0.00Vg"

Û

C1VA

Û

Start the adjustment according to the current setting.

Adjustment operation started.

Prompt to unload the balance.

Prompt to load the adjustment weight of 2000.00g.

Prompt to unload the balance.

Adjustment completed successfully.

Commands and Responses24 MT-SICS Interface Command

Page 27

See also

2 C0 – Adjustment setting}Page22

2 M19 – Adjustment weight}Page150

2 TST1 – Test according to current settings}Page233

2 M19 – Adjustment weight}Page150

Commands and Responses 25MT-SICS Interface Command

Page 28

C2 – Start adjustment with external weight

Description

Regardless of the [C0}Page22] setting, C2 carries out external adjustment with the reference weight defined

in [M19}Page150].

Syntax

Command

C2

First Responses

C2VB

C2VI

C2VL

Further Responses

C2V<"WeightValue>V<Unit">

C2VA

C2VI

Start the external adjustment. Query of the current

weight used by means of the [M19}Page150]

command.

The adjustment procedure has been started.

Command understood but currently not executable

(balance is currently executing another command).

No second response follows.

Command understood but not executable (e.g.

adjustment with an external weight is not admissible,

certified version of the balance). No second response

follows.

Prompt to unload or load the balance.

Command understood and executed successfully.

The adjustment was aborted as, e.g. stability not

attained or the procedure was aborted with the C key.

Parameters

Name Type Values Meaning

<"WeightValue">

Float Weight values specify the value of the weight for a

sensitivity adjustment requested from the user via the

display or interface

<"Unit">

String The unit corresponds to the definition unit, e.g. gram

(g)

Comments

• Commands sent to the balance during the adjustment operation are not processed and responded to in the

appropriate manner until the adjustment is at an end.

• Use [@}Page15] to abort a running adjustment.

• The value of the external adjustment weight needed for adjustment must be set accordingly by an

[M19}Page150] command.

• Check remaining ranges with [I50}Page108] command.

Example

C2

Ü

C2VB

Û

C2V"VVVVVVV0.00Vg"

Û

C2V"VVVV2000.00Vg"

Û

C2V"VVVVVVV0.00Vg"

Û

C2VA

Û

Start the external adjustment.

Adjustment operation started.

Prompt to unload the balance.

Prompt to load adjustment weight 2000.00g.

Prompt to unload the balance.

Adjustment completed successfully.

Commands and Responses26 MT-SICS Interface Command

Page 29

See also

2 M19 – Adjustment weight}Page150

2 TST2 – Test with external weight}Page235

2 M19 – Adjustment weight}Page150

2 M19 – Adjustment weight}Page150

Commands and Responses 27MT-SICS Interface Command

Page 30

C3 – Start adjustment with internal weight

Description

You can use C3 to start an internal adjustment procedure.

Syntax

Command

C3

First Responses

C3VB

C3VI

C3VL

Further Responses

C3VA

C3VI

Comments

• Commands sent to the balance during the adjustment operation are not processed and responded to in the

appropriate manner until the adjustment is at an end.

• Use [@}Page15] to abort a running adjustment.

• Check remaining ranges with [I50}Page108] command.

Start the internal adjustment.

The adjustment procedure has been started. Wait for

second response.

Adjustment can not be performed at present as another

operation is taking place. No second response

follows.

Adjustment operation not possible (e.g. no internal

weight). No second response follows.

Adjustment has been completed successfully.

The adjustment was aborted as, e.g. stability not

attained or the procedure was aborted with the C key.

Example

C3

Ü

C3VB

Û

C3VA

Û

See also

2 TST3 – Test with internal weight}Page236

Start the internal adjustment.

Adjustment operation started.

Adjustment completed successfully.

Commands and Responses28 MT-SICS Interface Command

Page 31

C4 – Standard / initial adjustment

Description

An initial adjustment is a procedure that determines a new adjustment factor between the built-in weight used

for internal adjustment and the external weight defined by the [M19}Page150] command. All internal

adjustments following this procedure will show the same weighing results as if the adjustment were done with

the external weight. The initial adjustment thus allows tuning of the internal adjustment of several weigh

modules to one external weight standard.

Syntax

Command

C4

First Responses

C4VB

C4VI

C4VL

Further Responses

C4V<"WeightValue">V<"Unit">

C4VA

C4VI

Start initial adjustment .

Initial adjustment procedure has been started. Wait for

second response.

Initial adjustment cannot be performed at present

because another operation is taking place (e.g. zero

setting or taring), or the current weight value is outside

the permissible range.

Command understood but not executable (parameter

not allowed). No second response follows.

Prompt to unload or load the weighing module.

The adjustment has been completed successfully.

The adjustment procedure was aborted because, e.g.

the stability needed for this operation was not

achieved within the timeout limit, or a wrong weight

was loaded.

Parameters

Name Type Values Meaning

<"WeightValue">

Float Weight values specify the value of the weight for a

sensitivity adjustment requested from the user via the

display or interface

<"Unit">

String The unit corresponds to the definition unit, e.g. gram

(g)

Comments

• In order to perform an initial adjustment, the actual load seen by the weight module must be within plus/

minus (2g + 1% of weighing capacity) relative to the load when the weight module was switched on.

• The criterion that must be fulfilled to reach stability for initial adjustment depends on the type of the weigh

module and cannot be changed.

• The timeout may be set using the [M67}Page177] command.

• The value of the external adjustment weight needed for initial adjustment must be set accordingly by an

[M19}Page150] command if preload exists.

• The new factor determined by the initial adjustment procedure will be reset to the adjustment factor

evaluated in the factory when the FSETV0 or FSETV1 command is performed. With FSETV2, the initial

calibration by the user is retained.

• Check remaining ranges with [I50}Page108] command.

Example

C4

Ü

Start the internal adjustment.

Commands and Responses 29MT-SICS Interface Command

Page 32

C4VB

Û

C4V"VVV100.0000Vg"

Û

C4V"VVVVV0.0000Vg"

Û

C4VA

Û

Adjustment operation started.

Prompt to load weight of 100.0000g used for initial

adjustment.

Prompt to unload the module.

Adjustment completed successfully.

Commands and Responses30 MT-SICS Interface Command

Page 33

C5 – Enabling/disabling step control

Description

Use C5 to enable and disable step control (user interaction) during the adjustment procedures triggered by the

adjustment commands C6 – C8.

Syntax

Commands

C5

C5V<Status>

Responses

C5VAV<Status>

C5VA

C5VI

C5VL

Parameter

Name Type Values Meaning

<Status>

Integer 0 Step control is turned off (all adjustment procedures

1 Step control is turned on (all adjustment procedures

Query the status of the step control.

Enable / disable the step control.

Current status of the step control.

Command understood and executed successfully.

Command understood but currently not executable.

Command understood but not executable (incorrect

parameter).

run without user interaction)

which support step control need a user confirmation

when the weight is placed on the pan)

Comments

• Adjustment methods using internal weights and adjustment commands without parameter ‘Method’ will

ignore the state of C5 and only work without step control.

• Use the command I62 to read out the timeout for user interaction.

Example

C5

Ü

Û

C5VAV1

Query the status of the step control.

Step control is enabled.

See also

2 C6 – Customer linearization and sensitivity adjustment}Page32

2 C7 – Customer standard calibration}Page35

2 C8 – Sensitivity adjustment}Page38

2 I62 – Timeout}Page119

Commands and Responses 31MT-SICS Interface Command

Page 34

C6 – Customer linearization and sensitivity adjustment

Description

Use C6 to start the adjustment of the customer linearization. With these measurement values also an

adjustment of the customer sensitivity scaling is done.

Syntax

Commands

C6

C6V<Method>

C6V<Method>V<Load>

Responses

C6VBV<Method>

…

C6VAV<Method>

C6VB

C6VBV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

C6VBV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

…

C6VBV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"DevPerMille">

C6VA

C6VB

C6VCV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

C6VC

C6VBV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

C6VCV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

…

C6VBV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"DevPerMille">

C6VA

C6VEV<Error>

C6VA

C6VI

C6VL

Request the whole list of available methods.

Execute the command with or without the step control

C5.

Execute the command with or without the step control

C5 and with the parameter <Load>.

Current list of available methods.

Content of a specific method without step control

C5V0.

Content of a specific method with step control C5V1.

Error occurred during the adjustment.

Command understood and executed successfully.

Command understood but currently not executable.

Command understood but not executable (incorrect

parameter).

Parameters

Name Type Values Meaning

<Method>

Integer

0, 2

0: use default method of the adjustment (=2)

2: Adjustment with external weights

<Load>

Float Calibration load in the host unit (default using the M19

value).

Load used in step control ('Execute C6VC Load')

modifies the required weight value of the actual

adjustment state

Commands and Responses32 MT-SICS Interface Command

Page 35

Name Type Values Meaning

<Index>

<State>

Integer Step number of the procedure

Char

R, D or C

Actual state of the adjustment process

R = requesting external weight

D = waiting for stability

C = calibration deviation (procedure is finished,

corrected calibration deviation is given in parameter

"DevPerMille")

<WgtState>

Char

+, -, o

Actual weight state

+ load is above tolerances

- load is below tolerances

o (small omega) load is within tolerances

<"LoadInstruction">

String Instruction, which load to place on the pan

String with the load combination to place on the pan

separated by "+". The string contains as many

numbers as different loads are used in the procedure

"0" = do not place the load "1" = place load 1 "1+2"

= place load 1 and load 2 "0+2" = only place load 2

<"ValueHostUnit">

String Load information of the actual adjustment state

(weight and host unit)

<"DevPerMille">

String Deviation of the measured calibration load (before

adjustment) relative to the exact calibration load in per

mille (‰). Value is rounded to the resolution of the

finest range

<Error>

Integer

0, 1 or 2

Parameter showing the source of the error

0: Timeout

1: Cancel

2: Internal weight not supported

Comments

• The parameter <Load> and also the load value corrected with step control are tested against range

definitions. A logic error (L) is returned for values violating the range definitions.

• The procedure can be canceled by command C.

Examples

C6

Ü

Û

C6VBV0

C6VAV2

Request the whole list of available methods

Methods 0 and 2 are available. Other methods are not

implemented

Commands and Responses 33MT-SICS Interface Command

Page 36

C6V2

Ü

C6VB

Û

C6VBV0VRV–V"0+0"V"VVVVV0.00Vg"

C6VBV0VDVoV"0+0"V"VVVVVVVV"

C6VBV1VRV–V"1+0"V"VVVV200.00Vg"

C6VBV1VDVoV"1+0"V"VVVVVVVV"

C6VBV2VRV–V"1+2"V"VVVV400.00Vg"

C6VBV2VDVoV"1+2"V"VVVVVVVV"

C6VBV2VCVoV"1+2"V"0.23"

C6VA

C6V2V400

Ü

C6VB

Û

C6VCV0VRV–V"0+0"V"VVVVVV0.00Vg"

C6VC

Û

C6VBV0VDVoV"0+0"V"VVVVVVVV"

Û

C6VCV1VRV-V"1+0"V"VVV200.00Vg"

C6VCV220.00

Û

C6VCV1VRV-V"1+0"V"VVV220.00Vg"

Û

C6VC

Û

C6VBV1VDVoV"1+0"V"VVVVVVVV"

Û

C6VCV2VRV-V"1+2"V"VVV400.00Vg"

C6VC

Û

C6VBV2VDVoV"1+2"V"VVVVVVVV"

Û

C6VBV2VCVoV"1+2"V"0.23"

C6VA

Start the linearization adjustment method 2 (without

step control C5V0.

Linearization adjustment is started

Request weight for first step.

Capture weight of first step.

Request weight of second step (ext. load L1).

Capture weight of third step.

Request weight of third step (ext. load L1+L2).

Capture weight of third step.

Corrected calibration deviation in per mille (‰).

Linearization adjustment finished.

Start linearization adjustment method 2 with step

control C5V1.

Linearization adjustment is started .

Request weight for first step (ext. & int. unload).

User confirms placed weight.

Capture weight of first step.

Request weight for second step (ext. load L1).

User changes requested weight value.

Request weight for second step (ext. load L1).

User confirms placed weight.

Capture weight of second step.

Request weight for third step (ext. load L1+L2).

User confirms placed weight.

Capture weight of third step.

Corrected calibration deviation in per mille (‰) .

Linearization adjustment finished.

C6V2˽400

Ü

C6VB

Û

C6VCV0VRV–V"0+0"V"VVVVVV0.00Vg"

C6VEV0

Û

See also

2 C – Cancel all commands}Page21

2 C5 – Enabling/disabling step control}Page31

Start linearization adjustment (method 2).

Linearization adjustment is started.

Request weight for first step (ext. & int. unload).

Timeout error response.

Commands and Responses34 MT-SICS Interface Command

Page 37

C7 – Customer standard calibration

Description

Use C7 to start the standard calibration which defines the exact weight value of the internal calibration loads.

Syntax

Commands

C7

C7V<Method>

C7V<Method>V<Load>

Responses

C7VBV<Method>

...

C7VAV<Method>

C7VB

C7VBV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

C7VBV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

…

C7VA

C7VB

C7VCV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

C7VC

C7VBV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

C7VCV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

C7VCV<Load>

C7VCV<Index>V<State>V<WgtState>V

<"LoadInstruction">V<"ValueHostUnit">

C7VC

…

C7VA

C7VA

C7VI

C7VL

Request the whole list of available methods.

Execute the command with or without the step control

C5.

Execute the command with or without the step control

C5 and with the optional parameter <Load>.

Current list of available methods.

Execute the command without step control C5V0 and

with optional parameter <Load>.

Execute the command with step control C5V1 and with

modifying a required weight value of one state during

the adjustment. The state which is corrected is

displayed again and must be confirmed by the

operator.

Command understood and executed successfully.

Command understood but currently not executable

(balance is currently executing another command).

No second response follows.

Command understood but not executable (incorrect

parameter)

Parameters

Name Type Values Meaning

<Method>

Integer

0…2

0

1or2

List of available methods (model dependent)

Use default method of the adjustment

Method 1: For direct force translation (without lever

arms)

Method 2: For hybrid force translation (with lever

arms)

Commands and Responses 35MT-SICS Interface Command

Page 38

Name Type Values Meaning

<Load>

Float Calibration load in the definition unit (default using the

M19 value)

Load used in step control (Execute C5VCVLoad)

modifies the required weight value of the actual

adjustment state

<Index>

<State>

Integer Step number of the procedure

Char

R or D

Actual state of the adjustment process

R = requesting external weight

D = waiting for stability

<WgtState>

Char

+, -, o

Actual weight state:

+ load is above tolerances

- load is below tolerances

o (small omega) load is within tolerances

<"LoadInstruction">

String

0

Instruction, which load to place on the pan

String with the load combination to place on the pan

separated by "+". The string contains as many

numbers as different loads are used in the procedure.

If the actual step uses internal weights, the string will

be empty.

• "0" = do not place the load

• "1" = place load 1

• "1+2" = place load 1 and load 2

• "0+2" = only place load 2

<"ValueHostUnit">