Page 1

MS

MS

MS

MS

Precision and Analytical Balances

MS-TS

Operating Instructions

Page 2

Page 3

Table of Contents

Introduction1 7

Safety Information2 8

Design and Function3 10

Installation and Putting into Operation4 16

Weighing Made Simple5 24

Conventions and symbols used in these operating instructions1.1 7

Definition of signal warnings and symbols2.1 8

Product safety information2.2 8

Components3.1 10

Terminal keys3.2 11

User Interface3.3 11

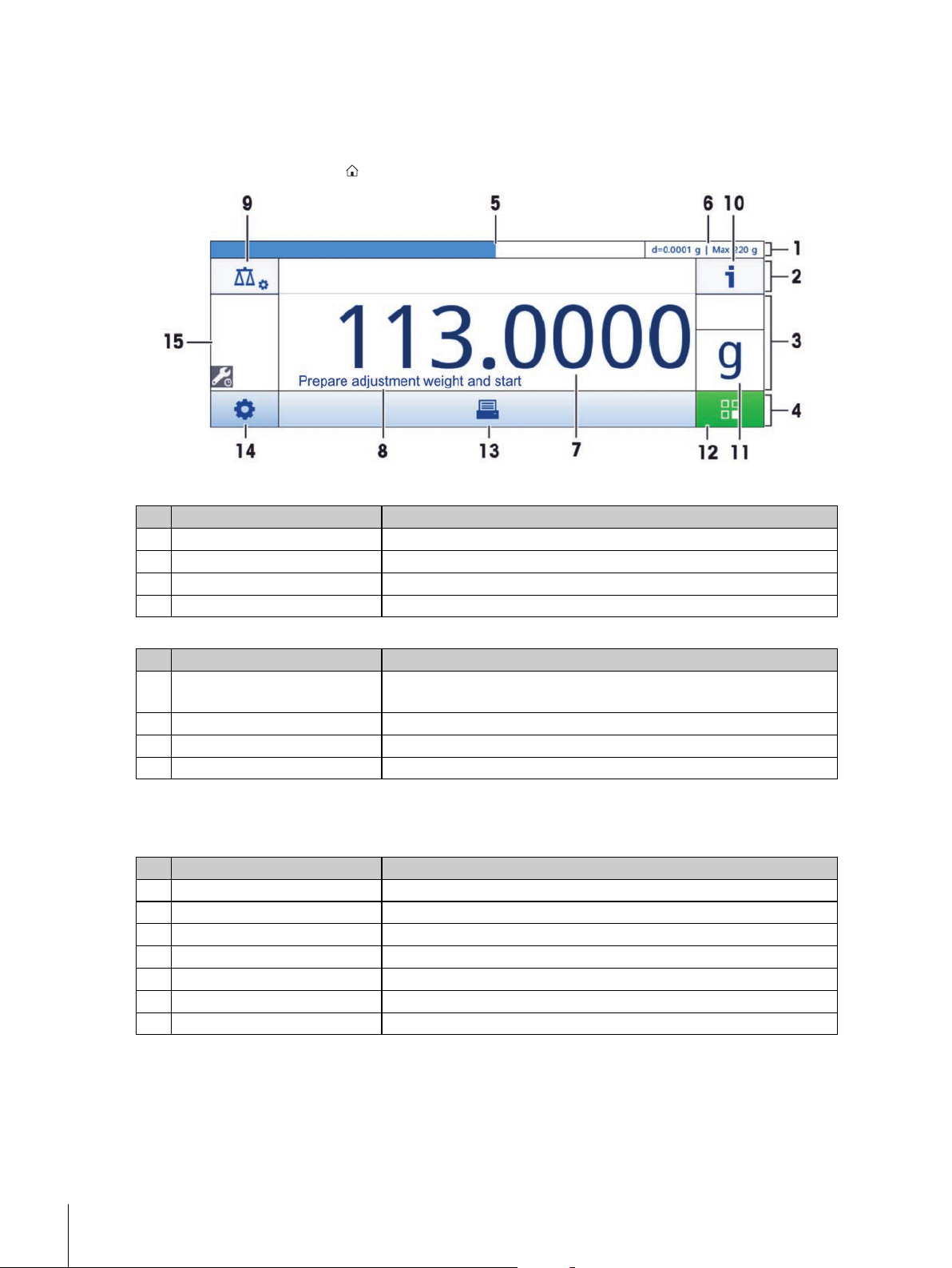

Application home screen3.3.1 12

Input Dialogs3.3.2 13

Entering Characters and Numbers3.3.2.1 13

Changing the time and date3.3.2.2 14

Lists and tables3.3.3 15

Scope of delivery4.1 16

Installing the components4.2 17

Selecting the location4.3 18

Connecting the instrument4.4 19

Leveling the balance4.5 20

Leveling the balance with the level indicator4.5.1 20

Leveling the balance using the leveling assistant4.5.2 21

Transporting the balance4.6 22

Weighing below the balance4.7 22

General requirements4.8 23

Warming up the balance4.8.1 23

Adjusting the balance4.8.2 23

Switching on the balance5.1 24

Switching off the balance5.2 24

Main settings and activities at a glance5.3 25

Navigation on the touch screen5.4 26

Opening an application5.4.1 26

Scrolling5.4.2 26

Using shortcuts5.4.3 27

Performing a simple weighing5.5 27

Switching the weighing unit5.6 28

Changing the resolution5.7 31

Zeroing5.8 32

Taring5.9 32

Working with IDs5.10 33

Defining an ID5.10.1 33

Workflow handling options5.10.2 34

Table of Contents 3

Page 4

Statistics5.11 35

Activities6 36

Activities - Weighing and other applications6.1 36

Weighing6.1.1 37

Counting6.1.2 38

Percent Weighing6.1.3 40

Formulation6.1.4 42

Dynamic Weighing6.1.5 44

Check Weighing6.1.6 46

Factor Weighing6.1.7 50

Totaling6.1.8 51

Activities - Adjustments and tests6.2 53

FACT Fully automatic internal adjustment6.2.1 54

Internal Adjustment6.2.2 55

External Adjustment6.2.3 56

General Settings7 57

Quick settings/Preferences7.1 57

Date and time7.1.1 57

Brightness7.1.2 57

Sound7.1.3 58

Language7.1.4 58

Glove mode7.1.5 58

Quick Adjustment7.1.6 58

Leveling assistant7.1.7 58

General configuration and data7.2 59

Weighing options7.2.1 59

Publishing7.2.2 60

Devices and connectivity7.2.3 62

System settings7.2.4 63

ISO-log7.2.5 63

Access protection7.2.6 64

Communication with Peripheral Devices8 65

PC-Direct Function8.1 65

USB Device Interface8.2 66

Firmware (Software) Updates9 68

Operating principle9.1 68

Update procedure9.2 69

Error and Status Messages10 70

Maintenance11 71

Cleaning the glass draft shield (0.1 mg and 1 mg models)11.1 71

Disposal11.2 73

Interface Specification12 74

RS232C interface12.1 74

USB host12.2 75

USB device12.3 75

Table of Contents4

Page 5

MT-SICS interface commands and functions12.4 76

Technical Data13 77

General data13.1 77

Model-specific data13.2 78

Balances with readability of 0.1 mg, S platform with draft shield13.2.1 78

Balances with readability of 1 mg, S platform with draft shield13.2.2 80

Balances with readability of 0.01 g, S platform13.2.3 82

Balances with readability of 0.1 g to 1 g, S platform13.2.4 85

Dimensions13.3 86

Balances with readability of 0.1 mg and draft shield13.3.1 86

Balances with readability of 1 mg and draft shield13.3.2 87

Balances with readability of 0.01 g13.3.3 88

Balances with readability of 0.1 g13.3.4 89

Accessories and Spare Parts14 90

Accessories14.1 90

Spare parts14.2 95

Index 96

Table of Contents 5

Page 6

Page 7

1Introduction

1

2

…

Thank you for choosing a METTLER TOLEDO balance. The precision and analytical balances of the MS-TS line

combine a large number of weighing possibilities with easy operation.

These operating instructions apply to all balance models of the MS-TS line and are based on the initially

installed firmware (software) version V 3.30.

1.1Conventions and symbols used in these operating instructions

Key and button designations are indicated by a picture or text in square brackets (e.g. [ ]).

These symbols indicate an instruction:

Requirements

Steps

Results

u www.mt.com/balances

7Introduction

Page 8

2Safety Information

2.1Definition of signal warnings and symbols

Safety notes are marked with signal words and warning symbols. These show safety issues and warnings.

Ignoring the safety notes may lead to personal injury, damage to the instrument, malfunctions and false results.

WARNING for a hazardous situation with medium risk, possibly resulting in severe

injuries or death if not avoided.

CAUTION for a hazardous situation with low risk, resulting in damage to the device or

the property or in loss of data, or minor or medium injuries if not avoided.

Attention (no symbol)

for important information about the product.

Note (no symbol)

for useful information about the product.

General hazard Electrical shock

2.2Product safety information

Intended use

Your balance is used for weighing. Use the balance exclusively for this purpose. Any other type of use and

operation beyond the limits of technical specifications without written consent from Mettler-Toledo AG, is con

sidered as not intended.

It is not permitted to use the instrument in explosive atmosphere of gases, steam, fog, dust

and flammable dust (hazardous environments).

General safety information

This balance complies with current industry standards and the recognized safety regulations; however, it can

constitute a hazard in use. Do not open the balance housing: The balance contains no user-serviceable parts.

In the event of problems, please contact a METTLER TOLEDO representative.

Always operate and use your instrument only in accordance with the instructions contained in this manual. The

instructions for setting up your new instrument must be strictly observed.

If the instrument is not used according to these Operating Instructions, protection of the instrument may

be impaired and METTLER TOLEDO assumes no liability.

Staff safety

These operating instructions must be read and understood before using the balance. These operating instruc

tions must be retained for future reference.

The balance must not be altered or modified in any way. Only use METTLER TOLEDO original spare parts and

accessories.

8 Introduction

Page 9

Safety notes

CAUTION

Damage to the balance

a) Only use indoors in dry locations.

b) Do not use pointed objects to operate the touch screen!

The balance is of a very sturdy design, but is still a precision instrument. It must be han

dled with care.

c) Do not open the balance:

The balance contains no user-serviceable parts. In the event of problems, please contact

a METTLER TOLEDO representative.

d) Only use METTLER TOLEDO original accessories and peripheral devices for the balance.

These are specifically designed for the balance.

WARNING

Risk of electric shock

Use only the original universal AC/DC adapter delivered with your balance, and check that

the voltage printed on it is the same as your local power supply voltage. Only plug the

adapter into a socket which is grounded.

9Safety Information

Page 10

3Design and Function

C

0.1 g

10

9

7

1

2514

0.01 g

9

5

10

1

2

7

14

6

MS

MS

3

101 2

5

7

4

3

14

MS

MS

0.1 mg

10

1

2

5

7

4

14

6

11

12

8

1

3

15

14

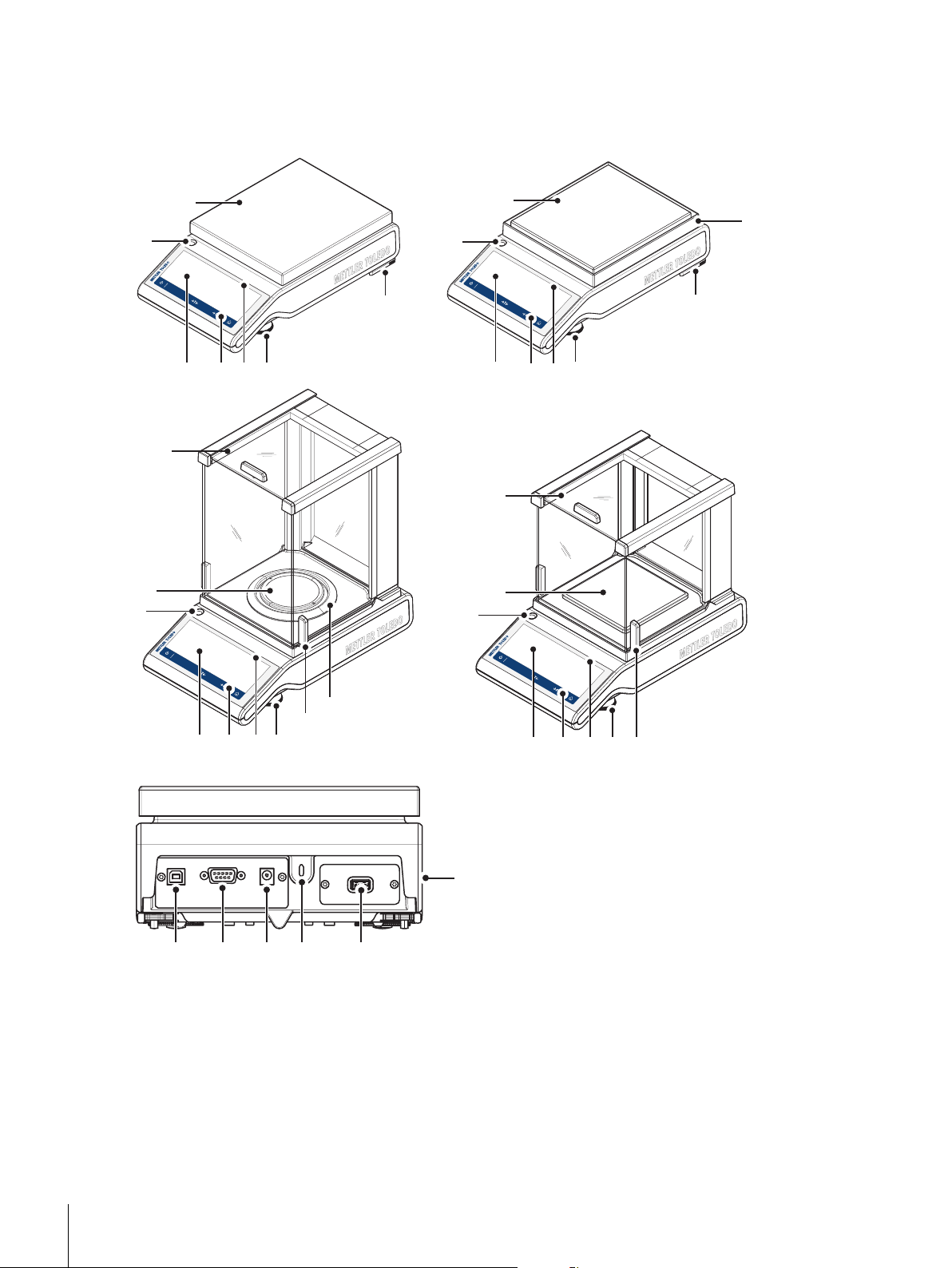

3.1Components

10 Safety Information

1 Capacitive color TFT touch screen

2 Operation keys

3 Glass draft shield

4 Handle for operation of the draft shield door

5 Weighing pan

6 Draft ring element

7 Level indicator

8 Kensington slot for anti-theft purposes

9 Safety feet (0.01 g and 0.1 g models)

10 Leveling foot

11 USB Device connection

12 RS232C serial interface

13 Socket for AC/DC adapter

14 USB Host connection

15 Product label

Page 11

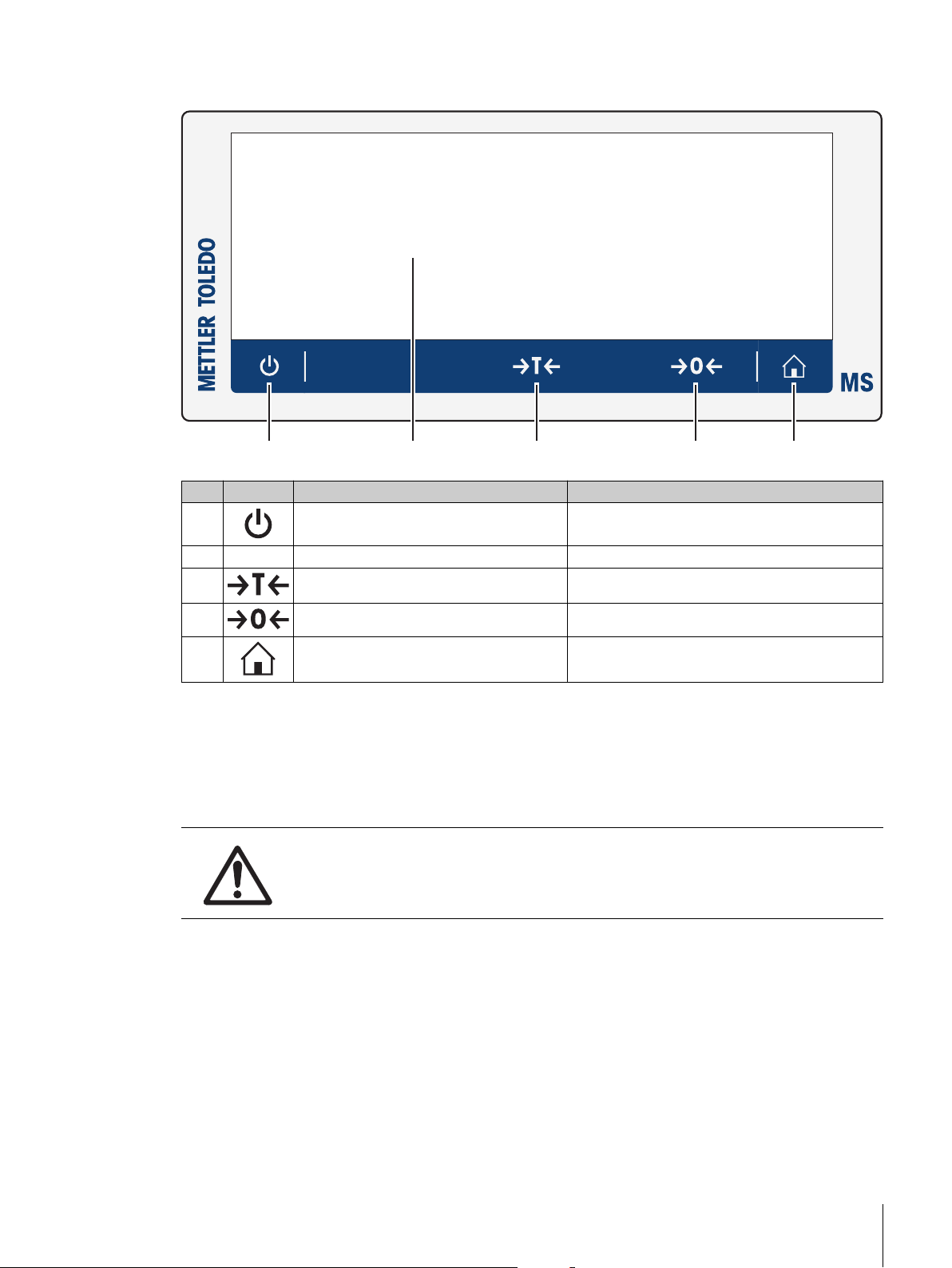

3.2Terminal keys

53 4

1

2

No. Key Name Explanation

1 ON/OFF To switch the instrument on or off.

2 Capacitive color TFT touch screen General navigation

3 Tare To tare the balance.

4 Zero To zero the balance.

5 Home To return from any menu level, or other window

3.3User Interface

The screen is a capacitive color TFT touch screen. The screen not only displays information, it also allows the

user to enter commands by tapping on certain areas on its surface. You can choose the information displayed

on the screen, change balance settings or perform certain operations on the instrument.

Only those elements which are available for the current dialog appear on the display.

to the application home screen.

CAUTION

Do not touch the touch screen with pointed or sharp objects!

This may damage the touch screen.

11Design and Function

Page 12

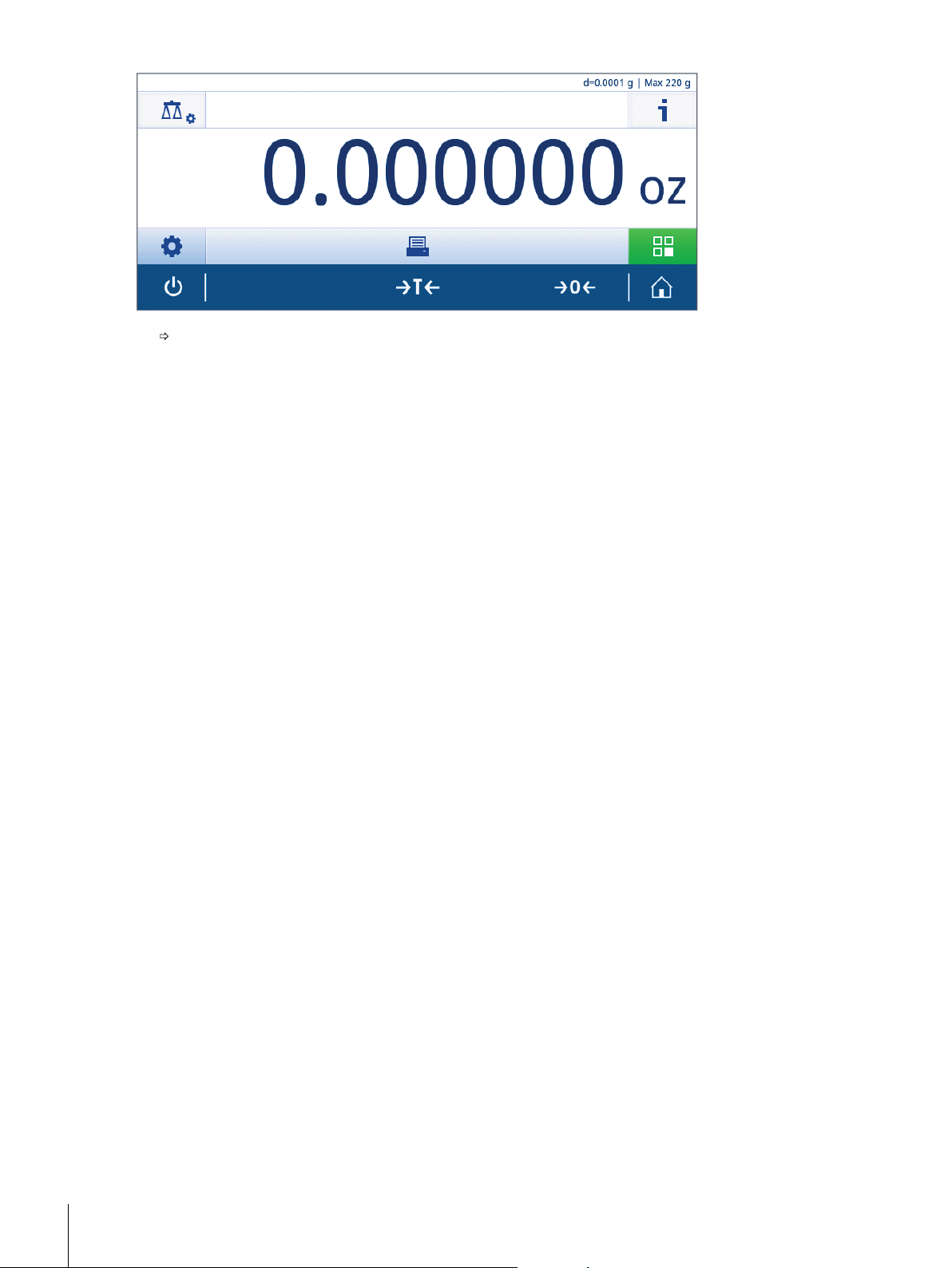

3.3.1Application home screen

The application home screen appears after the startup of the instrument. It always shows the last application

that was being used before the balance was switched off. The application home screen is the main screen of

the balance, from where every function can be accessed. You can always return to the application home screen

by pressing on the home button [ ] in the lower right corner of the screen.

Information and work bars

Name Explanation

1 Weighing information bar Shows the weighing-in aid and general balance information.

2 Work title bar Shows information about the current activity.

3 Value bar Shows information about the current weighing process.

4 Main navigation Work-related functions.

Information fields

Name Explanation

5 Weighing-in aid A dynamic graphic indicator shows the used amount of the total

weighing range.

6 Short balance information Readability and capacity of the balance.*

7 Weighing value field Shows the value of the current weighing process.

8 Coach text field Shows instructions for the current weighing process.

* For approved balances: Min (minimum capacity) and e (Verification scale interval) are shown in the left

upper corner.

Action buttons

Name Explanation

9 Main activity configuration To configure the current application (e.g. Weighing).

10 Detailed balance Information Shows detailed technical data about the balance.

11 Weighing unit Shows the unit of the current weighing process.

12 Activities To open the activities selection.

13 Print To produce a print.

14 Settings/Preferences To configure settings/preferences.

15 Status information field Shows information about the system status.

12 Design and Function

Page 13

3.3.2Input Dialogs

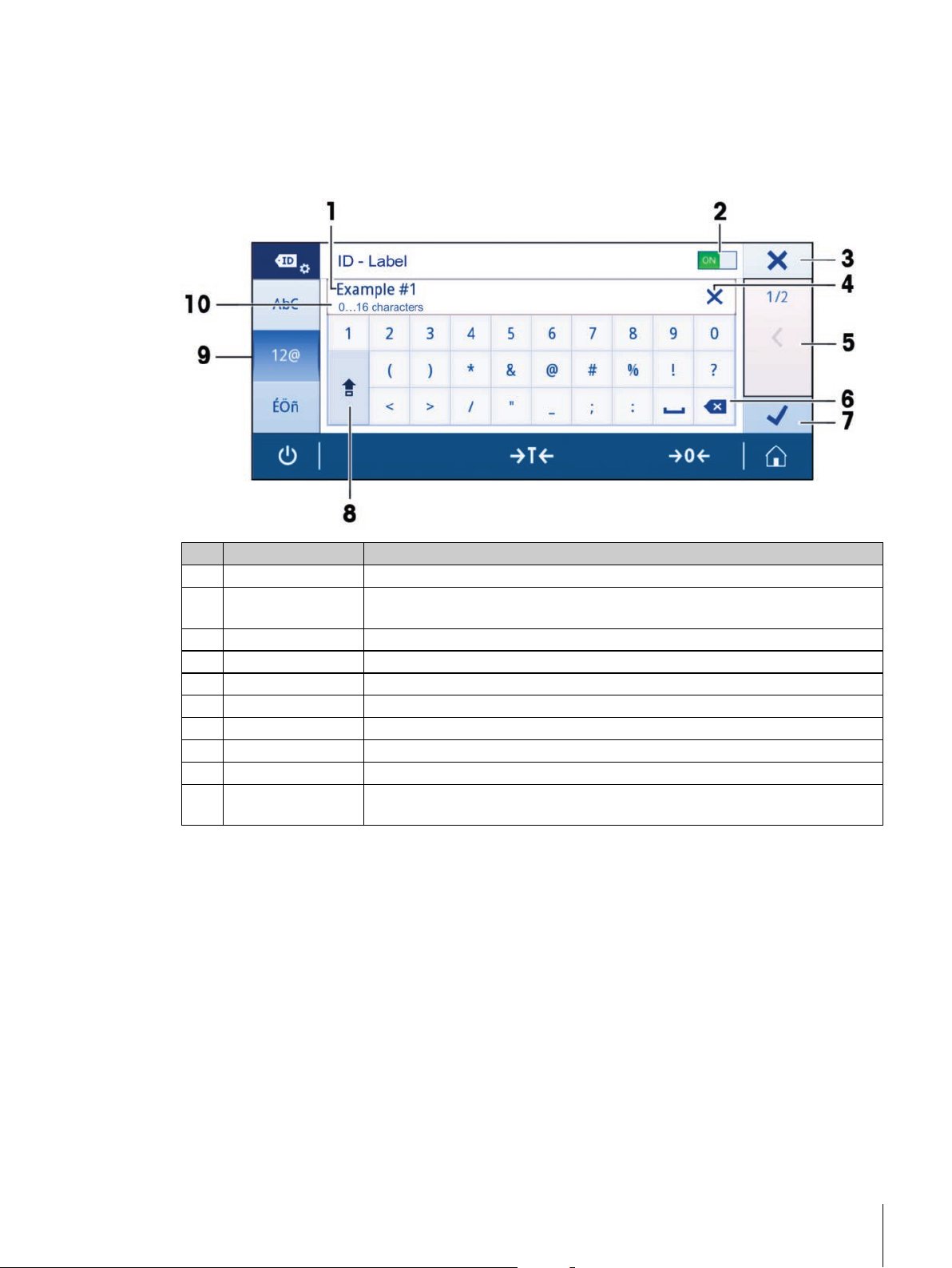

3.3.2.1Entering Characters and Numbers

The keyboard dialog allows the user to enter characters including letters, numbers and a variety of special char

acters.

Name Explanation

1 Input field Shows the characters that have been entered.

2 Switch If a switch appears on the right side in the content title bar, it must be switched

on in order to enter a value.

3 Discard To discard the entered data and to exit the dialog.

4 Delete all To delete all entered characters.

5 Page indicator To navigate when the dialog consists of several steps.

6 Delete To delete the last entered character.

7 Confirm To confirm the data entered.

8 Shift To switch between lower or upper case letters.

9 Specialized tabs To switch the keyboard mode for entering letters, numbers or special characters.

10 Explanation field Extra information about the value to enter (e.g. the maximum number of charac

ters available).

13Design and Function

Page 14

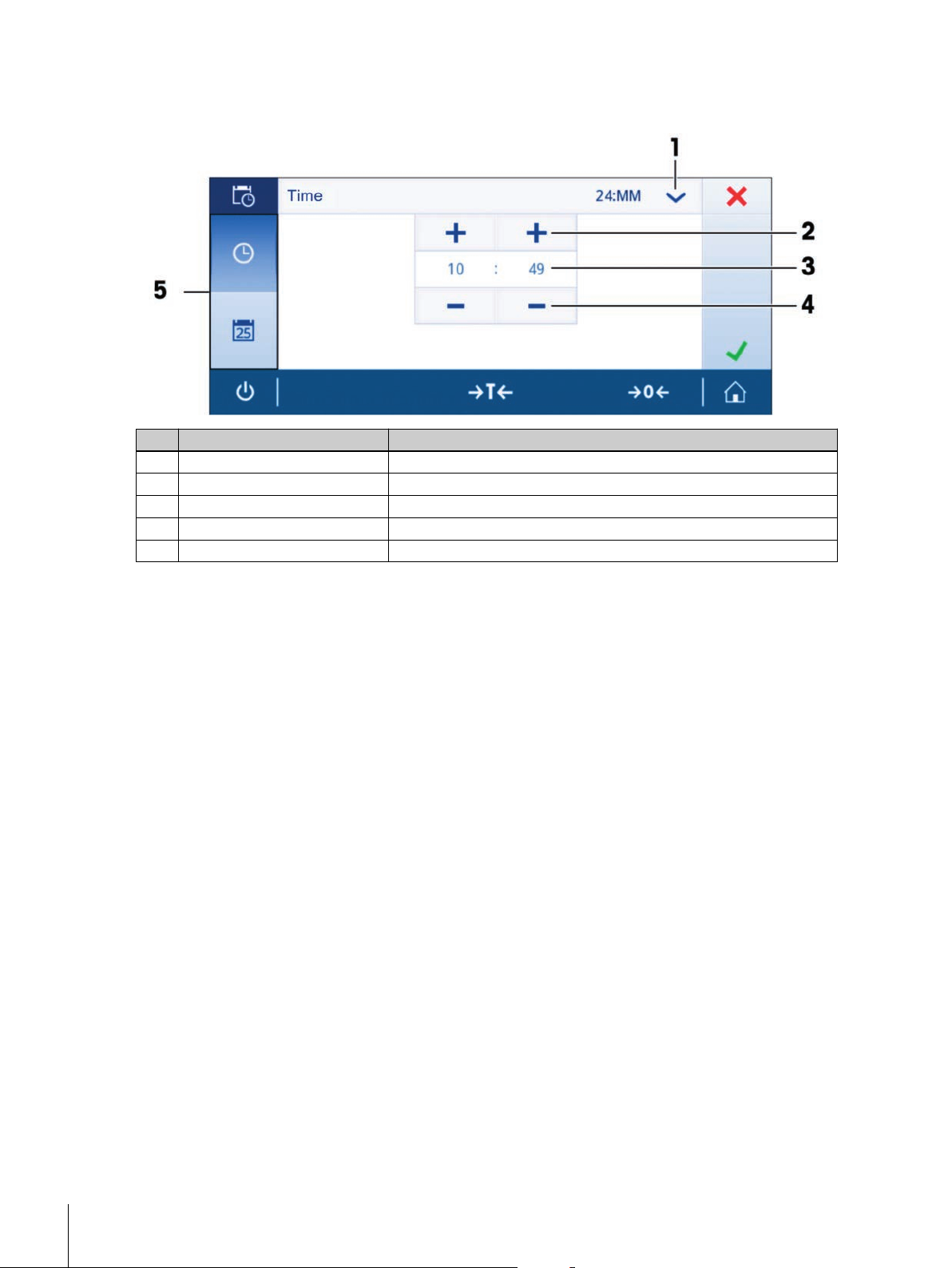

3.3.2.2Changing the time and date

The dialog (Picker view) allows the user to set the time and date.

Name Explanation

1 Change time/date format Various time/date formats can be chosen.

2 Pick button Increment

3 Picker field Shows the defined time/date.

4 Pick button Decrement

5 Selection tabs Tabs of the selectable sub-categories

14 Design and Function

Page 15

3.3.3Lists and tables

Basic elements of a simple list include a content title and a list of sub-elements. Tapping on an element opens

a list of sub-elements or an input dialog.

Name Explanation

1 List title Title of the current list

2 Back button To go one step back.

3 List element title Title of the list element

4 List element description Shows the sub-elements.

5 Scroll position The list can be scrolled.

6 Selection tabs Tabs of the selectable sub-categories.

15Design and Function

Page 16

4Installation and Putting into Operation

This section describes how to put the new instrument into operation.

4.1Scope of delivery

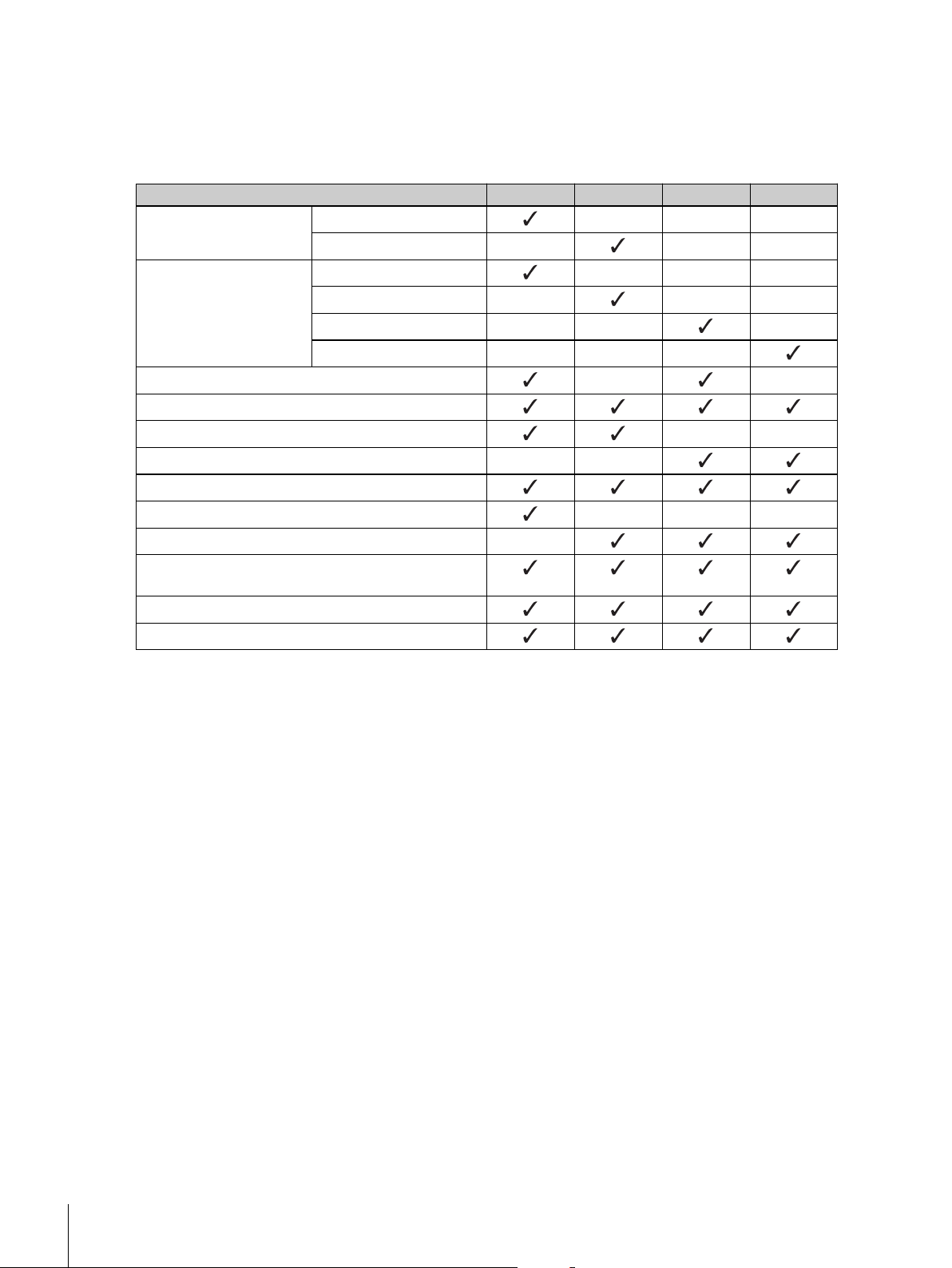

Components 0.1 mg 1 mg 0.01 g 0.1 g

236 mm – – –Draft shield

168 mm – – –

Weighing pan

Draft shield element – –

Pan support

Bottom plate – –

ESD plate – –

Protective cover

Universal AC/DC adapter (country-specific) - - -

AC/DC adapter (without power cable) -

Operating instructions printed or on CD-ROM (countryspecific)

Quick guide

EC declaration of conformity

Ø 90 mm – – –

127 x 127 mm – – –

170 x 200 mm – – –

190 x 226 mm – – –

16 Design and Function

Page 17

4.2Installing the components

3

4

5

6

1

2

2

M

S

3

4

5

1

2

MS

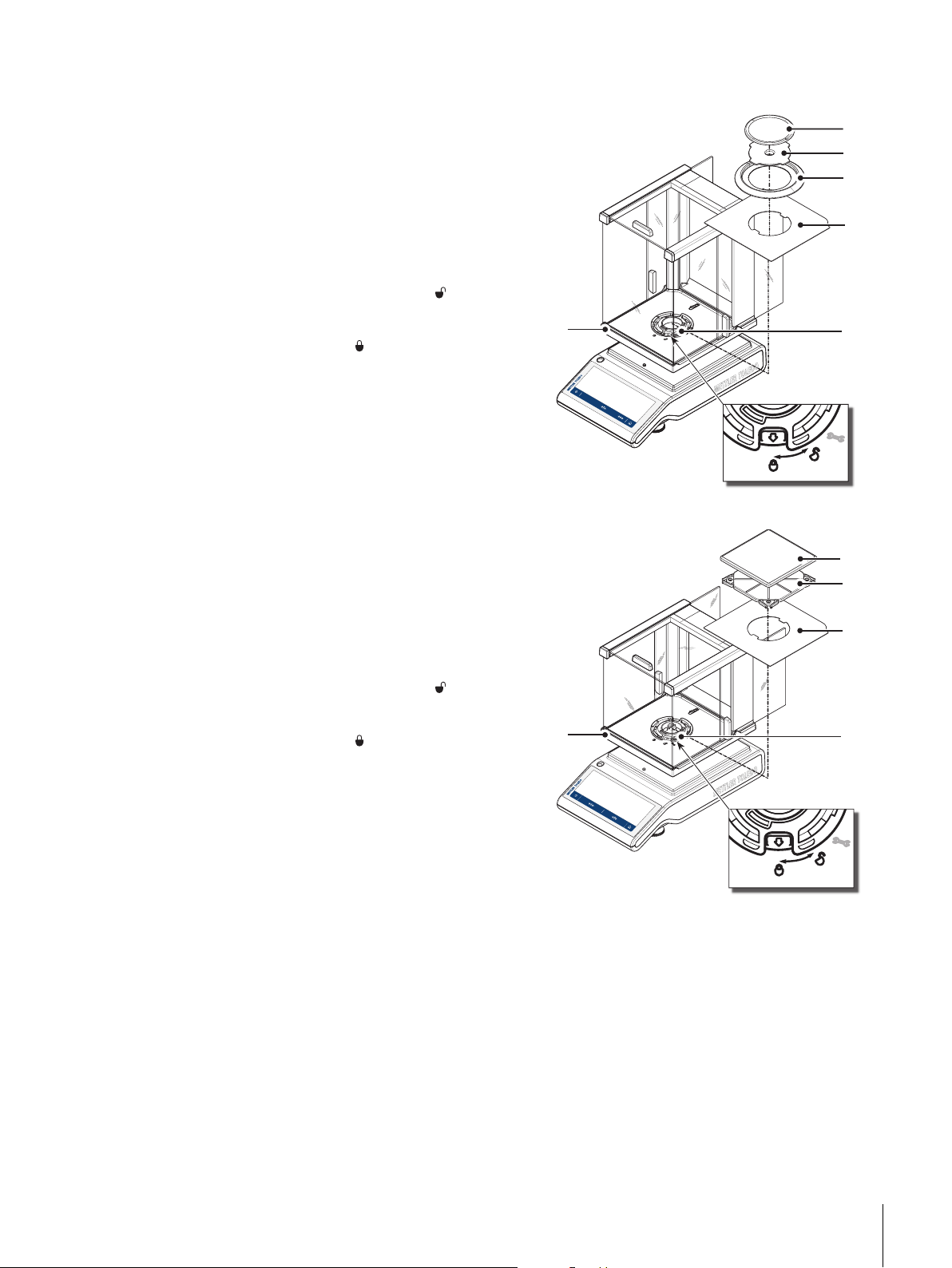

Balances with readability of 0.1 mg and draft shield

(236mm)

Place the following components on the balance in the

specified order:

Note

Push the side glass back as far as it will go and hold

the draft shield (1) with both hands on the bars at the

top.

1 Turn draft shield lock (2) to position (unlock).

2 Place draft shield on the balance.

3 Turn draft shield lock to (lock) and place bottom

plate (3).

4 Place draft ring element (4) and weighing pan (6)

with pan support (5).

Note

For cleaning the draft shield see section Cleaning the

glass draft shield (0.1 mg and 1 mg models)

(page71).

Balances with readability of 1 mg and draft shield

(168mm)

Place the following components on the balance in the

specified order:

Note: Push the side glass back as far as it will go

and hold the draft shield (1) with both hands on the

bars at the top.

1 Turn draft shield lock (2) to position (unlock).

2 Place draft shield on the balance.

3 Turn draft shield lock to (lock) and place bottom

plate (3).

4 Place weighing pan (5) with pan support (4).

Note

For cleaning the draft shield see section Cleaning the

glass draft shield (0.1 mg and 1 mg models)

(page71).

17Installation and Putting into Operation

Page 18

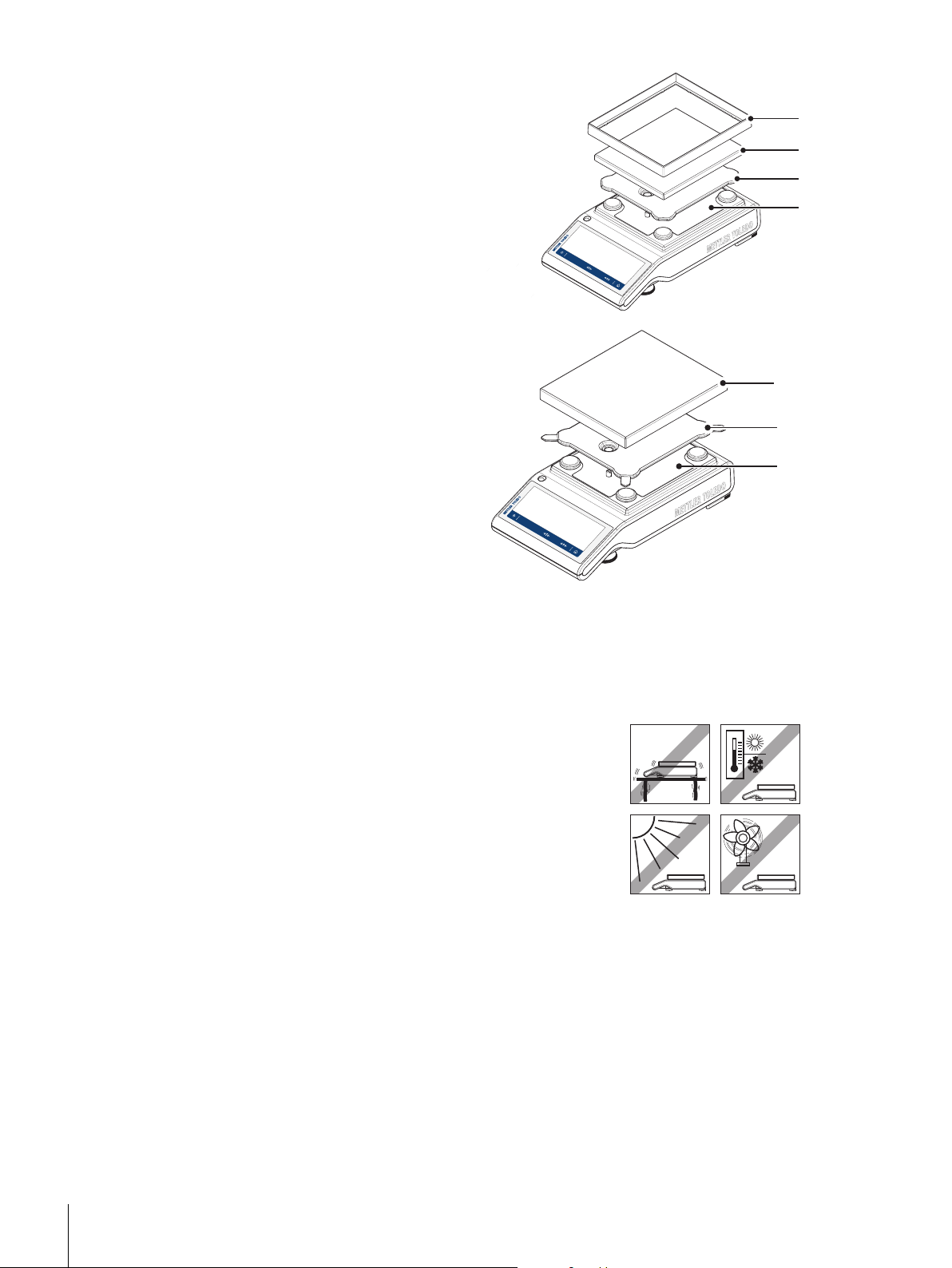

Balances with readability of 0.01 g

MS

2

3

4

1

MS

3

2

1

– Place the following components on the balance in

the specified order:

●

ESD plate (1)

●

Pan support (2)

●

Weighing pan (3)

●

Draft ring element (4)

Balances with readability of 0.1 g

– Place the following components on the balance in

the specified order:

●

ESD plate (1)

●

Pan support (2)

●

Weighing pan (3)

4.3Selecting the location

Your balance is a precision instrument and will reward you for finding its optimum location with higher accura

cy and dependability. Select a stable surface that is as horizontal as possible. The surface must be able to

safety carry the weight of a fully loaded balance.

Observe ambient conditions (see Technical Data).

Avoid the following:

●

Direct sunlight

●

Powerful drafts (e.g. from fans or air conditioners)

●

Excessive temperature fluctuations

●

Vibrations

18 Installation and Putting into Operation

Page 19

4.4Connecting the instrument

The balance is supplied with a country-specific AC/DC adapter or with a country-specific power cable. The pow

er supply is suitable for all line voltages in the range: 100 - 240 VAC, 50/60 Hz. For detailed specifications,

see the section Technical Data.

CAUTION

Allow the balance to warm up for 30 minutes (0.1 mg models need 60 minutes) to adapt itself to the ambient

conditions.

Connect the AC/DC adapter to the connection socket on the back of your balance

and to the power line.

Attention

●

Check if the local power supply falls within this range. If this is not the case, under no circumstances con

nect the AC/DC adapter to the power supply, but contact a METTLER TOLEDO representative.

●

The power plug must be accessible at all times.

●

Prior to use, check the power cable for damage.

●

Route the cable in such a way that it cannot be damaged or cause a hindrance when working.

●

Ensure that no liquid ever comes into contact with the AC/DC adapter.

19Installation and Putting into Operation

Page 20

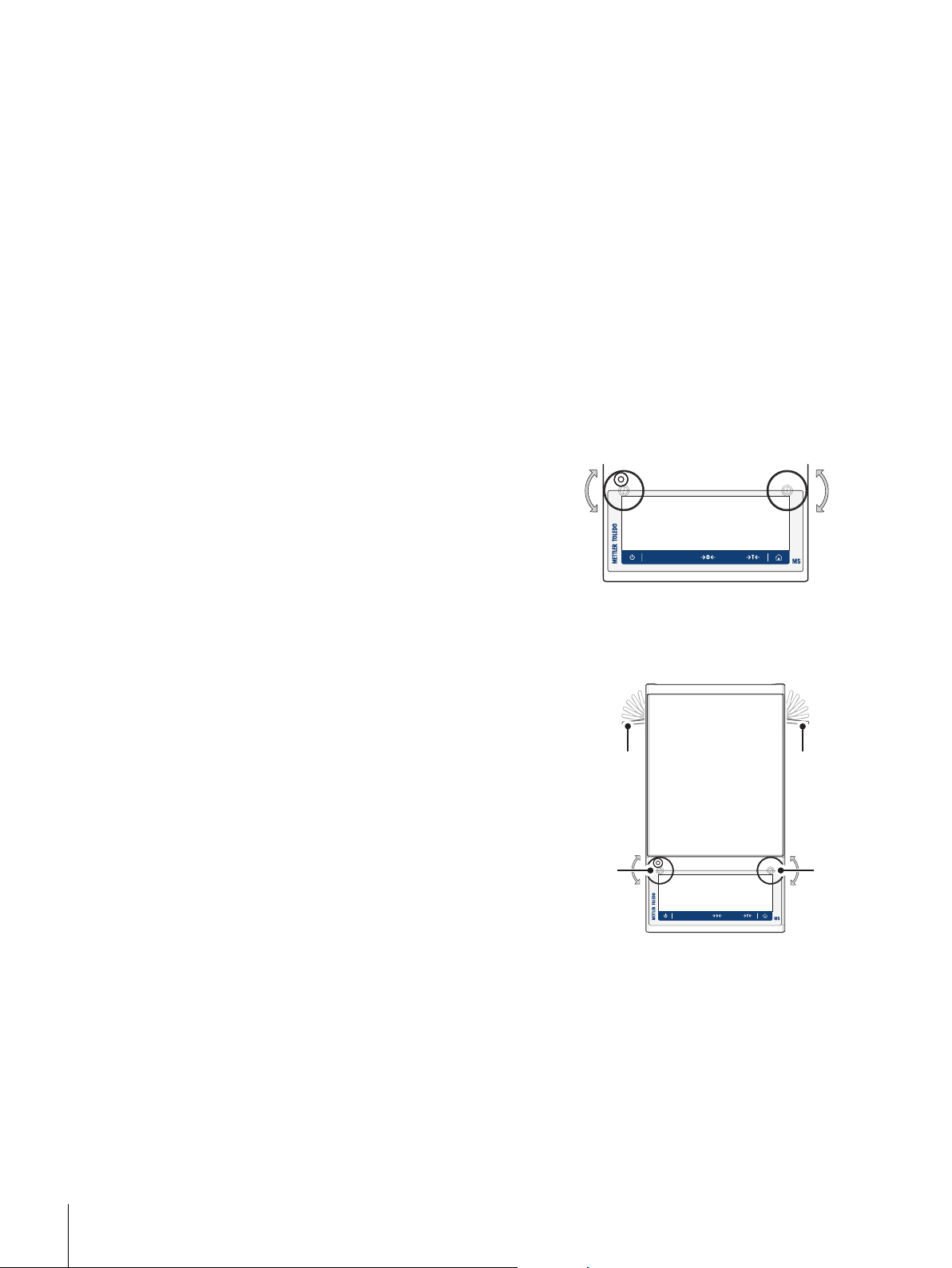

4.5Leveling the balance

B

B

A

A

Exact horizontal positioning and stable installation are prerequisites for repeatable and accurate weighing

results.

Note

To compensate for small irregularities or inclinations (±2 %) at the location, the instrument must be leveled

and adjusted each time it is moved to a new location.

The balance can be levelled with the leveling assistant and/or with the level indicator on top of the terminal.

There are two adjustable leveling feet to compensate for slight irregularities in the surface of the weighing

bench.

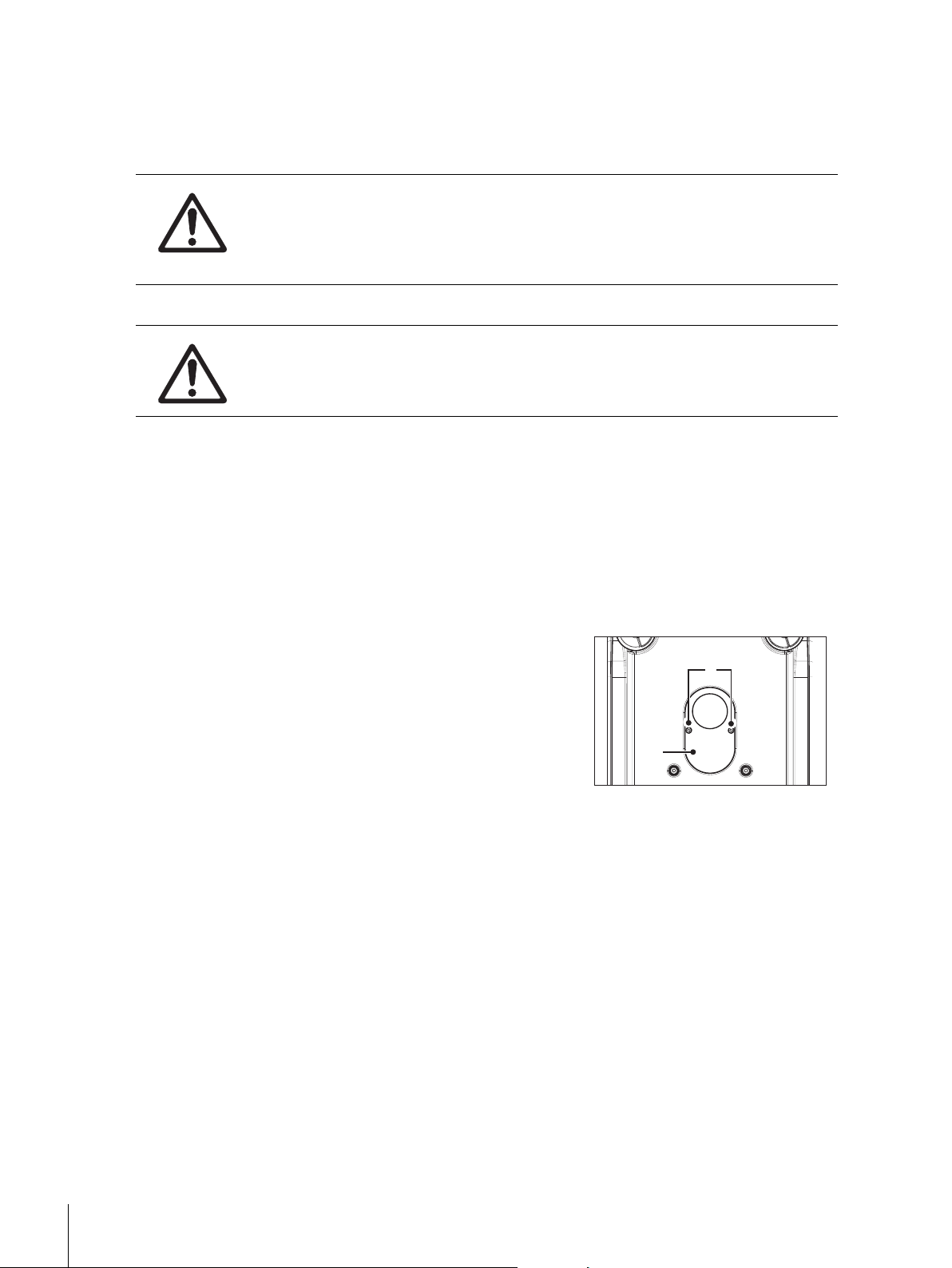

4.5.1Leveling the balance with the level indicator

All balances have a level indicator with an air bubble to level the balance manually.

Leveling balances with readability of 0.1 mg and 1 mg

– Adjust the two leveling feet until the bubble comes to rest

exactly in the middle of the glass:

Air bubble at "12 o'clock" turn both feet clockwise.

Air bubble at "3 o'clock" turn left foot clockwise, right

foot counterclockwise.

Air bubble at "6 o'clock" turn both feet counterclockwise.

Air bubble at "9 o'clock" turn left foot counterclockwise,

right foot clockwise.

Leveling balances with readability of 0.01 g and 0.1 g

1 Remove the clamps (A) for the safety feet by turning them out

wards.

2 Turn the clamps (A) outwards as far as they will go (~ 90°), so

that the safety feet can move freely.

3 Now level the balance by turning both leveling screws (B) until the

bubble is in the inner circle of the level indicator (see procedure

above).

4 Secure the safety feet by turning the clamps (A) inwards as far as

they will go.

20 Installation and Putting into Operation

Page 21

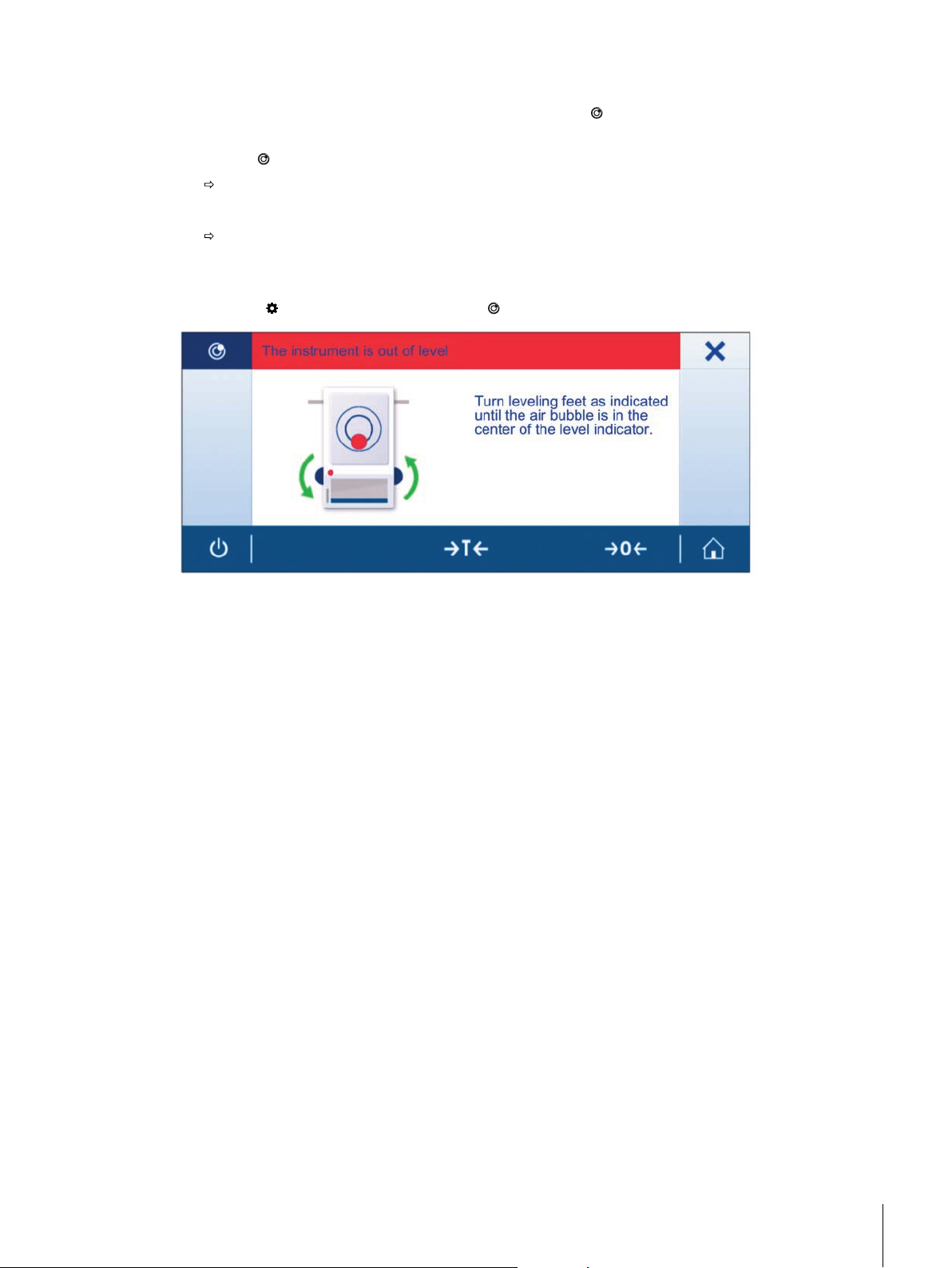

4.5.2Leveling the balance using the leveling assistant

When the balance is switched on at its new location, the symbol The instrument is out of level appears in

the status information field at the left side of the screen.

1 Tap on [ ].

The screen Notifications opens.

2 Select The instrument is out of level.

The function Leveling assistant opens.

The function Leveling assistant is a step-by-step guidance that helps in leveling the balance.

Navigation: [ ] Quick settings/Preferences > [ ] Leveling assistant

After following the instructions, the leveling assistant will show the next steps. Follow the steps until the balance

is levelled.

Note

Always use the physical air bubble of the level indicator as a reference.

21Installation and Putting into Operation

Page 22

4.6Transporting the balance

B

A

Switch off the balance and remove the power cable and any interface cable from the balance. Refer to the notes

in section Selecting the location (page18) regarding the choice of an optimal location.

Transporting over short distances

CAUTION

For balances with a draft shield:

Never lift the balance by its glass draft shield. The draft shield is not sufficiently fastened to

the balance.

Transporting over long distances

CAUTION

If you would like to transport or send your balance over long distances, use the complete

original packaging.

4.7Weighing below the balance

The balances are equipped with a hanger for carrying out weighings below the work surface.

CAUTION

●

Do not place the balance on the pan support location bolt (0.1 mg and 1 mg models).

●

Models with a glass draft shield: Carefully lift the draft shield from the weighing platform and put it aside.

1 Switch off the balance and remove the power cable and any inter

face cable from the balance.

2 Remove the draft ring element (10 mg models).

3 Remove the weighing pan and pan support.

4 Remove the bottom plate and unlock the draft shield (models with

draft shield). Carefully lift the draft shield from the weighing plat

form and put it aside.

5 Turn the balance carefully on its side.

6 Remove and retain the 2 screws (A) and the cover plate (B). The

hanger is now accessible.

7 Then return the balance to its normal position and simply reinstall

all components in the reverse order.

22 Installation and Putting into Operation

Page 23

4.8General requirements

4.8.1Warming up the balance

Before working with the balance, it must be warmed up in order to obtain accurate weighing results. To reach

operating temperature, the balance must be connected to the power supply for at least:

●

30 minutes for balances with a readability of 1mg (0.01ct) to 5g.

●

60 minutes for balances with a readability of 0.1mg (0.001ct) and higher.

4.8.2Adjusting the balance

To obtain accurate weighing results, the balance must be adjusted to match the gravitational acceleration at its

location and depending on the ambient conditions. After reaching the operation temperature, an adjusting is

necessary in the following cases:

●

Before the balance is used for the first time.

●

When the balance (readability of 0.1 mg) was disconnected from the power or in case of power failure.

●

After a change of location and after the warming-up phase.

●

At regular intervals during weighing service.

23Installation and Putting into Operation

Page 24

5Weighing Made Simple

This section describes how to perform a simple weighing. In addition, the basic concept of the navigation and

the basic functions of the balance are explained.

5.1Switching on the balance

Switching on the balance for the first time

1 Remove any load from the weighing pan.

2 Connect the balance using the AC/DC adapter to the mains.

After the start screen has disappeared, the balance starts with the application home screen.

After the balance has switched on for the first time, it can be switched on by pressing long on [ ].

Note

When the balance is switched on for the first time, the home screen of the application Weighing opens. If the

balance is switched on again, it always starts with the home screen of the application that was used before

switching off.

5.2Switching off the balance

1 Press on [ ] and hold until the dialog Switch-off appears.

2 Tap on [ ].

the balance switches off and goes into standby mode.

Note

●

After switching on from standby mode, the balance needs no warm-up time and is immediately ready for

weighing.

●

If the balance has been switched off after a preselected time, the display is dimly lit and shows the time and

the date.

●

If the balance has been switched off manually, the display is off.

To completely switch off the balance, it must be disconnected from the power supply.

24 Installation and Putting into Operation

Page 25

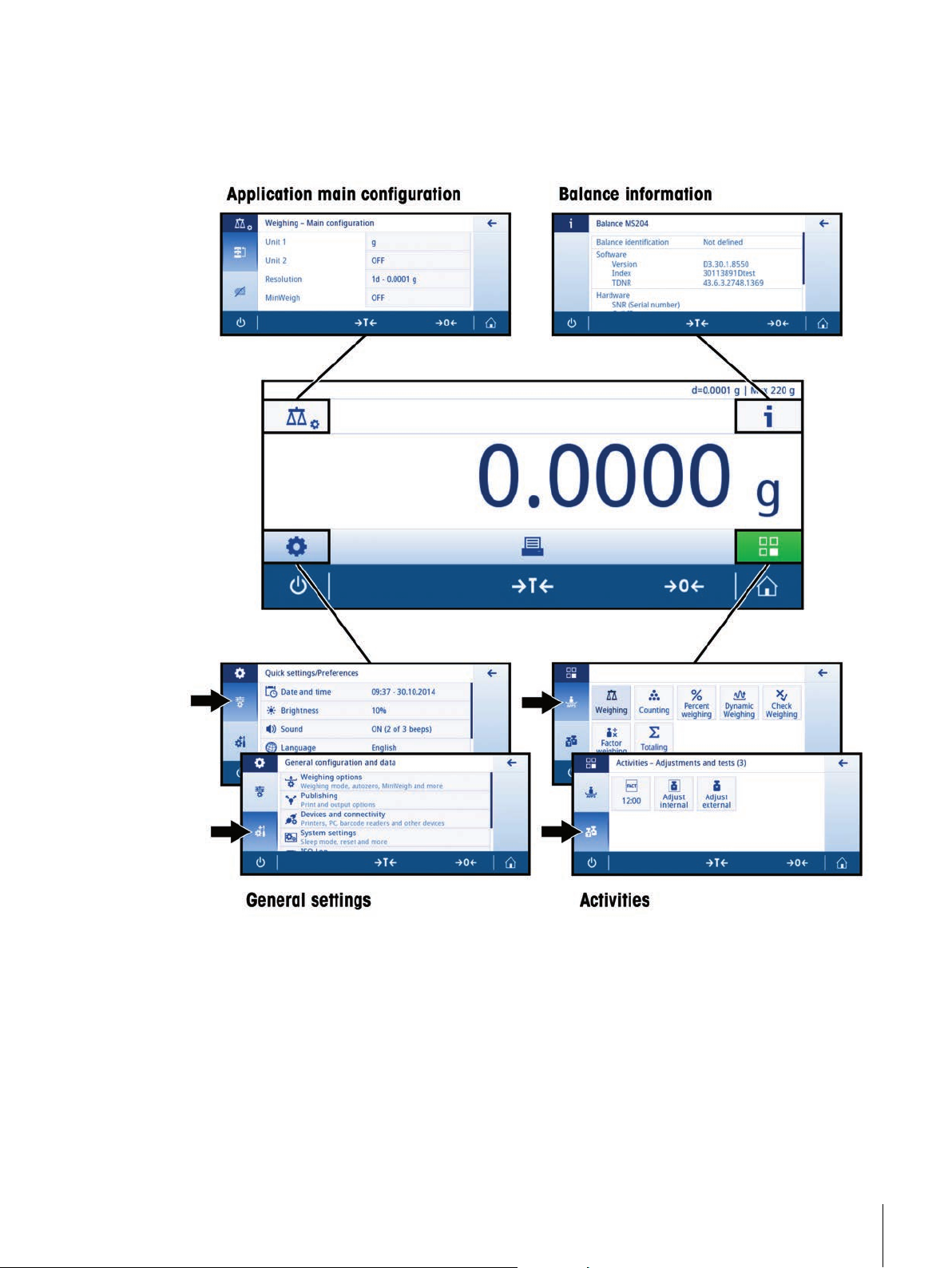

5.3Main settings and activities at a glance

The diagram below provides an overview of the main settings of an application (e.g. Weighing). Depending on

the application, the selectable options and their content can differ. Every application is based on this concept.

25Weighing Made Simple

Page 26

5.4Navigation on the touch screen

To interact with the balance, use the screen and the operating keys at the bottom of the screen. The navigation

on the screen is similar to the navigation of a smart phone or tablet PC.

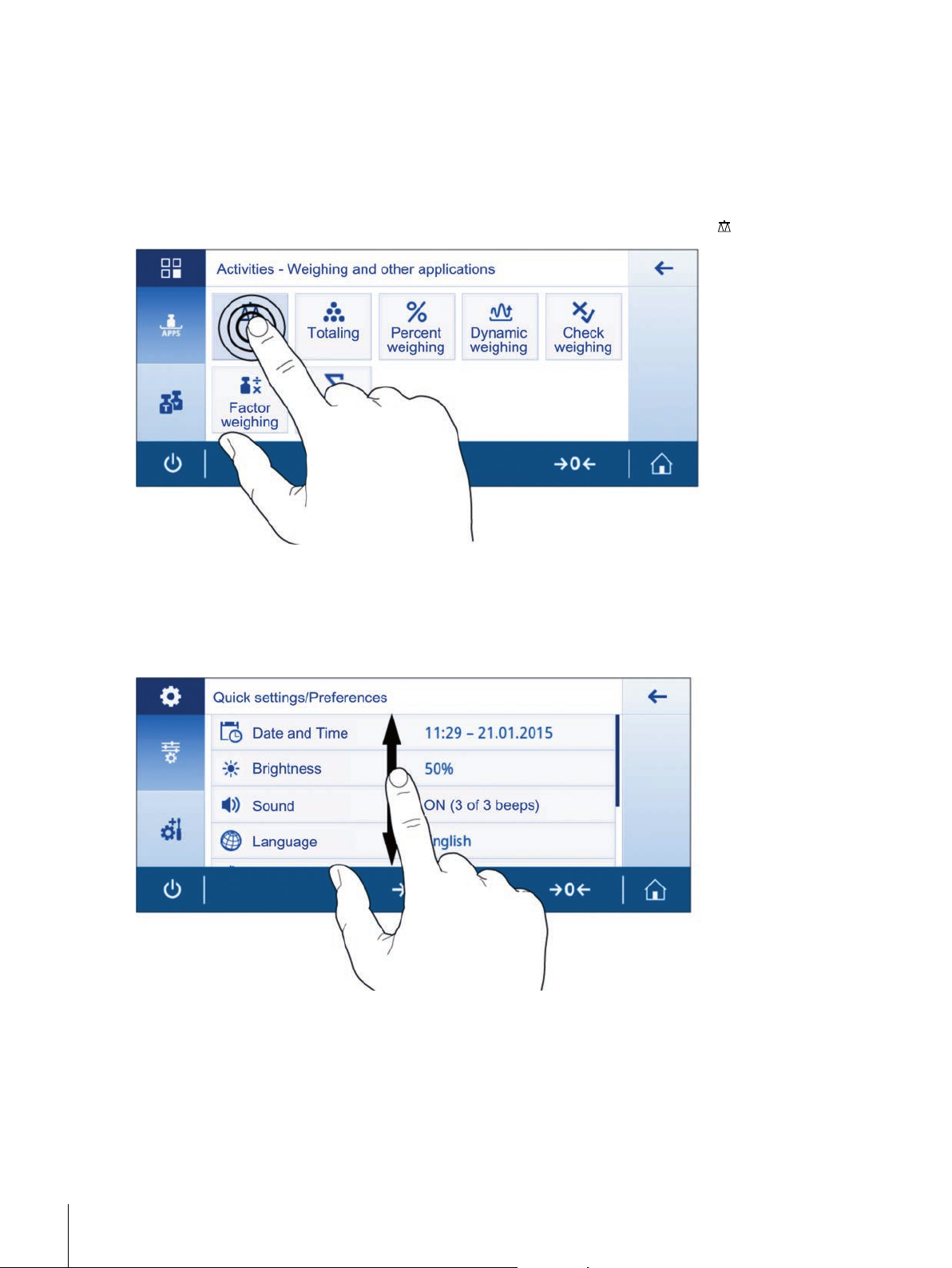

5.4.1Opening an application

To open settings or applications, tap with your finger on the symbol of the application (e.g. [ ] Weighing).

5.4.2Scrolling

When the options are too numerous to be shown on one screen, a blue bar on the right side appears. This

means that the user can scroll up and down. For scrolling, simply place your finger somewhere in the list and

drag it up or down.

26 Weighing Made Simple

Page 27

5.4.3Using shortcuts

To simplify navigation on the capacitive color TFT touch screen, there are a few shortcuts that allow quick

access to the most important areas of the balance. The weighing value field on the application home screen for

example works as a shortcut (see diagram below), so does the weighing unit next to the weighing value field.

Depending on the application, there may be other shortcuts that can be used.

Note

Every setting that can be changed directly via shortcut, can also be changed in the main configuration settings

of the application.

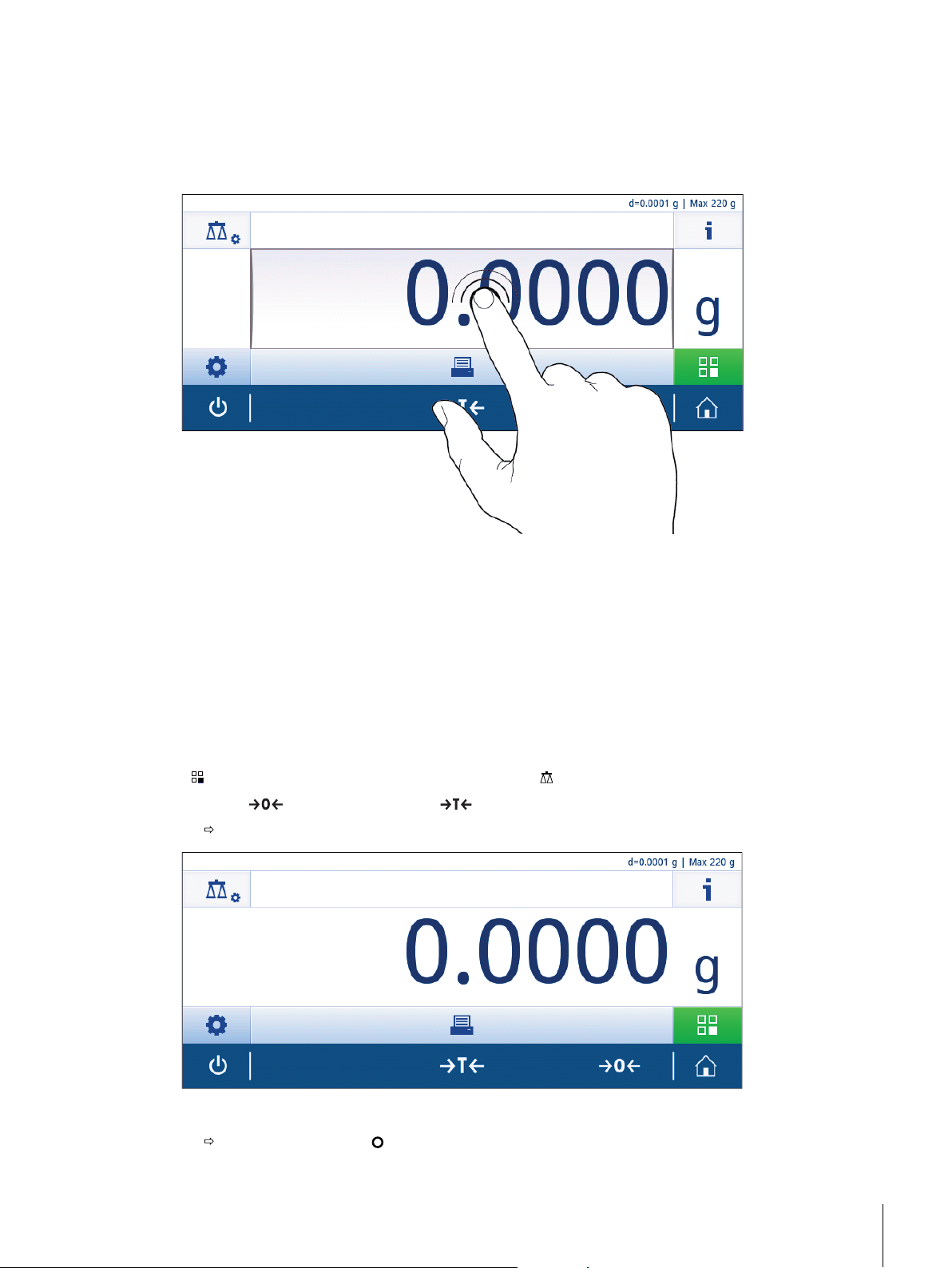

5.5Performing a simple weighing

When you switch on the balance for the first time, the home screen of the application Weighing opens auto

matically. If the balance was used already, the last used application before the balance was switched off

opens. If another application is running, switch to the application Weighing.

Navigation:

[ ] > Activities - Weighing and other applications > [ ] Weighing

1 Press [ ] to zero the balance or [ ] to tare the balance.

The initial screen looks like this:

2 Place a sample on the weighing pan.

The unstability symbol appears and the value in the weighing value field becomes light blue.

27Weighing Made Simple

Page 28

After a short period of time, the weighing pan is stable. The unstability symbol disappears and the

value in the weighing value field becomes dark blue again.

The weighing process is finished. The result appears on the screen.

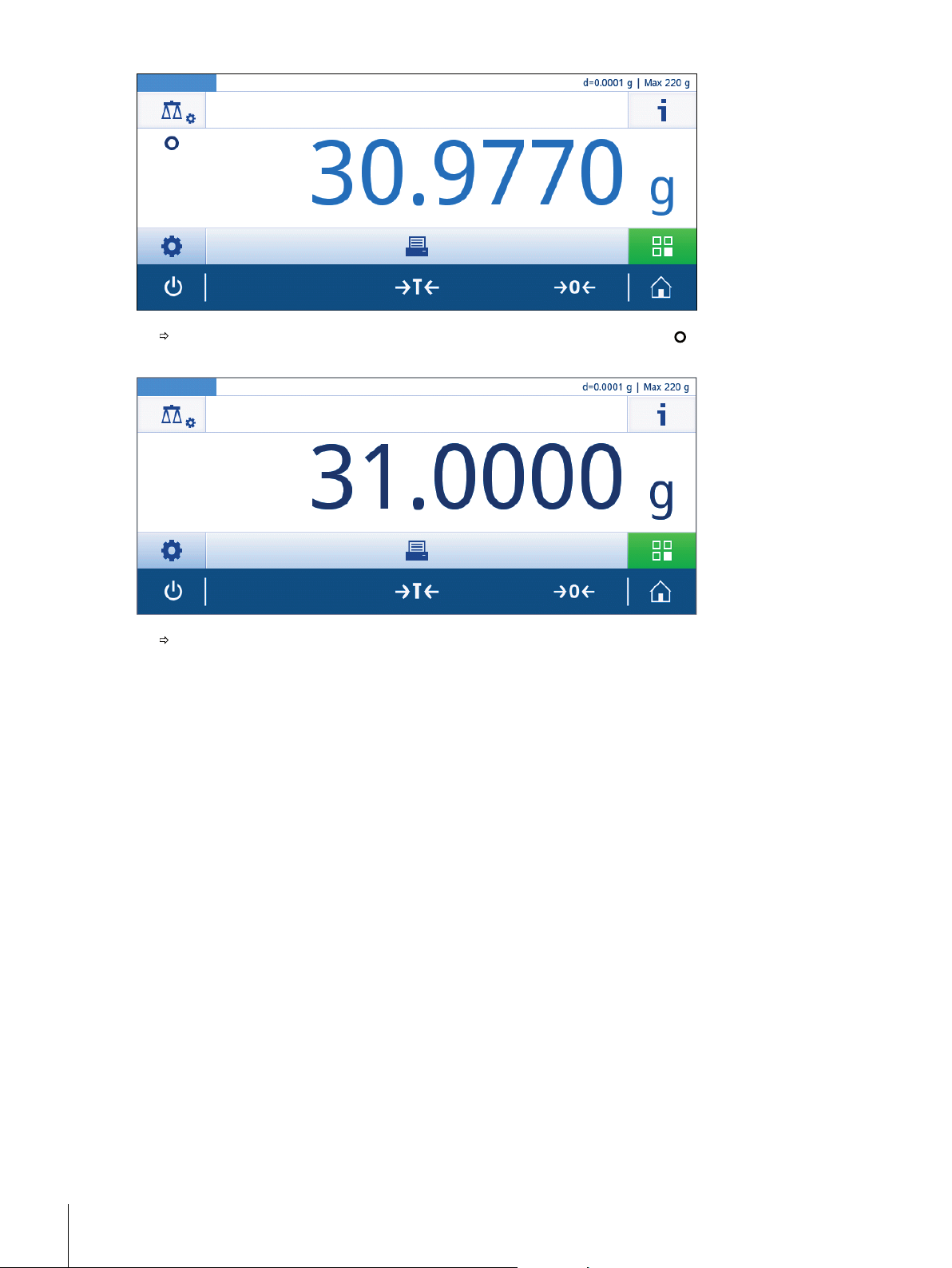

5.6Switching the weighing unit

There are several weighing units available. The default value is country-specific.

The weighing unit can be chosen via the main configuration of the current application or via shortcut. This

example describes how to change the weighing unit via shortcut.

1 Tap on the weighing process unit (shortcut) gram (g).

28 Weighing Made Simple

Page 29

the screen Main unit opens.

2 Put your finger somewhere in the list and drag up to scroll down.

3 Choose another weighing unit (e.g. ounce (oz)) by tapping on it.

4 Tap on [ ] to confirm the chosen weighing unit.

29Weighing Made Simple

Page 30

The weighing unit gram (g) has been changed to ounce (oz).

Note

With approved balances, this menu topic has a fixed setting and cannot be changed.

30 Weighing Made Simple

Page 31

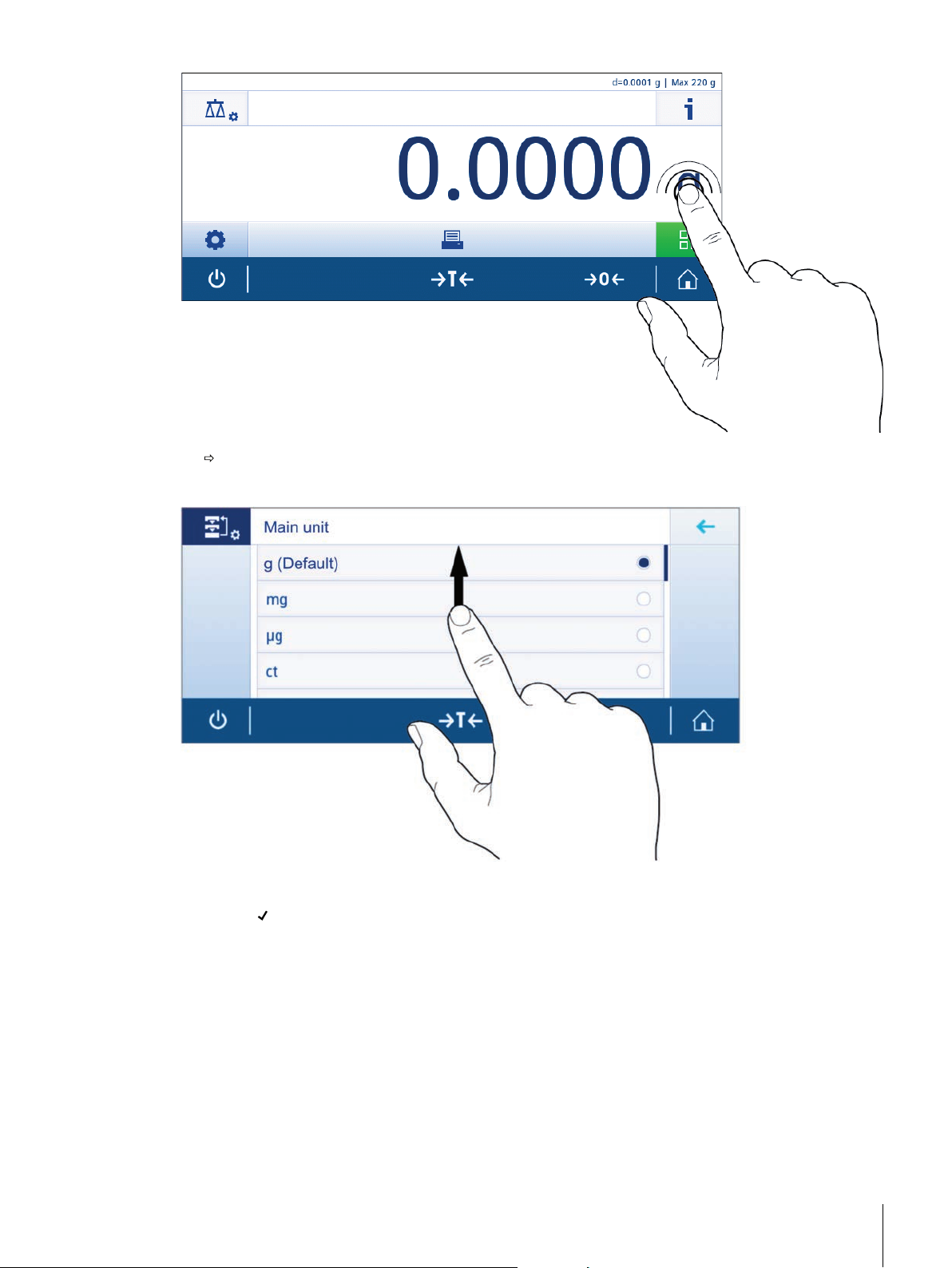

5.7Changing the resolution

There are several resolutions available. The default resolution is instrument-specific.

The resolution can be changed as follows:

1 Tap on the weighing value field.

2 Tap on 1d - 0.0001 g (Default).

3 Confirm the chosen resolution by tapping on [ ].

31Weighing Made Simple

Page 32

5.8Zeroing

1 Unload the balance.

2 Press [ ] to set the balance to zero.

All weight values are measured in relation to the zero point.

Note

Press [ ] before starting the weighing process.

5.9Taring

1 Tap on [ ] to set the balance to zero.

2 Place the empty container on the balance.

3 Press [ ] to tare the balance.

The resolution has been changed.

The weight is displayed.

The status information field shows Net and the weighing value field shows 0.000 g.

32 Weighing Made Simple

Page 33

5.10Working with IDs

Identifications (IDs) contain descriptive text for individual measurements, which enables samples to be easily

allocated to specific tasks or customers. This feature defines identifications in order to comment measurements,

such as company ID, badge ID or sample ID.

Identifications must be defined in the contextual settings of an application. Usage and definition of the ID differ

depending on the application the ID is used for.

Identification dialog screen

The Identification dialog screen can slightly differ depending on the application in which the ID is used. The dia

log screen always consists of two parts:

●

The table with the ID definitions on the upper part of the screen.

●

The Workflow handling options on the lower part of the dialog screen.

5.10.1Defining an ID

A new ID is defined as follows:

1 Open an application (e. g. Weighing).

2 Tap on the Main configuration symbol on the upper left corner.

3 Tap on [ID] Identifications

4 Tap on ID 1.

The input dialog ID 1 opens. The input dialog is inactive.

5 Activate ID 1 with the switch in the title bar.

The input dialog ID 1 is activated.

The title bar shows ID 1 - Label.

6 Define ID 1 - Label.

7 Tap on [ ] to confirm the definition.

The input dialog ID 1 - Value opens.

8 Define ID 1 - Value.

9 Tap on [ ] to confirm the definition.

The screen Identifications opens showing the defined ID.

10 Tap on [ ] to accept the defined ID.

Repeat the steps for the other IDs.

33Weighing Made Simple

Page 34

Note

The maximum length of an ID is 16 characters.

The picture below shows an example of defined IDs. IDs 1-3 are defined, ID 4 is still inactive.

5.10.2Workflow handling options

The workflow handling options differ depending on the application in which they are used. The following func

tions are available:

●

Input prompt

●

Autoincrement

●

Assign to sample

Input prompt

The function Input prompt can be used for every ID. If the function Input prompt is activated, the ID will be

prompted on the display before it is used. The user can decide whether to use the default value that has been

defined with the ID or to define an individual value.

Autoincrement

The function Autoincrement specifies that the last part of the ID is incremented with each use of that ID. There

are two basic functions depending on how the ID is defined:

●

If there is no counter in the ID, the system automatically adds a counter to the ID starting with 1 (e.g. the ID

Process will be Process1 in the next use).

●

If a counter is part of the ID, the system automatically increments the ID starting at that counter (e.g. the ID

Process 1 will be Process 2 in the next use).

Note

●

The counter must be set at the end of the ID, otherwise the system doesn't recognize the number as a

counter (e.g. in 567Apple the system doesn't recognize 567 as a counter).

●

If the ID has no counter and a maximum length of 16 characters, the last few characters will be overwritten

by the counter.

Assign to sample

If the option Assign to sample is activated, the ID will be used for each sample.

34 Weighing Made Simple

Page 35

5.11Statistics

The function Statistics generates statistics for a series of values. The option is available for every application.

Defining Statistics

1 Open an application (e.g. Weighing).

2 Tap on the main configuration symbol of the application.

The main configuration screen opens.

3 Tap on [ ].

The screen Statistics opens.

4 Activate the function Statistics.

5 Define the available options.

6 Tap on [ ] to confirm the adjustments.

Statistics configuration

The following options can be defined:

Parameter Explanation Values

Acceptance

range

Accepting mode To define if a weight sample is added automatically to the result.

* Factory setting

Note

The function Statistics is not available for the applications Totaling and Formulation.

To define the acceptable deviation in relation to the average val

ue.

The sample is automatically accepted if: the sample is at least

10d and a deflection according to the SNR command described

in the MT-SICS manual MT-SICS interface commands and func

tions (page76) was detected.

1%...100% (10%*)

Manual* | Automatic

35Weighing Made Simple

Page 36

6Activities

The section Activities can be opened by tapping on [ ]. The section Activities includes the following two sub-sections:

●

Activities - Weighing and other applications

●

Activities - Adjustments and tests

6.1Activities - Weighing and other applications

Activities - Weighing and other applications includes the following applications:

●

Weighing see at section Weighing (page37) and Weighing Made Simple (page24)

●

Counting see section Counting (page38)

●

Percent Weighing see section Percent Weighing (page40)

●

Formulation see section Formulation (page42)

●

Dynamic Weighing see section Dynamic Weighing (page44)

●

Check Weighing see section Check Weighing (page46)

●

Factor Weighing see section Factor Weighing (page50)

●

Totaling see section Totaling (page51)

36 Weighing Made Simple

Page 37

6.1.1Weighing

The application Weighing allows the user to perform simple weighings. For more information about the basic weighing functions see the section Weighing Made Simple (page24).

Navigation

[ ] Activities > Activities - Weighing and other applications > [ ] Weighing

Weighing – Main configuration

The following options can be defined:

Parameter Explanation Values

Main unit To define the main unit of the weighing process. Available values are

Additional unit To define an additional weighing unit. Available values are

Resolution To define the resolution of the weighing process. Available values are

model-specific.

model-specific.

model-specific

37Activities

Page 38

6.1.2Counting

The application Counting determines a specific number of pieces, based on pre-determined reference piece weight.

Navigation

[ ] Activities > Activities - Weighing and other applications > [ ] Counting

Defining Reference piece weight

To define the Reference piece weight, Reference piece number and Reference weight must successively be

defined. The system will automatically navigate from one option to the other.

Defining Reference piece number

1 Tap on [ ].

the screen Counting – Main configuration opens.

2 Tap on [Reference piece weight].

The dialog screen Reference piece number opens.

3 Delete the value by tapping on [ ].

4 Enter the number of reference pieces.

5 Tap on [ ] to confirm the defined reference piece number.

Note

The reference piece number must be a natural number between 1 to 999.

Defining Reference weight

Reference weight can be defined manually by entering the weight of the reference pieces or by weighing the

reference pieces.

Defining Reference weight manually

1 Delete the reference weight by tapping on [ ].

2 Enter the new reference weight.

3 The reference unit can be changed by tapping in the sensitive area at the right side of the input field.

4 Confirm the new value by tapping on [ ].

The reference piece weight has been defined.

5 Confirm the new reference piece weight by tapping on [ ].

Defining Reference weight by weighing

1 Tap on [ ].

2 Place reference weight on the weighing pan.

3 Tap on [ ] to confirm the weight.

The screen Counting – Main configuration opens.

4 Tap on [ ] to confirm the configurations.

38 Activities

Page 39

The following picture shows the home screen of the application. The work title bar displays the defined Refer

ence piece number and Reference piece weight that can be used as shortcuts.

Note

A fixed minimum reference piece number of 10 and inactive reference weight options for approved balances

(except for some selected countries).

Counting – Main configuration

The following options can be defined:

Parameter Explanation Values

Reference piece

weight

Additional unit To activate/deactivate and define the additional unit of the weigh

* Factory setting

To define the number and the weight of the reference piece/s. 1...999

(10*)

Available values are

ing process.

model-specific.

39Activities

Page 40

6.1.3Percent Weighing

With the application Percent Weighing a sample weight can be checked as percentage to a reference target weight.

Navigation

[ ] Activities > Activities - Weighing and other applications > [ ] Percent Weighing

Defining Reference weight

There are two possible ways to define the reference weight: The reference weight can be defined manually by

entering the value or by weighing the reference weight.

Defining the reference weight by weighing

1 Tap on [ ].

The screen Percent weighing – Main configuration opens.

2 Tap on Reference weight.

3 Tap on [ ].

4 Press [ ] to zero the balance.

5 Place the reference weight on the weighing pan.

6 Tap on [ ] to accept the value of the reference weight.

The screen Reference weight reappears.

7 Tap on [ ] to accept the reference weight.

8 Tap on [ ] to accept the reference weight and to return to the application home screen.

Defining the Reference Weight manually

1 Tap on [ ].

2 Tap on Reference weight.

3 Delete the default value by tapping on [ ].

4 Enter the value of the reference weight.

5 Confirm the reference weight by tapping on [ ].

The reference weight has now been defined and will be shown in the work title bar.

40 Activities

Page 41

The picture shows the home screen of the application Percent Weighing. The work title bar displays a defined

reference weight of 200g that can be used as shortcut.

Percent weighing – Main configuration

The following options can be defined:

Parameter Explanation Values

Reference

weight

Main unit To define the main unit of the weighing process. Available values are

To define the reference weight manually or by weighing. -220.0000 ... -

0.0010 | 0.0010 ...

220.0000

model-specific.

41Activities

Page 42

6.1.4Formulation

The application Formulation allows the user to:

●

Weigh-in (add and store) up to 999 individual component weights and display the total.

●

Tare/pre-tare and store up to 999 container weights and display the total.

●

fill up the sum of all component net weight values by adding a further component to a higher value.

Note

Total number of containers + component weights ≤ 999.

Navigation

[ ] Activities > Activities - Weighing and other applications > [ ] Formulation

Performing Formulation

1 Press [ ] to zero the balance

2 If a container is used: Place container on the weighing pan and press [ ] to tare the balance.

If the balance is tared, the status information field shows Net.

3 Place the first component weight.

The weighing value field shows the value of the first component weight.

4 Tap on [ ] to add the first component weight.

5 Place the second component weight.

The weighing value field shows the value of the second component weight.

6 Tap on [ ] to add the second component weight.

7 Continue adding components untill all the components are weighed.

Defining Fill up sample

With the function Fill up sample an additional component weight can be added to the total weight of all com

ponents to reach a desired target weight.

The weighing value field shows the total net weight.

1 Tap on [ ].

2 Place the fill up sample.

3 Tap on [ ] to confirm.

Discard value

The last weighing result can be discarded as follows:

1 Tap on [ ].

The dialog screen Confirm discard opens. It is an overview of all the weighing results within the current

weighing process.

2 Tap on [ ] to discard the last weighing result.

CAUTION

Discard is only possible until the last time the balance has been tared.

42 Activities

Page 43

Display results

When the weighing process is finished, the results can be shown as follows:

1 Tap on [ ].

2 Tap on [ ] View result.

Note

The results can also be displayed by using the shortcut in the work title bar.

Note

Depending on the procedure, several containers can be used (number of used containers ≤ 999).

Pause the application

1 Tap on [ ].

2 Tap on [ ] Pause.

The application Formulation is paused and another application can be used in the meantime.

3 Open the application Formulation again.

4 Tap on [ ].

The process can be continued.

Formulation – Main configuration

The following options can be defined:

Parameter Explanation Values

Main unit To define the main unit. Available values are

model-specific.

Resolution To define the resolution of the weighing process. Available values are

model-specific.

Terminate the application

1 Tap on [ ].

2 Tap on [ ] Finish and discard data.

The home screen of the application Formulation opens.

43Activities

Page 44

6.1.5Dynamic Weighing

The application Dynamic Weighing determines the weights of unstable samples or when the weighing process is being executed under unstable ambient conditions. The balance calculates the weight as an average of a number of weighing operations over a defined time.

Navigation

Activities > Activities - Weighing and other applications > [ ] Dynamic Weighing

Defining Measuring time

1 Tap on [ ].

The screen Dynamic weighing – Main configuration opens.

2 Tap on [Measuring time].

The dialog screen Measuring time in seconds opens.

3 Tap on [ ] to delete the value in the input field.

4 Enter a value between 3 and 120 seconds.

5 Tap on [ ] to confirm the entered value.

The screen Dynamic weighing – Main configuration opens.

6 Tap on [ ] to confirm the defined measuring time.

Note

The displayed measuring time on the application home screen can be used as shortcut to define the measuring

time.

Defining Start mode

1 Tap on [ ].

2 Tap on Start mode.

3 Chose Automatic or Manual.

4 Tap on [ ] to confirm the chosen option.

5 Tap on [ ] again.

The home screen of the application Dynamic Weighing opens again.

Performing Dynamic Weighing

When the measuring time and the start mode have been defined, the dynamic weighing process can be started.

1 Press [ ] to zero the balance.

2 If using a container: place container on the weighing pan and press [ ] to tare the balance.

3 Place sample weight.

If the option Start mode is set to Automatic, the weighing process start automatically with relative sta

bility.

It the option Start mode is set to Manual, Tap on [ ] to start the weighing process.

The weighing process starts. The defined measuring time in the work title bar is counting down.

44 Activities

Page 45

When the weighing process has finished, the screen looks as follows:

Note

The weighing process will automatically be aborted when an overload or underload is detected.

Dynamic weighing – Main configuration

The following options can be defined:

Parameter Explanation Values

Measuring time To define the measuring time in seconds. 3...120

(3 seconds*)

Start mode To define the start mode. Automatic*

Manual

Main unit To define the main weighing unit. Available values are

model-specific.

Additional unit To define the additional weighing unit. Available values are

model-specific.

Resolution To define the resolution of the weighing process. Available values are

model-specific.

* Factory setting

45Activities

Page 46

6.1.6Check Weighing

The application Check Weighing allows the user to check the deviation of a sample weight within a tolerance limit to a reference target weight. The target weight can be determined manually or by weighing; the tolerance limit must be defined manually.

Navigation

[ ] Activities > Activities - Weighing and other applications > [ ] Check Weighing

Before performing Check Weighing

Before performing a check weighing, the following options can be defined:

●

Target weight

●

± Tolerance limits

●

Tolerance threshold

Defining the target weight manually by entering the nominal weight

1 Tap on [ ] .

The screen Check weighing - Main configuration opens.

2 Tap on [Target, tolerance].

3 Tap on [ ] Target weight.

4 Delete the default value by tapping on [ ].

5 Enter the nominal weight.

Tap on [ ] to confirm the defined nominal weight.

46 Activities

Page 47

Defining the target weight by weighing

1 Tap on [ ].

The screen Check weighing - Main configuration opens.

2 Tap on [Target, tolerance].

3 Tap on [ ] Target weight.

4 Tap on [ ] to open the weighing dialog.

5 Place the reference weight on the weighing pan.

6 Tap on [ ] to confirm the defined target weight.

Defining the lower and upper limits manually by entering a percentage value or weight

1 Tap on [ ].

The screen Check weighing - Main configuration opens.

2 Tap on [Target, tolerance].

3 Tap on [ ] ± Tolerance limits.

4 Delete the default value by tapping on [ ].

5 Enter the tolerance limit.

6 Tap on [ ] to accept the new tolerance limit.

Defining Tolerance threshold

With the option Tolerance threshold a value limit can be set. Is the value of the check weight below the defined

threshold, it won't be checked.

1 Tap on [ ]. .

The screen Check weighing - Main configuration opens.

2 Tap on Tolerance threshold.

3 Define Tolerance threshold.

4 Tap on [ ].

5 Tap on [ ] to confirm.

Note

The option Tolerance threshold always refers to the lower tolerance limit.

47Activities

Page 48

Performing Check Weighing

After defining the target weight and the tolerance limits, the application Check Weighing can be performed. The

weighing-in aid at the top bar provides a visual confirmation whether the sample falls within the defined toler

ances.

In the example below, the defined target weight is 100.000g and the tolerance limit is ±2.5%. The sample

weight is 97.0000g.

– Place the sample weight on the weighing pan.

The weight is stable and the unstability symbol disappears.

The value is out of tolerance, the weighing-in aid bar and the weighing value field are red.

In the example below, the defined target weight is still 100.000g and the tolerance limit is ±2.5%. The sam

ple weight is 99.0000g.

– Place the sample weight on the weighing pan.

The weight is stable and the unstability symbol disappears.

The value is within tolerances, the weighing-in aid bar and the weighing value field are green.

Note

If the weight is below a defined tolerance threshold, the background color of the screen doesn't change.

48 Activities

Page 49

Check weighing - Main configuration

The following options can be defined:

Parameter Explanation Values

Target, toler

ance

To define the target weight in the defined unit and its tolerance

limits in %.

Target weight: 100g*

± Tolerance limits:

0.10...100 (2.5%*)

Tolerance

threshold

Within tolerance

To define the threshold. Values below the defined threshold are

1%...100% (1%*)

not being checked.

To create an acoustic signal when the result is within tolerance. OFF* | ON

beeps

Main unit To define the main unit of the weighing process. Available values are

model-specific.

Resolution To define the resolution of the weighing process. Available values are

model-specific.

* Factory setting

Note

The selectable weighing units and the resolution can differ depending on the balance model.

●

Only those weight units allowed by the appropriate national legislation are selectable.

●

With approved balances, this menu topic has fixed settings and cannot be changed.

49Activities

Page 50

6.1.7Factor Weighing

The application Factor Weighing multiplies or divides a pre-defined factor by the measured weight value (in grams) and calculates it to a predefined number of decimal places.

Navigation

[ ] Activities > Activities - Weighing and other applications > [ ] Factor Weighing

Defining Factor, step

1 Tap on [ ].

The screen Factor weighing – Main configuration opens.

2 Tap on [Factor, step].

The dialog screen Factor – Multiplication opens.

3 Tap on [ ] to delete the defined value.

4 Define Factor.

5 Tap on [ ] to change the operation from Multiplication to Division or vice versa.

6 Tap on [ ] to confirm.

7 Tap on [ ].

The dialog screen Step opens.

8 Define Step.

9 Tap on [ ] to confirm.

10 Tap on [ ] again to confirm the defined adjustments.

Note

The allowed range for the steps depends on the defined factor and the resolution of the balance.

Factor weighing – Main configuration

The following options can be defined:

Parameter Explanation Values

Factor, step To define the factor and the step. Factor | Step

Additional unit To define an additional weighing unit. Available values are

model-specific.

50 Activities

Page 51

6.1.8Totaling

The application Totaling allows the user to weigh different samples, adding their weight values and to totalize them.

Navigation

[ ] Activities > Activities - Weighing and other applications > [ ] Totaling

Performing Totaling

1 Press [ ] to zero the balance.

2 If using a container: Place empty container on the weighing pan and press [ ] to tare the balance.

3 Place the first weight.

4 Wait until the unstability symbol disappears.

5 Tap on [ ] to accept the weight and to start the procedure.

6 Place next sample weight.

7 Tap on [ ] to accept the second sample weight.

When the balance is stable, the weighing value becomes dark blue.

The work title bar shows the number of samples (2 samples) and the total weight of the samples ( =

30.0000g).

Discard value

If a weighing value was incorrect, it can be discarded from the result as follows:

1 Tap on [ ].

The screen Confirm discard opens.

2 Tap on [ ].

The incorrect value has been deleted. The weighing process can be continued.

Display results

1 Tap on [ ].

2 Tap on [ ] View result.

Note

The results can also be displayed by using the shortcut in the work title bar.

51Activities

Page 52

Pause the application

1 Tap on [ ].

2 Tap on [ ] Pause.

The application Totaling is paused and another application can be used in the meantime.

3 Open the application Totaling again.

4 Tap on [ ].

The process can be continued.

Totaling – Main configuration

The following options can be defined:

Parameter Explanation Values

Accepting mode To define if a weight sample is added automatically to the result.

The sample is automatically accepted if: the sample is at least

10d and a deflection according to the SNR command described

in the MT-SICS manual MT-SICS interface commands and func

tions (page76) was detected.

Main unit To define the main unit of the weighing process. Available values are

Resolution To define the resolution of the weighing process. Available values are

Terminate the application

1 Tap on [ ].

2 Tap on [ ] Finish and discard data.

The home screen of the application Totaling opens.

Note

If the option Workflow reports is set to Automatic, a printer symbol appears in the list element. By tapping on

[ ] Discard data the process can be aborted without printing the reuslts.

Manual* | Automatic

model-specific.

model-specific.

52 Activities

Page 53

6.2Activities - Adjustments and tests

Activities - Adjustments and tests contains the following elements:

●

FACT, see section FACT Fully automatic internal adjustment (page54)

●

Internal Adjustment, see section Internal Adjustment (page55)

●

External Adjustment, see section External Adjustment (page56)

53Activities

Page 54

6.2.1FACT Fully automatic internal adjustment

FACT stands for Fully Automatic Calibration Technology. It is activated as default value.

FACT means that the balance adjusts itself based on the following criteria:

●

in case the conditions change (temperature difference > 2°C), which could lead to a noticeable deviation in

the measurement.

●

on a predefined day time programmed by the user.

Setting FACT

You can define the day time of FACT as follows:

1 Tap on [ ].

2 Tap on [ ]. .

The screen Activities - Adjustments and tests opens.

3 Tap on [FACT].

4 Activate Fully automatic adjustment.

The Fully automatic adjustment dialog opens.

5 Select the time (hours : minutes) with the pick buttons.

6 Tap on [ ] to confirm the defined time.

The time underneath FACT has been updated and shows the time of the daily adjustment.

CAUTION

If the function FACT is not activated, all the FACT functionalities, such as temperature FACT and time FACT are

inactive.

Note

When defining the time, hold the pick button to scroll faster.

54 Activities

Page 55

6.2.2Internal Adjustment

Note

The function Internal Adjustment is available for models with internal weight only (see technical data).

Perform an internal adjustment manually

1 Tap on [Internal Adjustment].

The internal adjustment procedure starts. The screen shows Adjustment ongoing, please wait....

When the internal adjustment procedure is successfully completed, the results of the internal adjustment

appear.

2 Tap on [ ] to confirm the results.

Note

If the balance is configured and connected to a printer, the results of the adjustment process are printed.

55Activities

Page 56

6.2.3External Adjustment

Note

Because of certification legislation, approved balances cannot be adjusted with an external weight (depending

on the certification legislation of the selected country).

Performing an external adjustment

1 Open Activities - Adjustments and tests. 2 Tap on External Adjustment.

The External Adjustment screen opens.

3 Tap on [ ] to define the adjustment weight according to the weight certificate.

4 Confirm the adjustment weight by tapping on [ ].

5 Prepare the adjustment weight and tap on [ ] to start the adjustment process.

6 Load the adjustment weight in the center of the weighing pan.

7 Unload the adjustment weight from the weighing pan.

When the external adjustment procedure is successfully completed, the result of the external adjustment

appear.

56 Activities

Page 57

7General Settings

The section General settings is divided into two sub-sections:

●

Quick settings/Preferences

●

General configuration and data

7.1Quick settings/Preferences

The following options are available:

●

Date and Time

●

Brightness

●

Sound

●

Language

●

Glove mode

●

Quick Adjustment

●

Leveling assistant

7.1.1Date and time

In this menu topic, the date and time can be defined. Tap on [ ] for Time and tap on [25] for Date.

The following parameters can be defined:

Parameter Explanation Values

Time To define the time format. 24:MM* | 12:MM |

The date can be defined with the pick buttons. Hours | Minutes

Date To define the date format. DD.MM.YYYY* |

The date can be defined with the pick buttons. Day | Month | Year

* Factory setting

24.MM | 12.MM

D.MMM YYYY |

MM/DD/YYYY | MMM

DD YYYY | YYYY-MMDD

7.1.2Brightness

In this menu topic the brightness of the display can be defined.

Parameter Explanation Values

Brightness To define the level of brightness. 10...100 % (50 %*)

* Factory setting

57General Settings

Page 58

7.1.3Sound

In this menu topic, the sound can be defined.

Parameter Explanation Values

Stability beep Notifies when an unstable weight becomes stable. OFF | Low* | Medium |

Workflow feed

back beep

Touch beep Notifies every touch of interactive elements on touch display and

* Factory setting

7.1.4Language

The following languages can be chosen:

English Русский Português BRA.

Deutsch Polski Türkçe

Français Česky 中文

Español Magyar 日本語

Italiano Nederlands 한국어/조선말

Notifies when zero/tare bar actions are not available, provides

additional feedback in case of input errors, messages and status

notifications.

zero/tare bar.

High

OFF | Low* | Medium |

High

OFF* | Low | Medium |

High

7.1.5Glove mode

With the function Glove mode activated, the touch-screen becomes more sensitive and easier to navigate when wearing gloves.

Parameter Explanation Values

Glove mode To activate or deactivate the function Glove mode. ON | OFF*

* Factory setting

7.1.6Quick Adjustment

Parameter Explanation Values

Quick Adjust

ment

* Factory setting

Note If the option Quick Adjustment is activated, the symbol appears in the main navigation of an application.

7.1.7Leveling assistant

The function Leveling assistant helps to adjust the balance (e.g. when the balance has changed location).

For more information, see section Leveling the balance (page20).

To activate/deactivate and define the function Quick Adjustment. Internal Adjustment |

External Adjustment

58 General Settings

Page 59

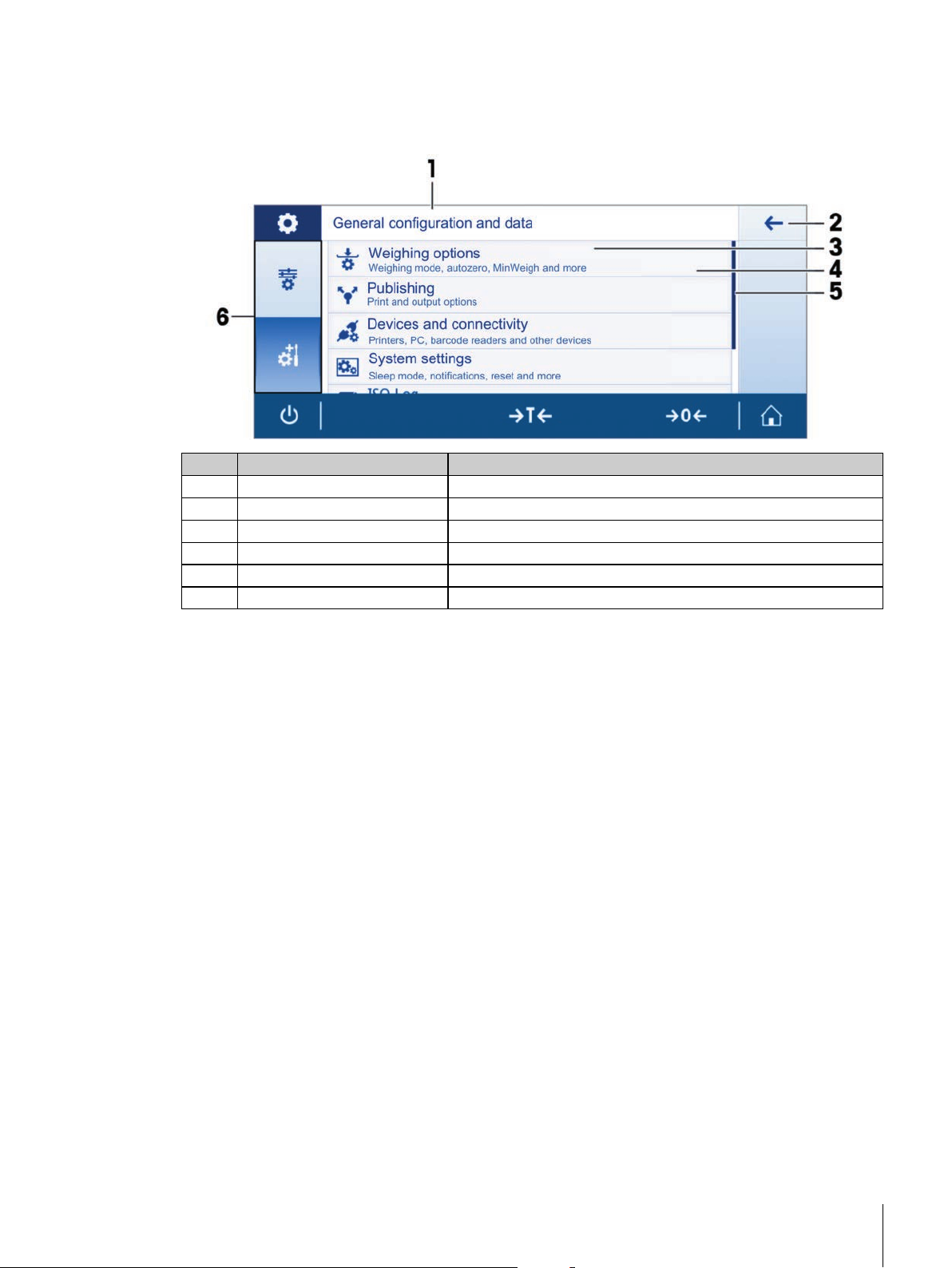

7.2General configuration and data

The following options are available:

●

Weighing options

●

Publishing

●

Devices and connectivity

●

System settings

●

ISO-Log

●

Access protection

7.2.1Weighing options

The following options can be defined:

Parameter Explanation Values

Weighing mode To define Weighing mode. Universal* = for stan

Environment To adapt the balance to the environmental circumstances. Standard* = for stan

Autozero To activate or deactivate Autozero ON* | OFF

AutoTare To activate or deactivate AutoTare ON | OFF*

MinWeigh To define MinWeigh Not defined* | Cus

Recall To retain and recall the last stable weight. ON | OFF*

* Factory setting

Note

The function Autozero can not be deactivated for approved balances (except for some selected countries).

dard weighing applica

tions

Dosing = for dosing liq

uid or powdery samples

dard environments

Unstable = for unstable

environments

Stable = for stable

environments

tomized | Certificate

59General Settings

Page 60

MinWeigh method

The option MinWeigh method notifies when a measurement value is not fulfilling the required weighing accura

cy. The usage of MinWeigh is application-specific (contextual settings).

Defining MinWeigh method

1 Tap on MinWeigh.

The dialog MinWeigh configuration opens.

2 Tap on MinWeigh method.

The dialog MinWeigh method opens.

3 Select method and confirm by tapping on [ ].

Depending on the chosen method, the selectable options in the dialog MinWeigh configuration vary.

The following methods are available:

●

Customized

●

Certificate

●

OIML

Note

The method OIML is only available for approved balances.

7.2.2Publishing

In this section, the print and output options can be defined.

Note

Depending on the connected peripheral device (see section Devices and connectivity (page62)) the available

options in this section can differ. It is possible that not every options described in this section is available for

the used peripheral device.

Print

This option can be activated or deactivated.

The following options can be defined:

Parameter Values

Single values Manual, stable* | Manual, all values | Automatic, stable

Workflow

reports

Automatic* |

Manual

FACT report ON* | OFF

* Factory setting

60 General Settings

Page 61

Printouts data (Weighing applications only)

The following options can be defined:

Parameter Explanation Values

Date, time To add date and time. ON | OFF*

Balance infor

mation

MinWeigh Infor

mation

Leveling infor

mation

Gross/Tare To add gross/tare to single values. ON | OFF*

Signature line To add the signature line. ON | OFF*

Empty lines To add empty lines. ON | OFF*

* Factory setting

Send weight value

This option can be activated or deactivated.

The following options can be chosen:

Parameter Explanation

Manual, stable* Send next stable weight at will

Manual, all val

ues

Automatic, sta

ble

Automatic, con

tinuous

* Factory setting

To add information about the balance. ON | OFF*

To activate/deactivate MinWeigh Information ON | OFF*

To activate/deactivate Leveling information ON | OFF*

Send any stable or unstable weight at will

Send next stable weight automatically

Send any stable or unstable weight automatically

Autopublish

The option Autopublish can be activated or deactivated with the switch in the work title bar.

A numerical value for the function Autopublish can be defined.

61General Settings

Page 62

7.2.3Devices and connectivity

This section describes how the peripheral devices can be configured.

RS232

The following options can be defined:

Parameter Values

Allocated device RS-P2X | P5X | Printer | Host* | PC-Direct | Second display | Barcode Reader

Baudrate 600 | 1200 | 2400 | 4800 | 9600* | 19200 | 38400 | 57600 | 115200

Bit/Parity 8/No* | 7/No | 7/Mark | 7/Space | 7/Even | 7/Odd

Stop bits 1 bit* | 2 bits

Handshake Xon/Xoff* | RTS/CTS | None

Character set IBM/DOS* | ANSI/WIN | UTF-8

End of line <CR><LF>* | <CR> | <LF> | <TAB>

* Factory setting

USB Device

The following options can be defined:

Parameter Values

Allocated device Host* | PC-Direct

Command set MT-SICS* | MT-PM | Sartorius 16 | Sartorius 22

End of line <CR><LF>* | <CR> | <LF> | <TAB>

* Factory setting

62 General Settings

Page 63

7.2.4System settings

The following options can be defined:

Parameter Explanation Values

Balance identifi

cation

Sleep mode To activate/deactivate and define the function Sleep mode. After 30 seconds

Backlight OFF To define the functionBacklight OFF. After 30 seconds

Out of level noti

fication

Service due

notification

* Factory setting

System and data management

The following options can be defined:

Parameter Explanation

Touch screen

adjustment…

Level indicator

center

adjustment…

Reset balance… To reset the balance to default.

Note

Run the Level indicator center adjustment only when the electronic in/out level notification (status icon) and the

visual bubble position don't match.

CAUTION

By resetting the balance, any changes to general settings and contextual settings that have been made as well

as any temporary collected data (e.g. paused applications or statistics) will be lost.

A balance identification that can be defined by the user. Values can be defined

individually.

After 1 minute

After 2 minutes

After 5 minutes

After 10 minutes*

After 1 minute

After 2 minutes

After 5 minutes

After 10 minutes

To activate/deactivate the function Out of level notification. ON* | OFF

To activate/deactivate the function Service due notification. ON* | OFF

The balance is executing a screen adjustment.

The adjustment sets the exact center position of the level indicator and corrects any possi

ble shifts.

7.2.5ISO-log

In this section, detailed history information about performed adjustments, intensity of use and settings can be

displayed.

The following options can be selected:

Parameter Explanation

ISO-Log –

Adjustments

ISO-Log – Bal

ance

ISO-Log – Set

tings and status

Shows detailed information about the performed adjustments.

Shows detailed information about the balance history.

Shows detailed information about changes of the settings.

63General Settings

Page 64

7.2.6Access protection

With the function Access protection, certain functionalities of the balance can be protected by a numerical passcode.

The following options can be defined:

Parameter Explanation Values

Applications To protect the application. ON | OFF*

Adjustments and

tests

Settings To protect all settings. ON | OFF*

Passcode To define the passcode by the user. 1....9 (1-16 digits)

* Factory setting

User passcode

The user passcode can be defined by the user. The default value is 12345678. The length of the freely change

able user passcode is restricted to 16 digits.

Note

Passcode and access options are not affected by a balance reset.

What if you forgot the passcode?

When you forgot or lost the passcode, please contact a Mettler Toledo representative or visit the Mettler Toledo

balance support site.

To protect adjustments and tests. ON | OFF*

64 General Settings

Page 65

8Communication with Peripheral Devices

8.1PC-Direct Function

The numerical value displayed at the balance can be transferred to the cursor position in Windows Applications

(e.g. Excel, Word), by typing with the keyboard.

Note: The units will not be transferred.

Requirements

●

PC with one of the following Microsoft Windows® operating systems 32bit/64bit: XP (SP3), Vista (SP2),

Win 7 (SP1) or Win 8

●

Serial interface RS232, USB or BT option

●

Administrator rights for installing software (for USB not required)

●

Windows Application (e.g. Excel)

●

Balance to PC connection with cable RS232 or USB

Settings on the balance:

CAUTION

Disconnect the USB connection from the balance prior to changing settings.

Balance Interface Settings (see Interface Menu):

●

Topic RS232 or USB Device: set PC-Direct and select the most appropriate option for the desired weighing

result.

●

Topic End of line (transmitted end of line character):

– set <TAB> to write into the same row (e.g. in Excel).

– set <CR><LF> to write into the same column (e.g. in Excel).

●

Save changes.

Settings on the PC:

Installing SerialPortToKeyboard

Operation of PC-Direct via serial port RS232 requires the installation of SerialPortToKeyboard on your host

computer.

Using CD-ROM

1 Insert the product CD in the CD/DVD drive of the host computer.

2 Double click the folder SerialPortToKeyboard.

Using internet

1 Go to the site http://www.mettler-toledo-support.com.

2 Log in to the METTLER TOLEDO Balance Support Site (registration with the serial number of a METTLER

TOLEDO instrument is required).

3 Click Customer Support

4 Click appropriate product folder and save the program file SerialPortToKeyboard.exe on your specified

storage location.

Installation procedure

1 Right-click on SerialPortToKeyboard.exe and select Run as Administrator from the menu.

2 Follow the installer's instructions.

65Communication with Peripheral Devices

Page 66

Settings for SerialPortToKeyboard

➀

➁

➂

1 Select the serial port (COM) to be used for connec

tion with the balance.

2 Set the baud rate to 9600.

3 Activate "Connect"

Note

Note

●

The window can be minimized.

●

Closing the window terminates the session.

Checking operation

1 Start SerialPortToKeyboard (RS232)

2 Start Excel (or another application) on the PC.

3 Activate a cell in Excel.

According to your selected PC-Direct option, the displayed values will appear e.g. in the column one after the

other one in the different rows.

8.2USB Device Interface

To perform the functionality USB DEVICE with a PC equipped only with a USB Interface, you have to install an

appropriate USB Driver on the PC first.

Requirements

●

Balance with USB Device Interface.

●

PC with one of the Microsoft Windows® operating system 32bit/64bit: XP (SP3), Vista (SP2), Win 7 (SP1)

or Win 8.

●

Administrator rights for installing software.

●

PC to balance USB connection cable.

Installing USB driver on the PC:

Using CD-ROM

1 Insert the product CD in the CD/DVD drive of the host computer.

2 Double click the folder USB Driver.

3 Click USBDriverInstaller.exe.

Using internet

1 Connect to the Internet

2 Go to the site http://www.mettler-toledo-support.com.

3 Log in to the METTLER TOLEDO Balance Support Site (registration with the serial number of a METTLER

TOLEDO instrument required).

4 Click Customer Support.

5 Click appropriate product folder.

6 Click USB Driver.

66 Communication with Peripheral Devices

Page 67

7 Click USBDriverInstaller.exe.

Installing procedure

1 Click Save to download to your specified location.

2 Right-click on the downloaded install program: USBDriverIn

staller.exe

3 If a safety warning appears, allow Windows to install.

4 Click Next and follow the installer's instructions.

Installing instrument

1 Switch the balance off.

2 Connect the balance to the preferred USB Port on the PC.

3 Switch the balance on.

4 Follow the instructions of the Wizard and install the software auto

matically (recommended)

Note: The wizard appears again for each USB port, either on your PC

or if another balance is connected.

Warning: Do not click Cancel as for the connected USB port, it might

not be possible anymore to perform the installation process.

67Communication with Peripheral Devices

Page 68

9Firmware (Software) Updates

METTLER TOLEDO is continuously improving its balance firmware (software) for the benefit of customers. In

order that the customer can benefit quickly and easily from further developments, METTLER TOLEDO makes the

latest firmware versions available on the Internet. The firmware made available on the Internet has been devel

oped and tested by Mettler-Toledo AG using processes that meet the guidelines of ISO 9001. Mettler-Toledo AG

does not, however, accept liability for consequences that might arise from updating the firmware.

9.1Operating principle

You will find all the relevant information and updates for your balance on the METTLER TOLEDO website at the

following address:

www.mettler-toledo-support.com

A program known as "e-Loader II" is loaded onto your computer together with the firmware update. You can

use this program to download the firmware to the balance. The "e-Loader II" can also save the settings in your

balance before the new firmware is downloaded to it. You can reload the saved settings into the balance manu

ally or automatically after the software is downloaded.

If the selected update includes an application that is not described in these instructions (or that has been updat

ed in the meantime) you can download the corresponding instructions in Adobe Acrobat® PDF format.

Note

New applications might not be visible unless the type data are updated by a service technician.

Requirements

The minimum requirements for obtaining applications from the Internet and downloading them into your bal

ance are as follows:

●

PC with one of the following Microsoft Windows® operating systems:

•

Microsoft® Windows® XP Home or Professional with Service Pack 3 (32 bit)

•

Microsoft® Windows Vista® Home Premium, Business, Ultimate, or Enterprise with Service Pack 2 (32 bit

and 64 bit)

•

Microsoft® Windows 7 with Service Pack 1 Home Premium, Professional, Ultimate, or Enterprise (32 bit

and 64 bit)

•

Microsoft ® Windows ® 8 , Professional or Enterprise

●

Administrator rights for installing software.

●

PC to balance connection cable (e.g. No. 11101051 see chapter accessories)

68 Communication with Peripheral Devices

Page 69

9.2Update procedure

Installing "e-Loader II" software from the Internet onto the PC.

1 Connect to the Internet.

2 Go to the site http://www.mettler-toledo-support.com.

3 Log in to the METTLER TOLEDO Balance Support Site (registration with the serial number of a METTLER

TOLEDO instrument required).

4 Click on Customer Support.

5 Click the appropriate product folder.

6 Click the firmware version (e-Loader II) you need and save it on your specified storage location.

7 Right-click on the firmware SNxxx.exe.

8 Follow the installer's instructions.

Loading the new firmware into the balance.

1 Right-click on METTLER TOLEDO e-Loader II and select Run as Administrator from the menu.

2 Follow the instructions, which will take you step-by-step through the installation.

69Firmware (Software) Updates

Page 70

10Error and Status Messages

Error messages in the display draw your attention to incorrect operation or that the balance could not execute a

procedure properly.

Error message Cause Rectification

NO STABILTY No stability Ensure more stable ambient condi

Adjustment aborted - Weight out

of range

EEPROM error - Please contact

your MT-Support representative.

Wrong adjustment weight on the

weighing pan or none at all.

●

EEPROM (memory) error.

●

Excessive mains voltage fluctu

ation or strong glitches

occurred.

tions. If not possible, check settings

for environment.

Place required adjustment weight in

center of pan.

Please contact your MT-Support

representative.

Wrong cell data - Please contact

your MT-Support representative.

No standard adjustment - Please

contact your MT-Support repre

sentative.

Program memory defect - Please