Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Page 2

Operating instructions

METTLER TOLEDO MultiRange

Table and stand scales

KA3s/KA6s/KA15s/KA32s

KB60/KCC150/KCC300

www.mt.com/support

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

3

1 General information ...................................................................4

2 Safety precautions .....................................................................4

3 Equipotential bonding ................................................................5

4 Removing the transportation lock at the KA3s/6s .........................6

5 Switching-on/-off routine ............................................................6

6 Operating limits .........................................................................7

7 Cleaning the weighing platform ..................................................8

7.1 Notes on cleaning ........................................................................................... 8

7.2 Subsequent treatment ...................................................................................... 9

7.3 Cleaning the measuring cell ............................................................................. 9

8 Standard accessories ...............................................................11

9 Technical data of the measuring cell .........................................13

10 Disposal ..................................................................................13

Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

4

The weighing platform is part of a modular system. The associated components, such as terminals, application pacs and the extensive range of accessories, allow you to assemble a

weighing system ideally tailored to the needs of your operation.

▲ The explosion-protected weighing platform is approved for operation in Zones 2 (gases)

and 22 (dusts) hazardous areas. There is an increased danger of injuries and damage

when using the weighing platform in hazardous areas! Exercise particular care when using

in such areas. The rules for behaviour are based on the concept of "Safe Distribution" established by METTLER TOLEDO.

▲ Explosion-protected weighing platforms may be used in hazardous areas of Zones 2 and

22 only in conjunction with weighing terminals that have the appropriate approval and interface specification.

▲ The connection cable may not be separated from the weighing terminal while it is ener-

gised.

▲ Tighten the knurled nut of the IDNet connection cable with 10 Nm of force.

Selecting installation location

▲ The foundation must be capable of safely

support the weight of the weighing platform at its support points when it carries

the maximum load. At the same time, it

should be so stable that no vibrations occur during weighing operations. These requirements also apply when the weighing

platform is integrated in conveying systems and the like.

▲ Ensure that there are no vibrations from

machines near the installation site.

▲ Ensure that there are no drafts at the in-

stallation site.

Ambient cond itions

▲ Use powder-coated/enamelled weighing platforms only in a dry environment.

▲ In a damp environment, in wet operation or when working with chemicals: use stainless-

steel weighing platforms.

1 General information

2 Safety precautions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

5

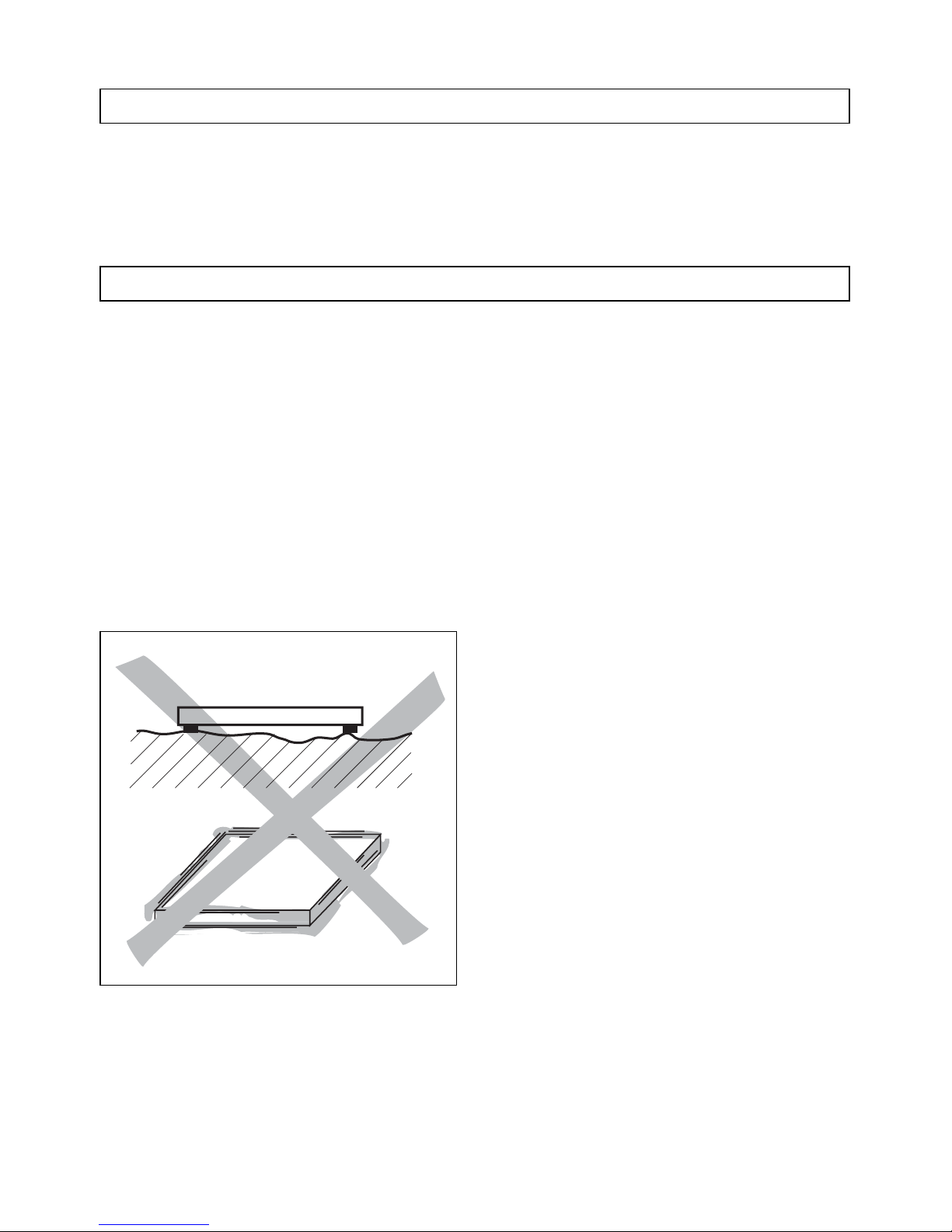

The equipotential bonding must be installed by a professional electrician when using the

weighing platform in Zones 2 and 22. METTLER TOLEDO Service only has a monitoring and

consulting function here.

➜ Connect equipotential bonding (PA) of all devices (weighing platform and service termi-

nal) in accordance with the country-specific regulations and standards. In the process,

make sure that all device housings are connected to the same potential via the PA terminals.

Equipotential bond ing with KA...

(1) Serrated lock washer A 4.3 DIN 6798

(2) Hexagonal lock nut M4 DIN 934

(3) Washer 4.3 DIN 125

(4) Base frame

(5) Equipotential bonding clamp

Mounting materials are enclosed with the

ID7xx, IND690xx or IND4..xx weighing terminal.

Equipotential bond ing with KB..., KCC...

(1) Frame body

(2) Fillister head screw M5x12 DIN 912

(3) Washer 5.3 DIN 125

(4) Serrated lock washer 5.3 DIN 6798

(5) Washer 5.3 DIN 125

(6) Hexagonal lock nut M5 DIN 934

(7) Hexagonal lock nut M4 DIN 934

(8) Washer 4.3 DIN 125

(9) Serrated lock washer A 4.3 DIN 6798

(10) Potential plate weighing platform

(11) Equipotential bonding clamp

Mounting materials are enclosed with the

ID7xx, IND690xx or IND4..xx weighing terminal.

3 Equipotential bonding

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

6

KA3s/6s weighing platforms have a transportation lock in order to protect the weighing cell against damage during transportation.

Removing the transportation lock

➜ Take off the wind protection and remove

the transportation locks outwards.

➜ Put the wind protection back on.

Caution

Possible measured value drift through

improper switching on and off!

➜ The following cooling times must be

observed before restarting after a voltage drop or after the weighing system

has been switched off:

KA3s/6s min. 2 h

KA15s/32, KB60,

KCC150/300 min. 1 h

4 Removing the transportation lock at the KA3s/6s

5 Switching-on/-off routine

1h / 2h

C

1.

2.

3.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

7

The weighing platform has such a rugged design that no damage should result if the maximum weighing capacity is occasionally exceeded.

The static load-bearing capacity, i.e. the maximum permissible load, is dependent on the type

of loading (positions A – C).

Maximum permissible load

A with central load

B with side load

C with one-sided corner load

▲ Falling loads, shocks and lateral impacts

must be avoided.

6 Operating limits

KA3s

KA6s

KA15s KA32s

A 20 kg 50 kg 50 kg

B 15 kg 40 kg 40 kg

C 10 kg 30 kg 30 kg

KB60 KCC150

KCC300

A 120 kg 500 kg

B 80 kg 300 kg

C 40 kg 150 kg

A

B

C

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

8

Maintenance of the weighing platform is limited to regular cleaning and subsequent oiling.

The procedure depends both on the type of surface (powder-coated/enamelled or stainless

steel) and on the environmental conditions prevailing at the installation location. Remove dirt

and deposits at regular intervals from the outside and inside of the weighing platform.

7.1 Notes on cleaning

CAUTION

Incorrect use of cleaning agents may cause damage to the weighing platform!

•Use only such cleaning agents that do not act on the plastics used in the

weighing platform.

•Be particularly careful when cleaning the measuring cell.

Powder-coated/enamelled version, dry

surroundings

• Wipe with a damp cloth.

• Use household cleaning agents.

Stainless-steel version

• Wipe with a damp cloth.

• Water jet up to 60 °C.

• Use household cleaning agents.

Corrosive surround ings

• Water jet up to 60 °C.

• Remove corrosive substances at regular

intervals.

• Only use disinfectants and cleaning

agents in accordance with the manufacturer's specifications and instructions.

7 Cleaning the weighing platform

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

9

7.2 Subsequent treatment

Carry out the following subsequent treatment in order to protect the weighing platform:

• Rinse the weighing platform with clear water.

• Dry off the weighing platform with a lint-free cloth.

• Treat the inside and outside of the weighing platform with an oil suitable for foodstuffs.

7.3 Cleaning the measuring cell

The draft guard or load plate has to be removed in order to clean the measuring cell.

KA3s/KA6s: Removing the draft guard (1)

KCC...: Removing the load plate

• Lift both side handles vertically (1.) and

then pivot them outward (2.).

1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

10

Cleaning the measuring cell

CAUTION

The measuring cell can be damaged!

▲ During cleaning work, never touch, direct

an airflow against or spray the rubber diaphragm (1) of the measuring cell.

➜ Blow out dirt or rinse out with a moder-

ate water jet.

Placing load plate at KCC weighing platforms

➜ After placing the load plate, swing the

handles inward (3.) and reengage in

the initial position (4.), i.e. the handles

must be in the bottom position and vertical.

When the handles are correctly engaged, it

should not be possible to lift off the load

plate.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

11

Order No.

Stand

Rigid frame construction

2 feet with casters

1 fixed foot with screw adjustment

height approx. 560 mm

for KB60

powder-coated/enamelled

stainless steel

for KCC150, KCC300

powder-coated/enamelled

stainless steel

00 503 631

00 503 632

00 504 853

00 504 854

Pillar support

for KB60, KCC150, KCC300

for mounting terminals on stand

incl. fastenings

for ID1 Plus, ID3s or ID7

powder-coated/enamelled

stainless steel

for IND690

stainless steel

for IND4x9

stainless steel

00 504 127

00 504 128

22 011 986

22 014 835

Scale stand

for KA15s, KA32s, KB60

for mounting ID1 Plus or ID3s

terminal on the weighing platform,

all stainless steel

00 504 439

8 Standard accessories

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

12

Scale stand

for KA..., KB60

for mounting IND4x9 terminal on

the weighing platform,

330 mm high, all stainless steel

22 014 836

Roller track

Steel-clad rollers with rust

protection, for dry surroundings

lengthwise motion

for KB60 (8 rollers)

for KCC150, KCC300 (9 rollers)

00 503 640

00 504 852

Steel-clad rollers with rust

protection, for wet surroundings

lengthwise motion

for KB60 (8 rollers)

for KCC150, KCC300 (9 rollers)

22 001 647

22 001 648

Extension cable

Length 10 m, connector at both

ends

for remote setup of ID terminal

00 504 134

Cable adapter kit for ID terminals

for infinite extension of connection

cable to 100 m

comprising two junction boxes

Box at terminal end with connection

cable of 2.5 m length

00 504 133

Special cable from the roll

used with adapter kit for ID

terminals for infinite extension of

connection cable to required length

00 504 177

Order No.

max.

95 m

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

13

Types TBrick 6, TBrick 15, TBrick 32

Ignition protection type II 3G Ex nA II T6

–10 °C ≤ T

a

≤ +40 °C

II 3D Ex tD A22 IP67 T 70 °C

DMT 02 E 012

The following safety-related variables must be ensured by the

connected weighing terminal:

Supply circuit U

max

, ≤ 20 V DC

Interface circuit U

max, CL

≤ 27 V DC

I

max, CL

≤ 30 mA

U

max Diff, RS422

≤ 10 V DC

Power consumption 12 V DC ± 20 %; 125 mA; 1.4 VA

IP protection type IP67

In accordance with the requirements of the European Directive 2002/96

EC about Waste Electrical and Electronic Equipment (WEEE) this

equipment may not be disposed of in the household refuse.

This applies correspondingly for countries outside the EC in accordance

with the applicable national regulations.

➜Please dispose of this product in accordance with the local regula-

tions in a separate collection for electrical and electronic equipment.

Should you have any questions, please contact the responsible

authorities or the dealer from whom you purchased this equipment.

If this equipment is passed on (for example for private or commercial/

industrial further use), this specification has to be passed on correspondingly as well.

Many thanks for your contribution to protecting the environment.

9 Technical data of the measuring cell

10 Disposal

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

METTLER TOLEDO products stand for highest quality and precision. Careful handling in accordance with these operating instructions as well as regular maintenance and inspection by

our professional customer service ensure the long and reliable function and maintenance of

value of your measuring instruments. Our experienced service team will be pleased to inform

you about corresponding service agreements or calibration services.

Please register your new product under www.mt.com/productregistration

, so that we can inform you about improvements, updates and further important information about your METTLER TOLEDO product.

*22007212E*

22007212E

Subject to technical changes © Mettler-Toledo (Albstadt) GmbH 10/09 Printed in Germany 22007212E

Mettler-Toledo (Albstadt) GmbH

D-72458 Albstadt

Tel. ++49-7431-14 0, Fax ++49-7431-14 232

Internet: http://www.mt.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Loading...

Loading...