Page 1

Operating instructions

METTLER TOLEDO MultiRange

Floor scales/Pit scales

KC300/KCS300

KC600/KCS600

KD600/KD1500

KE1500/KE3000

KES1500/KES3000

www.mt.com/support

Page 2

2

Page 3

1 General information

The weighing platform is part of a modular system. The associated components, such as

terminals, application pacs and the extensive range of accessories, allow you to assemble a

weighing system ideally tailored to the needs of your operation.

2 Safety precautions

▲ The explosion-protected weighing platform is approved for operation in Zone 2 (gases) and

Zone 22 (dusts) hazardous areas. There is an increased danger of injuries and damage

when using the weighing platform in hazardous areas! Exercise particular care when using

in such areas. The rules for behaviour are based on the concept of "Safe Distribution"

established by METTLER TOLEDO.

▲ Explosion-protected weighing platforms may be used in hazardous areas of Zones 2 and

22 only in conjunction with weighing terminals that have the appropriate approval and interface specification.

▲ The connection cable may not be separated from the weighing terminal while it is

energised.

Selecting installation location

▲ The foundation must be capable of safely

support the weight of the weighing platform at its support points when it carries

the maximum load. At the same time, it

should be so stable that no vibrations occur during weighing operations. These requirements also apply when the weighing

platform is integrated in conveying systems and the like.

▲ Ensure that vibrations due to machines

near the installation site are kept to a

minimum.

Ambient conditions

▲ Use powder-coated/enamelled weighing platforms only in a dry environment.

▲ In a damp environment, in wet operation or when working with chemicals: use stainless-

steel or hot-galvanised weighing platforms.

3

Page 4

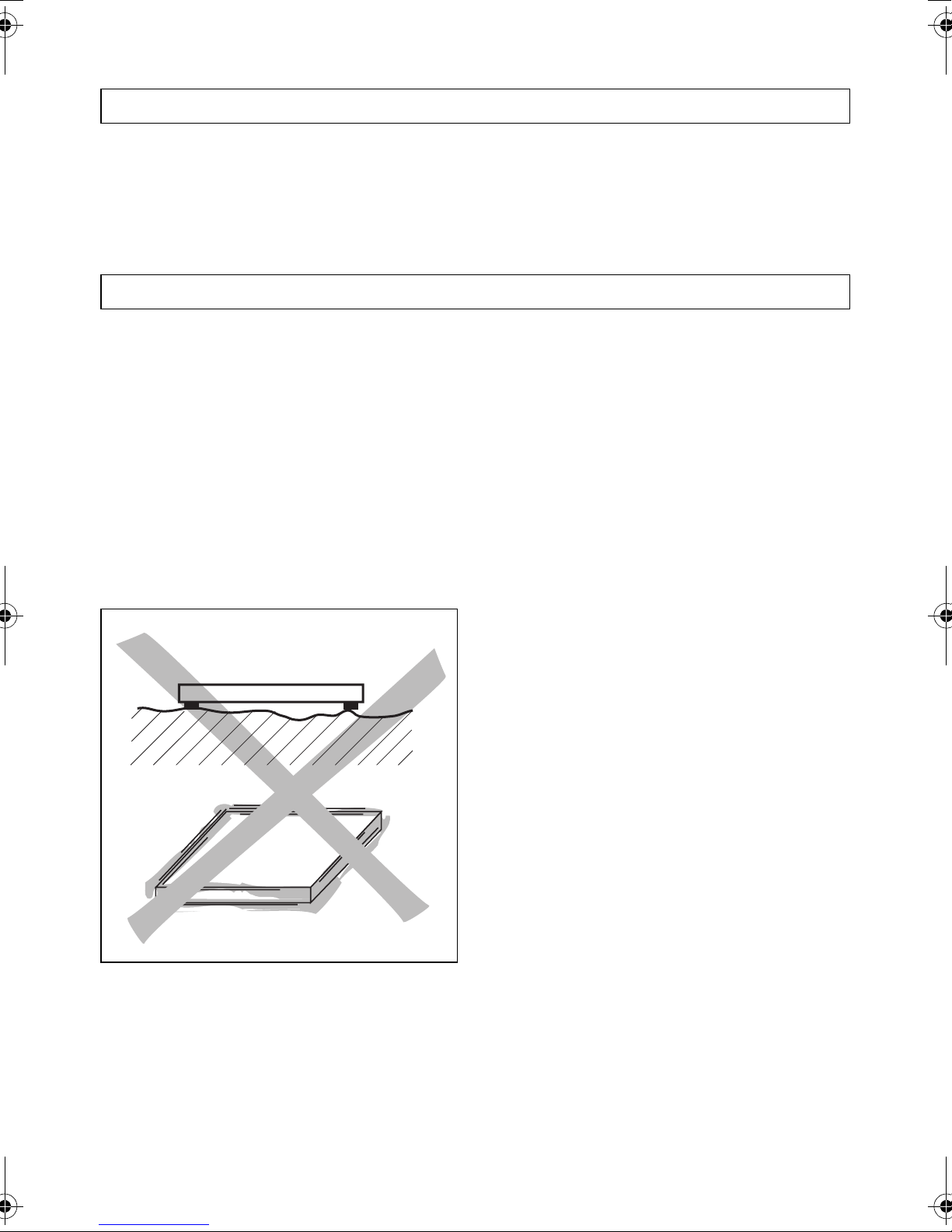

3 Equipotential bonding

The equipotential bonding must be installed by a professional electrician when using the

weighing platform in Zones 2 and 22. METTLER TOLEDO Service only has a monitoring and

consulting function here.

➜ Connect equipotential bonding (PA) of all devices (weighing platform and service

terminal) in accordance with the country-specific regulations and standards. In the

process, make sure that all device housings are connected to the same potential via the

PA terminals.

Equipotential bonding with KC..., KCS...

(1) Equipotential bonding clamp

(2) Potential plate weighing platform

(3) Serrated lock washer 4.3 DIN 6798

(4) Washer 4.3 DIN 125

(5) Hexagonal lock nut M4 DIN 934

(6) Fillister head screw M5x12 DIN 912

(7) Washer 5.3 DIN 125

(8) Serrated lock washer 5.3 DIN 6798

(9) Frame bracket, thread M5 is present

Mounting materials are enclosed with the

ID7xx, IND690xx and IND4..xx weighing

terminal.

Equipotential bonding with KD..., KE..., KES...

➜ Secure equipotential bonding clamp to a suitable area of the base frame.

Mounting materials are enclosed with the ID7xx, IND690xx and IND4..xx weighing terminal.

4

Page 5

4 Operating limits

The weighing platform has such a rugged design that no damage should result if the

maximum weighing capacity is occasionally exceeded.

The static load-bearing capacity, i.e. the maximum permissible load, is dependent on the type

of loading (positions A – C).

Maximum permissible load

A

B

C

KC300

KCS300

A 500 kg 1000 kg

B 330 kg 650 kg

C 165 kg 330 kg

KD600

KD1500

A 3500 kg 4500 kg

B 2300 kg 3000 kg

C 1150 kg 1500 kg

A with central load

KC600

KCS600

KE1500

KE3000

KES1500

KES3000

B with side load

C with one-sided corner load

▲ Falling loads, shocks and lateral impacts

must be avoided.

5

Page 6

▲ When travelling across recessed weigh-

ing platforms with lift trucks, ensure that

the axle load does not exceed the maximum side load (see above).

5 Cleaning the weighing platform

Maintenance of the weighing platform is limited to regular cleaning and subsequent oiling.

The procedure depends both on the type of surface (powder-coated/enamelled or stainless

steel) and on the environmental conditions prevailing at the installation location. Remove dirt

and deposits at regular intervals from the outside and inside of the weighing platform.

5.1 Notes on cleaning

DANGER

Danger of injury through shutting load plate

at KE...sk- und KES...sk weighing platforms!

▲ Only open and close the load plate with

the supplied tools!

▲ Never work under an opened unsecured

load plate!

CAUTION

Incorrect use of cleaning agents may cause damage to the weighing platform!

•Use only such cleaning agents that do not act on the plastics used in the

weighing platform.

•Be particularly careful when cleaning the measuring cell.

6

Page 7

Powder-coated/enamelled version, dry

surroundings

• Wipe with a damp cloth.

• Use household cleaning agents.

Stainless-steel and hot-galvanised

versions

• Wipe with a damp cloth.

• Water jet up to 60 °C.

• Use household cleaning agents.

Corrosive surroundings

• Water jet up to 60 °C.

• Remove corrosive substances at regular

intervals.

• Only use disinfectants and cleaning

agents in accordance with the manufacturer's specifications and instructions.

Cleaning a recessed weighing platform

• Ensure gap (1) between weighing platform and pit frame is always kept clear.

• Remove larger dirt deposits at pit bottom

(2) at regular intervals.

• Check pit drainage channel (3) for

blockage at regular intervals.

7

Page 8

5.2 Subsequent treatment

Carry out the following subsequent treatment in order to protect the weighing platform:

• Rinse the weighing platform with clear water.

• Dry off the weighing platform with a lint-free cloth.

• Treat the inside and outside of the weighing platform with an oil suitable for foodstuffs.

Special treatment for scales installed in the floor or a pit

• Treat all the moving parts, such as flexible bearings, knife edges and bearings, thoroughly

with an oil suitable for foodstuffs after cleaning them.

5.3 Cleaning the measuring cell

The load plate has to be removed in order to clean the measuring cell. For details please refer

to the next section.

CAUTION

The measuring cell can be damaged!

• During cleaning work, never touch, direct

an airflow against or spray the rubber

diaphragm (1) of the measuring cell.

• Blow out dirt or flush with a mediumpower water jet.

8

Page 9

5.4 Information on removing the load plate

KC and KCS weighing platforms

• Remove the load plate by pivoting the two

side handles (1) outward.

• Replace the load plate (1) so that the

1

symbol O is located above the level indicator. Make sure that the load supports

(2) in the corners of the weighing platform are vertical.

2

K...sk weighing platforms

• Open the quick-release locks (2) with the

special key (1) and pivot up the load

plate.

CAUTION

The gas-filled springs can be damaged!

▲ Do not clean gas-filled springs with

steam jet.

▲ Do not oil the piston rod.

9

Page 10

6 Standard accessories

Pit frame

Installation kit incl. fastening

materials

for KC300, KC600

hot-galvanised

stainless steel

for KCS300, KCS60

hot-galvanised

stainless steel

Order No.

00 503 635

00 503 636

00 504 550

00 504 551

for KD... , hot-galvanised

for KD... , stainless steel

for KE..., hot-galvanised

for KE..., stainless steel

for KES..., hot-galvanised

for KES..., stainless steel

for KE...sk, stainless steel

for KES...sk, stainless steel

Pit frame with cleaning recess on

both sides

Installation kit incl. fastening

materials

hot-galvanised

for KD...

for KE...

for KES...

00 504 077

00 506 399

00 504 079

00 506 400

00 504 512

00 506 401

00 505 270

22 007 261

00 504 078

00 504 080

00 504 513

10

Page 11

Order No.

Access ramp

for KC300, KCS300, KC600,

KCS600

Symmetrical steel design, hotgalvanised checker plate surface

Loading capacity 1000 kg

Additional load plate

for KC300, KC600

polished stainless steel

Bell-shaped for placing over

existing load plate

Surface protection for stricter

hygienic requirements

Load plates

for KD...

enamelled

hot-galvanised

stainless steel

00 503 638

00 503 629

00 503 617

00 503 618

00 503 619

for KE...

enamelled

hot-galvanised

stainless steel

for KES...

enamelled

hot-galvanised

stainless steel

00 503 620

00 503 621

00 503 622

00 504 504

00 504 505

00 504 506

11

Page 12

Order No.

max.

95 m

Extension cable

Length 10 m, connector at both

ends

for remote setup of ID terminal

Cable adapter kit for ID terminals

for infinite extension of connection

cable to 100 m

comprising two junction boxes

Box at terminal end with connection

cable of 2.5 m length

Special cable from the roll

used with adapter kit for ID

terminals for infinite extension of

connection cable to required length

00 504 134

00 504 133

00 504 177

12

Page 13

7 Technical data of the measuring cell

7.1 TBrick 15, TBrick 32 measuring cells

Ignition protection type II 3G EEx nA II C T6

–10 °C ≤ T

≤ +40 °C

a

II 3D IP67 T 70 °C

The following safety-related variables must be ensured by the

connected weighing terminal:

Supply circuit U

Interface circuit U

≤ 20 V DC

max,

max, CL

I

max, CL

U

max Diff, RS422

≤ 27 V DC

≤ 30 mA

≤ 10 V DC

Power consumption 12 V DC ± 20 %; 125 mA; 1.4 VA

IP protection type IP67

7.2 Pik 15, K52 measuring cells

Ignition protection type II 3G EEx nA II C T4

+10 °C ≤ T

Power consumption 12 V DC + 10 % / – 15 %; 150 mA; 1.8 VA

32 V DC + 10 % / – 15 %; 100 mA; 3.2 VA

≤ +30 °C

a

IP protection type IP67

EXPLOSION HAZARD

• Only use the measuring cell K52 in combination with the ID1Plus

weighing terminal in Category 3G hazardous areas. The ID1Plus

weighing terminal has to be installed in the safe area.

13

Page 14

Page 15

Page 16

*22007218C*

22007218C

Subject to technical changes © Mettler-Toledo (Albstadt) GmbH 01/06 Printed in Germany 22007218C

Mettler-Toledo (Albstadt) GmbH

D-72458 Albstadt

Tel. ++49-7431-14 0, Fax ++49-7431-14 232

Internet: http://www.mt.com

Loading...

Loading...