Page 1

®

Industrial Scale Terminal

Technical Manual

D15896200A

(03/05).00

www.mt.com/support

Page 2

This manual describes the operation and functionality of the JAGXTREME terminal. The software number ("B"

revision) is displayed during the power-up sequence.

COPYRIGHT

Copyright 2003 Mettler-Toledo, Inc. This documentation contains proprietary information of Mettler-Toledo, Inc. It

may not be copied in whole or in part without the express written consent of Mettler-Toledo, Inc.

METTLER TOLEDO reserves the right to make refinements or changes to the product or manual without notice.

U.S. Government Restricted Rights Legend: This software is furnished with Restricted Rights. Use, duplication, or

disclosure of the Software by the U.S. Government is subject to the restrictions as set forth in subparagraph (C) (1)

(ii) of the Rights in Technical Data and Computer Software clause at 40 C.F.R. Sec. 252.227-7013 or in

subparagraphs (c) (1) and (2) of the Commercial Computer Software-Restricted Rights clause at 40 C.F.R. Sec.

52-227-19, as applicable.

FCC NOTICE

This device complies with Part 15 of the FCC Rules and the Radio Interference Requirements of the Canadian

Department of Communications. Operation is subject to the following conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his or her own expense.

ORDERING INFORMATION

It is most important that the correct part number is used when ordering parts. Parts orders are machine processed,

using only the part number and quantity as shown on the order. Orders are not edited to determine if the part

number and description agree.

TRADEMARKS

METTLER TOLEDO® ,JAGUAR®, JAGXTREME and DigiTOL are registered trademarks of Mettler-Toledo, Inc.

All other brand or product names are trademarks or registered trademarks of their respective companies.

Page 3

CUSTOMER FEEDBACK

Your feedback is important to us! If you have a problem with this product or its documentation, or a suggestion on how we can serve you

better, please fill out and send this form to us. Or, send your feedback via email to:

United States, you can mail this postpaid form to the address on the reverse side or fax it to (614) 438-4355. If you are outside the

United States, please apply the appropriate amount of postage before mailing.

Your Name: Date:

Organization Name: METTLER TOLEDO Order Number:

Address: Part / Product Name:

Part / Model Number:

Serial Number:

Company Name for Installation:

Phone Number: ( ) Fax Number: ( ) Contact Name:

E-mail Address: Phone Number:

Please check the appropriate box to indicate how well this product met your expectations in its intended use?

Met and exceeded my needs

Met all needs

Met most needs

Met some needs

Did not meet my needs

Comments/Questions:

DO NOT WRITE IN SPACE BELOW; FOR METTLER TOLEDO USE ONLY

Retail Light Industrial Heavy Industrial Custom

RESPONSE: Include Root Cause Analysis and Corrective Action Taken.

quality_feedback.mtwt@mt.com. If you are in the

Page 4

E

FOLD THIS FLAP FIRST

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 414 COLUMBUS, OH

NO POSTAGE

NECESSARY IF

MAILED IN THE

UNITED STATES

POSTAGE WILL BE PAID BY ADDRESSE

Mettler-Toledo, Inc.

Quality Manager - MTWT

P.O. Box 1705

Columbus, OH 43216

USA

Please seal with tape.

Page 5

DECLARATION OF CONFORMITY

Konformitätserklärung

Déclaration de conformité

Declaración de Conformidad

Conformiteitsverklaring

Dichiarazione di conformità

We/Wir/Nous/Wij/Noi: Mettler-Toledo, Inc.

1150 Dearborn Drive

Worthington, Ohio 43085

USA

declare under our sole responsibility that the product,

erklären, in alleiniger Verantwortung, daß dieses Produkt,

déclarons sous notre seule responsabilité que le produit,

declaramos, bajo nuestra sola responsabilidad, que el producto,

verklaren onder onze verantwoordelijkheid, dat het product,

dichiariamo sotto nostra unica responsabilitá, che il prodotto,

Model/Type: Jaguar and JagXtreme

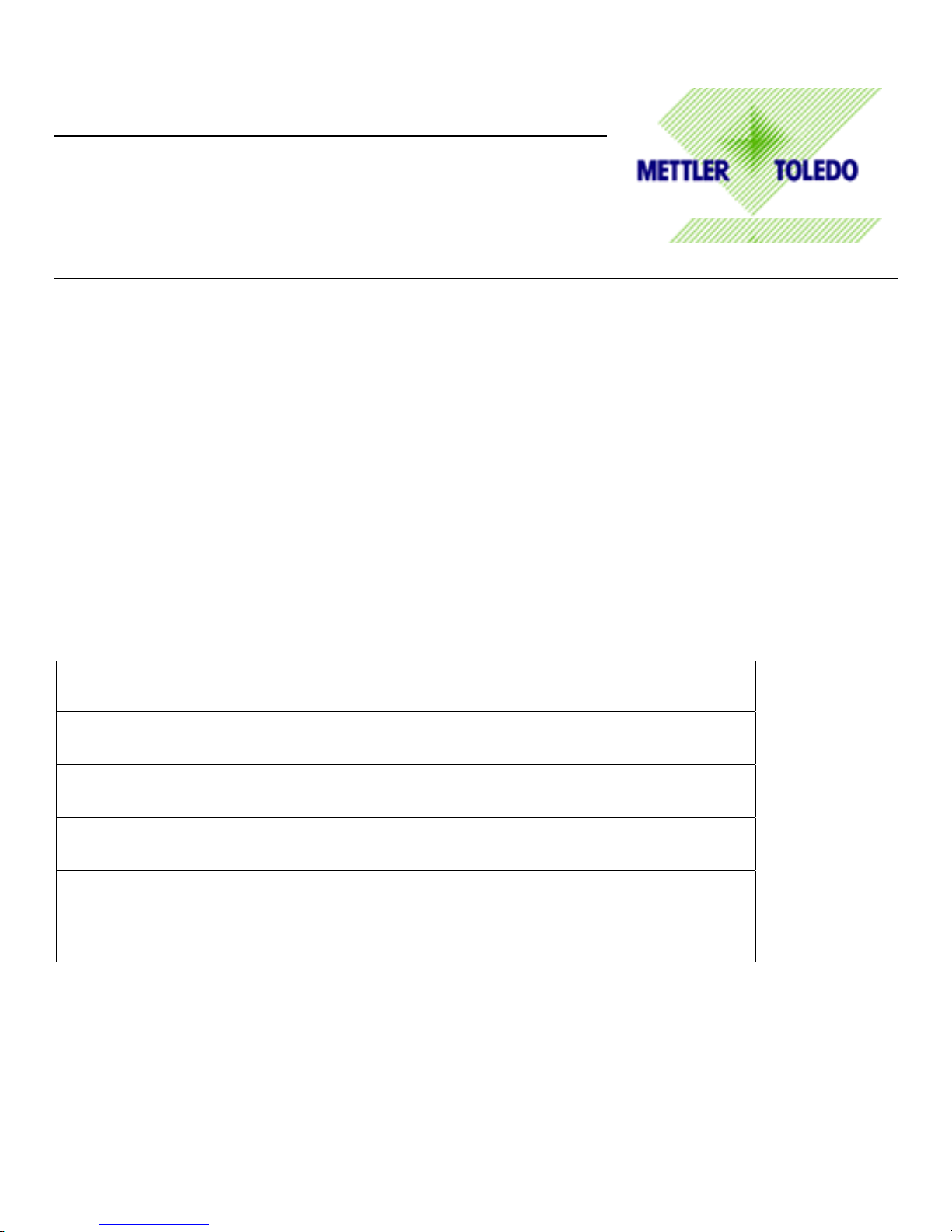

to which this declaration relates is in conformity with the following standard(s) or other normative document(s).

auf das sich diese Erklärung bezieht, mitder/den folgenden Norm(en) oder Richtlinie(n) übereinstimmt.

Auquel se réfère cette déclaration est conforme à la (aux) norme(s) ou au(x) document(s) normatif(s).

Al que se refiere esta declaración es conforme a la(s) norma(s) u otro(s) documento(s) normativo(s).

Waarnaar deze verklaring verwijst, aan de volende norm(en) of richtlijn(en) beantwoordt.

A cui si riferisce questa dichiarazione è conforme alla/e sequente/i norma/e o documento/i normativo/i.

in combination with a weighing platform p oduced by Mettler-Toledo is in confo mity with the following directives and standards. r r

Council directive on the harmonization of the laws of the Member

states:

relating to non-automatic weighing instruments (90/384/EEC) amended

by directive (93/68/EEC)

relating to electromagnetic compatibility (89/336/EEC) amended by

directive (93/68/EEC; 92/31/EEC)

relating to electrical equipment designed for use within certain voltage

limits (73/23/EEC amended by directive (93/68/EEC)

Relating to electrical equipment designed for use in potentially explosive

atmospheres (94/9/EC) (Refer to note 1)

Worthington, Ohio USA, April, 2003 Mettler-Toledo, Inc.

Darrell Flocken, Manager - Weights & Measures

Office of Weights and Measures

Notes:

1. Certificate KEMA 02ATEX1023 X applies only to JagXtreme units only. Refer to Section (17) of the certificate for special conditions.

Original issue: July, 1995

Revised: October, 1996 added compliance to Low Voltage Directive

May, 2000 added JagXtreme

standards:

EN 45501:1992

Article 1.2.a

EN 55022, B

EN 60950

EN 50021 : 1999

EN 50281-1-1 : 1998

Certificate number

(if applicable)

TC 2618

KEMA 02ATEX1023 X

(Refer to note 1)

April, 2003 added compliance to ATEX Directive.

Page 6

PRECAUTIONS

READ this manual BEFORE

operating or servicing this

equipment.

FOLLOW these instructions

carefully.

SAVE this manual for future

reference.

DO NOT allow untrained

personnel to operate, clean,

inspect, maintain, service, or

tamper with this equipment.

ALWAYS DISCONNECT this

equipment from the power

source before cleaning or

performing maintenance.

CALL METTLER TOLEDO for parts,

information, and service.

WARNING

DISCONNECT ALL POWER TO THIS UNIT BEFORE

INSTALLING, SERVICING, CLEANING, OR

REMOVING THE FUSE. FAILURE TO DO SO COULD

RESULT IN BODILY HARM AND/OR PROPERTY

DAMAGE.

CAUTION

OBSERVE PRECAUTIONS FOR HANDLING

ELECTROSTATIC SENSITIVE DEVICES.

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO

SERVICE THIS EQUIPMENT. EXERCISE CARE

WHEN MAKING CHECKS, TESTS AND

ADJUSTMENTS THAT MUST BE MADE WITH

POWER ON. FAILING TO OBSERVE THESE

PRECAUTIONS CAN RESULT IN BODILY HARM.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK

HAZARD, CONNECT TO PROPERLY GROUNDED

OUTLET ONLY. DO NOT REMOVE THE GROUND

PRONG.

Page 7

IN ORDER TO INSTALL THE DIVISION 2 APPROVED

JAGXTREME PANEL-MOUNT OR HARSH TERMINAL

UTILIZING THE FACTORY MUTUAL APPROVAL, METTLER

TOLEDO CONTROL DRAWING 157043R MUST BE

FOLLOWED WITHOUT EXCEPTION. IN ORDER TO INSTALL

THE CATEGORY 3 JAGXTREME PANEL-MOUNT OR HARSH

TERMINAL UTILIZING THE KEMA APPROVAL THE KEMA

APPROVAL CERTIFICATE 02ATEX1023X AND ALL LOCAL

REGULATIONS MUST BE FOLLOWED WITHOUT EXCEPTION.

FAILURE TO DO SO COULD RESULT IN BODILY HARM

AND/OR PROPERTY DAMAGE. REFER TO THE JAGXTREME

DIVISION 2 AND ZONE 2/22 INSTALLATION GUIDE,

16088600A FOR ADDITIONAL INFORMATION.

WARNING

WARNING

EARLIER MODELS OF THE JAGXTREME TERMINAL THAT

ARE NOT MARKED (FACTORY-LABELED) AS DIVISION 2

OR EUROPEAN CATEGORY 3 APPROVED MUST NOT BE

INSTALLED IN A DIVISION 2 OR ZONE 2/22

ENVIRONMENT.

IF THE KEYBOARD, DISPLAY LENS OR ENCLOSURE IS

DAMAGED ON A DIVISION 2 APPROVED OR CATEGORY 3

MARKED JAGXTREME PANEL-MOUNT OR HARSH

TERMINAL THAT IS USED IN A DIVISION 2 OR ZONE 2/22

AREA, THE DEFECTIVE COMPONENT MUST BE REPAIRED

IMMEDIATELY. REMOVE AC POWER IMMEDIATELY AND

DO NOT REAPPLY AC POWER UNTIL THE DISPLAY LENS,

KEYBOARD OR ENCLOSURE HAS BEEN REPAIRED OR

REPLACED BY QUALIFIED SERVICE PERSONNEL. FAILURE

TO DO SO COULD RESULT IN BODILY HARM AND/OR

PROPERTY DAMAGE.

WARNING

Page 8

CONTENTS

1 Introduction .................................................................................................... 1-1

Model Identification .............................................................................................................1-1

References/Resources.................................................................................................1-2

Accessories...............................................................................................................1-2

Other Compatible Products..........................................................................................1-6

Software .............................................................................................................................1-7

Specifications ......................................................................................................................1-8

Display and Keypad...................................................................................................1-9

Physical Dimensions................................................................................................1-10

Power Requirements ................................................................................................1-15

Controller PCB.........................................................................................................1-15

Temperature and Humidity ........................................................................................1-16

Environmental Protection ..........................................................................................1-16

Standards Compliance........................................................................................................1-16

UL and cUL Listing...................................................................................................1-16

Weights and Measures Approvals ..............................................................................1-16

CE Conformity .........................................................................................................1-17

Conducted and Radiated Emissions (RFI)...................................................................1-17

Radio Frequency Interference Susceptibility..................................................................1-17

AC Power Line Voltage Variation ................................................................................1-17

2 Installation ..................................................................................................... 2-1

Overview.............................................................................................................................2-1

Unpacking and Inspection.....................................................................................................2-1

Standards Compliance..........................................................................................................2-2

UL and cUL Listing.....................................................................................................2-2

Environmental Considerations ...............................................................................................2-2

Temperature and Humidity ..........................................................................................2-2

Environmental Protection ............................................................................................2-2

Power Considerations...........................................................................................................2-2

Connecting to the JAGXTREME Terminal.................................................................................2-4

Connecting the Load Cell ............................................................................................2-4

Serial Port Connections Controller PCB .........................................................................2-9

Discrete Wiring........................................................................................................2-13

Optional Multifunction I/O PCB Serial and Discrete Connections .....................................2-15

Connecting the Power Cable......................................................................................2-17

Installing the General Purpose Model...................................................................................2-18

Installing the Panel Mount Model ........................................................................................2-20

Installing the Blind Panel Mount Unit ...................................................................................2-21

Installing the Harsh Environment Enclosure ..........................................................................2-22

Opening the Harsh Environment Terminal ...................................................................2-22

Mounting the Harsh Environment Terminal..................................................................2-23

Ethernet Connection...........................................................................................................2-24

JAGXTREME Terminal Jumper and Switch Settings................................................................2-25

Page 9

Controller PCB.........................................................................................................2-25

Analog Load Cell PCB ..............................................................................................2-26

Single Channel Analog Load Cell PCB ........................................................................2-27

Dual Channel Analog Load Cell PCB ..........................................................................2-28

Allen-Bradley RIO PCB..............................................................................................2-28

POWERCELL PCB ....................................................................................................2-29

MMR (IDNET) PCB...................................................................................................2-29

Multifunction I/O PCB ...............................................................................................2-30

Installing Options...............................................................................................................2-30

Apply Power ......................................................................................................................2-31

Power-up Sequence ...........................................................................................................2-32

Scale Build Determination...................................................................................................2-32

Minimum Increment Size for Bench and Portable Single DLC Scale Bases.......................2-32

Minimum Increment Size For Optional Analog Scale Input .............................................2-33

Sample Calculation..................................................................................................2-34

Seal the Enclosure - Weights and Measures Applications.......................................................2-34

Panel Mount Enclosure.............................................................................................2-34

General Purpose Enclosure .......................................................................................2-35

Harsh Environment Enclosure....................................................................................2-35

3 Programming and Calibration ........................................................................... 3-1

General Information .............................................................................................................3-1

Front Panel Display....................................................................................................3-1

Key Functions............................................................................................................3-2

Accessing Setup ........................................................................................................3-3

Navigating ................................................................................................................3-4

Audible Messages......................................................................................................3-5

Reset to Factory.........................................................................................................3-5

Configuring Terminals With Multiple Scales and a Summing Scale...................................3-6

Alibi Memory.............................................................................................................3-7

Program Block Overview.......................................................................................................3-8

Scale Interface Program Block...............................................................................................3-9

1. Market Sub-block.................................................................................................3-10

2. Scale Type Sub-block...........................................................................................3-10

3. Calibration Unit Sub-block.....................................................................................3-12

4. Capacity Sub-block..............................................................................................3-12

5. Increment Size Sub-block......................................................................................3-13

6. Shift Adjustment Sub-block....................................................................................3-14

7. Linearity Correction Sub-block ...............................................................................3-14

8. Calibration Sub-block...........................................................................................3-14

9. Zero Adjustment Sub-block....................................................................................3-16

10. Span Adjustment Sub-block.................................................................................3-16

11. Scale Test Sub-block.........................................................................................3-16

12. Add in Sum Sub-block........................................................................................3-16

13. Gravity Adjustment Sub-block..............................................................................3-17

14. Reset to Factory Sub-block..................................................................................3-17

Using the JAGXTREME with IDNET Bases .............................................................................3-17

Service Mode for IDNET Bases...................................................................................3-17

Page 10

JAGXTREME IDNET Calibration procedure....................................................................3-18

NATION Sub-block ...................................................................................................3-24

RESET Sub-block .....................................................................................................3-24

SCALE PARAMETERS Sub-block .................................................................................3-25

LINEARITY Sub-block................................................................................................3-25

CALIBRATION Sub-block ...........................................................................................3-26

SAVE PARAMETERS Program Sub-block......................................................................3-26

RETURN Sub-block...................................................................................................3-26

Application Environment Program Block ...............................................................................3-27

1. Character Set Sub-block........................................................................................3-28

2. Language Sub-block ............................................................................................3-28

3. Keyboard Type Sub-block .....................................................................................3-28

4. Scale ID Sub-block...............................................................................................3-28

5. Time and Date Sub-block......................................................................................3-29

6. Alternate Weight Units Sub-block............................................................................3-30

7. Power Up Operation Sub-block ..............................................................................3-31

8. Tare Operation Sub-block......................................................................................3-32

9a. Zero Operation Sub-block....................................................................................3-34

9b. Zero Operation Sub-block for IDNET Bases ............................................................3-35

10a. Stability Detect Sub-block..................................................................................3-35

10b. Stability Detect Sub-block for IDNET Bases ..........................................................3-35

11. Beeper Operation Sub-block ................................................................................3-36

12. Inhibit Memory Sub-Block...................................................................................3-36

13. Application Type Sub-block .................................................................................3-36

14. Vibration Rejection Sub-block ..............................................................................3-37

14a. Vibration Rejection Sub-block for IDNET ..............................................................3-38

Serial Interface Program Block ............................................................................................3-39

1. Configure Port Sub-block ......................................................................................3-40

2. Configure Template Sub-Block...............................................................................3-44

Configure Discrete Program Block .......................................................................................3-49

1. Discrete Inputs Sub-block .....................................................................................3-50

2. Discrete Outputs Sub-block ...................................................................................3-51

3. Assign Setpoints Sub-block ...................................................................................3-52

Configure Memory Program Block........................................................................................3-53

1. Configure Literals Sub-block..................................................................................3-53

2. Configure Prompts Sub-block ................................................................................3-54

3. Configure Consecutive Numbering Sub-block ..........................................................3-55

4. Alibi Memory.......................................................................................................3-56

Configure JagBASIC Program Block.....................................................................................3-57

1. Password Sub-block ............................................................................................3-58

2. Keyboard Sub-block.............................................................................................3-58

3. Display Sub-block................................................................................................3-58

4. Auto Start Sub-block.............................................................................................3-59

5. Manual Start Sub-block ........................................................................................3-59

6. LPRINT Port.........................................................................................................3-59

7. Send RAM Files Sub-block ....................................................................................3-59

8. Initialize RAM Disk Sub-block ................................................................................3-60

9. Password Maintenance Sub-block .........................................................................3-60

Configure Network Program Block .......................................................................................3-61

Network Overview ..............................................................................................................3-62

Page 11

General Networking Considerations .....................................................................................3-63

IP addresses ...........................................................................................................3-63

Clustering JAGXTREME Terminals ........................................................................................3-64

1. Ethernet Sub-block...............................................................................................3-68

2. Name-Password Sub-block...................................................................................3-68

3. Cluster IP Sub-block.............................................................................................3-69

4. PC Data Access (Reserved for Future Use) ..............................................................3-69

5. Email .................................................................................................................3-69

6. Web Server Sub-block ..........................................................................................3-70

7. FTP Server Sub-block ...........................................................................................3-70

8. PLC SP Control Sub-block.....................................................................................3-70

Configure Diagnostics Program Block ..................................................................................3-71

1. Memory Test Sub-block ........................................................................................3-72

2. Display Test Sub-block.........................................................................................3-72

3. Keyboard Test Sub-block ......................................................................................3-72

4. Scale Test Sub-block............................................................................................3-73

5. Serial Test Sub-block............................................................................................3-76

6. Parallel I/O Test Sub-block....................................................................................3-77

7. Network Test Sub-block ........................................................................................3-78

8. Ethernet Send BRAM Sub-block..............................................................................3-78

9. Zmodem Send BRAM Sub-Block ............................................................................3-79

10. Print Setup Sub-block .........................................................................................3-79

11. Reset to Factory Sub-block..................................................................................3-80

Configure Maintenance Program Block.................................................................................3-81

1. Calibration Management Sub-block........................................................................3-82

2. Calib Chk Parms Sub-block ..................................................................................3-83

3. Calib Mon Parms Sub-block..................................................................................3-84

Predictive Failure (Only for RAAD Box and POWERCELL Platforms) Sub-block.................3-86

Calibrate Check Sub-block ........................................................................................3-88

Maintenance Reports Sub-block.................................................................................3-89

Network Stats Sub-block...........................................................................................3-89

Reset to Factory.......................................................................................................3-89

Options Program Block .......................................................................................................3-90

4 Using the Web Server ...................................................................................... 4-1

System Requirements...........................................................................................................4-1

Setup..................................................................................................................................4-1

Operating Modes .................................................................................................................4-2

Navigation Bar Menu............................................................................................................4-2

Page 12

5 The Optional JagMAX Application Software........................................................ 5-1

Application Setup.................................................................................................................5-1

Starting the Application...............................................................................................5-1

Entering Application Setup...........................................................................................5-2

Moving Through Application Setup ...............................................................................5-2

General Setup............................................................................................................5-3

Weigh Mode Setup.....................................................................................................5-5

Re-Weigh Mode Setup................................................................................................5-6

Double Mode Setup....................................................................................................5-7

Triple Mode Setup ......................................................................................................5-7

Moving Van Mode Setup.............................................................................................5-8

ID Mode Setup...........................................................................................................5-8

Send Setup File........................................................................................................5-10

Print Setup ..............................................................................................................5-10

Transaction Report .............................................................................................................5-10

In-Process Report ..............................................................................................................5-11

Accumulation Report ..........................................................................................................5-12

End Program .....................................................................................................................5-13

Printing .............................................................................................................................5-13

6 Installing and Using JAGXFILES ........................................................................ 6-1

Hardware and Software Requirements ...................................................................................6-1

Installing JAGXFILES ............................................................................................................6-1

Browser and JAGXTREME Setup ............................................................................................6-1

Starting JAGXFILES ..............................................................................................................6-2

Configuring JAGXFILES on Your PC ..............................................................................6-2

Creating a Configuration File.................................................................................................6-2

Configuring Option Boards..........................................................................................6-3

Menu Items.........................................................................................................................6-4

File.....................................................................................................................................6-4

Open........................................................................................................................6-5

Save ........................................................................................................................6-6

Restore.....................................................................................................................6-7

Backup.....................................................................................................................6-8

All Other Menu Items ..................................................................................................6-8

Shutting Down JAGXFILES.....................................................................................................6-8

7 Service and Maintenance ................................................................................. 7-1

Tools and Supplies...............................................................................................................7-1

Cleaning and Regular Maintenance .......................................................................................7-1

Troubleshooting ...................................................................................................................7-1

Status Lights .............................................................................................................7-2

Error Codes and Actions .......................................................................................................7-2

Page 13

Diagnostic Tests ................................................................................................................7-18

AC Power Test .........................................................................................................7-18

Voltage Test ............................................................................................................7-18

Backup Battery Test..................................................................................................7-20

Ground Test ............................................................................................................7-20

External Equipment Test............................................................................................7-20

Internal Testing........................................................................................................7-21

20 mA /RS-232 Printer Tests.....................................................................................7-21

Replacing the Power Supply................................................................................................7-22

Replacing the Battery Back-up ............................................................................................7-23

8 Parts and Accessories ..................................................................................... 8-1

Panel Mount Parts ...............................................................................................................8-2

General Purpose Parts (Front View).......................................................................................8-4

General Purpose Parts (Rear View) .......................................................................................8-6

Harsh Environment Parts ......................................................................................................8-7

Line Cord Assemblies...........................................................................................................8-9

Controller PCB...................................................................................................................8-10

Analog Load Cell PCB ........................................................................................................8-11

Dual Analog Load Cell PCB.................................................................................................8-12

Power Supply ....................................................................................................................8-13

Allen-Bradley RIO Option ....................................................................................................8-14

CIP Interface Card .............................................................................................................8-15

PROFIBUS Option...............................................................................................................8-15

MODBUS Plus PCB.............................................................................................................8-16

Dual Analog Output Option..................................................................................................8-17

POWERCELL PCB...............................................................................................................8-18

Multifunction PCB ..............................................................................................................8-19

IDNET PCB ........................................................................................................................8-20

Optional Accessories..........................................................................................................8-21

Optional Panels .................................................................................................................8-22

Recommended Spare Parts.................................................................................................8-22

9 Appendices..................................................................................................... 9-1

Appendix 1: Serial Interface Reference...................................................................................9-1

Hardware Connections ...............................................................................................9-2

Output Modes and Formats.........................................................................................9-3

Standard Status Bytes A, B, and C................................................................................9-4

4-Setpoint Status Bytes A, B, and C..............................................................................9-5

Multi Cont 1 ..............................................................................................................9-6

Multi Cont 2 ..............................................................................................................9-6

Default Template Formats ...........................................................................................9-9

Input Modes............................................................................................................9-11

ASCII Characters ......................................................................................................9-16

Appendix 2: Discrete I/O Reference .....................................................................................9-20

Inputs.....................................................................................................................9-20

Page 14

Outputs ..................................................................................................................9-21

Appendix 3: Network Reference ..........................................................................................9-22

Keyboard/Display Sharing.........................................................................................9-22

Redirecting Serial Output...........................................................................................9-23

A-B RIO / PROFIBUS / MODBUS+ Option Sharing .........................................................9-24

Internet Explorer Proxy Server Setup............................................................................9-24

Appendix 4: Loading JAGXTREME Software ..........................................................................9-25

Using E_FLASH........................................................................................................9-25

E-FLASH Serial.........................................................................................................9-26

E-FLASH Ethernet .....................................................................................................9-27

FLASHPRO ..............................................................................................................9-27

Appendix 5: JAGXTREME Master Reset and Default Values....................................................9-29

Appendix 6: Gravity Factors ................................................................................................9-35

Appendix 7: Multiple Range/Multi-Interval Operation .............................................................9-36

Multiple Range Operation..........................................................................................9-36

Multi-Interval Operation.............................................................................................9-37

Appendix 8: Market Destination (Finish) Codes ....................................................................9-38

Page 15

1 Introduction

Model Identification

The JAGXTREME® Internet-enabled scale terminal is designed to help companies provide

cost-effective, flexible methods of production while maximizing engineering time and

effort. It offers connectivity to all METTLER TOLEDO technologies, as well as open

connectivity to the leading industry technologies, to facilitate communication and data

exchange with companies’ control, manufacturing execution, and enterprise systems.

The JAGXTREME terminal is available with various operator interfaces and enclosure

types, as well as with the optional JAGXTREME operator interface and optional JAGMAX

truck scale software. (Special instructions for programming the optional JAGMAX truck

scale software are included in this manual. Separate documentation is available for the

JAGXTREME operator interface). Please refer to the following Factory Number Reference

chart to identify the JAGXTREME terminal with which you will be working. A detailed

description of each designation is given to help you determine the specifications for

each model. A brief description of the optional accessories appears on the next page.

If you are upgrading an existing METTLER TOLEDO JAGUAR

JAGXTREME terminal, refer to the instructions provided with your upgrade kit.

Chapter 1: Introduction

Model Identification

®

terminal to a new

For users of the JAGXTREME terminal’s predecessor, METTLER TOLEDO’s JAGUAR

terminal, please pay special attention to the programming and calibration section.

Programming and calibration of the JAGXTREME terminal can be performed via the

embedded web server as well as through the front panel of the unit.

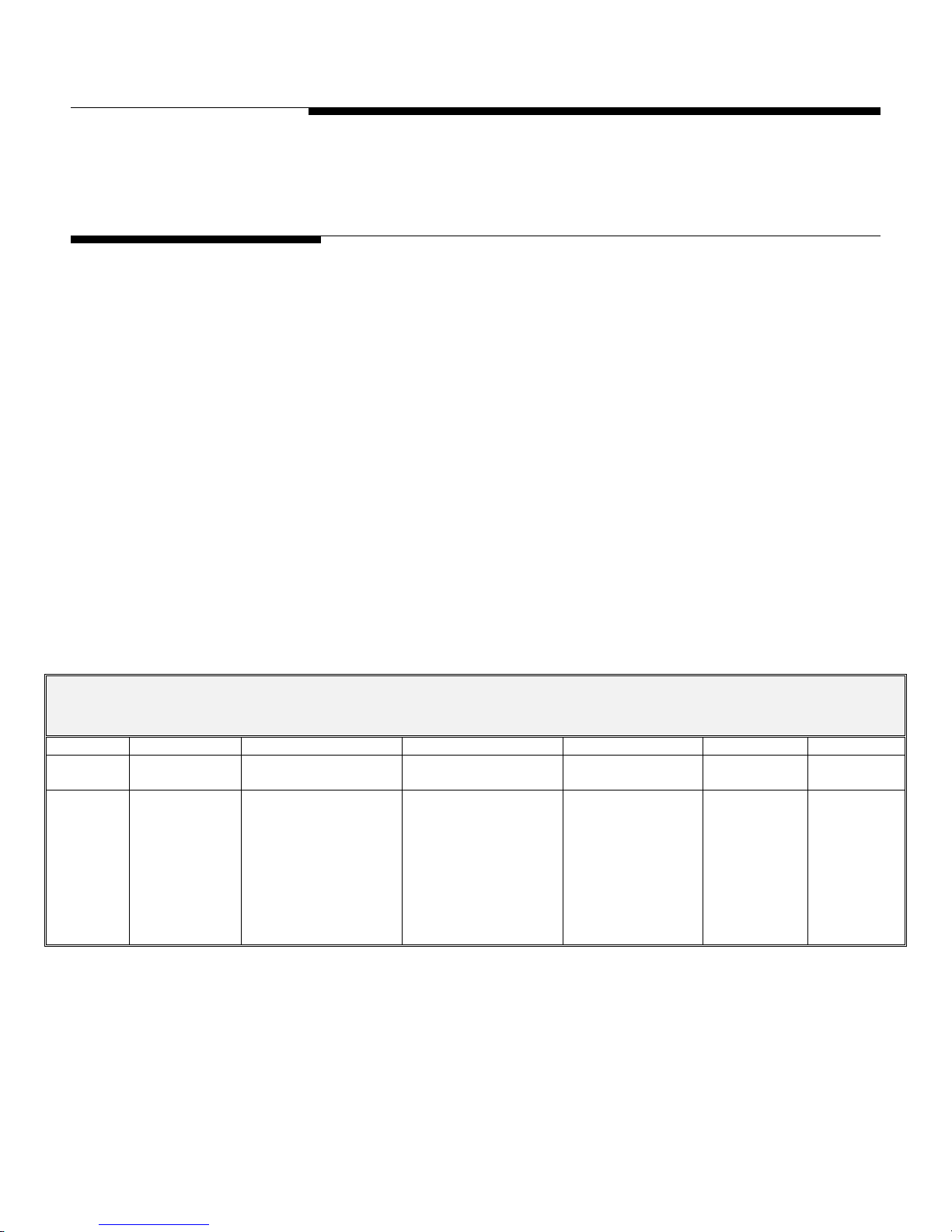

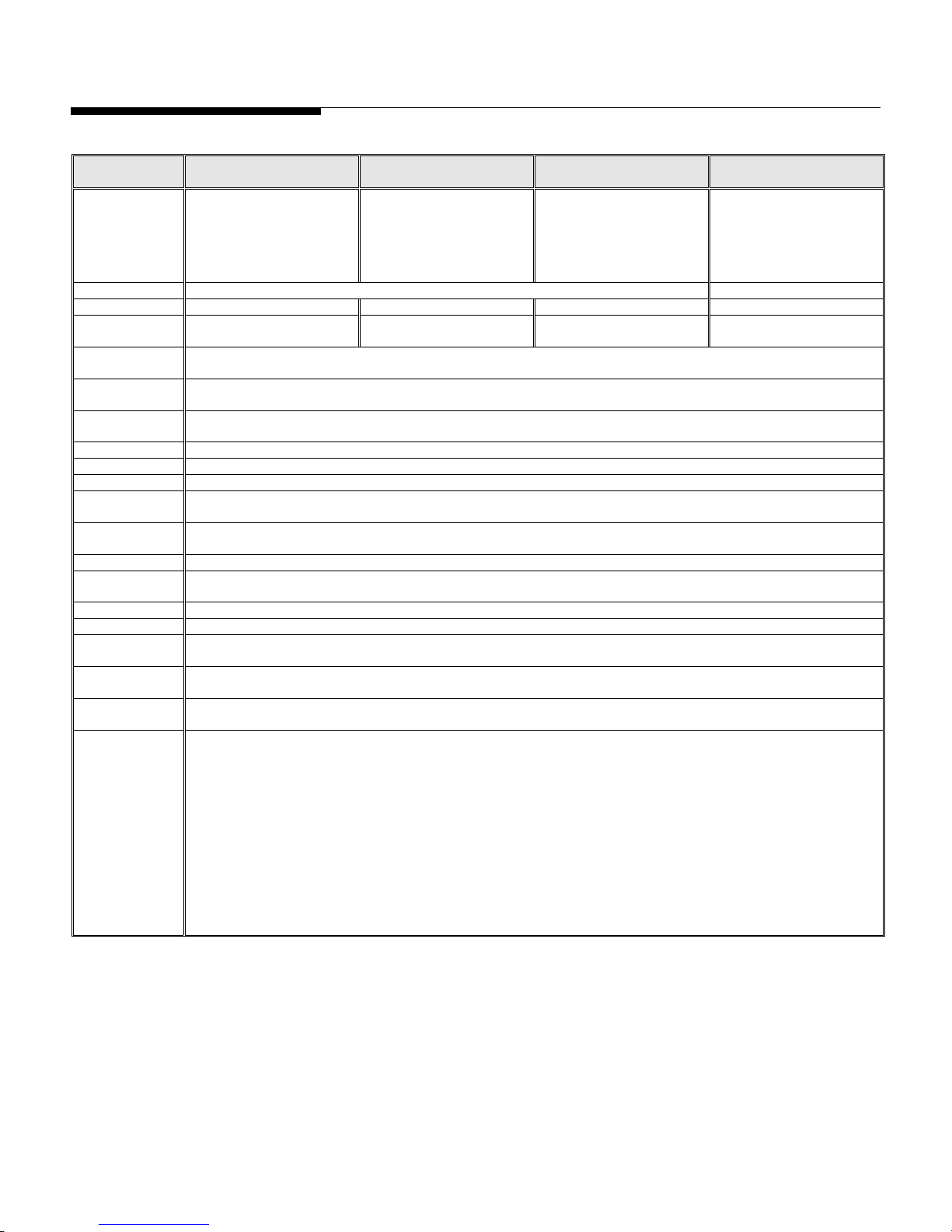

FACTORY NUMBER REFERENCE CHART

JAGXTREME TERMINAL MODEL CONFIGURATION

JX XX X X X X XXX

Terminal Enclosure

Display

JAGXTREME

Terminal

PB=Panel, Blind

PA=Panel, A/N

GA=General

Purpose A/N

HA=Harsh, A/N

Slot #1

Accessory

0=Cover Plate

1=Analog Scale

2=RE* Analog Scale

3=POWERCELL

4=IDNET

A=Dual Analog Scale

B=Dual RE* Analog Scale

®

Slot #2

Accessory

0=Cover Plate

1=Analog Scale

2= RE*Analog Scale

3=POWERCELL

4=IDNET

7=Multifunction I/O

A=Dual Analog Scale

B=Dual RE* Analog Scale

Slot #3

Accessory

0=Cover Plate

5=Modbus Plus

6=Allen Bradley RIO

7=Multi-function I/O

8=Dual Channel

Analog Output

9=PROFIBUS

C= CIP Interface**

Application

Software

0=Standard

JagBASIC

(included)

2 = JAGMAX™

Destination

Market

000=USA

See the Market

Codes in the

Appendix for

additional

destination

codes

*RE – Reduced Excitation. JAGXTREME terminals with harsh environment enclosures are not approved for use in hazardous areas.

As an example, the factory number JXPB-1002-000 denotes a JAGXTREME blind

panel-mount terminal with analog scale card and JAGMAX software for use in the USA.

Note: To order a JAGXTREME operator interface, you must use a separate model

number. Consult your METTLER TOLEDO representative or the JAGXTREME Operator

Interface documentation.

** Note: CIP connot be used with JXGA models.

(02/05)

1-1

Page 16

METTLER TOLEDO JAGXTREME Terminal Technical Manual

References/Resources

This manual provides information for configuring and serving the JAGXTREME terminal.

For information on installing the terminal, please refer to the Installation Guide that

accompanies the terminal. An electronic copy is also included on the documentation

CD-ROM that accompanies the unit. The CD-ROM includes the following resources:

• JAGXTREME Terminal Installation Guide

• JAGXTREME Terminal User's Guide

• JAGXTREME Terminal Technical Manual

• JAGXTREME Operator Interface Installation Guide

• JAGXTREME Operator Interface Technical Manual

• XTREMEBUILDER Software (with on-line help and programmer's reference guide)

®

• JagBASIC

• JAGXTREME PLC Analog Output Interfaces Technical Manual

• CIP Interface Technical Manual

• JAGMAX Application Software User's Guide

• JAGMAX Application Software Printer Templates Guide

Programmer's Guide

Accessories

• JAGXFILES™ (utility)

• Eflash (utility)

For additional information, contact your authorized METTLER TOLEDO representative or

http://www.mt.com.

go to:

A number of accessories are available for use with the JAGXTREME terminal. The model

configurator designation number appears in parentheses. Please contact your

authorized METTLER TOLEDO representative for more information.

Cover Plate (0)

This thin metal plate is used to cover the opening in the back of the regular or blind

chassis panel-mount terminal if an optional PCB is not installed at this location.

Analog Scale (1)

This option is required when interfacing analog-type load cells. A 15-volt excitation

voltage is used to power up to 16 350-ohm load cells from one analog PCB. A jumper

is provided to select operation with 2 mV/V or 3 mV/V load cells. The JAGXTREME

terminal will operate with load cells of impedances other than 350 ohms or other mV/V

specifications, but the total scale resistance must not be less than 22 ohms. A quiet

analog signal section, combined with a proprietary analog-to-digital converter and

coprocessor implementing METTLER TOLEDO TraxDSP

vibration rejection performance unequaled in the industry.

®

filters, provides weighing and

1-2

(02/05)

The zero temperature coefficient is 0.15 µV/degree C. The span temperature coefficient is

6 ppm/degree C. When using this option, the display update rate is limited to 10

updates per second. The actual A/D conversion rate exceeds 300 cycles per second.

This high-speed process allows the terminal to filter out noise while providing a weight

update rate of up to 50 updates per second for setpoint control and other functions.

Page 17

Chapter 1: Introduction

Model Identification

Each analog scale option board has a removable EEPROM that stores calibration

parameters for the scale. If an EEPROM is transferred to another board, all calibration

parameters transfer. A detachable seven-position terminal strip is used to terminate the

analog load cell cable on the rear of the PCB. Signal, excitation, sense, and shield

connections are provided with easy-to-read descriptions. Two LEDs are visible through

holes in the rear panel of the PCB to indicate the status of the analog PCB.

Reduced Excitation Analog Scale (2)

This option, when used with a protective load cell barrier, allows operation of the

JAGXTREME terminal with analog load cells located in an area classified as hazardous

by the National Electrical Code.

Division 2 or Category 3 approved terminal. The excitation voltage is lowered to 5 volts

for this option. The standard JAGXTREME terminal cannot be located inside a Division 1

or Zone 0/1 hazardous area

available from METTLER TOLEDO for applications which require the terminal to be

located inside a Division 1 or Zone 0/1 classified area.

The zero temperature coefficient is 0.15 µV/degree C. The span temperature coefficient is

6 ppm/degree C. When using this option, the display update rate is limited to 10

updates per second. The actual A/D conversion rate exceeds 300 cycles per second.

This high-speed process allows the terminal to filter out noise while providing a weight

update rate of up to 50 updates per second for setpoint control and other functions.

This option is required if the terminal is to be used as a

without special precautions. Purged enclosures are

Note: If a single IDNET card

is installed, it has to be

designated as Scale 1.

Each option board has a removable EEPROM that stores calibration parameters for the

scale. If an EEPROM is transferred to another board, all calibration parameters transfer

as well. A detachable seven-position terminal strip is used to terminate the analog load

cell cable on the rear of the PCB. Signal, excitation, sense, and shield connections are

provided, each with an easy-to-read description. Two LEDs are visible through holes in

the rear panel of the PCB to indicate its operating status.

POWERCELL (3)

The POWERCELL interface must be used when the JAGXTREME terminal is used with a

METTLER TOLEDO POWERCELL load cell system or RAAD box(es). It supports up

to a total of 24 DigiTOL POWERCELLs or six RAAD boxes. An external power supply is

needed when using more than 14 POWERCELLs or three RAAD boxes. METTLER

TOLEDO also offers intrinsically safe barriers for use with POWERCELL

systems located in hazardous areas. Please contact your METTLER TOLEDO

representative for more information about applications in hazardous environments.

IDNET (4)

The IDNET interface allows you to interface a METTLER TOLEDO multi-range base or lab

balance with IDNET option with the JAGXTREME terminal. When utilizing this interface,

the terminal acts as a “front end” for the base. Setup and calibration of the base is

identical to the procedure used by the ID family of indicators. Scale-related information

is stored in the scale base as well as the terminal, allowing its access by external

devices such as a PLC.

*Only one can be loaded

into the JAGXTREME

terminal.

Modbus Plus* (5)

The Modbus Plus interface enables the terminal to directly interface with Modbus Plus

devices such as PLCs manufactured by MODICON. The JAGXTREME terminal interface

acts as a single Modbus Plus node, which can support up to four scales, and has been

fully certified by the Modicon Test Center.

(02/05)

1-3

Page 18

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Allen-Bradley RIO* (6)

This option allows the JAGXTREME terminal to exchange data with an Allen-Bradley PLC

like a remote 1771 module on the Allen-Bradley remote I/O. A direct connection to an

Allen-Bradley controller is possible via this “blue hose” connection. If the terminal has

two or more scales installed, all share the same RIO option board. If multiple terminals

are combined in a “cluster” using Ethernet, up to four scales can share the RIO option.

Each scale requires one-quarter rack of RIO address space. JAGXTREME terminals

support quarter rack addressing.

JAGXTREME terminals support discrete and block transfer modes of data interface. Both

are bi-directional. Discrete mode is used for data, status, and command exchange.

Block transfer allows more extensive data exchange and allows the PLC to write

messages to the terminal’s lower alphanumeric display. Connection to the RIO option is

made via a detachable three-position terminal strip on the rear of the RIO option.

Multifunction I/O (7)

The Multifunction PCB option expands the number of serial and discrete input and

output ports supported by the JAGXTREME terminal. The Multifunction PCB adds two

serial ports. COM3 can be used for RS-232 communications. COM4 can be used for

RS-232 or RS-422/RS-485 communications. COM4 can be used for a single DigiTOL

or UltraRes understructure interface. The Multifunction PCB adds eight programmable

discrete inputs (PAR 3). Eight programmable discrete outputs (PAR 4). PAR 3 and PAR

4 assignments are user-configurable.

*Only one can be loaded

into the JAGXTREME

terminal.

Dual Channel Analog Output* (8)

The Analog Output module provides two channels of analog output, one for each of up

to two scales connected to the terminal. The channels may be selected to provide either

a 0 to 10 V or a 4 to 20 mA analog output signal. The output is the result of a 16-bit

digital to analog conversion.

PROFIBUS Interface* (9)

The JAGXTREME terminal with the PROFIBUS interface module is a fully L2-DP

compliant device which can be used with a wide range of PROFIBUS compatible

devices. This module provides the process control engineer with the ability to access

weight information, status of the scale, and to download a setpoint or tare weight. The

Profibus option has been fully certified by the Siemens Profibus Test Center.

Dual Analog Scale (A)

This option is required when interfacing analog-type load cells. A 15-volt excitation

voltage is used to power up to 16 350-ohm load cells from one analog channel. The

dual channel card can support a maximum of 20 load cells and up to four analog

platforms. A jumper is provided to select operation with either 2mV/V or 3mV/V load

cells. The terminal will operate with load cells of impedances other than 350 ohms or

other mV/V specifications, but the total scale resistance must not be less than 22 ohms.

A quiet analog signal section, combined with an analog-to-digital converter and coprocessor that use METTLER TOLEDO TraxDSP filters, provides weighing and vibration

rejection performance unequaled in the industry. The zero temperature coefficient is 0.15

uV/degree C. The span temperature coefficient is 6 ppm/degree C.

1-4

(02/05)

When using this option, the display update rate is limited to 10 updates per second.

The actual A/D conversion rate exceeds 300 cycles per second. The high-speed process

allows the terminal to filter out noise while providing a weight update rate up to 50

updates per second for setpoint control and other functions.

Page 19

Chapter 1: Introduction

Model Identification

The dual channel analog scale option board has a removable EEPROM for each scale

channel that stores calibration parameters for that scale channel. If an EEPROM is

transferred to another board, all calibration parameters transfer as well.

A detachable seven-position terminal strip is used to terminate each analog load cell

cable on the rear of the PCB. Signal, excitation, sense, and shield connections are

provided with easy-to-read descriptions. Two LEDs are visible through holes in the rear

panel of the PCB to indicate the status of the Analog PCB. The terminal supports up to

two dual analog scale cards.

Reduced Excitation Dual Analog Scale (B)

This option is used with a protective load cell barrier to permit operation of a

JAGXTREME terminal with analog load cells located in an area classified as hazardous

by the National Electrical Code. It can support up to four analog platforms. The

excitation voltage is lowered to 5 volts. A METTLER TOLEDO Reduced Excitation module

is required for these applications. The standard terminal cannot be located inside the

hazardous area as is. Purged enclosures are available from METTLER TOLEDO if the

terminal must be located inside a hazardous area. The Reduced Excitation module can

only support up to 12 analog load cells or a total resistance of 58 ohms. Jumpers are

provided to select operation with 2mV/V or 3mV/V load cells. The terminal will operate

with load cells of impedances other than 350 ohms or other mV/V specifications, but

the total scale resistance must not be less than 22 ohms.

The zero temperature coefficient is 0.15 uV/degree C. The span temperature coefficient is

6 ppm/degree C. When using this option, the display update rate is limited to 10

updates per second. The actual A/D conversion rate exceeds 300 cycles per second.

The high-speed process allows the terminal to filter out noise and still provide a weight

update rate up to 50 updates per second for setpoint control and other scale functions.

The dual channel analog scale option board has a removable EEPROM for each scale

channel that stores calibration parameters for that scale channel. If an EEPROM is

transferred to another board, all calibration parameters transfer as well.

A detachable seven-position terminal strip is used to terminate each analog load cell

cable on the rear of this PCB. Signal, excitation, sense, and shield connections are

provided, each with an easy-to-read description. Two LEDs are visible through holes in

the rear panel of this PCB to indicate the status of the Analog PCB. The JAGXTREME

terminal will support one or two Reduced Excitation dual analog scale cards.

**CIP Network Interface (ControlNET) (C)

The CIP network interface enables the JAGXTREME terminal to directly interface with a

CIP network (ControlNet or Ethernet/IP). The JAGXTREME terminal interface supports

both the ControlNet and Ethernet/IP network protocol utilizing the following types of

message:

• Class 1, connected, scheduled messaging

• Connected, unscheduled, explicit messaging, using ControlNet Object,

Instance, and Attributes ID’s.

** Note: CIP card cannot be used with JXGA models due to ControlNet connector size.

(02/05)

1-5

Page 20

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Other Compatible Products

RAAD Box

METTLER TOLEDO’s RAAD (Remote Addressable Analog to Digital) junction box is used

to transform conventional strain gauge load cell systems into advanced sensor

networks. Instead of analyzing the combined signal from every load cell in the system,

the RAAD box embeds intelligence into each individual load cell, enabling you to

analyze your system at the lowest level. When used with the JAGXTREME terminal, the

RAAD box can detect failures immediately to help guard against costly downtime or

product waste. The RAAD box can also be used with METTLER TOLEDO’s COUGAR

terminal.

8624 Remote Display

The METTLER TOLEDO 8624 Remote Display allows an operator to remotely view

weight and status with the JAGXTREME terminal. The 8624 connects to the JAGXTREME

serial port and can be located remote from the JAGXTREME chassis.

8618 Scoreboard

The METTLER TOLEDO 8618 scoreboard allows an operator to remotely view weight

with the JAGXTREME terminal. The 8618 connects to one of the JAGXTREME serial ports

and can be located remote form the JAGXTREME chassis.

Printers

METTLER TOLEDO offers a family of reliable printers well suited for industrial

applications. The printers connect to one of the JAGXTREME serial ports and can be

located remote from the JAGXTREME chassis.

DNB Module

The METTLER TOLEDO DNB module (DeviceNet bridge) allows a PLC to access weigh

and status with the JAGXTREME terminal. The DNB module connects to the JAGXTREME

serial port and can be located remote from the JAGXTREME chassis.

JAGXTREME Operator Interface (JXOI)

The JXOI is an Ethernet-enabled graphic terminal with object-based programming. It is

available in pedestal and panel-mount versions (graphical display only) or a harsh

environment terminal version (comprised of a blind JAGXTREME terminal and a

graphical display in an enclosure.)

The JXOI features a 1/4 VGA, 240 x 320 pixels, STN color display. It uses a coldcathode fluorescent backlight (CCFL). The CCFL provides high contrast and easy

readability and is replaceable. The contrast is software-controlled and compensated for

temperature.

The JXOI comes equipped with one RS-232 serial port with an Ethernet port and a PS/2

keyboard port. It stores the firmware and the user application in a compressed format in

flash memory and then transfers them to RAM memory when the JXOI is powered on.

1-6

(02/05)

Page 21

Software

Chapter 1: Introduction

Software

JAGXTREME Operating System

The JAGXTREME operating system is available in four configurations. The configurations

define the language of the HTML web pages and are determined by the country finish

code of the terminal part number. The available configurations are:

English/Chinese

English/French

English/German

English/Spanish

JagBASIC

JagBASIC software is standard in the JAGXTREME terminal. JagBASIC is a tool for

customizing the JAGXTREME industrial scale terminal. JagBASIC programs reside along

side the standard JAGXTREME terminal program. The JagBASIC interpreter runs as a

separate task using the terminal’s multi-tasking operating system. This allows the

custom JagBASIC program to interact with the other JAGXTREME terminal tasks and

resources using the terminal’s exclusive shared memory design. For example, to

monitor a scale gross weight, the JagBASIC program relates a BASIC variable to the

terminal shared data variable for gross weight then uses the BASIC variable as desired.

All of the shared memory in the terminal may be accessed by the JagBASIC program

using this construct.

The high level of integration permits the programmer to exploit the standard functions in

the JAGXTREME terminal, making it easier to implement solid solutions in record time.

To print a standard ticket or report, a JagBASIC program can load data into a

JAGXTREME terminal shared data variable then print by using a standard template that

is designed in the terminal setup. Rather than monitoring setpoint coincidence in the

JagBASIC program, a standard setpoint shared data variable can be loaded in the

program then monitored by an associated JAGXTREME terminal scale task.

JAGMAX

The optional JAGMAX software enables the JAGXTREME terminal to be used in a truck

stop weigh station application. With the JAGMAX software, trucks can be weighed in Idle

Mode, Semi-Automatic Mode, and Automatic Mode.

(02/05)

1-7

Page 22

METTLER TOLEDO JAGXTREME Terminal Technical Manual

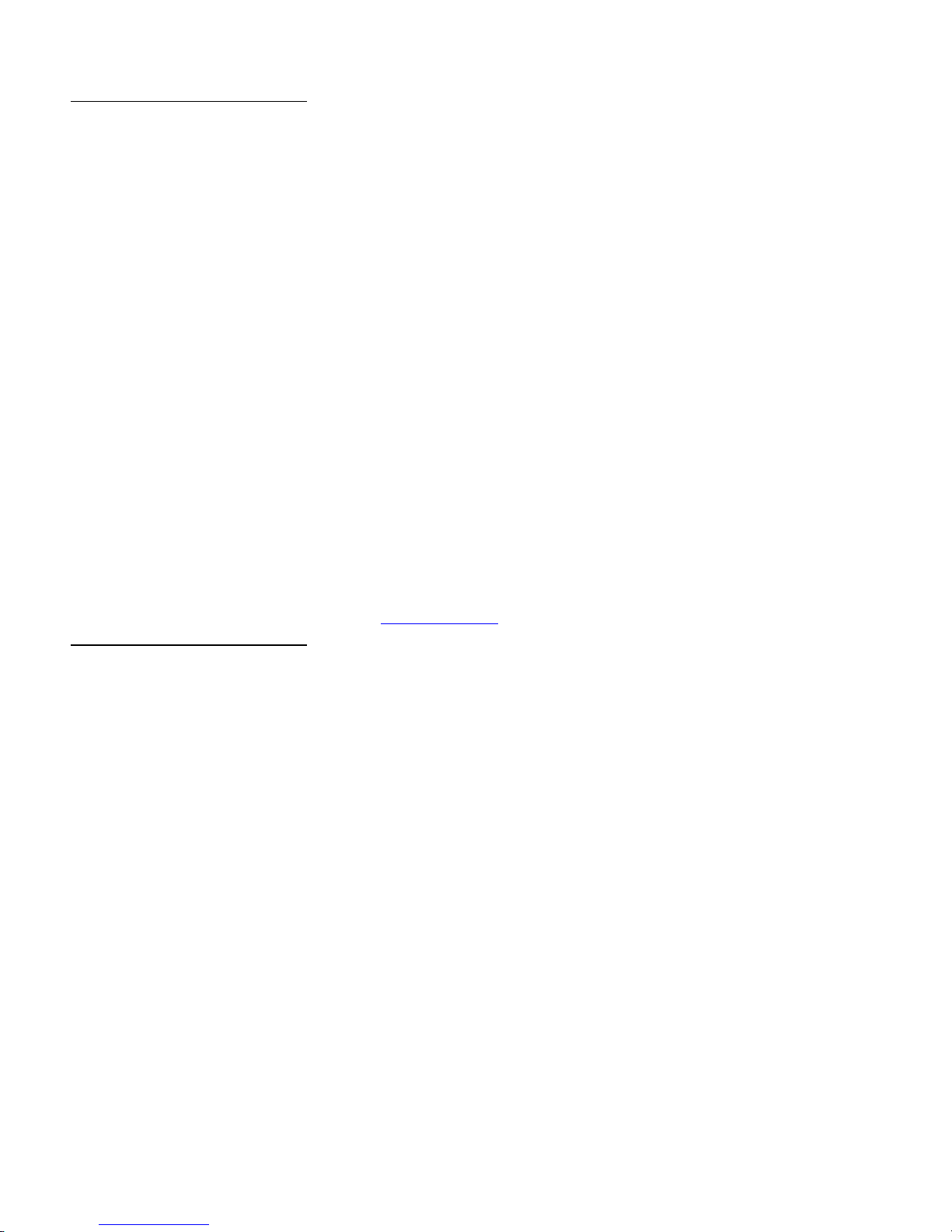

Specifications

Model General Purpose Panel Mount Panel Mount – Blind Chassis Harsh Environment/Harsh with

Dimensions

Construction

Mounting Options

Degree of

Protection

Ethernet

Connection

Attachable

Platforms

Display

Keypad

Interfaces

A/D Rate

Digital

Input/Output

Maintenance

Monitoring

Signal Processing

Power

Requirements

Setup

Scripting Language

Operating

Temperature

Storage

Temperature

Options

Approvals

10.05 in (255 mm) wide x

7.86 in (200 mm) high x 10.6

in (270 mm) deep

Column, desktop Panel Blind panel Wall, column

Designed to TYPE 4X standards Designed to TYPE 4X standards

10BASE-T. Uses crossover cable from RJ-45 Ethernet port on the back of the JAGXTREME terminal to a PC (point to-point connection) or

standard cable to connect to other equipment through a hub.

4 analog, 4 POWERCELL

®

up to 3 POWERCELLs, 2 analog and 2 POWERCELLs, 1 PC with 1 IDNET and 1 DigiTOL

Upper display: 7 segment 0.5" (13 mm); lower display: 16-character, 5 x 7 dot matrix display 0.25" (6 mm)

TraxEMT™ Embedded Maintenance Technician system for self-diagnosis and predictive failure analysis

Analog, Dual Analog, Analog Reduced Excitation, Dual Analog Reduced Excitation, Dual Analog Output, Modbus Plus, Profibus, A-B RIO,

Multifunction I/O, IDNet, POWERCELL, PCJagBASIC EDITOR, JAGMAX Truck Scale Software, HMI Pedestal or Panel, ControlNet/Ethernet IP

Class III and IIIL non-automatic weighing instruments as defined in the National Standards Commission, Document 100

10.05 in (255 mm) x 5.6 in

(140 mm) at front of terminal

9.5 in (240 mm) x 4.91 in

(125 mm) at the rear

8.03 in (210 mm) deep

Aluminum Stainless steel

(front panel)

,

2 IDNET, 2 DigiTOL®, 1 single analog and 1 single IDNET, 1 single analog and 1 DigiTOL, 1 single analog and

4 x 5 matrix tactile-feel keypad with 0-9, letters A-Z, and function keys

85 to 264 VAC with a line frequency of 47 to 63 Hz

Via embedded web server, with the front keypad or using the JagXFILES tool box.

14° F to 104° F (-10° C to 40° C) at 10% to 95% relative humidity, non-condensing

40° F to 140° F (-40° C to 60° C) at 10% to 95% relative humidity, non-condensing

90/384/EU – Non-automatic Balances and Scales

EN45501:1992 – Adopted European Standard

NTEP Certificate of Conformance No. 94-096A4

10,000 division rating and approval AM-5041

10.75 in (270 mm) x 4.91 in

(124 mm) at base

10.25 in (260 mm) x 3.91 in

(100 mm) c-c mounting

9.5 in (241 mm) x 5.00 in

(130 mm) chassis

Designed to TYPE 1 standards CERTIFIED TYPE 4, TYPE 12

Two vacuum fluorescent displays.

Ethernet, serial, discrete, PLC, analog

>300 per second

Maximum 12 in/12 out

TraxDSP

three-stage filtering

®

JagBASIC (standard)

CE Conformity

89/336/EU—EMC Directive

EN55022, 1998, Class A

Weights and Measures (US)

Class III or IIIL devices

Weights and Measures (Canada)

Weights and Measures (Australia)

Graphical Display

12.62 in (321 mm) x 9.56

(242.8) x 9.42 (239.3 mm)

1-8

(02/05)

Page 23

Display and Keypad

Chapter 1: Introduction

Specifications

Alphanumeric Display (xA)

The JAGXTREME terminal contains two vacuum fluorescent displays and a 4 × 5 matrix

tactile feel keypad in a diecast, zinc-aluminum alloy front housing.

The upper weight display is a seven-digit, seven-segment 0.5 in. (13 mm) high

vacuum fluorescent numeric display used to indicate weight values. Each of the seven

digits has a decimal point/comma and an annunciator associated with it. The

annunciators are used to indicate gross or net weights, a preset tare value, pound or

kilogram weights, the center of zero, and motion.

The lower display is a 16-character, 5×7 dot matrix, 0.25 in. (6 mm) high vacuum

fluorescent alphanumeric display. Each character has a period/comma and an

annunciator associated with it. This display is used to indicate tare, alternate weight

units, operator prompting, errors and other messages. The first 10 annunciators are

used to indicate which terminal number (1 through 6) and internal scale (A-D) are

currently displayed. The remainder indicates summation and weighing range.

The lens on both the general purpose and panel-mount models are polycarbonate with

hardcoating. The harsh environment model lens is polyester with hardcoating.

The keypad consists of a tactile-feel membrane switch covered with a polyester overlay.

Audible beeps sound when a key is depressed. The keypad contains the numbers 0 -9

and the letters A - Z. Other function keys include Escape, Memory, Tare, Select, Clear,

space, decimal point, Zero, Enter, and Function.

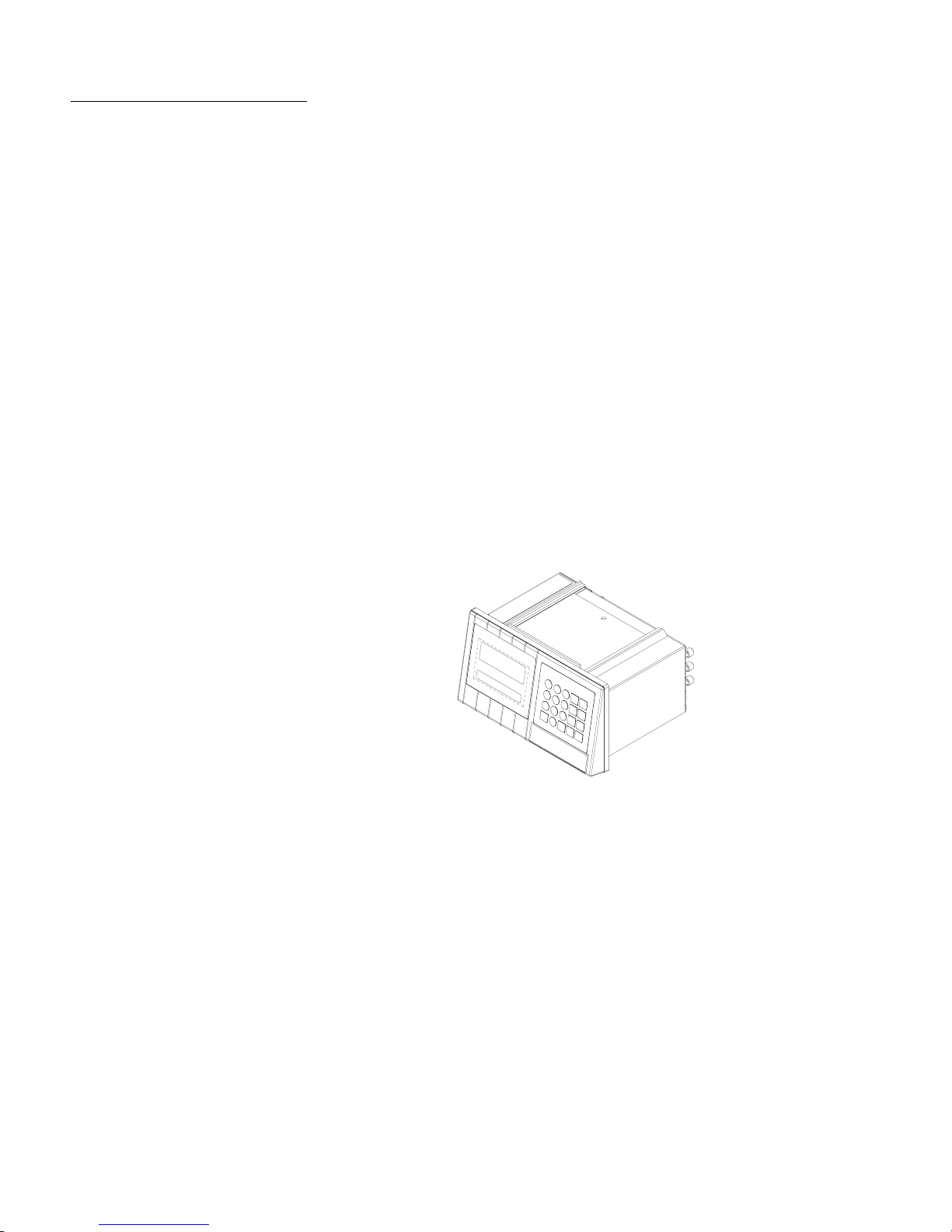

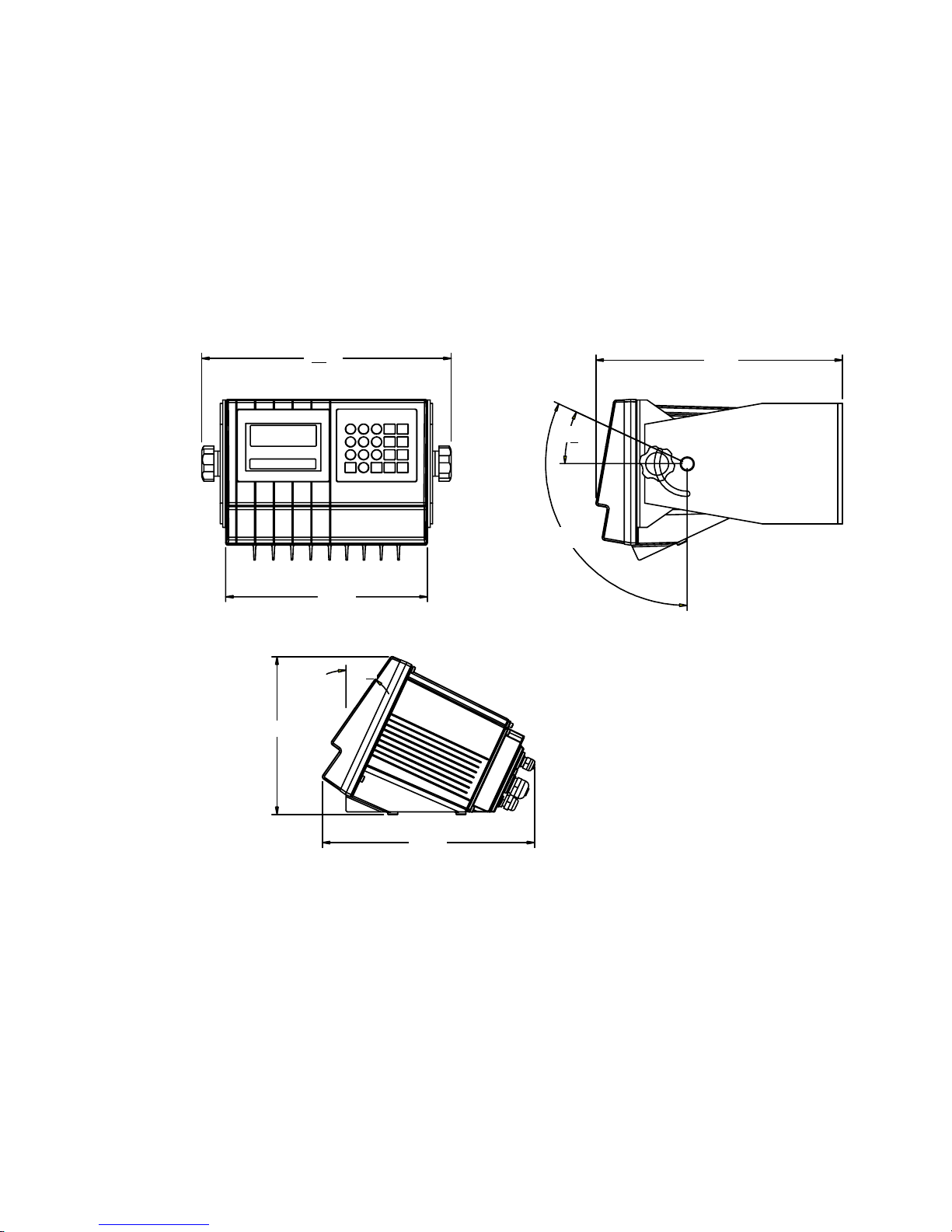

1-a: Display and keypad on panel-mount version of the JAGXTREME terminal

(02/05)

1-9

Page 24

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Physical Dimensions

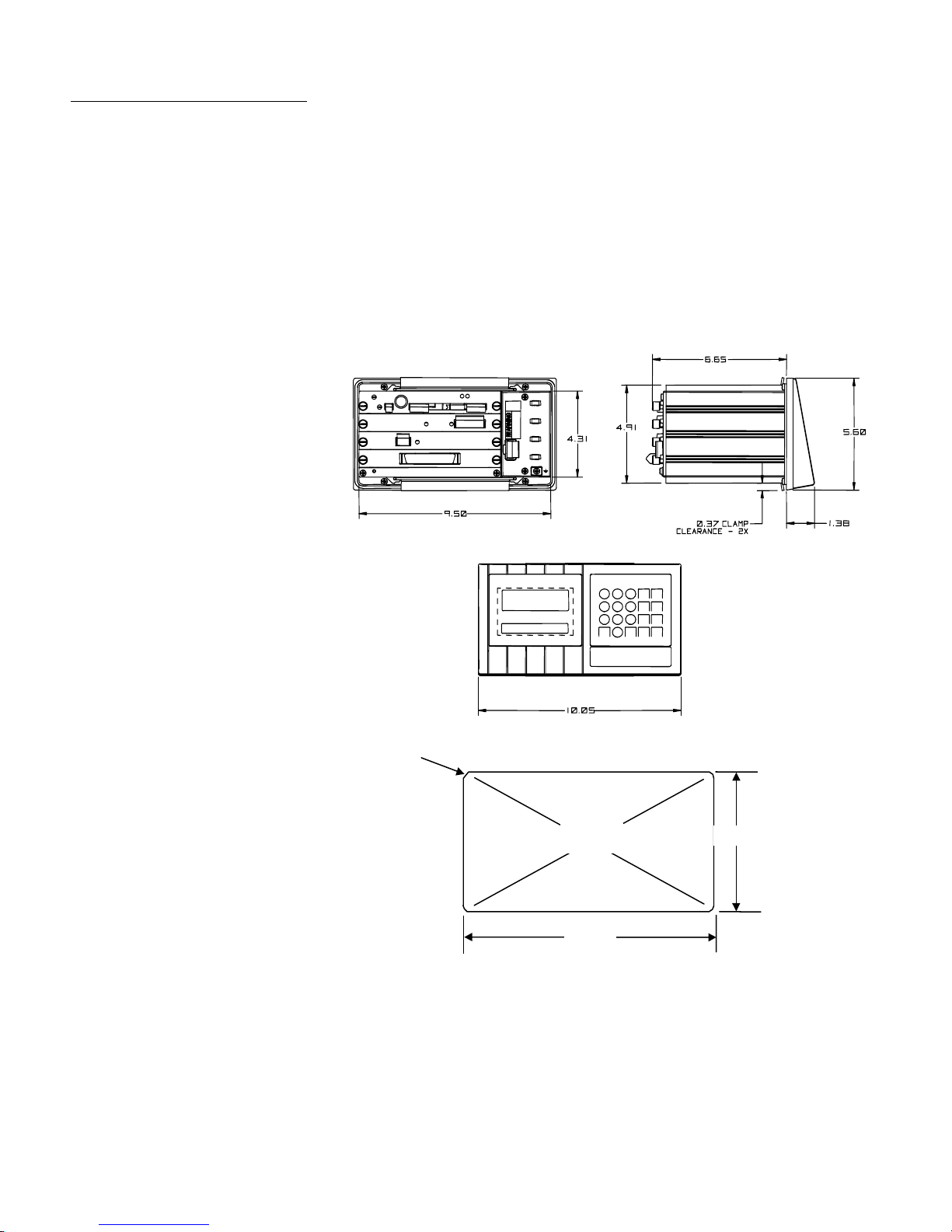

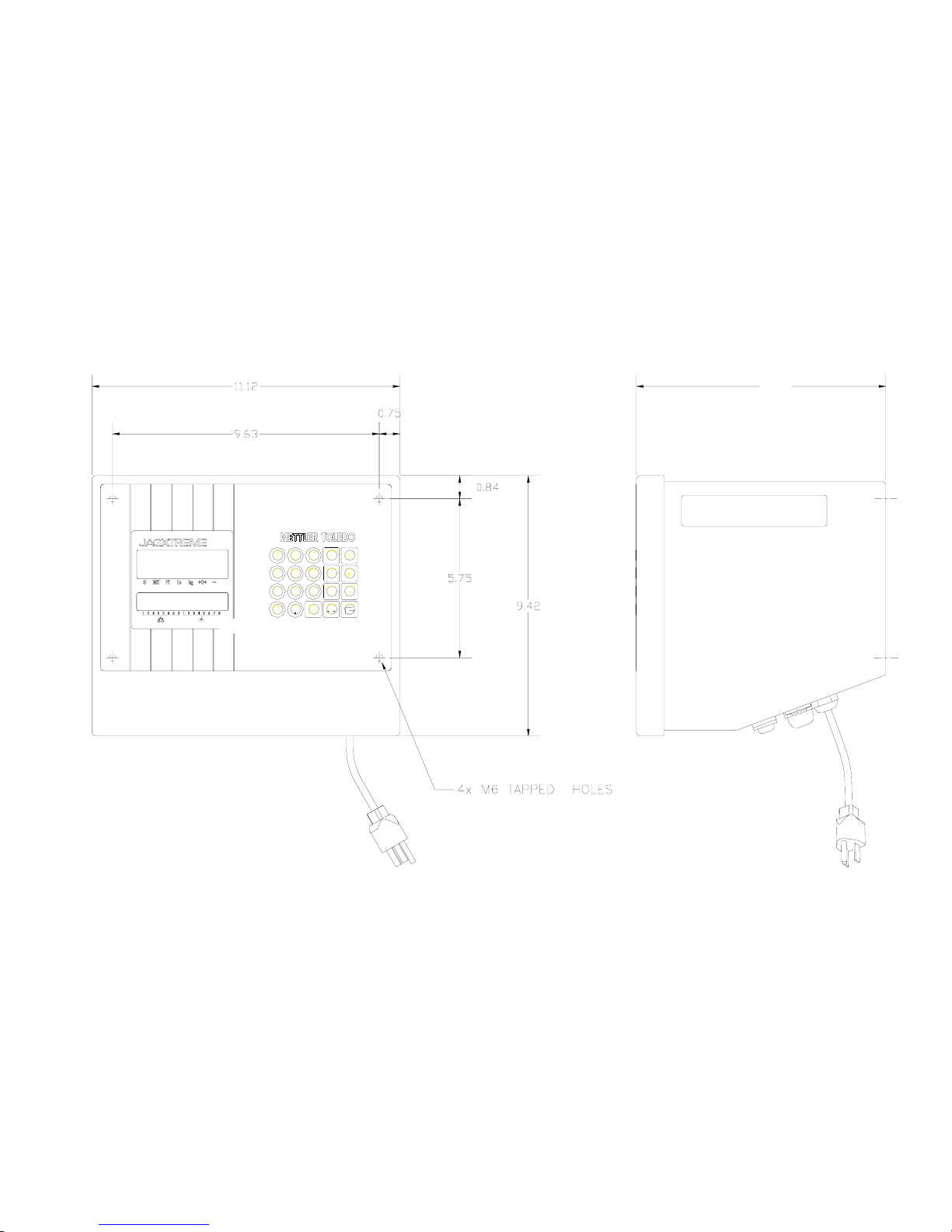

Panel Mount Enclosure—Alphanumeric (PA)

Two integral brackets are used to mount this unit through a flat panel. The front panel

and associated panel clamping mechanism are designed to provide a TYPE 4 seal and

accommodate a panel thickness from 16 to 11 gauge.

The panel-mount model measures:

• 10.05 in. (255 mm) × 5.6 in. (140 mm) at the front of the terminal

• 9.5 in. (240 mm) × 4.91 in. (125 mm) at the rear

• 8.03 in. (210 mm) deep

4XR 0.25±.01

OPEN

Abra

9.58±.06

5.12±.0

1-10

(02/05)

Figure 1-b: JAGXTREME Panel Mount Model and Cutout Dimensions

Page 25

Chapter 1: Introduction

Specifications

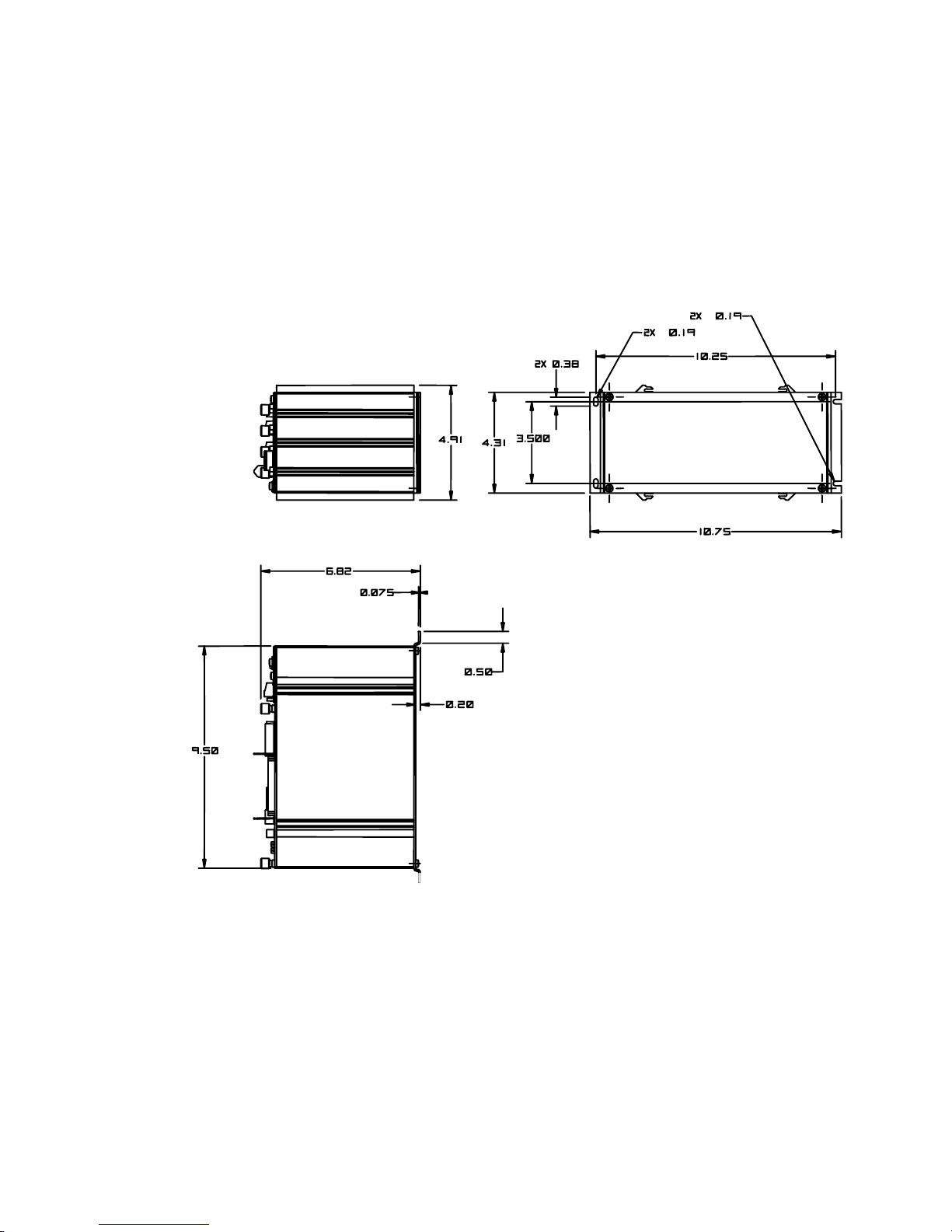

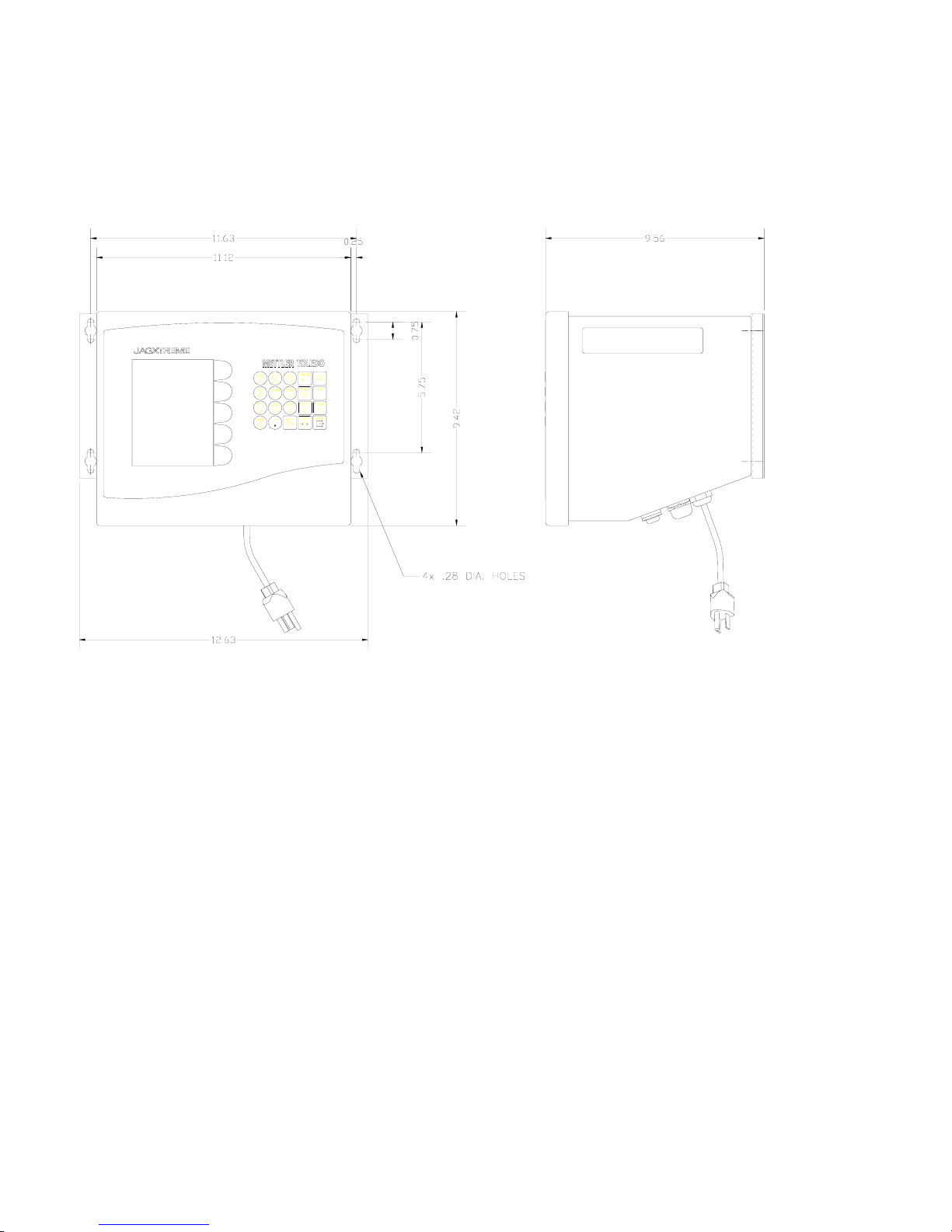

Panel Mount Enclosure—Blind Chassis (PB)

The front of the panel mount enclosure has a blank plate to cover the electronics and to

provide a method of mounting. There is no keyboard or display on the front of the unit.

This allows the terminal’s use as a “blind” terminal (installed behind a panel,) sharing

another JAGXTREME terminal’s keyboard and display via the Ethernet connection. The

terminal enclosure designed to TYPE 1 requirements with a “blind” front panel.

The blind chassis mount model measures:

10.75 in. (270 mm) × 4.91 in. (125 mm) at the base

10.25 in. (260 mm) × 3.91 in. (100 mm) c-c mounting

9.5 in. (241 mm) × 5.00 in. (130 mm) chassis

Figure 1-c: JAGXTREME Blind Chassis Model Dimensions

(02/05)

1-11

Page 26

METTLER TOLEDO JAGXTREME Terminal Technical Manual

General Purpose Enclosure (GA)

This enclosure, which is designed to provide TYPE 4X protection, is a die-cast zincaluminum alloy with an aliphatic urethane powder-coated finish. The unit is designed

to sit on a flat surface or may be wall- or column-mounted with an accessory bracket kit

(0917-0209). The rear cover contains grip bushings to seal all cables entering the

enclosure.

The general-purpose JAGXTREME terminal model measures:

10.05 in. (255 mm) wide × 7.86 in. (200 mm) high x 10.6 in. (270 mm) deep

In figure 1-d, the top views show optional wall/column brackets (P/N 0917-0209).

7.85

12.45

10.05

39°

12.31

29°

°

115°

°

°

1-12

(02/05)

10.59

Figure 1-d: JAGXTREME General Purpose Model Dimensions

Page 27

NOTE: Units sold prior to

July, 2001 may have

different dimensions. Refer

to the previous revision of

the JAGXTREME Terminal

Technical Manual for

information.

Chapter 1: Introduction

Specifications

Harsh Environment Enclosure (HA)

The harsh environment enclosure is designed to provide TYPE 4 and TYPE 12 protection

and is intended for applications in which the terminal is exposed to high humidity, direct

washdown, or corrosive environments. It is constructed of 304L stainless steel and

meets all US FDA and comparable European requirements.

A full 4-slot JAGXTREME terminal chassis is mounted inside the enclosure. All field

wiring enters into the unit through cable seals that maintain the washdown protection of

the enclosure. The cable seals are located at the bottom rear of the unit. Two brackets

are provided for wall mount applications. An interface adapter (0917-0233) is

available for column mount applications.

The harsh environment unit measures: 12.62 in (321 mm) x 9.56 (242.8 mm) x

9.42 (239.3 mm)

9.56

* Shown with wall mount brackets

(included with enclosure) installed.

Figure 1-f: Harsh Environment Model Dimensions

(02/05)

1-13

Page 28

METTLER TOLEDO JAGXTREME Terminal Technical Manual

Harsh Environment Enclosure (JXHG)

The JXHG (harsh environment enclosure with graphic display) is comprised of a

JAGXTREME chassis and a graphical display housed in an enclosure.

Dimensions: 9.42 x 12.62” x 9.56" (239.3 x 321 x 242.8 mm)

Figure 1-g

1-14

(02/05)

Page 29

Power Requirements

Chapter 1: Introduction

Specifications

85 to 264 VAC with a line frequency of 47 to 63 Hz.

Power consumption -- 20 Watts maximum.

Power termination -- single three-position removable terminal strip.

The wire size range -- 12 to 16 AWG.

Note: The integrity of the power ground for equipment is important for both safety and

dependable operation of the JAGXTREME terminal and its associated scale bases. A

poor ground can result in an unsafe condition if an electrical short develops in the

equipment. A good ground connection is needed to assure extraneous electrical noise

pulses are minimized. It is important that equipment does not share power lines with

noise generating equipment like heavy load switching, motor starter circuits, RF thermal

heaters, inductive loads and the like.

To confirm ground integrity, a commercial branch circuit analyzer is recommended. This

instrument uses a high amperage pulse to check ground resistance. It measures the

voltage from the neutral wire to the ground connection and will provide an assessment

of the line loading. Instructions with the instrument give guidelines about limits that

assure good connections.

The power line for the JAGXTREME terminal must not be shared with equipment such as

motors, relays, or heaters that generate line noise. If adverse power conditions exist, a

dedicated power circuit or power line conditioner may be required.

Controller PCB

When a Division 2 approved JagXtreme is installed in an area classified as Division 2

or Zone 2/22, special AC wiring requirements must be met. See document 16088600A,