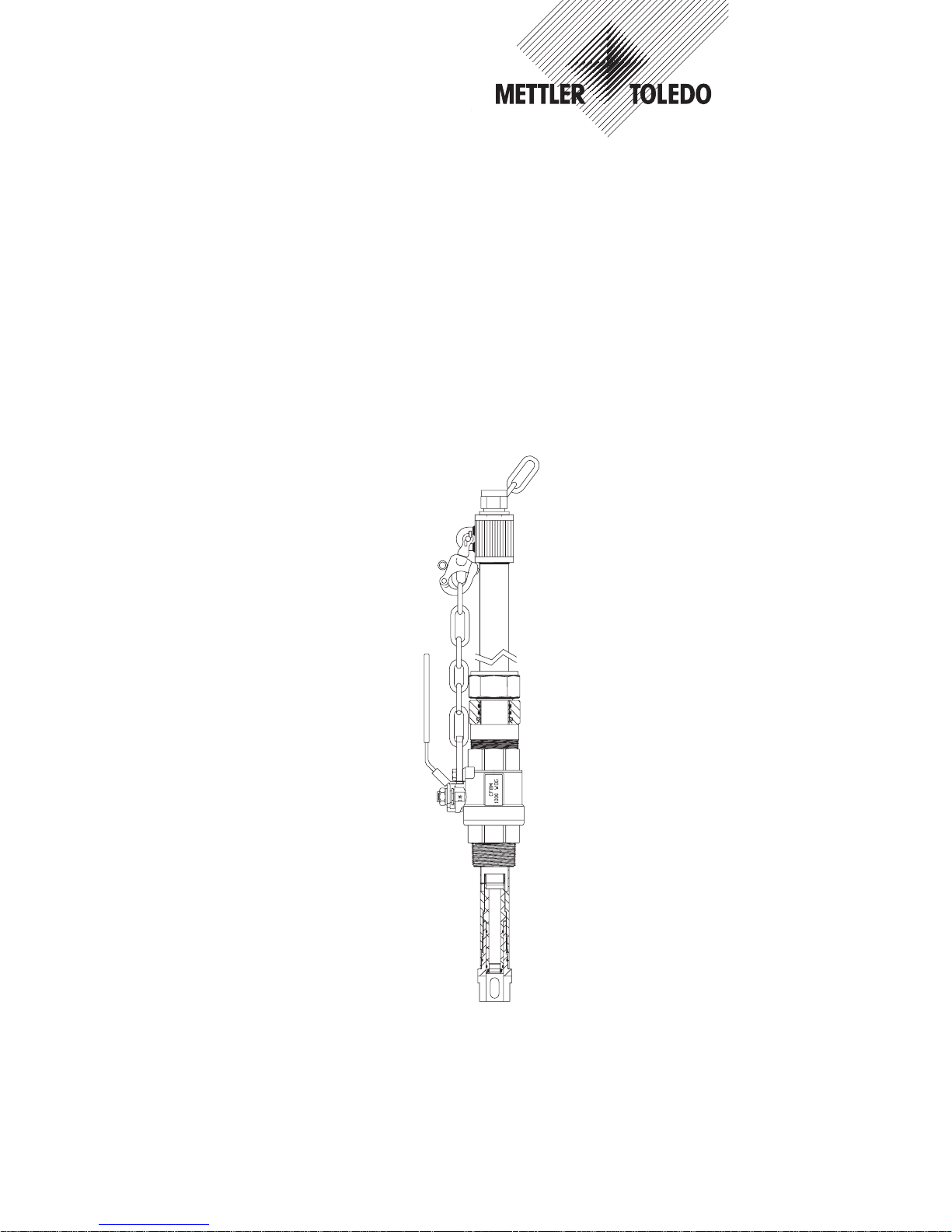

Mettler Toledo InTrac 787 Instruction Manual

In Trac 787-01-CH

52 402 481

InTrac®787

Instruction manual

Betriebsanleitung

Instructions d’utilisation

English Page 3

Deutsch Seite 19

Français Page 35

InTrac®787 3

© 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee InTrac 787-01-CH

Printed in Switzerland 52 402 481

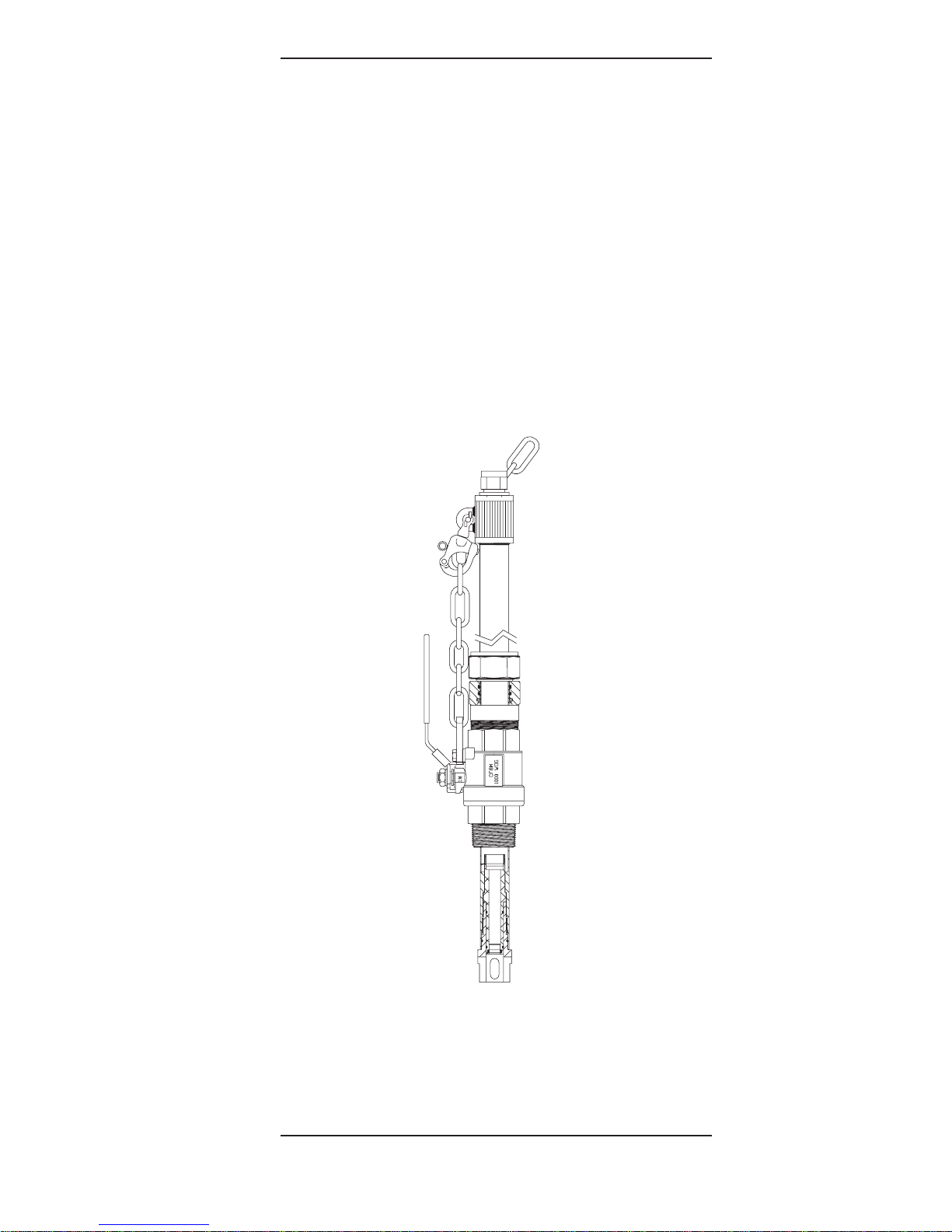

InTrac®787

Instruction manual

4 InTrac®787

InTrac 787-01-CH © 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee

52 402 481 Printed in Switzerland

Contents

1 Introduction..........................................................................5

2 Important remarks ................................................................6

2.1 Checking the shipment ...........................................................6

2.2 Notes on operating instructions ...............................................6

2.3 Normal use...........................................................................7

2.4 Safety instructions..................................................................7

3 Description of function..........................................................9

4 Installation/Startup and shutdown........................................10

4.1 Preparation of the equipment.................................................11

4.2 Fitting and installation works.................................................11

4.2.1 Attaching the flushing lines ...................................................11

4.2.2 Fitting the electrode/sensor....................................................12

4.4 Startup procedure.................................................................12

4.5 Shutdown procedure ...........................................................12

5 Maintenance ......................................................................13

5.1 Important information on maintenance ...................................13

5.2 Replacing seals in contact with the process medium................13

6 Trouble-shooting.................................................................14

7 Product specifications.........................................................15

7.1 Standard equipment.............................................................15

7.2 Technical data.....................................................................15

7.3 Spare parts list ....................................................................16

InTrac®787 5

© 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee InTrac 787-01-CH

Printed in Switzerland 52 402 481

1 Introduction

This operating instructions contains all the information needed

for safe and proper use of the retractable housings InTrac

®

787.

The operating instructions are intended for personnel entrusted

with the operation and maintenance of the retractable housings.

It is assumed that these persons are familiar with the equipment

in which the retractable housing is installed.

Construction of the retractable housings employs leading-edge

technology and complies with safety regulations currently

in force (Mettler-Toledo GmbH as the manufacturer has been

awarded ISO 9001/ EN29001 certification). Notwithstanding

this, improper use could lead to hazards for the user or a thirdparty, and/or adverse effects on the plant or other equipment.

Therefore, the operating instructions must be read and under-

stood by the persons involved before work is started with the

retractable housing.

In addition to these operating instructions, you should also be

familiar with the following:

– all local safety regulations.

– all information and warnings in the documentation dealing

with the products used together with the retractable housing

(electrodes/sensors, control system, etc.).

– all safety regulations governing the equipment in which the

retractable housing is installed.

– all information and warnings affixed to the retractable hous-

ing.

6 InTrac®787

2 Important remarks

Please read through this section carefully. It contains several

important points which will help you use the retractable housing in a safe and proper manner.

2.1 Checking the shipment

On receipt of the shipment, check immediately:

• the retractable housing and accessories for transport damage. Report any damage immediately to the carrier and your

supplier.

• the type designation on the housing body.

• the shipment for completeness. Please notify your supplier

immediately if the shipment is incomplete (see Section 7.1

“Standard equipment”) or does not concur with the order and

delivery documents.

2.2 Notes on operating instructions

Restriction

The information contained in this operating instruction applies

only to the InTrac

®

787. Detailed information on the electrodes

and their installation is not given in these instructions. Such information can be found in the separate documentation accompanying these products. Where necessary, appropriate cross-references to such publications are given in these operating

instructions.

Conventions

This pictogram represents safety and hazard warnings which,

if ignored, could result in injuries to personnel and/or material

damage.

Storage

Please keep these operating instructions in a safe place where

they are always accessible. If these instructions are lost, please

contact your supplier for a replacement.

InTrac 787-01-CH © 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee

52 402 481 Printed in Switzerland

2.3 Normal use

The InTrac®787 is intended solely for measurement with the

specified METTLER TOLEDO 12 mm pH and redox screwcap

electrodes as well dissolved oxygen sensors.

Use the retractable housings solely for this purpose. Usage which

differs from or exceeds this normal usage will be regarded as

usage not for the intended purpose.

The manufacturer/supplier accepts no responsibility for any

damage resulting from such improper usage. The risk is borne

entirely by the user.

Normal use also includes:

– Compliance with the instructions, regulations and informa-

tion in this operating instruction for the InTrac®787 retractable housings.

– Adherence to the stipulated inspection and maintenance

intervals.

– Correct maintenance of the retractable housing.

– Operation with due observance of the stipulated environmen-

tal and operating and the admissible mounting positions.

2.4 Safety instructions

The retractable housings InTrac®787 should be installed, operated, maintained and, if need be, repaired only by personnel

familiar with the housing and who are qualified for such work.

The customer is responsible for ensuring that:

– only trained and authorized personnel work with the

retractable housings.

– the operating instructions should be supplemented by in-

house instructions regarding supervisory duties and obliga-

tion to report, work organization, personnel qualification, etc.

– the chain has to be always adjusted to the shortest possible

length.

Ensure that the material specification of your retractable housing and of the seals satisfies the requirements of the process and

is compatible with the (vessel) cleaning solutions used.

Before every startup, the retractable housing must be checked

for:

– damage to the connections, fastening, etc.

– leaks

A defective retractable housing must neither be installed nor

put into service. If it is suspected that hazard-free operation is

no longer possible (e.g. housing damaged, connections leaking), the retractable housing and the equipment in which the

retractable housing is installed must be shut down and secured

against inadvertent operation.

InTrac®787 7

© 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee InTrac 787-01-CH

Printed in Switzerland 52 402 481

8 InTrac®787

Before dismounting the entire retractable housing or commencing any maintenance work on it, ensure that the equipment in

which the housing is installed is in a safe condition (depressurize, empty, rinse, purge, vent, etc.).

In the measuring position no maintenance work must be

done.

Only the maintenance and repair work described in these operating instructions may be performed on the retractable housings.

When changing faulty components, use only original spare

parts obtainable from your supplier.

No attachments or modifications to the retractable housings

and the accessories are allowed. The manufacturer/supplier

accepts no responsibility for damage caused by unauthorized

attachments and modifications or the incorporation of non-original spare parts. The risk is borne entirely by the user.

The rinse connections of the InTrac®787 have a direct connection to the process when the ball valve is open. This means that

you will have the effective process pressure on the rinsing tubes

as well. Never do any manipulation on this connections while

the ball valve is open.

InTrac 787-01-CH © 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee

52 402 481 Printed in Switzerland

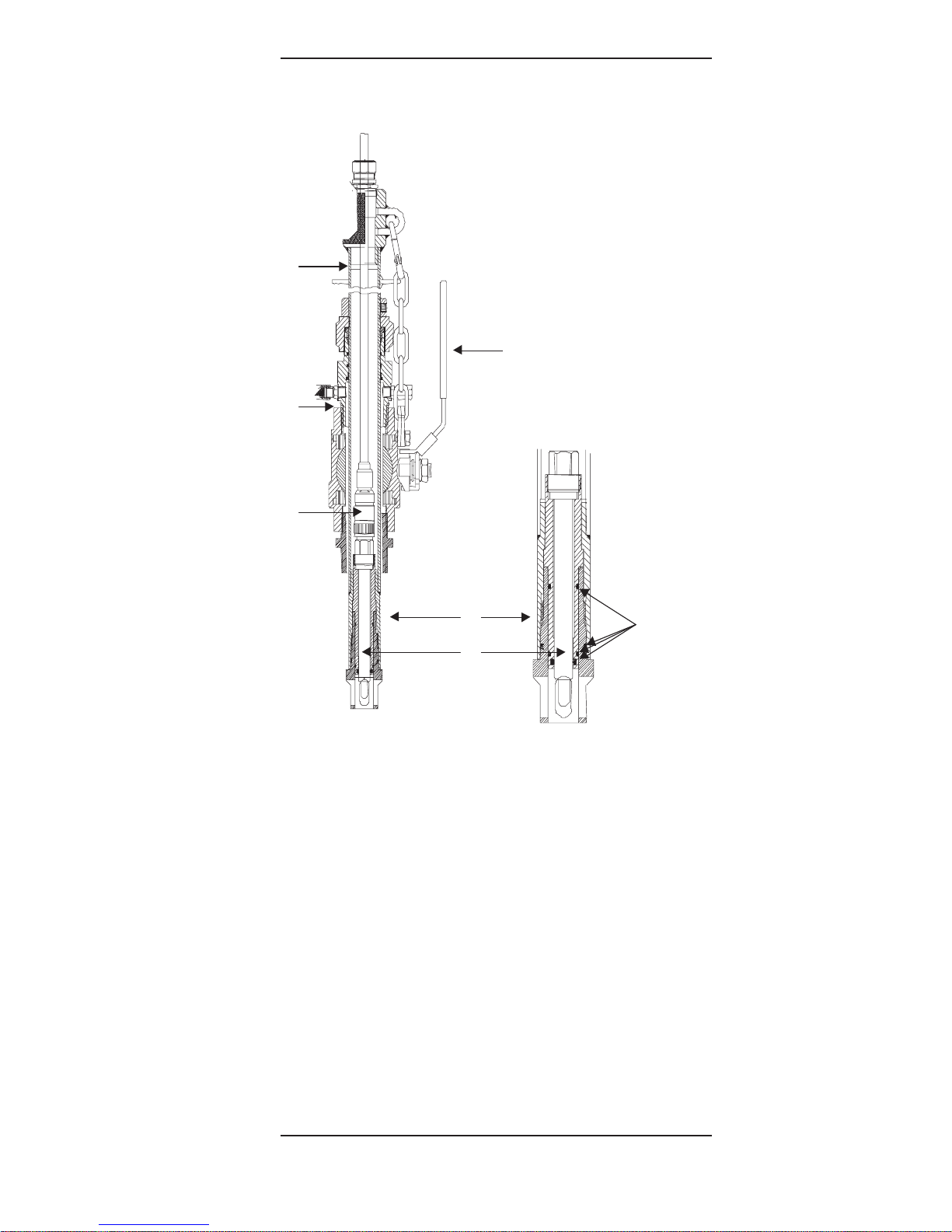

3 Description of function

With the InTrac®787 retractable housings, electrodes can be

cleaned or replaced without interrupting the ongoing process.

The process can be closed safely with the integrated ball valve.

The integrated flushing port allow a rinsing of the electrode in

the housing.

The immersion tube is moved into the desired end position

(“Measuring” or “Maintenance”) by hand.

– In the “Measuring” position, the immersion tube is fully in-

serted in the process.

– In the “Maintenance” position, the electrode can be cleaned

or removed/exchanged. The ball valve seals the housing

against ingress of process medium.

InTrac®787 9

© 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee InTrac 787-01-CH

Printed in Switzerland 52 402 481

10 InTrac®787

4 Installation/Startup and shutdown

4.1 Preparation of the equipment

The housings are mounted and fixed on the vessel (reactor, tank,

pipe, etc.) a flange connection or a 1” MNPT external (male)

thread.

– The retractable housing should be mounted in a position

which allows sufficient clearance for its correct functioning

(correct measuring position in the medium) and maintenance (checks, installation and removal of the electrodes/

sensors).

– Avoid mounting the retractable housing at exposed posi-

tions. If this is not possible, appropriate measures must be

taken to protect against damage.

4.2 Fitting and installation works

Warning! For all installation work described below, ensure that

the equipement in which the housing is installed is in a nonhazardous condition (depressurized, empty, rinsed, purged,

etc.).

4.2.1 Attaching the flushing lines

Important information

– When the electrode/sensor is withdrawn, small amounts of

the process medium adhere to the electrode/sensor tip and

can enter the outflow line during the rinsing process. If the

process medium is an environmentally harmful substance

(toxic, corrosive, etc.), it is essential to comply with the local

regulations governing the installation of wastewater services.

– Use only corrosion-resistant and chemically resistant mate-

rials for the rinsing water installation.

Recommendation for proper operation and safe use

Flushing lines must be equipped with valves which may only be

opened when the retractable part of the housing is in the maintenance position. After the flushing and maintenance of the sensors, the flushing valves must be closed.

Basic installation

The basic installation is intended for cleaning/flushing of the

electrodes/sensors when the housing is in the “Maintenance”

position. In the optional accessories you will find Serto or

Swagelok fitting to connect your flushing lines. The position of

the Inlet and Outlet has nor influence to the performance.

InTrac 787-01-CH © 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee

52 402 481 Printed in Switzerland

4.2.2 Fitting the electrode/sensor

InTrac®787 11

© 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee InTrac 787-01-CH

Printed in Switzerland 52 402 481

1. Pull out the immersion tube.

2. Close the ball valve.

3. Disconnect the immersion tube right at the ball valve.

4. Disconnect the electrode holder by turning it counterclockwise.

5. Disconnect the electrode cable.

6. Remove the electrode.

7. Check washers and O-rings on electrodes for damage

and replace if necessary.

8. Remove watering cap from electrode tip and rinse electrode/

sensor with water.

9. Carefully insert the electrode into the electrode holder and

screw in by hand as far as it will go. Important: use no tools!

10. Re-Install the complete housing.

1

2

3

4

5

6

7

12 InTrac®787

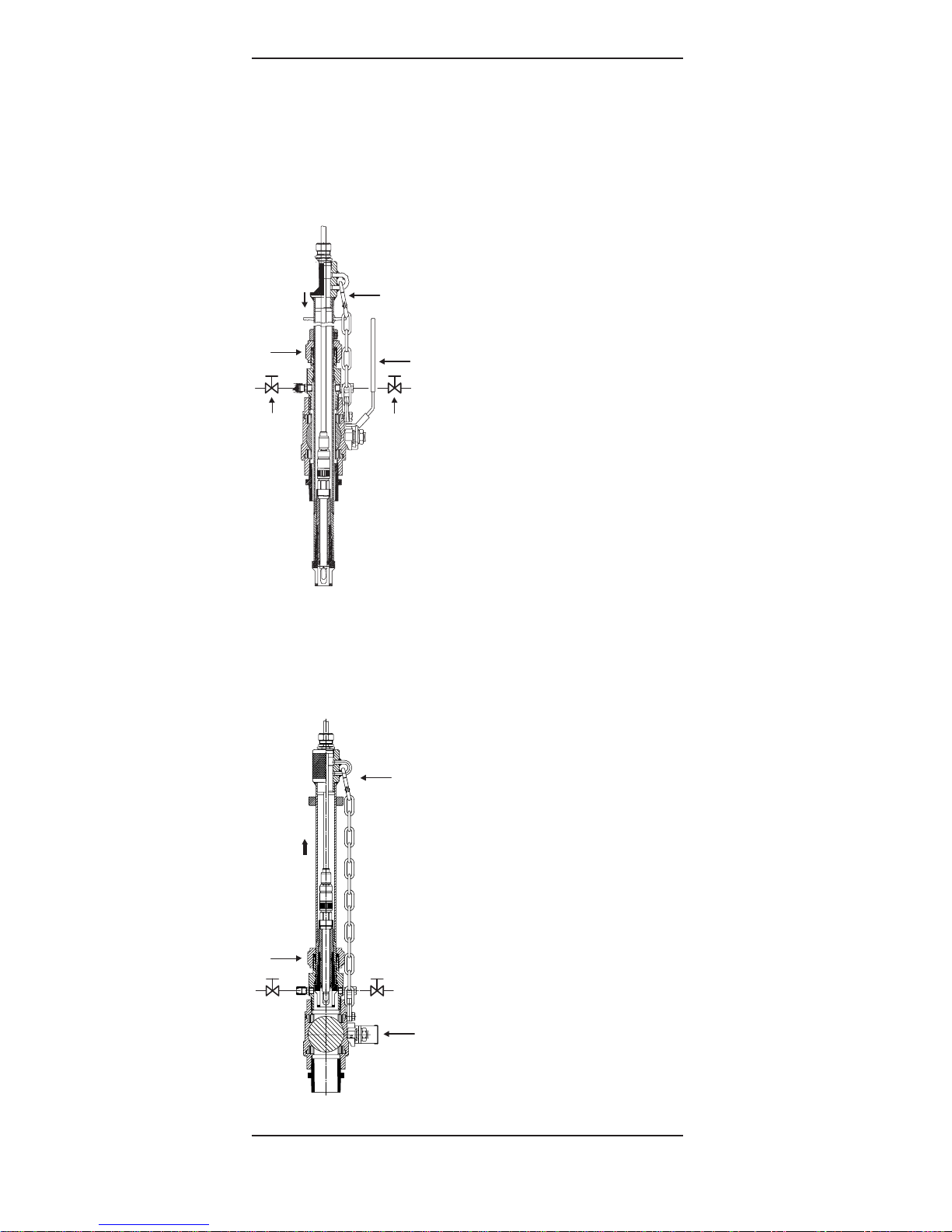

4.3 Startup procedure

Before startup, all fitting and installation work must have been

completed and the immersion tube must be secured to the ball

valve with the safety chain!

InTrac 787-01-CH © 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee

52 402 481 Printed in Switzerland

4

2

1

3

1

5

1

4

3

2

1. Warning! Close the valves on both con-

nections of the flushing chamber. Otherwise process media can escape while the

ball valve is opened!

2. Open the ball valve.

3. Carefully push the immersion tube by

hand into the process.

4. Secure immersion tube in this position by

tightening the locking nut.

5. Shorten the safety chain to the shortest

possible length.

4.4 Shutdown procedure

1. Loosen the locking nut.

2. Hold immersion tube, then disconnect

the safety chain.

3. Move immersion tube by hand to “Maintenance” position.

4. Close the ball valve.

5. Caution! Make sure that the process ves-

sel or line is in a non-hazardous condition (depressurized, empty, rinsed,

purged, etc.) when the housing has to be

removed.

5 Maintenance

5.1 Important information on maintenance

Attention! Maintenance and service work on the housings may

only be carried out by trained personnel.

Warning! It is possible that the process medium could harm the

environment and your health (toxic, corrosive, etc.). Hence,

ensure that the equipment is in a non-hazardous condition

before you start with maintenance work.

– The electrode and housing must kept clean.

– Replace any damages seals or components of the housing

– Details in the maintenance of the electrode are contained in

the electrode operation instructions.

5.2 Replacing seals in contact with the

process medium

All seals which come into contact with the process medium

should always be replaced at least once a year for reasons

of safety.

With corrosive media, the seals may need to be changed at correspondingly shorter intervals.

Warning!

– Retractable housings may only be stripped down after hav-

ing been completely dismounted.

– Check the quality of the seals and examine for possible dam-

age. Ensure correct positioning.

InTrac®787 13

© 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee InTrac 787-01-CH

Printed in Switzerland 52 402 481

14 InTrac®787

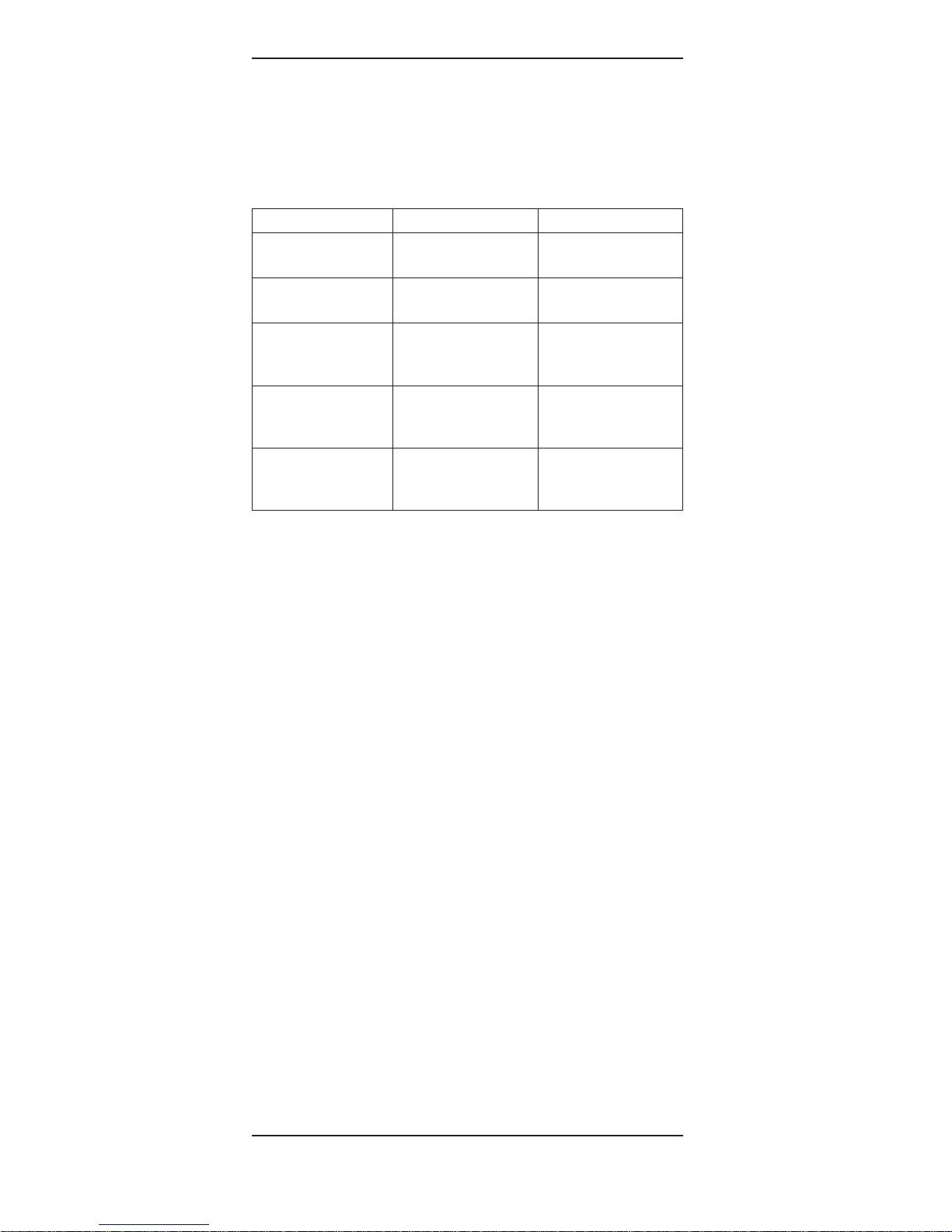

6 Trouble-shooting

In this section you will find an overview of possible malfunctions

which can occur during operation of the retractable housing, as

well as information on how to rectify them.

Malfunction Cause Remedial action

InTrac 787-01-CH © 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee

52 402 481 Printed in Switzerland

Immersion tube con

not be inserted.

Ball valve is not completely opened.

Check the ball valve

position.

Immersion tube can

not be pulled out.

Retention nut is not

open.

Loosen the retention nut.

Immersion tube can

not be pulled out

completely.

Ball valve is not completely opened.

Ceck the ball valve

position.

Process liquid is flowing out of the rinsing

chamber.

Rinsing chamber is not

closed.

Close the outlet of the

rinsing chamber with

covers or with valves.

Process fluid is entering into the immersion

tube.

O-ring defective. Replace the O-ring in

the electrode holder

(order O-ring set)

7 Product specifications

7.1 Standard equipment

InTrac®787 is supplied with:

– Immersion tube (100mm or 300mm)

– Electrode holder

– Ball valve

– Safety chain

– Electrode holder

– Threat connector 1

1

/2”

– Nut to secure immersion tube

7.2 Technical data

Dimensions see dimensional drawing

Maximum Pressure* 9 bar (130 psi)

Maximum Temperature* 140°C ( 266°F)

Insertion Length variable 0 to 100 (300) mm /

0” to 4(12)”

Wetted Parts Housing: 316L Stainless Steel (3.1B)

O-Rings: Viton

®

Ball valve: Ball 316 (1.4401)

Housing CF-8M (1.4408)

Sealing PTFE

Ball Valve DN40, 1.5” NPT full port

* See electrode specification

InTrac®787 15

© 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee InTrac 787-01-CH

Printed in Switzerland 52 402 481

16 InTrac®787

InTrac 787-01-CH © 02/02 Mettler-Toledo GmbH, CH-8606 Greifensee

52 402 481 Printed in Switzerland

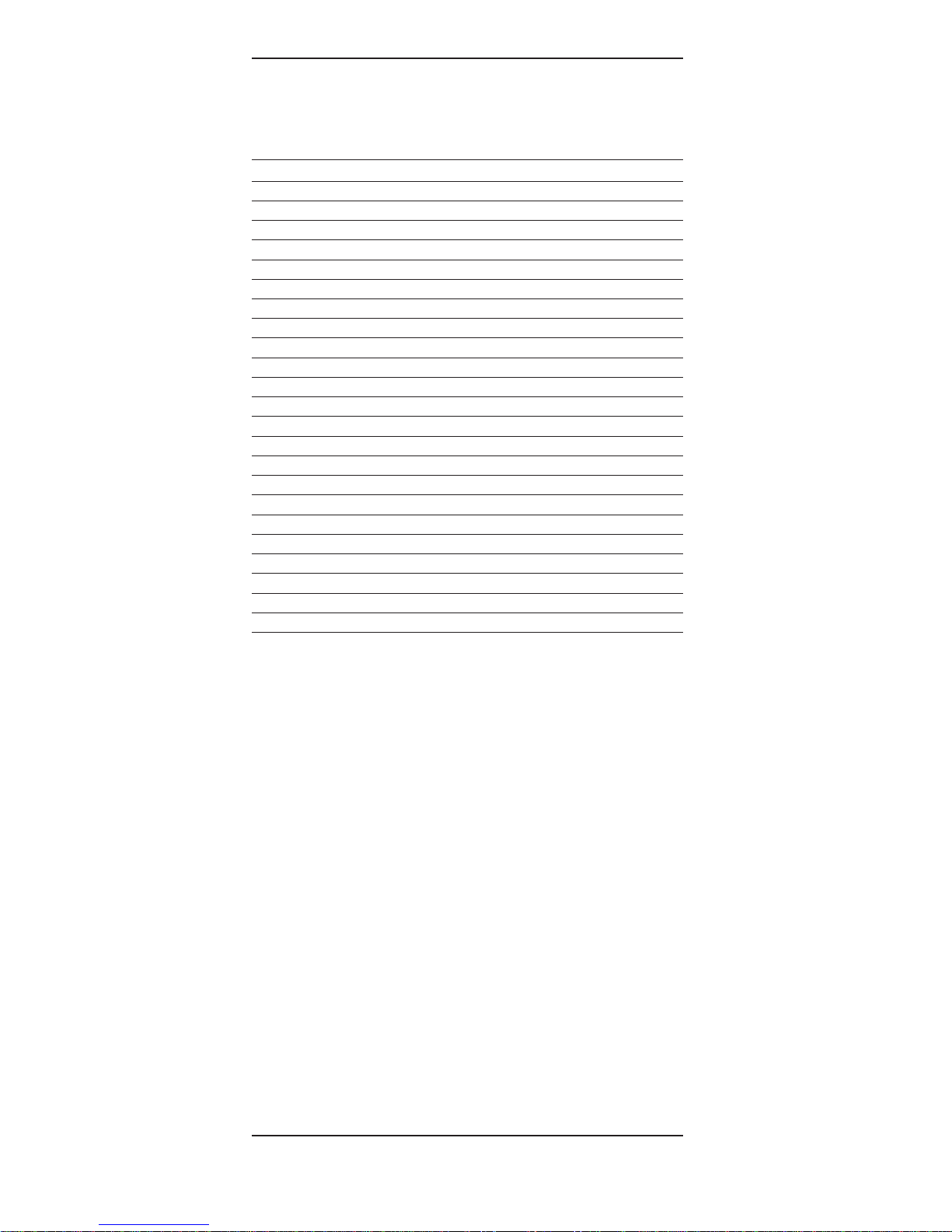

7.3 Spare parts list

Order No. Description

52402422 Ball Valve DN40-1 1/2” NPT 3.1B

52402421 Double nipple 1 1/2” NPT / 787

52402403 O-Ring-Set InTrac®787 Vi(5)cpl.

52402463 O-Ring Set Electr.-hold 787 Vi

52402464 Flushing chamber 787

52402469 Electrode holder 787cpl. 120mm

52402470 Chain 787 cpl.

52402471 Cable fitting 787 cpl.

52402465 Fitting set 787 6 mm SERTO

52402467 Fitting set 787 6 mm SWAGELOCK

52402466 Fitting set 787 6.35 mm SERTO

52402468 Fitting set 787 6.35 mm SWAGEL.

52402402 InTrac®787/300

52402401 InTrac®787/100

52402389 Imm. tube 787 cpl. 100 mm 3.1B

52402390 Imm. tube 787 cpl. 300 mm 3.1B

52402362 Basket guard 787 120 mm 3.1B

52402404 Flange C40 DIN 2566 1 1/2” NPT

52402423 Spanning nut 787

52402391 Spanner ring 787

52402481 Instruction manual InTrac®787 (g,e,f)

52402504 Flyer InTrac®787 (d)

52402505 Flyer InTrac®787 (e)

52402506 Flyer InTrac®787 (f)

Loading...

Loading...