Mettler Toledo InSUS Instruction Manual

InSUS Head

30 283 375 C

InSUS Head for Optical

Single-Use O2Sensors

Instruction manual

Bedienungsanleitung

Instructions d’utilisation

2 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

English Page 3

Deutsch Seite 23

Français Page 43

InSUS Head 3

© 10/2018 Mettler-Toledo GmbH InSUS Head

Printed in Switzerland 30 283 375 C

InSUS Head for Optical

Single-Use O2Sensors

Instruction manual

4 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

1 Introduction.....................................................................5

2

Important notes ...............................................................6

2.1 Notes on operating instructions ..........................................6

2.2 Intended use ....................................................................6

2.3 Safety instructions.............................................................7

2.4 Examples of some typical applications................................7

3

Product description..........................................................8

3.1 General information ..........................................................8

3.2 Principle ..........................................................................8

3.3 Scope of delivery ..............................................................9

4 Installation....................................................................10

4.1 Connection ....................................................................10

4.1.1 Connection of the single-use sensor to the InSUS head........10

4.1.2 Digital connection of the InSUS head to a transmitter...........10

4.1.3 Analog connection of the InSUS head to a tranmitter or

controller .......................................................................11

4.1.4 Power connection of sensor head .....................................11

5 Operation......................................................................12

5.1 Configuration .................................................................12

5.1.1 Sensor head detection .....................................................12

5.1.2 Sampling rate.................................................................12

5.1.3 LED mode......................................................................12

5.2 Calibration .....................................................................13

5.2.1 Purpose of calibration .....................................................13

5.2.2 Factory calibration ..........................................................14

5.2.3 Single point calibration (Slope or Process Calibration) ........14

5.2.4 Process calibration ........................................................14

5.2.5 Dual point calibration with M400/M800 transmitter ...........15

5.2.6 Calibration when connected with analog signal

(via M50)......................................................................16

6 Maintenance .................................................................17

6.1 Sensor head inspection ...................................................17

6.1.1 Visual inspection ............................................................17

6.1.2 Testing the sensor with the transmitter...............................17

7 Storage.........................................................................18

8 Product specification .....................................................19

8.1 Specifications.................................................................19

9 Ordering information .....................................................20

9.1 Sensors .........................................................................20

9.2 Accessories....................................................................20

9.3 Recommended transmitters..............................................20

Contents

InSUS Head 5

© 10/2018 Mettler-Toledo GmbH InSUS Head

Printed in Switzerland 30 283 375 C

1

Introduction

Thank you for buying the optical oxygen sensor head

from METTLER TOLEDO.

T

he construction of INGOLD’s optical oxygen sensors

employs leading edge tech nology and complies with

s

afety regulations currently in force. Notwithstanding

this, improper use could lead to hazards for the user

or a third-party, and /or adverse effects on the plant or

other equipment.

Therefore, the operating instructions must be read

and understood by the persons involv ed before work

is started with the sensor.

The instruction manual must always be stored close at

hand, in a place accessible to all people working with

the sensor.

If you have questions, which are not or insufficiently

answered in this instruction manual, please contact

your METTLER TOLEDO supplier. They will be glad to

assist you.

6 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

2 Important notes

2.1 Notes on operating instructions

These operating instructions contain all the information

n

eeded for safe and proper use of the optical sensor

head.

The operating instructions are intended for personnel

entrusted with the operation and maintenance of the

sensors. It is assumed that these persons are familiar

with the equipment in which the sensor is installed.

Warning notices and symbols

This instruction manual identifies safety instructions

and additional information by means of the following

symbols:

This symbol draws attention to safety instructions and

warnings of potential danger which, if neglected,

could result in injury to persons and/or damage to

property.

This symbol identifies additional information and

instructions which, if neglected, could lead to defects,

inefficient operation and possible loss of production.

2.2 Intended use

METTLER TOLEDO optical O2sensors are intended

solely for inline measurement of the oxygen partial

pressure, as described in this instruction manual.

Any use of these sensors which differs from or exceeds

the scope of use described in this instruction manual

will be regarded as inappropriate and incompatible

with the intended purpose. The manufacturer/supplier

accepts no responsibility whatsoever for any damage

resulting from such improper use. The risk is borne entirely by the user/ operator.

Other prerequisites for appropriate use include:

– compliance with the instructions, notes and

requirements set out in this instruction manual.

– acceptance of responsibility for regular inspection,

maintenance and functional testing of all asso ci ated components, also including compliance

with local operational and plant safety regulations.

– compliance with all information and warnings

given in the documentation relating to the products

used in conjunction with the sensor (single-use

bags, transmitters, etc.).

– observance of all safety regulations governing the

equipment in which the sensor is installed.

– correct equipment operation in conformance with

the prescribed environmental and operational

conditions, and admissible installation positions.

– consultation with Mettler-Toledo Process Analytics

in the event of any uncertainties.

InSUS Head 7

© 10/2018 Mettler-Toledo GmbH InSUS Head

Printed in Switzerland 30 283 375 C

2.3 Safety instructions

– The plant operator must be fully aware of the

potential risks and hazards attached to operation

of the particular process or plant. The operator is

responsible for correct training of the workforce, for

signs and markings indicating sources of possible

danger, and for the selection of appropriate,

state-of-the-art instrumentation.

– It is essential that personnel involved in the

commissioning, operation or maintenance of these

sensors or of any of the associated equipment (e.g.

single-use bags, transmitters, etc.) be properly

trained in the process itself, as well as in the use

and handling of the associated equipment. This

includes having read and understood this instruction manual.

– The safety of personnel as well as of the plant itself

is ultimately the responsibility of the plant operator.

This applies in particular in the case of plants

operating in hazardous zones.

– The oxygen sensors and associated components

have no effect on the process itself and cannot

influence it in the sense of any form of control

system.

– Maintenance and service intervals and schedules

depend on the application conditions, composition

of the sample media, plant equipment and signi ficance of the safety control features of the

measuring system. Processes vary considerably,

so that schedules, where such are specified, can

only be regarded as tentative and must in any case

be individually established and verified by the plant

operator.

– Where specific safeguards such as locks, labels,

or redundant measuring systems are necessary,

these must be provided by the plant operator.

– A defective sensor head must neither be installed

nor put into service.

– Only maintenance work described in this operating

instruction may be performed on the sensors.

– When changing faulty components, use only

original spare parts obtainable from your METTLER

TOLEDO supplier (see spare parts list, “Section 9”).

– No modifications to the sensors and the acces-

sories are allowed. The manufacturer accepts no

responsibility for damages caused by unauthorised

modifications. The risk is borne entirely by the user.

2.4 Examples of some typical applications

Below is a list of examples of typical fields of application for the oxygen sensors. This list is not exhaustive.

Measurement in liquids:

– Fermentation

– Bio-Tech

8 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

3 Product description

3.1 General information

The optical single-use oxygen sensor, the InSUS fiber

optical cable (with integrated temperature probe), and

t

he InSUS head are used for measurement of oxygen in

single-use devices.

The single-use sensors are gamma irradiation steriliz-

able and are typically integrated in single-use devices

such as single-use bags and other similar applications. Please also refer to the documentation provided

by your single-use device supplier.

3.2 Principle

The optical oxygen sensors are based on an optical detection method, the so called fluorescence quenching.

Here is a short summary of the principle. In contrast to

the polarographic Clark-electrode, which detects a redox

reaction of oxygen at the electrode, the optical method is

based on an energy transfer between a chromophore

and oxygen.

– A chromophore, embedded in the sensor is illuminat-

ed with blue light. This chromophore absorbs the energy and if no oxygen is present emits red fluorescence light with a specific lifetime. This emitted light

is being detected by a detector in the sensor head.

– In the presence of oxygen, the chromophore transfers

the energy to the oxygen molecule. Oxygen is then

able to transfer this energy as heat to the surrounding

area and no fluorescence is emitted.

– The total intensity of the fluorescence and the lifetime

of the fluorescence is related to the Oxygen partial

pressure in the medium.

– To analyze the lifetime of the fluorescence, the exci-

tation light is pulsed with a constant frequency, the

emitted light shows the same course but with a time

delay to the excitation. This delay is called Phase

shift or Phase angle (Phi). The phase shift is dependent on the oxygen level and follows the Stern-Vollmer

correlation.

– The sensor head detects this phase shift and calcu-

lates the oxygen concentration.

– The oxygen value ist digitally transferred from the

InSUS Head to the transmitter.

InSUS Head 9

© 10/2018 Mettler-Toledo GmbH InSUS Head

Printed in Switzerland 30 283 375 C

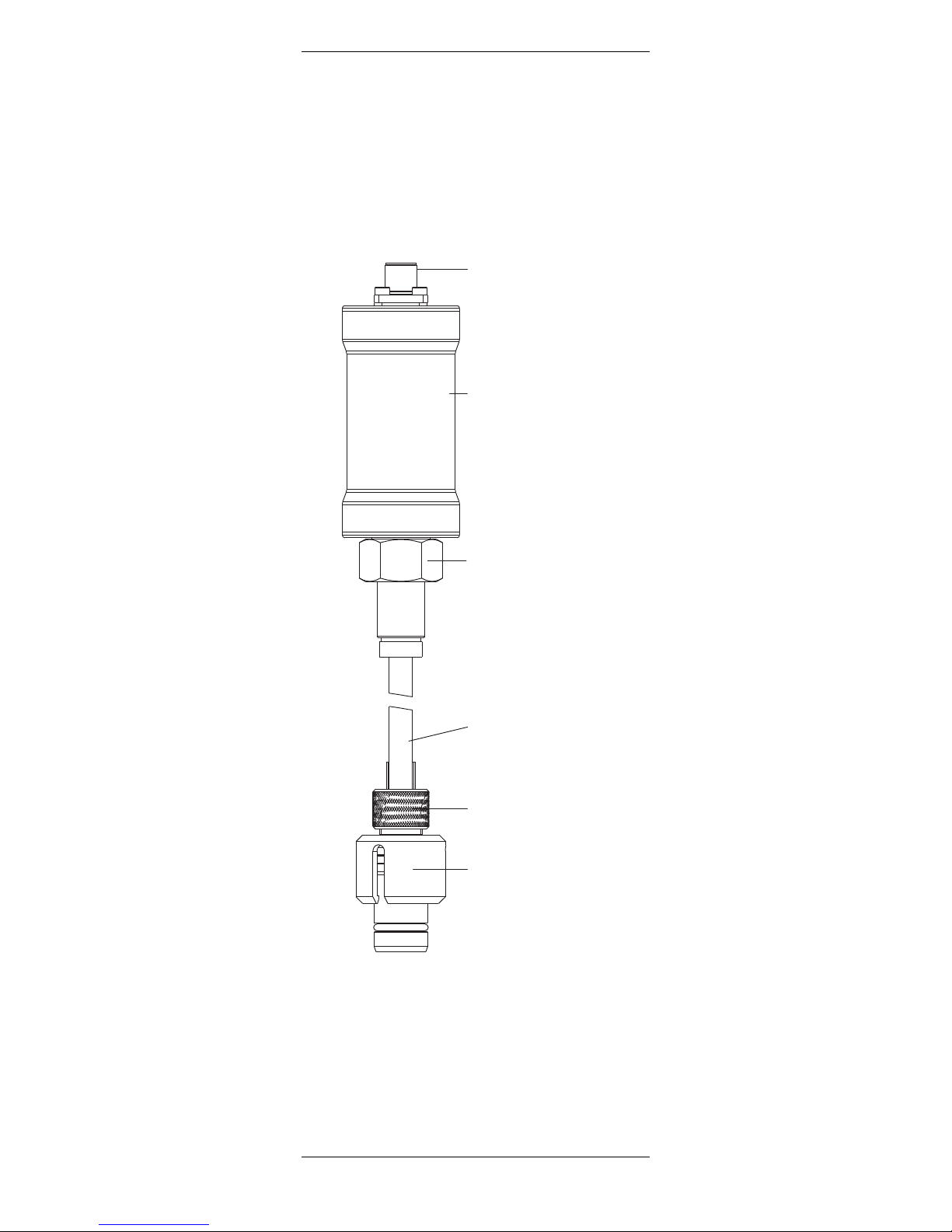

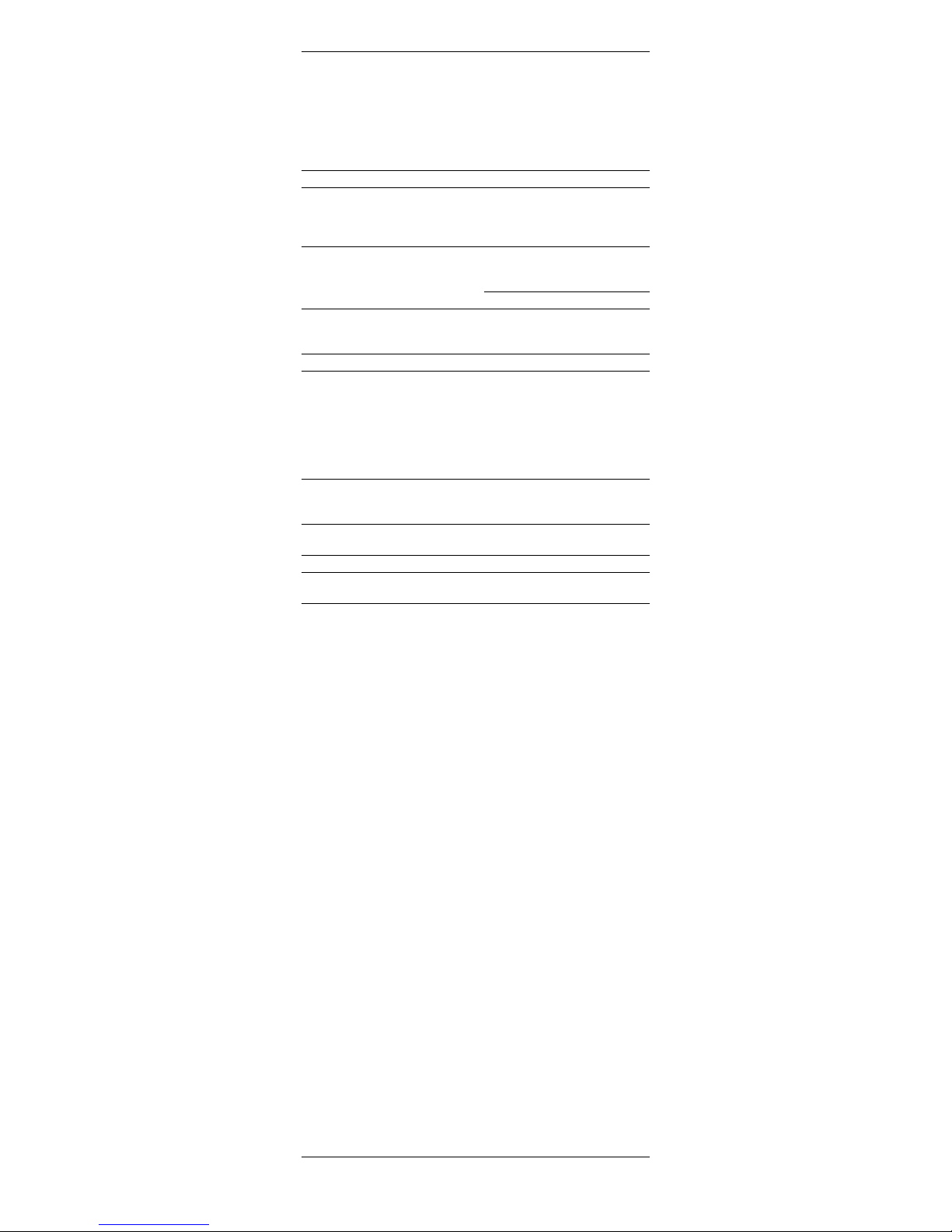

3.3 Scope of delivery

Each sensor is supplied fully assembled and factory

tested and calibrated for correct function together with:

– a certificate of calibration

– this instruction manual

5 Pin

connector

InSUS head

InSUS head

connector

InSUS fiber

optical cable

Sensor connection

(M16 thread)

Single-use sensor

(integrated in

single-use device)

10 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

4

Installation

4.1 Connection

4.1.1 Connection of the single-use sensor to the InSUS

head

Remove the protection cap from the single-use sensor.

Connect the single-use sensor and the InSUS head

with the corresponding InSUS fiber optical cable. Obs

erve the information sheet that accompanies the InSUS fiber optic cable, then tightly screw both plugs on

the sensor and the sensor head.

4.1.2 Digital connection of the InSUS head to a transmitter

Transmitter M400 or M800

The sensor head is connected to the transmitter via a

5 pin data cable. The cables are available from

METTLER TOLEDO in different lengths. The data cable

ensures a secure connection between the transmitter

and the sensor head under harsh industrial conditions.

To connect the data cable to the sensor head align the

slit of the connector with the pin in the plug, then tightly

screw the plug to fasten the two parts.

Transmitter M400

Note: For connecting the cable to the terminals of the

transmitter, please refer also to the instructions given

in the METTLER TOLEDO transmitter manual.

Connect the data cable to the tranmitter as described

in the tables below.

RS485 cable for InSUS Head

M400 M800 M800

1/2 channel 4 channel

Color Function TB4 TB2 TB2 or TB4

brown 24 VDC+ 19 9

black 24 VDC–2 10 10

gray shield 6 12 12

yellow shield 6 15 15

blue RS485–7 13 13

white RS485+ 8 14 14

InSUS Head 11

© 10/2018 Mettler-Toledo GmbH InSUS Head

Printed in Switzerland 30 283 375 C

4.1.3 Analog connection of the InSUS head to a transmitter or controller

A

METTLER TOLEDO M50 signal converter RS485 /

nano-Ampere mimics a polarographic Clark sensor.

The M50 signal converter is connected to an analog

signal input of a transmitter, e.g. M300, or biocont

roller. Please refer to the instructions given in the

METTLER TOLEDO M50 converter manual.

4.1.4 Power connection of sensor head

If the sensor is used with a 4-wire transmitter (M400 /

M800/M50), the Sensor Head is powered over the

transmitter.

Power Supply Specification: 24 VDC; 500 mA

12 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

5

Operation

5.1 Configuration

5.1.1 Sensor head detection

B

efore installing an optical sensor, please refer to the

manual for the transmitter and configure the transmitter

for automatic sensor detection. Date and time must be

set correctly in the transmitter.

In the case wrong date and time are set, the calibration

and setup might be corrupted

5.1.2 Sampling rate

Optical oxygen sensors do not measure permanently.

Each measurement cycle has a duration of approx.

1 second. The measurement interval can be set to any

value between 1 and 60 seconds. Please choose the

appropriate setting. Default setting is 3 seconds which

is sufficient for most applications.

5.1.3 LED mode

The measurement can be switched off if the system is

not needed.

When the sensor head is not measuring, the sensor

LED is off. In this state the sensor head sends a constant measurement value of –1% air to the transmitter

and the transmitter is set to the “Hold mode”. To configure the “Hold mode” please refer to the transmitter

manual.

Automatic switch off at high temperature

If the LED mode is set to “Auto” (default setting) the sensor LED will be switched off as soon as a specific

process temperature is reached.

Temperatures

Maximum operating Default switch

temperature off temperature

InSUS Head 60°C/140°F 60°C/140°F

This limit can be set to an individual value by the user.

Using the transmitter (M400 ot M800) or with iSense.

These settings are also active if the sensor is operated

with an M50 signal converter. The switch off temperature

should be set at least 5° higher then the highest process

temperature. For example, if the process temperature is

37°C/ 99°F, 42°C/ 104°F should be the minimum setpoint. In this situation, as soon as the temperature exceeds 42°C/ 104°F the sensor will stop measuring and

the LED will be switched off. For the switch on, a hysteresis of 3° is implemented, meaning that the sensor

(and LED) will be switched on as soon as the temperature drops below 39°C/101°F.

Manual switch off of the sensor head

(M400/M800 transmitter)

The sensor can be switched off manually via the transmitter menu (see the transmitter manual) by setting

the LED mode to “off”. To restart the measurement, the

LED mode needs to be set manually to “on” via the

InSUS Head 13

© 10/2018 Mettler-Toledo GmbH InSUS Head

Printed in Switzerland 30 283 375 C

transmitter menu, or via a remote signal (digital input).

Remote switch off of the sensor head

(

M400/M800 transmitter)

The M400 transmitter can be set to “Hold” by applying

an external digital signal (see the transmitter manual).

In this situation the sensor and the sensor LED are

s

witched off. As soon as the “Hold Mode” is off, the optical sensor will continue to measure using the previous

settings.

5.2 Calibration

5.2.1 Purpose of calibration

Information about the calibration, you find also in the

manual of the transmitter.

Calibration must be performed every time a new single-use sensor is connected to the InSUS head via the

InSUS optical fiber cable.

Since the correlation between the measured phase and

the oxygen value is not linear, a calibration of an optical sensor must be performed very accurately. Wrong

calibrations may significantly reduce the measurement

accuracy.

Each oxygen sensor has its own individual phase

angle at zero oxygen (phi 0) and hundred percent air

saturation (phi 100).

Several methods for calibration are available for the

optical oxygen sensors. The highest measurement accuracy is achieved by performing a 2-point calibration

with air and a zero gas e.g. N

2

or CO2with a purity of

at least 99.9%.

Note: Please take into account the correct air pressure and humidity. Small deviations in air (± 3%)

are due to differences in humidity and process pressure settings. The sensor calculates for 100 % humidity if it is set to dissolved oxygen measurement.

General remarks:

– Calibration must be performed after gamma ster-

ilization of the single-use device.

– For calibration in gas the single-use device in

which the single-use sensor is integrated must be

filled with air (phi 100) or zero point gas (phi

0).

– Make sure that the settings for oxygen saturation

of the calibration is correct and remains constant

during calibration.

– In the event of calibration in water or sample medium,

the calibration medium must be in equilibrium

with the air. Oxygen exchange between water and

air is very slow. Therefore it takes quite long time until

water is saturated with atmospheric oxygen.

– Make sure that all other parameters, such as

temperature and pressure, are constant.

– Calibration always needs accurate pressure and

temperature measurement. Only process scaling is

14 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

independent of those parameters (see chapter

5.2.4).

– Make sure that the correct calibration pressure, hu-

midity and salinity values are set in the transmitter

b

efore the calibration is started.

–

Please refer also to the transmitter or biocontroller

manual for detailed informations

5.2.2 Factory calibration

The sensor head is delivered pre calibrated and ready

for use.

The factory calibration data are stored in the sensor

and can not be changed by the user.

5.2.3 Single point calibration (Slope or Process Calibration)

For most applications, a single point calibration should

be sufficient.

By carrying out a single point calibration, the factual

phase at the desired oxygen value e.g. at hundred percent oxygen (phi 100) of the sensor can be established. The corresponding calibration curve is calculated.

The calibration medium can be either air or a calibration gas with known O

2

concentration or water with a

known oxygen concentration.

Before starting the calibration in gas, the correct pres-

sure and the correct humidity have to be set in the

transmitter.

Note: Wrong pressure values are the most common

reasons for bad measurement accuracy.

E.g. 50 mbar difference between the ambient pressure

and the value set in the transmitter result in 5% measurement error at air.

For calibration in gas it is important that the temperature reading of the sensor is stable and represents the

real gas temperature.

After the sensor signal has stabilized, the complete

meas uring system can then be calibrated to the 100 %

value of the desired measurable variable, e.g. 100%

air, 20.95% O2, or 8.26 ppm at 25°C (77°F) and

normal pressure (see instruction manual for the

transmitter).

5.2.4 Process calibration

For detailed information please refer also to the trans mitter manual.

Two different routines for process calibration are possible:

– Process calibration

– Process scaling (M400/ M800 transmitter)

InSUS Head 15

© 10/2018 Mettler-Toledo GmbH InSUS Head

Printed in Switzerland 30 283 375 C

Process calibration is performed when a reliable control value is available and process pressure is known.

Process pressure is only needed if the system is meas

uring in saturation (% air or % O

2

)

or gas (ppm gas)

units. During this calibration the phase values of the

calibration curve are adjusted.

Process scaling is performed mainly in biopharma

applications when the user desires to set the system to

an initial value. During this calibration the phase valu

es of the sensor are not adjusted, only the displayed

values and the 4 – 20 mA output are rescaled to the desired value.

Note: For process calibration the operator can use either the process pressure or the calibration pressure,

depending on how the reference value is taken.

After the sensor signal has stabilized, the complete

measurement system can be calibrated to the desired

variable, e.g. % air, % O

2

, ppm or ppb (see instruction

manual for the transmitter).

Note: For this type of calibration an accurate reference value and correct pressure settings are essential.

5.2.5 Dual point calibration with M400 / M800 transmitter

To receive a maximum accuracy of the measured values over the full measuring range, a dual point calibration is required.

By carrying out a dual point calibration both phase

angles at zero oxygen (phi 0) and at hundred percent

oxygen (phi 100) of the sensor can be established.

Point 1: Slope correction (with air or other calibration

media with known O2value)

After the sensor signal has stabilized, the complete

meas uring system can then be calibrated to the 100 %

value of the desired measurable variable, e.g. 100%

air, 20.95% O2, or 8.26 ppm at 25°C (77°F) and

normal pressure (see instruction manual for the

transmitter).

Point 2: Zero point

After the sensor signal has stabilized, the sensor can

be calibrated to the 0% value of the desired measurable variable, e.g. 0% air, 0.0% O

2

, or 0 ppm at

25˚C/77 ˚F (see instruction manual for the transmitter).

Note: Incorrect zero point calibration is a frequent

source of measurement error. For correct calibration, we recommend the use of nitrogen gas or other

oxygen-free medium with a level of purity of at least

99.9%.

16 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

5.2.6 Calibration when connected with analog signal

(via M50)

As soon as a sensor is connected with an analog communication, only rescaling of the M50 output is available.

The procedures can be performed the same way as

with amperometric sensors:

1. Slope correction

2

. Offset correction

InSUS Head 17

© 10/2018 Mettler-Toledo GmbH InSUS Head

Printed in Switzerland 30 283 375 C

6

Maintenance

Note: All maintenance work can be done without any

tools.

6.1 Sensor head inspection

6.1.1 Visual inspection

T

o check your sensor head, we recommend the follow-

ing procedure:

– The contacts of the connector must be dry. Moisture,

corrosion and dirt in the connector can lead to false

readings.

– Check the cable for buckling, brittle areas or ruptures.

– Check the contacts of the InSUS fiber optical cable.

Attention! Do not use any cleaning agents contai ning alcohol or any solvents. This could damage the

sensor head.

6.1.2 Testing the sensor with the transmitter

If the measured values differ from the expected value,

a air calibration should be performed.

Appropriate phase values after a correct calibration:

Depending on the age of the single-use sensor the

phase values typically decrease over time compared

with a new single-use sensor (see table).

New sensor Limit for old sensor

Phi0 Phi100 Phi0 Phi100

62°±3° 35°±3° <58° >38°

The phase values of the sensor are stored in the cali-

bration history. The actual phase value can be checked

in the “Calibration – Verify” menu.

If after such procedures the above mentioned values

are still not reached, the sensor should not be used.

Zero oxygen measurement can be done by using

CO2or nitrogen (N2), alternatively in a sample medium

saturated with one of these gases.

After 2 minutes in an oxygen-free sample medium, the

reading on the transmitter should drop to below 5% of

the reading in ambient air, and within 10 minutes the

value should have dropped to below 1%.

If after such procedures the above mentioned values

are still not reached, the sensor should not be used.

18 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

7 Storage

For storage, the sensor head should be clean and dry.

T

he protection caps have to be placed on the sensor

and the cable connectors.

InSUS Head 19

© 10/2018 Mettler-Toledo GmbH InSUS Head

Printed in Switzerland 30 283 375 C

8

Product specification

8.1 Specifications

InSUS Head

Measurement principle optical

Power requirements

U

min

= 19.5 VDC

U

max

= ≤25 VDC

P

m

ax

= 0.75 W ➝ 33 … 40 mA

Design features

Temperature compensation automatic with built-in RTD in InSUS

fiber optical cable

Cable connection (digital) data cable 5 pin

Single-use O

2

sensor integrated in

single-use device

Sensing element Optical spot

Measuring range 0…250% air

Accuracy under defined laboratory < 2.5% for the range 50– 100%

conditions air after 1-point calibration in

100% air

<1% after two point calibration in

100% air and 0% oxygen

Response time T98<30s

Temperature probe Pt1000 class B according to DIN

EN60751, integrated in InSUS opti-

cal fiber cable

Recommended wetting time 10 minutes

(preconditioning time)

Operating temperature 5°C to 60°C (41 °F to 140°F)

Sensor cable connection Glass fiber extension, M16 ×1

thread

20 InSUS Head

InSUS Head © 10/2018 Mettler-Toledo GmbH

30 283 375 C Printed in Switzerland

9

Ordering information

For more detailed information ask your local distributor.

9.1 Sensors

InSUS Head 30 015 171

InSUS fiber optical cable (1.5m/4.9 ft) 30 020 711

9.2 Accessories

M50 Signal converter 52 121 854

iSense 30 130 614

iSense CFR21 ready 30 283 620

iLink RS485 52 300 399

Data cable (5 pin)

Temperature range – 30 … 80 °C (– 22 … 176 °F)

2m (6.6ft) 52 300 379

5m (16.4ft) 52 300 380

10m (32.8ft) 52 300 381

15m (49.2ft) 52 206 422

25m (82.0ft) 52 206 529

50m (164ft) 52 206 530

9.3 Recommended transmitters

Transmitter

M400, Type 2 52 121 349

M400, Type 3 52 121 350

M800 1-channel 30 026 633

M800 2-channel 52 121 813

M800 4-channel 52 121 853

Loading...

Loading...