Mettler Toledo InPro 8300 RAMS Instruction Manual

InPro 8300 RAMS

Optical Product Monitor

Instruction manual

Bedienungsanleitung

Manuel d’utilisation

InPro 8300 RAMS Optical Product Monitor

52 801 115

2 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

English Page 3

Deutsch Seite 35

Français Page 67

InPro 8300 RAMS Optical Product Monitor 3

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

InPro 8300 RAMS

Optical Product Monitor

Instruction manual

Bedienungsanleitung

Instructions d’utilisation

4 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

1 Safety ......................................................................................................................................5

2

Product Description...........................................................................................................................6

2.1 General Description ......................................................................................................................6

2.2 Highlights

....................................................................................................................................6

2.3 InPro 8300 RAMS types................................................................................................................7

2.4 Measuring Cell.............................................................................................................................7

3 T

echnical Data ..................................................................................................................................8

3.1 InPro 8300 RAMS ........................................................................................................................8

3.2 Measuring Cell

.............................................................................................................................9

4 Installation of the InPro 8300 RAMS

................................................................................................10

4.1 Contents of Package...................................................................................................................10

4.2 Mechanical installation

...............................................................................................................10

4.3 Dimensions...............................................................................................................................12

4.4 Electrical Connection of the InPro 8300 RAMS ...............................................................................13

4.4.1 Electrical connection of the InPro 8300 RAMS without connection module..............................13

4.4.2 Electrical connection of the InPro 8300 RAMS with connection module..................................15

4.4.3 Electrical connection of the InPro 8300 RAMS with interface modules....................................16

4.4.4 Using interface modules ...................................................................................................17

5 Connecting the InPro 8300 RAMS to a PC ........................................................................................18

5.1 Use of the software.....................................................................................................................18

5.1.1 Installation of the InPro 8300 RAMS CONFIG Operating Program

...........................................18

5.1.2 Starting the Program ........................................................................................................18

5.1.3 Displaying Measuring Values............................................................................................19

5.2 Operating Elements of the InPro 8300 RAMS Configuration .............................................................19

5.2.1 File menu .......................................................................................................................19

5.2.2 Info menu.......................................................................................................................20

5.2.3 Operating mode...............................................................................................................20

5.2.4 Zero adjustment...............................................................................................................21

5.2.5 Other settings..................................................................................................................21

5.3 Product data (digital mode) ........................................................................................................22

5.4 Operating Mode .........................................................................................................................25

5.4.1 Analog operating mode ....................................................................................................25

5.4.2 Digital operating mode.....................................................................................................26

5.5 Zero Adjustment .........................................................................................................................26

5.5.1 Procedure.......................................................................................................................26

6. InPro 8300 RAMS CALI / RAMS COMBINE – Suitable for Calibration

..................................................27

7 Yeast Pitching.................................................................................................................................29

8 Maintenance...................................................................................................................................31

9 Ordering information .......................................................................................................................32

Contents Page

InPro 8300 RAMS Optical Product Monitor 5

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

1 Safety

This instruction manual lists the main points of how to use the InPro 8300 RAMS from METTLER

TOLEDO for best results and in the intended manner.

This instruction manual, and the safety requirements in particular, must be observed by the opera-

tor and all other persons working with this equipment.

The instruction manual must always be stored close at hand, in a place accessible to all people work

-

ing with the InPro 8300 RAMS.

Warning notices and symbols

This instruction manual identifies safety instructions and additional information by means of the

following symbols:

This symbol draws attention to safety instructions and warnings of potential danger which, if

neglected, could result in injury to persons and/or damage to property

.

Always take note of the warnings to protect yourself, the production plant, the product, the InPro 8300

RAMS and the control and evaluation devices connected to the InPro 8300 RAMS from damage.

We strongly emphasise that we do not accept any liability for damage or losses sustained in connection with the use of these operating instructions or the products described herein.

Our products are constantly advanced. Subject to technical modifications.

This symbol identifies additional information and instructions which, if neglected, could lead to

defects, inefficient operation and possible loss of product.

Intended use

Any other use, or use not mentioned here, that is incompatible with the technical specifications is deemed

inappropriate. The operator is solely responsible for any damage arising from such use.

Other prerequisites for appr

opriate use include:

– observing the instructions, notes and requirements set out in this instruction manual

– correct care and maintenance of the unit, according to the instruction manual

– observing the prescribed environmental and operational conditions

– compliance with local statutes

6 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

2 Product Description

2.1 General Description

The InPro 8300 RAMS is an optical device for monitoring product/water phase separation processes

and for the continuous measurement of turbidity and colour in various wavelength ranges.

In process automation applications, the unit supplies the switching signal for product/water or product/product phase separation. When a range of products is manufactured, it allows clear identification

of the different products.

8 parameters are registered about 5 times a second; using 4 different wavelengths, the transmitted light

and the back-scattered light are measured. This method allows virtually all liquids to be monitored, independently of their colour and turbidity.

2.2 Highlights

• Use of durable and lasting stable LEDs

• No cumbersome and expensive lamp replacement

• Excellent zero stability

• Configuration using a commercial PC or notebook

• Easy to retrofit to VARINLINE

®

access units or VARINLINE®sight glasses without the need of

welding work

• In parallel to processing the switching outputs and the analog output in the PLC, visualization via a

separate PC is possible

• A PC can be connected to record measured data

• Product identification can be displayed in table or chart form

• Easy copying of data into Excel

• An additional mA signal can be connected for product identification together with the 8 InPro 8300

RAMS parameters.

• Monitoring of fine turbidity and colour using one single unit

• Automatic self-monitoring if there is a risk of condensation forming on the optical windows

• Sapphire windows available as an option

• High temperature version available as an option

InPro 8300 RAMS Optical Product Monitor 7

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

2.3 InPro 8300 RAMS types

• InPro 8300 RAMS TCS

Turbidity or Colour

InPro 8300 RAMS optimized for phase separation. A jumper is used to determine whether the unit is

used for turbid or clear or coloured products. It works as absorption monitor

. The InPro 8300 RAMS

TCS does not have any reflection parameters (see separate brochure). Unlike all the other InPro 8300

RAMS types, the InPro 8300 RAMS TCS does not have an additional communication interface, but

only a 4–20mA analog output.

• InPro 8300 RAMS BASIC

Basic version of the InPro 8300 RAMS.

It is mainly used for product monitoring, product identification and phase separation. It is used where

turbid, clear or coloured products flow through one and the same pipe.

• InPro 8300 RAMS CALI

InPro 8300 RAMS suitable for calibration.

Up to 3 calibration curves can be implemented with the InPro 8300 RAMS CALI. This enables you e.g.

to continuously measure the turbidity and colour of different products at the same time. Exter

nal digi-

tal signals are used to switch between these measurements.

• InPro 8300 RAMS COMBINE

InPro 8300 RAMS suitable for calibration with special functions:

– Used to measure low turbidities e.g. in water supply systems or in swimming baths.

– In the brewery it is used for turbidity measurements at the lauter tun and supplies results that are

compliant with MEBAK guidelines.

– Apart from turbidity

, the product can also be monitored for colour changes, e.g. for SAC (436nm)

in water supply systems.

– Calculation of the yeast cell count in yeast pitching control

2.4 Measuring Cell

A VARINLINE®in-line access unit or VARINLINE®sight glass is used as a measuring cell. If fittings are

already installed on site, the InPro 8300 RAMS is easy to retrofit without the need of welding work.

VARINLINE

®

is a registered trademark of the company Tuchenhagen.

8 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

3 Technical Data

3.1 InPro 8300 RAMS

Measuring cycle (all 8 parameters) approx. 5 measurements per second

Span 400…2000 RAMS units

Repeatability

6

1% of measuring range

Power supply 24 V DC

Current consumption <50 mA plus total of output currents, polarity

reversal protection up to 30V

Digital inputs (in analog mode)

Input voltage Low max. 2V

Residual current of driver max. 0.1mA

Input voltage High 16...28V

Input current High max. 1.6mA

Digital outputs (in digital mode)

Output current max. 350mA (total of all output currents)

Output voltage High Power supply –3.0 V

Output voltage Low max. 2.0V

Analog input (ext. mA) 0/4 …20mA

Input resistance max. 222Ohm

Measuring error <0.3%

Measuring resolution approx. 25µA

Measuring cycle 200ms

Admissible input current –22…+ 44mA

Analog output 4…20mA

Load max. 500Ohm

Output current resolution approx. 2.5µA

Response time <10ms

Parameter setting interface RS-232

Operating conditions

Ambient temperature 0…40°C

Product temperature 0…105°C (140 °C as an option)

Temperature compensation 0…50°C in steps of 0.1 °C

>50°C in steps of 0.5°C

Rel. humidity 0…100%

Protection class IP67

Storage temperature –40…+ 125°C

Temperature measurement (in the electronics)

Measuring range –40…+ 120°C

Accuracy tolerance max. 63°C absolute

Humidity measurement (in the electronics)

Measuring range 0…100%

Accuracy tolerance max. 62.5% absolute

InPro 8300 RAMS Optical Product Monitor 9

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

Materials

Optics housing 1.4404

Seals EPDM

Viewing window PVC

Cable glands brass / nickel plated

Connecting cable Ölflex, 430.75mm

2

3.2 Measuring Cell

Housing material 1.4404

Sealing material EPDM

Glass quality Borosilicate

Option: Sapphire (only in connection with OPL bits)

Operating pressure max. 10bar

Product temperature – 5…+180°C (depending on the sealing material)

10 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

4 Installation of the InPro 8300 RAMS

The InPro 8300 RAMS can be fitted to existing VARINLINE®measuring cells or VARINLINE®sight glasses. Make sure that the measuring cells are welded into the pipe so that the electronic parts of the

InPro 8300 RAMS face each other horizontally.

4.1 Contents of Package

The package contains the following components:

• InPro 8300 RAMS

• Screwdriver

• Face spanner

• installation wrench for OPL bits

• 2 OPL bits

• Container with spare desiccant capsules

• 2 O-rings, 34.59

3 2.62

• Manual

• Software CD for the InPro 8300 RAMS CALI and the InPro 8300 RAMS COMBINE

4.2 Mechanical installation

Insert the OPL bits or the 68mm windows and the VARINLINE®adapters in the measuring cell and

secure them using hinged clamps; tool required:

a/f 10 mm open-ended, ring or socket spanner. Make sure that the recesses for the securing pins (11)

are facing downwards. This way you ensure that the cable glands will also point downwards once you

have fitted the InPro 8300 RAMS.

Carry out the following steps for both electronic parts in succession:

• Remove the protective caps from the InPro 8300 RAMS’s optical elements.

• Insert a 34.59

3 2.62 mm O-ring into the groove .

• Take the desiccant capsule out of the tube and place it in the recess (17) in the electronic part.

Immediately close the desiccant tube again!

• Fit the electronic part to the VARINLINE

®

adapter or the OPL bit and use the face spanner to fasten

it. The active electronic part has to be mounted at the side with the window 68 mm or with the

shorter OPL bit.

InPro 8300 RAMS Optical Product Monitor 11

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

1 VARINLINE

®

housing

2 Hinged clamps

3 Passive electronic part of the InPro 8300 RAMS

4 Active electronic part of the InPro 8300 RAMS (when using an OPL bit and a 68mm window

always mount it on the side where the big window is fitted, when using 2 OPL bits mount it on

the side where the short OPL bit is fitted)

5 Threaded ring

7 OPL bit

9 O-ring, 60 3 3

10 O-ring, 34.59

3 2.62

11 Spacer (only when 2 OPL bits are used)

12 Threaded ring

13 Thrust ring

14 Window 28mm

15 O-ring, 22

3 3

16 Securing pin

17 Recess for desiccant capsule

12 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

4.3 Dimensions

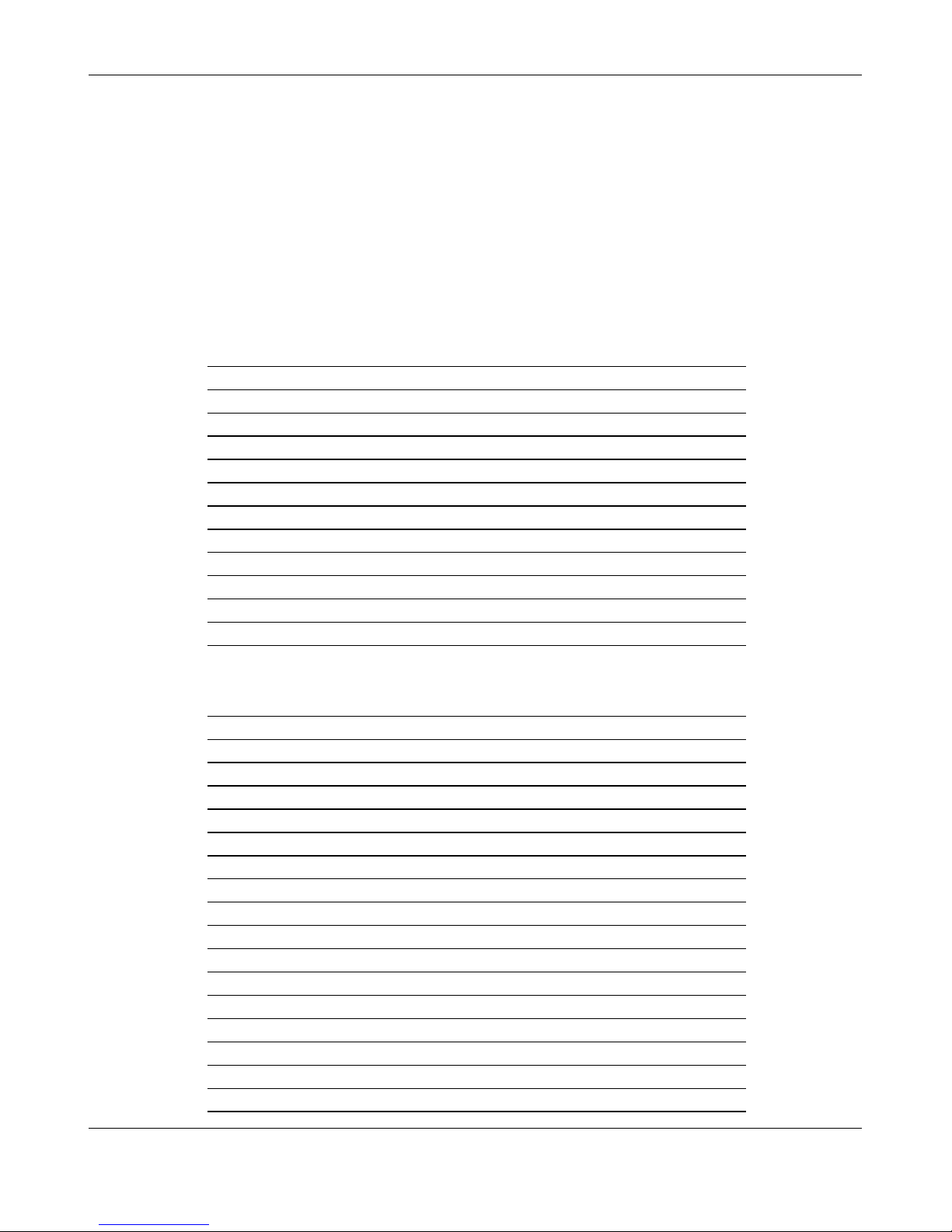

DN D1 D2 L A

40 38 42 180 37

50 50 54 180 44

65 66 70 250 52

80 81 85 250 60

100 100 104 250 69

125 125 129 250 82

Outer Diameter D1 D2 L A

1" 22.2 25.4 90 60

11/2" 34.9 38.1 90 73

2" 47.6 50.8 90 85.5

21/2" 60.3 63.5 125 98

3" 73 76.2 125 111

4" 97.4 101.6 125 135.5

I.P.S. D1 D2 L A

2" 56.3 60.3 114.3 95

3" 84.3 88.9 152.4 123

4" 109.7 114.3 152.4 148

6" 162.7 168.3 152.4 200

InPro 8300 RAMS Optical Product Monitor 13

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

4.4 Electrical Connection of the InPro 8300 RAMS

The InPro 8300 RAMS is supplied with the connection cable firmly connected between active and passive part. Once the InPro 8300 RAMS has been installed mechanically, the electrical connections can

be established.

Procedure:

• Unscrew the window plate from the InPro 8300 RAMS

• Pass the stripped cable through the cable gland

– Cable diameter 4…10mm

– Core cross section 0.75mm

2

• Connect the cable cores in accordance with the circuit diagram.

• Insert the desiccant capsule in the terminal compartment

• Replace the window plate

Tools required:

• Open-ended wrench a/f 22 mm (not included)

• Cable stripper (not included)

• Screwdriver 2.4 mm (included in the InPro 8300 RAMS accessories kit)

• Desiccant capsules (2 pcs, included in the InPro 8300 RAMS accessories kit)

4.4.1 Electrical connection of the InPro 8300 RAMS without connection module

RX = receiving line of the serial interface

TX = sending line of the serial interface

Iin = external mA input (+)

1– 4 = digital inputs / outputs (in analog mode inputs to the InPro 8300 RAMS in digital mode

outputs of the InPro 8300 RAMS)

Iout = mA output (+)

L+ = power supply, 24V DC

L- = ground

14 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

7-segment display

Digital signal in digital mode

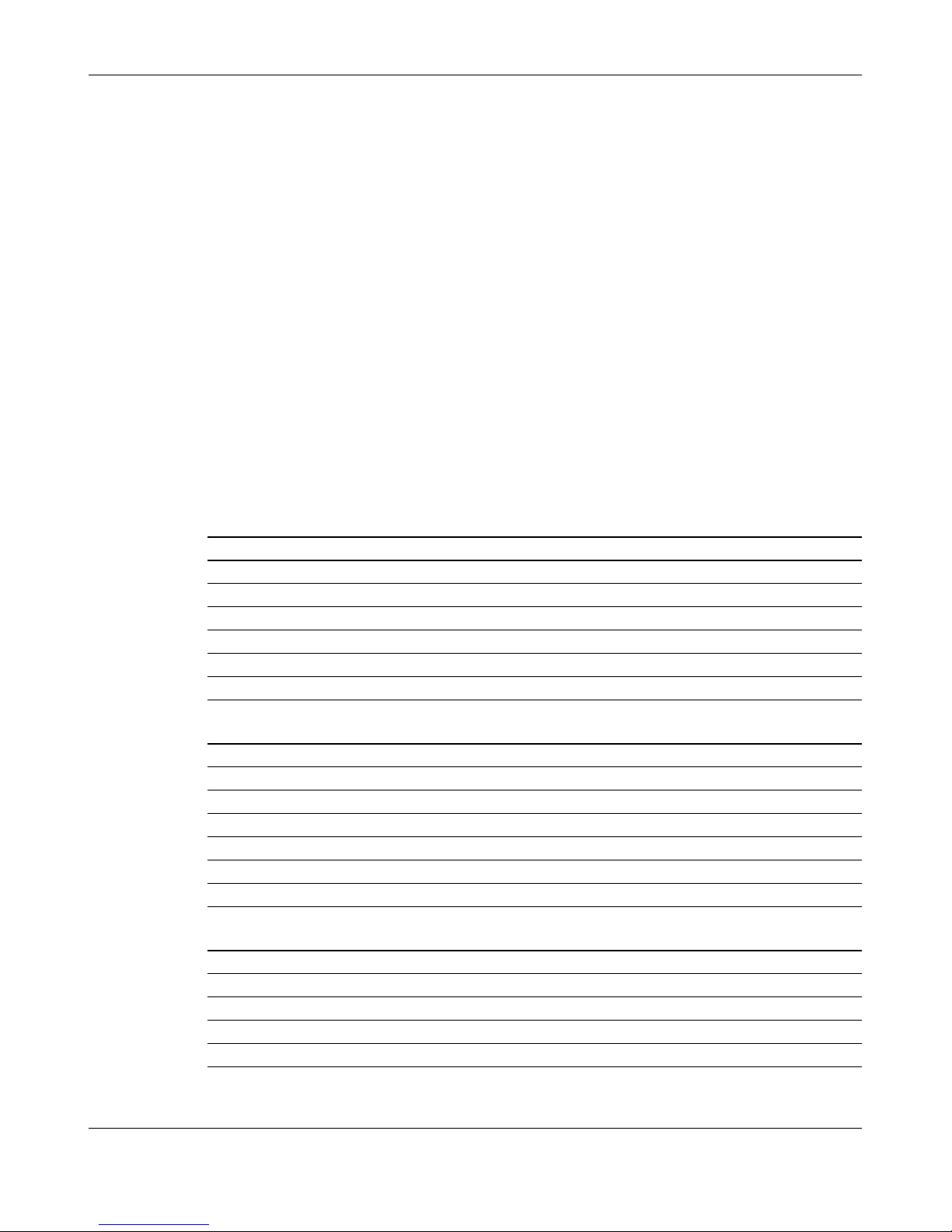

Operating status 7- Segment display Outputs 4|3|2|1

Water identified 0 0|0|0|0

Product 1 identified 1 0|0|0|1

Product 2 identified 2 0|0|1|0

Product 3 identified 3 0|0|1|1

Product 4 identified 4 0|1|0|0

Product 5 identified 5 0|1|0|1

Product 6 identified 6 0|1|1|0

Product 7 identified 7 0|1|1|1

Product 8 identified 8 1|0|0|0

No Product identified Segm. a,g,d 1|0|1|0

Temperature > 75°C Segm. a,g,e 1|1|0|0

Digital signal in analog mode

Input 4|3|2|1 mA output 7- Segment indicator

0|0|0|0 switched off Segment g

0|0|0|1 Conn. to NIR refl. 1

0|0|1|0 Conn. to red refl. 2

0|0|1|1 Conn. to green refl. 3

0|1|0|0 Conn. to blue refl. 4

0|1|0|1 Conn. to NIR conc. 5

0|1|1|0 Conn. to red conc. 6

0|1|1|1 Conn. to green conc. 7

1|0|0|0 Conn. to blue conc. 8

1|0|0|1 Conn. to ext. mA input 9

1|0|1|0 Conn. to temperature A

1|0|1|1 Conn. to dew point Segment b

1|1|0|0 Conn. to ambient light C.

1|1|0|1 Conn. to calc. value 1 d.

1|1|1|0 Conn. to calc. value 2 E.

1|1|1|1 Conn. to calc. value 3 F.

InPro 8300 RAMS Optical Product Monitor 15

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

4.4.2 Electrical connection of the InPro 8300 RAMS with connection module

Analog and digital input/output signals are measured against L-.

Important: Terminals 20, 21 and 22 are not used at present!

16 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

4.4.3 Electrical connection of the InPro 8300 RAMS with interface modules

Analog and digital input/output signals are measured against L-.

InPro 8300 RAMS Optical Product Monitor 17

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

4.4.4 Using interface modules

From connection module To the PC

18 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

5 Connecting the InPro 8300 RAMS to a PC

5.1 Use of the software

The InPro 8300 RAMS possesses a serial interface type RS-232. Please use the interface cable supplied to connect the InPro 8300 RAMS to a PC. If your computer does not have a serial interface, please

obtain a commercially available USB serial adapter. Upon request, we can supply one.

5.1.1 Installation of the InPro 8300 RAMS CONFIG Operating Program

Insert the CD-ROM supplied into the CD-ROM drive of your PC. Start Explorer and then click the relevant

drive symbol. Double-click the installation icon (to which the arrow points) to start the installation routine.

Follow the instructions on the screen.

5.1.2 Starting the Program

After successful installation you can start RAMS CONFIG from the WINDOWS Start menu or from the

desktop.

If the program is unable to establish a connection to the InPro 8300 RAMS it will ask you whether a

InPro 8300 RAMS has been connected. If you answer this question with “No”, it is possible to view recorded data. Otherwise the program will request you to check the connection to the InPr

o 8300 RAMS

and whether all components work properly.

InPro 8300 RAMS Optical Product Monitor 19

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

5.1.3 Displaying Measuring Values

The InPro 8300 RAMS has 8 parameters. Using 4 wavelengths (NIR = near, infrared, red, green and

blue), the transmitted light = concentration and the reflection = back-scattered light are measured. The

InPro 8300 RAMS also has an mA input. Here, the signal supplied by an external sensor (conductivity

, density, etc.) can be connected to take parameters into account e.g. when identifying products to

decide which product is running through the pipe.

5.2 Operating Elements of the InPro 8300 RAMS Configuration

The basic functions of the operating elements of the InPro 8300 RAMS configuration are explained below. For details on the function of certain operations please refer to the relevant sections of the operating

instructions.

Operator-controllable fields

These are identified by their background colour (white) and the form of the mouse cursor (pointing hand)

when this is pointing at the operating elements. Some fields can only be operated after others have been activated, which is indicated by a colour change (from yellow to white) and by the mouse cursor

changing.

5.2.1 File menu

Click “menu” to open the File menu.

Load

A project that has already been saved can be loaded into the program via the “Load” menu item, can

then be changed or additions can be made and can finally be transferred to the connected InPro 8300

RAMS. The file extension is automatically set to “.rms” by the program and cannot be changed. The

“Open” Windows dialog box only includes files with this extension.

20 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

Save

Clicking the “Save” menu item opens the Windows “Save as” dialog box. The file name and the directory to which the file is to be saved are already set: the file name is composed of the InPr

o 8300 RAMS’s

serial number and the extension “rms”. It is saved to the directory C:/RAMS_Projekte. You should not

change the defaulted storage location as the program will later search this directory and the file in accordance with the serial number of the InPro 8300 RAMS connected.

Comment

Clicking the “Comment” menu item opens a text field where you can enter any comment with regard to

this measuring point. This comment is saved together with the project and is available again when the

configuration is edited at a later stage.

Selecting the language

Here you can select the dialog language you wish to use when working with the program.

End program

Click the “End program” menu item to close RAMS CONFIG and to return to the Windows user interface of your computer

.

5.2.2 Info menu

Click “Info” to open the Info menu.

Version

Click the “Version” menu item to obtain information about the version number of the InPro 8300 RAMS

configuration you are using.

Operating instructions

Click “Operating instructions” to open the operating instructions in the selected language. Requirement:

ACROBA

T READER is installed on your computer. If it does not exist on your computer, please install the

program from the CD supplied.

5.2.3 Operating mode

Analog

The analog operating mode is active by default upon program start and is displayed in the text window

of the “Operating mode” frame. You can switch to digital mode by clicking the “Change-over” button. A

message box will open where you need to click“Y

es”. If you click “No” in the message box, the system

remains in analog mode. Please refer to section 5.3 for details on when the analog operating mode is

used.

InPro 8300 RAMS Optical Product Monitor 21

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

Digital

If you wish to switch to digital mode, you can do so by clicking the “Change-over” button in the “Operating mode” frame and confirming your selection by clicking “Y

es” in the message box that opens. If

you click “No” in the message box, the system remains in analog mode.

5.2.4 Zero adjustment

Carrying out zero adjustment

When you click this button, the program attempts to set the zero points for the InPro 8300 RAMS parameters. For the exact procedure and the points to be noted please refer to section 5.5.

5.2.5 Other settings

Moisture alarm

Relative humidity is measured in the InPro 8300 RAMS electronics. This value should always be below 15% as otherwise there is a danger of condensation forming. If the moisture alarm function is

active, an alarm will be triggered if a relative humidity of 15

% is overshot by reducing the mA output

to a value of 2.96 for approx. 1 second. This will cause a fault in the downstream control system which

can be interpreted as a moisture alarm. After replacing the desiccant capsules, the alarm must be acknowledged by clicking “Reset”.

Measuring point

In the “Measuring point” field a measuring point designation can be entered.

Created by

The name of the author of the project can be entered here.

Created on

This field cannot be accessed. The date of creation is set automatically (system date).

22 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

Changed by

When the configuration is changed, the name of the person revising the project can be entered here.

Changed on

When you double-click this field, the current system date is entered here.

5.3 Product data (digital mode)

Product

The InPro 8300 RAMS is able to identify up to 8 products on its own. For this purpose, a product can

be entered in plain text in the “Product” fields. First of all, initialize the table cell to be edited by clicking

on it. After right-clicking a menu opens from which you can select the required function (e.g. Enter product name). Click this menu item to open an input box where you can enter the product name.

SP

In the same way you can enter the setpoints for the individual parameters which are to be used for identifying the product. Here it is also possible to adopt a certain measuring value as the setpoint by clicking

the relevant menu items or to enter the measuring values for all parameters in the setpoint fields.

Tol.

After creating a setpoint, “ina” (=inactive) is entered into the “T

ol.” field next to it. The setpoint is activated by right-clicking the relevant Tol. field and then selecting the switching function from the list that

opens.

Write product data

When you click this button, the product data entered, “SP” and “Tol”, is written to the InPro 8300 RAMS.

Read product data

When you click this button, the “SP” and “Tol.” product data effective in the InPro 8300 RAMS is read

out and entered into the table.

mA output

Clicking the “mA output” button opens a list. When you click an entry in this list, the mA output is connected to the relevant parameter

.

InPro 8300 RAMS Optical Product Monitor 23

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

Read measured values

When you click this button, the current values are read once from the InPro 8300 RAMS and entered

into the relevant fields

Read measured values cyclically On/Off

Switches the repeated reading of measured values at intervals of 1–2 seconds on and off again. The

labelling changes to “Read measured values cyclically Off”. If the function is active, a red signal field

indicates that the program is “busy”. The other operating elements are not active.

Record measured values Start/Stop

After clicking this button, please enter the time interval in seconds (in the range 3…3600 seconds)

for recording the data into the dialog box that opens. The labelling of the button then changes to “Stop

recording measured values”. If the function is active, a red signal field indicates that the program is

“busy”. The other operating elements (with the exception of the “View measured values” button) are

disabled.

24 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

View measured values

When you click this button a table opens and then the Windows dialog box to open a file. Select the file that contains the measured values you are interested in. The file name is composed of the InPr

o 8300

RAMS’s serial number and the recording date.

Transfer saved measured values to Excel

When you click the field in the table at the top left, all of the data is selected. Use the “Ctr” + “C” shortcut to copy the data to the Windows clipboard and, after starting Excel, use “Ctr” + “V” to paste it into

the Excel spreadsheet.

“Load” in the “File” menu

Clicking the “Load” menu item L opens the “Open” Windows dialog box again. Here you can select

other files that interest you.

Read system data

Clicking allows you to read the InPro 8300 RAMS’s system data, which are:

T

emperature in °C, measured in the electronics housing on the connection side near the window;

the colour of the display window changes and the LEDs are switched off if the

temperatures exceed approx. 75°C. When the temperature has dropped below this

value, the InPro 8300 RAMS switches the LEDs back on.

Ambient light values between 400 and 2000, caused by other sources of light in the pipe (e.g.

sight glass with illumination); the display field colour changes if the values overs

hoot 403.

InPro 8300 RAMS Optical Product Monitor 25

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

Relative humidity in %, measured in the electronics housing on the connection side near the window;

the colour of the display window changes and an alarm is triggered if the values

exceed 15%.

Serial number of the InPro 8300 RAMS

Firmware informs about the release status of the internal InPro 8300 RAMS software.

Processor shows the software installed in the InPro 8300 RAMS:

00.00 = BASIC – used for phase separation, as limit value switch for turbidity or

colour and for product identification.

00.41 = CALI – for the continuous measurement of turbidity and/or colour

00.47 = COMBINE – for the continuous measurement of turbidity (also fine

turbidity) and/or colour

, used in special applications.

Digital or analog operating mode

mA output connected to which parameter

The connection status is displayed for all read and write operations. When a transmission error

occurs when writing or reading data, this is indicated in the text field under Connection status.

Change-over

Here you can toggle between BASIC and CALI or between BASIC and COMBINE (not possible on

InPro 8300 RAMS BASIC).

Calibration 1/2/3

This takes you to the InPro 8300 RAMS calibration mode. See section 6.

Correct

A new window opens where the InPro 8300 RAMS calibration can be adjusted to the results obtained

in the plant laboratory (function not included on InPro 8300 RAMS BASIC).

5.4 Operating Mode

The InPro 8300 RAMS has 2 operating modes:

• Digital

• Analog

5.4.1 Analog operating mode

Use

•

Preferably when different InPro 8300 RAMS parameters are to be monitored by an external control

system

• For signalling phase interfaces. Limit values are generated by the plant control system.

• Units of the InPro 8300 RAMS CALI or COMBINE type generally operate in the analog mode.

26 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

In analog mode, the digital signals are used as inputs to the InPro 8300 RAMS in order to connect an

external parameter to the mA output. The signals must be wired accordingly. Digital outputs must be

provided in the external control system for this purpose (see Electrical connection). Rash change-over

can cause damage to the external control unit! For details about wiring see page 13.

5.4.2 Digital operating mode

Upon program start and when a new project is created, analog operating mode is set by default.

If you wish to use the device in digital mode you can achieve this by clicking the ’Change-over

’ button

and confirming your selection by clicking ’Yes’ in the message box that opens. If you click ’No’ in the

message box, the system remains in analog mode.

Use

• For the identification of up to 8 different products which flow through the same pipe.

• For quality monitoring of products and to signal deviations from the tolerance.

• For signalling of phase interfaces between products with different turbidities or between clear or

coloured products.

The digital signals are used as InPro 8300 RAMS outputs here. The signals must be wired accordingly.

Digital inputs must be provided in the external control system for this purpose. Rash change-over can

cause damage to the external control unit! For details about wiring see page 13.

5.5 Zero Adjustment

Zero adjustment should be carried out after certain periods of time (approx. once a year).

The reference for all parameters is water! Before carrying out a zero adjustment, make sure that clean,

bubble-free water is flowing through the pipe.

5.5.1 Procedure

Adjustment without a connected PC

By pressing the red button for approx. 5 seconds. This sets the values for the concentration parameters to 400 and the values for the reflection parameters to 1000.

Adjustment when a PC is connected

When you have made sure that bubble-free, clean water is running through the pipe, that your PC is

connected to the InPro 8300 RAMS and that you have started RAMS CONFIG, click “Read measured values”. If the measured values for the concentration parameters deviate too much from 400 or if the

reflection parameters deviate too much from 1000, click “Set zero point”.

InPro 8300 RAMS Optical Product Monitor 27

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

Possible problems when setting the zero point

Should a value of 296 be displayed for one or several of the parameters, one reason for this may be

that the water does not meet the a/m requirements. It is essential that the water is clean and without

any bubbles to ensure stable conditions for setting the zero point and to ensure that the measured values do not fluctuate.

If these results are obtained despite a good water quality

, the relevant parameters cannot be used. You

should then check e.g. whether relative humidity is below 15%, as condensation may otherwise have been formed on the optical windows. Another reason could also be that the windows are dirty.

Repeat zero point setting if necessary.

6. InPro 8300 RAMS CALI/RAMS COMBINE – Suitable for Calibration

Instruments with the processor designation 00.41, 00.47 and 12.41 can be calibrated to a turbidity

or colour unit. When the program starts up and a InPro 8300 RAMS is connected, this instrument option is automatically identified. When the CALI function is used, InPro 8300 RAMS analog mode is

activated.

After switch-over, the InPro 8300 RAMS CALI (or COMBINE) can also be used as InPro 8300 RAMS

BASIC in digital mode. However, this is not possible vice-versa.

Meaning of display fields and function of the operating elements

• Calculated value 1/2/3 – The InPro 8300 RAMS can record up to 3 calibration curves. This

means it can be used for the continuous measurement of turbidity and colour at the same time.

•

Calibrated RAMS units – Display range 400…2000 corresponding to 4– 20mA in proportion to

the measuring range

• Start of measuring range – Zero point of the calibration

• End of measuring range – End point of the calibration

• Calibrated measuring value – Measuring value in the physical unit

• Unit – physical unit in which calibration was made

• Parameters – The RAMS parameter used for the calibration

• Correct – To adjust the InPro 8300 RAMS measured values to the values obtained in the

laboratory

• Calibration 1/2/3 – To access calibration mode

The InPro 8300 RAMS is calibrated at the factory before delivery. If it turns out that the unit requires recalibration for another measuring range, the manufacturer will supply a file which is loaded into the

InPro 8300 RAMS configuration from where it is transferred to the InPro 8300 RAMS.

Procedure

• Copy the file you have obtained into the directory “RAMS_Projekte” of drive C.

• Start RAMS CONFIG.

• Click “Load” in the “File” menu and select the file with the same name as the InPro 8300 RAMS’s

serial number.

• After a few seconds, a message box is displayed which asks you whether the new data should

now be transferred to the InPro 8300 RAMS. Click “Y

es” to finish the process. The InPro 8300

RAMS has now been recalibrated.

28 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

Correcting the Calibration

If there are any deviations between measurements made in the plant laboratory and the results produced by the InPro 8300 RAMS, the calibration can be corrected.

Procedure

• To do so, click the relevant “Correct” button in the “RAMS Configuration” screen for the parameter for

which deviations have been detected.

•

Enter the relevant values in the “RAMS” and “Laboratory value” fields.

• Decide on the type of correction and click the corresponding button.

Type of correction

• Correction of the entire curve – is used to obtain the same change in terms of percentage for the

entire range to be displayed. This function should only be executed once at the beginning of the

correction. When several products are produced, differ

ent deviations can occur. These should then

be eliminated by carrying out a partial correction.

• Partial correction – is used to eliminate the deviations relating to different products in the part of the

measuring range in which the measuring values of these products occur.

• Parallel displacement – Is used to shift the calibration curve by an absolute amount; it can also be

shifted through the zero point. It is preferably used for measuring ranges where the zero point of the

calibration does not start with the water value (400 for the concentration parameters or 1000 for

the reflection parameters), but on a higher colour or turbidity level.

InPro 8300 RAMS Optical Product Monitor 29

© 04/09 Mettler-Toledo AG, Greifensee InPro 8300 RAMS Optical Product Monitor

Printed in Switzerland 52 801 115

7 Yeast Pitching

Function

• InPro 8300 RAMS 1 = InPro 8300 RAMS CALI – Instrument with the lower serial number

–

Measures the basic turbidity of the wort in the measuring range 0…1000 EBC and transfers

the result to the parameter “Calculated value 1”.

• InPro 8300 RAMS 2 = InPro 8300 RAMS BASIC or InPro 8300 RAMS TCS

–

Monitors “yeast draw-off” so that metering can only be started when yeast has arrived at the

metering point.

Commissioning procedure

• Before commissioning using wort and yeast, the zero points of all units must be adjusted to water.

•

When wort (without yeast) runs through the pipe, the turbidity values measured by the two

InPro 8300 RAMS units must be identical. If the measured values deviate, one of the two units mus

be adjusted using the RAMS CONFIG program.

• This correction must be repeated if necessary.

• While yeast is being added, the measured values for the yeast cell count obtained by InPro 8300

RAMS 2 must be verified in the laboratory. Several tests in the laboratory are advisable. If the

deviation is detected several times, the measured value also needs to be corrected.

• If different setpoints are used for different types of beer, the measuring results should be checked in

the laboratory for each of these setpoints and the values corrected if necessary.

30 InPro 8300 RAMS Optical Product Monitor

InPro 8300 RAMS Optical Product Monitor © 04/09 Mettler-Toledo AG, Greifensee

52 801 115 Printed in Switzerland

Electrical connection of the InPro 8300 RAMS units

InPro 8300 RAMS 1 is the unit upstream of the metering point

InPro 8300 RAMS 2 is the unit downstream of the metering point

M+/M- are connections for the uninterruptible measurement of the output currents of the InPro 8300

RAMS units.

The outputs are non-floating and are measured against L-.

The 4–20 mA output for the yeast cell count is available at terminal 20 of the connection module.

The PC can be connected to the socket of the connection module. By toggling the switch you can switch

between the communication with InPro 8300 RAMS 1 and InPro 8300 RAMS 2.

Before switch-over always end the program, after switch-over restart the pr

ogram, since otherwise the

calibration files in the RAMS_Projekte folders might be overwritten. Should this happen, you will find a

backup in the folder c:\RAMS_Projekte\Factory which you can copy to c:\RAMS_Projekte.

Loading...

Loading...