Mettler Toledo InPro 8200/S, InPro 8000, InPro 8050, InPro 8200/H, InPro 8100/S Instruction Manual

InPro®8000 Series

52 800 247

InPro®8000 Series

Turbidity sensors

Trübungssensoren

Sondes de turbidité

Instruction manual

Bedienungsanleitung

Instructions d'utilisation

English page 3

German page 21

French page 39

InPro®8000 Series 3

© 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee InPro®8000 Series

Printed in Switzerland 52 800 247

InPro®8000 Series

Turbidity sensors

Instruction manual

Subject to technical changes without prior notice.

© It is strictly forbidden to reprint this instruction manual or any parts

thereof without the written permission of Mettler-Toledo GmbH, Process

Analytics, Industrie Nord, 8902 Urdorf, Switzerland. No section or excerpt

whatsoever may be reproduced or with the assistance of electronic systems be edited, duplicated or distributed, in particular in the form of

photocopies, photographs, magnetic media or other recording methods.

All rights reserved, especially the right of duplication and translation as

well as in regard to patent and registration rights.

Mettler-Toledo GmbH, 8606 Greifensee, Switzerland

4 InPro®8000 Series

InPro®8000 Series © 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee

52 800 247 Printed in Switzerland

Contents

1 Product description 5

1.1 Introduction 5

1.2 Equipment and scope of delivery 6

1.3 Technical data 6/7/8

2 Safety 9

2.1 Application compatibility 9

2.2 Proper utilization 9

2.3 Safety measures 9

2.4 Ex-Declaration 10

2.4.1 Use in Ex-zones 10

2.4.2 Ex-Classification 11

3 Initial start-up 12

3.1 Handling 12

3.2 Installation in vessels/reactors 12

3.3 Installation in pipes 13

3.4 Calibration in open laboratory vessels 13

3.5 Fiber optic cable extensions 13

4 Maintenance and troubleshooting 14

4.1 Conditions of warranty 14

4.2 Maintenance 14

5 Removal from operation, storage, disposal 15

5.1 Removal from operation 15

5.2 Storage 15

5.3 Disposal 15

6 Dimensional drawings 16

7 Ordering information 17

7.1 Sensors 17

7.2 Accessories 17/18

8 Certificates 19

8.1 Material certificate 19

InPro®8000 Series 5

© 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee InPro®8000 Series

Printed in Switzerland 52 800 247

1. Product description

1.1 Introduction

We thank you for your decision to purchase a METTLER TOLEDO

InPro®8000 Series fiber optic measuring sensor with operation based on

the principle of backward scattered light.

Please keep this instruction manual in a safe place where it is readily to

hand for users of this sensor. If you have any questions regarding function

of the sensor and ancillary equipment, or if you consider that the descriptions/instructions do not tally or are lacking, please contact your nearest

METTLER TOLEDO Authorized Distributor, who will be pleased to provide

assistance.

Markings

The markings labeled on each sensor state the following information:

METTLER TOLEDO

Serial no. xxxxxx Order no. 52 xxx xxx

The code following the model designation of the InPro®8100 and

InPro®8200 Sensors as printed on the package label provides information

on the shaft material, sealing material for the optical window (if present),

and the length of the shaft in mm.

e.g. InPro®8200/S/Kalrez®-FDA/205

with S = stainless steel shaft DIN1.4435 or 1.4404 (316L)

Kalrez®-FDA 6230 window seal

shaft length = 205 mm (8.07").

In addition:

H = Hastelloy C276 shaft

Epoxy = Epoxy bonded window

See also chapter 7.1: Ordering information sensors.

6 InPro®8000 Series

InPro®8000 Series © 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee

52 800 247 Printed in Switzerland

1.2 Equipment and scope of delivery

Scope of delivery

The sensors of the InPro®8000 Series are delivered ready for use including

fiber optic cable. Each sensor is accompanied by this instruction manual.

A METTLER TOLEDO Process System for the measurement of turbidity or of

suspended particles is completed by a METTLER TOLEDO Turbidity Transmitter Type Trb8300 (order no. 52 800 204). Detailed information for

calibration of the measuring system can be found in the following relevant

transmitter instruction manuals:

German Order no. 52 800 243

English Order no. 52 800 244

French Order no. 52 800 245

Packaging

The packaging consists of cardboard and foamed plastic. Safekeep the

packaging for later use during storage or transportation of the sensor. Should

you wish to dispose of the packaging material, please observe your local

regulations as well as those data and instructions given in chapter 5.3 of

this manual.

Unpacking and inspection

Please check the sensors immediately during unpacking in order to

determine possible damage or missing items. Any irregularities should

immediately be notified to your carrier and to your supplier.

1.3 Technical data

Function

Sensors of the InPro®8000 Series are optical sensors which measure the

concentration of suspended particles in a liquid medium on the basis of the

principle of backscattered light. The Transmitter Trb8300 is equipped with

a LED which beams a light – almost in the infra-red range (wavelength 880

nm) – via a fiber optic cable into the liquid medium. If the light hits on particles, then it is scattered in all directions. The light scattered at an angle of

InPro®8000 Series 7

© 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee InPro®8000 Series

Printed in Switzerland 52 800 247

180° (backscattered light) is captured and led back via a fiber optic cable

to a photodiode in the transmitter, processed as photocurrent and the

signal transformed into a value for the transmitter display.

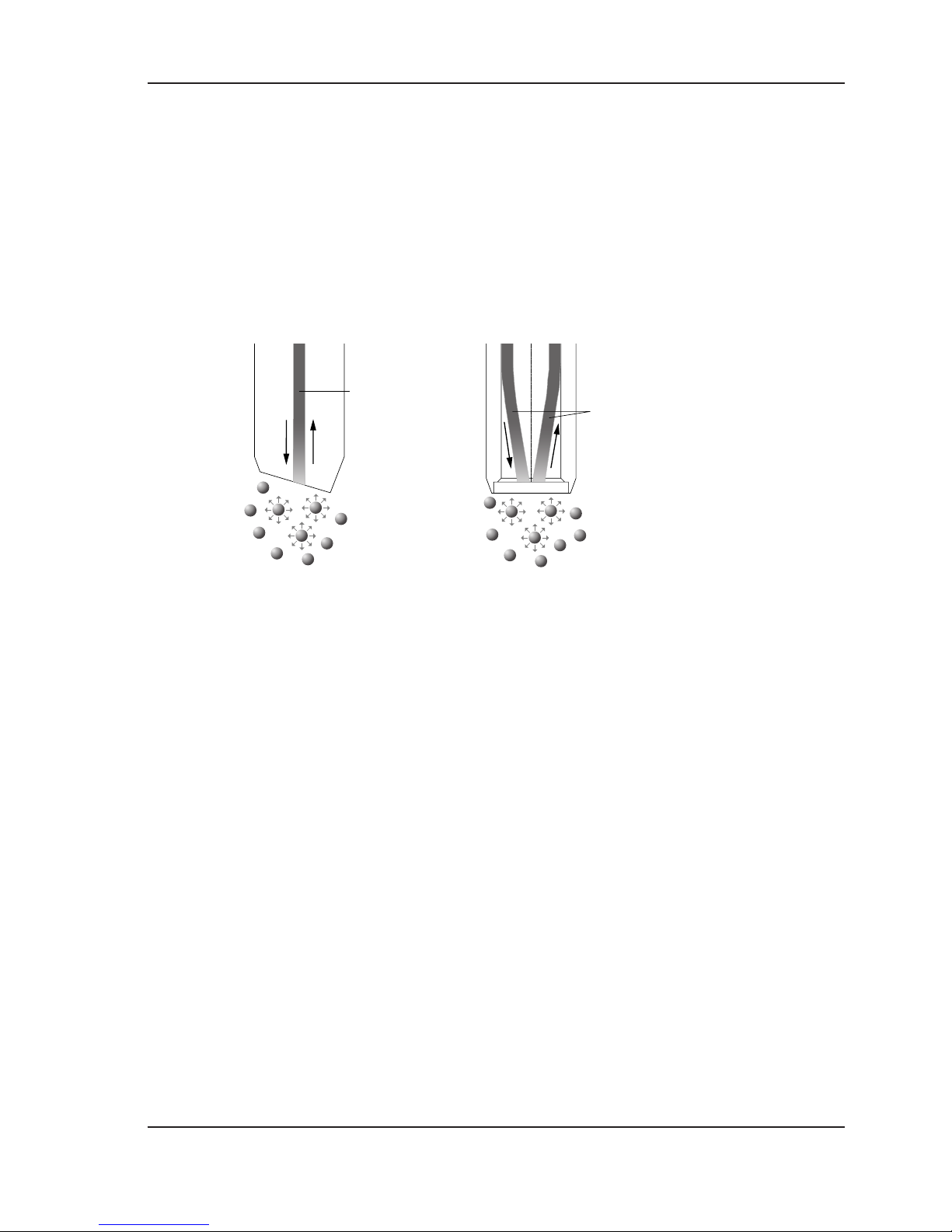

The sensors are divided into two types, single and dual optical fiber

sensors. The difference relates to the number of optical fibers present at the

end (nose) of the sensor shaft.

At low particle concentrations, the measuring range is expressed in FTU

(Formazin Turbidity Units). At high concentrations, the measurements are

given in grams of suspended solids per liter of sample volume, using

diatomaceous earth as reference substance.

optical fiber

optical fibers

8 InPro®8000 Series

InPro®8000 Series © 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee

52 800 247 Printed in Switzerland

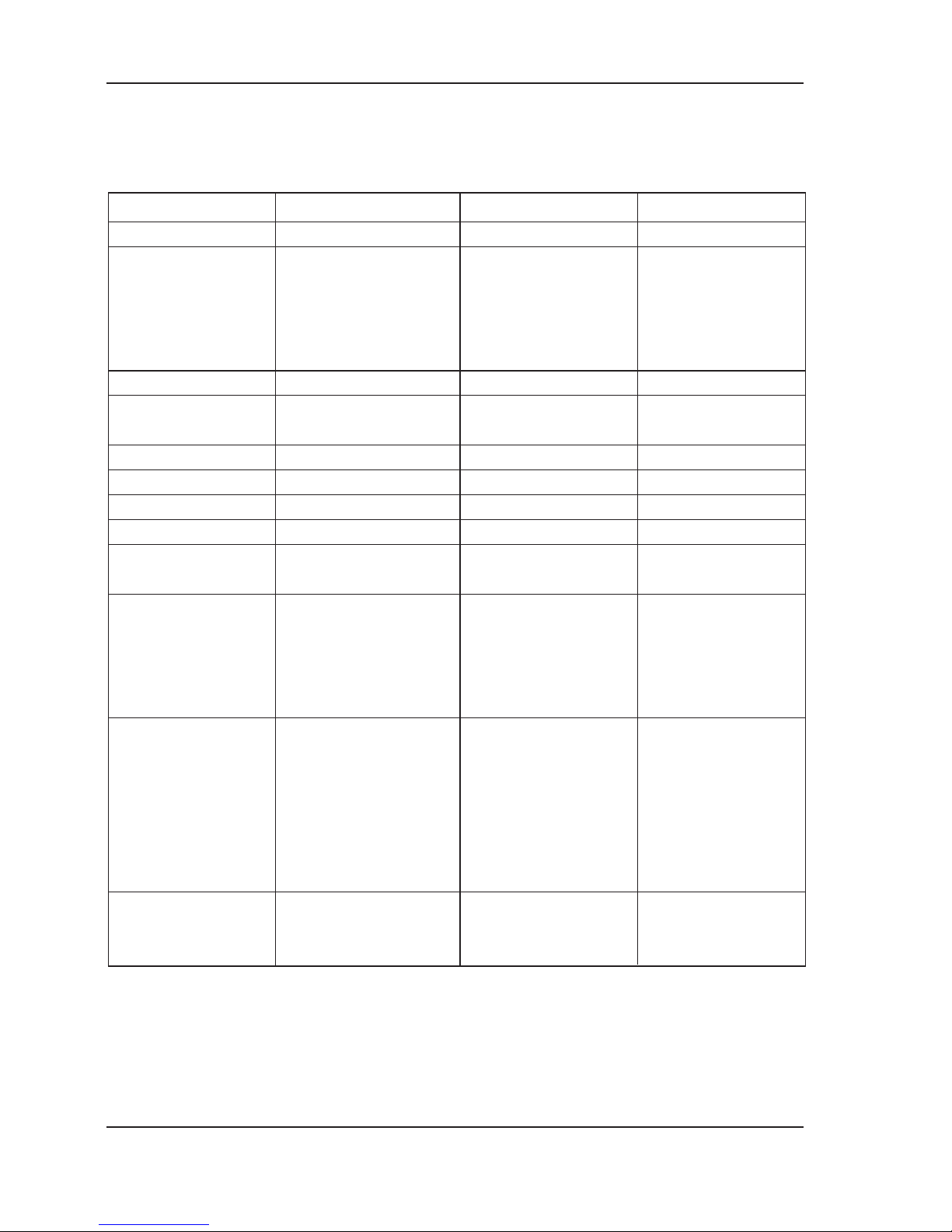

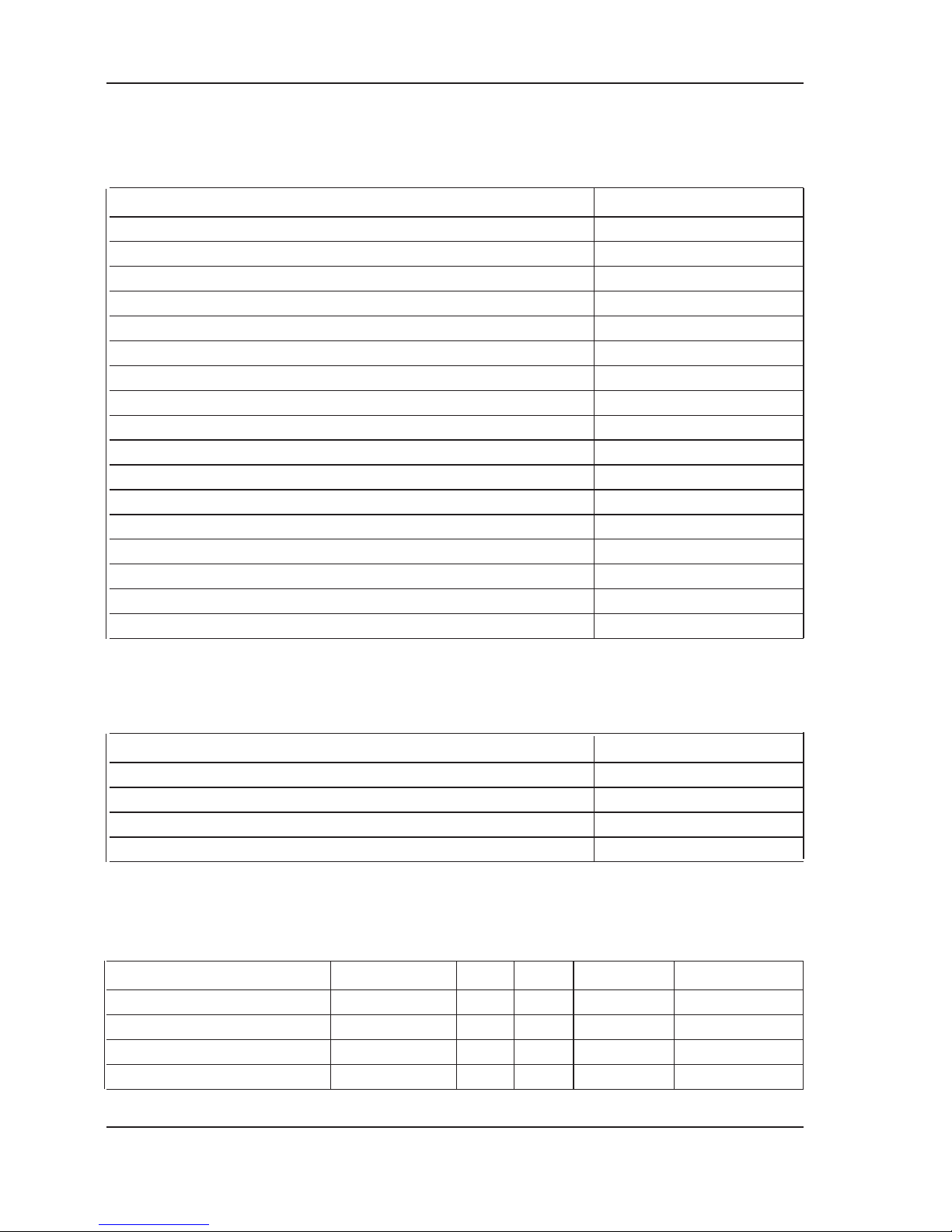

Technical data

Technical data InPro®8200/S(H) InPro®8100/S InPro®8050

Meas. principle dual fiber single fiber single fiber

Shaft material DIN1.4435 or 1.4404 1.4435 or 1.4404 PSU (Polysulfone)

(316L) (316L)

or Hastelloy C276

(available only with

Epoxy sealed window)

Shaft diameter 12 mm 12 mm 12 mm

Shaft length 120, 205, 120, 205, 120 mm

297 or 407 mm 297 or 407 mm

Window material Sapphire without window Sapphire spigot

O-ring sealing Viton®-FDA Viton®-FDA Viton®-FDA

Process adaption Pg13.5 Pg 13.5 Pg13.5

Plug 2 x SMA 2 x SMA 2 x SMA

Measuring range 5 FTU…4000 FTU 10 FTU…4000 FTU 10 FTU…4000 FTU

0…30 g/l 0…250 g/l 0…250 g/l

Pressure range 0…6 bar (0…87 psi) 0…6 bar (0…87 psi) 0…2 bar (0...29 psi)

with Kalrez®-FDA sealed

window

0...16 bar (0...232 psi)

with Epoxy bonded window

Temperature range –10…130 °C –30…130 °C 0…60 °C

(14…266 °F) (–22…266 °F) (32…140 °F)

with Kalrez®-FDA sealed

window

–30…130 °C

(–22…266 °F) with

Epoxy bonded window

Steam-sterilizable 130 °C (only with 130 °C non-sterilizable

Kalrez®-FDA sealed

window)

Subject to technical changes.

All sensors fall into the category described in Article 3, Paragraph 3 of the Pressure

Equipment Directive, 97/23/EC.

InPro®8000 Series 9

© 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee InPro®8000 Series

Printed in Switzerland 52 800 247

2. Safety

2.1 Application compatibility

The wetted material parts of the sensor (shaft, window, window sealing material, O-ring) can under circumstance be non-compatible with the particular composition of the process medium and/or of the operating conditions. Responsibility to verify application compatibility lies wholly with the

user.

The compatibility of different types of material are outlined on http://www.

coleparmer.com/techinfo/chemcomp.asp

. Mettler-Toledo GmbH, Process

Analytics accepts no responsibility whatsoever for the correctness or accuracy of such details.

2.2 Proper utilization

METTLER TOLEDO InPro®8000 Series sensors are intended solely for the

measurement of suspended particles or turbidity in aqueous solutions in

industrial applications.

Any other use, or any operation over and above that intended by the

manufacturer, are deemed to be non-permissible and incorrect, and can

lead to harm or injury to material/equipment and persons. This is also

relevant for applications which do not comply with the technical data of the

sensor. For any damage possibly arising from such misuse, the user

assumes full and sole responsibility.

2.3 Safety measures

The sensors InPro®8000 Series have been manufactured in line with

state-of-the-art technology and in accordance with accepted technical

safety regulations. Nevertheless, the sensors can still represent a source of

risk and danger:

– if the sensors are operated by insufficiently trained personnel,

– if the sensors are employed incorrectly or not as intended by

the manufacturer

– if the sensors are not regularly maintained or serviced.

10 InPro®8000 Series

InPro®8000 Series © 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee

52 800 247 Printed in Switzerland

Local legislation and regulations must be observed at all times. Such

stipulations do not form an integral part of this instruction manual.

It is on principle necessary for persons handling or using the sensors

to wear personal safety outfit such as protective goggles and protective

clothing.

The user is responsible for the instruction and training of personnel. In this

respect, additional copies of the instruction manual can be ordered from

your supplier. This instruction manual is an essential element of the sensor equipment and must at all times be readily to hand for operators

directly at the location of employment of the sensors.

Before the sensor is removed from the process/process adapter, it must be

ensured that the process pressure has been reduced to a safe level and the

process temperature lowered to a safe range. Any escape of hot process

medium under pressure can cause damage to material/equipment or injury to persons.

No modification whatsoever may be carried out on the sensors. Any

unauthorized modification or manipulation of the sensors results in immediate expiry of the full scope of warranty granted by the manufacturer.

2.4 Ex-Declaration

2.4.1 Use in Ex-zones

Note: Before installation in Ex-zones, please read and observe the follo-

wing guidelines:

Ex-Classification:

II 1/2G T6/T5/T4

Designation and number of the test certificate:

SNCH 03 ATEX 3565 X

InPro®8000 Series 11

© 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee InPro®8000 Series

Printed in Switzerland 52 800 247

2.4.2 Ex-Classification II 1/2G T6/T5/T4 according to

EU type test certificate SNCH 03 ATEX 3565 X

Introduction

The turbidity sensors METTLER TOLEDO InPro 81XX/82XX */*/*/* may be

used in accordance with EN 60079-14:1997 in the categories 1 to 3 (Zones 0 to 2) and gas groups IIA, IIB und IIC subject to explosion risk through

combustible materials in the range of temperature classes T4 to T6.

Radiation flux < 5,19 mW

Pulse energy < 0,519 µJ

Mean radiation flux < 0,13 mW

Mean intensity of irradiation

at end of fiber-optic light guide < 0,458 mW/mm2

Irradiation H am

at end of fiber-optic light guide <

1,835 µJ/mm2

Turbidity sensor operated in conjunction with transmitter Trb 8300.

Special conditions

The maximum permissible ambient temperature for each individual temperature class is as shown in the following table:

Temperature class Max. ambient temperature

T 6 80 °C

T 5 95 °C

T 4 130 °C

– The turbidity sensors METTLER TOLEDO InPro 81XX/82XX */*/*/* may

only be used in the suitable METTLER TOLEDO housings InFit Typ 76**** or InTrac Typ 7**-*** in areas subject to explosion risk.

– The measuring system drawings must be followed for installation.

– The metal body of the turbidity sensors as well as the safety weld-in

sockets and housings METTLER TOLEDO InFit Typ 76*-*** and InTrac

Typ 7**-*** must be electrically connected to the potential equalizing

system of the installation.

12 InPro®8000 Series

InPro®8000 Series © 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee

52 800 247 Printed in Switzerland

– The metal body of the turbidity sensors as well as the safety weld-in

sockets METTLER TOLEDO housing InFit Typ 76*-*** and InTrac 7**-***

are, if necessary, to be included into the recurring pressure test of the unit.

– The turbidity sensors may only be operated in conjunction with the

transmitter Trb 8300.

3. Initial start-up

3.1 Handling

The fiber optic cables have a core of Hard Clad Silica (HCS) fibers. When

laying fiber optic cables, the bend radius must always exceed at least

10 cm (4"). Fiberoptic cables may never be shortened independently.

Fitting of the SMA plug requires special tooling. The transparent plastic cap

on the sensor is to be removed before use. Any formation of deposits of

solid particles on the surface is to be avoided. Gas bubbles in the process

medium are also able to produce a signal and are therefore to be avoided

wherever possible. If this is not viable, please refer to the instruction

manual of the METTLER TOLEDO Transmitters Trb8300 (chapter:

«Calibration»).

3.2 Installation in vessels/reactors

The turbidity sensors are to be installed at a distance of at least 10 cm (4")

from the walls of the vessel, agitator and other internals, in order to prevent

disturbances through reflections. When employing special METTLER

TOLEDO retractable housings InTrac with modified immersion tubes, the

installation guideline valid for each individual housing is to be observed.

This step likewise, is to avoid measurement disturbances arising from

irrelevant light reflections (see chapter 7.2: «Accessories/Housings»).

InPro®8000 Series 13

© 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee InPro®8000 Series

Printed in Switzerland 52 800 247

3.3 Installation in pipes

The turbidity sensors are to be installed such that the distance from the pipe

walls is at least 10 cm (4"). If this is not feasible in pipes of small diameter, then the sensor can be installed sloped, at an angle of 15…45° or, alternatively, in a knee bend. The pipe must always be completely full of liquid.

3.4 Calibration in open laboratory vessels

If the turbidity measuring system is calibrated off-line, it is recommended

to use the METTLER TOLEDO calibration tool, «CaliCap» (order no. 52 800

210), for fitting on the sensor shaft. If «CaliCap» is not used, a minimum

distance of 10 cm (4") to the vessel walls has to be observed as well.

During calibration, the sample should be stirred in order to prevent the

sedimentation of solid particles.

3.5 Fiber optic cable extensions

Fiber optic cables are available according to the list in chapter 7.2

«Accessories». The duplex cable extensions are supplied complete with

four fitted SMA plugs and two couplings. The two SMA plugs of the sensor

fixed cable are to be screwed hand-tight onto the couplings. Two SMA plugs

of the extension cable can then also be screwed by hand onto the couplings

in any order. To protect the cable connection from dust and splashwater, it

is recommended to use the METTLER TOLEDO Connection Box IP65

(Nema 4X) (order no. 52 800 241).

If extension cables are installed subsequently at a later date, the

measuring system has to be newly calibrated (see instruction manual for

the METTLER TOLEDO Transmitters Trb8300, chapter: «Calibration»).

14 InPro®8000 Series

InPro®8000 Series © 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee

52 800 247 Printed in Switzerland

4. Maintenance and troubleshooting

4.1 Conditions of warranty

METTLER TOLEDO guarantees the quality of materials and workmanship

within a narrow range of manufacturing tolerances, so that the product

purchased is free from any substantial deviations from material and

manufacturing quality standards. The warranty is valid for the period of one

year from date of delivery ex works. If within this warranty period, any

repair or replacement should become necessary, and such cause is not due

to misuse or incorrect application, please return the sensor, carriage paid,

to your appropriate METTLER TOLEDO agency. Repair work will be carried

out free of charge. Final decision on whether the defect is due to a manufacturing error or to incorrect operation of the sensor by the customer is made

at the option of the Customer Service department of METTLER

TOLEDO. After expiry of the period of warranty, faulty sensors will be

repaired or replaced on an exchange basis against payment of the costs

involved.

4.2 Maintenance

Dirty or contaminated sensors can deliver incorrect measurement values.

If fouling is presumed, the sensor is to be removed and cleaned. Suitable

cleaning solutions are mild detergents or strongly diluted acids (< 0.5 %

by wt.) such as hydrochloric acid.

When handling acids, precautionary measures are to be taken at all times.

InPro®8000 Series 15

© 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee InPro®8000 Series

Printed in Switzerland 52 800 247

5. Removal from operation, storage, disposal

5.1 Removal from operation

The sensor is only conditionally subject to aging. When employed correctly as intended and appropriately maintained and serviced, the lifetime of

the sensor can extend to several years.

Before removing the sensor from the process/process adapter, it must be

ensured that the process pressure has been reduced to a safe level and the

process temperature lowered to a safe range. Any escape of hot process

medium under pressure can cause damage to material/equipment or

injury to persons.

After demounting, the sensor should first be flushed with clear water.

If the sensor incurs a defect, it can as a rule not be repaired and must

be disposed under observance of prevailing regulations.

5.2 Storage

If the sensor is not needed for use, it can be stored dry.

5.3 Disposal

Disposal is to be carried out by the user in line with valid local regulations.

The user must either deliver the sensor to an authorized private or public

collection undertaking, or dispose of it himself in accordance with the

regulations for such items/materials.

The packaging consists of:

– cardboard

– foamed plastic

The sensor is comprised of:

– shaft, O-ring, sealing and window material as per specification

– HCS fiber optic cable, PVC sheathing

– protective tube of DIN1.4435 (316L) or polyamide

16 InPro®8000 Series

InPro®8000 Series © 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee

52 800 247 Printed in Switzerland

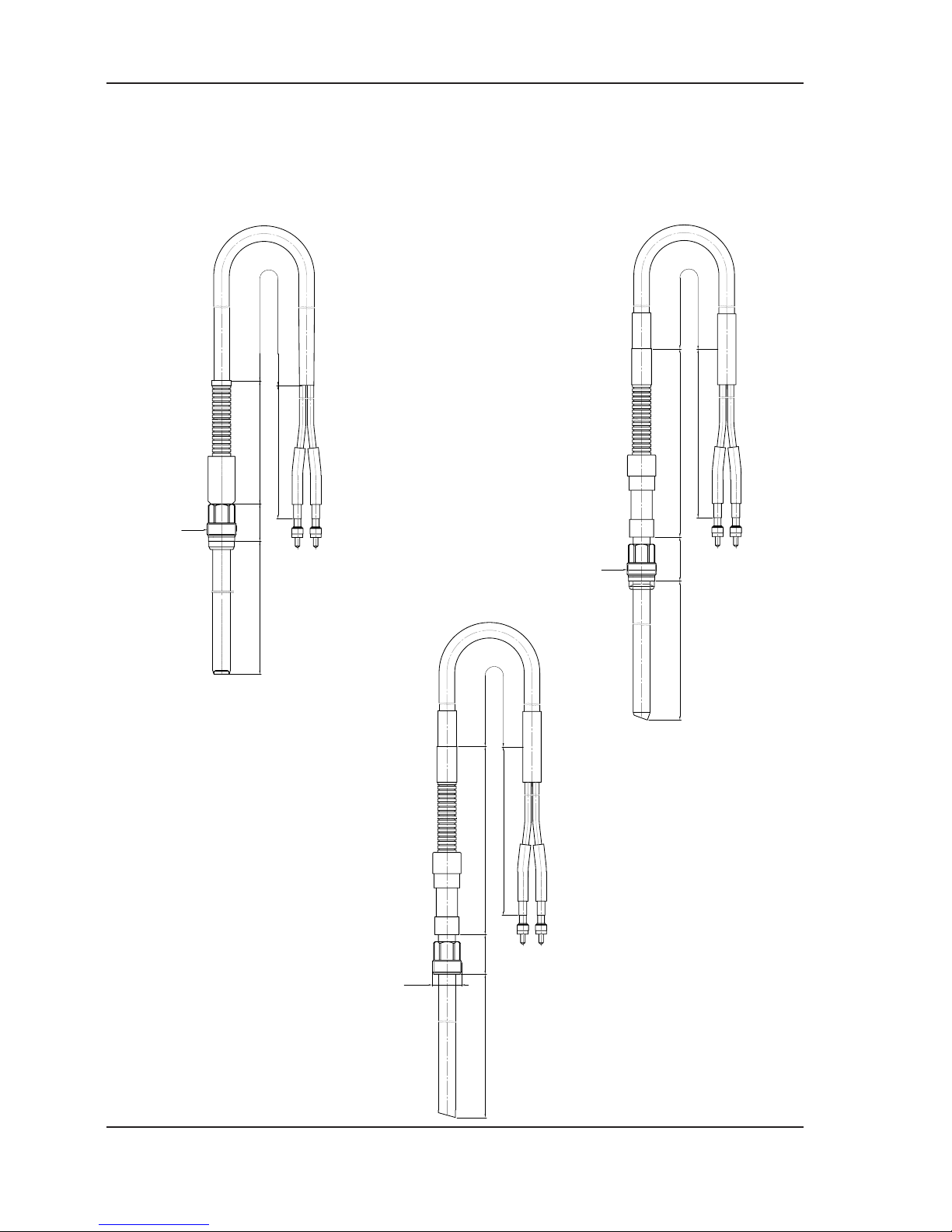

6. Dimensional drawings

InPro®8200/S(H) InPro®8100/S

InPro®8050

Pg13.5

122

26 1000 +/-30 4900 +/-50

300 +/-10

InPro8100/S

Typ a

120 mm 122 mm

205 mm 207 mm

297 mm 299 mm

407 mm 409 mm

Pg13.5

31

a

O-SMA

1900 +/-301000 +/-30

300 +/-10

InPro8200/S(H)/Epoxy

InPro8200/S/Kalrez®-FDA

Typ a

120 mm 120 mm

205 mm 205 mm

297 mm 297 mm

407 mm 406.5 mm

O-SMA

2350 +/-30520 +/-30

350 +/-10

27

a

Pg13.5

InPro®8000 Series 17

© 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee InPro®8000 Series

Printed in Switzerland 52 800 247

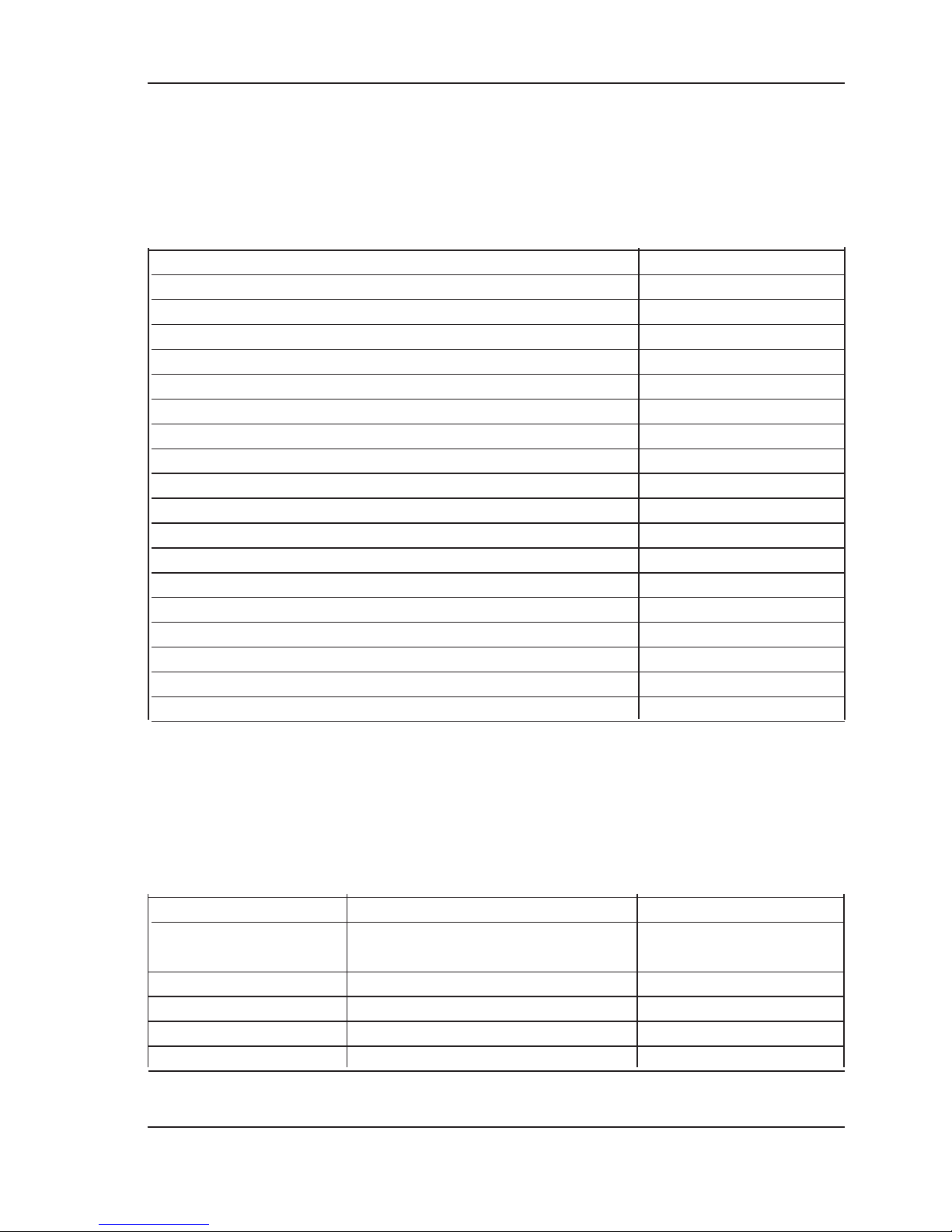

7. Ordering information

7.1 Sensors

Designation Order no.

InPro8050 52 800 209

InPro8100/S/120 52 800 205

InPro8100/S/205 52 800 206

InPro8100/S/297 52 800 207

InPro8100/S/407 52 800 208

InPro8200/S/Epoxy/120 52 800 216

InPro8200/S/Epoxy/205 52 800 217

InPro8200/S/Epoxy/297 52 800 218

InPro8200/S/Epoxy/407 52 800 219

InPro8200/H/Epoxy/120 52 800 220

InPro8200/H/Epoxy/205 52 800 221

InPro8200/H/Epoxy/297 52 800 222

InPro8200/H/Epoxy/407 52 800 223

InPro8200/S/Kalrez-FDA/120 52 800 224

InPro8200/S/Kalrez-FDA/205 52 800 225

InPro8200/S/Kalrez-FDA/297 52 800 226

InPro8200/S/Kalrez-FDA/407 52 800 227

InPro8200/H/Kalrez-FDA/407* 52 800 215

* shaft material Hastelloy C22

7.2 Accessories

O-rings, for all sensors:

Standard O-ring Additional O-rings Order no.

Viton®-FDA 20 302 1000

(10.77 x 2.62 mm)

Silicon-FDA (10.77 x 2.62 mm) 20 301 1136

Kalrez®(10.77 x 2.62 mm) 20 304 1000

Kalrez®-FDA (10.77 x 2.62 mm) 20 304 1034

EPDM-FDA (10.77 x 2.62 mm) 20 303 1206

18 InPro®8000 Series

InPro®8000 Series © 01/04 Mettler-Toledo GmbH, CH-8606 Greifensee

52 800 247 Printed in Switzerland

Fiber optic cable extensions including two couplings, for all sensors:

Designation Order no.

Fiber-Kit, 3 m (10 ft) 52 800 228

Fiber-Kit, 5 m (15 ft) 52 800 229

Fiber-Kit, 6 m (18 ft) 52 800 230

Fiber-Kit, 10 m (30 ft) 52 800 231

Fiber-Kit, 15 m (45 ft) 52 800 232

Fiber-Kit, 20 m (60 ft) 52 800 233

Fiber-Kit, 25 m (75 ft) 52 800 234

Fiber-Kit, 30 m (100 ft) 52 800 235

Fiber-Kit, 40 m (130 ft) 52 800 236

Fiber-Kit, 45 m (150 ft) 52 800 172

Fiber-Kit, 50 m (165 ft) 52 800 237

Fiber-Kit, 65 m (200 ft) 52 800 238

Fiber-Kit, 75 m (230 ft) 52 800 177

Fiber-Kit, 90 m (275 ft) 52 800 239

Fiber-Kit, 100 m (330 ft) 52 800 154

Fiber-Kit, 125 m (380 ft) 52 800 158

Fiber-Kit, 170 m (520 ft) 52 800 196

Additional accessories, for all sensors:

Designation Order no.

«CaliCap» 52 800 210

Couplings 52 800 240

Coupling box IP65 52 800 241

Swagelok adapter NPT1/2"

1)

52 800 242

1)

only to be used with InPro®8200/S/Epoxy Sensors for pressure range 0…60 bar (0…870 psi)

Housings for InPro®8100 and InPro®8200 (examples):

Designation Material H a O-ring Order no.

InFit761-25 CP/70/4435/Vi DIN1.4435 70 120 Viton

®

00 761 3042

InFit761-25 CP/70/C22/Vi Hastelloy C22 70 120 Viton

®

00 761 3105

InFit761-25BTB/70 DIN1.4435 70 120 Silicon-FDA 00 761 3093

InFit761-25CIP/70 3.1B DIN1.4435 70 120 Silicon-FDA 52 400 491

Loading...

Loading...