Mettler Toledo InPro 7250 Instruction Manual

InPro®7250

52 002 799

InPro®7250 Series

Inductive Conductivity Sensors

Induktive Leitfähigkeitsmesszellen

Sondes de conductivité inductive

Instruction Manual

Bedienungsanleitung

Instructions d’utilisation

1258

2 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

English Page 3

Deutsch Seite 25

Français Page 49

InPro®7250 Series 3

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

InPro®7250 Series

Instruction Manual

© It is forbidden to reprint this Instruction Manual in whole or part.

No part of this manual may be reproduced in any form, or modified,

copied or distributed using electronic systems, in particular in the

form of photocopies, photographs, magnetic or other recordings,

without written consent of Mettler-Toledo GmbH, Process Analytics,

CH- 8902 Urdorf, Switzerland.

All rights reserved, in particular reproduction, translation

and patenting/registration.

4 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

Contents

1 Introduction ..................................................5

2 Important notes ............................................6

2.1 Notes on operating instructions................................6

2.2 Intended use..........................................................6

2.3 Safety instructions ..................................................7

2.4 Use in hazardous zones..........................................8

2.5 Ex-classification ATEX............................................8

2.5.1 Introduction ..........................................................8

2

.5.2 Rated data ............................................................8

2.5.3. Special conditions for safe use ................................9

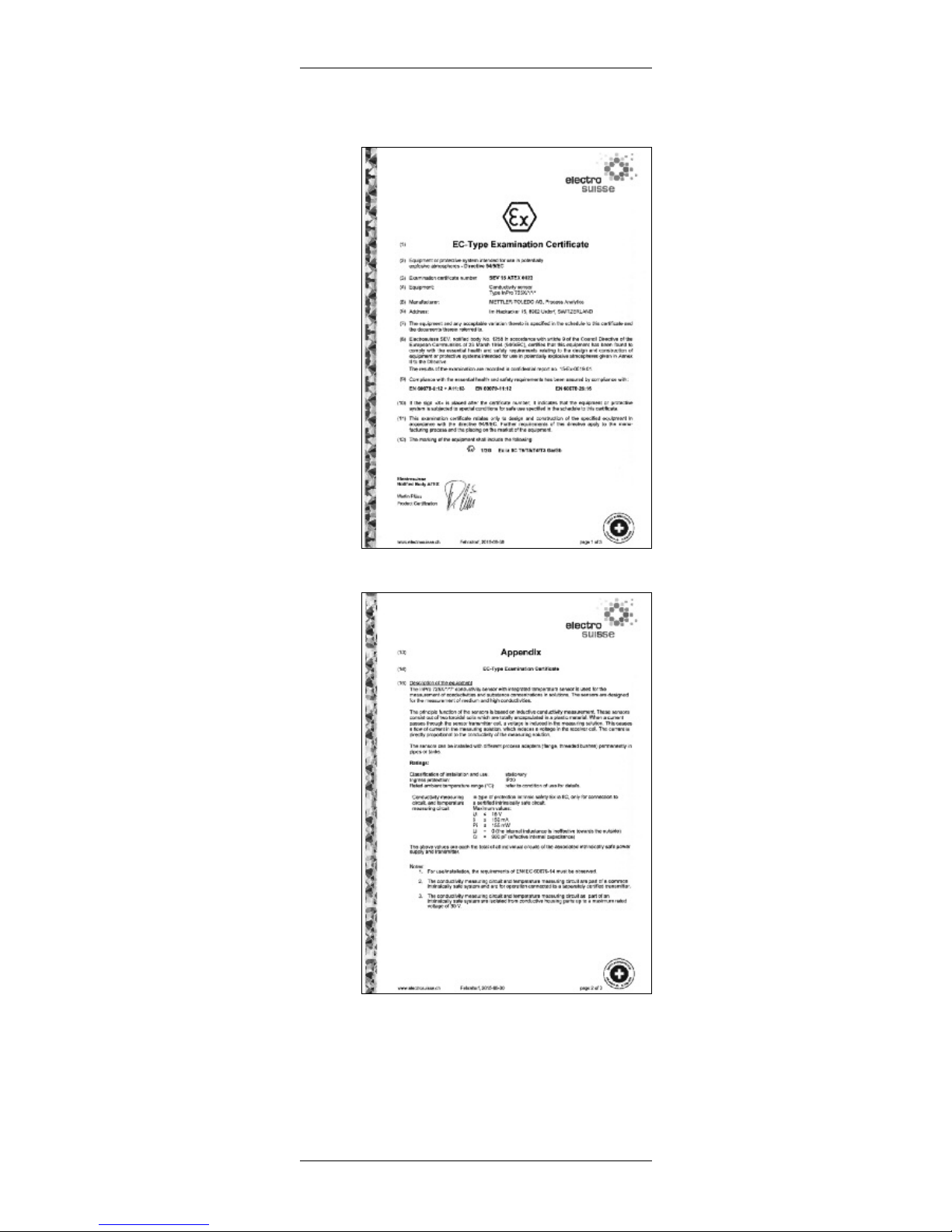

2.5.4 ATEX certificate ....................................................10

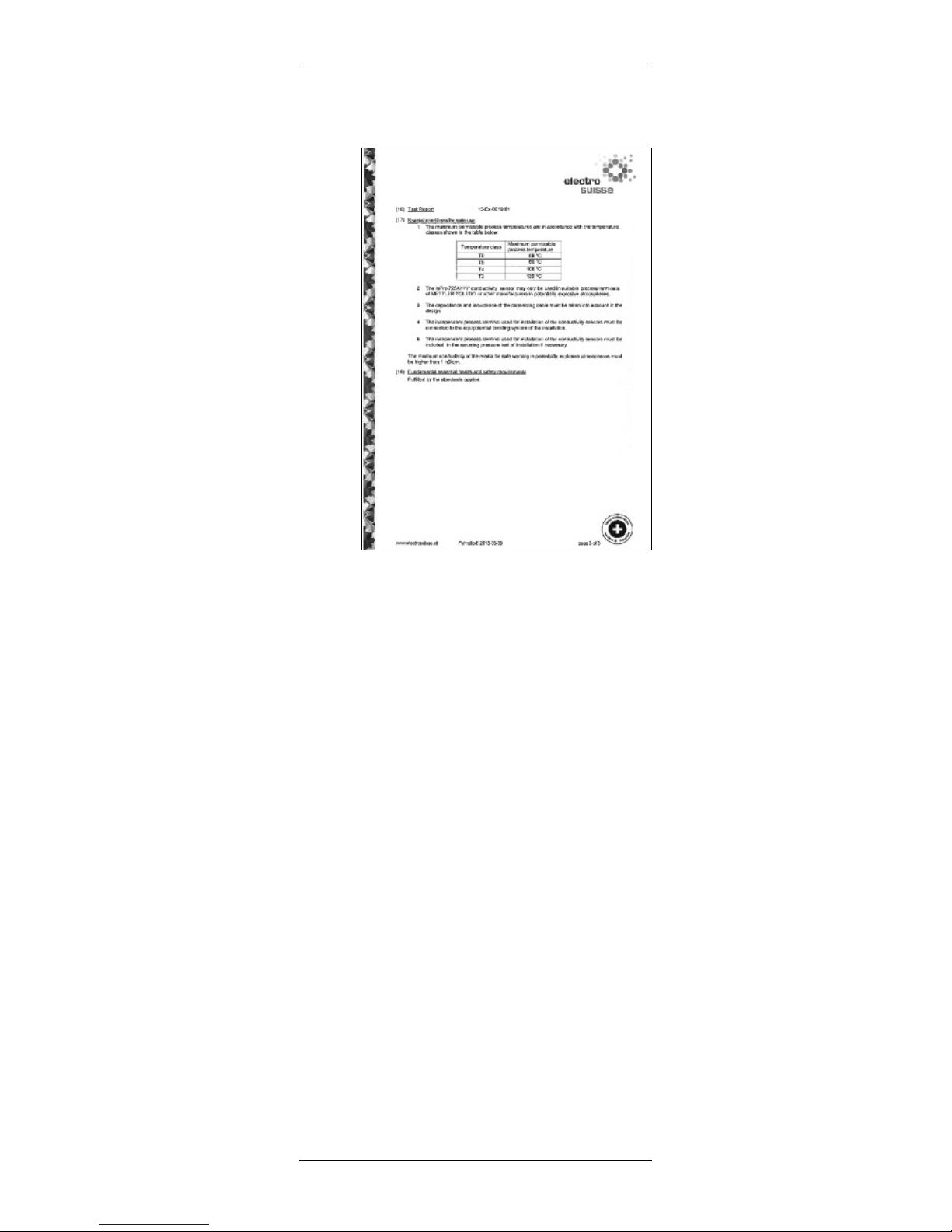

2.5.5 IECEx Certificate of Conformity ..............................12

2.6 Ex-classification FM Approved ..............................14

2.7 Declaration of conformity ......................................15

3 Product description ....................................16

3.1 General information..............................................16

3.2 Principle ............................................................16

3.3 Sensor identification ............................................16

3.4 Sensor applications..............................................17

4 Installation, operation and maintenance ......18

4.1 Sensor installation................................................18

4.2. Connection of the sensor ......................................20

4.3 Flange installation................................................20

4.4 Bushing installation..............................................21

4.5 Immersion installation with an InDip 550 Ind ..........21

4.6 Sanitary installation..............................................22

4.7 Disposal ............................................................22

5 Product specifications ................................23

5.1. Sensor specifications............................................23

6 Ordering information ..................................24

6.1. Sensors ..............................................................24

6.2 Spare parts..........................................................24

6.3 Process Connections and Accessories ....................24

6.4 Transmitter M700(x), module Cond Ind 7700(x) ....25

6.5 Transmitter M400, (4-wire Transmitter) ..................25

InPro®7250 Series 5

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

1 Introduction

T

hank you for buying the InPro 7250 Series sensor from

METTLER TOLEDO.

The construction of the InPro 7250 Series sensors

employs leading edge technology and complies with

safety regulations currently in force. Notwithstanding

this, improper use could lead to hazards for the user or

a third-party, and/or adverse effects on the plant or other

equipment. Therefore, the operating instructions must

be read and understood by the persons involved before work is started with the sensor.

The instruction manual must always be stored close at

h

and, in a place accessible to all people working with

the sensor.

If you have questions, which are not or insufficiently

answered in this instruction manual, please contact your

METTLER TOLEDO supplier. They will be glad to assist

you.

6 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

2 Important notes

2.1 Notes on operating instructions

T

hese operating instructions contain all the information

needed for safe and proper use of the InPro 7250 Series

sensor.

T

he operating instructions are intended for personnel

entrusted with the operation and maintenance of the

sensors. It is assumed that these persons are familiar

with the equipment in which the sensor is installed.

Warning notices and symbols

This instruction manual identifies safety instructions and

additional information by means of the following

symbols:

This symbol draws attention to safety instructions and

warnings of potential danger which, if neglected, could

result in injury to persons and/or damage to property.

This symbol identifies additional information and

instructions which, if neglected, could lead to defects,

inefficient operation and possible loss of production.

2.2 Intended use

The sensors InPro 7250 Series are intended to be used

to measure conductivity and concentration of liquids, in

accordance with the data in this instruction manual. Any

use of these sensors which differs from or exceeds the

scope of use described in this instruction manual will be

regarded as inappropriate and incompatible with the

intended purpose.

The manufacturer/supplier accepts no responsibility

whatsoever for any damage resulting from such improper

use. The risk is borne entirely by the user/operator.

Other prerequisites for appropriate use include:

– compliance with the instructions, notes and require-

ments set out in this instruction manual.

– acceptance of responsibility for regular inspection,

maintenance and functional testing of all associated

components, also including compliance with local

operational and plant safety regulations.

– compliance with all information and warnings given

in the documentation relating to the products used in

conjunction with the sensor (housings, transmitters,

etc.).

– observance of all safety regulations governing the

equipment in which the sensor is installed.

InPro®7250 Series 7

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

– correct equipment operation in conformance with the

p

rescribed environmental and operational conditions,

and admissible installation positions.

–

consultation with METTLER TOLEDO Process Ana lytics in the event of any uncertainties.

2.3 Safety instructions

– The plant operator must be fully aware of the potential

risks and hazards attached to operation of the

particular process or plant. The operator is responsible for correct training of the workforce, for signs and

markings indicating sources of possible danger,

and for the selection of appropriate, state-of-the-art

instrumentation.

– It is essential that personnel involved in the commis-

sioning, operation or maintenance of these sensors

or of any of the associated equipment (e.g. housings,

transmitters, etc.) be properly trained in the process

itself, as well as in the use and handling of the

associated equipment. This includes having read and

understood this instruction manual.

– The safety of personnel as well as of the plant itself is

ultimately the responsibility of the plant operator. This

applies in particular in the case of plants operating in

hazardous zones.

– The conductivity sensors and associated components

have no effect on the process itself and cannot influence it in the sense of any form of control system.

– Maintenance and service intervals and schedules

depend on the application conditions, composition of

the sample media, plant equipment and significance

of the safety control features of the measuring system.

Processes vary considerably, so that schedules,

where such are specified, can only be regarded as

tentative and must in any case be individually

established and verified by the plant operator.

– Where specific safeguards such as locks, labels, or

redundant measuring systems are necessary, these

must be provided by the plant operator.

– A defective sensor must neither be installed nor put

into service.

– Only maintenance work described in this operating in-

struction may be performed on the sensors.

– No modifications to the sensors and the accessories

are allowed. The manufacturer accepts no respon sibility for damages caused by unauthorised modi fications. The risk is borne entirely by the user.

8 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

2.4 Use in hazardous zones

F

or an installation in hazardous zones please read the

guidelines following hereafter:

Ex-classification ATEX:

II 1/2G Ex ia IIC T6/T5/T4/T3 Ga/Gb

Number of the test certificate:

SEV 15 ATEX 0123

IECEx SEV 15.0011X

2.5 Ex-classification ATEX

2.5.1 Introduction

According to Directive 94/9/EC (ATEX 95) Appendix I,

InPro 725X/*/*/* conductivity sensors are devices of

equipment group II, category 1/2G which can be used

in zone 0/1 or 1/2 or 1 or 2 as well as gas groups IIA,

IIB and IIC, which are potentially explosive due to combustible substances in the temperature classes T3 to T6.

For use/ installation, the requirement of

EN/IEC 60079-14 must be observed.

The conductivity measuring circuit and temperature

measuring circuit are part of a common intrinsically safe

system and are for operation connected to a separately

certified transmitter.

The conductivity measuring circuit and temperature

measuring circuit as part of an intrinsically safe system

are isolated from conductive housing parts up to a

maximum rated voltage of 30 V.

The sensors can be installed with different process

adapters (flange, threaded bushes) permanently in pipes

or tanks.

2.5.2 Rated data

Conductivity measuring circuit, and temperature measuring circuit1:

In type of protection intrinsic safe Ex ia IIC, only for

connection to a certified intrinsically safe circuit.

Maximum values:

U

i

≤ 16 V, Ii≤ 150 mA, Pi≤ 155 mW

Li= 0 (the internal inductance is ineffective towards the

outside)

C

i

= 900 pF (effective internal capacitance)

The above values are each the total of all individual circuits of the associated intrinsically safe power supply

and transmitter.

InPro®7250 Series 9

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

2.5.3. Special conditions for safe use

1. The maximum permissible process temperatures are

in accordance with the temperature classes shown in

the table below:

Temperature class Maximum permissible

process temperature

T6 68 °C

T5 80 °C

T4 108 °C

T3 130 °C

2

. The InPro 725X/*/*/* conductivity sensors may only

be used in suitable process terminals of METTLER

TOLEDO or other manufacturers in potentially explosive atmospheres.

3. The capacitance and inductance of the connecting

cable must be taken into account in the design.

4. The independent process terminal used for installa -

tion of the conductivity sensors must be connected to

the equipotential bonding system of the installation.

5. The independent process terminal used for installa-

tion of the conductivity sensors must be included

in the recurring pressure test of the installation if

necessary.

6. The minimum conductivity of the media for safe

working in potentially explosive atmospheres must be

higher than 1 nS/cm.

10 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

2.5.4 ATEX certificate

Page 1 of 3

Page 2 of 3

InPro®7250 Series 11

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

Page 3 of 3

12 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

2

.5.5 IECEx Certificate of Conformity

Page 1 of 4

Page 2 of 4

InPro®7250 Series 13

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

P

age 3 of 4

Page 4 of 4

14 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

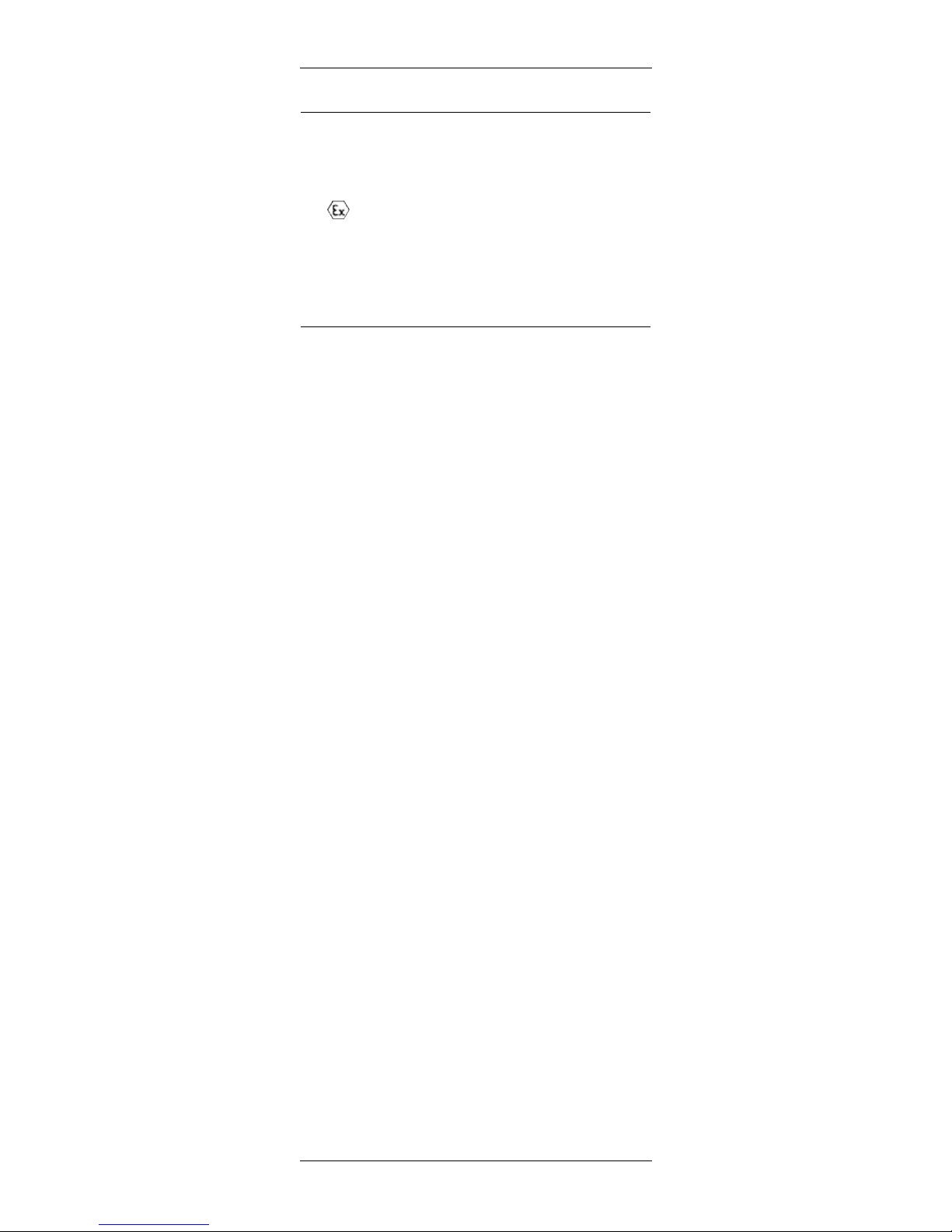

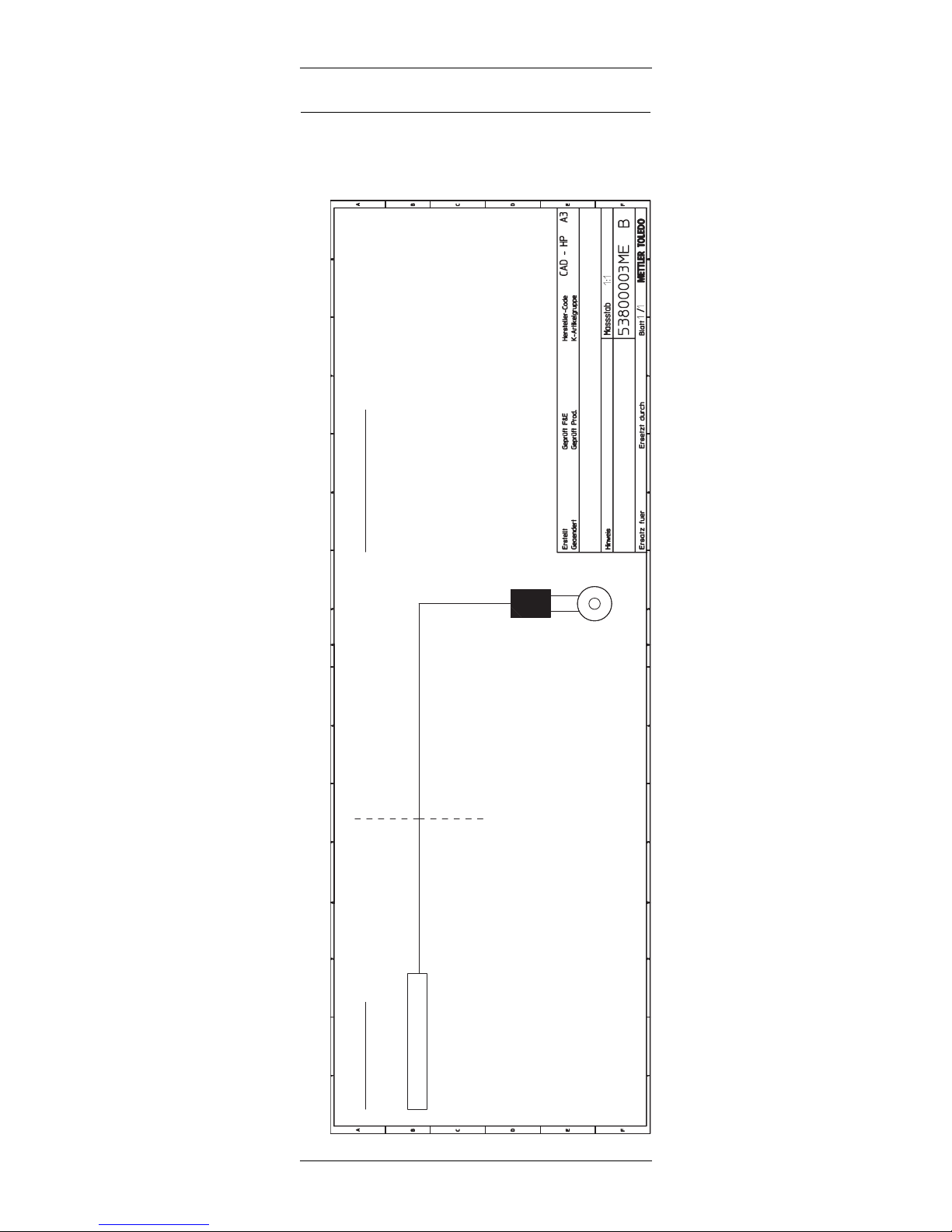

2.6 Ex-classification FM Approved

I

S/ I, II, III /1/ABCDEFG /T6 Ta = 60 °C

FM control drawing:

Non-Hazardous Location

Hazardous (Classified) Location

Class I, Division 1, Groups A, B, C and D

Class II, Division 1, Groups E, F and G

Class III, Division 1

T6 Ta= 60 C

Any FMRC A ppro ved Sin gle

Mult i-Chan nel Barrier or App aratus

Prob e

Mettl er-Toledo GmbH

Proce ss Ana lytics

CH-89 02 Urd orf

10/02 /2005 M. Bles sing

15/07 /2005 F. Trefz

FM control drawing Cond Ind

Wir b ehalte n uns a lle Rec hte an diesem Dokume nt und an alle n Beila gen vo r. Der Em pfänge r anerk ennt

diese Recht e und w ird die genann ten Unt erlage n nicht ohne u nsere v orgäng ige sch riftlic he Erm ächtigu ng

Dritt en zug änglich machen oder a usserha lb des Zwecke s verwe nden, z u dem sie ihm überge ben wor den sin d.

Enti ty Par amet ers:

V

t

=16 V, I

t

=150 mA, P

max

= 155 mW

C

i

= 900 pF, L

i

0.3 mH

Note s:

WARN ING: subst itut ion of compon ents may inpai r in trinsic safet y.

1. No rev isio n to th is draw ing is per mitted withou t FM RC appr oval

2. V

max

> V

t

; I

max

> I

t

; (C

i

of all lo ops + C cab le) < C

a

; (L

i

of all lo ops + L cab le) < L

a

; P

max

or P

i

> P

0

3. Single Mul ti-Chan nel IS Barrie r or Appara tus mu st b e FMRC Approv ed

5. Instal lati on must be in accord ance with A rticle 500 of the NEC

®

(ANS I/NFPA 70)

and A NSI/ ISA RP1 2.6.

4. Single Mul ti-Chan nel IS Barrie r or Appara tus ma nufa cturer' s cont rol draw ings

must be f ollowed when i nstall ing the Sys tem. I S Ba rrier o r Equi pmen t ma y be

insta lled within the Ha zardou s (C lassifie d) loc atio n for w hich i t is app roved.

InPro®7250 Series 15

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

2.7 Declaration of conformity

I

nPro 725X HT

InPro 725X ST

16 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

3 Product description

3.1 General information

T

he conductivity sensors InPro 7250 Series with inte grated temperature sensor are intended to be used to

measure conductivity and concentrations of liquids. The

sensor is designed for the measurement of medium and

h

igh conductivity values.

3.2 Principle

The sensors InPro 7250 Series measure an induced

current in a loop of solution.

Two toroidally wound coils are encapsulated in close

proximity within the sensor which is immersed in the

solution. An AC signal, applied to one toroidal coil,

in duces a current in the second coil which is directly

proportional to the conductance of the solution.

3.3 Sensor identification

Type designation

A sensor can be identified by the article number and the

model name on the label located on the cable.

InPro 7250xx/yy/zz

xx: Type of sensor

ST = Sensor for temperature up to 100 °C

(212 °F), without EX approval

HT = Sensor for temperature up to 180 °C,

(356 °F) with EX approval

PFA = Sensor in PFA* for Temperatures up to

125°C (257°F)

yy: type of the integrated temperature sensor

zz: cable length

Serial number

The serial number is located on the end of the mounting

thread.

Sensor certificate number

The labels located on the sensor cable provide the

information about the sensor certifications.

*PFA: Perfluoralkoxy-Copolymer

InPro®7250 Series 17

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

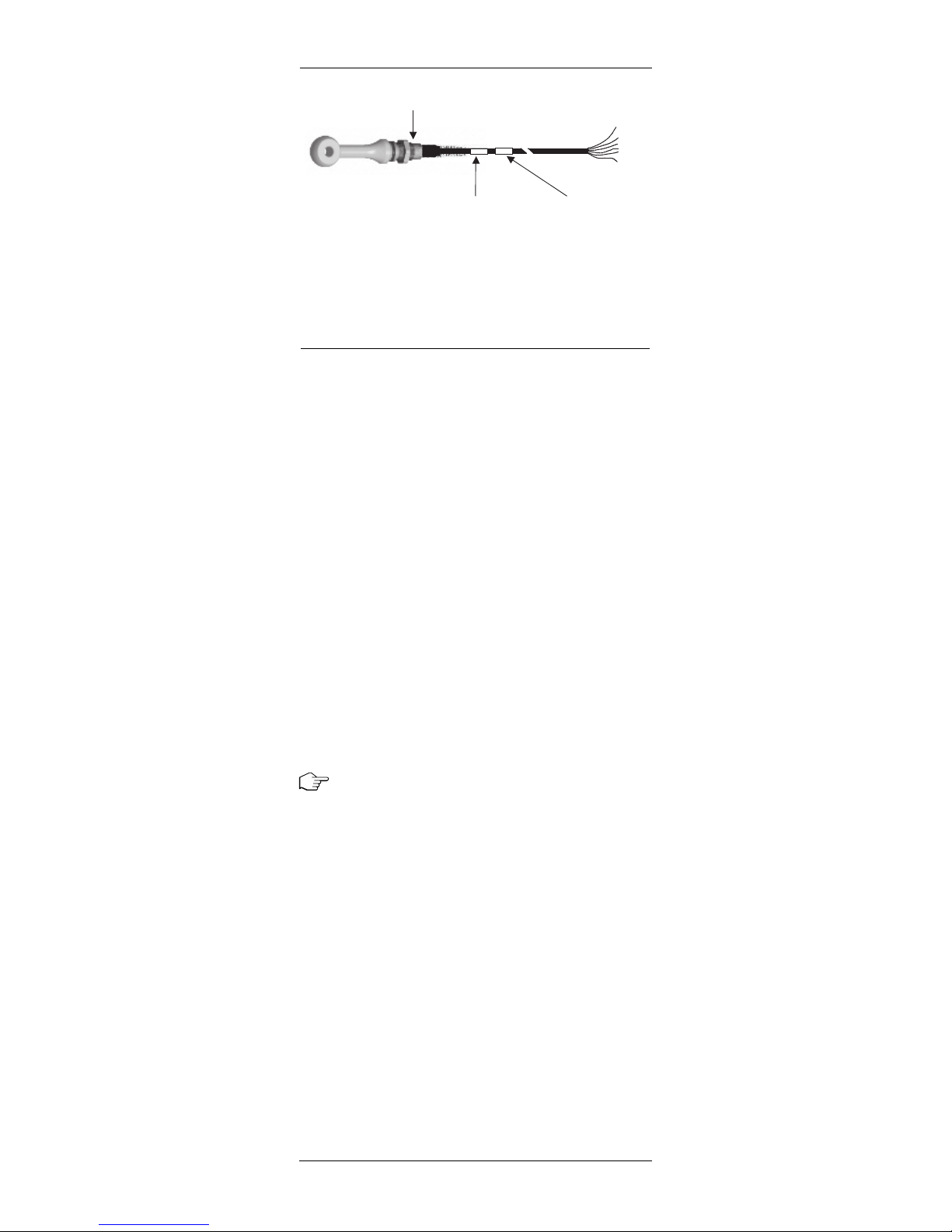

Figure 1: Sensor identification

3.4 Sensor applications

InPro 7250 ST

This sensor may be used for most routine applications

like conductivity measurement in industrial wastewater

systems. For applications at higher temperatures and for

use in hazardous areas the sensor InPro 7250 HT is the

preferred alternative.

InPro 7250 HT

The InPro 7250 Series sensor is suitable for the majority of all electrodeless conductivity applications. Its

compact size enables it to be mounted in a multitude of

methods, including insertion (flange, bushing), and

immersion. Typical applications include salinity and

brine measurements, steel pickling, scrubbing towers,

ion exchange regeneration, plating baths, rinse water,

caustic metal cleaning, and textile measurements in

scouring, mercerizing, and carbonizing baths.

InPro 7250 PFA

This sensor is particularly suited for heavy-duty chemical

applications such as Oleum (highly concentrated sulfuric acid), as well as applications in the pharmaceutical

and biopharmaceutical industry (CIP skids, acid and base concentration).

Notes:

– PEEK is a thermoplastic material with excellent

strength and chemical resistance properties over a

wide range of process temperatures and pressures.

– PEEK material displays excellent chemical resis-

tance to most aqueous solutions of acids, bases, and

salts. It is also excellent for organic solvents such as

toluene, ethyl acetate, acetone, gasoline, and carbon

tetrachloride. It is not recommended for sulfuric or

nitric acid solutions above 70 %, nor is it recommended for Oleum applications.

– PFA is a type of fluorcarbons with similar properties

as PTFE. PFA is resistant against nearly all chemicals

and has a high temperature resistance. The PFA quality used here does not contain glass fibres (virgin

PFA).

S

erial number

A

rticle number and

model name

S

ensor

certificate number

18 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

4 Installation, operation

and maintenance

4.1 Sensor installation

The sensor shaft is equipped with a conical G3/4"

mounting thread. The installation of the sensor is made

by threaded bushes or flanges. The process area is

sealed perfectly with flat gasket and an O-ring.

Note: When mounted in-line, the sensor should

be in stalled centered to avoid pipe wall effects. If there is

less than 30 mm (1.18 inch) spacing between sensor

and pipe, a product calibration with a sensor built in

the process is re commended to meet the specified

accuracies.

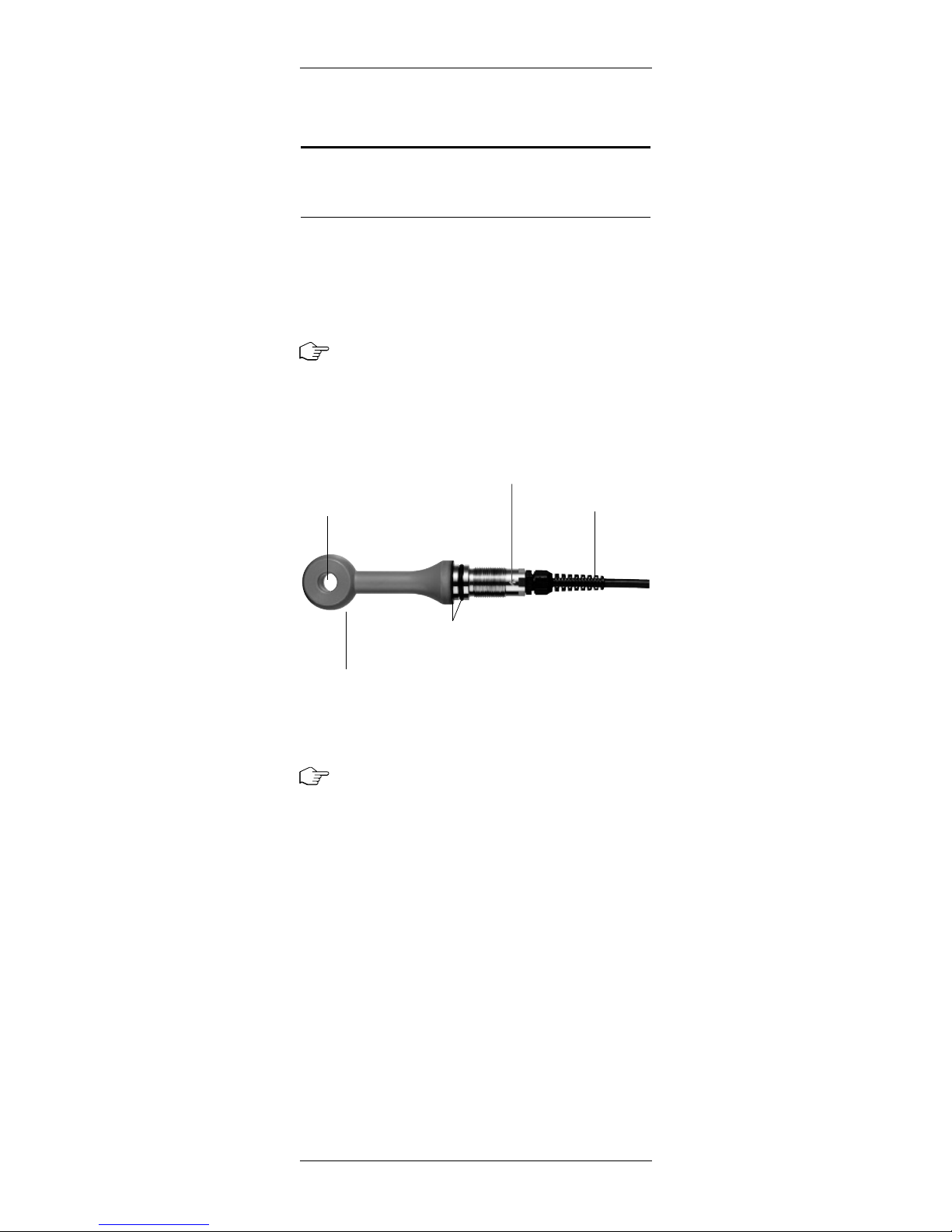

Figure 2: Sensor overview

Note: Proper installation of the sensor is important for

efficient and accurate operation. For all applications and

sensor configurations, mounting arrangements must be

located so that:

– Sample at the sensing area is representative of the

solution.

– Solution circulates actively and continuously past the

sensing area.

– Position and orientation of the sensor does not trap

air bubbles within sensing area.

– Deposits of sediment or other foreign material do not

accumulate within the sensing area. If cable is in stalled in a conduit (recommended), either flexible

conduit should be used or some other provision

made for removal of sensor from the process.

Bore

Arrow for the

sensor direction

Cable cap

Sensor doughnut

Flat gasket and O-ring

for safe process sealing

A

InPro®7250 Series 19

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

Notes:

–

The sensors of the InPro 7250 Series are marked with

an arrow, which indicates the flat (upstream) face of

the sensor, for correct installation in a pipe or a tank.

The marking is at the upper end of the sensor mount

ing thread (see Figure 2).

W

arning!

Incorrect O-ring position or a damaged O-ring could

result in process leakage, causing injury to personnel.

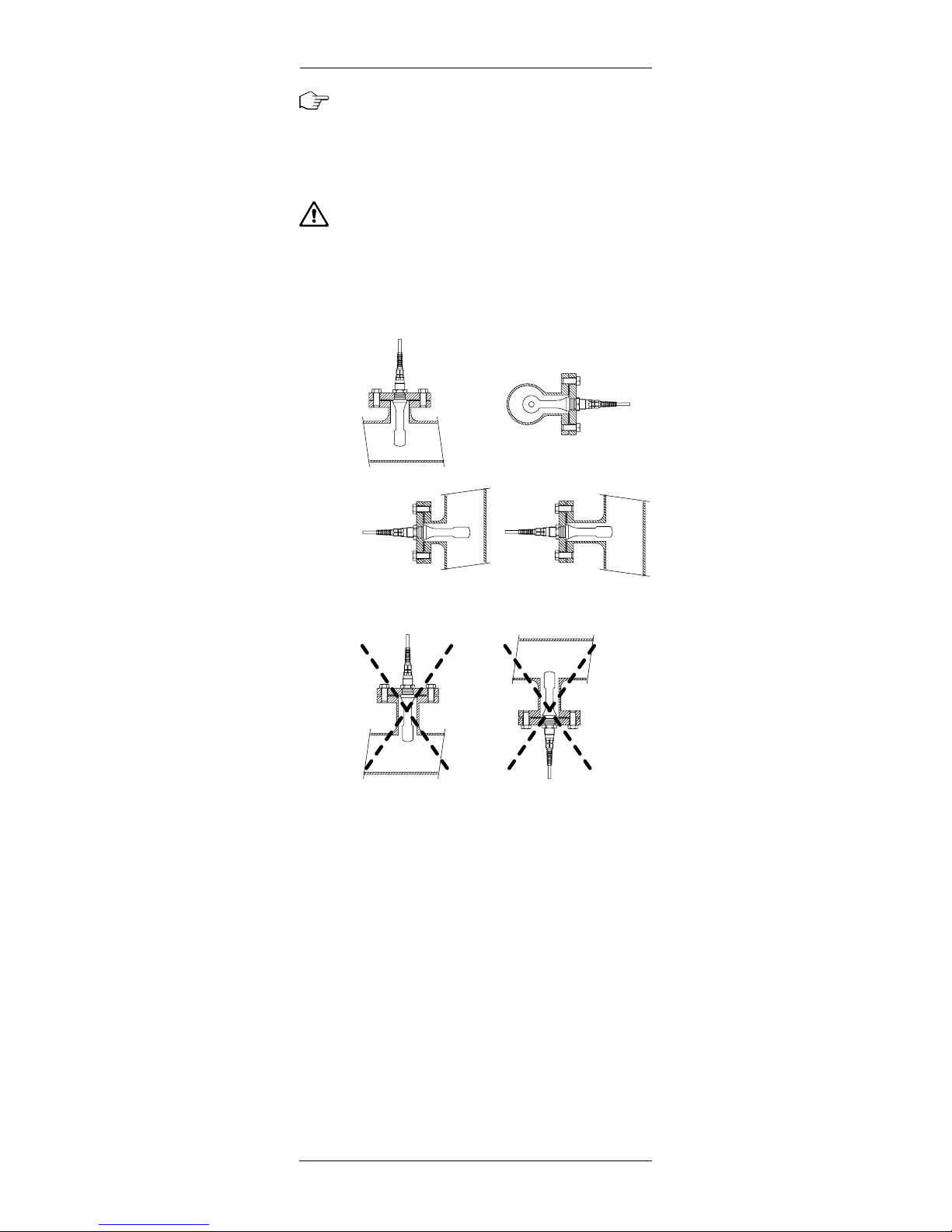

Figure 3:

Installation examples of the InPro7250 sensor

Air entrapment Solid deposits

Recommended

Not recommended!

20 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

4.2. Connection of the sensor

C

able configuration

InPro 7250 ST / PFA InPro 7250 HT

receive hi black red

receive lo red yellow

send lo brown violet

send hi blue black

RTD green green

R

TD white white

RTD sense grey grey

shield green/yellow green/yellow

Transmitter connection

The sensors InPro 7250 Series are suitable for connection to the following METTLER TOLEDO transmitters:

M 700(X), Module Cond Ind 7700(X):

«Premium line» transmitter,

modular measuring system

M400, Type 1 Cond Ind:

«Advanced Line» transmitter, 4-wire

Note: In order to connect the sensor with the transmitter,

please consider the instruction manual of the METTLER

TOLEDO transmitter.

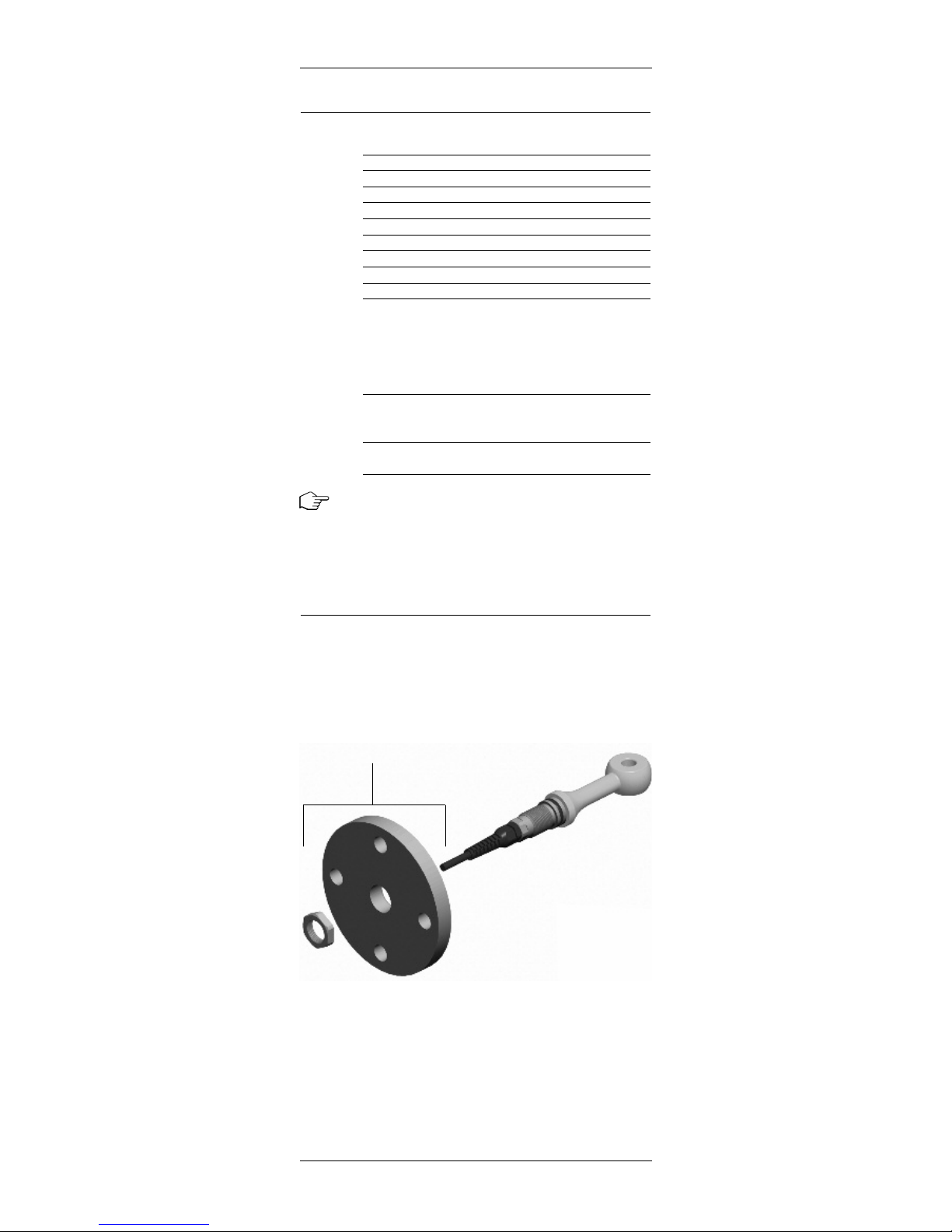

4.3 Flange installation

METTLER TOLEDO flanges are used for permanent installations in pipelines and tanks. Flanges are used with

electrodeless conductivity sensors in systems using

DN50 or 2-inch and larger process piping. Flanges are

provided complete with locknut.

Figure 4: Flange installation

Flange with locknut

InPro®7250 Series 21

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

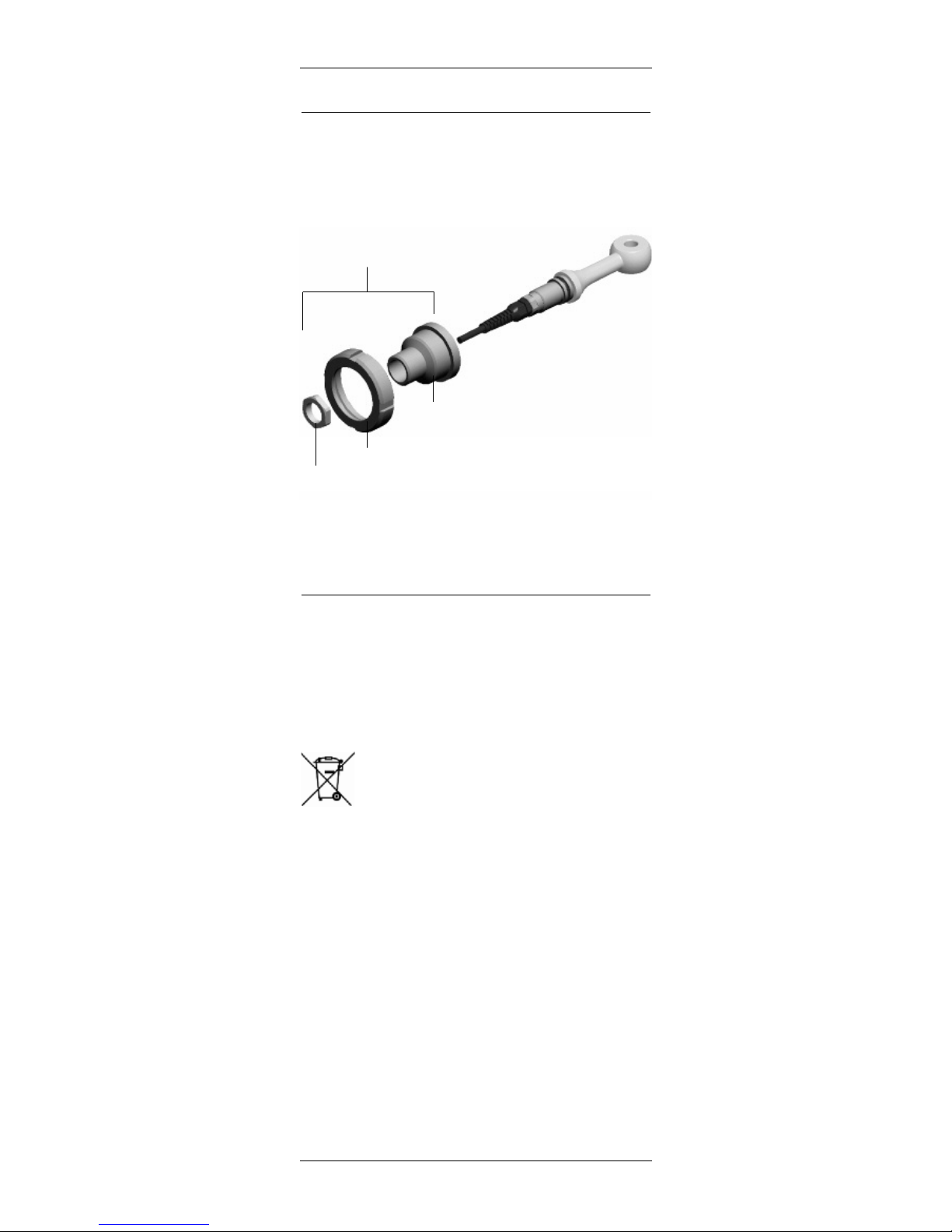

4.4 Bushing installation

S

upplied METTLER TOLEDO bushings are used for in stallations in pipelines and tanks and are provided

complete with locknut.

Figure 5: Bushing installation

4.5 Immersion installation with an

InDip 550 Ind

For open tanks or inlet channel the sensor can be installed in an immersion housing InDip 550Ind.

Figure 6: Installation with an immersion housing

«InDip 550Ind»

Bushing with

locknut

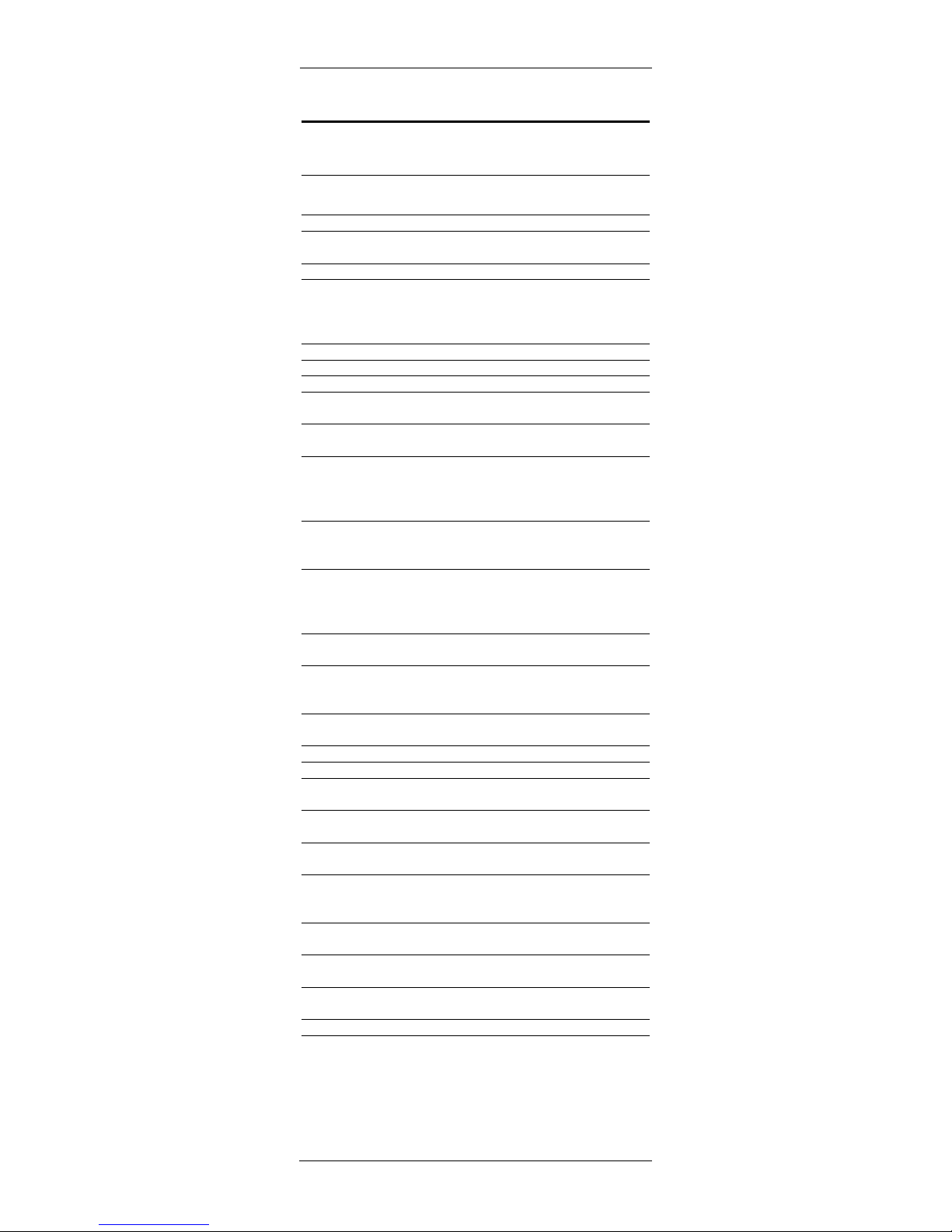

4.6 Sanitary installation

M

ETTLER TOLEDO offers a dairy adapter according to DIN

11851 (DN50) as well as an aseptic adapter DIN

11864-1 (DN50) for the inductive sensors of the InPro

7250 series.

Figure 7: Installation with sanitary adapters

4.7 Disposal

The sensors described in this manual usually cannot be

repaired. Their disposal is to the responsability of the

user. Sensors contain electronic components (coils,

cables) that require special disposal without any health

hazard for humans, and with no risk of harm for the

environment.

Disposal (Directive 2002/96/EC of January 27, 2003):

Please observe the applicable local or national regu lations concerning the disposal of "waste electrical and

electronic equipment".

22 InPro®7250 Series

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

Adapter with

accessories

Locknut

Ringnut

Adapter

5 Product specifications

5.1. Sensor specifications

InPro 7250 ST/HT InPro 7250 PFA

Measuring principle inductive inductive

Sensor data

Measuring range 0…2000 mS/cm 0…2000 mS/cm

Measurement ST: ± (0.5 % of meas. ± (0.5% of meas.

value deviation value + 25 µS) value + 25 µS)

HT: ± (0.5% of meas.

value + 1 µS)

Cell factor nominal

1

)

2.175 2.30

Transfer ratio 120 120

Temperature sensor Pt 1000 Pt 1000

Temperature

response (t90) approx. 5 min approx. 5 min

Ambient conditions

2

)

Process temperature ST: –20 °C…+100 °C –20 °C…+125 °C

(general purpose) (–4 °F…+212 °F) (–4…+257 °F)

HT: –20 °C…+180 °C

(–4…+356 °F)

Process temperature ST: – –20 °C…+125 °C

(In Ex-classified HT: –20 °C…+130 °C (–4…+257 °F)

area installation) (–4…+266 °F)

Process ST: max. 8 bar max. 16 bar

pressure

3

)

(max. 116 psi) (max. 232 psi)

HT: max. 20 bar

(max. 290 psi)

Sensor materials

Sensor PEEK PFA

(medium wetted) 4) glass-fiber reinforced not glass-filled

(GF30)

Sensor mounting

thread (G 3/4") stainless steel stainless steel

O-ring Viton® FEP

Flat gasket Viton® PTFE

Cable

Type ST: single coaxial cable simple coaxial cable

HT: double coaxial cable

Cable jacket ST: PVC PVC

HT: silicone

Available cable lengths 3, 5 and 10 m 3, 5 and 10 m

(9.8, 16.4 (9.8, 16.4

and 32.8 ft) and 32.8 ft)

Approvals and certificates

ATEX ST: – –

HT: • •

FM ST: – –

HT: • •

Quality/End control • •

1)

This value depends on the installation.

The exact value must be determined with a calibration.

2)

The combination of high pressure, high temperature and/or

aggressive process medium reduces the sensor life span.

3)

Depending on the installation.

4)

This material is not FDA listed.

InPro®7250 Series 23

© 01/2016 Mettler-Toledo GmbH CH -8606 Greifensee

Printed in Switzerland 52 002 799

Loading...

Loading...