Mettler Toledo InPro 7005-VP, InPro 7001/120-VP, InPro 7002-VP, InPro 7001/225-VP, InPro 7000-VP Instruction Manual

InPro 7000-VP Series

2-electrode conductivity sensors

2-Pol-Leitfähigkeits-Messzellen

Sondes de conductivité à 2 électrodes

Instruction manual

Bedienungsanleitung

Manuel d’utilisation

InPro 7000-VP Series

52 002 091

English Page 3

Deutsch Seite 19

Français Page 35

InPro 7000-VP Series 3

InPro 7000-VP Series

2-electrode conductivity sensors

Instruction manual

Subject to technical changes without prior notice.

© It is strictly forbidden to reprint this instruction manual or any parts thereof without

the written permission of Mettler-Toledo GmbH, Process Analytics, Im Hackacker 15,

8902 Urdorf, Switzerland. No section or excerpt whatsoever may be reproduced or with

the assistance of electronic systems be edited, duplicated or distributed, in particular in

the form of photocopies, photographs, magnetic media or other recording methods. All

rights reserved, especially the right of duplication and translation as well as in regard

to patent and registration rights.

InPro is a registered trademark of the Mettler Toledo Group in Switzerland and a further

twelve countries.

Mettler-Toledo GmbH, 8606 Greifensee, Switzerland

© 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee InPro 7000-VP Series

Printed in USA 52 002 091

4 InPro 7000-VP Series

Contents

1 Product description 5

1.1 Introduction 5

1.2 Equipment and scope of delivery 5

1.3 Technical data 7

2 Safety 8

2.1 Application compatibility 8

2.2 Proper utilization 9

2.3 Safety measures 9

2.4 Use in Ex-zones 10

3 Initial start-up 12

3.1 Installation 12

3.2 Electrical connections 13

4. Maintenance and troubleshooting 14

4.1 Conditions of warranty 14

4.2 Maintenance 14

4.3 Troubleshooting 15

5 Removal from operation, storage, disposal 16

5.1 Removal from operation 16

5.2 Storage 16

5.3 Disposal 16

6 Dimensional drawings 17

7 Accessories 18

InPro 7000-VP Series © 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee

52 002 091 Printed in USA

InPro 7000-VP Series 5

1 Product description

1.1 Introduction

Thank you for buying this InPro® 7000-VP Series 2-electrode conductivity

sensor from METTLER TOLEDO. InPro 7000-VP Series 2-electrode conductivity sensors are intended to be used to measure conductivity in low

(high purity water) to medium conductivity water. The sensors are available in a wide selection of process connections to meet every application

need.

Markings

The printed markings on each InPro 7000-VP Series 2-electrode conductivity

sensor contain the following information:

Mettler Toledo Sensor manufacturer

InPro 700X-VP Type of sensor

Cell M: XXXXXX Cell constant

Temp M: XXXXXX Temperature constant

Serial No: XXXXXXXXX Serial number

Ex-classification II I/2 G Ex ia IIC T3/T4/T5/T6 Ga/Gb

(metallic sensors / metallic sensors with

plastic surface)

Examination certificate number: SEV 14 ATEX 0129 X

Notified body: Electrosuisse SEV, (No.: 1258)

1.2 Equipment and scope of delivery

Scope of delivery

The InPro 7000-VP Series sensors are delivered ready for use. Each sen-

sor is accompanied by this instruction manual, an individual «Certificate

of Quality», CE Declaration of Conformity Certificate and a Material Certificate

following EN 10204 (exceptions: InPro 7000-VP and InPro 7005-VP).

Other Certificates may be included as specified for the individual product.

Please check that the details given in the Certificate of Quality match the

sensor label. For each sensor, the relevant cell constant has been determined individually in an ultrapure water system at 25 °C (77 °F) during the

© 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee InPro 7000-VP Series

Printed in USA 52 002 091

6 InPro 7000-VP Series

manufacturing process, and the value documented in the accompanying

«Certificate of Quality».It is not necessary to re-calibrate the sensor be fore

initial operation.

Packaging

The packaging consists of cardboard and plastic material.

Keep the packaging for later use during storage or transportation of the

sensor. Should you wish to dispose of the packaging material, please

observe your local regulations as well as those data and instructions given

in Chapter 5.3 of this manual.

Unpacking and inspection

Please check the sensors immediately during unpacking in order to deter-

mine possible damage or missing items. Any irregularities should immediately be reported to your carrier and to your supplier.

InPro 7000-VP Series © 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee

52 002 091 Printed in USA

InPro 7000-VP Series 7

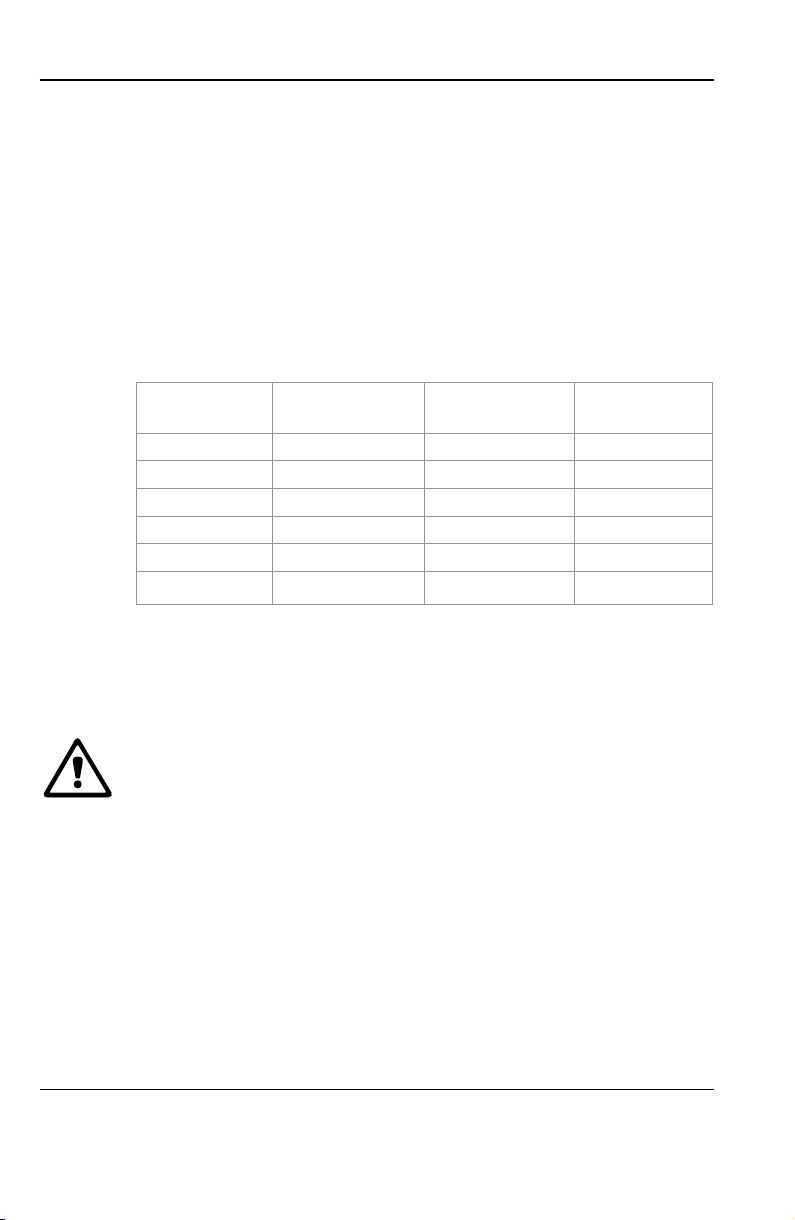

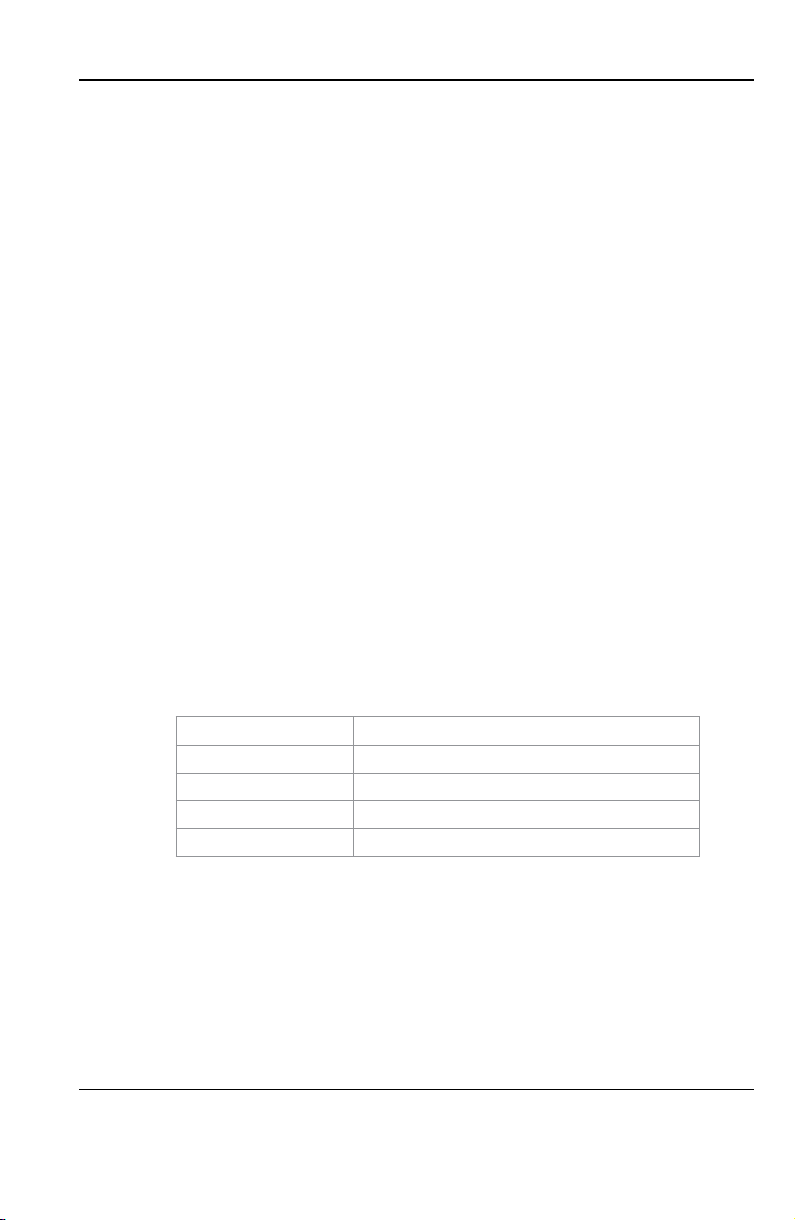

fP

Specifications 2-electrode sensors (InPro 7000-VP Series)

the particular transmitter.

97/23/EC, Art. 3, Sec. 3).

1.3 Technical data

Measurement principle 2-electrode sensor 2-electrode sensor 2-electrode sensor 2-electrode sensor

Electrode material Titanium Titanium SS 316L SS 316L

Body material PVDF PTFE-coatedSS316L SS 316L

RTD Built-in Pt1000 Built-in Pt 1000 Built-in Pt1000 Built-in Pt 1000

Sensor diameter See drawing See drawing 12 mm See drawing

Insertion length 29 mm 34 mm 120/225 mm 85/104mm

Max. sensor length 153.20 mm 75 mm 194/299 mm 156 /175mm

Process connection –

Measuring range See separate table on page 8

Cellconstant nominal 0.1 cm

Cellconstant accuracy ± 1.0 %±1.0%±1.0 %±1.0%

System accuracy

Working conditions

Max. pressure 34 bar 17 bar 17 bar 31 bar

at 25°C (77°F) (500 psi) (250 psi) (250 psi) (449.5 psi)

Max. pressure 7 bar 7 bar 7 bar 10 bar

at 95°C (203°F)

Measuring –10 …100°C –10 …100 °C –10…100 °C –10…120°C

temperature range (14…212 °F)(14… 212 °F)(14…212°F) (14 …248°F)

Temperature range N/A N/A –10…131°C –10…155°C

(sterilization) (14…268°F) (14 …311°F)

Temperature accuracy ± 0.25°C±0.25 °C ± 0.25 °C ± 0.25°C

at 25°C (77°F) (± 0.5°F) (± 0.5°F)(±0.5 °F)(±0.5 °F)

Design

Temperature Pt 1000 Pt1000 Pt 1000 Pt1000

compensation IEC class A IEC classA IEC class A IEC class A

Cableconnection Vario Pin (IP 68) VarioPin(IP 68)cVarioPin(IP 68) Vario Pin (IP 68)

Wetted parts:

–MetalsTitanium (Grade 2) Titanium (Grade 2) SS 316L SS 316L

–Plastics PVDF (FDA) PTFE-coated ––

– O-rings Viton®(FDA) Viton®(FDA) Viton®(FDA) Viton®(FDA)

–Insulation PEEK (FDA) PEEK (FDA) PEEK (FDA) PEEK (FDA)

– Surfaceroughnesso

wettedmetal parts

Certificates

Cellconstant •• ••

Materialcertificate

EN10204 3.1– –• •

Materialspecification 2.1• •• •

Surface roughness –– ••

ATEX •• ••

Captions

a Thesystem accuracy depends

on themeasuring range and

a

b

InPro 7000-VP InPro 7005-VP InPro7001/120-VP InPro 7002/ *-VP

SS 316/1.4401

(1.15")(1.35") (4.71/8.86") (3.35 /4.09")

(6.03")(2.95") (7.64/11.77") (6.14 / 6.88")

3

⁄4"NPT –3⁄4"NPT –Pg13.5–Tri-Clamp 1.5"

–1"NPT Conduit – Tri-Clamp 2"

–1

±3.0 %orbetter±3.0%or better ±3.0 %or better ± 3.0 %or better

(100 psi) (100 psi) (100 psi) (145psi)

d

N/A N/A Ra<0.2 µm(< 8µin)Ra<0.2µm (<8µin)

b Accordingto PED

(Pressure EquipmentDirective,

–1

0.1 cm

SS 316/1.4401

c TheVPisatthe end of an

InPro7001/225-VP

–1

0.1cm

Sterilizable Sterilizable

olished Electropolished

approx. 0.5 mlongfixed cable.

d Exceptatactiveelectrode areas.

–Tuchenhagen-

Varivent

DN 40–DN125

–1

0.1 cm

© 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee InPro 7000-VP Series

Printed in USA 52 002 091

8 InPro 7000-VP Series

For each sensor, the cell constant and temperature constant have been

measure / established individually and the values documented in the accompanying Quality Certificate. All calibrations can be traced back to NIST

and / or ASTM Standards.

Both the measuring range and the system measurement accuracy strongly

depend upon which type of transmitter is employed.

Practical measuring range

InPro 7000-VP /

Transmitter

M300 0.02 – 2,000 0.02 – 500 0.02 – 2,000

M300 ISM – – –

M400 4-w / 2-w 0.02 – 2,000 0.02 – 500 0.02 – 2,000

M700 0.02 – 10,000 0.02 – 500 0.02 – 2,000

M800 1-channel 0.02 – 2,000 0.02 – 500 0.02 – 2,000

System accuracy

7005-VP

± 3 % ± 3 % ± 3 %

InPro 7001-VP InPro 7002-VP

2 Safety

2.1 Application compatibility

The wetted material parts of the sensor (several different materials come

into contact with the sample medium) can under some circumstance be

incompatible with the particular composition of the process medium and/or

of the operating conditions. Responsibility to verify application compatibil ity

lies wholly with the user.

The compatibility of different types of material are outlined on

http://www.coleparmer.com/techinfo/chemcomp.asp.

Mettler-Toledo GmbH, Process Analytics accepts no responsibility whatso-

ever for the correctness or accuracy of such details.

InPro 7000-VP Series © 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee

52 002 091 Printed in USA

InPro 7000-VP Series 9

2.2 Proper utilization

METTLER TOLEDO InPro 7000-VP Series sensors are intended solely for

the precise measurement of conductivity in aqueous and some limited

non- aqueous solutions in industrial applications.

Any other use, or any operation over and above that intended by the

manufacturer, are not recommended and can lead to harm or injury to

material / equipment and persons. This is also relevant for applications

which do not comply with the technical data labeled on the sensor. For any

damage arising from such misuse, the user assumes full and sole

responsibility.

2.3 Safety measures

The InPro 7000-VP Series sensors have been manufactured in line with

state-of-the-art technology and in accordance with accepted technical

safety regulations. Nevertheless, the sensors can still represent a source

of risk and danger:

– if the sensors are operated by insufficiently trained personnel,

– if the sensors are employed incorrectly or not as intended by the

manufacturer,

– if the sensors are not regularly maintained or serviced.

Local legislation and regulations must be observed at all times. Such

stipulations do not form an integral part of this instruction manual.

It is necessary to use protective gear, including gloves, for persons coming

in contact with the fluid. It is recommended to use gloves when handling

the electrodes of the sensor to limit contamination of the sensor.

The user is responsible for the instruction and training of personnel. Addi-

tional copies of the instruction manual can be ordered from your supplier.

This instruction manual is an essential element of the sensor equipment

and must at all times be readily available to operators directly at the mea-

surement site.

Before the sensor is removed from the process/process adapter, it must be

ensured that the process pressure has been reduced to a safe level and the

process temperature lowered to a safe range. Any escape of hot process

fluid under pressure can cause damage to material/equipment or injury to

persons.

© 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee InPro 7000-VP Series

Printed in USA 52 002 091

10 InPro 7000-VP Series

No modification whatsoever may be carried out on the sensors. Any

unauthorized modification or manipulation of the sensors results in immediate expiration of the full scope of warranty granted by the manufacturer.

2.4 Use in Ex-zones

Note!

For intended installation in an Ex-classified area, please observe the fol-

lowing guidelines:

Ex- classification:

II 1/2 G Ex ia IIB T3/T4/T5/T6 Ga/Gb (plastic sensors)

II 1/2 G Ex ia IIC T3/T4/T5/T6 Ga/Gb (metallic sensors/metallic

sensors with plastic surface)

Marking and number of the test certificate:

SEV 14 ATEX 0129 X

Introduction

1. The conductivity sensors made of plastic are according to Directive

94/9/EC (ATEX 95) Annex I equipment group II, category 1/2G after

RL 99/92/EC (ATEX 137) in the zones 0/1 or 0/2 or 1/2 and the gas

groups IIA and IIB, explosion hazards due to flammable substances

in the field of temperature classes T1 to T6, may be used.

2. The conductivity sensors made of metal or metal coated with plastic

to Directive 94/9/EC (ATEX 95) Annex I to equipment group II, category 1/2G after RL 99/92/EC (ATEX 137) in zones 0/1 or 0/2 or 1/2

and gas groups IIA, IIB and IIC, explosion hazards due to flammable

substances in the field of temperature classes T1 to T6, may be used.

3. For use/installation, the requirements according to EN 60079-14

must be observed.

InPro 7000-VP Series © 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee

52 002 091 Printed in USA

InPro 7000-VP Series 11

Electrical ratings

Conductivity measuring circuit and temperature sensing circuit in type of

protection intrinsic safety Ex ia IIC only for connection to a certified intrinsically safe circuit.

Maximum values:

Ui ≤ 16 V

li ≤ 190 mA

Pi ≤ 200 mW

The effective internal inductance and capacitance are negligible.

The values above apply, each as the sum of all the individual circuits of

the associated intrinsically safe supply and evaluation unit.

Special conditions for safe use

1. The relationship between the maximum permissible ambient or media

temperature and temperature class is shown in the following table:

For Ui ≤ 16 V, Ii ≤ 190 mA, Pi ≤ 200 mW.

Conductivity measuring circuit and temperature measuring circuits:

Temperature class Maximum ambiant or media temperature

T6 51 °C

T5 63 °C

T4

T3 143 °C

91 °C

2. For installation, the system drawings and wiring diagrams of the measurement systems should be observed.

3. The capacitance and inductance of the connecting cable has to be considered.

© 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee InPro 7000-VP Series

Printed in USA 52 002 091

12 InPro 7000-VP Series

4. The metal body of the conductivity sensors or the safety weld-in socket

or the fitting InFit 76*-*** or InTrac 7**-*** or other appropriate fitting

must be electrically connected to the equipotential bonding system.

5. The metal body of the conductivity sensors or the safety weld-in socket or

the fitting InFit 76*-*** or InTrac 7**-*** or other appropriate fitting is

optionally included in the routine pressure test of the system.

3 Initial start-up

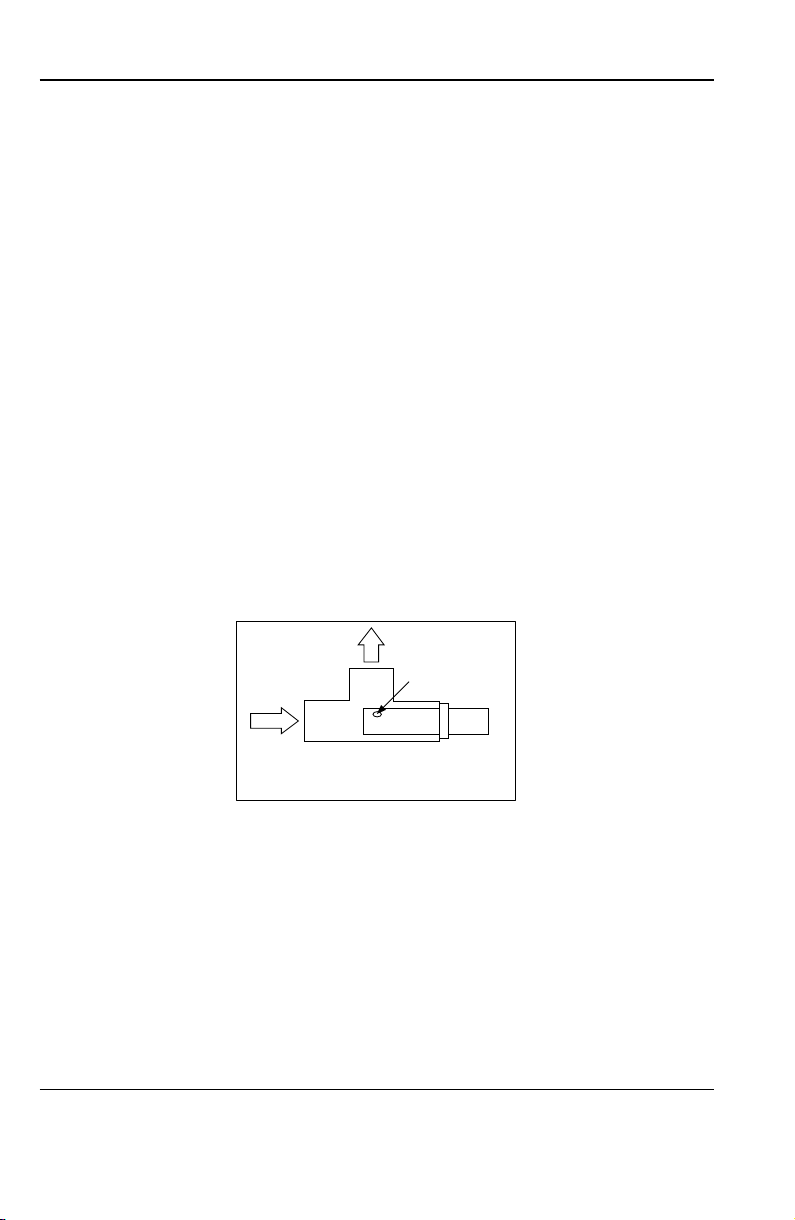

3.1 Installation

The sensors are to be mounted in such a way that the sample medium

flows directly into the sensor through the orifice at the tip and re-emerges

through the vent holes. Any other installation position of the sensors can

create the risk of formation of airlocks, or of contamination through deposits of solid matter.

Flow direction

Flow

direction

Orientation in fluids

with low velocity

Vent hole

Sensor

T-piece

Flow of sample medium must be toward the face of the sensor. Air bubbles

and solid matter deposits are to be avoided. A minimum clearance of 0.6

cm (1/4") between sensor and pipe wall must be maintained at the tip of

the sensor.

Vertical mounting (top entry) in a pipe is recommended only if the pipe is

full and no air bubbles are able to develop in the flow.

In the event of side mounting (side entry) of the sensor, vertical upward

flow of sample process medium must be ensured.

InPro 7000-VP Series © 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee

52 002 091 Printed in USA

InPro 7000-VP Series 13

3.2 Electrical connections

All of the InPro 7000-VP Series sensors can be connected to the asso ciated

transmitter using the appropriate multiwire cable from METTLER TOLEDO.

Depending on which type of transmitter is employed, not all cable strands

may have to be used.

Colors and function of the cable strands (supplied separately)

Connection to the relative transmitter must be followed according to the

wiring diagram below.

2-electrode sensor Color

Inner electrode white

Outer electrode white / blue

RTD green

RTD sense red

RTD / GND Bare shield

Connection to the relative transmitter must be followed according to the

wiring diagram (see respective transmitter instruction manual for detail).

METTLER TOLEDO supplies the cables. Please refer to chaper 7 “Accesso-

ries” for ordering information

© 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee InPro 7000-VP Series

Printed in USA 52 002 091

14 InPro 7000-VP Series

4. Maintenance and troubleshooting

4.1 Conditions of warranty

METTLER TOLEDO guarantees the quality of materials and workmanship

within a narrow range of manufacturing tolerances, so that the product

purchased is free from any substantial deviations from material and

manufacturing quality standards. The warranty is valid for a period of

one year from date of delivery: If within this warranty period, any repair or

replacement should become necessary, and such cause is not due to

misuse or incorrect application, please return the sensor, freight pre-paid,

to your appropriate METTLER TOLEDO supplier. Repair work will be carried out free of charge. Final decision on whether the defect is due to a

manufacturing error or to incorrect operation of the sensor by the customer

is made at the option of the Customer Service department of METTLER

TOLEDO. After expiration of the warranty period, sensors will be repaired

or replaced on an exchange basis against payment of the costs involved.

4.2 Maintenance

Dirty or contaminated sensors can deliver incorrect measurement values.

If fouling is presumed, the sensor is to be removed from operation and the

electrodes as well as the insulation between the electrodes cleaned with

a soft cloth. Suitable cleaning solutions are mild detergents or diluted

acids (< 0.5 % by wt.) such as nitric acid. Never use clean ing agents that

are not compatible with the material to be cleaned.

When handling acids, precautionary measures are to be taken.

The sensor must be thoroughly flushed with distilled or deionized water

prior to re-installation.

Following cleaning and re-installation into the process, it can take from

several minutes up to several hours until the sensor delivers the originally

measured value.

InPro 7000-VP Series © 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee

52 002 091 Printed in USA

InPro 7000-VP Series 15

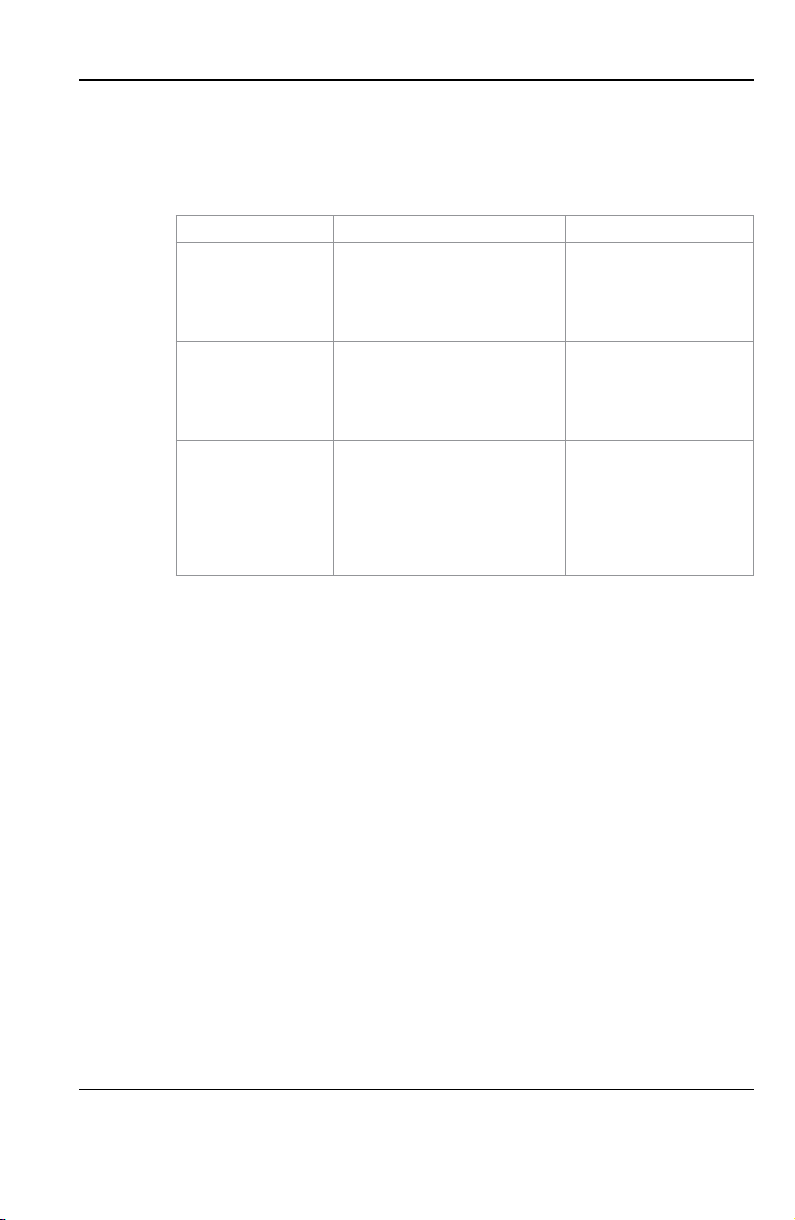

4.3 Troubleshooting

Error Possible cause Corrective action

No signal on display Electrical connections either missing

or incorrectly in place

Check all connections and

associated cabling

Sensor is not in contact with the

sample medium

No temperature signal Temperature probe is not connected

Transmitter does not support

Pt1000 RTD

Incorrect or unstable

measurement reading

Sensor is contaminated/fouled

Sensor is installed too close to pipe

wall

Check installation for air

pockets

Check all connections and

associated cabling

Replacement of transmitter or

sensor necessary

Clean the sensor

(electrodes)

Ensure minimum distance

of 0.6 cm (1/4") between

sensor tip and pipe wall is

maintained.

© 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee InPro 7000-VP Series

Printed in USA 52 002 091

16 InPro 7000-VP Series

5 Removal from operation, storage, disposal

5.1 Removal from operation

The sensor is only conditionally subject to aging. When used as intended

and appropriately maintained and serviced, the lifetime of the sensor can

extend to several years.

Before removing the sensor from the process/process adapter, it must be

ensured that the process pressure has been reduced to a safe level and

the process temperature has lowered to a safe range. Any escape of hot

process medium under pressure can cause damage to material/equipment

or injury to persons.

After removal from the process the sensor should first be flushed with

distilled water.

If the sensor incurs a defect, it can not be repaired and must be disposed

under observance of prevailing local regulations.

5.2 Storage

If the sensor is not use, it can be stored dry. However, it has to be recon-

ditioned in the process fluid accordingly prior to renewed operat ion. This

procedure may take several hours to complete.

5.3 Disposal

The user is responsible for the proper disposal of the conductivity sensor. The

sensor contains electronic components that must be disposed of correctly

in order to avoid hazards to people or to the environment.

InPro 7000-VP Series © 02 / 2017 Mettler-Toledo GmbH, CH - 8606 Greifensee

52 002 091 Printed in USA

Loading...

Loading...