Mettler Toledo InPro 6800 Instruction Manual

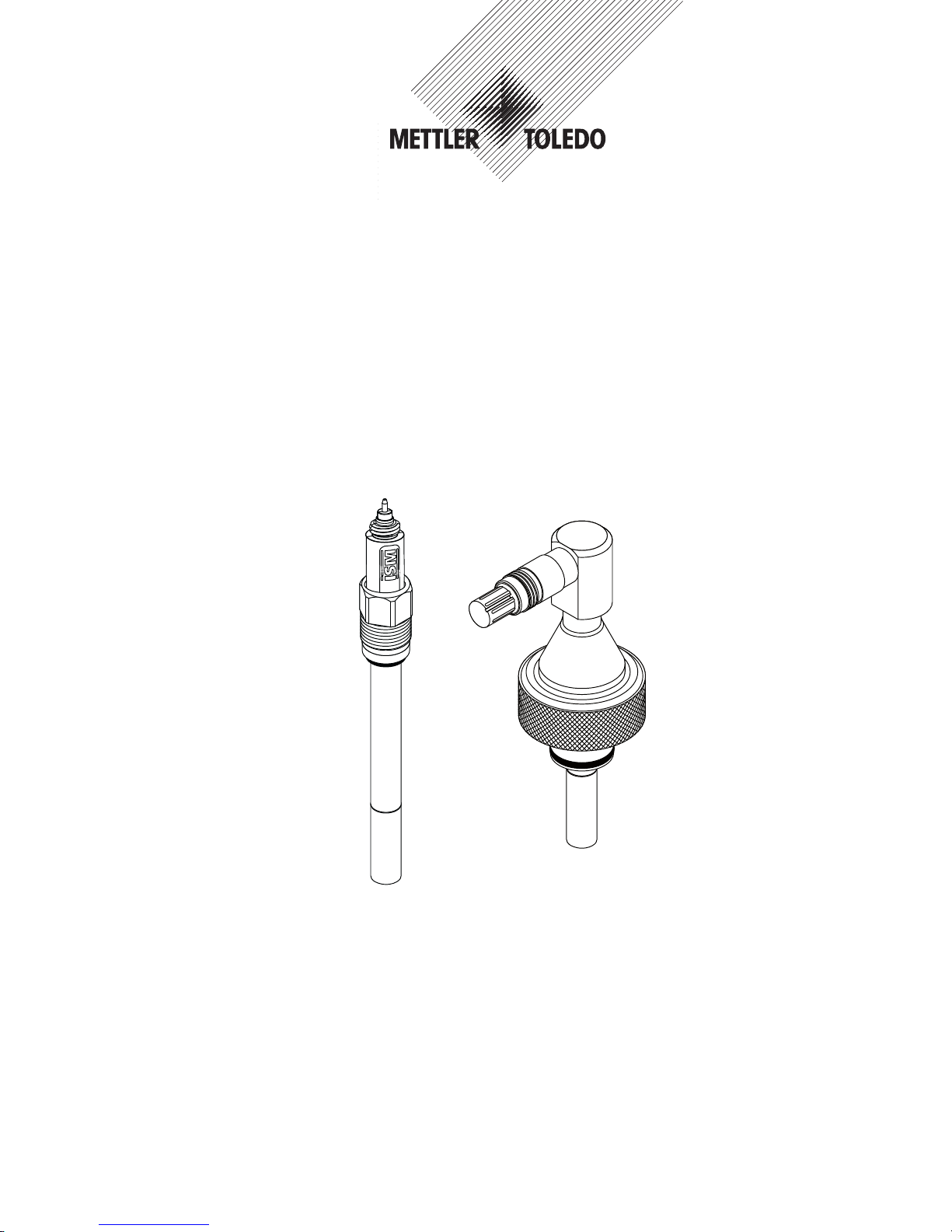

InPro 6800 Series O2Sensors

Instruction manual

Bedienungsanleitung

Instructions d’utilisation

InPro 6800

52 200 953

2 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

English Page 3

Deutsch Seite 36

Français Page 69

InDip, InFit, InPro, ISM, and InTrac are registered trademarks

of the Mettler Toledo Group in Switzerland and a further twelve countries.

InPro 6800 Series O2Sensor 12/25 mm 3

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

InPro 6800 Series O2Sensors

Instruction manual

4 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

1 Introduction................................................................5

2 Important notes ..........................................................6

2.1 Notes on operating instructions .....................................6

2.2 Intended use ...............................................................6

2.3 Safety instructions........................................................7

2.4 Examples of some typical applications...........................8

2.5 Use in Ex-zones...........................................................8

2.6 Ex-classification ATEX ..................................................9

2.6.1 Introduction.................................................................9

2.6.2 Rated data..................................................................9

2.6.3 Special conditions......................................................10

2.7 Ex-classification FM approved.....................................11

3.1 General information....................................................12

3.2 Principle...................................................................12

3.3 Scope of delivery .......................................................12

3.4 Equipment features ....................................................13

4 Installation...............................................................15

4.1 Mounting the sensor...................................................15

4.2 Connection................................................................15

4.2.1 Connecting the InPro 6800 to a cable..........................15

4.2.2 Connecting the VP or AK9 cable to the transmitter..........16

5 Operation .................................................................17

5.1 Start-up and polarizing...............................................17

5.2 Calibration................................................................18

5.2.1 Purpose of calibration ................................................18

5.2.2 What you have to know for calibration .........................18

5.2.3 Single point calibration...............................................19

5.2.4 Dual point calibration.................................................20

6 Maintenance ............................................................21

6.1 Inspection of the sensor..............................................21

6.1.1 Visual inspection .......................................................21

6.1.2 Testing the sensor with the METTLER TOLEDO O

2

Sensor-Master InPro 6800..........................................22

6.1.3 Testing the sensor via a transmitter..............................23

6.2 Changing the electrolyte, the membrane body or

the interior body.........................................................24

7 Storage ....................................................................27

8 Product specification ................................................27

8.1 Certificates................................................................27

8.2 Specifications............................................................28

9 Ordering information.................................................29

9.1 Sensors....................................................................29

9.2 Accessories...............................................................29

9.3 Spare parts ...............................................................30

9.4 Recommended transmitters.........................................30

9.5 Recommended housings............................................30

10 Theory of the polarographic sensor............................31

10.1 Introduction...............................................................31

10.2 Principle of the design of an oxygen electrode...............32

10.3 Parameters determining current...................................32

10.4 Polarization voltage ...................................................33

10.5 Temperature..............................................................33

10.6 Dependence on flow...................................................34

10.7 Oxygen partial pressure – oxygen concentration............35

Contents

InPro 6800 Series O2Sensor 12/25 mm 5

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

1 Introduction

Thank you for buying the InPro®6800 sensor from

METTLER TOLEDO.

The construction of the InPro 6800 sensors employs

leading edge tech nology and complies with safety

regulations currently in force. Notwithstanding this,

improper use could lead to hazards for the user or a

third-party, and/or adverse effects on the plant or

other equipment. Therefore, the operating instruc-

tions must be read and understood by the persons

involv ed before work is started with the sensor.

The instruction manual must always be stored close at

hand, in a place accessible to all people working with

the InPro 6800.

If you have questions, which are not or insufficiently

answered in this instruction manual, please contact

your METTLER TOLEDO supplier. They will be glad to

assist you.

6 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

2 Important notes

2.1 Notes on operating instructions

These operating instructions contain all the information

needed for safe and proper use of the InPro 6800

sensor.

The operating instructions are intended for personnel

entrusted with the operation and maintenance of the

sensors. It is assumed that these persons are familiar

with the equipment in which the sensor is installed.

Warning notices and symbols

This instruction manual identifies safety instructions

and additional information by means of the following

symbols:

This symbol draws attention to safety instructions and

warnings of potential danger which, if neglected,

could result in injury to persons and/or damage to

property.

This symbol identifies additional information and

instruc tions which, if neglected, could lead to defects,

inefficient operation and possible loss of production.

2.2 Intended use

METTLER TOLEDO InPro 6800 sensors are intended

solely for inline measurement of the oxygen partial

pressure in liquids and gases, as described in this instruction manual.

Any use of these sensors which differs from or exceeds

the scope of use described in this instruction manual

will be regarded as inappropriate and incompatible

with the intended purpose.

The manufacturer/supplier accepts no responsibility

whatsoever for any damage resulting from such

improper use. The risk is borne entirely by the user/

operator.

Other prerequisites for appropriate use include:

– compliance with the instructions, notes and

requirements set out in this instruction manual.

– acceptance of responsibility for regular inspection,

maintenance and functional testing of all asso ci ated components, also including compliance

with local operational and plant safety regulations.

– compliance with all information and warnings

given in the documentation relating to the products

used in conjunction with the sensor (housings,

transmitters, etc.).

– observance of all safety regulations governing the

equipment in which the sensor is installed.

InPro 6800 Series O2Sensor 12/25 mm 7

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

– correct equipment operation in conformance with

the prescribed environmental and operational

conditions, and admissible installation positions.

– consultation with METTLER TOLEDO Process

Analytics in the event of any uncertainties.

2.3 Safety instructions

– The plant operator must be fully aware of the

potential risks and hazards attached to operation

of the particular process or plant. The operator is

responsible for correct training of the workforce, for

signs and markings indicating sources of possible

danger, and for the selection of appropriate,

state-of-the-art instrumentation.

– It is essential that personnel involved in the

commissioning, operation or maintenance of these

sensors or of any of the associated equipment (e.g.

housings, transmitters, etc.) be properly trained in

the process itself, as well as in the use and

handling of the associated equipment. This

includes having read and understood this instruction manual.

– The safety of personnel as well as of the plant itself

is ultimately the responsibility of the plant operator.

This applies in particular in the case of plants

operating in hazardous zones.

– The oxygen sensors and associated components

have no effect on the process itself and cannot

influence it in the sense of any form of control

system.

– Maintenance and service intervals and schedules

depend on the application conditions, composition

of the sample media, plant equipment and signi ficance of the safety control features of the

measuring system. Processes vary considerably,

so that schedules, where such are specified, can

only be regarded as tentative and must in any case

be individually established and verified by the plant

operator.

– Where specific safeguards such as locks, labels,

or redundant measuring systems are necessary,

these must be provided by the plant operator.

– A defective sensor must neither be installed nor put

into service.

– Only maintenance work described in this operating

instruction may be performed on the sensors.

– When changing faulty components, use only

original spare parts obtainable from your METTLER

TOLEDO supplier (see spare parts list, ”Section

9.3”).

8 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

– No modifications to the sensors and the acces-

sories are allowed. The manufacturer accepts no

responsibility for damages caused by unauthorised

modifications. The risk is borne entirely by the user.

2.4 Examples of some typical applications

Below is a list of examples of typical fields of application for the oxygen sensors. This list is not exhaustive.

Measurement in liquids:

– Fermentation

– Yeast propagation

– Wort aeration

– Spring water conditioning

– Storage ans processing of fruit juices

Measurement in gases:

– Monitoring of the oxygen limit value to protect

products from oxidation.

– Monitoring of the oxygen limit value in the exhaust

air of fermentation vessels.

– Monitoring of oxygen limit values during inertiza-

tion processes.

– Measurement of oxygen concentrations in process

gas mixtures.

2.5 Use in Ex-zones

Attention!

For an installation in Ex-zones please read the

guidelines following hereafter:

1258

Ex-classification ATEX:

Ex ia IIC T6/T5/T4/T3 Ga/Gb

Ex ia IIIC T69°C/T81°C/T109°C/T161°C Da/Db

Number of the test certificate:

SEV 14 ATEX 0169 X

IECEx SEV 14.0026X

Ex-classification FM approved:

IS / I, II, III /1/ABCDEFG / T6 Ta = 60 °C

- 53 800 002; Entity

InPro 6800 Series O2Sensor 12/25 mm 9

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

2.6 Ex-classification ATEX

2.6.1 Introduction

According to Directive 94/9/EC (ATEX 95) Appendix I,

the O

2

oxygen sensors type InPro 6XXX is a devices

of equipment group II, category 1/2G which, according to Directive 99/92/EC (ATEX 137) can be used in

zones 0/1 or 1/2 or 1 or 2 as well as gas groups IIA,

IIB and IIC, which are potentially explosive due to

combustible substances in the temperature T3 to T6.

The requirements specified in EN 60079-14 must be

observed during use / installation.

According to Directive 94/9/EC (ATEX 95) Appendix

I, the O

2

oxygen sensors type InPro 6XXX is a devices of equipment group II, category 1/2D which,

according to Directive 99/92/EC (ATEX 137) can be

used in zones 20/21 or 21/22 or 21 or 22, which

are potentially explosive due to combustible dust.

The requirements specified in EN 60079-14 must be

observed during use / installation.

For the analog version of the O

2

oxygen electrode,

the O2measurement circuit, temperature measurement circuit and data chip circuit are part of the common intrinsically safe system and are jointly connected to and operated by a separately certified

transmitter.

The digital version of the O

2

oxygen sensor is connected to and operated by two-wire cable to the certified transmitter.

The intrinsically safe circuits are galvanically isolated

from the non-intrinsically safe circuits up to a nominal voltage peak value of 375 V and from the earthed

parts up to a nominal voltage peak value of 30 V.

2.6.2 Rated data

Analog O

2

Oxygen sensor

With type of protection: intrinsic safety to Ex ia IIC

O

2

measuring circuit, temperature measuring

circuit and data chip circuit

Only for connection to certified intrinsically safe circuits. Maximum values:

Ui≤ 16 V, Ii≤ 190 mA, Pi≤ 200 mW

Li= 0 (effective internal inductance)

Ci= 900 pF (effective internal capacitance)

The values above apply, each as the sum of all the

individual circuits of the associated intrinsically safe

supply and evaluation unit (transmitter).

Digital O

2

Oxygen sensor

With type of protection: intrinsic safety to Ex ia IIC

10 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

Two-wire current circuit

Only for connection to certified intrinsically safe circuits. Maximum values:

Ui≤ 16 V, Ii≤ 30 mA, Pi≤ 50 mW

Li= negligible

Ci= negligible

2.6.3 Special conditions

– The relationship between the maximum permissi-

ble ambient or media temperature and temperature class, for category 1G applications, zone 0, is

shown in the following table:

Temperature class Max. ambient or

media temperature

T 6 68 °C

T 5 80 °C

T 4 108 °C

T 3 160 °C

– The relationship between the maximum permissi-

ble ambient or media temperature and temperature class, for category 1D applications, zone 20,

is shown in the following table:

Temperature class Max. ambient or

media temperature

T 69 °C 68 °C

T 81 °C 80 °C

T 109 °C 108 °C

T 161 °C 160 °C

– The capacitance and inductance of the connecting

cable has to be considered.

– The O

2

Oxygen sensor type InPro 6XXX can be

used in / with the fittings InFit®76*-*** or InTrac

®

7**-***, or in / with other suitable fittings in potentially explosive areas.

– The metal body of the O

2

Oxygen sensors, or the

fittings InFit 76*-*** or InTrac 7**-***, or other

appropriate fitting is optionally included in the routine pressure test of the system.

– The independent fitting used for installation of O

2

Oxygen sensor must be conductively connected to

the equipotential bonding system.

InPro 6800 Series O2Sensor 12/25 mm 11

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

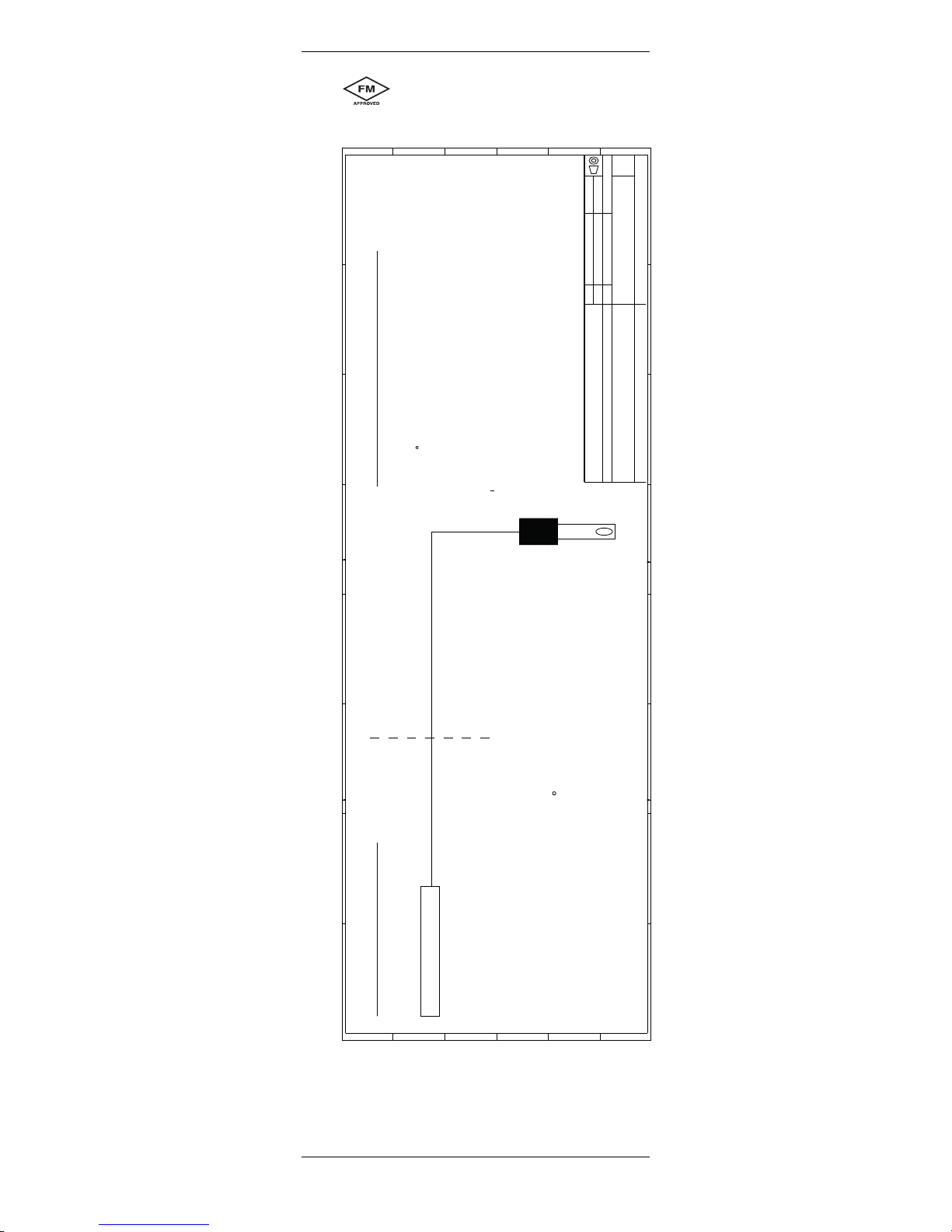

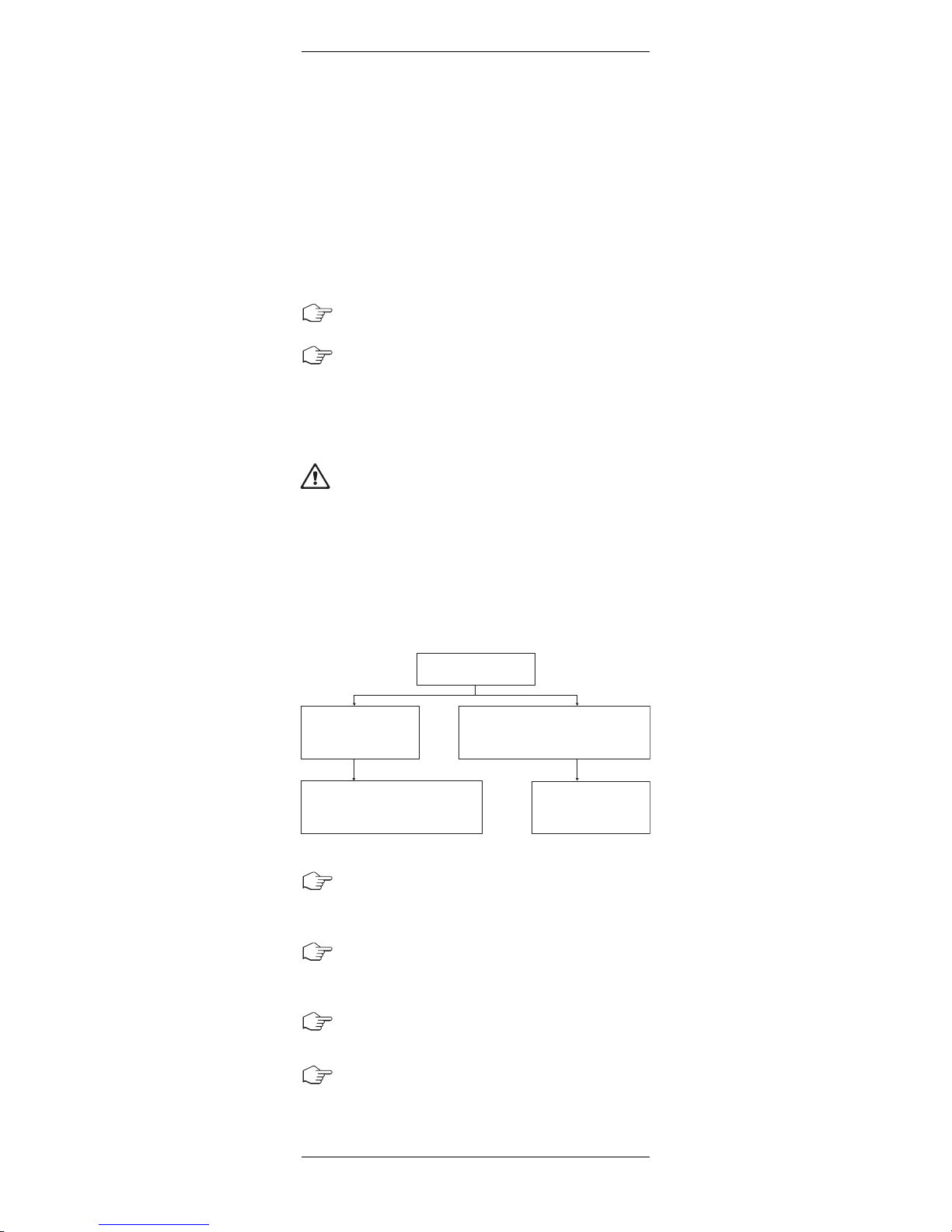

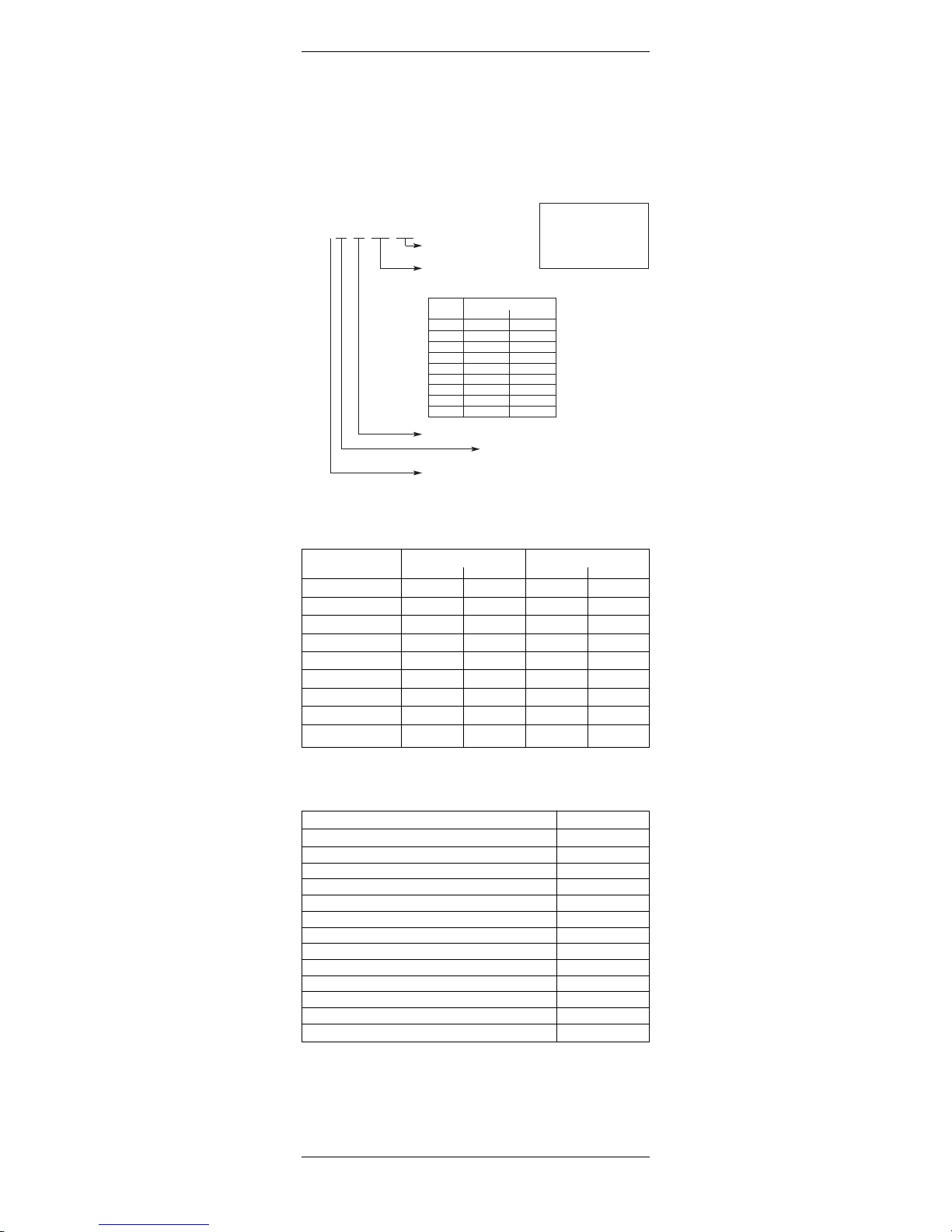

2.7 Ex-classification FM approved

A

B

C

D

E

F

F

E

D

C

B

A

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

Index

Title

Drawing No

METTLER TOLEDO

Process Analytics

CH-8902 Urdorf

Drawn F.Kogelmann 11-Dez-03 Scale 1:1

Change Dario Meier 25-Mai-16 Format DIN A3

Schutzvermerk ISO 16016 beachten / Refer to protection notice ISO 16016

Note - Replaces -

FM control drawing

53800002

E.4

Model: MODEL NAME

E.4

ArtikelNr: 53800002

Drawing: E.4 Rel.Level: Released Sheet: 1

/

1

R

Notes:

1. No revision to this drawing is permitted without FMRC approval.

2. Vmax > Vt; Imax > It; (Ci of all loops + C cable) < Ca; (Li of all loops + L cable) < La

Pmax or Pi > Po

3. Single Multi-Channel IS Barrier or Apparatus must be FMRC Approved.

4. Single Multi-Channel IS Barrier or Apparatus manufacturer`s control drawings

must be followed when installing the System. IS Barrier or Equipment may be

installed within the Hazardous (Classified) location for which it is approved.

5. Installation must be in accordance with Article 500 of the NEC (ANSI/NFPA 70) and

ANSI/ISA RP12.6.

WARNING: substitution of components may inpair intrinsic safety.

Entity Parameters:

Vmax (Ui)=16V, Imax (Ii)=50mA, Pi=0.25W

Ci=0.1 uF, Li=0 mH

Probe

Class I, Division 1, Groups A, B, C and D

Class II, Division 1, Groups E, F, and G

Class III, Division 1

T6 Ta=60 C

HAZARDOUS (CLASSIFIED) LOCATION

Any FMRC Approved Single

Multi-Channel Barrier or Apparatus

NONHAZARDOUS LOCATION

12 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

3 Product description

3.1 General information

The sensor InPro 6800 with integrated temperature

probe is used for oxygen meas ure ment.

The sensor is sterilizable and autoclavable and

compatible with CIP (cleaning in place).

InPro 6800 sensors with ISM®functionality offer Plug

and Measure as well as enhanced diagnostics

features.

ISM sensors are available with K8S (fully digital) or VP

connector.

3.2 Principle

Here is a short summary of the principle of pola rographic measurement on which this sensor is based

(Clark 1961).

a) The Clark polarographic sensor basically consist

of a working electrode (cathode), a counter/reference electrode (anode), and an oxygen permeable

mem brane which separates the electrodes from the

sample medium.

b) The transmitter supplies a constant polarization

voltage to the cathode, needed to reduce oxygen.

c) The oxygen molecules which migrate through the

permeable membrane are reduced at the cathode.

At the same time, oxidation takes place at the

anode and oxidized anode metal (silver) is libe rated as silver ions into the electrolyte. The electro lyte closes the electric circuit between anode and

cathode (ion conductivity).

d) The current produced by the reactions described

above is measured by the transmitter and is

proportional to the partial pressure of oxygen

(pO

2

) in the sample medium.

Please refer to Section 10 ”Theory of the polarogra phic

sensor” for further information.

3.3 Scope of delivery

Each sensor is supplied fully assembled and factorytested for correct function together with:

– a quality control certificate

– inspection certificates 3.1B

(complying with EN 10204.3/1B)

See electrolyte order details at section „Spare Parts“,

9.3.

InPro 6800 Series O2Sensor 12/25 mm 13

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

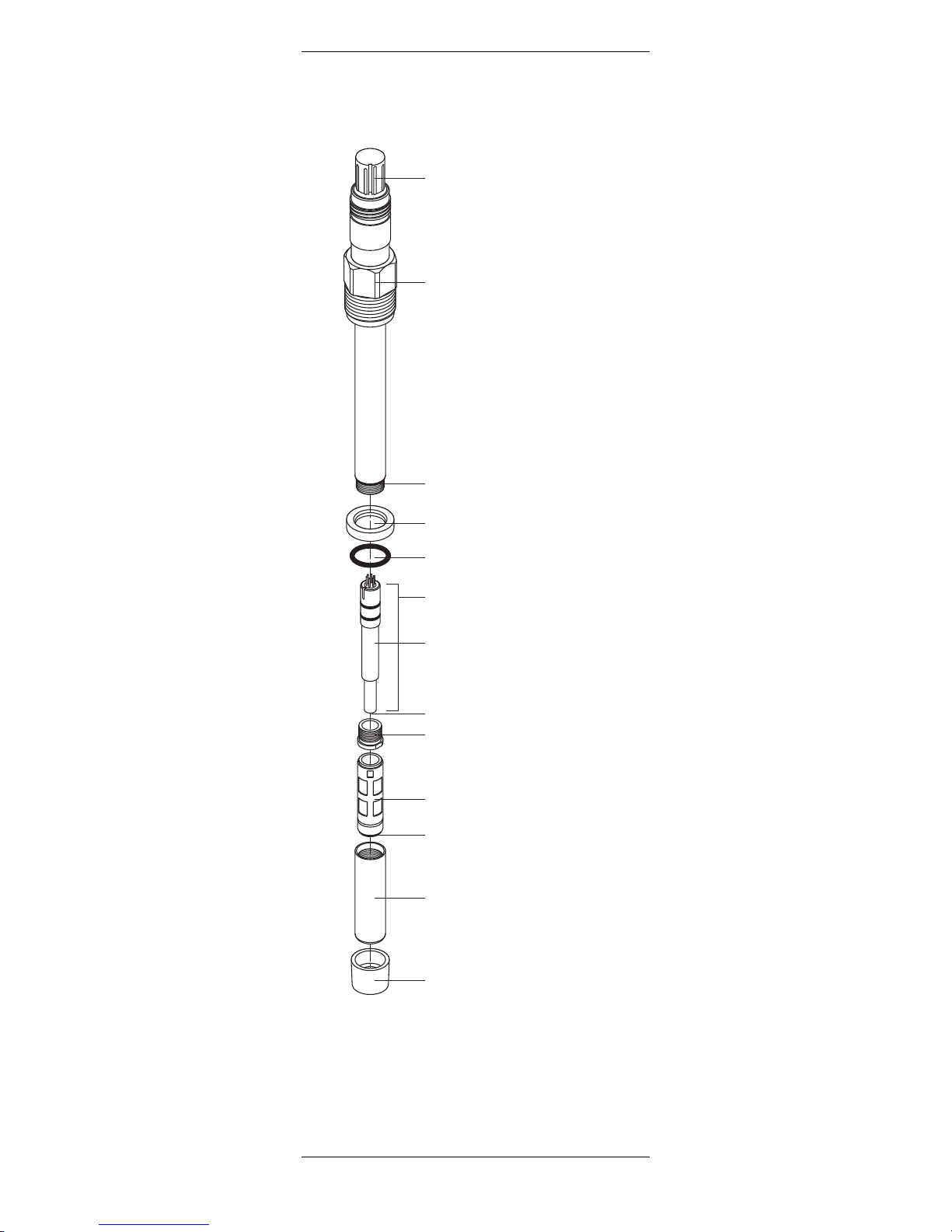

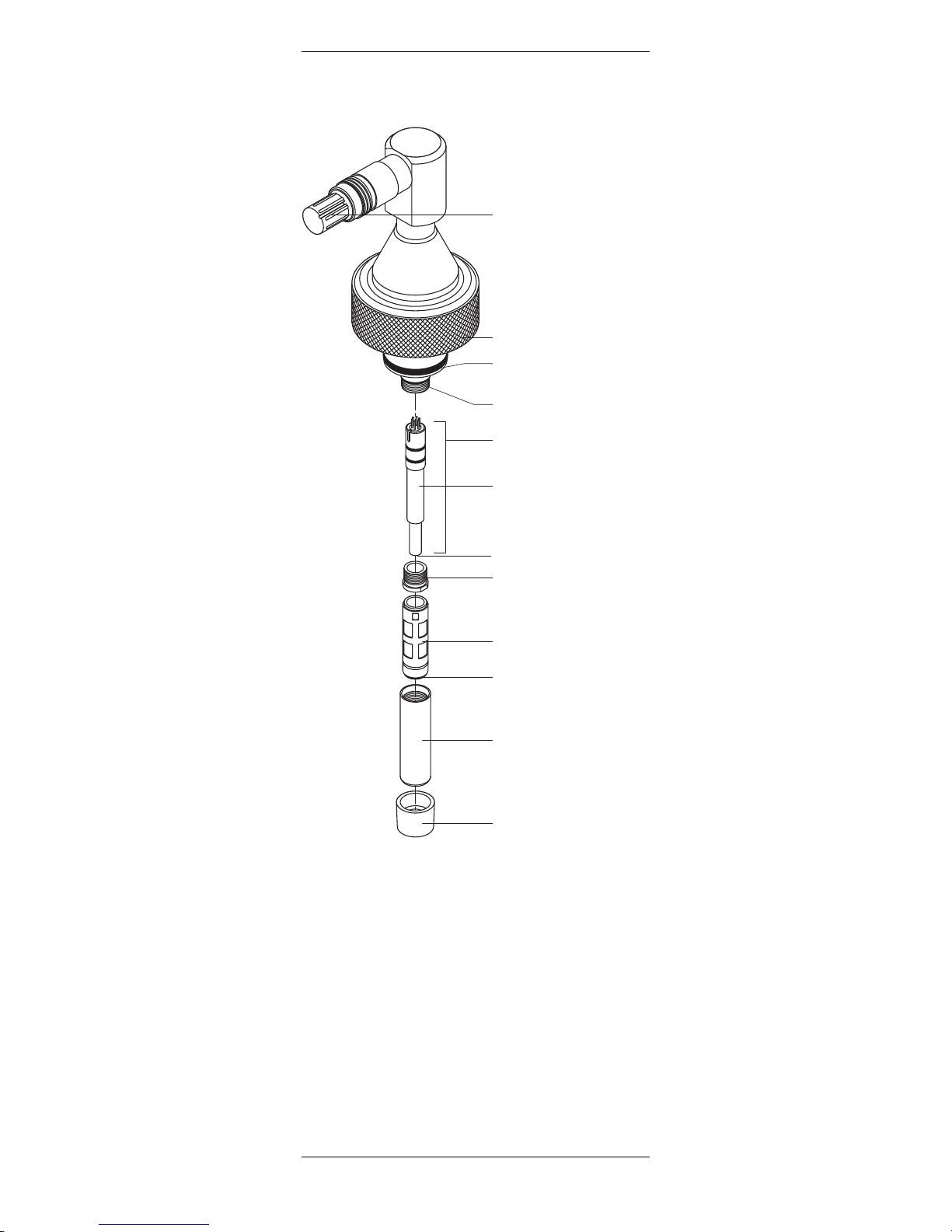

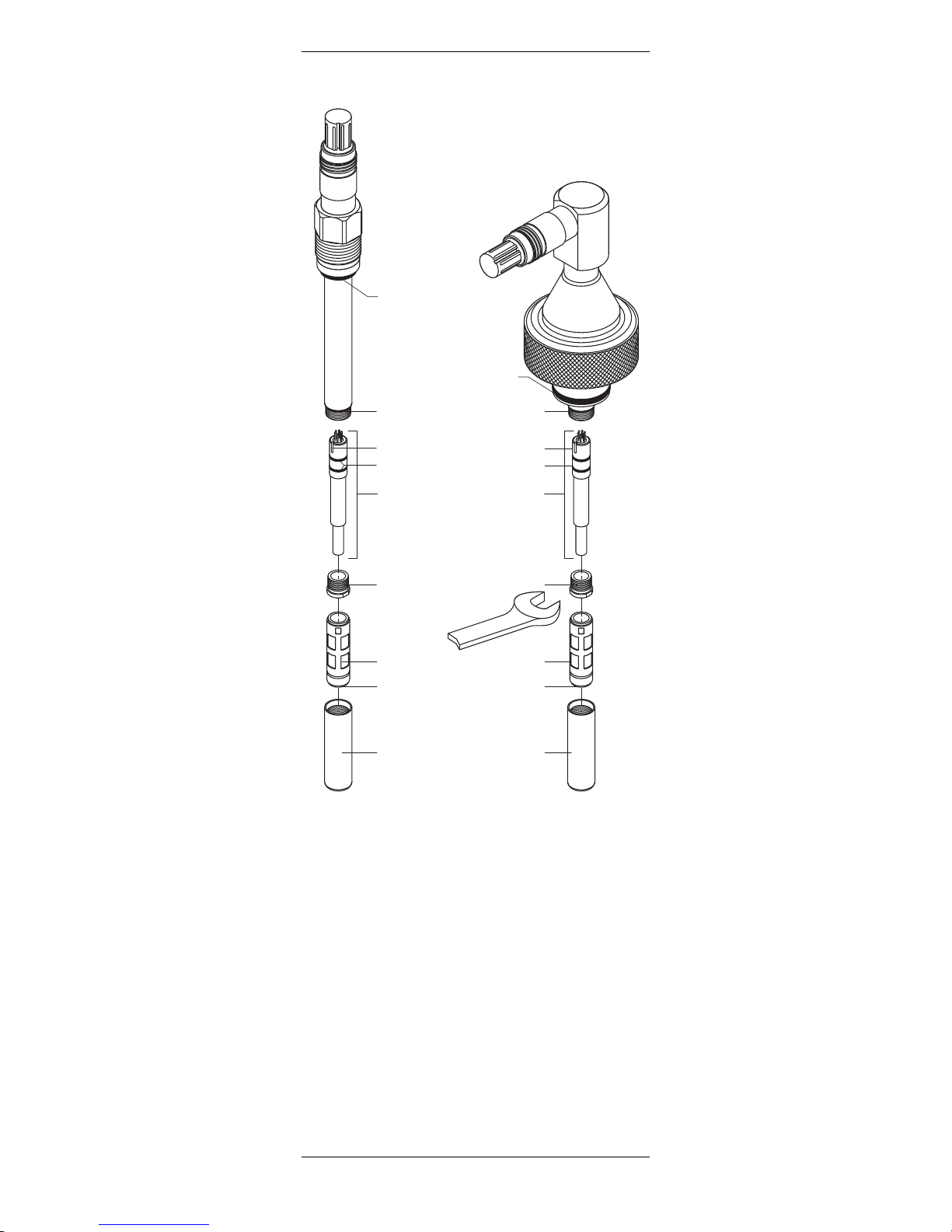

3.4 Equipment features

12 mm Sensor

VP connector

(straight version)

(K8S connector for digital ISM)

O-ring

(10.77x2.62 mm, Silicone FDA)

Interior body

Anode

(solid silver)

Cathode

Retainer nut

O-ring

(Silicone FDA/USP VI)

Cap sleeve (N-type)

Protection cap

Washer

Pg 13.5 threaded sleeve

O-ring

(9.0x1.0 mm, Silicone FDA/USP VI)

Membrane body

14 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

Cap nut G1"

O-ring

(20.29 x2.62 mm, Silicone FDA/

USP VI)

Interior body

Anode

(solid silver)

Cathode

Retainer nut

Membrane body

Cap sleeve (N-type)

Protection cap

25 mm Sensor

O-ring

(9.0x1.0 mm, Silicone FDA/

USP VI)

O-ring

(Silicone FDA/USP VI)

VP connector

(angled version)

(K8S connector for digital

ISM)

InPro 6800 Series O2Sensor 12/25 mm 15

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

4 Installation

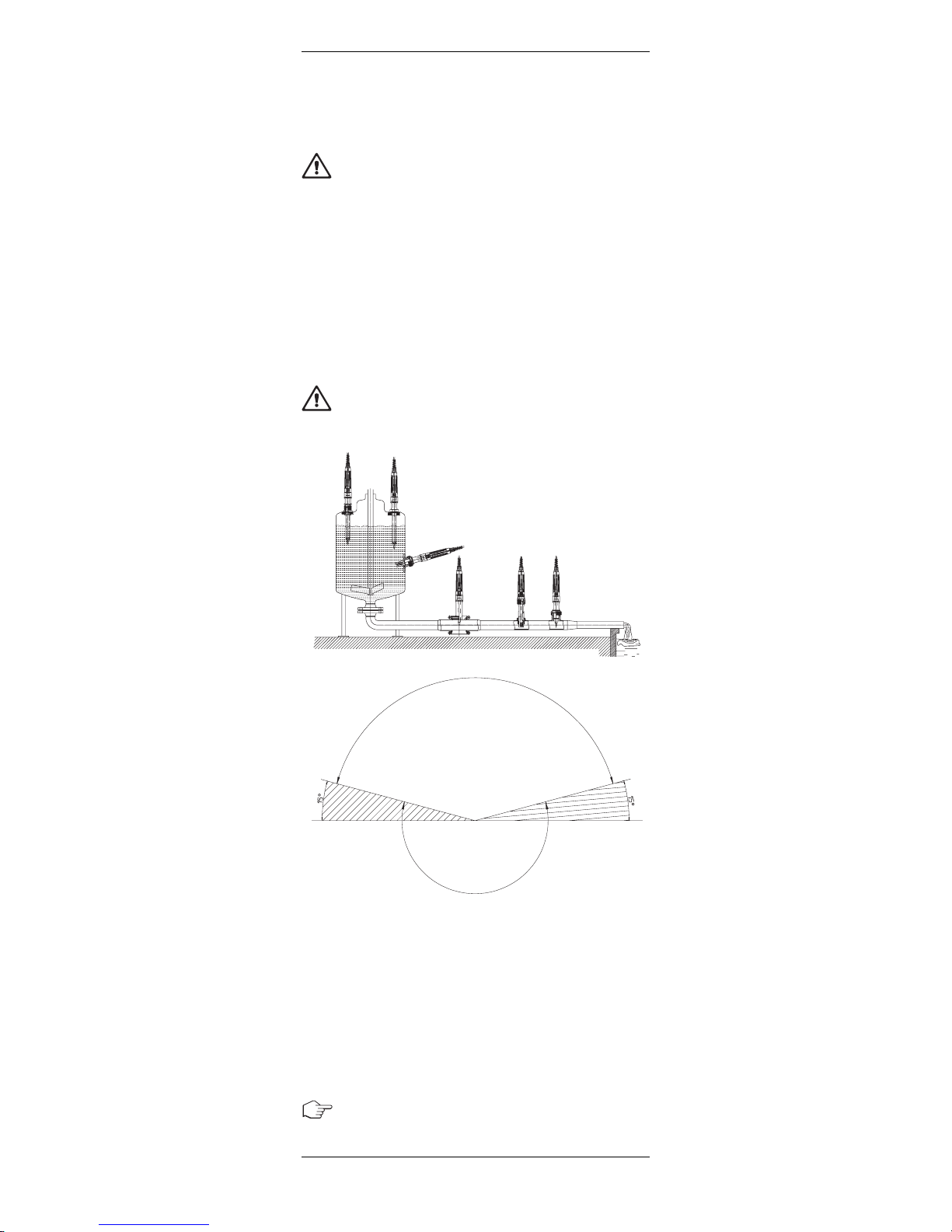

4.1 Mounting the sensor

Important! Remove the green protective cap before

mount ing the sensor.

Mounting the sensor in a housing

Please refer to the instruction manual of your housing

explaining on how to mount the sensor in place.

Mounting the sensor directly on a pipe or a vessel

The sensor can be mounted vertically or in an inclined

position. In the case of inclined mounting, the angle of

the housing must be equal to or greater than 15° above

the horizontal.

Caution! Installation outside the admissible range of

mounting positions is not allowed, otherwise correct

operation of the sensors / electrodes may be impaired.

52910536

admissible mounting positions

zulässige Einbaulagen

positionements de montage admis

admissible mounting position

zulässige Einbaulage

positionement de montage admis

inadmissible (except for optical sensors)

unzulässig (ausser für optische Sensoren)

ne pas admissible (sauf pour sondes optiques)

The 12 mm sensors can be mounted directly through

a socket with inside thread Pg 13.5 and securely tightened via the Pg 13.5 threaded sleeve.

The 25 mm sensors can be mounted directly through

a standard weld-in socket or the safety weld-in sockket

from METTLER TOLEDO.

4.2 Connection

4.2.1 Connecting the InPro 6800 to a cable

Sensors with ISM functionality require the use of a special AK9 cable as well as an ISM compatible O

2

trans-

16 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

4.2.2 Connecting the VP or AK9 cable to the transmitter

Note: Cable assignment can be found in the METTLER

TOLEDO VP or AK9 cable instruction manual.

Note: For connecting the cable to the terminals of the

transmitter, please refer to the instructions given in the

METTLER TOLEDO transmitter manual.

VP or AK9 cable

O

2

transmitter

VP-6 cable for standard use

AK9 cable for ISM functionality

Plug

Pin

Slit

VP connector

K8S connector for

digital ISM

mitter. The sensor is connected to the transmitter via a

AK9 cable. The AK9 cable ensures a secure connection

between the transmitter and the sensor under harsh

industrial conditions. The robust watertight IP68 connector housing guarantees maximum process safety.

If you have chosen to use a sensor with digital ISM

functionality, the K8S connector will incorporate a preamplifier. It is absolutely necessary to protect this electronic component against any electrical charge.

Do not touch the sensor at the VP connector plug.

To connect the VP cable to the sensor align the slit of

the VP connector with the pin in the plug. Then tightly

screw the plug to fasten the two parts.

InPro 6800 Series O2Sensor 12/25 mm 17

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

5 Operation

Attention! Before using the sensors for the first time,

the electrolyte should be replaced (see ”Chapter 6.2”).

Due to possible adverse conditions during transport

and storage (e.g. airfreight; pressure and temperature

variations), the quality of the electrolyte may become

impaired. Poor electrolyte quality can lead to erroneous

measurement values.

5.1 Start-up and polarizing

Attention! The protective cap at the tip of the sensor

must be removed before putting the sensor into

ope ration.

When the system is operated for the first time or if the

sensor has been disconnected from the voltage source

(transmitter or O

2

Sensor-Master) for longer than

5 min utes, the sensor has to be polarized prior to

calibration by connecting it to the operating O2transmitter or to a sensor master. After 6 hours, the sensor

is fully polarized and ready for operation.

A shorter polarization period is sufficient if the sensor

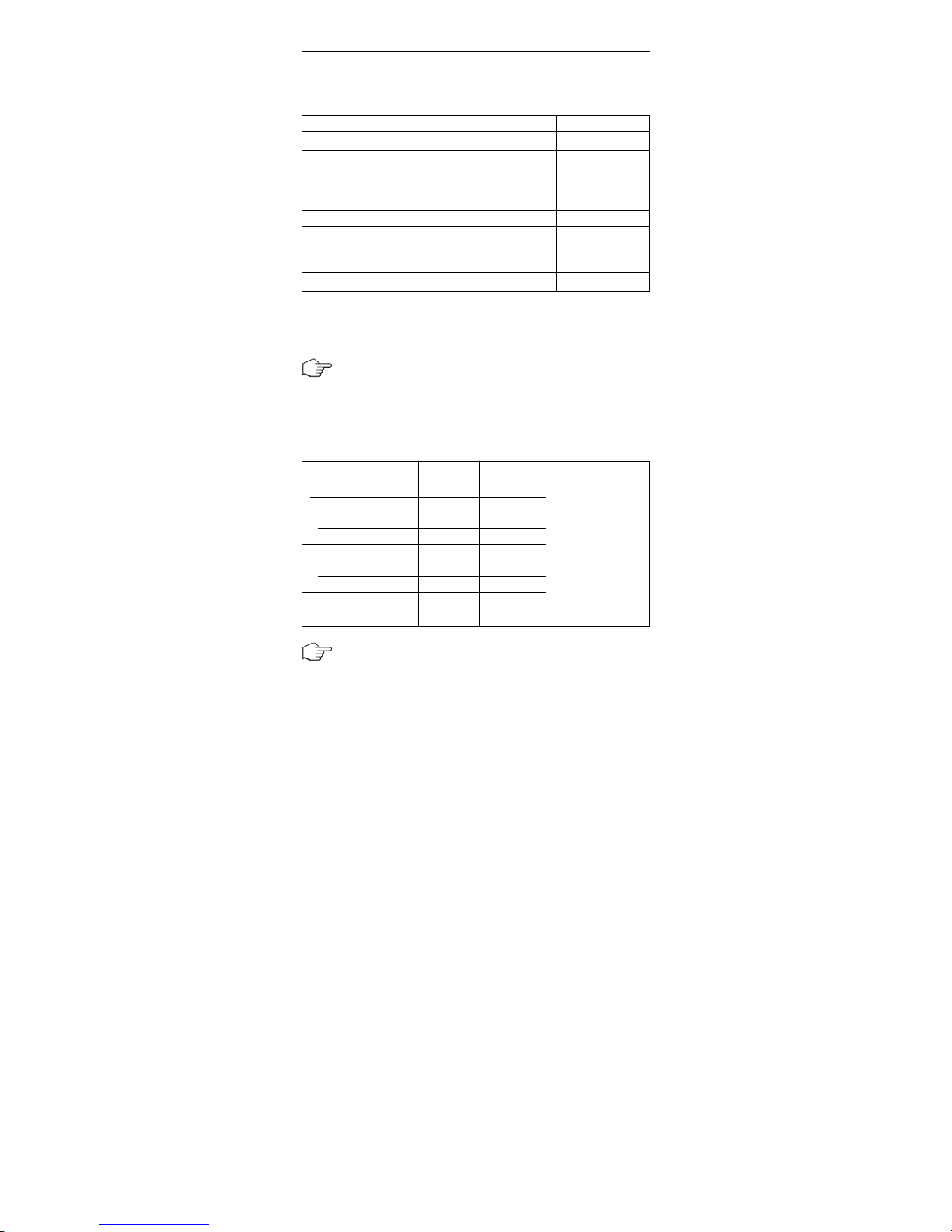

has been disconnected for only a few minutes. The

following table serves to establish the correct polari zation time in relation to the depolarization time.

Depolarization time1 Minimum required

t

depol

[Min.] polarization time2[Min.]

t

depol

> 30 360

30 > t

depol

> 15 6 * t

depol

15 > t

depol

> 5 4 * t

depol

t

depol

< 5 2 * t

depol

1 Depolarization time:

Time span in which the polarization voltage is cut off

from the sensor. This is the case during:

– change of electrolyte

– change of membrane body

– the time the cable is disconnected or no transmitter

or sensor master is connected to the cable

2 Polarization time:

Time span during which the sensor is under a polari zation voltage.

Attention! Setting of the polarization voltage on the

transmitter for correct measurements:

– Standard applications (e.g. measurement in

bio tech nology): – 675 mV

– Measurement of permanently low oxygen concen-

trations <500 ppb in the presence of volatile

acidic components (e.g. carbon dioxide during

measurements in breweries): – 500 mV

Important! To ensure the supply of the correct polariza tion voltage the transmitter must be set accordingly.

18 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

5.2 Calibration

5.2.1 Purpose of calibration

Each oxygen sensor has its own individual slope and

own individual zero point. Both values are subject to

change, for example, through electrolyte consumption

or after exchange of electrolyte or membrane body. To

ensure high measurement accuracy of the sensor, a

calibration must be carried out after each change of

electrolyte or membrane. Prior to calibration, the

sensor has to be polarized for at least 6 hours.

A zero point calibration is only advisable if very high

accuracy is required at low oxygen concentrations.

To check if your sensor needs a recalibration, you

may dry it and take it in the air to check that the

reading is close to 100%. If not, then the sensor

needs a new calibration.

5.2.2 What you have to know for calibration

Attention! If dissolved oxygen is being measured at

low concentrations (<500 ppb) in the presence of

volatile acidic components (e.g. carbon dioxide (CO

2

)

measurements in breweries), the calibration procedure

described below should be followed in order to achieve

the best measurement performance.

No special calibration procedure is required if dissolved

oxygen is being measured in standard applications

(e.g. measurement in biotechnology).

First step: Adjust the transmitter polarization voltage

to – 675 mV. Detailed information is given in the transmitter instruction manual.

Second step: After adjusting the polarization voltage

to – 675 mV, equilibration time is required. Wait for

about 5 minutes before carrying out step 3.

Third step: Perform calibration according to the transmitter’s instruction manual.

Fourth step: Adjust the transmitter polarization voltage

back to –500 mV.

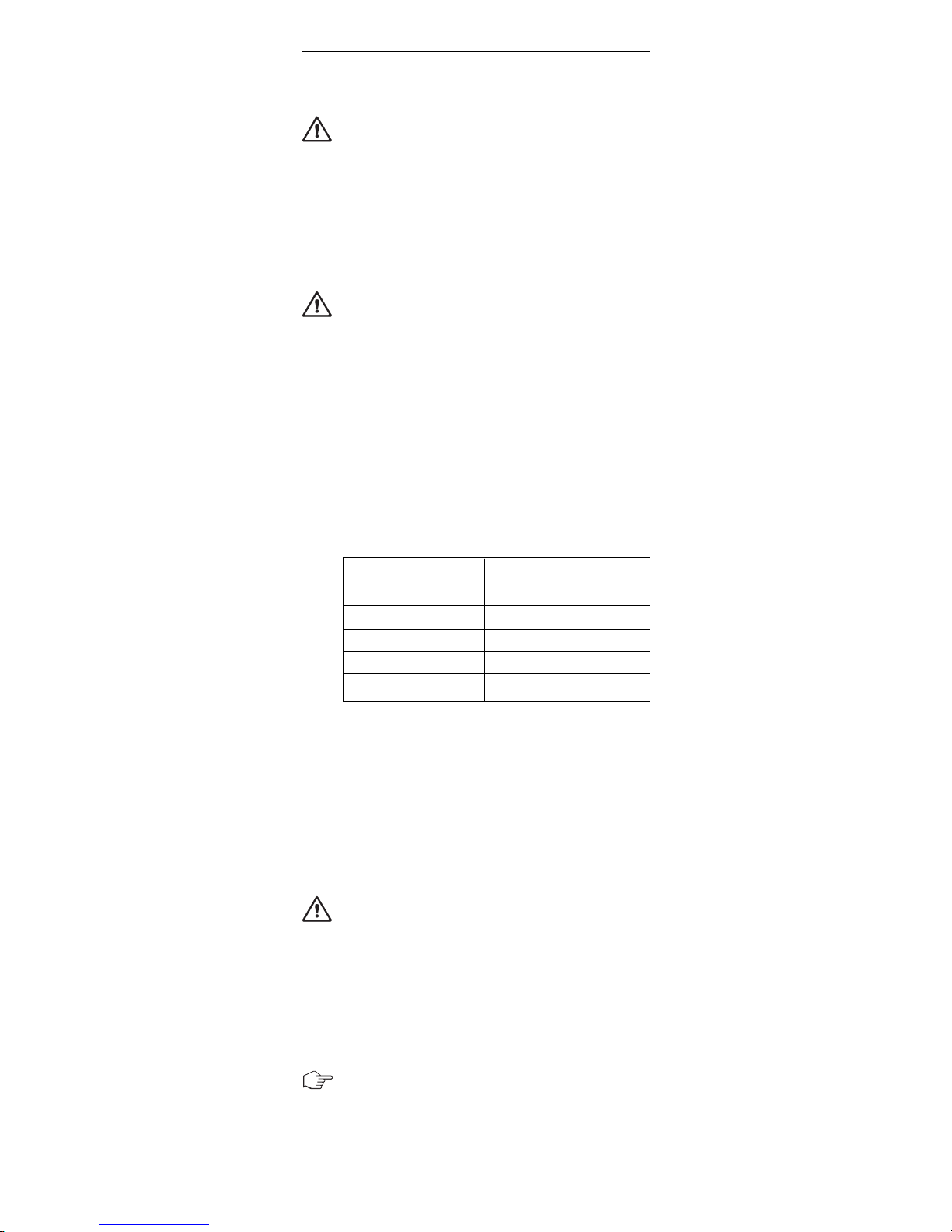

Where is oxygen

being measured?

Standard applications

(e.g. measurement in

biotechnology).

No special procedure required.

Refer to transmitter instruction

manual and general remarks below.

Follow step 1 to step 4

and general remarks

below.

Measurement of permanently low oxygen

concentrations (<500ppb) in the pre-

sence of volatile acidic components

(e.g. CO

2

at measurements in breweries).

InPro 6800 Series O2Sensor 12/25 mm 19

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

General remarks:

– For calibration in air, the sensor membrane must

be dry, since adhering water drops can falsify the

measured oxygen value.

– Make sure that the oxygen saturation index of the

calibration medium is correct and remains

constant during calibration.

– In the event of calibration in water or sample

medium, the calibration medium must be in

equilibrium with the air. Oxygen exchange

between water and air is only very slow. Therefore

it takes quite long time until water is saturated with

atmospheric oxygen.

– For correct calibration, a minimum flow rate of the

calibration medium is necessary.

– Calibration in a fermenter should be performed

after sterilization (as sterilization may alter the

sensor slope), but prior to innoculation. If it is not

possible to perform the calibration after sterilization,

the use of an existing membrane body that has

been pre-sterilized while mounted in the sensor is

recommended. A slope alteration of some per cent

can occur with new membrane bodies, particularly

after a first sterilization, as the tension of the membrane may be altered by the sterilization process.

– Make sure that all other parameters, such as

temperature and pressure, are constant.

For continuous applications, we recommend periodic

recalibration in line with your requirements on

accuracy, the type of process in operation and your

own experience. The frequency of the need for re-

calibration depends very much on the specific

application, and therefore appropriate intervals cannot

be exactly defined here.

5.2.3 Single point calibration

By carrying out a single point calibration, the factual

slope of the sensor can be established. The calibration

medium can be water with known oxygen saturation

index (e.g. air-saturated water) or air with known

water-vapor saturation (e.g. water-vapor saturated

air).

After the sensor signal has stabilized, the complete

meas uring system can then be calibrated to the 100 %

value of the desired measurable variable, e.g.100 %

Steps 1 to 4 can be accomplished automatically if you

use the M 700 transmitter. Thus the routine can be

minimized to a few keystrokes. In addition the M 700

transmitter must be equipped with the software function

SW-700-011 ”high CO

2

compensation”. Please ask

your local METTLER TOLEDO distributor.

20 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

air, 20.95 % O2, or 8.26 ppm at 25 °C (77 °F) and

normal pressure (see instruction manual for the trans mitter).

Single point calibration should be sufficient for almost

all process applications.

5.2.4 Dual point calibration

By carrying out a dual point calibration both slope and

zero point of the sensor can be established.

Important! In case of a dual point calibration, always

start by the zero point calibration before calibrating

the slope.

Due to the very low zero current of METTLER TOLEDO

sensors, dual point calibration is normally not necessary for standard applications.

As a rule, the zero point should be adjusted to zero

manually, or it is automatically performed by the

transmitter (see instruction manual for the transmitter).

A zero point calibration is only advisable if very high

accuracy is required at low oxygen concentrations.

Attention! Incorrect zero point calibration is a

frequent source of measurement error. For correct

calibration, we recommend the use of nitrogen gas

or other oxygen-free medium with a level of purity

of at least 99.995%.

After the sensor signal has stabilized (after 20…30

minutes), the sensor can be calibrated through the

relevant transmitter to the 100 % value of the desired

measurable variable, e.g. 0 % air, 0.0 % O

2

, or

0.0 ppm (see instruction manual for the transmitter).

InPro 6800 Series O2Sensor 12/25 mm 21

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

6 Maintenance

6.1 Inspection of the sensor

6.1.1 Visual inspection

To check your sensor, we recommend the following

procedure:

• The contacts of the connector must be dry.

Moisture, corrosion and dirt in the connector can

lead to false readings.

• Check the cable for buckling, brittle areas or

ruptures.

• Before calibration always examine the membrane

foil optically for signs of damage. The foil must be

intact and clean. Dirty membranes should be

wip ed clean using a soft, moist tissue.

Note: An undulated membrane has no influence on

the sensor performance, assuming the membrane

is intact.

• The membrane body must be replaced if the sensor

has too long a response time, the reading is

unstable or subject to drift, and if the sensor cannot

be calibrated or the membrane shows sign of

mechanical damage.

• Check the cathode area for discoloration, conta -

mination or cracks in the glass. If necessary rinse

with demineralized water and clean with a clean

soft brush or soft paper tissue.

Attention! Do not use any cleaning agents con taining

alcohol. This could damage the sensor or lead to

fault current.

Attention! The glass body is fragile and sensitive to

vibration.

22 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

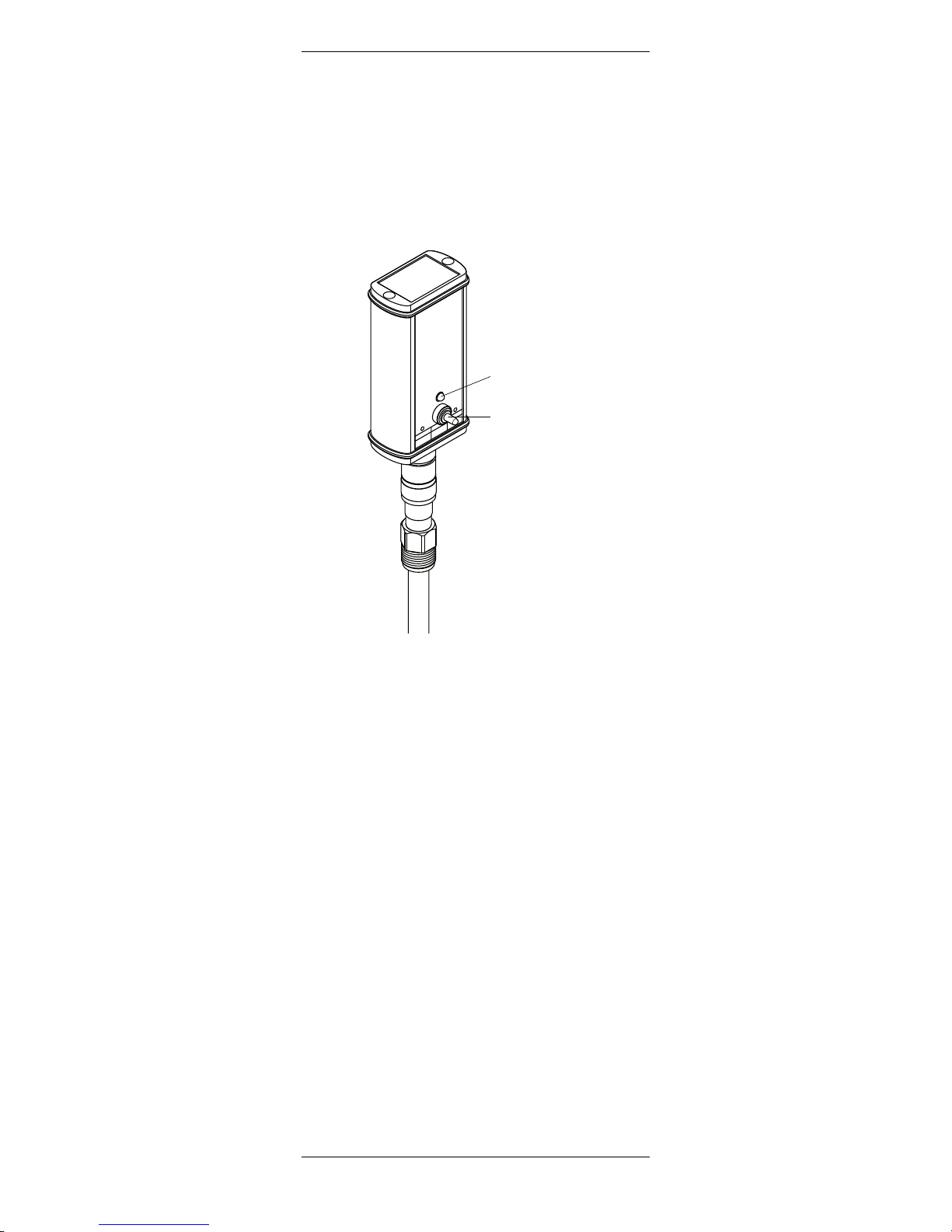

6.1.2 Testing the sensor with the METTLER TOLEDO

O2Sensor-Master InPro 6800

We recommend to use the METTLER TOLEDO O

2

Sensor-Master InPro 6800 to check the quality of your

sensor as follows (not applicable for digital ISM sensors):

• Connect the sensor to the O2Sensor-Master.

LED

Switch

As soon as the sensor is connected to the O

2

Sensor-Master, the polarization function is automatically activated. Please note: if the sensor was

disconnected from the transmitter for longer than

5 minutes, the sensor must be polarized first

(polarizing time see section 5.1) to get representative test results.

• Battery Check:

Push the switch to the left. If the battery is ok and

the O

2

Sensor-Master is operational the green LED

lights up. Otherwise, please consult the instruction

manual of the O2Sensor-Master.

• Sensor Check:

For this test the O2sensor must be fully polarized

and the membrane of the sensor must be dry and

clean.

Expose the sensor (connected to O

2

Sensor Master) to the air. By pushing the switch to the right

to the position ”2 – Sensor check”, the O2SensorMaster checks wether the electrode current for air

measurement delivered by the sensor is within the

admissible range (40 to 100 nA for InPro 6800).

If the green LED lights up the current for air

measurement is with in the admissible range.

METTLER TOLEDO

O

2

Sensor-Master

InPro 6800

Order No. 52 200 892

The polarization function

will be activated automatically

,

when a sensor is connected.

After the sensor polarization

you should check the functions

of the sensor as following:

1. Battery Check

2. Sensor Check

Green light = ok

left

Battery

Check

middle

Autom.

Polariz.

right

Sensor

Check

1

2

InPro 6800 Series O2Sensor 12/25 mm 23

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

If the LED does not light up, you should check the

battery of the O2Sensor-Master (see instruction

manual ”Accessories”). If the battery is working,

than there is probably a problem with your sensor.

You should change the electrolyte and/or the

membrane body of your sensor. If after a

membrane change the LED still does not light up,

this means that there is maybe something wrong

with the interior body of the sensor. You should

than change it (see ”Section 6.2”).

Important! The sensor check function only veryfies

the correctness of the electrode current for air

measurement. In order to be absolutely sure of the

functionality of the sensor, the residual signal in an

oxygen free medium should also be controlled (see

”Section 6.1.3”).

6.1.3 Testing the sensor via a transmitter

A periodic zero current measurement (no zero point

calibration) is recommended for verification of proper

sensor function.

At the time you carry out the zero current measurement, the sensor must be polarized.

Zero current measurement can be done by using zero ing gel (order no. 30 300 435) or nitrogen (N

2

) or

carbon dioxide (CO2) calibration gases with a purity of

at least 99.995 %, alternatively in a sample medium

saturated with one of these gases.

After 2 minutes in an oxygen-free sample medium, the

reading on the transmitter should drop to below 10 %

of the reading in ambient air, and within 10 minutes

the value should have dropped to below 1 %.

If the measured values are too high, this suggests a

depleted electrolyte or a defective membrane. In the

first instance replace the electrolyte, and in the second

case exchange both the membrane body and the electrolyte accordingly.

If after such procedures the above mentioned values

are still not reached, replace the interior body. If this

doesn't solve the problem too send the sensor to your

local METTLER TOLEDO representative for inspection.

Many sample media contain volatile substances

which, even at very low concentrations, have a clearly

perceptible smell. Similarly to oxygen, these

sub-stances are able to invade the electrolyte through

the gas-permeable membrane. Accordingly, they

become noticeable when changing the electrolyte. In

most cases, such substances have absolutely no

influence on the measuring properties of the sensor.

Slight discoloration of the electrolyte also has no effect

on the measuring properties.

24 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

6.2 Changing the electrolyte, the membrane body

or the interior body

METTLER TOLEDO DO sensors are supplied with fitted

membrane body and have been checked for proper

function.

However, if a sensor is to be stored for several months,

the electrolyte should be replaced before use.

If the membrane exhibits signs of failure (long

response time, increased current in an oxygen-free

medium, mechanical damage, etc.) the membrane

body has to be replaced.

Warning! The O

2

electrolyte has an alkaline pH value

of 13. Contact of electrolyte with mucous membrane

or eyes is to be avoided. Therefore protective gloves

and safety glasses have to be worn for the following

dismantling works.

If such contact occurs, the affected area should be well

rinsed with water. In the case of accident, or should

ever any adverse signs appear, get immediate medical

attention.

When changing the electrolyte, the membrane body or

the interior body, please observe the following instructions (see also the following illustration):

Attention! Make sure that this maintenance step is

carried out in clean place.

1. Unscrew the cap sleeve from the sensor shaft and

carefully pull it off the sensor.

2. Pull off the membrane body from the interior body.

If it is tight-fitted, eject by pushing it with the flat

finger tip. Before electrolyte is refilled, the membrane body must be removed from the cap sleeve.

3. Rinse the interior body with demineralized water

and carefully dab it dry with a paper tissue.

Note: steps 4 to 7 may only be carried out when

changing the interior body.

4. Unscrew the retainer nut of the interior body with

an adjustable wrench or with a 3/8" wrench.

5. Remove the interior body by pulling it out of the

sensor shaft. If necessary use a plier.

Warning! Do not twist the interior body. Otherwise the connection pins can be damaged.

InPro 6800 Series O2Sensor 12/25 mm 25

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

6. Insert the new interior body in the sensor shaft.

Turn the interior body in the shaft until the slit of the

interior body is aligned with the pin placed in the

shaft.

7. Press the body in the shaft and screw the new

retainer nut in place.

8. Examine the O-rings visually for mechanical

defects, and replace if necessary.

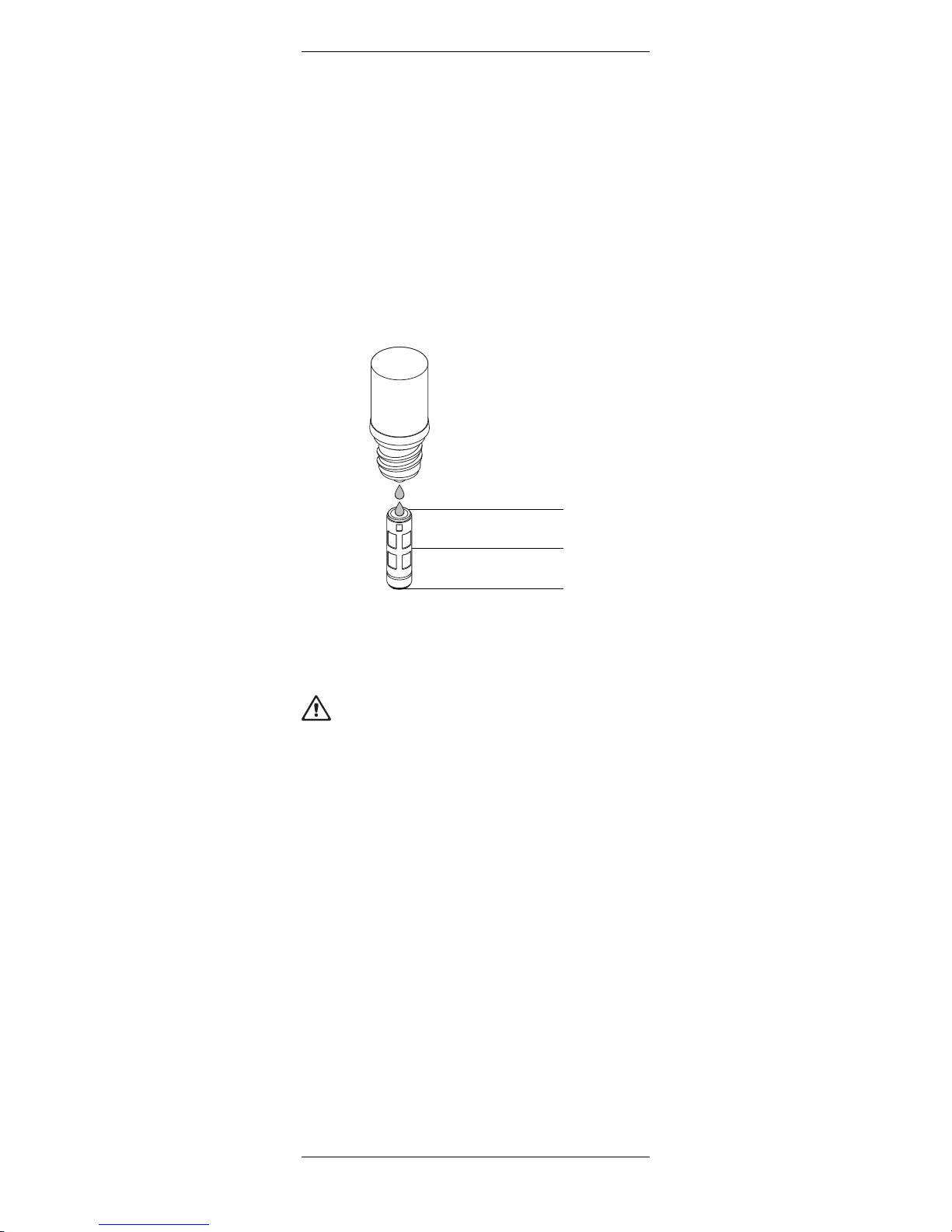

9. Half-fill the new membrane body with O

2

electrolyte and make sure that all bubbles are

removed. Air bubbles can be removed by care fully

tapping on the membrane body.

10. Slip the membrane body over the interior body

while holding the sensor in a vertical position. The

excess electrolyte will be displaced and have to be

removed with a paper tissue.

Attention! No electrolyte, sample media or contamination may be present between the membrane

body and the cap sleeve. Please check carefully.

11. Carefully slip the cap sleeve over the fitted

membrane body, holding the sensor in a vertical

position and screw it tight. The cap sleeve must be

clean and dry.

12. After each exchange of electrolyte or membrane

body, the sensor has to be repolarized and re calibrated.

1

/

2

1

/

2

O2electrolyte

26 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

3/8"

Slit

O-ring

9.0x1.0 mm, Silicone FDA/USP VI

O-ring

20.29x2.62 mm,

Silicone FDA/USP VI

O-ring

10.77x2.62 mm,

Silicone FDA/USP VI

O-rings

Interior body

Retainer nut

(O-ring inside)

Membrane body

Cap sleeve (N-type)

O-ring

Silicone FDA/USP VI

InPro 6800 Series O2Sensor 12/25 mm 27

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

7 Storage

The sensor can be stored for several months filled with

O2electrolyte (order no. 30 298 424) as long as the

protective cap is in place. In order to avoid the 6-hour

polarization time before reuse of the sensor, it can be

kept stored connected to the METTLER TOLEDO O

2

Sensor-Master InPro 6800.

Attention! The electrolyte should be replaced before

use if the storage period exceeds 3 months.

If the storage period exceeds 6 months, the sensor

should be stored dry, i.e. without any electrolyte in the

membrane body.

Attention! A sensor being stored dry (without

electrolyte in the membrane body) may on no account

be connected to the O2Sensor-Master InPro 6800.

8 Product specification

8.1 Certificates

Each sensor is delivered with a set of 3.1 B certificates

(complying with EN 10204.3/1.B).

All wetted metal parts (sensor shaft, cap sleeve and

membrane body) are identified with a engraved

symbol corresponding to the heat number on the

paper certificate delivered with the sensor.

Each wetted metal part (sensor shaft, cap sleeve and

membrane body) is polished in order to get a surface

roughness lower than 0.4µm (16µin). This represents

a roughness grade number of N5 (according to ISO

1320:1992).

28 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

8.2 Specifications

Attention! Please refer to the supplementary sheet

52 201 146 if the sensor, together with the membrane

body T-6800 gas, is been used for measurement of

oxygen partial pressure in gases. This supplementary

sheet is only included in the packaging of T-6800 gas

membrane bodies and kits.

InPro 6800

Measurement principle Amperometric/Polarographic

Working conditions

Pressure resistance measurement 0.2 – 6 bar absolute

[2.9 – 87.0 psi absolute]

Mechanical pressure resistance max. 12 bar absolute

[174.0 psi absolute]

Measuring temperature range 0…80°C [32…176°F]

Temperature range – 5…140 °C [23…284°F]

(sterilizable/autoclavable)

Construction

Temperature compensation Automatic with built-in RTD

Cable connection VarioPin (IP68) straight or angled

K8S straight (digital ISM sensors)

O-ring material Silicone FDA and

USP VI approved

Membrane material PTFE/ Silicone/ PTFE

(reinforced with steel mesh)

Wetted metal parts Stainless steel

Special material on request

Surface roughness of N5 (R

a

< 0.4 µm [16µin])

wetted metal parts (ISO 1320:1992)

Quick disconnect interior body Standard

Cathode Pt

Anode Ag

Guard ring No

Dimensions

Sensor diameter 12 or 25 mm (0.47" or 0.98")

Immersion length (a) for 12mm sensor 70, 120, 220, 320, 420 mm

(2.8, 4.7, 8.66, 12.6, 16.54")

Immersion length (a) for 25mm sensor 80,160, 260, 360 mm

(3.15, 6.3, 10.24, 14.17")

Performances

Detection limit 6 ppb

Accuracy ≤ ±[1% + 6 ppb]

of reading in liquids

Response time at 25°C / 77 °F (air ➝ N2) 98 % of final value <90 s

Sensor signal in ambient air (25 °C /77°F) 50…110 nA

Residual signal in oxygen-free medium <0.1 %

of the signal in ambient air

Maximum flow error ≤5%

Certification

EHEDG, 3A Yes

3.1 B (EN 10204.3/1.B) Yes

ATEX certificate Yes

FM Approval Yes

FDA / USP VI Yes

Quality control Yes

Compatibility

with METTLER TOLEDO transmitters see ”Section 9.4”

with METTLER TOLEDO housings see ”Section 9.5”

InPro 6800 Series O2Sensor 12/25 mm 29

© 02 / 17 Mettler-Toledo GmbH InPro 6800

Printed in Switzerland 52 200 953

9 Ordering information

For more detailed information refer to the technical

data sheet. Ask your local distributor.

9.1 Sensors

Sensor without ISM functionality

Immersion 12 mm diameter 25 mm diameter

length (a) straight angled straight angled

70 mm (2.8") 52 200 964 52 200 969 –– ––

80 mm (3.2") –– –– 52 200 974 52 200 978

120 mm (4.7") 52 200 965 52 200 970 –– ––

160 mm (6.3") –– –– 52 200 975 52 200 979

220 mm (8.7") 52 200 966 52 200 971 –– ––

260 mm (10.2") –– –– 52 200 976 52 200 980

320 mm (12.6") 52 200 967 52 200 972 –– ––

360 mm (14.2") –– –– 52 200 977 52 200 981

420 mm (16.5") 52 200 968 52 200 973 –– ––

9.2 Accessories

Accessories Order no.

O2Sensor-Master InPro 6800 52 200 892

O2Sensor-Simulator 52 200 891

Adapter T82 socket – VP plug 52 200 939

Adapter VP socket – T82 plug 52 200 940

VP cable VP6-ST/3 m 52 300 108

VP cable VP6-ST/5 m 52 300 109

VP cable VP6-HT/3 m 52 300 112

VP cable VP6-HT/5 m 52 300 113

VP cable VP8-ST/3 m 52 300 354

VP cable VP8-ST/5 m 52 300 355

VP cable VP8-HT/3 m 52 300 361

VP cable VP8-HT/5 m 52 300 362

Oxygen zeroing gel (3× 25 ml) 30 300 435

For other cable lengths or types, please contact your local METTLER TOLEDO

representative.

Intelligent Sensor Management (ISM) O2sensor configuration

InPro 6 _ _ _ / _ _ / _ _ _ / _ _ _

Blank: Standard functionality

ISM: Intelligent Sensor Management

Immersion length (a) in mm

For diameter/immersion lengths combinations,

please see table below:

(a) InPro 68xx

[ 12 [ 25

070 ✓ –

080 – ✓

120 ✓ –

160 ✓✓

220 ✓ –

260 – ✓

320 ✓ –

360 – ✓

420 ✓ –

Sensor diameter: 12 = 12 mm; 25 = 25 mm

00: VP Plug head, straight

10: VP Plug head, angled

8: InPro 68xx

Example configuration:

InPro 6800/12/120/ISM

➝ Sensor with ISM functionality

InPro 6810/25/260

➝ Sensor without ISM functionality

30 InPro 6800 Series O2Sensor 12/25 mm

InPro 6800 © 02 / 17 Mettler-Toledo GmbH

52 200 953 Printed in Switzerland

9.3 Spare parts

Spare parts Order no.

Membrane body, single T-96 52 200 071

Membrane kit T-96 52 200 024

(4 membrane bodies, 1 O-ring set,

25 ml Electrolyte bottle)

Membrane bodies (20 pcs.) T-96 52 200 791

O2Electrolyte pack (3× 25 ml) 30 298 424

Interior body InPro 6800 52 200 899

(with quick disconnect)

Cap sleeve N-type 52 200 037

Cap sleeve with protective cage P-type 52 200 038

9.4 Recommended transmitter

Note: Ask your local distributor or refer to the techni-

cal data sheet.

9.5 Recommended housings

Housings 12 mm Ø 25 mm Ø

Static housings

INGOLD ”safety

weld-in socket” – 3

InFit 761 CIP 3 –

Retractable housings

InFit 777 e 3 –

InFit 797 e 3 –

Immersion housing

InDip

®

550 3 –

Note: The housings are available in different versions.

Please contact your distributor to get the right odering

information.

Please ask

your local

METTLER

TOLEDO

representative.

Loading...

Loading...