Mettler Toledo InPro 6050 Instruction Manual

InPro 6050 Series O2Sensors

Instruction manual

Bedienungsanleitung

Instructions d’utilisation

InPro 6050

52 200 251

InPro 6050 Series O2Sensor

InPro 6050 © 02 / 16 Mettler-Toledo GmbH

52 200 251 Printed in Switzerland

2

English Page 3

Deutsch Seite 15

Français Page 27

InPro 6050 Series O2Sensor

© 02 / 16 Mettler-Toledo GmbH, InPro 6050

Printed in Switzerland 52 200 251

3

InPro 6050 Series O2Sensors

Instruction manual

InPro 6050 Series O2Sensor

InPro 6050 © 02 / 16 Mettler-Toledo GmbH

52 200 251 Printed in Switzerland

4

Contents

Page

1. Product description . . . . . . . . . . . . . . . . . . . 5

1.1. Utilization, conformity, identification . . . . .5

1.2. Key data and characteristics . . . . . . . . . 5

1.3. Equipment features and scope of delivery 6

2

. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1. Signs and symbols . . . . . . . . . . . . . . . . 7

2.2. Safety precautions . . . . . . . . . . . . . . . . 7

3. Your equipment . . . . . . . . . . . . . . . . . . . . . . 7

3.1. Design / description . . . . . . . . . . . . . . . . 7

3.2. Functions . . . . . . . . . . . . . . . . . . . . . . . 8

3.3. Integration in measuring system . . . . . . . 8

4. Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1. Installation . . . . . . . . . . . . . . . . . . . . . . 8

4.2. Connection . . . . . . . . . . . . . . . . . . . . . . 8

4.3. Initial start-up . . . . . . . . . . . . . . . . . . . . 9

5. Operation . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1. Operation of the equipment . . . . . . . . . . 10

5.2. Measurement in power failure . . . . . . . . 10

5.3. Errors and corrective actions . . . . . . . . . 10

5.4. Storage . . . . . . . . . . . . . . . . . . . . . . . 10

6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . 11

6.1. Safety precautions . . . . . . . . . . . . . . . . 11

6.2. Cleaning and care . . . . . . . . . . . . . . . . 11

6.3. Replacing membrane & electrolyte . . . . . 11

6.4. Calibrating the sensor . . . . . . . . . . . . . 12

6.5. Troubleshooting and rectification work . . 12

7. Shut down and waste disposal . . . . . . . . . . 13

7.1. Shut down . . . . . . . . . . . . . . . . . . . . . 13

7.2. Waste disposal . . . . . . . . . . . . . . . . . . 13

8. Spare parts . . . . . . . . . . . . . . . . . . . . . . . . 13

InPro 6050 Series O2Sensor

© 02 / 16 Mettler-Toledo GmbH, InPro 6050

Printed in Switzerland 52 200 251

5

1

. Product description

1.1. Utilization, conformity, identification

The InPro 6050 is a polarographic oxygen sensor

designed for the simultaneous measurement of diss

olved oxygen and temperature in water applications.

The robust detachable connector VP (Vario Pin) provides the same, waterproof performance of fixed cable electrodes, with the advantage of a detachable

connector for easy sensor maintenance and replacem

ent.

T

he serial number is engraved on the sensor thread

for traceability.

1.2. Key data and characteristics

Technical data

Length 120 mm

Diameter 12mm

Connector VarioPin connector VP-4G

IP 68

Cable VP Cable

Temperature sensor NTC

Material

Shaft PPS

Membrane T-96 PTFE/Silicone/PTFE

(reinforced with steel mesh)

O-Rings Viton®, silicone

Working conditions

Temperature range 0...60°C

Humidity 0...100%

Media The sensor is designed for

use in water

InPro 6050 Series O2Sensor

InPro 6050 © 02 / 16 Mettler-Toledo GmbH

52 200 251 Printed in Switzerland

6

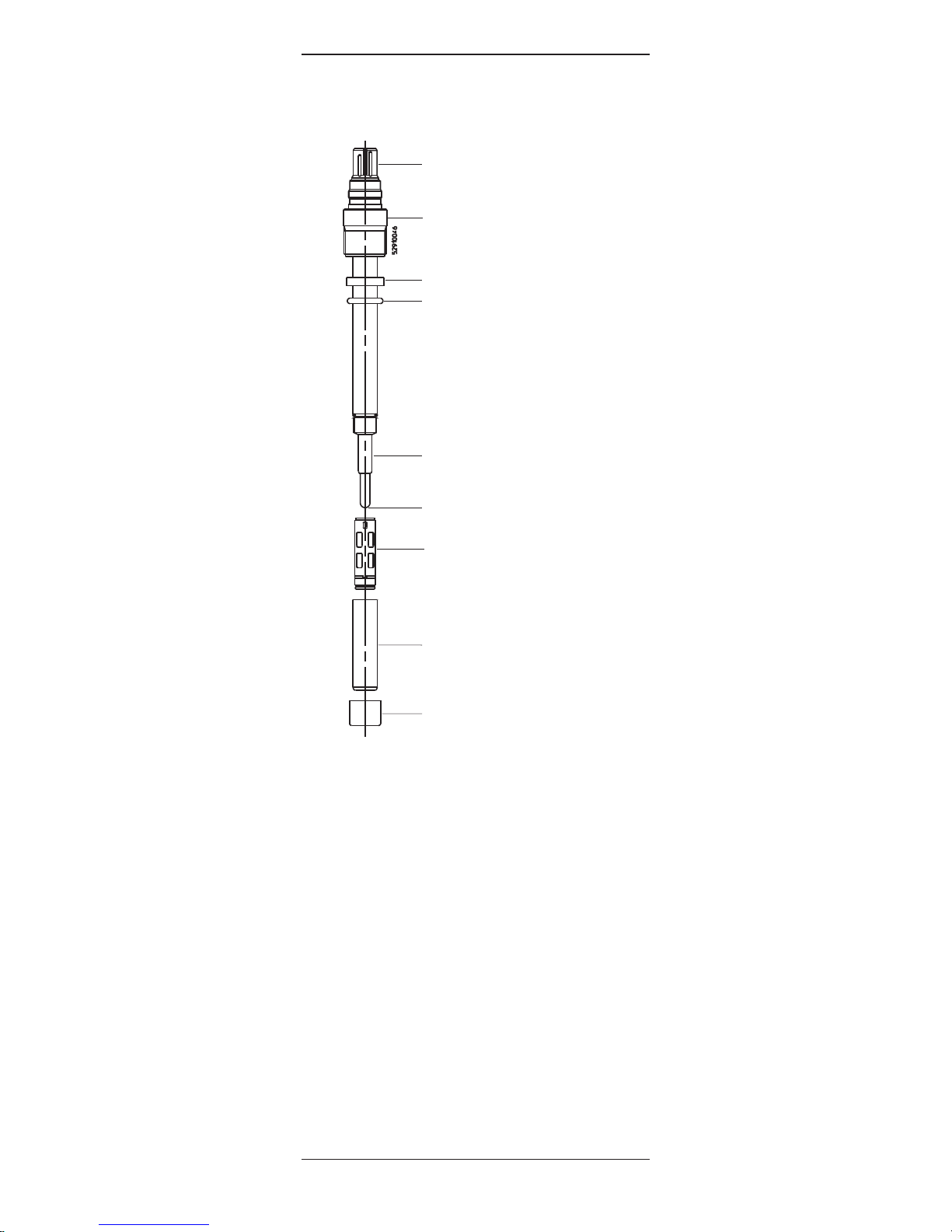

1.3. Equipment features and scope of delivery

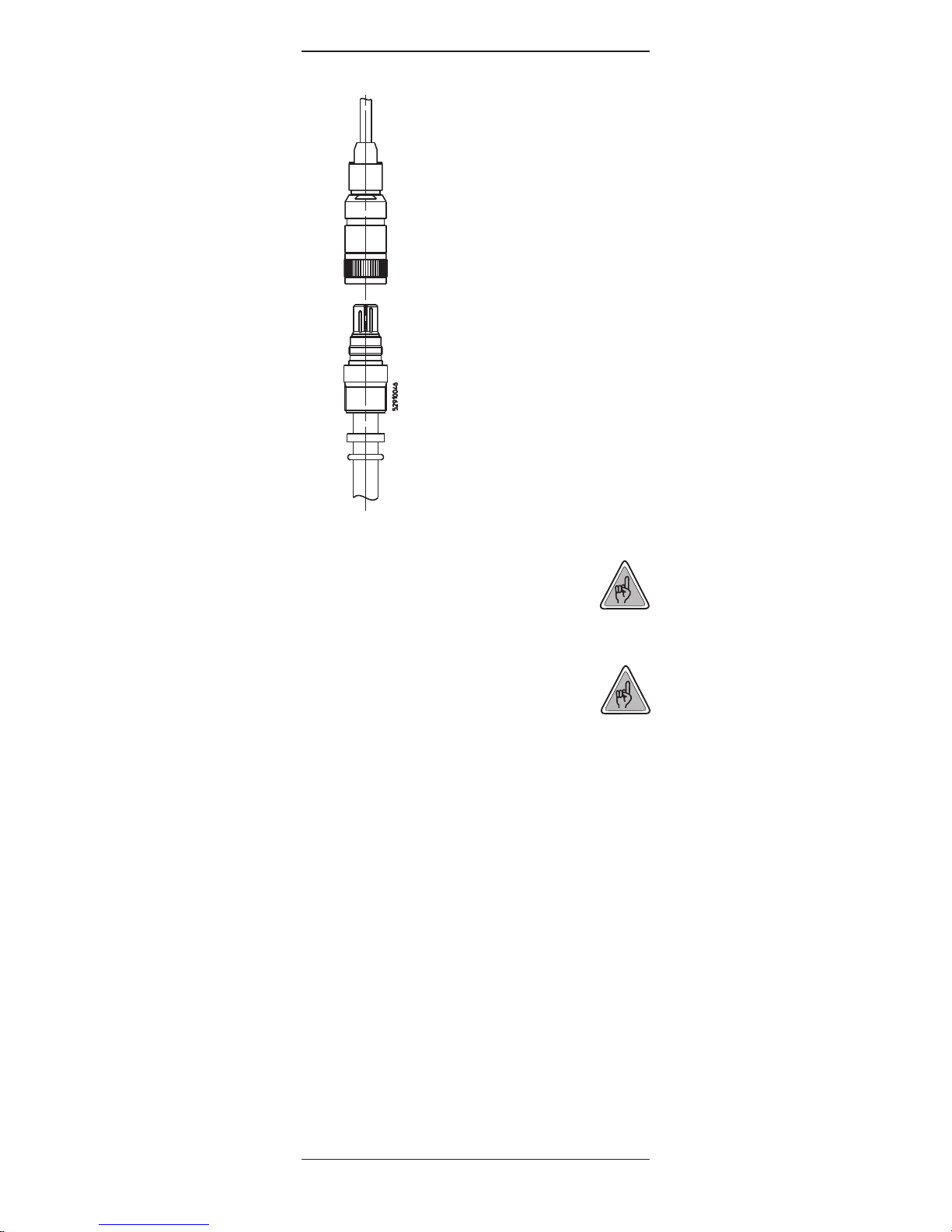

1

2

3

4

7

8

6

5

9

1 VP Connector

2 Pg 13.5 threaded sleeve

3 Washer

4 O-ring

5 Anode

6 Cathode

7 Membrane body

8 Cap sleeve

9 Protection cap

The oxygen sensor is shipped with a T-96 type membrane body in place. This membrane type has an additional PTFE layer on the process side for increased

durability. It also has a built-in temperature device

(NTC) that allows compensation for membrane permeability.

InPro 6050 Series O2Sensor

© 02 / 16 Mettler-Toledo GmbH, InPro 6050

Printed in Switzerland 52 200 251

7

2

. Safety

2

.1. Signs and symbols

The following symbols are used in this instruction

m

anual:

D

anger: warning of a danger which could

be fatal or lead to severe bodily harm

Caution: warning of a possibly dangerous

situation which could lead to minor injuries and/or material damage

Notice: reference to working methods

which facilitate use of equipment

2.2. Safety precautions

Please read this instruction manual entirely before

using the sensor.

The InPro 6050 is built under the strict quality guidelines for ISO 9001.

3. Your equipment

3.1. Design/description

The sensor is made of:

• A VP (VarioPin) connector

• A plastic shaft which contains an anode (silver)

and a cathode

• A membrane body filled with electrolyte

• A plastic cap sleeve

InPro 6050 Series O2Sensor

InPro 6050 © 02 / 16 Mettler-Toledo GmbH

52 200 251 Printed in Switzerland

8

3.2 Functions

This sensor technology is based on a polarographic

O2measurement (Clark type), which can be summarized as follow:

• It consists of a working electrode (cathode), a

counter electrode (anode) and an oxygen permeab

le membrane which separates the electrodes

from the medium.

• The transmitter supplies a constant voltage to the

cathode (polarization voltage). We recommend a

–675mV polarization voltage for aqueous applications.

• The oxygen molecules migrate from the medium

to the electrodes through the membrane and are

reduced at the cathode. At the same time an oxidation takes place at the anode. The electrolyte

completes the electric circuit between the anode

and the cathode.

3.3. Integration in measuring system

A complete measuring loop consists of a sensor,

a cable and a transmitter

4. Start-up

4.1. Installation

Before installation, we recommend you to:

• change the electrolyte as described in § 6.3 (you

do not need to change the membrane body)

• visually check the membrane for cracks or indents

(in case of damaged membrane, the membrane

body must be changed)

The sensor can be installed in pipes by using a flowthrough housing (InFlow 751) or a stationary housing (InFit 761). The sensor can also be immersed

directly in a tank by using an immersion housing (InDip 550/524).

Please refer to the instruction manuals of these housings for installation instructions.

Important: to guarantee a tight seal, a

washer must be used together with an

O-ring.

The sensor should be installed in a place where there

is enough fluid circulation (at least 1liter per hour

should pass by the head of the sensor). Placing the

sensor in a dead spot would lead to false results.

If the sensor is installed in a pipe, it is preferable to

install it at an angle against the flow to achieve the

best possible measurement.

4.2. Connection

To connect the sensor to the transmitter, a VP cable

should be used. This ensures a secure link between

the transmitter and the sensor under harsh industrial

conditions. The robust watertight IP 68 connector

housing guarantees maximum process safety. The

slit of the connector should be aligned with the pin of

the plug, and the two parts should be then screwed

tightly together.

InPro 6050 Series O2Sensor

© 02 / 16 Mettler-Toledo GmbH, InPro 6050

Printed in Switzerland 52 200 251

9

For instructions concerning the connection

of the VP cable to the transmitter, please

refer to the transmitter instruction manual.

4.3. Initial start-up

Notice: The protective cap at the tip of the

sensor should be removed before putting

the sensor into operation.

When the sensor is installed for the first time or has

been disconnected from the voltage source (polarization voltage from the transmitter or polarization module) for longer than 5 minutes, the sensor must be

polarized before calibration or the first measurements. This can be achieved by connecting the sensor to the transmitter or a polarization module for at

least six hours. The recommended polarization voltage is –675mV.

VP cable

Plug

Pin

Slit

Connector

InPro 6050

InPro 6050 Series O2Sensor

InPro 6050 © 02 / 16 Mettler-Toledo GmbH

52 200 251 Printed in Switzerland

1

0

5

. Operation

5

.1. Operation of the equipment

Once the sensor is properly calibrated (see § 6.4)

a

nd installed, you should refer to the instruction manual of the transmitter to learn how to operate the

complete system.

5.2. Measurement in power and failure

In case of power failure for more than

10-15 minutes the sensor must be repolarized over

a period of 6 hours (see Chapter 4.3).

In case of drop out for 5 to 15 minutes, the sensor

must be polarized for 45 minutes.

In case of a power drop-out less than 5 minutes, a

polarization time of 10 minutes is sufficient.

5.3. Errors and corrective actions

Make sure the sensor is mounted properly in a vertical position (VP connector up), or at a 15° angle

(against the flow) to prevent the accumulation of air

bubbles on the sensor head.

5.4. Storage

The sensor and the membrane must be cleaned

before storing the sensor.

The sensor can be stored for several months, provided it is filled with O2electrolyte and the protective

cap is placed over the membrane. To avoid the

6-hour polarization requirement after storage, the

sensor can be stored connected to a polarization

module.

InPro 6050 Series O2Sensor

© 02 / 16 Mettler-Toledo GmbH, InPro 6050

Printed in Switzerland 52 200 251

11

6

. Maintenance

When used in water applications, the sensor is desig

ned to require minimal service. However in some

cases it can be necessary to recalibrate the sensor or

to change the electrolyte or the membrane body.

6.1. Safety precautions

Danger: the electrolyte has an alkaline

pH-value of 13. Contact of the electrolyte

with the skin, especially mucous memb

rane or eyes, should be avoided. If such

contact occurs, the affected area should

be well rinsed with running water. Get medical attention if adverse signs appear.

As contact with the electrolyte is very likely during the

exchange of electrolyte or membrane body, the use

of protective gloves is recommended.

6.2. Cleaning and care

The sensor can be gently cleaned with soapy water

(or with a mild bleach) and rinsed thoroughly.

Inspect the membrane. If it has cracks or shows longer response time, then it should be replaced as follow:

6.3. Replacing the membrane and the electrolyte

Please follow the following instructions to change the

membrane body and the electrolyte:

a) Unscrew the cap sleeve from the shaft and

carefully pull it off the sensor.

b) Pull off the membrane body from the interior

body. If it remains inside the cap sleeve, eject by

pushing it with the flat finger tip. Before electrolyte

is refilled, the membrane body must be removed

from the cap sleeve.

c) Clean the interior body with a soft tissue.

d) Check the O-rings for mechanical defects and

replace if necessary.

e) Half fill the membrane body with O2electrolyte

and make sure it is bubble-free. Air bubbles can

be removed by carefully tipping on the membrane

body.

f) Slowly slip the membrane body over the interior

body while holding the sensor in a vertical position.

The excess electrolyte will be displaced and

should be wiped off with a paper tissue.

g) Carefully slip the cap sleeve over the fitted

membrane body and screw it down. The cap

sleeve must be clean and dry.

h) After each replacement of the electrolyte or of the

membrane, the sensor must be polarized over a

period of 6 hours.

i) When the sensor is polarized and connected to

the transmitter, it is necessary to start by recalibrating the system.

InPro 6050 Series O2Sensor

6.4. Calibrating the sensor

• For an air calibration, the sensor must be removed

from the medium, gently cleaned and dried.

W

ater droplets on the membrane must be removed, as they prevent the sensor from being correctly calibrated.

• To calibrate in water or sample medium, you must

know the exact oxygen concentration and ensure

that equilibrium between the air and the medium is

r

eached (this may take quite a long time).

Make sure that all other parameters (temperature

and pressure) are constant during the calibration.

Please note also that a minimum flow rate is necessary.

• For detailed calibration instructions, please refer to

the transmitter instruction manual.

• In case of an error message from the transmitter

after a calibration, clean the sensor, change the electrolyte and replace the membrane if this is damaged.

6.5. Troubleshooting and rectification work

On a regular basis, you can take the sensor out of

the water, clean and dry it. If it gives a reading of

100% saturation, the sensor does not need to be recalibrated.

If the sensor gives too high or too low values, it

should be recalibrated.

After a long storage time (more than 6 months) or after a certain period of time in operation (typically one

year for water applications), the electrolyte should be

replaced. Replace damaged membranes as necessary.

If after a calibration the sensor still gives too high or

too low values, you should change the electrolyte

and the membrane.

InPro 6050 © 02 / 16 Mettler-Toledo GmbH

52 200 251 Printed in Switzerland

1

2

Loading...

Loading...