Mettler Toledo InPro 5000 Instruction Manual

InPro®5000 CO2Sensors

Instruction manual

Bedienungsanleitung

Instructions d’utilisation

InPro5000

52 002 465

English Page 3

Deutsch Seite 21

Français Page 59

2

InPro5000 CO

2

S

ensor 12 mm

InPro5000 © 09/06 Mettler-Toledo AG

52 002 465 Printed in Switzerland

InPro®5000 CO2Sensors

Instruction manual

I

nPro5000 CO

2

S

ensor 12 mm 3

© 09/06 Mettler-Toledo AG InPro5000

Printed in Switzerland 52 002 465

Table of Contents

Page

1

Introduction .......................................................5

2

Important notes .................................................6

2.1 Notes on operating instructions .............................6

2.2 Intended use .......................................................6

2.3 Safety instructions ...............................................7

3 Product description ............................................8

3.1 General information .............................................8

3.2 Principles of CO2measurement.............................8

3.3 Scope of delivery .................................................8

3.4 Equipment features ..............................................9

4 Preparation......................................................10

4.1 Start-up ............................................................10

4.2 Calibration of the pH electrode ............................11

4.2.1 Connecting the InPro5000 sensor to a VP cable ...11

4.2.2 Connecting the VP cable to transmitter 5100e ......12

4.2.3 Calibration of pH electrode/transmitter 5100e.......12

4.3 Mounting the membrane body ............................13

4.4 Mounting the sensor ..........................................14

4.5 Sterilization.......................................................14

5 Operation.........................................................15

5.1 Calibration of the CO2sensor ..............................15

6 Maintenance....................................................16

6.1 Inspection ........................................................16

6.1.1 Visual inspection ...............................................16

6.1.2 Checking wiring and transmitter with the

pH simulator.....................................................16

6.2 Changing the CO2electrolyte and

membrane body................................................17

6.3 Maintenance of the pH electrode..........................17

6.4 pH electrode replacement ...................................17

7

Storage

............................................................17

8 Product specification ........................................18

8.1 Certificates........................................................18

8.2

Specifi

cations

....................................................

18

9 Ordering information ........................................19

9.1 Sensors............................................................19

9.2 Accessories ......................................................19

9.3

Spare parts

.......................................................19

9.4 Transmitter .......................................................19

4

InPro5000 CO

2

S

ensor 12 mm

InPro5000 © 09/06 Mettler-Toledo AG

52 002 465 Printed in Switzerland

I

nPro5000 CO

2

S

ensor 12 mm 5

© 09/06 Mettler-Toledo AG InPro5000

Printed in Switzerland 52 002 465

1 Introduction

Thank you for buying the InPro5000 sensor from

METTLER TOLEDO.

The construction of the InPro 5000 sensor employs

leading edge technology and complies with safety

regulations currently in force. Notwithstanding this,

improper use could lead to hazards for the user or

a third-party, and /or adverse effects on the plant

or other equipment.

Therefore, the operating instructions must be read

and understood by the persons involved before work

is started with the sensor.

The instruction manual must always be stored close at

hand, in a place accessible to all people working with

the InPro 5000.

If you have questions, which are not or insufficiently

answered in this instruction manual, please contact

your METTLER TOLEDO supplier. They will be glad to

assist you.

6

InPro5000 CO

2

S

ensor 12 mm

InPro5000 © 09/06 Mettler-Toledo AG

52 002 465 Printed in Switzerland

2 Important notes

2.1 Notes on operating instructions

These operating instructions contain all the

information needed for safe and proper use of

the InPro5000 sensor.

The operating instructions are intended for personnel

e

ntrusted with the operation and maintenance of the

sensors. It is assumed that these persons are familiar

w

ith the equipment in which the sensor is installed.

Warning notices and symbols

This instruction manual identifies safety instructions

and additional information by means of the following

symbols:

This symbol draws attention to

safety instructions

and warnings of potential danger which, if neglected,

could result in injury to persons and/ or damage

to property.

This symbol identifies

additional information and

instructions which, if neglected, could lead to defects,

inefficient operation and possible loss of production.

2.2 Intended use

InPro5000 sensors are intended solely for in line

measurement of dissolved CO2(carbon dioxide), as

described in this instruction manual.

Any other use, or use not mentioned here, that is incompatible with the technical specifications is deemed

inappropriate. The operator is solely responsible for

any damage arising from such use.

Other prerequisites for appropriate use include:

– observing the instructions, notes and requirements

set out in this instruction manual.

– observing all local safety regulations concerning

safety on work.

– observing all information and warnings in the

documentation dealing with the products used

together with the sensor (housings, transmitters,

etc.).

–

observing all safety regulations governing

the equipment in which the sensor is installed.

– observing the prescribed inspection and mainte-

nance intervals.

– correct care and maintenance of the unit,

according to the instruction manual.

– observing the prescribed environmental and

operational conditions, and permitted installation

positions.

I

nPro5000 CO

2

S

ensor 12 mm 7

© 09/06 Mettler-Toledo AG InPro5000

Printed in Switzerland 52 002 465

2.3 Safety instructions

– The InPro5000 sensors should be installed,

o

perated, maintained only by personnel familiar

with the sensor and who are qualified for such

work.

–

A defective sensor must neither be installed nor put

into service.

– Only the maintenance work described in these

operating instructions may be performed on the

sensors.

– When changing faulty components, use only

original spare parts obtainable from your METTLER

TOLEDO supplier (see section 9).

– No modifications to the sensors and the

accessories are allowed. The manufacturer/

supplier accepts no responsibility for damage

caused by unauthorised modifications. The risk is

borne entirely by the user.

8

InPro5000 CO

2

S

ensor 12 mm

InPro5000 © 09/06 Mettler-Toledo AG

52 002 465 Printed in Switzerland

3 Product description

3.1 General information

The sensor InPro5000 with integrated temperature

probe is used for dissolved carbon dioxide measurem

ent.

T

he sensor has been designed for accurate and precise

measurement at low to medium carbon dioxide partial

pressure.

The sensor is

sterilizable and compatible with CIP

(

cleaning in place).

The sensor consists of an exchangeable pH electrode

which is built in a steel shaft and fixed with a small

hexagonal screw.

3.2 Principles of CO2measurement

Here is a short summary of the principle of the

potentiometric measurement of CO2which this

sensor is based (Severinghaus). The InPro5000 sensor employs a gas permeable silicone membrane

which is tightly stretched around a special engineered

flat pH membrane. The CO

2

gas from the sample or

process diffuses across the membrane until its partial

pressure equilibrates within the electrolyte film in front

of the pH sensitive glass and the bulk of the internal

electrolyte.

The dissolved CO2gas reacts with water to form

bicarbonate and H+ions:

The formed H+ions lead to a pH change of the inner

electrolyte which is measured with the integrated pH

electrode. Thus, the CO

2

partial pressure can be

calculated using the pH and the temperature, which is

detected as well.

3.3 Scope of delivery

Each sensor is supplied together with:

– 1 bottle CO2-electrolyte 25 ml

– 1 quality control certificate

– 1 inspection certificate 3.1

(in accordance with EN 10204.3/3.1)

Membrane body and cap sleeve are not mounted.

The interior body is protected against drying out with

a wetting cap, filled with CO

2

-electrolyte.

Please check completeness.

CO2+H2O HCO

3

–

+ H

+

I

nPro5000 CO

2

S

ensor 12 mm 9

© 09/06 Mettler-Toledo AG InPro5000

Printed in Switzerland 52 002 465

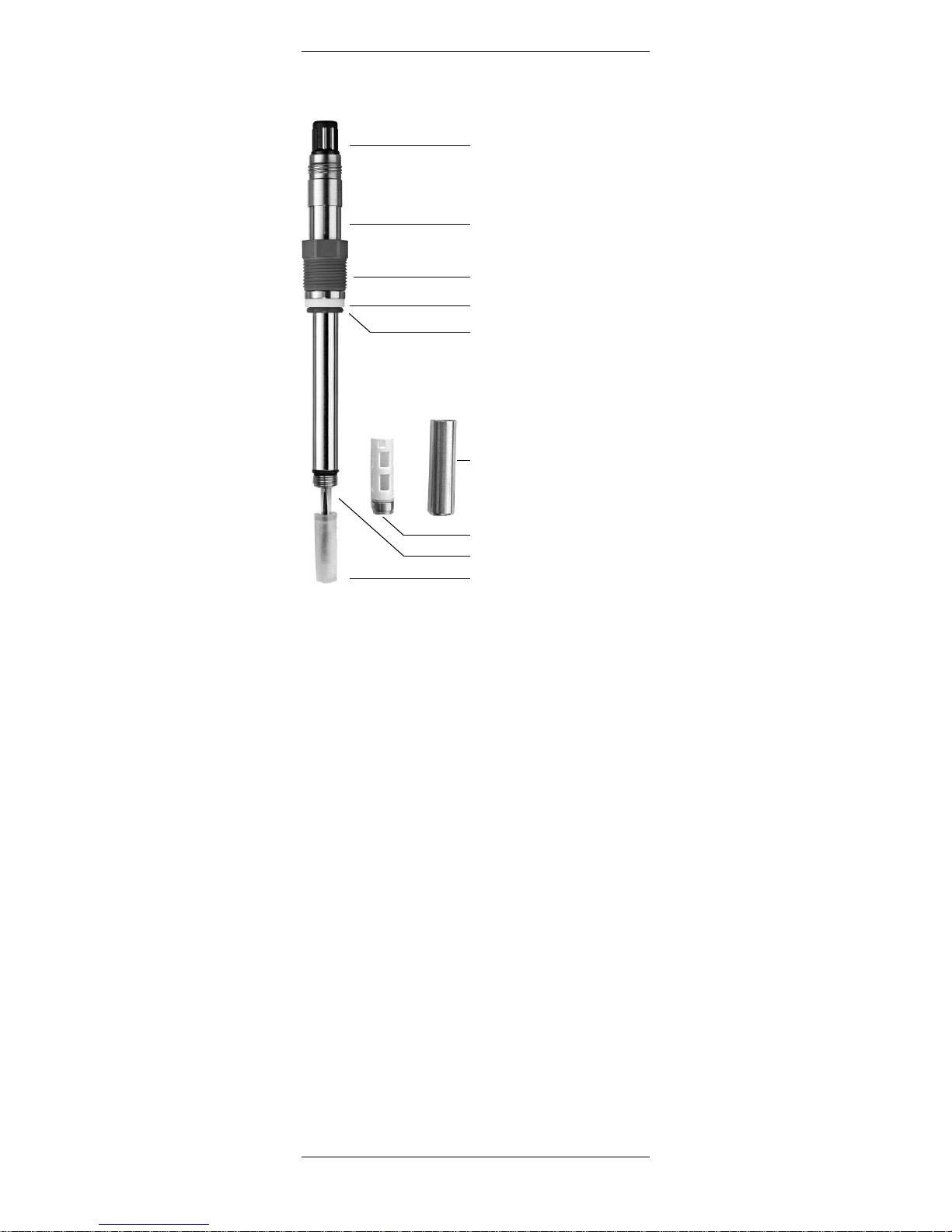

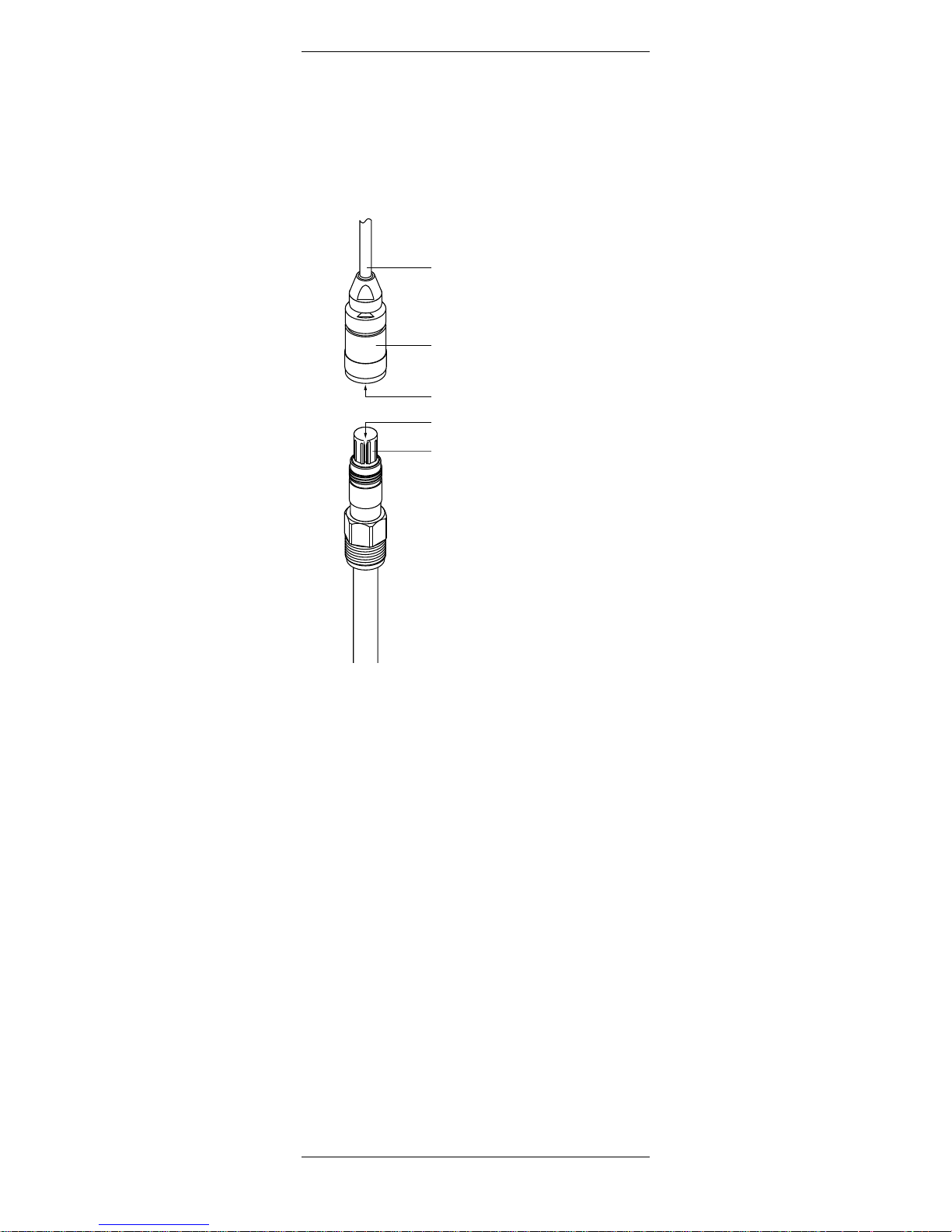

3.4 Equipment features

VP connector

O-ring (10.77 x 2.62 mm,

silicone FDA)

Pg 13.5 threaded sleeve

Washer PTFE

Cap sleeve

Membrane body

Wetting cap

Interior body (pH electrode)

H

exagonal screw

1

0 InPro5000 CO

2

S

ensor 12 mm

InPro5000 © 09/06 Mettler-Toledo AG

52 002 465 Printed in Switzerland

4 Preparation

4.1 Start-up

The interior body (pH electrode) is ready for calibration.

– On unpacking, check the pH electrode for

mechanical damage. Report any damage imme-

diately to your METTLER TOLEDO supplier.

– Remove the watering cap, cap sleeve, membrane

body and briefly rinse the sensor with de-ionized

water.

– After rinsing, the sensor should only be dapped dry

with a tissue. Do not rub the pH sensitive glass,

since this can lead to electrostatic charging and

sluggish response times.

– Check inside the pH sensitive glass for the presence

of any air bubbles and remove same by gently

swinging in a vertical plane (shaking down as with

a thermometer).

Before using the sensor for the first time, make sure that

the interior body (pH electrode) is well fixed into the

steel body. The VP connector must not be rotated in the

shaft. If so, the inner part has to be fixed by tightening

the small

hexagonal screw below the connector.

Ceramic

diaphragm

pH sensitive

glass

Air

bubbles

A: pH electrode

with air bubbles:

will not work.

B: Correct pH electrode

with removed bubbles.

AB

I

nPro5000 CO

2

S

ensor 12 mm 11

© 09/06 Mettler-Toledo AG InPro5000

Printed in Switzerland 52 002 465

4.2 Calibration

Purpose of calibration: Each CO2sensor and Interior

b

ody (pH electrode) has its individual slope and zero

point.

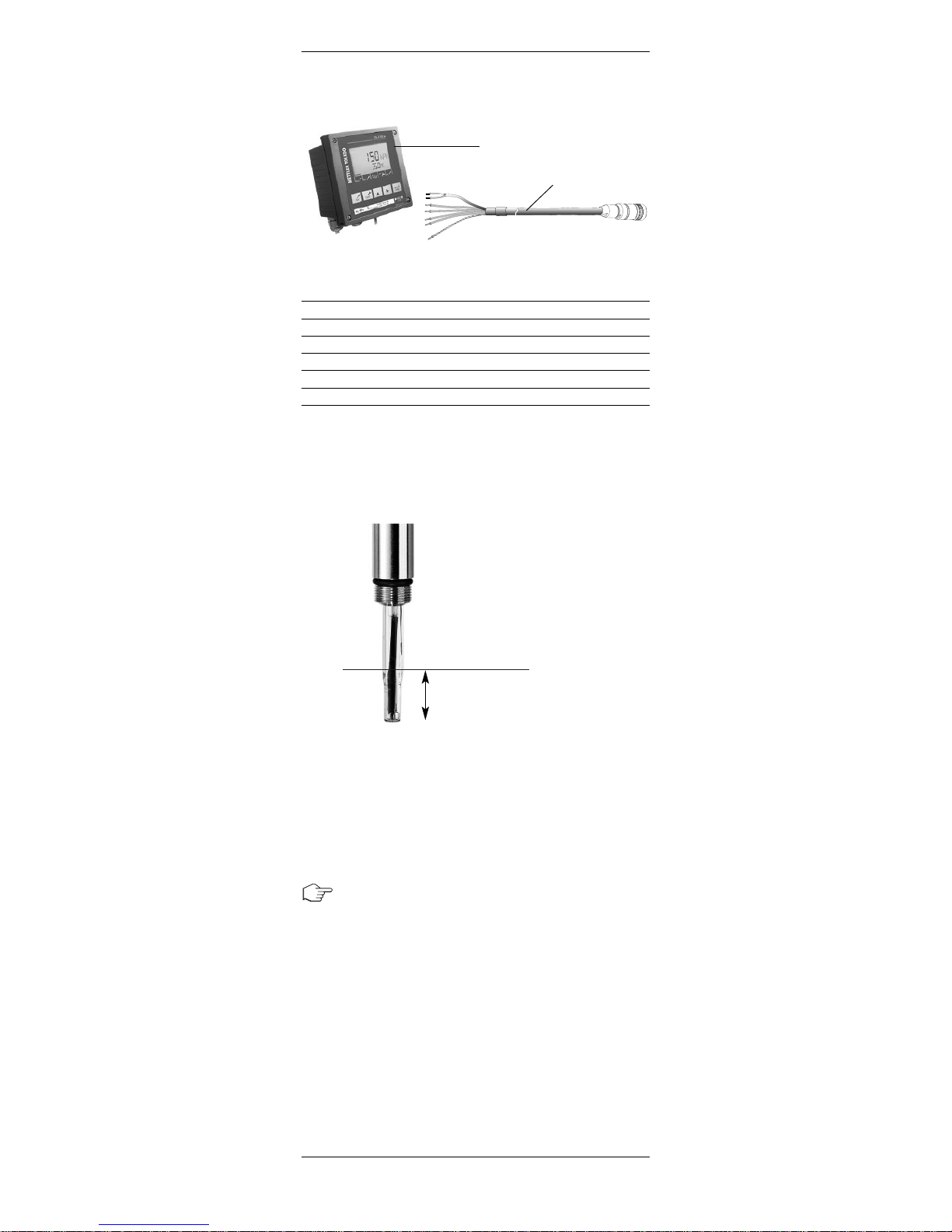

4.2.1 Connecting the InPro5000 to a VP cable

The sensor is connected to the transmitter 5100e via

a VP cable ensuring a secure connection under harsh

industrial conditions. The robust watertight IP68 connector housing guarantees maximum process safety.

To connect the VP cable to the sensor align the notch

of the VP connector with the key in the plug. Then tightly screw the plug to fasten the two parts.

VP cable

Plug

Pin

Notch

VP connector

1

2 InPro5000 CO

2

S

ensor 12 mm

InPro5000 © 09/06 Mettler-Toledo AG

52 002 465 Printed in Switzerland

4.2.2 Connecting the VP cable to the transmitter

Standard connection for CO2transmitter 5100e

Function VP cable wire Terminal connection

pH glass transparent 1

Reference red 2

Temperature 1 white E

Temperature 2 green D

Shielding green/yellow C

For further details check instruction manual of

the transmitter.

4.2.3 Calibation of pH electrode/transmitter 5100 e

Prepare electrode as described in section 4.1 “Startup”. We recommend a 2-point calibration in pH buffer

pH 7.00 and pH 9.21. Before calibration, first remove

wetting cap. Normally you start with buffer pH 7.00 for

determining zero point and then buffer pH 9.21

for determining the slope. Please refer to instruction

manual of the transmitter for further details.

Important settings: Temperature sensor select Pt1000.

VP Cable

CO

2

Transmitter

Min. immersion depth

,25 mm / 1"

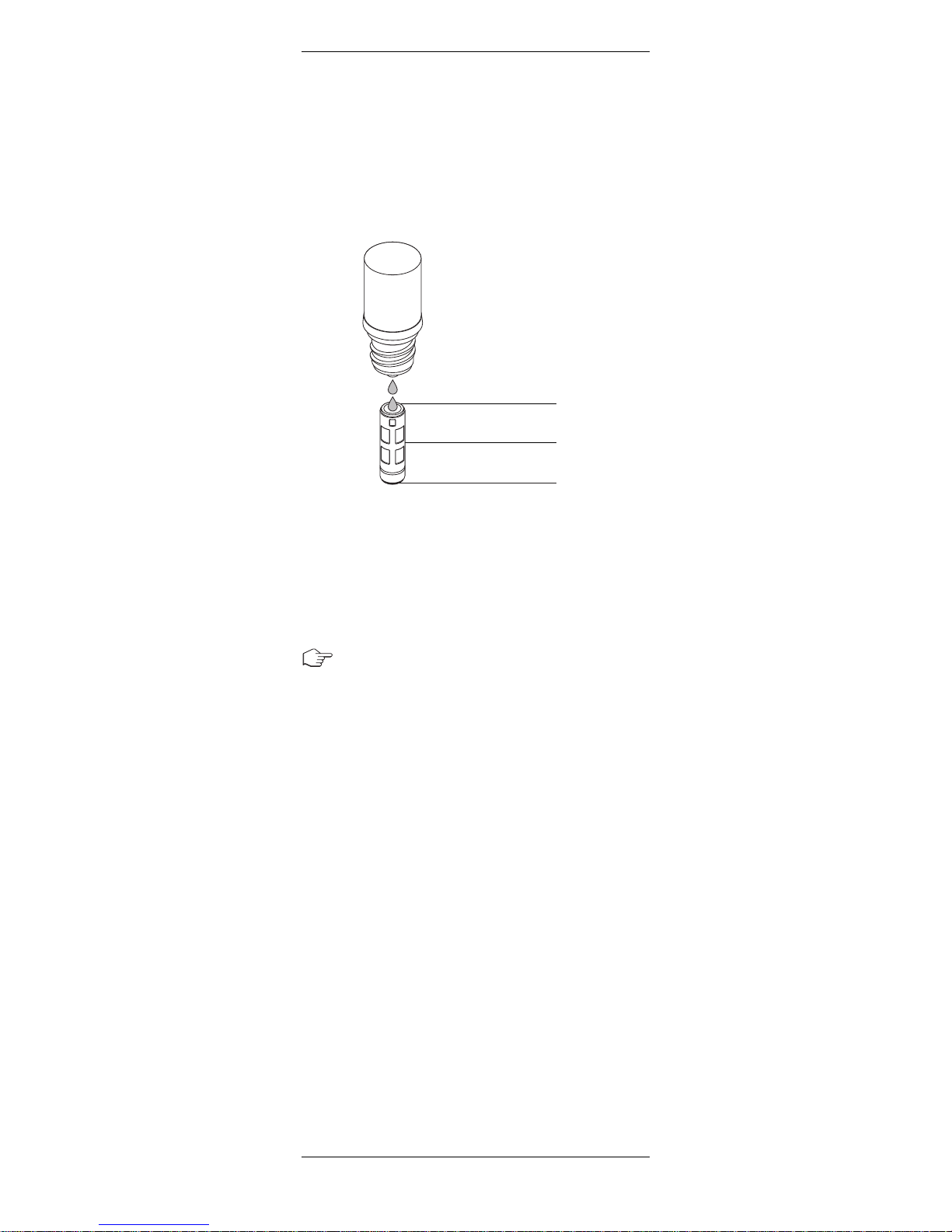

4.3 Mounting the membrane body

– After calibration of the pH electrode rinse the pH

electrode with de-ionized water and carefully dab

it with a paper tissue.

– Fill the new membrane body half way with CO

2

electrolyte.

Make sure that all air bubbles are removed from the

membrane body. Air bubbles can be removed by

carefully tapping on the membrane body.

– Slip the membrane body over the pH electrode

while holding the sensor in a vertical position.

The excess electrolyte will be displaced should

be wiped dry with a paper tissue.

Important: No electrolyte, sample media or

contamination may be present between the

membrane body and the cap sleeve. Please check

carefully.

– Carefully slip the cap sleeve over the fitted

membrane body, holding the sensor in a vertical

position and screw it tight. The cap sleeve must be

clean and tight.

I

nPro5000 CO

2

S

ensor 12 mm 13

© 09/06 Mettler-Toledo AG InPro5000

Printed in Switzerland 52 002 465

1

/

2

1

/

2

CO

2

electrolyte

1

4 InPro5000 CO

2

S

ensor 12 mm

InPro5000 © 09/06 Mettler-Toledo AG

52 002 465 Printed in Switzerland

4.4 Mounting the sensor

P

lease read carefully the instruction manual of the

particular housing (InFit761-... or InTrac797) for

correct sensor installation.

T

he InPro5000 sensor can be mounted directly on a

top plate of a small bioreactor or in a pipe with an

i

nside Pg 13.5 thread and securely tightened via the

Pg 13.5 threaded sleeve.

Remark: Mounting upside-down or horizontaly is not

possible due to internal pH electrode. An angle of 15°

or bigger to horizontal is needed.

4.5 Sterilization

The installed sensor will be sterilized together with the

bioreactor. The InPro5000 is in-situ sterilizable or in an

autoclave. After cooling down but before inoculation a

process calibration step, as described in chapter 5, is

needed to achieve accurate measurements.

Remark: For best accuracy please wait one hour after

cooling down before process calibration step according

chapter 5.1.

I

nPro5000 CO

2

S

ensor 12 mm 15

© 09/06 Mettler-Toledo AG InPro5000

Printed in Switzerland 52 002 465

5 Operation

5.1 Calibration of the CO2sensor

The InPro5000 sensor can be calibrated with CO

2

gas or a CO2/N2gas mixture. Example: If a CO

2

p

artial pressure of 150 mbar is expected, you can use

a

gas with 15% CO

2

/

85% N

2

i

n nitrogen to achieve

best results. The calibration can be made in a gas or

liquid phase. For calibration in a solution you have to

wait until an equilibrium is reached. Depending on the

p

H value of the solution a large amount of CO

2

w

ill

react to build bicarbonate ions before building-up a

constant partial pressure of CO2.

Recommendations:

• For small “benchtop” bioreactors the sensor can

be calibrated by flushing the empty or liquid

filled reactor with a CO

2

containing gas mixture.

• For larger bioreactors the gas consumption will be

too high,

therefore it is not recommended.

For larger bioreactors

the gas consumption would

be too high and therefore we recommend the

calibration with the aid of the retractable

housing InTrac797. Please operate the retractable

housing according the instruction manual

InTrac797 to ensure sterile operation. Additionally

the in- and outlet of the lower flushing chamber

must be equipped with sterile filters to avoid any

contamination with the calibration gas.

Calibration procedure:

• Sterilize CO2sensor InPro5000 in measuring

position (membrane inside bioreactor) together

with the bioreactor.

•

Sterilize lower and upper flushing chambers

of housing InTrac 797.

•

After cooling down retract sensor in maintenance

position (membrane in lower chamber).

• Flush lower chamber with sterile calibration gas.

The pressure inside the flushing chamber must be

known for proper calibration.

•

After calibration close in- and outlet of the

lower chamber and reinsert sensor in measuring

position. Sensor is now ready for measurement.

1

6 InPro5000 CO

2

S

ensor 12 mm

InPro5000 © 09/06 Mettler-Toledo AG

52 002 465 Printed in Switzerland

6 Maintenance

6.1 Inspection

6.1.1 Visual inspection

T

o check the sensor, we recommend the following pro-

c

edure:

•

The contacts of the VP connector must be dry.

Moisture, corrosion and dirt can lead to false readings.

• Check the cable for kinks, brittle areas or tears.

• Examine the membrane foil optically for signs of

damage. The foil must be intact and clean. Dirty

membranes should be wiped clean using a soft,

moist tissue.

Note: An undulated membrane has no influence on

the sensor performance, assuming the membrane

is intact.

•

The membrane body must be replaced if the sensor has a long response time, the reading is unstable or subject to excessive drift, and if the sensor cannot be calibrated with CO

2

gas or the

membrane shows sign of mechanical damage.

• Check the pH sensitive glass for cracks. The di-

aphragm should show a white color. If necessary

rinse with deionized water and clean carefully with

soft paper tissue.

Attention! Do not use any cleaning agents containing alcohol. This could damage the sensor or lead to

fault results.

Attention! The pH electrode is made of glass and

therefore fragile.

6.1.2 Checking wiring and transmitter

with the pH simulator

Necessary equipment:

pH simulator 112 (p/n 31 112 3003) and VP module

(p/n 52 120 939).

This equipment enables the testing of the VP cable

and correct wiring of the cable to the transmitter. Switch

the VP simulator to Pt1000 position. Additionally it is

possible to check the linearity, temperature compen

sation and quality of the input circuit (input resistance

and input current) of the CO2transmitter.

I

nPro5000 CO

2

S

ensor 12 mm 17

© 09/06 Mettler-Toledo AG InPro5000

Printed in Switzerland 52 002 465

6.2 Changing the CO2electrolyte

a

nd membrane body

W

e recommend to use a new membrane body after

each batch (see section 4.3). After each calibration of

the pH electrode (section 4.2) new CO2electrolyte

should be filled in the membrane body.

6.3 Maintenance of the interior body (pH electrode)

If the pH electrode shows a sluggish response

time and/ or insufficient sensitivity the pH sensitive

glass can be reactivated using a HF solution

(p/n 51 319 053). The pH sensitive glass part only

is immersed into this solution for 5

minutes, is then

immediately and thoroughly rinsed with deionized

water and then stored in 3 M KCl up to the diaphragm

for 12 hours. This procedure will make the electrode

faster but will limit the life time hardly.

6.4 Replacement of the interior body (pH electrode)

Typically after 10– 20 sterilization cycles the pH

electrode must be replaced. Please refer to the

instruction manual of the replacement interior body

InPro5000.

7 Storage

For storage we recommend to fill the membrane

body with fresh CO

2

electrolyte and rebuilt the

sensor together. The wetting cap, filled with water, will

prevent a drying-out of the membrane.

Loading...

Loading...