Mettler Toledo InFit 76 e, InFit 764 e, InFit 761 e Instruction Manual

InFit 761 e/InFit 764 e

Instruction Manual

1258

InFit 761 / InFit 764

52 403 547

2 InFit 76X e Series

© It is forbidden to reprint this Instruction Manual in

whole or part. No part of this manual may be repro duced

in any form, or modified, copied or distributed using

electronic systems, in particular in the form of photo copies, photog raphs, magnetic or other recordings,

without written consent of Mettler-Toledo GmbH, Process

Analytics, CH-8902 Urdorf, Switzerland.

All rights reserved, in particular reproduction, trans lation and patenting/registration.

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 3

InFit 761 e/InFit 764 e

Instruction Manual

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

4 InFit 76X e Series

How to use this Instruction Manual

This Instruction Manual is an integral part of

the METTLER TOLEDO insertion housing

InFit®76X e Series and contains notes and

instructions that are important for safety and

operation.

All persons working on or with the InFit 76X e

must have first read and understood the

sections appropriate to the work in hand.

Please read this Instruction Manual carefully

before using the housing. Keep this document

close to the unit, so that operating personnel

may easily be able to refer to it at any time.

Caution! Please first read Section 1

”Intro duction” and Section 2 ”Safety

instruc tions”.

Proprietary designations

The following are proprietary names and, for

the sake of simplicity, will be mentioned in this

Instruction Manual without the registration

marking, e.g.

– InFit is a registered trade mark of Mettler-

Toledo GmbH, CH-8606 Greifensee,

Switzerland.

– PTFE, Viton and Kalrez are regis tered trade-

marks of DuPont.

Use of warnings and symbols

Danger! Warning of a dangerous situation that

can lead to death or severe injury, or cause

extensive material damage.

Caution! Warning of a possibly dangerous

situation that can lead to light bodily harm

and/or material damage.

Attention: Information referring to technical

requirements. Non-adherence can lead to

malfunction, uneconomic working and

possibly also to loss of productivity.

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 5

Explanation of housing designations

The generic term InFit 76Xe Series used in this

Instruction Manual refers to:

– InFit 761e – Insertion housing for pH/

Redox electrodes with gel-type or polymer

electrolyte, O

ductivity sensors (with 12 mm diameter

, CO2, turbidity and con -

2

and Pg 13.5 thread).

– InFit 764 e – Insertion housing for pressur-

ized pH/Redox electrodes with liquid

electrolyte (such as InPro 2000).

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

6 InFit 76X e Series

Contents

Introduction ....................................................8

1

.1 Ex declaration ..................................................9

1

.1.1 Use in Ex classified areas (hazardous areas) ......9

1

1.1.2 Ex classification

II 1/2G c IIC TX Ga/Gb,

I 1/2D c IIIC TX Da/Db, designation and num-

I

ber of certificate SEV 13 ATEX 161 X ..................9

1.2 FM certification ..............................................11

1.2.1 Ex classification ”FM Approved” (drawing) ........12

2 Safety ..........................................................13

2.1 Introduction ....................................................13

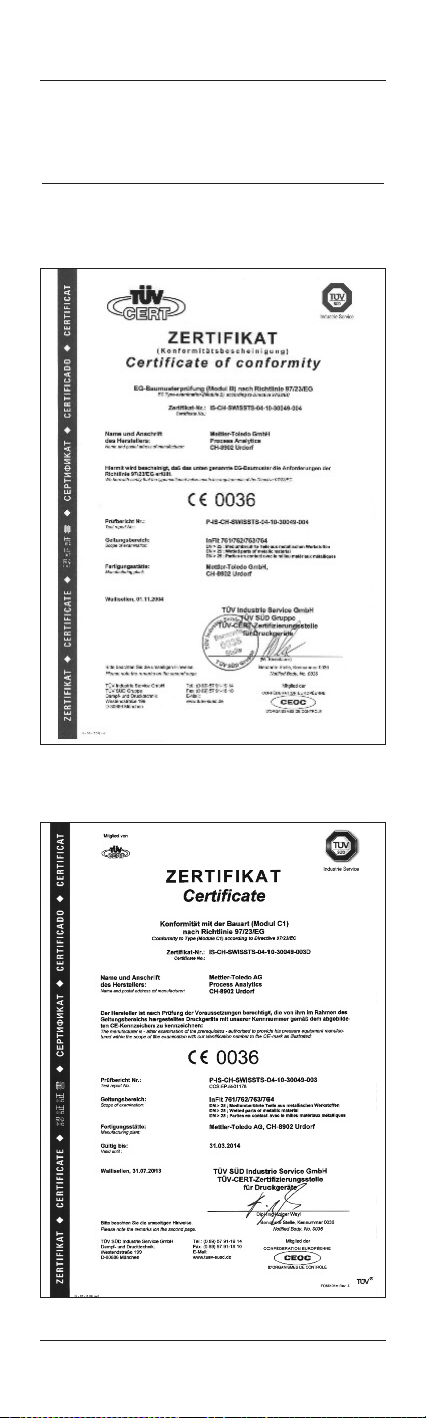

2.2 Declaration of conformity/ type examinations ....14

.3 Type examination in accordance

2

2.3.1 Type examination (Module B) in accordance

2.3.2 Type conformity (Module C1) in accordance

2.4 EC type examination certification in accordance

2

2.6 Housing designations......................................26

2.7 Intended use ..................................................27

2.8 Inappropriate use ............................................27

2.9 Basic principles ..............................................28

2.10 Warning notices and symbols ..........................28

2.11 Responsibilities, organizational measures..........29

2.11.1 Responsibilities of the operator ........................29

2.11.2 Responsibilities of the personnel ......................29

2.11.3 Selection and qualification of personnel –

2.12 Product-specific hazards..................................30

2.12.1 Removal of electrode/sensor ............................30

2.12.2 Manipulation and maintenance work

2.12.3 Plastic housings ............................................31

2.12.4 Installation in pressurized systems ....................32

2.12.5 Installation in potentially explosive areas

2.13 Residual hazards ............................................33

2.13.1 Leaky connections ..........................................33

2.13.2 Medium residues ............................................33

2.13.3 Heat protection ..............................................33

2.13.4 External impacts ............................................34

2.14 Emergency measures ......................................34

2.15 Safety measures ............................................34

2.16 Modifications ................................................35

3 Product description ......................................36

3.1 Scope of delivery ............................................36

3.2 Packing ........................................................36

3.3 Checking the shipment ....................................36

3.4 Product overview ............................................37

Product key ..................................................................46

3.5 Functional description of the housing ..............48

ith directive 97/23/EC ..................................16

w

with directive 97/23/EC ..................................16

ith directive 97/23/EC ..................................16

w

with directive 94/9/EC ....................................17

.5 FM certificate ..................................................18

basic duties....................................................30

on the housings..............................................31

(hazardous areas) ..........................................32

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 7

4 Installation and start-up ................................49

4.1 Preparation of the equipment............................49

.2 Fitting and installation work..............................51

4

4.2.1 Fitting the housing ..........................................51

4.2.1.1 Fitting with a weld-in socket ............................51

4.2.1.2 Fitting with a flange ........................................52

.2.1.3 Fitting via NPT external thread ..........................52

4

.2.1.4 Fitting with Tri-Clamp and Varivent flange

4

connection ....................................................52

4.2.1.5 Installation with NPSM thread ..........................53

.2.2 Fitting the electrode/sensor ..............................53

4

.2.2.1 InFit 761 e ....................................................53

4

4.2.2.2 InFit 764 e ....................................................55

4.3 Startup procedures for housings........................57

.4 Dismantling work ..........................................58

4

4.4.1 Removing the insertion housing........................58

4.4.2 Removing the electrode/sensor ........................58

.5 Sterilization ..................................................61

4

5 Operation ......................................................62

.1 Important information for everyday operation......62

5

5.2 Inspection work in everyday operation ..............62

5.3 Cleaning the electrode/ sensor ........................63

5.4 Calibrating the measuring system ....................63

6 Maintenance..................................................64

6.1 Important information on maintenance ..............64

6.2 Topping up reference electrolyte ........................65

6.3 Replacement of medium- wetted seals ..............65

7 Trouble shooting ............................................68

8 Product specifications ....................................70

8.1 Technical data ................................................70

8.1.1 Technical specifications InFit 761 e ..................70

8.1.2 Technical specifications InFit 764 e ..................72

8.2 Spare parts and accessories ............................74

9 Terms of warranty ..........................................78

10 Decommissioning, storage, disposal ..............79

10.1 Decommissioning ..........................................79

10.1.1 Proceed as described in

Section 4.4 ”Dismantling work”. ......................79

10.1.2 Repair ............................................................79

10.2 Storage ........................................................79

10.3 Disposal ......................................................80

11 Appendices....................................................81

11.1 Electrode/sensor selection ................................81

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

8 InFit 76X e Series

1 Introduction

– The insertion housing InFit 76Xe is safe to

operate and has been tested by METTLER

TOLEDO and dispatched ready for in stallation.

– Before starting to use the housing, care -

fully read this Instruction Manual: the

safety precautions and warnings con tained in it must be observed.

In addition to this Instruction Manual please

also note the following:

– All local safety regulations.

– All instructions and warning remarks in the

publications of the products that are used

in conjunction with the insertion housing

(electrodes, sensors, etc.).

– All safety precautions for the plant into

which the housing InFit 76X e will be

in stalled.

– All instructions and warnings labelled on

the housing InFit 76X e.

– All safety information relative to operation

in potentially explosive atmosphere/

hazardous areas (Ex classified zones).

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 9

1.1 Ex declaration

1.1.1 Use in Ex classified areas

(hazardous areas)

Caution! For intended installation in an Ex

classified area, please observe the following

guidelines (ATEX 94/9/EC). The Ex declaration

is only valid for housings with medium-wetted

parts made of metallic material.

– Ex classification:

II 1/2G c IIC TX Ga/Gb

II 1/2D c IIIC TX Da/Db

– Designation and number of certificate:

SEV 13 ATEX 0161 X

1.1.2 Ex classification II 1/2G c IIC TX

Ga/Gb, II 1/2D c IIIC TX Da/Db,

designation and number of certificate

SEV 13 ATEX 161 X

According to RL 94/9/EG (ATEX 95) Appendix l,

InFit 76X/*1*2/*3/*4/*5/*6*7*8 housings are

devices group ll, category 1/2G and according

to RL 99/92/EG (ATEX 137) may be used in

zones 0/1 or 0/2 and gas group IIC that are potentially explosive due to combustible substances in the temperatures classes T3 to T6.

For use/installation, the requirements of

EN 60079-14 must be observed.

According to RL 94/9/EG (ATEX 95)Appendix l,

InFit 76X/*1*2/*3/*4/*5/*6*7*8 housings are

devices group Ill, category 1/2D and according

to RL 99/92/EG (ATEX 137) may also be used

in zones 20/21 resp. 20/22 that contain combustible dusts.

For use/installation, the requirements of

EN 50281-1-2 must be observed.

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

10 InFit 76X e Series

Special conditions X for safe use

The housings with pneumatic actuation position of the sensors with electrical feedback signal may be operated in hazardous areas Zone

1 and Zone 2 or Zone 21 and Zone 22 with

separately certified intrinsically safe inductive

proximity switches e.g. Pepperl + Fuchs types

NCB2 ***- if the gas groups and temperature

classes coincide with the used flammable

substances and the special conditions of the

Certificates are observed.

1. The maximum permissible ambient or process temperatures for Zone 0 (flammable

gases or flammable liquids) shall be taken

according to the following table:

Temperature Max. ambient resp.

class TX process temperature

T6 68 °C

T5 80 °C

T4 108 °C

T3 140 °C

The maximum permissible ambient or process temperatures must not exceed the

aforementioned values and they will be

found in this instruction manual ”Section

8”.

2. The maximum permissible surface temperature for Zone 20 (combustible dust) shall

be taken accordingly to the following table:

Surface Max. ambient resp.

temp. TX process temperature

T 69 °C 68 °C

T 81 °C 80 °C

T 109 °C 108 °C

T 141 °C 140 °C

The maximum permissible ambient or process temperatures must not exceed the

aforementioned values and they will be

found in the instructions ”Section 8”.

3. The metallic body of the housing type

InFit 76X/*1/*2/*3/*4/*5/*6/*7/*8 has to

be connected conductively to the equipotential system of the plant.

4. The housings type InFit 76X/*1/*2/*3/*4/

*5/*6/*7/*8 are included in the periodic

pressure testing of the system, where appropriate.

Please refer to the ”Declaration of conformity”

on page 14 and 15 for detailed explanation of

the product key.

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 11

1.2 FM certification

Caution! For intended installation in an Ex

classified area, please observe the following

guidelines. The Ex declaration is valid only for

housings with medium-wetted parts made of

metallic material.

– Ex classification:

IS CL I,II,III, Div 1, GR ABCDEFG/T6

)

1

ntrinsically safe, with Entity parameters, for use

I

n Class I,II,III, Division 1, Groups A, B, C, D, E,

i

and G hazardous (classified) locations in ac-

F

cordance with manufacturer’s control drawing

no. 53 800 002.

– Designation and number of the decla -

ration: Original project ID 3021227

(Note the drawing on the following page,

”Section 1.2.1”)

1)

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

12 InFit 76X e Series

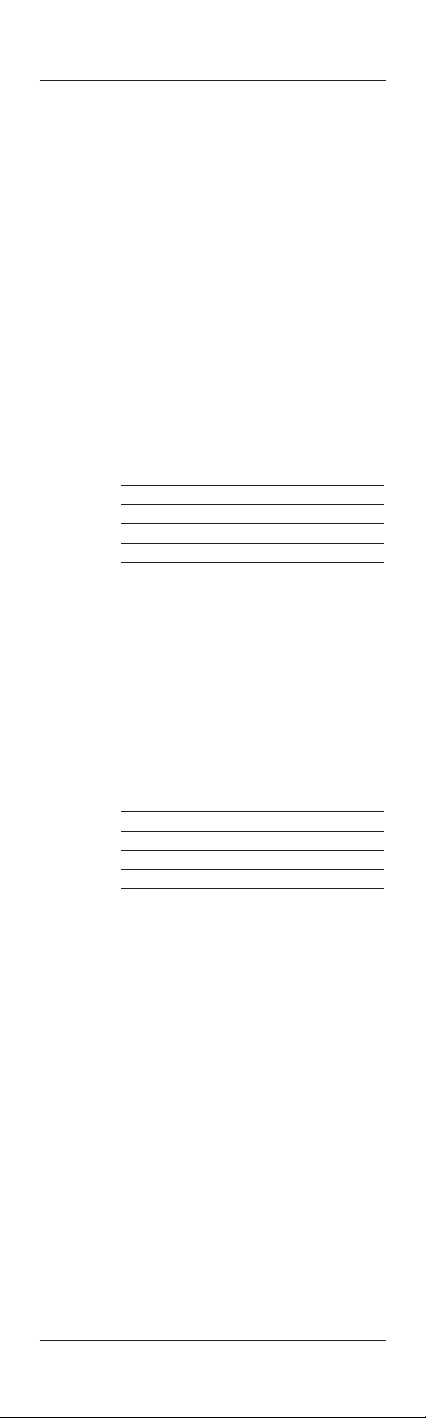

A

B

C

D

E

F

F

E

D

C

B

A

12345678

1234 5678

Index

Title

Drawing No

METTLER TOLEDO

Process Analytics

CH-8902 Urdorf

Drawn F.Kogelmann 11-Dez-03 Scale 1:1

Change Dario Meier 25-Mai-16 Format DIN A3

Schutzvermerk ISO 16016 beachten / Refer to protection notice ISO 16016

Note - Replaces -

FM control drawing

53800002

E.4

Model: MODEL NAME

E.4

ArtikelNr: 53800002

Drawing: E.4 Rel.Level: Released Sheet: 1

/

1

R

Notes:

1. No revision to this drawing is permitted without FMRC approval.

2. Vmax > Vt; Imax > It; (Ci of all loops + C cable) < Ca; (Li of all loops + L cable) < La

Pmax or Pi > Po

3. Single Multi-Channel IS Barrier or Apparatus must be FMRC Approved.

4. Single Multi-Channel IS Barrier or Apparatus manufacturer`s control drawings

must be followed when installing the System. IS Barrier or Equipment may be

installed within the Hazardous (Classified) location for which it is approved.

5. Installation must be in accordance with Article 500 of the NEC (ANSI/NFPA 70) and

ANSI/ISA RP12.6.

WARNING: substitution of components may inpair intrinsic safety.

Entity Parameters:

Vmax (Ui)=16V, Imax (Ii)=50mA, Pi=0.25W

Ci=0.1 uF, Li=0 mH

Probe

Class I, Division 1, Groups A, B, C and D

Class II, Division 1, Groups E, F, and G

Class III, Division 1

T6 Ta=60 C

HAZARDOUS (CLASSIFIED) LOCATION

Any FMRC Approved Single

Multi-Channel Barrier or Apparatus

NONHAZARDOUS LOCATION

1.2.1 Ex classification ”FM Approved”

drawing)

(

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 13

2 Safety

2.1 Introduction

The Instruction Manual contains the most

important information for using the InFit 76Xe

housings efficiently and in accordance with

regulations. A basic condition for safe handling and operation without malfunctions is the

knowledge of these safety instructions and the

observance of the further warnings in the

Instruction Manual.

This Instruction Manual, and in particular the

safety regulations, are intended for personnel

entrusted with the operation and maintenance

of the housings. It is assumed that these

persons are familiar with the equipment in

which the housing is installed. Therefore,

before any work is started with the housing,

this Instruction Manual must be read and

understood by those persons involved.

The Instruction Manual must be stored where

it is constantly accessible and available to any

person working with the InFit 76X e housing.

On receipt of the shipment, check imme dia tely:

– the housing and accessories for any sign

of transport damage. Report any damage

immediately to the carrier and to your

supplier.

– the type designation on the housing body.

– for completeness of the supply. Please

notify your supplier immediately if the

shipment is incomplete or in any way

incorrect (see Section 3.1 ”Scope of

delivery”).

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

14 InFit 76X e Series

2.2 Declaration of conformity/

type examinations

Attention: The ”Declarations of Conformity

and Type Examinations” are dependent on the

design and the individual type of housing, and

have no general validity for the complete InFit

product range.

Declarations of conformity and certificates

specific to particular products are available for

download in PDF format in the Product Info

Section of our Internet website (direct access

available via: www.mtpro.com/Service

1. Housings with CE marking with Notified

Body according to PED directives (Cat. 1

and Cat. 3) and Ex directives: mediumwetted parts made of metallic material

> DN25

2. Housings with CE marking with Notified

Body according to EX directives: mediumwetted parts made of metallic material

DN25

3. Housings with CE marking without Notified

Body according to PED directives (Cat. 1):

medium-wetted parts made of plastic

DN25.

4. Housings without CE marking: mediumwetted parts made of plastic DN25

).

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 15

Example of a declaration of conformity:

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

16 InFit 76X e Series

2.3 Type examination in

accordance with directive

97/23/EC

2.3.1 Type examination (Module B) in

2.3.2 Type conformity (Module C1) in

ccordance with directive 97/23/EC

a

accordance with directive 97/23/EC

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 17

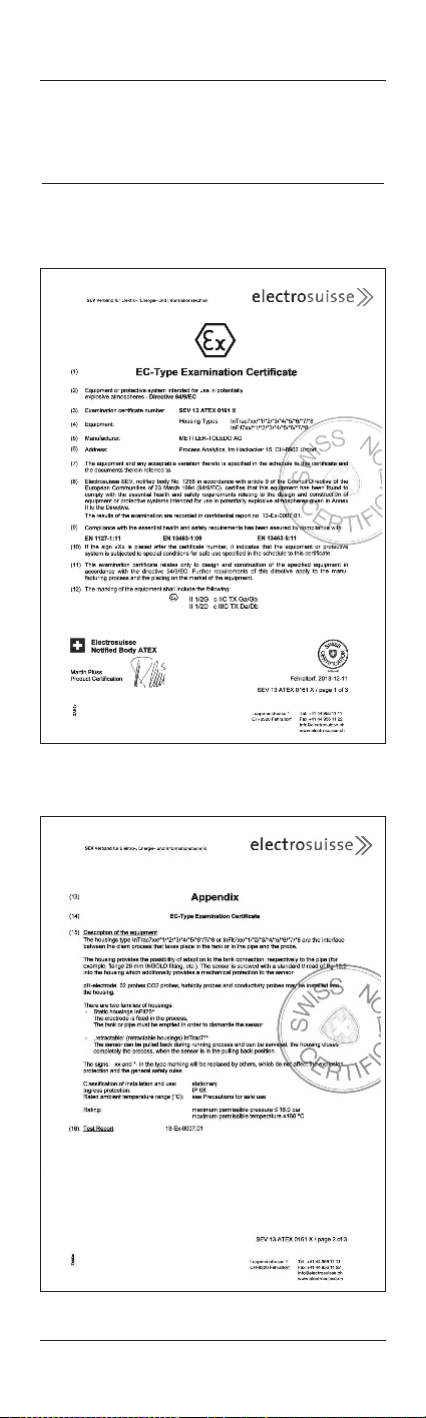

2.4 EC type examination certification in accordance with directive 94/9/EC

Certificate according to ATEX (page 1 of 3)

Certificate according to ATEX (page 2 of 3)

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

18 InFit 76X e Series

Certificates according to ATEX (page 3 of 3)

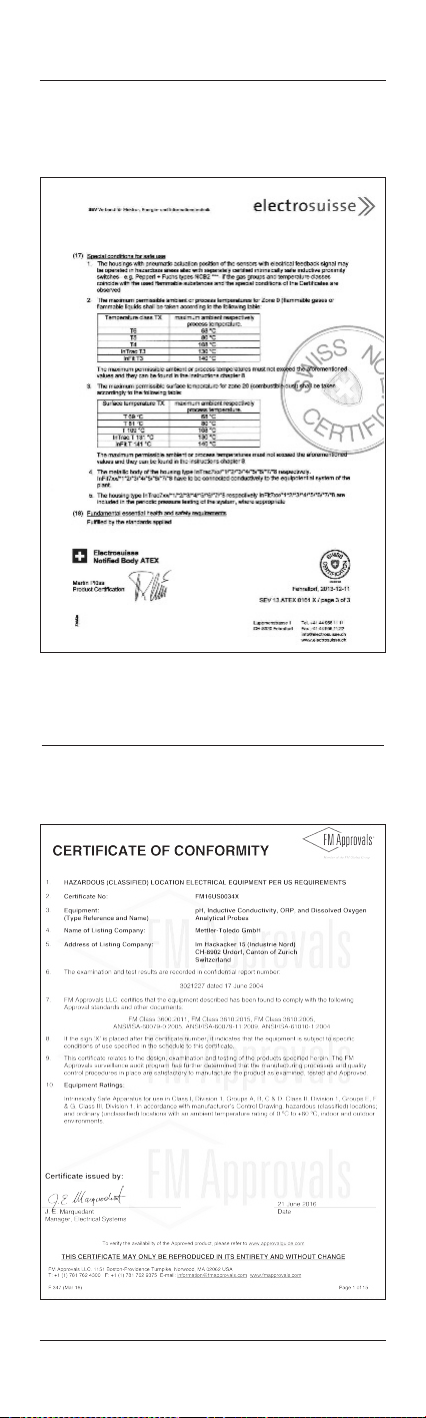

2.5 FM certificate

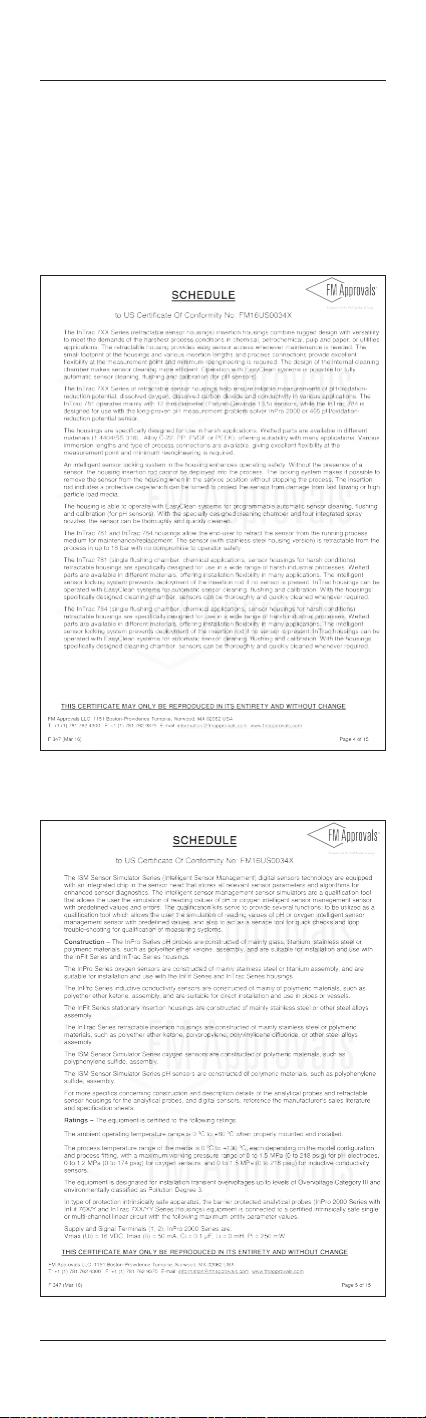

FM certificate (page 1 of 15):

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 19

FM certificate (page 2 of 15):

FM certificate (page 3 of 15):

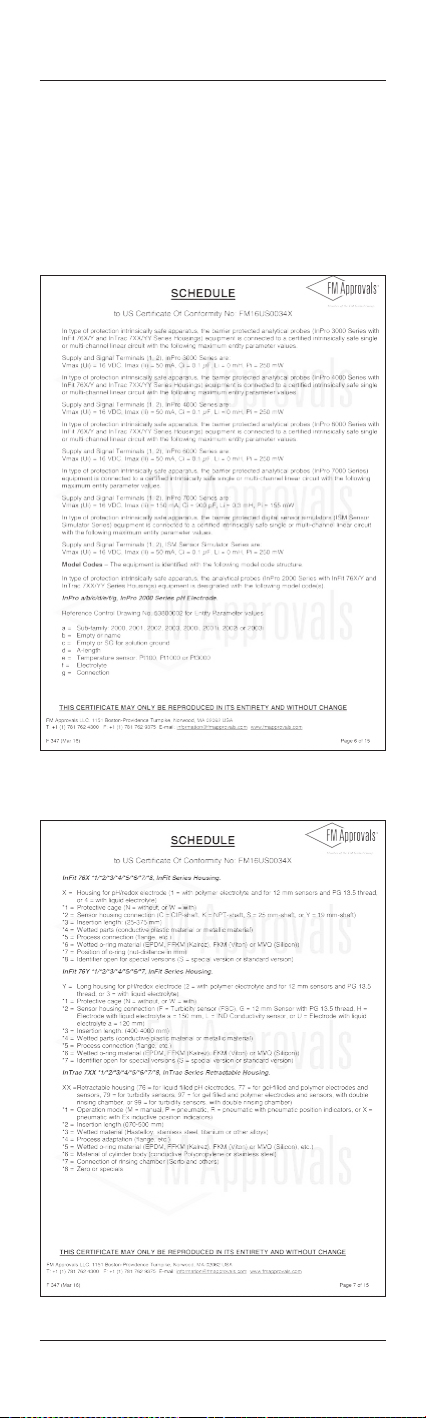

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

20 InFit 76X e Series

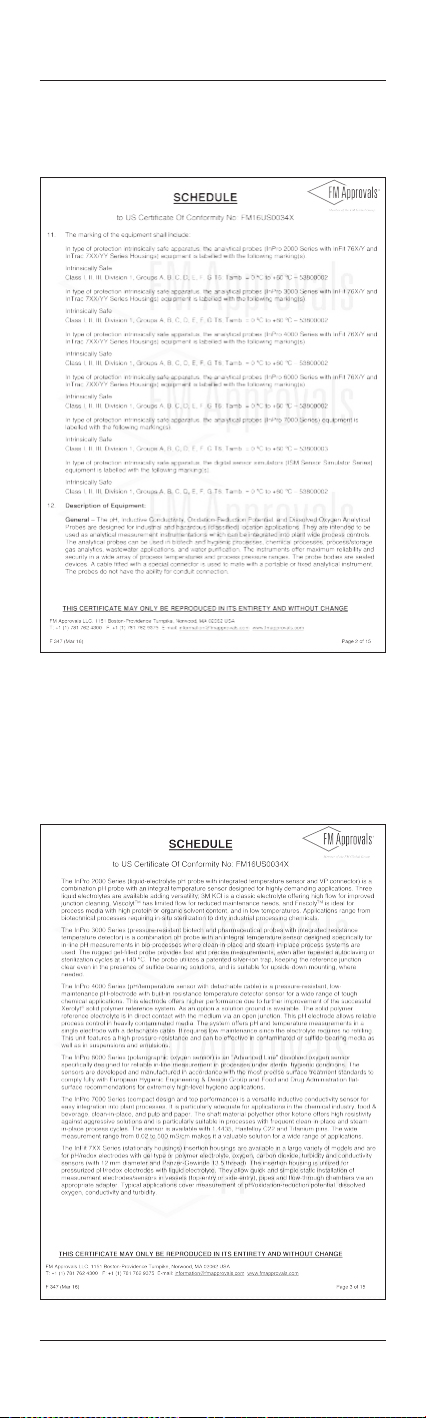

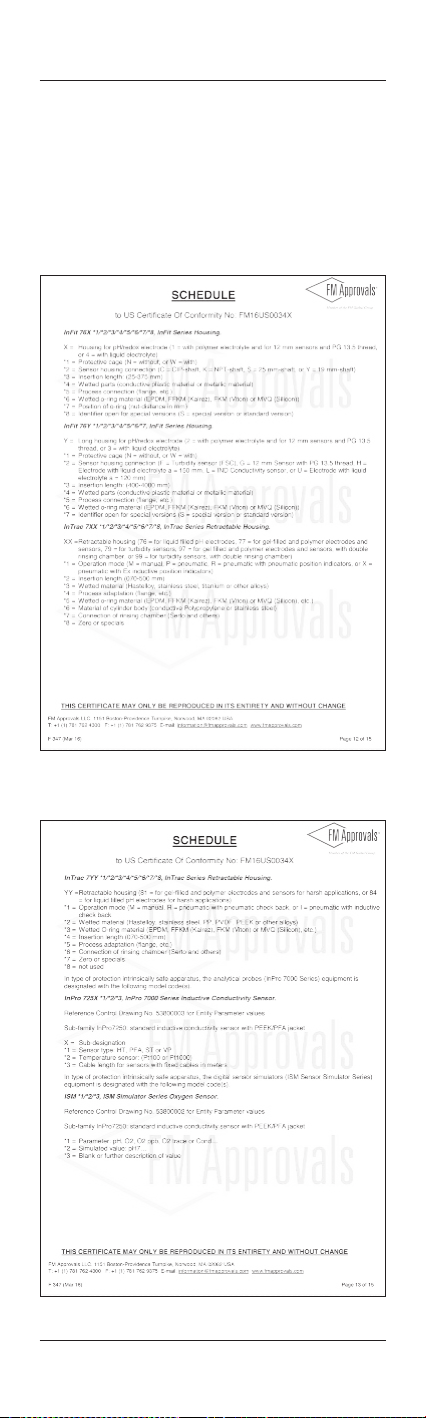

FM certificate (page 4 of 15):

FM certificate (page 5 of 15):

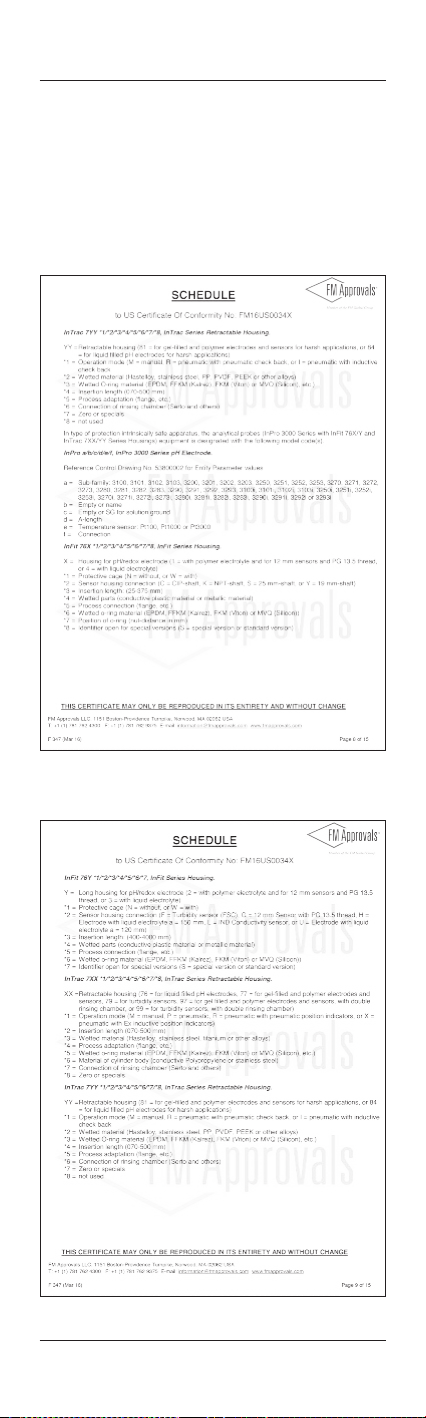

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 21

FM certificate (page 6 of 15):

FM certificate (page 7 of 15):

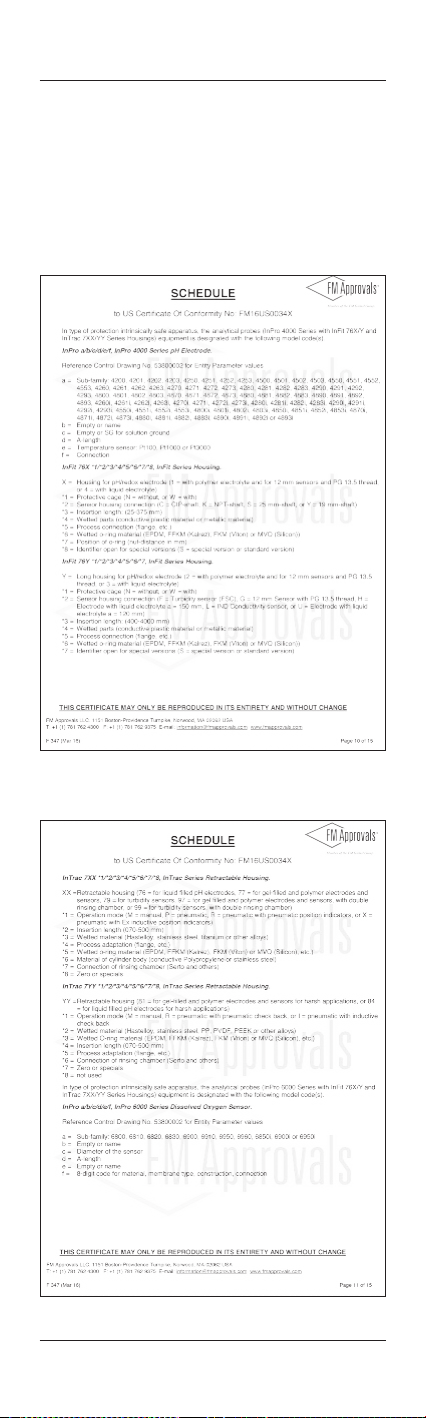

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

22 InFit 76X e Series

FM certificate (page 8 of 15):

FM certificate (page 9 of 15):

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 23

FM certificate (page 10 of 15):

FM certificate (page 11 of 15):

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

24 InFit 76X e Series

FM certificate (page 12 of 15):

FM certificate (page 13 of 15):

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

InFit 76X e Series 25

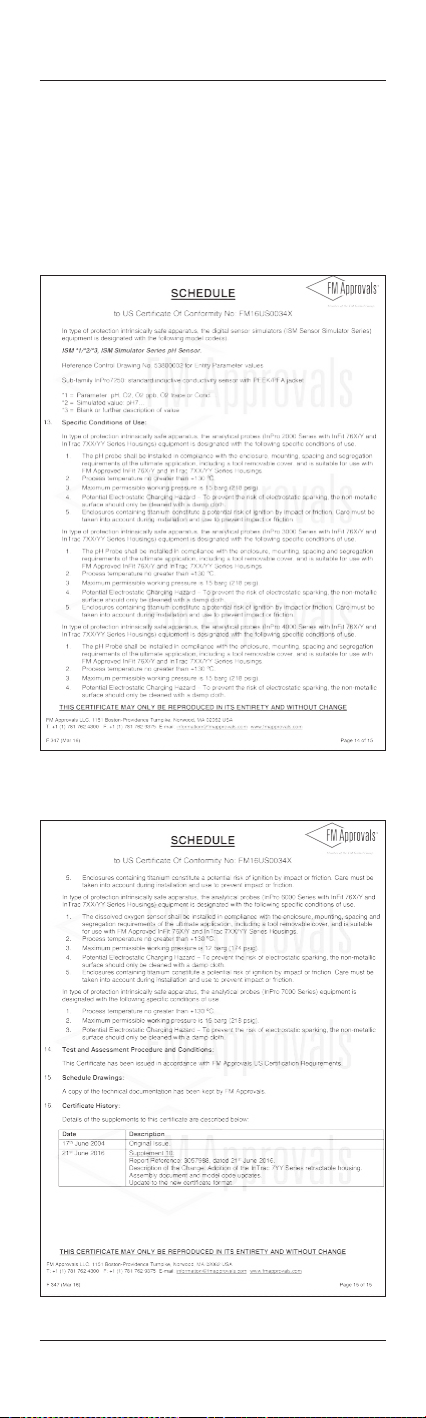

FM certificate (page 14 of 15):

FM certificate (page 15 of 15):

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 383

26 InFit 76X e Series

125 8

125 8

1

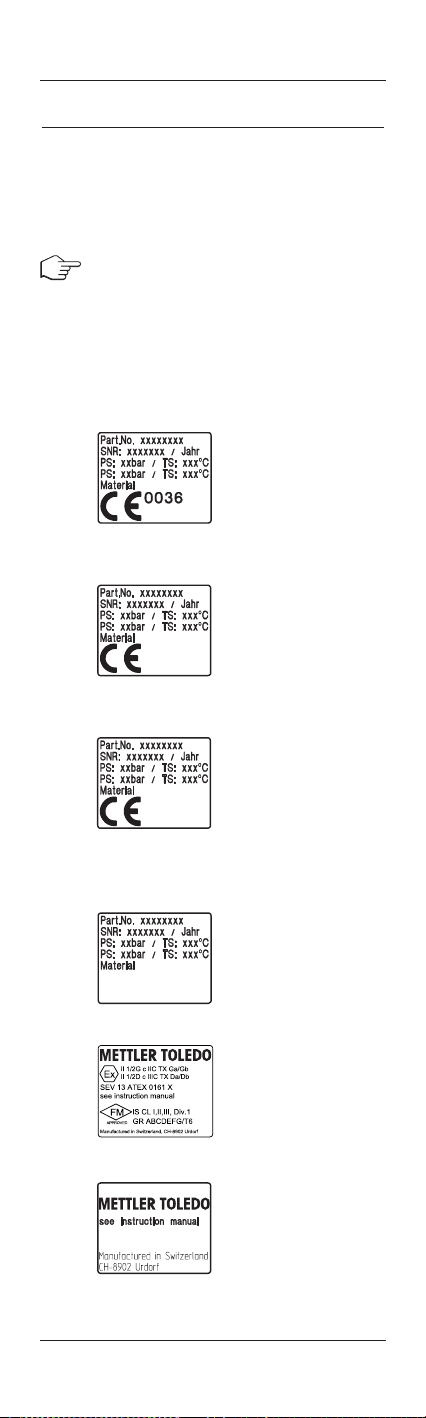

2.6 Housing designations

Housing designation as well as part and

serial numbers can be noted from the type

plate and used for clear identification when

communicating with the manufacturer.

Attention: The specifications shown on the

type plate are dependent on the design and the

individual type of housing and have no

general validity for the complete InFit product

range.

Label type 1:

Type plate in accordance with Ex directive

and PED directive 97/23/EC Cat. 3 + Cat. 1

Label type 2:

Type plate for Ex housings in accordance

with Ex directive

Label type 3:

Type plate for non-Ex housings in accordance

with PED directive 97/23/EC Cat. 1

Label type 4:

Type plate for non-Ex housings in

accordance with PED directive 97/23/EC

(art. 3, paragraph 3)

Label is used in combination

with label type 1 or 2

Label is used in combination

with label type 3 or 4

© 02 /17 Mettler-Toledo GmbH CH- 8606 Greifensee

Printed in Switzerland 52 403 547

Loading...

Loading...