Mettler Toledo IND310drive User Manual

IND310drive

Terminal

User’s Guide

71207921

(10/05)

R03

© METTLER TOLEDO 2005

No part of this manual may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopying and recording, for any

purpose without the express written permission of METTLER TOLEDO.

U.S. Government Restricted Rights: This documentation is furnished with

Restricted Rights.

Copyright 2005 METTLER TOLEDO. This documentation contains proprietary

information of METTLER TOLEDO. It may not be copied in whole or in part

without the express written consent of METTLER TOLEDO.

METTLER TOLEDO reserves the right to make refinements or changes to the

product or manual without notice.

COPYRIGHT

METTLER TOLEDO® is a registered trademark of METTLER TOLEDO. All other

brand or product names are trademarks or registered trademarks of their

respective companies.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE

REFINEMENTS OR CHANGES WITHOUT NOTICE.

FCC Notice

This device complies with Part 15 of the FCC Rules and the Radio Interference

Requirements of the Canadian Department of Communications. Operation is

subject to the following conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his or her own expense.

Declaration of conformity is located on the documentation CD.

PRECAUTIONS

• READ this manual BEFORE operating or servicing this equipment and FOLLOW

these instructions carefully.

• SAVE this manual for future reference.

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT TO

PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND

PRONG.

WARNING!

WARNING!

TO AVOID DAMAGE TO THE PCB OR LOAD CELL, REMOVE POWER FROM THE IND310drive

TERMINAL AND WAIT AT LEAST 30 SECONDS BEFORE CONNECTING OR DISCONNECTING

ANY HARNESS.

CAUTION

BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC COMPONENTS OR

INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT ALWAYS REMOVE POWER

AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY CONNECTIONS OR

DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE PRECAUTIONS COULD RESULT

IN DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT AND/OR BODILY HARM.

CAUTION

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

WARNING!

THE IND310drive TERMINAL IS NOT INTRINSICALLY SAFE! DO NOT USE

WITHIN AREAS CLASSIFIED AS HAZARDOUS DIVISION 1 OR ZONE 0/1

BECAUSE OF COMBUSTIBLE OR EXPLOSIVE ATMOSPHERES.

WARNING!

WHEN THIS EQUIPMENT IS INCLUDED AS A COMPONENT PART OF A

SYSTEM, THE RESULTING DESIGN MUST BE REVIEWED BY QUALIFIED

PERSONNEL WHO ARE FAMILIAR WITH THE CONSTRUCTION AND

OPERATION OF ALL COMPONENTS IN THE SYSTEM AND THE POTENTIAL

HAZARDS INVOLVED. FAILURE TO OBSERVE THIS PRECAUTION COULD

RESULT IN BODILY HARM AND/OR PROPERTY DAMAGE.

Contents

Chapter 1.0 Introduction ..............................................4H1-1

Operating Overview ....................................................................5H1-1

Gross State....................................................................................6H1-1

Net State........................................................................................7H1-2

Operating Modes ............................................................................8H1-2

Weighing Processes .......................................................................9H1-2

Installation and Programming...................................................... 10H1-3

Chapter 2.0 Operating Instructions ..............................11H2-1

Security..................................................................................... 12H2-1

Metrology Switch............................................................................13H2-2

Legal for Trade Settings...................................................................14H2-2

Display Operation....................................................................... 15H2-3

General Navigation.........................................................................16H2-4

Keystroke Functions........................................................................17H2-8

Default Screen.......................................................................... 18H2-11

No Vehicle Application Operation................................................ 19H2-11

Application Operation................................................................ 20H2-11

Direct Entry Option........................................................................21H2-12

Vehicle ID Weighing......................................................................22H2-12

New Vehicle ID.............................................................................23H2-14

Temporary ID Weighing.................................................................24H2-15

Index Weighing............................................................................25H2-17

Transient Vehicle Weighing............................................................26H2-18

Outbound Process........................................................................27H2-19

Inbound Process ..........................................................................28H2-22

Commodity Function.....................................................................29H2-22

Clear and Reset Functions .........................................................

30H2-22

Clearing the Alibi & Transaction Table.............................................31H2-23

Reset ..........................................................................................32H2-23

Table Searches ........................................................................33H2-24

Table Reports...........................................................................

34H2-25

Chapter 3.0 Service and Maintenance.........................35H3-1

Service...................................................................................... 36H3-1

Cleaning and Maintenance ..........................................................

Updating Software ...................................................................... 38H3-2

37H3-1

Appendix A

Basic Weighing Concepts ..........................39HA-1

Zero.......................................................................................... 40HA-1

Tare..........................................................................................

Autotare.........................................................................................42HA-1

Keyboard Tare................................................................................43HA-2

Additive Tare.................................................................................. 44HA-2

Tare Interlocks................................................................................45HA-2

41HA-1

Sections.................................................................................... 46HA-2

Setpoints...................................................................................

Inbound/Outbound Weighing .......................................................

47HA-2

48HA-3

Net Sign Correction..................................................................... 49HA-3

One-Pass Weighing.................................................................... 50HA-3

Appendix B Application Operation Flowcharts ...............51HB-1

Vehicle ID Weighing ...................................................................52HB-3

Temporary ID Weighing ..............................................................53HB-4

Index Weighing..........................................................................54HB-5

Transient Vehicle Weighing.......................................................... 55HB-6

Chapter 1.0

Introduction

This chapter covers

• Operating Overview

• Installation and Programming

The IND310drive Industrial Scale Terminal incorporates the latest

design innovations in vehicle weighing applications. The terminal

contains functionality not available in previous generations of

terminals; it employs a simple setup logic tree that will be carried

across future generations of METTLER TOLEDO terminals.

The simplicity of setup and operation coupled with specific

configurations for multiple applications reduces training costs and

operation setup time. The enhanced software capabilities enable

database storage of key information, which reduces operator error

and time-consuming entries.

Information on installing, programming, and servicing the

IND310drive terminal is located in the IND310drive Installation

Manual and the IND310drive Technical Manual. Review all

instructions and safety precautions carefully. Only authorized

personnel should perform installation and service procedures.

Please contact an authorized METTLER TOLEDO representative to

resolve any questions not covered in this manual or associated

manuals.

Operating Overview

See Appendix A,

Basic Weighing

Concepts for

more information

about basic

weighing

terminology.

To successfully use the IND310drive terminal's various functions, one must

understand

• Basic weighing terminology

• Differences between gross and net states

• The terminal's various operating modes and weighing processes

Gross State

The IND310drive terminal is in the gross state when a tare (the weight of a

container holding the product to be weighed) has not been taken. The full weight of

the items on the scale displays on the terminal.

1-1

IND310drive User Manual

Net State

The IND310drive terminal is in the net state after a tare has been taken. Only the

weight of the items on the scale after the tare is deducted displays, and the net

cursor is lit.

Operating Modes

Routine operations with all vehicle features enabled in setup include four modes of

terminal operation:

• Vehicle ID Weighing—Uses a permanent stored Vehicle ID table to identify the

tare value of the vehicle, and then follows the steps defined by the outbound

process to complete the procedure, which is also called a transaction. Vehicle

ID Weighing enables the accumulation of totals based on vehicle ID.

• Temporary ID Weighing—Coordinates the inbound and outbound processes

for vehicles that are not permanently stored in the Vehicle ID table through the

use of a Temporary ID table. Temporary ID Weighing stores the vehicle

information in the Temporary ID table and follows the inbound process. It also

removes this temporary entry when the vehicle returns and follows the

outbound process. Because the entry is temporary, no accumulation of totals

occurs.

• Index Weighing—Enables the Vehicle ID Weighing mode and Outbound

process to be condensed through the use of a special Index table that provides

a single ID reference for quick multiple ID look-ups.

• Transient Weighing—This mode enables weighing of vehicles that are not

part of normal operation in a manner similar to the Vehicle ID Weighing mode.

Transient Weighing does not use the Vehicle ID table, so the operator must

enter vehicle data. Transient Weighing transactions are not included in any

totals.

Weighing Processes

There are two weighing processes:

• Outbound—Completes the vehicle transaction. The gross, tare, and net weight

values are now known. Other transaction information may be collected (A1–A4

table data, Variable 1, and/or Variable 2 data). The completed transaction

information is stored and can be printed.

• Inbound—Enables the vehicle identification information and a stored weight

value to be collected. Other transaction information may be collected (A1–A4

table data). The inbound transaction information is stored and can be printed.

1-2

Installation and Programming

The IND310drive Installation Manual provides detailed information about

installation. This manual is included in printed format and on a CD with the initial

delivery of the terminal. Installation information for the IND310drive is also

available in the IND310drive Technical Manual, Appendix A.

The IND310drive Technical Manual contains advanced information for

IND310drive setup and programming.

IND310drive User Manual

1-3

IND310drive User Manual

For your notes

1-4

Chapter 2.0

Operating Instructions

This chapter covers

• Security

• Display Operation

• Default Screen

• No Application Operation

• Application Operation

• Clear and Reset Functions

• Table Searches

• Table Reports

Security

The IND310drive supports two levels of users/passwords for setup security:

Administrator and Limited. An administrator-level user can access all setup areas

of the terminal. A limited-access-level user can access all areas of the setup except

for the Scale and Diagnostics blocks.

The IND310drive Terminal is a simple to use, yet sophisticated

terminal with flexibility of configuration to meet a variety operating

requirements. The setup menu system provides the power of

configuration in a user-friendly operational environment.

While reading this manual and operating the terminal, keep in mind

that various functions may or may not be available and that the

screens shown in this manual may vary from terminal-to-terminal

based on the setup configuration.

This User Manual provides instructions for performing typical vehicle

weighing operations on the IND310drive terminal. Detailed

information about terminal configuration and setup is provided in the

IND310drive Technical Manual.

The terminal is pre-configured at the factory with a user name of “ADMIN” and a

user name of “Operator”. The pre-configured users (ADMIN and Operator) cannot

be changed, only the passwords can be added or modified. The factory default

passwords are null (no password). The unit as configured at the factory requires

no login or password entry to enter the setup mode. All functions of the terminal

will be available to all users until a password is entered. Be sure to remember the

password configured for the ADMIN user. If the password is changed or forgotten,

access to the setup menu will not be available. Be sure to protect the password

from access by unauthorized personnel. The password provides access to the

entire setup menu, unless the metrology switch is placed in the approved position.

Ensure that a password has been configured for the ADMIN user prior to

configuring any passwords for other users. Failure to configure the ADMIN user

password before configuring other user passwords could result in being

blocked from access to the entire system.

2-1

IND310drive User Manual

A

p

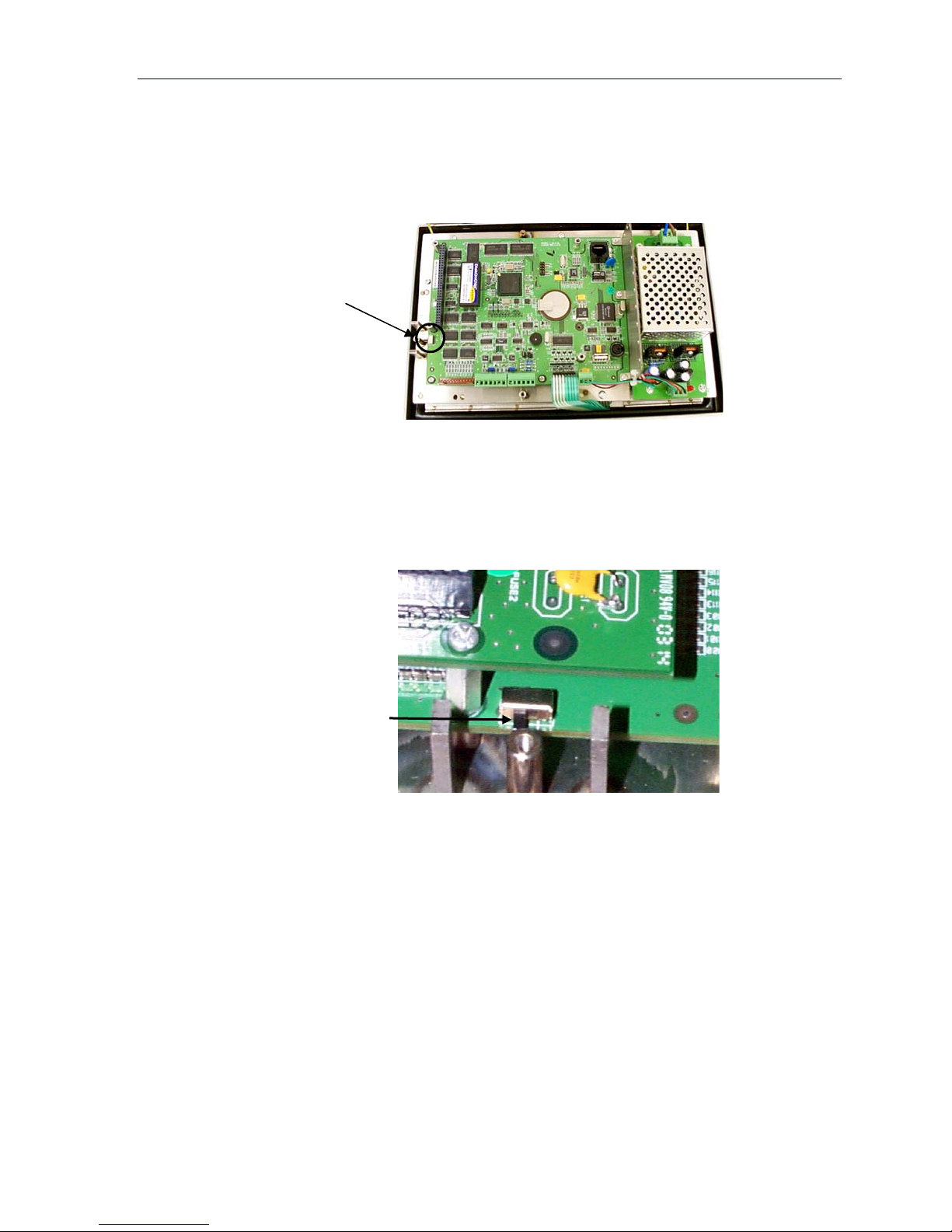

Metrology Switch

The metrology switch (Figure 2-1), which is sealed per Weights and Measures,

controls access to the scale submenu of the setup menu tree. This submenu

includes functions such as calibration, filter settings, tare settings and others.

Metrology switch

The Scale submenu is accessible (may be expanded) only when the Metrology

switch is in the non-approved position. If the metrology switch is in the approved

position (Figure 2-2) the user may enter setup, but will be unable to enter the scale

setup submenu. See the IND310drive Technical Manual for further information

about the metrology switch and accessing the setup menu tree.

Figure 2-1: Metrology Switch Location

pproved

osition

Figure 2-2: Metrology Switch in the Approved Position

Legal for Trade Settings

Legal for Trade settings are accessed through the Scale submenu in the menu tree.

The IND310drive operates within the weights and measurement rules associated

with the Legal for Trade settings. Ensure that the appropriate legal for trade

approval type is selected so that the IND310drive will display weight values in

accordance with specific local weights and measures rules. See the IND310drive

Technical Manual for information on how to change the Legal for Trade settings.

2-2

Display Operation

r

A

Application operation and setup display screens include the following basic

sections:

• Status bar

• Application area

• Softkeys

IND310drive User Manual

Figure 2-3 shows the location of each of these sections.

09 Jan 2005 08:47:19

Status ba

pplication

area

Softkeys

Figure 2-3: Default Weighing Operation Screen

Status Bar

The status bar shows the terminal's status, including the active scale, weight,

weighing units, date, and time.

Application Area

The application area displays the current application. For example, the application

area shown in Figure 2-3 indicates that a current vehicle ID needs to be entered.

Softkeys

Softkeys are used to select application operation modes. The positioning of

softkeys can be changed and functions enabled or disabled through the softkey

setup page.

2-3

IND310drive User Manual

General Navigation

Navigate in the applications and configure the IND310drive using

• Softkeys • Numeric keys

• Application keys • External Keyboard

• Scale function keys • Alpha keys

• Navigation keys

The locations of the above listed keys and the default weighing operation screen

are shown in Figure 2-4.

Softkeys

The softkey setup page is used to

• Change softkey positions

• Enable softkey functions

• Disable softkey functions

For example, a contrast softkey can be enabled for making quick adjustments to

the terminal screen’s contrast setting.

Five softkeys are located along the bottom of the display screen (see Figure 2-4).

Some screens might have up to three pages of softkeys for a total of 15 possible

functions. A DOWN ARROW icon

screen (to the far right of the softkey icons) indicates that more softkey selections

are available. Press the DOWN arrow navigation key to display additional softkey

screens. Press the UP arrow navigation key to display the previous softkey screen.

displayed on the lower-right corner of the

Default Weighing

Operation Screen

Application (A) Keys

2-4

Scale Function

Keys

Softkeys

Figure 2-4: Key Locations and Default Weighing Operation Screen

Numeric Keys

UP Arrow Navigation Key

Navigation Keys

DOWN Arrow Navigation Key

IND310drive User Manual

Application Keys

Application keys (A keys) are located below the softkeys (see Figure 2-4) and are

labeled

• A1

• A2

• A3

• A4

The application key setup screen is used to assign specific functions to the

application keys. For example, application keys could be configured to magnify the

display ten times, adjust contrast, or select user-defined table information.

Scale Function Keys

Scale function keys (see Figure 2-4) are:

Select Scale—Enables the operator to select a specific scale. Press the

SELECT SCALE key to switch between available scales.

Zero—Zero is the weight of the scale platform or weighbridge when it is

empty. The gross zero reference is recorded during calibration. Press the ZERO

scale function key to capture a new gross zero reference point if pushbutton zero is

enabled in configuration and the weight is within the zero range.

Tare—Tare is the weight of a vehicle when it is empty. Tare is normally

used to determine the net weight of the contents of a vehicle. Press the TARE scale

function key when an empty vehicle is on the scale. The terminal then displays a

zero weight. The vehicle is loaded and driven back onto the scale. The terminal

then displays the net weight of the contents. Pushbutton tare must be enabled to

use this key in this manner.

When the empty weight of the vehicle is a known value, enter the tare weight using

the numeric keys and then press the TARE scale function key. The terminal will

display the net weight of the contents of the vehicle. Keyboard tare must be

enabled in order to use this key in this manner.

Print—Press the PRINT scale function key to generate a hard-copy printout

of a report or of information displayed on the screen or to initiate a demand print of

an assigned print template. A printer must be connected to a serial port and the

terminal must be configured to match its serial port settings to the printer’s.

Communication connection and configuration is necessary to connect a template

or report to the selected serial port, and to define the selected template or report in

configuration.

2-5

IND310drive User Manual

Navigation Keys

Navigation keys (see Figure 2-4) enable navigation within the setup menu tree,

setup screens, and application screens. Navigation keys include:

• Up and down arrows—move the focus up or down to different setup

options within the menu tree or to different fields within setup pages. Focus is

indicated by highlighted text. These keys are also used to switch to another

page of softkeys.

• Left and right arrows—expand (right arrow) or collapse (left arrow)

the setup options in the menu tree. These arrows also move the cursor position

to a specific character in text areas, and enable left and right scrolling to view

all information available on a screen.

Enter—opens the setup page for viewing and editing setup parameters.

•

The Enter key moves the focus from a field label to a setup value for that field.

After entering a value, the enter key is used to accept new values and the focus

moves to the next field label.

Numeric Keys

Use the terminal’s 12-key numeric keypad (see Figure 2-4) to enter data and

commands.

To use numeric keys, position the cursor in the field (see Navigation Keys) and

press the numeric keys to enter the appropriate data. Press the DECIMAL key

(. key) to enter decimal points where necessary.

The CLEAR key (C key) functions like a backspace key. Position the cursor at the

end of data to be deleted and press the C key. Press the C key once for each

character to be deleted.

Alpha Keys

On some setup pages, softkeys and application keys function as alpha keys (see

Figure 2-5) that are used to enter alphabetic characters for setup parameters such

as passwords.

2-6

Loading...

Loading...