Page 1

User's Guide

IND256x

Weighing Terminal

Page 2

IND256x Weighing Terminal

Essential Services for Dependable Performance of Your IND256x Weighing Terminal

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper use of your

new equipment according to this Manual and regular calibration and maintenance by our factorytrained service team ensures dependable and accurate operation, protecting your investment.

Contact us about a service agreement tailored to your needs and budget. Further information is

available at www.mt.com/service

There are several important ways to ensure you maximize the performance of your investment:

1. Register your product: We invite you to register your product at

www.mt.com/productregistration so we can contact you about enhancements, updates and

important notifications concerning your product.

2. Contact METTLER TOLEDO for service: The value of a measurement is proportional to its

accuracy – an out of specification scale can diminish quality, reduce profits and increase

liability. Timely service from METTLER TOLEDO will ensure accuracy and optimize uptime and

equipment life.

.

a. Installation, Configuration, Integration and Training: Our service representatives are factory-

trained, weighing equipment experts. We make certain that your weighing equipment is

ready for production in a cost effective and timely fashion and that personnel are trained for

success.

b. Initial Calibration Documentation: The installation environment and application

requirements are unique for every industrial scale so performance must be tested and

certified. Our calibration services and certificates document accuracy to ensure production

quality and provide a quality system record of performance.

c. Periodic Calibration Maintenance: A Calibration Service Agreement provides on-going

confidence in your weighing process and documentation of compliance with requirements.

We offer a variety of service plans that are scheduled to meet your needs and designed to

fit your budget.

d. GWP® Verification: A risk-based approach for managing weighing equipment allows for

control and improvement of the entire measuring process, which ensures reproducible

product quality and minimizes process costs. GWP (Good Weighing Practice), the sciencebased standard for efficient life-cycle management of weighing equipment, gives clear

answers about how to specify, calibrate and ensure accuracy of weighing equipment,

independent of make or brand.

Page 3

© METTLER TOLEDO 2019

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose without the express written

permission of METTLER TOLEDO.

U.S. Government Restricted Rights: This documentation is furnished with Restricted Rights.

Copyright 2019 METTLER TOLEDO. This documentation contains proprietary information of METTLER

TOLEDO. It may not be copied in whole or in part without the express written consent of METTLER

TOLEDO.

METTLER TOLEDO reserves the right to make refinements or changes to the product or manual

without notice.

COPYRIGHT

METTLER TOLEDO® is a registered trademark of Mettler-Toledo, LLC. All other brand or product

names are trademarks or registered trademarks of their respective companies.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE REFINEMENTS OR CHANGES

WITHOUT NOTICE.

FCC Notice

This device complies with Part 15 of the FCC Rules and the Radio Interference Requirements of the

Canadian Department of Communications. Operation is subject to the following conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his or her expense.

Declaration of Conformity is available at

http://glo.mt.com/global/en/home/search/compliance.html/compliance/

.

Page 4

Warnings and Cautions

• READ this manual BEFORE operating or servicing this equipment and FOLLOW these instructions

carefully.

• SAVE this manual for future reference.

WARNING

DO NOT INSTALL OR PERFORM ANY SERVICE ON THIS EQUIPMENT BEFORE THE AREA IN WHICH THE

IND256x IS LOCATED HAS BEEN SECURED AS NON-HAZARDOUS BY PERSONNEL AUTHORIZED TO DO SO

BY THE RESPONSIBLE PERSON AT THE CUSTOMER’S SITE.

CAUTION

CONFIRM COMPLIANCE WITH APPLICABLE NATIONAL AND LOCAL WIFI REGULATIONS BEFORE INSTALLING

AND COMMISSIONING IND256x TERMINAL CONFIGURED WITH WIFI MODULE. METTLER TOLEDO ACCEPTS

NO RESPONSIBILITY FOR TERMINAL INSTALLATION IN COUNTRIES WHERE WIFI REGULATIONS ARE NOT

FULFILLED.

WARNING

IF THE IND256x KEYBOARD, DISPLAY LENS OR ENCLOSURE IS DAMAGED, THE DEFECTIVE COMPONENT

MUST BE REPLACED IMMEDIATELY. REMOVE POWER IMMEDIATELY AND DO NOT REAPPLY POWER UNTIL

THE DISPLAY LENS, KEYBOARD OR ENCLOSURE HAS BEEN REPAIRED OR REPLACED BY QUALIFIED

SERVICE PERSONNEL. FAILURE TO DO SO COULD RESULT IN BODILY HARM AND/OR PROPERTY DAMAGE.

CAUTION

USE ONLY METTLER TOLEDO SPARE PARTS WHEN REPLACING THE WiFi MODULE. METTLER TOLEDO

ACCEPTS NO RESPONSIBILITY FOR SAFETY OR COMPLIANCE RISKS CAUSED BY USE OF INCORRECT

COMPONENTS.

WARNING

AVOID ELECTROSTATIC CHARGING DURING OPERATION AND MAINTENANCE.

WARNING

OPERATION IS ONLY PERMITTED WHEN OPERATIONAL AND PROCESS-RELATED ELECTROSTATIC CHARGES

ARE NOT PRESENT.

WARNING

USE THE WEIGHING TERMINAL ONLY WHEN ELECTROSTATIC PROCESSES LEADING TO PROPAGATION

BRUSH DISCHARGE IS IMPOSSIBLE.

WARNING

KEEP THE TERMINAL AWAY FROM PROCESSES THAT GENERATE HIGH CHARGING POTENTIAL SUCH AS

ELECTROSTATIC COATING, RAPID TRANSFER OF NON-CONDUCTIVE MATERIALS, RAPID AIR JETS, AND

HIGH PRESSURE AEROSOLS.

Page 5

WARNING

DO NOT USE DRY CLOTH TO CLEAN THE WEIGHING TERMINAL. ALWAYS USE A DAMP CLOTH TO CLEAN

THE TERMINAL GENTLY.

WARNING

WEAR SUITABLE CLOTHING. AVOID NYLON, POLYESTER OR OTHER SYNTHETIC MATERIALS THAT

GENERATE AND HOLD CHARGE. USE CONDUCTIVE FOOTWEAR AND FLOORING.

WARNING

AVOID PLASTIC COVERS OVER THE TERMINAL.

WARNING

ENSURE PROPER EQUIPOTENTIAL GROUNDING OF THE TERMINAL, MOUNTING ACCESSORIES, AND THE

SCALE BASE.

WARNING

Warnings and Cautions

TERMINAL MUST BE PROTECTED FROM UV LIGHT.

WARNING

FOR THE DC VERSION OF THE IND256x TERMINAL, THERE IS NO GALVANIC SEPARATION BETWEEN NONINTRINSICALLY SAFE SUPPLY CIRCUIT AND INTRINSICALLY SAFE OUTPUT CIRCUITS. THE NONINTRINSICALLY SAFE CIRCUIT MUST BE SAFELY CONNECTED TO EARTH. AND POTENTIAL EQUALIZATION

MUST EXIST ALONG INTRINSICALLY SAFE CIRCUITS.

ALTERNATIVELY, THE NON-INTRINSICALLY SAFE SUPPLY CIRCUIT (SELV) MUST BE SAFELY SEPARATED

FROM EARTH.

WARNING

THE EXTERNAL CUSTOMER-PROVIDED DC POWER SUPPLY MUST HAVE A CATEGORY II MAXIMUM OVERVOLTAGE, ACCORDING TO IEC 60664-1.

WARNING

SUFFICIENT STRAIN RELIEF MUST BE ENSURED TO PREVENT TENSILE FORCES ON THE CABLE GLANDS.

WARNING

THE CABLE GLANDS MUST BE PROTECTED AGAINST DAMAGE FROM IMPACT.

WARNING

THE TERMINAL ASSEMBLED WITH WIFI ANTENNA SHALL BE INSTALLED IN A POSITION IN SUCH A WAY

THAT THE RISK FOR MECHANICAL DAMAGE IS LOW. REPLACE THE WIFI ANTENNA IMMEDIATELY IF

DAMAGED.

Page 6

WARNING

IND256x TERMINALS FACTORY-CONFIGURED WITH WIFI ARE APPROVED FOR USE IN ZONE 1 EQUIPMENT

GROUP IIB CLASSIFIED AREAS. IND256x TERMINALS FACTORY-CONFIGURED WITH WIFI MUST NOT BE

USED IN EQUIPMENT GROUP IIC CLASSIFIED AREA. USING THE IND256X TERMINAL FACTORYCONFIGURED WITH WIFI IN A CLASSIFIED AREA FOR WHICH IT IS NOT APPROVED COULD RESULT IN

BODILY HARM AND/OR PROPERTY DAMAGE.

WARNING

THE EXTERNAL CUSTOMER-PROVIDED DC POWER SUPPLY MUST HAVE A MAXIMUM OVER-VOLTAGE

CATEGORY II ACCORDING TO IEC 60664-1.

WARNING

DO NOT OPEN THE TERMINAL WHEN THE ATMOSPHERE IS EXPLOSIVE DUE TO DUST. TO PREVENT

IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE IND256x FROM ITS POWER SOURCE BEFORE

OPENING THE ENCLOSURE. KEEP COVER TIGHTLY CLOSED WHILE THE CIRCUIT IS ENERGIZED. DO NOT

OPEN WHEN AN EXPLOSIVE DUST ATMOSPHERE IS PRESENT.

WARNING

ALL EQUIPMENT MUST BE INSTALLED PER MANUFACTURER'S DOCUMENT DRAWING NUMBER

30282892B AND APPLICABLE LOCAL CODES.

WARNING

ONLY THE COMPONENTS SPECIFIED IN THE INSTALLATION MANUAL INCLUDED ON THE DOCUMENTATION

CD-ROM 30512916 CAN BE USED IN THIS DEVICE. ALL EQUIPMENT MUST BE INSTALLED IN

ACCORDANCE WITH THE INSTALLATION INSTRUCTIONS. INCORRECT OR SUBSTITUTE COMPONENTS

AND/OR DEVIATION FROM THESE INSTRUCTIONS CAN IMPAIR THE INSTRINSIC SAFETY OF THE TERMINAL

AND COULD RESULT IN BODILY INJURY AND/OR PROPERTY DAMAGE.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD, CONNECT TO PROPERLY GROUNDED POWER

SOURCE ONLY. DO NOT REMOVE THE GROUNDING CONNECTION.

WARNING

WHEN THIS EQUIPMENT IS INCLUDED AS A COMPONENT PART OF A SYSTEM, THE RESULTING DESIGN

MUST BE REVIEWED BY QUALIFIED PERSONNEL WHO ARE FAMILIAR WITH THE CONSTRUCTION AND

OPERATION OF ALL COMPONENTS IN THE SYSTEM AND THE POTENTIAL HAZARDS INVOLVED. FAILURE TO

OBSERVE THIS PRECAUTION COULD RESULT IN BODILY HARM AND/OR PROPERTY DAMAGE.

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THE IND256x. EXERCISE CARE WHEN MAKING

CHECKS, TESTS AND ADJUSTMENTS THAT MUST BE MADE WITH POWER ON. FAILING TO OBSERVE THESE

PRECAUTIONS CAN RESULT IN BODILY HARM AND/OR PROPERTY DAMAGE.

Page 7

In conformance with the European Directive 2002/96/EC on Waste Electrical and Electronic

WARNING

BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC COMPONENTS OR

INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT ALWAYS REMOVE POWER AND WAIT AT

LEAST THIRTY (30) SECONDS BEFORE ANY CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO

OBSERVE THESE PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT

AND/OR BODILY HARM.

NOTICE

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

Disposal of Electrical and Electronic Equipment

Equipment (WEEE) this device may not be disposed of in domestic waste. This also applies to

countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point specified

for electrical and electronic equipment.

If you have any questions, please contact the responsible authority or the distributor from which you

Warnings and Cautions

purchased this device.

Should this device be passed on to other parties (for private or professional use), the content of this

regulation must also be related.

Thank you for your contribution to environmental protection.

Page 8

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

1

Contents

1 Introduction ................................................................................. 1-1

1.1. IND256x Overview ........................................................................ 1-1

1.2. Product Specification ..................................................................... 1-2

1.3. Testing Standards ......................................................................... 1-4

1.4. Warnings and Precautions ............................................................. 1-6

1.5. Inspection and Contents Checklist ................................................... 1-6

1.6. Configuration ................................................................................ 1-7

1.7. Equipotential Bonding (EB) ............................................................ 1-9

1.8. Operating Environment .................................................................. 1-9

1.9. Dimensions ................................................................................ 1-10

1.10. Main Board ................................................................................ 1-12

1.11. Communication Option Boards ..................................................... 1-12

2 Operation .................................................................................... 2-1

2.1. Overview ...................................................................................... 2-1

2.2. Display and Keyboard ................................................................... 2-2

2.3. Data Input .................................................................................... 2-6

2.4. Main Display ................................................................................ 2-7

3 Configuration .............................................................................. 3-1

3.1. Enter Setup ................................................................................... 3-1

3.2. Exit Setup ..................................................................................... 3-2

3.3. Setup Menu .................................................................................. 3-2

3.4. Configuration Overview .................................................................. 3-3

3.5. Scale ........................................................................................... 3-4

3.6. Application ................................................................................. 3-24

3.7. Terminal .................................................................................... 3-33

3.8. Communication .......................................................................... 3-39

3.9. Maintenance .............................................................................. 3-49

4 Service and Maintenance ............................................................. 4-1

4.1. Terminal Cleaning and Maintenance ................................................ 4-1

4.2. Service ........................................................................................ 4-2

4.3. Error Messages ............................................................................. 4-2

4.4. System Information ....................................................................... 4-4

4.5. Firmware Upgrade ......................................................................... 4-5

Page 9

2

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

4.6. Backup and Restore Using InSite™ ................................................. 4-5

4.7. Troubleshooting ............................................................................ 4-5

4.8. Master Reset .............................................................................. 4-10

A. Parameter Values ........................................................................ A-1

B. Communication ........................................................................... B-1

B.1. Demand Output Mode.................................................................... B-1

B.2. Continuous Output Mode ................................................................ B-1

Contents

B.3. CTPZ ........................................................................................... B-3

B.4. Standard Interface Command Set (SICS) Protocol .............................. B-4

B.5. Reports ...................................................................................... B-13

B.6. Label Design and Printing ............................................................ B-15

C. GEO Codes .................................................................................. C-1

C.1. Original Site Calibration ................................................................. C-1

C.2. New Site GEO Code Adjustment ...................................................... C-1

Page 10

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

1-1

1 Introduction

1.1. IND256x Overview

The IND256x reflects the latest weighing technology from METTLER TOLEDO. The IND256x has

passed third-party certification for weighing in hazardous areas, and can be directly used in Zone

1/Zone 21 locations.

A high-performance single-range or multi-range weighing terminal, the IND256x uses analog load

cells to achieve reliable weighing at low cost, from grams to tons. It is easily integrated in an

existing weighing system.

By connecting the appropriate safety barrier or isolated barrier, the IND256x can provide various

intrinsically safe communication interfaces to communicate with PCs and printers in the safe area.

These features permit IND256x to support a majority of weighing applications in most industrial

fields, including:

• Pharmacy

• Powder processes

• Special chemicals

1.1.1. IND256x Terminal Version

The IND256x is available with three different power supply choices:

• AC power input, using external alternating voltage (187-250 V 50/60 Hz)

• DC power input, using external direct voltage (DC 18-30 V)

• Intrinsically safe power input, using an external Ex NiMH battery pack (64060627)

Each of these versions has received ATEX and IECEx approvals for use in Zone 1 and Zone 21

classified areas.

1.1.2. IND256x Product Features

• Basic weighing in hazardous areas, including zero, tare and print functions

• Harsh environment desk, column- or wall-mounted enclosure

• Connects to a single analog weighing platform

• 240 x 96 pixel white backlit LCD, 25mm high digits

• Petrochemicals

• Agriculture

• Paints and inks

• Fine chemical engineering

• Real-time clock (power-down save)

Page 11

1-2

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02| 11/2019

– Intrinsically safe 4-20 mA analog output

Enclosure

Dimensions h × w × d)

Transport weight

Protection grade

Storage environment

Service environment

• Includes one intrinsically safe serial port (COM1) for asynchronous two-way communication

and print output

• Support for the following internal option boards:

– WiFi communication module with antenna (only in IND256x terminals factory-

configured with WiFi module)

– Active current loop – for connection to an ACM200 communication module located

in the safe area, or to connect second IND256x terminal configured with passive

current loop option

Introduction

– Passive current loop (used as the second display to connect another terminal with

an active current loop)

• Supports three customized ID inputs

• Target table supports 25 pre-set targets for Checkweighing

• Tare table supports 20 pre-set tare values

• Supports g, kg, t, ton, lb and oz

• Saves 60,000 transaction data items

• Supports accumulation and accumulative total

• Permits the customization of five different print templates

• Supports weight-free calibration (CalFREE™)

1.2. Product Specification

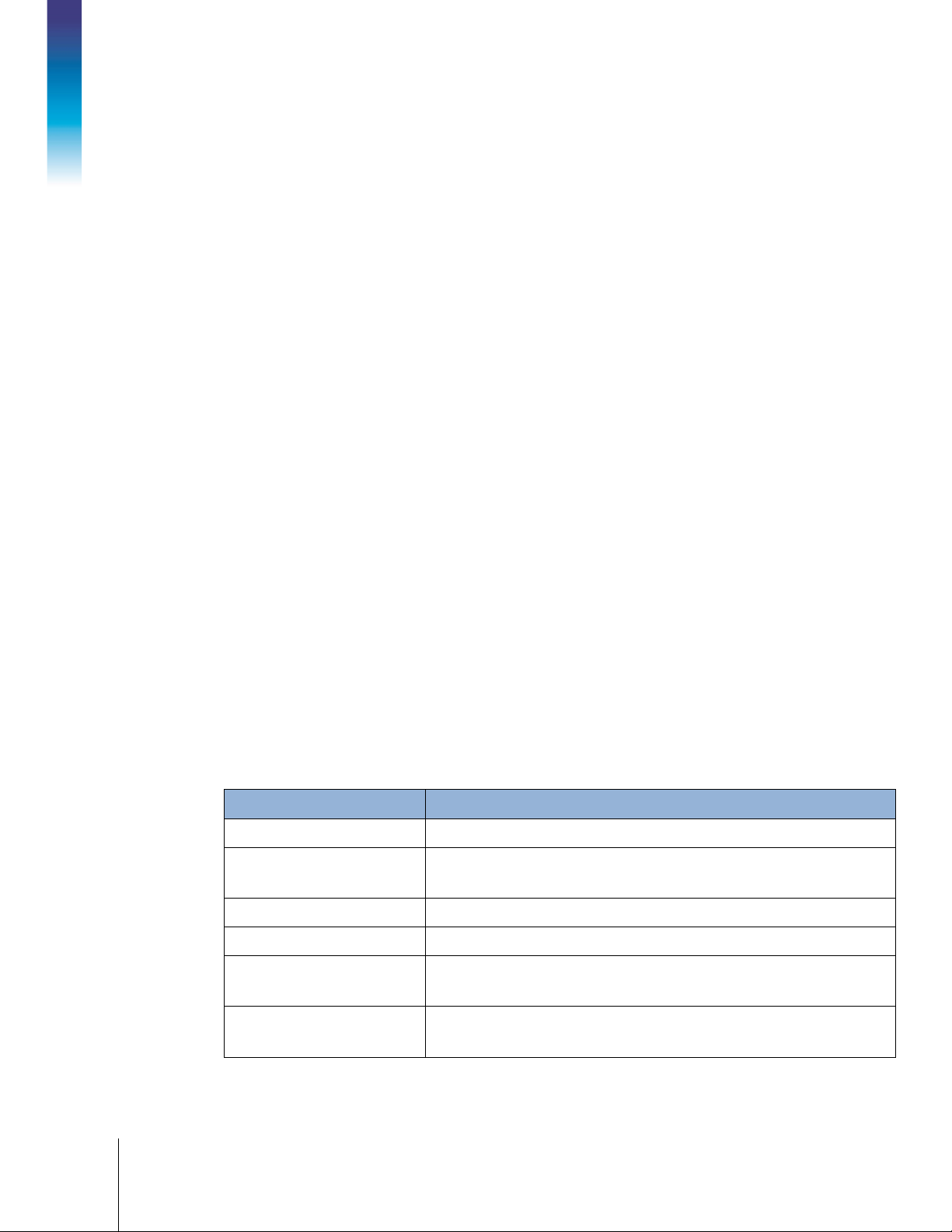

Table 1-1 shows the IND256x specifications.

Table 1-1: IND256x Specifications

Item Specification

304 stainless steel, can be wall- or pole-mounted

173 mm × 230 mm × 127 mm

(6.8 in. ×9.1 in. ×5.0 in.)

3.5 kg (8 lb)

IP66

Storage temperature range: –20°C to 60° C (–4° to 140°F)

Relative humidity: 10% to 95%, non-condensing

Operating temperature range: –10°C to 40° C (14° to 104°F)

Relative humidity: 10% to 95%, non-condensing

Page 12

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

1-3

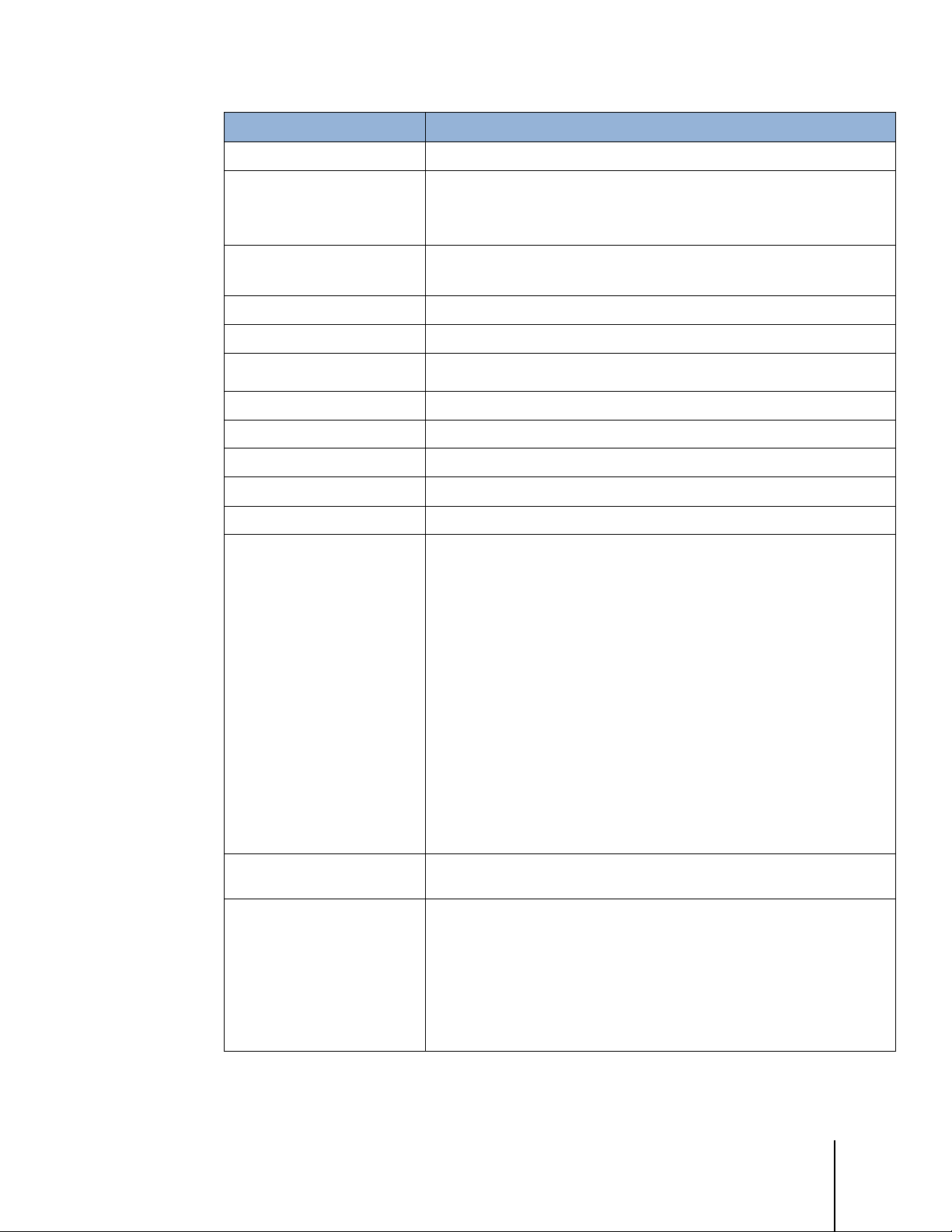

Item Specification

Hazardous area

Power supply

Display

Weight display

Weighing platform type

Sensor quantity

Maximum of four 350-ohm load cells (minimum 87 ohm), 2 mv/V or 3

mv/V

Weighing platform quantity

Refresh rate

Sensor excitation voltage

Minimum sensitivity

Keyboard

Communication mode

configurable templates), SICS command and report print

Metrological Approval

Europe: OIML R76; Class III, 6000e; TC10878

Hazardous Area Approval,

factory-configured WiFi version

Hazardous approval

IND256x is approved for use in Zone 1/Zone 21 hazardous areas

AC power (187-253V 50/60Hz)

DC power (CD 18-30 V)

External NiMH Ex battery pack (64060627)

240 x 96 pixel white backlit LCD, 25mm high digits

Display update rate: 10 Hz

Maximum 100,000 divisions

Analog load cell

Supports one weighing platform

>366 Hz

4.5 VDC

0.6µV/e

26 keys; 1.5mm thick membrane keyboard

Standard interface:

The mainboard is provided with an intrinsically safe RS232

communication interface

Interface options:

Intrinsically safe 4-20 mA analog output module, with16-bit D/A

conversion and 25 Hz update rate to PLC

or WiFi communication module (only in IND256x terminals factoryconfigured with WiFi module);

or Intrinsically safe active current loop

or Intrinsically safe passive current loop

Communication Protocols:

Serial port input: ASCII commands - CTPZ (Clear, Tare, Print, Zero), SICS

commands (supports SICS level 0 and level 1)

Serial port output: Toledo continuous output, command print output (5

Global: OIML R76; Class III, 6000e; R76-2006-A-NL1-18.27

with non-intrinsically safe power supply (AC version and DC version):

II 2G Ex eb ib [ib] mb IIB T4 Gb

II 2D Ex tb [ib] IIIC T60°C Db

with intrinsically safe battery:

II 2G Ex ib IIB T4 Gb

II 2D Ex tb [ib] IIIC T60°C Db

Page 13

1-4

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02| 11/2019

Hazardous Area Approval,

version without WiFi

Standard

Transmitting Power

RF Frequency Range

Encryption

WEP

WPA

Protocol

Work Mode

Transmitting distance

Approval

Item Specification

with non-intrinsically safe power supply (AC version and DC version):

II 2G Ex eb ib [ib] mb IIC T4 Gb

II 2D Ex tb [ib] IIIC T60°C Db

with intrinsically safe battery:

II 2G Ex ib IIC T4 Gb

II 2D Ex tb [ib] IIIC T60°C Db

Table 1-2: WiFi Module Specification (only for IND256x terminals factory-configured with WiFi module)

Item Specification

Introduction

1.3. Testing Standards

The IND256x terminal has been tested according to the following standards.

EN 60079-0:2012 + A11:2013 General requirements

EN 60079-7:2015 Increased safety "e"

802.11 b/g/n

14dBm (average)

2.4GHz – 2.497GHz

WEP, WPA

64 Bit, 128 Bit

WPA-TKIP, WPA2-AES

TCP/IP

Server, Client

Max 50 meters in the open air

China: SRRC

EN 60079-11:2012 Intrinsic safety "i"

EN 60079-18:2015 Encapsulation "m"

EN 60079-31:2014 Protection by Enclosure "t"

IEC 60079-0:2017, Ed. 7.0 General requirements

IEC 60079-7:2017, Ed. 5.1 Increased safety "e"

IEC 60079-11:2011, Ed. 6.0 Intrinsic safety "i"

IEC 60079-18:2017, Ed. 4.1 Encapsulation "m"

IEC 60079-31:2013, Ed .2.0 Protection by Enclosure "t"

FM3600 (2011) Electrical Equipment for Use In Hazardous (Classified) Locations -

General Requirements

Page 14

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

1-5

FM3610 (2010) Intrinsically Safe Apparatus and Associated Apparatus for Use in

FM3810 (2005) Electrical Equipment for Measurement, Control and Laboratory Use

ANSI/IEC 60529 Degrees of Protection Provided by Enclosure(IP Code)

CSA C22.2 No. 157-1992 / 2006 Intrinsically safe and non-Incentive equipment for use in hazardous

CSA C22.2 No. 142-1990 / 2004 Process control equipment

CSA C22.2 No. 61010.1-2004 Safety requirements for electrical equipment for measurement,

CAN/CSA 22.2 No. 60529-2005 Degrees of Protection Provided by Enclosure (IP Code)

1.3.1. Special Conditions for Safe Use

1. The apparatus must be protected from UV-light

2. Electrostatic charging during operation and maintenance has to be excluded. The terminal shall

only be installed in areas where operational and process related electrostatic charges are not

present.

Class I, II & III, Division 1, Hazardous (Classified) Locations

locations

control, and laboratory use – Part 1: General requirements

3. For versions with non-intrinsically safe DC-supply (type key ends with “44” or “46”): There is

no galvanic separation between non-intrinsically safe supply circuit and intrinsically safe output

circuits:

The non-intrinsically safe supply circuit has to be safely connected to earth. In this case, the intrinsically

safe circuits are earthed as well. Along the intrinsically safe circuits, potential equalization must exist.

or

The non-intrinsically safe circuit has to be safely separated from earth (e.g. SELV-circuit).

4. For DC version terminal, the supply circuit shall have at a maximum overvoltage category II

according to IEC 60664-1.

5. The cable glands Series HSK-M-Ex… and V-Ms-Ex… according to KEMA 99 ATEX 6971X resp.

IECEx BVS 07.0014X are tested with a reduced tensile force (25%) in accordance with clause

A.3.1 if IEC 60079-0 and may only be used for fixed installation of group II apparatus. The

user shall ensure adequate clamping of the cable.

6. The WiFi antenna is tested for low risk of mechanical danger (impact height 0.4m with 1kg

mass) and shall be protected against high impact energy levels.

Page 15

1-6

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02| 11/2019

1.4. Warnings and Precautions

Please read these instructions carefully before putting the new terminal into operation.

Although the IND256x is ruggedly constructed, it is nevertheless a precision instrument. Use care in

handling and installing the terminal.

WARNING

DO NOT INSTALL OR PERFORM ANY SERVICE ON THIS EQUIPMENT BEFORE THE AREA HAS

BEEN SECURED AS NON-HAZARDOUS BY PERSONNEL AUTHORIZED TO DO SO BY THE

Introduction

RESPONSIBLE PERSON AT THE CUSTOMER’S SITE.

WARNING

ONLY THE COMPONENTS SPECIFIED IN THIS MANUAL CAN BE USED IN THIS TERMINAL. ALL

EQUIPMENT MUST BE INSTALLED IN ACCORDANCE WITH THE INSTALLATION INSTRUCTIONS

DETAILED IN THIS MANUAL. INCORRECT OR SUBSTITUTE COMPONENTS AND/OR DEVIATION

FROM THESE INSTRUCTIONS CAN IMPAIR THE INTRINSIC SAFETY OF THE TERMINAL AND

COULD RESULT IN BODILY INJURY AND/OR PROPERTY DAMAGE.

WARNING

DO NOT OPEN WHEN ENERGIZED.

WARNING

POTENTIAL ELECTROSTATIC CHARGING HAZARD- SEE INSTRUCTIONS.

WARNING

DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT.

WARNING

THE TERMINAL ASSEMBLED WITH WIFI ANTENNA SHALL BE INSTALLED IN A POSITION IN

SUCH A WAY THAT THE RISK FOR MECHANICAL DAMAGE IS LOW. REPLACE THE WIFI

ANTENNA IMMEDIATELY IF DAMAGED!

1.5. Inspection and Contents Checklist

On receipt of IND256x , check that the packaging is intact. If the box is damaged, check whether

IND256x is damaged and, if necessary, lodge a freight claim with the carrier. If the packaging is

not damaged, unpack the IND256x, paying attention to its original packaging, and check that

nothing is damaged.

To ensure safe transport, it is best to use the original packaging and the correct packaging

method.

Page 16

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

1-7

The packaging box contains:

•

•

• Bag of accessories for use during installation

IND256x weighing terminal

1.6. Configuration

1.6.1. System Configuration

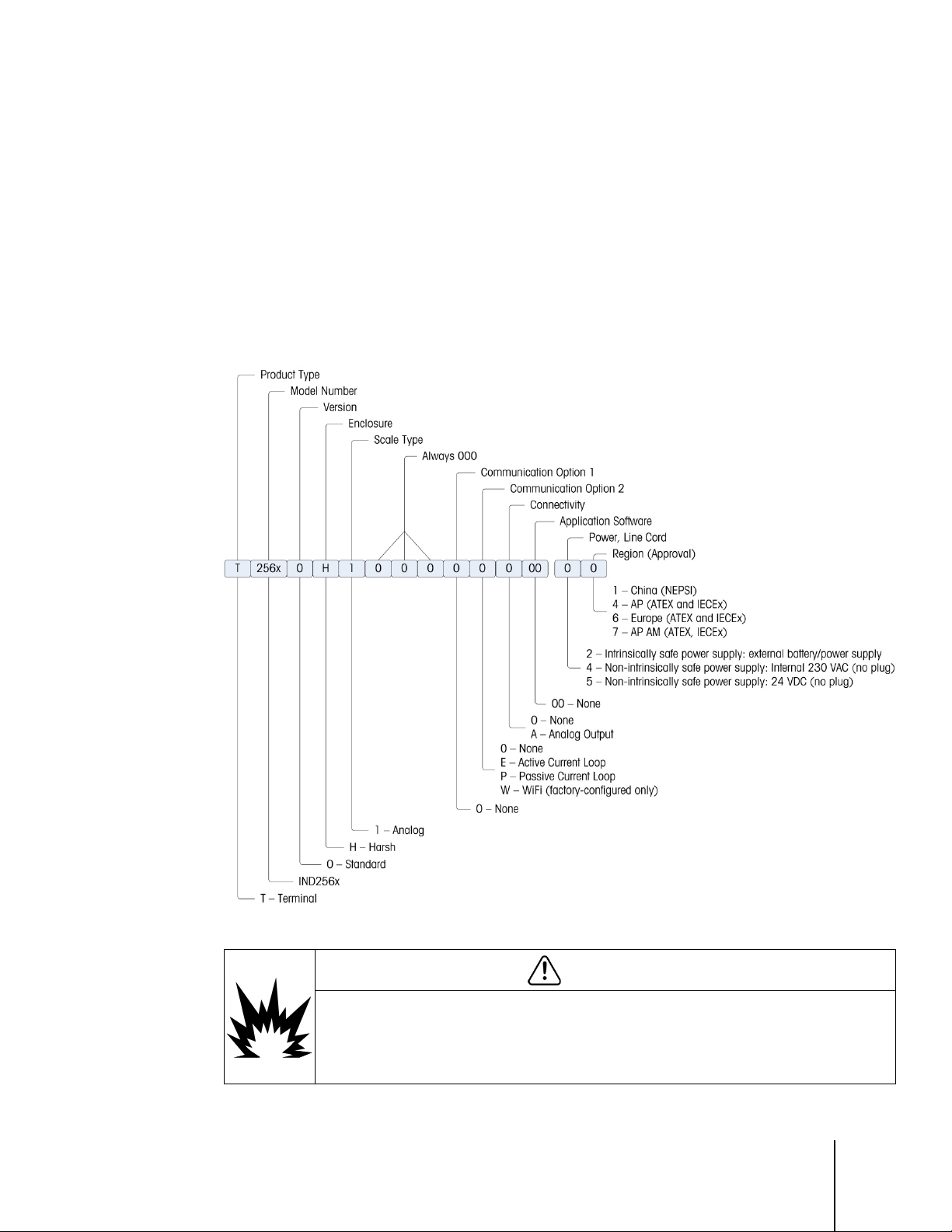

Figure 1-1 shows the configuration options for the terminal.

Documentation CD (including manual and certificate of inspection)

Figure 1-1: IND256x Configuration Chart

WARNING

IND256x TERMINALS FACTORY-CONFIGURED WITH WIFI ARE APPROVED FOR USE IN ZONE 1

EQUIPMENT GROUP IIB CLASSIFIED AREAS. IND256x TERMINALS FACTORY-CONFIGURED WITH

WIFI MUST NOT BE USED IN EQUIPMENT GROUP IIC CLASSIFIED AREA. USING THE IND256X

TERMINAL FACTORY-CONFIGURED WITH WIFI IN A CLASSIFIED AREA FOR WHICH IT IS NOT

APPROVED COULD RESULT IN BODILY HARM AND/OR PROPERTY DAMAGE.

Page 17

1-8

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02| 11/2019

Power input

AC power supply 220V (187-250V 50/60Hz) input (ATEX & IECEx version)

COM1 (standard)

intrinsically safe RS232

COM2 (optional)

intrinsically safe analog 4-20mA output or Wi-Fi communication module

NOTICE

WiFi CAPABILITY IS ONLY AVAILABLE IN IND256x TERMINALS SO CONFIGURED AT THE FACTORY.

1.6.2. Product Date Code

The manufacturing date or the date code for the terminal can be found on the serial data plate (on

the top of the enclosure).

The serial number will begin with a letter and a number (for example B212000371). The letter

represents the first three digits of the year per the date code chart in Table 1-3 (the letter “B” in our

Introduction

example represents “201x”) and the number is the unit’s digit of the year (the number “2” in our

example). So, “B4” decodes to the year 2014.

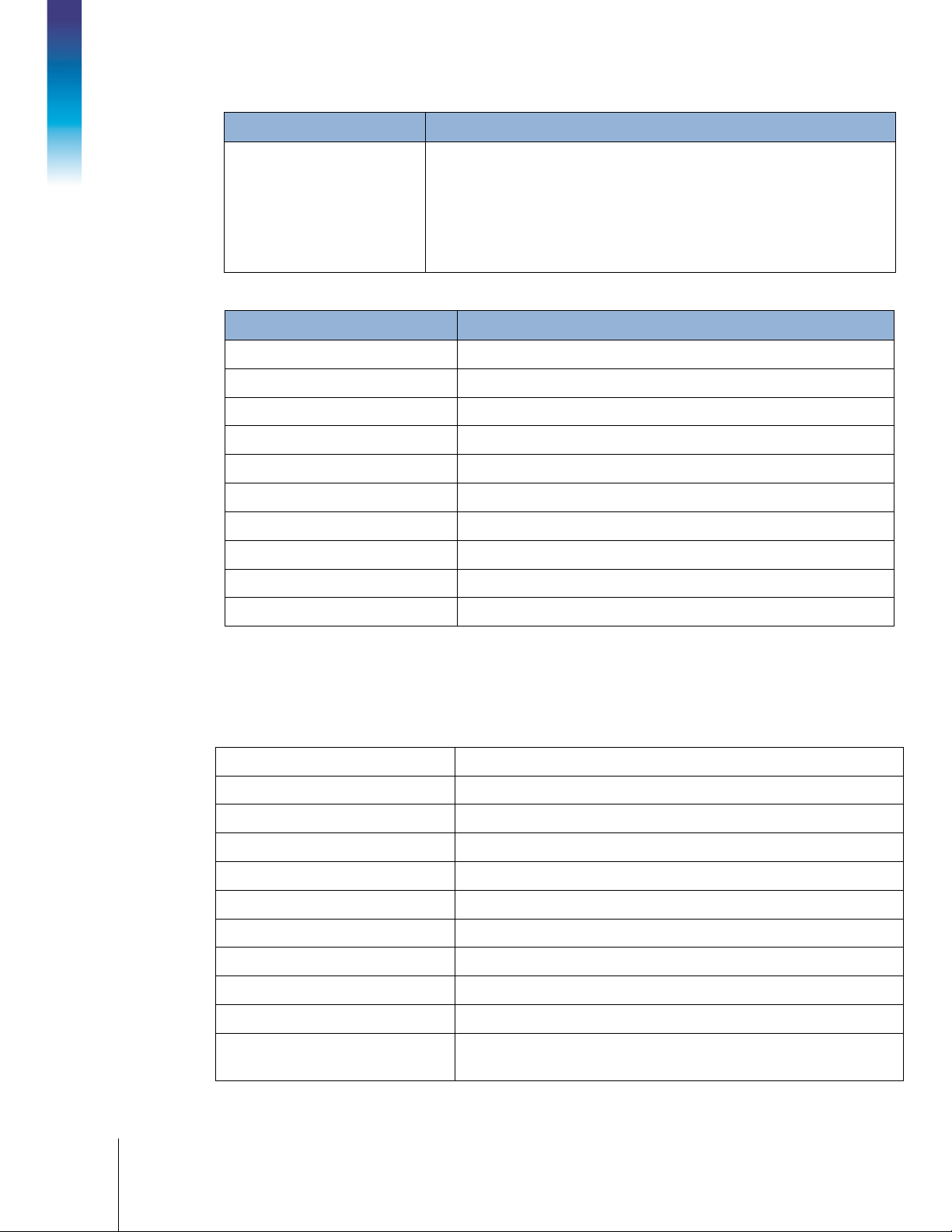

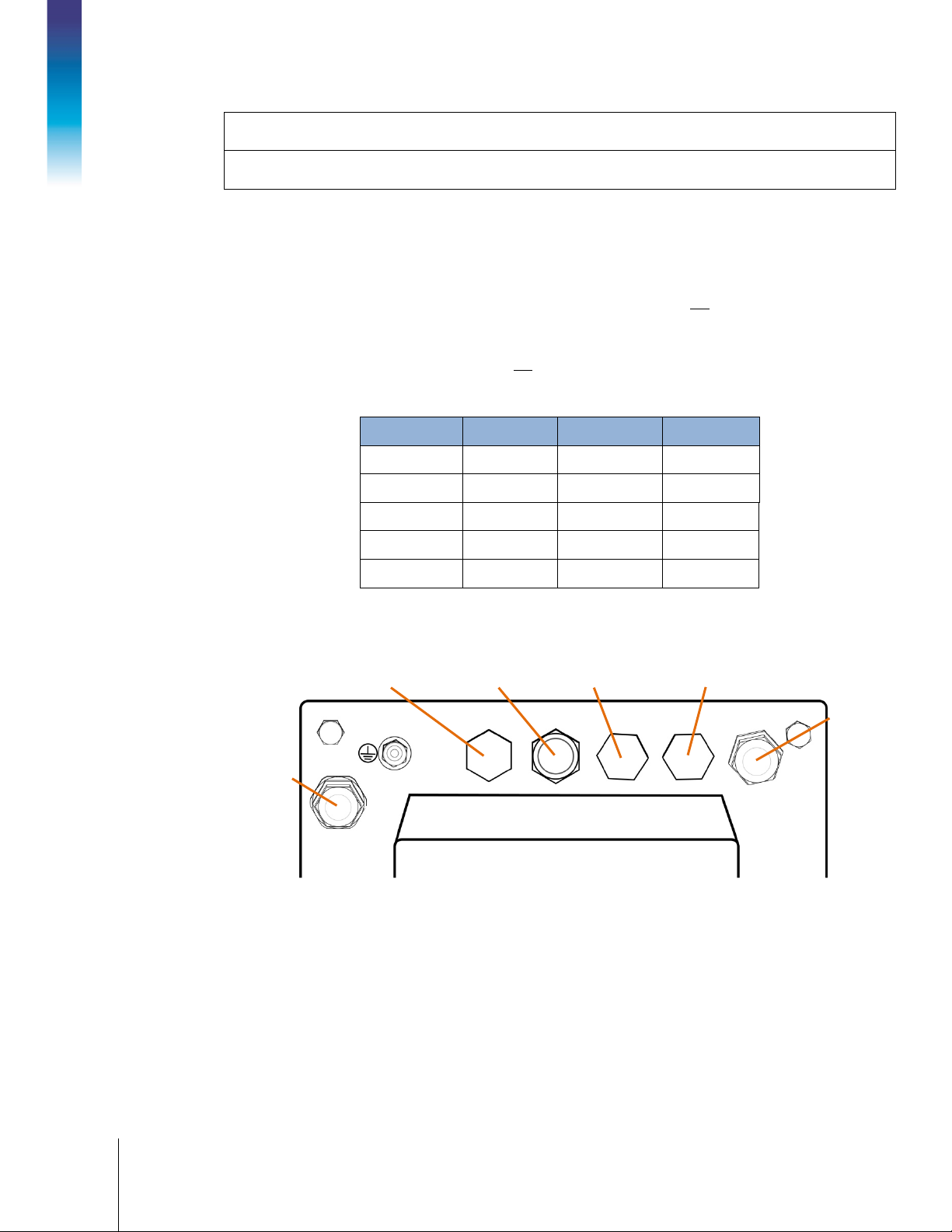

Table 1-3: Current and Later Date Code Formats

Date Code Year Date Code Year

A 200x F 205x

B 201x G 206x

C 202x H 207x

1.6.3. Connections

The following figure shows the connection locations on the back of the harsh enclosure.

COM3, optional COM2, optional COM, Reserved COM1, standard

Power input

D 203x J 208x

E 204x K 209x

Figure 1-2: IND256x Connection Port Locations

or

DC power supply 24V(18V-30V) input (ATEX & IECEx version)

or

external Ex battery

Weighing

platform

(factory-configured only)

Page 18

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

1-9

COM3 (optional)

intrinsically safe active current loop

COM Reserved

Not used

1.6.4. Warnings

1.6.4.1. CENELEC

Connection of EB per Country-Specific Regulations: It must be ensured that the housings of all

devices are connected to the same potential via the EB terminals. No circulating current may flow

via the shielding of the intrinsically safe cables.

1.6.4.2. cFMus

Connection of EB per ANSI/NFPA 70, Article 504, and ANSI/IA RP 12.06.01 or Canadian Electric

Code C22.2: It must be ensured that the housings of all devices are connected to the same

potential via the EB terminals. No circulating current may flow via the shielding of the intrinsically

safe cables.

or

intrinsically safe passive current loop

1.7. Equipotential Bonding (EB)

Equipotential bonding must be installed by an electrician authorized by the owner. METTLER

TOLEDO Service performs only a monitoring and consulting function for this procedure.

Connect equipotential bonding of all devices (power supply unit, weighing terminal, interface

converter and weighing platform) in accordance with the terminal diagram and all country-specific

regulations and standards. In the process, it must ensure that:

• All device housings are connected to the same potential via the EB terminals.

• No circulating current flows via the cable shielding for intrinsically safe circuits.

• The neutral point for equipotential bonding is as close to the weighing system as possible.

1.8. Operating Environment

When selecting a location:

• Choose a stable, vibration-free surface to mount the terminal

• Ensure there are no excessive fluctuations in temperature and there is

sunlight

no direct exposure to

1.8.1.1. Temperature and Humidity

• Avoid drafts on the weighing platform (for example, from open windows or air conditioning)

• Calibrate the terminal after any major change of geographical location

The IND256x can be stored and operated at temperatures and relative humidity conditions as listed

in Table 1-1.

Page 19

1-10

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02| 11/2019

1.8.1.2. Environmental Protection

The IND256x terminal has environmental protection as listed in Table 1-1.

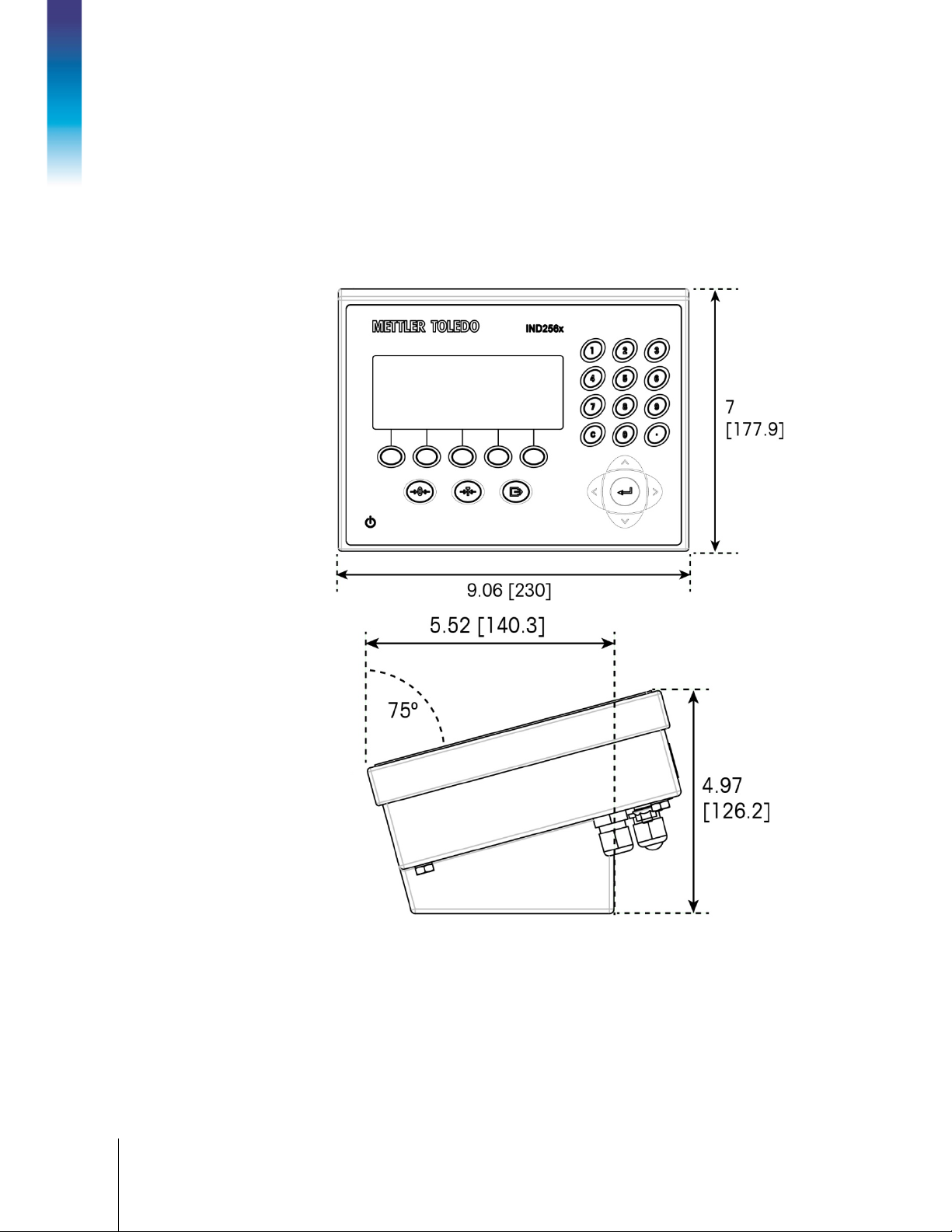

1.9. Dimensions

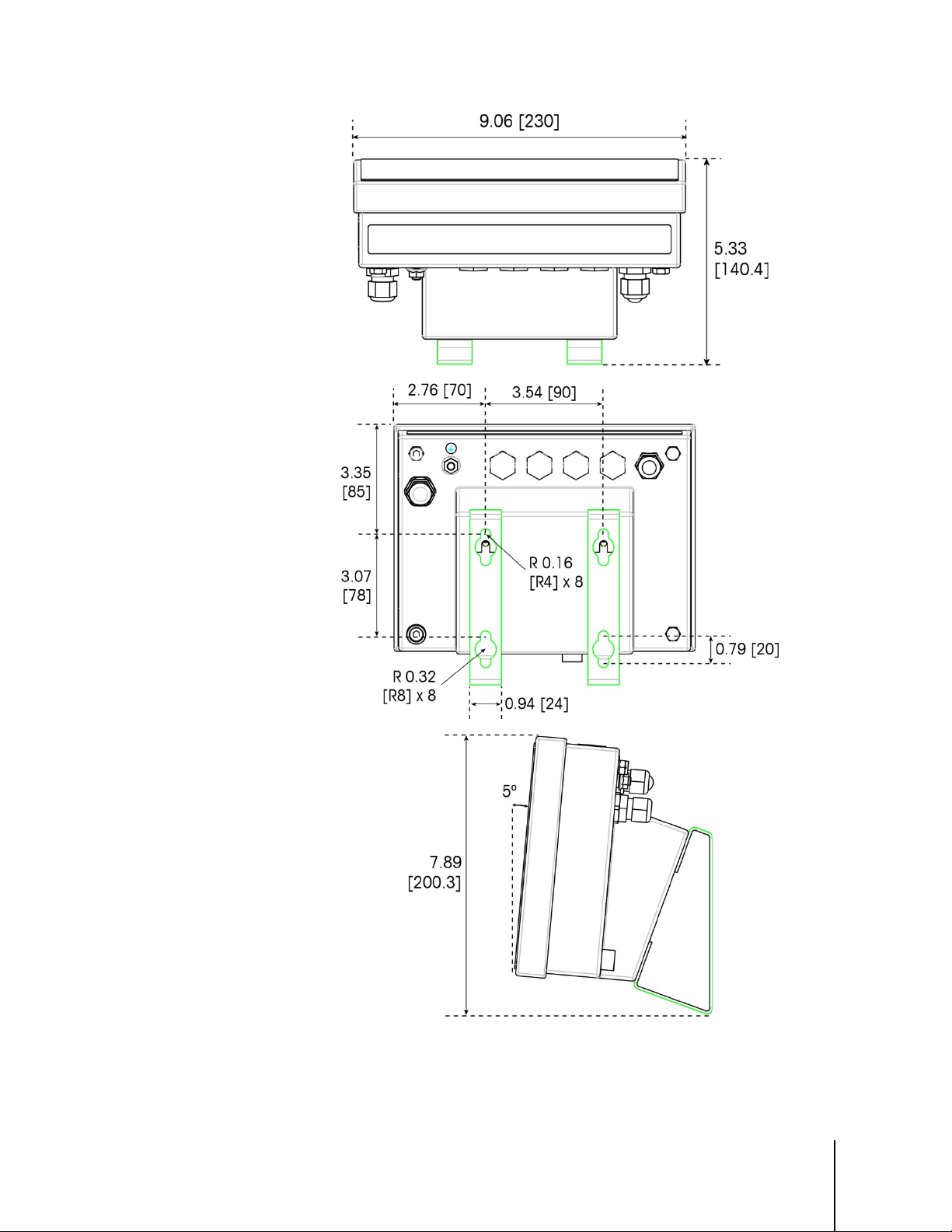

Figure 1-3 and Figure 1-4 show the terminal’s dimensions. Units are inches and [mm].

Introduction

Figure 1-3: IND256x Dimensions, Desktop Installation

Page 20

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

1-11

Figure 1-4: IND256x Dimensions, with Fixed Wall-Mount Bracket

Page 21

1-12

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02| 11/2019

1.10. Main Board

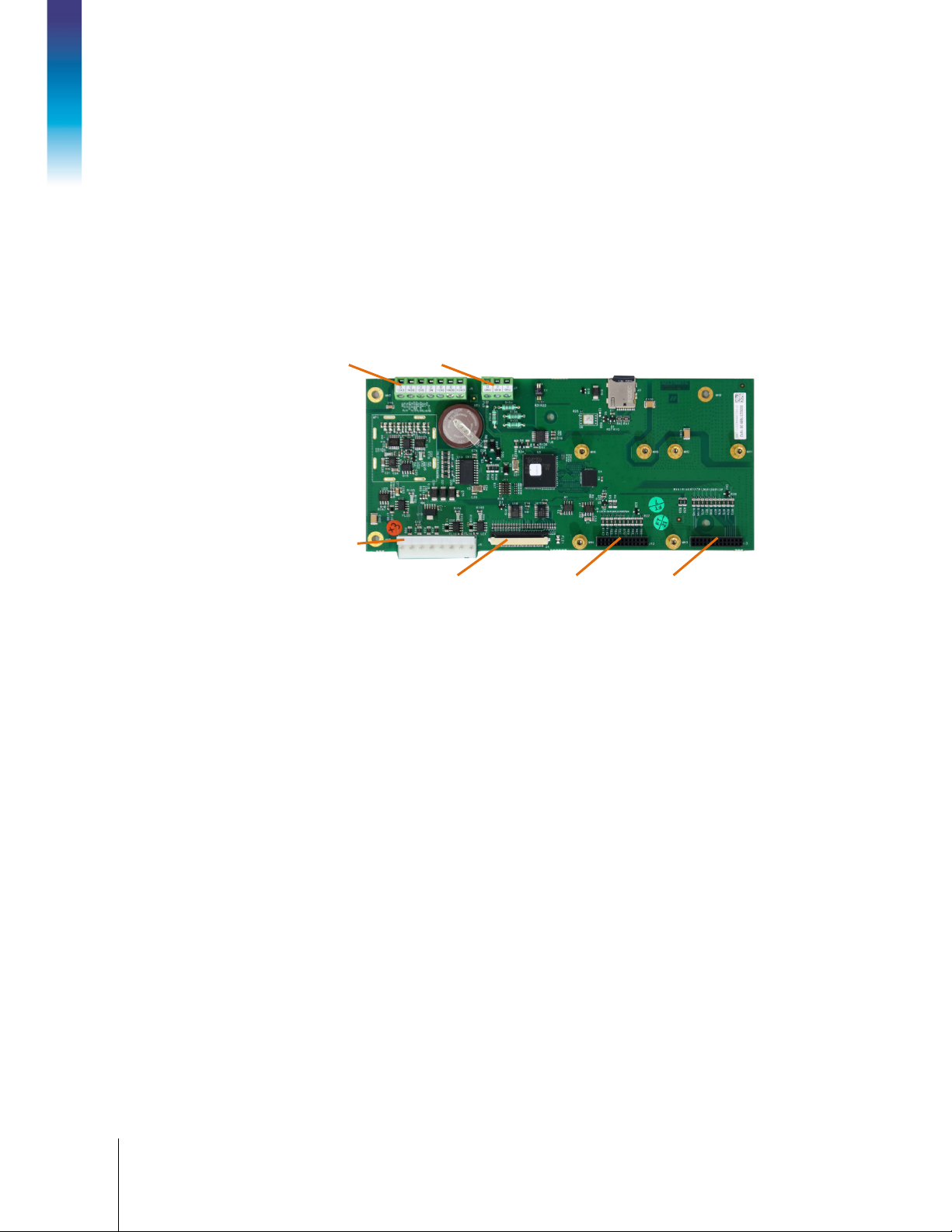

The IND256x main board has the following main connections, indicated in Figure 1-5:

1. Analog load cell weighing interface

2. Intrinsically safe power input interface, connecting the power module

3. Flat ribbon harness interface, used to connect the display

4. Intrinsically safe RS232 interface (COM1)

5. Two communication option board interfaces (COM2 and COM3)

Introduction

1

4

2

3 5: COM2 5: COM3

Figure 1-5: IND256x Main Board

1.11. Communication Option Boards

The IND256x can be configured with a maximum of two of the three communication option boards

installed inside its enclosure. The options are:

• WiFi communication module (available only in IND256x terminals factory-configured with

WiFi)

• Intrinsically safe 3-20 mA analog output

• Active current loop for connection to communication module ACM200 located in the safe area,

or to connect second IND256x terminal configured with passive current loop option

• Passive current loop (used as the second display to connect another IND256x with active

current loop)

Page 22

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

2-1

2 Operation

2.1. Overview

This chapter provides the navigation, basic features and functions of the IND256x terminal.

IND256x functions can be configured through the setup menu – refer to Chapter 3,

The specific operation of each IND256x terminal depends on the options installed, the functions

allowed in the setup menu, and the parameters configured.

2.1.1. User Security: Overview

Access to the terminal’s functions can be restricted according to the site’s security policies.

Restrictions may reflect legal and regulatory requirements, or site-specific standards.

The IND256x uses a password security mechanism to protect the setup menu. The password

function is off by default and can be enabled in setup.

Once set, the password must be kept safely. If the password is changed or forgotten, the setup

menu and some terminal functions will not be accessible. To recover access and functions, a

master reset must be performed, which will reset all user names and passwords and delete any

custom configuration.

Configuration.

2.1.2. Metrology Switch

The location of the metrology switch (S1-1) on the mainboard is indicated in Figure 2-1, and its

setting positions are shown in Figure 2-2. This switch is off by default; if it is

pressed), the terminal is sealed and users will not able to modify metrologically relevant setup

parameters.

on (the switch is

SW1-1 SW1-2

Figure 2-1: IND256x Metrology Switch Location

Page 23

2-2

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

S1-1 Off

S1-1 On

Scale function keys

Numeric keypad

ENTER and navigation

Power button

System info line

Main display

Softkey icons

Softkey buttons

Tare display

Battery status indication

WiFi status indicator

Operation

2.2. Display and Keyboard

The IND256x has an LCD with white backlight, with a display screen resolution of 240 x 96 pixels.

Figure 2-3 shows the main elements of the terminal interface.

Figure 2-3: IND256x keyboard and display

Figure 2-2: Metrology Switch S1 Settings

keys

The system line displays system messages, battery and WiFi status indictors, and any

asynchronous error information; the middle area includes the application related weight, tare and

SmartTrac display, as well as entered values such as target ID and other information; and the

softkey icons are displayed at the bottom. To the right of the softkeys, an arrow indicates when

more rows of keys are available. These are accessed by using the navigation keys to scroll up ( )

or down ( ). Up to fifteen softkeys can be assigned in three rows. Softkey selection and position

are configured in setup.

Three scale function keys – zero, tare and print –appear below the softkeys. At right, 12 numeric

keys are used to enter data and commands. These keys include a clear key and a decimal point

key.

The ENTER key and four navigation keys are located below the numeric keys. These are used for

navigation and data entry during operation and in setup.

Page 24

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

2-3

An ON/OFF key is located in the left lower part of the front panel.

2.2.1. Navigation Keys

The navigation keys (as shown in Figure 2-3) are used to browse the menu tree and set and apply

the window.

2.2.1.1. Up and Down Navigation Keys

These keys move the current cursor up and down to different settings in the menu tree (selected part

will be highlighted), move to different fields in the setting page to switch to another page of

available softkeys When the scroll bar indicates that there are two or three pages for configuration

fields related to specific parameters, up and down navigation keys are also used to move to next

page or previous page. The example in Figure 2-4 displays configuration parameter and it requires

two pages to display all relevant configuration fields. The scroll bar indication displays the specific

page in the two pages.

Scroll bar indicating

first page

Figure 2-4: Scroll Bar Example, Indicating Configuration Fields on Two Pages

Press the DOWN navigation key to move from Page 1 to Page 2. Press the UP navigation key to

move from Page 2 to Page 1.

2.2.1.2. Left and Right Navigation Keys

The left and right navigation keys are used to:

• Move into or out of levels in the menu tree

• Move within an editable field during data entry

• Allow left- and right-scrolling to the left and right, to view all available information in the

window

2.2.1.3. Enter Key

The ENTER key is used to:

• Open a setup page to view parameters, and enter the parameter’s configuration field in

order to modify or select its value

Scroll bar indicating

second page

Page 25

2-4

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

• Confirm the set value in the menu

• Accept the new value entered in the field and move the focus to next field label

2.2.2. Softkeys and Icons

There are five softkey buttons (indicated in Figure 2-3) along the bottom of the display window.

These correspond to the softkey icons displayed on-screen immediately above each key. Five

softkey icons can be displayed simultaneously, with a maximum of 15 overall, divided into three

separate rows. The down and up symbols to the right of the icons indicate the availability of more

rows; use the UP and DOWN navigation keys to display additional rows.

Operation

Softkey configuration and customization is detailed in Chapter 4,

Configuration.

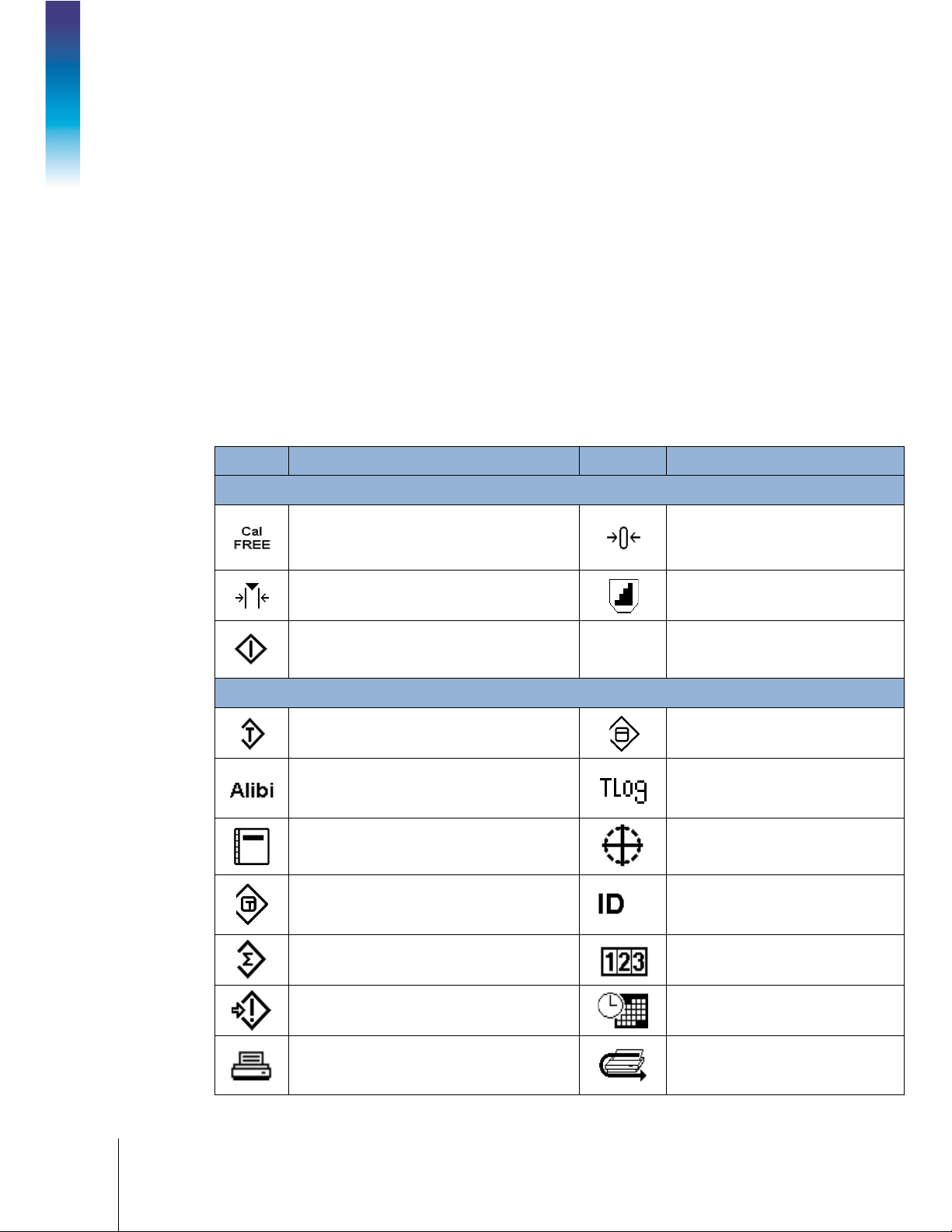

The softkey and application displays are identified by icons. Table 2-1 lists these icons and their

functions and classifies them according to their use in HMI.

Table 2-1: Softkey Icons and Functions

Icon Function Icon Function

Scale Calibration Icons

CalFree

Span calibration

Start calibration test

Tare Memory (access the tare table)

Table, Memory and Function access

Zero calibration

Step calibration

Target Value View (access the

target value table)

Alibi Memory

Report (set printing of Alibi memory,

transaction log, tare and target table)

Tare Value view

Totals Report

Enter setup menu

Print

Transaction log

Target Value

ID (customized information, ID1,

ID2 and ID3 available)

Transaction Counter

Date/Time setting

Repeat Print

Page 26

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

2-5

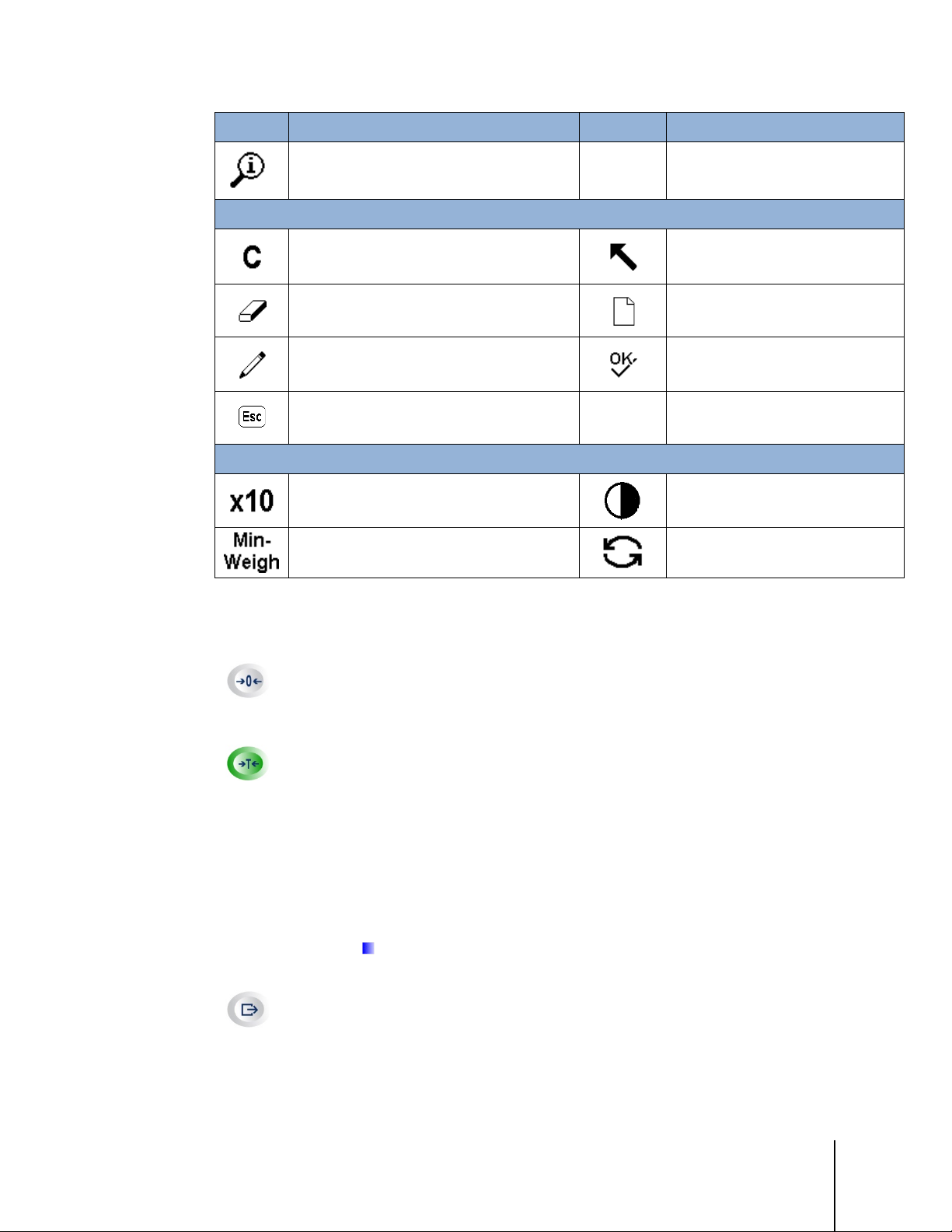

Icon Function Icon Function

ZERO

TARE

PRINT

Printing

View System Information

Edit

Clear All

Delete

Edit

Cancel (exit without saving)

Expand displayed resolution by 10

Minimum Weight function

2.2.3. Scale Function Keys

The scale function keys in Figure 3-2 are:

When the weighing platform is empty, the terminal displays 0 kg. Gross weight zero

reference is recorded during calibration. If pushbutton zero is allowed in the

configuration and the weight is within the zero range, the zero function key may be

pressed to capture a new gross weight zero reference point.

Display Icons

Exit (return to previous window)

New

Confirm input or transaction

Contrast Control

Unit switch – change units

Tare refers to the weight of an empty container. It is generally used to determine the

net weight of the container’s contents. Press the tare function key when an empty

container is placed on the weighing platform to display a net weight of zero. When

material is added to the container, the terminal displays their net weight.

When the empty weight of the container is known, the tare may be entered using the

numeric keypad and pressing the tare function key to store the value. The terminal will

display the net weight of the materials in the container. The keyboard tare must be

allowed, so that this method can be used for key tare operation. If the auxiliary tare

display is allowed, the tare value and tare type will be displayed in the bottom left of

the screen.

Pushbutton tare must be enabled in setup in order to use either of these methods

for tare operation.

Press the print function key to initiate a demand output of data in the print template

configured in setup. A serial or WiFi print connection must be configured to connect

the template to the selected serial or WiFi port. When a print command is issued, they

system line displays

for 3 seconds.

Page 27

2-6

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

CLEAR

In net weight mode, press the clear function key to clear the current tare value. The

Operation

2.2.4. Numeric Keypad

display will return to gross mode. Clear can be operated regardless of whether there is

motion on the platform. Please note that once the tare value has been cleared, it can

no longer be read back. It is necessary to re-execute the tare process described

above.

During numeric input using the keypad, the clear function is similar to a backspace

key. Use the right arrow key to place the cursor at the end of the data to be deleted

and press the clear key. A character is deleted by each press of the clear key. When

the data input box is entered for the first time, the previous input will be selected; in

this case, press clear to delete the existing value.

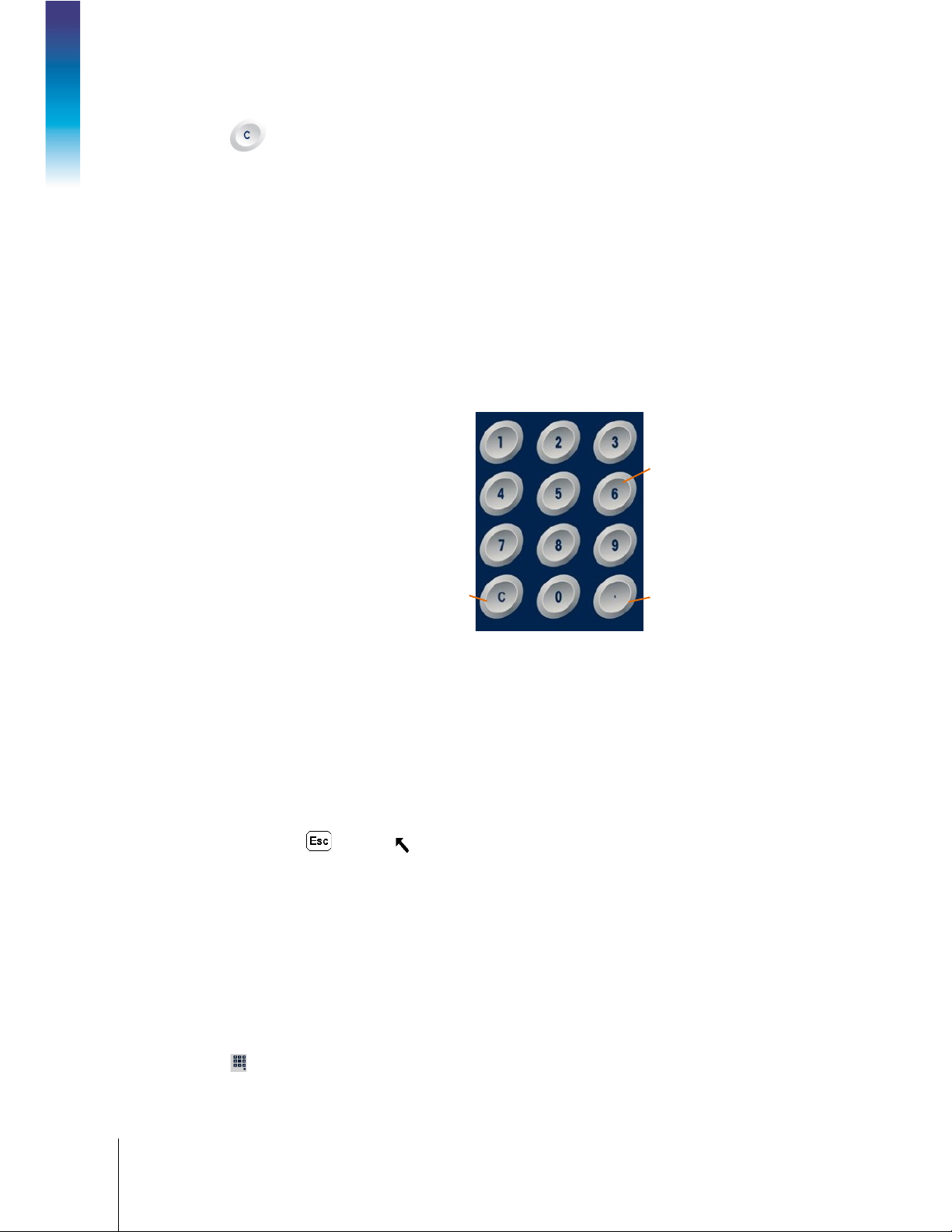

When data input is required, use the 12-key numeric keyboard (shown in Figure 2-5) to enter the

numbers.

Numeric key

Locate the cursor in the field as described in section 2.2.1, above) and press the numeric key to

enter the appropriate data. When necessary, press the decimal point key to enter a decimal point.

During data input, the clear key function functions like a backspace key. Locate the cursor at the

end of the data to be deleted and press C. One character is deleted by each press of the clear key.

When a data input field is selected for the first time, the whole data string is selected state. Press

clear to delete the existing input.

The Escape and Exit keys exit the data input process and abandon any newly-entered data.

Data that was in the field before the entry process began will be retained.

Once the required letter, number and character are entered in the proper field of the window, press

Enter to accept the input.

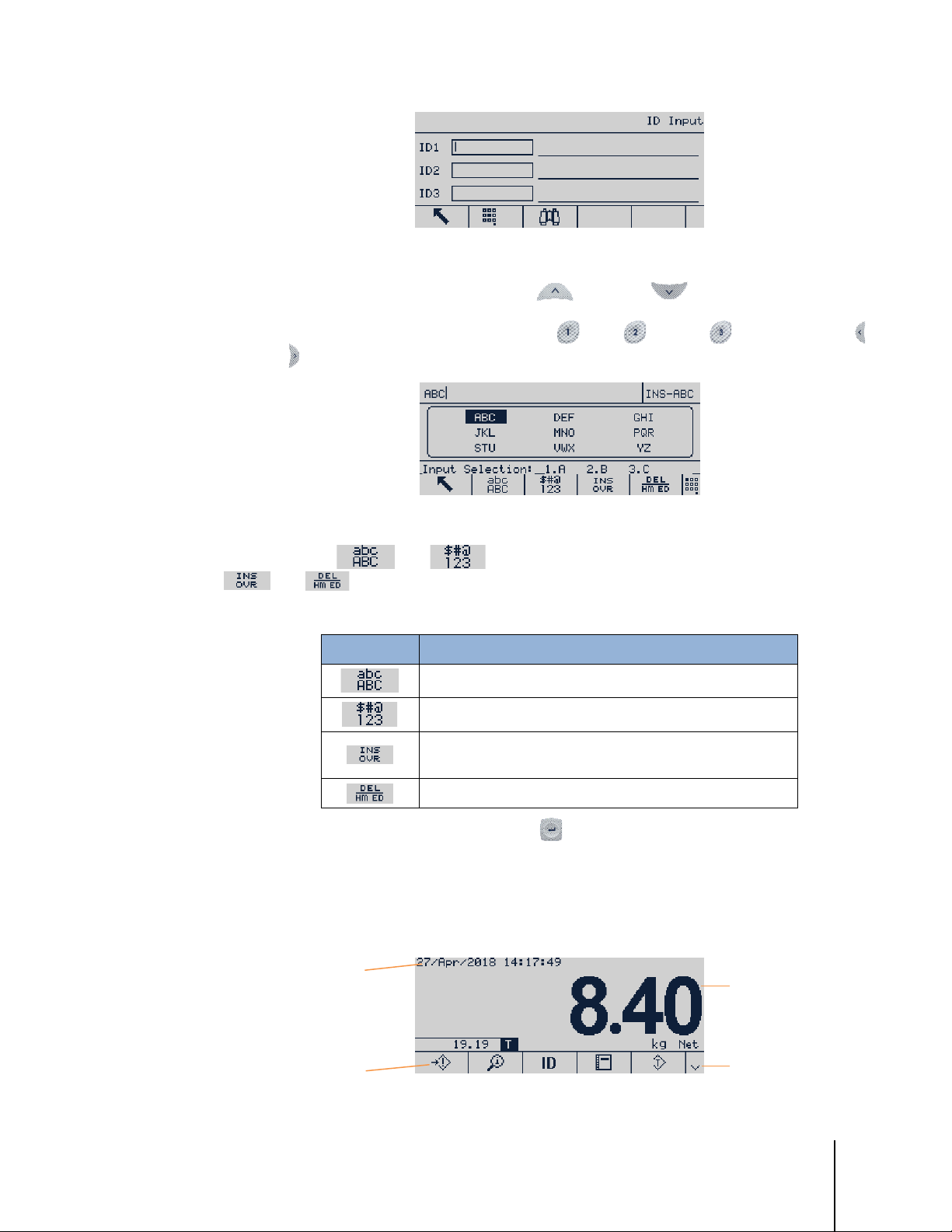

2.3. Data Input

The standard keypad only supports the entry of numeric characters; however, alphabetic entry is

supported for specific functions, such as the ID table shown in Figure 2-6. When the keypad softkey

( ) is displayed, pressing it opens the alpha character entry screen. INS-ABC will appear at upper

right, to indicate the entry mode.

Clear key

Figure 2-5: Numeric keyboard layout

Decimal point and

symbols key

Page 28

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

2-7

Figure 2-6: ID Input Display

System line

Softkey icons

Weight and

application area

More down symbol

indicate more soft

choices

Once in alphanumeric entry mode, use the up

and down

keys to select different

character blocks. Once the correct block is selected, use the numeric keys to select the character for

input. In the example shown in Figure 2-7, press for A, for B, or for C. Use the left

and right navigation keys to move the position of the selection in the array of character options.

Figure 2-7: Alphanumeric Input Screen

Use the softkeys

and

Softkey Function

and

to select alternative input modes. A further two softkeys

, select and delete the character next to the cursor, respectively.

Table 2-2: Softkey Function

Lower or upper case letters

Symbols or numbers

Select the character next to the cursor; the next character

entry will overwrite the selected character.

2.4. Main Display

Delete the character next to the cursor

When the data entry is complete, press ENTER to confirm.

Figure 2-8 shows the main display.

Figure 2-8: Main Display

key

Page 29

2-8

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

No WiFi Connection

WiFi Connected

The appearance of the display will vary according to the terminal configuration, but it can contain:

System Line

Weight and

Application Area

Softkey Icons

2.4.1. WiFi Status Indication

Operation

The WiFi status indicator shows when a WiFi connection exists, and displays bars to indicate

signal strength.

Displays system information and status, such as date/time, error message,

indication of WiFi connection

Displays the weight, unit, tare and specific weighing data of other applications

Displays the icons of currently available softkey functions. If the More Down and

More Up symbol is displayed at right, further softkeys are available in additional

rows.

Figure 2-9: WiFi Status Indicator

Page 30

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-1

3 Configuration

This chapter provides information about configuring the IND256x from the setup menus.

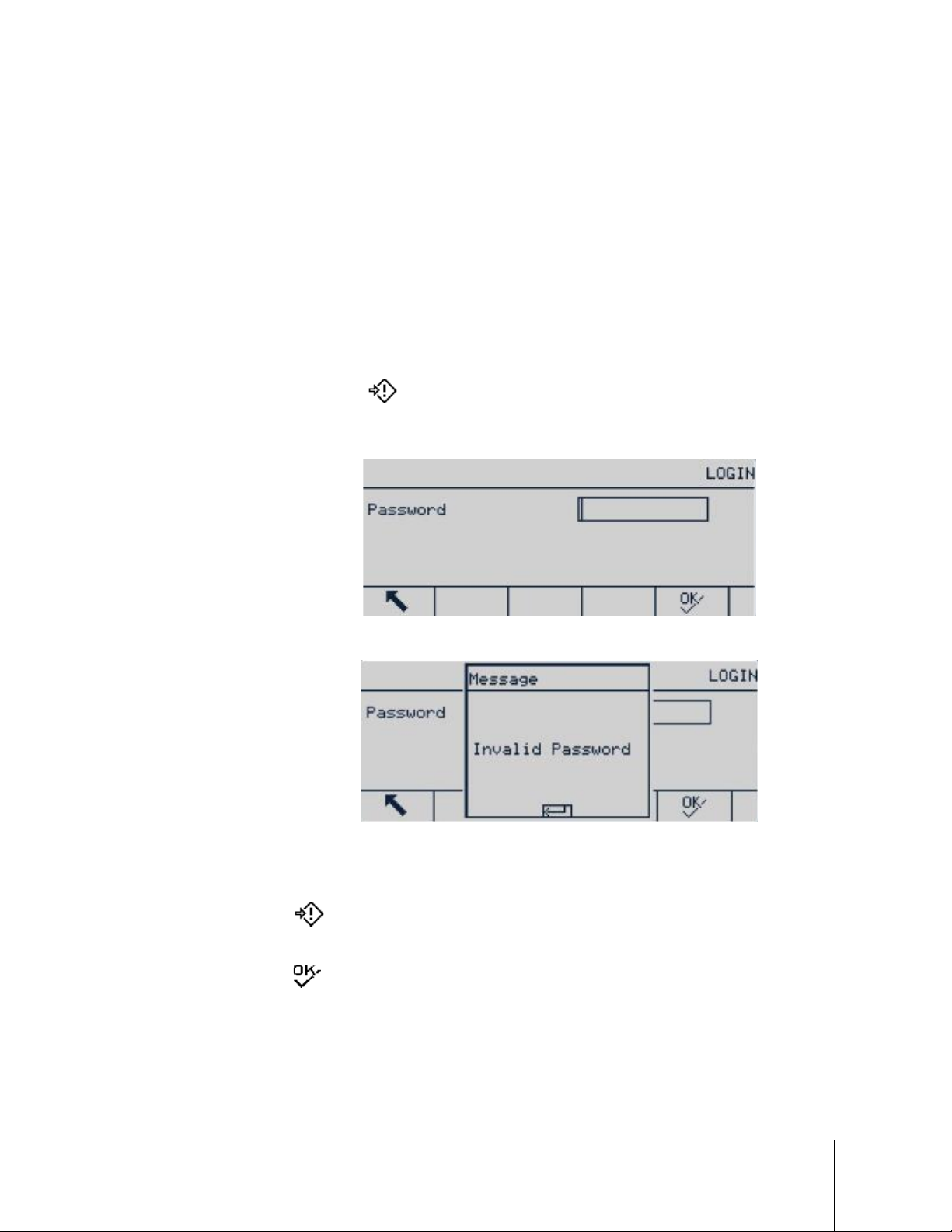

3.1. Enter Setup

Click the SETUP icon

set, a login screen appears. In this case, the setup menu may be entered only by entering a correct

user name and password.

to enter the terminal’s setup menu. If the user name and password are

Figure 3-1: Login Screen

Figure 3-2: Password Error Message

3.1.1. Enter Password

1. Press

2. Enter the numeric password.

3. Press

incorrect, an error prompt will be displayed. Press ENTER to directly exit to the weighing

interface.

to display the password input box.

key. If the password is correct, the setup menu tree will appear; if the password is

Page 31

3-2

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

Parameter label,

highlighted

Parameter value

3.2. Exit Setup

Press Exit

3.3. Setup Menu

The setup menu of IND256x is shown in Figure 3-3.

Configuration

Use the UP, DOWN, LEFT and RIGHT navigation keys to select item. The selected menu item

appears in a reverse highlight. When the desired item is selected, press OK to enter the submenu.

3.3.1. Setup Screens

The setup screens are used to view, enter or modify setup parameters.

to exit to the main menu.

Figure 3-3: Setup Menu

3.3.1.1. Selecting Parameters

Use the UP and DOWN navigation keys to move between different parameter labels. If the setup

screen of a parameter exceeds one page, a vertical scroll bar will appear in the right to indicate

this. The dark area of the scroll bar indicates which part of the screen is currently displayed.

3.3.1.2. Entering Data

Press Enter to move focus from the field label to the selection box or textbox; enter or edit data here.

Figure 3-4: Setup Screen Example (Time and Date Setting)

Page 32

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-3

Scale

Application

Terminal

Communication

Maintenance

Selection

box in focus

Figure 3-5: Setup Screen

If the parameter values are provided in a drop-down selection box, press ENTER to select the

current value. Choose other values from the selection box using the UP and DOWN navigation keys.

Once the desired value is selected, press OK to confirm. Focus will move to the next parameter

label.

If a parameter value is a textbox and allows alphanumeric entry, press the keypad softkey to

use the keypad.

Figure 3-6: Select Parameter

Refer to section 2.3, Data Input, in chapter 2, Operation, for further details.

3.4. Configuration Overview

All configuration screens may be accessed from the setup menu tree. In each branch’s main

screen, use the navigation keys to select the required setup screen, and then press Enter to display

that menu.

There are five main submenu branches in the setup menu:

This chapter explains the available parameters, their settings, and the use of each menu.

Page 33

3-4

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

3.5. Scale

If the metrology switch SW1-1 is ON, the user will not be able to access the Scale parameter

menus. Refer to section 2.1.2.,

The scale menu is used to configure the following parameters:

Metrology Switch, in chapter 2, Operation.

Configuration

A Reset operation located at the bottom of the list may be executed to reset some parameters in the

Scale menu to default values. This action does not clear metrological data.

3.5.1. Scale Type

The Scale Type menu is used to set the scale name, type, approval method and approval number.

Press the

3.5.1.1. Name

The Name field allows a name to be assigned to the scale. Enter identifying information of no more

than 20 characters and press

Figure 3-7: Scale Menu, Two Pages

Exit softkey to return the display to the Scale menu.

Figure 3-8: Scale Type Menu

Enter to store the name and move to the next parameter label.

3.5.1.2. Scale Type

Type field indicates the type of scale supported by the terminal and allows selecting remote display

mode. If

3.5.1.3. Approval

Approval refers to the approval configuration of the terminal and platform.

Various

Approval selection list contains:

Remote is selected, the approval option will be disabled. Options are:

Analog [used for analog version by default], Remote

Approval methods may be legally used for corresponding countries and regions. The

Page 34

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-5

None [default]

Thailand

Canada

Australia

OIML

USA

If any approval method is selected, the parameters related to metrology in the

locked and cannot be modified. Select OIML approval for China.

3.5.1.4. Certification No.

Enter an approval number of up to 20 digits.

3.5.2. Capacity & Increment

Use this menu to set the primary weighing unit, range and division value and overload display

range.

3.5.2.1. Primary Unit

Set the Primary units from the options in the selection box, including:

Scale menu will be

Figure 3-9: Capacity & Increment Screens

g, kg [default], lb, t, ton

3.5.2.2. Range/Intervals

Select multi-interval or multi-range mode and then set the number of ranges or intervals from the

selections:

1 [default], 2intervals, 2 ranges, 3 intervals, 3 ranges

3.5.2.2.1. >|1|< – range/interval value 1

Specify the capacity and then the increment size for range or interval

3.5.2.2.2. >|2|< – range/intervalvalue 2

When two ranges or intervals are selected, the second range or interval value should be entered.

The range 2 must be greater than the input value of range 1.

3.5.2.2.3. >|3|< – range/intervalvalue 3

When three ranges or intervals are selected, the third range or interval value should be entered.

Page 35

3-6

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

Disabled [default]

Only use zero and span

3 points

Use zero, midpoint and high point

4 points

Use zero, low point, midpoint and high point

5 points

Use zero, low point, midpoint, mid-high point and high point

3.5.2.3. Blank Over Capacity

Select the appropriate number of divisions to determine how many displayed divisions above

capacity the terminal can display before the display is blanked. In this overcapacity situation, a

dotted line will be displayed instead of a weight value, and the immediate data output is disabled.

3.5.3. Calibration

The GEO code adjustment value (gravitational acceleration factor), base (scale) serial number,

calibration unit and linearity adjustment are set in the calibration screen. When the Scale Type is set

Remote, the calibration branch is not available.

as

Configuration

Figure 3-10: Calibration Screens

3.5.3.1. GEO Code

In the GEO Code field, enter the appropriate geographical adjustment value for current geographic

position. The geo code is numbered from 0 to 31. Refer to Appendix C,

the correct GEO code for the installation site.

The GEO value is used to translate factory calibration values to local settings, making it

unnecessary to do an on-site calibration. It cannot be adjusted for a weighing system which has

been calibrated at the customer’s site.

3.5.3.2. Base Serial Number

If appropriate, enter the serial number of the connected scale. Entries of up to 13 characters are

accepted.

3.5.3.3. Calibration Units

The available calibration units are the same as the primary units, and include:

kg [default], lb, t

g,

3.5.3.4. Linearity Adjustment

Select linearity adjustment from the selection box. The options are:

Geo Codes, to determine

Page 36

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-7

3.5.3.5. Calibration SoftKeys

The softkeys displayed in the calibration setup screen are used for several calibration processes.

3.5.3.5.1. Capture Zero

The Capture zero softkey triggers an independent operation to reset the scale zero condition.

Capture Zero Steps

1. Press capture zero softkey .

2. A message appears instructing the user to clear the platform.

3. Clear the platform and press start softkey to display capture zero operation status.

Capture zero

Capture range

Figure 3-11: Zero Calibration

Step calibration

Calibration-free

Press Escape softkey to cancel the zero calibration process and return the display to

previous screen.

4. When the operation is complete, a final status message appears, indicating that zero capture is

complete.

If there is scale motion during the zero capture process, the terminal will accept the unstable

weight reading and then display a warning message to indicate the use of an in-motion value.

This message offers

Yes and No options, and the user may reject or accept the calibration.

Move the cursor to the desired action and then press ENTER.

Figure 3-12: Zero Calibration (Unstable)

5. When zero capture is successful, a message will appear, showing "Capture zero ok". If the zero

capture is not successful, an error message appears, showing "Capture zero failure ". In this

case, repeat the zero capture process. If the process continues to fail, contact your METTLER

TOLEDO representative for assistance.

Page 37

3-8

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

Figure 3-13: Zero Calibration (Failed)

6. Press the Esc softkey to return to the calibration screen.

3.5.3.5.2. Capture Span

Configuration

The Capture Span softkey

starts the process, which can be performed independent of

capturing zero. To capture span, enter the test load in the appropriate field. The method used

depends on whether

If Linearity is Disabled

Linearity is disabled or enabled.

1. Press CAPTURE SPAN

. The capture span setup screen will appear. Enter the full-scale

calibration weight, then press ENTER.

Figure 3-14: Test Load Entry Screen

2. Press START softkey to start the weight capture operation status. A display will indicate

progress. When the operation is finished, a status message appear indicating that span has

been captured successfully.

If required, press ESC softkey

to cancel the calibration process and return the display to

previous screen.

3. If capture span is successful, an approval message appears, showing "Capture span ok ". If

the capture span is not successful, an error message appears, showing "Capture span failure".

Repeat the capture span steps in case of calibration failure. If the process continues to fail,

contact your METTLER TOLEDO representative for assistance.

Figure 3-15: Span Calibration in Progress

Page 38

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-9

Figure 3-16: Span Calibration, Success and Failure

If there is scale motion during the span capture process, the terminal will accept the unstable

weight reading and then display a warning message to indicate the use of an in-motion value.

This message offers

Yes and No options, and the user may reject or accept the calibration.

Move the cursor to the desired action and then press Enter.

4. Press the ESC softkey to return to the calibration screen.

Figure 3-17: Span Calibration (Unstable)

If Linearity is Enabled

In this case, the screen will display two calibration weight input boxes. Enter load weights #1 and

#2 and press ENTER to confirm. Then enter the span calibration interface and press Start. The

message "Capture span ok" shows that the calibration is successful.

Page 39

3-10

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

Configuration

Figure 3-18: Span Calibration (Success)

"Calibration Failure” will be displayed if the terminal does not succeed in capturing the span.

Figure 3-19: Span Calibration (Failed)

If there is scale motion during the span capture process, the terminal will accept the unstable

weight reading and then display a warning message to indicate the use of an in-motion value.

This message offers

Move the cursor to the desired action and then press Enter.

Yes and No options, and the user may reject or accept the calibration.

Page 40

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-11

3.5.3.5.3. Step Calibration

In step calibration, the same amount of test weight is added at each step of the calibration

procedure.

To Execute Step Calibration

1. Press the step calibration softkey . The step calibration setup screen appears.

Figure 3-20: Range Calibration (Motion)

Figure 3-21: Accessing Step Calibration

2. Press ENTER to access the target weight field, and enter the weight of the test load. (The same

amount of test load weight will be used in each step). Press OK to confirm.

Figure 3-22: Entering Test Weight Value

3. Press the Start softkey . The step calibration screen appears. This screen displays the target

weight entered in previous screen, together with the prompt "Add test weight". Place the test

weight and press OK

4. Place the correct test weight on the scale and press OK

.

.

Page 41

3-12

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

Configuration

5. Repeat steps 3 and 4 until sufficient calibration steps have been completed. Once the process

is complete, a screen will show the final target value, then show a "Calibration Successful"

message.

6. Press Enter to return to the calibration screen.

At any step in the procedure, press EXIT to stop the process and return to the calibration screen.

3.5.3.5.4. CalFree (Weight-Free Calibration)

The CalFree softkey provides access to the span calculation screen and can achieve

platform calibration without test weights. Before CalFree operation, make sure that the correct value

has been entered for the analog gain jumper. If the value is not set correctly, it will cause error in

CalFree calculation.

Figure 3-23: Step Calibration in Progress

Figure 3-24: Step Calibration Sequence

Range Calibration Using CalFree

1. Press CALFREE softkey and CalFree screen appears.

2. Enter the load cell capacity, press ENTER and select appropriate unit.

The sum of the capacities of all the load cells should be entered here. For example, for a

storage tank with three 5000kg sensors, the sensor capacity will be 3 x 5000 kg, i.e.

15000 kg.

3. Enter the rated load cell sensitivity output value and then press ENTER.

Page 42

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-13

If several load cells are used, the average value of the sensitivity of all cells should be

entered here. The average output is determined by adding the output of all cells and then

dividing by the number of cells.

4. Enter the estimated preload value in relevant field. The estimated preload is any input. During

the calibration, the terminal tests whether there is analog/digital (A/D) converter input saturation

in full platform range. If a value is entered in this field, the estimated preload is accounted for in

the calculation. If the preload is unknown, leave this field blank.

This preload value is only used to determine the overload conditions and not used as zero

reference point. The zero reference point must be captured by the normal zero calibration

procedure.

Figure 3-25: Configuring CalFree

5. Press OK

6. If calibration succeeds, a message will appear, showing "Calibration ok". If calibration fails,

7. Press the EXIT softkey to return to the calibration screen.

3.5.4. Zero

Zero function is used to set or reset the initial zero reference point of the IND256x. There are three

zero setting modes:

in the pull-down menu.

Figure 3-26: CalFree Calibration Process

repeat the CalFree procedure. If the process continues to fail, contact your local METTLER

TOLEDO representative for help.

• Auto zero

• Power up zero

• Pushbutton zero

This section describes the auto zero, auto zero range, under zero blanking, power up zero and

pushbutton zero settings.

Page 43

3-14

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

Figure 3-27: Zero Screens

Press the Zero key within the allowed zero range and the weighing display controller will clear

the current weight value to zero.

If the platform is motion, the motion indicator will appear, and the terminal will not be able to

Configuration

3.5.4.1. Auto Zero

complete the zero operation.

Use the Auto Zero parameter to select auto zero maintenance parameters. The options are:

Disabled,

3.5.4.2. Auto Zero Range

Auto zero maintenance (AZM) allows IND256x to compensate for a small amount of weight

deviation (such as from debris on the scale), and return it to the center of zero. When the terminal

is within the AZM operation range and is not in motion, the terminal makes small adjustment to

current zero reading to gradually approach the true zero center weight. When the weight is beyond

the programmed AZM range, this function will not work.

The auto zero tracking range is in the unit of division(d) value. The options are

0.5d [default], 1d, 3d, 10d

3.5.4.3. Under Zero blanking

The underload range determines how far below calibrated zero the scale weight can fall before the

display blanks (displays a dotted line). This range is defined in divisions. The options are:

Disabled [default], 10d, 20d

3.5.4.4. Power Up Zero

If Power-Up Zero is enabled, the terminal attempts to capture zero at power up, provided the scale

is within the range specified here. If Power up zero is disabled, the initial reference at power up will

be recovered to the most recent zero reference. Power Up Zero Range

Gross [default], Gross and Net

When Power up zero is enabled, – Range and + Range fields will display. These are used to set the

range above and below the original calibration zero point of the platform within which the terminal

can use power up zero. The range unit is defined as a percentage of calibrated span. The options

are:

Disabled [default], +/-2%, +/-10%

Page 44

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-15

For example, if the power up zero and range setting is set at 2%, the power up zero will occur only

when the weight reading in the scale is less than 2% of the scale range above the original scale

calibrated zero reference.

If power up zero capture is enabled and the weight in the scale is beyond the zero capture range,

the display will indicate EEE until the weight is adjusted to within the range.

3.5.4.5. Pushbutton Zero

If Pushbutton Zero is enabled, the ZERO key in the keyboard can be used to capture a new zero

reference point. Pushbutton zero options are:

Disabled,

If Pushbutton Zero is disabled, a remote zero command may still be executed through SICS,

+/-2% [default], +/-20%

CPTZ and SMA commands from PC, discrete input or PLC. To set the zero point range of such

remote zero functions, enable pushbutton zero first, select the pushbutton zero range and then

disable pushbutton zero.

3.5.4.5.1. Pushbutton Zero Range

If Pushbutton zero is enabled, – Range and + Range fields will display. These are used to set the

range above and below the original calibration zero point of the platform where Pushbutton zero

can be used. The range unit is a percentage of calibrated span.

For example, if the pushbutton zero and range setting is set at 2%, the pushbutton zero will occur

only when the weight reading in the scale is less than 2% of the scale range above the original

scale calibration zero reference. If the pushbutton zero and range setting is set at 2%, the

pushbutton zero will occur only when the weight reading in the scale is less than 2% of the scale

range below the original scale calibration zero reference.

3.5.4.5.2. Using Pushbutton Zero

The Pushbutton (semi-automatic) zero function can be carried out in two ways:

• Press the ZERO scale function key

• Serial command (SICS or CTPZ protocol)

3.5.5. Tare

Tare refers to the weight of an empty container. Tare is used to subtract the weight of the container

from the scale gross weight to determine the net weight of the containers contents. If the platform is

in motion, Tare is disabled. This branch provides parameters for tare type, auto tare and auto clear.

Figure 3-28: Tare Menu

Page 45

3-16

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

1. Press the Tare key to use current weight as tare. The display will switch from gross weight

mode to net mode, and show a net weight of zero. The net weight indicator will display.

2. If the scale is in motion, the terminal will be unable to perform the tare function.

3. Press the CLEAR key to clear current tare value. The display will return to the gross weight

mode. The net weight cursor will be converted to gross weight cursor.

3.5.5.1. Tare Type

Use the Tare Types setup screen to enable or disable pushbutton tare, keyboard tare and net sign

correction.

Configuration

Figure 3-29: Tare Type Screen

3.5.5.1.1. Pushbutton Tare

If pushbutton tare is enabled, tare can be captured by placing an empty container on the scale and

pressing the Tare key

indicator. When the container is filled and placed back on the scale, the net weight of the material

will display. The options are:

Disabled,

If Pushbutton Tare is disabled, remote tare can still be executed through SICS, CPTZ and SMA

Enabled [default]

commands and discrete input from PC or through PLC command.

3.5.5.1.2. Keyboard Tare

When the keyboard tare is enabled, use the numeric keypad to enter the given value (preset tare) of

the empty container weight (tare), then press ENTER . The terminal will display the net weight of

the content in the container. Keyboard tare is automatically rounded to the nearest display division.

Options are:

Disabled,

3.5.5.1.3. Net Sign Correction

Net sign correction is used for factory receiving and shipping applications. If net sign correction is

enabled, the terminal will switch the gross weight and net weight fields in the printed bill when

necessary, so that the larger weight is always the gross weight and the smaller weight always the

tare, and their difference is always positive net weight. Net sign correction affects the print data

output and the terminal’s displayed weight. Continuous data output will continue to display negative

net weights. Options are:

. The terminal will display a zero net weight and the net weight mode

Enabled [default]

Disabled [default], Enabled

Page 46

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-17

Net sign correction will use pushbutton tare, preset tare or the tare record operation stored in the

Tare Table. Table 3-11 displays the example of the weight value with and without net sign

correction. In this example, the tare memory value is 53 kg and the existing weight on the scale is

16 kg.

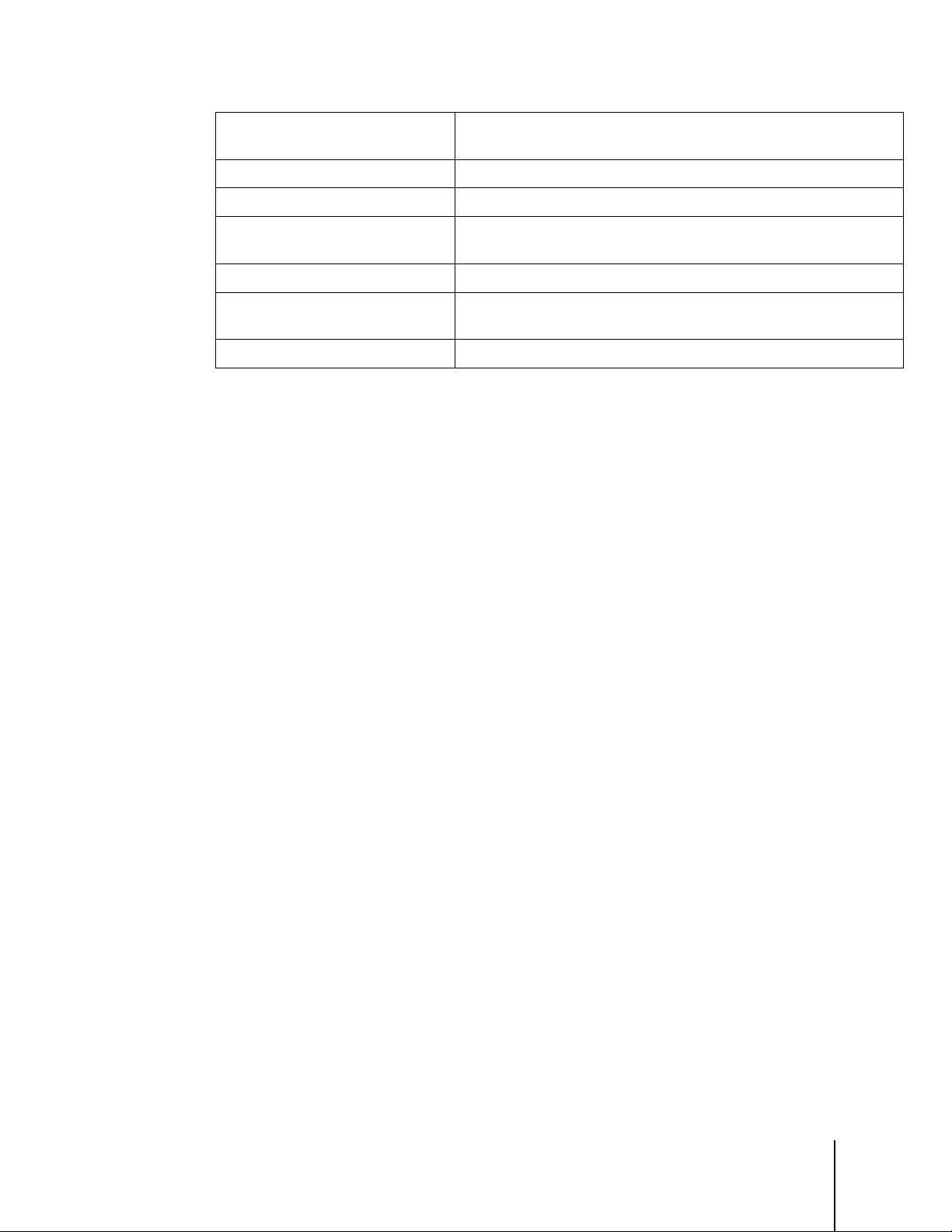

Table 3-1: Weight Value With and Without Net Sign Correction

When net sign correction is enabled, the tare field read from the display will be marked the

letter "M" to indicate "memory" rather than "T" or "PT".

3.5.5.2. Auto Tare

Use the Auto Tare screen to enable or disable auto tare, set tare and reset threshold weights, and

enable or disable motion check. Auto tare options are:

Printed and displayed Disabled Enabled

Gross weight 16 kg 53 kg

Tare 53 kg 16 kg

Net weight

Disabled [default], Enabled

Net Sign correction

− 37 kg

37 kg

3.5.5.2.1. Auto Tare

3.5.5.2.2. Tare Threshold Weight

Figure 3-30: Auto Tare Screens

When auto tare is enabled and a container heavier than the threshold weight is placed on the scale,

the tare operation is performed automatically once the scale is stable. Options are:

Disabled [default], Enabled

When the weight on the scale exceeds the set tare threshold and is stable, the terminal tares

automatically.

Page 47

3-18

METTLER TOLEDO IND256x Weighing Terminal User's Guide

30491440 | 02 | 11/2019

3.5.5.2.3. Reset Threshold Weight

Reset threshold weight must be less than the tare threshold weight. When the weight on the scale

falls to below the reset threshold, e.g. when the load has been taken away, the terminal compares

the current weight on the scale with the reset threshold weight. If current weight is below the

threshold value, the terminal is ready to execute the next auto tare operation, as described in

section 3.5.5.2.2.

3.5.5.2.4. Motion Check

When Motion Check is enabled, the terminal will check whether the weight on the scale is stable, so

as to judge whether to execute auto tare operation. Options are:

Configuration

3.5.5.3. Auto Clear

Disabled

Use the Auto Clear screen to set auto clear, set the clear threshold weight, enable or disable motion

check for auto clear, clear after print, clear when the scale is zeroed, and the power up setting. The

options are:

Disabled [default], Enabled

, Enabled [default]

Figure 3-31: Auto Tare Screens

3.5.5.3.1. Auto Clear

When auto clear is enabled and the weight is below the auto clear threshold, the terminal will clear

the tare automatically. The options are:

Disabled [default], Enabled

3.5.5.3.2. Clear Threshold Weight

Clear Threshold Weight will be displayed only when auto clear is enabled. When the gross weight

on the scale exceeds and then falls to below the configured clear threshold weight, the terminal will

clear automatically and return to gross weight mode.

Page 48

30491440 | 02 | 11/2019

METTLER TOLEDO IND256x Weighing Terminal User's Guide

3-19

3.5.5.3.3. Motion Check

None

g kg lb oz t

ton

The motion check field is displayed only when auto clear is enabled. The motion check is enabled

to prevent auto clear of the scale in motion. Options are:

Disabled,

3.5.5.3.4. Clear After Print

When Clear After Print is enabled, the tare is cleared after a print command is executed. Options

are:

Disabled [default], Enabled

3.5.5.3.5. Clear with Zero

When Clear with Zero is enabled, tare is cleared when the zero point is captured from the net weight

mode. Options are:

Disabled [default], Enabled

3.5.5.3.6. Power Up

The Restart power-up setting allows the terminal to use the most recently captured tare after the

terminal is powered down and powered up again. If

weight mode after power up and the last tare before power down is cleared. Options are:

Restart [default], Reset

3.5.6. Units

Enabled [default]

Reset is selected, the terminal returns to gross

This screen allows a second unit to be selected, and determines the unit it uses at power up.

3.5.6.1. Second Unit

Use Second Unit selection box to select second weighing unit.

Available weighing units are:

Figure 3-32: Units Screen