Page 1

User's Guide

IND246 and IND246 POWERCELL

Weighing Terminal

Page 2

IND246

IND246

and

POWERCELL Weighing Terminal

Service

METTLER TOLEDO Service

Essential Services for Dependable Performance of Your IND246 and IND246 POWERCELL

Weighing Terminal

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper use of your

new equipment according to this Manual and regular calibration and maintenance by our factorytrained service team ensures dependable and accurate operation, protecting your investment.

Contact us about a service agreement tailored to your needs and budget. Further information is

available at www.mt.com/service.

There are several important ways to ensure you maximize the performance of your investment:

1.

Register your product: We invite you to register your product at

www.mt.com/productregistration so we can contact you about enhancements, updates and

important notifications concerning your product.

2.

Contact METTLER TOLEDO for service: The value of a measurement is proportional to its

accuracy – an out of specification scale can diminish quality, reduce profits and increase

liability. Timely service from METTLER TOLEDO will ensure accuracy and optimize uptime and

equipment life.

Installation, Configuration, Integration and Training: Our service representatives are factory-

a.

trained, weighing equipment experts. We make certain that your weighing equipment is

ready for production in a cost effective and timely fashion and that personnel are trained for

success.

Initial Calibration Documentation: The installation environment and application

b.

requirements are unique for every industrial scale so performance must be tested and

certified. Our calibration services and certificates document accuracy to ensure production

quality and provide a quality system record of performance.

Periodic Calibration Maintenance: A Calibration Service Agreement provides on-going

c.

confidence in your weighing process and documentation of compliance with requirements.

We offer a variety of service plans that are scheduled to meet your needs and designed to

fit your budget.

GWP® Verification: A risk-based approach for managing weighing equipment allows for

d.

control and improvement of the entire measuring process, which ensures reproducible

product quality and minimizes process costs. GWP (Good Weighing Practice), the sciencebased standard for efficient life-cycle management of weighing equipment, gives clear

answers about how to specify, calibrate and ensure accuracy of weighing equipment,

independent of make or brand.

Page 3

© METTLER TOLEDO 2017

No part of this manual may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopying and recording, for any

purpose without the express written permission of METTLER TOLEDO.

U.S. Government Restricted Rights: This documentation is furnished with

Restricted Rights.

Copyright 2017 METTLER TOLEDO. This documentation contains proprietary

information of METTLER TOLEDO. It may not be copied in whole or in part

without the express written consent of METTLER TOLEDO.

METTLER TOLEDO reserves the right to make refinements or changes to the

product or manual without notice.

COPYRIGHT

METTLER TOLEDO® is a registered trademark of Mettler-Toledo, LLC. All other

brand or product names are trademarks or registered trademarks of their

respective companies.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE REFINEMENTS OR

CHANGES WITHOUT NOTICE.

FCC Notice

This device complies with Part 15 of the FCC Rules and the Radio Interference

Requirements of the Canadian Department of Communications. Operation is

subject to the following conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his or her expense.

Declaration of Conformity is available at

http://glo.mt.com/global/en/home/search/compliance.html/compliance/.

Page 4

Error! Unknown document property name.

Error! Unknown document property name.

In conformance with the European Directive 2002/96/EC on Waste Electrical and Electronic

© METTLER TOLEDO

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose without the express written

permission of METTLER TOLEDO.

U.S. Government Restricted Rights: This documentation is furnished with Restricted Rights.

Copyright

METTLER TOLEDO. This documentation

contains proprietary information of METTLER TOLEDO. It may not be copied in whole or in part

without the express written consent of METTLER TOLEDO.

METTLER TOLEDO reserves the right to make refinements or changes to the product or manual

without notice.

COPYRIGHT

METTLER TOLEDO® is a registered trademark of Mettler-Toledo, LLC. All other brand or product

names are trademarks or registered trademarks of their respective companies.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE REFINEMENTS OR CHANGES

WITHOUT NOTICE.

FCC Notice

This device complies with Part 15 of the FCC Rules and the Radio Interference Requirements of the

Canadian Department of Communications. Operation is subject to the following conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his or her expense.

Declaration of Conformity is available at

http://glo.mt.com/global/en/home/search/compliance.html/compliance/.

Disposal of Electrical and Electronic Equipment

Equipment (WEEE) this device may not be disposed of in domestic waste. This also applies

to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment.

If you have any questions, please contact the responsible authority or the distributor from

which you purchased this device.

Should this device be passed on to other parties (for private or professional use), the

content of this regulation must also be related.

Thank you for your contribution to environmental protection.

Page 5

Warnings and Cautions

• READ this manual BEFORE operating or servicing this equipment and FOLLOW these

instructions carefully.

• SAVE this manual for future reference.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT THE AC VERSION OF THE

IND246 TERMINAL TO PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND

PRONG.

WARNING

DO NOT USE THE IND246 TERMINAL IN AREAS CLASSIFIED AS HAZARDOUS BECAUSE OF

COMBUSTIBLE OR EXPLOSIVE ATMOSPHERES. CONTACT AN AUTHORIZED METTLER TOLEDO

REPRESENTATIVE FOR INFORMATION ABOUT HAZARDOUS AREA APPLICATIONS.

WARNING

WHEN THIS EQUIPMENT IS INCLUDED AS A COMPONENT PART OF A SYSTEM, THE

RESULTING DESIGN MUST BE REVIEWED BY QUALIFIED PERSONNEL WHO ARE FAMILIAR

WITH THE CONSTRUCTION AND OPERATION OF ALL COMPONENTS IN THE SYSTEM AND THE

POTENTIAL HAZARDS INVOLVED. FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN

BODILY HARM AND/OR PROPERTY DAMAGE.

CAUTION

THE BATTERY USED IN THIS DEVICE MAY PRESENT A RISK OF FIRE OR CHEMICAL BURN IF

MISTREATED. DO NOT CRUSH, DISASSEMBLE, HEAT ABOVE 60°C OR INCINERATE. REPLACE

BATTERY WITH 72253419 ONLY. USE OF ANOTHER BATTERY MAY PRESENT A RISK OF

BURN, FIRE OR EXPLOSION.

NOTICE

NiMH BATTERIES SLOWLY DISCHARGE WHEN NOT USED (FOR EXAMPLE WHEN STORED FOR FUTURE USE).

BATTERY OPERATED TERMINALS AND SPARE NiMH BATTERY PACKS IN STORAGE MUST BE FULLY CHARGED

EVERY THREE MONTHS TO PREVENT PERMANENT BATTERY DAMAGE.

NOTICE

DO NOT ATTEMPT TO CHARGE THE BATTERY IF THE BATTERY TEMPERATURE IS BELOW 0°C (32°F). CHARGING IS

NOT POSSIBLE AT OR BELOW THIS TEMPERATURE. DO NOT OPERATE THE BATTERY CHARGER OUTSIDE ITS

TEMPERATURE RANGE OF 0°C (32°F) TO 40°C (104°F).

DISPOSE OF USED BATTERY PROMPTLY. KEEP AWAY FROM CHILDREN. DO NOT DISASSEMBLE AND DO NOT

DISPOSE OF IN FIRE.

NOTICE

Page 6

NOTICE

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

Warnings and Cautions

Page 7

64084448 / Rev. 03 / 12/2017

METTLER TOLEDO IND246 and IND246 POWERCELL Weighing Terminal User's Guide 1

Contents

1 Introduction ...................................................................... 1-1

1.1. IND246 Overview ............................................................... 1-1

1.1.1. Standard Features .................................................................................. 1-1

1.1.2. IND246 Terminal Versions ...................................................................... 1-2

1.2. Specifications .................................................................... 1-2

1.3. Battery Performance ........................................................... 1-5

1.4. Use in Hazardous Areas ...................................................... 1-6

1.5. Inspection and Contents Checklist ........................................ 1-6

1.6. Model Identification ............................................................ 1-7

1.7. Physical Dimensions .......................................................... 1-8

1.8. Main PCB .......................................................................... 1-9

1.8.1. SD Memory ........................................................................................... 1-9

1.9. Scale Bases ...................................................................... 1-9

1.9.1. Analog .................................................................................................. 1-9

1.9.2. POWERCELL .......................................................................................... 1-9

1.9.3. PowerDeck .......................................................................................... 1-10

1.10. Options ........................................................................... 1-10

1.10.1. COM2 Serial Port .................................................................................. 1-10

1.10.2. Discrete I/O .......................................................................................... 1-11

1.10.3. USB .................................................................................................... 1-11

1.10.4. Ethernet ............................................................................................... 1-11

1.11. Display and Keyboard ...................................................... 1-12

1.11.1. Display Layout ..................................................................................... 1-12

1.11.2. Front Panel Keys .................................................................................. 1-12

2 Operation: Terminal .......................................................... 2-1

2.1. Overview ........................................................................... 2-1

2.2. Display Elements and Keypad Operation ............................... 2-1

2.2.1. Display Elements ................................................................................... 2-1

2.2.2. Keypad Operation ................................................................................... 2-3

2.3. Operator Menu ................................................................... 2-6

2.3.1. Language Selection – F Codes ................................................................. 2-6

2.3.2. Menu Navigation .................................................................................... 2-6

2.3.3. Alibi Memory ......................................................................................... 2-9

2.3.4. Adjust Contrast ....................................................................................... 2-9

2.3.5. Transaction Counter .............................................................................. 2-10

2.3.6. Totals Memory ..................................................................................... 2-10

2.3.7. Expand x 10 ........................................................................................ 2-10

2.3.8. Information Recall ................................................................................ 2-11

2.3.9. Setup Access ....................................................................................... 2-12

Page 8

2 METTLER TOLEDO IND246 and IND246 POWERCELL Weighing Terminal User's Guide

64084448 / Rev. 03 / 12/2017

2.4. Basic Functionality ........................................................... 2-12

2.4.1. Zero .................................................................................................... 2-12

2.4.2. Tare .................................................................................................... 2-13

2.4.3. Unit Switching ...................................................................................... 2-17

2.4.4. Expand By 10 ...................................................................................... 2-17

2.4.5. Print .................................................................................................... 2-17

2.4.6. Information Recall ................................................................................ 2-18

2.4.7. ID Entry ............................................................................................... 2-18

2.4.8. Time and Date ..................................................................................... 2-19

Contents

2.4.9. Totalization .......................................................................................... 2-19

2.4.10. Alibi Memory ....................................................................................... 2-19

2.5. Applications .................................................................... 2-20

2.5.1. Animal Weighing .................................................................................. 2-20

2.5.2. Checkweighing .................................................................................... 2-20

2.5.3. Counting ............................................................................................. 2-21

2.5.4. Peak Weight ........................................................................................ 2-21

2.5.5. Vehicle Weighing ................................................................................. 2-22

3 Configuration: Terminal ..................................................... 3-1

3.1. Entering Setup Mode ........................................................... 3-1

3.2. Security ............................................................................. 3-1

3.3. Exiting Setup Mode ............................................................. 3-2

3.4. Setup Menu Structure .......................................................... 3-2

3.4.1. Navigation ............................................................................................. 3-2

3.4.2. Setup Page ............................................................................................ 3-2

3.5. Configuration: Overview ...................................................... 3-5

3.6. Configuration: Scale ........................................................... 3-6

3.6.1. Type ..................................................................................................... 3-6

3.6.2. Load Cell ............................................................................................... 3-7

3.6.3. Capacity and Increment ........................................................................ 3-11

3.6.4. Calibration ........................................................................................... 3-13

3.6.5. Zero .................................................................................................... 3-14

3.6.6. Tare .................................................................................................... 3-15

3.6.7. Units ................................................................................................... 3-17

3.6.8. Filter ................................................................................................... 3-17

3.6.9. Stability ............................................................................................... 3-18

3.6.10. Log or Print ......................................................................................... 3-18

3.6.11. Scale Reset .......................................................................................... 3-19

3.7. Configuration: Application ................................................. 3-20

3.7.1. Memory............................................................................................... 3-20

3.7.2. Totalization .......................................................................................... 3-20

3.7.3. Discrete I/O .......................................................................................... 3-21

3.7.4. Function Key ........................................................................................ 3-21

3.7.5. Animal Weighing .................................................................................. 3-22

Page 9

64084448 / Rev. 03 / 12/2017

METTLER TOLEDO IND246 and IND246 POWERCELL Weighing Terminal User's Guide 3

3.7.6. Counting ............................................................................................. 3-23

3.7.7. Checkweighing .................................................................................... 3-24

3.7.8. Peak Weight ........................................................................................ 3-25

3.7.9. Vehicle Weighing ................................................................................. 3-26

3.7.10. Reset .................................................................................................. 3-26

3.8. Configuration: Terminal ..................................................... 3-27

3.8.1. Device ................................................................................................. 3-27

3.8.2. Display ............................................................................................... 3-27

3.8.3. Region ................................................................................................ 3-28

3.8.4. Transaction Counter .............................................................................. 3-30

3.8.5. User .................................................................................................... 3-30

3.8.6. Menu Keys .......................................................................................... 3-30

3.8.7. Reset .................................................................................................. 3-31

3.9. Configuration: Communication ........................................... 3-31

3.9.1. Templates............................................................................................ 3-31

3.9.2. Reports ............................................................................................... 3-33

3.9.3. Connections ........................................................................................ 3-33

3.9.4. Serial .................................................................................................. 3-36

3.9.5. Network............................................................................................... 3-38

3.9.6. Reset .................................................................................................. 3-39

3.10. Configuration: Maintenance ............................................... 3-39

3.10.1. Diagnostics ......................................................................................... 3-39

3.10.2. Scale .................................................................................................. 3-39

3.10.3. Replace Battery .................................................................................... 3-47

3.10.4. Install Software Update .......................................................................... 3-47

3.10.5. Backup to SD ....................................................................................... 3-47

3.10.6. Restore from SD ................................................................................... 3-47

3.10.7. POWERCELL Maintenance ..................................................................... 3-47

3.10.8. Reset All - Factory Default Settings.......................................................... 3-52

3.11. Restoring Factory Default Settings ....................................... 3-52

4 Applications: Configuration and Operation .......................... 4-1

4.1. Introduction ....................................................................... 4-1

4.2. Animal Weighing ................................................................ 4-1

4.2.1. Overview ............................................................................................... 4-1

4.2.2. Operational Features ............................................................................... 4-2

4.2.3. Configuration ......................................................................................... 4-3

4.2.4. Operating Sequence ................................................................................ 4-4

4.2.5. Remote Displays .................................................................................... 4-6

4.2.6. Serial Input Commands ........................................................................... 4-6

4.2.7. Print Formats ......................................................................................... 4-6

4.3. Checkweighing (Over/Under) ............................................... 4-8

4.3.1. Overview ............................................................................................... 4-8

4.3.2. Operational Features ............................................................................... 4-8

4.3.3. Configuration ......................................................................................... 4-9

Page 10

4 METTLER TOLEDO IND246 and IND246 POWERCELL Weighing Terminal User's Guide

64084448 / Rev. 03 / 12/2017

4.3.4. Operating Sequence .............................................................................. 4-14

4.3.5. Print Formats ....................................................................................... 4-18

4.4. Counting ......................................................................... 4-20

4.4.1. Overview ............................................................................................. 4-20

4.4.2. Operational Features ............................................................................. 4-21

4.4.3. Configuration ....................................................................................... 4-21

4.4.4. Operating Sequences ............................................................................ 4-24

4.4.5. Print Formats ....................................................................................... 4-28

4.5. Peak Weight Measurement ................................................ 4-30

Contents

4.5.1. Overview ............................................................................................. 4-30

4.5.2. Operational Features ............................................................................. 4-30

4.5.3. Configuration ....................................................................................... 4-31

4.5.4. Operating Sequences ............................................................................ 4-32

4.5.5. Memory Operation ................................................................................ 4-34

4.5.6. Print Formats ....................................................................................... 4-35

4.6. Vehicle Weighing ............................................................. 4-37

4.6.1. Overview ............................................................................................. 4-37

4.6.2. Operational Features ............................................................................. 4-38

4.6.3. Configuration ....................................................................................... 4-38

4.6.4. Operating Sequences ............................................................................ 4-42

4.6.5. Print Formats ....................................................................................... 4-47

5 Service and Maintenance .................................................. 5-1

5.1. Cleaning and Maintenance .................................................. 5-1

5.2. Service .............................................................................. 5-1

5.3. Battery Operation ................................................................ 5-2

5.3.1. Specifications ........................................................................................ 5-2

5.3.2. Battery Status Icon .................................................................................. 5-3

5.3.3. Accessing the Battery Pack ...................................................................... 5-3

5.3.4. Charging the Battery Pack ....................................................................... 5-5

5.3.5. Disposing of a Depleted Battery Pack ....................................................... 5-7

5.4. Troubleshooting ................................................................. 5-7

5.4.1. Blank Display ........................................................................................ 5-7

5.4.2. Power Test............................................................................................. 5-8

5.4.3. Problem Diagnosis ................................................................................. 5-8

5.4.4. Error Codes and Error Messages .............................................................. 5-9

5.4.5. Internal Diagnostics .............................................................................. 5-11

5.5. Replacing BRAM Battery .................................................... 5-14

5.6. System Backup and Restore .............................................. 5-15

5.6.1. Files, Media and Data ........................................................................... 5-15

5.6.2. Backup to SD Memory Card ................................................................... 5-16

5.6.3. Restore from SD Memory Card ............................................................... 5-16

5.7. Master Reset .................................................................... 5-17

Page 11

64084448 / Rev. 03 / 12/2017

METTLER TOLEDO IND246 and IND246 POWERCELL Weighing Terminal User's Guide 5

5.8. Upgrading Firmware ......................................................... 5-18

5.9. Board and Display Replacement ........................................ 5-18

5.9.1. Option Board Removal .......................................................................... 5-19

5.9.2. Main Board Removal ............................................................................ 5-19

5.9.3. Display Module Removal ...................................................................... 5-21

5.9.4. Display Module Installation ................................................................... 5-22

5.9.5. Main PCB Installation ........................................................................... 5-22

5.9.6. Option PCB Installation ......................................................................... 5-22

5.9.7. Final Steps........................................................................................... 5-23

A Default Templates ............................................................. A-1

A.1. Basic Functionality ............................................................. A-1

A.2. Vehicle Application ............................................................. A-2

A.3. Checkweighing Application .................................................. A-3

A.4. Peak Weight Application ..................................................... A-4

A.5. Animal Weighing Application ............................................... A-5

A.6. Counting Application ........................................................... A-5

B Parameter Values ............................................................. B-1

B.1. Scale Block, IND246 Analog ............................................... B-1

B.2. Scale Block, IND246 POWERCELL ....................................... B-5

B.3. Application Block ............................................................... B-8

B.4. Terminal Block ................................................................. B-15

B.5. Communications Block ..................................................... B-18

B.6. Maintenance Block, IND246 Analog ................................... B-24

B.7. Maintenance Block, IND246 POWERCELL ........................... B-26

C Alibi Memory .................................................................... C-1

C.1. Viewing Alibi Memory Records ............................................. C-1

C.2. Printing Alibi Memory Records ............................................. C-2

C.3. Alibi Memory Print Formats .................................................. C-3

C.3.1. Narrow Format, * Record Separator .......................................................... C-3

C.3.2. Wide Format, = Record Separator ............................................................ C-3

D Communications ............................................................... D-1

D.1. Serial Interface Parameters .................................................. D-1

D.2. Demand Output Mode ......................................................... D-2

D.2.1. Output Templates ................................................................................... D-2

D.3. Continuous Output Mode ..................................................... D-3

D.3.1. Standard Continuous Output .................................................................... D-3

D.3.2. Continuous Output in Animal Weighing ..................................................... D-5

D.3.3. Continuous – Extended Output ................................................................. D-5

Page 12

6 METTLER TOLEDO IND246 and IND246 POWERCELL Weighing Terminal User's Guide

64084448 / Rev. 03 / 12/2017

D.3.4. Multi-Continuous Out .............................................................................. D-8

D.4. Scoreboard Displays ......................................................... D-11

D.4.1. Continuous Output ................................................................................ D-12

D.4.2. Continuous Multi-1 Output ..................................................................... D-12

D.5. CTPZ .............................................................................. D-13

D.6. Standard Interface Command Set (SICS) Protocol ................. D-14

D.6.1. Version Number of the MT-SICS.............................................................. D-14

D.6.2. Command Formats ............................................................................... D-14

D.6.3. Response Formats ................................................................................ D-15

Contents

D.6.4. Tips for the Programmer ........................................................................ D-16

D.6.5. Commands and Responses MT-SICS Level 0 .......................................... D-16

D.6.6. Commands and Responses MT-SICS Level 1 .......................................... D-20

D.7. Reports ........................................................................... D-23

D.7.1. Alibi Memory ....................................................................................... D-23

D.7.2. Totals Report ....................................................................................... D-24

D.8. Variable Access ................................................................ D-24

D.8.1. Connection .......................................................................................... D-24

D.8.2. Commands ......................................................................................... D-24

D.8.3. Variable List ......................................................................................... D-26

E GEO Codes ....................................................................... E-1

E.1. Original Site Calibration ....................................................... E-1

E.2. New Site GEO Code Adjustment ............................................ E-1

Page 13

64084448 | 03 | 12/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

1-1

This chapter covers

1 Introduction

The IND246 and IND246 POWERCELL industrial scale terminals provide a

• Overview

• Specifications

• Use in Hazardous Areas

• Safe Disposal Requirement

• Inspection and Contents

Checklist

• Model Identification

• Physical Dimensions

• Main PCB

• Scale Bases

• Options

• Display and Keyboard

Standard applications include basic weighing, animal weighing, check weighing, counting, peak

weight measurement and vehicle weighing. Whether communicating weight data to a PC or

providing a serial output of data to a printer, the IND246 terminal offers solutions for a wide range

of applications.

compact yet flexible solution to a variety of weighing needs. Available as either AC

powered for stationary applications or battery-powered for portable analog load cell

applications, this terminal is at home in virtually any industrial environment.

Innovative use of Secure Data (SD) Memory technology expands the memory

available for data storage when required.

Unless stated otherwise, IND246 refers to both the analog and POWERCELL

versions.

Both 2mv/V and 3mv/V analog load cells are supported without the need for

any configuration change. The POWERCELL model supports the advanced

capabilities of POWERCELL PDX and GDD load cells, featuring sophisticated selfdiagnostics. The PowerDeck model for POWERCELL supports a connector for quick

home run cable termination, faster calibration and automatic addressing. The

IND246 delivers precision measurement data from grams to tons in a single, cost

effective package.

1.1. IND246 Overview

1.1.1. Standard Features

• Rugged stainless steel enclosure

• Supports one analog load cell platform with up to four (battery version), ten (AC version)

350Ω load cells; or one scale platform with up to 12 POWERCELL PDX load cells; or up to 3

PowerDeck scale platforms, each with 4 SLB615D load cells; or up to 12 SLC611D LCWM

load cells

• Large transflective graphic LCD display with backlight for vivid readability in all light

conditions

• One electrically isolated serial port (COM1) for asynchronous, bidirectional communication

• Powered by either 85–264 V AC or internal battery pack (selected by model)

• Support for the following option boards:

Choice of one serial/DIO option:

Page 14

1-2

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 12/2017

Enclosure Type

Dimensions (w ×

h × d)

Shipping Weight

o COM2 Serial Interface

o COM2 and Discrete I/O interface (analog version only)

o USB Serial Interface

o USB and Discrete I/O interface (analog version only)

Optional network interface:

o Ethernet TCP/IP

• Front panel key access to basic weighing functions – zero, tare, clear, unit switching and

print

• Alpha numeric keypad for simple, quick entry of tare and identification information

Introduction

• Selectable primary unit of measure including grams, kilograms, pounds, tons, metric tons

• Selectable second unit of measure including grams, kilograms, pounds, ounces, tons and

metric tons

• Backup and restore of configuration and calibration settings, using SD memory device or

• PC-based File Transfer Tool (included) exchanges application files and tables with the

®

SL PC tool (included)

InSite

IND246 terminal

• Automatic shutoff and backlight timeout features to help conserve energy on the battery

powered version

1.1.2. IND246 Terminal Versions

The terminal is available in the following four versions:

• IND246 Harsh enclosure, AC power

• IND246 Harsh enclosure, Battery power

• IND246 POWERCELL, AC power

• IND246 POWERCELL for SL_61xD, AC power

1.2. Specifications

The IND246 terminal conforms to the specifications listed in Table 1-1.

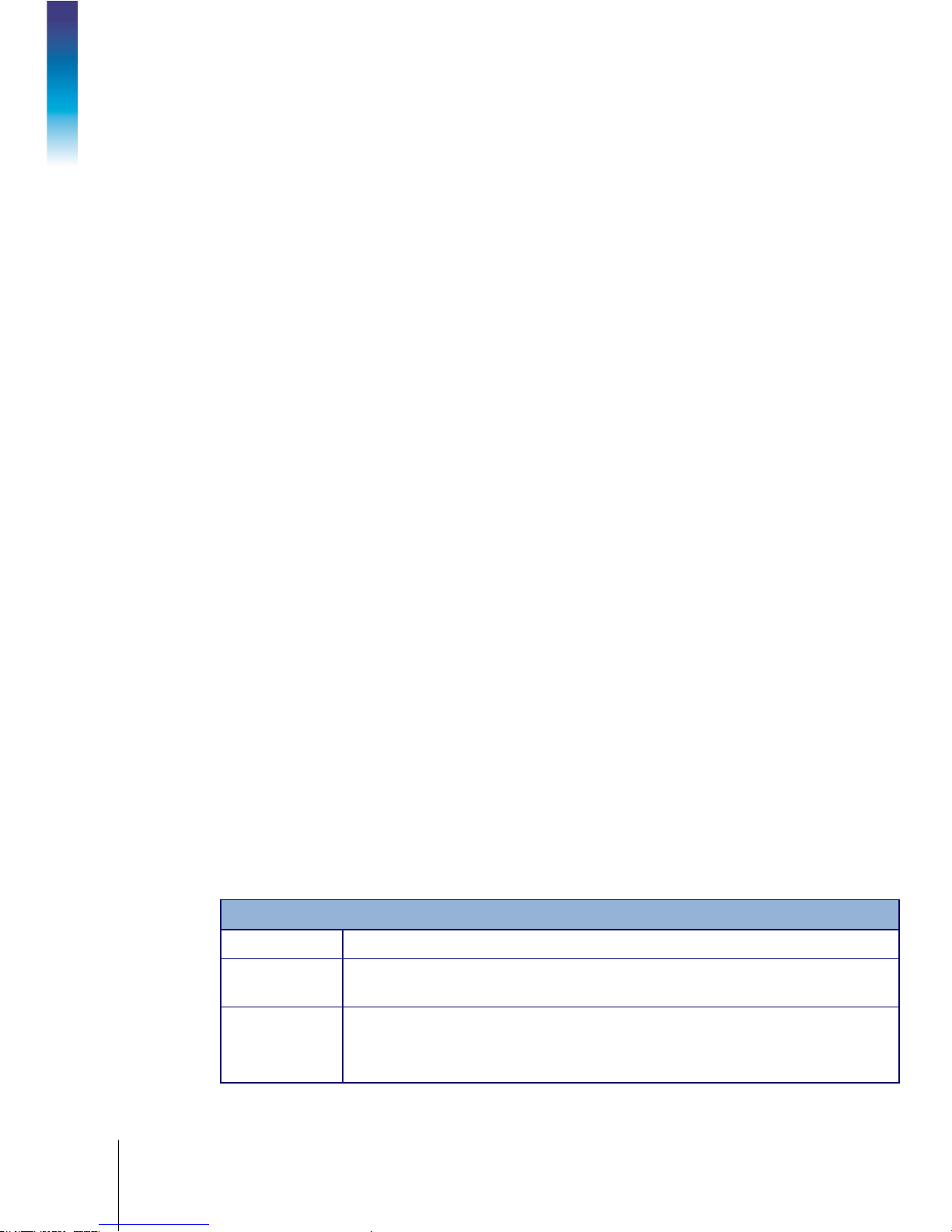

Table 1-1: Terminal Specifications

Stainless steel, configurable as desk top or wall mount enclosure

230 mm x 146 mm x 165 mm (9 in. x 5.75 in. x 6.5 in.)

AC Version: 3.4 kg (7.5 lb)

Battery Version: 3.9 kg (8.5 lb)

POWERCELL Version: 3.6 kg (7.9 lb)

IND246 Specifications

Page 15

64084448 | 03 | 12/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

1-3

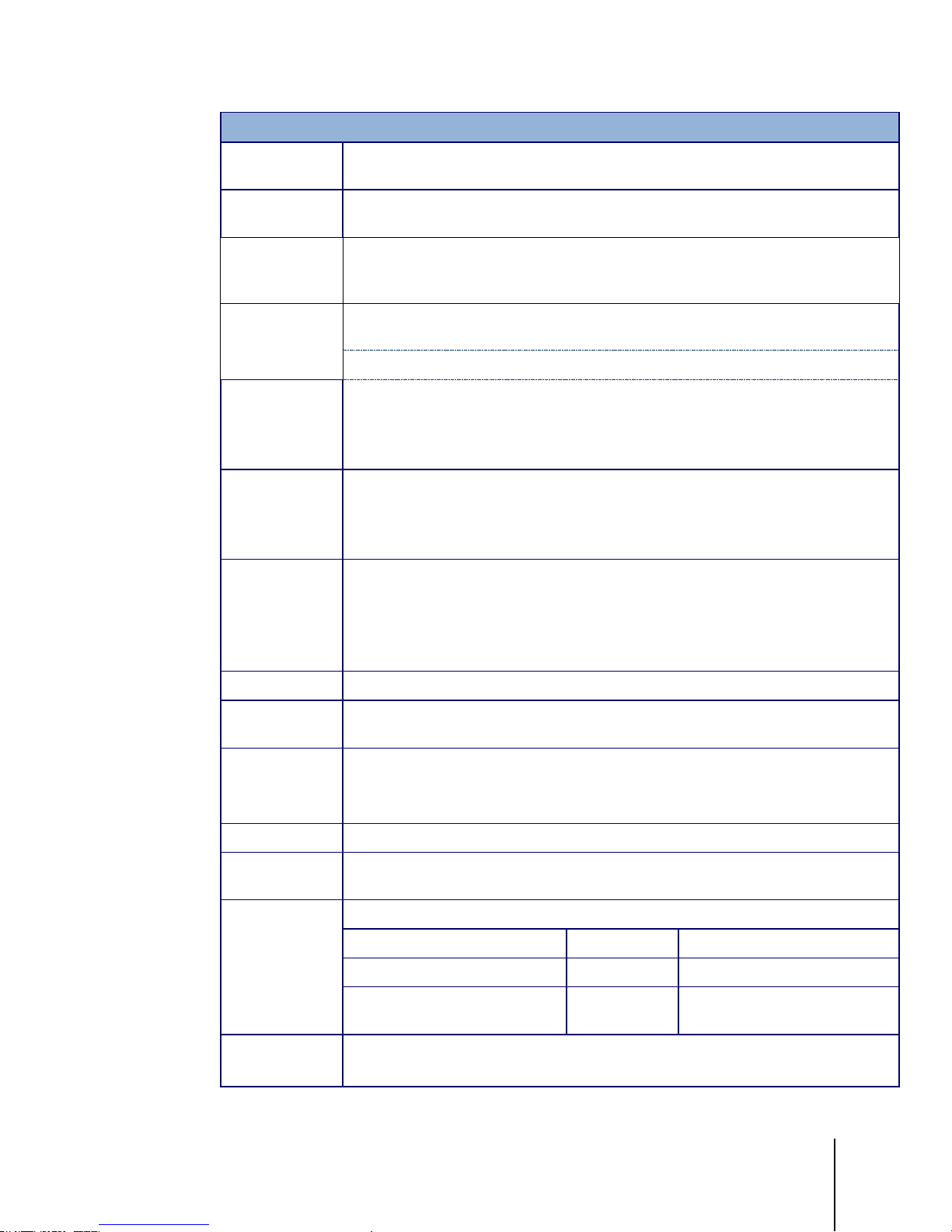

IND246 Specifications

Environmental

Protection

Operating

Environment

Hazardous Areas

Power

Power

Consumption

Power

Consumption

Display

Weight Display

Scale Types

Number of Cells

Number of Scales

Analog

Update Rate

POWERCELL

Update Rate

Update Rates (Hz)

Update Rate, Type

Synchronized Continuous Weight

Load Cell

Excitation Voltage

IP66 (comparable to Type 4x)

The terminal can be operated at temperatures ranging from −10° to 40° C (14° to

104° F) at 10% to 95% relative humidity, non-condensing.

The IND246 terminal cannot be operated in areas classified as Hazardous because of

combustible or explosive atmospheres in those areas. Contact an authorized METTLER

TOLEDO representative for information about hazardous area applications.

AC version: Operates at 85–264 VAC, 49–61 Hz and includes a power cord configured

for the country of use.

Battery version: Operates from internal NiMH battery pack

Refer to Table 1-2 for details of the AC version. Values shown are with internal COM2/DIO

option and Ethernet option installed and load cell input loaded with 8 x 350Ω load cells.

Refer to Table 1-3 for Refer to Table 1-4 for details of the battery life for the battery

powered version.

Refer to Table 1-2 for the AC version; Table 1-3 for IND246 POWERCELL; and Table 1-4

for the battery version.

Values shown in Table 1-2 are for an IND246 terminal with the internal COM2/DIO and

Ethernet options installed, and input from 8 x 350Ω load cells.

Backlit 240 x 96 dot graphic LCD including weight display, weight units, gross/net

indication and graphic symbols for motion and center of zero, SmartTrac, operator

prompts and data entry display. Update rate of 12 updates per second.

Basic weight mode: 27 mm (1.1 in) high weight display

Application mode: 20 mm (0.8 in) high weight display

Maximum displayed resolution of 50,000 divisions.

Analog load cells (AC or battery models), POWERCELL PDX, GDD, SLC611D or

SLD615D load cells (POWERCELL model),

AC Version: From one to ten 350-ohm load cells (2 or 3 mV/V)

Battery Version: From one to four 350-ohm load cells (2 or 3 mV/V)

POWERCELL Version: Up to 12 POWERCELL PDX, GDD, SLC611D or SLB615D load cells

One

Internal analog: 366 MHz

Vehicle, 12 load cells

Load Cell Network 25

Output

USB, COM1,

COM2, Ethernet

17 - 25

AC Version: 10 VDC

Battery Version : 5 V DC

Page 16

1-4

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 12/2017

Minimum

Sensitivity

Keypad

Communications

Approvals,

Analog Version

Approvals,

POWERCELL

Version

IND246 Specifications

0.1 microvolt per increment

25 keys; polyester overlay (PET) with polycarbonate display lens

Serial Interfaces

Standard: One isolated serial port (COM1) RS-232 (analog only); RS-232/RS-422-

RS-485 (POWERCELL only), 300 to 115,200 baud

Optional isolated serial port: (COM2) RS-232/485, 300 to 115,200 baud

Optional USB port: serial port bridge, 300 to 115,200 baud

Introduction

Ethernet Interface

Optional Ethernet port: 10/100 TCP/IP port

Protocol

Serial Inputs: ASCII commands for CTPZ (Clear, Tare, Print, Zero), SICS (most level 0

and level 1 commands)

Serial Outputs: Continuous, Extended continuous, Demand (limited formats), Reports,

SICS (most level 0 and level 1 commands) or Variable Access

Weights and Measures

USA: NTEP Class III/IIIL - 10,000d; Cert. #11-040

Canada: Class III - 10,000d; Class IIIHD - 20,000d; AM-5819

Europe: Class III 6000e, Class IIII 1000e; TC7918, T8030

OIML: Class III 6000e, Class IIII 1000e; R76/2006-NL1-15.49R1

Product Safety

UL, cUL, CE

Weights and Measures

USA: : NTEP Class III/IIIL - 10,000d; Cert. #11-040

Canada: Class III - 10,000d; Class IIIHD - 20,000d; AM-5819

Europe: Class III 6000e, Class IIII 1000e; TC7918, T8426

OIML: Class III 6000e, Class IIII 1000e; R76/2006-NL1-15.49R1

Product Safety

UL, cUL, CE

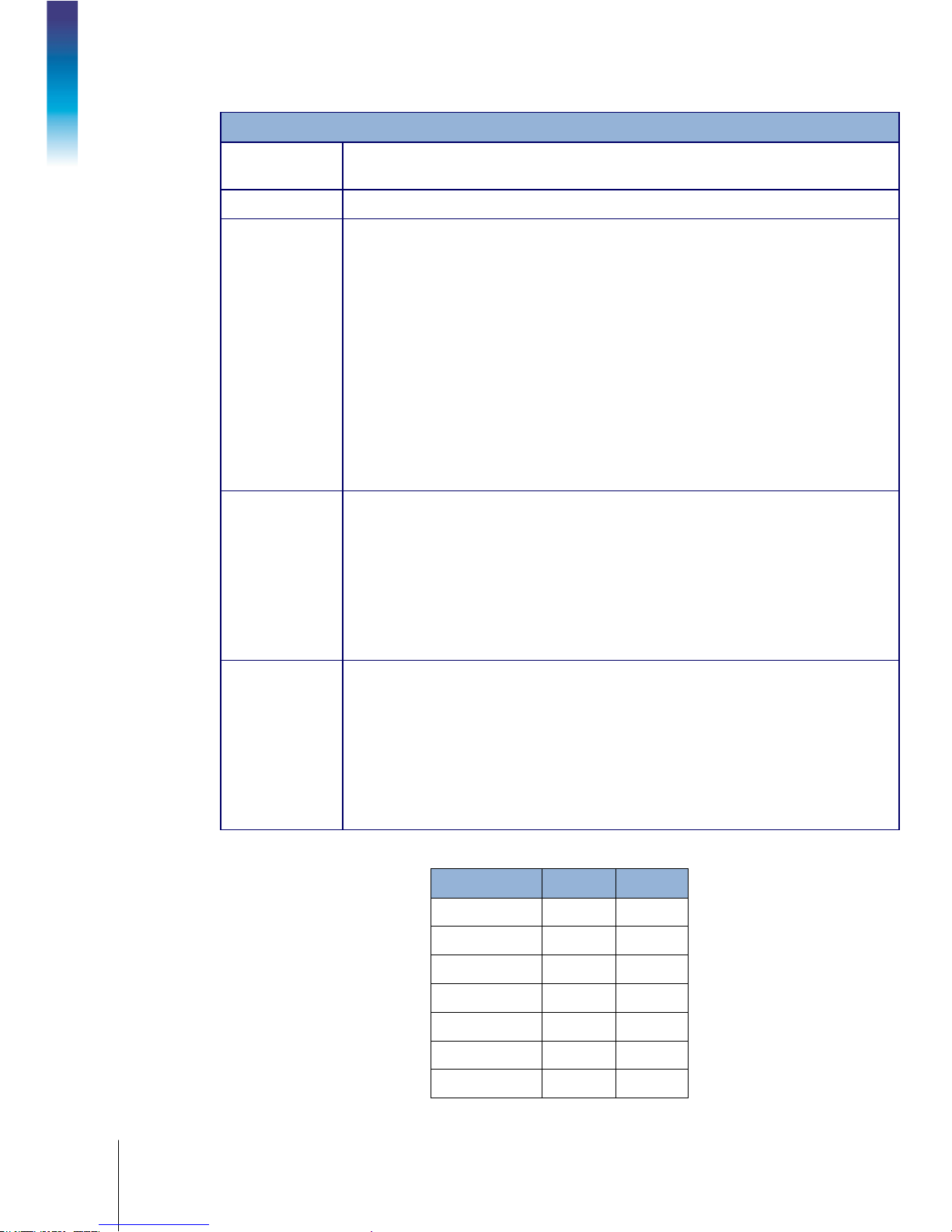

Table 1-2: IND246 Power Consumption (AC Source)

Input Voltage I (mA) P (W)

85V/50 Hz 167 7.9

110 V/50 Hz 133 7.7

240 V/50 Hz 64 7.9

264 V/50 Hz 59 7.9

85 V/60 Hz 163 7.9

110 V/60 Hz 128 7.7

240 V/60 Hz 62 7.9

Page 17

64084448 | 03 | 12/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

1-5

Input Voltage I (mA) P (W)

264 V/60 Hz 58 8.0

Values shown are with internal COM2/DIO option and Ethernet option installed and load cell input

loaded with 8 x 350Ω load cells.

Table 1-3: Power Consumption for POWERCELL Version

Input Voltage I(mA) P(W)

85V/50Hz 112 5.7

110V/50Hz 94 6

240V/50Hz 73 8.4

264V/50Hz 72 8.7

85V/60Hz 108 5.8

110V/60Hz 92 6

240V/60Hz 73 8.3

264V/60Hz 73 8.6

Table 1-4: IND246 Average Battery Life, Analog Version

Continuous Operation Load

1- 350Ω cell, no options 21.5 hrs 49 hrs

1 – 350Ω cell, COM2/DIO option 12.5 hrs 19 hrs

4 – 350Ω cells, no options 17. 5 hrs 32 hrs

4 – 350Ω cells, COM2/DIO option 11 hrs 15.5 hrs

1.3. Battery Performance

NiMH BATTERIES SLOWLY DISCHARGE WHEN NOT USED (FOR EXAMPLE WHEN STORED FOR FUTURE USE).

BATTERY OPERATED TERMINALS AND SPARE NiMH BATTERY PACKS IN STORAGE MUST BE FULLY CHARGED EVERY

THREE MONTHS TO PREVENT PERMANENT BATTERY DAMAGE.

Battery Life

w/Backlight

NOTICE

Battery Life w/o

Backlight

Page 18

1-6

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 12/2017

• IND246 Terminal

• Safety Instructions

1.4. Use in Hazardous Areas

WARNING

DO NOT USE THE IND246 TERMINAL IN AREAS CLASSIFIED AS HAZARDOUS BECAUSE OF

COMBUSTIBLE OR EXPLOSIVE ATMOSPHERES. CONTACT AN AUTHORIZED METTLER TOLEDO

REPRESENTATIVE FOR INFORMATION ABOUT HAZARDOUS AREA APPLICATIONS.

1.5. Inspection and Contents Checklist

Introduction

Verify the contents and inspect the package immediately upon delivery. If the shipping container is

damaged, check for internal damage and file a freight claim with the carrier if necessary. If the

container is not damaged, remove the terminal from its protective package, noting how it was

packed, and inspect each component for damage.

If shipping the terminal is required, it is best to use the original shipping container. The terminal

must be packed correctly to ensure its safe transportation.

The package should include:

• Battery Pack (battery version only)

• Mounting brackets (2; analog version only)

• Resource CD (includes all manuals)

• Bag of miscellaneous parts

Page 19

64084448 | 03 | 12/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

1-7

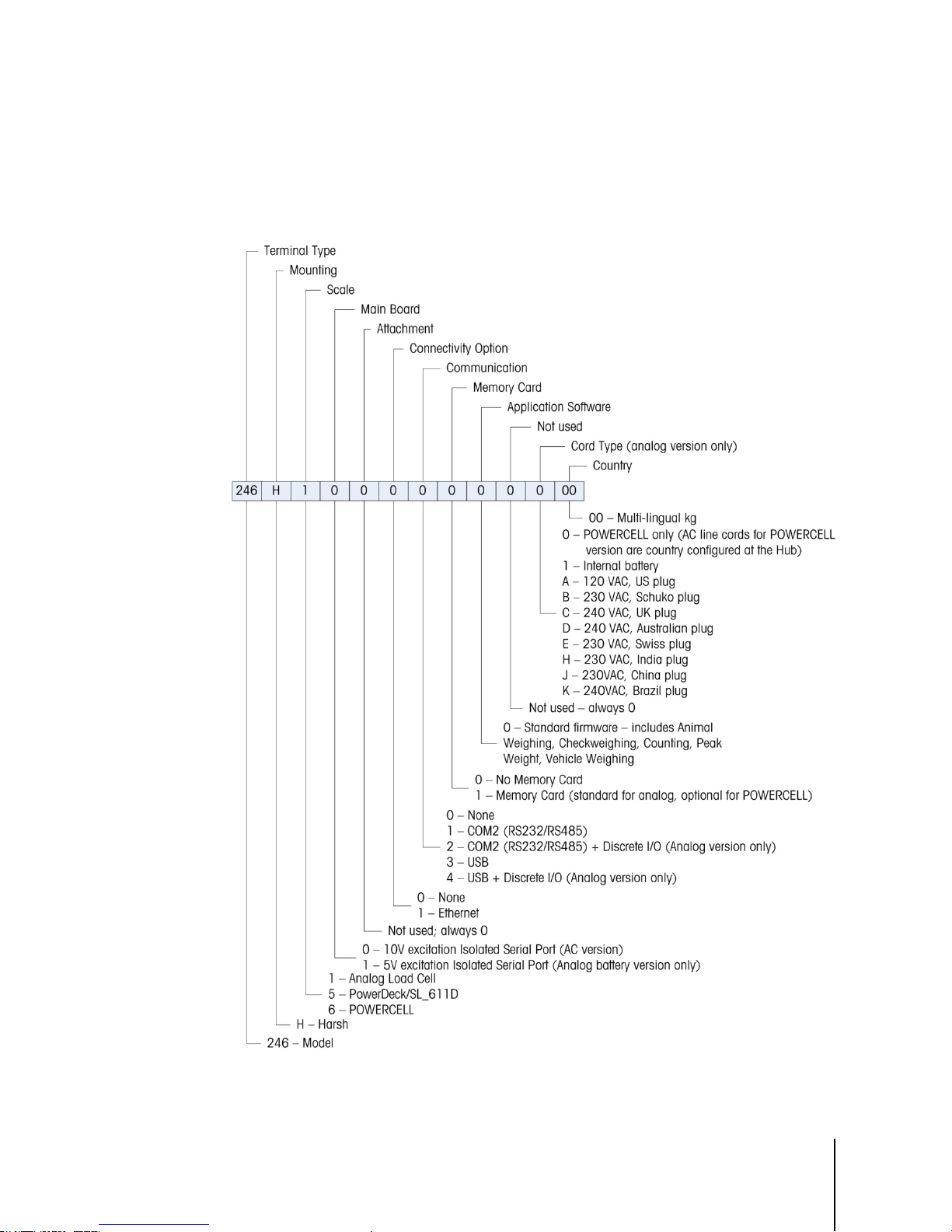

1.6. Model Identification

The IND246 and IND246 POWERCELL model number, factory number and serial number are

located on the data plate of the terminal. Refer to Figure 1-1 to verify the configuration of the

IND246 terminal when it left the METTLER TOLEDO factory.

Figure 1-1: IND246 Configuration Chart

Page 20

1-8

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 12/2017

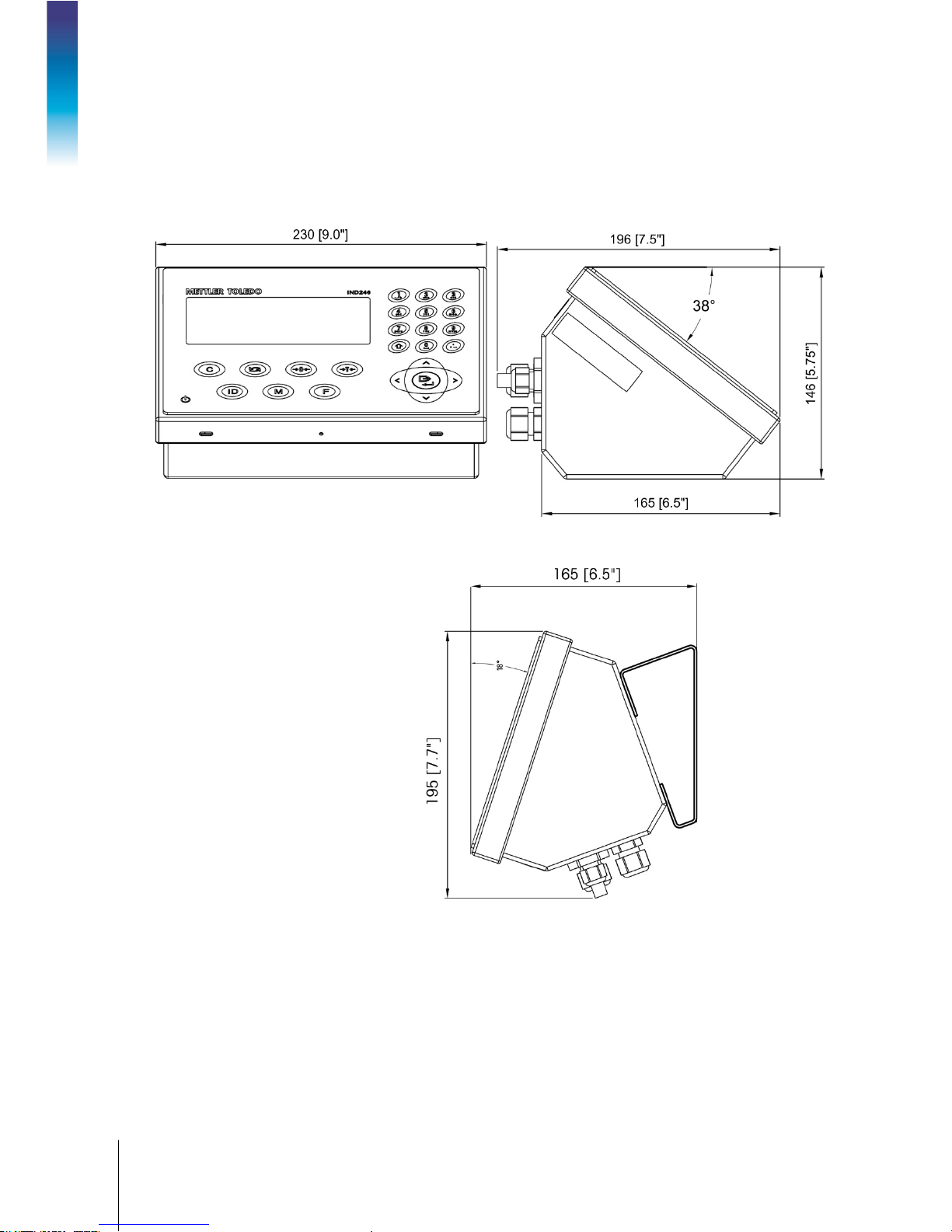

1.7. Physical Dimensions

The physical dimensions of the IND246 enclosure are shown in Figure 1-2 and Figure 1-3 in mm

and [inches].

Introduction

Figure 1-2: IND246 Enclosure Dimensions

Figure 1-3: IND246 Dimensions with Brackets

Page 21

64084448 | 03 | 12/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

1-9

1.8. Main PCB

The IND246 terminal’s main printed circuit board (PCB) provides the analog load cell scale

interface, as well as the COM1 RS-232 serial port. The IND246 POWERCELL main board provides

the load cell interface and a standard COM1 RS-232/RS-422/RS-485 isolated serial port.

The main board also contains the power input connection (for either AC supply or battery,

depending on the model), display interface, keypad interface and six-position DIP switch.

An SD memory card socket is mounted to the PCB to support the optional SD memory and bus

connectors are included for the option boards.

1.8.1. SD Memory

An SD Memory card is included as a standard feature of the analog version of the IND246, and is

available as an option for the POWERCELL version. The card provides a medium on which to store

files such as Alibi memory, transaction records in the vehicle application, IDs in the counting

application and target weights in the checkweighing application.

The SD memory can be used to extract and save the configuration and calibration settings of the

terminal. These can then be restored to the terminal or loaded to a different terminal.

1.9. Scale Bases

1.9.1. Analog

The standard IND246 terminal supports analog scale bases and provides either 10 volts (AC

version) or 5 volts (battery version) of excitation to drive analog load cells. Up to four (battery

version) or ten (AC version) 350Ω load cells can be powered by the terminal.

A six wire load cell connection is provided with sense lines to help maintain accuracy as the load

cell cable resistance changes with temperature variations.

1.9.2. POWERCELL

The IND246 POWERCELL terminal supports scale bases that use POWERCELL PDX, GDD,

SLC611D or SLB615D load cells. Up to 12 load cells can be configured in a single scale platform.

The load cell network provides monitoring and logging of a variety of factors that can affect system

integrity, including weighing errors, overloads and network health. The specific characteristics differ

by type of load cell.

Page 22

1-10

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 12/2017

1.9.3. PowerDeck

The IND246 POWERCELL supports PowerDeckTM weighing platforms. These provide calibration

without weights for fast installation and visual guidance for leveling the floor platform.

Introduction

Figure 1-4: IND246 POWERCELL with PowerDeck Platform

1.10. Options

The following options are available for all versions of the IND246:

• COM2 Serial Port

One RS-232/485 isolated serial COM port

COM2 and DIO (relay output)

•

One RS-232/485 isolated serial COM port

Internal, discrete I/O (2 inputs and 4 outputs; supported in analog version only)

─ Inputs are optically isolated solid state and switch selectable as either active or passive

─ Output relays provide one normally open contact per relay

•

USB Port

One USB 2.0 compliant port, hardware bridge. Acts as virtual (UCP) COM port

USB and DIO (relay output)

•

One USB 2.0 compliant port, hardware bridge. Acts as virtual (UCP) COM port

Internal, discrete I/O (2 inputs and 4 outputs; supported in analog version only)

─ Inputs are optically isolated solid state and switch selectable as either active or passive

─ Output relays provide one normally open contact per relay

•

Ethernet Port

One 10/100 Ethernet port with automatic link polarity detection and correction. Supports TCP/IP socket

connection. Does not support FTP

1.10.1. COM2 Serial Port

This optional port provides RS-232 and RS-485 communication at rates from 300 to 115.2k baud.

The port is bidirectional and can be configured for various functions such as demand output,

continuous output, extended continuous output, SICS host communications or ASCII command

input (C, T, P, Z).

Page 23

64084448 | 03 | 12/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

1-11

The COM2 port is galvanically isolated for both RS-232 and RS-485, to provide surge voltage

protection.

The RS-485 connection can be used as an RS-422 transmit only when sending continuous output

to a scoreboard or remote display.

1.10.2. Discrete I/O

The Discrete I/O option is supported only in the analog version of the IND246.

The discrete I/O interface option provides dry-contact relay outputs. The relay contacts will switch up

to 30 volts DC or 250 volts AC at 1A.

The inputs are switch selectable as either active (for simple pushbutton control) or passive (for

connection to devices that supply their own power for the inputs).

1.10.3. USB

The USB port provided is a hardware bridge acting as a virtual COM port, and is used for

conversion of serial data. The port is bidirectional and can be configured for various functions such

as demand output, continuous output, extended continuous output, SICS host communications or

ASCII command input (C, T, P, Z).

1.10.4. Ethernet

The IND246 Ethernet option provides an RJ45 jack for connection to an Ethernet network or host

device. A TCP socket connection can be made to port 1701 to transfer files or to exchange data

with a PC. This port can also operate as a print client to send data to a network printer.

Page 24

1-12

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 12/2017

System line

1.11. Display and Keyboard

The IND246 terminal uses a graphic, transflective type Liquid Crystal Display (LCD) with a white

LED backlight. The front panel including the display and keypad is shown in Figure 1-4.

Alphanumeric

keypad

Introduction

Scale Function keys

1.11.1. Display Layout

At the top of the display, a single system line displays terminal status and operator error displays

and messages. Time and date and the status of the Digital I/O can be displayed in this area, when

so configured in setup.

Below the system line is the weight display. During normal, basic weighing operation, the IND246

terminal display shows the Gross or Net weight in the larger 28.5mm (1.1 in.) size. When one of

the applications is running, the weight is shown in 20mm (0.8 in.) high characters. Below the

weight display is a single line to display the weight units, the weight legend, the center of zero icon,

weight range and motion icon. Tare values also appear on this line, to the left of the display.

LCD display

Navigation

keys

Print/Enter key

Operational

keys

ON/OFF key

Figure 1-5: IND246 Front Panel Layout

At the bottom of the normal basic weighing display is a line used for data entry. For display

operation during setup, refer to Chapter 3,

1.11.2. Front Panel Keys

The IND246 terminal provides a total of 25 keys as operator interfaces. The ON/OFF key, four scale

function keys and three operational keys are positioned under the display while the alpha-numeric

keys are positioned to the right of the display. The print/enter key and navigation keys are located at

the bottom right of the display. These keys are used to enter the setup menu, to navigate and select

setup elements, and to enter values in setup as described in Chapter 3,

Configuration.

Configuration.

Page 25

64084448 | 03 | 10/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

2-1

This chapter covers

2 Operation: Terminal

2.1. Overview

This chapter provides information about the basic functionality of the IND246 terminal,

• Overview

• Basic Functionality

• Display Operation

• Keypad Operation

• Operator Menu

• Applications

2.2. Display Elements and Keypad Operation

Refer to Figure 1-4 for an over view of the layout of the front panel of the IND246.

2.2.1. Display Elements

including display operation, keypad functions and menu navigation.

Operation of the terminal varies depending on which functions are enabled, and on the

configuration of parameters in setup. Configuration is described in Chapter 3,

Terminal.

Configuration:

When in the weighing mode, the display is used for indicating the weight value and other types of

information related to the weight. Refer to Figure 2-1.

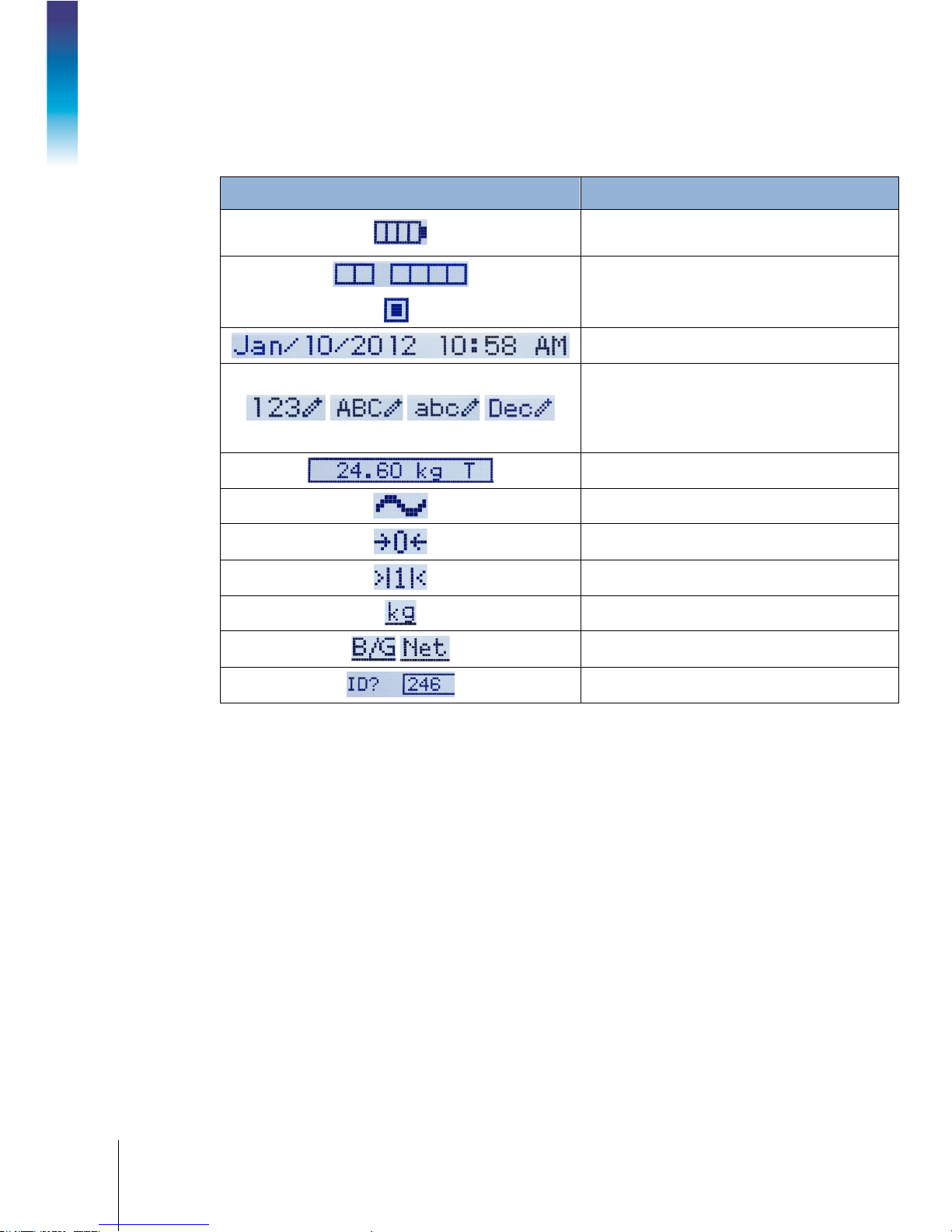

Figure 2-1: Elements of the Display

Page 26

2-2

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 10/2017

The symbols that may appear on the display are described in Table 2-1.

Table 2-1: Main Display Symbols

Symbol Explanation

Battery status indicator (battery-powered version

only)

= Input or output active

I/O status* (On and Off)

2 inputs, 4 outputs

Time and date*

Numeric, Upper case alpha, lower case alpha and

Decimal data entry mode.

Decimal mode is available only in the template

string entry screens

Operation: Terminal

Tare type and value indicator

Motion on platform

Center of zero

Weighing range*

Unit (kg, lb, oz, lb-oz, g, ton, t)

Bruto/Gross or Net operating mode

Prompt for ID entry and entry field

* These elements appear if configured to do so in setup.

Page 27

64084448 | 03 | 10/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

2-3

2.2.2. Keypad Operation

SHIFT

ZERO and SPACE

DECIMAL POINT, PERIOD,

1, HYPHEN, COMMA, SLASH, &

The front panel keys are used to operate and configure the IND246.

2.2.2.1. Alphanumeric Keypad

The IND246 permits the entry of both alphabetical and numeric data, using the 12-element keypad

to the right of the display.

2.2.2.1.1. Key Timeout Period

and additional punctuation

characters

Figure 2-2: Alphanumeric Keypad

When using the keys to enter data, after a set amount of time elapses the terminal accepts the

character that is currently displayed, and moves to the next position. Pressing the key without

allowing the Key Timeout period to elapse cycles through the current option for that key. For

instance, when the

The length of this timeout period is measured in tenths of a second, and can be configured in setup

Terminal > Terminal\Device.

at

2.2.2.1.2. SHIFT Key

The SHIFT key is used to determine the type of entry made when a key is pressed. Four entry

modes are available:

Numerical (123)

Upper case alphabetical (

Lower case alphabetical (

Decimal entry (

The current entry mode is indicated at the upper right corner of the display (Figure 2-1, Table 2-1).

2.2.2.1.3. Entering Numeric Data

To enter a number into either the ID (data) field in the main display, or into a field in one of the

setup screens:

4 key is pressed in mode, the display cycles through g, h and i.

ABC)

abc).

Dec) (This mode is available only when entering template strings.)

1. Check that the entry type display shows 123; if it does not, press the SHIFT key until 123

appears.

2. Then simply press the appropriate keys on the key pad – 0 to 9 and period.

Page 28

2-4

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 10/2017

SHIFT

ABC

8

T

SHIFT

abc

4 4

h

3 3

e

0

SHIFT SHIFT

4 4 4

I

6 6

N

3

D

SHIFT SHIFT

123

2 4 6

246

246

ENTER

Pressing a numeric key followed by TARE enters a manual tare value. Pressing the ID key

shifts focus to the prompt line at the bottom left of the screen, and allows data entry there.

To delete one or more characters, press the CLEAR key.

2.2.2.1.4. Entering Alphanumeric Data

To enter an alphabetic character:

1. Press the SHIFT key to access the character type (lower or upper case)

2. Press the appropriate key until the correct character displays.

For example, when the display is in its default (numeric, 123) entry mode, the key sequence to

enter

The IND246 (including a space) is shown in Table 2-2.

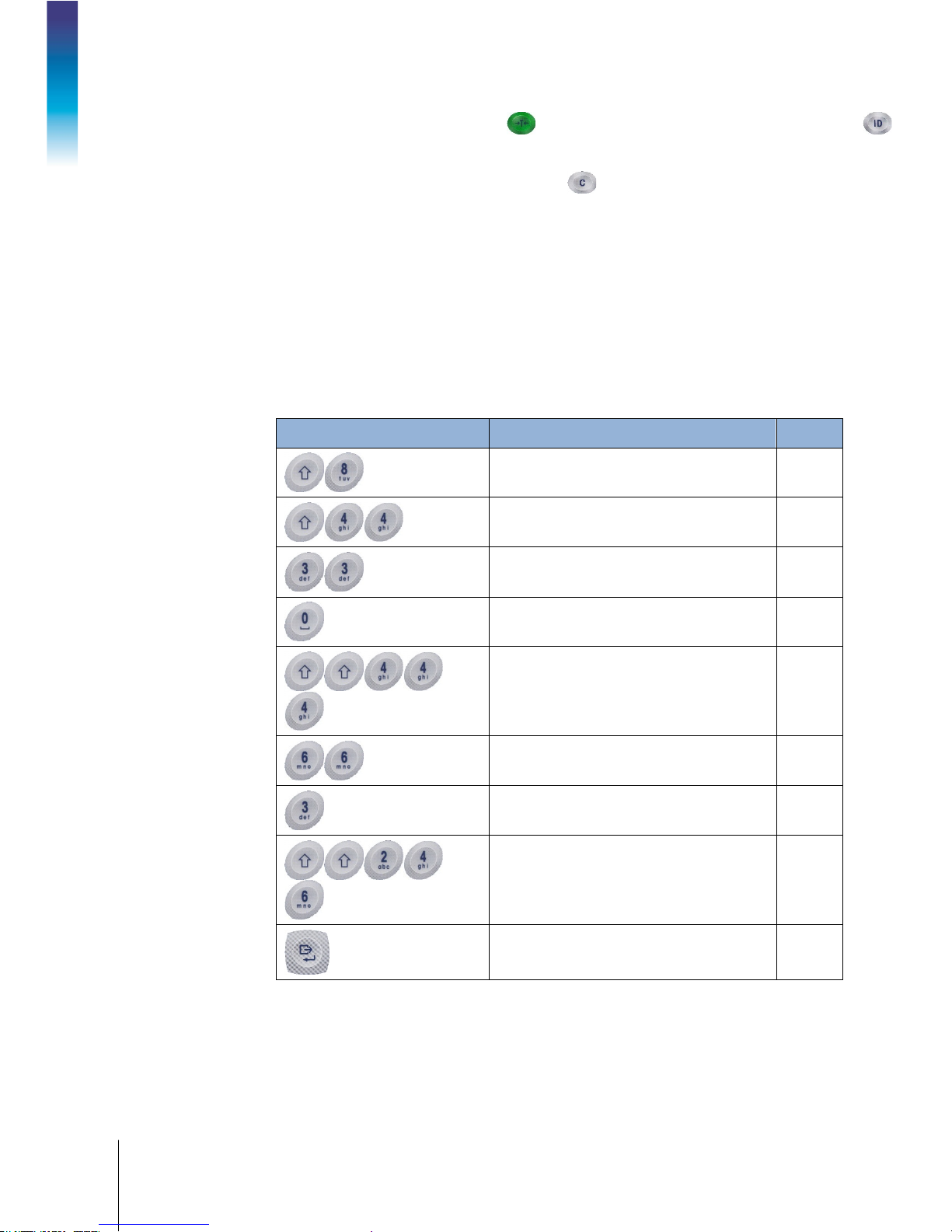

Table 2-2: Example Data Entry Sequence

Entry Explanation and Notes Result

Operation: Terminal

sets the input mode to

inputs a T

sets the input mode to

inputs an h

inputs an e

enters a space

returns input mode to ABC

inputs an I

inputs an N

inputs a D

sets the input mode to

inputs

confirms data entry

Page 29

64084448 | 03 | 10/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

2-5

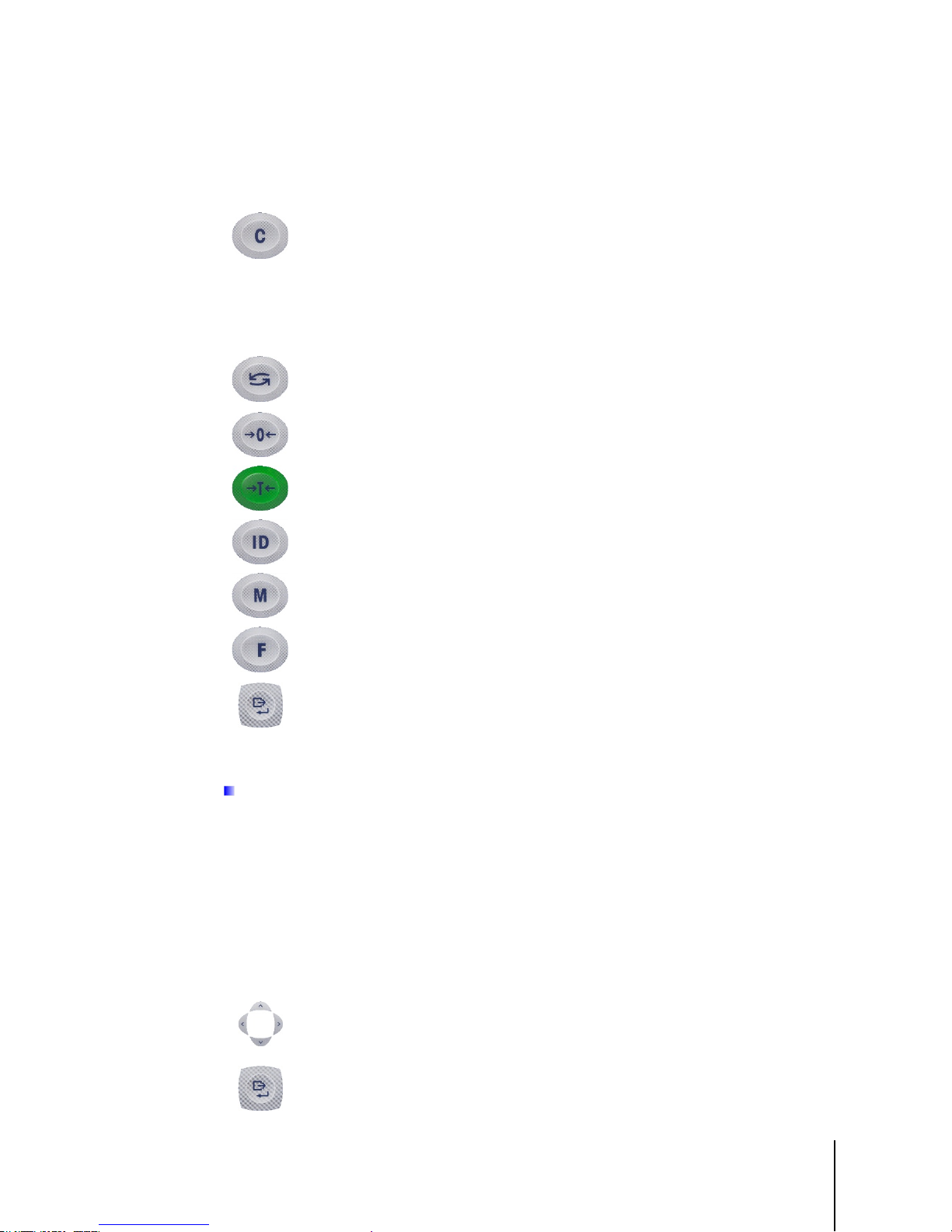

2.2.2.2. Function Keys

Scale > Units

Operator Menu

Table 2-3 explains the function of each of the keys during normal operation.

Table 2-3: Keypad Functions – Normal Operation

CLEAR

SWITCH UNITS

ZERO

TARE

MENU

FUNCTION

PRINT/ENTER

ID

When in the net weight mode, press CLEAR to clear the current tare value;

the display will revert to the gross weight value. CLEAR operates regardless

of motion on the scale. Note that once the tare value has been cleared, it

cannot be recalled. The complete tare process as described above must be

performed.

When in alphanumeric entry mode, press CLEAR to backspace and delete

the last character in a string.

Press to toggle between primary and secondary units, as configured in setup

at

.

Used to reset the displayed weight to Zero.

Captures current weight as a tare value, and sets terminal to Net mode.

Changes focus to the ID/data-entry field at the bottom left of the display.

Opens the Operator Menu – refer to the

section starting on

page 2-6.

Toggles between selected application and basic weighing.

Pressing the PRINT key in normal weighing mode will trigger a demand

output (if configured in setup)

During data entry, press ENTER to confirm current selection.

In menus, moves focus to next field label or entry/selection box.

The ZERO and TARE functions will not operate when there is motion on the scale. If one of these

keys is pressed while the scale is in motion, the command will be retained for the programmed

number of seconds while the terminal waits for no-motion. If a no-motion condition is not

detected within the timeout period, the request is cancelled and discarded.

2.2.2.3. Navigation Keys

The navigation keys are used for changing focus between on-screen items, for confirming a

selection, and to initiate a demand output.

ARROW KEYS

PRINT/ENTER

Table 2-4: Navigation Keys

Move focus, or the cursor, in the direction indicated. When the display is in

the menu mode, and the left-most item is selected, the LEFT arrow will return

to the previous screen.

Press the PRINT/ENTER key in the Navigation Keypad to accept the item or

selection in focus and move to the next display.

Page 30

2-6

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 10/2017

Icon in focus

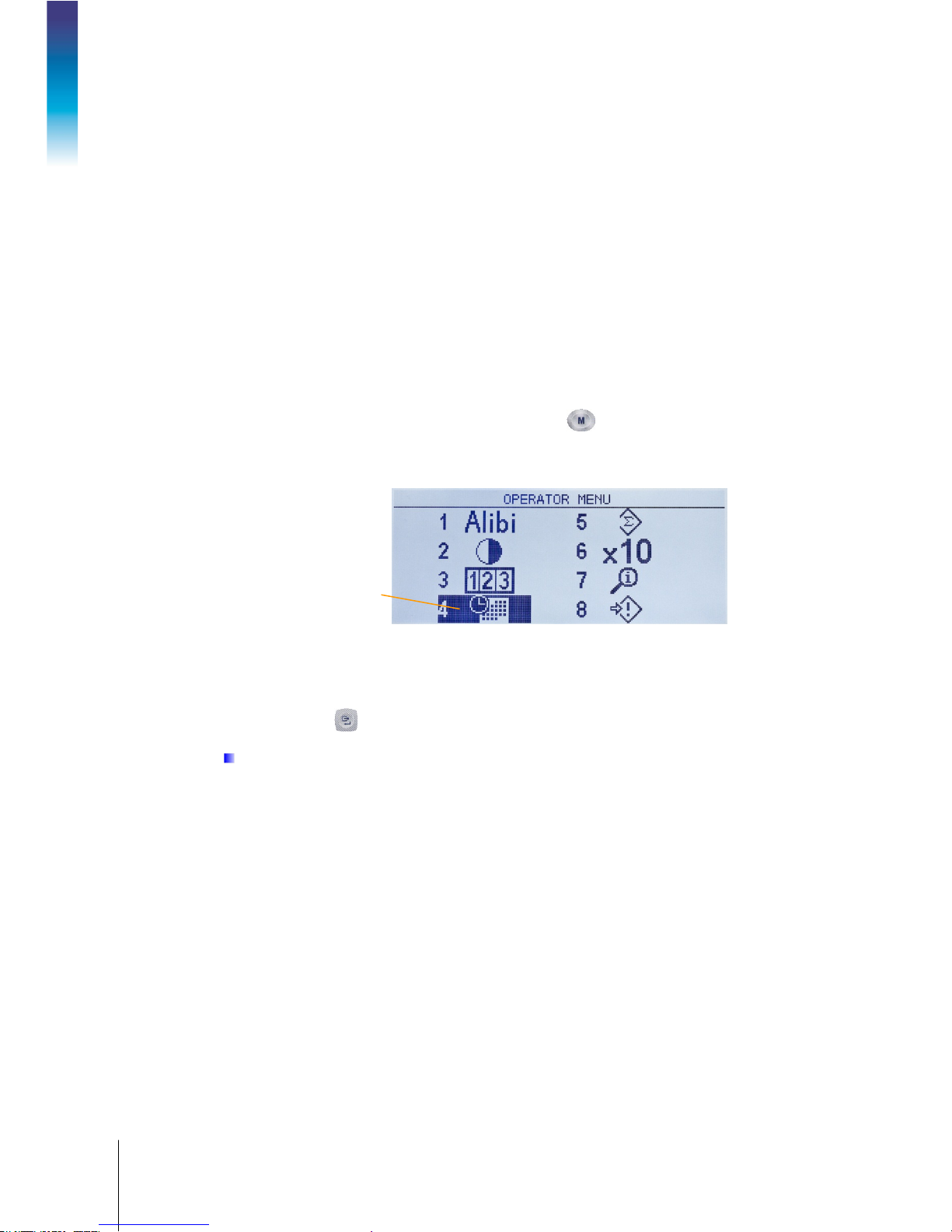

2.3. Operator Menu

There are a few functions that operators typically perform which are available in a top-level menu

system in the IND246 terminal. These include access to Alibi Memory, setting time and date,

adjusting contrast, viewing and resetting the transaction counter, viewing and clearing totals,

expanding the displayed weight resolution by 10, and recalling information. An explanation of how

to access these functions follows.

2.3.1. Language Selection – F Codes

Depending on the terminal’s language setup (at Terminal > Region > Language), parameter labels

in the operator menu will appear as words (“Hour”)

2.3.2. Menu Navigation

To access the operator menu, press the MENU key . The display will change from showing the

normal weigh display to an array of icons (Figure 2-3). The icons included depend on the

Operation: Terminal

terminal’s configuration – for details, refer to Table 2-5.

or as an F-code (“F3.3.2.1”).

Figure 2-3: Operator Menu Display

Items in this menu can be selected directly by pressing the corresponding number on the

alphanumeric keypad, or by using the arrow keys to move focus up, down, left and right and then

pressing ENTER .

When focus is in the left column, as in Figure 2-3 and Figure 2-4, pressing the LEFT arrow key

will exit the

SETUP menu and display the OPERATOR menu.

Page 31

64084448 | 03 | 10/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

2-7

2.3.2.1. Accessing Operator Screens

For instance, from the screen shown in Figure 2-3, pressing ENTER or pressing 4 displays the Time

& Date setup screen.

Here, items may be selected by number or by moving focus and pressing ENTER.

Figure 2-4: Set Time & Date

Note that the header line reflects the currently displayed screen, and the input mode icon is also

displayed at upper right.

In Figure 2-4, a field label (Hour) is in focus. In Figure 2-5, the numeric entry field for the Hour

value is selected. Use the number pad keys to modify the value. When the correct number is

displayed, press ENTER to confirm the selection and move to the next (

When all the time and date values are correctly set, press the LEFT arrow key to return to the

Operator Menu (Figure 2-3).

2.3.2.2. Operator Menu Items

Depending upon programming in the terminal and whether one of the Applications is enabled in

setup, the icons displayed will include a selection of those shown in Table 2-5. The

Recall and Setup icons will always appear last in the list. The other icons can be added or removed

from the operator menu by configuring the menu keys display in setup at

Figure 2-5: Time & Date Setup, Hour Field in Focus

Minutes) field label.

Information

Terminal > Menu Keys.

Page 32

2-8

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 10/2017

Standard

Alibi Memory

ALIBI SEARCH

Adjust Contrast

ADJUST CONTRAST

Transaction Counter

TRANSACTION COUNTER

Time and Date

SET TIME & DATE

Totals Memory

TOTALS

Expand x10

Information Recall

RECALL INFO

Setup

Terminal >

Users

Counting Application

Switch Sampling

Mode

ID Memory

ID Table

Reports

ID Table

Over/Under Application

Target

ACTIVE VALUES

Set Target

QUICK SET TARGET

Target Memory

TARGET TABLE

Reports

TARGET TABLE

Vehicle Application

Temporary ID

Temporary ID Table

Permanent ID

Permanent ID Table

Table 2-5: Operator Menu Icons

Icon Function Description

Displays the

Displays the

Displays the

Displays the

Displays the

on whether Subtotals are enabled or disabled.

screen.

screen.

screen.

screen.

screen. The contents of this screen vary depending

Changes the main display to add an additional digit to the displayed

weight. The appearance of the display will differ, depending on whether

the terminal is in approved or non-approved mode.

Operation: Terminal

Displays the

software version, last calibration date, etc., are displayed.

Enters the setup menu. Depending on the settings made at

, it may be necessary to enter a valid user name and password to

access the setup menus.

Switches sampling mode between piece sampling and APW entry.

Displays a view of the

screen, where the terminal’s serial number,

, from which an ID can be selected for use.

Displays the

Displays

for printing . The table can also be cleared .

screen, where target, tolerances and description

can be edited.

Displays

screen, where target, tolerances and

description can be entered using live scale weight.

Displays

Displays the

.

cleared

Displays a view of the

Displays a view of the

, from which a target can be selected for use.

for printing. Totals in the table can also be

.

.

Page 33

64084448 | 03 | 10/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

2-9

Icon Function Description

Reports

Vehicle ID Table

Temporary ID Table

Peak Weigh Application

Reports

PEAK WEIGHT MEMORY

Search Field 1

Transaction Counter*

Data Comparison

equal to (=)*

Data

2.3.3. Alibi Memory

The Alibi Memory key opens the ALIBI SEARCH screen. Here, the contents of Alibi memory can be

viewed and printed. The results can be filtered using comparisons with one or two search fields,

and printed. The elements of this search screen are summarized in Table 2-6. Default values are

indicated in bold.

Displays a printable

depending on which mode is active.

Displays the

printed or cleared

.

page. Values on the page can be

Table 2-6: Elements of the Alibi Search Screen

Field Function / Options

, Date (2010-11-07), Gross Weight, Net

Weight, Tare Weight, Time (15:51:40)

Less than (<), less than or equal to (<=),

or equal to (=>), greater than (>), not equal to (≠)

Alphanumeric entry field for value to be compared. Default is * (all).

or

,

,greater than

Once the search has been defined and executed, the ALIBI SEARCH VIEW screen opens, displaying

the results.

Press the UP and DOWN arrow keys to scroll through the entries.

Press the PRINT key to output the search results to a connected printer or the LEFT arrow to exit

the view.

To print a report, the communications port must have the assignment Reports.

2.3.4. Adjust Contrast

Displays the ADJUST CONTRAST screen. The display contrast can be set for best visibility. Press the

UP arrow to make the screen darker, and the DOWN arrows to make the screen lighter, and exit by

pressing the LEFT arrow.

Figure 2-6: Alibi Search View

Page 34

2-10

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 10/2017

Non-Approved Mode

123.45

123.456

Figure 2-7: Contrast Adjustment Screen

2.3.5. Transaction Counter

Opens the TRANSACTION COUNTER screen, in which a value can be entered in the Next Transaction

screen. Once the value is entered, press ENTER to confirm it, and the LEFT arrow key to exit the

screen.

Operation: Terminal

2.3.6. Totals Memory

Depending on how the terminal is configured in setup at Application > Totalization, this screen

displays the Grand Total of number of transactions and total weight, or both Grand Total and

Subtotal of transactions with accumulated weight for each.

2.3.7. Expand x 10

This icon toggles the weight display between standard and expanded mode. When this icon is

selected and ENTER pressed, the weight display appears. The appearance of the expanded display

differs, depending on whether or not the terminal is approved:

I

Figure 2-8: Transaction Counter Screen

Figure 2-9: Totals Memory

An extra digit of resolution is added to the main weight display (e.g.

becomes

The PRINT function prints weights in the expanded format.

) and the x10 indicator appears in place of the range symbol.

Page 35

64084448 | 03 | 10/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

2-11

Approved Mode

123.45

123.456

2.3.8. Information Recall

Model

Serial No.

Platform Model

Platform Serial Number

Option 1

Option 2

Firmware

The information recall function is always available in the operator menu. In the Operator Menu,

select the Information Recall icon and press ENTER, to recall specific information about the

terminal. The RECALL screen displays, with two screens of information available. Move between the

two screens by pressing the UP and DOWN arrow keys. Figure 2-10 shows an example of the two

pages of information, and Table 2-7 lists the elements in the sequence in which they appear. Some

items may not appear, depending on the configuration of the terminal. Press the LEFT arrow key to

exit the RECALL screen.

An extra digit of resolution is added to the main weight display, in a smaller size

(e.g.

The PRINT function is disabled.

becomes

). The range symbols operate normally.

Figure 2-10: Information Recall Screens

Table 2-7: Information Recall Menu Items

Item Value/Explanation

The model number of the terminal is shown.

Serial number of the terminal as entered in the setup mode.

The model number of the platform.

Serial number of the platform.

Shows installed hardware options, if any.

Shows the firmware revision number (2 lines).

Page 36

2-12

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

64084448 | 03 | 10/2017

Service

Approved

Certificate #

Calibrated

IP Address

• Zero

• Clearing Tare

• Information Recall

Tare

Print

Target

Item Value/Explanation

2.3.9. Setup Access

The last icon displayed in the OPERATOR menu accesses the SETUP menu, from which all the

Operation: Terminal

terminal’s programming parameters can be viewed and modified. The settings and options

available in setup are described in detail in Chapter 3,

It is not intended that operators enter the setup mode. After a weighing system is installed and is

operational, it should not be necessary for an operator to access setup.

Note that a security password can be enabled in setup. When a password is set, it must be entered

in order to access setup. This protects the setup parameters from inadvertent changes.

Shows date of most recent calibration.

A telephone number used to contact METTLER TOLEDO authorized

service.

or

No

Yes

Indicates whether the terminal has been programmed as Approved

for use in legal for trade applications.

Displays approval certificate number. An approval region must be

selected to enable the display of the certificate number.

IP address assigned to the terminal. Shown only when the Ethernet

option is installed.

Configuration: Terminal.

2.4. Basic Functionality

This section provides information about IND246 basic functionality. Functions addressed in this

section include:

•

Refer to Chapter 3, Configuration: Terminal, for further information about programming all the

functionality described in this section.

2.4.1. Zero

The Zero function is used to set or reset the initial zero reference point of the terminal. There are

three types of zero setting modes:

• Automatic Zero Maintenance

• Power Up Zero

• Pushbutton Zero

When the scale platform or weighbridge is empty, the terminal should indicate zero. The gross zero

reference is recorded during calibration. If pushbutton zero is enabled in configuration and the

weight is within the zero range pressing ZERO will capture a new gross zero reference point.

•

•

Page 37

64084448 | 03 | 10/2017

METTLER TOLEDO IND246 and IND246 POWERCELL User's Guide

2-13

2.4.1.1. Automatic Zero Maintenance

• Pushbutton Tare

• Net Sign Correction

• Keyboard (Preset) Tare

• Automatic Tare

Tare Clear

Automatic Zero Maintenance (AZM) enables the IND246 to compensate for the build up of small

amounts of weight and track itself back to the center of zero. Within the AZM operating range

(selectable from 0.5, 1, 3 or 10 divisions), when the terminal is in a no motion condition, it makes

small adjustments to the current zero reading to drive the weight reading toward the true center-ofzero. When the weight is outside of the programmed AZM range, this feature is not functional.

2.4.1.2. Power Up Zero

Power-Up Zero enables the IND246 terminal to capture a new zero reference point after power is

applied. If there is motion during a power-up zero capture function, the terminal will continue to

check for a no-motion condition until zero is captured.

Power-up zero can be disabled or enabled, and a range above and below calibrated zero can be

configured. The range is programmable from 0% to 100% of capacity and can include a positive

range and also a range below calibrated zero.

2.4.1.3. Pushbutton Zero

The pushbutton (semi-automatic) zero function can be accomplished by pressing the ZERO key

, by programming a discrete input or by issuing a serial command.

The range for all types of semi-automatic zero is selectable (Disabled, 2% or 20%) plus or minus

from the calibrated zero point.

Remote initiation of the semi-automatic Zero command is possible via a discrete input, or an ASCII

‘Z’ command sent serially (CPTZ and SICS interface modes).

2.4.2. Tare

Tare is the weight of an empty container. A tare value subtracts from the gross weight

measurement, providing the computation of the net weight (material without the container). The tare