Mettler Toledo IND231, IND236 Installation Manual

Installation Manual

IND231/IND236

Weighing Terminal

English

Essential Services for Dependable Performance of Your IND231/IND236 Weighing Terminal

Register your product

Contact METTLER TOLEDO for service

Installation, Configuration, Integration and Training

Initial Calibration Documentation

Periodic Calibration Maintenance

IND231/IND236

Weighing Terminal

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper use of your

new equipment according to this Manual and regular calibration and maintenance by our factorytrained service team ensures dependable and accurate operation, protecting your investment.

Contact us about a service agreement tailored to your needs and budget. Further information is

available at www.mt.com/service

There are several important ways to ensure you maximize the performance of your investment:

1.

www.mt.com/productregistration so we can contact you about enhancements, updates and

important notifications concerning your product.

.

: We invite you to register your product at

2.

accuracy – an out of specification scale can diminish quality, reduce profits and increase

liability. Timely service from METTLER TOLEDO will ensure accuracy and optimize uptime and

equipment life.

a.

trained, weighing equipment experts. We make certain that your weighing equipment is

ready for production in a cost effective and timely fashion and that personnel are trained for

success.

b.

requirements are unique for every industrial scale so performance must be tested and

certified. Our calibration services and certificates document accuracy to ensure production

quality and provide a quality system record of performance.

c.

confidence in your weighing process and documentation of compliance with requirements.

We offer a variety of service plans that are scheduled to meet your needs and designed to

fit your budget.

: The value of a measurement is proportional to its

: Our service representatives are factory-

: The installation environment and application

: A Calibration Service Agreement provides on-going

English

interference, and (2) this device must accept any interference received, including

© METTLER TOLEDO 2013

No part of this manual may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopying and recording, for any

purpose without the express written permission of METTLER TOLEDO.

U.S. Government Restricted Rights: This documentation is furnished with

Restricted Rights.

Copyright 2013 METTLER TOLEDO. This documentation contains proprietary

information of METTLER TOLEDO. It may not be copied in whole or in part

without the express written consent of METTLER TOLEDO.

METTLER TOLEDO reserves the right to make refinements or changes to the

product or manual without notice.

COPYRIGHT

METTLER TOLEDO® is a registered trademark of Mettler-Toledo, LLC. All other

brand or product names are trademarks or registered trademarks of their

respective companies.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE REFINEMENTS OR

CHANGES WITHOUT NOTICE.

FCC Notice

This device complies with Part 15 of the FCC Rules and the Radio Interference

Requirements of the Canadian Department of Communications. Operation is

subject to the following conditions: (1) this device may not cause harmful

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his or her expense.

Declaration of Conformity is located on the documentation CD.

RoHS Compliance Statement.

The majority of our products fall within categories 8 and 9. Those categories

currently do not fall within the scope of the Directive 2002/95/EG (RoHS) of

January 27, 2003. If our products are intended for use in other products

which themselves fall within the scope of the RoHS Directive, compliance

requirements have to be separately negotiated contractually.

Those products which fall within categories 1-7 and 10 will be in compliance

with the EU RoHS Directive from no later than July 1, 2006.

If it is not possible for technical reasons to replace any non-RoHS-compliant

substances in any of the above products as required, we plan to inform our

customers in a timely manner

Statement regarding harmful substances

We do not make direct use of harmful materials such as asbestos, radioactive

substances or arsenic compounds. However, we purchase components from

third party suppliers, which may contain some of these substances in very small

quantities.

English

Warnings and Cautions

• READ this manual BEFORE operating or servicing this equipment and FOLLOW these

instructions carefully.

• SAVE this manual for future reference.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT THE AC VERSION OF THE

IND231/IND236 TERMINAL TO PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE

GROUND PRONG.

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THE TERMINAL. EXERCISE CARE WHEN

MAKING CHECKS, TESTS AND ADJUSTMENTS THAT MUST BE MADE WITH POWER ON.

FAILING TO OBSERVE THESE PRECAUTIONS CAN RESULT IN BODILY HARM AND/OR

PROPERTY DAMAGE.

WARNING

THE IND231/IND236 IS NOT DESIGNED FOR USE IN AREAS CLASSIFIED AS HAZARDOUS

BECAUSE OF COMBUSTIBLE OR EXPLOSIVE ATMOSPHERES. DO NOT INSTALL AN

IND231/IND236 INTO AN EXPLOSIVE ENVIRONMENT.

WARNING

WHEN THIS EQUIPMENT IS INCLUDED AS A COMPONENT PART OF A SYSTEM, THE

RESULTING DESIGN MUST BE REVIEWED BY QUALIFIED PERSONNEL WHO ARE FAMILIAR

WITH THE CONSTRUCTION AND OPERATION OF ALL COMPONENTS IN THE SYSTEM AND THE

POTENTIAL HAZARDS INVOLVED. FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN

BODILY HARM AND/OR PROPERTY DAMAGE.

CAUTION

THE NiMH BATTERY USED IN THIS DEVICE MAY PRESENT A RISK OF FIRE OR CHEMICAL

BURN IF MISTREATED. DO NOT CRUSH, DISASSEMBLE, HEAT ABOVE 60°C OR INCINERATE.

REPLACE BATTERY WITH 30044650 ONLY. USE OF ANOTHER BATTERY MAY PRESENT A RISK

OF BURN, FIRE OR EXPLOSION.

CAUTION

USE CAUTION WHEN TESTING THE BATTERY. A LARGE AMOUNT OF CURRENT MAY BE

PRESENT IN THE BATTERY.

CAUTION

DISPOSE OF USED BATTERY PROMPTLY. KEEP AWAY FROM CHILDREN. DO NOT

DISASSEMBLE AND DO NOT DISPOSE OF IN FIRE.

Warnings and Cautions

CAUTION

BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC COMPONENTS OR

INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT ALWAYS REMOVE POWER

AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY CONNECTIONS OR

DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE PRECAUTIONS COULD RESULT IN

DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT AND/OR BODILY HARM.

NOTICE

DO NOT ATTEMPT TO CHARGE THE Ni-MH BATTERY IF THE BATTERY TEMPERATURE IS BELOW 0°C (32°F).

CHARGING IS NOT POSSIBLE AT OR BELOW THIS TEMPERATURE. DO NOT OPERATE THE BATTERY CHARGER

OUTSIDE ITS TEMPERATURE RANGE OF 0°C (32°F) TO 40°C (104°F).

NOTICE

TO AVOID DAMAGE TO THE PCB OR LOAD CELL, REMOVE POWER FROM THE IND231/IND236 TERMINAL AND

WAIT AT LEAST 30 SECONDS BEFORE CONNECTING OR DISCONNECTING ANY HARNESS.

NOTICE

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

Disposal of Electrical and Electronic Equipment

In conformance with the European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment (WEEE) this device may not be disposed of in domestic waste. This also applies

to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment.

If you have any questions, please contact the responsible authority or the distributor from

which you purchased this device.

Should this device be passed on to other parties (for private or professional use), the

content of this regulation must also be related.

Thank you for your contribution to environmental protection.

IND231/IND236 Terminal Installation Manual

English

Contents

1 Introduction ................................................................................. 1-1

1.1. IND231/IND236 Overview ............................................................. 1-1

1.1.1. Standard Features ............................................................................................... 1-1

1.1.2. IND231/IND236 Terminal Types ........................................................................... 1-2

1.2. Use in Hazardous Areas ................................................................. 1-2

1.3. Specifications ............................................................................... 1-2

1.4. Model Identification ....................................................................... 1-4

1.5. Inspection and Contents Checklist ................................................... 1-5

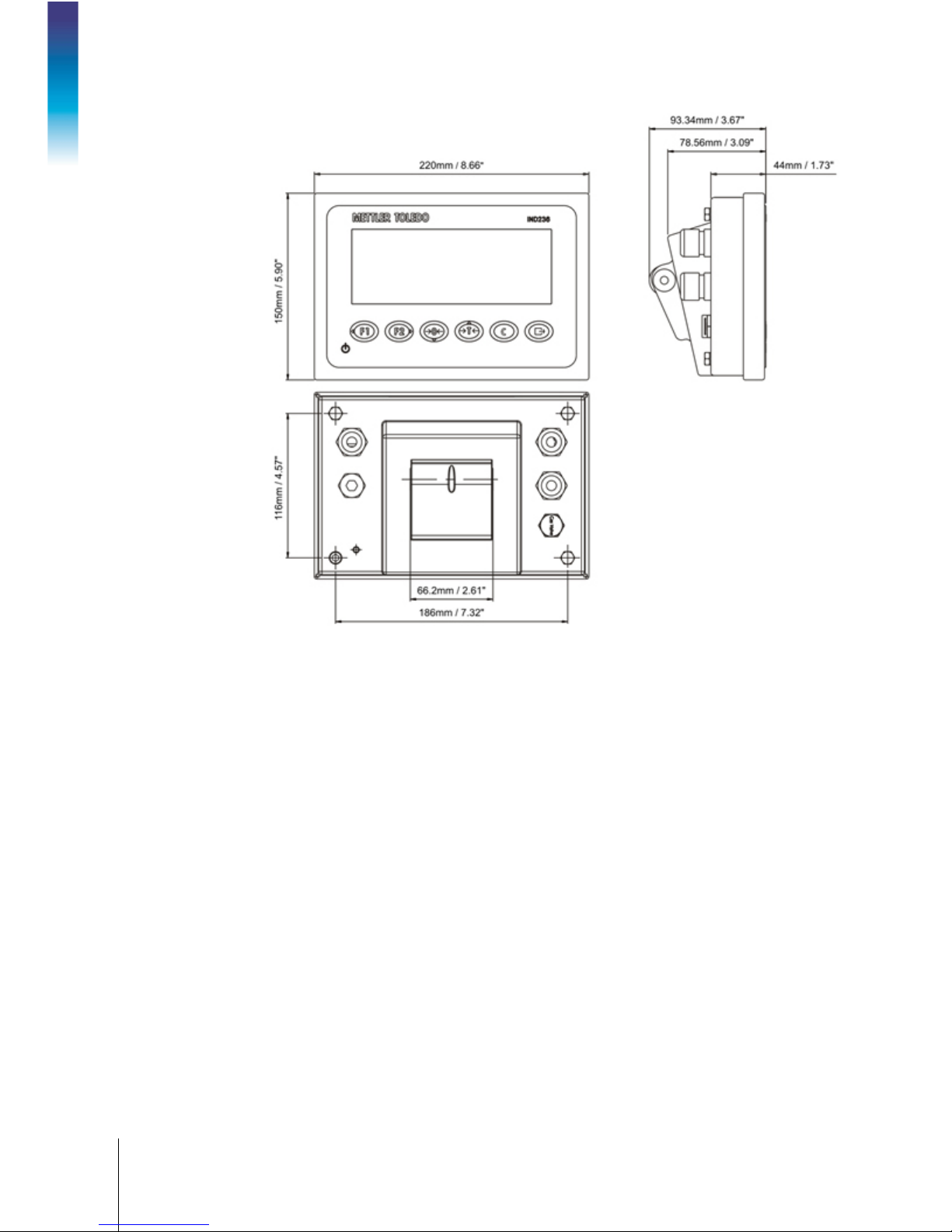

1.6. Physical Dimensions ..................................................................... 1-5

1.7. Main PCB .................................................................................... 1-6

1.8. Scale Bases ................................................................................. 1-7

1.9. Options ........................................................................................ 1-7

1.9.1. Isolated Serial interface RS232/RS422/RS485 ........................................................ 1-7

1.9.2. Discrete I/O ......................................................................................................... 1-7

1.9.3. USB ................................................................................................................... 1-7

1.10. Display and Keyboard ................................................................... 1-8

1.10.1. Display Layout .................................................................................................... 1-8

1.10.2. Front Panel Keys ................................................................................................. 1-8

2 Installation .................................................................................. 2-1

2.1. Opening the Enclosure ................................................................... 2-1

2.2. Environmental Protection ............................................................... 2-2

2.3. Mounting the Terminal ................................................................... 2-3

2.3.1. IND231Mounting ................................................................................................ 2-3

2.3.2. IND236 Mounting ............................................................................................... 2-4

2.4. Installing Cables and Connectors .................................................... 2-5

2.4.1. Connectors and Cable Glands ............................................................................... 2-6

2.4.2. PCB Identification ................................................................................................ 2-8

2.4.3. Main Board Wiring Connections ............................................................................ 2-8

2.4.4. AC Power Connection .......................................................................................... 2-9

2.4.5. Analog Load Cell Connection .............................................................................. 2-10

2.4.6. COM1 Serial Port Connection .............................................................................. 2-16

2.4.7. Wiring Connections for Options ........................................................................... 2-16

2.5. Capacity Label Instructions ........................................................... 2-21

2.6. Closing the Enclosure .................................................................. 2-22

2.6.1. Torque Specifications for Enclosure Fasteners ....................................................... 2-22

2.7. Sealing the Enclosure .................................................................. 2-22

30094803 | 00 | 08/2013

METTLER TOLEDO

1

Contents

2

METTLER TOLEDO IND231/IND236 Terminal Installation Manual

30094803 | 00 | 08/2013

English

This chapter covers

1 Introduction

The IND231/IND236 industrial scale terminal provides a compact yet flexible

• Overview of IND231/IND236

• Use in Hazardous Areas

• Specifications

• Model Identification

• Inspection and Contents

Checklist

• Physical Dimensions

• Main PCB

• Scale Bases

• Options

• Display and Keyboard

solution for a variety of weighing needs. Available as either AC powered for

stationary applications or battery-powered for portable applications, this terminal is

at home in virtually any industrial environment.

Both 2mv/V and 3mv/V load cells are supported without the need for any

configuration change. The IND231/IND236 delivers precision measurement data

from grams to kilograms in a single, cost effective package.

Standard applications include basic weighing, animal weighing, Over/Under

checkweighing, counting and accumulation. Pre-defined application-specific print

templates including date and time stamp, provide transmission of weighing

transaction information to printers and PC software applications.

1.1. IND231/IND236 Overview

1.1.1. Standard Features

• Easy to handle plastic enclosure design for the IND231, rugged stainless steel enclosure for

the IND236

• Supports one analog load cell platform with up to four 350Ω load cells

• Can be used as a remote display to show weight from a separate main terminal

• Large seven segment LCD display with white backlight and graphic icons for clear readability

in varying light conditions

• Powered by either 85–264 V AC or internal battery pack

• One standard serial port (COM1) for asynchronous, bidirectional communication

• Support for one of the following option boards:

COM2 electrically isolated RS232, RS422 and RS485 serial Interface

USB device Interface for connection to a PC

Discrete I/O interface

• Front panel key access to basic weighing functions – zero, tare, clear, configurable function

and print

• Selectable primary unit of measure including grams, kilograms, pounds and ounces

• Selectable second unit of measure including grams, kilograms, pounds and ounces

30094803 | 00 | 08/2013

METTLER TOLEDO IND231/IND236 Installation Manual

1-1

Introduction

Enclosure Type

Product Dimensions

(w × h × d)

Shipping Dimensions

(w × h × d)

Product Weight

Shipping Weight

Environmental Protection

Operating Environment

• Backup and restore of configuration and calibration settings, using InSite

• Automatic shutoff and backlight timeout features to help conserve energy and extend battery

life when using the battery powered version

1.1.2. IND231/IND236 Terminal Types

The terminal is available in the following four versions:

• IND231plastic housing, AC power (also designed for use with AA size alkaline cells)

• IND231plastic housing, Rechargeable Ni-MH Battery power

• IND236 stainless steel housing, AC power

• IND236 stainless steel, Rechargeable Ni-MH battery power

1.2. Use in Hazardous Areas

DO NOT USE THE IND231/IND236 TERMINAL IN AREAS CLASSIFIED AS HAZARDOUS

BECAUSE OF COMBUSTIBLE OR EXPLOSIVE ATMOSPHERES. CONTACT AN AUTHORIZED

METTLER TOLEDO REPRESENTATIVE FOR INFORMATION ABOUT HAZARDOUS AREA

APPLICATIONS.

WARNING

®

SL tool

1.3. Specifications

The IND231 and IND236 terminal conforms to the specifications listed in Table 1-1.

Table 1-1: Terminal Specifications

Specifications IND231 IND236

Plastic, configurable as desk top or

column/wall mount enclosure

220 mm x 150 mm x 102 mm

(8.66 in. x 5.90 in. x 4.02 in.)

350 mm x 220 mm x 195 mm

(13.78 in. x 8.66 in. x 7.68 in.)

AC Version: 1.2 kg (2.6 lb)

Battery Version: 1.5 kg (3.3lb)

2.0 kg 3.0 kg

IP54 IP66/67

Operating temperature range: -10 °C to +40 °C

Storage temperature range: -20 °C to +60 °C

Relative Humidity: 10-95%, non-condensing.

Stainless steel, configurable as desk

top or column/wall mount enclosure

220 mm x 150 mm x 93.3 mm

(8.66 in. x 5.90 in. x 3.67 in.)

AC Version: 2.2 kg (4.9 lb)

Battery Version: 2.5 kg (5.5 lb)

1-2

METTLER TOLEDO IND231/IND236 Installation Manual

30094803 | 00 | 08/2013

English

Hazardous Areas

Power

Display

Weight Display

Scale Types

Number of Cells

Number of Scales

Analog/Digital Update Rate

Load Cell Excitation Voltage

Minimum Sensitivity

Keypad

Communication options

Application

Specifications IND231 IND236

The terminal cannot be operated in areas classified as Hazardous because of

combustible or explosive atmospheres in those areas. Contact an authorized

METTLER TOLEDO representative for information about hazardous area

applications.

AC version: Operates at 85–264 VAC, 49–61 Hz and includes a power cord

configured for the country of use.

Battery version :

Six "AA" size alkaline batteries or

NiMH rechargeable battery pack

(about 120hrs for one load cell)

40 mm height character, seven digits seven segment LCD with white backlight

including weight display, weight units, gross/net indication and symbols for

motion, center of zero and variable applications

Maximum displayed resolution of 30,000 divisions

Analog load cells

Up to four 350 ohm load cells(2 or 3 mV/V)

Internal analog: 80 Hz

Seven keys: Zero, Tare, Clear, On/Off, Print, F1 & F2 (configurable)

Serial Interfaces

Standard: One serial port (COM1) RS-232, 1,200 to 115,200 baud

Optional isolated serial port: (COM2) RS-232/422/485, 1,200 to

115,200 baud

Discrete I/O Interface

Optional Discrete I/O port: 2 inputs/4 outputs

USB Interface

Optional USB device port

Protocol

Serial Inputs: ASCII commands for CTPZ (Clear, Tare, Print, Zero), SICS

(most level 0 and level 1 commands)

Battery version :

NiMH rechargeable battery (about

120hrs for one load cell)

One

5 VDC

0.5 µV/e

30094803 | 00 | 08/2013

Zero, Tare, Print, X10, Date & Time, Basic weighing, Animal weighing,

Counting with APW enhancement, Over/Under checkweighing with 10 records

database, Accumulation, Remote display

METTLER TOLEDO IND231/IND236 Installation Manual

1-3

Introduction

Approvals

Accessories

Specifications IND231 IND236

Weights and Measures,

USA:

NTEP Class III/IIIL - 10,000d; Cert. #13-049,

Canada:

Class III - 10,000d; Class IIIHD - 20,000d,

Europe:

Class III, 2 x 3000e and 6000e; TC8351, T5976

OIML:

Class III, 2 x 3000e and 6000e; R76/2006-NL1-13.06

Product Safety

UL, cUL, CE

Wall mount/column mount bracket; desk bracket.

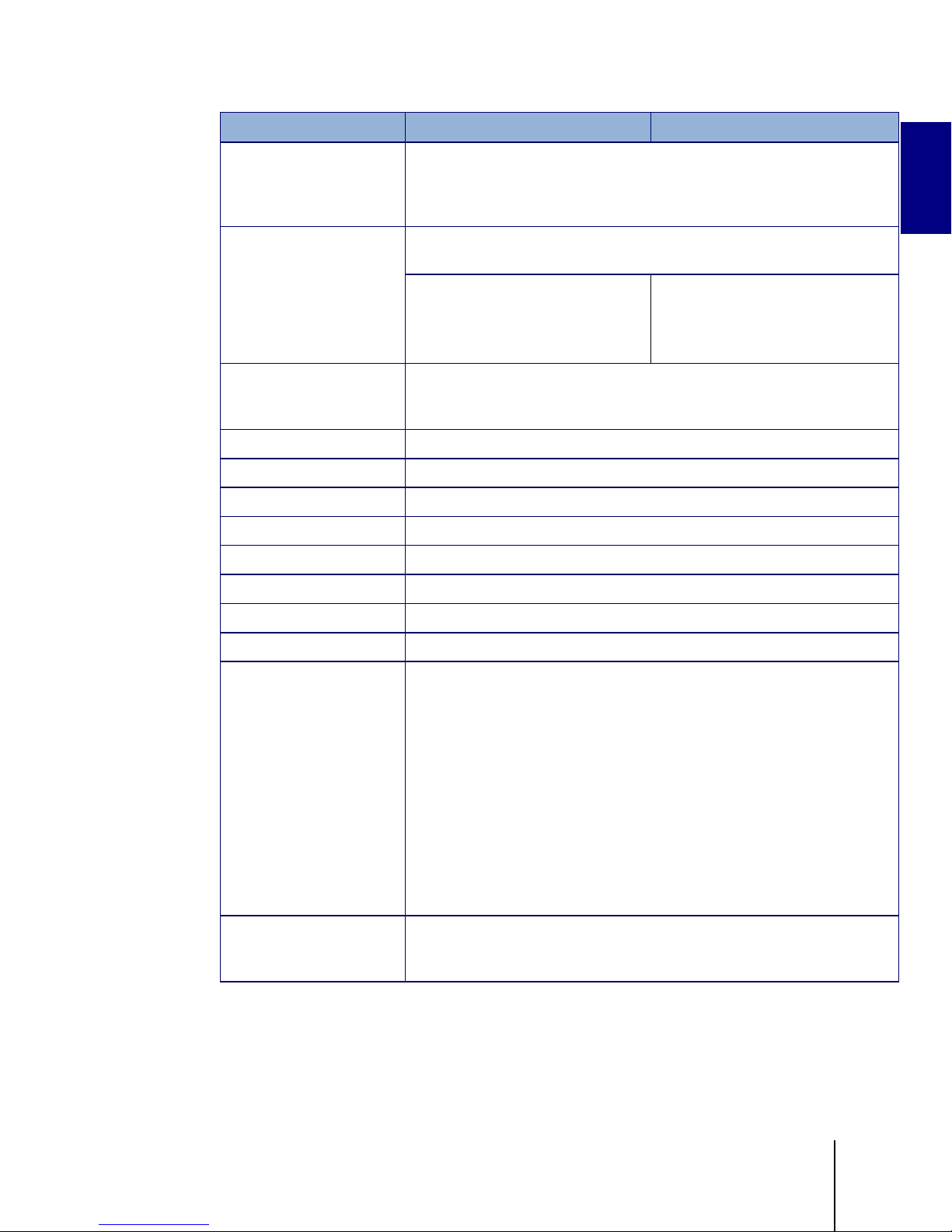

1.4. Model Identification

The IND231/IND236 model number, factory number and serial number are located on the data

plate of the terminal. Refer to Figure 1-1 to verify the configuration of the IND231/IND236 terminal

when it left the METTLER TOLEDO factory.

1-4

METTLER TOLEDO IND231/IND236 Installation Manual

Figure 1-1: IND231 Configuration Chart

30094803 | 00 | 08/2013

English

1.5. Inspection and Contents Checklist

Verify the contents and inspect the package immediately upon delivery. If the shipping container is

damaged, check for internal damage and file a freight claim with the carrier if necessary. If the

container is not damaged, remove the terminal from its protective package, noting how it was

packed, and inspect each component for damage.

If shipping the terminal is required, it is best to use the original shipping container. The terminal

must be packed correctly to ensure its safe transportation.

The package should include:

• IND231 or IND236 Terminal • User manual (or resource CD)

• Installation Manual (or Safety Instructions) • Battery Pack (battery version only)

• Power cord • Mounting brackets (1)

• Bag of miscellaneous parts

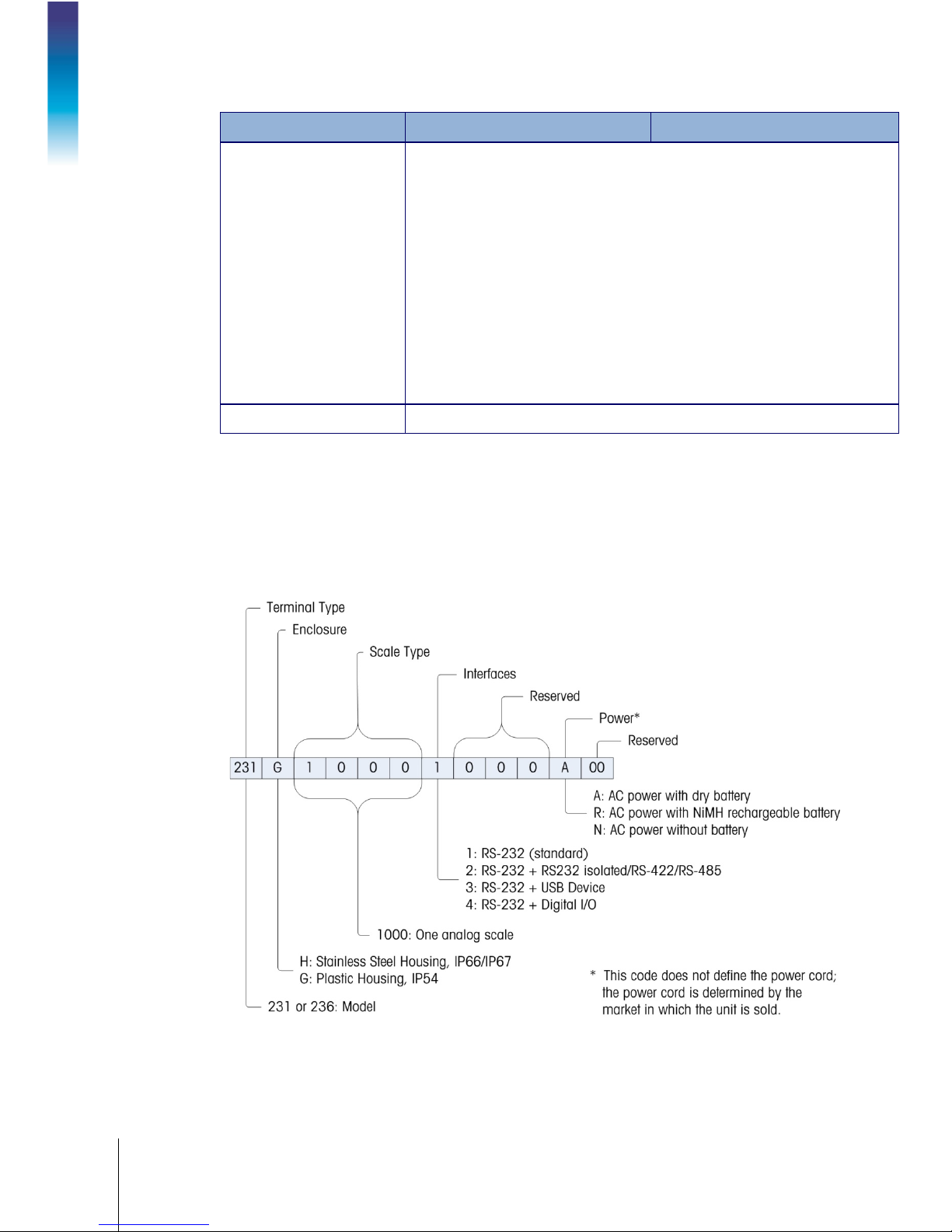

1.6. Physical Dimensions

The physical dimensions of the IND231/IND236 enclosure are shown in Figure 1-2 and Figure 1-3

in mm and [inches].

30094803 | 00 | 08/2013

Figure 1-2: IND231 Enclosure Dimensions

METTLER TOLEDO IND231/IND236 Installation Manual

1-5

Introduction

Figure 1-3: IND236 Enclosure Dimensions

1.7. Main PCB

The IND231/IND236 terminal’s main printed circuit board (PCB) provides the analog load cell

scale interface, as well as the COM1 RS-232 serial port. The COM1 RS-232 serial port supports bidirectional communications at speeds up to 115200 bps. This port can be used for saving terminal

configuration data to a PC via the InSite

The main board also contains the DC power input connection, display interface, keypad interface,

and interface port for the options.

An AC/DC power board supplies the terminal with DC +12V/1A output.

An optional charging board is included with the rechargeable battery powered version.

®

SL tool.

1-6

METTLER TOLEDO IND231/IND236 Installation Manual

30094803 | 00 | 08/2013

English

1.8. Scale Bases

The IND231/IND236 terminal supports analog scale bases and provides 5 volts of excitation to

drive analog load cells. Up to four 350Ω load cells can be powered by the terminal.

A four- or six-wire load cell connection is provided, with sense lines to help maintain accuracy as

the load cell cable resistance changes due to variations in temperature.

1.9. Options

Three kinds of option interface can be mounted on COM2. The connection pin specifications are

printed on the PCB.

The following options are available for the IND231 and IND236.

1.9.1. Isolated Serial interface RS232/RS422/RS485

This optional port provides RS-232 and RS-422/485 communication which can be configured in

setup. The port is bidirectional and can be used for various functions such as print, auto print,

Toledo continuous output or SICS communications.

The COM2 port is galvanically isolated for both RS-232 and RS-485, to provide surge voltage

protection.

The RS-485 connection can be used as an RS-422 transmit only, when sending continuous output

to a scoreboard or remote display.

The interface RS422/485 is required for data transmission with higher baud rate over longer

distances up to 500 m.

Communication settings can be configured in the terminal setup menu.

1.9.2. Discrete I/O

The discrete I/O interface option provides four dry-contact relay outputs. The relay contacts will

switch up to 30 volts DC or 250 volts AC at 1A.

The two inputs are switch selectable as either active (for simple pushbutton control) or passive (for

connection to devices that supply their own power for the inputs).

1.9.3. USB

The USB port provided is a UART-USB device bridge acting as a virtual COM port, and is used for

communication of serial data to devices such as a PC. The port is bidirectional and can be

configured for various functions such as print, auto print, Toledo continuous output or SICS

communications. USB external keyboards and bar code scanners are not supported.

30094803 | 00 | 08/2013

METTLER TOLEDO IND231/IND236 Installation Manual

1-7

Introduction

User’s Guide

Configuration.

Configurable

1.10. Display and Keyboard

IND231/IND236 uses a transflective type segment LCD display with a white backlight. The main

character height is 40 mm. The front panel, including display and keypad, is shown in Figure 1-4.

The only keypad difference between IND231 and IND236 is the name on the upper right corner of

the terminal.

Function keys

Print Key

ON/OFF key

Figure 1-4: IND231 Front Panel Layout

1.10.1. Display Layout

At the top of display, a single system line displays terminal status such as range number, center of

zero, checkweighing status, counting, accumulation and auto accumulation.

Below the system line is the weight display block. During normal, basic weighing operation, the

terminal display shows the gross or net weight in the larger 40 mm (1.57 in.) size. When one of

the applications is running, prompting messages or menu index characters are also shown in 40

mm (1.57 in.) height. At the right of weight display is a vertical column displaying the gross and

net symbols, average piece symbol, and weight units. The star symbol, minus symbol and

dynamic symbol appear in a column to the left of the weight display block.

At the bottom of the normal basic weighing display is a block used for assigning functions to

and

. For display and keypad operation during setup, refer to Chapter 3 in the

,

1.10.2. Front Panel Keys

The IND231/IND236 terminal operator interface provides a total of seven membrane keys. The print

key and five scale function keys (three with fixed function, two with configurable functions) are

positioned under the display.

Arrows on the first four keys indicate their use in menu navigation.

1-8

METTLER TOLEDO IND231/IND236 Installation Manual

30094803 | 00 | 08/2013

English

User’s Guide

Operation

The ON/OFF key is located at the bottom left of the display. These keys are used to enter the setup

menu, to navigate and select setup elements as described in Chapter 2 of the

.

,

30094803 | 00 | 08/2013

METTLER TOLEDO IND231/IND236 Installation Manual

1-9

Introduction

1-10

METTLER TOLEDO IND231/IND236 Installation Manual

30094803 | 00 | 08/2013

English

2 Installation

This chapter covers

• Opening the Enclosure

• Environmental Protection

• Mounting the Terminal

• Installing Cables and

Connections

• Capacity Label Instructions

• Closing the Enclosure

• Sealing the Enclosure

This chapter provides installation instructions for the IND231/IND236 terminal.

Please read these procedures thoroughly before beginning installation.

This section includes details about opening and mounting the enclosure, and

explains how to install cables and PCBs. Instructions for labeling, closing and

sealing the enclosure are also provided.

2.1. Opening the Enclosure

BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC COMPONENTS OR INTERCONNECTING

WIRING BETWEEN ELECTRONIC EQUIPMENT ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30)

SECONDS BEFORE ANY CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT AND/OR BODILY HARM.

CAUTION

The front panel of the IND231/IND236 terminal is locked in place by four screws which attach it to

the rear housing of the enclosure. To access the terminal’s PCB in order to install options, connect

internal wiring and set switches, separate the front panel from the enclosure as follows:

1. For IND231, use a T-20 torx screwdriver to loosen three of the screws. Use a slotted

screwdriver to loosen the sealing screw, indicated in Figure 2-1.

2. For IND236, use a 10mm socket wrench to loosen three of the screws. Use a 5mm Allen Head

insert screwdriver to loosen the sealing screw, indicated in Figure 2-2. Note that the screws are

captive, and remain attached to the rear cover of the IND236.

30094803 | 00 | 08/2013

Figure 2-1: IND231 Screws (left) and IND236 Sealing Screw (right)

METTLER TOLEDO IND231/IND236 Installation Manual

2-1

Installation

Sealing Screw

Figure 2-2: Opening the Enclosures – IND231 (left) and IND236 (right)

3. Separate the front housing from the rear housing, as shown in Figure 2-3.

Figure 2-3: Removing the Cover

2.2. Environmental Protection

The IND231/IND236 terminal is designed for standard industrial use. IND231 has been tested and

found to meet IP54 standards. The IND236 meets the requirements of IP66/IP67.

2-2

METTLER TOLEDO IND231/IND236 Installation Manual

WARNING

THE IND231/IND236 IS NOT DESIGNED FOR USE IN AREAS CLASSIFIED AS HAZARDOUS

BECAUSE OF COMBUSTIBLE OR EXPLOSIVE ATMOSPHERES. DO NOT INSTALL AN

IND231/IND236 INTO AN EXPLOSIVE ENVIRONMENT.

30094803 | 00 | 08/2013

English

2.3. Mounting the Terminal

The terminal can be placed on a desktop, attached to a vertical surface or fastened to a column.

Mount the terminal where viewing is optimal and the terminal keypad is easily accessible.

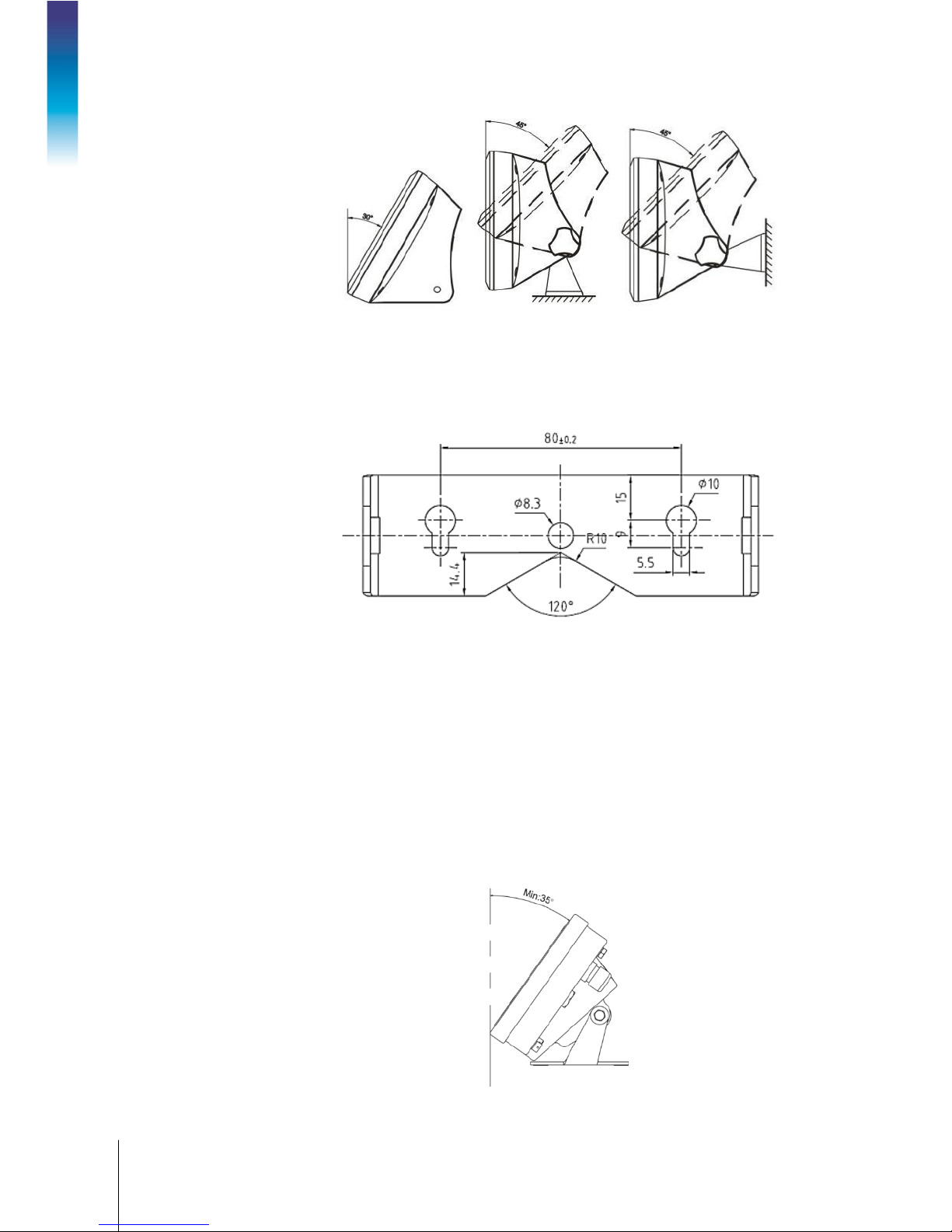

2.3.1. IND231Mounting

2.3.1.1. Desktop Mounting

The IND231 has two self-adhesive rubber feet (Figure 2-4) attached to the bottom of the housing to

prevent sliding.

Figure 2-4: IND231 – Rubber Feet

2.3.1.2. Wall Mounting& Column Mounting

One mounting bracket and two tightening knobs are included with the IND231. These can be used

to mount the terminal either to a column or to a vertical surface.

1. Use two bracket hand knobs to attach the brackets to the bottom of the terminal, as shown in

Figure 2-5.

Figure 2-5: Bracket and Tightening Knobs

2. The bracket allows a wide range of adjustment, as shown in Figure 2-6.

30094803 | 00 | 08/2013

METTLER TOLEDO IND231/IND236 Installation Manual

2-3

Installation

Figure 2-6: Adjusting the Bracket for Mounting on Wall or Column

3. Mark the position of the bracket mounting holes on the surface to which the terminal will be

mounted using the dimensions shown in Figure 2-7, or by holding the terminal up to the

surface and marking through the bracket holes.

Figure 2-7: Hole Pattern Template for Mounting Brackets

4. The hardware to mount the terminal bracket is not included with the terminal—it must be

supplied locally. Ensure that the mounting hardware is capable of supporting the weight of the

terminal, which is approximately 2.0 kg (4.4 lb). Using the locally supplied hardware, secure

the terminal bracket to the surface.

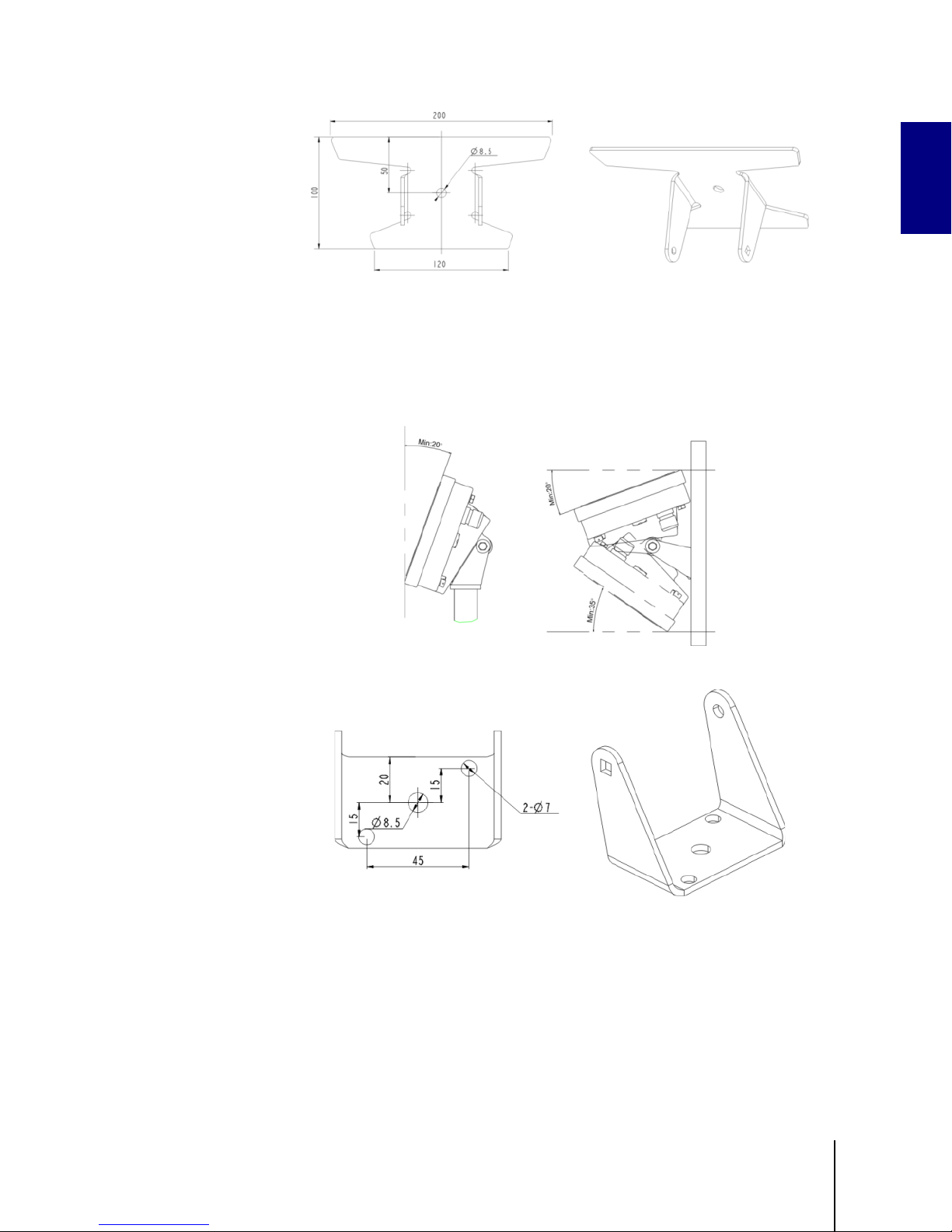

2.3.2. IND236 Mounting

2.3.2.1. Desktop Mounting

When the IND236 terminal will be mounted on a flat surface, an optional desktop mounting bracket

(PN: 22021070) is available for purchase.

2-4

METTLER TOLEDO IND231/IND236 Installation Manual

Figure 2-8: IND236 with desktop mounting Brackets

30094803 | 00 | 08/2013

English

Figure 2-9: IND236 desktop Bracket Dimensions

2.3.2.2. Wall Mounting & Column Mounting

One mounting bracket is included with the IND236. This can be used to mount the terminal either to

a column or to a vertical surface. The bracket allows a wide range of adjustment, as shown in

Figure 2-10.

Figure 2-10: IND236 Mounted to Column (left) and Wall (right)

Figure 2-11: IND236 Wall and Column Bracket Dimensions

2.4. Installing Cables and Connectors

Information for installing cables and connectors for the IND231/IND236 terminal is provided in this

section, including the following:

• Connectors and Cable Glands

• Enclosure Opening Assignments

30094803 | 00 | 08/2013

METTLER TOLEDO IND231/IND236 Installation Manual

2-5

Installation

• PCB Identification

• Main Board Wiring Connections

• AC Power Connection

• Charging Board and Rechargeable Battery Pack Connections

• Analog Load Cell connection

• COM1 Serial Port Connection

• Wiring Connections for Options

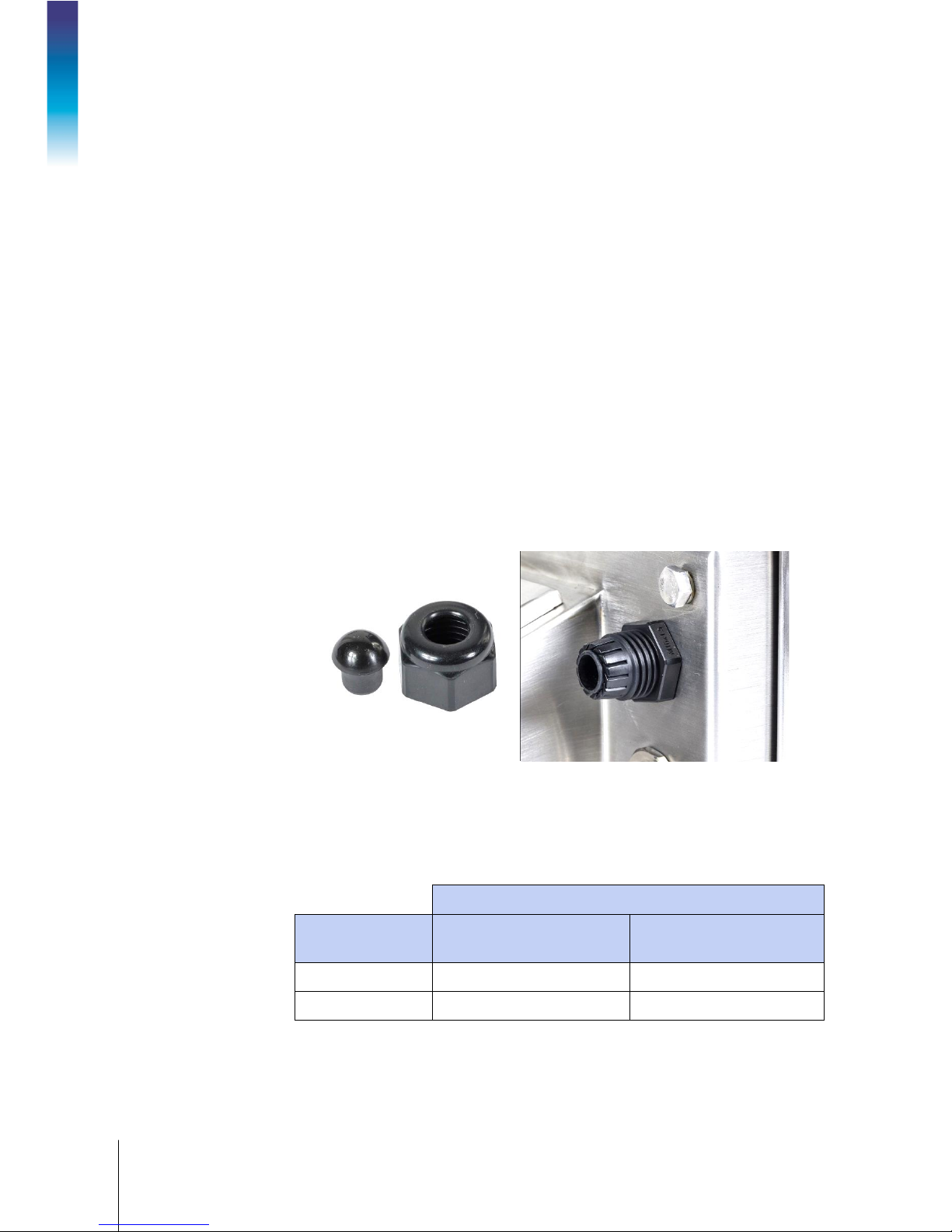

2.4.1. Connectors and Cable Glands

The IND231 uses standard (IEC320 C14) power socket and DSUB-9 connectors for RS-232

communication. Cable glands are used for load cell and option connections.

The IND236 terminal is designed to withstand severe wet environments. However, care must be

taken when installing cables and/or connectors that enter the terminal enclosure. To ensure a

watertight seal:

• Before connecting wires, pass the cables through an appropriately sized cable gland. Figure

2-12 shows a cable gland with its clamping nut removed.

Figure 2-12: Cable Gland

• Depending upon the diameter of the cable to be installed, select (Table 2-1) one of the rubber

grommets (if required) to properly seal around the cable.

Table 2-1: Gland, Grommet and Cable Sizes

IND231

Grommet

None 4–8 mm 5–10 mm

Small grommet 3–6.5 mm

When making cable terminations inside the enclosure, ensure that the cable length from the

Load Cell Cable Gland

Cable Diameter

IND236

and Option Cable Gland

4.5–6.8 mm

terminal strip/connector to the terminal housing is sufficient so that no strain is placed on the

connector assembly when the housing is in the fully open position.

2-6

METTLER TOLEDO IND231/IND236 Installation Manual

30094803 | 00 | 08/2013

English

1

2

3

4

After making the wiring connections described in the next section, ensure that the nut on the

cable gland is tightened properly to seal around the cable. The seal must be watertight.

2.4.1.1. Enclosure Opening Assignments

The Figure 2-13 shows the openings in the IND231 enclosure.

1 2 3 4

Figure 2-14 shows the openings in the IND236 enclosure and Table 2-2 indicates the assignment

of each opening.

Figure 2-13: IND231 Enclosure Openings

1 4

2 3

Figure 2-14: IND236 Enclosure Openings

Table 2-2: Connectors and Cable Gland Assignments

Assignment

Position

Standard connection Optional connection

AC Power Cord -

None (option port) Isolated RS-232/422/485 USB Discrete I/O

COM1 (RS-232) -

Load Cell Cable -

30094803 | 00 | 08/2013

METTLER TOLEDO IND231/IND236 Installation Manual

2-7

Installation

This is the only method

to change scale parameters in an approved terminal.

Entering Setup Mode

Scale |

Type Approval

User’s Guide, Configuration

Option board

2.4.2. PCB Identification

The IND231/IND236 terminal circuit boards all mount on the PCB support assembly. The AC

connection board is only needed for the IND236. The charging board is only used for terminals

powered by a rechargeable battery pack. The option boards all mount in the same location. Figure

shows the location of each type of board.

2-15

AC/DC power board

AC connection board

location

(IND236 only)

(beneath cover

Main board

Option board

location

Charging board

location (For

rechargeable battery

only)

Figure 2-15: Circuit Board Locations

2.4.3. Main Board Wiring Connections

The Figure 2-16 shows the assignment of connectors on the main board. Be sure to attach cables

to the correct socket.

AA Cell Enclosure

DC power

Charging board socket

COM1 RS-232

Metrology

switch

Keypad

Load Cell

The metrology switch is a momentary contact switch. When it is pressed, the terminal enters setup

at the F1 Scale settings menu, where scale parameters can be configured.

2-8

METTLER TOLEDO IND231/IND236 Installation Manual

sections in Chapter 3 of the

Display

Figure 2-16: Main Board Connections

Refer to the

Backlight

and

, for more details.

30094803 | 00 | 08/2013

English

2.4.4. AC Power Connection

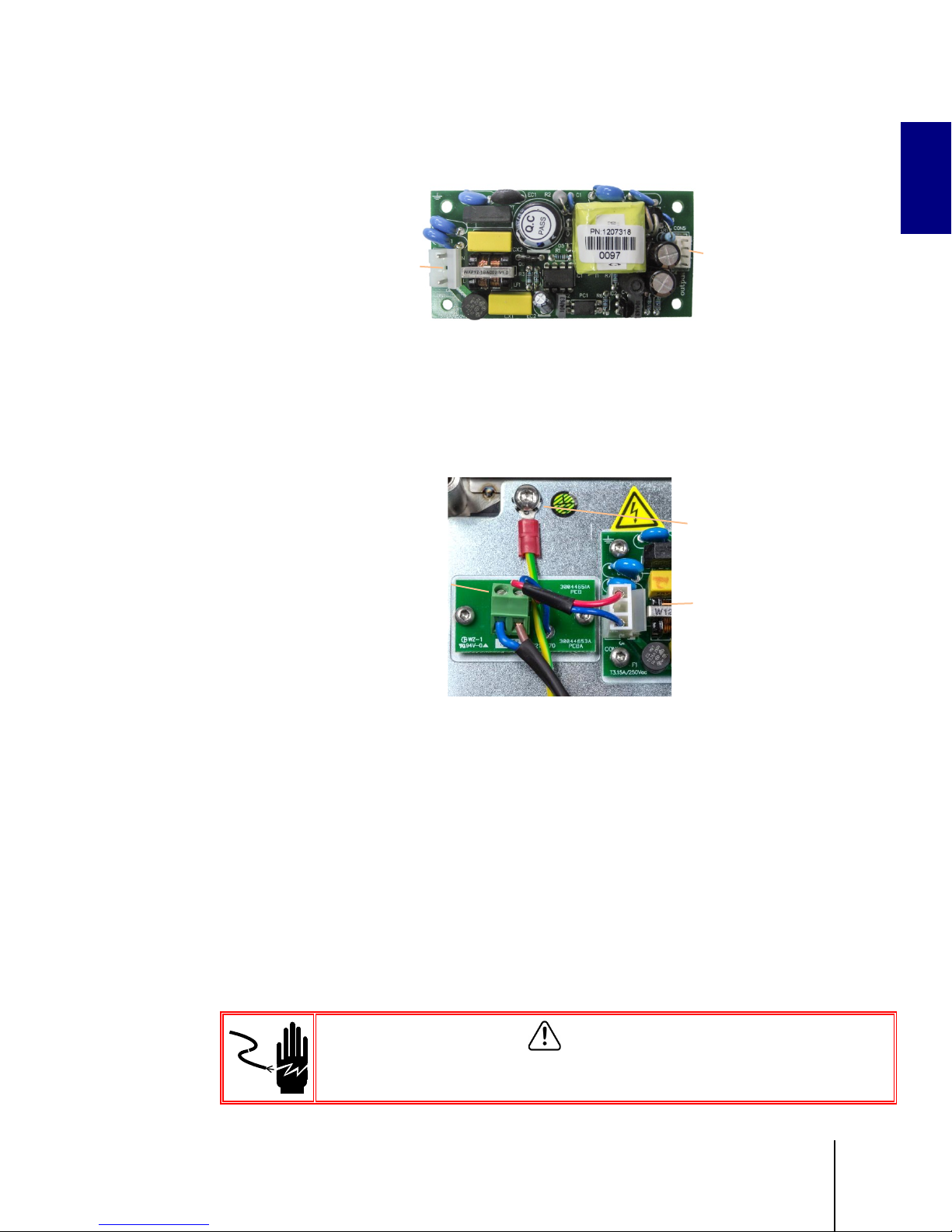

Figure 2-17 shows an AC Power board without its protective cover.

AC Lines input

DC lines output

Figure 2-17: Power Board

An external power cord with a standard power socket (IEC320 C14) is supplied for the IND231.

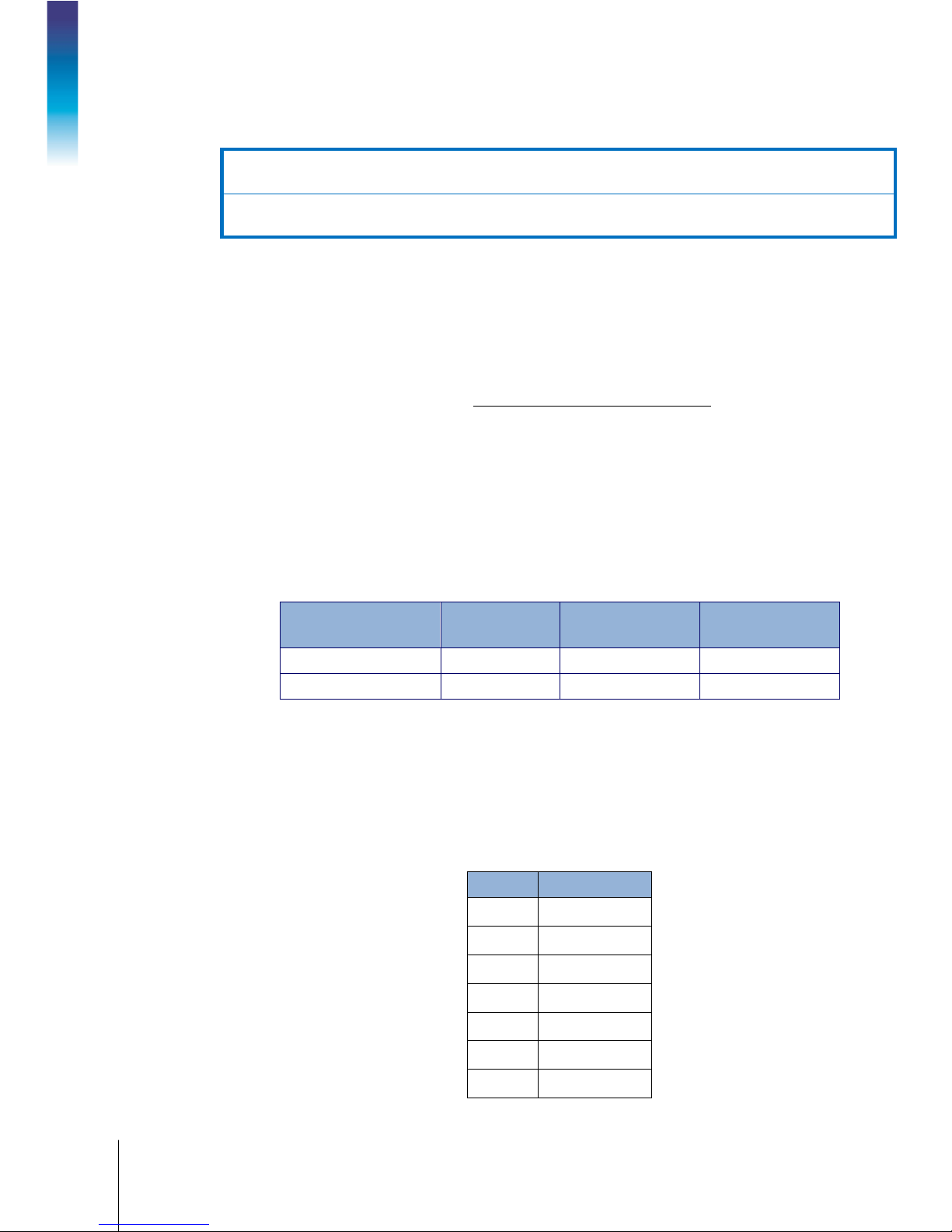

A permanently attached line cord supplies AC power to the AC version of the IND236 terminal. The

ground wire has a loop terminal for connection to the ground connection inside the terminal (Figure

2-18).

Power cord ground

wire connected to

grounding point

Connection board

Power board

(protective cover

removed)

Figure 2-18: IND236 AC Power Connection Board and Grounding

In the IND236, an interface PCB transfers power from the line cord to the power board (Figure

2-18).

The terminal requires 85 to 264 VAC (at 176 mA maximum) with a line frequency of 49 to 61 Hz

of power. It is internally fused at 3.15 amps, 250 volts.

The integrity of the power ground for equipment is important for both safety and dependable

operation of the terminal and its associated scale base. A poor ground can result in an unsafe

condition should an electrical short develop in the equipment. A good ground connection minimizes

extraneous electrical noise pulses. The IND231/IND236 should not share power lines with noisegenerating equipment. To confirm ground integrity, use a commercial branch circuit analyzer. If

adverse power conditions exist, a dedicated power circuit or power line conditioner might be

required.

30094803 | 00 | 08/2013

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT TO PROPERLY GROUNDED

OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

METTLER TOLEDO IND231/IND236 Installation Manual

2-9

Installation

2.4.5. Analog Load Cell Connection

NOTICE

TO AVOID DAMAGE TO THE PCB OR LOAD CELL, REMOVE POWER FROM THE IND231/IND236 TERMINAL AND WAIT

AT LEAST 30 SECONDS BEFORE CONNECTING OR DISCONNECTING ANY HARNESS.

Load cell connections are made to the load cell connector on the main board, indicated in Figure

2-16.

The IND231/236 terminal is designed to power up to four 350-ohm load cells (or a minimum

resistance of approximately 87 ohms). To confirm that the load cell load for this installation is

within limits, the total scale resistance (TSR) must be calculated, as follows:

TSR =

Load Cell Input Resistance (Ohms)

Number of Load Cells

Before connecting the load cells, ensure that the TSR of the load cell network to be connected to the

IND231/IND236 has a resistance greater than the minimums listed above. If the resistance is

below the minimum, the IND231/IND236 will not operate properly.

In addition, the maximum cable distance must be reviewed. Table 2-3 provides recommended

maximum cable lengths based on TSR and cable gauge.

Table 2-3: Recommended Maximum Cable Lengths

TSR (Ohms)

350 243/800 610/2000 1219/4000

87 (4-350 Ω cells)

24 Gauge

(meters/feet)

60/200 182/600 304/1000

20 Gauge

(meters/feet)

16 Gauge

(meters/feet)

The IND231/IND236 terminal is designed to support both 2mV/V and 3mV/V load cells from the

same circuitry. A load cell output rating selection jumper is not required.

Table 2-4 and Figure 2-19 show the terminal definitions for the analog load cell terminal strip. Note

that when using four-wire load cells, jumpers must be placed between the +Excitation and +Sense

terminals and between the −Excitation and −Sense terminals.

2-10

METTLER TOLEDO IND231/IND236 Installation Manual

Table 2-4: Load Cell Termination Pin Assignments

Pin Signal

1 +EXC

2 +SEN

3 +SIG

4 Shield

5 -SIG

6 -SEN

7 -EXC

30094803 | 00 | 08/2013

Loading...

Loading...