Page 1

ICS426x

ICS466x

ICS466x

ICS4_6x-series

English

中文

Quick Guide ICS4_6x-series Explosion-protected weighing solutions

快速使用指南 ICS4_6x 系列 防爆称重方案

Page 2

Page 3

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper use of your new

equipment according to this Manual and regular calibration and maintenance by our factory-trained service

team ensures dependable and accurate operation, protecting your investment. Contact us about a service

agreement tailored to your needs and budget. Further information is available at

www.mt.com/service

There are several important ways to ensure you maximize the performance of your investment:

1 Register your product: We invite you to register your product at

www.mt.com/productregistration

so we can contact you about enhancements, updates and important notifications concerning your

product.

2 Contact METTLER TOLEDO for service: The value of a measurement is proportional to its accuracy – an

out of specification scale can diminish quality, reduce profits and increase liability. Timely service from

METTLER TOLEDO will ensure accuracy and optimize uptime and equipment life.

ð Installation, Configuration, Integration and Training: Our service representatives are factory-trained

weighing equipment experts. We make certain that your weighing equipment is ready for production

in a cost effective and timely fashion and that personnel are trained for success.

ð Initial Calibration Documentation: The installation environment and application requirements are

unique for every industrial scale so performance must be tested and certified. Our calibration

services and certificates document accuracy to ensure production quality and provide a quality

system record of performance.

ð Periodic Calibration Maintenance: A Calibration Service Agreement provides on-going confidence

in your weighing process and documentation of compliance with requirements. We offer a variety of

service plans that are scheduled to meet your needs and designed to fit your budget.

en

ICS4_6x-series

Page 4

ICS4_6x-series

Page 5

Table of Contents

1 Safety instructions 3

1.1 Intended use ............................................................................................................... 3

1.2 Misuse ....................................................................................................................... 3

1.3 Safety notes for operation in hazardous areas ................................................................. 3

2 Introduction 4

2.1 Weighing terminals of the ICS4_6x-series....................................................................... 4

2.2 About this document .................................................................................................... 4

2.3 Further documents ....................................................................................................... 4

3 Installation 5

3.1 Installation, configration service and repair ..................................................................... 5

3.2 Leveling...................................................................................................................... 5

4 Operation 6

4.1 Display....................................................................................................................... 6

4.2 Keyboard.................................................................................................................... 8

4.3 Switching on/off........................................................................................................... 9

4.4 Zeroing....................................................................................................................... 9

4.5 Straight weighing......................................................................................................... 9

4.6 Taring ........................................................................................................................ 10

4.7 Printing or transferring data........................................................................................... 10

4.8 Switching weight unit ................................................................................................... 10

4.9 Counting (ICS466x only).............................................................................................. 11

4.10 Over/Under Checkweighing (ICS466x only) .................................................................... 12

4.11 Totalizing (ICS466x only)............................................................................................. 13

en

5 Maintenance 14

5.1 Cleaning..................................................................................................................... 14

5.2 Disposal..................................................................................................................... 14

6 Technical data 15

Table of Contents 1ICS4_6x-series

Page 6

Table of Contents2 ICS4_6x-series

Page 7

1 Safety instructions

1.1 Intended use

Weighing terminals of the ICS4_6x-series are part of a modular explosion-protected weighing system

consisting of a METTLER TOLEDO weighing terminal as indicator and at least one weighing platform.

Weighing terminals of the ICS4_6x-series are approved for operation in hazardous areas of Category 2 /

Division 1.

• Use the weighing terminal only for weighing in accordance with this Quick guide and the corresponding

User manual.

• The weighing terminal is intended for indoor use only.

• Any other type of use is considered as not intended.

Legal metrology

• For use in legal metrology, only use approved weighing systems.

• When using in legal metrology, the operating company is responsible for observing all national

weights& measurements requirements.

• Please contact the METTLER TOLEDO Service organization for questions related to the use in legal for

trade applications.

1.2 Misuse

• Do not use the weighing terminal other than for weighing operations.

• Do not modify the weighing terminal.

• Do not use the weighing terminal beyond the limits of the technical specifications.

en

1.3 Safety notes for operation in hazardous areas

Weighing terminals of the ICS4_6x-series are approved for operation in Category 2 / Division 1 hazardous

areas.

The operating company is responsible for the safe operation of the explosion-protected weighing system.

DANGER

Explosion hazard

1 Strictly observe the instructions of the operating company.

2 Comply with all national regulations for operation in hazardous areas, as well as the

instructions and information in this Quick guide.

Safety instructions 3ICS4_6x-series

Page 8

2 Introduction

2.1 Weighing terminals of the ICS4_6x-series

This Quick guide focuses on the following weighing terminals:

Type Numeric

keypad

ICS426x

ICS466x

Scale interfaces

Weighing terminals of the ICS4_6x-series are available with various scale interfaces. The built-in scale

interface is indicated directly after the terminal type.

ICS4_6x ... ...a ...d

Scale interface

– – Category 2 /

x x optional, e.g., with PBK9-/PFK-9 series

2.2 About this document

Soft keys Environment Terminal and platform combination

with PBK9-/PFK-9 series

Division 1

analog (ICS466x only) IDNet / SICSpro

This document contains all information for the operator of the weighing terminals of

the ICS4_6x-series.

• Read this document carefully before use.

• Keep this document for future reference.

• Pass this document on to any future owner or user of the product.

with option Category 2 / Division 1

with option Category 2 / Division 1 or PBA430x

2.3 Further documents

In addition to this printed document you can download the following documents from http://www.mt.com:

• Operator manuals

• Technical manuals

• Installation manuals

• Data sheets

• Videos

• Brochures

• Type approval documents

• For terminal and platform combinations: User manuals of the connected weighing platforms

Type approval documents

ICS4_6x Category 2 BVS 13 ATEX E042X

IECEx BVS 13.0050X

Division 1 FM16US0098X, FM16CA0056X

Introduction4 ICS4_6x-series

Page 9

3 Installation

CAUTION

Risk of personal injury, damage to property, erroneous operation or voided

warranty

Use only genuine METTLER TOLEDO accessories and cable assemblies with this product.

Use of unauthorized or counterfeit accessories or cable assemblies may result in voided

warranty, improper or erroneous operation, or damage to property (including the unit)

and personal injury.

3.1 Installation, configration service and repair

− For installation, configuration, service and repair of an explosion-protected weighing system call the

METTLER TOLEDO Service.

3.2 Leveling

ICS4_6x weighing terminals are available as terminal and platform combination.

Only weighing platforms that have been leveled precisely horizontally

provide accurate weighing results. Weights and Measures approved

weighing platforms have a level bubble to simplify levelling.

− Turn the adjustable feet of the weighing platform until the level

bubble’s air bubble is inside the inner circle.

en

Installation 5ICS4_6x-series

Page 10

4 Operation

1

2

3

4

5

6

7

8

–10 °C ... +40 °C

4.1 Display

4.1.1 Default layout

Metrological data line

1

Weight value

2

Spanner icon: service needed

3

Net/Gross

4

Unit

5

Soft keys (factory setting, page 1, ICS466x only)

6

Auxiliary data line: The contents is defined in the menu, see User manual.

7

Symbols and info line

8

Metrological data line

The metrological data is stored in the weighing platform. The weighing terminal only serves as

indicator.

In the metrological data line, the following information is displayed:

Symbol Information

, , ,

, ,

,

Accuracy classes

Weighing range information

Maximum capacity

Minimum capacity

Approved resolution

Display resolution

Approved weighing device

Temperature range

Operation6 ICS4_6x-series

Page 11

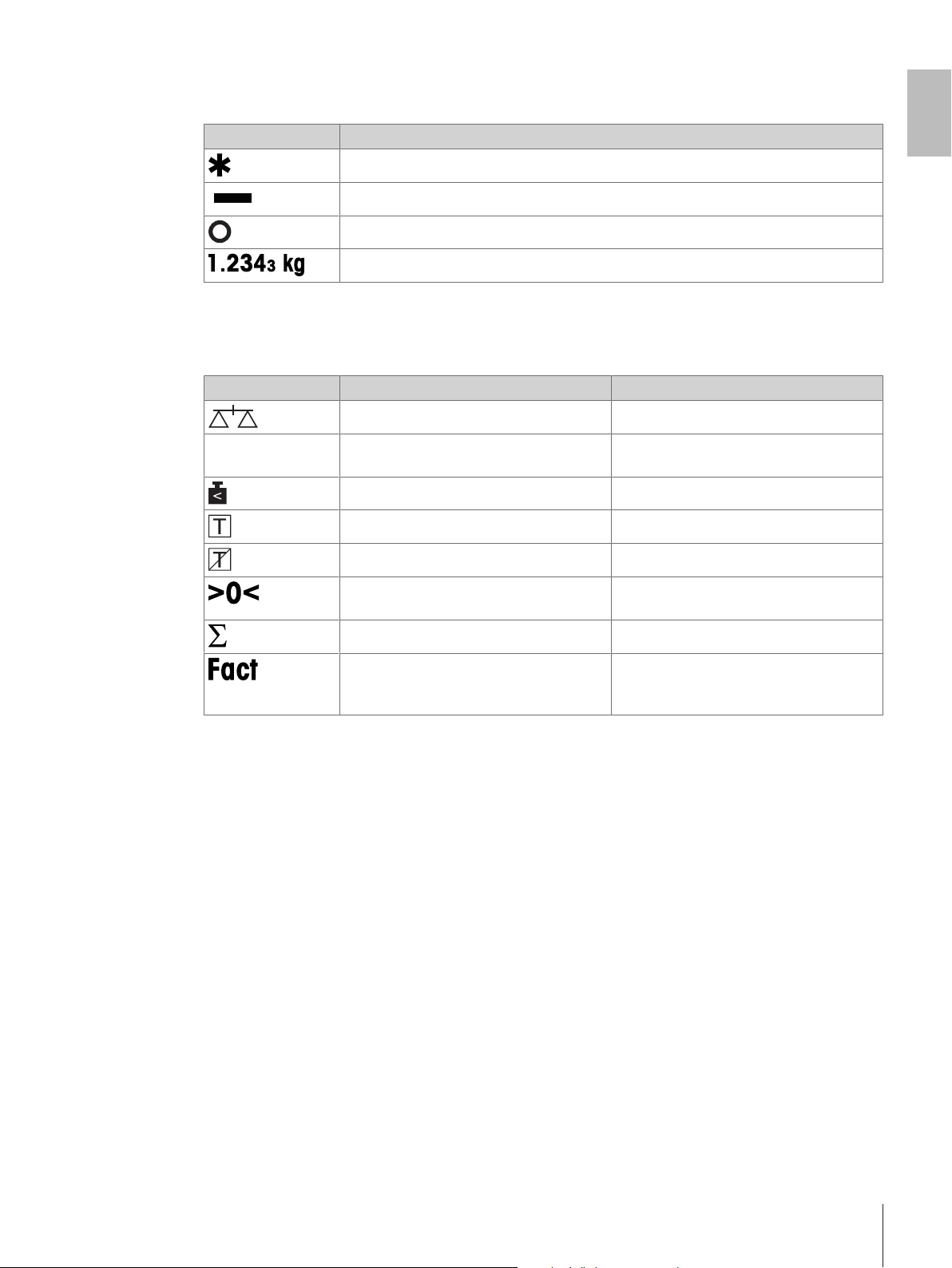

4.1.2 Weight value

I<–>I1

The weight value can be marked with the following symbols:

Symbol Information

Calculated weight value

Sign for negative weight values

Stability monitor for unstable weight values

Non-approved last digit with e > d

4.1.3 Symbols and info line

In the symbols and info line the following information can be displayed. For more symbols, refer to the User

manual.

Symbol Information Availability

Scale number Not for ICS426x

Weighing range For multi range or multi interval scales

Weight below minimum weight

Automatic taring

Automatic clearing of the tare weight

en

only

Center of zero indication Depending on local Weights and

Measures regulations

Totalization Not for ICS426x

Fact needs to be done Displayed only if the function is

supported by the weighing platform, e.g.,

PBK9-/PFK9-series

Operation 7ICS4_6x-series

Page 12

4.2 Keyboard

VAR

FIX

Σ

4.2.1 Function keys

Key Name Key Name

Power Tare

Clear Info

Switch Transfer

Zero

4.2.2 Main soft keys (ICS466x only)

To meet your specific application requirements, ICS466x weighing terminals offer soft keys which can be

configured in the menu. For more soft keys, refer to the User manual.

ICS4_6x Menu setting Function

Ref n var Determine the average piece weight, freely adjustable

Ref n fix Determine the average piece weight, fixed reference sizes

Weight/count Switch between weight display and display of pieces

Totalizing Start totalizing

Over/Under Checkweighing Enter Over/Under Checkweighing parameters

Save article Save the current article parameters in the database

Recall article Recall parameters from the database

Operation8 ICS4_6x-series

Page 13

4.3 Switching on/off

Switching on

Switching off

4.4 Zeroing

en

Press and hold until OFF is displayed.

4.5 Straight weighing

Zeroing corrects the influence of slight changes on

the load plate or minor deviations from the zero

point.

Operation 9ICS4_6x-series

Page 14

4.6 Taring

4.7 Printing or transferring data

When the scale is tared, the NET symbol is

displayed.

When the tare is cleared, the gross weight is

displayed.

• The printer or computer has to be located in the

safe area.

• The data have to be transferred to the safe area

via the ACM200 interface converter.

4.8 Switching weight unit

Operation10 ICS4_6x-series

Page 15

4.9 Counting (ICS466x only)

0.123

kg

10

PCS

VAR

10

235

PCS

235

PCS

2.890

kg

0

PCS

en

Use the number of reference parts indicated on the

soft key, in this example: 10 pieces.

Switch between the display of the number of pieces

and of the weight.

Clearing counting

Press the C key to clear the counting parameters.

The weight is displayed.

Operation 11ICS4_6x-series

Page 16

4.10 Over/Under Checkweighing (ICS466x only)

0 9

0 9

Setting target values

For other tolerance types, refer to the User manual.

You can either weigh the target weight or enter it

numerically.

Over/Under Checkweighing display

Leaving Over/Under Checkweighing

esc

C

Leave Over/Under Checkweighing, but keep the target values.

Leave Over/Under Checkweighing and clear target values.

Weight within the tolerances

Weight above the tolerances

Weight below the tolerances

Operation12 ICS4_6x-series

Page 17

4.11 Totalizing (ICS466x only)

0.000

kg

esc

+

-

Σ

1.105

kg

1.105

kg

1

1.185

kg

2.190

kg

2

5

10.750

kg

en

The totalizing soft keys are displayed.

1st item totalized.

Unload the scale and place the 2nd item.

2nd item totalized.

5 items totalized and last item removed.

Total cleared.

Operation 13ICS4_6x-series

Page 18

5 Maintenance

Maintenance of the weighing terminal is limited to regular cleaning.

5.1 Cleaning

WARNING

Explosion hazard

1 Strictly observe the instructions of the operating company.

2 Avoid electrostatic charging by wearing suitable working clothes when operating in

hazardous areas.

Notes on cleaning

• Only use a clean damp cloth and gently wipe the keypad.

• Use water or mild, non-abrasive cleaning agents.

• Do not spray cleaner directly on the weighing terminal.

• Do not use any acids, alkalis or strong solvents.

• Do not clean the weighing terminal using high-pressure or high-temperature water.

• Observe all existing regulations on cleaning intervals and permissible cleaning agents.

• Do not use compressed air or vacuum.

• Remove dust layers.

5.2 Disposal

In accordance with the requirements of European Directive 2002/96 EC on Waste

Electrical and Electronic Equipment (WEEE), this device may not be disposed of

with domestic refuse. This also applies for countries outside the EU in

accordance with their respective national regulations.

− Please dispose of this product in accordance with local regulations for the

separate collection of waste electrical and electronic equipment.

Should you have any questions, please contact the corresponding authorities or the dealer from whom this

device was purchased.

If this device is passed on (for example for further private or commercial/industrial use), this regulation is

also to be passed on.

Many thanks for your contribution to the protection of the environment.

Maintenance14 ICS4_6x-series

Page 19

6 Technical data

Weighing terminals ICS426x ICS466x

Housing Stainless steel

Display Monochrome LCD graphical display

Backlighting

Keyboard Tactile touch membrane keypad (PET), scratch-resistant labeling

Net weight 2.8 kg / 6.1 lb

Protection type IP65

Mains connection via APS768x

Ambient

conditions

Ignition

protection

type

W & M approvals OIML Class II, III, IIII

Interfaces 1 interface RS232-IS and

Applications Straight weighing

Application indoor use only

Temperature

range Class III

Humidity Max. rel. humidity 85 %, for temperatures up to 40°C / 104 °F

EN/IECEx II 2G Ex ib IIC T4 Gb, –10 °C ... + 40 °C

CFMUS

–10 °C ... 40 °C / 14 °F ... 104 °F

II 2D Ex ib IIIC T60°C Db

IP65

IS Class I, II, III; Division 1

Group A, B, C, D, E, F, G; T4; Ta = 40 °C

Aex ib IIC T4; IP65; Type 4

NTEP Class II, III

1 scale interface integrated

1 additional optional communi-

cation interface

Average weighing

Clever print

Monochrome LCD graphical display

Colored backlighting

1 interface RS232-IS and

1 scale interface integrated

1 additional optional communication interface

1 additional optional scale interface

Straight weighing

Average weighing

Clever print

Over/Under Checkweighing

Counting

Totalizing

Database

Prompting

Alibi Memory

en

Technical data 15ICS4_6x-series

Page 20

Analog scale interface (ICS466x only)

96

190

290

195

120

95

M5

Impedance 80 ... 3,000 Ohms

Excitation 3.3 V

Sensitivity up to 3 mV/V

Max. resolution 10,000 e (OIML)

300,000 d (non approvable)

Min. verification interval 0.26 µV/e

Dimensional drawing ICS4_6x-series

Technical data16 ICS4_6x-series

Page 21

恭喜您选择了 METTLER TOLEDO 的品质与精密。如果您能够依照本手册正确使用新设备,并且由

我们厂商培训的服务团队进行定期校准和维护,本设备将能可靠与精确地运行,保证您购买的产

品物有所值。如需了解按照您的需求和预算量身订制的服务协议,请联系我们。欲知详情,请登

陆

www.mt.com/service

为了让您购买的设备发挥最高性能,须注意下列几点:

1 注册您的产品:我们邀请您在

www.mt.com/productregistration

注册您的产品,以便我们通知您与产品有关的增强功能、更新及重要通知。

2 联系 METTLER TOLEDO 进行维护:量具的价值与其精确度成正比——不合规格的秤台会降低品

质、减少利润并增加责任风险。由 METTLER TOLEDO 及时进行维护能够保证精确,延长设备的

运行时间及使用寿命。

ð 安装、配置、集成与培训:我们的服务代表均为厂商培训的称重设备专家。我们承诺我们

的称重设备能够经济并及时地生产,并且我们的员工训练有素。

ð 初次校准文件:每个工业秤都有其独有的安装环境及应用要求,所以需要对运行情况进行

测试和验证。我们的校准服务及验证文件精确无误,保证了生产质量,并能提供良好的系

统运行记录。

zh

ð 定期校准维护:校准服务协议让我们对于您的称重程序和遵守规程证明充满信心。我们提

供多样化的服务计划,专为您的需求和预算而定制。

ICS4_6x 系列

Page 22

ICS4_6x 系列

Page 23

目录

1 安全说明 3

1.1 预期用途................................................................................................................... 3

1.2 误用 .......................................................................................................................... 3

1.3 危险区域的安全操作说明.......................................................................................... 3

2 说明 4

2.1 ICS4_6x 系列称重仪表............................................................................................... 4

2.2 关于此文件 ............................................................................................................... 4

2.3 其他相关文件............................................................................................................ 4

3 安装 5

3.1 安装、配置服务与维修 ............................................................................................. 5

3.2 调平 .......................................................................................................................... 5

4 操作 6

4.1 显示屏 ...................................................................................................................... 6

4.2 键盘 .......................................................................................................................... 8

4.3 打开/关闭.................................................................................................................. 9

4.4 归零 .......................................................................................................................... 9

4.5 简单称重................................................................................................................... 9

4.6 去皮 .......................................................................................................................... 10

4.7 打印或传输数据 ........................................................................................................ 10

4.8 切换重量单位............................................................................................................ 10

4.9 计数(仅适用于 ICS466x) ....................................................................................... 11

4.10 过载/欠载(仅适用于 ICS466x) ............................................................................... 12

4.11 累加称重(仅适用于 ICS466x) ................................................................................ 13

zh

5 维护 14

5.1 清洁 .......................................................................................................................... 14

5.2 废弃处置................................................................................................................... 14

6 技术规格 15

目录 1ICS4_6x 系列

Page 24

目录2 ICS4_6x 系列

Page 25

1

安全说明

1.1

预期用途

ICS4_6x 系列称重仪表是模块化防爆称重系统的组成部分,防爆称重系统包含一个作为指示器的

METTLER TOLEDO 称重仪表以及至少一个秤体。

ICS4_6x 系列称重仪表经认证可用于 Category 2 / Division 1 危险区域。

• 根据此《快速指南》与相应的《用户手册》仅将称重仪表用于称重。

• 此称重仪表仅供室内使用。

• 任何其他类型的使用视为非预期使用。

法定计量

• 对于法定计量方面的使用,仅可使用经认证的称重系统。

• 在用于法定计量方面时,操作公司有责任遵守国家制定的所有度量衡要求。

• 对于与贸易应用法规相关的使用如有疑问,请联系 METTLER TOLEDO 服务组织。

1.2

误用

• 请勿将称重仪表用于称重操作以外的用途。

• 请勿改动称重仪表。

zh

• 请勿超出技术规格范围使用称重仪表。

1.3

危险区域的安全操作说明

ICS4_6x 系列称重仪表经认证可用于 Category 2 / Division 1 危险区域。

操作公司负责防爆称重系统的安全操作。

危险

爆炸危险

1 严格遵守使用公司说明。

2 遵守国家关于危险区域操作的所有条例以及此《快速指南》中的相关说明与信

息。

安全说明 3ICS4_6x 系列

Page 26

2

说明

2.1

ICS4_6x 系列称重仪表

此《快速指南》重点说明以下称重仪表:

类型 数字小

键盘

ICS426x

ICS466x

秤台接口

ICS4_6x 系列称重仪表提供各种秤台接口。内置型秤台接口直接显示在仪表型号之后。

ICS4_6x ... ...a ...d

秤台接口

2.2

关于此文件

– – Category 2 /

x x 选配式,例如,在 PBK9-/PFK-9 系列上

此文件包含适用于 ICS4_6x 系列称重仪表操作员的所有信息。

• 请在使用前认真阅读此文件。

• 妥善保管此文件供将来参考用。

• 将此文件转交给此产品的今后任何所有者或用户。

软键 环境 仪表与秤体组合

适用于 PBK9-/PFK-9 系列

Division 1

模拟(仅限 ICS466x) IDNet / SICSpro

提供 Category 2 / Division 1 选配设置

提供 Category 2 / Division 1 或 PBA430x

选配设置

2.3

其他相关文件

除了此份打印文件,您还可以从 http://www.mt.com 下载以下文件:

• 操作员手册

• 技服手册

• 安装手册

• 数据表

• 视频

• 产品小册子

• 相关认证文档

• 对于仪表与秤体组合:所连接的称体的《用户手册》

相关认证文档

ICS4_6x Category 2 BVS 13 ATEX E042X

IECEx BVS 13.0050X

Division 1 FM16US0098X, FM16CA0056X

说明4 ICS4_6x 系列

Page 27

3

安装

小心

人身伤害、财产损失、错误操作或保修无效的风险

本产品仅使用 METTLER TOLEDO 原装配件和电缆组件。 使用未经授权或伪造的配

件或电缆组件可能会导致保修失效、不当或错误操作或财产(包括本机)损失和

人身伤害。

3.1

安装、配置服务与维修

− 要安装、配置、维护与维修防爆称重系统,请致电 METTLER TOLEDO 服务部。

3.2

调平

ICS4_6x 称重仪表可作为仪表与秤体组合使用。

秤体只有经过精确的水平校准,方可获得准确的称重结果。符合

度量衡规范的秤体有一个调平水泡,可简化调平过程。

− 转动秤体的调节脚,直至调平水泡中的气泡位于内圆中。

zh

安装 5ICS4_6x 系列

Page 28

4.1

1

2

3

4

5

6

7

8

–10 °C ... +40 °C

4

操作

显示屏

4.1.1

默认输出

计量数据行

1

称重值/称重结果

2

扳手图标:需要维修

3

净重/毛重

4

单位

5

软键(出厂设置,第 1 页,仅 ICS466x)

6

辅助数据行:内容如菜单所定义;参见《用户手册》

7

图标和信息行

8

计量数据栏

计量数据将储存在秤台中。称重仪表仅用作指示器。

计量数据栏显示如下信息:

符号 信息

、 、 、 精度等级

、 、 称重范围信息

、 最大量程

最小量程

认证分度

显示分度

认证称量设备

温度范围

操作6 ICS4_6x 系列

Page 29

4.1.2

I<–>I1

称重值/称重结果

称重值/称重结果可用如下符号标识:

符号 信息

所计称重值/称重结果

负称重值/称重结果符号

针对不稳定称重值/称重结果的稳态图表

e>d 时不核准最后一位数字

zh

4.1.3

图标和信息行

图标和信息行将显示如下信息。如欲了解更多符号,请参考《用户手册》。

符号 信息 适用性

秤台号 不适用于 ICS426x

称重范围 仅用于多范围或多分度秤台

重量低于最小重量

自动去皮

自动皮重清零

零中心刻度指示 根据当地度量衡规范

累加 不适用于 ICS426x

需进行全自动校准 仅当秤体支持此功能时方显示,例如

PBK9-/PFK9 系列

操作 7ICS4_6x 系列

Page 30

4.2

VAR

FIX

Σ

键盘

4.2.1

4.2.2

功能键

键 名称 键 名称

电源 去皮

清零 信息

切换 转换

清零

主要软键(仅适用于 ICS466x)

为满足您的特定应用要求,可在 ICS466x 称重仪表菜单中配置软键。如欲了解更多软键,请参考

《用户手册》。

ICS4_6x 菜单设置 功能

自定义采样 确定平均单重,可自由调整

固定采样 确定平均单重,采样大小固定

称重/计数 在重量显示与单件显示之间切换

累加称重 开始累加称重

过载/欠载 输入过载/欠载参数

保存日志 将当前数量参数保存至数据库

调用日志 从数据库中读取参数

操作8 ICS4_6x 系列

Page 31

4.3

打开/关闭

打开

zh

关闭

长按 直至显示 OFF (关闭)。

4.4

4.5

归零

清零可以消除承重盘上轻微变化所带来的影

响,或是纠正零点上的微弱偏差。

简单称重

操作 9ICS4_6x 系列

Page 32

4.6

去皮

4.7

打印或传输数据

在对秤台去皮时,显示“净重”符号。

在去皮清零时,显示总重。

4.8

切换重量单位

• 应将打印机或电脑放置在安全区域。

• 通过 ACM200 接口转接头将数据传输至安全

区域。

操作10 ICS4_6x 系列

Page 33

4.9

0.123

kg

10

PCS

VAR

10

235

PCS

235

PCS

2.890

kg

0

PCS

计数(仅适用于 ICS466x)

zh

使用软键上显示的采样部件的数量,本例中

为:10 件。

在件数与重量显示之间切换。

清零计数

按下 C 键清零计数参数。显示重量。

操作 11ICS4_6x 系列

Page 34

4.10

0 9

0 9

过载/欠载(仅适用于 ICS466x)

设置目标值

如欲了解其他公差类型,请参考《用户手

册》。

您可以对目标重量进行称重或输入其重量数

值。

过载/欠载显示

退出过载/欠载

esc

C

重量在公差范围内

重量高于公差范围

重量低于公差范围

退出过载/欠载,但保留目标值。

退出过载/欠载,并清零目标值。

操作12 ICS4_6x 系列

Page 35

4.11

0.000

kg

esc

+

-

Σ

1.105

kg

1.105

kg

1

1.185

kg

2.190

kg

2

5

10.750

kg

累加称重(仅适用于 ICS466x)

显示累加称重软键。

第 1 个

对

商品进行累加称重。

zh

清除秤台上的称重物并放置

第 2 个

对

商品进行累加称重。

第 2 个

商品。

对 5 个商品进行累加称重并清除最后一个商

品。

清除总计。

操作 13ICS4_6x 系列

Page 36

5

维护

称重仪表的维护限于定期清洁:

5.1

清洁

警告

爆炸危险

1 严格遵守使用公司说明。

2 在危险区域进行操作时,应穿戴合适的工作装以避免产生静电。

有关清洁的注意事项

• 仅用干净的湿布轻柔地擦拭键盘。

• 使用水或温和的非腐蚀性清洁剂。

• 请勿将清洁剂直接喷撒在称重仪表上。

• 请勿使用任何酸、碱或强溶剂。

• 请勿用高压水或高温水清洁称重仪表。

• 请完全遵照现行规范,按对应清洁周期,利用允许使用之清洁剂进行清洁。

• 请勿使用压缩空气或真空吸尘器。

• 清除灰尘。

5.2

废弃处置

根据有关废弃电气和电子设备 (WEEE) 的欧盟指令 2002/96 EC 的要求,

该设备不得与生活垃圾共同处置。这也适用于欧盟以外的国家,同时须遵

守各个国家的相关法规。

− 请根据当地有关单独收集废弃电气和电子设备法规来处置该产品。

如您有任何疑问,请联系相关部门或向您销售该设备的经销商。

如果该设备转用在其他方面(如用于其他私人或商业/工业用途),该法规也将同样适用。

感谢您为保护环境做出的努力。

维护14 ICS4_6x 系列

Page 37

6

技术规格

称重仪表 ICS426x ICS466x

外壳 不锈钢

显示屏 单色 LCD 图形显示屏

有背景灯

键盘 触摸膜键盘 (PET),带防刮擦标志

净重 2.8 千克/ 6.1 磅

保护等级 IP65

电源连接 通过 APS768x

环境条件 应用 仅限室内使用

温度范围 III级–10 °C ... 40 °C / 14 °F ... 104 °F

湿度 在温度高达 40°C / 104 °F 时,最大相对湿度为 85 %

点火保护等级EN/IECEx II 2G Ex ib IIC T4 Gb, –10 °C ...+40 °C

II 2D Ex ib IIIC T60°C Db

IP65

CFMUS

W & M 认证 OIML II、III、IIII 级

IS Class I、II、III ;Division 1

Group A、B、C、D、E、F、G;T4;Ta = 40 °C

Aex ib IIC T4;IP65;Type 4

NTEP II、III 级

单色 LCD 图形显示屏

有颜色背景灯

zh

接口 1 个 RS232-IS 接口与

1 个秤台接口集成

附加 1 个选购的通讯接口

应用 简单称重

平均称重

智能打印

1 个 RS232-IS 接口与

1 个秤台接口集成

附加 1 个选购的通讯接口

附加 1 个选购的秤台接口

简单称重

平均称重

智能打印

过载/欠载

计数

累加称重

数据库

向导

Alibi 日志

技术规格 15ICS4_6x 系列

Page 38

模拟秤台接口(仅适用于 ICS466x)

96

190

290

195

120

95

M5

电阻 80 ...3,000 欧姆

激励 3.3 V

灵敏度 最高为 3 mV/V

最大分度 10,000 e (OIML)

300,000 d (未认证)

最小检定分度值 0.26 µV/e

ICS4_6x 系列尺寸图

技术规格16 ICS4_6x 系列

Page 39

Page 40

Mettler-Toledo GmbH

30361364

Im Langacher 44

8606 Greifensee, Switzerland

www.mt.com/contact

Subject to technical changes.

© Mettler-Toledo GmbH 03/2017

30361364C en zh

www.mt.com

For more information

Loading...

Loading...