Page 1

User Manual

ICS241

Counting Scales

Page 2

Service XXL

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper use

according to these instructions and regular calibration and maintenance by factorytrained service team ensure dependable and accurate operation to protect your

investment.

Contact us about a ServiceXXL agreement tailored to your needs and budget.

We invite you to register your product at

www.mt.com/productregistration

So we can contact you about enhancements, updates and important notifications

concerning your METTLER TOLEDO product.

2

Mettler-Toledo

User Manual ICS241

08/11

Page 3

Contents

Contents

ContentsContents

1.

1. General Information

General Information ................................

1.1.

General InformationGeneral Information

1.1

Safety Instructions ............................................................................................................................................ 4

1.2

Power supply connection ................................................................................................................................. 4

1.3

Introduction ..................................................................................................................................................... 5

1.4

Commissioning ............................................................................................................................................. 11

2.

2. Basic operation

Basic operation ................................

2.2.

Basic operationBasic operation

2.1

Switching on and off ...................................................................................................................................... 12

2.2

Zeroing / Zero point correction ......................................................................................................................... 12

2.3

Simple weighing ............................................................................................................................................ 12

2.4

Weighing with tare ......................................................................................................................................... 13

2.5

Working with identifications ............................................................................................................................ 14

2.6

Printing results .............................................................................................................................................. 14

2.7

Verification test .............................................................................................................................................. 15

2.8

Display Information........................................................................................................................................ 15

3.

3. Application

Application ................................

3.3.

ApplicationApplication

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

................................................................

................................................................

Piece counting .............................................................................................................................................. 16

Reference optimization ................................................................................................................................... 17

Minimum sample weight ................................................................................................................................ 19

Totalize ........................................................................................................................................................ 20

Switch scale .................................................................................................................................................. 22

Log files ....................................................................................................................................................... 23

Checkweighing/counting ................................................................................................................................ 25

Using stored preset parameters ....................................................................................................................... 28

Edit letter and number .................................................................................................................................... 30

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

..............................................................

................................................................

................................................................

................................................................

.............................. 4444

............................................................

..................................

................................................................

........................................

................................................................

........ 16

................

.. 12

12

....

1212

16

1616

4.

4. Menu settings

Menu settings ................................

4.4.

Menu settingsMenu settings

4.1

4.2

4.3

4.4

4.5

4.6

5.

5. Event and error messages

Event and error messages ................................

5.5.

Event and error messagesEvent and error messages

5.1

5.2

6.

6. Technical data and accessories

Technical data and accessories ................................

6.6.

Technical data and accessoriesTechnical data and accessories

6.1

6.2

7.

7. Appendix

Appendix ................................

7.7.

AppendixAppendix

7.1

................................................................

................................................................

Operating the menu ....................................................................................................................................... 31

Scale menu block .......................................................................................................................................... 34

Application menu block .................................................................................................................................. 37

Terminal menu block ..................................................................................................................................... 41

Communication menu block ........................................................................................................................... 46

Maintenance menu block ............................................................................................................................... 51

................................................................

................................................................

Error conditions ............................................................................................................................................. 52

Errors and warnings....................................................................................................................................... 53

Weighing terminal technical data .................................................................................................................... 54

Interface definition .......................................................................................................................................... 55

................................................................

................................................................

Geo Values ................................................................................................................................................... 56

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

...................................................

................................................................

....................................

................................................................

............................................

................................................................

...........................................

................................................................

.... 31

31

........

3131

................... 52

......................................

............ 54

........................

........... 56

......................

52

5252

54

5454

56

5656

08/11

Mettler Toledo

User Manual ICS241

3

Page 4

General Information

1.

1. General Information

1.1.

General Information

General InformationGeneral Information

1.1

Safety Instructions

Safety Instructions

Safety InstructionsSafety Instructions

In order to make your counting scale work in best condition, please read this user

In order to make your counting scale work in best condition, please read this user

In order to make your counting scale work in best condition, please read this user In order to make your counting scale work in best condition, please read this user

instr

instructions carefully before using

uctions carefully before using it!

instrinstr

uctions carefully before usinguctions carefully before using

The scale must be powered off and unplugged during maintenance and clean, or it

will cause electric shock or damage to counting scale.

Flush the weighing platform with water is forbidden. Wet cloth wrung can be used to

wipe weighing platform or scale pan.

Chemicals such as solvent can’t be touched, in case it corrodes the surface of scale

and damages internal devices.

The METTER TOLEDO’s counting scale is a high precision instrument. Please

maintain carefully. Do not impact the scale with heavy weight. Make the scale work in

best condition.

Only authorized personnel may open the device.

Devices with built-in storage battery

Ensure that the power socket outlet for the device is earthed and easily accessible, so

that it can be de-energized rapidly in emergencies.

Ensure that the supply voltage at the installation site lies within the range of 100 V to

240 V.

Check the power cable regularly for damage. If it is damaged, disconnect the device

immediately from the power supply.

it!

it!it!

1.2

4

Mettler-Toledo

User Manual ICS241

Power supply connection

Power supply connection

Power supply connectionPower supply connection

CAUTION

CAUTION

CAUTIONCAUTION

Risk of e

Risk of electric shock!

Risk of eRisk of e

Before connecting the power supply, check whether the voltage value printed on the

Do not under any circumstances connect the device if the voltage value on the rating

Make sure the weighing platform has reached room temperature before switching on

After it has been connected, the device runs a self-test. The device is ready to operate when

zero appears on the display.

lectric shock!

lectric shock!lectric shock!

rating plate corresponds to your local system voltage.

plate deviates from the local system voltage.

the power supply.

Plug the power plug into the power socket.

08/11

Page 5

2222

10

1010

10

9999

1

3333

2222

8888

1

6666

8888

1

2222

1.3

1.3.1

1.3.1

1.3.11.3.1

Introduction

Introduction

IntroductionIntroduction

Display

Display

DisplayDisplay

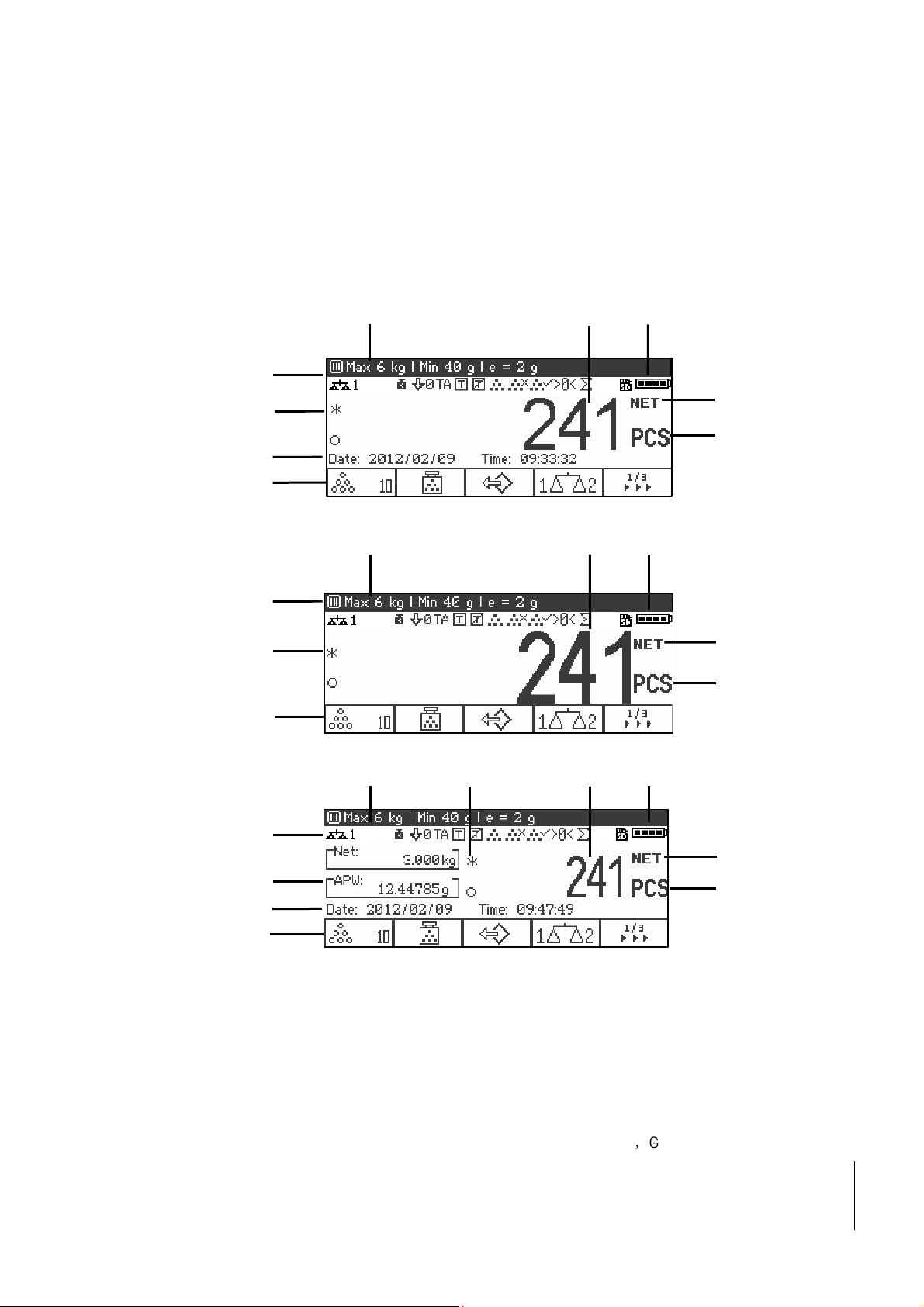

Three different display layouts are selectable in the terminal menu.

Default layout

Default layout

Default layoutDefault layout

5555

Big font mode

Big font mode

Big font modeBig font mode

3333----line mode

line mode

line modeline mode

1. Metrological data -- for details see below

2. Gross/Net display

3. Battery symbol

4. Symbol and info line – for details see below

5. Weight value with star, minus sign and stability monitor – for details see below

6. Auxiliary data – can be defined in the menu

7. Customization soft keys

8. Net/Gross

9. Unit

10. Net/Average piece weight (Piece counting mode),Gross/Tare(Straight weighing mode)

08/11

Mettler Toledo

User Manual ICS241

5

Page 6

General Information

Metrological data line

Metrological data line****

Metrological data lineMetrological data line

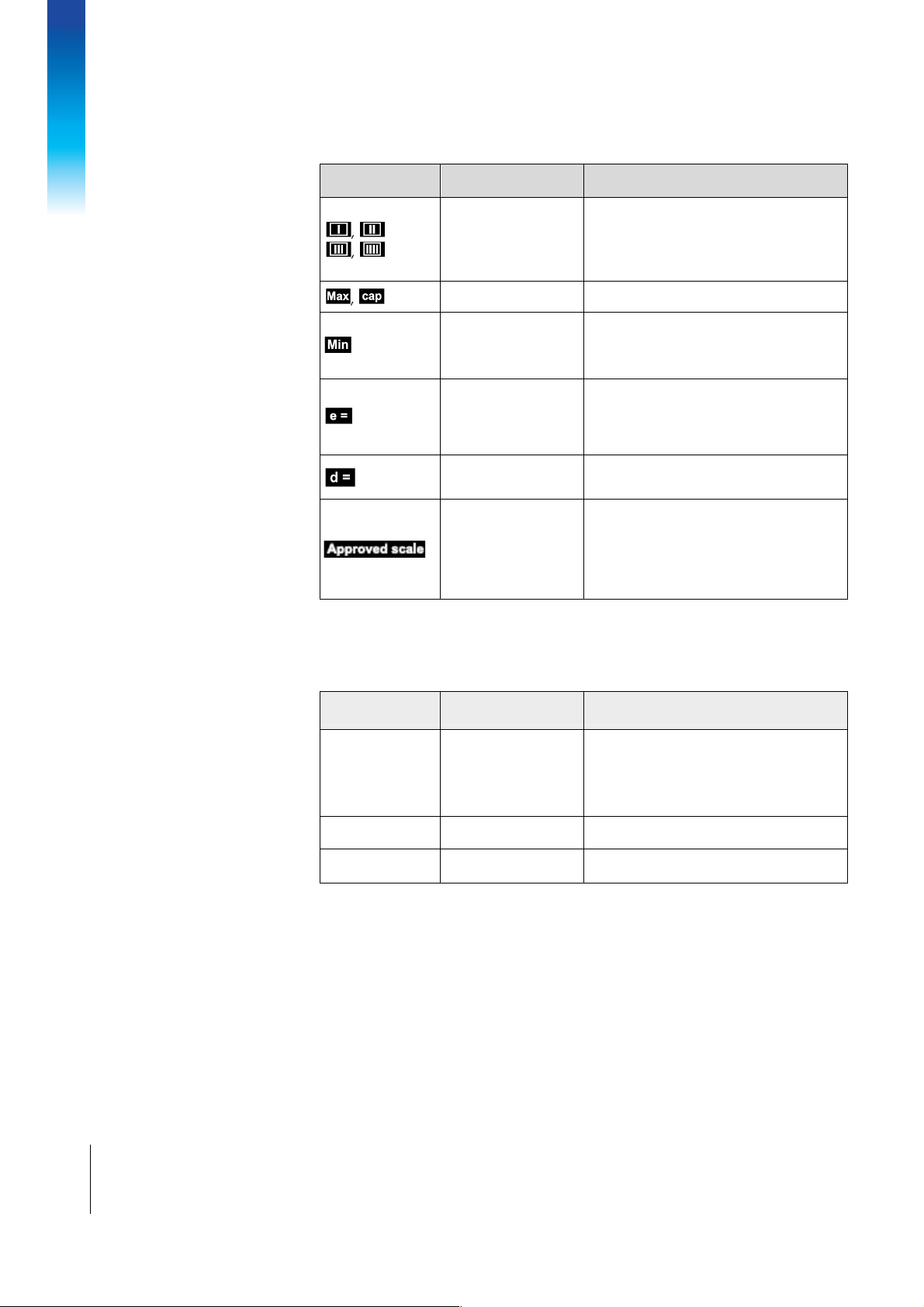

In the metrological data line the following information is displayed:

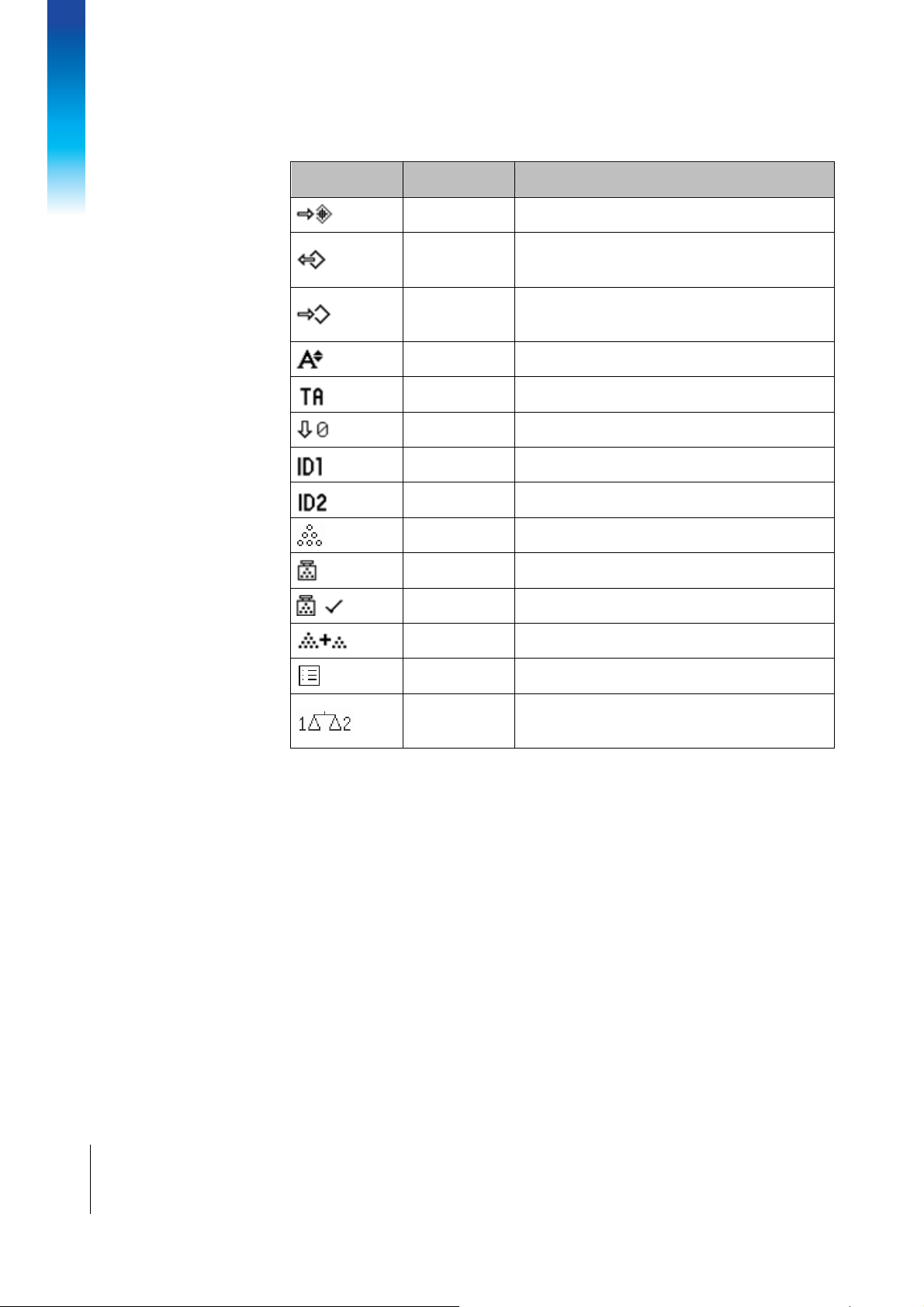

Symbol

Symbol Information

SymbolSymbol

Information Note

InformationInformation

Accuracy classes

Note

NoteNote

Display if the scale is approved

according to the applicable Weights and

Measures guidelines

Maximum capacity

Minimum capacity

Approved resolution

Display resolution

Approved

weighing device

*It’s only for China W&M approval.

Weight display

Weight display

Weight display Weight display

The weight value can be marked with the following symbols:

Symbol

Symbol Information

SymbolSymbol

Information Note

InformationInformation

Display if the scale is approved

according to the Weights and Measures

guidelines

Displayed only if the scale is approved

according to the Weights and Measures

guidelines

Displayed only if the scale is not

approved or if d is different from e

Metrology display disabled,

Weights and Measures data must be

indicated on a label near the site of

weight display.

Note

NoteNote

E.g. Weight hold status or sample

weight is below the minimum sample

weight

Calculated weight

value

Sign For negative weight values

Stability monitor For unstable weight values

6

Mettler-Toledo

User Manual ICS241

08/11

Page 7

Symbols and info line

Symbols and info line

Symbols and info lineSymbols and info line

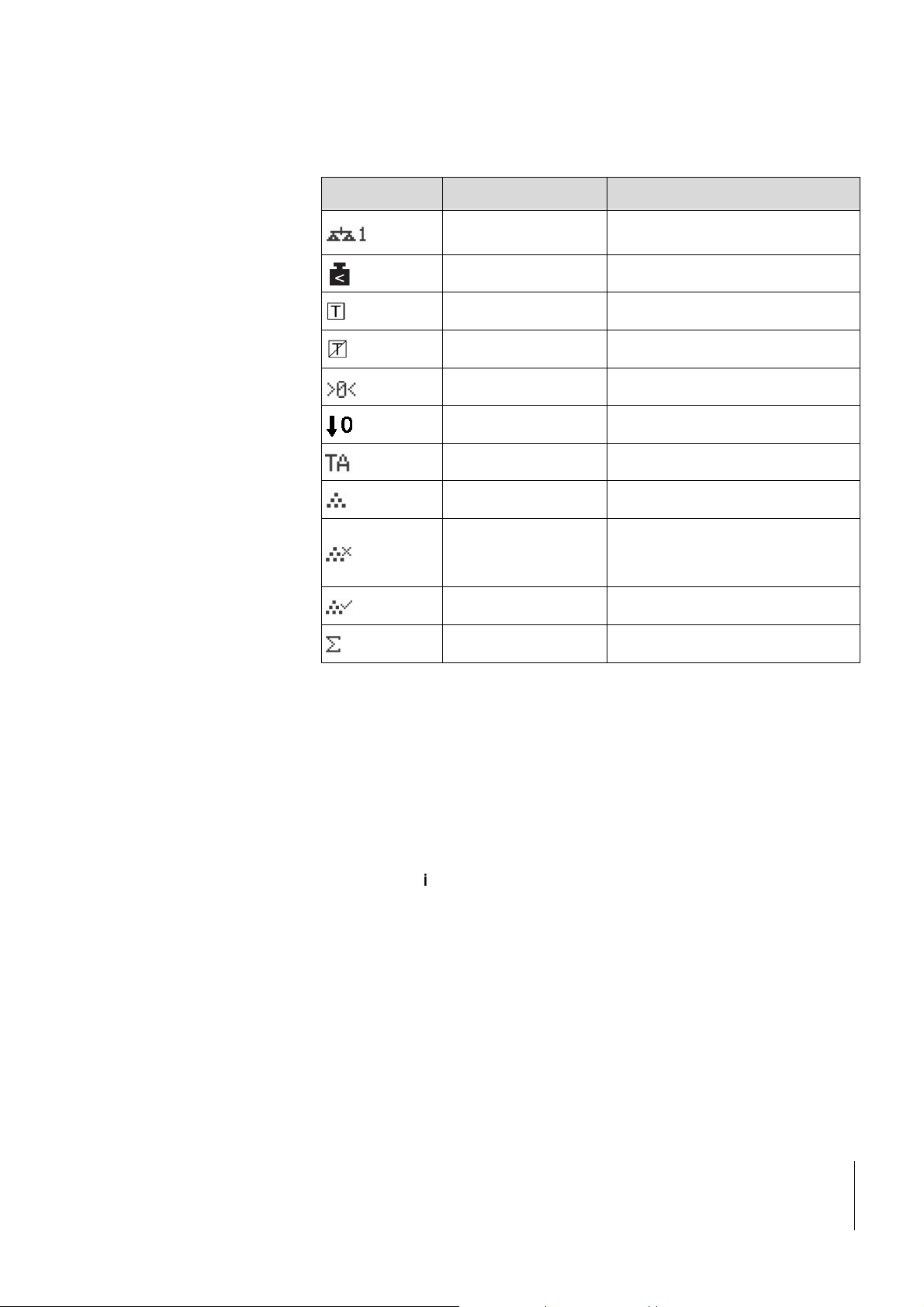

In the symbols and info line the following information can be displayed:

Symbol

Symbol Information

SymbolSymbol

Information Note

InformationInformation

Note

NoteNote

number

Weight below minimum

The Current scale

weight

Automatic taring

Automatic clearing of

the tare weight

Center of zero indication

Only available for 2nd scale version.

MinWeigh must be activated in the

menu.

Auto Tare must be activated in the

menu.

Auto Clear Tare must be activated in

the menu.

Availability depending on local

Weights and Measures regulations.

Check weighing to zero To zero must be assigned to a soft

key in the menu.

Take-away mode Take away must be assigned to a soft

Auto sampling

Auto clear APW

(average piece weight)

APW (average piece

weight) optimization

Auto totalize

key in the menu.

Auto sampling must be activated in

the menu.

Auto clear APW must be activated in

the menu.

APW optimization must be activated

in the menu.

Auto totalize must be activated in the

menu.

Device

Device info

information

infoinfo

rmation

rmationrmation

DeviceDevice

ICS241 offers the possibility to configure the following device information to identify

the device according to your company’s needs:

• Device identifier

• Device location

In addition the device name provides the complete type information already entered in

the factory, e.g., ICS241-03001.

This device information can be used as follows:

• displayed in the auxiliary line of the display.

• displayed via .

• printed/transferred together with the weight value.

Please ask the METTLER TOLEDO service technician to configure device identifier and

Device location according to your specific requirements.

08/11

Mettler Toledo

User Manual ICS241

7

Page 8

General Information

1.3.2

1.3.2

1.3.21.3.2

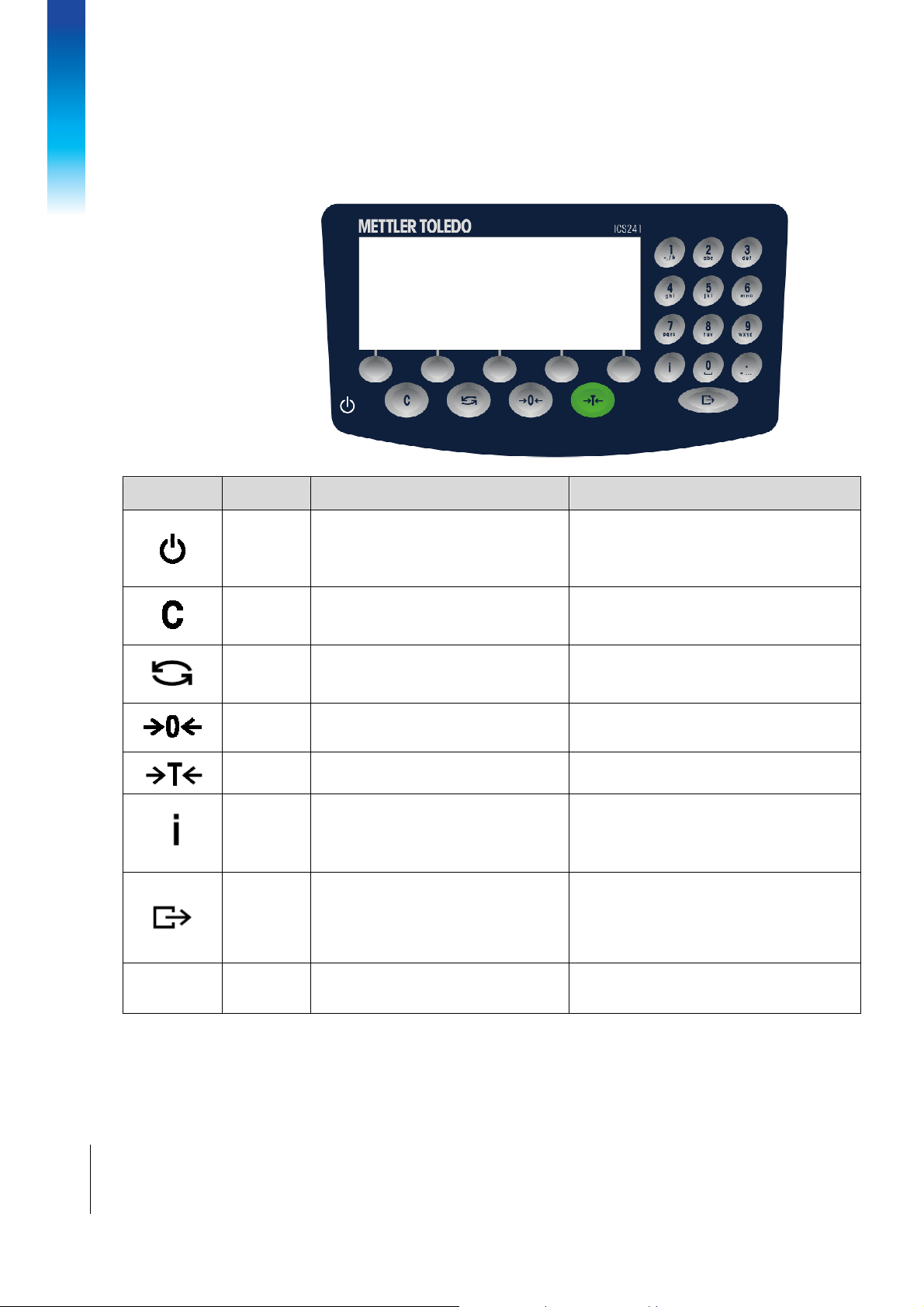

Key

Key Name

KeyKey

Name Function in the operating mode

NameName

Function keys

Function keys

Function keysFunction keys

Function in the operating mode Function in the menu

Function in the operating modeFunction in the operating mode

Function in the menu

Function in the menuFunction in the menu

0…9

0…9

0…90…9

Alpha-number

Power

Clear

Switch Switch weight unit Switch input method in edit status

Zero Set scale to zero, clear tare

Tare Set tare, clear tare

Info

Transfer

Power on/off

Cancel editing

Clear tare

Leave info page

Activate info screen

Proceed to next info line / info page

Freeze and release startup screen

Transfer data to a printer or computer

Long key press: Call up menu

Value presetting, e.g. tare, piece

weight or reference n

Cancel editing

Exit menu

Clear value, clear numbers or characters

Enter menu item (scroll right)

Confirm entry / selection

Edit numbers, change menu setting

Edit characters, change article info.

8

Mettler-Toledo

User Manual ICS241

08/11

Page 9

1.3.3

1.3.3

1.3.31.3.3

Soft keys

Soft keys

Soft keysSoft keys

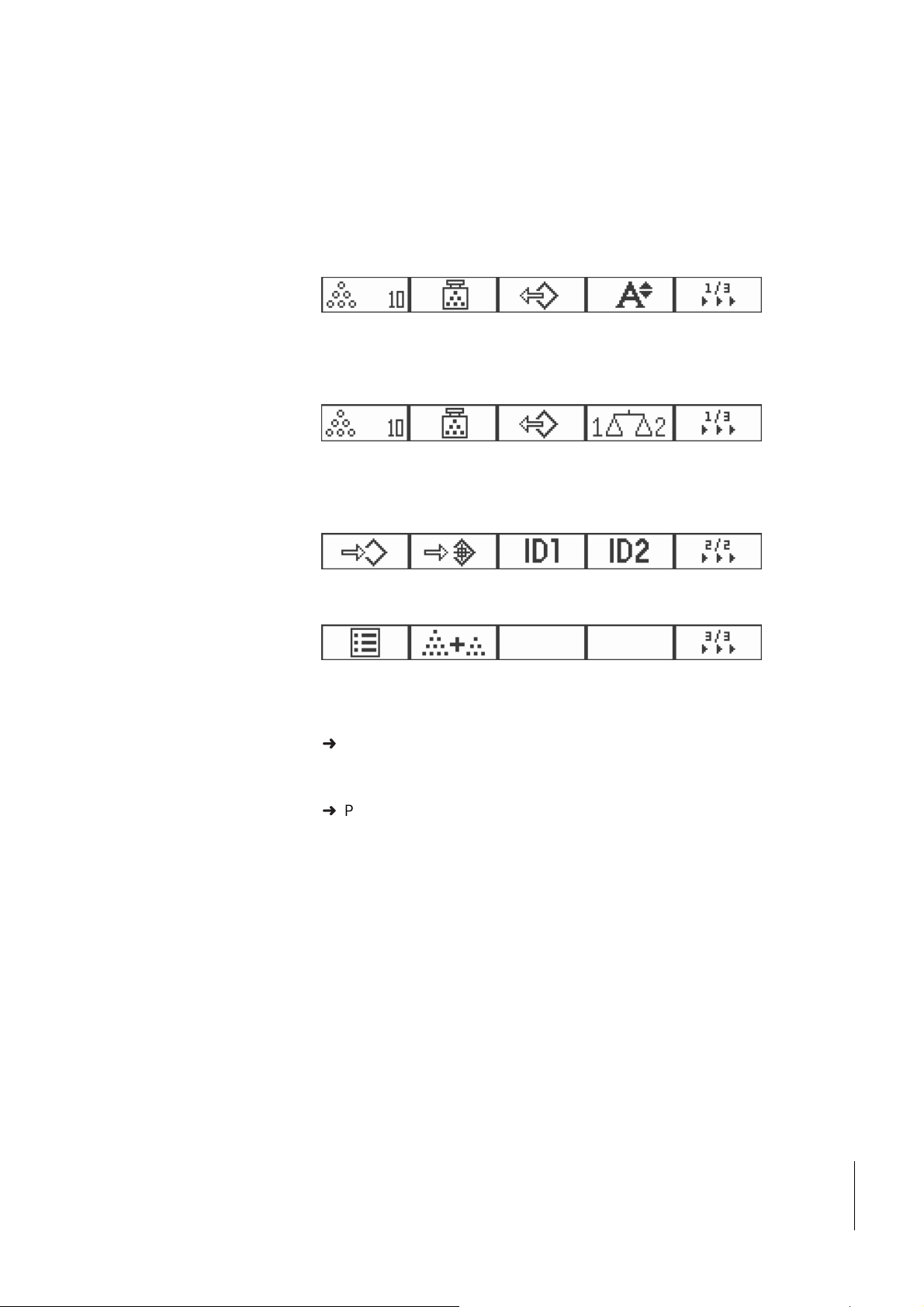

To meet your specific application requirements ICS241 offers 12 soft keys which can

be configured in the terminal menu. The soft keys are divided into three lines (pages).

Default setting

Default setting

Default settingDefault setting

Page 1 (single scale version)

Reference

10

Page 2 (dual-scale version)

Reference

10

Page 2

Store Target ID1 ID2

Page 3

Log files Totalize

Operating soft keys

Operating soft keys

Operating soft keysOperating soft keys

➜

Press the key below the desired function.

Changing soft key line

Changing soft key line

Changing soft key lineChanging soft key line

➜

Press soft key ►►► to switch from page1 via page2 to page3 and vice versa.

Average

piece

weight

Average

piece

weight

Recall Display

Recall Switch

scales

08/11

Mettler Toledo

User Manual ICS241

9

Page 10

General Information

Possible soft key setti

Possible soft key settings

Possible soft key settiPossible soft key setti

Symbol

Symbol Menu setting

SymbolSymbol

ngs

ngsngs

Menu setting Function

Menu settingMenu setting

Function

FunctionFunction

Target Set checkweighing/counting parameters

Recall

Store

Display

Take away Activate / deactivate Take-away mode

To zero Display checkweighing/counting to zero

ID1

ID2

Reference n Determine the average piece weight

Average PW Enter the average piece weight

APW opt. Average piece weight optimization.

Totalizing Totalize application

Recall article parameters from the database

Store article parameters in the database

Switch over display mode

Enter identification 1

Enter identification 2

Log files Check weighing data logs

Switch scale

Switch between two scales (only available for

dual-scale version)

10

Mettler-Toledo

User Manual ICS241

08/11

Page 11

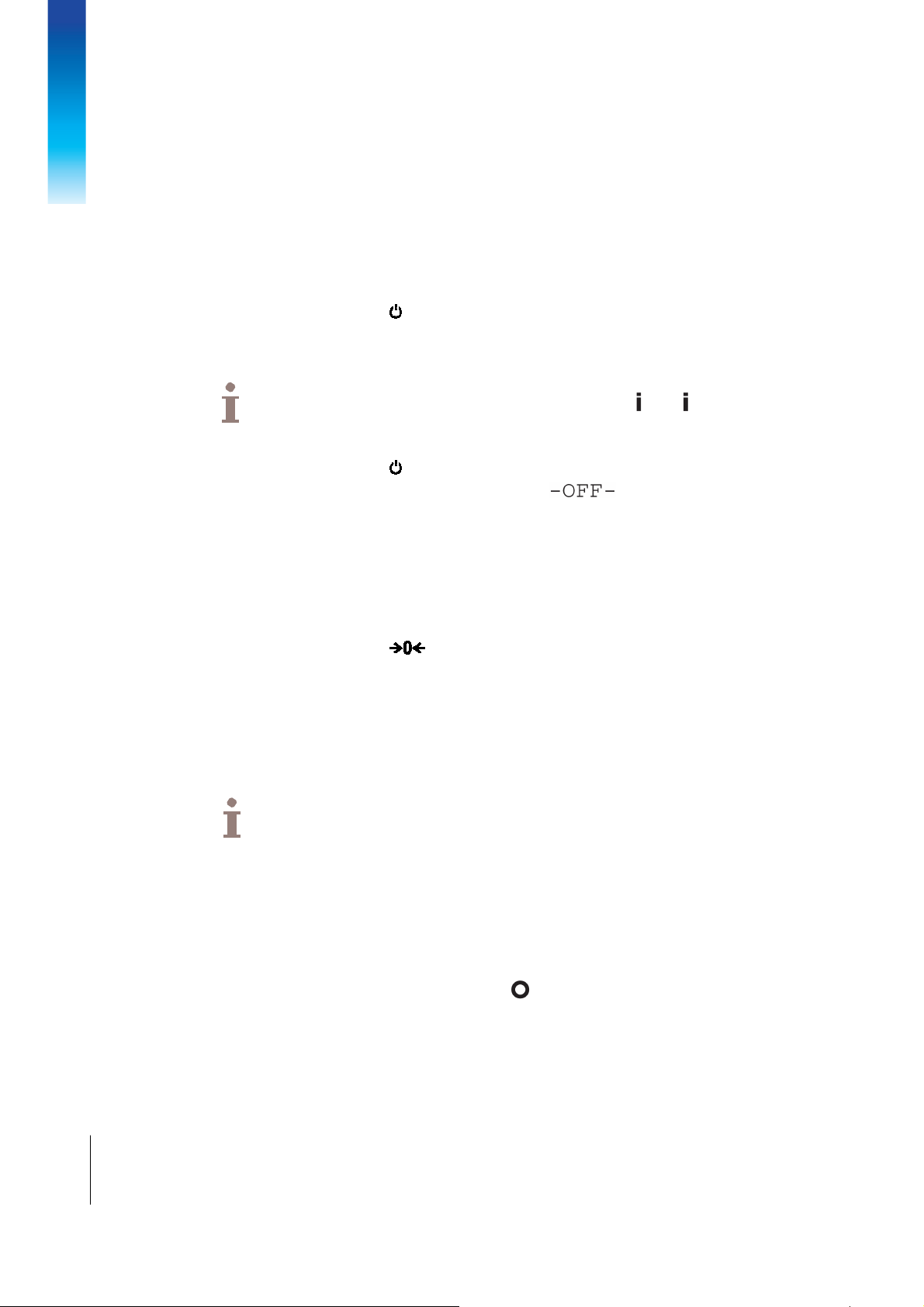

P

ower

connector

2nd

scale connector

Digital I/O connector

COM1 (RS232)

(

dual-serial port

)

1.4

1.4.1

1.4.1

1.4.11.4.1

Commissioning

Commissioning

CommissioningCommissioning

Selecting the weighing platform location

Selecting the weighing platform location

Selecting the weighing platform locationSelecting the weighing platform location

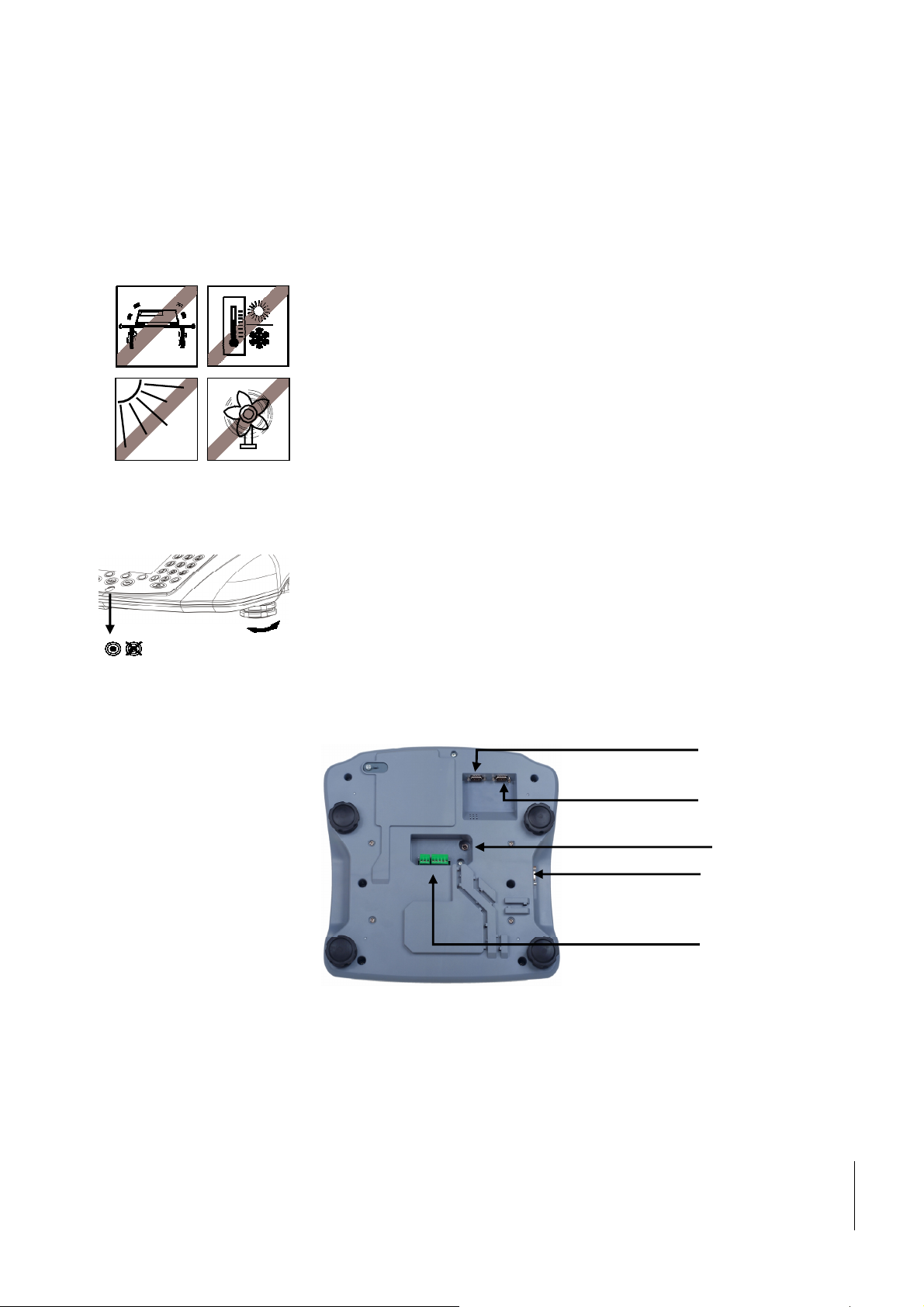

The correct location is crucial for the accuracy of the weighing results.

Select a stable, vibration-free and a horizontal location for the weighing platform.

Observe the following environmental conditions:

– No direct sunlight

– No strong drafts

– No excessive temperature fluctuations

1.4.2

1.4.2

1.4.21.4.2

Levelling the weighing p

Levelling the weighing platform

Levelling the weighing pLevelling the weighing p

Only weighing platforms that have been levelled precisely horizontally provide accurate

weighing results. Weights and Measures approved weighing platforms have a spirit level

to simplify levelling.

Leveling the weighing platform as the following

Leveling the weighing platform as the following procedure shows:

Leveling the weighing platform as the followingLeveling the weighing platform as the following

1. Turn the adjustable feet of the weighing platform until the bulb level’s air bubble is

inside the inner circle(as the picture shows).

2. Tighten the lock nuts of the adjustable feet.

latform

latformlatform

procedure shows:

procedure shows:procedure shows:

1.4.3

1.4.3

1.4.31.4.3

Interface schematic diagram

Interface schematic diagram

Interface schematic diagramInterface schematic diagram

COM2 (RS232)

(dual-scale type)

(digital I/O type)

08/11

Mettler Toledo

User Manual ICS241

11

Page 12

Basic operation

Power

PowerPower

Power

on

on on

on

Manual

ManualManual

Manual

AAAA

utomati

utomatiutomati

utomati

cccc

Power

PowerPower

Power

off

off off

off

2.

2. Basic operation

2.2.

Basic operation

Basic operationBasic operation

2.1

SSSSwitching on and

witching on and off

witching on andwitching on and

Press .

For a few seconds, the device shows a start-up screen with device name, software

version, serial number of the scale and the Geo value.

off

offoff

You can freeze the start-up screen by pressing .Press again can unfreeze the screen

and come back to normal start-up

2.2

Press

Before the display shuts down, appears briefly.

Zeroing / Zero point correction

Zeroing / Zero point correction

Zeroing / Zero point correctionZeroing / Zero point correction

1. Unload scale.

2. Press .

Zero appears in the display.

In the case of non-approved scales, the automatic zero point correction can be deactivated

in the menu or the zero range can be changed. Approved scales are set fixed to 0.5 d.

As standard, the zero point of the scale is automatically corrected when the scale is

unloaded.

The zero function is only available within a limited weighing range.

After zeroing the scale, the whole weighing range is still available.

Zeroing will always delete the tare weight.

.

12

Mettler-Toledo

User Manual ICS241

2.3

Simple weighing

Simple weighing

Simple weighingSimple weighing

Place weighing the sample on the scale.

Wait until the stability monitor disappears.

Read the weighing result.

08/11

Page 13

2.4

2.4.1

2.4.1

2.4.12.4.1

2.4.2

2.4.2

2.4.22.4.2

2.4.3

2.4.3

2.4.32.4.3

Weigh

Weighing with tare

WeighWeigh

TTTTaring

aring

aringaring

The zero display and the symbol appear.

The tare weight remains stored until it is cleared.

Clearing the tare

Clearing the tare

Clearing the tareClearing the tare

The symbol appears, the gross weight appears in the display.

If the symbol is on, i.e., the automatic clearing of the tare weight function is activated

in the menu

under Scale -> Tare, the tare weight is automatically cleared as soon as the scale is

unloaded.

Au

Automatic clearing of the tare

tomatic clearing of the tare

AuAu

tomatic clearing of the taretomatic clearing of the tare

The tare weight is automatically cleared when the scale is unloaded.

Prerequisite

Prerequisite

PrerequisitePrerequisite

ing with tare

ing with tareing with tare

Place the empty container on the scale and press .

Press .

√

The symbol lights in the display, i.e. the tare function automatic clearing of the

tare weight is activated in the menu under Scale -> Tare.

2.4.4

2.4.4

2.4.42.4.4

2.4.5

2.4.5

2.4.52.4.5

Automatic taring

Automatic taring

Automatic taringAutomatic taring

If you place a weight on an empty scale, the scale tares automatically and the symbol

is displayed.

Prerequi

Prerequisite

PrerequiPrerequi

√

The weight can be tared automatically when packaging material is heavier than 9d.

Chain tare

Chain tare

Chain tareChain tare

With this function it is possible to tare several times if, e.g. cardboard is placed between

individual layers in a container. It's convenient using this function to do several chain tare.

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

Place the first container or packaging material on the scale and press .

The packaging weight is automatically saved as the tare weight, the zero display and the

symbol appear.

Weigh the weighing sample and read/print out the result.

site

sitesite

The symbol lights in the display, i.e. the tare function automatic clearing of the

tare weight is activated in the menu under Scale -> Tare.

The tare function Chain tare is activated in the menu under Scale –> Tare.

08/11

Mettler Toledo

User Manual ICS241

13

Page 14

Basic operation

Place the second container or packaging material on the scale and press again.

The total weight on the scale is saved as the new tare weight. The zero display appears.

Weigh the weighing sample in the second container and read/print the result.

Repeat steps 3 and 4 for the other containers.

2.4.6

2.4.6

2.4.62.4.6

Tare preset

Tare preset

Tare presetTare preset

If you know the weight of your containers, you can scan barcodes or input SICS command

to enter the tare weight. So you do not have to tare the empty container. See section 4.5.2

RS232 menu discription.

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

Please set the destination of ‘External input mode’ as ‘preset tare’.

Enter the known tare weight by scanning bar codes or input SICS command.

The weight display shows the negative tare weight and the symbol appears.

Place the full container on the weighing platform.

The net weight is displayed.

The entered tare weight is valid until a new tare weight is entered or the tare weight is

cleared.

2.5

2.6

Working with identifications

Working with identifications

Working with identificationsWorking with identifications

Weighing series can be assigned 2 identification numbers ID1 and ID2 with up to 40

characters that are also printed out in the protocols. If for example a customer number and

an article number are assigned, it can be clearly seen in the protocol which article was

weighed for which customer.

You can enter ID via

You can enter ID via bar

You can enter ID viaYou can enter ID via

√

Set ID1 or ID2 as destination of ‘External input mode’.

√

ID1 or ID2 can be displayed in the auxiliary line.

You can enter ID via SICS command(

You can enter ID via SICS command(These t

You can enter ID via SICS command(You can enter ID via SICS command(

√

ID1 or ID2 can be displayed in the auxiliary line.

Pri

Printing results

nting results

PriPri

nting resultsnting results

If a printer or computer is connected, weighing results and other information can be printed

out or transferred to a computer.

Press .

The defined data is printed out or transferred to the computer.

The printout content can be defined in the ttttemplates

bar code

code scanning (only one of the ID c

barbar

scanning (only one of the ID can be entered)

code code

scanning (only one of the ID cscanning (only one of the ID c

These two ID

wo IDssss can be entered

These tThese t

wo IDwo ID

emplates menu.

emplatesemplates

an be entered)....

an be entered)an be entered)

can be entered separately) .

can be entered can be entered

separately) .

separately) .separately) .

14

Mettler-Toledo

User Manual ICS241

08/11

Page 15

2.7

Verification test

Verification test****

Verification testVerification test

The weighing instrument is verified if

• the accuracy class is displayed in the metrological line,

• the securing seal is not tampered with,

• the validity is not expired.

The weighing instrument is also verified if:

• ‘Approved scale’ is displayed in the metrological line,

• Labels with the metrological data are placed near the weight display,

• The securing seal is not tampered with,

• The validity is not expired.

The period of validity is country-specific. It is in the responsibility of the owner to renew

verification in due time.

Combinations of a weighing terminal and an analog weighing platform use a Geo Code to

compensate for gravitational influence.

The manufacturer of the weighing instrument uses a defined Geo Code value for verification.

Please check if the Geo Code in the instrument corresponds with the Geo Code value

defined for your location.

The Geo Code value is displayed when you switch on the instrument.

The Geo Code for your location is shown in the appendix.

Call the METTLER TOLEDO service technician if the Geo Code values do not match.

*It’s only for China W&M approval.

2.8

Display Information

Display Information

Display InformationDisplay Information

Up to 20 different items for display can be configured in the menu for the info key.

Depending on the configuration in the menu Terminal –> Device –> Keyboard–> Info key,

the following data can be assigned in a free order, e.g.:

•

Date & Time

•

Weight values

•

Identifications

•

Device information

Press .

The (first) info screen is displayed.

Press again.

With one info screen only, the weight display appears.

With several info screens, the next info screen is displayed.

With several info screens press to exit the info screens.

An info screen is displayed until is pressed again or is pressed.

08/11

Mettler Toledo

User Manual ICS241

15

Page 16

Application

3.

3. Application

3.3.

Application

ApplicationApplication

3.1

3.1.1

3.1.1

3.1.13.1.1

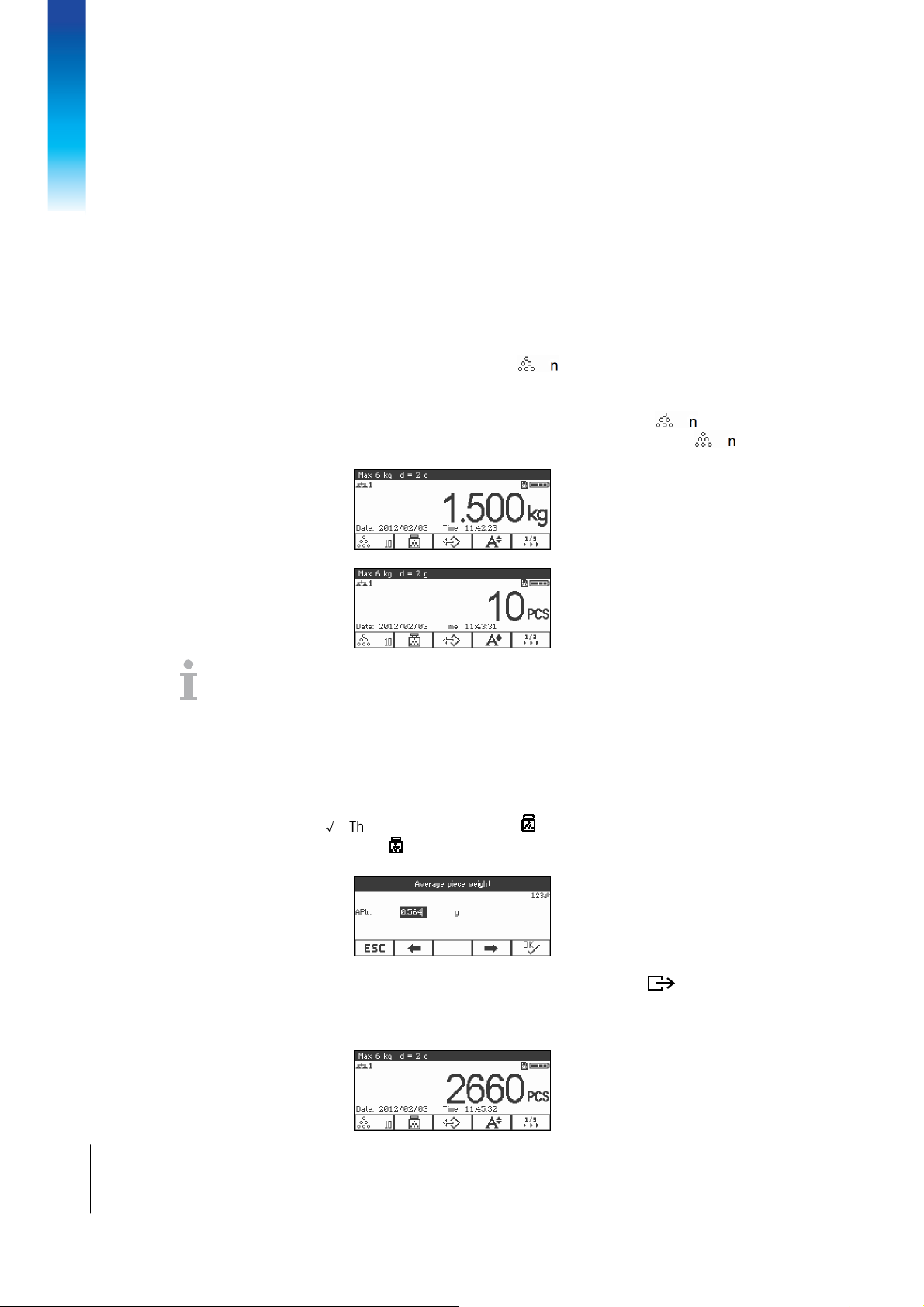

Piece counting

Piece counting

Piece counting Piece counting

Piece counting with a fixed number of reference pieces

Piece counting with a fixed number of reference pieces

Piece counting with a fixed number of reference piecesPiece counting with a fixed number of reference pieces

Prerequisite

Prerequisite

PrerequisitePrerequisite

√ The corresponding soft key is activated in the terminal menu.

1. Load the reference parts

2. If it is the default number of reference parts, press .

3. Otherwise enter the number of reference parts and press .

n: specify reference piece number.

4. Display reference pieces: the value of n.

• The average piece weight remains stored until a new average piece weight is

determined.

• The auxiliary line and the info page can be configured to show the average piece weight.

16

Mettler-Toledo

User Manual ICS241

3.1.2

3.1.2

3.1.23.1.2

Piece counting with a known piece weight

Piece counting with a known piece weight

Piece counting with a known piece weightPiece counting with a known piece weight

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

The corresponding soft key is activated in the terminal menu.

1. Press .

Input of the average piece weight (APW) is requested.

2. Enter the average piece weight and confirm with .

The weight unit changes to PCS.

3. Load the parts to be counted.

The number of pieces is displayed.

08/11

Page 17

• You can enter the average piece weight via barcode if the external input destination is

configured to "Average piece weight".

• The average piece weight remains stored until a new average piece weight is

determined.

3.1.3

3.1.3

3.1.33.1.3

Exit piece counting

Exit piece counting

Exit piece countingExit piece counting

Press .

’Clear’ is displayed on the screen.

Average piece weight is cleared, and straight weighing value is displayed.

The device operates in straight weighing mode.

3.2

3.2.1

3.2.1

3.2.13.2.1

Reference optimization

Reference optimization

Reference optimizationReference optimization

Reference optimization serves to re-calculate new average piece weight using a greater

number of reference pieces.

Reference optimization can be performed either manually or automatically

Manual Reference Optimization

Manual Reference Optimization

Manual Reference OptimizationManual Reference Optimization

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

For manual ref. opt, activate soft key in the menu’Terminal->Device>Keyboard->Soft keys’.

√

Soft key is only available in the counting mode, and the average piece weight

is obtained via sample counting, not fixed input.

1. Piece counting with a fixed number of reference pieces. (Repeat step 1-3 of 3.1.1).

2. Add several reference pieces.

Display the total number of two counting times.

3. Press ,

The new average piece weight is obtained.

• The second added number of reference pieces must be less than the first number of

reference pieces.

• If there is a great difference between the result of second average piece weight and first

average piece weight, ‘Optimization’ function can’t be executed.

08/11

Mettler Toledo

User Manual ICS241

17

Page 18

Application

3.2.2

3.2.2

3.2.23.2.2

Automatic Reference Optimization

Automatic Reference Optimization

Automatic Reference OptimizationAutomatic Reference Optimization

Prerequis

Prerequisite

PrerequisPrerequis

√

√

1. Piece counting with a fixed number of reference pieces. (Repeat step 1-3 of 3.1.1).

2. Display the total number of two counting times, the function of optimization is

• The second added number of reference pieces must be less than the first number of

• If there is a great difference between the result of second average piece weight and first

ite

iteite

Be activated in the menu ‘Application->Auto totalize->Activate’.

will appear in the symbols line.

Auto totalize is only available in the counting mode, and the average piece weight is

obtained via sample counting, not fixed input.

Add several reference pieces.

enabled after the number levels off.

The new average piece weight is obtained.

reference pieces.

average piece weight, ‘Optimization’ function can’t be executed.

18

Mettler-Toledo

User Manual ICS241

08/11

Page 19

3.3

Minimum sample weight

Minimum sample weight

Minimum sample weightMinimum sample weight

In order to ensure obtaining more precise average piece weight during reference number

counting, minimum resolution can be specified to set minimum sample weight.

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

Specify the minimum percentage accuracy of the reference weight in the menu

‘Application->Count-> Min. sample weight’.

1. The scale calculates the average piece weight as discussed in step 1-2 of 3.1.1.

2. It has determined that the percentage accuracy for the reference weight is below the

value set as Minimum sample weight.

It will calculate the number of pieces that you have to place on the scale to reach the

desired percentage accuracy.

3. After placing the specific number of pieces on the scale, the average piece weight will

be optimized.

It is possible to override the minumum sample weight checking by pressing the

key when you are prompted to add pieces on the scale. This will enable you to use

the calculated piece weight, but note that a “*” appears on the display to incate that

the sample weight is below the desired percentage accuracy.

08/11

Mettler Toledo

User Manual ICS241

19

Page 20

Application

3.4

3.4.1

3.4.1

3.4.13.4.1

Totalize

Totalize

TotalizeTotalize

Manual totalizing

Manual totalizing

Manual totalizingManual totalizing

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

For manual totalization, soft key must be activated in the menu ’Terminal>Device->Keyboard->soft keys’.

√

If you want to display the totalized result on the screen, please specify ‘Total net’ in

Auxiliary line(Terminal->Device->Display->Auxiliary line) and/or accumulate number

‘n’ in Info key (Terminal->Device->Keyboard->Info key).

Totali

Totalizzzzing

ing

TotaliTotali

inging

1. Press soft key to enter totalization interface in weighing or counting mode.

2. Weigh the first batch and press the soft key+, the total net and the number of items

are displayed.

Unload the scale.

3. Load the next batch and press the soft key + again, the total net and the number of

items have increased.

4. Unload the scale.

Repeat Step 3 and 4 for further items.

If you need to cancel the former step, press soft key , but this action only cancels

the lastest operation.

5. After totalization is completed, press soft key ∑. Safe instruction appears.

6. Press soft key YES to clear the totalized result.

– or –

Press soft key NO to continue totalizing.

Piece counting results and Checkweighing/counting results can be totalized the same way.

20

Mettler-Toledo

User Manual ICS241

08/11

Page 21

3.4.2

3.4.2

3.4.23.4.2

AAAAutomatic totalizing

utomatic totalizing

utomatic totalizingutomatic totalizing

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

Activate the function in the menu “Application->Auto totalize”.

√

Symbol Σ appears in the symbols line.

√

Activate ‘Good print’ for Under/Over Checkweighing.

– or –

√

Activate ‘Auto print’ for other weighing application.

√

Enter totalization interface by pressing soft key , clear the totalized result by

pressing soft key Σ.

√

If you want to display the totalized result on the screen, please specify ‘Total net’ in

Auxiliary line(Terminal->Device->Display->Auxiliary line) and/or accumulate number

‘n’ in Info key (Terminal->Device->Keyboard->Info key).

Automatic totalize

1. Load the first batch, if auto print works, automatic totalizing will be excuted and total

net & pieces number will be updated.

If Auxiliary line or info key is set, total net and pieces number will be displayed in that

area.

2. Unload the scale.

Load the next batch, total net and pieces number will be increased.

3. Repeat Step 1.

4. Unload the scale.

Repeat Step 3 and 4 for further items.

If you need to cancel the former step, press soft key , but this action only cancels

the latest operation.

5. After totalization is completed, press soft key ∑. Safe instruction appears.

6. Press soft key ’Yes’ to clear the totalized result.

- or -

Press soft key NO to continue totalizing.

Piece counting results and checkweighing/counting results can be totalized the same way.

08/11

Mettler Toledo

User Manual ICS241

21

Page 22

Application

3.5

Switch scale

Switch scale

Switch scaleSwitch scale

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

This function is only available in dual- scale version.

√

The 2nd scale is activated in the menu ‘Scale ->Scale 2->activate’.

• Soft key will automatically appear in the 4th position of soft keys.

• Press soft key , it switchs over from scale 1 to scale 2 or vice versa.

• The current activated scale symbol appears on the top of screen symbols and info line.

• Info line symbol will display the current scale number .

‘1’ indicates the current display scale is ICS241 internal scale.

‘2’ indicates the current display scale is ICS241 second scale.

• The position ‘1’&’2’ of soft key can help recognize the current scale in use.

‘1’ on the left of indicates the current display scale is ICS241 internal scale.

‘2’ on the left of indicates the current display scale is ICS241 second scale.

22

Mettler-Toledo

User Manual ICS241

08/11

Page 23

3.6

Log files

Log files

Log filesLog files

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

Ensure SD card is inserted, and is displayed in symbols and info line.That

indicates SD card is properly identified.(SD card: secure digital memory card, a kind

of small card interted into the scale for data storage)

√

If you need to check log files, activate soft key (log files) in the menu’ terminal>device->keyboard->Soft keys’.

√

If you need to save weighing logs, activate it in the menu ‘Application->Log files>Activate”.

√

The default former 6 lines as follows,’ Date’, ’Net’,’ Tare’, ’Gross’, ‘Scale No.’.

√

If you have other requirements, specify ‘Item 7-Item 10’ in the menu’ Application>Log files’.

Viewing log files

Viewing log files

Viewing log filesViewing log files

1. In the status of weighing, counting or checkweighing, press soft key to enter the

interface of viewing logs. The last weighing record appears.

2. Press soft key / or numeric keys to see more other records.

3. When contents are assigned in Item 7- 10, more detailed results can be viewed by

pressing to turn over the page.

Printing weighing info log files.

Printing weighing info log files.

Printing weighing info log files.Printing weighing info log files.

1. When weighing(transaction) records are displayed, press the flip key , the

second page of soft key appears, press the print key .

Following options are offered in the screen:

Print selected record

Print whole memory

Print today’s records

Print records by number

Print records by date

08/11

Mettler Toledo

User Manual ICS241

23

Page 24

Application

2. Press the cursor key / to choose the required printing mode, then press

or to confirm.

3. If print records by number or print records by date is chosen, you need to enter start

number and end number, or start date and end date.

Then press , all selected weighing (transaction) info records will be printed.

Edit print range in ‘print records by number’ mode.

Searching weighing info records

Searching weighing info records

Searching weighing info recordsSearching weighing info records

1. When weighing (transaction) records are displayed, press soft key .

2. Press soft key to select search criteria: ‘search by date’ or ‘search by rec. No.’,

then press to confirm.

3. Enter weighing info record number or date, press to confirm.

All needed weighing info appears.

Delete weighing info log files.

Delete weighing info log files.

Delete weighing info log files.Delete weighing info log files.

The action is operated in the menu ’Application->log files->weighing info log’.

24

Mettler-Toledo

User Manual ICS241

08/11

Page 25

3.7

3.7.1

3.7.1

3.7.13.7.1

Checkweighing

Checkweighing/counting

CheckweighingCheckweighing

The device offers checkweighing/counting functions. The respective settings in the menu

are described in the application menu section.

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

The soft keys for checkweighing/counting are activated in the terminal menu section.

Specifying target values

Specifying target values

Specifying target valuesSpecifying target values

Different entries are required at the beginning of checkweighing or checkcounting,

depending on the tolerance type setting.

Tolerance type "Absolute"

Tolerance type "Absolute"

Tolerance type "Absolute"Tolerance type "Absolute"

A low and a high weight value must be entered. These weights and all weights within this

range are treated as being within tolerance.

Toleran

Tolerance type "Relative"

ce type "Relative"

ToleranToleran

ce type "Relative"ce type "Relative"

Target weight (Target) as well as lower tolerance (Tol –) and upper tolerance (Tol +) have

to be specified. The tolerances are displayed as relative deviations from the target weight.

Tolerance type "Percent"

Tolerance type "Percent"

Tolerance type "Percent"Tolerance type "Percent"

Target weight (Target) as well as lower tolerance (Tol –) and upper tolerance (Tol +)

have to be specified in percent. At checkweighing the weight value is represented as a

percentage of the target weight. The target weight 100 % is striven for, or 0 % at over/

under checkweighing to zero.

/counting

/counting/counting

3.7.2

3.7.2

3.7.23.7.2

Weighing in target values

Weighing in target values

Weighing in target valuesWeighing in target values

The following section describes the course of the factory setting for the

checkweighing/counting application.

1. Press .

The current checkweighing parameters are displayed.

2. Use soft key to change the tolerance type and soft key to proceed to the first

low target.

With a tolerance type selected in the menu, this step does not appear.

3. Type in requested weight and press soft key .

The next parameter is highlighted.

4. Repeat step 3 until "New target set!" is displayed.

The checkweighing display appears, the scale is ready for checkweighing.

• If tolerance default values have been set in the menu, only the target has to be specified

with tolerance types "Relative" and "Percent".

08/11

Mettler Toledo

User Manual ICS241

25

Page 26

Application

• The upper tolerance value has to be greater than or equal the lower one (High ≥ Low)

or, respectively, the target weight has to be greater than or equal the lower tolerance

value and smaller than or equal the upper tolerance (Tol + ≥ Target ≥ Tol –).

3.7.3

3.7.3

3.7.33.7.3

Specifying target number of

Specifying target number of pieces

Specifying target number ofSpecifying target number of

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

At least one of the counting soft keys is activated.

Determining the piece weight

➜

Apply the reference parts (factory setting: 10 pieces) and press .

The number of reference pieces is displayed.

• For alternate procedures to determine the piece weight refer to the counting section.

• If you use the unit PCS, the tolerance type percent is not available.

Weighing in the target number of pieces

➜

Proceed as described in section "Weighing in target values".

The display unit is PCS.

pieces

piecespieces

26

Mettler-Toledo

User Manual ICS241

08/11

Page 27

3.7.4

3.7.4

3.7.43.7.4

Default layout

Default layout

Default layoutDefault layout

Big font mode

Big font mode

Big font modeBig font mode

Checkweighing

Checkweighing/counting

CheckweighingCheckweighing

Prerequisite

Prerequisite

PrerequisitePrerequisite

√

Target weighing or counting has been setted.

/counting display

/counting/counting

display

displaydisplay

Weight in Tolerance

Over weight

Under weight

3333----line mode

line mode

line modeline mode

In big font mode, soft keys line will disappear automatically if no key is pressed within 2

seconds.Checkweighing status information is displayed. If any soft key is pressed, soft key

line will appear again instead of checkweighing status info.

If checkweighing result meets the specified checkweighing range requirement, target value

line will be highlighted, indicating the current result meets the checkweighing range

requirement.

08/11

Mettler Toledo

User Manual ICS241

27

Page 28

Application

3.8

3.8.1

3.8.1

3.8.13.8.1

Using

Using stored

Using Using

SSSStore

tore article parameters

toretore

Article parameters include the following: Preset Tare, Average piece weight, Article

number ,Article name.

Tolerance type, target weight and tolerance can be saved during checkweighing

application.

50 target values can be stored in terminal at most.

1. In the status of tare, average piece weight or checkweighing.

2. If necessary, you can choose one record via numeric keys or direction soft keys / .

3. If necessary, press soft key to edit article number and article name.

stored preset parameters

storedstored

article parameters

article parametersarticle parameters

Press , the first record number in status ’free’ will be displayed.

Press .

preset parameters

preset parameters preset parameters

‘Record loaded!’ appears shortly on the screen. Target record is stored under the selected

number.

If

If the selected record is already occupied,

the selected record is already occupied, ’’’’Occupied

If If

the selected record is already occupied, the selected record is already occupied,

1. If you want to overwrite the old record, please press soft key .

‘Overwrite record?’ appears.

Press ‘Yes’ to overwrite it, press ‘No’ to cancel!

2. If article number or article name existed, the later same article number or article

name can’t be stored. If so, ‘Overwrite record?’ will appears.

Press ‘Yes’ to overwrite it, press ‘No’ to cancel, then re-edit it.

Quick store

Quick store

Quick storeQuick store

After define article parameters, please enter a numeric key whose number status is

free, press .

Article parameters will be quickly stored!

Occupied’’’’ status is displayed.

OccupiedOccupied

status is displayed.

status is displayed.status is displayed.

28

Mettler-Toledo

User Manual ICS241

08/11

Page 29

3.8.2

3.8.2

3.8.23.8.2

Recall targeted record

Recall targeted record

Recall targeted recordRecall targeted record

1. Press .

The first used record is displayed.

2. Enter the required record number or choose one record using direction keys / .

3. Press .

‘Record loaded!’ appear shortly on the screen. The display turns back to weighing

interface. Tare, Average piece weight, article number, article name or

Checkweighing/counting will be specified based on preset parameters.

Quick Recall

Quick Recall

Quick RecallQuick Recall

Enter the required record number, press .

08/11

Mettler Toledo

User Manual ICS241

29

Page 30

Application

3.9

Edit letter and

Edit letter and number

Edit letter and Edit letter and

ICS241 supports the input of numbers, English letters and punctuation. Lots of information

can be enterd via the keyboard, e.g. article information, article number, ID1, ID2.

When letters or numbers are required to input, one of the following symbos is displayed

on the upper right corner of the screen:

• Numeric input.

• Capital Letters and other special characters input.

• Lowercase and other special characters input.

Press key, to switch between capital letters and lowercase letters.

The method of text input is similar to the operation on cellphone.

Each numeric key is distributed four letters at most.

Confirm input pressing the key .

Example: Input ‘ICS241’.

1. Ensure is displayed.

2. Press key 4 three times to enter letter’I’.

3. Press key 2 three times to enter letter’C’.

4. Press key 7 four times to enter letter’S’.

5. Press key two times to switch numeric enter

6. Enter digit 2.

7. Enter digit 4.

8. Enter digit 1.

9. Press key to confirm.

number

numbernumber

30

Mettler-Toledo

User Manual ICS241

08/11

Page 31

4.

4. Menu settings

4.4.

Menu settings

Menu settingsMenu settings

In the menu settings can be changed and functions can be activated. This enables

adaptation to individual weighing requirements.

The menu consists of the following 5 main blocks containing various submenus on

several levels.

Scale

Application see section 4.4

Terminal see section 4.5

Communication see section 4.6

Maintenance see section 4.7

see section 4.2

4.1

Operator menu

Supervisor menu

Operating the menu

Operating the menu

Operating the menuOperating the menu

Calling up the menu and entering the password

The menu has 2 different operating levels: Operator and Supervisor. The supervisor level

can be protected by a password. When the device is delivered, both levels are accessible

without a password.

Press and keep it pressed until Enter code appears.

Press again.

The menu item Terminal

Press and keep it pressed until Enter code appears.

Enter the password and confirm with .

The first menu item Scale is highlighted.

No supervisor password has been defined when the device is first delivered. Therefore,

confirm the password inquiry with when you call up the menu for the first time.

If a password has still not been entered after a few seconds, the scale returns to the

weighing mode.

Emergency password for Supervisor access to the menu

If a password has been issued for Supervisor access to the menu and you have forgotten

it, you can still enter the menu:

Press and keep it pressed until Enter code appears

Press 3 times and confirm with .

Display presentation in the menu

Menu items are displayed together with their parental level. The following example shows

the menu start screen.

Terminal is displayed. Only parts of the submenu are accessible.

TerminalTerminal

08/11

Mettler Toledo

User Manual ICS241

31

Page 32

Settings in the menu

1. Menu info line, i.e. menu path of the current menu item

2. Menu items; the selected menu item is highlighted

3. Scroll flag (left), like the scroll bar of your PC

4. Navigation line

5. Scroll flag (right), like the scroll bar of your PC

6. Sub-menu items

4.1.1

4.1.1

4.1.14.1.1

Supervisor menu

4.1.2

4.1.2

4.1.24.1.2

Numeric

Numeric oper

NumericNumeric

Change highlight displayed digits: directly press digital keyboard(0—9),digits can be

entered.

Press

of the current one).

Repeat step 1 and 2 until all digits are set.

Press to confirm.

Exit menu

Exit menu

Exit menuExit menu

1. Press .

2. The last menu item End appears. ‘Save settings ?’ is displayed.

3. Press OK or .

4. menu changes are saved and the terminal returns to the weighing mode

-or -

Press ESC and return to menu settings.

-or -

Press NO to discard changes and return to the weighing mode.

operation in the menu, e.g.

ation in the menu, e.g. enter date

operoper

ation in the menu, e.g.ation in the menu, e.g.

,

move to next digit (right of the current one), press ,move to former digit(left

enter date

enter dateenter date

4.1.3

4.1.3

4.1.34.1.3

Selecting and setting paramete

Selecting and setting parameters in the menu

Selecting and setting parameteSelecting and setting paramete

Example: Setting of the Chain tare function

1. In the menu start screen press the soft key to switch to the right side.

The first submenu ‘Application’ gets highlighted.

2. Use the soft keys / to select Tare.

The Tare submenus are displayed on the right side.

rs in the menu

rs in the menurs in the menu

3. Press the soft key to open the selected (highlighted) menu item Tare.

The Tare submenus are displayed on the left side.

1) Use the soft keys / to select Chain tare.

32

Mettler-Toledo

User Manual ICS241

08/11

Page 33

The current Chain tare setting is displayed on the right side.

2) Press the soft key to open the selected (highlighted) menu item Chain tare.

All possible Chain tare settings are displayed, the current setting is highlighted

on the right side.

3) Use the soft keys / to change the Chain tare setting

4) Confirm the entry with or soft key .

If chain tare is displayed, either soft key or transfer key can be used to confirm

settings.

08/11

Mettler Toledo

User Manual ICS241

33

Page 34

Settings in the menu

4.2

4.2.1

4.2.1

4.2.14.2.1

Level 1

Level 1 Level 2

Level 1Level 1

Calibration

Display/Units

Zero AZM Off, 0.5d, 1d, 2d, 5d, 10d

Tare

Restart Off

Level 2 Level 3

Level 2Level 2

Unit 1

Unit 2

Resolution

Unit roll On,

Auto tare Off, On

Chain tare Off, On

Auto clear tare Off, On, 9d

Off, On

OffOff

Scale menu block

Scale menu block

Scale menu blockScale menu block

Factory settings are printed in bold in the following overview.

Overview

Overview

OverviewOverview

Level 3

Level 3Level 3

g,kg

kg,oz,lb,t

kgkg

gggg,kg,oz,lb,t

On, Off

Off

On,On,

OffOff

Vibration Low, Medium

Filter

MinWeigh Function Off

Reset Perform Reset?

Perform calibration

Perform calibration????

Perform calibrationPerform calibration

Process Universal

Stability Fast, Sta

4.2.2

4.2.2

4.2.24.2.2

1111 Unload scale.

2222 Start calibration with .

3333 If necessary, change the weight value displayed with .

4444 Place the calibration weight on the scale and confirm with .

The scale calibrates with the calibration weight loaded.

After calibration is completed, -Done- appears briefly on the display.

Description of the Scale menu block

Description of the Scale menu block

Description of the Scale menu blockDescription of the Scale menu block

Scale

Scale ––––> Calibration

> Calibration

Scale Scale

> Calibration> Calibration

This menu item is not available for verified scales.

The scale determines the zero point’ -0-‘appears in the display.

The calibration weight to be placed on the scale flashes in the display.

Medium, High

MediumMedium

Universal, Dosing

UniversalUniversal

Stannnndard

dard, Precise

StaSta

darddard

Off, On

OffOff

Note

34

Mettler-Toledo

User Manual ICS241

Abort the calibration process by pressing .

08/11

Page 35

Scale

Scale ––––> Display/Units

> Display/Units –––– Weighing unit and display accuracy

Scale Scale

> Display/Units > Display/Units

Weighing unit and display accuracy

Weighing unit and display accuracyWeighing unit and display accuracy

Unit

Unit 1111

Unit Unit

Unit

Unit 2222

Unit Unit

Resolution

Resolution

ResolutionResolution

Select weighing unit 1: g, kg, oz, lb, t

Select weighing unit 2: g, kg, oz, lb, t

Select readability (resolution), the possible settings depends on the connected scale

capacity.

Unit roll

Unit roll When unit roll is switched on, the weight value can be displayed in all available units

Unit rollUnit roll

with .

Notes In case of verified scales, individual sub-items of the Display menu item may not

be available or only to a limited extent, depending on the respective country.

Scale

Scale ––––> Zero

AZM(Automatic

zone

maintenance)

> Zero –––– Automatic zero update

Scale Scale

> Zero > Zero

On verified scales, this menu item does not appear.

Switching on/off automatic zero update and selecting zeroing range.

Possible settings: Off; 0.5 d

Automatic zero update

Automatic zero updateAutomatic zero update

0.5 d; 1 d; 2 d; 5 d; 10 d

0.5 d0.5 d

Scale

Scale ––––> Tare

Scale Scale

Auto tare

Auto tare Switching on/off

Auto tareAuto tare

Chain tare

Chain tare Switching on

Chain tareChain tare

off automatic taring

offoff

on/off chain tare

onon

> Tare –––– Tare function

> Tare > Tare

Tare function

Tare functionTare function

AAAA----Clear tare

Clear tare Switching on/off automatic clearing of the tare weight when the load is removed from

Clear tareClear tare

the scale.

• On The tare weight is automatically cleared if the gross weight is 0 or below zero

• Off

Off No automatic clearing of the tare weight

OffOff

• 9 d The tare weight is automatically cleared if the gross weight is within +/– 9

display steps.

Scale

Scale ––––> Res

> Restart

tart –––– Automatic saving of zero point and tare value

Scale Scale

> Res> Res

Restart

Restart When the restart function is activated, the last zero point and the tare value are saved.

RestartRestart

Automatic saving of zero point and tare value

tart tart

Automatic saving of zero point and tare valueAutomatic saving of zero point and tare value

After switching the scale off/on or after a power interruption, the device continues to

work with the saved zero point and tare value.

Scale

Scale ––––> Filter

Vibration

Vibration

VibrationVibration

Low

Medium

Medium

MediumMedium

High

> Filter –––– Adaptation of the ambient conditions and the weighing type

Scale Scale

> Filter > Filter

Adaptation to the environment conditions

• Very steady and stable environment. The scale works very rapidly, but is very

sensitive to external influences.

• Normal environment. The scale operates at medium speed.

Adaptation of the ambient conditions and the weighing type

Adaptation of the ambient conditions and the weighing typeAdaptation of the ambient conditions and the weighing type

• Restless environment (slight vibrations). The scale works more slowly, but is less

sensitive to external influences.

08/11

Mettler Toledo

User Manual ICS241

35

Page 36

Settings in the menu

Process

Process

ProcessProcess

Universal

Universal

UniversalUniversal

Dosing

Stability

Stability

StabilityStability

Fast

Standard

Standard

StandardStandard

Precise

Function

Function

FunctionFunction

Adaptation to the weighing process

• Universal setting for all weighing samples and normal weighing goods.

• Dispensing liquid or powdery weighing samples.

Adjusting the stability detector

• The scale operates very fast.

• The scale operates at medium speed.

• The scale operates with the greatest possible reproducibility.

Slower the scale works, greater the reproducibility of the weighing results.

Scale

Scale ––––> MinWeigh

> MinWeigh –––– Minimum weighing

Scale Scale

> MinWeigh > MinWeigh

Before you can use this function, the METTLER TOLEDO service technician has to

determine and to enter a minimum weight value.

Switching minimum weight function on/off.

If the weight on the scale drops below the stored minimum weight, appears in the

symbols and info line.

Scale

Scale ––––> Reset

> Reset –––– Resetting scale settings to factory settings

Scale Scale

> Reset > Reset

Minimum weighing value

Minimum weighingMinimum weighing

Resetting scale settings to factory settings

Resetting scale settings to factory settingsResetting scale settings to factory settings

value

valuevalue

Perform reset ?

Perform reset ?

Perform reset ?Perform reset ?

Confirmation inquiry

• Reset the analog scale settings to factory settings with YES

• Do not reset scale settings with NO

NO.

NONO

YES.

YESYES

36

Mettler-Toledo

User Manual ICS241

08/11

Page 37

4.3

4.3.1

4.3.1

4.3.14.3.1

Level 1

Level 1 Level 2

Level 1Level 1

Count Reference n 1-60000

Over/Under Tolerance Off,

Application menu block

Application menu block

Application menu blockApplication menu block

Factory settings are printed in bold

Overview

Overview

OverviewOverview

Level 2 Level 3

Level 2Level 2

Min. sample weight

Accurancy display

APW(average piece

weight) optimization

Auto sampling Off

Auto clear APW(average

piece weight)

Default values Activate Off

Level 3 Level 4

Level 3Level 3

Off

Off,97.5%,99.0%,99.5%

OffOff

Off

Off,On

OffOff

Off

Off,On

OffOff

Off,On

OffOff

Off

Off,On

OffOff

Off, Absolue,Relative,Percent

Off, Off,

Relative weight Tolerance-, Tolerance+

bold in the following overviews

boldbold

Level 4

Level 4Level 4

Off,On

OffOff

Percent weight Tolerance-, Tolerance+

Relative pieces Tolerance-, Tolerance+

Output Setpoint tol-

Good print Off

Data storage Article name Activate Off

Article number Activate Off

Delete all Start?

Delete record

Print records ?

Log files Activate Off

Item 7

…

Item 10

Auto totalize Activate Off

Reset Perform reset?

Off,On

OffOff

Not used

Not used, Average piece weight, Quantity, Article name, Article

Not usedNot used

number, ID1 , ID2, Device identifier, Device location,

SNR(serial number) scale

Off, On

OffOff

Off,On

OffOff

Off,On

OffOff

Off,On

OffOff

08/11

Mettler Toledo

User Manual ICS241

37

Page 38

Settings in the menu

.

steady, the terminal will auto clear

(Secure digital

4.3.2

4.3.2

4.3.24.3.2

Description

Description

DescriptionDescription

Application

Application---->>>>Count

ApplicationApplication

Count

CountCount

Reference n

Reference n

Reference nReference n

Min. sample weight

Min. sample weight

Min. sample weightMin. sample weight

APW opt.

APW opt.

APW opt.APW opt.

(average piece

(average piece

(average piece (average piece

weight optimization)

weight optimization)

weight optimization)weight optimization)

Auto sampling

Auto sampling Activate /deactivate Auto sampling.

Auto samplingAuto sampling

Setting reference number(1-60000)

After setting, the n in soft key will automatically display the set number.

Setting the min. sample weight.

Off

Off: no requirement to sample weight.

OffOff

97.5%,99.0%,99.5%:min. sample weight. It will remind user that more pieces

need to be added to reach the defined sample weight.

Activate /de

After activation, the precision of the APW(average piece weight) can be improved by

adding sample pieces.

Note:

If this symbol is displayed in the info line, the added number of sample pieces

must be smaller than the current number of pieces, or the function will be invalid.

After activation, this symbol will be displayed in info line. Load samples in the

weighing platform, the number of samples must be the same as the ‘reference number’

After the sample is steady, the terminal will auto sample. The display contents changes

from sample weight to the number of samples piece.

deactiv

activate

ate APW(average piece weight) optimization function.

dede

activactiv

ateate

Application

Application---->Count

ApplicationApplication

>Count ---->>>> Auto sampling

>Count>Count

Auto sampling &&&& Auto clear APW

Auto samplingAuto sampling

Auto clear APW

Auto clear APWAuto clear APW

Auto clear

Auto clear

Auto clear Auto clear

APW

APW(average piece

(average piece

APWAPW

(average piece (average piece

weight)

weight)

weight)weight)

Activate?

Activate?

Activate?Activate?

Item 7

Item 7…………Item 10

Item 7Item 7

Item 10

Item 10Item 10

Activate /deactivate Auto clear APW(average piece weight).

After activation, this symbol will be displayed in info line. If the current status is

counting , unload the weighing platform. After being

APW(average piece weight) ,exiting counting mode and returning to weighing interface.

Application

Application---->>>> Log files

ApplicationApplication

If activated, all weighing information will be saved in log files in SD card

memory card: A slot of SD card is in the front of scale, customers can insert the card if

they need to use the function of log files.)

Other additional info can be saved besides the 6 fixed items.

1. Select the item number.

2. Assign contents to this item.

Before you delete all the stored weighing records, a warning message will appear.

Log files ---->>>> Set log files

Log filesLog files

Set log files

Set log filesSet log files

38

Mettler-Toledo

User Manual ICS241

08/11

Page 39

Application

Application---->>>> Over/Under

ApplicationApplication

Over/Under ---->>>>Set

Over/UnderOver/Under

Set ccccheckweighing

Set Set

heckweighing parameter

heckweighingheckweighing

parameterssss

parameterparameter

Tolerance type

Tolerance type

Tolerance typeTolerance type

Off

Absolute

Relative

Percent

Default values

Default values

Default valuesDefault values

Activate

Relative weight

Percent weight

Relative pieces

Specify which parameters have to be entered for checkweighing.

• No tolerance type predefined, it can be set individually when entering

checkweighing/counting parameters.

• A low and a high weight value must be entered. These weights and all weights

within this range are treated as being within tolerance.

• The target weight has to be entered as an absolute weight, upper and lower

tolerances as weight deviations from the target weight.

• The target weight has to be entered as an absolute weight, upper and lower

tolerances as deviations in percent from the target weight.Not possible for

counting.

If you always use the same tolerances for checkweighing/counting, you can store

these tolerances and thus avoid entering tolerances all the time.

Activating usage of default tolerance values.

• Off

Off default tolerance values not used

OffOff

• On default tolerance values used

Relative weight enter the weight values for Tolerance – and Tolerance +.

Percent weight enter the percentages for Tolerance – and Tolerance +.

Relative pieces enter Tolerance – and Tolerance + in pieces.

Outpu

Outputttt

OutpuOutpu

Setpoint tol–-

Good print

Setting display and printing options.

This setpoint is available on the optional digital I/O interface as well.

when you are already near the target or if you need an additional setpoint for I/O

control.

Possible settings: 0 ... 100 % (of the “Tolerance –“ value)

Automatic printout

• Off No automatic printout

• On Automatic printout when a stable weight value within the tolerance values

exists.

08/11

Mettler Toledo

User Manual ICS241

39

Page 40

Settings in the menu

Appl

Application

Article name

Article name