Page 1

Operating instructions

HR83 and HR83-P Moisture Analyzers

Page 2

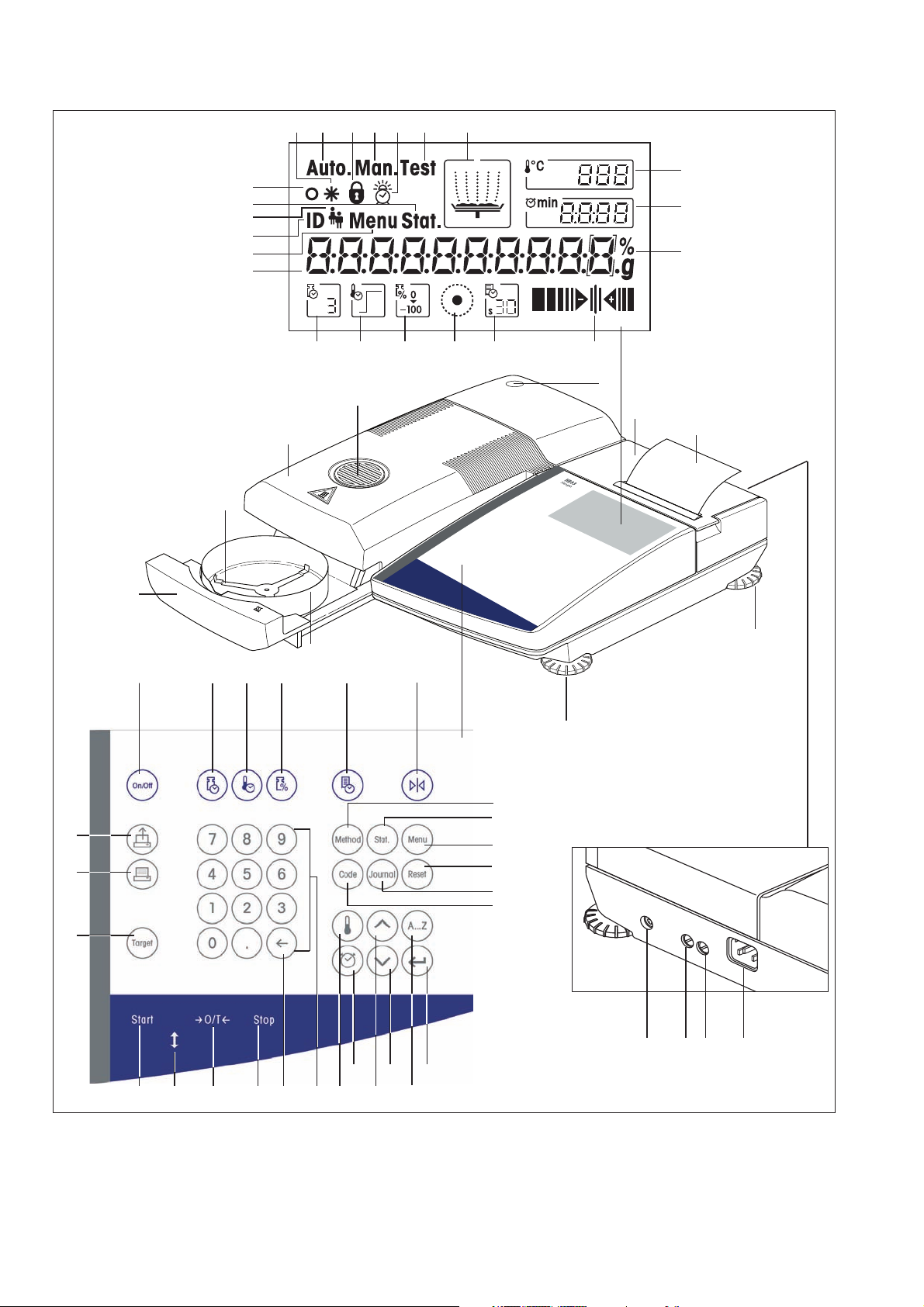

Overview of your HR83 Halogen Moisture Analyzer

30

3128 29

26

25

24

23

22

21

33

3227

12

13

14

17

7

6

5

2

4

3

38 3935 373634

1516181920

8

9

10

1

11

11

60

59

58

57

40

41

42

43

44

45

62 62 6163

464850

5556

54

53 52

51 49

47

Page 3

Display, controls and connections of your HR83

No. Designation Info see

Section

1 Display all

2 Keypad all

3 Draft shield 2.3

4 Automatic sample chamber 2.6

5 Sample pan holder 2.3

6 Heating module 7.6

7 Inspection window and vent 6.4

8 Level indicator (level) 2.3

9 Printer cover 7.2

10 Built-in printer (option) 7.5

11 Leveling screw 2.3

12 Display of drying temperature 4.3

13 Display of drying time /

Method number (Selection) /

Comment line (C1 – C4) 4.4

14 Display of unit (percent or grams) 4.5

15 Weighing-in aid 4.7

16 Function display “Print interval” 4.6

17 Function display “AutoMet” 4.12

18 Function display “Display mode” 4.5

19 Function display “Drying program” 4.2

20 Function display “Switch-off criterion” 4.4

21 Dialog display (measured values, menu

dialog, text entry, etc.) all

22 Menu symbol 6

23 Method symbol 5

24 Symbol for record comment 4.9

25 Statistics symbol 5.12

26 Stability detector 8.2/8.3

27 Symbol for calculated result 2.6/5.11

28 Symbol for automatic operating mode of

the automatic sample chamber 6.11

29 Symbol for Key protection

(with and without password) 6.13

30 Symbol for manual operating mode of the

automatic sample chamber 6.11

No. Designation Info see

Section

31 Symbol for audio signal device (beeper) 6.12

32 Symbol for test measurement 4.11/4.12

33 Status display (User guide) 2.6

34 Key «On/Off» 2.6

35 Function key «Switch-off criterion» 4.4

36 Function key «Drying program» 4.2

37 Function key «Display mode» 4.5

38 Function key «Print interval» 4.6

39 Key «Target weight» (weighing-in aid) 4.7

40 Key «Method» (method selection) 5.2

41 Key «Stat.» (statistics) 5.12

42 Key «Menu» 6

43 Key «Reset» 2.6

44 Key «Journal» 5.11

45 Key «Code» (record comment) 4.8

46 Key «Accept entry» all

47 Key «A...Z» (alphanumeric entry) 4.8/5.3

48 Key «Scroll down» 2.5

49 Key «Scroll up» 2.5

50 Key «Drying time» 4.4

51 Key «Drying temperature» 4.3

52 Numeric keypad 4.1

53 Key «Delete» 4.1

54 Key «Stop» (stop drying) 4.9/4.10

55 Key «Tare» (zero) 2.6

56 Key «Open/close auto sample chamber» 2.6

57 Key «Start» (start of drying) 2.6

58 Key «Target» 4.12

59 Key «Print» 4.10/6.1

60 Key «Paper feed» 2.4/7.2

61 Power supply receptacle 2.3

62 Power line fuses 7.3

63 LocalCAN universal interface port 9.2

Page 4

Contents

4

Contents

1 Getting to know your Moisture Analyzer .................................................................................................6

1.1 Introduction ..........................................................................................................................................6

1.2 What is the Halogen Moisture Analyzer used for? ...................................................................................... 6

1.3 Safety has priority .................................................................................................................................. 7

1.4 Disposal .............................................................................................................................................. 9

1.5 Important information for these instructions ............................................................................................10

2 Your first measurement in next to no time ...........................................................................................11

2.1 Unpacking and checking the standard equipment ................................................................................... 11

2.2 Selecting the location ...........................................................................................................................12

2.3 Setting up, leveling and connecting to power supply ................................................................................ 12

2.4 Preparing the printer ............................................................................................................................15

2.5 Setting the date and time ......................................................................................................................16

2.6 Your first measurement ........................................................................................................................18

3 How to obtain the best results .............................................................................................................22

3.1 Measurement principle of the Halogen Moisture Analyzer .........................................................................22

3.2 Notes on adjustment of the balance and the heating module ....................................................................23

3.3 Optimum sample preparation ............................................................................................................... 23

3.4 Further information on moisture determination ........................................................................................24

4 Practical application of your Moisture Analyzer ................................................................................... 25

4.1 Operating principles ............................................................................................................................. 25

4.2 Selecting the drying program ................................................................................................................26

4.3 Setting the drying temperature ...............................................................................................................27

4.4 Selecting the switch-off criterion ............................................................................................................30

4.5 Selecting the display mode ...................................................................................................................33

4.6 Defining the print interval ...................................................................................................................... 35

4.7 Working with the weighing-in aid .......................................................................................................... 36

4.8 Comment lines .................................................................................................................................... 38

4.9 Information on the measurement record ................................................................................................. 40

4.10 Performing a measurement .................................................................................................................. 42

4.11 Test measurement ...............................................................................................................................46

4.12 AutoMet test measurement ....................................................................................................................47

5 Methods facilitate your work ............................................................................................................... 51

5.1 What is a method? ..............................................................................................................................51

5.2 Recalling a method ............................................................................................................................. 52

5.3 Naming, compiling or changing methods .............................................................................................. 52

5.4 Method menu ..................................................................................................................................... 55

5.4.1 Freely selectable switch-off criterion .......................................................................................................56

5.4.2 Free factor (-MC) ................................................................................................................................. 57

5.4.3 Free factor (g) ..................................................................................................................................... 58

5.4.4 Compiling methods ............................................................................................................................. 58

5.4.5 High resolution ................................................................................................................................... 60

5.4.5.1 Standby temperature ............................................................................................................................ 60

5.4.5.2 Recording the settings ..........................................................................................................................62

5.4.6 Drying temperature to 200 °C without time limitation ...............................................................................63

5.5 Printing out methods ........................................................................................................................... 63

5.6 Measured value journal ........................................................................................................................ 65

5.7 Measured value statistics .....................................................................................................................66

Page 5

Contents

6 The menu (basic settings of the instrument) ........................................................................................69

6.1 Password protection ............................................................................................................................70

6.2 Adjusting the balance .......................................................................................................................... 73

6.3 Testing the balance ............................................................................................................................. 74

6.4 Adjusting the heating module ................................................................................................................ 75

6.5 Testing the heating module ................................................................................................................... 77

6.6 Resetting to the factory settings ............................................................................................................. 80

6.7 Clearing the method memory ................................................................................................................81

6.8 Setting the time ...................................................................................................................................81

6.9 Entering the date ................................................................................................................................. 82

6.10 Setting the vibration adapter ................................................................................................................. 82

6.11 Selecting operating mode of the automatic sample chamber ....................................................................83

6.12 Audio signal ....................................................................................................................................... 83

6.13 Protecting your settings against change .................................................................................................84

6.14 Superimposing or removing the function symbols ................................................................................... 84

6.15 Switching the printer on or off ............................................................................................................... 85

6.16 Entering company name for printed records ............................................................................................85

6.17 Selecting the type of record ................................................................................................................... 86

6.18 Defining the free print interval ................................................................................................................86

6.19 Switching the statistics and journal functions on and off .......................................................................... 87

6.20 Selective clearing of comment lines .......................................................................................................87

6.21 Defining the test weight ........................................................................................................................88

6.22 Tolerance for balance test .....................................................................................................................88

6.23 Selecting the dialog language ...............................................................................................................89

6.24 Menu overview HR83 .......................................................................................................................... 90

7 Servicing and replacing individual parts .............................................................................................. 91

7.1 Cleaning ............................................................................................................................................ 91

7.2 Changing the printer paper and ribbon ...................................................................................................92

7.3 Replacing the power line fuses .............................................................................................................. 93

7.4 Printer test ..........................................................................................................................................94

7.5 Installing the built-in printer ..................................................................................................................94

7.6 Dismantling and replacing the heating module .......................................................................................94

8 If problems arise on occasion .............................................................................................................96

8.1 Notes on the error messages ................................................................................................................96

8.2 Meaning of the error messages ............................................................................................................. 97

8.3 What if...? .......................................................................................................................................... 99

9 Further useful information ................................................................................................................103

9.1 Notes on interpretation of the measurement results and the ideal sample weight .......................................103

9.2 LocalCAN universal interface ............................................................................................................... 103

9.3 Barcode Reader ................................................................................................................................ 104

9.4 Application brochure ..........................................................................................................................104

9.5 Switch-off criterion “Weight loss per unit of time” ................................................................................... 104

9.6 Comments on certified version ............................................................................................................105

9.7 Technical data .................................................................................................................................. 106

9.8 MT-SICS Interface commands and functions .........................................................................................109

9.9 Optional equipment, expendable material and spare parts ..................................................................... 111

10 Index ...............................................................................................................................................112

5

Page 6

Getting to know your Moisture Analyzer

6

1 Getting to know your Moisture Analyzer

Please read through this Section carefully, it contains important information for safe and economical operation of

your Moisture Analyzer.

1.1 Introduction

Thank you for deciding to purchase a Halogen Moisture Analyzer from METTLER TOLEDO – you have made a wise

choice. Your Moisture Analyzer is fast and reliable. It offers a high level of operating convenience and useful

functions to facilitate determination of the moisture content of your samples

Behind your instrument stands METTLER TOLEDO, a leading manufacturer of not only balances and scales for the

lab and production, but also analytical measuring instruments. A customer service network covering the entire globe

with well trained personnel is at your service at all times, whether you are choosing accessories or require guidance

for a specific application to ensure optimum utilization of your instrument.

To ensure you make full use of the possibilities offered by your Moisture Analyzer, we advise you to read through

these operating instructions very carefully.

1.2 What is the Halogen Moisture Analyzer used for?

Your Halogen Moisture Analyzer is used for determining the moisture content of almost any substance. The

instrument works on the thermogravimetric principle: At the start of the measurement the Moisture Analyzer

determines the weight of the sample, the sample is then quickly heated by the integral halogen heating module

and the moisture vaporizes. During the drying process the instrument continually measures the weight of the

sample and displays the reduction in moisture. Once drying has been completed, the moisture or solids content

of your sample is displayed as the final result.

Of decisive importance in practice is the rate of heating. In comparison with conventional infrared heating or the

drying oven method, for example, the halogen heating module of your instrument needs a shorter time to reach its

maximum heating power. It also allows use of high temperatures, an additional factor in shortening the drying time.

Uniform heating of the sample material ensures good repeatability of the drying results and makes it possible to

use a smaller amount of sample.

All parameters of a measurement (drying temperature, drying time, etc.) can be preselected. But your Moisture

Analyzer offers many other possibilities. To avoid exceeding the scope of this introduction, only a few of these are

listed here:

– In the built-in methods database 40 different methods can be individually optimized to suit your samples. They

are simple to activate at the touch of a key.

– You can set a reference value for which the optimum switch-off criterion is determined automatically in a test

measurement (AutoMet).

– You can choose between various types of result display at any time.

– Your settings and measurement results can be recorded, stored and protected (3-level password protection).

– Up to 4 comment lines can be entered per measurement (with optional use of a Barcode Reader).

– Thanks to the built-in rechargeable battery your valuable data remain stored even on power failure.

Page 7

Getting to know your Moisture Analyzer

This wealth of functions notwithstanding, your Moisture Analyzer is very simple to operate. The status display (User

guide) guides you step by step through the measurement cycle. You always know which particular stage in a

measurement is currently being executed by the instrument and the next operating step. To exclude faulty handling

in routine work, the keypad can be locked (3-level password protection) to prevent access to all but the elementary

functions. The motorized, automatic sample chamber offers the operating convenience you are familiar with from

compact disk (CD) players. Moreover, the motorized sample chamber opens up new possibilities for automatic

operation of the instrument (loading by means of robots) when used with the LocalCAN universal interface installed

as standard.

Besides operating convenience, however, the quality of the measurement results is still what counts above all. The

built-in weighing cell meets the high standard which has made METTLER TOLEDO the worldwide market leader in

the field of high-resolution precision balances.

A brief word regarding standards, directives and procedures for quality assurance. The Moisture Analyzer conforms

with all common standards and directives. It supports stipulations, work techniques and result records as demanded

by all international quality assurance systems, e.g. GLP (Good Laboratory Practice), GMP (Good Manufacturing

Practice). The instrument has a EC declaration of conformity and METTLER TOLEDO as the manufacturer has been

awarded ISO 9001 and ISO 14001 certification. This provides you with the assurance that your capital investment

is protected in the long term by a high product quality and a comprehensive service package (repairs, maintenance,

servicing, calibration service).

You will find further information in the following Sections of these operating instructions. Please read through this

information carefully to ensure you can use your instrument in an optimum and safe manner.

7

1.3 Safety has priority

Your Moisture Analyzer employs state of the art technology and meets the latest demands

regarding instrument safety. This notwithstanding, improper operation can endanger personnel

and cause damage to tangibles. For safe and dependable operation, please comply with the

following instructions:

– The Moisture Analyzer is used for determining the moisture in samples. Please use the

instrument exclusively for this purpose. Any other type of use can endanger personnel and

damage the instrument or other tangibles.

– The Moisture Analyzer must not be operated in a hazardous environment and only under the

ambient conditions specified in these instructions.

– The Moisture Analyzer may be operated only by trained personnel who are familiar with the

properties of the samples used and with the handling of the instrument.

– Your Moisture Analyzer is supplied with a 3-pin power cable with an equipment grounding

conductor. Only extension cables which meet the relevant standards and also have an

equipment grounding conductor may be used. Intentional disconnection of the equipment

grounding conductor is prohibited.

Page 8

Getting to know your Moisture Analyzer

8

The Halogen Moisture Analyzer works with heat!

– Ensure sufficient free space around the instrument to avoid heat accumulation and

overheating (approx. 1 m free space above the instrument).

– The vent over the sample must never be covered, plugged, taped over or tampered with in

any other way.

– Do not place any combustible materials on, under or next to the instrument when it is

connected to the power supply, since the area around the heating module becomes hot.

– Exercise caution when removing the sample. The sample itself, the automatic sample

chamber and any sample vessels used may still be very hot.

– During operation, you should never open the heating module as the ring-shaped heating

module or its protective glass can reach 400 °C! If you have to open the heating module on

occasion, disconnect the instrument from the power supply and wait until the heating module

has cooled down completely.

– No modifications must be made within the heating module. It is particularly dangerous to

bend any components or remove them, or to make any other changes.

Certain samples require special care!

With certain types of samples, there is a possibility of danger to personnel or damage to

tangibles through:

Fire or explosion:

– Flammable or explosive substances

– Substances containing solvents

– Substances which evolve flammable or explosive gases or vapors when heated.

With such samples, work at a drying temperature that is low enough to prevent the formation

of flames or an explosion and wear protective goggles. Should there be any uncertainty

regarding the flammability of a sample, always work with a small amounts of sample (max.

1 gram). In such cases, never leave the instrument unattended! In cases of doubt, perform

a careful risk analysis.

Poisoning, burning:

– Substances which contain toxic or caustic components. Such substances may be dried only

in a fume cupboard.

Corrosion:

– Substances which evolve corrosive vapors when heated (e.g. acids). In the case of such

substances, we advise you to work with small amounts of sample as the vapor can condense

on cooler housing parts and cause corrosion (if necessary, the heating module can be

changed very easily by the user, see Section 7.6).

Please note that the user always takes responsibility and assumes liability for damage

caused by use of the types of samples mentioned above!

Page 9

Getting to know your Moisture Analyzer

– Never make any modifications or constructional alterations to the instrument and use only

original spare parts and optional equipment from METTLER TOLEDO.

– Your Moisture Analyzer is a rugged precision instrument – but you should still treat it carefully;

it will then thank you with many years of trouble-free operation.

– Please comply with all notes and instructions in these operating instructions. Keep the

instructions in a safe place where they are immediately to hand if any points are unclear.

If you lose these instructions, please contact your METTLER TOLEDO dealer for an

immediate replacement.

Moisture determination applications must be optimized and validated by the user according

to local regulations. Application-specific data provided by METTLER TOLEDO is intended for

guidance only.

9

1.4 Disposal

In conformance with the European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment (WEEE) this device may not be disposed of in domestic waste.

This also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment.

If you have any questions, please contact the responsible authority or the distributor from which

you purchased this device.

Should this device be passed on to other parties (for private or professional use), the content

of this regulation must also be related.

Thank you for your contribution to environmental protection.

Page 10

Getting to know your Moisture Analyzer

10

1.5 Important information for these instructions

These instructions guide you step by step through the operation of your Moisture Analyzer. The first two Sections

help you put the instrument into operation quickly, safely and properly and perform your first measurement within

a short space of time. In Sections 3 through 6 you become intimately acquainted with the wide range of functions

of your Moisture Analyzer. During this learning phase, you will find the table of contents and the detailed index in

Section 10 a valuable orientation aid. Sections 7 through 9 contain additional information on the maintenance of

your instrument, troubleshooting and the available options. As soon as you are familiar with your Moisture Analyzer,

you will find the illustrations at the beginning of these instructions and the associated references (in the key) useful

for quick access.

The following identifications and symbols are used in these instructions:

– Key designations are shown enclosed by twin angle brackets «». Keys with inscribed text are

shown with the actual inscription (e.g. «On/Off» or «Start»). For all keys with symbols,

designations are used in the text which describe the function of the particular key («Print»,

«Accept entry» or «Scroll down»).

– This symbol indicates safety and hazard instructions. If these are not complied with, injury

to the user, damage to your instrument or other tangibles and malfunctions can result.

– This symbol indicates additional information and directions which facilitate your handling of

the instrument and contribute to proper and economical use.

These instructions are also available in foreign languages. Should you require a set of

instructions in a different language, please contact your METTLER TOLEDO dealer. You will find

the address of your nearest dealer in the attached “Declaration of Conformity 11780294”.

Page 11

Your first measurement in next to no time

11

2Your first measurement in next to no time

In the Section you will learn how to put your new Moisture Analyzer into operation and obtain measurement results

within a very short space of time.

2.1 Unpacking and checking the standard equipment

Open the package and remove the instrument and the accessories. Check the completeness of the delivery. The

following accessories are part of the standard equipment of your new Moisture Analyzer:

– 80 aluminum sample pans

–1 sample holder

–1 sample handler

–1 specimen sample (circular, absorbent glass fiber filter)

–1 draft shield element

–1 power cable

–1 set of operating instructions, 1 set of short-form operating instructions

–1 Application brochure “Methods of moisture content determination”

–1 EC declaration of conformity (in separate brochure 11780294)

– Setup instructions

Remove the wrapping from the instrument.

Check the instrument for transport damage. Immediately inform your METTLER TOLEDO dealer if you have any

complaints or parts are missing.

Store all parts of the packaging. This packaging guarantees the best possible protection for the

transport of your instrument.

To prevent transport damage, the instrument is provided with a transport arrestment, which you

have to remove before putting the instrument into operation for the first time. The procedure for

removing the transport arrestment is explained in the description “Setup instructions 11780556”

enclosed with the package.

Page 12

Your first measurement in next to no time

12

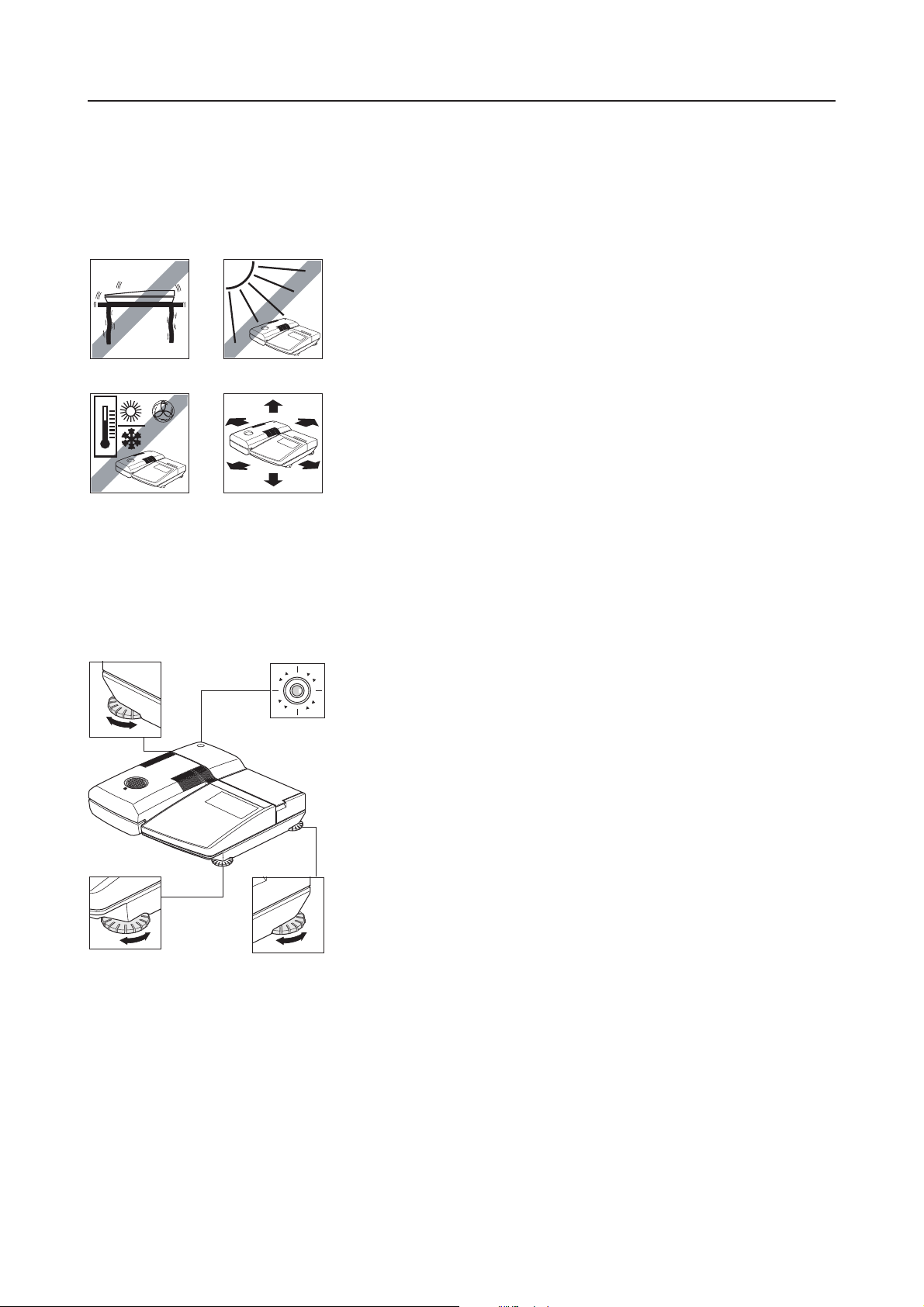

2.2 Selecting the location

Your Moisture Analyzer is a precision instrument. An optimum location guarantees accuracy and dependability:

– Firm, horizontal location as free from vibrations as possible

– Avoid direct sunlight

– No excessive temperature fluctuations

– No powerful drafts

– Surroundings as free from dust as possible

– Adequate free space at the front for opening the sample chamber and

sufficient clearance around the instrument to allow warm air to dissipate.

– Sufficient distance from heat-sensitive materials in the vicinity of the

instrument.

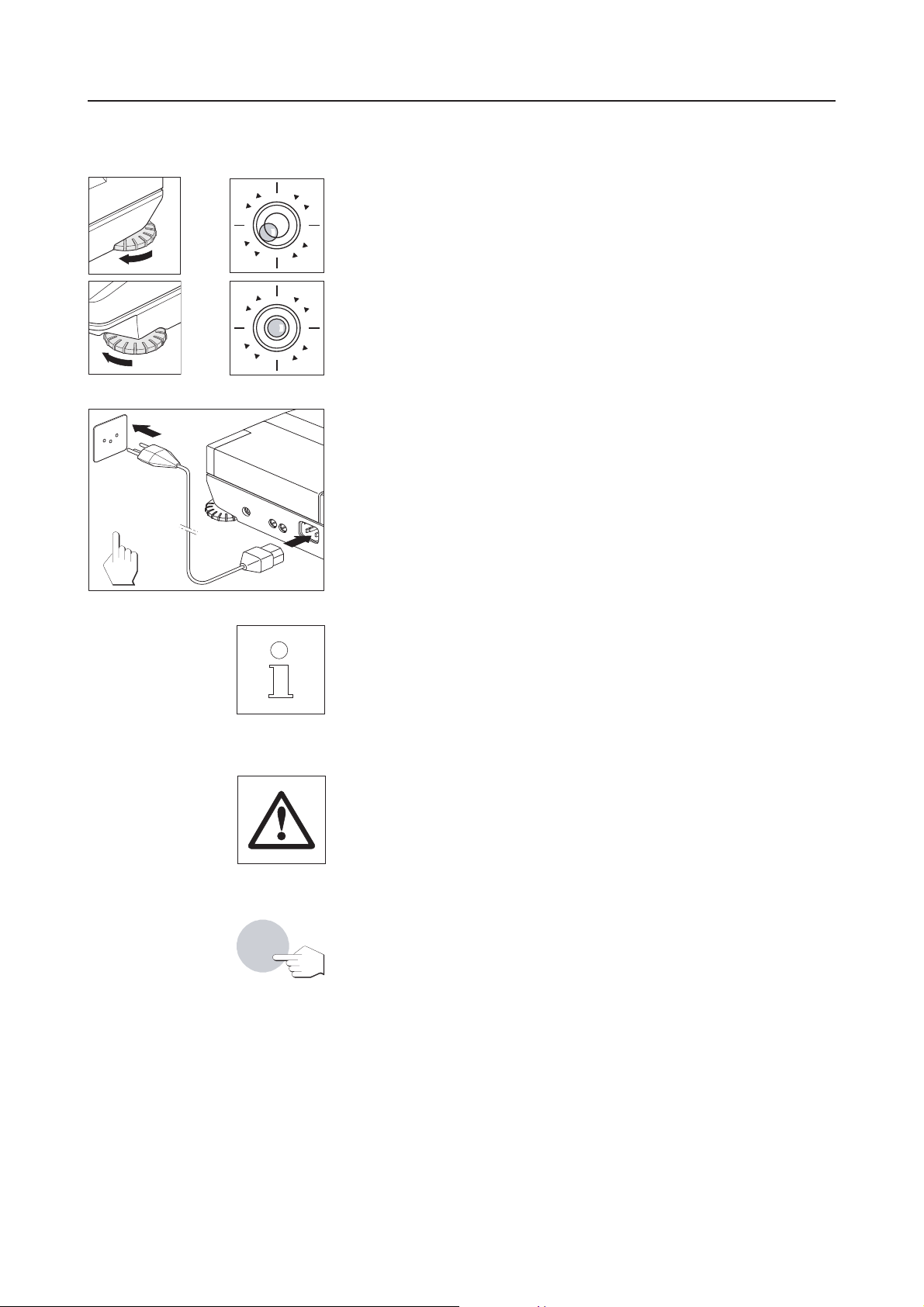

2.3 Setting up, leveling and connecting to power supply

Exact horizontal positioning and stable installation are prerequisites for repeatable results. To compensate small

irregularities or inclinations (±2%) at the location, the instrument can be leveled.

For exact horizontal positioning, the Moisture Analyzer has a level indicator

R

L

R

(level) and 3 leveling screws. As soon as the air bubble is precisely in the

L

middle of the cross hairs, the instrument is exactly horizontal. To level it,

proceed as follows:

Position your Moisture Analyzer at the selected location.

Screw in the right front leveling screw completely (it is not needed for

leveling). The instrument is now standing on the front left, nonadjustable

foot, as well as on the two rear leveling screws.

Turn the two rear leveling screws until the air bubble is located in the middle

of the level indicator. The arrows and the leveling screw designations (R =

right rear leveling screw, L = left rear leveling screw) on the cross hairs will

facilitate the setting:

Page 13

Your first measurement in next to no time

13

R

L

indicates the right leveling screw must be turned in a clockwise direction.

Unscrew the front right leveling screw until it contacts the support and the

If the air bubble is located at the bottom left, for instance, the inscription

R

L

instrument is resting firmly on all 4 feet. Ensure that the air bubble remains

in the center of the level indicator.

R

L

R

Note: The instrument should be releveled each time its location is changed.

L

Connect the instrument to the power supply.

Warning

If the power cable supplied is not long enough, use only a 3-pin extension

cable with equipment grounding conductor!

For technical reasons, the halogen heating module is designed specifically

for a particular line voltage (110 V AC or 230 V AC). A heating module is

installed in the factory that is matched to the particular line voltage of the

country of destination. If you are not sure whether the heating module built

into your instrument is suitable for your local line voltage, check the voltage

data in the interior of the heating module before you connect the Moisture

Analyzer to the power supply!

Connection to a line voltage that is too high can lead to blowing of the fuses,

whereas a supply voltage that is too low will prolong the drying process.

On/Off

Ensure that the transport arrestment is removed. Instructions on how to

remove the transport arrestment can be found on the leaflet enclosed with the

package.

Switch the instrument on with the «On/Off» key.

Note: When putting into operation for the first time, leave the instrument

connected to the power supply for at least 5 hours to allow the built-in battery

to charge up! If the instrument is later disconnected from the power supply

for several months, the battery will become discharged. This leads to data

loss. To recharge the battery, leave the instrument connected to the power

supply for at least 5 hours.

Page 14

Your first measurement in next to no time

14

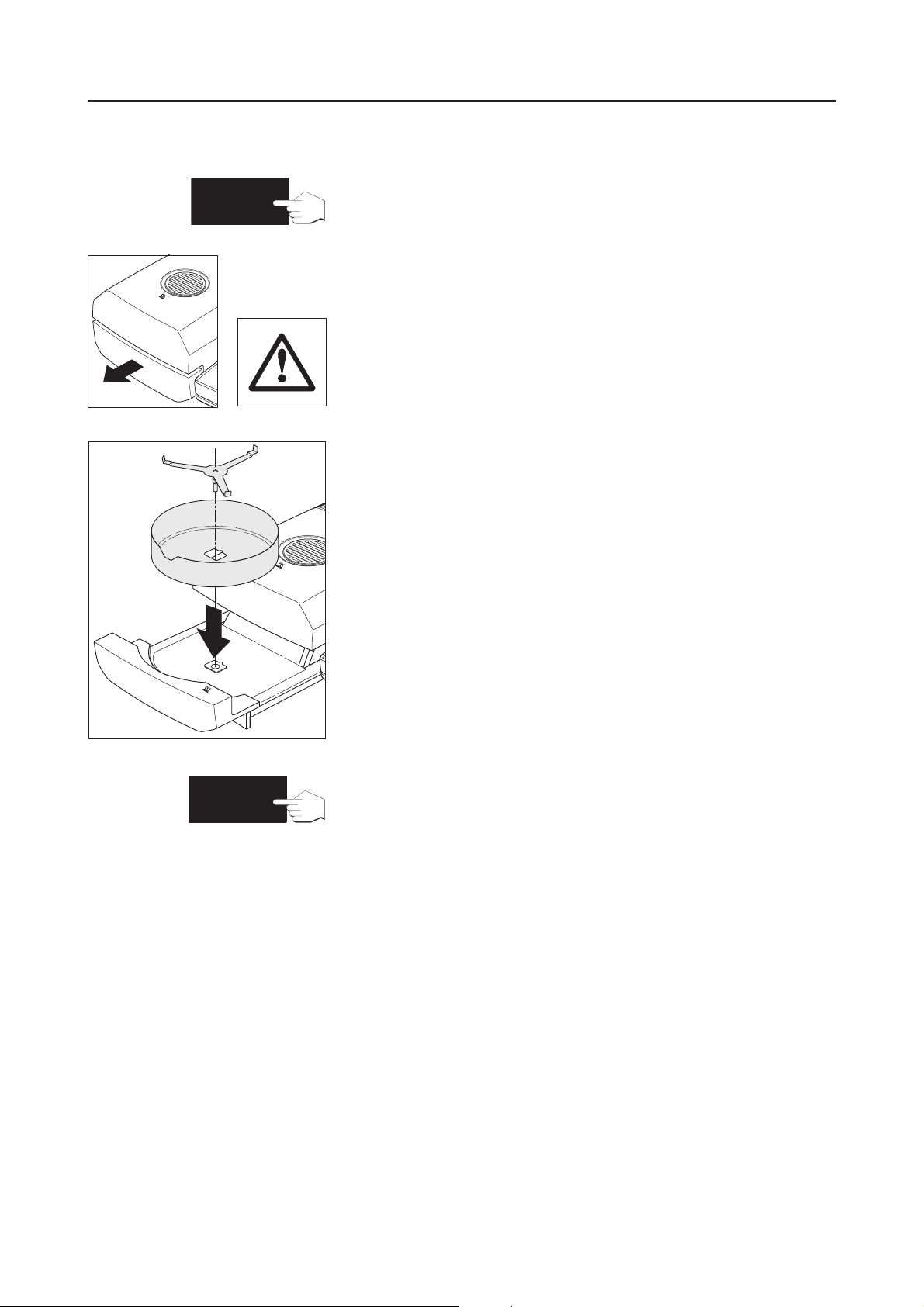

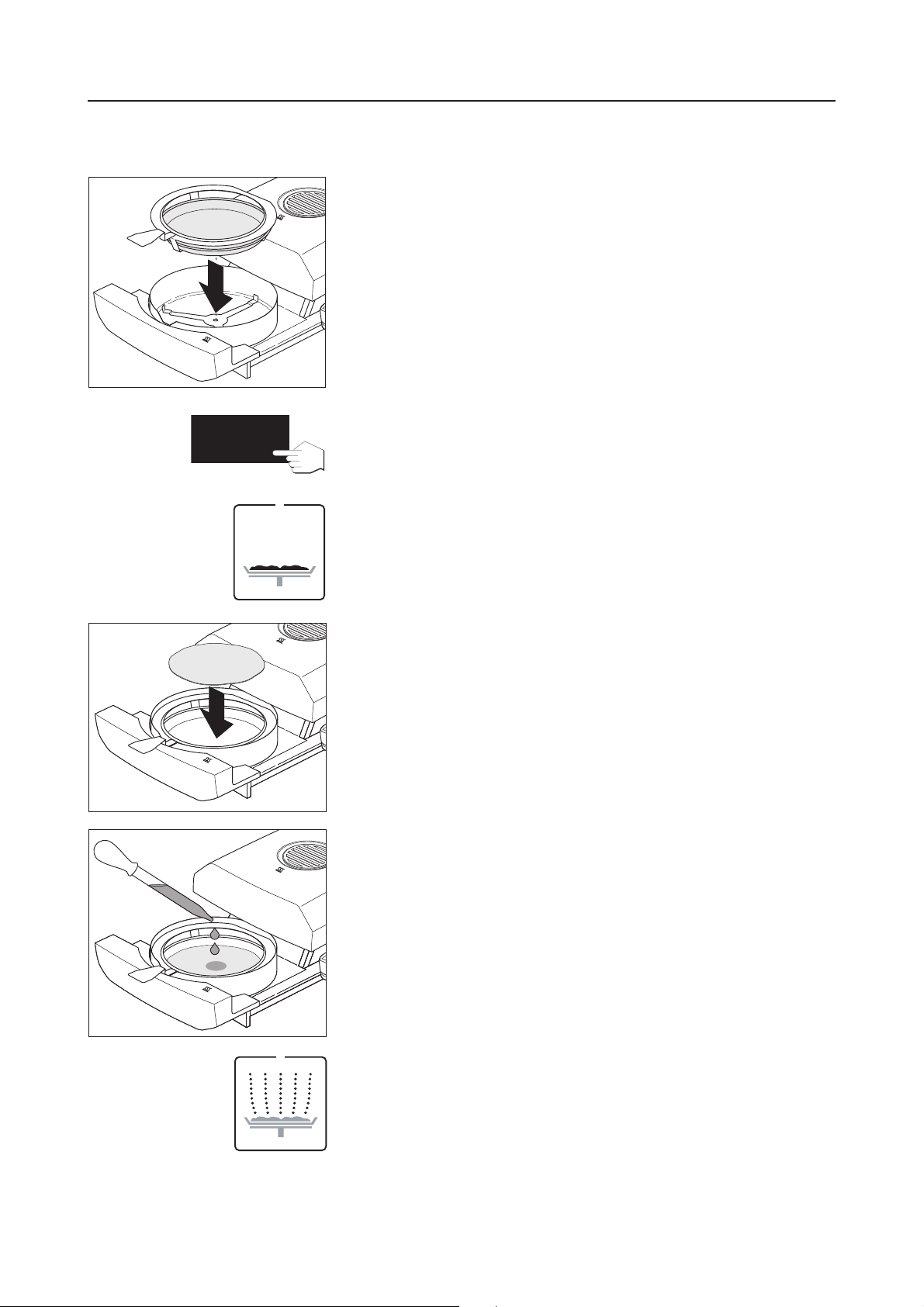

Press the «Open/close auto sample chamber» key and ...

2

… the motorized, automatic sample chamber opens.

Always ensure sufficient free space in front of the instrument since the

emerging automatic sample chamber could knock over objects in its path

or push them off the bench.

Install the draft shield element (only one position possible) and then the

sample pan holder. Turn the sample pan holder until it engages. In the locked

position, the rear arm of the sample pan holder points exactly in the direction

of motion of the automatic sample chamber.

2

Press the «Open/close auto sample chamber» key and ...

… the motorized, automatic sample chamber closes.

Page 15

Your first measurement in next to no time

15

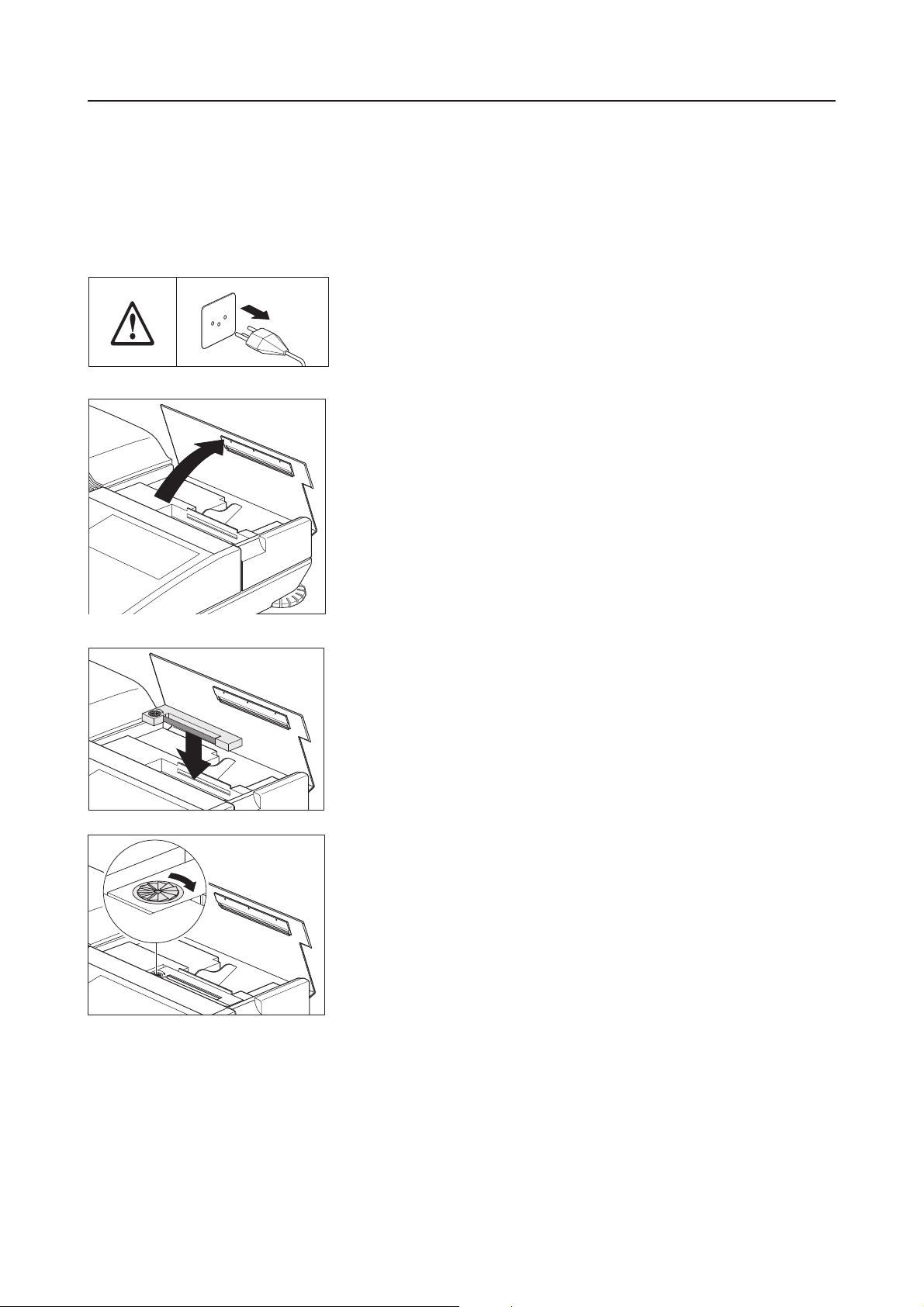

2.4 Preparing the printer

If your Moisture Analyzer is not equipped with a built-in printer, there is no need to read this Section. You can always

order the built-in printer at a later date and install it yourself.

You can prepare the built-in printer for use as follows:

Disconnect the instrument from the power supply.

Swing back the cover of the printer.

HR73

Halogen Moisture Analyzer

HR73

Halogen Moisture Analyzer

HR73

Halogen Moisture Analyzer

Insert the ribbon cassette in the printer and press it down until you hear it click

into place.

EJECT

H

S

U

P

Tension the ribbon by turning the small wheel on the left of the cassette in

the direction shown by the arrow.

EJECT

H

S

U

P

Page 16

Your first measurement in next to no time

16

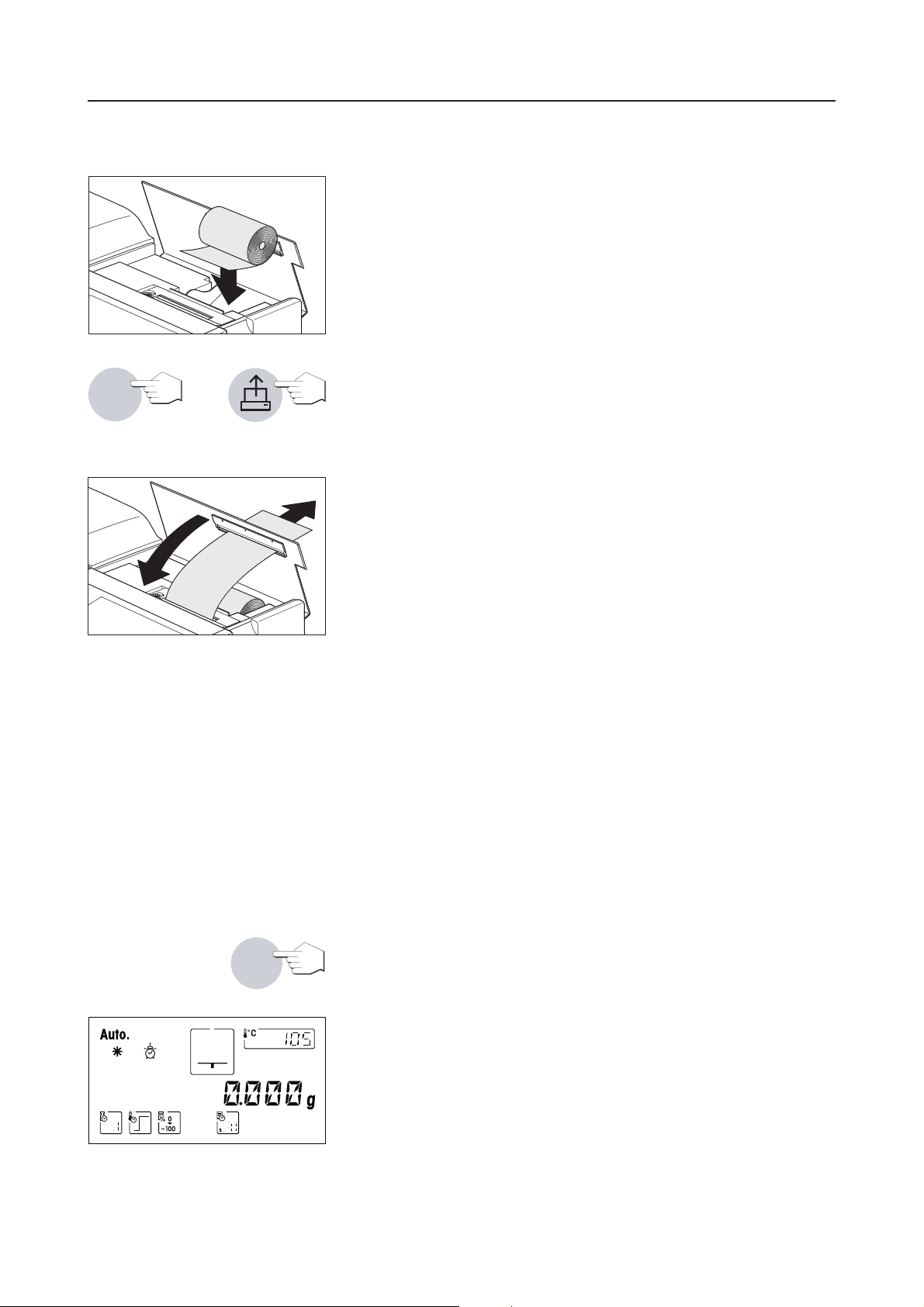

Place the roll of paper in the paper compartment and feed the paper

horizontally through the slot at the back of the printing unit.

HR73

Halogen Moisture Analyzer

EJECT

H

S

U

P

Connect the instrument to the power supply and switch it on with the «On/

On/Off

Off» key. Press the «Paper feed» key until the leading edge of the paper exits

the printing unit at the top.

Lead the paper through the slot in the cover of the built-in printer and close

the cover.

HR73

Halogen M

oisture Analyzer

EJECT

H

S

U

P

2.5 Setting the date and time

Your Moisture Analyzer prints out the date and time on every record. When you put your new instrument into operation

for the first time, you should enter the current date and the time. These settings are retained even if you disconnect

your instrument from the power supply.

In this Section you will enter the menu for the first time, although this is described in detail in a later section. Do not

worry if you have to press keys whose function you are not familiar with, simply follow the instructions step by step.

We describe the menu in detail in Section 6.

Note: Various languages are available for the dialog with your instrument and can be selected in the menu. You

will find further details on language selection in Section 6.23.

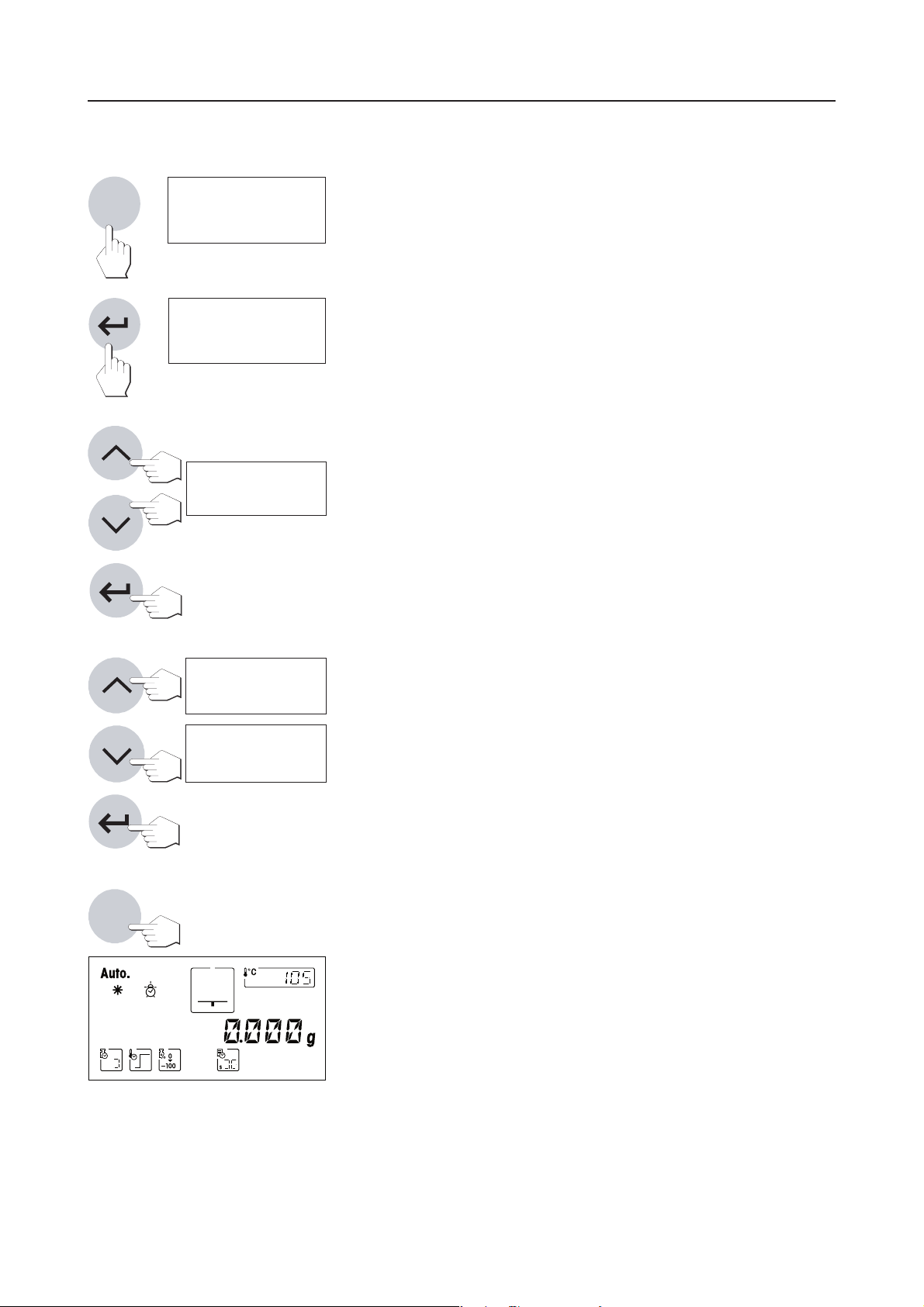

Press the «On/Off» key to switch the instrument on.

On/Off

After it has been switched on, the instrument performs a self-test. Wait until

the display shown opposite appears.

Page 17

Your first measurement in next to no time

17

Menu

Menu

P∑SEÎ NO

Menu

TIMË 1‹04

Menu

TIMË 1Æ28

Press the «Menu» key. You are now already in the menu.

Press the «Accept entry» or «Menu» key repeatedly until the display shown

1

opposite for entry of the time appears.

Important: Do not press any other key, otherwise you could possibly change

the factory settings of your instrument!

Use the «Scroll up» and «Scroll down» keys to set the time (00:00–23:59).

By pressing and holding the keys you can accelerate the change in the time.

1

Confirm your setting with the «Accept entry» key. The instrument stores the

time.

Reset

Menu

DAÎ 2{0“03

Menu

DAÎ 0[0#0#

After confirmation of the time, the display for entry of the current date appears.

2

Use the «Scroll up» and «Scroll down» keys to set the date in the format “Day

– Month – Year” (DD.MM.YY). By pressing and holding the keys you can

accelerate the change in the date. Confirm your entry with the «Accept entry»

2

key and the instrument stores the date.

Note: With US English as the dialog language, the following applies to entry

of the date format “Month – Day – Year” (MM/DD/YY).

This completes your entry of the date and time, and you can now quit the

menu by pressing the «Reset» key. Your settings are stored and remain so

even in the event of a power failure. The Moisture Analyzer is now ready for

your first measurement.

Page 18

Your first measurement in next to no time

18

2.6 Your first measurement

After you have successfully put your new Moisture Analyzer into operation for the first time, you can immediately

perform your first measurement. In doing so, you will become familiar with the instrument and the status display

and at the same time perform a function check.

Please use the specimen sample supplied for your first measurement. This sample is an absorbent glass fiber filter.

During your first measurement, the instrument operates with the factory settings.

Your Moisture Analyzer has a novel graphical status display (User guide)

which you will become acquainted with in this section. The status display

informs you continuously about the current status of the instrument and

prompts you to execute the next operating step (shown flashing).

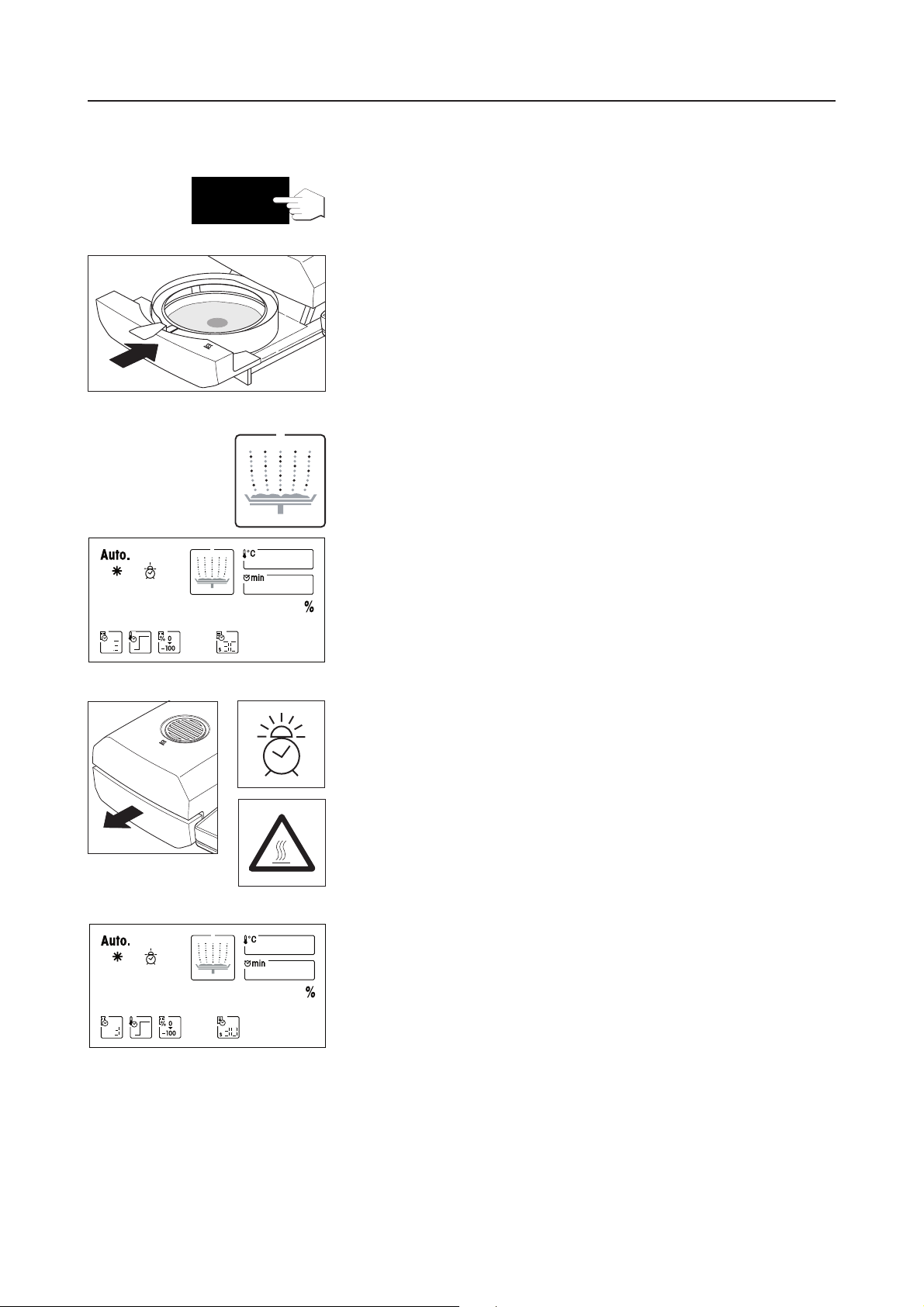

Switch the instrument on with the «On/Off» key.

On/Off

2

Initial status with closed automatic sample chamber.

Press the «Open/close auto sample chamber» key and …

… the motorized, automatic sample chamber opens.

Always ensure sufficient free space in front of the instrument since the

emerging automatic sample chamber could knock over objects in its path

or push them off the bench.

Status: Ready for taring

The status display flashes and prompts you to load the empty sample pan

and tare.

Page 19

#

Your first measurement in next to no time

19

Place the empty sample pan in the sample pan handler (this is possible

without tilting the sample pan if you insert this in the pan handler from the

side directly below the round flange). Place the sample pan handler in the

automatic sample chamber. Ensure that the tongue of the pan handler fits

exactly in the slot of the draft shield element. The sample pan must lie flat

in the pan holder.

Note: We advise you to work with the sample pan handler at all times. The

pan handler is ergonomic, safe and provides protection against possible

burns due to the hot sample pan.

Press the «Tare (zero)» key. This sets the balance installed in the Moisture

Analyzer to zero. For taring, the automatic sample chamber closes briefly

then opens again.

Status: Ready for weighing

After taring, the status display flashes and prompts you to place the sample

in the sample pan.

Place the specimen sample in the sample pan.

Wet the specimen sample with a few drops of water.

Status: Ready for start

The status display flashes and prompts you to start the drying process.

Page 20

Your first measurement in next to no time

20

Press the «Start» key and …

Start

… the motorized, automatic sample chamber closes. The instrument starts

the drying and measurement.

Status: Drying and measurement

You can follow the drying and measurement process in the display:

– The status display uses rising bubbles to symbolize the drying process.

– The current temperature in the heating module is displayed as well as the

104

≠30

-|84

– Further, the display shows information on the selected settings. You will

elapsed drying time and the current drying value.

find additional information on the meaning of the displays and the various

setting possibilities in Section 4. If your instrument has a built-in printer,

the measurement results will be printed out continually (at intervals of

30 seconds).

‹10

ENfl -1Ç52

At the end of the drying time, an audio signal sounds and the sample

chamber is automatically opened.

Warning: Sample pan and sample are still hot!

You can now read off the moisture content of your sample in the display.

59

Page 21

Your first measurement in next to no time

21

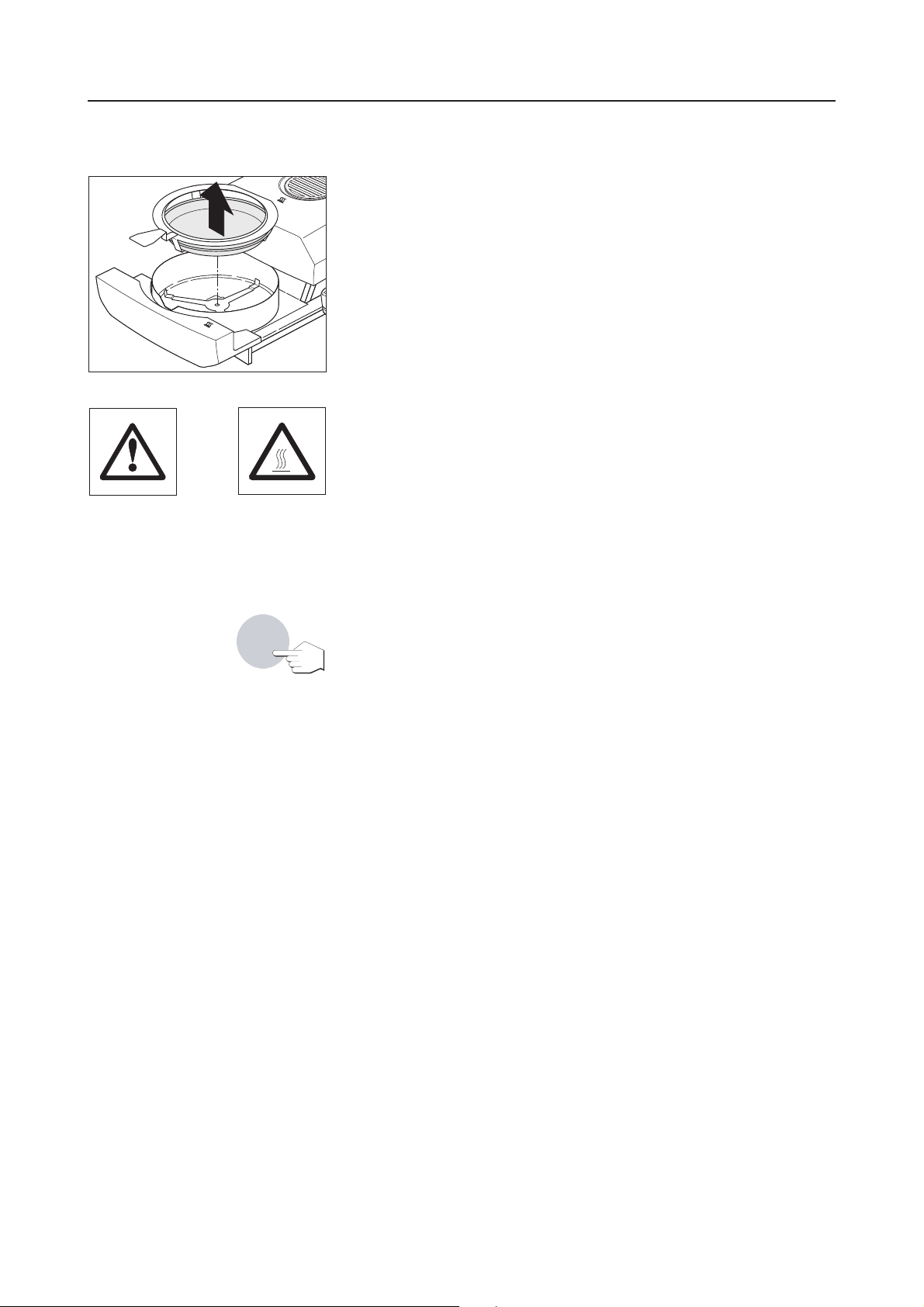

Carefully remove the sample pan handler from the automatic sample

chamber.

Warning: As the pan and sample may still be hot, you should let these

cool down before removing the pan from the handler!

Reset

To remove the sample pan from the handler, lift the pan slightly from below

and pull it sideways out of the handler (if you no longer need the sample and

the pan, you can simply tilt the handler until the pan slides out).

Press the «Reset» key to delete the measurement result from the display. The

instrument is now ready for the next measurement. If you do not wish to

perform another measurement, press the «Open/close auto sample chamber» key. The automatic sample chamber closes.

Congratulations!

You have just performed your first measurement with your new Moisture

Analyzer. In the following section you will find important information on the

operating principle of your instrument, its calibration and optimum preparation of your samples.

Notes on the automatic sample chamber

– Before every automatic closure of the automatic sample chamber, an

audio signal sounds.

– For reasons of safety, the open automatc sample chamber is automati-

cally closed after 2 minutes. If a weight change occurs or a key is pressed

during this time, the 2 minute period starts over again.

Page 22

How to obtain the best results

22

3 How to obtain the best results

Following your first practical work with the Moisture Analyzer, in this Section you will find important information on

how to obtain optimum results. You will discover what parameters influence the measurement process and how

you can match the instrument optimally to your particular measurement task.

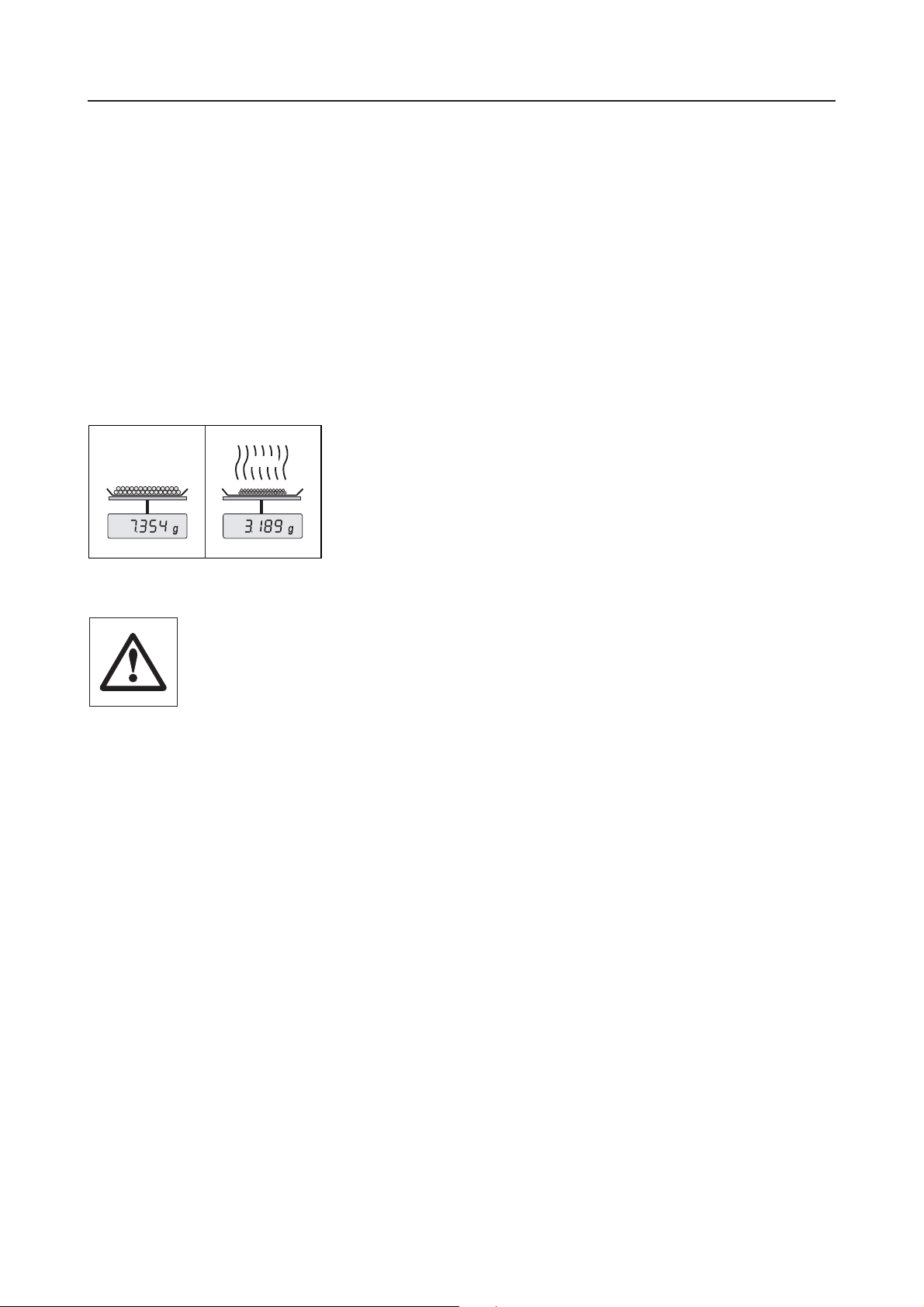

3.1 Measurement principle of the Halogen Moisture Analyzer

Your instrument performs measurements based on the thermogravimetric principle, i.e. the moisture is determined

from the weight loss of a sample dried by heating.

In principle, your instrument thus comprises two instruments: a precision

120

balance and a heating module. In contrast to other thermogravimetric

methods (drying oven, infrared, microwave), the Halogen Moisture Analyzer

operates with a halogen heating module. This ensures fast heating of the

sample and thus guarantees rapid availability of the measurement results.

Irrespective of the measurement method, the quality of the measurement results stands or falls by the preparation

of the sample and a correct choice of the important measurement parameters:

– Sample size

– Drying temperature

– Switchoff mode

– Drying time

Inappropriate setting of these parameters can cause the results to be incorrect or

misleading. For this reason, check that the results for each type of sample are what might

reasonably be expected.

You will find detailed information on the relationships between these parameters in the application brochure for

moisture determination (see Section 9.4), enclosed to your instrument.

In practice, however, not only the quality of the measurement results, but also the speed of the measurement

process is important. Thanks to its drying principle (with the heat generated by a halogen radiator), the Halogen

Moisture Analyzer is very fast. You can increase the speed even further through optimum setting of the instrument.

The optimum drying temperature and the drying time are dependent on the nature and size of the sample and

on the desired accuracy of the measurement results. These can be determined only by experiment. The Halogen

Moisture Analyzer supports you in this task: It offers automatic performance and result recording of test

measurements. The ideal settings can quickly be determined with AutoMet (see Section 4.12).

Page 23

How to obtain the best results

23

3.2 Notes on adjustment of the balance and the heating module

You should adjust your Moisture Analyzer regularly (e.g. every six months) if this is stipulated by your quality

assurance system (e.g. GLP, GMP, ISO 9001).

The balance and the integral heating module in your instrument can be adjusted using the appropriate accessories

(see Section 9.9). The heating module and balance can also be tested (to check the adjustment). The operator

can define a test weight or the test temperature, together with permissible tolerances for this test. A test report is

printed out showing the test result as “Passed” or “Failed” (see Section 6.3 and 6.5).

By adjusting the heating module you can ensure comparability with results from other instruments of the same

design. This is done by using an appropriate thermometer, which is provided in the form of a temperature

adjustment set with calibration certificate (see Section 9.9). This adjustment set comprises a black plate with a

thermometer, which allows a reproducible adjustment of the heating module.

A Moisture Analyzer is typically used in place of or in addition to the oven method. In an oven heat energy is

transferred by the flow of air, which establishes an equilibrium between the sample temperature and the ambient

temperature. This is not the case in a Moisture Analyzer. The actual sample temperature primarily depends on the

specific absorption properties of the sample (“dark” samples absorb more heat), which can change during the

measurement process. There can also be differences between the temperature at the surface of the sample and the

temperature inside the sample. The heat output is therefore not dependent on the true sample temperature but

instead is regulated by a temperature sensor underneath the halogen heating module.

For the reasons explained above, the temperature setting on the instrument will therefore by deviate to the true

sample temperature. By regularly adjusting the heating module, you will ensure a consistent and reproducible heat

output for the entire lifetime of your instrument.

Note: METTLER TOLEDO offers an adjustment service – please contact your local dealer.

– If you also use your instrument as a high precision lab balance, you should adjust the balance at regular intervals.

– If you replace the heating module, you must adjust it using the temperature adjustment set, which is available

as an accessory.

The procedure for adjusting the balance and heating module is described in Section 6.

3.3 Optimum sample preparation

Preparation of the sample is decisive for the speed of the measurement process and the quality of the measurement

results.

Please note the following basic rules for the preparation of your sample:

The amount of sample you select should be as small as possible and only as large as necessary

Excessive amounts of sample require more time for drying and thus prolong the measurement process. If the amount

of sample is too small, the measurement result may possibly not be representative. The following always holds:

The greater the inhomogeneity of the sample, the larger the amount of sample needed to obtain a repeatable result

(please see also the list in Section 9.1).

Page 24

How to obtain the best results

24

Distribute the sample evenly over the sample pan

You thus increase the surface area of the sample and facilitate heat absorption. The base of the pan should be evenly

covered.

With liquid, fat-containing, melting and highly reflecting samples, you should cover the sample with the glass fiber

filter available as optional equipment (HA-F1 214464, see Section 9.9). This also applies to samples which form

a skin on their surface when heated. The glass fiber filter ensures even and rapid heat distribution and prevents the

formation of a skin impervious to moisture on the sample surface.

3.4 Further information on moisture determination

You will find further information on the moisture determination, the importance of the parameters and the preparation

of the samples in the Application Brochure “Methods of moisture content determination” dealing with moisture

determination (see Section 9.4).

Useful tips and a variety of example methods (comparison between Halogen Moisture Analyzer results and the oven

method) can be downloaded from www.mt.com/moisture.

If you require information on specific applications, your METTLER TOLEDO dealer will be pleased to help you.

Moisture determination applications must be optimized and validated by the user according

to local regulations. Application-specific data provided by METTLER TOLEDO is intended for

guidance only.

Page 25

Practical application of your Moisture Analyzer

25

4 Practical application of your Moisture Analyzer

In this Section we introduce you to the wide range of setting possibilities of your Moisture Analyzer and offer

information and tips for optimum setting of the parameters.

4.1 Operating principles

You already performed your first measurement in Section 2. This measurement was carried out using the factory

settings. However, your instrument offers a number of setting possibilities to match the measurement process to

your specific requirements. For instance, you can preselect the drying temperature, the type of result display and

many other parameters.

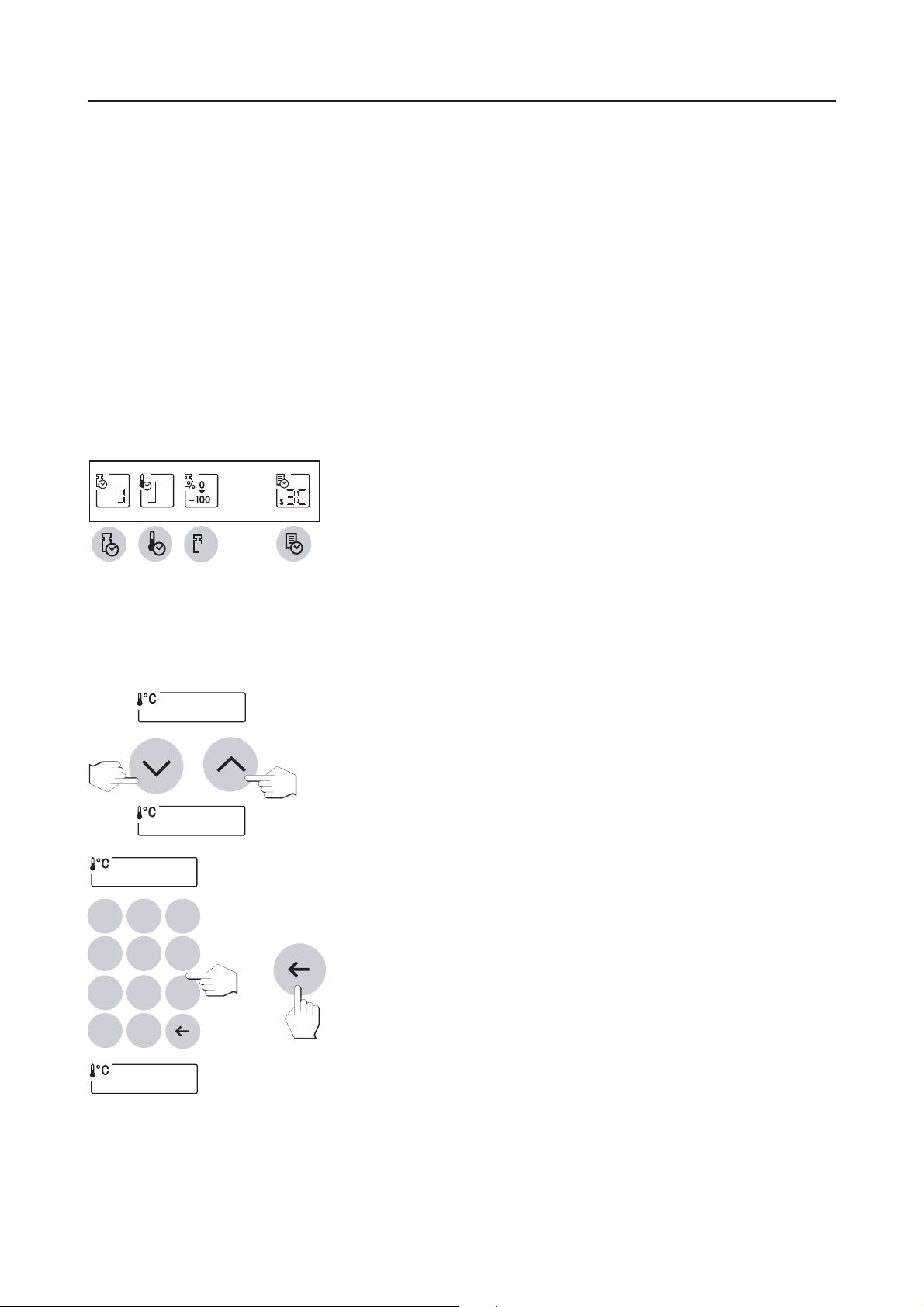

Settings are made using the function keys. These keys are right at the top of

the keypad, directly below the display. The setting you select appears in the

display directly above the associated key.

95

1 2 3

%

95

125

987

654

You will learn the available setting possibilities and the function keys in detail

in the following Sections. Further, you will also discover how to set the drying

temperature and the drying time and how to work with the weighing-in aid.

Finally, you will perform a complete measurement with the specific settings

for your sample.

Numeric entries:

With some settings (e.g. the drying temperature), numeric entries are

required. There are two different ways of entering numerical values:

You can change the flashing displayed value with the «Scroll up» or «Scroll

down» key or ...

... you can key in the new value directly with the numeric keypad.

You can remove wrong numbers with the «Delete» key.

0

.

125

Page 26

Practical application of your Moisture Analyzer

26

As soon as you have entered the desired value, press the «Accept entry» key.

The value will be stored.

Preliminary information on the methods:

All settings for a sample which you will learn in the following Sections can be collected in a so-called “Method”.

You have 40 methods freely available thus giving you the possibility of defining a method for a particular sample

and recalling it at any time. This eases the work load considerably as each time you switch to a different type of

sample there is no need to repeat all the parameter settings. The methods are retained when the instrument is

switched off. You will find information on the compilation and use of methods in Section 5.

4.2 Selecting the drying program

This function key offers you four different drying programs for optimum matching of the drying characteristics to the

sample used.

Each time this key is pressed, the next program appears. After the fourth and

last program, the first reappears in the display. As soon as you have selected

the desired program, the setting is active and you do not have to confirm or

store it.

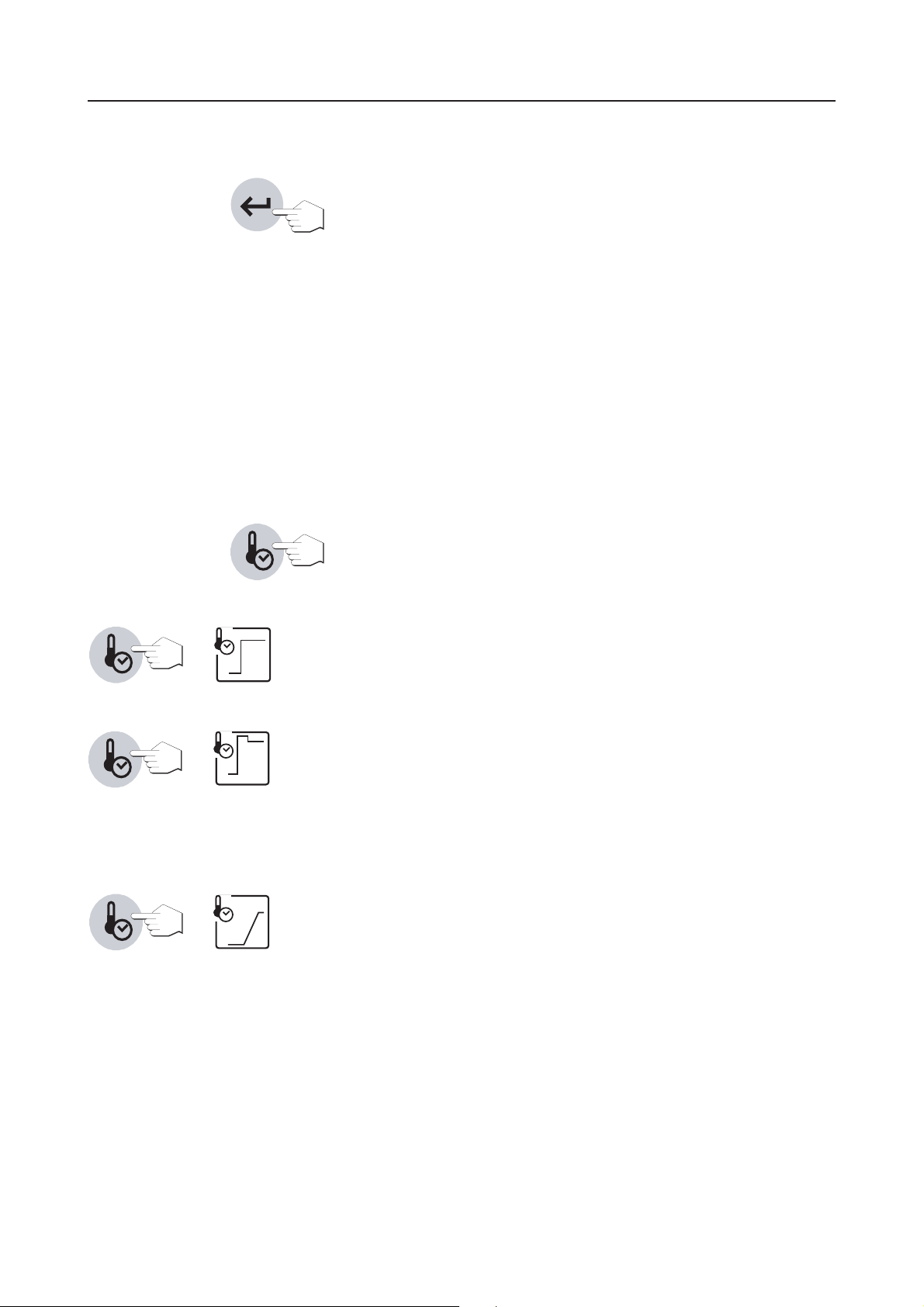

Standard drying

This drying program is set in the factory and is suitable for most samples.

The sample is heated to the drying temperature (set temperature) and held

constant at this temperature.

Rapid drying

This program is primarily suitable for samples with a moisture content over

30%. Following the start, the selected temperature is exceeded by 40% for

3 minutes to compensate the cooling due to vaporization and accelerate the

drying process. The drying temperature is then lowered to the set value and

maintained. You will find details on how to enter the drying temperature in

the Section 4.3.

Gentle drying

This program is suitable for the gentle drying of substances which tend to

form a skin (e.g. substances containing sugar). With this program the

temperature is continuously increased and attains the selected drying

temperature only after the elapse of the so-called "ramp time". The “ramp”,

i.e. the time that should elapse between the start of drying and attainment of

the final temperature is preselectable. The setting of the “ramp” is described

in the next Section 4.3.

Page 27

Practical application of your Moisture Analyzer

27

Step drying

This program is suitable for the drying of substances composed of several

components which vaporize at different temperatures (e.g. ethereal oils).

With this program drying is performed stepwise, i.e. the sample is preheated

to a particular temperature (1st step) and kept at this temperature for the

selected time (hold time).

The temperature is then increased to the next value (2nd step) and again

maintained for a certain time. Finally, the temperature is raised to the

preselected drying temperature (set temperature) and held constant at this

value until the end of drying. With this program you can preselect the

temperature and time for each step. These settings are described in the

Section 4.3. If only one step is needed, the time of step 2 must be set to 0.

Step drying can also be useful for the rapid determination of substances

with a high moisture content. Here, the 1st step is set higher than the final

temperature to compensate the cooling due to vaporization.

4.3 Setting the drying temperature

After pressing this key you can enter the drying temperature (set temperature).

The type of entry depends on the selected drying program (see Section 4.2).

If you have selected one of the programs “Standard drying” or “Rapid drying”,

you need enter only the drying temperature. For the two programs “Gentle

drying” and “Step drying”, additional entries are required to define the ramp

or the steps. The different entry procedures are described below.

Note: The admissible input range for temperatures is 40°C–200 °C.

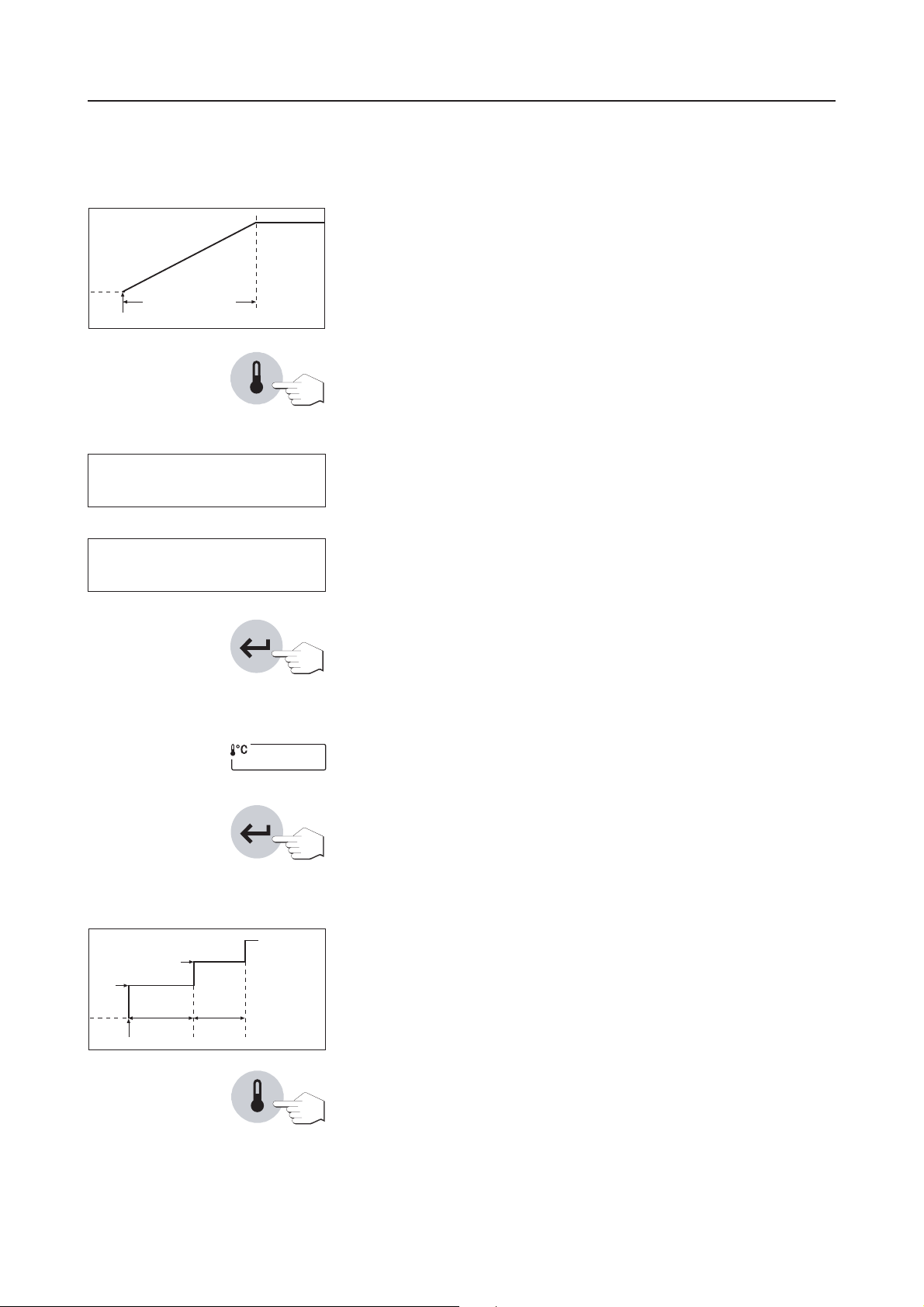

Selecting drying temperature for standard drying and rapid drying

Final temperature

Start of drying

You need enter only the desired final temperature.

Press the «Drying temperature» key and enter the desired drying temperature

(see Section 4.1).

– either with the «Scroll up» and «Scroll down» keys or

– directly via the numeric keypad

125

Press the «Accept entry» key.

Page 28

Practical application of your Moisture Analyzer

28

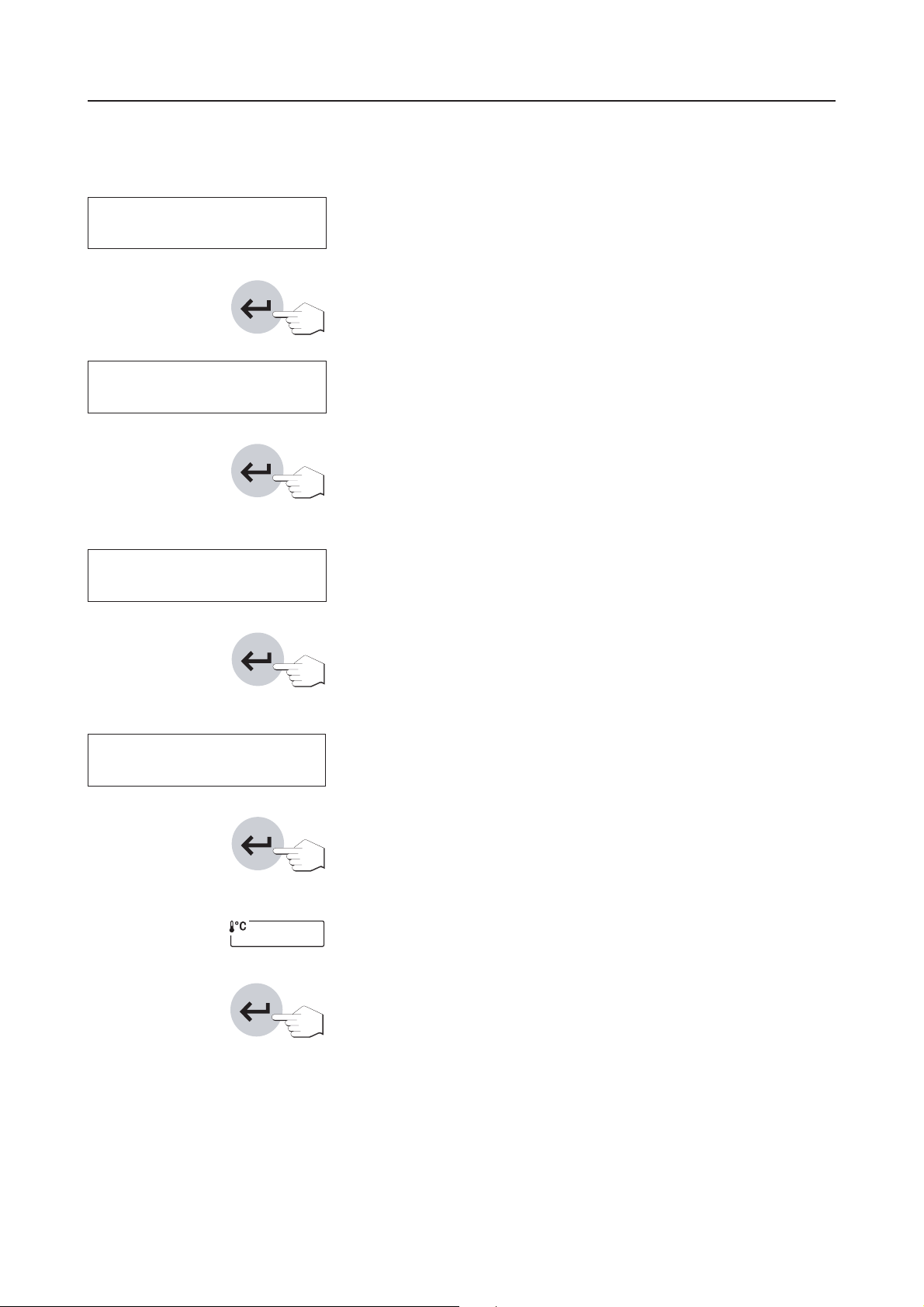

Selecting drying temperature for gentle drying

Final

temperature

Ramp time

Start of drying

RAM∏ ‹00

RAM∏ ⁄30

For this temperature program you first define the so-called “ramp”, i.e. the

time that should elapse between the start of drying and attainment of the final

temperature. You then select the drying temperature (final temperature). The

ramp is started once the temperature reaches 50 °C.

Press the «Drying temperature» key.

Entering the ramp time:

The instrument prompts you to define the ramp time. In the factory the ramp

time is set to 3 minutes.

Enter the desired value.

Press the «Accept entry» key.

Entering the drying temperature:

125

The instrument now prompts you to enter the drying temperature (final

temperature). Enter the desired temperature (e.g. 125 °C).

Press the «Accept entry» key.

Selecting drying temperatures for step drying

For this temperature program you define the temperature and the hold time

for each step.

Press the «Drying temperature» key.

Temp.

Step 1

Hold time

Step 1

Start of drying

Temp.

Step 2

Final

temperature

Hold time

Step 2

Page 29

TEMπ∞ 100

TIM™∞ ⁄30

TEMπ” 125

Practical application of your Moisture Analyzer

29

Entering the drying temperature and hold time for the first step:

The instrument prompts you to define the temperature for the first step. Enter

the desired temperature.

Press the «Accept entry» key.

The instrument now prompts you to enter the hold time for the first step. Enter

the desired time.

Press the «Accept entry» key.

Entering the drying temperature and hold time for the second step:

The instrument now requests entry of the temperature for the second step.

Enter the desired temperature.

TIM™” ‹00

160

Press the «Accept entry» key.

Define the hold time for the second step.

Press the «Accept entry» key.

Entering the final temperature:

Finally, you enter the desired final temperature.

Press the «Accept entry» key.

Page 30

Practical application of your Moisture Analyzer

30

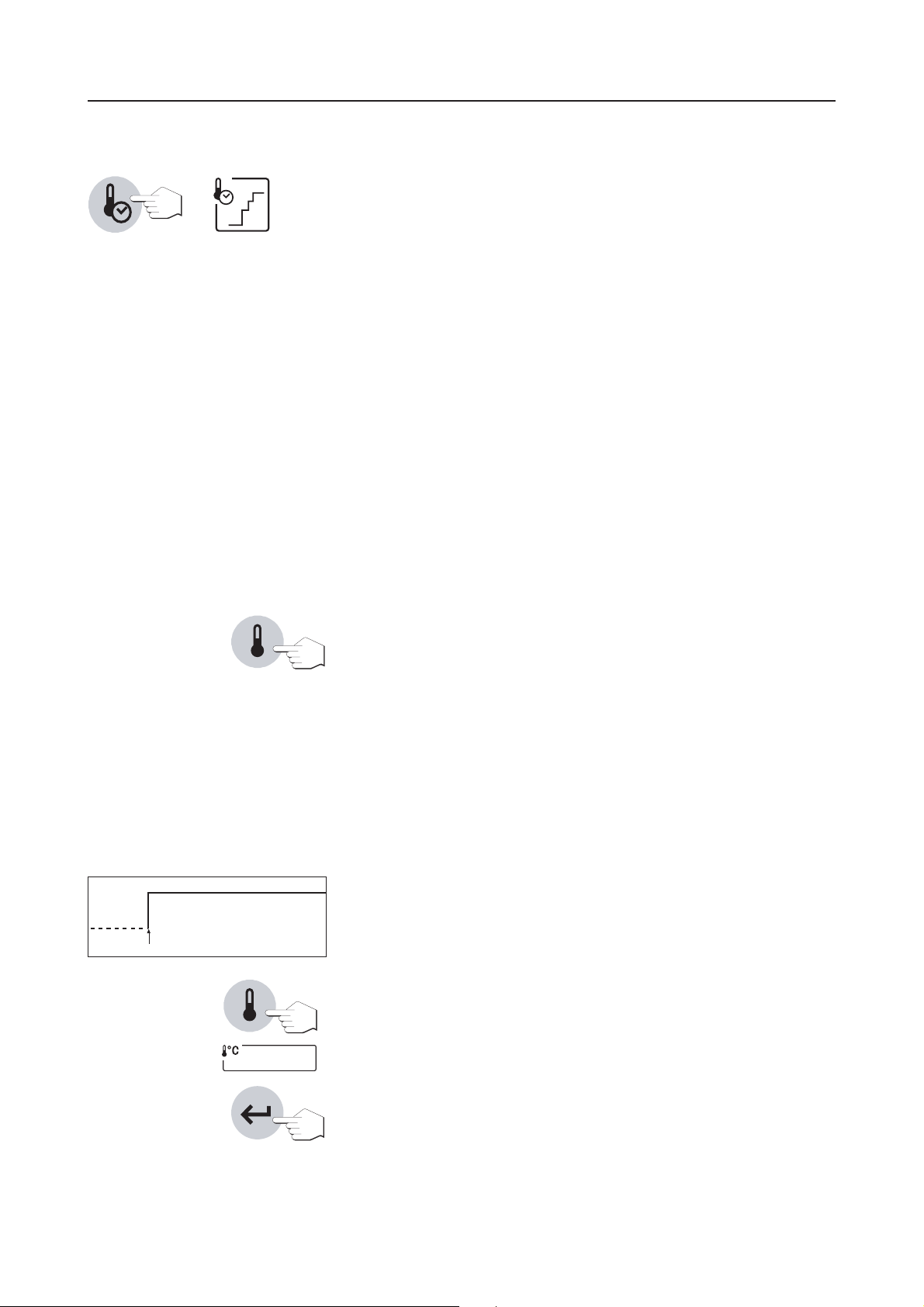

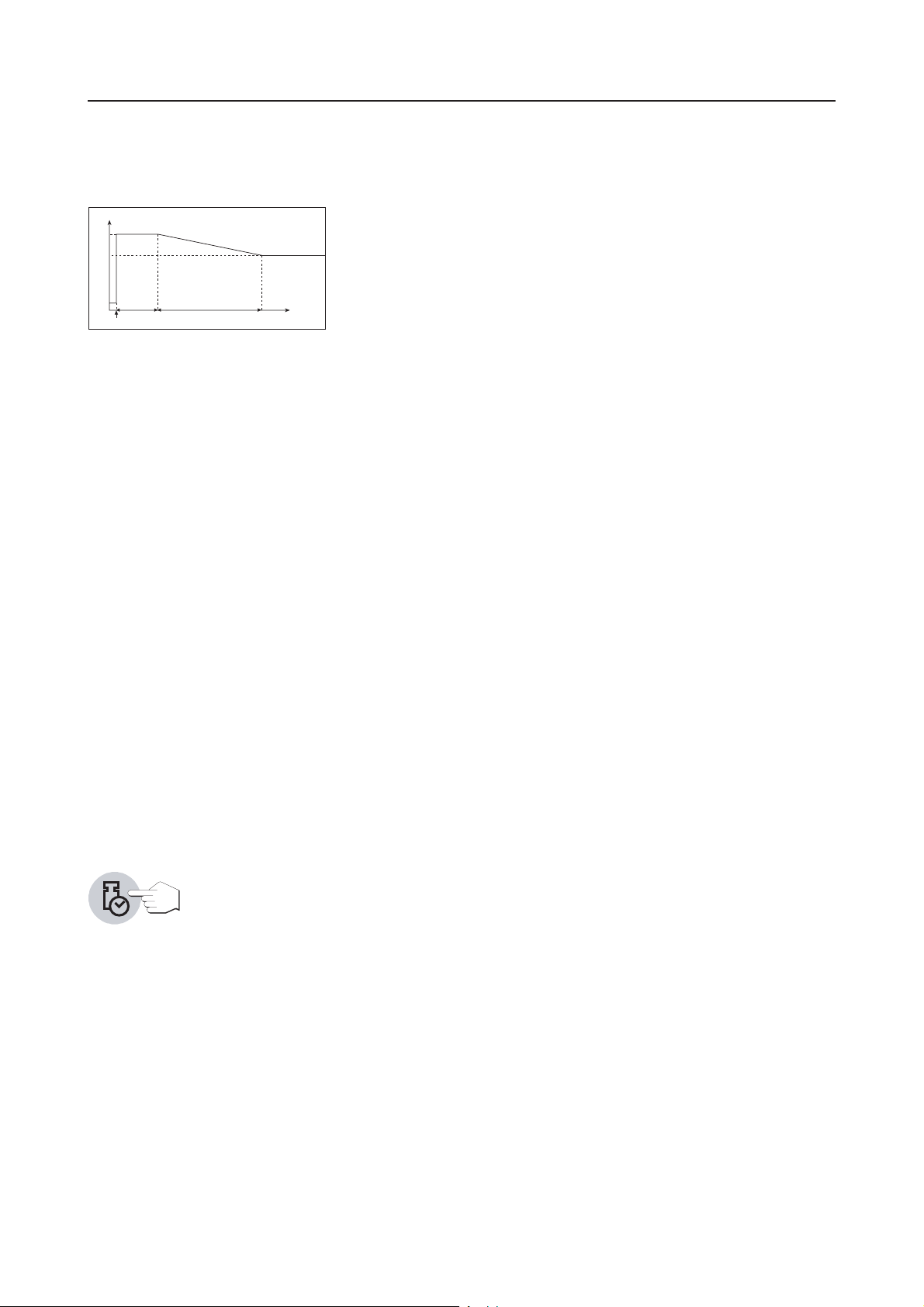

Temperature limitation

°C

200

160

Start

10 50

t (min.)

With regard to high temperatures, the moisture analyzer has several

protective mechanisms that work independently of each other:

– At temperatures above 160 °C a time limit becomes active. The higher the

temperature, the shorter the time until the instrument starts to lower the

temperature (envelope curve, see illustration opposite). Note: If necessary, this time-controlled lowering of the temperature can be deactivated in

the Methods menu (Section 5.4). If deactivated, temperatures from

160 °C - 200 °C are available without time limitation.

–A temperature switch independent of the normal black temperature sensor

over the sample (see Section 7.1) is triggered when it detects exceptionally high temperatures. This situation could arise, for example, if the

sample begins to burn or the heating module adjustment is defective. If

this happens, the heating module is tripped out by a mechanical switch,

and the instrument cannot be restarted. Please refer to Section 8.3 for

troubleshooting.

When working with temperatures over 180 °C we recommend that you

always wait 2 - 3 minutes between individual measurements, in order to

ensure good reproducibility of the readings.

Note: A measurement cannot be started until the drying temperature is

higher than the temperature in the measuring room. This avoids a false start

(Error 10, Section 8.2).

4.4 Selecting the switch-off criterion

This function key offers you different switch-off criteria. A switch-off criterion defines when the instrument should end

the drying. Switch-off criteria save you having to keep checking your watch and stopping the drying manually.

The following settings can be selected for the switch-off criterion:

– “Weight loss per unit of time” (5 settings)

– “Free switch-off criterion” (if activated in the Methods menu,

Section 5.4)

– “Manual switch-off”

– “Timed switch-off”

– “Test measurement” for determination of the suitable switch-off criterion

Weight loss per unit of time

This switch-off criterion is based on a weight loss per unit of time. As soon as the mean weight loss is less that a

preset value during a specified time, the instrument considers drying as complete and automatically discontinues

the measurement process. During the drying, the time display shows you how long the measurement process has

been in progress. The switch-off criterion is inactive during the first 30 sec. You will find additional information in

Section 9.5.

Page 31

Practical application of your Moisture Analyzer

31

The following 5 settings are available:

This setting is suitable for samples which dry very quickly (surface moisture)

or for (relatively inaccurate) fast measurements to determine a trend.

This setting is suitable for quick drying samples.

This is the factory setting. It is suitable for most types of samples.

This setting is suitable for samples which dry moderately quickly.

This setting is suitable for samples which dry very slowly (trapped moisture,

skin formation).

Note: If you do not know the behavior of a sample, perform a test measurement to determine the suitable switch-off criterion. The procedure is described later in this section under the title “Test measurement”.

Free switch-off criterion

This setting possibility is available only if you have activated it in the Methods menu (Section 5.4). There is one

free switch-off criterion available for each method. The free switch-off criterion is based on a user-defined mean

weight loss per unit of time.

You will find information on the activation and definition of the individual

switch-off criterion in Sections 5.4.1 and 9.5.

Note: The free switch-off criterion can be determined automatically with

AutoMet (Section 4.12).

Manual

With this switch-off criterion the measurement process continues until you stop it with the «Stop» key.

The time shown in the display tells you how long the current measurement

has been in progress.

Page 32

Practical application of your Moisture Analyzer

32

Timed switch-off

With this switch-off criterion the measurement lasts until the preset drying time has elapsed (the time display

provides you with continuous information on the drying time).

If you select this criterion, you must then enter the desired drying time as

follows:

Press the «Drying time» key.

⁄30

Test measurement

Enter the desired drying time.

Press the «Accept entry» key.

Press “t” to perform a test measurement which will help you to determine

suitable switch-off criteria (Section 4.11).

Using AutoMet test measurement is a quick way of determining a Halogen

Moisture Analyzer method that corresponds most closely to your reference value

(target value) (Section 4.12).

Page 33

Practical application of your Moisture Analyzer

33

4.5 Selecting the display mode

With this function key you can select the desired type of result display. You also define what values are printed on

the records.

The following display modes are available:

Moisture content

The moisture content of the sample is displayed (and printed out) as a

%

percentage of the wet weight (= ww = initial weight = 100%). This is the

factory setting.

When the results are printed out, the moisture content is marked by “%MC”

(Moisture Content) (e.g. –11.35 %MC) and shown as a negative value.

WW

WW

%

100%

Before

drying

100%

Before

drying

After

drying

After

drying

DW

DW

MC

=

[%]

MC [0…100%] = – *

Wet weight WW – Dry weight DW

Wet weight WW

100%

During the drying the current measured value is continuously displayed in

percent.

Dry content

The dry content of the sample is displayed (and printed out) as a percentage

of the wet weight (= ww = initial weight = 100%).

When the results are printed out, the dry content is marked by “%DC” (Dry

Content) (e.g. 88.65 %DC).

DC

=

[%]

During the drying the current measured value is continuously displayed in

DC [100…0%] = *

Dry weight DW

Wet weight WW

100%

percent.

Weight in grams

%

The weight of the sample is displayed (and printed out) in grams. With this

setting, the Moisture Analyzer is used as a precision balance.

During the drying the current weight is continuously displayed in grams.

Page 34

Practical application of your Moisture Analyzer

34

ATRO moisture content

The moisture content of the sample is displayed (and printed out) as a

%

percentage of the dry weight ( = DW = final weight = 100%).

When the results are printed out, the ATRO moisture content is marked by

“%AM” (ATRO Moisture Content) (e.g. –255.33 %AM) and shown as a

negative value

AM

=

WW

Before

drying

100%

After

drying

[%]

DW

=

During the drying, the current measured value is continuously displayed in

percent.

ATRO dry content (Wet weight)

The wet weight of the sample is displayed (and printed out) as a percentage

%

of the dry weight (= DW = final weight = 100%).

When the results are printed out, the ATRO dry content is marked by “%AD”

(ATRO Dry Content) (e.g. 312.56 %AD).

AM [0…-1000%] = – *

Wet weight WW – Dry weight DW

Dry weight DW

100%

=

[%]

AD

WW

Before

drying

100%

After

drying

DW

=

AD [100…1000%] = *

Wet weight WW

Dry weight DW

100%

During the drying, the current measured value is continuously displayed in

percent.

Comment on the ATRO display mode

If the current measured value in the ATRO display mode is greater or less than

the predefined limit value (i.e. greater than 999.99 %AD or less than

–999.99 %AM), a warning beep sounds and the instrument automatically

switches the display mode (from %AM to %MC and from %AD to %DC). A

display in the ATRO mode is no longer possible in this case, even if you have

started your drying operation in the %MC, %DC or “g” (grams) display

mode. If your measurement series contains such an inadmissible ATRO

measured value, the statistical evaluation (see Section 5.7) will also be

performed in the new, automatically selected mode.

Page 35

Practical application of your Moisture Analyzer

35

4.6 Defining the print interval

One point before we start: This setting possibility is available only if the built-in printer is activated in the menu

(see Section 6.15).

The print interval determines the printout frequency of the intermediate results of an ongoing measurement.

The following settings are available under this function key:

Printout at intervals

These 6 settings allow printout of the intermediate results at fixed, preset

intervals. You can thus trace the drying process using the printed record. The

following print intervals are available:

– Printout every 5 seconds

– Printout every 10 seconds

– Printout every 30 seconds (factory setting)

– Printout every minute

– Printout every 2 minutes

– Printout every 10 minutes

Free print interval

This setting possibility is available only if you have activated it in the menu.

You will find information on the activation and definition of the free print

interval in Section 6.18.

Manual printout

With this setting there is no automatic printout. However, you can print out

the intermediate results at any time with the «Print» key.

Page 36

Practical application of your Moisture Analyzer

36

4.7 Working with the weighing-in aid

The weighing-in aid can be defined for each method and facilitates weighing in of the sample to a preset weight

value (target value).This is particularly useful if you require all the samples you wish to process to have same weight

in order to improve the repeatability of the measurement results. In addition, the weighing-in aid can be configured

so that the drying process cannot be started if the weight of sample is outside the set tolerance. You are therefore

compelled to weigh in the correct quantity of sample (“Weighing-in aid active”).

Target weight

lower weight limit

Underweight

WGªBAÈ OFF

WGªBAÈ PAS

upper weight limit

Overweight

The weighing-in aid in the bottom right corner of the display comprises two

opposite facing bars and triangles with a minus or plus symbol.

The weighing-in aid is available only if it has been activated. If the minus

or plus symbol is visible after taring, the weighing-in aid is activated.

If you want to switch on the weighing-in aid, press the «Target weight

(Weighing-in aid)».

In the factory the weighing-in aid is switched off (“OFF”).

You can use the «Scroll up» and «Scroll down» keys to select either the

“Weighing-in aid passive” or “Weighing-in aid aktive” setting.

If the “Weighing-in aid passive” setting is selected, the weighing-in aid is

switched on and a target weight can be defined. With this setting the drying

process can be started even if the sample weight lies outside the set limits.

These are defined by the target weight and the sample weight tolerance as

a % of the target weight (see below).

WGªBAÈ ACT

TAR‚ “500

With the weighing-in aid set at “Weighing-in aid active” the drying process

cannot be started if the sample weight is outside the set limits. You are

therefore compelled to weigh in the correct quantity of sample, and are

prevented from inadvertently starting the drying process with the wrong

sample weight.

After selecting the desired mode for the weighing-in aid, confirm your

selection by pressing the «Accept entry» key.

Enter the desired target weight (0.100 g to 80.000 g) via the numeric

g

keypad (Factory setting: 2.5 g) and confirm with the «Accept entry» key.

Page 37

Practical application of your Moisture Analyzer

37

BA®LI˚ 10

%

keypad) to define the sample weight tolerance in the range 1% to 25%. The

sample weight tolerance (Factory setting: 10%) defines the lower and

upper sample weight limits. Confirm your entry with the «Accept entry» key.

The symbols of the weighing-in aid appear in the display after you have tared

the balance.

How the weighing-in aid operates

Before the start of weighing (standby mode)

Start of weighing (sample weight too low)

Lower weight limit reached (sample weight in tolerance range). The status

display (user guide) indicates with its flashing ‘rising bubble’ graphic that

the instrument is ready to run.

You can now use the «Scroll up» and «Scroll down» keys (or the numeric

Target weight reached (sample weight in tolerance range). The status

display (user guide) indicates with its flashing ‘rising bubble’ graphic that

the instrument is ready to run.

Upper weight limit reached (sample weight in tolerance range). The status

display (user guide) indicates with its flashing ‘rising bubble’ graphic that

the instrument is ready to run.

Upper weight limit exceeded (sample weight too high)

After initiation of the measurement with the «Start» key, the bars of the

weighing-in aid disappear.

Page 38

Practical application of your Moisture Analyzer

38

4.8 Comment lines

You can include up to 4 comment lines in your measurement records, e.g. in order to enter different sample IDs.

These comment lines are called C1 to C4 (see Section 6.20). The alphanumeric comment lines can be up to 20

characters in length and are method specific. To enter a comment:

-MOISTURE DETERMINATIONMETTLER TOLEDO

Halogen MoistureAnalyzer

Type: HR83

SNR: 1234567890

SW: 2.01

Method:

30 COFFEE POWDER

C1: QUALITY CHECK

C2: BEFORE PACKING

C3: CHARGE 4711

C4: HANS MUSTER

Standard drying

A

C

A...Z

Code

Press the «Code» key. The input field for the record header comment appears.

The name of the comment line (C1 to C4) appears on the display in input

mode.

If a comment has been entered previously, it appears in the display. The

procedure for changing existing comments is described later. If you want to

enter a new comment, or completely overwrite an old one, proceed as

follows:

Press the «A…Z» key. A flashing “A” appears at the first input position on the

extreme left and signals that the instrument is ready for your entry.

You can now use the «Scroll up» and «Scroll down» keys to select the first

letter of the comment (uppercase letters only) or a special character (+, -,

etc.).

CA

A...Z

1 2 3

0

.

Confirm your selection with the «A…Z» key. The flashing “A” again appears,

but at the second position.

987

654

Enter a further character of the desired comment as described above.