Page 1

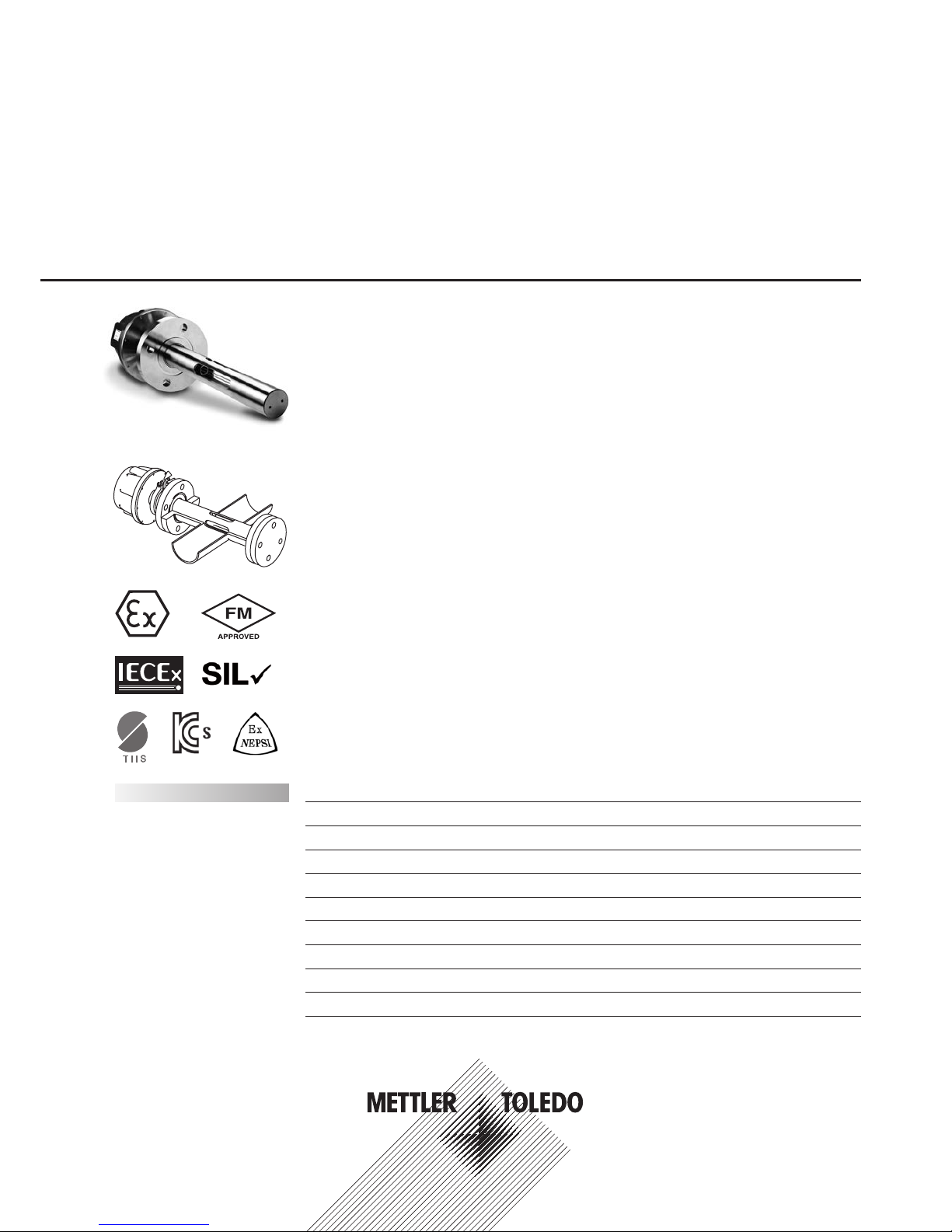

GPro 500 TDL Series

Compact Spectrometer

with Versatile Process Adaptions

Technical Data

Short description

The GPro

®

500 TDL Series is designed for tough and challenging gas measurement applications. The

series is highly suited to demanding process applications where accuracy and fast response is crucial

despite a varying background gas composition and a high dust load. The range of process adaptions

provides the ultimate in convenient process connection exibility, including for the rst time the ability to

operate without the requirement for process purge on low particulate applications using the optional non-

purge probe design. The GPro Series can be easily calibrated without interrupting the process, providing a

reliable, low maintenance and exible in situ gas measurement solution.

Outstanding features

– Interference-free in situ or extractive measurement technology

– Easy calibration without interrupting the process

– 12 month recommended verication interval

– Highly exible process adaptions

– Different styles and insertion lengths to suit applications with all types of geometry,

incl. DN50 pipes with the wafer cell

– Large selection of materials for the wetted parts

– Easy installation with either one ange, or for short pathlengths a two ange conguration,

with in-line “wafer“ cell, or with extractive cell

– No pre-alignment of anges required

– Process purge-free option for clean/dry gases (application dependent)

– Approval for hazardous areas ATEX zone 1, IECEx and FM Class 1 Div 1

– Optional SIL2 compliant direct current outputs for installation without M400

Overvi ew / General op eration 2

Inuences on the measurement / Typical applications 3

Installation examples (drawings and tables) 4

System overview 19

Measurement specications 21

Technical specications 25

Signal cable connections 27

Wiring diagrams (ATEX and US version) 28

Gas analyzer GPro 500 product key 30

Ordering information 32

Contents

GPro 500 TDL

Page 2

2

Overview / General operation GPro 500 TDL Series

Overview

Process gas analyzers are used for continuous determination of the concentration of one or more gases in

a gaseous mixture. The concentration of gases in a process is decisive for the automation and optimization

of processes to ensure product quality.

The fast measurement of gas concentrations directly in the process is the main advantage of in situ diode

laser gas analyzers. This is because in situ analytical procedures feature physical measurements directly

in the actual process. In contrast to extractive gas analysis, no sample needs to be extracted, conditioned

and routed into the analyzer via a sample line. Alternatively, the GPro 500 can be installed in a bypass line

with respect to process accessibility for manual intervention, in case of high process temperature, pressure

and / or specic geometry of the measurement location. Flexibility of the connection to the process is key to

delivering a simple to install analyzer that allows a truly representative measurement of the gas to be made

at the optimum location in the process line. A variety of insertion probes or alternative in-line wafer cells

make the GPro Series the ultimate in process connection convenience. An analyzer carrying out in situ

measurements must always take into account changing process conditions and be able to automatically

compensate for them. Therefore, accurate temperature and pressure compensation is highly recommended.

Also, extreme ruggedness of the system is important since it is in direct contact with the process gas.

The GPro 500 gas analyzer offers compact, service-friendly design with simple operation and exceptional

performance data. It is extremely rugged, requires little maintenance and provides high availability.

The GPro 500 operates in a wide range of process temperatures and pressures and remains uninuenced

by varying concentrations of dust (particles) in the gas. These features, together with fast measurements,

mean that diode laser gas analysis with the GPro 500 provides the ideal alternative to the drawbacks of

established extractive gas measurement methods.

General operation

A diode laser emits a beam of near-infrared light, which passes through the process gas and is then

reected back into the detector by an optical device that is situated and the end of the probe. The wavelength of the laser diode output is tuned to a gas specic absorption line. The laser continuously scans the

absorption lines with a very high spectral resolution. For analysis, absorption, strength and line shape of

the return signal is used. The inuence of cross interferences from background gases is negligible, since

the wavelength specic laser light is absorbed very selectively by only one specic molecule. The minimum

detectable limit, the accuracy and the resolution is dependent on the probe length (optical path length), the

process temperature and pressure.

GPro is a registered trademark of the METTLER TOLEDO Group in Switzerland, India, USA, China, European

Union, Japan, South Korea and Russia.

ISM is a registered trademark of the METTLER TOLEDO Group in Switzerland, Brazil, USA, China, European

Union, South Korea, Russia and Singapore.

Kalrez is a registered trademark of DuPont Performance Elastomers LLC.

All other trademarks are the property of their respective holders.

Page 3

3

Inuences on the measurement / Typical applications GPro 500 TDL Series

Inuences on the measurement

Dust load

As long as the laser beam is able to generate a signal for the detector, the dust load of the process gases

does not inuence the analytical result. By amplifying the signal automatically, measurements can be

carried out without any negative impact. The inuence from high dust load is complex and is dependent on

the optical path length (probe length), particle size and particle size distribution. At longer path lengths the

optical attenuation increases rapidly. Smaller particles also have a signicant impact on the optical attenuation: the smaller the particles are, the more difcult the measurement will be. For high dust load applications, please consult your local METTLER TOLEDO representative.

Temperature

The temperature inuence on an absorption line must be compensated for. An external temperature sensor

can be connected to the GPro 500. The signal is then used to correct the measurement results. Without

temperature compensation the measurement error caused by process gas temperature changes affects the

measurement substantially. Therefore, in most cases an external temperature signal is recommended.

Pressure

The process gas pressure affects the line shape of a molecular absorption line and inuences the measurement results. An external pressure sensor can be connected to the GPro 500. When the correct process gas

pressure is supplied, the GPro 500 uses a special algorithm to adapt the line shape and effectively compensate for the pressure inuence as well as the density effect. Without compensation the measurement

error caused by process gas pressure changes is substantial. Therefore, in most cases an external pressure

signal is recommended.

Cross interference

Since the GPro 500 derives its signal from one or more fully-resolved molecular absorption lines, cross

interference from other gases is eliminated. The GPro 500 is therefore able to measure the desired gas

component very selectively.

Note:

Always take great care when choosing the measurement location. Positions where there are fewer particles,

the temperature is lower or there is a more suitable process pressure, are recommended. The more optimized the measurement location is, the better the overall performance of the system will be. For advice on

the optimal measurement location, please contact your local METTLER TOLEDO representative.

Solar radiation and process radiated heat.

Exposure of the head of the GPro 500 to very high temperatures, for example, solar radiation and / or excessive localized heat sources (such as radiated heat from process walls or adjacent equipment) can cause

internal overheating of the device. See manual for further information.

Typical applications

Industry Safety Control Process Control Inertization

Chemical • • •

Petrochemical • • •

Rening • • •

Power – •

Hazardous waste – •

Tank farms / Vapor recovery • – •

Page 4

4

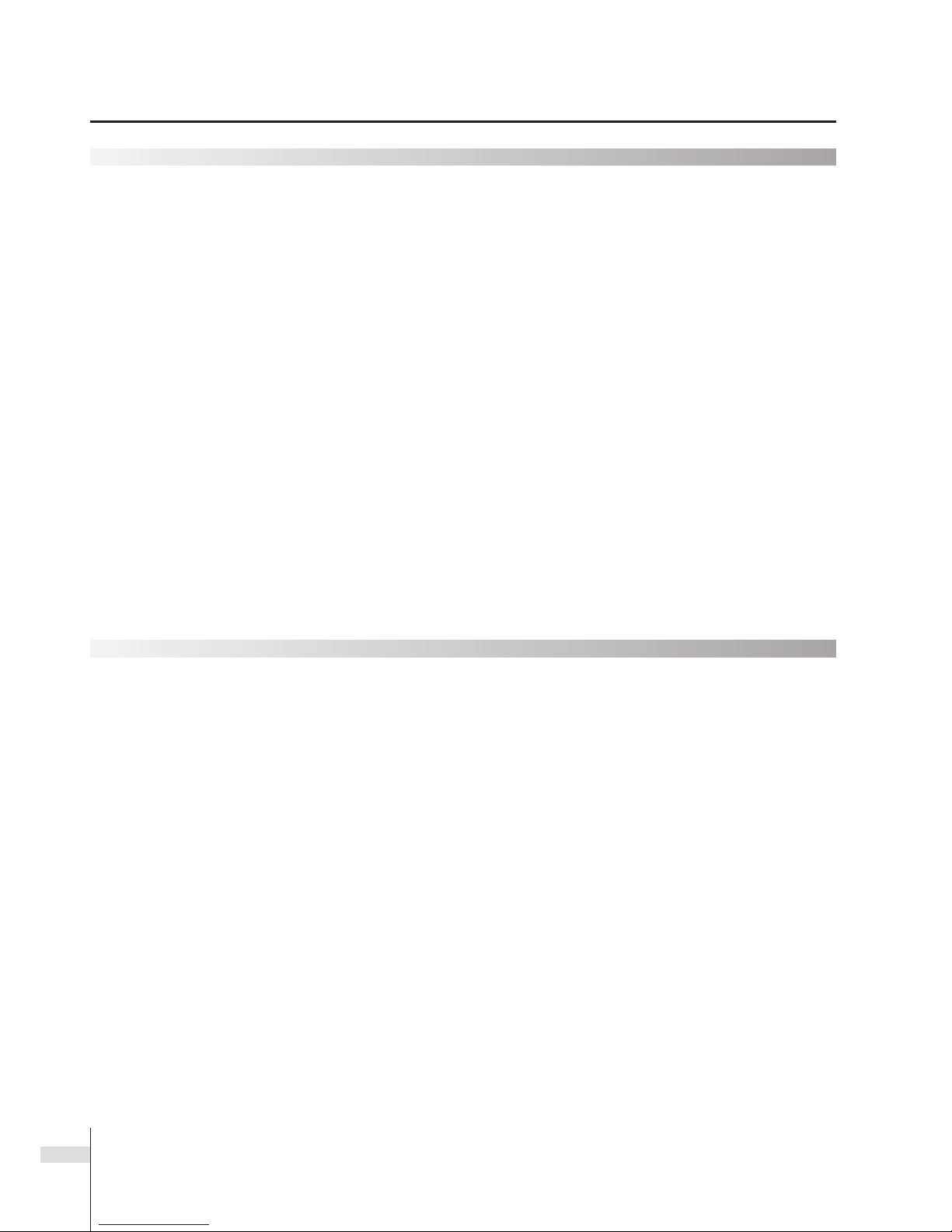

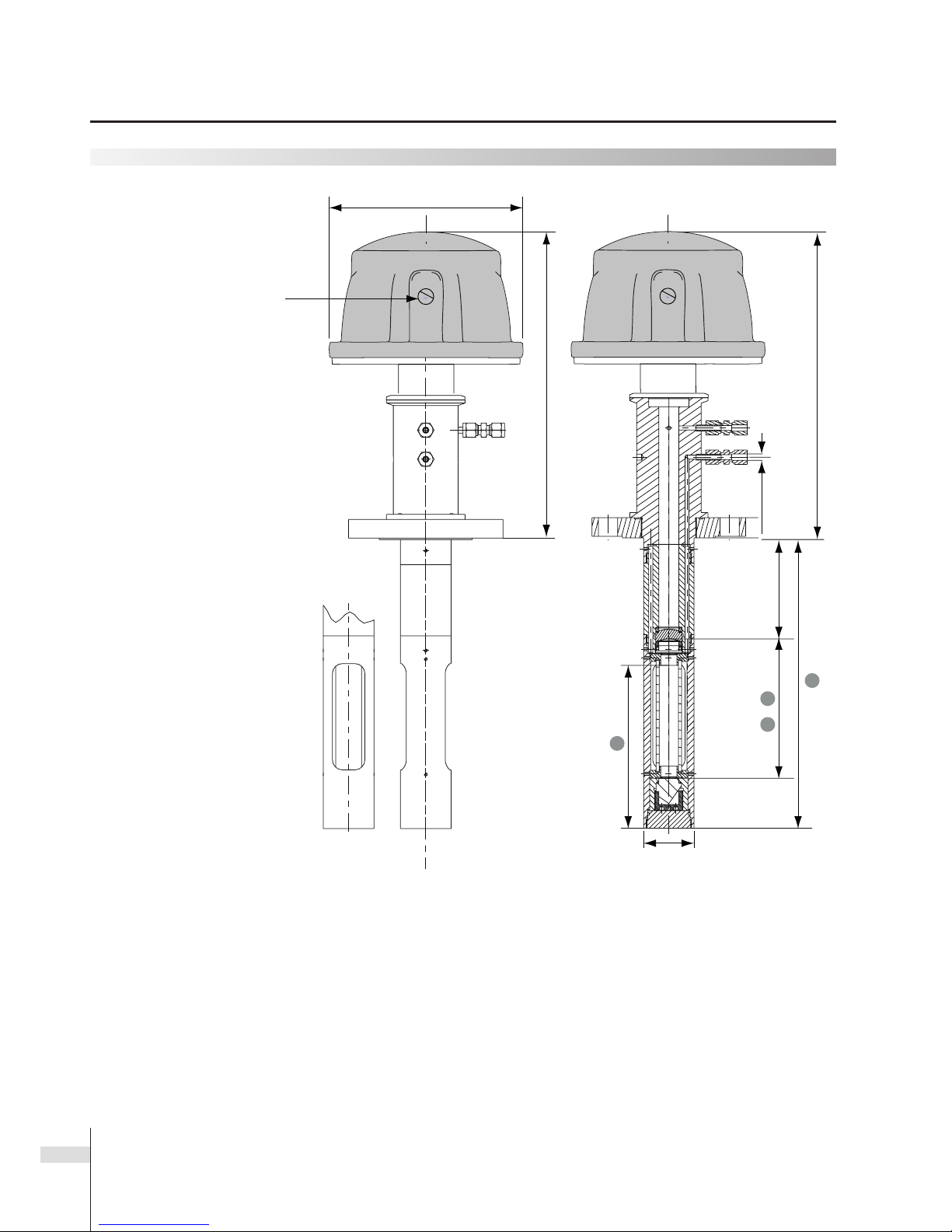

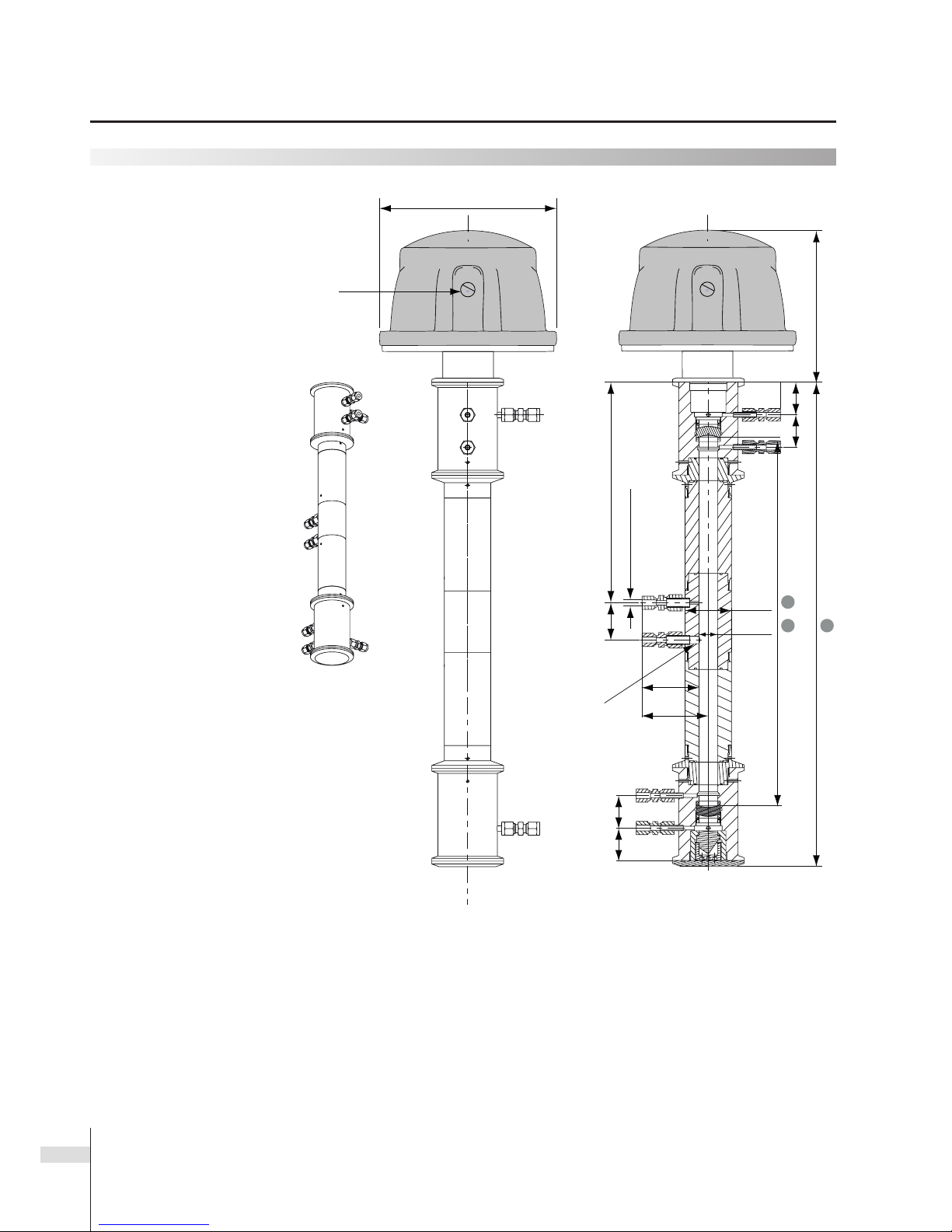

Installation examples

Dimensions of the

standard purged

probe (SP)

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered.

It corresponds to the effective path length without purging.

➋

Probe length, the physical length of the probe.

➌

Insertion length, the part of the probe that has to protrude into the pipe for effective purging.

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

1

3

D = ¼"

or 6 mm

4

2

119 mm (4.68")

115 mm (4.52")

50 mm (± 0,3 mm)

(1.97" [± 0.01"])

f

290 mm (11.42")

175,5 mm (6.91")

½" NPT

Installation examples (drawings) GPro 500 TDL Series

Page 5

5

Installation examples (drawings) GPro 500 TDL Series

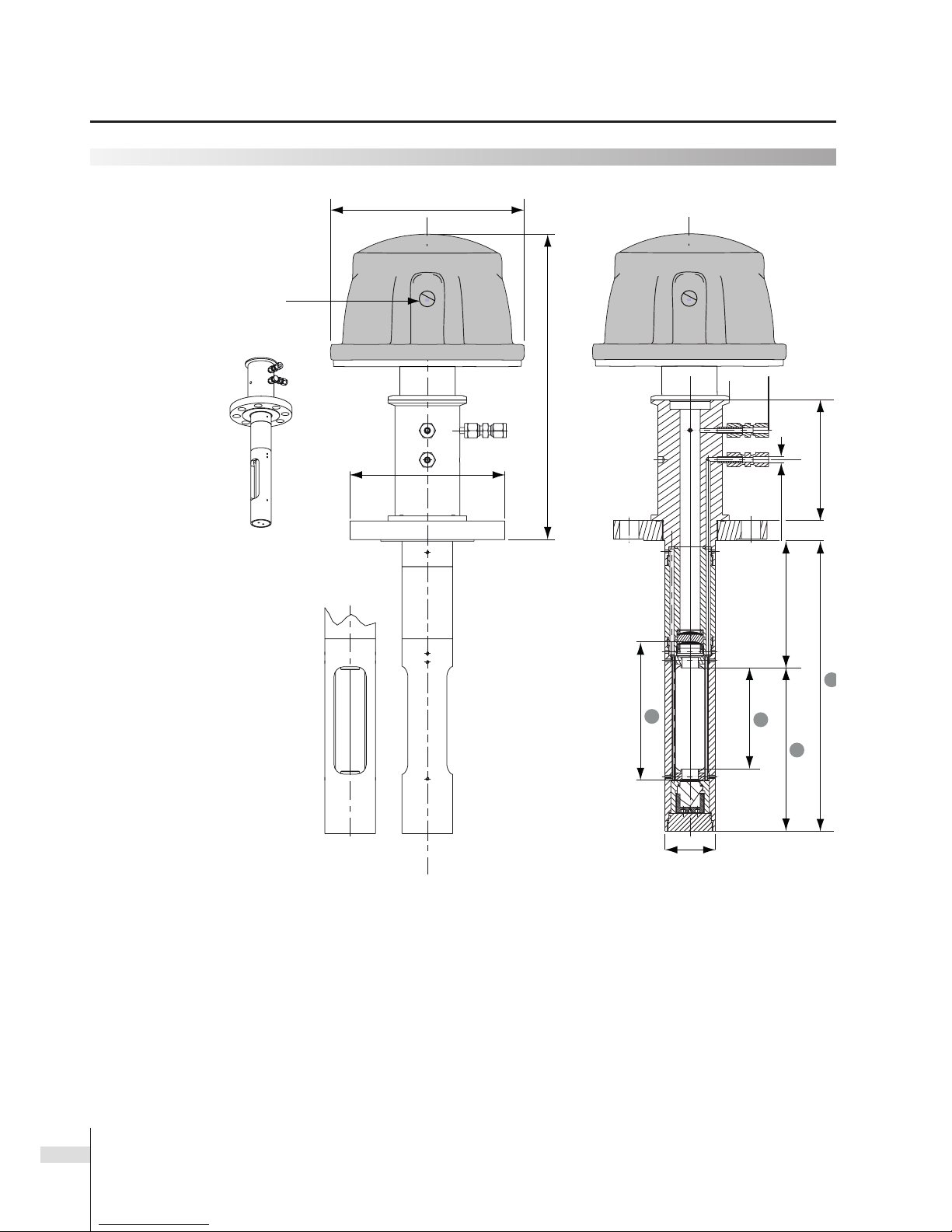

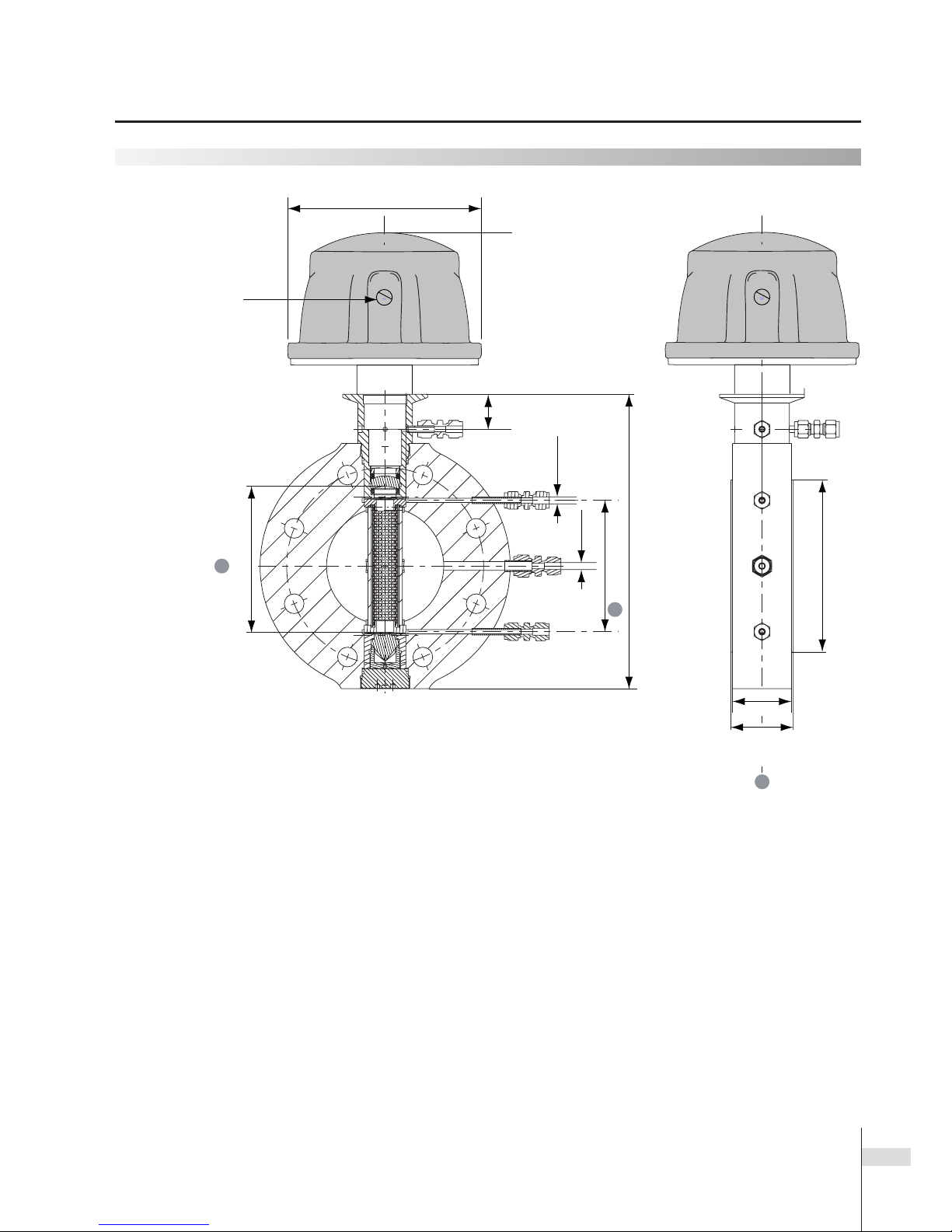

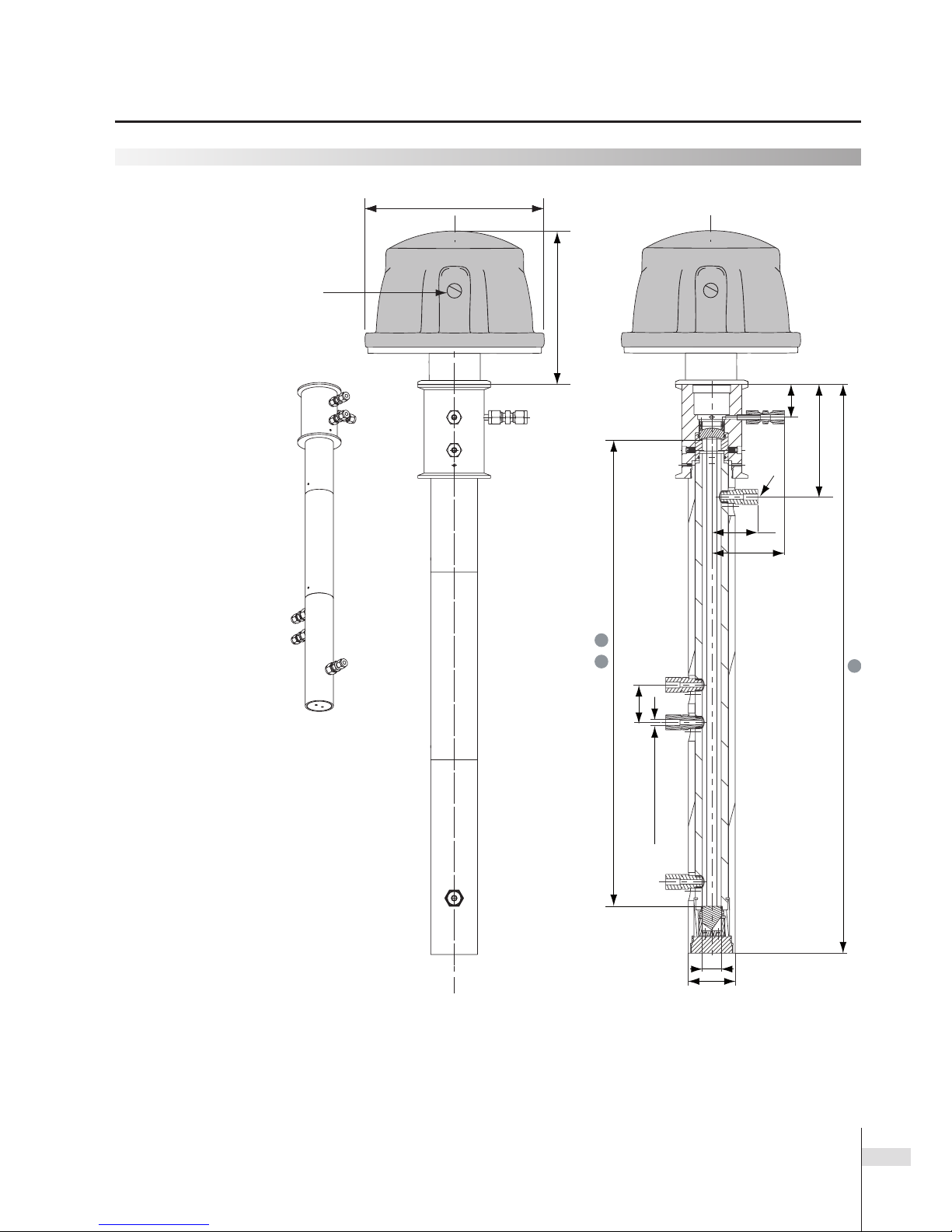

Installation examples

Dimensions of the

non-purged probe (NP)

with optional lter

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered.

It corresponds to the effective path length without purging.

➋

Probe length, the physical length of the probe.

➌

Insertion length, the part of the probe that has to protrude into the pipe for effective purging.

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

Note:

•

When using the PTFE lter, the maximum process gas temperature is 150 °C (302 °F).

•

Metal lters available: 3 µm, 40 µm, 100 µm, 200 µm.

50 mm (± 0,3 mm)

(1.97" [± 0.01"])

3

119 mm (4.68")

D = 6 mm or ¼"

1 4

2

138 mm (5.43")

120 mm (4.72")

29 mm (1.14")

175,5 mm (6.91")

½" NPT

290 mm (11.42")

Page 6

6

Installation examples (drawings) GPro 500 TDL Series

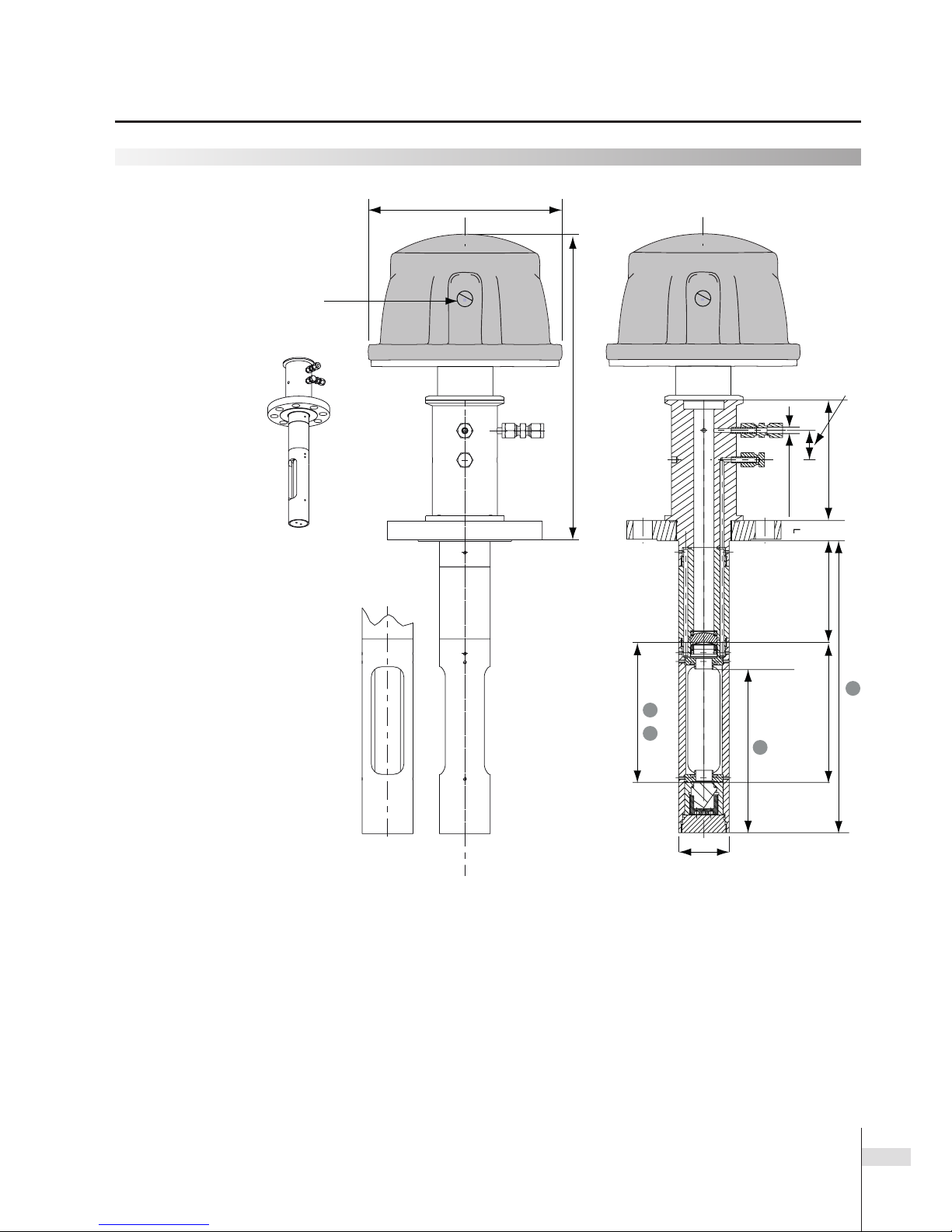

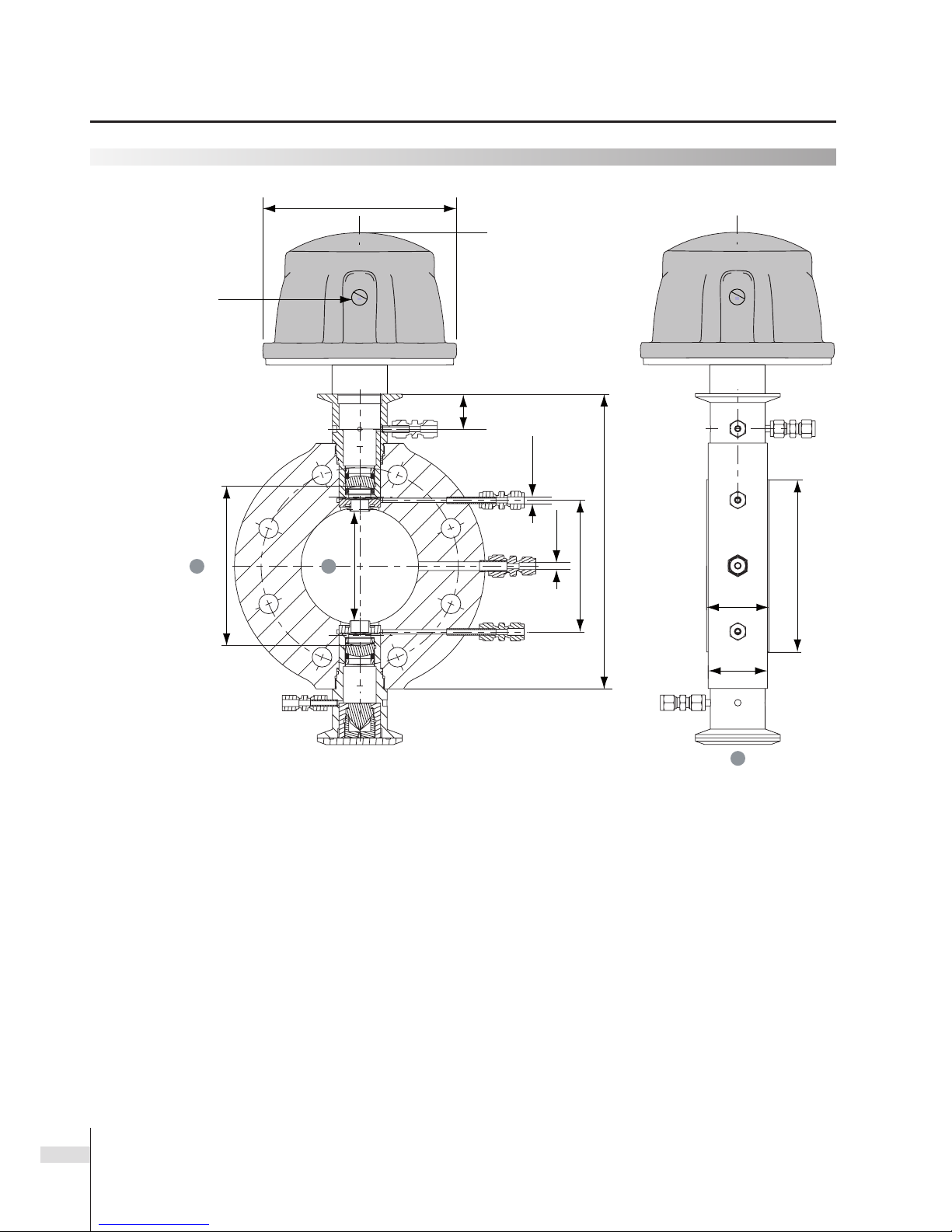

Installation examples

Dimensions of the non-purged

probe (B) with blow-back lter

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered.

It corresponds to the effective path length without purging.

➋

Probe length, the physical length of the probe.

➌

Insertion length, the part of the probe that has to protrude into the pipe for effective purging.

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

Note:

•

When using the PTFE lter, the maximum process gas temperature is 302 °F (150 °C).

•

Metal lters available: 3 µm, 40 µm, 100 µm, 200 µm.

50 mm (± 0,3 mm)

(1.97" [± 0.01"])

3

1

2

4

120 mm (4.72")

300 mm (11.81")

D = 6 mm or ¼"

f

290 mm (11.42")

175,5 mm (6.91")

½" NPT

Page 7

7

Installation examples (drawings) GPro 500 TDL Series

Installation examples

Dimensions of

the wafer (W)

with optional

lter

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered.

It corresponds to the effective path length without purging.

➌

Insertion length, wafer thickness (distance between pipe anges).

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

Note:

•

Filters only available on DN100/4" wafers.

•

When using the PTFE lter, the maximum process gas temperature is 302 °F (150 °C).

•

Metal lters available: 3 µm, 40 µm, 100 µm, 200 µm.

D1 = ¼"

or 6 mm

269 mm (10.59")

134.5 mm (5.29")

32 mm

(1.26")

D2 = ¼"

or 6 mm BT

120 mm (4.72")

1

4

157.20 mm (6.20")

54 mm

(2.13")

57 mm

(2.24")

3

175,5 mm (6.91")

½" NPT

Page 8

8

Installation examples (drawings) GPro 500 TDL Series

Installation examples

Dimensions of

the Wafer (W)

Dual Window

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered.

It corresponds to the effective path length without purging.

➌

Insertion length, wafer thickness (distance between pipe anges).

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

157.2 mm (6.20")

54 mm

(2.13")

57 mm

(2.24")

3

D1 = ¼"

or 6 mm

320 mm (12.60")

134.5 mm (5.29")

32 mm

(1.26")

D2 = ¼"

or 6 mm BT

120 mm (4.72")

1

4

100 mm (3.94")

175,5 mm (6.91")

½" NPT

Page 9

9

Installation examples (drawings) GPro 500 TDL Series

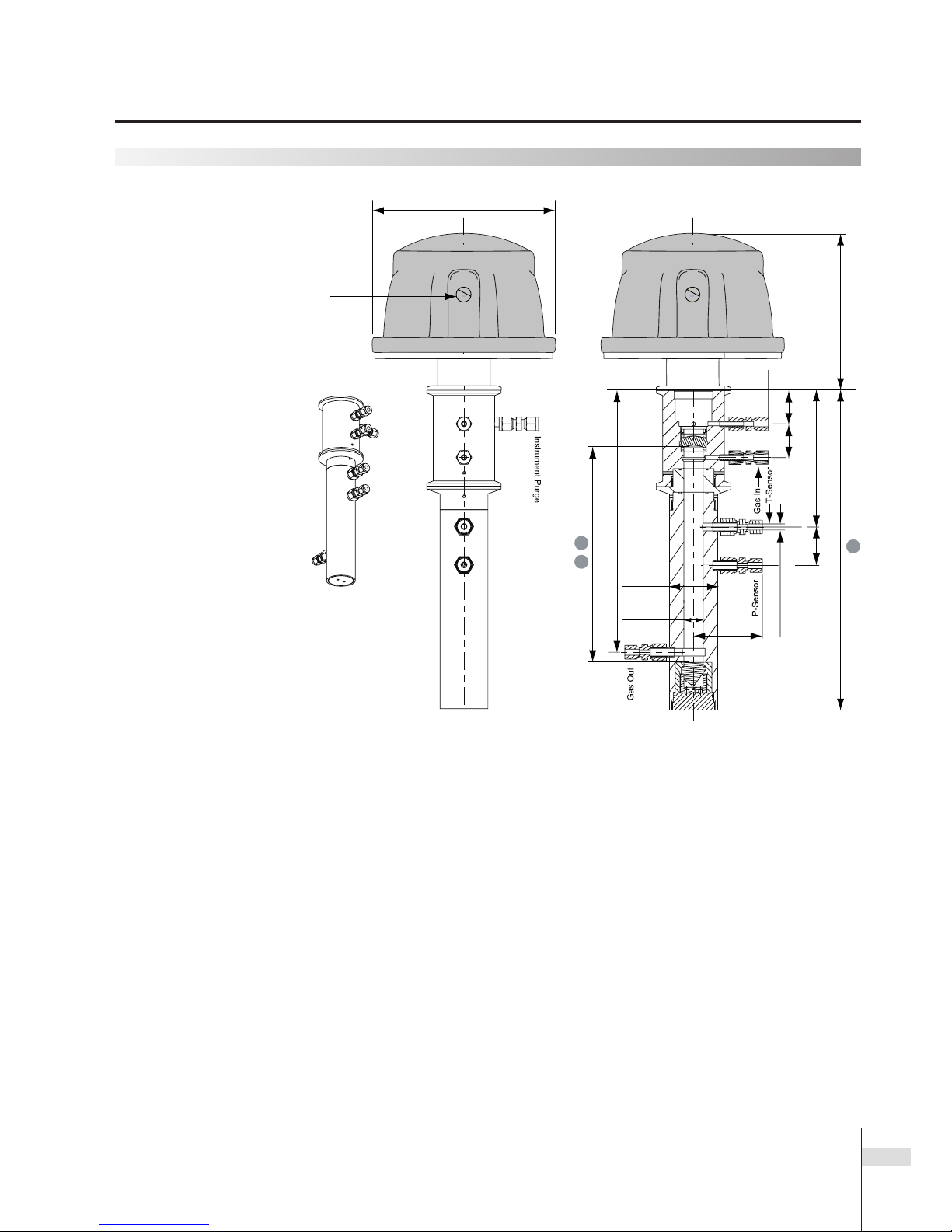

Installation examples

Dimensions of the

extractive cell (E)

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered.

It corresponds to the effective path length without purging.

➋

Probe length, the physical length of the probe.

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

272 mm (10.70")

150 mm (5.90")

D = 6 mm or ¼" (BT)

35 mm

(1.37")

35 mm

(1.37")

50 mm

(1.96")

20 mm

(0.78")

71 mm

(2.79")

142 mm (5.59")

40 mm

(1.57")

2

41

175,5 mm (6.91")

½" NPT

Page 10

10

Installation examples (drawings) GPro 500 TDL Series

Installation examples

Dimensions of the extractive

cell dual window (DW)

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered.

It corresponds to the effective path length without purging.

➋

Probe length, the physical length of the probe.

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

35 mm

(1.37")

35 mm

(1.37")

2

1 4

35 mm

(1.37")

35 mm

(1.37")

50 mm

(1.97")

20 mm

(0.78")

238 mm (9.37")

40 mm

(1.57")

D = 6 mm or ¼" (BT)

61 mm

(2.40")

71 mm

(2.79")

150 mm (5.90")

Bore-through

P-Sensor

T-SensorGas IN

Gas OUT

175,5 mm (6.91")

½" NPT

Page 11

11

Installation examples

Dimensions of the

extractive cell (E) PFA

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered.

It corresponds to the effective path length without purging.

➋

Probe length, the physical length of the probe.

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

2

35 mm

(1.38")

120 mm (4.72")

49 mm

(1.92")

78 mm

(3.07")

41

40 mm

(1.57")

PFA, D = 6 mm or

¼" (BT)

50 mm (1.96")

20 mm (0.78")

Gas IN

Gas

OUT

P-SensorT-Sensor

150 mm (5.90")

175,5 mm (6.91")

½" NPT

Installation examples (drawings) GPro 500 TDL Series

Page 12

12

Installation examples

Dimensions of the

extractive (E) white cell

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered.

It corresponds to the effective path length without purging.

➋

Probe length, the physical length of the probe.

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

Note:

•

For oxygen measurement only.

1

4

100 mm

(± 0,3 mm)

(3.93")

(± 0.01")

Gas

Outlet

Gas

Inlet

2

175,5 mm (6.91")

½" NPT

G ¼" G ¼"

Installation examples (drawings) GPro 500 TDL Series

Page 13

13

Installation examples (drawings) GPro 500 TDL Series

Installation examples

Dimensions of the

cross pipe

Denition of the dimensions:

➊

Nominal path length, the default length when GPro 500 is delivered (conguration dependent).

It corresponds to the effective path length without purging.

➍

Effective path length, when conguring the GPro 500 with the M400, the double value of the effec-

tive path length must be keyed in (23 effective path length).

D = 6 mm

or ¼"

1

4

300 mm (11.81")

136 mm (5.35")

129 mm (5.07")

44 mm

(1.73")

25 mm

(0.98")

Process Purge

45 mm

(1.77")

31 mm

(1.22")

82 mm (3.22")

175,5 mm (6.91")

½" NPT

Page 14

14

Installation examples (tables) GPro 500 TDL Series

Installation examples

Probes, wafer and cell dimensions

Process interface OPL Dimension

➊

Dimension ➋ Dimension ➌ Dimension

➍

Standard purged (SP) 200 mm 138 mm 288 mm 161.5 mm 100 mm

(7.9") (5.4") (11.3") (6.4") (3.9")

Standard purged (SP) 400 mm 238 mm 388 mm 261.5 mm 200 mm

(15.7") (9.4") (15.3") (10.3") (7.9")

Standard purged (SP) 800 mm 438 mm 588 mm 461.5 mm 400 mm

(31.5") (17.2") (23.1") (18.2") (15.7")

Non-purged probe (NP) 200 mm 138 mm 288 mm 161.5 mm 138 mm

(7.9") (5.4") (11.3") (6.4") (5.4")

Non-purged probe (NP) 400 mm 238 mm 388 mm 261.5 mm 238 mm

(15.7") (9.4") (15.3") (10.3") (9.4")

Non-purged probe (NP) 800 mm 438 mm 588 mm 461.5 mm 438 mm

(31.5") (17.2") (23.1") (18.2") (17.2")

Non-purged probe (NP) with lter 200 mm 138 mm 288 mm 161.5 mm 138 mm

(7.9") (5.4") (11.3") (6.4") (5.4")

Non-purged probe (NP) with lter 400 mm 238 mm 388 mm 261.5 mm 238 mm

(15.7") (9.4") (15.3") (10.3") (9.4")

Non-purged probe (NP) with lter 800 mm 438 mm 588 mm 461.5 mm 438 mm

(31.5") (17.2") (23.1") (18.2") (17.2")

Non-purged lter probe with blow-back (NB) 200 mm 138 mm 288 mm 161.5 mm 138 mm

(7.9") (5.4") (11.3") (6.4") (5.4")

Non-purged lter probe with blow-back (NB) 400 mm 238 mm 388 mm 261.5 mm 238 mm

(15.7") (9.4") (15.3") (10.3") (9.4")

Non-purged lter probe with blow-back (NB) 800 mm 438 mm 588 mm 461.5 mm 438 mm

(31.5") (17.2") (23.1") (18.2") (17.2")

DN 50 wafer (W) 110 mm 79 mm n.a. 54 mm 55 mm

(4.33") (3.11") (2.13") (2.17")

DN 80 wafer (W) 164 mm 121 mm n.a. 54 mm 82 mm

(6.46") (4.76") (2.13") (3.29")

DN 100 wafer (W) 214 mm 157 mm n.a. 54 mm 107 mm

(8.43") (6.18") (2.13") (4.21")

ANSI 2" wafer (W) 104 mm 77 mm n.a. 54 mm 52 mm

(4.09") (3.03") (2.13") (2.05")

ANSI 3" wafer (W) 154 mm 99 mm n.a. 54 mm 77 mm

(6.06") (3.90") (2.13") (3.03")

ANSI 4" wafer (W) 214 mm 157 mm n.a. 54 mm 107 mm

(8.43") (6.18") (2.13") (4.21")

Cross pipe 2000 – 6000 mm 2000 – 6000 mm n.a. n.a.

➊

– 300 mm

(78.74" – 236.22") (78.74" – 236.22") (

➊

– 118 .1 " )

continued on next page

Page 15

15

Installation examples (tables) GPro 500 TDL Series

Probes, wafer and cell dimensions, continued

Process interface OPL Dimension

➊

Dimension ➋ Dimension ➌ Dimension

➍

Extractive cell (E) 200 mm 125 mm 232mm N.A 125 mm

(7.9") (4.9") (9.1") N.A (4.9")

Extractive cell (E) 400 mm 225 mm 332 mm N.A 225 mm

(15.7") (8.9") (13.1") N.A (8.9")

Extractive cell (E) 800 mm 425 mm 532 mm N.A 425 mm

(31.5") (16.7") (20.9") N.A (16.7")

Extractive cell (E) 1000 mm 525 mm 632 mm N.A 525 mm

(39.4") (20.7") (24.9") N.A (20.7")

Extractive cell Dual Window(E) 400 mm 200 mm 321 mm N.A 200 mm

(15.7") (7.9") (12.6") N.A (7.9")

Extractive cell Dual Window(E) 800 mm 400 mm 521 mm N.A 400 mm

(31.5") (15.7") (20.5") N.A (15.7")

Extractive cell Dual Window(E) 1000 mm 500 mm 621 mm N.A 500 mm

(39.4") (19.7") (24.4") N.A (19.7")

Extractive cell (E) PFA 1000 mm 500 mm 606.5 mm N.A 500 mm

(39.4") (19.7") (23.9") N.A (19.7")

Extractive white cell (E) 10000 mm 250 mm 432 mm N.A 250 mm

(393.7.0") (9.8") (17.0") N.A (9.8")

* Note: Dimension

➋

in above table applies for standard 100 mm stand-off. For total probe length dimensions for other stand-off lengths,

please refer to product congurator.

Page 16

16

Installation examples (tables) GPro 500 TDL Series

Sampling and conditioning system (SCS) Design requirements

• Sampled gases must be dry and dust-free. Flow can be user-dened.

• Heat tracing of the cell up to the maximum design temperature is allowed, but maximum spectrameter ambient temperature is 55 °C

(131 °F ).

Internal volume Maximum design pressure Maximum design temperature

Extractive cell (E) 10 bar a 250 °C / 482 °F

Extractive cell (E) 10 bar a 250 °C / 482 °F

Extractive cell (E) 10 bar a 250 °C / 482 °F

Extractive cell (E) 10 bar a 250 °C / 482 °F

Extractive cell Dual Window(E) 10 bar a 250 °C / 482 °F

Extractive cell Dual Window(E) 10 bar a 250 °C / 482 °F

Extractive cell Dual Window(E) 10 bar a 250 °C / 482 °F

Extractive cell (E) PFA 5 bar a 150 °C / 302 °F

Extractive white cell (E) 10 bar a 150 °C / 302 °F

Page 17

17

Installation examples (tables) GPro 500 TDL Series

Installation examples

Required anges for some typical standard probe (SP) congurations (100 mm stand-off)

➊

Nominal

➋

Probe

➌

Insertion

➍

Effective Pipe size Number of

path length length length path length * DN / SPS anges

138 mm 288 mm 161.5 mm 100 mm 100 mm 2

(5.4") (11.3") (6.4") (3.9") (3.94")

138 mm 288 mm 161.5 mm 100 mm 150 mm 2

(5.4") (11.3") (6.4") (3.9") (5.91")

138 mm 288 mm 161.5 mm 100 mm 200 mm 1

(5.4") (11.3") (6.4") (3.9") (7.87)

238 mm 388 mm 261.5 mm 200 mm 200 mm 2

(9.4") (15.3") (10.3") (7.9") (7.87")

238 mm 388 mm 261.5 mm 200 mm 250 mm 2

(9.4") (15.3") (10.3") (7.9") (9.84")

238 mm 388 mm 261.5 mm 200 mm 300 mm 1

(9.4") (15.3") (10.3") (7.9") (11.81")

438 mm 588 mm 461.5 mm 400 mm 300 mm 2

(17.2") (23.1") (18.2") (15.7") (11.81")

438 mm 588 mm 461.5 mm 400 mm 400 mm 2

(17.2") (23.1") (18.2") (15.7") (15.75")

438 mm 588 mm 461.5 mm 400 mm 500 mm 1

(17.2") (23.1") (18.2") (15.7") (19.69")

438 mm 588 mm 461.5 mm 400 mm 600 mm 1

(17.2") (23.1") (18.2") (15.7") (23.62")

* When conguring the GPro 500 with the M400, the double value of the effective path length must be

keyed in (23 effective path length).

Page 18

18

Installation examples GPro 500 TDL Series

Installation examples (SP probe)

One and two ange conguration

By-pass conguration (SP probe)

Example of typical by-pass conguration.

* Default stand-off length shown.

100 mm

(4")

(*)

100 mm

(4")

DIN 50 or ANSI 2"

DIN 65 or ANSI 2½"

min. clearance: 61,5 mm

(schedule 40)

min. clearance: 77,5 mm

(schedule 80)

(*)

One ange conguration

Default* stand-off for standard probe (SP).

Other stand-offs distances available:

200 mm (8") and 300 mm (12").

Two ange conguration

Default* stand-off for standard probe (SP).

Other stand-off distances available:

200 mm (8") and 300 mm (12").

300 mm

(11.81'')

100 mm

(4'')

100 mm

(4'')

100 mm

(4'')

*

Page 19

19

System overview

The GPro Series consists of four main components:

➊

Sensor head

The combined transmitter and receiver unit is called the sensor head. This part contains the laser, optics

and all the electronics for laser control, signal processing, line locking, detector electronics, etc. The sensor

head has an Ethernet interface for high level maintenance by the use of METTLER TOLEDO Process Analytics specic soft ware. All parts of the sensor head are non-wetted and are never in contact with the process.

If this feature has been selected when purchasing the analyzer, the GPro 500 can also provide 2 3 4 … 2 0

mA passive analog outputs directly from the sensor head (SIL2).

➋

Process adaption

The probe exists in several standard versions where both material of construction and insertion length can

be customized to particular needs. The wafer is available in a variety of sizes, to suit pipes sizes of DN50,

DN80, DN100 or ANSI 2", ANSI 3" or ANSI 4".

➌

M400 G2 type 3 transmitter

The M400 is the GPro 500 user interface. Using the M400, the user can set the necessary parameters for

operation, and control the alarm and I / O setup. The M400 will also display the measured gas concentration, the process temperature and pressure as well as the transmission (signal quality / strength). It features

class 1 Div 2 FM approval (ATEX zone 2) and four active 4 – 20 mA analog outputs.

➍

Junction box

A junction box is required between the sensor head and the M400. An existing junction box can be used,

or one can be ordered as an accessory. The 4 – 20 mA signals for temperature and pressure compensation

are connected to the sensor’s head through the junction box. The Ethernet interface can be accessed

through the junction box as well.

➌

➊

➋

➍

(optional)

System overview GPro 500 TDL Series

Page 20

20

System overview GPro 500 TDL Series

System overview

Material of construction for process adaptions

Wetted Parts 1.4404 (comparable to 316L), 1.4571, Hastelloy C22, PFA

Glass, Optics AR coated Quartz, AR coated Borosilicate, Sapphire

O-rings, Gaskets Kalrez

®

6375, Kalrez® (FDA) 6230, 6380 (Spectrum), 0090 (RGN),

Graphite, PFA-O-Seal PTFE

Probe lengths. Standard purged (SP)

290 mm / 11.42"

390 mm / 15.35"

590 mm / 23.23"

Probe lengths. Non-purge probes (NP)

290 mm / 11.42"

390 mm / 15.35"

590 mm / 23.23"

Probe lengths. Non-purged lter probe with blow-back (NB)

290 mm / 11.42"

390 mm / 15.35"

590 mm / 23.23"

Probe lengths. Non-purged probes (NP) with lter

290 mm / 11.42"

390 mm / 15.35"

590 mm / 23.23"

Wafer sizes (to t pipe diameter)

DN 50, 80 or 100; PN16/PN40

ANSI 2", 3" or 4"; 150 lbs

Other materials of construction as well as different probe lengths are available upon request.

Page 21

21

Measurement (All measurement specications with reference to standard conditions T & P with no dust or particulates)

O

2

O

2

and temperature CO (ppm)

Optical path length • Optical path length (OPL) can vary between 100 mm and 10 m depending on the selected process adaption

(see “Installation examples” on page 14).

• The OPL can be multiplied by 2 (MR2) or 4 (MR4) when using the multi-reflection cell (MR).

Measurement range and standard

conditions (ambient temperature and

pressure, 1 m path length)

0 – 100 % 1 – 100 %

0 – 150 °C (32 – +302 °F)

0 – 2 %

Lower Detection Limit (in 1 meter path

length at ambient standard conditions,

dry gas, no dust load, in N

2

back-

ground)

100 ppm-v 100 ppm-v

2 °C (35.6 °F)

1 ppm-v

Accuracy 2 % of reading or 100 ppm O

2

( whichever is greater)

2 % of reading or 100 ppm O

2

( whichever is greater)

2 % of reading or 1 ppm

( whichever is greater)

Linearity Better than 1 % Better than 1 % Better than 1 %

Resolution < 0…01 % vol O

2

(100 ppm-v) < 0…01 % vol O

2

(100 ppm-v) 1 ppm-v

Drift Negligible (< 2 % of measurement ran-

ge between maintenance intervals)

Negligible (< 2 % of measurement ran-

ge between maintenance intervals)

Negligible (< 2 % of measurement ran-

ge between maintenance intervals)

Sampling rate 1 second 1 second 1 second

Response Time (T90) O

2

in N

2

21 % > 0 % in < 2 se c O

2

in N

2

21 % > 0 % in < 2 se c CO in N

2

300 ppm-v to 0 % in < 4 sec

Warm up time Typically <1 hour Typically <1 hour Typically <1 hour

Repeatabilit y ± 0.25 % of re ading or 0.05 % O

2

(whichever is greater)

± 0.25 % of re ading or 0.05 % O

2

(whichever is greater)

± 0.25 % of reading or 5 ppm-v CO

(whichever is greater)

Process pressure range 0.3 bar – 10 bar (abs)/

4.35 psi – 145.03 psi (abs)*

0.8 bar – 5 bar (abs)/

11.63 psi – 72.52 psi (abs)

0.8 bar – 2 bar (abs)/

11.63 psi – 29.00 psi (abs)

Process temperature range 0 to + 250 °C (+ 32 to + 482 °F) Standard

0 to + 600 °C (0 to +1112 °F) with built in thermal barrier,

0 to +150 °C (+ 32 to + 302 °F) (White cell, PFA, PTFE filter)

* from Firmware 6.23 or higher

Measurement specications GPro 500 TDL Series

Page 22

22

Measurement (All measurement specications with reference to standard conditions T & P with no dust or particulates)

CO ( %) H

2

O CO

2

( %)

Optical path length • Optical path length (OPL) can vary between 100 mm and 10 m depending on the selected process adaption

(see “Installation examples” on page 14).

• The OPL can be multiplied by 2 (MR2) or 4 (MR4) when using the multi-reflection cell (MR).

Measurement range and standard

conditions (ambient temperature and

pressure, 1m path length)

0 – 100 % 0 – 20 % 0 – 100 %

Lower Detection Limit (in 1meter path

length at ambient standard conditions,

dry gas, no dust load, in N

2

back-

ground)

1500 ppm-v 5 ppm-v 1000 ppm-v

Accuracy 2 % of reading or 1500 ppm,

(whichever is greater)

2 % of reading or 10 ppm,

(whichever is greater)

2 % of reading or 1000 ppm,

(whichever is greater)

Linearity Better than 1 % Better than 1 % Better than 1 %

Resolution 1500 ppm-v 5 ppm-v 1000 ppm-v

Drift Negligible (< 2 % of measurement ran-

ge between maintenance intervals)

Negligible (< 2 % of measurement ran-

ge between maintenance intervals)

Negligible (< 2 % of measurement ran-

ge between maintenance intervals)

Sampling rate 1 second 1 second 1 second

Response Time (T90) CO in N

2

1% to 0% in < 4 sec H

2

O in N

2

1 % to O % in < 4 sec CO

2

in N

2

1 % to O % in < 4 sec

Warm up time Typically <1 hour Typically <1 hour Typically <1 hour

Repeatabilit y ± 0.25 % of reading or 0.75 %-v CO

(whichever is greater)

± 0.25 % of reading or 50 ppm-v H

2

O

(whichever is greater)

± 0.25 % of re ading or

5000 ppm-v CO

2

(whichever is greater)

Process pressure range 0.8 bar – 1.5 bar (abs)/

11.63 psi – 21.75 psi (abs)

0.8 bar – 2 bar (abs)/

11.63 psi – 29.00 psi (abs)

0.8 bar – 2 bar (abs)/

11.63 psi – 29.00 psi (abs)

Process temperature range 0 to + 250 °C (+ 32 to + 482 °F) Standard

0 to + 600 °C (0 to +1112 °F) with built in thermal barrier,

0 to +150 °C (+ 32 to + 302 °F) (White cell, PFA, PTFE filter)

Measurement specications GPro 500 TDL Series

Page 23

23

Technical specications GPro 500 TDL Series

Measurement (All measurement specications with reference to standard conditions T & P with no dust or particulates)

CO

2

%/ CO % HCl (ppm) H

2

S (%)

Optical path length • Optical path length (OPL) can vary between 100 mm and 10 m depending on the selected process adaption

(see “Installation examples” on page 14).

• The OPL can be multiplied by 2 (MR2) or 4 (MR4) when using the multi-reflection cell (MR).

Measurement range and standard

conditions (ambient temperature and

pressure, 1m path length)

0 – 100 %

(CO

2

and CO)

0 – 3 % 0 –50 %

Lower Detection Limit (in 1meter path

length at ambient standard conditions,

dry gas, no dust load, in N

2

back-

ground)

1000 ppm-v (CO

2

)

1500 ppm-v (CO)

0.6 ppm-v 20 ppm-v

Accuracy 2 % of reading or 1000 ppm

(whichever is greater)

2 % of reading or 0.6 ppm

(whichever is greater)

2 % of reading or 20 ppm

(whichever is greater)

Linearity Better than 1 % Better than 1 % Better than 1 %

Resolution 1000 ppm-v 0.6 ppm-v 20 ppm-v

Drift Negligible (< 2 % of measure ment

range between maintenance intervals)

Negligible (< 2 % of measure ment

range between maintenance intervals)

Negligible (< 2 % of measure ment

range between maintenance intervals)

Sampling rate 1 second 1 second 1 second

Response Time (T90) CO

2

in N

2

1 % to O % in < 4 sec HCl in N

2

1 % to O % in < 4 sec H

2

S in N

2

1 % to O % in < 4 sec

Warm up time Typically <1 hour Typically <1 hour Typically <1 hour

Repeatabilit y ± 0.25 % of re ading or

5000 ppm-v CO

2

or CO

(whichever is greater)

± 0.25 % of reading or 3 ppm-v HCl

(whichever is greater)

± 0.25 % of reading or 100 ppm-v H

2

S

(whichever is greater)

Process pressure range 0.8 bar – 2 bar (abs)/

11.63 psi – 29.00 psi (abs)

0.8 bar – 3 bar (abs)/

11.6 psi – 43.5 psi (abs)

0.8 bar – 2 bar (abs)/

11.6 psi – 29 psi (abs)

Process temperature range 0 to + 250 °C (+ 32 to + 482 °F) Standard

0 to + 600 °C (0 to +1112 °F) with additional thermal barrier,

0 to +150 °C (+ 32 to + 302 °F) (White cell, PFA, PTFE filter)

Page 24

24

Measurement (All measurement specications with reference to standard conditions T & P with no dust or particulates)

CH

4

ppm NH

3

ppm

Optical path length • Optical path length (OPL) can vary between 100 mm and 10 m depending on the selected process adaption

(see “Installation examples” on page 14).

• The OPL can be multiplied by 2 (MR2) or 4 (MR4) when using the multi-reflection cell (MR).

Measurement range and standard

conditions (ambient temperature and

pressure, 1m path length)

0 – 1 % 0 – 1 %

Lower Detection Limit (in 1meter path

length at ambient standard conditions,

dry gas, no dust load, in N

2

back-

ground)

1 ppm-v 1 ppm-v

Accuracy 2 % or 1 ppm

(whichever is greater)

2 % or 1 ppm

(whichever is greater)

Linearity Better than 1 % Better than 1 %

Resolution 1 ppm 1 ppm

Drift Negligible (< 2 % of measure ment

range between maintenance intervals)

Negligible (< 2 % of measure ment

range between maintenance intervals)

Sampling rate 1 second 1 second

Response Time (T90) CH

4

in N

2

1% to 0% in < 4 sec NH

3

in N

2

1% to 0% in < 4 sec

Warm up time Typically <1 hour Typically <1 hour

Repeatabilit y ± 0.25 % of re ading or

5 ppm-v CH

4

,

(whichever is greater)

± 0.25 % of re ading or

5 ppm-v NH

3

,

(whichever is greater)

Process pressure range 0.8 bar – 3 bar (abs)/

11.63 psi – 43.5 psi (abs)

0.8 bar – 3 bar (abs)/

11.63 psi – 43.5 psi (abs)

Process temperature range 0 to + 250 °C (+ 32 to + 482 °F) Standard

0 to + 600 °C (0 to +1112 °F) with additional thermal barrier,

0 to +150 °C (+ 32 to + 302 °F) (White cell, PFA, PTFE filter)

Measurement specications GPro 500 TDL Series

Page 25

25

Technical specications GPro 500 TDL Series

Technical specications

Electrical inputs & outputs

Communication interface RS 485 (to transmit ter) or direct current outputs (optional)

Service interface Ethernet (to PC) as direct service interface for FW updates (not using

the M400 transmitter), for off-line diagnostics and conguration

database up / download

Memory slot interface SD card reader / writer for data retrieval (measurement & diagnos-

tics), FW update and remote diagnostics (conguration le up / download) (to be accessed using Ethernet port). Space for data storage: 4

GB.

Analog outputs (on M400) 4 3 4 – 20 mA (22 mA): process temperature, pressure, % conc,

% transmission

Number of direct analog outputs 2 (optional)

Current outputs Passive 4…20 mA outputs, galvanically isolated,

alarms to 3.6 mA or 22 mA conform to NAMUR NE43 guidelines

Measurement error Non-linearity < ± 0.002 mA over the 1 to 20 mA range

through analog outputs Offset error < ± 0.004 mA (zero scale)

Gain error < ± 0.04 mA (full scale)

Analog output conguration Linear

Load Max 500 Ohms

Hold mode input Yes, via Ethernet (using the MT-TDL suite)

Analog inputs 2 3 4 – 20 mA (passive) for pressure and temperature

(optional: xed values)

Display On M400, see M400 technical datasheet

Relays 4 relays (on M400)

Power supply 24 VDC, ± 10% , 5 – 60 W

Fuse 1 A slow blow type FC

Calibration

Calibration (factory) Full calibration

Calibration (user) One-point and process calibration

Operating conditions

Ambient temperature range – 20 … + 55 °C (– 4 … +131 °F) during operation;

– 40 … +70 °C (– 40 … +158 °F) during transport and storage

(< 95 % non-condensing humidity)

Maximum design

(non- operating) Pressure Design: 25 bar (abs) / 362.6 psi (abs);

extractive cells: 15 bar (PFA version: 6 bar)

Probes with DN 100 anges: 10 bar

Max. dust load @ nom. EPL Application dependent

Temperature & pressure Using analog 4 … 20 mA input signals or manually set values in

compensation M400 (menu congure / measurement).

Automatic plausibility check of analog inputs

Page 26

26

Purging

Process side purging For standard purged (SP) and wafer cells, a process side purge is

(standard probes [SP]) normally required.

and wafer cells For oxygen applications, nitrogen with a purity > 99.7 % (minimum

recommended) at a ow rate of between 0.5 and 10 L / min (applica-tion dependent) is required. For other gas applications, instru-

ment grade air can be used instead of nitrogen. All purge gases

should be clean / dry and conform to standard ISO 8573.1. class 2 3,

for instrument air quality.

Instrument side purging Yes, ow < 0.5 L / min (all process adaptions)

Corner cube purging Yes, via process side purging

ISM

ISM

®

diagnostics parameters % Transmission (available as a 4 … 20 mA analog output)

Window fouling (➝ TTM: Time to Maintenance)

Laser lifetime (➝ DLI: Dynamic Lifetime Indicator)

Alarms

Alarm triggers Too low transmission (min. transmission value to be set in

M400 menu Cong / ISM setup)

All alarms (incl SW / HW errors etc) listed into Chapter 8.5.1 of man-

ual M400

Mechanical specications

Insertion length see installation examples

Weight 12 – 14 kg / 26 – 30 lbs, depending on conguration

Insulation / rating IP 65 / NEMA Type 4X

Data logger

Function Logging of all sensor data on SD card

Interval Freely selectable using the METTLER TOLEDO TDL software

(on documentation CD)

Format SPC

Certicates

Quality certicate (nal inspection), Material certicate 3.1,

EX II 1/2G – Ex op is / [op is T6 Ga] d IIC T6 Ga / Gb,

EX II 1/2D – Ex op is / [op is T86°C Da] tb IIIC T80°C Da / Db,

IECEx IBE 15.0013 X

Cl I, Div 1, Grp A, B, C, D, T6

Cl II, III, Div 1, Grp E, F, G, T6

FM, CE, PED, IP 65, NEMA 4X

Technical specications GPro 500 TDL Series

Page 27

27

Signal cable connections

Connections in the junction box

➊

Connections to the GPro 500 – cable numbers below

➋

Power from an external source or optionally from the M400

➌

RS 485 from the M400

➍

4 … 20 mA from temperature sensor

➎

4 … 20 mA from pressure sensor

➏

SIL2 direct analog outputs (optional)

➐

Ethernet

Signal Description Cable no. Color

Power + 24 V Power 24 V, 5 W 1 Red

GND (Power) 2 Blue

RS 485 A Interface M400 (RS 485) 3 Green

RS 485 B 4 Yellow

RS 485 GND 5 Brown

4 … 20 mA pos Current input temperature 6 Purple

4 … 20 mA neg 7 Black

4 … 20 mA pos Current input pressure 8 Pink

4 … 20 mA neg 9 Grey

+ 24 V Passive analog outputs 10 Red / blue

Out 1 11 Grey / pink

Out 2 12 White

TX+ Ethernet 13 White / yellow

TX– 14 Yellow / brown

RX+ 15 White / green

RX– 16 Brown / green

1

2 3 6 74 5

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Signal cable connections GPro 500 TDL Series

Page 28

28

Active analog inputs (ATEX and US version)

Wiring diagram with active analog inputs (ATEX and US version).

Wiring diagrams (ATEX and US version) GPro 500 TDL Series

Page 29

29

Loop-powered analog inputs (ATEX and US version)

Wiring diagram with loop-powered analog inputs (ATEX and US version).

Wiring diagrams (ATEX and US version) GPro 500 TDL Series

Page 30

30

Gas analyzer GPro 500 product key GPro 500 TDL Series

Gas analyzer GPro 500 product key

Gas Analyzer

GPro 500

ATA0PBKS020PD1XS__/AX

30 027 126 GPro 500

YYYYYYYYYYYYYYYYYY/YY

* Other configurations upon request

|||||||||||||||||||

|

Hazardous area approvals

|||||||||||||||||||

|

ATEX/IECEx Ex d

A

T

|||||||||||||||||

|

FM Class 1 Div 1

U

S

|||||||||||||||||

|

Gases

|||||||||||||||||

|

Oxygen

A

0

|||||||||||||||

|

Oxygen and Temperature

A

1

|||||||||||||||

|

CO

C

0

|||||||||||||||

|

H2O

H

0

|||||||||||||||

|

CO2 %

C

2

|||||||||||||||

|

C O %

C

1

|||||||||||||||

|

CO % + CO2 %

C

C

|||||||||||||||

|

H2S

S

1

|||||||||||||||

|

HCl ppm

L

0

|||||||||||||||

|

CH4 ppm

M

0

|||||||||||||||

|

NH3 ppm N 0

|||||||||||||||

|

Process interfaces

|||||||||||||||

|

Standard Probe purged (SP)

P

|||||||||||||||

Non-purged Filter Probe (NP)

F

|||||||||||||||

Non-purged Filter Probe with Blow-back (BP)

B

|||||||||||||||

Wafer (W)

W

|||||||||||||||

Extractive Cell (E)

E

|||||||||||||||

Cross-pipe Folded Path (C)

C

|||||||||||||||

Process optics*

|||||||||||||||

Borosilicate

B

|||||||||||||

|

Quartz

Q

|||||||||||||

|

Sapphire

S

|||||||||||||

|

Dual Window Borosilicate

C

|||||||||||||

|

Dual Window Quartz R

|||||||||||||

|

Dual Window Sapphire

T

|||||||||||||

|

Process sealings*

|||||||||||||

|

Kalrez® 6375

K

|||||||||||||

Graphite G

|||||||||||||

Kalrez® (FDA grade) 6230 F

|||||||||||||

Kalrez® 6380 S

|||||||||||||

Kalrez® 0090 R

|||||||||||||

PFA-coated FEP P

|||||||||||||

Wetted materials*

|||||||||||||

1.4404 (equivalent to 316L)

S

0

|||||||||||

1.4 571

S

1

|||||||||||

Hastelloy C22

C

0

|||||||||||

Optical path probes and extractive cell*

|||||||||||

200 mm (7.9")

2

0

|||||||||

400 mm (15.7") 4 0

|||||||||

800 mm (31.5") 8 0

|||||||||

1 m (3.3 ft) 0 1

|||||||||

2 m (6.6 ft) 0 2

|||||||||

3 m (9.8 ft) 0 3

|||||||||

Page 31

31

Gas analyzer GPro 500 product key GPro 500 TDL Series

Gas Analyzer

GPro 500

ATA0PBKS020PD1XS__/AX

30 027 126 GPro 500

YYYYYYYYYYYYYYYYYY/YY

* Other configurations upon request

|||||||||||||||||||

|

4 m (13.1 ft) 0 4

|||||||||

5 m (16.4 ft) 0 5

|||||||||

6 m (19.7 ft) 0 6

|||||||||

10 m (32.8 ft) 1 0

|||||||||

None

X

X

|||||||||

Process connections*

|||||||||

DN 50/PN 25

P

D

|||||||

ANSI 2"/300 lbs

P

A

|||||||

DN 50/PN 16

L

D

|||||||

ANSI 2"/150 lbs

L

A

|||||||

DIN 80/PN 16

G

D

|||||||

ANSI 3"/150 lbs

G

A

|||||||

DIN100/PN25

N

D

|||||||

ANSI 4"/300 lbs N A

|||||||

DN 50/PN 16 and 40

W

1

|||||||

DN 80/PN 16 and 40

W

2

|||||||

DN 100/PN 40

W

3

|||||||

ANSI 2"/150 lbs

W

4

|||||||

ANSI 3"/150 lbs W 5

|||||||

ANSI 4"/150 lbs

W

6

|||||||

Swagelok 6 mm

E

M

|||||||

Swagelok ¼"

E

I

|||||||

Wall thickness*

|||||||

100 mm

1

|||||

|

200 mm

2

|||||

|

300 mm

3

|||||

|

None

X

|||||

|

Filters*

|||||

|

Filter A – 40 µm

A

|||||

Filter B – 100 µm

B

|||||

Filter C – 200 µm

C

|||||

Filter D – 3 µm D

|||||

Filter PTFE Membrane

E

|||||

No Filter

X

|

|||

|

Add-on modules*

|

|||

|

None

X__

/

|

|

With Thermal Barrier (up to 600 °C)

H__

/

|

|

2-fold Multireflection Cell

2__

/

|

|

4-fold Multireflection Cell

4__

/

|

|

Cable

|

|

5 m (16.4 ft)

A

|

15 m (49.2 ft)

B

|

25 m (82.0 ft)

C

|

40 m (131.2 ft)

D

|

None X

|

Communication interfaces

|

RS 485 (for M400)

X

RS 485 and Direct Analog

A

Page 32

32

Ordering information GPro 500 TDL Series

Ordering information

Spare parts Order number

Kit Flat gasket ST 30 080 914

Kit Flat gasket HT (Graphite) 30 080 915

Spares Kit FM spectrometer 30 252 641

Sunk-in screws set (20 pc) 1.4404 30 297 253

Sunk-in screws set (10 pc) 1.4571 30 297 254

Sunk-in screws set (5 pc) 30 297 255

Accessories Order number

Thermal barrier 30 034 138

Junction box 30 034 149

Purging box for M400 Ex d 30 034 148

Calibration kit 30 034 139

Check valve To be provided by the user

Cable GPro 500 ATEX, FM 5 m 30 077 735

Cable GPro 500 ATEX, FM 15 m 30 077 736

Cable GPro 500 ATEX, FM 25 m 30 077 737

Cable GPro 500 ATEX, FM 40 m 30 428 055

GPro 500 cross-pipe installation positioning kit 30 392 869

GPro 500 cross-pipe verication kit 30 428 120

M400, Type 3 30 374 113

M400 Pipe mount kit 30 300 480

M400 Panel mount kit 30 300 481

M400 Protective hood 30 073 328

GPro Pin Spanner 30 129 726

Tri-Clamp safety bolts set (4 pc) 30 297 256

Corner cube module O-ring set

for Standard Temperature (ST):

Kalrez

®

6375 30 428 051

Kalrez

®

6230 (FDA grade) 30 428 052

Kalrez

®

6380 30 468 293

Kalrez

®

0090 30 468 294

PFA-coated FEP 30 468 295

Filter O-ring set for all metal lters (A, B, C, D)

Kalrez

®

6375 30 428 053

Kalrez

®

6230 (FDA grade) 30 428 054

Kalrez

®

6380 30 468 296

Kalrez

®

0090 30 468 297

PFA-coated FEP 30 468 298

Graphite 30 428 055

Page 33

33

Notes GPro 500 TDL Series

Page 34

34

Notes GPro 500 TDL Series

Page 35

35

Notes GPro 500 TDL Series

Page 36

www.mt.com/pro

Subject to technical changes.

03/2018 © METTLER TOLEDO. All ri ghts reserved.

eCopy only. 30 031 663 B

Met tle r-Toledo GmbH, Pr oce ss An aly tics

Im Hackacker 15, CH - 8902 Urdorf, Switzerland

Phone + 41 44 729 62 11, Fax +41 44 729 66 36

METTLER TOLEDO Market Organizations

9001

certified

ISO

14001

certified

ISO

Sales and Ser vice:

Australia

Mettler-Toledo Limited

220 Turner Street, Port Melbourne,

VIC 3207 Australia

Phone +61 1300 659 761

e-mail info.mtaus@mt.com

Austria

Mettler-Toledo Ges.m.b.H.

Laxenburger Str. 252/2

AT - 1230 Wien

Phone +43 1 607 4356

e-mail prozess@mt.com

Brazil

Mettler-Toledo Ind. e Com. Ltda.

Avenida Tamboré, 418, Tamboré

BR - 06460-000 Barueri / SP

Phone +55 11 4166 7400

e-mail mtbr@mt.com

Canada

Mettler-Toledo Inc.

2915 Argentia Rd #6

CA - ON L5N 8G6 Mississauga

Phone +1 800 638 8537

e-mail ProInsideSalesCA@mt.com

China

Mettler-Toledo International Trading

(Shanghai) Co. Ltd.

589 Gui Ping Road, Cao He Jing

CN - 200233 Shanghai

Phone +86 21 64 85 04 35

e-mail ad@mt.com

Croatia

Mettler-Toledo d.o.o.

Mandlova 3, HR - 10000 Zagreb

Phone +385 1 292 06 33

e-mail mt.zagreb@mt.com

Czech Republic

Mettler-Toledo s.r.o.

Trebohosticka 2283 / 2

CZ - 100 00 Praha 10

Phone +420 226 808 150

e-mail sales.mtcz@mt.com

Denmark

Mettler-Toledo A /S

Naverland 8

DK - 2600 Glostrup

Phone +45 43 27 08 00

e-mail info.mtdk@mt.com

France

Mettler-Toledo

Analyse Industrielle S.A.S.

30, Boulevard de Douaumont

FR - 75017 Paris

Phone +33 1 47 37 06 00

e-mail mtpro-f@mt.com

Germany

Mettler-Toledo GmbH

Prozeßanalytik

Ockerweg 3, DE - 35396 Gießen

Phone +49 641 507 444

e-mail prozess@mt.com

Great Britain

Mettler-Toledo LTD

64 Boston Road, Beaumont Leys

GB - Leicester LE4 1AW

Phone +44 116 235 7070

e-mail enquire.mtuk@mt.com

Hungary

Mettler-Toledo Kereskedelmi KFT

Teve u. 41

HU - 1139 Budapest

Phone +36 1 288 40 40

e-mail order.mt-hu@mt.com

India

Mettler-Toledo India Private Limited

Amar Hill, Saki Vihar Road, Powai

IN - 400 072 Mumbai

Phone +91 22 4291 0111

e-mail sales.mtin@mt.com

Indonesia

PT. Mettler-Toledo Indonesia

GRHA PERSADA 3

rd

Floor

Jl. KH. Noer Ali No. 3A

Kayuringin Jaya

Kalimalang, Bekasi 17144, ID

Phone +62 21 294 53919

e-mail

mt-id.customersupport@mt.com

Italy

Mettler-Toledo S.p.A.

Via Vialba 42

IT - 20026 Novate Milanese

Phone +39 02 333 321

e-mail

customercare.italia@mt.com

Japan

Mettler-Toledo K.K.

Process Division

6F Ikenohata Nisshoku Bldg.

2-9-7, Ikenohata, Taito-ku

JP - 110-0008 Tokyo

Phone +81 3 5815 5606

e-mail helpdesk.ing.jp@mt.com

Malaysia

Mettler-Toledo (M) Sdn Bhd

Bangunan Electroscon Holding, U 1-01

Lot 8 Jalan Astaka U8 / 84

Seksyen U8, Bukit Jelutong

MY - 40150 Shah Alam Selangor

Phone +60 3 78 44 58 88

e-mail

MT-MY.CustomerSupport@mt.com

Mexico

Mettler-Toledo S.A. de C.V.

Ejército Nacional #340

Polanco V Sección

C.P. 115 60

MX - México D.F.

Phone +52 55 1946 0900

e-mail mt.mexico@mt.com

Norway

Mettler-Toledo AS

Ulvenveien 92B

NO - 0581 Oslo Norway

Phone +47 22 30 44 90

e-mail info.mtn@mt.com

Philippines

Mettler-Toledo Philippines Inc.

6F NOL Towers, Commerce Ave.

Madrigal Business Park

Ayala Alabang

Muntinlupa 1780 Philippines

Phone +63 2 528 8920

e-mail

MT-PH.CustomerSupport@mt.com

Poland

Mettler-Toledo (Poland) Sp.z.o.o.

ul. Poleczki 21

PL - 02-822 Warszawa

Phone +48 22 440 67 00

e-mail polska@mt.com

Russia

Mettler-Toledo Vostok ZAO

Sretensky blvd. 6/1

Office 6

RU - 1010 00 M osc ow

Phone +7 495 621 56 66

e-mail inforus@mt.com

Singapore

Mettler-Toledo (S) Pte. Ltd.

Block 28

Ayer Rajah Crescent # 05- 01

SG - 139959 Singapore

Phone +65 6890 00 11

e-mail

mt.sg.customersupport@mt.com

Slovakia

Mettler-Toledo s.r.o.

Hattalova 12 / A

SK - 8 31 03 Bratislava

Phone +421 2 4444 1221

e-mail predaj@mt.com

Slovenia

Mettler-Toledo d.o.o.

Pot heroja Trtnika 26

SI -1261 Ljubljana-Dobrunje

Phone +386 1 547 49 05

e-mail darko.divjak@mt.com

South Korea

Mettler-Toledo (Korea) Ltd.

1 & 4

F, Yeil Building 21

Yangjaecheon- ro 19-g il

SeoCho-Gu, Seoul 06753 Korea

Phone +82 2 3498 3500

e-mail Sales_MTKR@mt.com

Spain

Mettler-Toledo S.A.E.

C / Miguel Hernández, 69 – 71

ES - 08908 L’Hospitalet de Llobregat

(Barcelona)

Phone +34 902 32 00 23

e-mail mtemkt@mt.com

Sweden

Mettler-Toledo AB

Virkesvägen 10

Bo x 9 2161

SE - 12008 Stockholm

Phone +46 8 702 50 00

e-mail sales.mts@mt.com

Switzerland

Mettler-Toledo (Schweiz) GmbH

Im Langacher, Postfach

CH - 8606 Greifensee

Phone +41 44 944 47 47

e-mail ProSupport.ch@mt.com

Thailand

Mettler-Toledo (Thailand) Ltd.

272 Soi Soonvijai 4

Rama 9 Rd., Bangkapi

Huay Kwang

TH - 10320 Bangkok

Phone +66 2 723 03 00

e-mail

MT-TH.CustomerSupport@mt.com

Turk ey

Mettler-Toledo Türkiye

Haluk Türksoy Sokak No: 6 Zemin ve 1.

Bodrum Kat

34662 Üsküdar - Istanbul, TR

Phone +90 216 400 20 20

e-mail sales.mttr@mt.com

USA

METTLER TOLEDO

Process Analytics

900 Middlesex Turnpike, Bld. 8

Billerica, MA 01821, USA

Phone +1 781 301 8800

Freephone +1 800 352 8763

e-mail mtprous@mt.com

Vietnam

Mettler-Toledo (Vietnam) LLC

G Floor, SCS Building, Plot T2-4

D1 Street, Saigon Hi-tech Park

Tan Phu Ward, District 9

Ho Chi Minh City, Vietnam

Phone +84 28 73 090 789

e-mail

MT-VN.CustomerSupport@mt.com

Management System

certified according to

ISO 9001 / ISO 14001

9001

certified

ISO

14001

certified

ISO

Loading...

Loading...